Page 1

255427-YTG-F-1006

DESCRIPTION

This unique modular system allows the flexibility to handle any

application. These versatile coils and blowers may be used for

upflow, downflow, or horizontal left or right applications. They

may be combined to function as a cooling only unit or with a heat

pump including electric heat for 1 and 3 phase applications. The

blower and electric heater could be used as stand alone electric

furnaces.

TECHNICAL GUIDE

MODELS: MV

MODULAR VARIABLE SPEED AIR HANDLERS

FOR USE WITH SPLIT SYSTEM

COOLING & HEAT PUMP

1200 - 2000 CFM BLOWERS

3 - 5 TON COILS

OPTIONAL 1 & 3

φ ELECTRIC HEATERS

ISO 9001

Certified Quality

Management System

FEATURES

BLOWERS - Models to match any air flow or voltage require-

ment. The compact size allows easy installation. Blowers are

sized to deliver design air quantity both efficiently and quietly.

The motors provide a selection of air quantities to match any

application. All models include a one-minute blower off delay as

standard to enhance system efficiency ratings. The durable, prepainted steel protects the unit against rust and corrosion. All

models have 1 inch foil face fiber glass insulation, provid ing a

thermal insulation value of R-4.2.

COILS - Staggered rows of rifled copper tubes are mechanically

expanded into enhanced surface aluminum fins to provide high

heat transfer and long-lasting quality. The MC multi-position

coils may be used for upflow, downflow, and horizontal left or

right applications. Coil cabinets are insulated with 3/4" foil face

insulation to prevent sweating.

ELECTRIC HEATERS - Both single and three phase electric

heater models are available to match any requirement. All heaters include nickel-chromium elements with a 5-year limited warranty on 1 Ø heating elements and 1 year limited warranty on 3

Ø heating elements. Sequential operation is provided to control

heaters in all models. Circuit breakers are used in 208/230 volt,

single-phase heaters of 15 KW and larger.

Models equipped with circuit breakers may be altered in the field

to use multi-source power supply. Over-temperature limit

switches provide protection from airflow loss with fusible link

backup protection.

ACCESSORIES - A full line of matching accessories available

for use with the blower and coils to allow any type application.

LIMIT ATIONS - These units must be wired and installed in

accordance with all national and local safety codes.

Voltage limits are as follows:

AIR HANDLER VOLTAGE

208/230-1-60 187 - 253

* Rated in accordance with ARI Standard 110, utilization range “A”.

Air flow must be within the minimum and maximum limits approved for electric

heat, evaporator coils and outdoor units.

NORMAL OPERATING

VOLTAGE RANGE*

Due to continuous product improve m en t, specifications

subject to change without notice.

