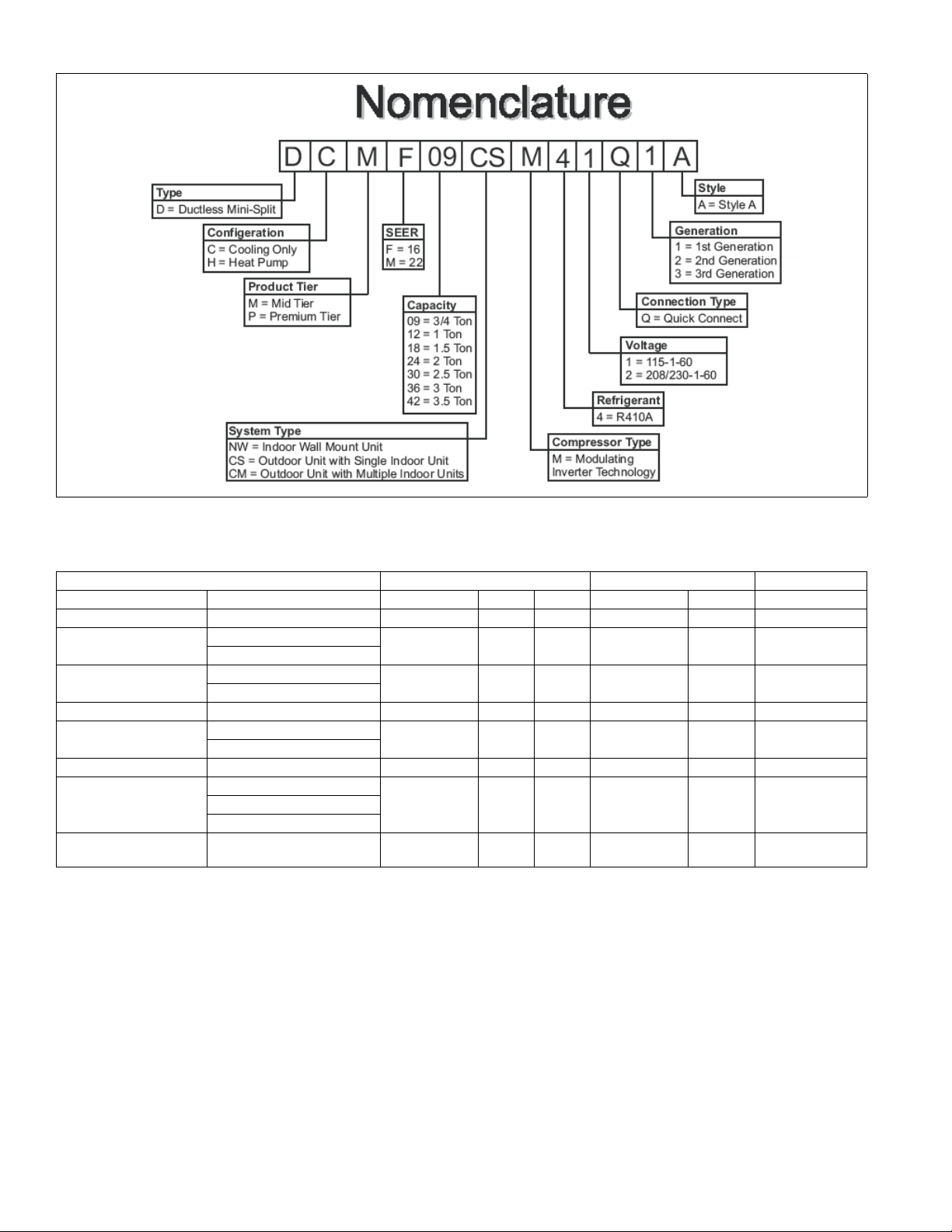

York Multi-Zone Mini-Split Technical Guide

LX SERIES

DUCTLESS MULTI-ZONE SPLIT

HEAT PUMPS

16 SEER – 1 PHASE

1.5 THRU 3.5 NOMINAL TONS

MODELS:

INDOOR-DHPM/OUTDOOR-DHMF

Due to continuous product improvement, specifications

are subject to change without notice.

Visit us on the web at

www.upgnet.com

Additional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY*

Standard 2-Years limited parts warranty.

Standard 6-Years limited compressor warranty.

TECHNICAL

GUIDE

TECHNICAL

GUIDE

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

923212-UTG-B-0114

DESCRIPTION

The Multi Zone Series are ductless climate systems. They are designed

with a matching indoor unit for optimum performance and efficiency.

These climate systems are supported with accessories and documents

to serve specific functions.

FEATURES

Variable Frequency Rotary Compressor - Twin rotary in ve rte r co mpressor

on all models features high efficiency operation that modulates down to 15

Hz and as high as 120 Hz for red uced vibrat ion and qu iet opera tion. Brus hless DC motor uses powerful Neodymium magnets that are approximately

15-20 times stronger than ferrite magnets used in conventional AC compressors. The DC Inverter Control provides continuous operation, while adjusting

capacity according to room temp eratur e. Th e accur ate s ensing of co oling or

heating loads prevents frequen t changes in capacity and ensur es efficient,

economical operation.

Low Ambient Cooling Operation Down to 5 °F - This feature allows for a

space to be air-conditioned eve n in outdoor temperatures as low as 5 °F.

This cooling ability is important when de aling with server equipment rooms,

surveillance mechanical rooms, restaurant kitchens, fitness centers, and

more.

Load Variat io n Mana ge ment S ys tem - The outdoor coil thermistor continuously monitors the temperature and commun icates wit h the micro process or.

Depending on the temperature measured, the compressor will be allowed to

increase the frequency if nee ded to meet the load or reduce frequen cy as

the load is reduced.

High Pressure Discharge Temperature - The compressor discharg e line

thermistor continuously monitors the temperature and communicates with

the microprocessor. Depending on the temperature me as ured, the compressor will be allowed to in crea se t he f r equen cy t o me et th e lo ad o r is fo rc ed to

run at the current or reduced f requency. If the temperature gets excessi vely

high, the compressor will be de-e nergized.

Defrost Control (Heat Pump Models) - Defrost cycle is automatically

enabled if there is a build-up of frost on the outdoor coil. Outdoor fan and

indoor blower operation is terminated during the defrost cycle. H1 is displayed on the indoor unit panel on the front cover during a defrost cycle.

Reversing Valve (Heat Pump Models) - 4-way inter change reversing valve

effects a rapid change in direction of refrigerant flow resulting in quick

changeover from cooling to h eating and vice vers a. Valve operates on system pressure differential betw e en outdoor unit and indoor unit.

