Page 1

TM

Packaged Roof top

Air Conditioning Units

FORM 100.50-EG3 (802)

Meets ASHRAE 90.1 - 2001

Efficiency Requirements

00566VIP

ASHRAE

90.1

COMPLIANT

50 THROUGH 100 TONS

R-407C and R-22

400VAC/3PH/50Hz

Page 2

Introduction

The eco2 packaged rooftop – Designed to meet the demands of the market for today and tomorrow.

Better Economy...

Reduce Energy Consumption

• High-efficiency eco2 rooftop units are optimized for

both R-22 and HFC-407C refrigerant, and are the

first environmentally responsible rooftop units that

meet the ASHRAE 90.1-2001 ef ficiency standards.

• Multiple steps of capacity-control offer superior of fdesign energy performance, while maintaining better control of occupant comfort.

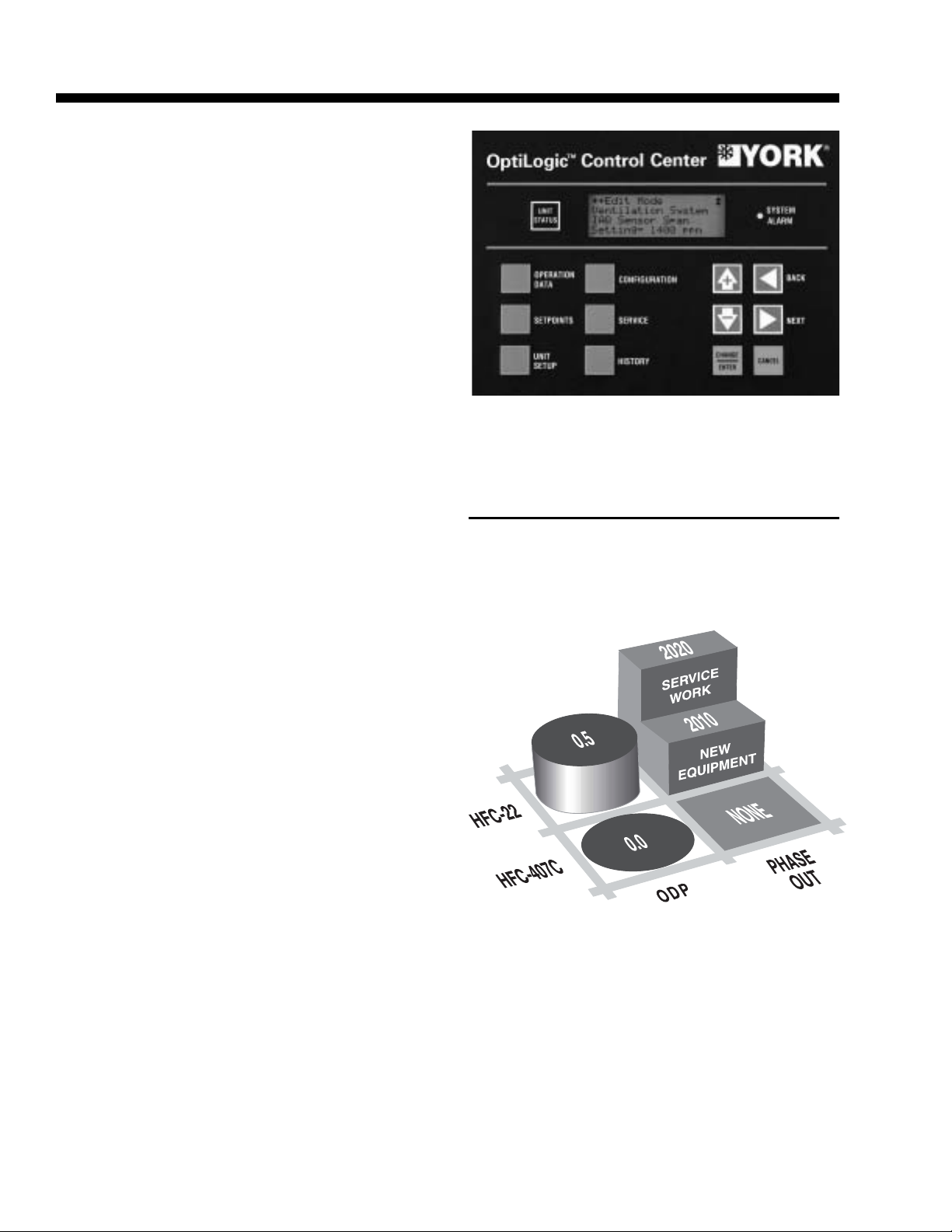

• The OptiLogic

more than the proper amount of ventilation air is

utilized, avoiding the energy cost of conditioning

excess air.

TM

Control Center ensures that no

LD07431

The OptiLogicTM Control Center uses microprocessor logic to optimize operation of the eco2 rooftop unit.

Better Ecology...

Air Quality Features for the Indoor Environment

• A double-sloped stainless steel design ensures that

all condensate is voided from the drain pan. The drain

pan is also visible and accessible for the periodic inspection and cleaning required by IAQ standards.

• Double-wall construction of the roof, floor, doors,

and walls prevents insulation fiber from entering

the supply air. The inner liner also facilitates periodic cleaning of the unit to prevent harmful buildup of bacteria or contaminants.

• The OptiLogicTM Control Center uses microprocessor logic to analyze and optimize ventilation decisions.

• A true airflow-measurement station can be supplied,

to ensure the proper ventilation at all supply-air

volumes.

• An available sensor can monitor the CO2 level within

the building and adjust the ventilation rate on demand, to maintain the air quality at a healthy level.

HFC-407C Refrigerant

for the Global Environment

LD07430

2

YORK INTERNATIONAL

Page 3

TABLE OF CONTENTS

FORM 100.50-EG3 (802)

