Page 1

LX SERIES

DUCTLESS SINGLE-SPLIT

AIR CONDITIONERS AND HEAT PUMPS

16 SEER – 1 PHASE

3/4 THRU 2 NOMINAL TONS

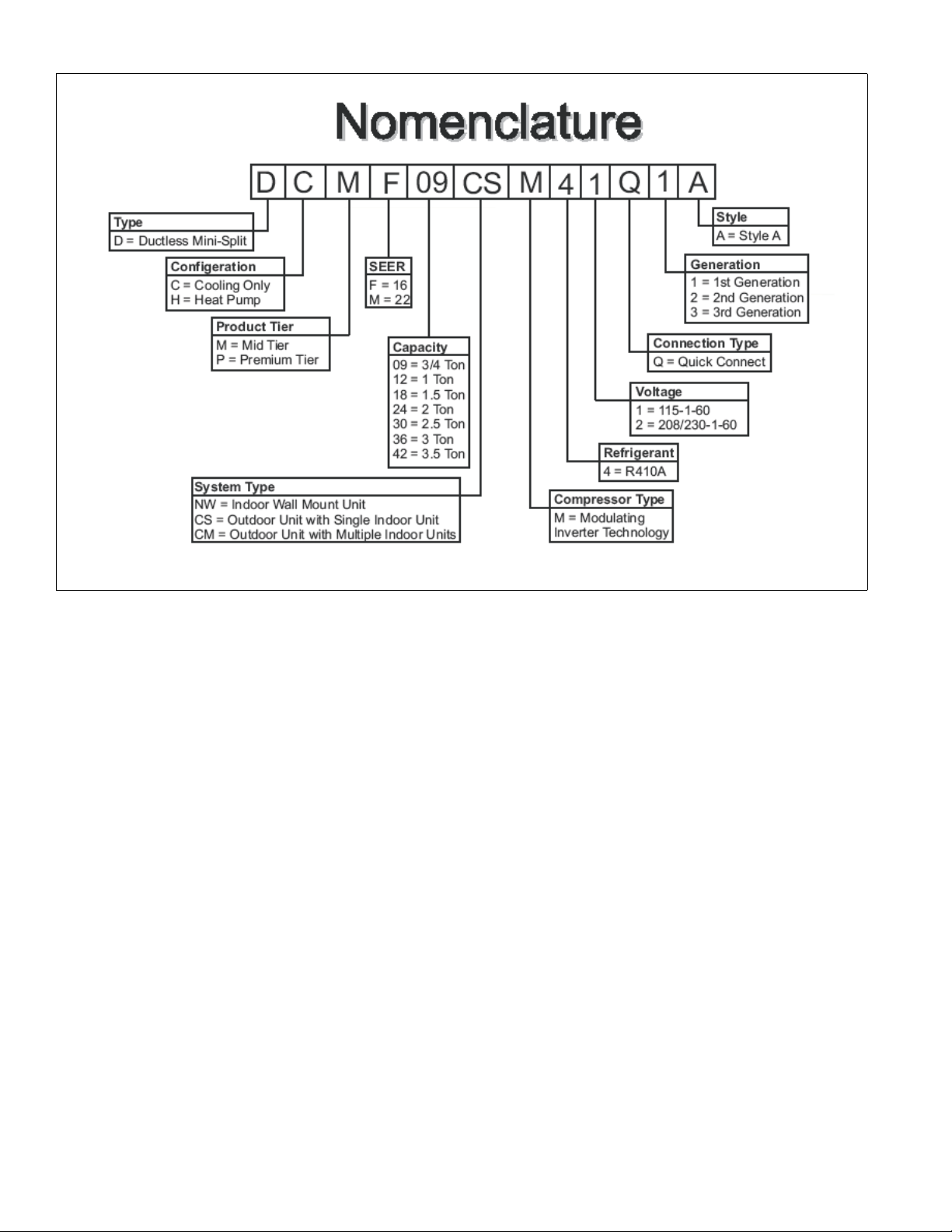

MODELS: DCMF/DHMF

Due to continuous product improvement, specifications

are subject to change without notice.

Visit us on the web at

www.upgnet.com

Additional rating information can be found at

www.ahridirectory.org

WARRANTY SUMMARY*

Standard 2-Years limited parts warranty.

Standard 6-Years limited compressor warranty.

TECHNICAL

GUIDE

TECHNICAL

GUIDE

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

923178-UTG-B-0114

DESCRIPTION

The Single-Split Series are ductless climate systems. They are

designed with a matching indoor unit for optimum performance and efficiency. These climate systems are supported with accessories and documents to serve specific functions.

FEATURES

Variable Frequency Rotary Compressor - Twin rotary in ve rte r co mpressor

on all models features high efficiency operation that modulates down to 15

Hz and as high as 120 Hz for red uced vibrat ion and qu iet opera tion. Brus hless DC motor uses powerful Neodymium magnets that are approximately

15-20 times stronger than ferrite magnets used in conventional AC compressors. The DC Inverter Control provides continuous operation, while adjusting

capacity according to room temp eratur e. Th e accur ate s ensing of co oling or

heating loads prevents frequen t changes in capacity and ensur es efficient,

economical operation.

Low Ambient Cooling Operation Down to 5 °F - This feature allows for a

space to be air-conditioned eve n in outdoor temperatures as low as 5 °F.

This cooling ability is important when de aling with server equipment rooms,

surveillance mechanical rooms, restaurant kitchens, fitness centers, and

more.

Load Variat io n Mana ge ment S ys tem - The outdoor coil thermistor continuously monitors the temperature and commun icates wit h the micro process or.

Depending on the temperature measured, the compressor will be allowed to

increase the frequency if nee ded to meet the load or reduce frequen cy as

the load is reduced.

High Pressure Discharge Temperature - The compressor discharge li ne

thermistor continuously monitors the temperature and communicates with

the microprocessor. Depending on the temperatur e me as u red, the compressor will be allowed to in crea se t he f r equen cy t o me et th e lo ad o r is fo rc ed to

run at the current or reduced f requency. If the temperature gets excessi vely

high, the compressor will be de-e nergized.

Defrost Control (Heat Pump Models) - Defrost cycle is automatically

enabled if there is a build-up of frost on the outdoor coil. Outdoor fan and

indoor blower operation is terminated during the defrost cycle. H1 is displayed on the indoor unit panel on the front cover during a defrost cycle.

Reversing Valve (Heat Pump Models) - 4-way inter change reversing valve

effects a rapid change in direction of refrigerant flow resulting in quick

changeover from cooling to h eating and vice vers a. Valve operates on system pressure differential betw e en outdoor unit and indoor unit.

R-410A Refrigerant - Unit is pre- charged with R410A refrigerant that uses

PVE refrigerant oil. Polyvinyl ether (PVE) is an innovative refrigerant oil specially formulated for hydrofluorocarbon (HFC) refrigeration systems. In addition to providing lubricati ng propert ies, it al so has a nu mber of othe r applied

advantages that help to increase the reliability of the refrigeration systems

where it is applied.

