Page 1

TECHNICAL GUIDE

MODELS: MV

MODULAR VARIABLE SPEED AIR HANDLERS

FOR USE WITH SPLIT SYSTEM

COOLING & HEAT PUMP

1200 - 2000 CFM BLOWERS

3 - 5 TON COILS

OPTIONAL 1 & 3

ELECTRIC HEATERS

Due to continuous product improvement,

specifications are subject to change without notice.

Visit us on the web at:

www.york.com

Additional rating information can be found at:

www.ahridirectory.org

ISO 9001

Certified Quality

Management System

550569-YTG-D-1212

DESCRIPTION

This unique modular system allows the flexibility to handle an y

application. These versatile coils and blowers may be used for

upflow, downflow, or horizontal left or right applications. They

may be combined to function as a cooling only unit or with a

heat pump including electric heat for 1 and 3 phase applications. The blower and electric heater could be used as stand

alone electric furnaces.

FEATURES

Blowers - Models to match any air flow or voltage requirement.

The compact size allows easy installation. Blowers are sized to

deliver design air quantity both efficiently and quietly. The

motors provide a selection of air quantities to match any a pplication. All models include a one-minute blower off delay as

standard to enhance system efficiency ratings. The durable,

pre-painted steel protects the unit against rust and corrosion. All

models have 1 inch foil face fiber glass insulation, prov iding a

thermal insulation value of R-4.2.

Coils - Staggered rows of rifled copper tubes are mechanically

expanded into enhanced surface aluminum fins to provide high

heat transfer and long-lasting quality. The MC multi-position

coils may be used for upflow, downflow, and horizontal left or

right applications. Coil cabinets are insulated with 3/4" fo il face

insulation to prevent sweating.

Thermal Expansion Valves - Coils are ordered as “Flex-coil”

unit without a factory installed mertering device. Flex-coil models allow for field installed R-22 or R-410A TXV’s for added flexibility to meet refrigerant system choice.

Electric Heaters - Both single and three phase electri c heater

models are available to match any requirement. All heaters

include nickel-chromium elements with a 5-year limited warranty on 1 Ø heating elements and 1 yea r li mi ted w arranty o n 3

Ø heating elements. Sequential operation is provided to control

heaters in all models. Circuit breakers are used in 208/230 volt,

single-phase heaters of 15 KW and larger.

Models equipped with circuit breakers may be altered in the

field to use multi-source power supply. Over-temperature limit

switches provide protection fro m ai rfl o w lo ss w it h fu si bl e li nk

backup protection.

Communication - These models may be connected as part of

a communciations system using a 4-wire connection bus.

Accessories - A full line of matching accessories available for

use with the blower and coils to allow any type application.

LIMITATIONS

These units must be wired and installed in accordance with all

national and local safety codes.

Voltage limits are as follows:

AIR HANDLER VOLTAGE

208/230-1-60 187 - 253

* Rated in accordance with ARI Standard 110, utilization range “A”.

Air flow must be within the minimum and maximum limits approved for electric

heat, evaporator coils and outdoor units.