Introduction.............................................................2

Features and Benefits ............................................4

Nomenclature .........................................................7

Application Data .....................................................8

Physical Data........................................................12

Cooling Performance Data ...................................16

Heating Performance Data – Gas/Electric Heat ...36

Supply Fan Data................................................... 37

Component Static Pressure Drop s .......................40

Gas Heat Pressure Drops ....................................44

Electric Heat Pressure Drops ...............................46

Exhaust Fan Data.................................................48

Component Static Pressure Drop s .......................50

Electrical Data ......................................................52

Controls................................................................54

Power Wiring........................................................60

Field Control Wiring..............................................63

General Arrangement Drawings ...........................64

Curb Layout Drawing ............................................69

Power/Control Entry Drawing................................70

Guide Specifications.............................................71

TABLES

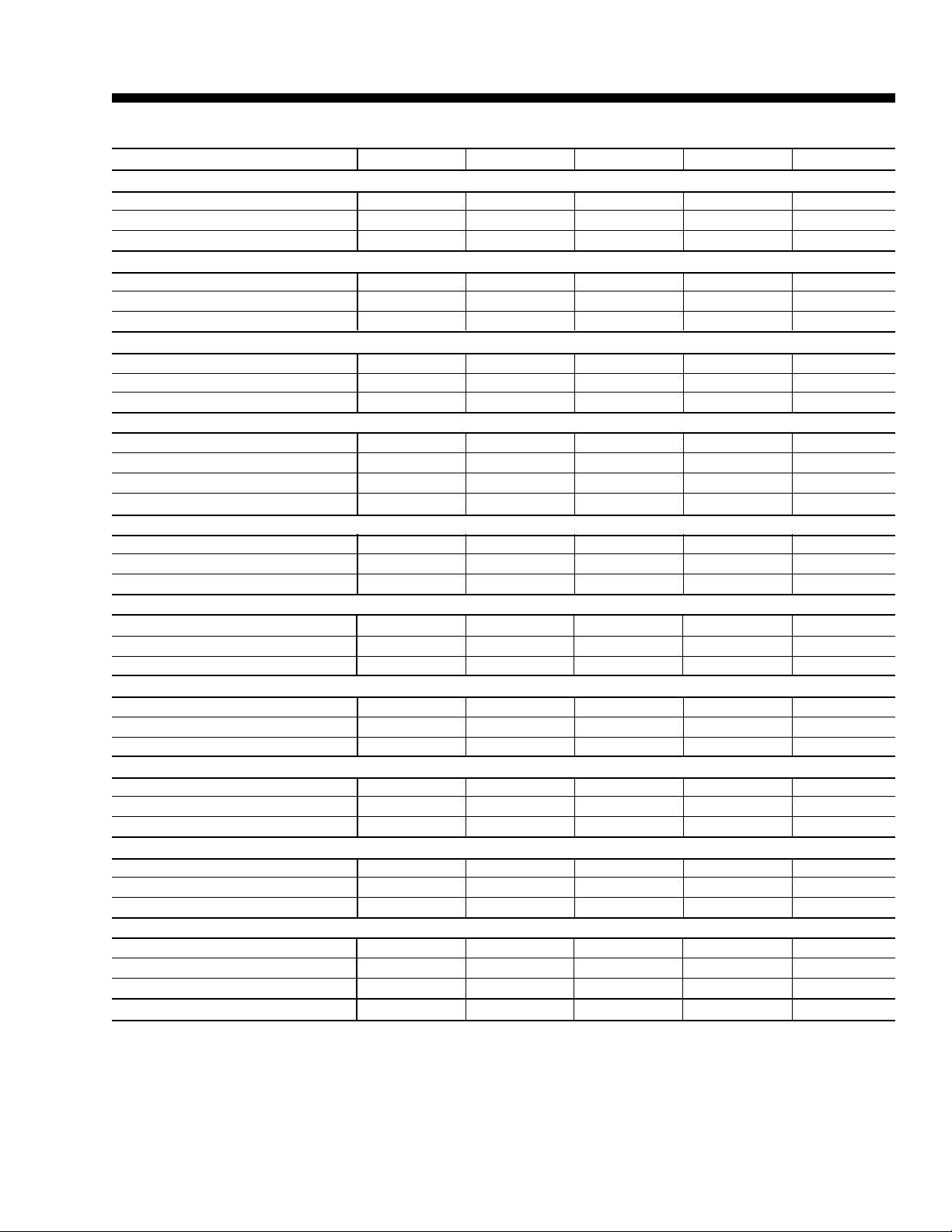

1 Physical Data ................................................. 12

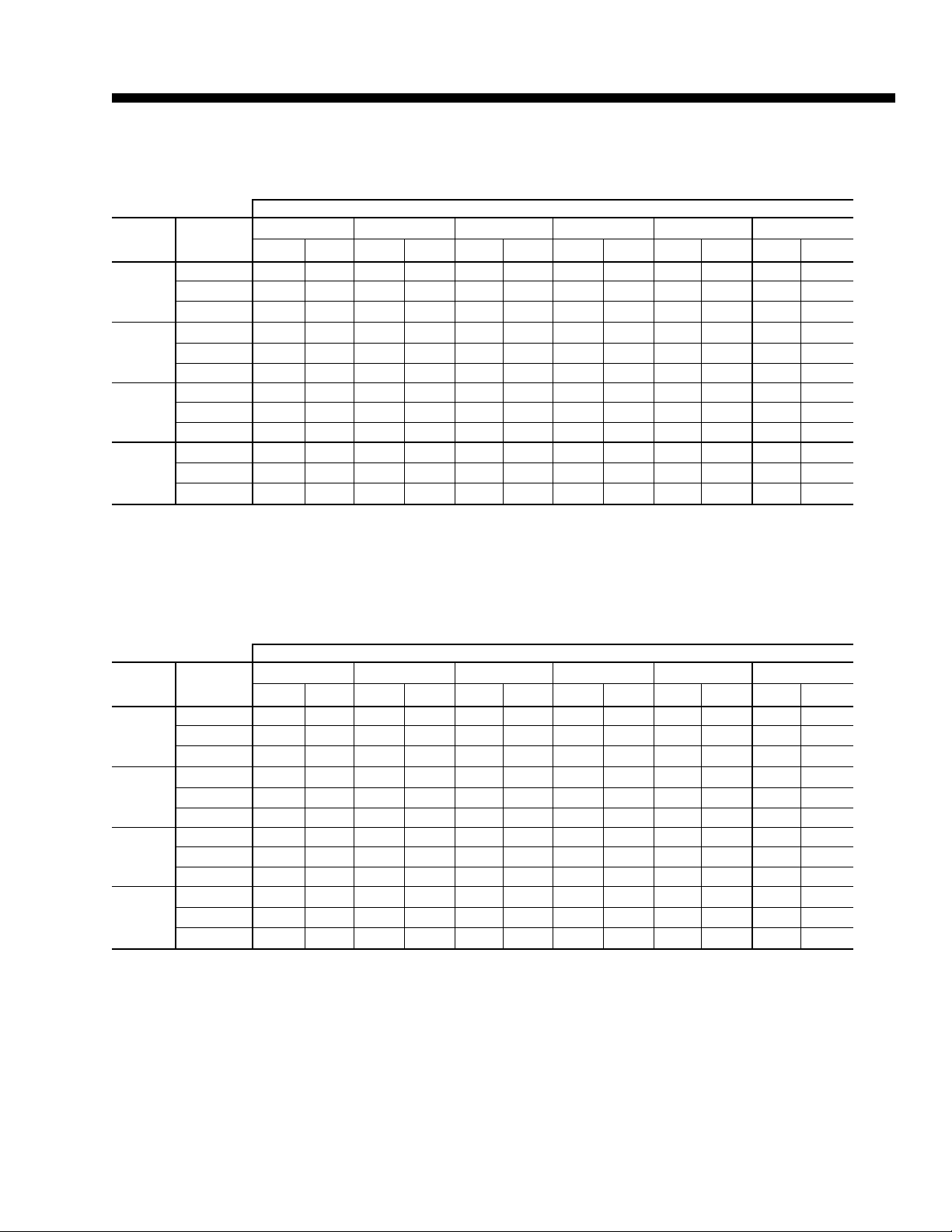

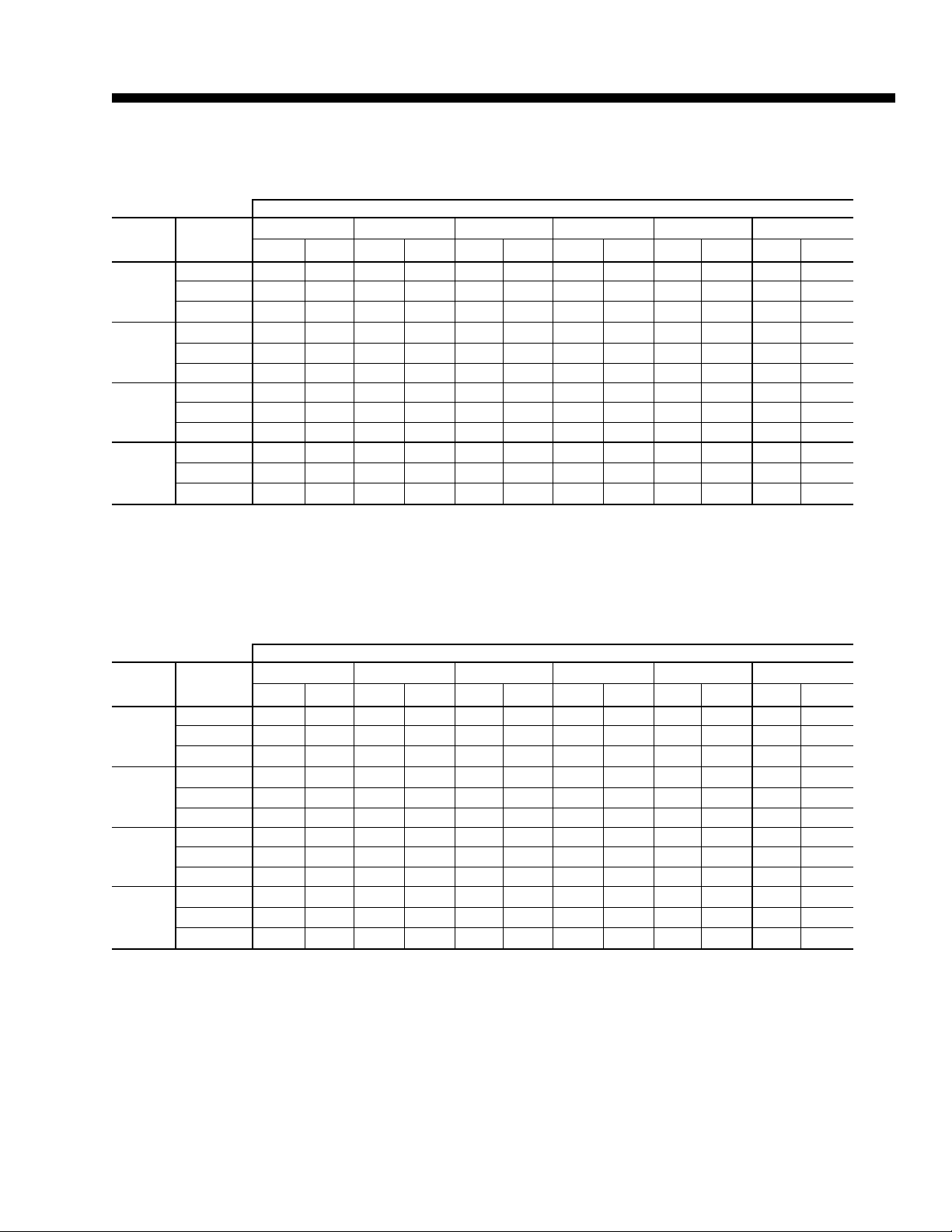

2 Cooling Performance Data – 50 Ton Model....16

3 Cooling Performance Data – 55 Ton Model....18

4 Cooling Performance Data – 60 Ton Model....20

5 Cooling Performance Data – 65 Ton Model....22

6 Cooling Performance Data – 70 Ton Model....24

7 Cooling Performance Data – 75 Ton Model....26

8 Cooling Performance Data – 80 Ton Model....28

9 Cooling Performance Data – 85 Ton Model....30

10 Cooling Performance Data – 90 Ton Model....32

11 Cooling Performance Data – 95 Ton Model....34

12 Gas Heat Performance Data..........................36

13 Electric Heat Performance Data.....................36

14 50 Through 65 T on Supply Fan Data..............37

15 70 Through 85 T on Supply Fan Data..............38

16 90 Through 95 T on Supply Fan Data..............39

17 Component Static Pressure Drops ................. 40

18 Gas Heat Pressure Drops..............................44

19 Electric Heat Pressure Drops.........................46

20 60 Through 65 T on Exhaust Fan Data............48

21 70 Through 85 T on Exhaust Fan Data............49

22 90 Through 95 T on Exhaust Fan Data............49

23 Component Static Pressure Drop s................. 50

24 Compressor Data........................................... 52

25 Supply and Exhaust Fan Motor

Electrical Data................................................ 53

26 Condenser Fan Motors ..................................53

27 Control Transformer....................................... 53

28 Electric Heat...................................................53

29 General Arrangement – 50-65 Ton Models

(Bottom Supply/Bottom Return) ....................... 64

30 General Arrangement – 50-65 Ton Models

(Side Supply/Front Return) ..............................65

31 General Arrangement – 70-95 T on Models

(Bottom Supply/Bottom Return).......................66

32 General Arrangement – 70-95 Ton Models

(Side Supply/Front Return).............................67

33 General Arrangement – 70-95 T on

Optional Side Return......................................68

34 Curb Layout Dimensions................................69

35 Power/Control Dimensions.............................70

FIGURES

1 Single-Point Power Supply Wiring.................. 60

2 Single-Point Power Supply Wiring with

Non-Fused Disconnect .................................. 61

3 Dual-Point Power Supply Wiring ....................62

4 Field Control Wiring .......................................63

5 Gen. Agmt. Dwg. – 50-65 Ton Models

(Bottom Supply/Bottom Return) ...................... 64

6 Gen. Agmt. Dwg. – 50-65 T on Models

(Side Supply/Front Return) ..............................65

7 Gen. Agmt. Dwg. – 70-95 T on Models

(Bottom Supply/Bottom Return) ...................... 66

8 Gen. Agmt. Dwg. – 70-95 Ton Models

(Side Supply/Front Return) ..............................67

9 Gen. Agmt. Dwg. – 70-95 Ton Models

(Optional Side Return) ...................................68

10 Curb Layout Drawing ..................................... 69

1 1 Power/Control Entry Drawing –

50-95 Ton Model ............................................70

YORK INTERNATIONAL

3

Page 4

Features and Benefits

QUALITY ROOFTOP UNIT DESIGNED T O TODA Y’S

STANDARDS

Ecological and Economical Design

• First packaged RTU that meets ASHRAE 90.1-2001

with both R-22 and R-407C Refrigerants.

• Cooling and Heating – Superior operating performance provides lower operating costs. Smaller steps

of cooling capacity provide tighter control of building

environment and occupant comfort while optimizing

energy efficiency .

• Indoor Air Quality (IAQ) – Outside air economizer

provides energy savings in free cooling mode, and

can provide a healthier and more comfortable building environment by introducing fresh outside air into

the building as needed. Indoor Air Quality (IAQ) requirements for building ventilation and comfort are

controlled through the microprocessor control panel.

Optional air flow measurement provides an accurate

means of tracking air quality and alerting the occupants or building owner to unhealthy situations.

• Premium Efficiency – Premium-efficiency motors

are available for optimum energy efficiency. All motors used on the eco2 packaged rooftop air conditioner meet U.S. EP ACT 1992 minimum requirements.

• VFDs Standard on V A V Units – V ariable-frequencydrives provide the HVAC designer with a high-efficiency, quiet and more reliable means of variable air

volume control from a packaged rooftop. On larger

rooftops, ASHRAE 90.1-1999 st andard specifies part

load efficiency requirements that make VFDs the

cost-effective solution for meeting the standard.

VFDs can save the owner up to 40% of the energy

costs compared to inlet guide vanes offered on competitive units by reducing the power requirement.

VFDs use fewer parts, which leads to more reliability . Also, with fewer moving parts, and the reduction

of speed in the fan, the VFD operates at significantly

quieter operation than the inlet guide vane which

restricts a high volume of airflow, which can actually

increase noise at part load conditions.

Additionally, the YORK VFD includes DC link reactors as standard that have harmonic filtration comparable to an AC line reactor. VFDs also provide the

added benefit of soft-starting the supply fan, which

helps to minimize demand charges associated with

inrush currents.

• Network Connectivity with BACnet, LON or Roof-

Link Interface – Through optional communications

protocols, the eco2 rooftop unit can communicate to

any building automation system. There are four options available: BACnet Internet Protocol (Ethernet),

BACnet MSTP (RS485), LON or a generic RoofLink

BAS interface, depending on the type of building

automation system. Without network communications, the eco2 is designed to operate in stand-alone

mode, or via contact closures for basic control.

• Professional Appearance – A high quality powder

coat paint finish is applied to the galvanized steel

2

exterior of the eco

unit to protect it from aggressive

environments helping to maintain a factory-quality

appearance for years.

• FlexSys Underfloor Air System Configuration –

the eco

2

rooftop is the first packaged rooftop product

with designs specifically for use with the YORK FlexSys underfloor air system. Ask your local YORK

representative for more information.

Indoor Air Quality (IAQ)

• Double-Sloped Stainless Steel Drain Pan – This

double-sloped inclined stainless steel drain pan facilitates removal of evaporator condensate. Sloped

in two directions, this drain pan swiftly drains any

condensate from the unit. Best of all, the drain pan

is accessible for periodic cleaning required by IAQ

standards.

• Smart Ventilation – YORK maintains the leadership role in IAQ products with adaptive ventilation

control. The OptiLogic

TM

controls provide continuous

monitoring of air quality and take action by opening

the outside air dampers, bringing in the right amount

of fresh air before air impurities reach uncomfortable

or even dangerous levels.

• Air Flow Measurement – Precise measurement

of ventilation air flow is possible using an air flow

measurement station which can be installed in the

economizer section. Proper ventilation air flow is

required to ensure sufficient fresh air is in the building. A myriad of air flow measurement options are

available from minimum air flow to high-accuracy

full air flow capabilities. The complete system is designed as an integrated component of the

OptiLogicTM control system to ensure optimum system performance.

• Double Wall Construction – Rigid double-wall construction throughout provides ease of cleaning and

protects against insulation fiber entrainment in the

breathable air. Double-wall construction also helps

improve the acoustical characteristics of the air handling unit.

• Enhanced Filtration – The eco2 unit gives designers the flexibility to meet various IAQ requirements

with a full range of rigid and throwaway filter options

at various efficiency levels.

• Demand Ventilation – Control of the economizer

is available to maintain a desired ventilation level

based on a 0-10VDC input from a sensor . A factorysupplied CO2 sensor is available for installation in

the occupied space.

4

YORK INTERNATIONAL

Page 5

FORM 100.50-EG3 (802)

Reliable Cooling and Heating Technology

• Reliable, efficient, trouble-free operation is the true

measure of a packaged rooftop’s value. That’ s why

YORK eco2 Packaged Rooftop Air Conditioners use

established scroll-compressor technology to deliver

dependable, economical performance in a wide

range of applications. With the eco

2

Packaged

Rooftop, you get the latest generation of compressor enhancements added to the scroll’s inherent

strengths. The simplicity of a hermetic scroll compressor allows the use of fewer moving parts to

minimize breakdown. YORK also employs the latest sealing technology to avoid metal-to-metal contact. Axial sealing is accomplished with floating tip

seals, while radial sealing utilizes a microcushion

of oil. The result: a maintenance-free compressor

providing minimum wear and maximum runtime.

• Gas Furnace – The eco2 rooftop gas furnace is an

induced-draft gas furnace designed for high efficiency and reliability. The furnace uses an aluminized steel tubular heat exchanger and operates

at temperatures sufficient to prevent acidic exhaust

gases from condensing in the heat exchanger at

low fire rates, unlike drum and tube style furnaces

that generate condensation formation.

Gas heat units are U.L./C.U.L. listed and are tested

to ANSI standard Z21.47. Multiple modules provide redundancy not available in single power

burner applications.

Serviceability

• Filter Maintenance Alarm – An optional filter maintenance alarm indicates when a filter becomes dirty

and requires replacement or cleaning.

Install with Ease and Safety

• Factory Run-T ested – Each unit is subjected to a

series of quality assurance checks as well as an

automated quality control process before being runtested. Fans and drives are balanced at the factory

during testing. The factory run-test ensures safe,

proper operation when the unit is installed and reduces installation and commissioning time.

• Single-Point Power Connection – Single-point

power connection reduces installation time by providing a single-point for incoming power, including

the optional convenience outlet. All incoming power

is connected in one location, reducing the cost of

distributed power wiring.

• Rain Hoods Rotate Into Place – No bulky , field- in-

stalled rain hoods here. eco2 rain hoods ship rotated

inside the unit. Once on the job, the installer merely

rotates the hood upward, caulks and fastens it in place

with sheet metal screws – an easy , one-person job.

• Factory-mounted and Wired Controls – All control points within the unit are factory-installed, wired

and tested.

• Non-Fused Disconnect – An optional factory-installed non-fused disconnect switch simplifies unit

installation and serviceability by eliminating the need

for a separate disconnect switch. Check local codes

for acceptability .

• OptiLogicTM – Fully-integrated factory-packaged

controls are standard on every unit and include a

display unit with a 4x20 character LCD display.

OptiLogicTM continually monitors all control setpoints

and configurations. If a unit sensor fails, the controller indicates an alarm. If desired, YORK service

can provide remote monitoring and automatically

schedule a service technician to make the repair

and maintain your comfort.

• Access Doors – Full-sized access doors provide

easy access into the unit for routine maintenance

and inspection.

• Suction & Discharge Service Valves – Oversized

service valves to provide isolation and quick reclamation and charging of system refrigerant are available to minimize downtime and simplify the service

and repair task.

• Convenience Outlet – For maintenance tasks requiring power tools, an optional 110V GFCI power

supply can power lights, drills or any other power

hand tool needed.

YORK INTERNATIONAL

Design Flexibility

• Low Ambient Operation – Head-pressure control

is accomplished via a VFD motor controller rather

than an inefficient and noisy condenser fan damper.

By varying the speed of the condenser fan, better

control and quieter operation is obtained during the

cooler weather. Low ambient controls are available

on all systems offering higher mechanical cooling

capacity at low ambient conditions than competitive units.

• Hot Gas Bypass – Optional on constant volume units,

hot gas bypass reduces the cycling of compressors

which helps prolong the life of the equipment.

• Duct Air Openings – Horizontal connections are

available on select configurations, offering more

flexibility for duct layout and improving sound transmission characteristics.

• Compressor Sound Blankets – For applications

in sound-sensitive areas, compressor sound blankets are available to reduce sound emitted from

the rooftop unit.

5

Page 6

Features and Benefits (continued)

• Fan Spring Isolators – One-inch spring isolation

is used to prevent vibration transmission from the

rooftop unit’s supply fan to the building. Two-inch

spring isolation is also available.