Visit us on the web at www.york.com

Additional rating information can be found at

www.ari.org/aridirectory

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

255427-YTG-F-1006

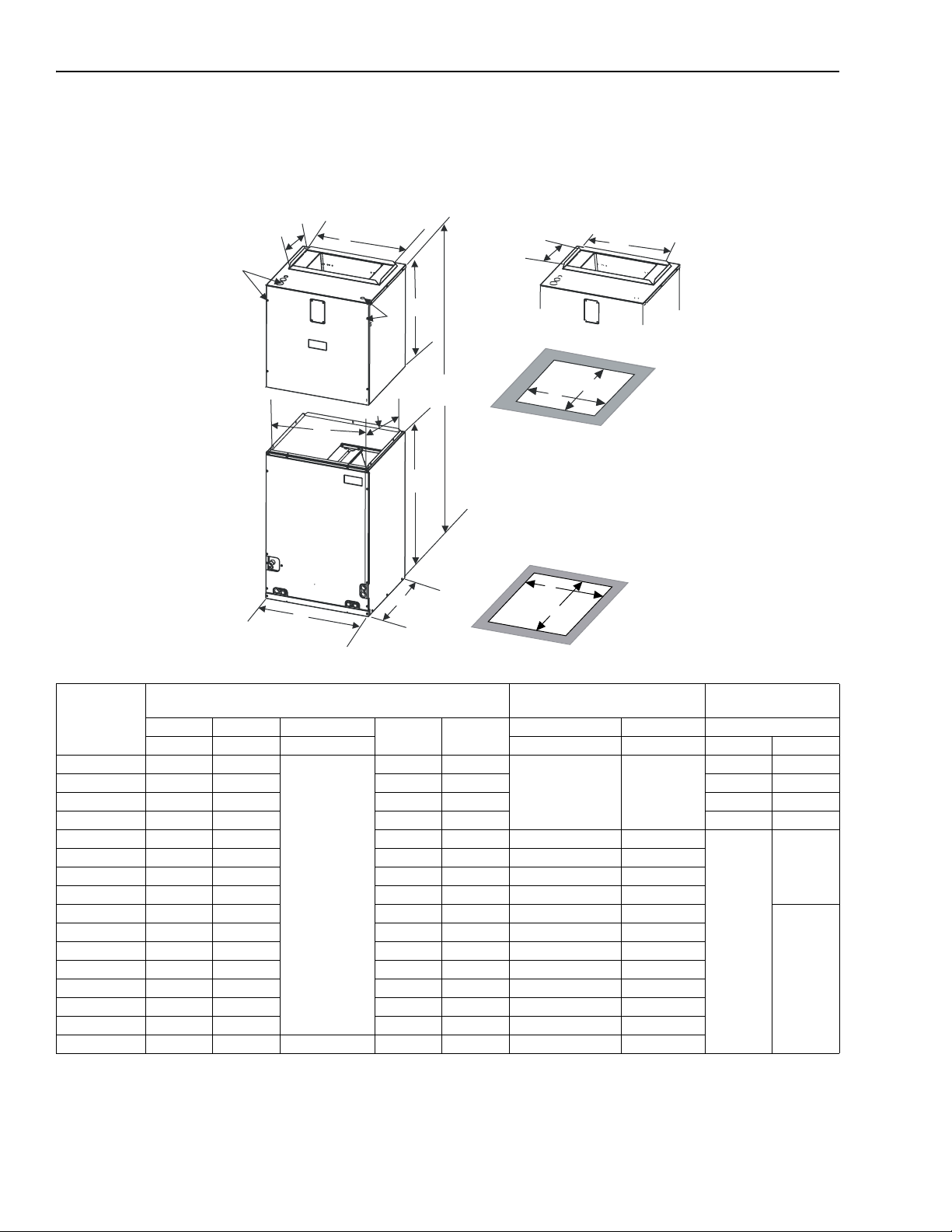

DIMENSIONS - (BLOWER WITH MC COILS)

NOTE: Power wiring may be brought into the unit through one of the knockouts in either the top or the left side panel. Multiple

knockouts are provided to accommodate all of the electric heat and transformer accessories that are available. Use the knockouts that provide the best wire routing for the accessory being used.

AIR HANDLER TOP (All Models)

10-3/8”

D

D

20-1/4”

E

20-1/2”

COIL BOTTOM OPENING

J

AIR HANDLER

MA / MV

COIL

MC

10-3/8”

E

A

K

C

(TOTAL HEIGHT)

20-3/8”

E

A

21.5”

B

AIR HANDLER BOTTOM OPENING

DIMENSIONS

Dimensions

Model

MV12B 25 17-1/2

AB C

Height Width Total Height Power Control Liquid Vapor

DE

16-1/2 14-19/32

MV12D 25 24-1/2 23-1/2 21-19/32 – –

MV16C 25 21 20 18-3/32 – –

Wiring K.O.’s

JKLine Size

7/8" (1/2")

1-3/8" (1")

1-23/32" (1-1/4")

1

7/8" (1/2")

MV20D 25 24-1/2 23-1/2 21-19/32 – –

MC24B**H 26-1/2 17-1/2 16-1/2 16-3/8 – –

MC30B**H 26-1/2 17-1/2 16-1/2 16-3/8 – –

MC35B**H 22 17-1/2 16-1/2 16-3/8 – –

MC35C**H 26-1/2 21 20 19-7/8 – –

MC36B**H 26-1/2 17-1/2 16-1/2 16-3/8 – –

47 to 57

Depending

on combination.