NORMAL OPERATING

VOLTAGE RANGE*

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

550569-YTG-D-1212

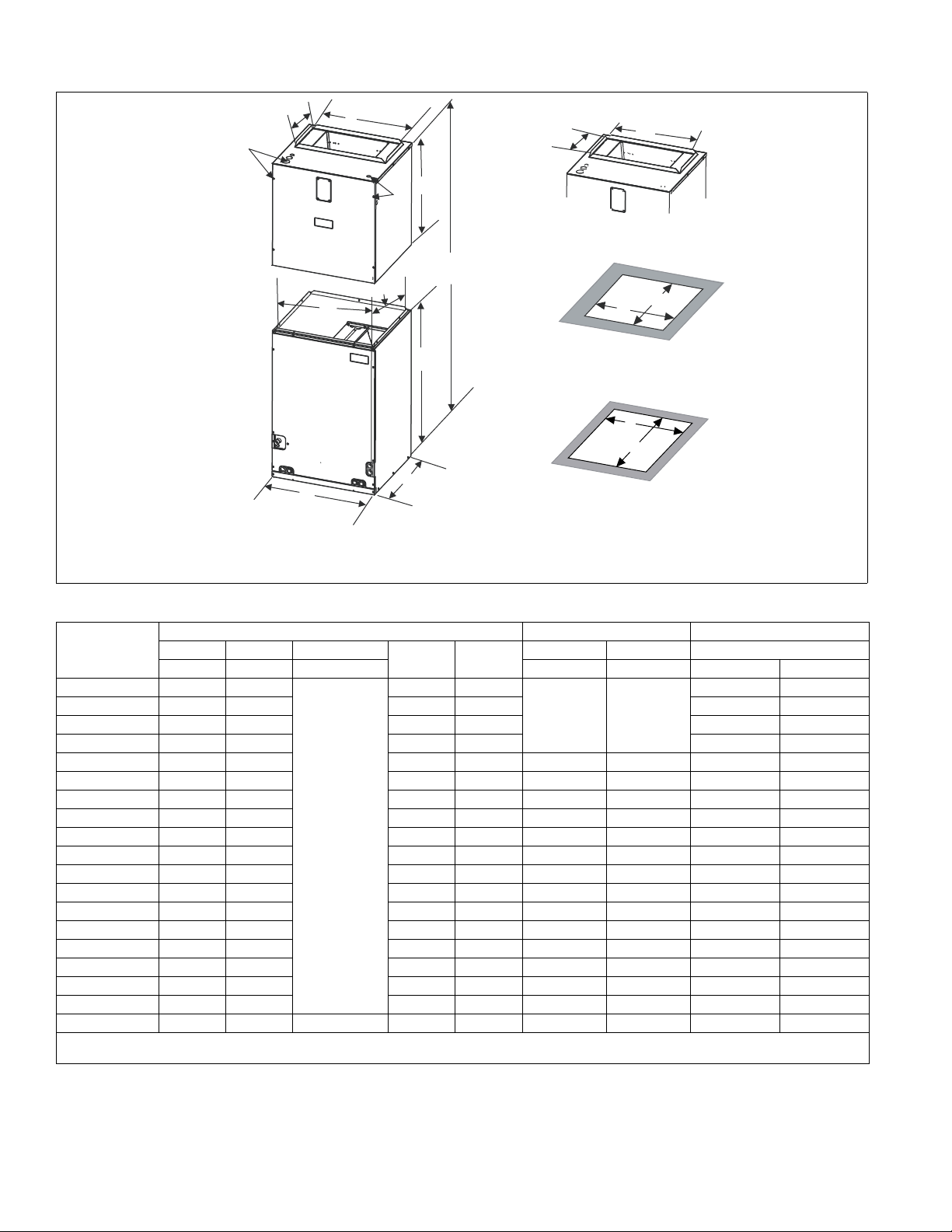

AIR HANDLER

MA / MV

COIL

MC

21.5”

B

A

C

(TOTAL HEIGHT)

E

20-3/8”

J

K

A

E

10-3/8”

10-3/8”

E

D

20-1/4”

D

20-1/2”

AIR HANDLER TOP (All Models)

AIR HANDLER BOTTOM OPENING

COIL BOTTOM OPENING

NOTE: Power wiring may be brought into the unit through one of the knockouts in either the top or the left side panel.

Multiple knockouts are provided to accommodate all of the electric heat and transformer accessories that are available.

Use the knockouts that provide the best wire routing for the accessory being used.

DIMENSIONS - (BLOWER WITH MC COILS)

DIMENSIONS

Dimensions Wiring K.O.’s

Model

MV12B 25 17.5

MV12D 25 24.5 23.5 21-19/32 – –

MV16C 25 21 20 18-3/32 – –

MV20D 25 24.5 23.5 21-19/32 – –

MC18B3XC1 22 17.5 16.5 16 3/8 – – 3/8 3/4

MC24B3XC1 26.5 17.5 16.5 16 3/8 – – 3/8 3/4

MC30B3XC1 26.5 17.5 16.5 16 3/8 – – 3/8 3/4

AB C

Height Width Total Height Power Control Liquid Vapor

DE

16.5 14-19/32

JK Line Size

7/8" (1/2")

1-3/8" (1")

1-23/32" (1-

1/4")

MC35B3XC1 22 17.5 16.5 16 3/8 – – 3/8 3/4

MC35C3XC1 22 21 20 19 7/8 – – 3/8 3/4

MC36B3XC1 26.5 17.5 16.5 16 3/8 – – 3/8 7/8

MC36C3XC1 26.5 21 20 19 7/8 – – 3/8 7/8

MC42B3XC1 32 17.5 16.5 16 3/8 – – 3/8 7/8

MC42C3XC1 32 21 20 19 7/8 – – 3/8 7/8

MC43B3XC1 26.5 17.5 16.5 16 3/8 – – 3/8 7/8

MC43C3XC1 26.5 21 20 19 7/8 – – 3/8 7/8

MC48C3XC1 32 21 20 19 7/8 – – 3/8 7/8

47 to 57

Depending

on combination

MC48D3XC1 32 24.5 23.5 23 3/8 – – 3/8 7/8

MC60D3XC1 32 24.5 23.5 23 3/8 – – 3/8 7/8

MC62D3XC1 36 24.5 61 23.5 23 3/8 – – 3/8 7/8

All MC coils include a factory installed horizontal drain pan.

(3X) = Models require field installed metering device.

1. Parenthesis indicate conduit size.

1

7/8" (1/2")