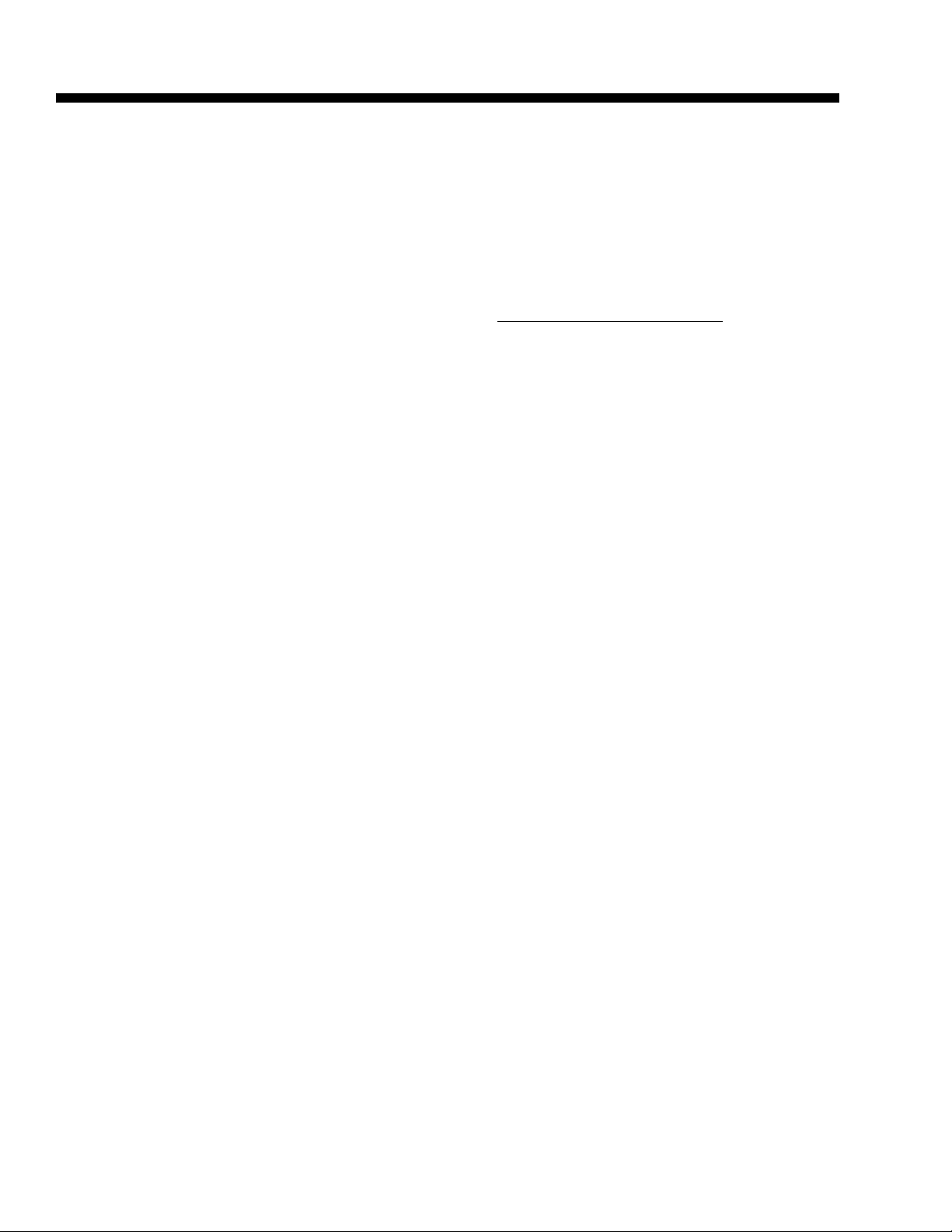

DISTRIBUTOR

OPTIONAL

REPLACEABLE

CORE FILTER

DRIERS

OPTIONAL

HORIZONTAL

SUPPL Y AIR

OPENINGS

TUBES

PROTECTED

IN PLASTIC

SLEEVES

• Harsh Environments – A variety of coil coating and

materials are available as well as hail guards to protect coils from weather damage.

ANGLED OR

RIGID FLAT

FILTER

SECTION

OPTIONAL

AIRFLOW

MEASUREMENT

STATION

RAINHOODS TO

PREVENT

MOISTURE

FROM ENTERING

THE UNIT

FACTORYINSTALLED

OPTILOGIC

ROOFTOP

UNIT

CONTROLLER

V-BANKED

CONDENSER

COILS TO

PROTECT

FROM HAIL

DAMAGE

COMPLETE

DOUBLE-WALL

CONSTRUCTION

OF WALLS,

FLOORS,

CEILING,

AND PANELS

DOUBLE-SLOPED

STAINLESS STEEL

IAQ DRAIN

PAN AND

INTERMEDIATE

DRAIN PAN

ANGLED

EVAPORATOR

COIL FOR

LOWER

FACE

VELOCITIES

DOORS ON BOTH

SIDES OF UNIT

AND TIE BACKS

FOR UNIT

SERVICING

CENTRIFUGAL

FAN POWERED

EXHAUST

00567VIP

6

YORK INTERNATIONAL

Page 7

FORM 100.50-EG3 (802)

NOMENCLATURE

BASIC MODEL NUMBER

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

BASE PRODUCT TYPE NOMINAL CAP ACITY APPLICATION REFRIGERANT VOLTAGE DUCT LOCA TIONS DESIGN SPECIAL

Y 0 5 0 B 45 B A

P055 C L X

: YORK

: Packaged

Rooftop

A065 B

: Air-Cooled

L075 C S

: Scroll

: 50-ton

: 55-ton

: 60-ton

060 RS

: 65-ton

: 70-ton

070 R

: 75-ton

: 80-ton

080 N

: 85-ton

085 G

: 90-ton

090 E

: 95-ton

095 C

: Cooling Only

: Natural Gas Heat

: Natural Gas Heat SS HX

: Electric Heat

: Constant Volume

V

: VAV, VFD

F

: FlexSys

: R-407C

: R-22

: 400 / 3 / 50

: Bottom Supply

: Left Supply

: Right Supply

: Bottom Return

: Front Return

: Side Return

: Rev. Level A

: Special

: Std. Product

YORK INTERNATIONAL

7

Page 8

Application Data

LOCATION

Of the many factors that can affect the acoustical characteristics of a rooftop installation, one of the most important is the unit location. Ideally , the rooftop unit should

be installed away from sound-sensitive areas, such as

conference rooms, auditoriums and executive offices.

Possible locations could be above storage areas, hallways, mechanical or utility rooms, or bathrooms.

The eco

door installation. When selecting a site for installation,

be guided by the following conditions:

• Unit must be installed on a level surface.

• For the outdoor location of the unit, select a place

• Also avoid locations beneath windows or between

• Optional condenser coil protection should be used

• The unit should be installed on a roof that is struc-

• Location of unit(s) should also be away from build-

• Be sure the supporting structures will not obstruct

• Proper service clearance space of 6-feet around

RIGGING

2

air conditioning units are designed for out-

having a minimum sun exposure and an adequate

supply of fresh air for the condenser.

structures.

for seashore locations or other harsh environments.

turally strong enough to support the weight of the

unit with a minimum of deflection. It is recommended that the unit(s) be installed not more than

15 feet from a main support beam to provide proper

structural support and to minimize the transmission

of sound and vibration. Ideally, the center of gravity should be located over a structural support or

building column.

ing flue stacks or exhaust ventilators to prevent possible reintroduction of contaminated air through the

outside air intakes.

the duct, gas or wiring connections.

the perimeter of the unit, 8-feet on one side for coil

servicing, and 12-feet to any adjacent units is required to eliminate cross contamination of exhaust

and outdoor air, and for maintenance tasks such

as coil pull and cleaning. No obstructions should

be above the condensing unit section.

Spreader bars must be used by cranes to prevent damage to the unit casing. All lifting lugs must be used when

lifting the rooftop unit. Fork lifts will damage the roof top

unit and are not recommended.

Care must be taken to keep the unit in the upright position during rigging and to prevent damage to the watertight seams in the unit casing. Avoid unnecessary jarring or rough handling.

Ground Level Locations

It is important that the units be installed on a substantial base that will not settle, causing strain on the refrigerant lines and sheet metal and resulting in possible

leaks. A one-piece concrete slab with footers extended

below the frost line is highly recommended. Additionally , the slab should be isolated from the main building

foundation to prevent noise and vibration transmission

to the building structure.

For ground level installations, precautions should be

taken to protect the unit from tampering by , or injury to,

unauthorized persons. Erecting a fence around the unit

is common practice.

ECONOMIZER

The economizer section is used for ventilation of the

conditioned space to maintain indoor air quality, and

also to reduce energy consumption by using outdoor

air cooling in lieu of mechanical cooling. If outdoor air

is appropriate for cooling, but not sufficient for the cooling demand, mechanical cooling will stage on as necessary until the cooling load is met.

Dual (comparative or differential) enthalpy operation is

the most accurate and efficient means of economizer

operation. The OptiLogicTM control monitors the return

and outside air energy content, and selects the lower of

the two for operation.

V AV SUPPLY AIR PRESSURE CONTROL

Traditional packaged rooftop systems use inlet guide

vanes (IGVs) for duct static pressure control. These control supply duct pressure by modulating dampers (introduc ing losses and inefficiencies) on the inlet of the fan,

open and closed. YORK’s variable frequency drives

(VFDs) offer superior fan speed control and quieter,

energy efficient operation.

Proper rigging and handling of the equipment is mandatory during unloading and setting it into position to

retain warranty status.

8

YORK INTERNATIONAL

Page 9

FORM 100.50-EG3 (802)

For V AV applications, the YORK eco2 unit uses a VFD

to modulate fan speed and maintain a constant duct

static pressure. VFDs offer superior control over the

operation of the unit at part load, and offer the additional benefits of quieter and more efficient operation

when compared to IGV.

HARSH ENVIRONMENTS – CONDENSER AND

EV APORATOR COIL PROTECTION

For harsh environmental conditions such as seashore

applications, YORK offers three types of coil protection: copper fin material, black fin and Technicoat coatings. YORK recommends that for corrosive environments that copper fins be used to protect the evaporator and/or condenser coils. In areas where chemicals

that can corrode copper are present, such as ammonia, YORK recommends that the black fin or Technicoat

coating be used for maximum protection.

Copper Fin Condenser Coil

Copper fins can be used instead of aluminum for additional corrosion protection, however it is not suitable

for areas that are subject to acid rain or exposed to

ammonia.

Pre-Coated Condenser Fins

Black fin coating (yellow fin for evaporator fins) is precoated application epoxy on aluminum fin stock to guard

from corrosive agents and insulate against galvanic potential. It is used for mild seashore or industrial locations. This can provide corrosion resistance comparable

to copper fin coils in typical seashore locations.

Post-Coated Condenser Fins

T echnicoat (a post-coated application of epoxy) can be

used for seashore and other corrosive applications with

the exception of strong alkaloides, oxidizers, wet bromide, chlorine and fluorine in concentrations greater

than 100 ppm.

Any of the above suitable options should be selected

based on the particular project design parameters and

related environmental factors. The application should

be further reviewed and approved by the consulting engineer or owner based on their knowledge of the job

site conditions.

BUILDING EXHAUST SYSTEMS

Building exhaust systems are often necessary when

economizers are used to bring in outdoor air. Without

proper building exhaust, the building may become overpressurized. The exhaust system maintains the proper

building pressure by expelling the appropriate amount

of air from the building. Exhaust systems are typically

designed to exhaust approximately 10% less air than

what is entering the building. This provides a slight positive pressure in the building.

100% modulating exhaust with building static

pressure sensing and control

The 100% exhaust system can be configured with either control actuated dampers or VFDs for modulating

control. The unit controller monitors the building pressure using a differential pressure transducer and maintains the required building static pressure by modulating the exhaust control. If the building has other means

of exhaust or building pressure is not important, on/off

or barometric control may be used.

Powered exhaust with fan on/off control

The 100% exhaust system can be configured for on/off

operation eliminating the expense of the damper actuators or VFDs. This exhaust system can be controlled

by either the outside air damper position, or a building

static pressure sensor.

Barometric exhaust

Barometric exhaust can be used when smaller amounts

of air at low static pressure variations within the building or other means of building exhaust are employed.

Barometric exhaust is commonly used where there are

only small fluctuations in building pressure or where

building static pressure control is not necessary .

ROOF CURB

YORK offers optional roof curbs designed specifically

for the eco

2

footprint. These curbs come disassembled

and require field assembly and installation. For bottom

supply and return openings, the curbs have matching

connections to ease installation. A pipe chase that

matches the rooftop unit pipe chase is also included in

the curb footprint for through-the-curb utility connections.

YORK INTERNATIONAL

9

Page 10

Application Data (continued)

The curb should be located according to the location

recommendations above, and properly sealed to prevent moisture and air leakage into and out of the duct

system. Flexible collars should be used when connecting the duct work to prevent unit noise transmission

and vibration into the building.

Duct work should be supported independently of the

unit.

ACOUSTICAL CONSIDERA TIONS

The eco

competitive units by using flexible fan connections, fan

spring isolators, double-wall construction, and lower

speed and horsepower fans. For VAV applications,

VFDs are used instead of inlet guide vanes. Additional

sound attenuation can be obtained using compressor

sound blankets and field-supplied sound attenuators

when necessary.

Even with these equipment design features, the acoustical characteristics of the entire installation must never

be overlooked. Additional steps for the acoustical characteristics of a rooftop installation should be addressed

during the design phase of a project to avoid costly alterations after the installation of the equipment. During

the design phase of a project, the designing engineer

should consider, at a minimum, the imp act of the equipment location, rooftop installation, building structure, and

duct work.

2

unit is designed for lower sound levels than

Select Unit:

1. Determine the internal static pressure drop of the

cabinet by referencing Table 17.

Wet evaporator coil 0.58

Bottom return opening 0.15

Two-inch pleated filters 0.12

Mod. econ. dampers 0.56

Total 1.41 IWG

2. Determine the total static pressure by adding the

internal to the external static pressure.

TSP = 1.41 IWG + 2.25 IWG = 3.66 IWG total static pressure

3. Determine the BHP of the supply fan from Table 15

using the supply air flow and total static pressure.

From the table, we interpolate to get 26.3 BHP at

724 rpm.

4. Determine the motor heat gain of supply air flow by

first calculating the motor energy and converting it

into Btuh.

Motor Energy

Motor kW = BHP x .746/efficiency

Motor kW = 26.3 x 0.746/0.94

Motor kW = 20.9 kW

SELECTION PROCEDURE

Given:

Total Cooling Load 920 mbh

Sensible Heat 610 mbh

Required Heating Capacity 875 mbh

Design Cooling Ambient Temp. 95°F

Indoor Air Temperature 80°F db/67°F wb

Supply Air Flow 24,000 cfm

External Static Pressure 2.25 in. w.c.

Electrical Service 460V/3ph/60 Hz

Unit Configuration/Options: 0-100% modulating economizer, barometric relief, premium ef ficiency supply fan

motor and VFD, and two-inch pleated filters, bottom

supply, bottom return.

10

Motor Heat Rejection (MHR)

MHR = 2545 x BHP/efficiency

MHR = 2545 x 26.3/0.94

MHR = 71.2 mbh

5. Calculate actual required tot al cooling capacity by

adding specified cooling capacity to motor heat

rejection.

Required T ot al Cooling Capacity

920 mbh + 71.3 mbh = 991 mbh

Required Sensible Cooling Capacity

610 mbh + 71.3 mbh = 681 mbh

YORK INTERNATIONAL

Page 11

FORM 100.50-EG3 (802)

6. Required total and sensible capacities are 991 mbh

and 681 mbh, respectively . The total capacity is 82.6

tons, therefore a model YP AL085 is selected. Use

the Cooling Performance Data in Table 9. Locate

the table with the correct ambient air temperature.

Next, trace the 80°F entering air dry bulb temperature to match the 24,000 cfm and 67°F entering

wet bulb temperature condition. The resulting conditions are, from the table, 996.5 mbh total cooling

capacity and 688.9 mbh sensible cooling capacity .