Refrigerant Line Connections, Service Valve - Outdoor units are designed

with easy service and mai nten an ce in mi n d. Ma in te nanc e p oi nts are loc at ed

behind easy-access panels, to m ake installation and s ervice a breeze for a

trained technician. Flare connection lines are located on side of unit cabinet.

Fully serviceable brass service valve prevents corrosion an d provide access

to refrigerant system. Shut -off valve that can be fully shut off while 2-way

suction/vapor valve (with service port) may be front seated to manage refrigerant charge while servicing system.

Air Deflection Louvers - Horizontal louvers default to the cooling or heating

position when the unit i s operating. Horizontal louvers can be set to a preset

oscillating range or fixed position from the wireless remote control. Full oscillating is the default settin g when button is pushed. Vertical louvers can be

manually adjusted to direct th e airflow for optimal comfort.

Indoor Coil Freeze Protectio n - The indoor coil thermistor monitors the coil

temperature continuously. Any time the coil tempera ture drops below 30°F,

the compressor and the outdoor fan (30 secon ds later) will be switched off

until the coil temperature r ises above 43°F and the compressor has been off

for a minimum of 3 minutes.

I FEEL Function - When I FEEL is activated, the system will sat isfy the coo ling or heating temperature setpoint where the remote control is located.

When I FEEL is deactivated, th e system will satisfy the cooling or heating

temperature setpoint where the indoor u nit is lo cated. This feature pr ovides

homeowners with optimum comfort whether the y are near or far from the

indoor unit.

Hot Heat Pump (cold air prevention) - In heating mode, the indoor fan wil l

be delayed from 1 to 3 minutes to allow refrigerant to warm up and avoid

cold blow. This may occur during:

• Initial start-up of a heating cycle

• Immediately after completion of an Auto mode operation

• Heating under extremely low indoor temperatures

Page 2

923178-UTG-B-0114

2 Johnson Controls Unitary Products

Page 3

923178-UTG-B-0114

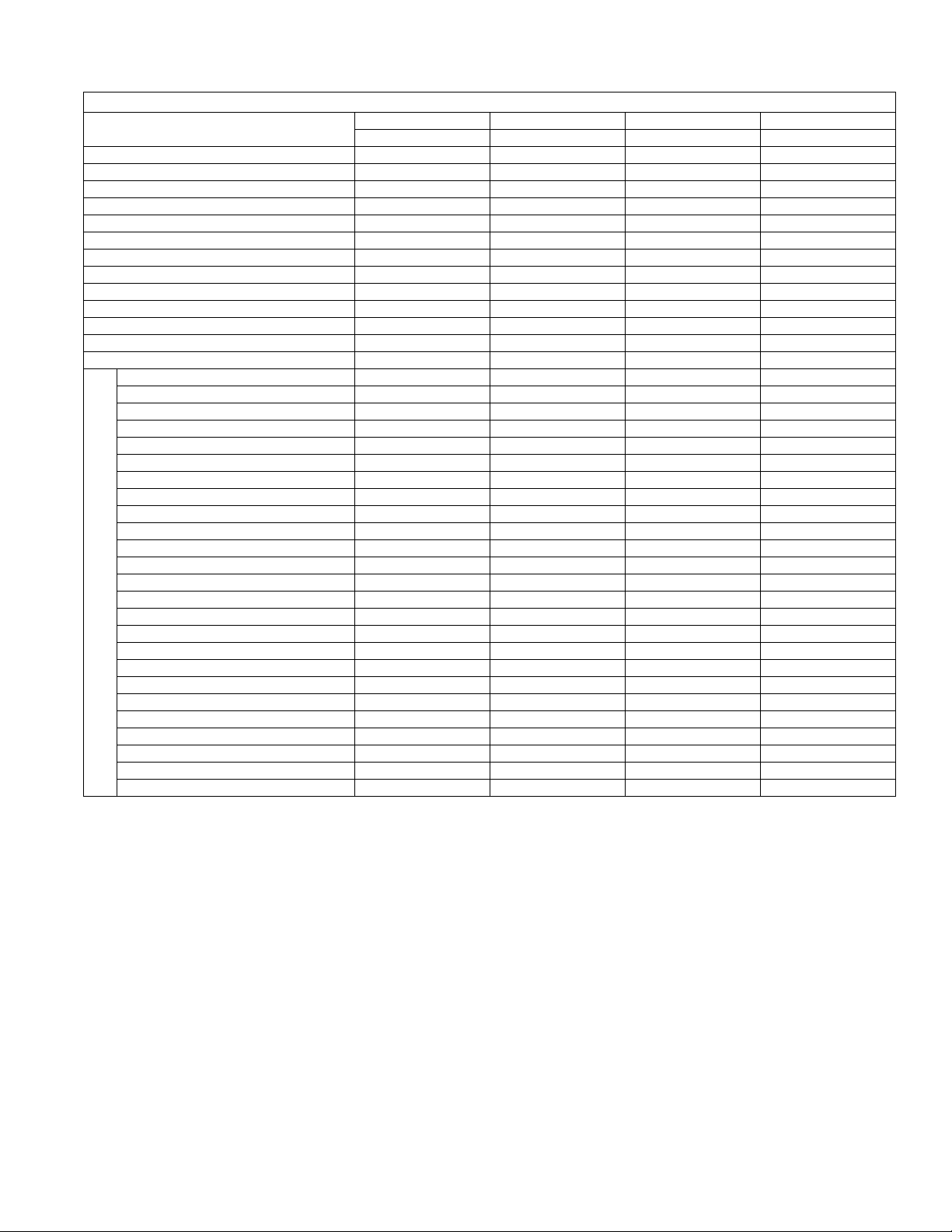

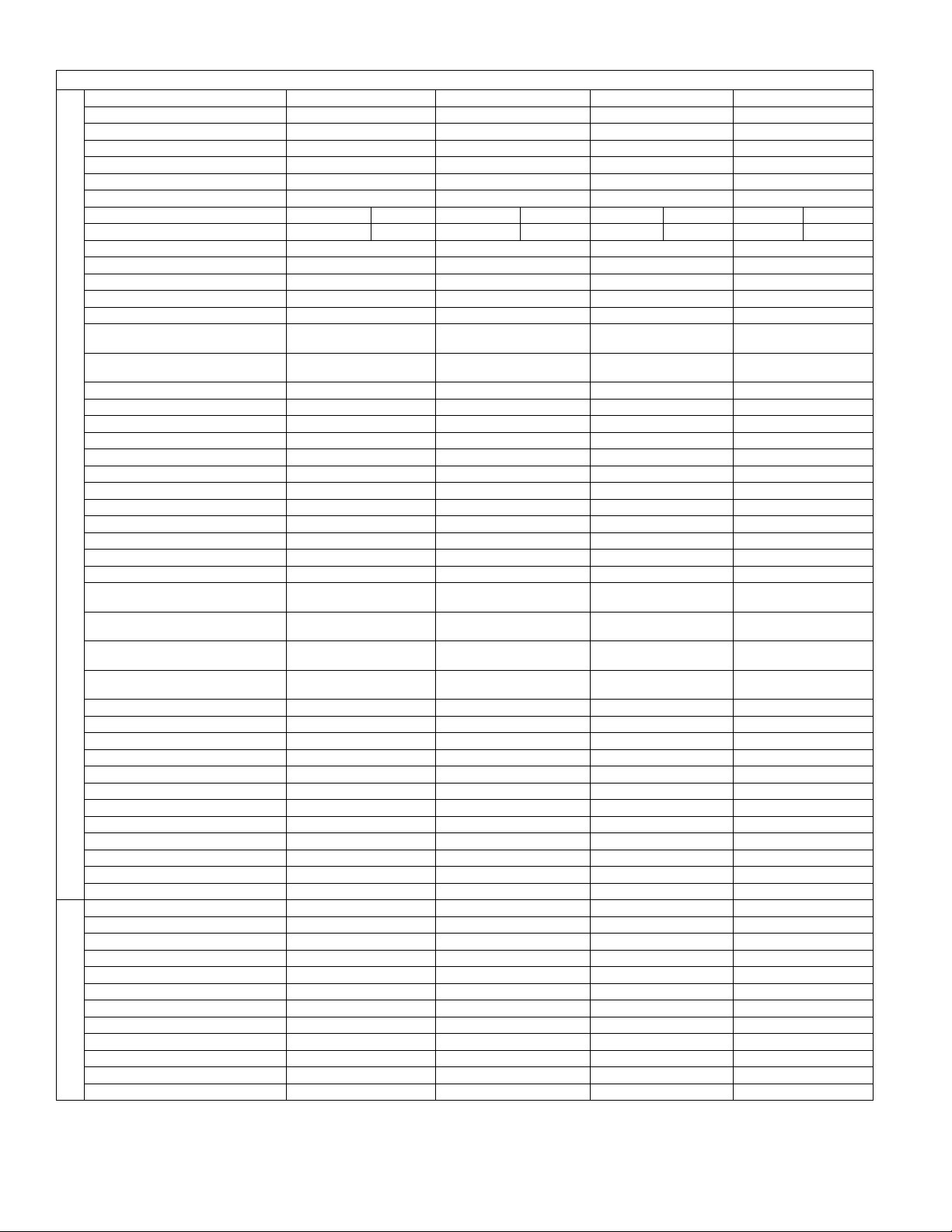

SPECIFICATIONS

AIR CONDITIONERS

Model (Indoor/Outdoor)

Function Cooling Cooling Cooling Cooling

Rated Voltage 208/230 208/230 208/230 208/230

Frequency (Hz) 60Hz 60Hz 60Hz 60Hz

Total Capacity (BTUH) (High/Standard/Low) 11500/9000/3800 12500/12000/3300 21000/18000/4500 24000/22000/6400

Total Capacity (W) (High/Standard/Low) 3370/2637/1114 3663/3516/967 6155/5276/1319 7032/6446/1875

Rated Power Input (W) 882 1224 1621 2200

Nominal Input Current (A) 4.01 5.56 7.37 10.00

SEER 16.00 16.00 16.00 16.00

Air Flow Volume (CFM) (H/M/L) 330/300/260/210 340/300/260/210 470/400/330/270 590/440/300/200

Air Flow Volume (m3/h) (H/M/L) 560/510/440/370 580/520/440/370 800/680/560/460 1000/750/520/350

Dehumidifying Volume (cu.ft./h) 0.028 0.049 0.064 0.075

Dehumidifying Volume (l/h) 0.80 1.40 1.80 2.13

EER 10.2 9.8 11.1 10

Model of Indoor Unit DCMF09NWM42Q1 DCMF12NWM42Q1 DCMF18NWM42Q1 DCMF24NWM42Q1

Fan Motor Speed (r/min) (SH/H/M/L) 1300/1100/900/700 1350/1150/950/750 1400/1150/1000/850 1450/1180/1000/850

Output of Fan Motor (w) 15 15 20 36

Fan Motor Capacitor (uF) 1.2 1.2 1.5 2.5

Fan Motor RLA (A) 0.19 0.19 0.32 0.45

Fan Type-Piece Cross-flow - 1 Cross-flow - 1 Cross-flow - 1 Cross-flow - 1

Diameter-Length (inch) 3.6 × 23.4 3.6 × 23.4 3.9 × 25.6 3.9 × 30.1

Diameter-Length (mm) 92 × 594 92 × 595 98 × 650 98 × 765

Evaporator Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter (inch) Φ 0.276 Φ 0.276 Φ 0.276 Φ 0.276

Pipe Diameter (mm) φ7 φ7 φ7 φ7

Row-Fin Gap (inch) 2 - 0.055 2 - 0.055 2 - 0.055 2 - 0.059

Row-Fin Gap (mm) 2-1.4 2-1.4 2-1.4 2-1.5

Coil length (L) x height (H) x coil width (W) (inch) 24.0 × 11.6 × 0.9 24.0 x 11.6 × 0.9 25.9 × 12.0 × 1.0 30.1 × 13.5 × 1.0

Indoor Unit

Coil length (L) x height (H) x coil width (W) (mm) 610 × 24 × 294 610 × 24 × 294 657 × 25.4 × 304.8 765 × 25.4 × 342.9

Output of Swing Motor (W) 1.5 1.5 2 3

Fuse (A) 3.15 3.15 3.15 3.15

Sound Pressure Level dB (A)(SH/H/M/L) 43 / 38 / 32 / 26 44 / 39 / 33 / 28 48 / 43 / 38 / 34 49 / 43 / 39 / 34

Sound Power Level dB (A)(SH/H/M/L) 53 / 48 / 42 / 36 54 / 49 / 43 / 38 58 / 53 / 48 / 43 59 / 53 / 49 / 44

Dimension (W/D/H) (inch) 30.3 × 7.9 × 11.1 30.3 × 7.9 × 11.1 34.1 × 8.5 × 12.0 39.7 × 8.7 × 12.4

Dimension (W/D/H) (mm) 770 × 201 × 282 770 × 201 × 282 865 × 216 × 305 1008 × 221 × 315

Dimension of Package (L/W/H) (inch) 33.3 × 10.9 × 13.9 33.3 × 10.9 × 13.9 37.3 × 12.2 × 15.1 42.2 × 12.3 × 15.6

Dimension of Package (L/W/H) (mm) 847 × 276 × 352 847 × 276 × 352 948 × 310 × 383 1073 × 313 × 395

Net Weight /Gross Weight (lbs) 19 / 25 20 / 27 27 / 35 33.0 / 44.0

Net Weight /Gross Weight (kg) 8.6 / 11.5 9.0 / 12 12.0 / 16 15 / 20

Continued on next page.