Refrigerant Connections

––

2 Johnson Controls Unitary Products

Page 3

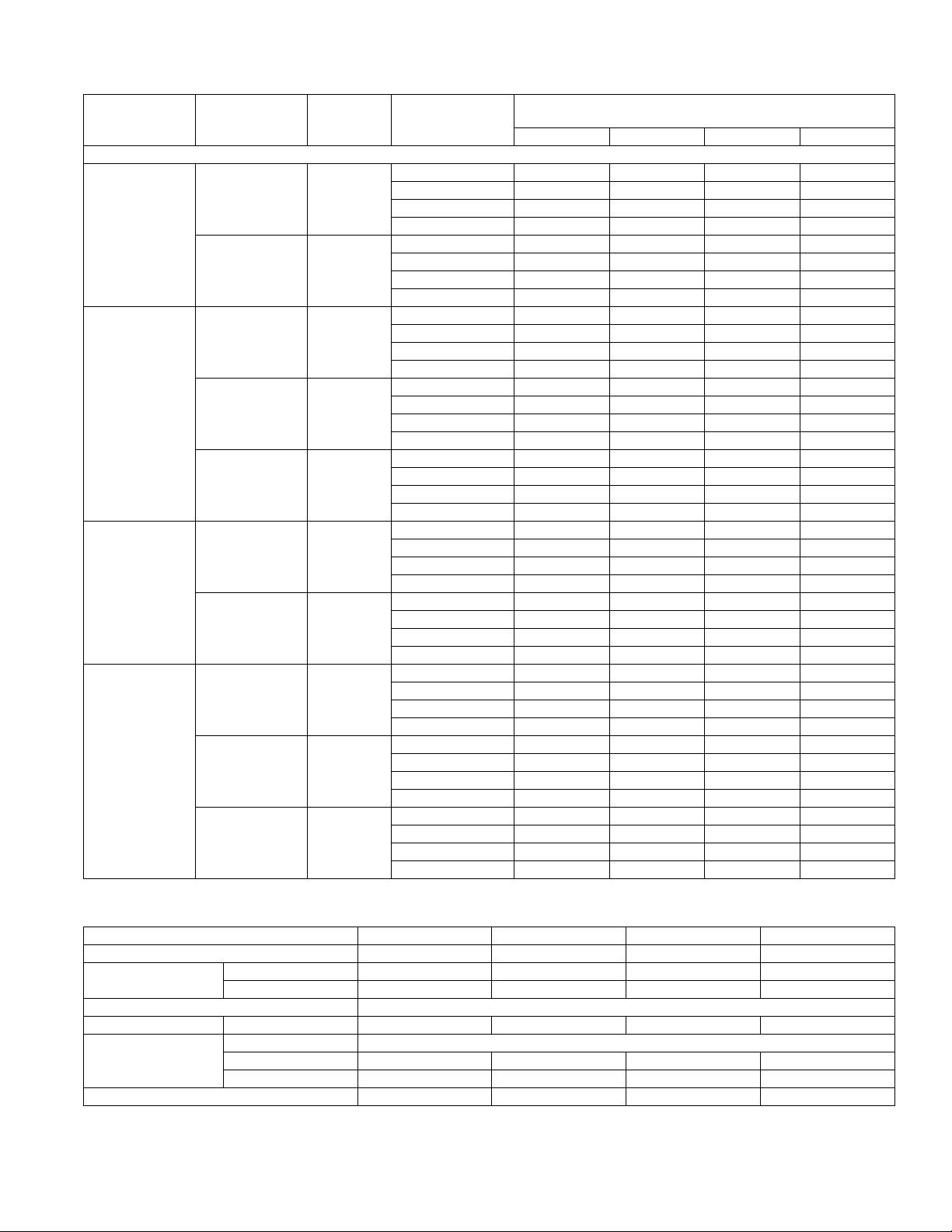

COOLING CAPACITY - Coil Only

Blower

Model

MV12B

MV12D

MV16C

MV20D

Coil

Model

MC30B**C 1025

MC36B**C 1250

MC48D**C 1125

MC60D**C 1275

MC62D**C 1450

MC42C**C 1400

MC48C**C 1650

MC48D**C 1725

MC60D**C 2000

MC62D**C 2200

Rated

CFM

Multi-Position - Upflow/Downflow/Horizontal

Entering Air F

(Dry/Wet Bulb)