7. The high heat option for the YPAL085 provides

900 mbh of heat capacity with an input of 1,125

mbh. This is sufficient for the 875 mbh heating

requirement.

8. Determine net cooling and heating capacities if

required.

Net Cooling Capacity (NCC)

mbh = 996.5 mbh – 71.3 mbh

mbh = 925 mbh

Net Sensible Heat Capacity (NSHC)

mbh = 688.9 mbh - 71.3 mbh

mbh = 618 mbh

Net Heating Capacity (NHC)*

mbh = 875 mbh + 71.3 mbh

mbh = 946 mbh

* Note, net heating capacity is approximate because this example

uses the bhp calculated based on a wet evaporator coil (for

cooling mode).

YORK INTERNATIONAL

11

Page 12

Physical Data

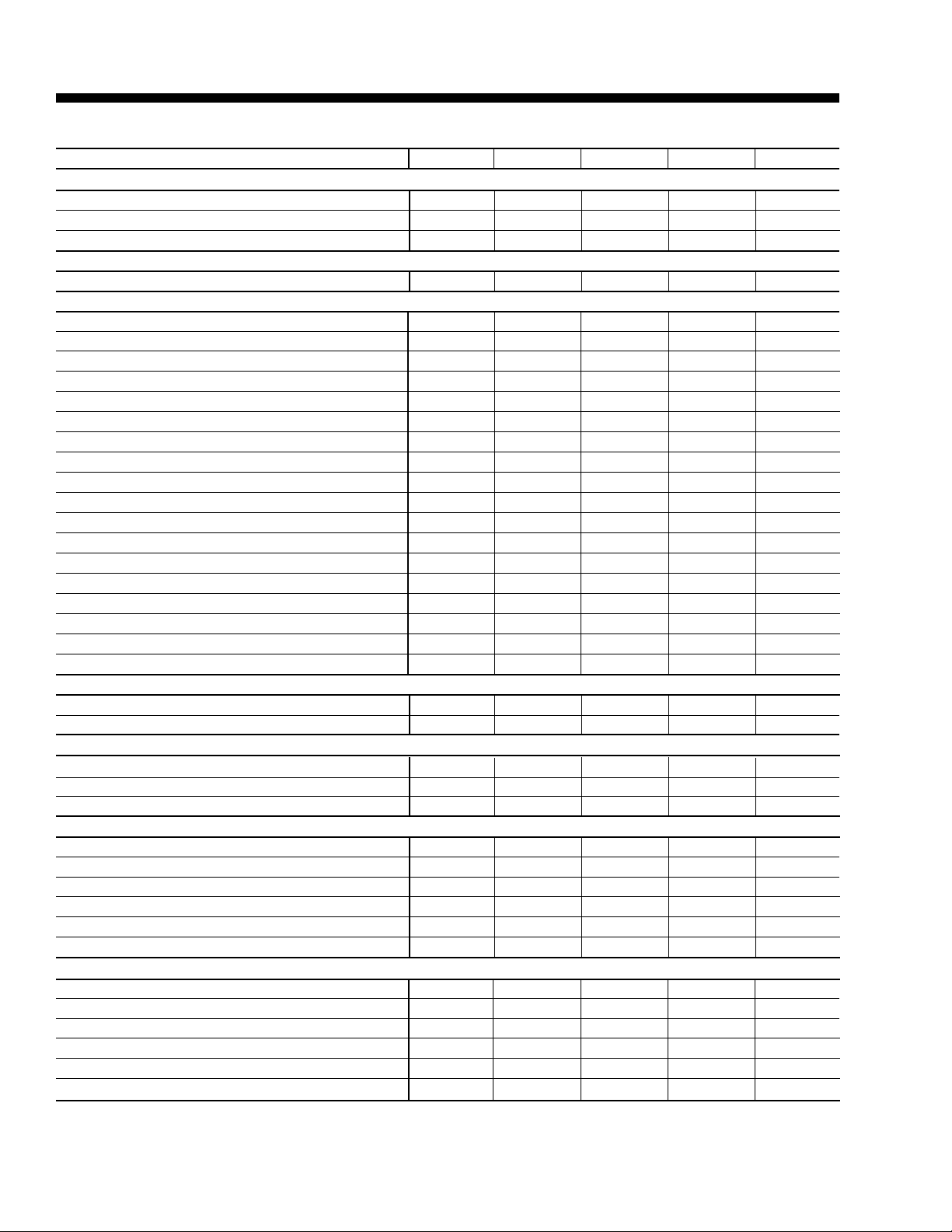

T ABLE 1 – PHYSICAL DATA – MODELS 50-70

MODEL SIZE 050 055 060 065 070

GENERAL DATA

Length (cm) w/o Hood 874 874 874 874 1140

Width (cm) w/o Hood 234 234 234 234 234

Height (cm) 208 208 208 208 208

Operating Weights (Kg) (Base Unit, No Options)

Cooling Only (Rigging & R407C) 3701 3797 3934 4029 5799

Option Weights (Kg)

Power Exhaust (Blower, Motor, Fan Skid & Mod Damper) 284 284 284 284 341

Power Exhaust (Blower, Motor, Fan Dkid, VFD & Baro Damper) 287 287 287 287 332

100% AMS (Measurement Station & Mounting) 50 50 50 50 57

25/75% AMS (Measurement Station & Mounting) 59 59 59 59 66

Min. AMS (Measurement Station & Mounting) 18 18 18 18 20

Barometric Only 16 16 16 16 20

375 MBH Gas Heat 73 73 73 73 73

750 MBH Gas Heat 147 147 147 147 147

1125 MBH Gas Heat n/a n/a n/a n/a 220

40 kW 195 195 195 195 204

80 kW 222 222 222 222 231

108 kW 204 204 204 204 213

150 kW 213 213 213 213 222

200 kW 222 222 222 222 231

250 kW 231 231 231 231 240

Condenser Wire Guard 15 15 15 15 18

Copper Condenser Coils (additional) 280 280 360 360 280

Copper Evaporator Coils (additional) 119 145 181 227 127

Roof Curb Weights (Kg)

14" Full Perimeter Roof Curb 374 374 374 374 463

14" Open Condenser Roof Curb 252 252 252 252 262

Compressor Data

Quantity/Size (Nominal HP) 4x13 4x13 4x15 4x15 4x10, 2x13

Type Scroll Scroll Scroll Scroll Scroll

Capacity Steps (%) 4x25 4x25 4x25 4x25 4x15, 2x20

Supply Fan and Drive

Quantity 1 1 1 1 1

Type FC FC FC FC FC

Size 25-22 25-22 25-22 25-22 28-25

Motor Size Range (Min. to Max. HP) 7.5-40 7.5-40 7.5-40 7.5-40 7.5-60

Air Flow Range (Min. to Max. m3/hr) 16,988-38,228 16,988-38,228 23785-45875 23785-45875 23785-54,367

Static Pressure Range (Min. to Max. ESP) 0-995 Pa 0-995 Pa 0-995 Pa 0-995 Pa 0-995 Pa

Exhaust Fan

Quantity 2 2 2 2 2

Type FC FC FC FC FC

Size 15-15 15-15 15-15 15-15 18-18

Motor Size Range (Min. to Max. HP) 5-20 5-20 5-20 5-20 10-20

Air Flow Range (Min. to Max. m3/hr) 0-33980 0-33980 0-33980 0-33980 0-33980

Static Pressure Range (Min. to Max. ESP) 0-498 Pa 0-498 Pa 0-498 Pa 0-498 Pa 0-498 Pa

12

YORK INTERNATIONAL

Page 13

FORM 100.50-EG3 (802)

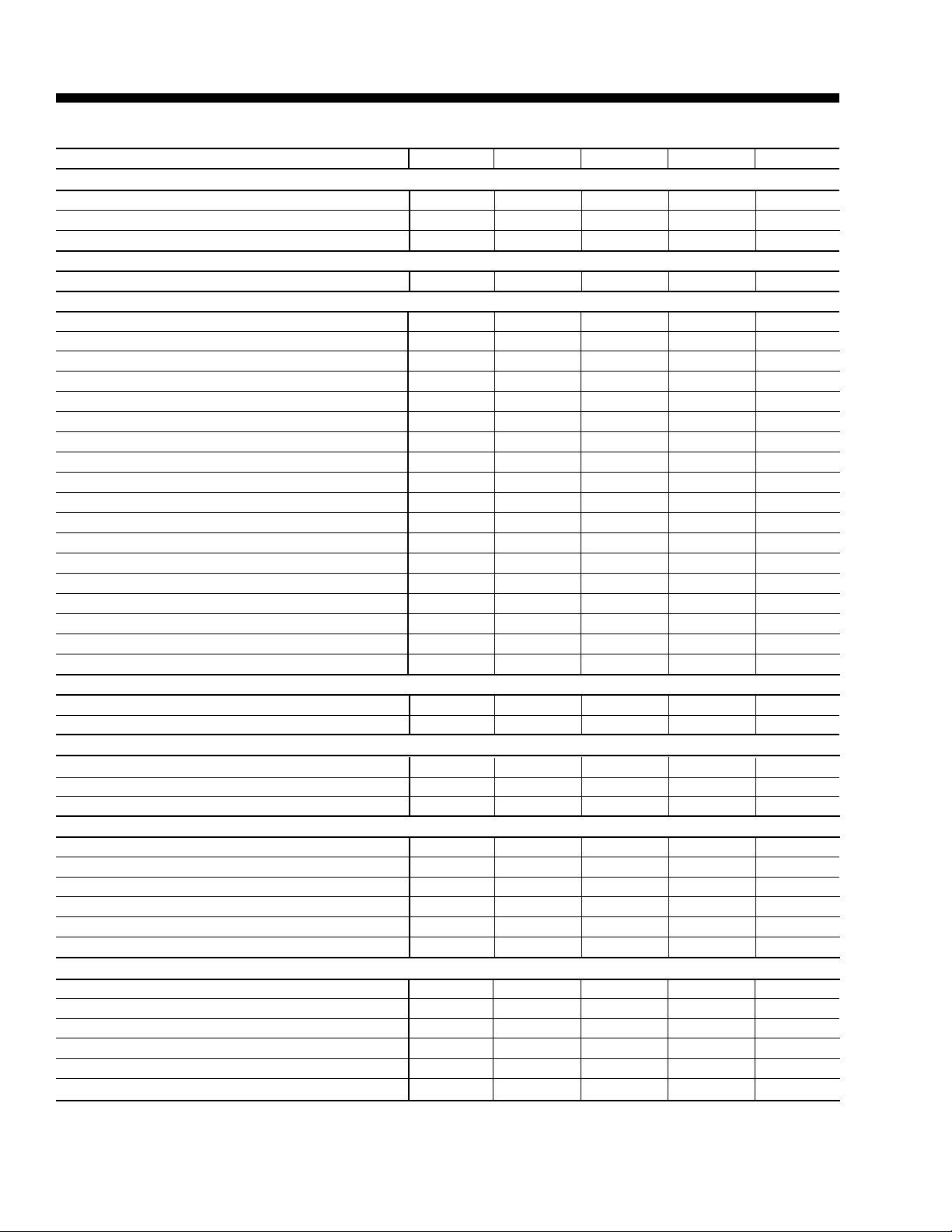

T ABLE 1 – PHYSICAL DATA – MODELS 50-70 (CONT’D)

MODEL SIZE 050 055 060 065 070

Evaporator Coil

Size (Square Meters) 5 5 5 5 5

Number of Rows/Fins per cm 1 1 1 1 1

Tube Diameter (cm) /Surface 5/4 /enhanced 5/4 /enhanced 5/4 /enhanced 5/4 /enhanced 5/4 /enhanced

Condenser Coil (Aluminum Fins)

Size (Square Meters) 11 11 11 11 182

Number of Rows/Fins per cm 1 1 0 0 0

Tube Diameter (cm) 1 1 1 1 1

Condenser Coil (Copper Fins - Opt)

Size (square meters) 11 11 11 11 17

Number of rows/fins per cm 1 1 0 0 0

Tube Diameter 1 1 1 1 1

Condenser Fans

Quantity 4 4 4 4 6

Type Prop. Prop. Prop. Prop. Prop.

Diameter (Meters) 1 1 1 1 1

Power (Hp Each) 2 2 2 2 2

Filters - 5.08cm Throwaway

Quantity 8 / 12 8 / 12 8 / 12 8 / 12 10 / 15

Size (Length x Width) (Meters) .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 6 6 6 6 7

Filters - 5.08cm Cleanable

Quantity 8 / 12 8 / 12 8 / 12 8 / 12 10 / 15

Size (Length x Width) (Meters) .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 6 6 6 6 7

Filters - 5.08cm Pleated (30% Efficient)

Quantity 8 / 12 8 / 12 8 / 12 8 / 12 10 / 15

Size (Length x Width) (Meters) .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 6 6 6 6 7

Filters -30.48cm Rigid 65%, 5.08cm 30% Prefilter

Quantity 1 / 4 / 9 1 / 4 / 9 1 / 4 / 9 1 / 4 / 9 2 / 8 / 9

Size (Length x Width) (Meters) .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5

Total Filter Face Area (Square Meters) 1 1 1 1 1

Filters -30.48cm Rigid 95%, 5.08cm 30% Prefilter

Quantity 1 / 4 / 9 1 / 4 / 9 1 / 4 / 9 1 / 4 / 9 2 / 8 / 9

Size (Length x Width) (Meters) .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5

Total Filter Face Area (Square Meters) 1 1 1 1 1

Filters - 5.08cm Carbon (30% Efficient)

Quantity 1 / 4 / 9 1 / 4 / 9 1 / 4 / 9 1 / 4 / 9 10 / 15

Size (Length x Width) (Meters) .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 1 1 1 1 2

Minimum OA Temp. for Mech. Cig. 45 45 45 45 45

YORK INTERNATIONAL

13

Page 14

Physical Data (continued)

T ABLE 1 – PHYSICAL DATA – MODELS 75-95

MODEL SIZE 075 080 085 090 095

GENERAL DATA

Length (cm) w/o Hood 1140 1140 1140 1240 1240

Width (cm) w/o Hood 234 234 234 234 234

Height (cm) 208 208 208 234 234

Operating Weights (Kg) (Base Unit, No Options)

Cooling Only (Rigging & R407C) 5897 5994 6092 6496 6594

Option Weights (Kg)

Power Exhaust (Blower, Motor, Fan Skid & Mod Damper) 341 341 341 347 347

Power Exhaust (Blower, Motor, Fan Skid, VFD & Baro Damper) 332 332 332 337 337

100% AMS (Measurement Station & Mounting) 57 57 57 64 64

25/75% AMS (Measurement Station & Mounting) 66 66 66 73 73

Min. AMS (Measurement Station & Mounting) 20 20 20 23 23

Barometric Only 20 20 20 25 25

375 MBH Gas Heat 73 73 73 73 73

750 MBH Gas Heat 147 147 147 147 147

1125 MBH Gas Heat 220 220 220 220 220

40 kW 204 204 204 222 222

80 kW 231 231 231 249 249

108 kW 213 213 213 231 231

150 kW 222 222 222 240 240

200 kW 231 231 231 249 249

250 kW 240 240 240 259 259

Condenser Wire Guard 18 18 18 20 20

Copper Condenser Coils (Additional) 280 480 480 540 540

Copper Evaporator Coils (Additional) 209 127 209 209 263

Roof Curb Weights (Kg)