DCMF09NWM42Q1 DCMF12NWM42Q1 DCMF18NWM42Q1 DCMF24NWM42Q1

DCMF09CSM42Q1 DCMF12CSM42Q1 DCMF18CSM42Q1 DCMF24CSM42Q1

Johnson Controls Unitary Products 3

Page 4

923178-UTG-B-0114

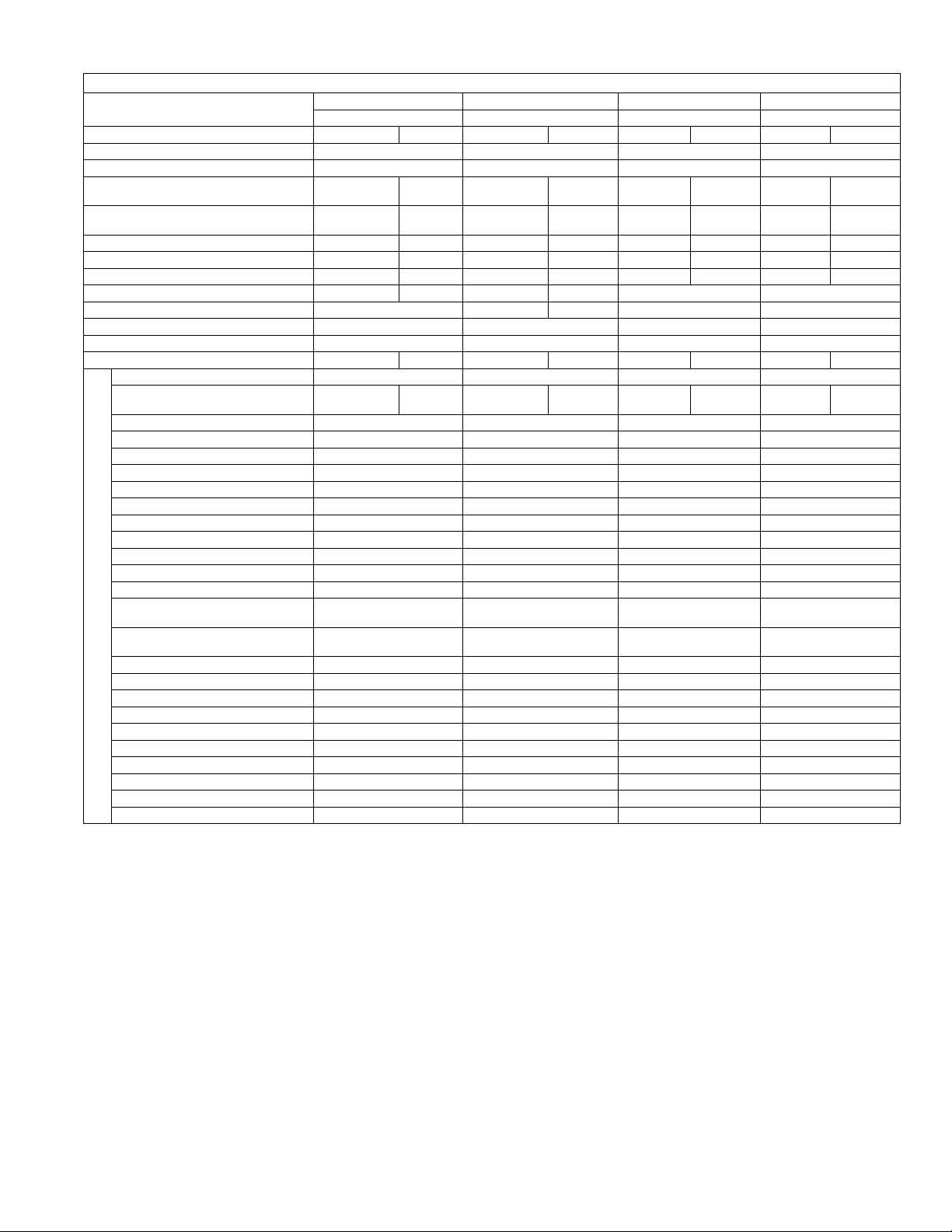

AIR CONDITIONERS (Continued)

Model of Outdoor Unit DCMF09CSM42Q1 DCMF12CSM42Q1 DCMF18CSM42Q1 DCMF24CSM42Q1

Compressor Manufacturer/trademark GREE GREE MITSUBISHI SANYO

Compressor Type Inverter Rotary Inverter Rotary Inverter Rotary Inverter Rotary

L.R.A. (A) 16.50 16.50 27 41

Compressor RLA (A) 6.22 6.22 10.86 11.38

Compressor Power Input (W) 950 950 1245 1630

Throttling Method Capillary Capillary Capillary EXV

Working Temp Range (oF) 5 ~ 115 5 ~ 115 5 ~ 115 5 ~ 115

Working Temp Range (°C) -15 ~ 46 -15 ~ 46 -15 ~ 46 -15 ~ 46

Condenser Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter (inch) Φ 0.276 Φ 0.276 Φ 0.276 Φ 0.276

Pipe Diameter (mm) φ7 φ7 φ7 φ7

Rows-Fin Gap (inch) 1 - 0.055 2 - 0.055 2 - 0.055 2 - 0.055

Rows-Fin Gap (mm) 1-1.4 2-1.4 2-1.4 2-1.4

Coil length (L) x height (H) x coil width (L) (inch) 25.5 × 20.8 × 0.8 25.5 × 20.8 × 1.5 33.0 × 26.0 × 1.5 33.6 × 26.0 × 1.5

Coil length (L) x height (H) x coil width (L) (mm) 647 × 19.05 × 528 647 × 38.1 × 528 837 × 38.1 × 660 853 × 38.1 × 660

Fan Motor Speed (rpm) 880±20 880±20 690 690

Output of Fan Motor (W) 21 21 60 60

Fan Motor RLA (A) 0.25 0.25 0.62 0.62

Fan Motor Capacitor ( uF) 2 2 3 3.5

Fuse (A) 15A 15A 25A 25A

Air Flow Volume of Outdoor Unit (CFM) 944 944 1887 1887

Air Flow Volume of Outdoor Unit (m3/h) 1600 1600 3200 3200

Fan Type-Piece Axial-flow-1 Axial-flow-1 Axial-flow-1 Axial-flow-1

Fan Diameter (inch) 14.6 14.6 20.5 20.5

Outdoor Unit

Fan Diameter (mm) 370 370 520 520

Defrosting Method Automatic Defrosting Automatic Defrosting Automatic Defrosting Automatic Defrosting

Climate Type T1 T1 T1 T1

Permissible Excessive Operating

Pressure for the Discharge Side (PSI)

Permissible Excessive Operating

Pressure for the Discharge Side (MPa)

Permissible Excessive Operating

Pressure for the Suction Side (PSI)

Permissible Excessive Operating

Pressure for the Suction Side (MPa)

Sound Pressure Level dB (A) 49 52 56 56

Sound Power Level dB (A) 59 62 66 66

Dimension (W/D/H) (mm) 28.0 × 12.5 × 21.7 28.0 × 12.5 × 21.7 37.9 × 15.6 × 27.6 37.9 × 15.6 × 27.6

Dimension (W/D/H) (mm) 711 × 318 × 551 711 × 318 × 551 963 × 396 × 701 963 × 396 × 701

Dimension of Package (L/W/H) (inch) 30.4 × 13.7 × 23.3 30.4 × 13.7 × 23.3 40.4 × 17.9 × 28.9 40.4 × 17.9 × 28.9

Dimension of Package (L/W/H) (mm) 771 × 348 × 592 771 × 348 × 592 1026 × 455 × 735 1026 × 455 × 735