85/72 41.5 37.8 33.7 29.5

80/67 36.2 32.4 28.6 24.5

75/62 29.1 25.3 24.0 19.2

70/57 24.1 21.5 18.7 15.8

85/72 52.0 47.3 42.3 37.3

80/67 41.7 36.8 32.3 27.4

75/62 32.5 27.3 29.8 22.2

70/57 27.9 25.8 23.8 22.2

85/72 46.8 42.4 37.6 33.0

80/67 37.4 33.3 29.4 24.3

75/62 28.9 24.6 21.7 19.6

70/57 25.1 23.3 21.7 19.6

85/72 53.7 48.4 43.5 37.5

80/67 43.0 38.0 33.3 27.7

75/62 33.1 28.1 24.5 22.4

70/57 28.8 26.5 24.5 22.4

85/72 91.7 78.4 68.1 52.3

80/67 73.4 61.5 52.0 38.6

75/62 57.3 45.6 38.4 31.2

70/57 49.2 43.0 38.4 31.2

85/72 88.4 76.0 63.3 50.0

80/67 70.8 59.4 48.4 37.0

75/62 55.2 43.9 35.8 29.9

70/57 47.4 41.5 35.8 29.9

85/72 100.5 86.4 72.0 56.8

80/67 80.4 67.5 55.0 42.1

75/62 62.7 49.9 40.7 34.0

70/57 53.9 47.2 40.7 34.0

85/72 119.9 101.0 80.0 62.2

80/67 96.0 79.2 62.6 45.8

75/62 74.0 58.6 46.2 37.0

70/57 64.3 55.4 46.2 37

85/72 124.8 105.2 85.3 64.7

80/67 99.9 82.5 65.2 47.7

75/62 77 61.1 48.1 38.6

70/57 66.9 57.7 48.1 38.6

85/72 131.0 110.5 89.6 67.9

80/67 104.9 86.6 68.5 50.1

75/62 81.8 64.2 50.5 40.5

70/57 70.2 60.6 50.5 40.5

35/61.5 40/68.5 45/76.0 50/84.0

550569-YTG-D-1212

MBH @ Evaporator Temperature and

Corresponding Pressure °F/PSIG

PHYSICAL & ELECTRICAL DATA

Model MV12B MV12D MV16C MV20D

Blower - Diameter x Width 10 x 7 10 x 10 10 x 10 10 x 10

Motor

Voltage 208/230

Amps Full Load (230) 4.3 4.3 5.0 7.0

Permanent Filter

Shipping/Operating Weight (lbs.) 75/71 88/82 88/82 94/88

1. Field Supplied.

1

HP 1/2 1/2 3/4 1

Nominal RPM 1200 1200 1200 1200

Type DISPOSABLE OR PERMANENT

Size 16 x 20 x 1 24 x 20 x 1 20 x 20 x 1 24 x 20 x 1

Filter Bulk Kit 1PF0601BK 1PF0604BK 1PF0602BK 1PF0604BK

Johnson Controls Unitary Products 3

Page 4

550569-YTG-D-1212

FULL CASED “A” TYPE MULTI-POSITION

Model Application

MC18B3XC1

MC24B3XC1

MC30B3XC1

MC35B3XC1

MC35C3XC1

MC36B3XC1

MC36C3XC1

MC42B3XC1

MC42C3XC1

MC43B3XC1

MC43C3XC1

MC48C3XC1

MC48D3XC1

MC60D3XC1

MC62D3XC1

Note: MC coils available with a factory installed horizontal drain pan option.

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Cooling/

Heat Pump

Refrig.

Conn.

Types

Sweat 3.40 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced None 53

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 56

Sweat 4.38 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced None 56

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 65

Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced None 67

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 65

Sweat 4.86 2 14 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 65

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 72

Sweat 5.83 2 14 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 72

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 73

Sweat 4.86 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced None 75

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 82

Sweat 5.35 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced None 82

Sweat 5.83 3 12 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced None 86

Sweat 6.80 3 12 (2) 28 x 17.5 1 x 0.866 3/8 Enhanced None 98

Face

Area

(Sq. Ft.)

Rows

Deep

Fin Per

In.

Coil Size

Tube

Geometry

Tube Dia. Fin Type TXV

Operating

Weight

(Lbs.)

4 Johnson Controls Unitary Products

Page 5

ELECTRICAL DATA - 208/230-1-60

Model Heater Model*

4HK*6500506 0.5 Heat-C 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

4HK*6500806 0.5 Heat-C 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

MV12B

4HK*6501006 0.5 Heat-B 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

4HK16501306 0.5 Heat B 9.8 13 33.3 44.4 3.3 4.3 6.5 8.7 9.8 13.0

4HK165N1506 0.5 Heat-B 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK*6500506 0.5 Heat-C 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

4HK*6500806 0.5 Heat-C 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

4HK*6501006 0.5 Heat-B 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

MV12D

4HK16501306 0.5 Heat B 9.8 13 33.3 44.4 3.3 4.3 6.5 8.7 9.8 13.0

4HK16501506 0.5 Heat-B 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK16501806 0.5 Heat-A 13.2 17.6 45.1 60.1 3.3 4.4 6.6 8.8 13.2 17.6

4HK16502006 0.5 Heat-A 14.4 19.2 49.2 65.5 3.6 4.8 7.2 9.6 14.4 19.2

4HK*6500506 0.5 Heat-D 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

4HK*6500806 0.5 Heat-D 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

4HK*6501006 0.5 Heat-C 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

MV16C

4HK16501306 0.5 Heat C 9.8 13 33.3 44.4 3.3 4.3 6.5 8.7 9.8 13.0

4HK16501506 0.5 Heat-C 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK16501806 0.5 Heat-B 13.2 17.6 45.1 60.1 3.3 4.4 6.6 8.8 13.2 17.6

4HK16502006 0.5 Heat-B 14.4 19.2 49.2 65.5 3.6 4.8 7.2 9.6 14.4 19.2

4HK*6500506 0.5 Heat-C 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

4HK*6500806 0.5 Heat-C 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

4HK*6501006 0.5 Heat-C 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

MV20D

4HK16501306 0.5 Heat C 9.8 13 33.3 44.4 3.3 4.3 6.5 8.7 9.8 13.0

4HK16501506 0.5 Heat-C 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK16501806 0.5 Heat-C 13.2 17.6 45.1 60.1 3.3 4.4 6.6 8.8 13.2 17.6

4HK16502006 0.5 Heat-C 14.4 19.2 49.2 65.5 3.6 4.8 7.2 9.6 14.4 19.2

4HK16502506 0.5 Heat-C 18.0 24.0 61.5 81.9 3.6 4.8 10.8 14.4 18.0 24.0

1. See conversion table on Page 7.

* May be 0 (no breaker) or 1 (with breaker).

Max.

Static

Min.

Speed

Tap

550569-YTG-D-1212

Total Heat

kW MBH W1 Only W2 Only W1 + W2

208V 230V 208V 230V 208V 230V 208V 230V 208V 230V

1

KW Staging

ELECTRICAL DATA - 208/230-3-60

Total Heat

kW MBH W1 Only W2 Only W1 + W2

Models

Heat Kit -

Three Phase

Max.

Static

Min.