R-410A Refrigerant - Unit is pre- charged with R410A refrigerant that uses

PVE refrigerant oil. Polyvinyl ether (PVE) is an innovative refrigerant oil specially formulated for hydrofluorocarbon (HFC) refrigeration systems. In addition to providing lubricati ng propert ies, it al so has a nu mber of othe r applied

advantages that help to increase the reliability of the refrigeration systems

where it is applied.

Refrigerant Line Connections, Service Valve - Outdoor units are designed

with easy service and mai nten an ce in mi n d. Ma in te nanc e p oi nts are loc at ed

behind easy-access panels, to m ake installation and s ervice a breeze for a

trained technician. Flare connection lines are located on side of unit cabinet.

Fully serviceable brass service valve prevents corrosion an d provide access

to refrigerant system. Shut -off valve that can be fully shut off while 2-way

suction/vapor valve (with service port) may be front seated to manage refrigerant charge while servicing system.

Air Deflection Louvers - Horizontal louvers default to the cooling or heating

position when the unit i s operating. Horizontal louvers can be set to a preset

oscillating range or fixed position from the wireless remote control. Full oscillating is the default settin g when button is pushed. Vertical louvers can be

manually adjusted to direct th e airflow for optimal comfort.

Indoor Coil Freeze Protectio n - The indoor coil thermistor monitors the coil

temperature continuously. Any time the coil tempera ture drops below 30°F,

the compressor and the outdoor fan (30 secon ds later) will be switched off

until the coil temperature r ises above 43°F and the compressor has been off

for a minimum of 3 minutes.

I FEEL Function - When I FEEL is activated, the system will sat isfy the coo ling or heating temperature set point where the remote control is located.

When I FEEL is deactivated, th e system will satisfy the cooling or heating

temperature set point where the i ndoor unit i s loca ted. Thi s fea ture pr ovid es

homeowners with optimum comfort whether the y are near or far from the

indoor unit.

Hot Heat Pump (cold air prevention) - In heating mode, the indoor fan wi ll

be delayed from 1 to 3 minutes to allow refrigerant to warm up and avoid

cold blow. This may occur during:

• Initial start-up of a heating cycle

• Immediately after completion of an Auto mode operation

Heating under extremely low indoor temperatures

923212-UTG-B-0114

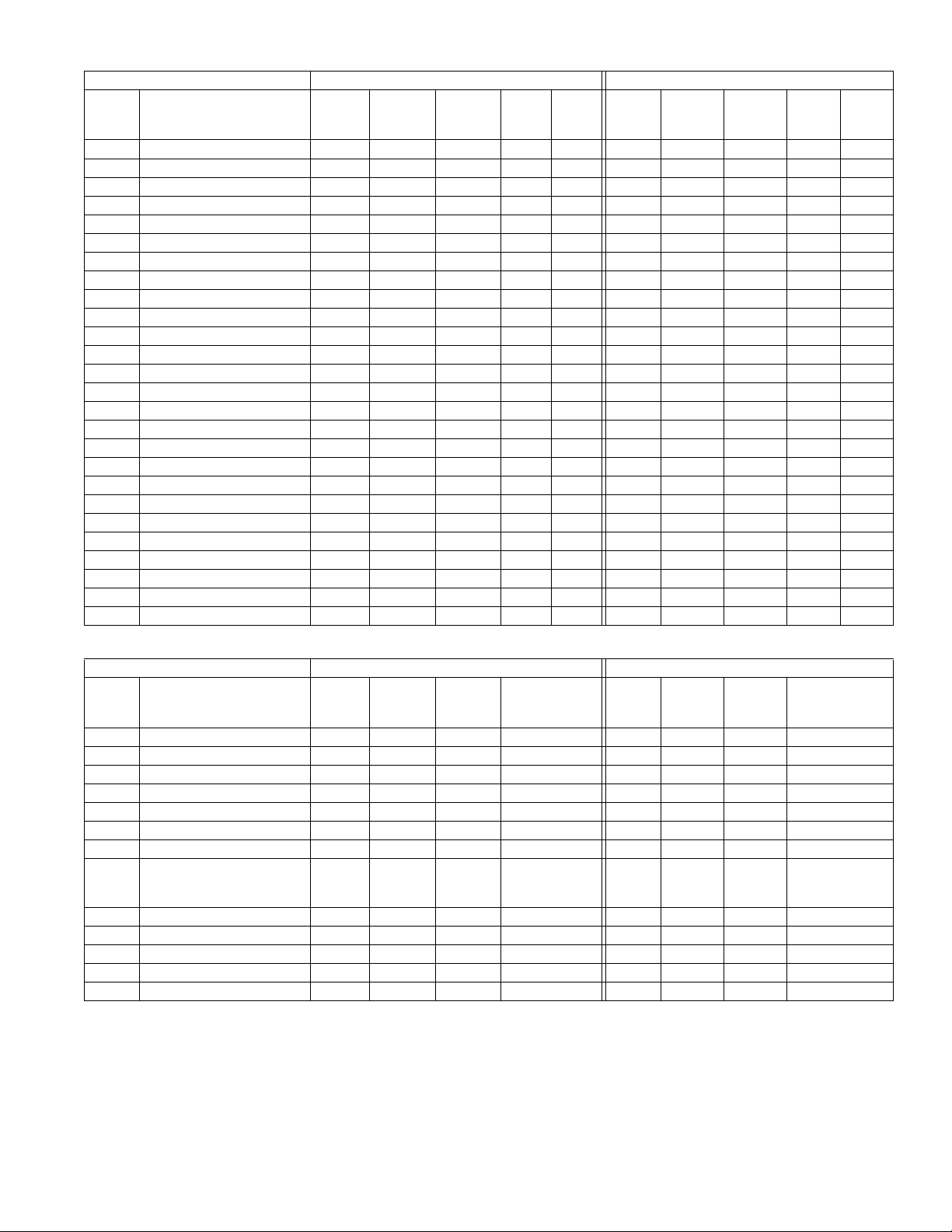

SPECIFICATIONS

Systems With AHRI Certified Performance Ratings

LX 16 SEER Multi-Splits HP Models Cooling High Heating 47 °F Low Heating 17 °F

Outdoor Model Number Indoor Model Number Capacity (Btuh) EER SEER Capacity (Btuh) HSPF Capacity (Btuh)