Net Weight /Gross Weight (lbs) 64 / 73 68 / 77 104 / 115 112 / 123

Net Weight /Gross Weight (kg) 29 / 33 31 / 35 47 / 52 51 / 56

Refrigerant Charge (oz) 26.1 35.3 44.1 54.7

Refrigerant Charge (kg) 0.74 1.00 1.25 1.55

MCA 10.0 10.0 15.0 16.0

MOP 15.0 15.0 25.0 25.0

Length (ft) 25 25 25 25

Length (m) 7.5 7.5 7.5 7.5

Gas additional charge (oz/ft) 0.2 0.2 0.2 0.2

Gas additional charge (g/m) 15 15 15 15

Outer Diameter Liquid Pipe (inch) Φ 1/4 Φ 1/4 Φ 1/4 Φ 1/4

Outer Diameter Liquid Pipe (mm) φ6 φ6 φ6 φ6

Outer Diameter Gas Pipe (inch) Φ 3/8 Φ 3/8 Φ 1/2 Φ 1/2

Outer Diameter Gas Pipe (mm) φ9.52 φ9.52 φ12 φ12

Connection Pipe

Max Height Distance (ft) 32.8 32.8 32.8 32.8

Max Height Distance (m) 9.9 9.9 9.9 9.9

Max Length Distance (ft) 49.2 49.2 82 82

Max Length Distance (m) 14.9 14.9 24.9 24.9

624 624 624 624

4.3 4.3 4.3 4.3

363 363 363 363

2.5 2.5 2.5 2.5

4 Johnson Controls Unitary Products

Page 5

923178-UTG-B-0114

HEAT PUMPS

Model (Indoor/Outdoor)

Function Cooling Heating Cooling Heating Cooling Heating Cooling Heating

Rated Voltage 208/230 208/230 208/230 208/230

Frequency (Hz) 60Hz 60Hz 60Hz 6 0Hz

Total Capacity (Btu/h) (High/Standard/Low)

Total Capacity (W) (High/Standard/Low)

Rated Power Input (W) 882 799 1224 1065 1621 2123 2200 3118

Nominal Input Current (A) 4.01 3.63 5.56 4.84 7.37 9.65 10.00 14.17

SEER/HSPF 16.00 8.5 16.00 8.5 16.00 8 16 9.5

Air Flow Volume (CFM) (H/M/L) 330/300/260/210 330 340/300/260/210 341 470/400/330/270 590/440/300/200

Air Flow Volume (m

Dehumidifying Volume (cu.ft./h) 0.028 0.049 0.064 0.075

Dehumidifying Volume (l/h) 0.80 1.40 1.80 2.13

EER / C.O.P 10.2 3.32 9.8 3.3 11.1 2.65 10 2.5

Model of Indoor Unit DHMF09NWM42Q1 DHMF12NWM42Q1 DHMF18NWM42Q1 DHMF24NWM42Q1

Fan Motor Speed (r/min) (SH/H/M/L)

Output of Fan Motor (w) 15 15 20 36

Fan Motor Capacitor (uF) 1.2 1.2 1.5 2.5

Fan Motor RLA(A) 0.19 0.19 0.32 0.45

Fan Type-Piece Cross-flow - 1 Cross-flow - 1 Cross-flow - 1 Cross-flow - 1

Diameter-Length (inch) 3.6 × 23.4 3.6 × 23.4 3.9 × 25.6 3.9 × 30.1

Diameter-Length (mm) 92 × 594 92 × 595 98 × 650 98 × 765

Evaporator Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter (inch) Φ 0.276 Φ 0.276 Φ 0.276 Φ 0.276

Pipe Diameter (mm) φ7 φ7 φ7 φ7

Row-Fin Gap (inch) 2 - 0.055 2 - 0.055 2 - 0.055 2 - 0.059

Row-Fin Gap (mm) 2-1.4 2-1.4 2-1.4 2-1.5

Coil length (L) x height

(H) x coil width (W) (inch)

Indoor Unit

Coil length (L) x height

(H) x coil width (W) (mm)

Output of Swing Motor (W) 1.5 1.5 2 3

Fuse (A) 3.15 3.15 3.15 3.15

Sound Pressure Level dB (A) (SH/H/M/L) 43 / 38 / 32 / 26 44 / 39 / 33 / 28 48 / 43 / 38 / 34 49 / 43 / 39 / 34

Sound Power Level dB (A)(SH/H/M/L) 53 / 48 / 42 / 36 54 / 49 / 43 / 38 58 / 53 / 48 / 43 59 / 53 / 49 / 44

Dimension (W/D/H) (inch) 30.3 × 7.9 × 11.1 30.3 × 7.9 × 11.1 34.1 × 8.5 × 12.0 39.7 × 8.7 × 12.4

Dimension (W/D/H) (mm) 770 × 201 × 283 770 × 201 × 283 865 × 215 × 305 1008 × 221× 315

Dimension of Package (L/W/H) (inch) 33.3 ×10.9 × 13.9 33.3 × 10.9 × 13.9 37.3 × 12.2 × 15.1 42.2 × 12.3 × 15.6

Dimension of Package (L/W/H) (mm) 847 × 276 × 352 847 × 276 × 352 948 × 310 × 383 1073 × 313 × 395

Net Weight /Gross Weight (lbs) 19 / 25 20 / 27 27 / 35 33.0 / 44.0

Net Weight /Gross Weight (kg) 8.6 / 11.5 9.0 / 12.0 12.0 / 16.0 15 / 20

Continued on next page.

3

/h) (H/M/L) 560/510/440/370 580/520/440/370 580 800/680/560/460 1000/750/520/350

DHMF09NWM42Q1 DHMF12NWM42Q1 DHMF18NWM42Q1 DHMF24NWM42Q1

DHMF09CSM42Q1 DHMF12CSM42Q1 DHMF18CSM42Q1 DHMF24CSM42Q1

11500/9000/

3800

3370/2637/

1114

1300/1100/

900/700

24.0 × 11.6 × 0.9 24.0 × 11.6 × 0.9 25.9 × 12.0 × 1.0 30.1 × 13.5 × 1.0

610 × 24 × 294 610 × 24 × 294 657 × 25.4 × 304.8 765 × 25.4 × 342.9

11500/9000/

3300

3370/2637/

967

1300/1150/

980/820

12500/12000/

3300

3663/3516/

967

1350/1150/

950/750

12500/12000/

3400

3663/3516/

996

1350/1190/

1020/850

21000/18000/

4500

6155/5276/

1319

1400/1150/

1000/850

23000/19200/

4000

6741/5276/

1172

1450/1250/

1100/950

24000/22000/

6400

7032/6446/

1875

1400/1180/

1000/850

26600/26600/

7796/6446/

1450/1380/

1200/1150

4100

1202

Johnson Controls Unitary Products 5

Page 6

923178-UTG-B-0114

HEAT PUMPS (Continued)

Model of Outdoor Unit DHMF09CSM42Q1 DHMF12CSM42Q1 DHMF18CSM42Q1 DHMF24CSM42Q1

Compressor Manufacturer/trademark GREE GREE MITSUBISHI SANYO

Compressor Type Inverter Rotary Inverter Rotary Inverter Rotary Inverter Rotary

L.R.A. (A) 16.50 16.50 27 41

Compressor RLA(A) 6.22 6.22 10.86 11.38

Compressor Power Input (W) 950 950 1245 1630

Throttling Method Capillary Capillary Capillary EXV

Working Temp Range (

Working Temp Range (°C) -15 ~ 46 -10 ~ 24 -15 ~ 46 -10 ~ 24 -15 ~ 46 -10 ~ 24 -15 ~ 46 -10 ~ 24