14" Full Perimeter Roof Curb 463 463 463 472 472

14" Open Condenser Roof Curb 262 262 262 279 279

Compressor Data

Quantity/Size (Nominal Hp) 4x10, 2x13 6x13 6x13 2x13, 4x15 2x13, 4x15

Type Scroll Scroll Scroll Scroll Scroll

Capacity Steps (%) 4x15, 2x20 6x16 6x16 4x18, 2x15 4x18, 2x15

Supply Fan and Drive

Quantity 1 1 1 1 1

Type FC FC FC FC FC

Size 28-25 28-25 28-25 28-28 28-28

Motor Size Range (Min. to Max. Hp) 7.5-60 7.5-60 7.5-60 7.5-60 7.5-60

Air Flow Range (Min. to Max. m3/hr) 23785-54,367 23785-54,367 30582-61164 30582-61164 30582-61164

Static Pressure Range (Min. to Max. ESP) 0-995 Pa 0-995 Pa 0-995 Pa 0-995 Pa 0-995 Pa

Exhaust Fan

Quantity 2 2 2 2 2

Type FC FC FC FC FC

Size 18-18 18-18 18-18 18-18 18-18

Motor Size Range (Min. to Max. HP) 10-20 10-20 10-20 10-20 10-20

Air Flow Range (Min. to Max. m3/hr) 0-33980 0-33980 0-33980 0-33980 0-33980

Static Pressure Range (Min. to Max. ESP) 0-498 Pa 0-498 Pa 0-498 Pa 0-498 Pa 0-498 Pa

14

YORK INTERNATIONAL

Page 15

FORM 100.50-EG3 (802)

T ABLE 1 – PHYSICAL DATA – MODELS 75-95 (CONT’D)

MODEL SIZE 075 080 085 090 095

Evaporator Coil

Size (Square Meters) 5 5 5 5 5

Number of Rows/Fins per cm 1 1 1 1 1

Tube Diameter (cm) /Surface 5/4 /enhanced 5/4 /enhanced 5/4 /enhanced 5/4 /enhanced 5/4 /enhanced

Condenser Coil (Aluminum Fins)

Size (Square Meters) 17 17 17 17 17

Number of Rows/Fins per cm 0 0 0 0 0

Tube Diameter (cm) 1 1 1 1 1

Condenser Coil (Copper Fins - Opt)

Size (Square Meters) 17 17 17 17 17

Number of Rows/Fins per cm 0 0 0 0 0

Tube Diameter 1 1 1 1 1

Condenser Fans

Quantity 6 6 6 6 6

Type Prop. Prop. Prop. Prop. Prop.

Diameter (Meters) 1 1 1 1 1

Power (Hp Each) 2 2 2 2 2

Filters - 5.08cm Throwaway

Quantity 10 / 15 10 / 15 10 / 15 12 / 18 12 / 18

Size (Length x Width) (Meters) 6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 7 7 7 9 9

Filters - 5.08cm Cleanable

Quantity 10 / 15 10 / 15 10 / 15 12 / 18 12 / 18

Size (Length x Width) (Meters) .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 7 7 7 9 9

Filters - 5.08cm Pleated (30% Efficient)

Quantity 10 / 15 10 / 15 10 / 15 12 / 18 12 / 18

Size (Length x Width) (Meters) .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 7 7 7 9 9

Filters -30.48cm Rigid 65%, 5.08cm 30% Prefilter

Quantity 2 / 8 / 9 2 / 8 / 9 2 / 8 / 9 8 / 12 8 / 12

Size (Length x Width) (Meters) .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 1 1 1 2 2

Filters -30.48cm Rigid 95%, 5.08cm 30% Prefilter

Quantity 2 / 8 / 9 2 / 8 / 9 2 / 8 / 9 8 / 12 8 / 12

Size (Length x Width) (Meters) .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .4x.5 /.6x.4 /.6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 1 1 1 2 2

Filters - 5.08cm Carbon (30% Efficient)

Quantity 10 / 15 10 / 15 10 / 15 12 / 18 12 / 18

Size (Length x Width) (Meters) .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5 .6x.4 / .6x.5

Total Filter Face Area (Square Meters) 2 2 2 2 2

Minimum OA Temp. for Mech. Cig. 45 45 45 45 45

YORK INTERNATIONAL

15

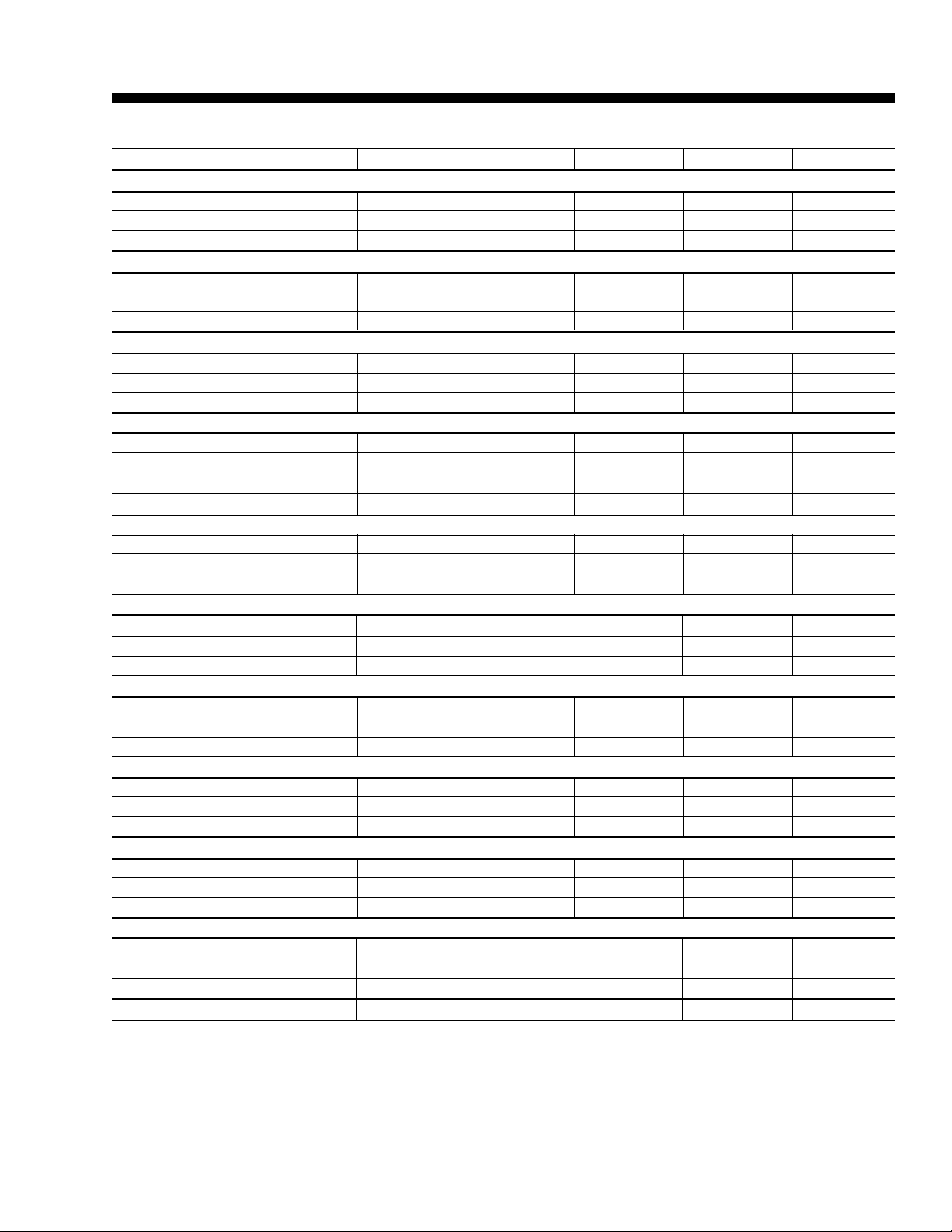

Page 16

Cooling Performance Data – 50 Ton Model

T ABLE 2 – COOLING PERFORMANCE DA TA* – 50 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

22653 19 179 162 175 148 173 134 173 121 171 108 170 96

25485 19 180 165 175 150 173 135 173 122 172 109 171 97

29733 19 181 168 176 152 175 138 174 124 173 110 172 97

31148 19 186 184 181 163 180 147 179 130 178 115 176 100

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 189 141 188 125 187 111 186 99 186 86 – –

17 179 179 170 172 164 169 160 156 156 143 157 125

22 190 143 189 126 188 112 187 100 187 8 6 – –

17 180 180 172 174 166 168 161 153 157 140 158 122

22 191 146 190 128 189 113 188 101 187 8 7 – –

17 181 181 173 176 167 164 162 150 158 137 159 119

22 196 156 193 134 193 119 192 104 191 8 9 – –

17 189 189 181 183 175 179 167 158 165 144 164 126

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

22653 19 173 159 170 146 167 131 167 118 165 107 164 93

25485 19 174 162 171 148 168 133 168 119 166 107 165 94

29733 19 175 165 171 150 169 135 169 120 167 107 166 94

31148 19 182 182 175 159 174 144 173 128 171 109 170 9 7

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 182 138 181 121 180 108 180 96 179 83

17 173 173 166 167 159 150 156 140 153 128 153 114

22 183 140 182 123 181 109 180 97 180 84 – –

17 175 175 167 169 160 152 157 142 154 130 154 115

22 184 143 183 124 182 110 181 97 180 84 – –

17 177 177 169 171 162 155 158 144 155 132 155 117

22 188 153 187 132 186 116 185 101 184 8 7 – –

17 184 184 176 178 169 169 162 153 159 140 159 125

32 30 28 27 25 23

16

YORK INTERNATIONAL

Page 17

FORM 100.50-EG3 (802)

T ABLE 2 – COOLING PERFORMANCE DATA* – 50 TON MODEL (CONT’D)

40.5°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

22653 19 164 154 162 142 160 128 160 114 160 102 159 90

25485 19 165 156 163 144 161 130 161 115 161 103 160 90

29733 19 167 160 164 146 162 132 162 117 162 104 161 91

31148 19 175 177 169 157 167 141 166 125 165 109 164 9 4

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 175 136 175 119 174 105 173 93 173 80 – –

17 168 168 161 163 150 147 150 135 148 126 147 111

22 176 138 176 120 174 106 174 94 173 81 – –

17 169 169 162 164 152 149 151 137 149 127 148 113

22 177 140 176 122 175 108 175 95 174 81 – –

17 171 171 164 166 154 152 152 140 150 129 149 114

22 181 149 180 129 179 113 178 98 177 83 – –

17 179 179 171 173 163 164 155 151 153 137 152 120

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

22653 19 159 153 155 138 154 126 152 112 151 99 151 87

25485 19 160 156 156 140 154 127 153 113 152 100 151 87

29733 19 162 158 157 142 155 129 154 114 153 101 152 88

31148 19 169 172 160 151 160 137 159 121 158 106 156 9 1

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 168 133 167 115 165 101 164 90 163 78