Speed

Tap

208V 230V 208V 230V 208V 230V 208V 230V 208V 230V

MV12B 4HK06501025 0.5 Heat-B 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

4HK06501025 0.5 Heat-B 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

MV12D

4HK06501525 0.5 Heat-B 10.8 14.4 36.9 49.1 10.8 14.4 10.8 14.4 10.8 14.4

4HK06501825 0.5 Heat-A 12.9 17.2 44.7 58.7 12.9 17.2 12.9 17.2 12.9 17.2

4HK06501025 0.5 Heat-C 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

MV16C

4HK06501525 0.5 Heat-C 10.8 14.4 36.9 49.1 10.8 14.4 10.8 14.4 10.8 14.4

4HK06501825 0.5 Heat-B 12.9 17.2 44.7 58.7 12.9 17.2 12.9 17.2 12.9 17.2

4HK06501025 0.5 Heat-C 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

MV20D

4HK06501525 0.5 Heat-C 10.8 14.4 36.9 49.1 10.8 14.4 10.8 14.4 10.8 14.4

4HK16502525 0.5 Heat-C 18.0 24.0 61.4 81.4 9.0 12.0 18.0 24.0 18.0 24.0

1. See conversion table on Page 7.

1

KW Staging

Johnson Controls Unitary Products 5

Page 6

550569-YTG-D-1212

ELECTRICAL DATA (FOR SINGLE SOURCE POWER SUPPLY) - COPPER WIRE 208/230-1-60

Model Heater Model

1,*

Heater Amps

240V

Ampacity Min. Circuit Max. O.C.P.

208V 230V 208V 230V 208V 230V

4HK*6500506 20.0 27.54 30.38 30 35 10 8

4HK*6500806 31.3 39.73 44.50 40 45 8 8

MV12B

4HK*6501006 40.0 49.21 55.38 50 60 8 6

4HK16501306 54.2 64.00 72.80 70 80 4 2

4HK165N1506 60.0 70.88 80.38 90 90 4 3

4HK*6500506 20.0 27.54 30.38 30 35 10 8

4HK*6500806 31.3 39.73 44.50 40 45 8 8

4HK*6501006 40.0 49.21 55.38 50 60 8 6

MV12D

4HK16501306 54.2 64.00 72.80 70 80 4 2

4HK16501506 60.0 70.88 80.38 90 90 4 3

4HK16501806 73.3 85.32 97.00 90 100 4 3

4HK16502006 80.0 92.54 105.38 100 125 3 1

4HK*6500506 20.0 29.29 31.88 30 35 10 8

4HK*6500806 31.3 41.48 46.00 45 50 8 8

4HK*6501006 40.0 50.96 56.88 60 60 6 6

MV16C

4HK16501306 54.2 66.40 75.20 70 80 4 2

4HK16501506 60.0 72.63 81.88 90 90 3 3

4HK16501806 73.3 87.07 98.50 90 100 3 2

4HK16502006 80.0 94.29 106.88 100 125 3 1

4HK*6500506 20.0 29.29 31.88 30 35 10 8

4HK*6500806 31.3 41.48 46.00 45 50 8 8

4HK*6501006 40.0 53.08 58.75 60 60 6 6

MV20D

4HK16501306 54.2 68.40 77.20 70 80 4 2

4HK16501506 60.0 74.75 83.75 90 90 3 3

4HK16501806 73.3 89.19 100.38 90 110 3 2

4HK16502006 80.0 96.42 108.75 100 125 3 1

4HK16502506 100.0 118.08 133.75 125 150 1 1/0

1. 30 kW 3 phase not approved for single source power supply.

2. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

* May be 0 (no breaker) or 1 (with breaker).

Field Wiring

2

Amps/Type Wire Size - AWG 75°C

ELECTRICAL DATA (FOR SINGLE SOURCE POWER SUPPLY) - COPPER WIRE 208/230-3-60

Heater

Amps

240V

Min. Circuit Ampacity Max. O.C.P.

208V 230V 208V 230V 208V 230V

Models

Heat Kit -

Three Phase

MV12B 4HK06501025 23.1 30.9 34.3 35 35 8 8

4HK06501025 23.1 30.9 34.3 35 35 8 8

MV12D

4HK06501525 34.7 43.4 48.8 45 50 8 8

4HK06501825 41.4 50.6 57.1 50 60 8 6

4HK06501025 23.1 32.6 35.1 35 35 8 8

MV16C

4HK06501525 34.7 45.1 49.6 45 50 8 8

4HK06501825 41.4 52.4 58.0 60 60 6 6

MV20D

1. O.C.P. = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

4HK06501025 23.1 34.8 37.6 35 40 8 8

4HK06501525 34.7 47.3 52.1 50 60 8 6

Field Wiring

1

Amps/Type 75°C Wire Size - AWG

Electrical Data - (For Multi-Source Power Supply) - Copper Wire - 208/230-3-60

Minimum Circuit Ampacity Max. O.C.P.

Models

Heater

Model

1st 2nd 3rd 1st 2nd 3rd 1st 2nd 3rd

208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

MV20D 4HK16502525 41.0/44.9 31.3/36.1 – 45/45 35/40 – 8/8 8/8 –

1. O.C.P. = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

1

Amps/Type 75°C Wire Size - AWG

Circuit

6 Johnson Controls Unitary Products

Page 7

ELECTRICAL DATA (FOR MULTI SOURCE POWER SUPPLY) - COPPER WIRE 208/230-1-60

ELECTRIC HEAT

WITHOUT CIRCUIT BREAKER

SINGLE SOURCE (2.5 - 10 KW)

GND. LUG

POWER

SUPPLY

GND.

LUG

ELECTRIC HEAT

WITHOUT CIRCUIT BREAKER

3 PHASE (10 - 15 KW)

GND. LUG

POWER

SUPPLY

GND.

LUG

1 PHASE ELECTRIC HEAT

WITH CIRCUIT BREAKER

AS SHIPPED FROM FACTORY

SINGLE SOURCE

(2.5 - 25 KW) - 25 KW SHOWN

GND. LUG

POWER

SUPPLY

GND.