DHMF18CMM42Q1 (2) DHPM09NWM42Q1 18,000 10.20 16 19,000 8.20 9,600

DHMF18CMM42Q1

DHMF24CMM42Q1

DHMF24CMM42Q1 (3) DHPM09NWM42Q1 26,000 8.20 16 29,000 8.20 17,000

DHMF24CMM42Q1

DHMF30CMM42Q1 (4) DHPM09NWM42Q1 29,000 7.30 16 30,400 8.20 16,500

DHMF30CMM42Q1

DHMF42CMM42Q1

(1) DHPM09NWM42Q1 +

(1) DHPM12NWM42Q1

(2) DHPM09NWM42Q1 +

(1) DHPM12NWM42Q1

(1) DHPM09NWM42Q1 +

(2) DHPM12NWM42Q1

(1) DHPM09NWM42Q1 +

(1) DHPM18NWM42Q1

See Following Table for possi-

ble indoor combinations

18,000 10.20 16 19,000 8.20 9,600

26,000 8.20 16 29,000 8.20 17,000

26,000 8.20 16 29,000 8.20 17,000

29,000 7.30 16 30,400 8.20 16,500(2) DHPM12NWM42Q1 +

40,000 9.30 16 44,500 8.00 24,800

2 Johnson Controls Unitary Products

923212-UTG-B-0114

42K Outdoor Unit And Possible Indoor Combinations With AHRI Certified Performance Rating

Multi-Splits HP Models Cooling Capacity (Btu/h) Heating Capacity (Btu/h)

Outdoor

Unit

Model

42K 9K + 12K + 18K 8,530 10,918 16,036 - - 10,663 13,648 20,046 - 42K 9K + 18K + 18K 7,165 15,013 15,013 - - 8,155 17,084 17,084 - 42K 12K + 12K + 12K 11,771 11,771 11,942 - - 14,716 14,716 14,928 - 42K 12K + 12K + 18K 10,918 10,918 13,648 - - 13,648 13,648 17,060 - 42K 12K + 18K + 18K 9,554 15,013 15,013 - - 10,871 17,084 17,084 - 42K 18K + 18K + 18K 13,193 13,193 13,193 - - 15,012 15,012 15,012 - 42K 9K + 9K + 9K + 12K 8,189 8,189 8,189 10,918 - - 10,236 10,236 10,236 13,648 42K 9K + 9K + 9K + 18K 7,848 7,848 7,848 16,036 - 8,929 8,929 8,929 18,247 42K 9K + 9K + 12K + 12K 7,165 7,165 10,577 10,577 - 8,957 8,957 13,222 13,222 42K 9K + 9K + 12K + 18K 6,824 6,824 10,577 15,354 - 7,766 7,766 12,038 17,473 42K 9K + 9K + 18K + 18K 6,483 6,483 13,307 13,307 - 7,377 7,377 15,142 15,142 42K 9K + 12K + 12K + 12K 7,848 10,577 10,577 10,577 - 8,929 12,038 12,038 12,038 42K 9K + 12K + 12K + 18K 7,165 8,701 8,701 15,013 - 8,155 9,902 9,902 17,084 42K 12K + 12K + 12K + 12K 9,895 9,895 9,895 9,895 - 11,260 11,260 11,260 11,260 42K 12K + 12K + 12K + 18K 8,359 8,359 8,359 14,501 - 9,513 9,513 9,513 16,500 42K 12K + 12K + 18K + 18K 7,848 7,848 11,942 11,942 - 8,929 8,929 13,590 13,590 42K 9K + 9K + 9K + 9K + 9K 7,916 7,916 7,916 7,916 7,916 9,008 9,008 9,008 9,008 9,008

42K 9K + 9K + 9K + 9K + 12K 7,421 7,421 7,421 7,421 9,895 8,445 8,445 8,445 8,445 11,260

42K 9K + 9K + 9K + 9K + 18K 6,824 6,824 6,824 6,824 12,283 7,766 7,766 7,766 7,766 13,979

42K 9K + 9K + 9K + 12K + 12K 7,165 7,165 7,165 9,042 9,042 8,155 8,155 8,155 10,291 10,291

42K 9K + 9K + 9K + 12K + 18K 6,483 6,483 6,483 8,274 11,857 7,377 7,377 7,377 9,414 13,491

42K 9K + 9K + 9K + 18K + 18K 6,483 6,483 6,483 10,065 10,065 7,377 7,377 7,377 11,454 11,454

42K 9K + 9K + 12K + 12K + 12K 6,483 6,483 8,871 8,871 8,871 7,377 7,377 10,096 10,096 10,096

42K 9K + 9K + 12K + 12K + 18K 5,971 5,971 8,018 8,018 11,601 6,793 6,793 9,124 6,124 13,201

42K 9K + 12K + 12K + 12K + 12K 6,483 8,274 8,274 8,274 8,274 7,377 9,414 9,414 9,414 9,414

42K 12K + 12K + 12K + 12K + 12K 7,916 7,916 7,916 7,916 7,916 9,008 9,008 9,008 9,008 9,008

Indoor Unit Model Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

Systems With No AHRI Certified Performance Ratings Listed

Multi-Splits HP Models Cooling Capacity (Btu/h) Heating Capacity (Btu/h)

Outdoor

Unit

Model

24K 9K + 18K 8,400 16,600 - 9,000 18,000 - 24K 12K + 12K 12,000 12,000 - 13,000 13,000 - 24K 12K + 18K 10,000 15,000 - 11,200 16,800 - 24K 18K + 18K 12,750 12,750 - 14,250 14,250 - 24K 9K + 9K + 9K 8,667 8,667 8,667 - 9,667 9,667 9,667 24K 9K + 9K + 18K 7,000 7,000 12,000 - 6,000 6,000 17,000 24K 12K + 12K + 12K 8,667 8,667 8,667 - 9,667 9,667 9,667 -

Outdoor

Unit

Model

30K 9K + 12K + 18K 6,800 7,200 13,000 - 7,050 9,350 14,100 30K 12K + 12K + 12K 8,667 8,667 8,667 - 9,667 9,667 9,667 30K 12K + 12K + 18K 6,500 6,500 15,000 - 8,700 8,700 13,100 30K 9K + 9K + 9K + 12K 7,000 7,000 7,000 7,000 7,100 7,100 7,100 9,200