17 161 161 154 156 145 147 142 132 140 123 139 109

22 169 135 168 116 166 102 165 90 164 78 – –

17 163 163 155 157 147 149 143 135 140 124 139 110

22 170 137 169 118 167 104 166 91 165 79 – –

17 165 165 157 158 149 151 144 138 142 126 140 111

22 174 147 172 125 171 109 170 95 169 80 – –

17 172 172 163 165 157 160 150 150 146 134 145 118

32 30 28 27 25 23

YORK INTERNATIONAL

17

Page 18

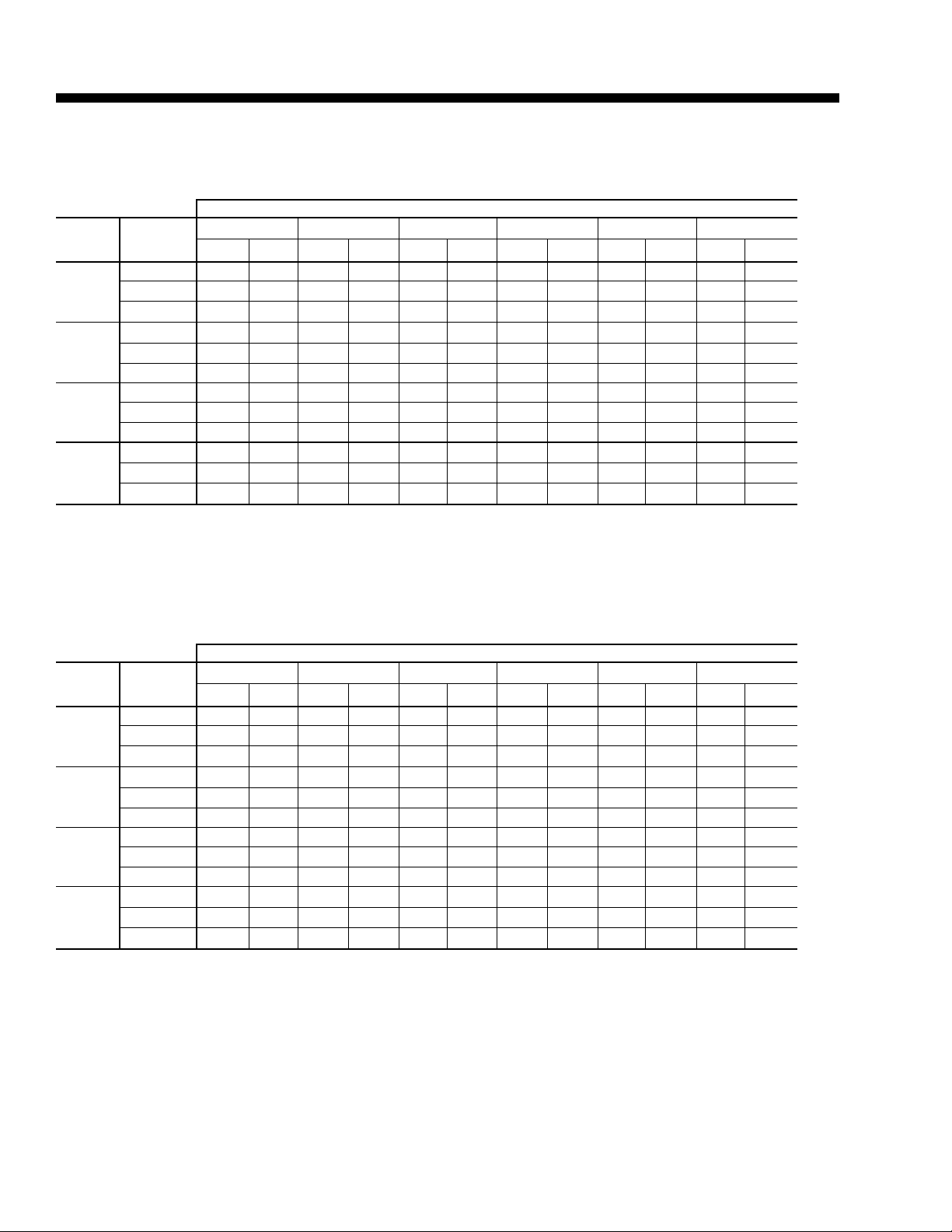

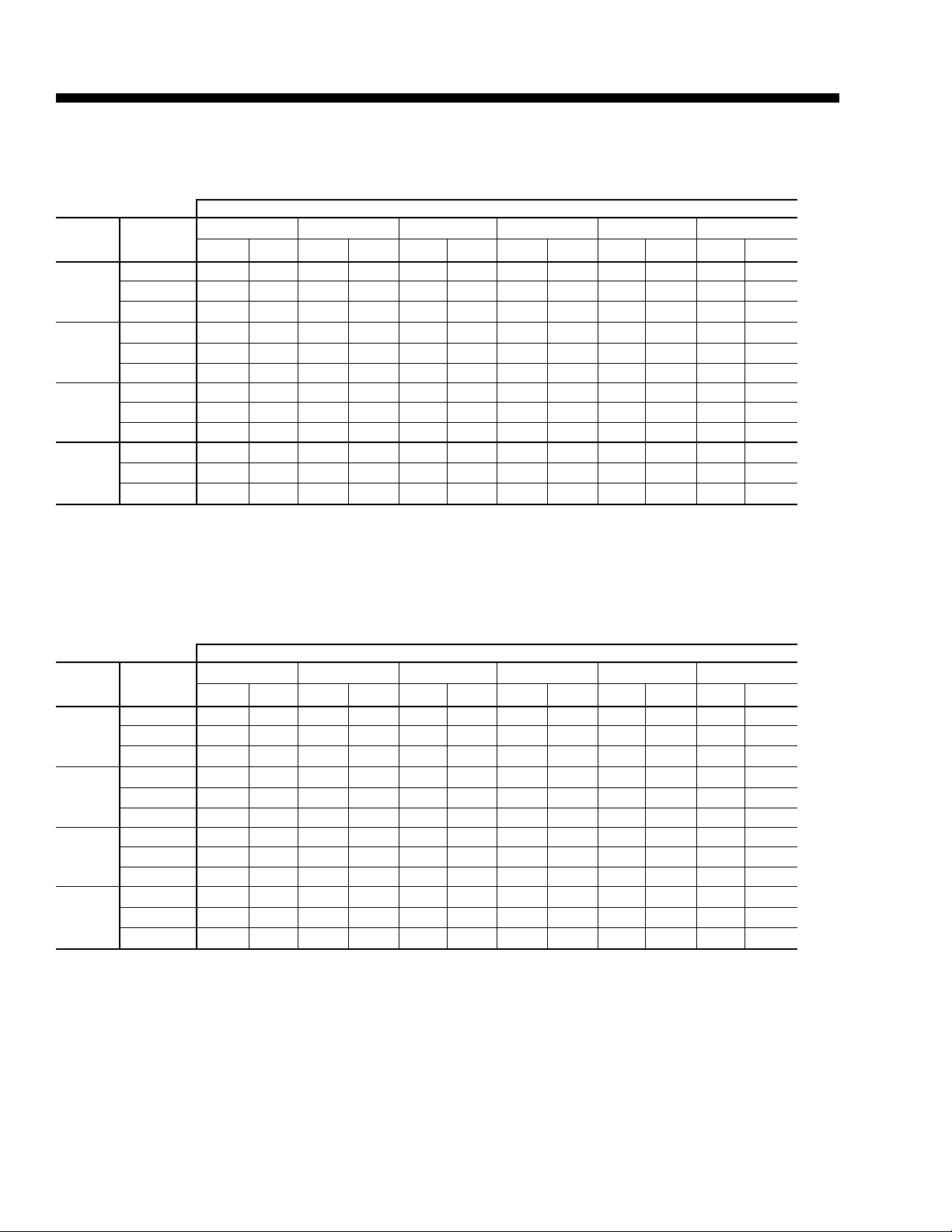

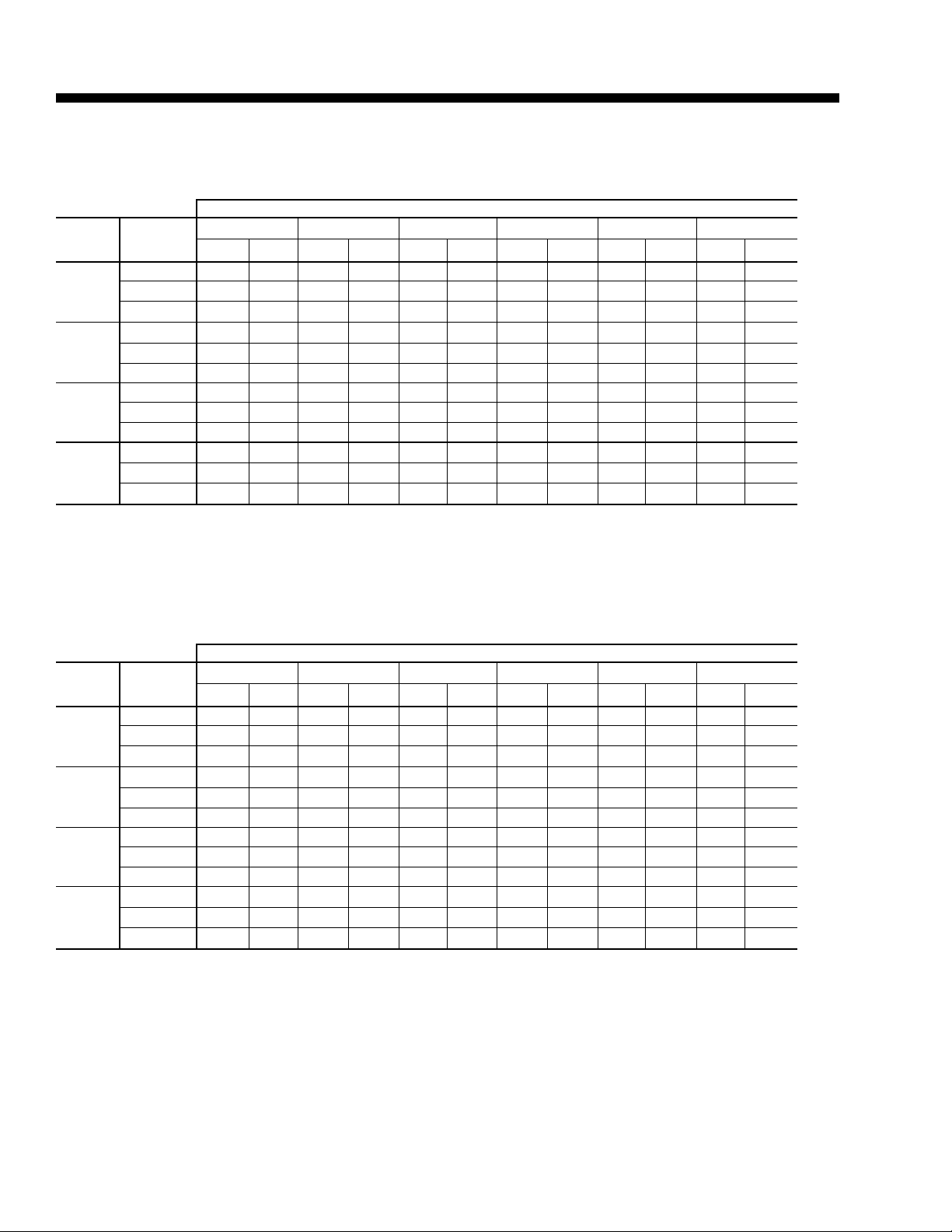

Cooling Performance Data – 55 Ton Model

T ABLE 3 – COOLING PERFORMANCE DA TA* – 55 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

20388 19 185 167 181 153 181 139 182 125 180 113 178 100

27184 19 192 186 186 166 186 150 186 134 185 119 183 104

32706 19 202 2 11 193 183 193 164 192 145 192 127 190 109

33980 19 204 213 194 185 193 166 193 147 193 128 191 110

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 197 148 197 130 196 116 195 103 194 8 9 – –

17 183 183 175 178 166 171 167 147 166 136 166 123

22 202 159 201 138 201 123 200 107 198 92 – –

17 193 193 185 187 177 174 173 159 171 146 171 131

22 209 175 207 150 207 132 206 113 204 96 – –

17 206 206 197 199 190 195 180 176 178 159 177 141

22 210 177 208 151 208 133 206 114 205 96 – –

17 208 208 199 201 192 197 181 178 179 161 178 143

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

20388 19 178 162 175 150 175 136 175 122 174 113 173 97

27184 19 186 182 180 162 179 147 179 131 178 113 177 101

32706 19 197 205 187 178 186 162 185 143 184 122 183 106

33980 19 198 207 187 180 187 164 186 144 185 123 184 107

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 190 145 190 126 189 113 189 100 187 8 7 – –

17 178 178 171 173 163 167 162 145 161 133 160 119

22 195 156 194 135 193 120 193 107 192 89 – –

17 188 188 180 182 172 170 167 156 165 143 165 128

22 201 171 200 148 199 129 198 129 197 92 – –

17 200 200 192 194 184 189 173 171 171 157 171 140

22 202 173 201 149 200 130 199 132 198 92 – –

17 202 202 193 196 185 190 174 173 172 158 172 142

32 30 28 27 25 23

18

YORK INTERNATIONAL

Page 19

FORM 100.50-EG3 (802)

T ABLE 3 – COOLING PERFORMANCE DATA* – 55 TON MODEL (CONT’D)

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

20388 19 166 159 164 144 162 130 161 116 161 104 161 91

27184 19 175 174 169 157 168 141 167 125 165 111 165 96

32706 19 191 200 181 176 180 159 179 140 175 121 177 104

33980 19 194 202 183 179 181 161 181 142 177 123 178 105

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 177 139 175 120 174 106 173 94 172 80 – –

17 166 166 160 162 152 151 149 137 147 127 146 113

22 182 150 181 130 180 115 180 105 178 84 – –

17 177 177 170 172 162 164 156 153 154 137 153 121

22 193 166 193 144 193 127 191 128 190 90 – –

17 195 195 186 188 179 184 167 174 165 153 164 135

22 195 168 194 146 194 128 193 131 192 91 – –

17 197 197 188 190 182 187 169 176 167 156 166 137

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

20388 19 166 158 164 144 161 130 161 115 161 104 160 91

27184 19 173 173 166 154 165 140 165 124 164 110 164 95

32706 19 184 192 170 169 171 154 171 136 169 118 168 100

33980 19 185 193 171 171 172 156 172 137 170 119 169 101

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 177 139 175 119 174 106 173 94 172 80 – –