MC36C**H 26/1/2 21 20 19-7/8 – –

MC42B**H 32 17-1/2 16-1/2 16-3/8 – –

MC42C**H 32 21 20 19-7/8 – –

MC48C**H 32 21 20 19-7/8 – –

MC48D**H 32 24-1/2 23-1/2 23-3/8 – –

MC60D**H 32 24-1/2 23-1/2 23-3/8 – –

MC61D**H 36 24-1/2 61 23-1/2 23-3/8 – –

1. Parenthesis indicate conduit size

Refrigerant

Connections

––

3/8

3/4

7/8

2 Unitary Products Group

Page 3

255427-YTG-F-1006

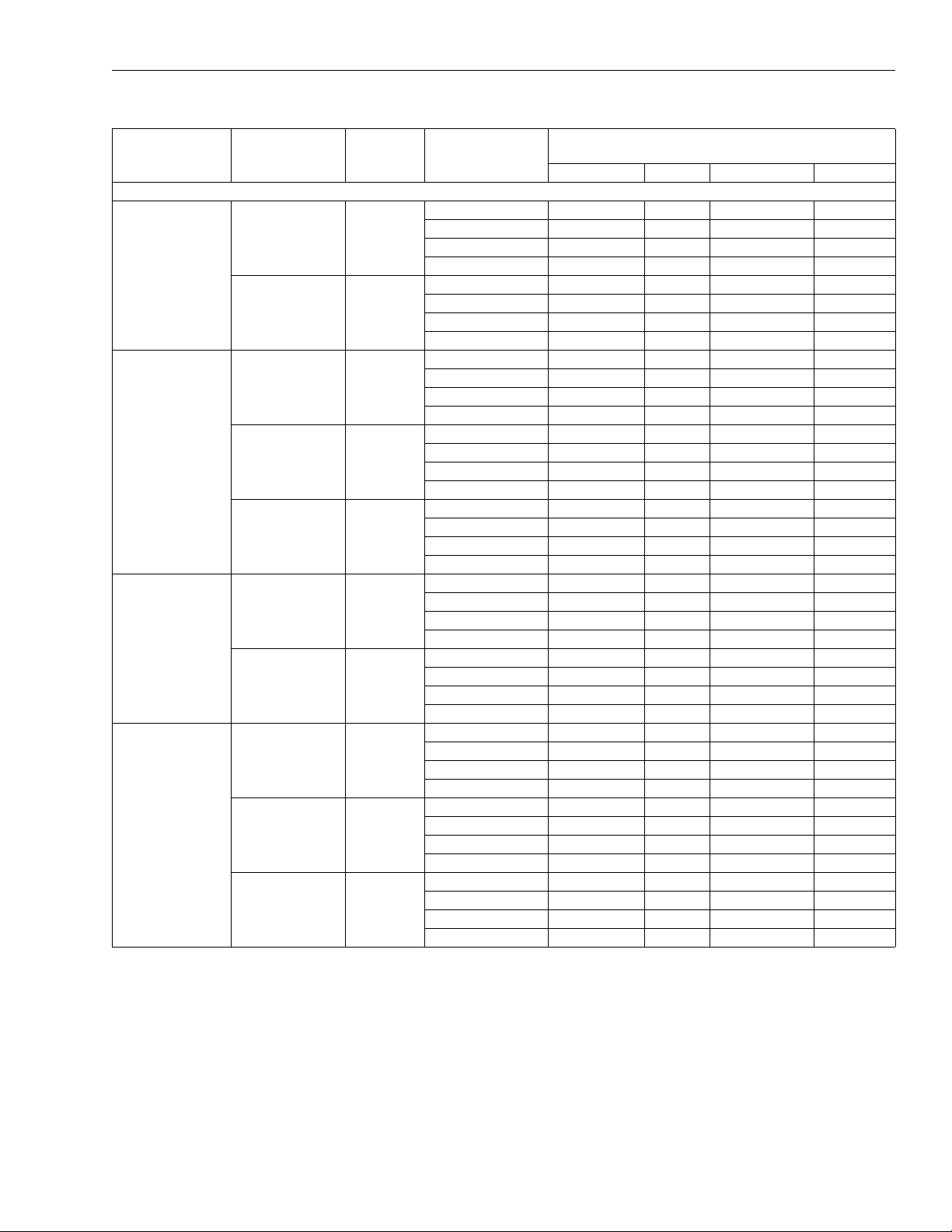

COOLING CAPACITY - COIL ONLY

Blower

Model

MV12B

MV12D

MV16C

MV20D

Coil

Model

MC30B**H 1025

MC36B**H 1250

MC48D**H 1125

MC60D**H 1275

MC61D**H 1450

MC42C**H 1400

MC48C**H 1650

MC48D**H 1725

MC60D**H 2000

MC61D**H 2200

Rated

CFM

Multi-Position - Upflow / Downflow / Horizontal

Entering Air °F

(Dry / Wet Bulb)