30K 9K + 9K + 12K + 12K 6,800 6,800 7,700 7,700 6,500 6,500 9,000 9,000

Indoor Unit Model Zone 1 Zone 2 Zone 3 Zone 4 Zone 1 Zone 2 Zone 3 Zone 4

Indoor Unit Model Zone 1 Zone 2 Zone 3 Zone 4 Zone 1 Zone 2 Zone 3 Zone 4

Johnson Controls Unitary Products 3

923212-UTG-B-0114

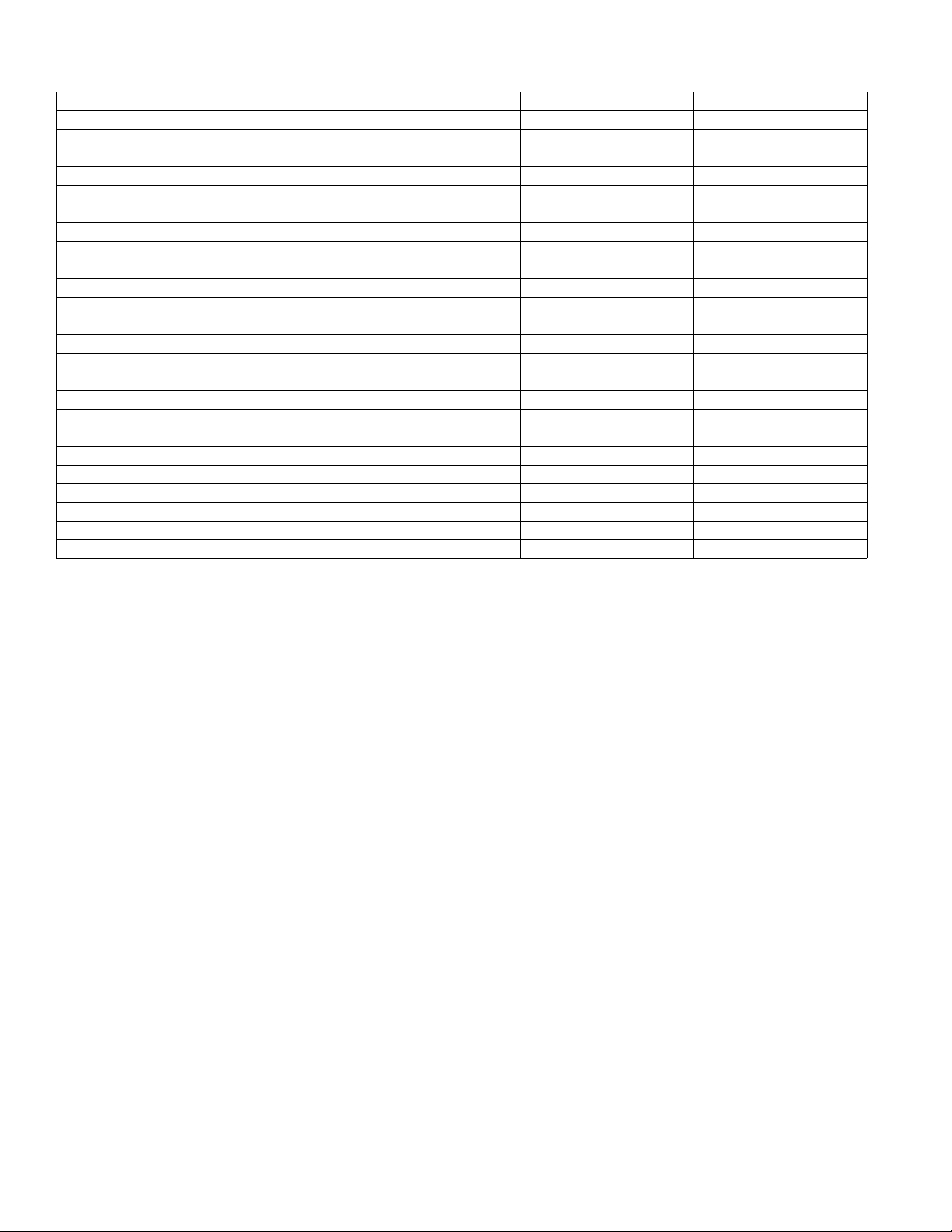

Indoor Unit Specification

Model of Indoor Unit DHPM09NWM42Q1 DHPM12NWM42Q1 DHPM18NWM42Q1

Fan Motor Speed (r/min) (SH/H/M/L) 1260/1100/950/750 1330/1100/950/750 1500/1200/1050/900

Output of Fan Motor (w) 20 20 20

Fan Motor Capacitor (uF) 1 1 1.5

Fan Motor RLA(A) 0.2 0.2 0.28

Fan Type-Piece Cross-flow - 1 Cross-flow - 1 Cross-flow - 1

Diameter-Length (inch) 3.6 x 25.4 3.6 x 25.4 3.9 x 28.0

Diameter-Length (mm) 92×645 92×645 98×710

Evaporator Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter (inch) Φ 0.276 Φ 0.276 Φ 0.276

Pipe Diameter (mm) φ7 φ7 φ7

Row-Fin Gap (inch) 2 - 0.055 2 - 0.055 2 - 0.055

Row-Fin Gap (mm) 2-1.4 2-1.4 2-1.4

Coil length (L) x height (H) x coil width (W) (inch) 22.9 x 1.0 x 10.4 22.9 x 1.0 x 10.4 28.1 x 1.0 x 12.0

Coil length (L) x height (H) x coil width (W) (mm) 581×25.4×264 581×25.4×264 715×25.4×304.8

Output of Swing Motor (W) 2 2 2.5

Fuse (A) 3.15 3.15 3.15

Sound Pressure Level dB (A) (SH/H/M/L) 42 / 38 / 35 / 32 44 / 39 / 36 / 33 49 / 44 / 40 / 35

Sound Power Level dB (A)(SH/H/M/L) 52 / 48 / 45 / 42 54 / 49 / 46 / 43 59 / 5 4 / 50 / 45

Dimension (W/D/H) (inch) 33 x 7 x 11 33 x 7 x 11 37 x 8 x 12

Dimension (W/D/H) (mm) 838 × 178 × 279 838 × 178 × 279 940 × 203 × 305

Dimension of Package (L/W/H) (inch) 36.1 x 10.2 x 14.6 36.1 x 10.2 x 14.6 39.8 x 11.2 x 15.0

Dimension of Package (L/W/H) (mm) 918 × 258 × 370 918 × 258 × 370 1010 × 285 × 380

Net Weight /Gross Weight (lbs) 22.0 / 37 22.0 / 37 28.6 / 46

Net Weight /Gross Weight (kg) 10 / 17 10 / 17 13 / 17

4 Johnson Controls Unitary Products

923212-UTG-B-0114

Outdoor unit Specification

Model of Outdoor Unit DHMF18CMM42Q1A DHMF24CMM42Q1A DHMF30CMM42Q1A DHMF42CMM42Q1A

Function Cooling

Compressor Manufacturer/trademark MITSUBISHI MITSUBISHI MITSUBISHI MITSUBISHI

Compressor Type Inverter Rotary Inverter Rotary Inverter Rotary Inverter Rotary

L.R.A. (A) 27 45 45 60

Compressor RLA(A) 9.56 14.698 19.62 19.07

Compressor Power Input (W) 1245 2200 2200 3010

Throttling Method Electron Expansion Valve Electron Expansion Valve Electron Expansion Valve Electron Expansion Valve