17 166 166 160 162 152 151 149 137 147 126 146 113

22 181 150 179 129 178 113 177 98 176 83 – –

17 175 175 166 168 160 162 155 152 152 136 151 121

22 185 165 185 141 183 122 184 105 181 87 – –

17 187 187 175 176 172 177 164 172 158 150 157 131

22 186 167 185 143 184 123 185 106 182 87 – –

17 189 189 176 178 173 178 165 173 159 151 158 133

32 30 28 27 25 23

YORK INTERNATIONAL

19

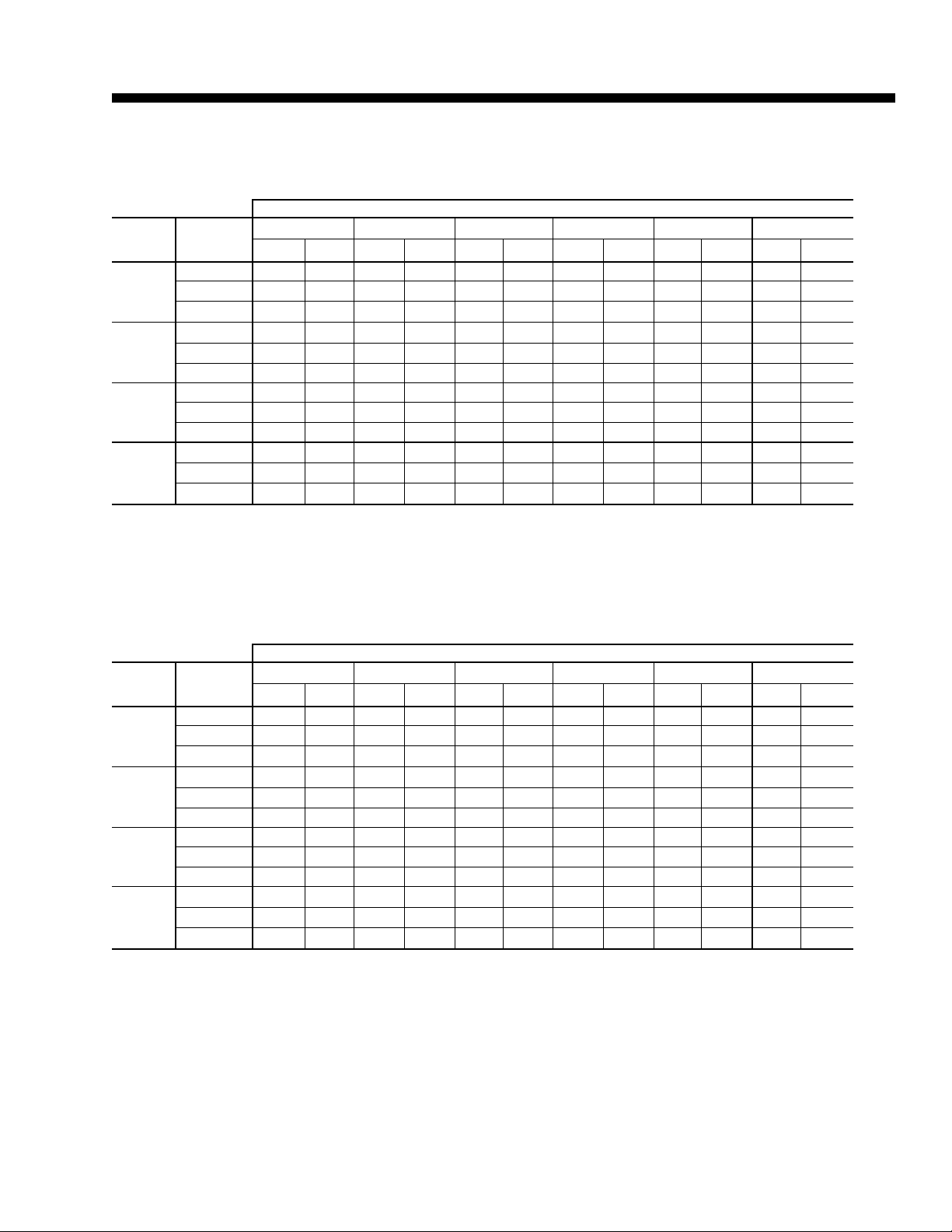

Page 20

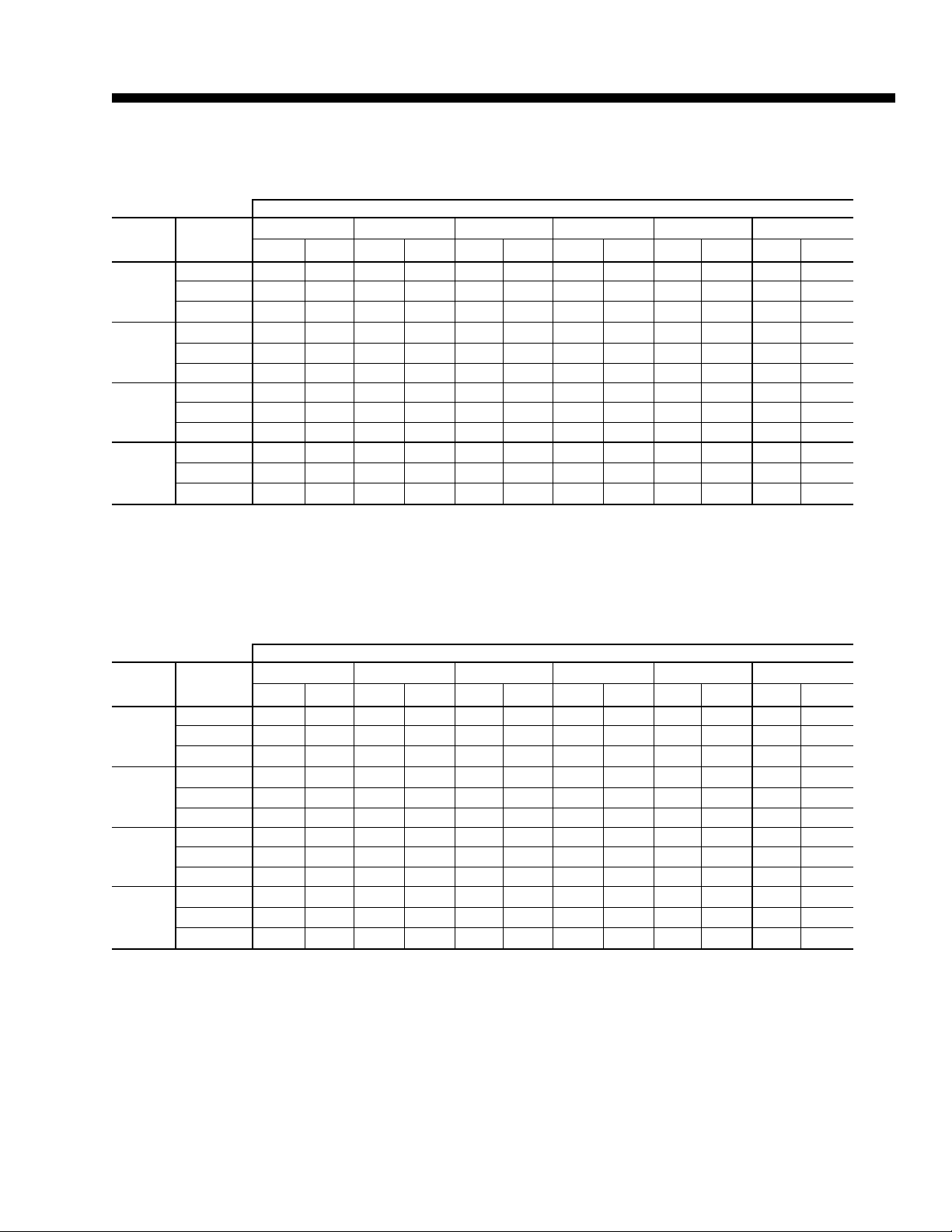

Cooling Performance Data – 60 Ton Model

T ABLE 4 – COOLING PERFORMANCE DA TA* – 60 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 213 199 205 177 205 147 204 144 204 129 202 113

30582 19 224 225 213 199 213 173 212 160 212 141 210 121

35679 19 232 242 219 215 219 195 218 171 217 149 215 126

38228 19 234 244 221 219 220 201 219 174 219 151 216 127

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 224 170 223 150 222 119 221 117 219 101 – –

17 209 209 200 203 196 169 189 175 186 160 187 139

22 232 192 229 165 229 138 228 125 226 106 – –

17 225 225 215 218 208 202 198 192 196 180 195 170

22 238 208 234 176 233 156 232 131 231 110 – –

17 237 237 226 228 217 224 204 205 203 199 201 195

22 239 213 235 178 234 161 233 133 232 111 – –

17 239 239 229 231 220 226 206 208 205 204 203 202

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 208 186 199 160 198 154 197 141 196 127 195 110

30582 19 218 216 210 182 206 173 205 156 203 133 202 117

35679 19 225 235 218 210 212 191 210 167 208 142 207 123

38228 19 227 236 221 217 213 196 211 170 209 144 208 124

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 216 167 214 146 213 126 213 113 2 11 98 – –

17 204 204 195 197 188 179 184 168 182 153 183 135

22 223 188 221 162 220 139 219 122 218 103 – –

17 219 219 209 211 201 199 192 187 187 179 184 169

22 229 204 226 174 225 151 223 129 222 107 – –

17 229 229 219 222 210 216 198 201 191 198 185 192

22 230 208 227 177 226 155 225 130 223 108 – –

17 232 232 222 224 213 219 199 205 192 202 186 195

32 30 28 27 25 23

20

YORK INTERNATIONAL

Page 21

FORM 100.50-EG3 (802)

T ABLE 4 – COOLING PERFORMANCE DATA* – 60 TON MODEL (CONT’D)

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 200 187 190 171 190 154 190 137 189 122 188 106

30582 19 210 208 198 188 197 172 197 152 195 133 194 11 4

35679 19 218 227 204 209 203 185 201 163 199 141 198 11 9

38228 19 220 229 206 217 204 189 202 166 200 144 199 121

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 208 165 206 143 205 126 205 110 204 94 – –

17 197 197 189 191 179 179 177 163 175 150 175 133

22 213 182 212 158 211 139 210 119 209 99 – –

17 211 211 202 205 193 197 185 183 180 166 181 147

22 217 195 217 168 216 148 214 125 213 103 – –

17 222 222 212 214 204 209 190 197 183 178 185 157

22 218 198 218 171 217 150 215 127 214 104 – –

17 224 224 214 217 206 212 192 200 184 181 186 159

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 187 187 182 169 182 150 181 134 179 118 178 103

30582 19 200 206 190 187 188 168 188 149 186 130 185 11 0

35679 19 210 219 195 200 193 180 193 159 191 138 190 11 5

38228 19 213 222 197 204 194 184 194 162 192 140 191 11 7

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 199 160 197 138 195 121 194 106 192 91 ––

17 190 190 181 183 172 174 167 160 165 147 165 131

22 203 177 203 154 202 134 200 115 199 96 ––

17 204 204 192 194 186 190 179 182 173 162 173 144

22 206 190 207 166 206 143 205 121 204 100 ––

17 214 214 200 202 197 202 188 196 178 173 178 154

22 207 193 208 169 208 145 206 123 205 100 ––

17 216 216 202 204 199 205 190 199 179 176 180 156

32 30 28 27 25 23

YORK INTERNATIONAL

21

Page 22

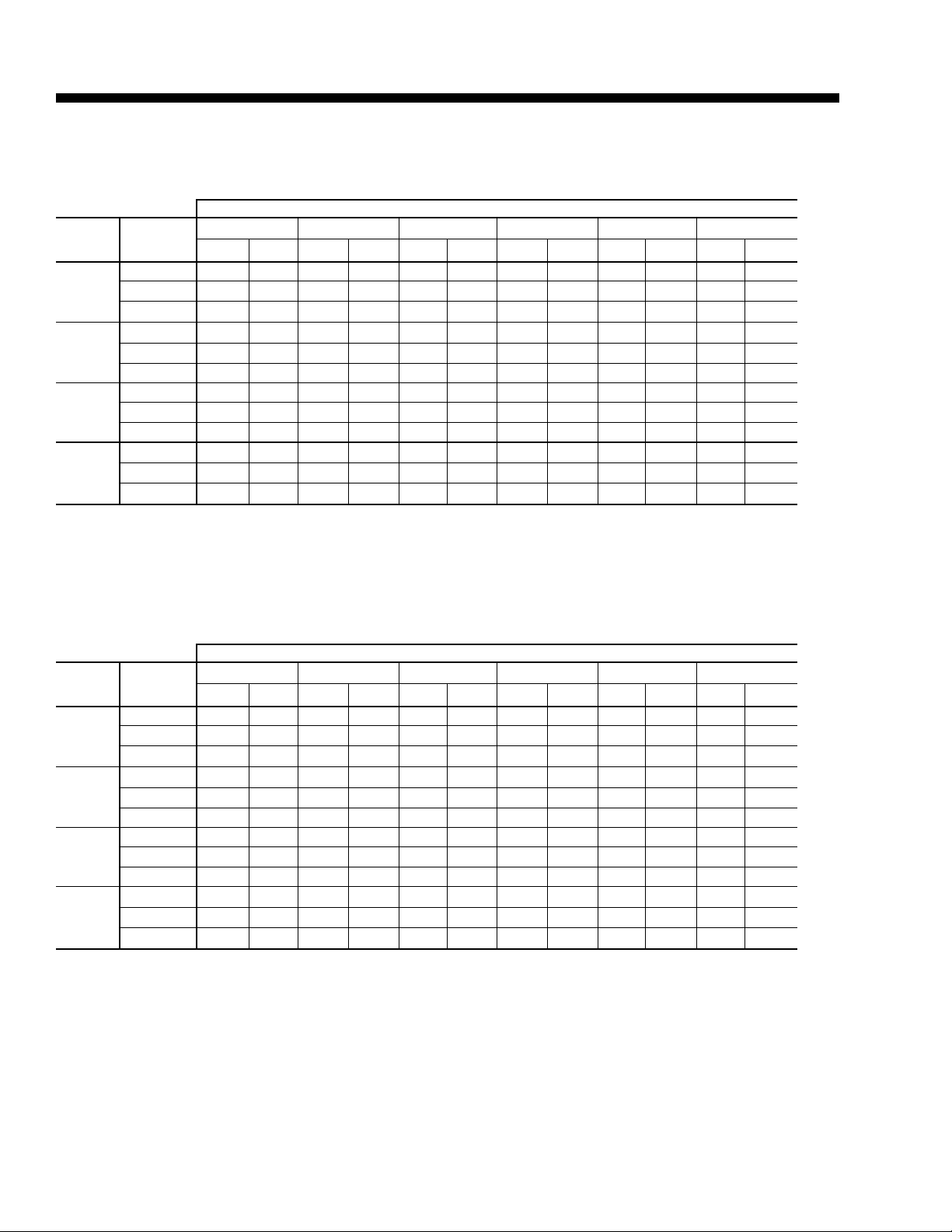

Cooling Performance Data – 65 Ton Model

T ABLE 5 – COOLING PERFORMANCE DA TA* – 65 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 215 196 209 179 208 162 208 146 207 130 206 114

30582 19 225 226 217 201 217 182 216 161 215 142 214 122

35679 19 234 244 223 216 222 194 221 171 220 149 218 128

38228 19 236 246 224 219 223 197 222 173 221 151 220 129

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 226 172 226 150 225 134 224 118 223 102 – –

17 211 211 202 205 193 186 194 172 192 159 192 143

22 235 193 233 166 232 147 231 127 230 108 – –

17 227 227 218 220 209 210 202 193 200 176 199 157

22 240 206 238 177 237 155 236 133 234 111 – –

17 238 238 227 224 219 215 208 196 205 177 204 155

22 241 210 239 180 238 157 237 134 236 112 – –

17 240 240 230 213 222 194 209 173 206 154 205 132

32 30 28 27 25 23

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 210 193 201 175 201 159 201 142 200 127 199 111

30582 19 218 220 209 197 209 178 208 157 207 138 206 119

35679 19 227 237 214 212 214 190 212 167 211 146 210 124

38228 19 229 239 216 215 215 193 214 170 212 148 211 125

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 218 168 217 147 217 131 216 115 214 99 – –

17 205 205 197 199 188 182 187 169 185 156 184 139

22 226 189 224 163 224 143 223 123 221 104 – –

17 221 221 211 214 203 204 195 189 193 173 192 154

22 231 203 229 173 228 151 227 129 225 108 – –

17 231 231 220 221 212 217 200 202 197 184 196 162

22 232 206 230 176 229 153 228 131 226 109 – –

17 233 233 221 218 215 216 201 203 199 185 198 162

32 30 28 27 25 23

22

YORK INTERNATIONAL

Page 23

FORM 100.50-EG3 (802)

T ABLE 5 – COOLING PERFORMANCE DATA* – 65 TON MODEL (CONT’D)

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 202 189 194 172 193 155 193 138 192 123 191 107

30582 19 210 213 202 194 200 174 200 154 198 135 197 11 5

35679 19 219 229 207 207 205 186 204 164 202 142 201 120

38228 19 222 231 209 211 206 189 205 166 204 144 202 121

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 210 165 209 143 208 127 207 111 206 95 – –

17 199 199 190 193 181 179 180 165 178 152 177 135

22 217 186 215 159 215 140 214 120 212 100 – –

17 214 214 204 207 196 199 187 185 185 169 184 149

22 222 199 219 169 219 148 218 126 216 104 – –

17 223 223 213 215 205 211 192 198 189 180 188 158

22 223 203 220 172 220 150 219 127 217 105 – –

17 225 225 215 218 207 213 193 202 190 183 189 161

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

23786 19 194 186 186 168 185 152 185 135 184 120 183 104

30582 19 202 207 192 188 192 170 191 150 190 131 189 111

35679 19 211 220 196 201 196 182 195 159 193 138 192 11 6

38228 19 214 223 197 205 197 185 196 162 194 140 193 11 8

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 201 161 200 139 199 123 198 107 197 91 – –

17 191 191 184 187 173 175 172 161 170 148 170 131

22 208 182 206 156 205 136 205 116 203 97 – –

17 206 206 195 197 188 192 182 184 177 165 176 145

22 212 195 211 166 209 144 209 122 207 100 – –

17 215 215 201 202 197 196 189 186 181 165 180 143

22 213 198 212 169 210 146 210 123 207 101 – –

17 217 217 202 199 200 183 191 162 182 142 181 120

32 30 28 27 25 23

YORK INTERNATIONAL

23

Page 24

Cooling Performance Data – 70 Ton Model

T ABLE 6 – COOLING PERFORMANCE DA TA* – 70 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 223 222 220 194 220 176 220 157 218 139 216 121

33980 19 239 249 234 224 230 199 229 175 227 153 225 131

37378 19 244 255 241 240 234 210 232 183 231 159 229 135

38228 19 245 256 242 242 234 212 233 185 231 160 229 136

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 238 186 237 162 236 147 235 125 233 106 – –