85 / 72 41.5 37.8 33.7 29.5

80 / 67 36.2 32.4 28.6 24.5

75 / 62 29.1 25.3 24.0 19.2

70 / 57 24.1 21.5 18.7 15.8

85 / 72 52.0 47.3 42.3 37.3

80 / 67 41.7 36.8 32.3 27.4

75 / 62 32.5 27.3 29.8 22.2

70 / 57 27.9 25.8 23.8 22.2

85 / 72 46.8 42.4 37.6 33.0

80 / 67 37.4 33.3 29.4 24.3

75 / 62 28.9 24.6 21.7 19.6

70 / 57 25.1 23.3 21.7 19.6

85 / 72 53.7 48.4 43.5 37.5

80 / 67 43.0 38.0 33.3 27.7

75 / 62 33.1 28.1 24.5 22.4

70 / 57 28.8 26.5 24.5 22.4

85 / 72 91.7 78.4 68.1 52.3

80 / 67 73.4 61.5 52.0 38.6

75 / 62 57.3 45.6 38.4 31.2

70 / 57 49.2 43.0 38.4 31.2

85 / 72 88.4 76.0 63.3 50.0

80 / 67 70.8 59.4 48.4 37.0

75 / 62 55.2 43.9 35.8 29.9

70 / 57 47.4 41.5 35.8 29.9

85 / 72 100.5 86.4 72.0 56.8

80 / 67 80.4 67.5 55.0 42.1

75 / 62 62.7 49.9 40.7 34.0

70 / 57 53.9 47.2 40.7 34.0

85 / 72 119.9 101.0 80.0 62.2

80 / 67 96.0 79.2 62.6 45.8

75 / 62 74.0 58.6 46.2 37.0

70 / 57 64.3 55.4 46.2 37

85 / 72 124.8 105.2 85.3 64.7

80 / 67 99.9 82.5 65.2 47.7

75 / 62 77 61.1 48.1 38.6

70 / 57 66.9 57.7 48.1 38.6

85 / 72 131.0 110.5 89.6 67.9

80 / 67 104.9 86.6 68.5 50.1

75 / 62 81.8 64.2 50.5 40.5

70 / 57 70.2 60.6 50.5 40.5

MBH @ Evaporator Temperature and

Corresponding Pressure °F / PSIG

35 / 61.5 40 / 68.5 45 / 76.0 50 / 84.0

Unitary Products Group 3

Page 4

255427-YTG-F-1006

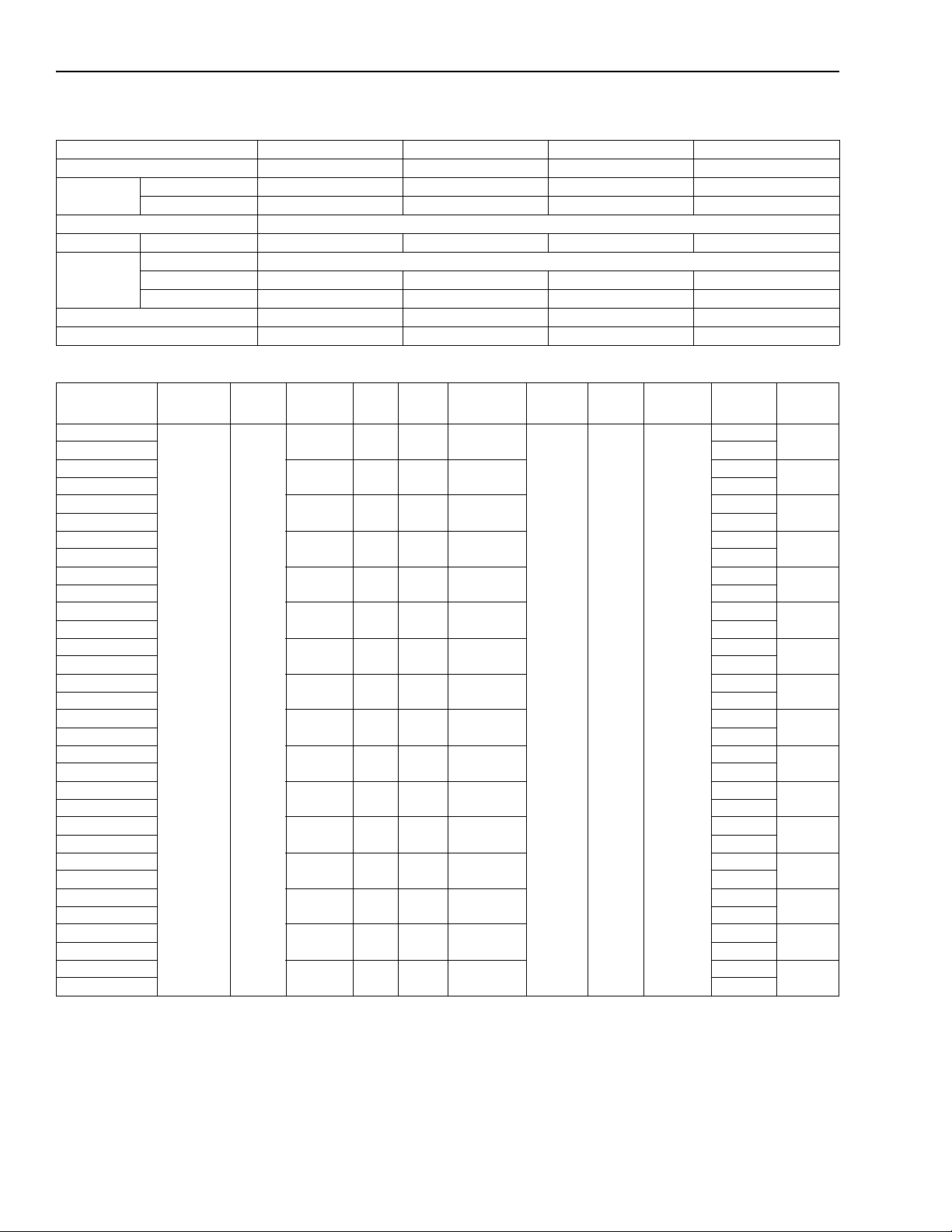

PHYSICAL & ELECTRICAL DATA

Model MV12B MV12D MV16C MV20D

Blower - Diameter x Width 10 x 7 10 x 10 10 x 10 10 x 10

Motor

HP 1/2 1/2 3/4 1

Nominal RPM 1200 1200 1200 1200

Voltage 208/230

Amps Full Load (230) 4.3 4.3 5.0 7.0

Type DISPOSABLE OR PERMANENT

Filter

Size

Permanent Type Kit

16 x 20 x 1 22 x 20 x 1 20 x 20 x 1 22 x 20 x 1

1PF0601BK 1PF0603BK 1PF0602BK 1PF0603BK

Filter Rack 1FR0717 1FR0724 1FR0721 1FR0724

Shipping / Operating Weight (lbs.) 68 / 62 88 / 82 75 / 69 93 / 87

COILS

Model Application

MC18A3XH1

MC18A2AH1 2A

MC18B3XH1

MC18B2AH1 2A

MC24A3XH1

MC24A2AH1 2A

MC24B3XH1

MC24B2AH1 2A

MC30A3XH1

MC30A2AH1 2A

MC30B3XH1

MC30B2AH1 2A

MC35B3XH1

MC35C3XH1 None

MC36A3XH1

MC36A2AH1 2A

MC36B3XH1

MC36B2AH1 2A

MC36C3XH1

MC36C2AH1 2A

MC42B3XH1

MC42B2CH1 2C

MC42C3XH1

MC42C2CH1 2C

MC48C3XH1

MC48C2CH1 2C

MC48D3XH1

MC48D2CH1 2C

MC60D3XH1

MC60D2CH1 2C

MC61D3XH1

MC61D2CH1 2C

Cooling /

Heat Pump

Refrig.

Conn.

Types

Sweat

Face

Area

(Sq. Ft.)

3.40 2 14 (2) 14 x 17.5

3.40 2 14 (2) 14 x 17.5

4.38 2 14 (2) 18 x 17.5

4.38 2 14 (2) 18 x 17.5

4.38 2 14 (2) 18 x 17.5

4.38 2 14 (2) 18 x 17.5

3.90 3 12 (2) 16 x 17.5

4.86 2 14 (2) 20 x 17.5

4.86 2 14 (2) 20 x 17.5

4.86 2 14 (2) 20 x 17.5

5.83 2 14 (2) 24 x 17.5

5.83 2 14 (2) 24 x 17.5

5.35 3 12 (2) 22 x 17.5

5.35 3 12 (2) 22 x 17.5

5.83 3 12 (2) 24 x 17.5

6.80 3 12 (2) 28 x 17.5

Rows

Deep

Fin

Per

In.

Coil Size

Tube

Geometry

1 x 0.866 3/8 Enhanced

Tube

Dia.

Fin

Type

TXV

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

Operating

Weight

(Lbs.)

53

53

56

56

56

56

65

64

65

65

72

72

82

82

86

98

4 Unitary Products Group

Page 5

255427-YTG-F-1006

ELECTRICAL DATA - 208/230-1-60

Model Heater Model*

4HK*6500506 0.5 Heat-D 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

MV12B

MV12D

MV16C

MV20D

1. See conversion table on Page 7.

* May be 0 (no breaker) or 1 (with breaker).