Working Temp Range (oF) 1 ~ 110 14 ~ 75 1 ~ 110 14 ~ 75 1 ~ 110 14 ~ 75 1 ~ 110 14 ~ 75

Condenser

Pipe Diameter (inch) Φ 5/16 Φ 3/8 Φ 3/8 Φ 5/16

Rows-Fin Gap (inch) 2 - 0.055 2 - 0.055 2 - 0.055 2 - 0.055

Coil Length (l) x height (H) x coil width (L) (inch) 30.6 x 21.7 x 1.5 35.0 x 25.0 x 1.7 35.0 x 25.0 x 1.7 40.2 x 41.6 x 1.5

Fan Motor Speed (rpm) 830/670/500 690/600/500 690/600/500 860/650/550

Output of Fan Motor (W) 60 60 60 140

Fan Motor RLA(A) 0.54 0.59 0.59 1.1

Fan Motor Capacitor (uF) 3.5 3.5 3.5 7

Fuse (A) 20 30 30 40

Air Flow Volume of Outdoor Unit (CFM) 1533 1533 1533 3244

Fan Type-Piece Axial-flow-1 Axial-flow-1 Axial-flow-1 Axial-flow-1

Fan Diameter (inch) 17.5 20.5 20.5 20.5

Defrosting Method Automatic Defrosting Automatic Defrosting Automatic Defrosting Automatic Defrosting

Climate Type T1 T1 T1 T1

Permissible Excessive Operating

Pressure for the Discharge Side (PSI)

Permissible Excessive Operating

Pressure for the Suction Side (PSI)

Sound Pressure Level dB (A) 56 56 56 58

Sound Power Level dB (A) 66 66 66 68

Dimension (W/D/H) (inch) 35 x 14.9 x 23.5 37 x 15.6 x 27.6 37 x 15.6 x 27.6 43 x 17.3 x 43.4

Dimension of Package (L/W/H)(inch) 37.2 x 16.4 x 24.8 40.4 x 17.9 x 28.9 40.4 x 17.9 x 28.9 45.5 x 18.9 x 43.9

Net Weight /Gross Weight (lbs) 95 / 106 135 / 146 137 / 148 225 / 247

Refrigerant Charge (oz) 47.62 77.6 77.6 169.3

Refrigerant Charge (kg) 1.4 2.2 2.2 4.8

Minimum Circuit Amps (MCA) 15.0

Minimum Output Power (MOP) 20.0

Length (ft) 24.6 24.6 24.6 24.6

Outer Diameter Liquid Pipe (inch) Φ 1/4 Φ 1/4 Φ 1/4 Φ 1/4

Outer Diameter Gas Pipe (inch) Φ 3/8 Φ 3/8 Φ 3/8 Φ 5/8

Max Height Distance (ft) 33

Max Length Distance With Multi Indoor Units (ft) 82

Note: Maximum length distance with multi indoor units (feet). Reference the installation manual for complete piping guidelines/limitations.

Aluminum Fin-copper

Heating

Tube

624 624 624 624

363 363 363 363

Cooling

Aluminum Fin-copper

Heating

Tube

20.0

30.0

33

82

Cooling

Aluminum Fin-copper

Heating

Tube

26.0

30.0

33

82

Cooling

Aluminum Fin-copper

Heating

Tube

26.0

40.0

33

82

Johnson Controls Unitary Products 5

923212-UTG-B-0114

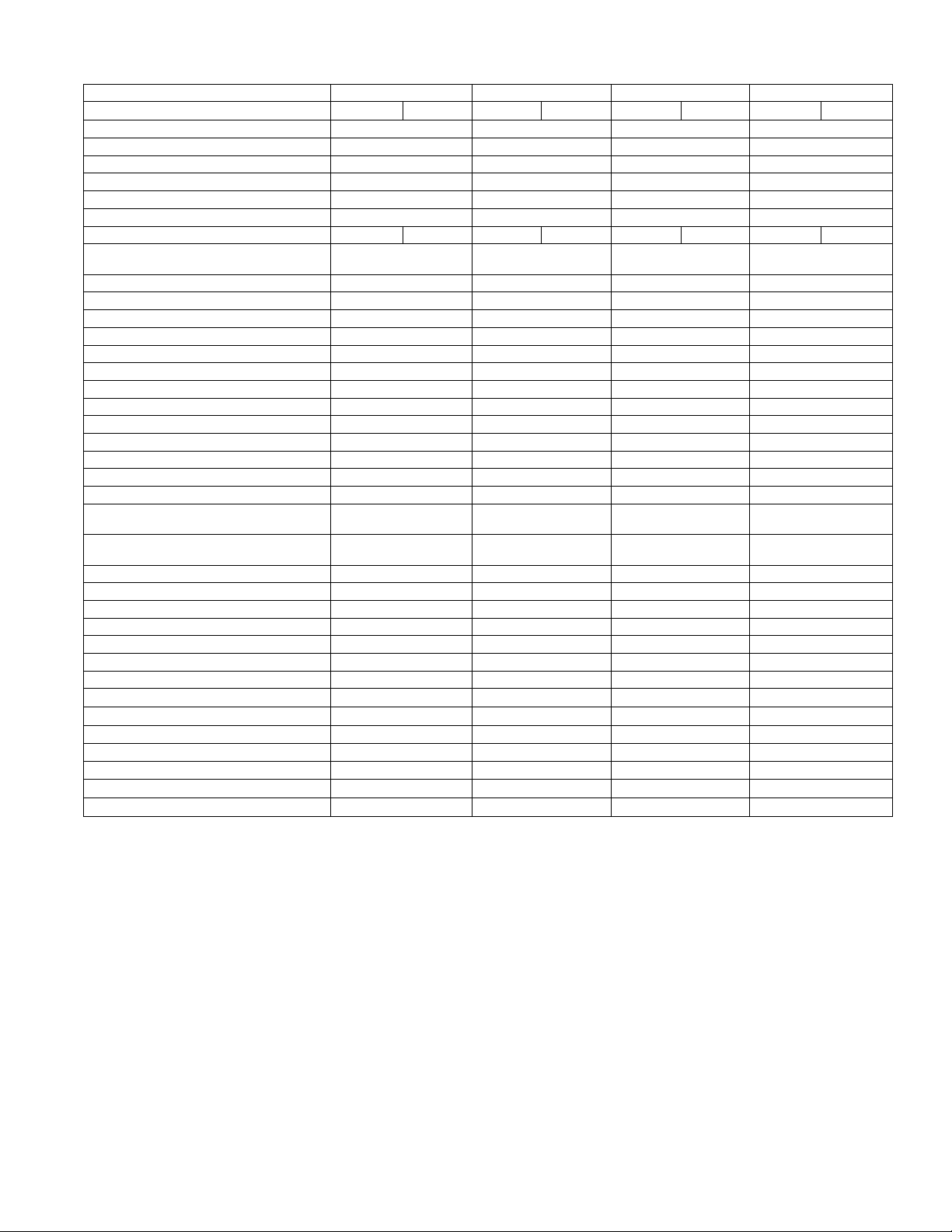

18K (9K + 9K)