17 226 226 220 219 209 206 206 188 202 171 202 153

22 249 211 246 180 246 162 244 136 242 114 – –

17 243 243 240 242 224 230 220 214 212 192 211 170

22 252 224 250 190 249 169 247 140 246 117 – –

17 249 249 247 250 229 235 227 226 216 202 214 178

22 253 226 250 191 249 170 248 141 246 118 – –

17 250 250 248 251 229 235 229 228 217 204 215 179

32 30 28 27 25 23

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 223 218 213 192 212 173 212 153 210 136 209 118

33980 19 239 244 226 221 222 195 221 170 219 149 218 127

37378 19 244 255 233 236 225 206 224 179 222 155 221 131

38228 19 245 256 235 239 226 207 224 180 223 156 221 132

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 230 183 229 159 228 140 227 122 225 104 – –

17 226 226 213 212 208 206 198 184 195 168 195 149

22 240 208 238 177 237 154 236 133 231 109 – –

17 243 243 232 235 224 230 212 209 205 189 203 166

22 244 220 241 186 240 161 239 137 234 112 – –

17 249 249 239 242 228 235 219 221 208 199 206 173

22 244 222 242 188 240 162 239 138 235 113 – –

17 249 249 241 243 229 235 220 224 209 200 207 175

32 30 28 27 25 23

24

YORK INTERNATIONAL

Page 25

FORM 100.50-EG3 (802)

T ABLE 6 – COOLING PERFORMANCE DATA* – 70 TON MODEL (CONT’D)

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 216 215 205 196 204 174 204 153 202 134 201 11 4

33980 19 232 242 218 216 213 191 212 167 211 145 209 123

37378 19 237 247 225 231 217 201 215 175 214 151 212 127

38228 19 238 248 226 233 217 203 216 176 214 152 213 128

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 221 185 220 159 218 139 218 119 216 100 – –

17 219 219 205 204 201 199 191 186 187 169 187 149

22 231 203 229 173 227 150 227 129 225 108 – –

17 236 235 224 226 216 222 204 204 196 184 195 161

22 234 215 232 182 230 157 230 133 228 111 – –

17 241 241 230 233 221 227 211 216 200 194 198 169

22 235 217 232 183 230 158 230 134 228 111 – –

17 242 242 232 234 221 228 212 218 201 195 199 170

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 213 211 202 194 198 172 197 152 196 133 195 11 3

33980 19 224 234 209 212 205 187 204 163 202 141 201 11 9

37378 19 229 239 216 226 208 197 206 171 205 147 203 123

38228 19 230 240 217 228 209 199 207 172 205 148 204 124

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 215 184 213 157 212 138 211 118 209 99 – –

17 215 215 202 201 197 195 188 184 183 168 181 148

22 222 200 220 169 219 147 217 125 216 104 – –

17 228 228 215 217 209 215 196 200 189 181 187 158

22 225 211 223 178 221 153 220 129 218 107 – –

17 233 233 221 224 213 219 202 211 192 190 190 165

22 226 213 223 179 222 154 221 130 219 107 – –

17 234 234 222 225 214 220 204 213 193 192 191 167

32 30 28 27 25 23

YORK INTERNATIONAL

25

Page 26

Cooling Performance Data – 75 Ton Model

T ABLE 7 – COOLING PERFORMANCE DA TA* – 75 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 228 210 217 191 216 174 216 155 215 137 214 119

33980 19 244 237 231 220 227 198 226 174 224 153 223 131

37378 19 252 246 238 234 230 209 229 184 228 160 226 136

38228 19 254 247 239 237 231 212 230 186 228 161 227 136

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 244 183 233 159 233 141 232 123 230 104 – –

17 228 219 215 214 202 201 202 184 200 170 199 151

22 255 211 243 181 242 158 241 136 240 112 – –

17 248 238 234 237 217 224 216 209 2 11 193 209 170

22 259 224 247 191 245 166 244 141 243 116 – –

17 255 245 242 245 223 229 224 220 215 205 212 179

22 259 226 247 193 246 168 245 142 243 117 – –

17 256 246 243 246 224 230 225 222 216 207 213 180

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 220 210 217 191 216 174 216 155 215 137 214 119

33980 19 236 237 231 220 227 198 226 174 224 153 223 131

37378 19 244 246 238 234 230 209 229 184 228 160 226 136

38228 19 245 247 239 237 231 212 230 186 228 161 227 136

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 235 183 233 159 233 141 232 123 230 104 – –

17 224 219 215 214 202 201 202 184 200 170 199 151

22 246 211 243 181 242 158 241 136 240 112 – –

17 243 238 234 237 217 224 216 209 2 11 193 209 170

22 250 224 247 191 245 166 244 141 243 116 – –

17 250 245 242 245 223 229 224 220 215 205 212 179

22 250 226 247 193 246 168 245 142 243 117 – –

17 251 246 243 246 224 230 225 222 216 207 213 180

32 30 28 27 25 23

26

YORK INTERNATIONAL

Page 27

FORM 100.50-EG3 (802)

T ABLE 7 – COOLING PERFORMANCE DATA* – 75 TON MODEL (CONT’D)

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

22718484271 19 219 210 217 191 216 174 216 155 215 137 214 119

33980 19 235 237 231 220 227 198 226 174 224 153 223 131

37378 19 243 246 238 234 230 209 229 184 228 160 226 136

38228 19 244 247 239 237 231 212 230 186 228 161 227 136

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 226 183 233 159 233 141 232 123 230 104 – –

17 219 219 215 214 202 201 202 184 200 170 199 151

22 236 211 243 181 242 158 241 136 240 112 – –

17 238 238 234 237 217 224 216 209 211 193 209 170

22 240 224 247 191 245 166 244 141 243 116 – –

17 245 245 242 245 223 229 224 220 215 205 212 179

22 241 226 247 193 246 168 245 142 243 117 – –

17 246 246 243 246 224 230 225 222 216 207 213 180

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 212 210 217 191 216 174 216 155 215 137 214 11 9

33980 19 227 237 231 220 227 198 226 174 224 153 223 131

37378 19 235 246 238 234 230 209 229 184 228 160 226 136

38228 19 236 247 239 237 231 212 230 186 228 161 227 136

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 217 183 233 159 233 141 232 123 230 104 – –

17 212 219 215 214 202 201 202 184 200 170 199 151

22 227 211 243 181 242 158 241 136 240 112 – –

17 230 238 234 237 217 224 216 209 211 193 209 170

22 231 224 247 191 245 166 244 141 243 116 – –

17 237 245 242 245 223 229 224 220 215 205 212 179

22 231 226 247 193 246 168 245 142 243 117 – –

17 238 246 243 246 224 230 225 222 216 207 213 180

32 30 28 27 25 23

YORK INTERNATIONAL

27

Page 28

Cooling Performance Data – 80 Ton Model

T ABLE 8 – COOLING PERFORMANCE DATA* – 80 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 248 224 244 204 244 186 243 167 241 149 240 131

30582 19 256 239 250 216 250 196 249 175 247 156 246 136

37378 19 272 268 261 240 260 216 259 191 257 167 255 145

45307 19 293 301 271 265 269 237 268 208 265 180 263 154

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 265 195 264 172 262 153 261 135 259 116 – –

17 251 251 239 233 226 216 225 196 224 182 223 162

22 272 207 270 181 269 160 267 140 266 120 – –

17 259 259 251 250 237 236 231 208 230 192 229 171

22 282 228 281 198 279 173 277 150 275 127 – –

17 277 277 268 271 253 260 247 236 239 210 238 185

22 290 252 289 216 287 187 285 160 283 133 – –

17 298 298 278 281 264 271 267 274 247 230 246 200

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 240 220 235 200 235 181 234 163 233 146 231 127

30582 19 247 235 242 212 241 191 240 171 239 152 237 132

37378 19 263 264 252 235 251 211 250 186 248 164 246 140

45307 19 284 296 262 260 259 232 258 202 256 176 254 149

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 256 192 254 168 253 150 252 131 250 112 – –

17 243 243 231 225 226 216 218 193 215 177 215 158

22 262 203 261 176 259 156 258 137 256 117 – –

17 251 251 243 241 237 236 224 205 221 187 220 167

22 272 224 271 193 269 169 267 146 265 123 – –

17 268 268 259 262 253 260 239 233 230 204 230 181

22 280 247 279 211 277 183 275 156 273 129 – –

17 289 289 268 272 263 271 259 270 238 224 237 195

32 30 28 27 25 23

28

YORK INTERNATIONAL

Page 29

FORM 100.50-EG3 (802)

T ABLE 8 – COOLING PERFORMANCE DA TA* – 80 TON MODEL

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 235 229 227 196 226 177 226 160 224 142 222 123

30582 19 242 245 233 208 232 187 232 167 230 148 228 128

37378 19 257 269 242 231 241 206 241 182 239 159 237 136

45307 19 277 289 252 255 249 227 248 199 246 171 244 145

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 247 189 245 164 244 146 242 127 241 109 – –

17 237 237 222 216 219 209 210 189 207 173 206 154

22 253 200 251 172 250 153 248 133 246 114 – –

17 245 245 233 232 230 228 216 200 213 182 212 162

22 262 221 260 188 259 165 257 142 255 120 – –

17 262 262 249 252 245 252 230 227 221 200 221 176

22 270 243 268 206 267 178 265 151 262 126 – –

17 282 282 258 261 255 262 249 260 228 219 228 190

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 235 229 219 194 217 174 216 155 215 138 213 120

30582 19 242 244 224 206 223 184 222 162 220 143 219 124

37378 19 257 269 234 228 232 202 230 177 229 154 227 132

45307 19 277 289 243 251 239 223 238 193 236 166 234 141

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 237 185 235 161 234 142 233 124 231 105 – –

17 237 237 214 209 212 202 202 184 198 169 198 150

22 243 196 241 169 240 148 238 129 236 109 – –

17 245 245 225 224 222 220 208 196 204 178 203 158

22 252 216 250 185 249 160 247 138 245 115 – –

17 261 261 240 243 236 243 221 222 212 195 212 172

22 259 238 258 202 256 173 255 147 252 121 – –

17 282 282 249 252 246 253 239 250 219 213 218 185

32 30 28 27 25 23

YORK INTERNATIONAL

29

Page 30

Cooling Performance Data – 85 Ton Model

T ABLE 9 – COOLING PERFORMANCE DA TA* – 85 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 260 232 255 213 255 194 255 175 253 156 252 137

30582 19 267 249 263 227 262 206 262 184 260 164 259 143

37378 19 285 280 274 253 273 228 272 202 271 178 269 153

45307 19 309 315 284 281 283 252 281 221 279 192 277 164

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 277 204 277 180 275 160 274 141 273 121 – –

17 258 258 247 239 239 220 236 204 234 190 233 171

22 285 217 284 190 282 169 281 148 279 125 – –

17 269 269 260 257 246 235 244 218 241 201 240 180

22 296 242 294 209 293 184 292 159 290 134 – –

17 290 290 277 281 264 262 258 247 252 222 250 196

22 306 269 303 229 302 200 300 170 298 142 – –

17 314 314 289 293 287 292 276 283 261 245 258 214

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 250 229 246 209 246 190 245 171 244 152 243 133

30582 19 257 245 254 222 253 202 252 180 251 160 249 139

37378 19 275 276 265 248 263 223 262 197 261 173 259 149

45307 19 297 310 274 275 273 247 270 215 269 187 267 159

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 267 200 267 176 266 157 264 137 263 117 ––

17 249 249 240 232 232 224 228 201 225 185 225 166

22 275 213 273 186 272 165 271 144 269 122 ––

17 259 259 252 250 239 238 235 214 232 196 231 175

22 286 237 284 204 283 180 281 155 279 130 ––

17 279 279 269 272 256 263 249 243 242 216 241 191

22 295 264 292 224 291 195 289 166 287 138 ––

17 302 302 281 284 279 287 267 278 251 238 249 208

32 30 28 27 25 23

30

YORK INTERNATIONAL

Page 31

FORM 100.50-EG3 (802)

T ABLE 9 – COOLING PERFORMANCE DA TA* – 85 TON MODEL

40.5°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 241 223 237 204 236 185 236 166 234 148 233 129

30582 19 248 239 244 217 242 196 242 175 241 155 240 135

37378 19 264 269 254 242 253 218 252 192 250 168 249 144

45307 19 286 299 263 268 262 241 260 210 258 182 257 154

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 257 196 256 172 255 153 254 133 252 114 – –

17 239 239 233 225 232 223 219 196 217 181 216 162

22 264 209 263 181 262 161 261 140 259 118 – –

17 249 249 244 242 239 238 226 209 223 192 222 170

22 275 233 273 199 272 175 270 151 268 126 – –

17 269 269 261 264 256 263 240 237 233 212 231 186

22 284 258 281 218 280 190 278 161 276 134 – –

17 291 291 272 276 279 287 256 268 242 234 239 203

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

46.1°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

27184 19 231 219 227 199 226 181 226 162 225 144 224 124

30582 19 238 234 234 212 232 192 232 171 231 151 230 130

37378 19 254 263 244 237 242 212 242 187 240 164 239 140

45307 19 275 287 252 263 251 235 249 204 247 176 246 149

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 246 191 246 168 245 149 244 129 242 110 – –

17 230 230 224 217 224 216 210 191 208 177 207 157

22 253 204 252 177 251 156 250 135 248 114 – –

17 240 240 235 233 231 230 216 204 214 187 213 165

22 263 227 262 195 261 170 259 146 257 122 – –

17 258 258 251 254 247 254 230 231 223 206 222 181

22 272 252 270 213 269 185 267 156 264 130 – –

17 280 280 262 265 270 277 245 256 232 228 229 197

32 30 28 27 25 23

YORK INTERNATIONAL

31

Page 32

Cooling Performance Data – 90 Ton Model

TABLE 10 – COOLING PERFORMANCE DATA* – 90 TON MODEL

29.4°C AIR ON CONDENSER COIL

CAPACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

33980 19 292 272 286 247 286 224 285 200 283 179 282 156

40776 19 311 307 298 277 297 249 296 220 294 195 293 168

45307 19 325 328 305 295 304 265 301 233 300 205 298 175

50970 19 335 345 310 310 308 277 306 242 304 212 302 180

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 310 233 308 206 307 183 306 161 304 137 – –

17 293 293 286 286 269 258 266 239 262 219 262 195

22 322 260 320 228 318 201 317 174 315 146 – –

17 317 317 305 308 289 287 281 269 274 243 272 214

22 329 278 325 242 324 211 322 182 320 152 – –

17 330 330 314 318 302 305 290 290 280 258 278 225

22 334 292 330 252 328 219 326 188 324 157 – –

17 341 341 321 325 313 319 297 305 284 269 282 234

32 30 28 27 25 23

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

35°C AIR ON CONDENSER COIL

CAP ACITY (kW) AT ENTERING DRY BULB (°C)

m3/hr

33980 19 281 268 277 243 276 220 275 196 273 174 272 152

40776 19 300 302 288 272 287 244 285 215 284 189 282 163

45307 19 313 322 295 291 293 260 291 227 289 199 287 169

50970 19 323 337 300 305 298 272 295 236 293 206 291 175

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

ENTERING

WB (°C) CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC CAP SHC

22 299 233 298 202 296 179 295 157 293 133 – –