Condenser Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube Aluminum Fin-copper Tube

Pipe Diameter (inch) Φ 0.276 Φ 0.276 Φ 0.276 Φ 0.276

Pipe Diameter (mm) φ7 φ7 φ7 φ7

Rows-Fin Gap (inch) 1 - 0.055 2 - 0.055 2 - 0.055 2 - 0.055

Rows-Fin Gap (mm) 1-1.4 2-1.4 2-1.4 2-1.4

Coil length (l) x height (H) x

coil width (L) (inch)

Coil length (l) x height (H) x

coil width (L) (mm)

Fan Motor Speed (rpm) 880±20 880±20 690 690

Output of Fan Motor (W) 21 21 60 60

Fan Motor RLA(A) 0.25 0.25 0.62 0.62

Fan Motor Capacito r ( uF) 2 2 3 3.5

Fuse (A) 15A 15A 25A 25A

Air Flow Volume of Outdoor Unit (CFM) 944 944 1887 1887

Air Flow Volume of Outdoor Unit (m

Fan Type-Piece Axial-flow-1 Axial-flow-1 Axial-flow-1 Axial-flow-1

Fan Diameter (inch) 14.6 14.6 20.5 20.5

Outdoor Unit

Fan Diameter (mm) 370 370 520 520

Defrosting Method Automatic Defrosting Automatic Defrosting Automatic Defrosting Automatic Defrosting

Climate Type T1 T1 T1 T1

Permissible Excessive Operating

Pressure for the Discharge Side (PSI)

Permissible Excessive Operating

Pressure for the Discharge Side (MPa)

Permissible Excessive Operating

Pressure for the Suction Side (PSI)

Permissible Excessive Operating

Pressure for the Suction Side (MPa)

Sound Pressure Level dB (A) 49 52 56 56

Sound Power Level dB (A) 59 62 66 56

Dimension (W/D/H) (mm) 28.0 × 12.5 × 21.7 28.0 × 12.5 × 21.7 37.9 × 15.6 × 27.6 37.9 × 15.6 × 27.6

Dimension (W/D/H) (mm) 711 × 318 × 551 711 × 318 × 551 963 × 396 × 701 963 × 396 × 701

Dimension of Package (L/W/H) (inch) 30.4 × 13.7 × 23.3 30.4 × 13.7 × 23.3 40.4 × 17.9 × 28.9 40.4 × 17.9 × 28.9

Dimension of Package (L/W/H) (mm) 771 × 348 × 592 771 × 348 × 592 1026 × 455 × 735 1026 × 455 × 735