Current(A)

Compressor Speed (rps)

0

20 40 60 80 100

0

2

4

6

8

10

12

Cooling

12

10

8

6

4

2

0

002040608001

Compressor Speed (rps)

Current(A)

Heating

24K/30K (9K + 9K + 9K)

Heating

Cooling

12

10

8

6

4

2

002040608001

Compressor Speed (rps)

Current(A)

16

14

18

20 18

14

16

Current(A)

Compressor Speed (rps)

0 20406080 100

2

4

6

8

10

12

0

6 Johnson Controls Unitary Products

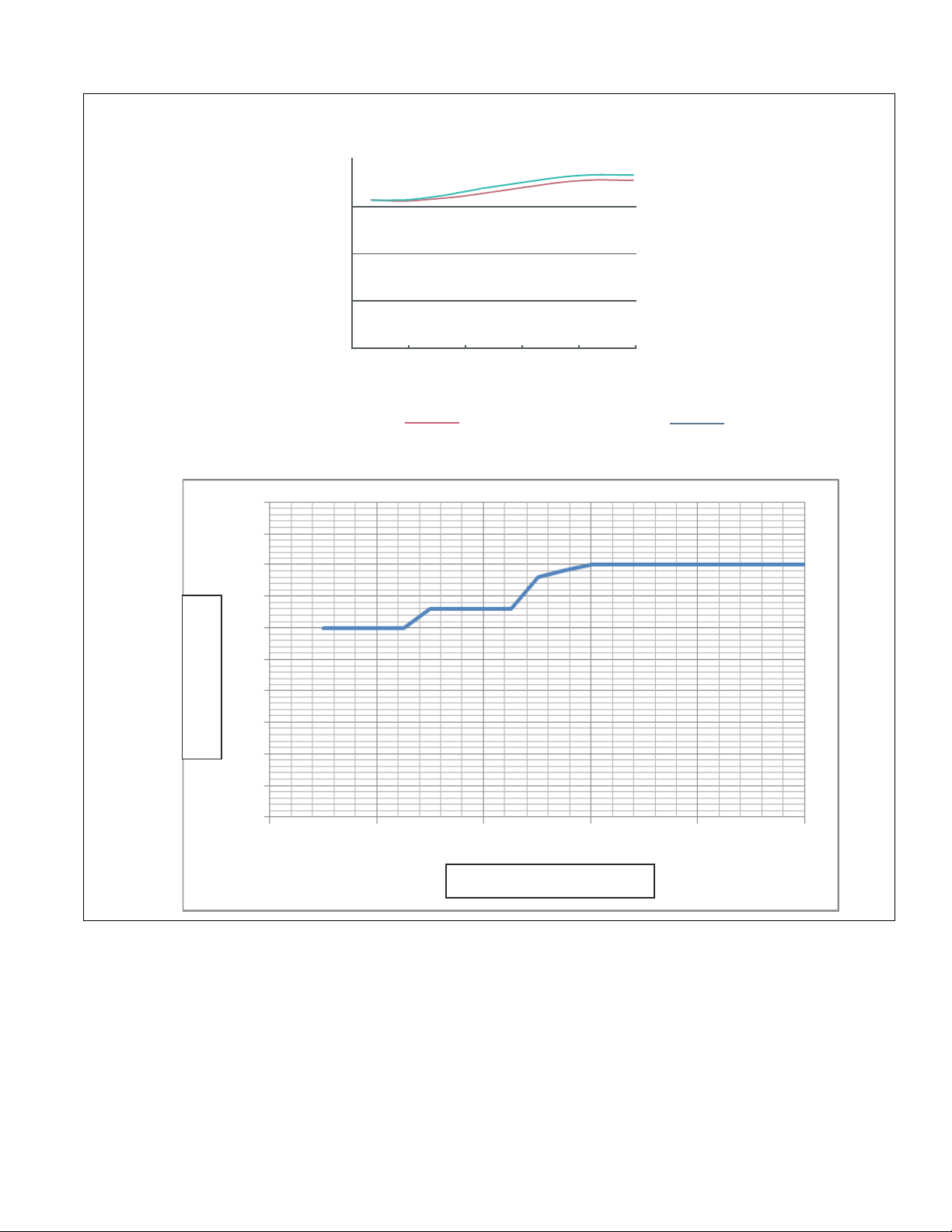

PRODUCT CAPACITY VARIATION RATIO

42K

0

5

10

15

20

25

020406080

Compressor Speed (rps)

Current (A)

0

5

10

15

20

25

020406080100

Compressor Speed (rps)

Current (A)