LUG

1 PHASE ELECTRIC HEAT

WITH CIRCUIT BREAKER

& BREAKER BAR REMOVED

MULTI-SOURCE (15 - 25 KW) - 25 KW SHOWN

GND. LUG

POWER

SUPPLY 1

GND.

LUG

POWER

SUPPLY 2

POWER

SUPPLY 3

TYPICAL WIRING WITHOUT ELECTRIC HEAT

GND. LUG

POWER

SUPPLY

GND.

LUG

POWER WIRING (208/230-1-60)

NOTE: USE ONLY COPPER CONDUCTORS

TERMINAL

BLOCK

TERMINAL

BLOCK

MAYBE1,2,OR3

CIRCUIT BREAKERS

MAYBE1,2,OR3

CIRCUIT BREAKERS

(JUMPER BAR)

CONNECT LEADS WITH WIRE NUTS

(TYPICAL ALL HEAT KITS)

Min. Circuit Ampacity Max. O.C.P.1 Amps/Type 75°C Wire Size - AWG

Model

Heater

Model

1st 2nd 3rd 1st 2nd 3rd 1st 2nd 3rd

Circuit Circuit Circuit

208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

MV12B

4HK16501306 41.7/47.9 22.4/25.0 – 50/50 30/30 – 6/6 12/10 –

4HK165N1506 49.2/55.4 21.7/25.0 – 50/60 25/25 – 8/6 10/10 –

4HK16501306 41.7/47.9 22.4/25.0 – 50/50 30/30 – 6/6 12/10 –

MV12D

4HK16501506 49.2/55.4 21.7/25.0 – 50/60 25/25 – 8/6 10/10 –

4HK16501806 45.6/51.2 39.7/45.8 – 50/60 40/50 – 8/6 8/8 –

4HK16502006 49.2/55.4 43.3/50.0 – 50/60 45/50 – 8/6 8/8 –

4HK16501306 42.9/49.1 23.6/26.2 – 50/50 30/30 – 6/6 12/10 –

MV16C

4HK16501506 51.0/56.9 21.7/25.0 – 50/60 25/25 – 8/6 10/10 –

4HK16501806 17.3/52.7 39.7/45.8 – 50/60 40/50 – 8/6 8/8 –

4HK16502006 51.0/56.9 43.3/50.0 – 50/60 45/50 – 8/6 8/8 –

4HK16501306 43.9/50.1 24.6/27.2 – 50/60 30/30 – 6/6 10/10 –

4HK16501506 53.1/58.8 21.7/25.0 – 60/60 25/25 – 6/6 10/10 –

MV20D

4HK16501806 49.5/54.6 39.7/45.8 – 50/60 40/50 – 8/6 8/8 –

4HK16502006 53.1/58.8 43.3/50.0 – 60/60 45/50 – 6/6 8/8 –

4HK16502506 49.3/56.5 43.3/50.0 21.7/25.0 50/60 45/50 25/25 8/6 8/8 10/10

1. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

KW & MBH CONVERSIONS

FOR

208-VOLT

230-VOLT 240-VOLT .918

OPERATION MULTIPLY

240-VOLT

TABULATED KW & MBH BY

550569-YTG-D-1212

.751

ELECTRICAL DA TA - COOLING UNIT ONL Y (60 Hz)

MODEL

MV12B 4.7 4.3 5.9 5.4 15 14

MV12D 4.7 4.3 5.9 5.4 15 14

MV16C 6.1 5.0 7.6 6.9 15 14

MV20D 7.8 7.0 9.7 8.8 15 14

1. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

POWER WIRING

Johnson Controls Unitary Products 7

Total Motor Amps Minimum Circuit Ampacity

60 Hertz 60 Hertz

208V 230V 208V 230V

Max. O.C.P.

1

Minimum Wire Size

Amps/Type

AWG @ 75°C

Page 8

550569-YTG-D-1212

1/2”

22”

C

19-7/8”

B

D

1-1/2”

3-1/2”

A

22”

21”

1/2”

(All four sides)

2” Max

Thick

Filter

3/4”

1/2”

3-1/2”

1/2”

7/8”

NOTE: May be used with up to a 2” filter.

Required for downflow application.

May also be used in upflow application.

Comes with 1” permanent filter.

All dimensions are inches. They are subject to change

without notice. Certified dimensions will be provided upon

request.

1”

A

16-1/2”

20”

23-1/2”

ACCESSORY FOOTPRINT

ACCESSORIES

Refer to Price Manual for specific model numbers.

Electric Heaters - Models shown under Electrical Data include

sequencers and temperature limit switches and fusible links for

safe, efficient operation. Circuit breakers are provided where

shown.

Suspension Kit - Suspension Kit Model 1BH0601 is designed

specifically for upflow application of the units contained in this

technical guide. For suspension of these units in horizontal

applications, it is recommended to use angle support brackets

with threaded rods at locations shown in air handler installation

instructions.

Filter Rack - One of the following external filter rack accessories: 1FR07* or 1FR08* must be used when unit is installed for

application outlined.

Combustible Floor Base - If an electric h eat accessory which

is rated for greater than zero clearance to combustible surfaces

is installed in these air handlers in the downflow operating positions on a combustible floor, one of the following combustible

floor base accessories is required: 1FB1817, 1FB1821, or

1FB1824.