4HK*6500806 0.5 Heat-D 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

4HK*6501006 0.5 Heat-D 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

4HK165N1506 0.5 Heat-D 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK*6500506 0.5 Heat-D 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

4HK*6500806 0.5 Heat-D 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

4HK*6501006 0.5 Heat-D 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

4HK16501506 0.5 Heat-D 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK16501806 0.5 Heat-D 13.2 17.6 45.1 60.1 3.3 4.4 6.6 8.8 13.2 17.6

4HK16502006 0.5 Heat-D 14.4 19.2 49.2 65.5 3.6 4.8 7.2 9.6 14.4 19.2

4HK*6500506 0.5 Heat-D 3.6 4.8 12.3 16.4 3.6 4.8 3.6 4.8 3.6 4.8

4HK*6500806 0.5 Heat-D 5.6 7.5 19.2 25.6 2.8 3.75 5.6 7.5 5.6 7.5

4HK*6501006 0.5 Heat-D 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

4HK16501506 0.5 Heat-D 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK16501806 0.5 Heat-D 13.2 17.6 45.1 60.1 3.3 4.4 6.6 8.8 13.2 17.6

4HK16502006 0.5 Heat-D 14.4 19.2 49.2 65.5 3.6 4.8 7.2 9.6 14.4 19.2

4HK*6501006 0.5 Heat-D 7.2 9.6 24.6 32.8 3.6 4.8 7.2 9.6 7.2 9.6

4HK16501506 0.5 Heat-D 10.8 14.4 36.9 49.1 3.6 4.8 7.2 9.6 10.8 14.4

4HK16501806 0.5 Heat-D 13.2 17.6 45.1 60.1 3.3 4.4 6.6 8.8 13.2 17.6

4HK16502006 0.5 Heat-D 14.4 19.2 49.2 65.5 3.6 4.8 7.2 9.6 14.4 19.2

4HK16502506 0.5 Heat-D 18.0 24.0 61.5 81.9 3.6 4.8 10.8 14.4 18.0 24

Max.

Static

Min.

Speed

Tap

Total Heat

KW MBH W1 Only W2 Only W1 + W2

208V 240V 208V 240V 208V 240V 208V 240V 208V 240V

1

KW Staging

ELECTRICAL DATA - 208/230-3-60

Models

MV12BN21 4HK06501025 0.5 Heat-D 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

MV12DN21

MV16CN21

MV20DN21

1. See conversion table on Page 7.

Heat Kit -

Three Phase

4HK06501025 0.5 Heat-D 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

4HK06501525 0.5 Heat-D 10.8 14.4 36.9 49.1 10.8 14 .4 10.8 14.4 10.8 14.4

4HK06501825 0.5 Heat-D 12.9 17.2 44.7 58.7 12.9 17 .2 12.9 17.2 12.9 17.2

4HK06501025 0.5 Heat-D 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

4HK06501525 0.5 Heat-D 10.8 14.4 36.9 49.1 10.8 14 .4 10.8 14.4 10.8 14.4

4HK06501825 0.5 Heat-D 12.9 17.2 44.7 58.7 12.9 17 .2 12.9 17.2 12.9 17.2

4HK06501025 0.5 Heat-D 7.2 9.6 24.6 32.8 7.2 9.6 7.2 9.6 7.2 9.6

4HK06501525 0.5 Heat-D 10.8 14.4 36.9 49.1 10.8 14 .4 10.8 14.4 10.8 14.4

4HK16502525 0.5 Heat-D 18.0 24.0 61.4 81.4 9.0 12.0 18.0 24.0 18.0 24.0

Max.

Static

Min.

Speed

Tap

208V 240V 208V 240V 208V 240V 208V 240V 208V 240V

Total Heat

KW MBH W1 Only W2 Only W1 + W2

1

KW Staging

Unitary Products Group 5

Page 6

ELECTRICAL DATA (FOR SINGLE SOURCE POWER SUPPLY) - COPPER WIRE 208/230-1-60

Field Wiring

1,*

Model

Heater Model

Heater Amps Ampacity Min. Circuit

Max. O.C.P.

240V 208V 240V 208V 240V 208V 240V

4HK*6500506 20.0 27.54 30.38 30 35 10 8

MV12B

4HK*6500806 31.3 39.73 44.50 40 45 8 8

4HK*6501006 40.0 49.21 55.38 50 60 8 6

4HK165N1506 60.0 70.88 80.38 90 90 4 3

4HK*6500506 20.0 27.54 30.38 30 35 10 8

4HK*6500806 31.3 39.73 44.50 40 45 8 8

MV12D

4HK*6501006 40.0 49.21 55.38 50 60 8 6

4HK16501506 60.0 70.88 80.38 90 90 4 3

4HK16501806 73.3 85.32 97.00 90 100 4 3

4HK16502006 80.0 92.54 105.38 100 125 3 1

4HK*6500506 20.0 29.29 31.88 30 35 10 8

4HK*6500806 31.3 41.48 46.00 45 50 8 8

MV16C

4HK*6501006 40.0 50.96 56.88 60 60 6 6

4HK16501506 60.0 72.63 81.88 90 90 3 3

4HK16501806 73.3 87.07 98.50 90 100 3 2

4HK16502006 80.0 94.29 106.88 100 125 3 1

4HK*6501006 40.0 53.08 58.75 60 60 6 6

4HK16501506 60.0 74.75 83.75 90 90 3 3

MV20D

4HK16501806 73.3 89.19 100.38 90 110 3 2

4HK16502006 80.0 96.42 108.75 100 125 3 1

4HK16502506 100.0 118.08 133.75 125 150 1 1/0

1. 30 KW 3 phase not approved for single source power supply.

2. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

* May be 0 (no breaker) or 1 (with breaker).

2

Amps/Type

255427-YTG-F-1006

Wire Size - AWG 75°C

ELECTRICAL DATA (FOR SINGLE SOURCE POWER SUPPLY) - COPPER WIRE 208/230-3-60

Models

Heat Kit -

Three Phase

Heater

Amps

240V

Min. Circuit Ampacity

208V 240V 208V 240V 208V 240V

12B 4HK06501025 23.1 30.9 34.3 35 35 8 8

4HK06501025 23.1 30.9 34.3 35 35 8 8

12D

4HK06501525 34.7 43.4 48.8 45 50 8 8

4HK06501825 41.4 50.6 57.1 50 60 8 6

4HK06501025 23.1 32.6 35.1 35 35 8 8

16C

4HK06501525 34.7 45.1 49.6 45 50 8 8

4HK06501825 41.4 52.4 58.0 60 60 6 6

20D

4HK06501025 23.1 34.8 37.6 35 40 8 8

4HK06501525 34.7 47.3 52.1 50 60 8 6

1. O.C.P. = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

TA BLE 1: Electrical Data - (For

Models

Heater

Model

Multi-Source

Minimum Circuit Ampacity

1st 2nd 3rd 1st 2nd 3rd 1st 2nd 3rd

Power Supply) - Copper Wire - 208/230-3-60

Max. O.C.P.

Circuit

208/240 208/240 208/240 208/240 208/240 208/240 208/240 208/240 208/240

20D 4HK16502525 41.0 / 44.9 31.3 / 36.1 - / - 45 / 45 35 / 40 - / - 8 / 8 8 / 8 - / -

1. O.C.P. = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

Field Wiring

Max. O.C.P.

1

Amps/Type

1

Amps/Type

75°C Wire Size - AWG

75°C Wire Size - AWG

6 Unitary Products Group

Page 7

255427-YTG-F-1006

ELECTRICAL DATA (FOR MULTI SOURCE POWER SUPPLY) - COPPER WIRE 208/230-1-60

Model

Heater

Model

Min. Circuit Ampacity

Circuit Circuit Circuit

1st 2nd 3rd 1st 2nd 3rd 1st 2nd 3rd

Max. O.C.P.1 Amps/Type

208/240 208/240 208/240 208/240 208/240 208/240 208/240 208/240 208/240

MV12B 4HK165N1506 49.2 / 55.4 21.7 / 25.0 – 50 / 60 25 / 25 – 8 / 6 10 / 10 –

4HK16501506 49.2 / 55.4 21.7 / 25.0 – 50 / 60 25 / 25 – 8 / 6 10 / 10 –

MV12D

4HK16501806 45.6 / 51.2 39.7 / 45.8 – 50 / 60 40 / 50 – 8 / 6 8 / 8 –

4HK16502006 49.2 / 55.4 43.3 / 50.0 – 50 / 60 45 / 50 – 8 / 6 8 / 8 –

4HK16501506 51.0 / 56.9 21.7 / 25.0 – 50 / 60 25 / 25 – 8 / 6 10 / 10 –

MV16C

4HK16501806 17.3 / 52.7 39.7 / 45.8 – 50 / 60 40 / 50 – 8 / 6 8 / 8 –

4HK16502006 51.0 / 56.9 43.3 / 50.0 – 50 / 60 45 / 50 – 8 / 6 8 / 8 –

4HK16501506 53.1 / 58.8 21.7 / 25.0 – 60 / 60 25 / 25 – 6 / 6 10 / 10 –

MV20D

4HK16501806 49.5 / 54.6 39.7 / 45.8 – 50 / 60 40 / 50 – 8 / 6 8 / 8 –

4HK16502006 53.1 / 58.8 43.3 / 50.0 – 60 / 60 45 / 50 – 6 / 6 8 / 8 –

4HK16502506 49.3 / 56.5 43.3 / 50.0 21.7 / 25.0 50 / 60 45 / 50 25 / 25 8 / 6 8 / 8 10 / 10

1. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

KW & MBH CONVERSIONS

208-VOLT

FOR

230-VOLT 240-VOLT .918

OPERATION MULTIPLY

240-VOLT

TABULATED KW & MBH BY

.751

75°C Wire Size - AWG

ELECTRICAL DATA - COOLING UNIT ONLY (60 Hz)

Total Motor Amps Minimum Circuit Ampacity

MODEL

60 Hertz 60 Hertz

Max. O.C.P.

208V 230V 208V 230V

MV12B 4.7 4.3 5.9 5.4 15 14

MV12D 4.7 4.3 5.9 5.4 15 14

MV16C 6.1 5.0 7.6 6.9 15 14

MV20D 7.8 7.0 9.7 8.8 15 14

1. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

1

Amps/Type

POWER WIRING

TYPICAL WIRING WITHOUT ELECTRIC HEAT

GND. LUG

POWER

SUPPLY

1 PHASE ELECTRIC HEAT

WITH CIRCUIT BREAKER

& BREAKER BAR REMOVED

MULTI-SOURCE (15 - 25 KW) - 25 KW SHOWN

GND. LUG

POWER

SUPPLY 1

POWER

SUPPLY 2

POWER

SUPPLY 3

MAYBE1,2,OR3

CIRCUIT BREAKERS

GND.