Net Weight /Gross Weight (lbs) 64 / 73 68 / 77 106 / 117 115 / 126

Net Weight /Gross Weight (kg) 29 / 33 31 / 35 48 / 53 52 / 57

Refrigerant Charge (oz) 26.1 35.3 44.1 54.7

Refrigerant Charge (kg) 0.74 1.00 1.25 1.55

MCA 10.0 10.0 15.0 16.0

MOP 15.0 15.0 25.0 25.0

Length (ft) 25 25 25 25

Length (m) 7.5 7.5 7.5 7.5

Gas additional charge (oz/ft) 0.2 0.2 0.2 0.2

Gas additional charge (g/m) 20 20 20 20

Outer Diameter Liquid Pipe (inch) Φ 1/4 Φ 1/ 4 Φ 1/4 Φ 1/4

Outer Diameter Liquid Pipe (mm) φ6 φ6 φ6 φ6

Outer Diameter Gas Pipe (inch) Φ 3/8 Φ 3/8 Φ 1/2 Φ 1/2

Outer Diameter Gas Pipe (mm) φ9.52 φ9.52 φ12 φ12

Connection Pipe

Max Height Distance (ft) 32.8 32.8 32.8 32.8

Max Height Distance (m) 9.9 9.9 9.9 9.9

Max Length Distance (ft) 49.2 49.2 82 82

Max Length Distance (m) 14.9 14.9 24.9 24.9

o

F) 5 ~ 115 14 ~ 75 5 ~ 115 14 ~ 75 5 ~ 115 14 ~ 75 5 ~ 115 14 ~ 75

25.5 × 20.8 × 0.8 25.5 × 20.8 × 1.5 33.0 × 26.0 × 1.5 33.6 × 26.0 × 1.5

647 × 19.05 × 528 647 × 38.1 × 528 837 × 38.1 × 660 853 × 38.1 × 660

3

/h) 1600 1600 3200 3200

624 624 624 624

4.3 4.3 4.3 4.3

363 363 363 363

2.5 2.5 2.5 2.5

6 Johnson Controls Unitary Products

Page 7

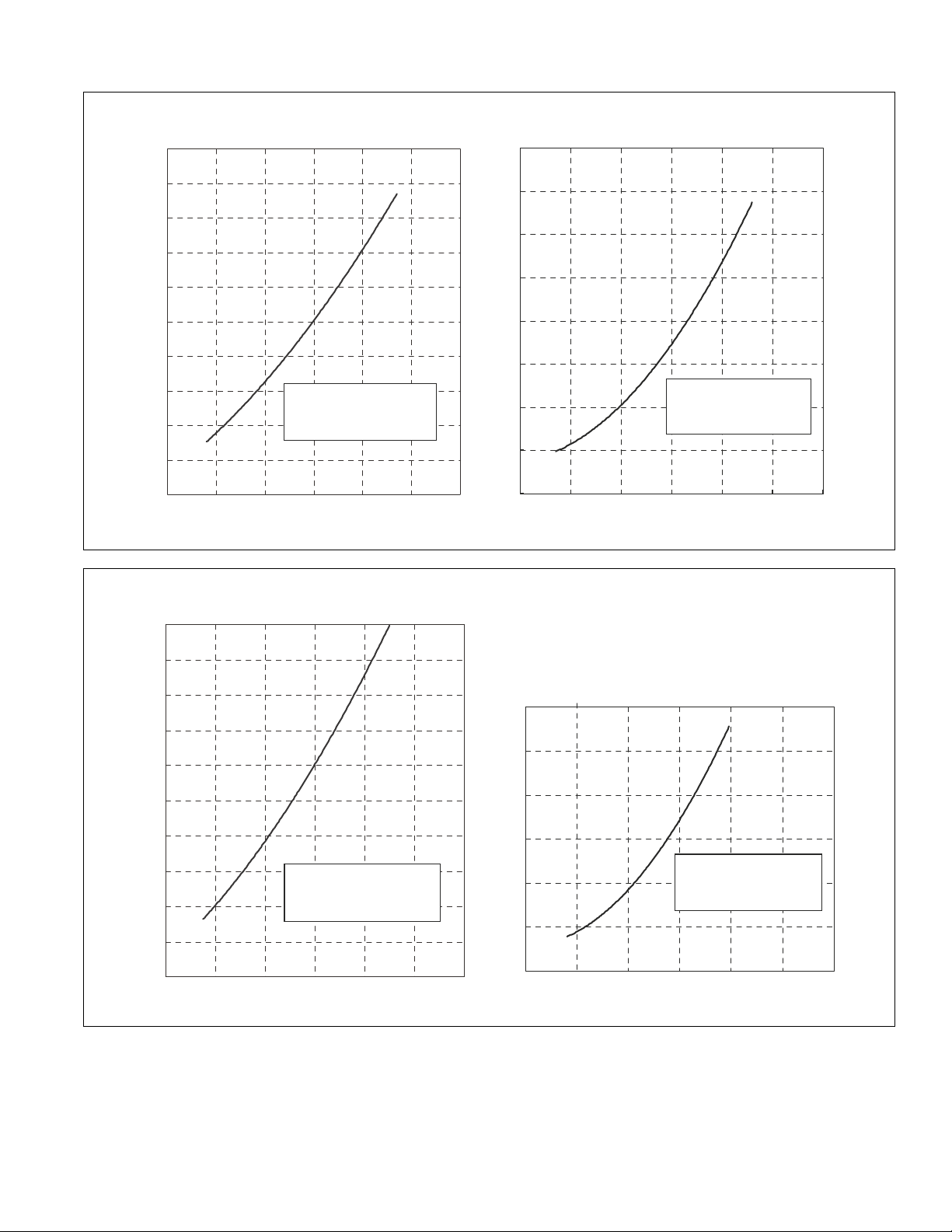

PRODUCT OPERATION CHARACTERISTIC CURVES

Cooling Heating

0

1

2

3

4

5

6

7

8

9

10

0 20 40 60 80 100 120

Condition

F°6.08 BD:roodnI

WB66.2

°F

Indoor air flow: Super High

Pipe length:24.6ft

0

1

2

3

4

5

6

7

8

0 20 40 60 80 100 120

Condition

Indoor:DB 68°F

Indoor air flow: Super High

Pipe length:24.6ft

Current(A)

Current(A)

09K 12K

Compressor Frequency(Hz)

Compressor Frequency(Hz)

18K

Cooling

Heating

0

1

2

3

4

5

6

7

8

9

10

020406080

100 120

Condition

F°6.08 BD:roodnI

WB66.2

°F

Indoor air flow: Super High

Pipe length:24.6ft

Compressor Frequency(Hz)

0

2

4

6

8

10

12

0 20 40 60 80 100 120

Condition

Indoor:DB 68°F

Indoor air flow: Super High

Pipe length:24.6ft

Compressor Frequency(Hz)

Current(A)

Current(A)

923178-UTG-B-0114

Johnson Controls Unitary Products 7

Page 8

923178-UTG-B-0114

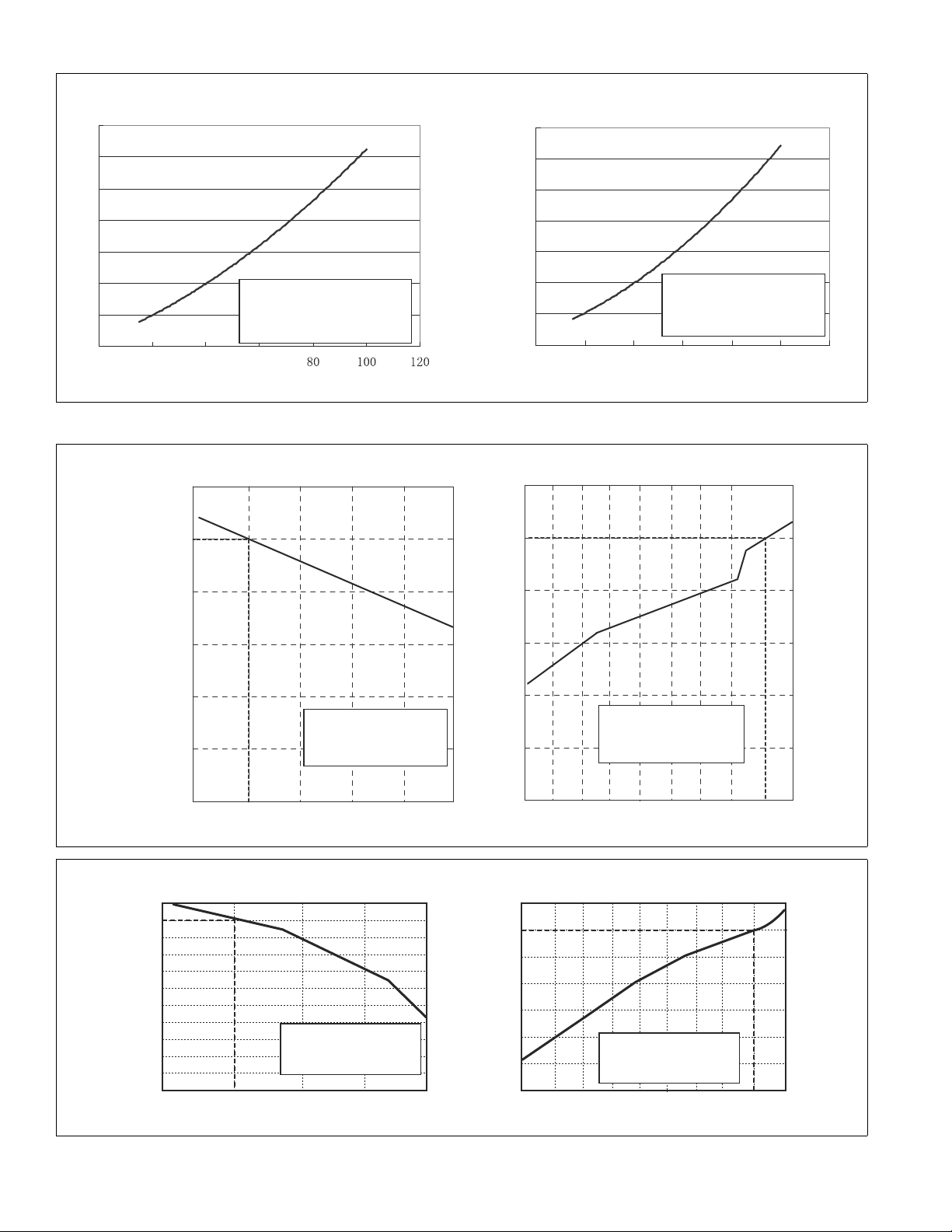

Cooling

Heating

24K

0

2

4

6

8

10

12

14

0204060

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120

Conditio

n

F°6.08 BD:roodnI

WB66.2

°F

Indoor air flow: Super High

Pipe length:24.6ft

Condition

Indoor:DB 68°F

Indoor air flow: Super High

Pipe length:24.6ft

Compressor Frequency(Hz)

Compressor Frequency(Hz)

09K 12K

Heating

Cooling

50

60

70

80

90

100

110

Capacity ratio(%)

Condition

Indoor air flow: Super High

Pipe length:

24.6ft

Outdoor temp. (°F)

0

20

40

60

80

100

120

510152025 3035404550

Capacity ratio(%)