FILTER RACK ACCESSORY

DIMENSIONS

Filter Rack Model

Multi-PositionHorizontal Only ABCDWidthLengthThickness

Used With

1FR0817 1FR0717 MV12B 17-1/2 16-3/8 15-1/2 21 16 20 1

1FR0821 1FR0721 MV16C 21 19-7/8 19 21 20 20 1

1FR0824 1FR0724 MV12D, MV20D 24-1/2 23-3/8 22-1/2 21 24 20 1

8 Johnson Controls Unitary Products

Rack Dimensions Inches Filter Dimensions Inches

Page 9

550569-YTG-D-1212

DOWNFLOW

AIR HANDLER

WARM AIR PLENUM

WITH 1” FLANGES

FIBERGLASS

INSULATION

FIBERGLASS TAPE

UNDER FLANGE

COMBUSTIBLE FLOOR

BASE ACCESSORY

A

B

B

A

AIR HANDLER

DEPTH

FRONT

FLOOR

1

10-47/64

PLENUM

12-1/2

FLOOR OPENING

APPROX. 1/2”

CLEARANCE

ALL AROUND

FLOOR

A

AIR HANDLER

WIDTH

COMBUSTIBLE

FLOOR BASE

11

APPROX. 1/2”

CLEARANCE

ALL AROUND

C

FLOOR OPENING

B

PLENUM

All dimensions are in inches. They are subject to change without notice.

Certified dimensions will be provided upon request.

UPFLOW

DOWNFLOW

HORIZONTAL RIGHT

HORIZONTAL LEFT

COMBUSTIBLE FLOOR BASE ACCESSORY

DIMENSIONS

Floor Base Model Used with

ABCD

1FB1817 MV12B 19.9 18.0 14.9 16.9

1FB1821 MV16C 23.4 21.5 18.4 20.4

1FB1824 MV12D, MV20D 26.9 25.0 21.9 23.9

Dimensions

APPLICATION FACTORS - Rated CFM vs. Actual CFM

% OF RATED AIR FLOW 80% 9 0% RATED CFM 110% 120%

CAPACITY FACTOR 0.96 0.98 1.00 1.02 1.03

TYPICAL APPLICATIONS WITH MC MULTI-POSITION COILS

Johnson Controls Unitary Products 9

Page 10

550569-YTG-D-1212

Air Handler Control Wiring

Typical A/C - Cooling only Applications

THERMOSTAT

AIR HANDLER

BOARD

1-STAGE

AIR CONDITIONING

RR

G

Y

W1

W2

C

G

W1

W2

Y

C

Y/Y2

Y1

O

HUM

X/L

COM

HUMIDISTAT

*

THERMOSTAT

AIR HANDLER

BOARD

1-STAGE

AIR CONDITIONING

RR

G

Y

W1

W2

C

G

W1

W2

Y

C

Y/Y2

Y1

O

HUM

X/L

COM

HUMIDISTAT

*

Air Handler Control Wiring

Typical A/C with Electric Heat Applications

y

Two Stage H/P with York Guard VI Board & Copeland “Ultra Tech”

Conventional Application - Not Hot Heat Pump

THERMOSTAT

AIR HANDLER

BOARD

2 - STAGE SCROLL

HEAT PUMP

RR R

GG

Y2

E

W

W

O O

O

X/L X/L X/L

C

C

Y/Y2

Y1

Y1

Y2 OUT

Y2

W2 OUT

W1 OUT

BS

W2

W1

HUM

COM

HUMIDISTAT

*

Y1

7RXFK6FUHHQ

&RPPXQLFDWLQJ&RQWURO

$

5

%

&

$LU+DQGOHU

&RPPXQLFDWLQJ&RQWURO

&

%

5

:

:

$

2

+80

;/

5

*

<<

<

&20

$LU&RQGLWLRQHU+HDW3XPS

&RPPXQLFDWLQJ&RQWURO

&

%

5

$

CONVENTIONAL CONTROL WIRING (24 VAC)

* Optional dehumidification humidistat switch contacts open on humidity rise.