Cooling

Heating

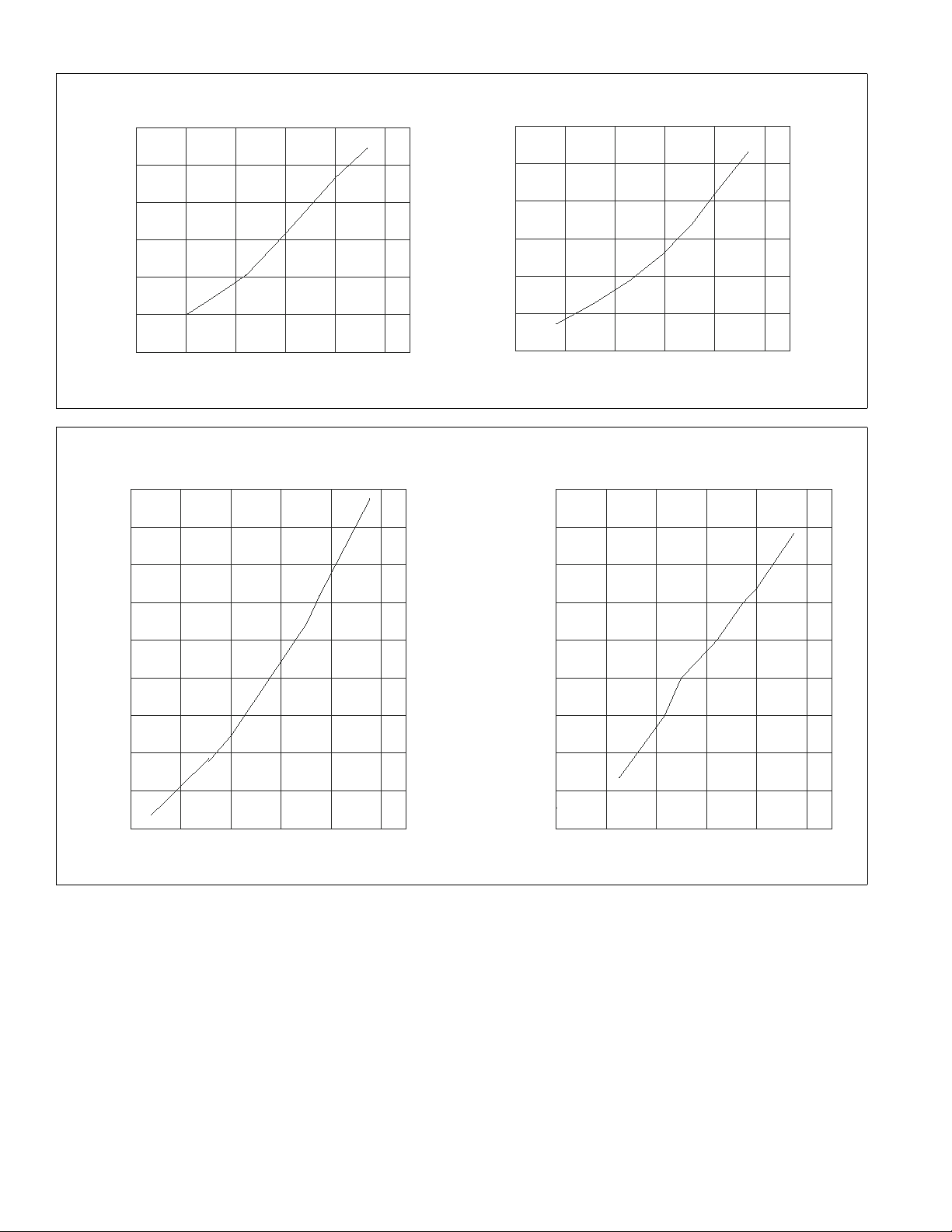

18K (9K + 9K)

Capacity Ratio (%)

Outdoor Temp (°F)

520 404550

60

70

80

90

100

110

120

50

4040

50

Heating

Cooling

120

110

100

90

80

70

60

1101051009590

Outdoor Temp (°F)

Capacity Ratio (%)

35

24K/30K (9K + 9K + 9K)

Capacity Ratio (%)

Outdoor Temp (°F)

Heating

Cooling

Outdoor Temp (°F)

Capacity Ratio (%)

35

90 95 100 105 110

60

70

80

90

100

110

120

50

40 40

50

120

110

100

90

80

70

60

50454020

5

923212-UTG-B-0114

Johnson Controls Unitary Products 7

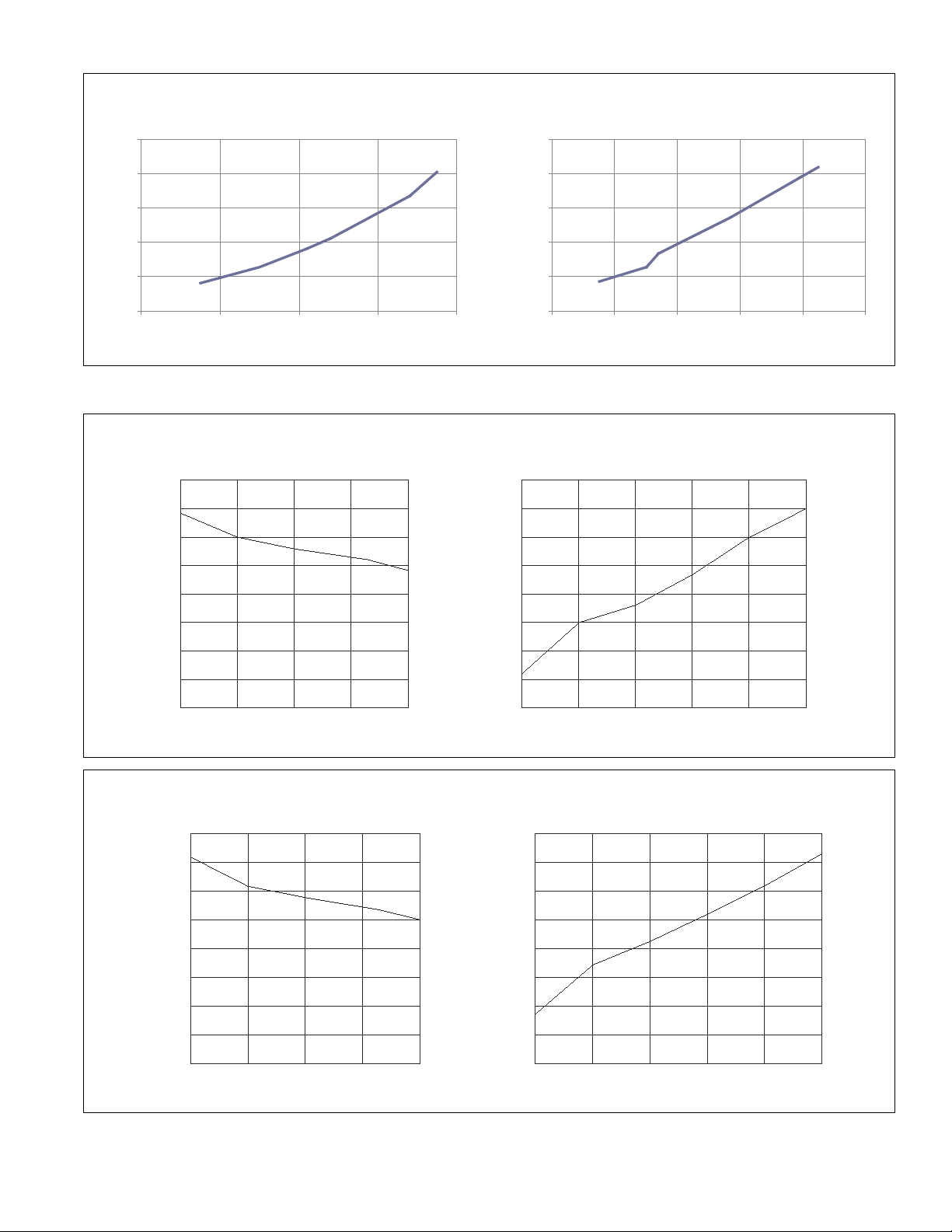

923212-UTG-B-0114

42K

Capacity Ratio (%)