LUG

GND.

LUG

ELECTRIC HEAT

WITHOUT CIRCUIT BREAKER

3 PHASE (10 - 15 KW)

GND. LUG

POWER

SUPPLY

ELECTRIC HEAT

WITHOUT CIRCUIT BREAKER

SINGLE SOURCE (2.5 - 10 KW)

GND. LUG

POWER

SUPPLY

CONNECT LEADS WITH WIRE NUTS

(TYPICAL ALL HEAT KITS)

GND.

LUG

TERMINAL

BLOCK

GND.

LUG

TERMINAL

BLOCK

1 PHASE ELECTRIC HEAT

WITH CIRCUIT BREAKER

AS SHIPPED FROM FACTORY

SINGLE SOURCE

(2.5 - 25 KW) - 25 KW SHOWN

GND. LUG

POWER

SUPPLY

(JUMPER BAR)

MAYBE1,2,OR3

CIRCUIT BREAKERS

POWER WIRING (208/230-1-60)

NOTE: USE ONLY COPPER CONDUCTORS

Minimum Wire Size

AWG @ 75°C

GND.

LUG

Line Power

Unitary Products Group 7

Page 8

255427-YTG-F-1006

ACCESSORIES

Refer to Price Manual for specific model numbers.

Electric Heaters - Models shown under Electrical Data

include sequencers and temperature limit switches and fusible links for safe, efficient operation. Circuit breakers are provided where shown.

Suspension Kit - Suspension Kit Model 1BH0601 is

designed specifically for upflow application of the units contained in this technical guide. For suspension of these units in

horizontal applications, it is recommended to use angle support brackets with threaded rods at locations shown in air

handler installation instructions.

1/2”

C

19-7/8”

NOTE: May be used with up to a 2” filter.

Required for downflow application.

May also be used in upflow application.

All dimensions are inches. They are subject to change

without notice. Certified dimensions will be provided upon

request.

22”

Filter Rack - One of the following external filter rack accessories: 1FR07* or 1FR08* must be used when unit is installed

for application outlined.

Combustible Floor Base - If an electric heat accessory

which is rated for greater than zero clearance to combustible

surfaces is installed in these air handlers in the downflow

operating positions on a combustible floor, one of the following combustible floor base accessories is required: 1FB1817,

1FB1821, or 1FB1824.

1/2”

1”

3-1/2”

A

D

B

A

ACCESSORY FOOTPRINT

1-1/2”

3-1/2”

22”

21”

3/4”

2” Max

Thick

Filter

7/8”

1/2”

1/2”

(All four sides)

16-1/2”

20”

23-1/2”

FILTER RACK ACCESSORY

Filter Rack Model

Multi-PositionHorizontal Only ABCDWidthLengthThickness

Used With

1FR0817 1FR0717 MV12B 17-1/2 16-3/8 15-1/2 21 17-1/2 22 1

1FR0821 1FR0721 MV16C 21 19-7/8 19 21 21 22 1

1FR0824 1FR0724 MV12D, MV20D 24-1/2 23-3/8 22-1/2 21 24-1/2 22 1

Rack Dimensions Inches Filter Dimensions Inches

8 Unitary Products Group

Page 9

255427-YTG-F-1006

AIR HANDLER

DEPTH

FRONT

DOWNFLOW

AIR HANDLER

WARM AIR PLENUM

WITH 1” FLANGES

A

B

B

FIBERGLASS

INSULATION

A

COMBUSTIBLE FLOOR

BASE ACCESSORY

FIBERGLASS TAPE

UNDER FLANGE

All dimensions are in inches. They are subject to change without notice. Certified dimensions will be provided upon request.

COMBUSTIBLE FLOOR BASE ACCESSORY

Floor Base Model Used with

1FB1817 MV12B 19.9 18.0 14.9 16.9

1FB1821 MV16C 23.4 21.5 18.4 20.4

1FB1824 MV12D, MV20D 26.9 25.0 21.9 23.9

FLOOR

APPROX. 1/2”

10-47/64

1

FLOOR

PLENUM

12-1/2

FLOOR OPENING

A

AIR HANDLER

WIDTH

B

APPROX. 1/2”