CONTROL WIRING USING COMMUNICATION

10 Johnson Controls Unitary Products

Page 11

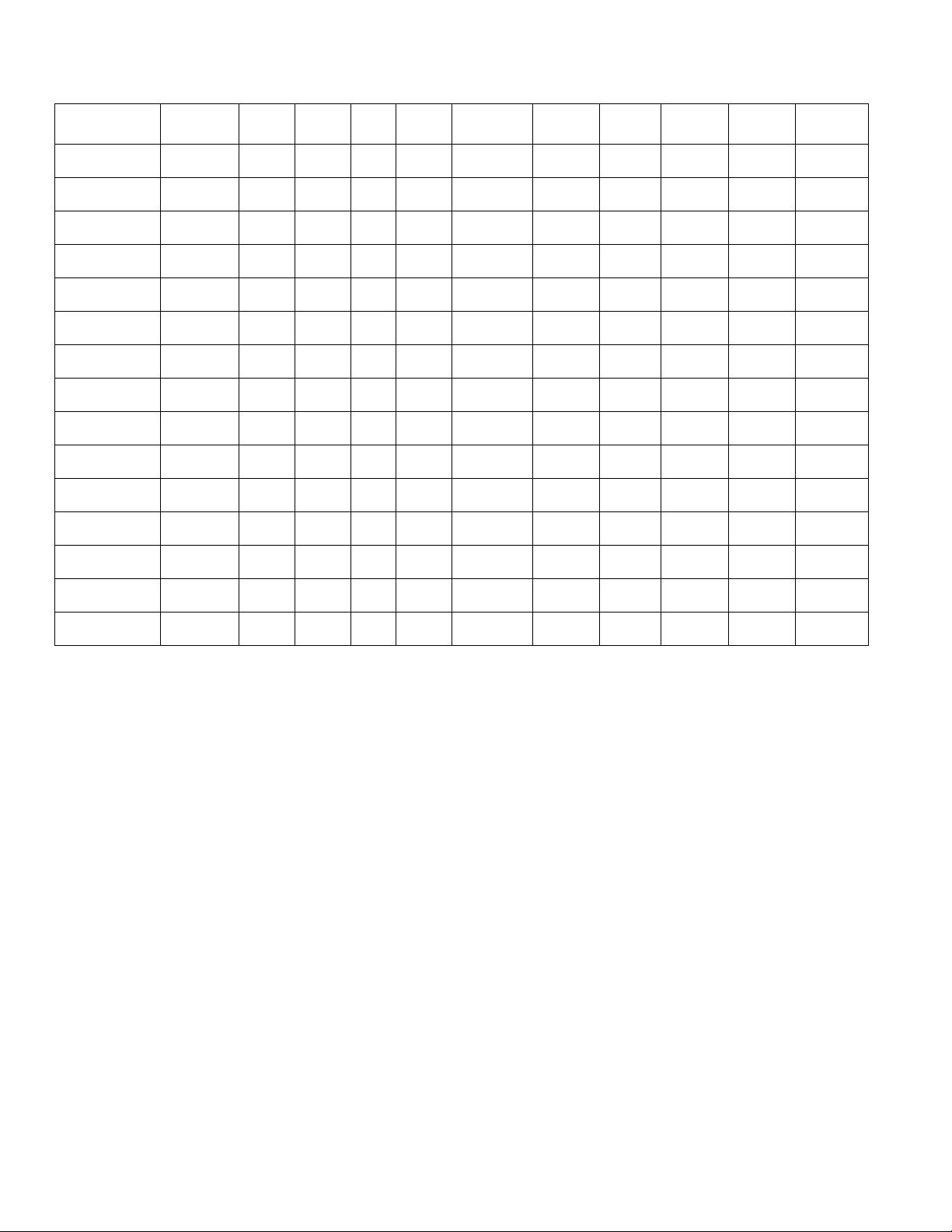

AIR HANDLER AIR FLOW DATA

12B 12D

High Low High Low COOL Tap ADJ Tap

1385 896 1411 907 A B

1137 745 1159 767 B B

1203 777 1227 799 A A

1019 650 1007 662 B A

1085 690 1083 716 A C

943 615 958 629 C B

889 585 908 603 B C

746 493 767 537 D B

817 537 840 568 C A

646 467 660 516 D A

738 481 780 532 C C

580 465 603 517 D C

16C 20D JUMPER SETTINGS

High Low High Low COOL Tap ADJ Tap

2005 1433 2404 1579 A B

1768 1145 2022 1313 B B

2009 1299 2167 1388 A A

1615 1040 1801 1159 B A

1787 1159 1924 1256 A C

1524 988 1818 1175 C B

1445 940 1620 1024 B C

1350 883 1638 1049 D B

1384 906 1628 1030 C A

1215 800 1442 929 D A

1236 810 1434 911 C C

1086 716 1305 859 D C

HIGH/LOW SPEED COOLING AND HEAT PUMP AIRFLOW

CFM

550569-YTG-D-1212

JUMPER SETTINGS

HIGH/LOW SPEED ELECTRIC HEAT AIRFLOW

CFM

12B 12D

High Low High Low HEAT Tap ADJ Tap

1385 900 1411 913 A N/A

1228 795 1258 817 B N/A

1137 748 1159 769 C N/A

917 603 928 619 D N/A

16C 20D JUMPER SETTINGS

High Low High Low HEAT Tap ADJ Tap

2006 1411 2408 1515 A N/A

1868 1243 2218 1285 B N/A

1468 983 1902 1070 C N/A

1248 840 1407 823 D N/A

1. Airflow at nominal voltage, bottom return at 0.5 external sta tic pressure, tested without filter installed, dry coil conditions.

2. These units have variable speed motors that automatically adjust to provide constant CFM from 0.0” to 0.6” w.c. static pressure.

3. From 0.6” to 1.0” static pressure, CFM is reduced by 2% per 0.1” increase in static.

4. Operation on duct systems with greater than 1.0” w.c. external static pressure is not recommended.

5. Both the COOL and the ADJUST tap must be set to obtain the cooling airflow desired (CFM).

6. The ADJ tap does not affect the HEAT tap setting.

7. Low speed cooling used only with two stage outdoor units. (Speed is preset to 65% of high speed).

8. Dehumidification speed is 85% of jumper selected COOL tap and ADJUST tap.

9. When operating in both heat pump and electric heat modes, the airflow (CFM) will be per HEAT Tap CFM values only.

10. At some settings, LOW COOL and/or LOW HEAT airflow may be lower than what is required to operate an airflow switch on certain models of electronic air

cleaners. Consult the instructions for the electronic air cleaner for further details.

11. Airflow (CFM) indicator light (LED2) flashes once for every 100 CFM (i.e.: 12 Flashes is 1200 CFM) – blinks are approximate +/- 10% of actual CFM.

JUMPER SETTINGS

Johnson Controls Unitary Products 11

Page 12

NOTES

Subject to change without notice. Published in U.S.A. 550569-YTG-D-1212

Copyright © 2012 by Johnson Controls, Inc. All rights reserved. Supersedes: 550569-YTG-C-1010

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...