Outdoor Temp (°F)

Heating

Cooling

Outdoor Temp (°F)

Capacity Ratio (%)

110

100

90

80

70

60

50

89.6

93.2 96.8 100.4

104.0

105.8

111.2 114.8

120

110

100

90

80

70

60

5.0

14.0 23.0

32.0

41.0

50.0

50

40

40

45

30

35

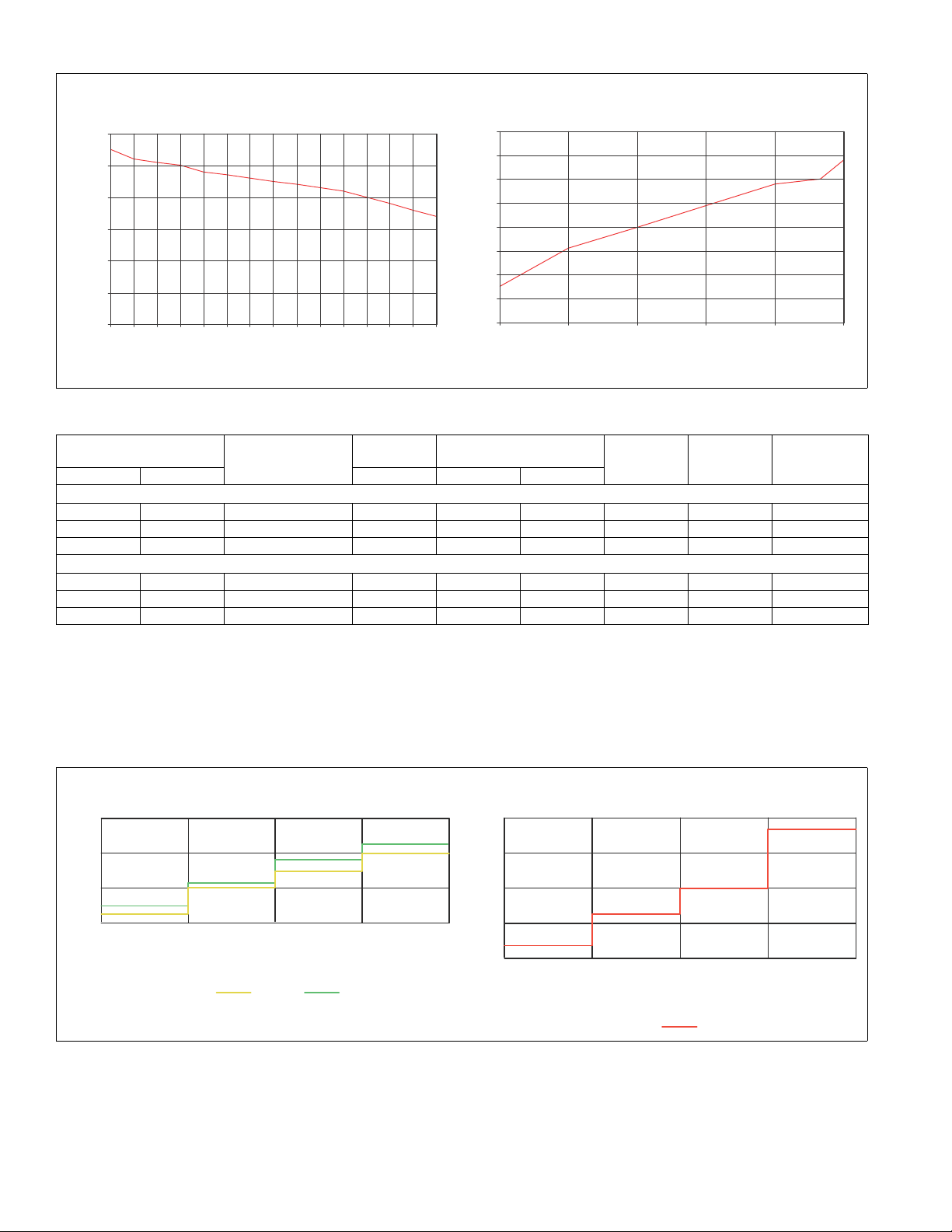

Indoor side noise when running

Indoor fan motor rotating speed

Low Middle High

Super High

Noise/dB(A)

12K

09K

09K/12K/18K Unit

50

55

40

45

35

Indoor side noise when running

Indoor fan motor rotating speed

Low Middle High

Super High

Noise/dB(A)

18K

OPERATION DATA

Temperature Condition (°F)

Model name

Standard

Pressure

Indoor O utdoor P (MPa) T1 (°F) T2 (°F)

80/66.9 95/75 18K(9K+9K) 0.9 to 1.1 50 to 55 150 to 104 Super High High 76

80/66.9 95/75 24K/30K(9K+9K+9K) 0.9 to 1.1 54 to 59 158 to 104 Super High High 70

80/66.9 95/75 42K 0.9 to 1.1 53.6 to 57.2 158 to 104 Super High High 75

70/60 46.9/43 18K(9K+9K) 2.3 to 2.7 150 to 100 35 to 40 Super High High 76

70/60 46.9/43 24K/30K(9K+9K+9K) 2.3 to 2.7 150 to 100 35 to 40 Super High High 76

70/60 46.9/43 42K 2.3 to 2.8 158 to 95 33.8 to 41.0 Super High High 85

Notes:

Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent. (Thermistor thermometer).

Connecting piping condition: 24.6 ft.

P: pressure of air pipe connected to the indoor and outdoor units (gas valve side),

T1: Inlet and outlet temperature for evaporator,

T2: Inlet and outlet temperature for condenser.

Heat Exchanger

Pipe Temperature

COOLING

HEATING

Indoor Fan

Mode

Outdoor Fan

Mode

Compressor

Frequency (Hz)

SOUND DATA

INDOOR UNITS

8 Johnson Controls Unitary Products

OUTDOOR UNITS

18K/24K/30K Unit

Outdoor side noise

18K(9K+9K)

24K/30K(9K+9K+9K)

60

6

50

40

40

30

20

002

Compressor Frequency/Hz

Compressor Frequency(Hz)

Noise level dB

(

A

)

42K Unit

80 100

70

65

60

55

50

45

40

35

30

25

20

0 20 40 60 80 100

923212-UTG-B-0114

Johnson Controls Unitary Products 9

Loading...

Loading...