CLEARANCE

ALL AROUND

11

PLENUM

C

FLOOR OPENING

CLEARANCE

ALL AROUND

COMBUSTIBLE

FLOOR BASE

Dimensions

ABCD

Unitary Products Group 9

Page 10

255427-YTG-F-1006

COOLING AIRFLOW DATA - MV MODELS

HIGH / LOW SPEED COOLING AND HEAT PUMP CFM

12B Air Handler 12D Air Handler

CFM

3

m

/min

CFM

m3/min

High Low High Low High Low High Low COOL Tap ADJ Tap*

1307 882 37.0 25.0 1366 869 38.7 24.6 A B

1080 756 30.6 21.4 1097 717 31.1 20.3 B B

1270 862 36.0 24.4 1312 856 37.2 24.2 A A

943 689 26.7 19.5 957 646 27.1 18.3 B A

1146 786 32.5 22.3 1167 761 33.0 21.5 A C

1050 726 29.7 20.6 1051 703 29.8 19.9 C B

870 632 24.6 17.9 863 580 24.4 16.4 B C

771 594 21.8 16.8 739 520 20.9 14.7 D B

931 668 26.4 18.9 927 629 26.2 17.8 C A

693 565 19.6 16.0 658 495 18.6 14.0 D A

851 624 24.1 17.7 830 567 23.5 16.1 C C

655 567 18.5 16.1 594 488 16.8 13.8 D C

16C Air Handler 20D Air Handler

CFM

3

m

/min

CFM

m3/min

High Low High Low High Low High Low COOL Tap ADJ Tap*

1920 1321 54.4 37.4 2209 1394 62.6 39.5 A B

1699 1189 48.1 33.7 2022 1394 57.3 39.5 B B

1884 1296 53.3 36.7 2178 1381 61.7 39.1 A A

1558 1094 44.1 31.0 1798 1378 50.9 39.0 B A

1714 1193 48.5 33.8 1965 1226 55.6 34.7 A C

1451 1037 41.1 29.4 1843 1143 52.2 32.4 C B

1403 1009 39.7 28.6 1596 1226 45.2 34.7 B C

1288 947 36.5 26.8 1700 1066 48.1 30.2 D B

1336 978 37.8 27.7 1608 1023 45.5 29.0 C A

1214 888 34.4 25.1 1493 967 42.3 27.4 D A

1239 915 35.1 25.9 1430 911 40.5 25.8 C C

1098 839 31.1 23.8 1334 877 37.8 24.8 D C

All CFM’s are shown at 0.5” w.c. external static pressure.These units have variable speed motors that automatically adjust to provide constant CFM from 0.0” to

0.6” w.c. static pressure. From 0.6 ” to 1.0” stat ic pressure , CFM is red uced by 2% per 0.1 ” increase in st at ic. Operat ion on duct syst ems with great er than 1. 0” w.c.

external static pressure is not recommended.

NOTE: At some settings, LOW COOL and/or LOW HEA T airflow may be lower than wha t is required to opera te an airflow switch on cert ain model s of electronic air

cleaners. Consult the instructions for the electronic air cleaner for further details.

* The ADJ “D” tap should not be used.

JUMPER SETTINGS

JUMPER SETTINGS

HEATING AIRFLOW DATA - MV MODELS

HIGH / LOW SPEED COOLING AND HEAT PUMP CFM

12B Air Handler 12D Air Handler

CFM

3

m

/min

CFM

m3/min

JUMPER SETTINGS

High Low High Low High Low High Low COOL Tap ADJ Tap*

1270 791 36.0 22.4 1312 762 37.2 21.6 A A

943 714 26.7 20.2 957 668 27.1 18.9 B A

931 643 26.4 18.2 927 591 26.2 16.7 C A

693 567 19.6 16.1 658 488 18.6 13.8 D A

16C Air Handler 20D Air Handler

CFM

3

m

/min

CFM

m3/min

JUMPER SETTINGS

High Low High Low High Low High Low COOL Tap ADJ Tap*

1884 1217 53.3 34.5 2178 1217 61.7 34.5 A A

1558 1065 44.1 30.2 1798 1036 50.9 29.3 B A

1336 823 37.8 23.3 1608 748 45.5 21.2 C A

1214 727 34.4 20.6 1493 551 42.3 15.6 D A

All CFM’s are shown at 0.5” w.c. external static pressure.These units have variable speed motors that automatically adjust to provide constant CFM from 0.0” to

0.6” w.c. static pressure. From 0.6 ” to 1.0” stat ic pressure , CFM is red uced by 2% per 0.1 ” increase in st at ic. Operat ion on duct syst ems with great er than 1. 0” w.c.

external static pressure is not recommended.

NOTE: At some settings, LOW COOL and/or LOW HEA T airflow may be lower than wha t is required to opera te an airflow switch on cert ain model s of electronic air

cleaners. Consult the instructions for the electronic air cleaner for further details.

* The ADJ “D” tap should not be used.

10 Unitary Products Group

Page 11

255427-YTG-F-1006

Horizontal Right

Horizontal Left

APPLICATION FACTORS - RATED CFM VS. ACTUAL CFM

% OF RATED AIR FLOW 80% 90% RATED CFM 110% 120%

CAPACITY FACTOR 0.96 0.98 1.00 1.02 1.03

Up Flow

Down Flow

Typical Applications with MC Multi-Position Coils

MA SERIES - Air Handler Control Wiring

Typical A/C - Cooling only Applications

THERMOSTAT

G

Y

W1

W2

C

AIR HANDLER

BOARD

RR

G

Y/Y2

Y1

W2

W1

O

HUM

X/L

COM

AIR CONDITIONING

1-STAGE

Y

C

COOLING MODELS WITH ELECTRIC HEAT

CONTROL WIRING - MA Series - Air Handler & New UPG HP Systems

Two Stage H/P with York Guard VI Board & Copeland “Ultra Tech”

Conventional Application - Not Hot Heat Pump

THERMOSTAT

RR R

GG

Y2

Y1

E

W

O O

X/L X/L X/L

C

HUMIDISTAT

AIR HANDLER

BOARD

Y/Y2

Y1

W2

W1

O

HUM

COM

*

MA SERIES - Air Handler Control Wiring

Typical A/C with Electric Heat Applications

THERMOSTAT

W2

W1

AIR HANDLER

BOARD

RR

G

Y

C

HUMIDISTAT

G

Y/Y2

Y1

W2

W1

O

HUM

X/L

COM

*

1-STAGE

AIR CONDITIONING

Y

HUMIDISTAT

C

2 - STAGE SCROLL

HEAT PUMP

Y2

Y2 OUT

Y1

W2 OUT

W1 OUT

W

BS

C

*

CONTROL WIRING - MV SERIES

Unitary Products Group 11

Page 12

NOTES

Subject to change without notice. Printed in U.S.A. 255427-YTG-F-1006

Copyright © by York International/JCI. 2006. All rights reserved. Supersedes: 255427-YTG-E-0906

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...