Condition

Indoor air flow: Super High

Pipe length:

24.6ft

Outdoor temp. (°F)

Indoor:DB 68°F

Indoor:DB 80.6°F

WB66.2

°F

90 95 100 105 110 115

18K 24K

<Cooling> <Heating>

95 100 105 110

51015202530354045 50

100

105

95

90

85

80

75

70

65

60

55

50

Outdoor temp. (˚F)

110

100

90

80

70

60

50

40

Outdoor temp. (˚F)

Capacity ratio (%)

Conditions

Indoor:

Indoor air flow : High

Pipe length :

24.6ft

90

Capacity ratio (%)

DB 80.6°F

WB66.2

°F

Condition

Indoor:DB 68°F

Indoor air flow: Super High

Pipe length:24.6ft

PRODUCT CAPACITY VARIATION RATIO

8 Johnson Controls Unitary Products

Page 9

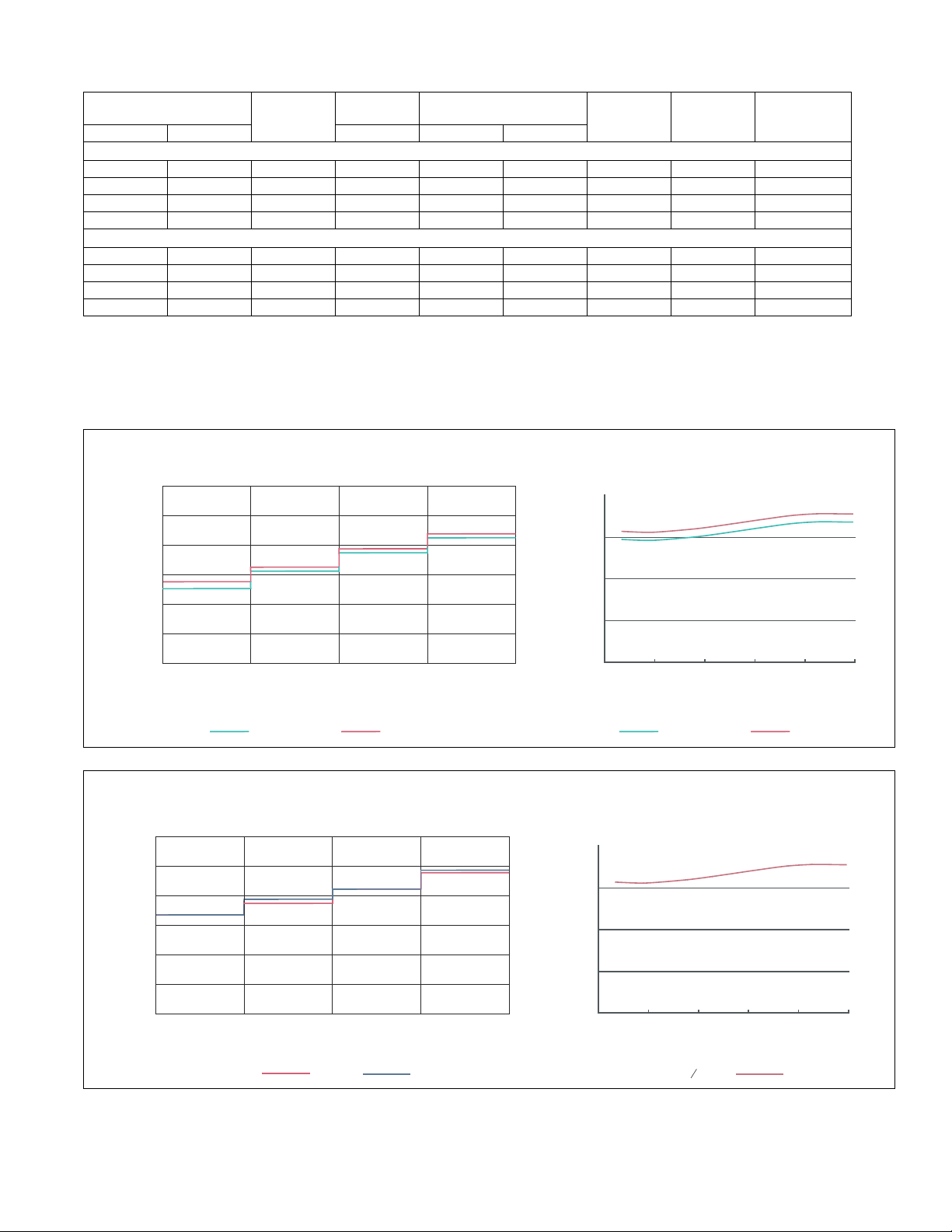

OPERATION DATA

Indoor side noise when blowing

Outdoor side noise

60

60

60 80 100

50

50

40

40

40

30

30

20

20

20

10

0

0

Indoor Fan Motor Rotating Speed

Noice/dB(A)

Noice/dB(A)

low

Middle

High Super High

Compressor frequency/Hz

09K 12K 09K 12K

09K 12K

Indoor side noise when blowing

Outdoor side noise

18K

24K

60

60

60 80 100

50

50

40

40

40

30

30

20

20

20

10

0

0

Indoor Fan Motor Rotating Speed

Noice/dB(A)

low

Middle

High Super High

Compressor frequency/Hz

18 24K

18K 24K

Noice/dB(A)

Temperature Condition (°F)

Indoor Outdoor P (MPa) T1 (°F) T2 (°F)

80/66.9 95/75 09K 0.9 to 1.1 53.6 to 57.2 158 to 104 Super High High 73

80/66.9 95/75 12K 0.9 to 1.1 53.6 to 57.2 158 to 104 Super High High 71

80/66.9 95/75 18K 0.9 to 1.1 53.6 to 57.2 176 to 104 Super High High 75

80/66.9 95/75 24K 0.9 to 1.1 53.6 to 57.2 176 to 104 Super High High 89

70/60 46.9/43 09K 2.5 to 2.7 158 to 95 35.6 to 39.2 Super High High 76

70/60 46.9/43 12K 2.5 to 2.7 158 to 95 35.6 to 39.2 Super High High 76

70/60 46.9/43 18K 2.2 to 2.4 158 to 104 33.8 to 41.0 Super High High 90

70/60 46.9/43 24K 2.2 to 2.4 158 to 104 33.8 to 41.0 Super High High 87

Notes:

Measure surface temperature of heat exchanger pipe around center of heat exchanger path U bent. (Thermistor thermometer).

Connecting piping condition: 24.6 ft.

P: pressure of air pipe connected to the indoor and outdoor units (g as valve side),

T1: Inlet and outlet temperature for evaporator,

T2: Inlet and outlet temperature for condenser.

Model name

Standard

Pressure

Heat Exchanger

Pipe Temperature

COOLING

HEATING

Indoor Fan

Mode

Outdoor Fan

Mode

SOUND DATA

923178-UTG-B-0114

Compressor

Frequency (Hz)

Johnson Controls Unitary Products 9

Page 10

923178-UTG-B-0114

5.0 21.6

3.7

09K 12K

7.221.3

5.5

18K

7.6

27.05.1

24K

A

C

B

B

A

C

G

D

E

F

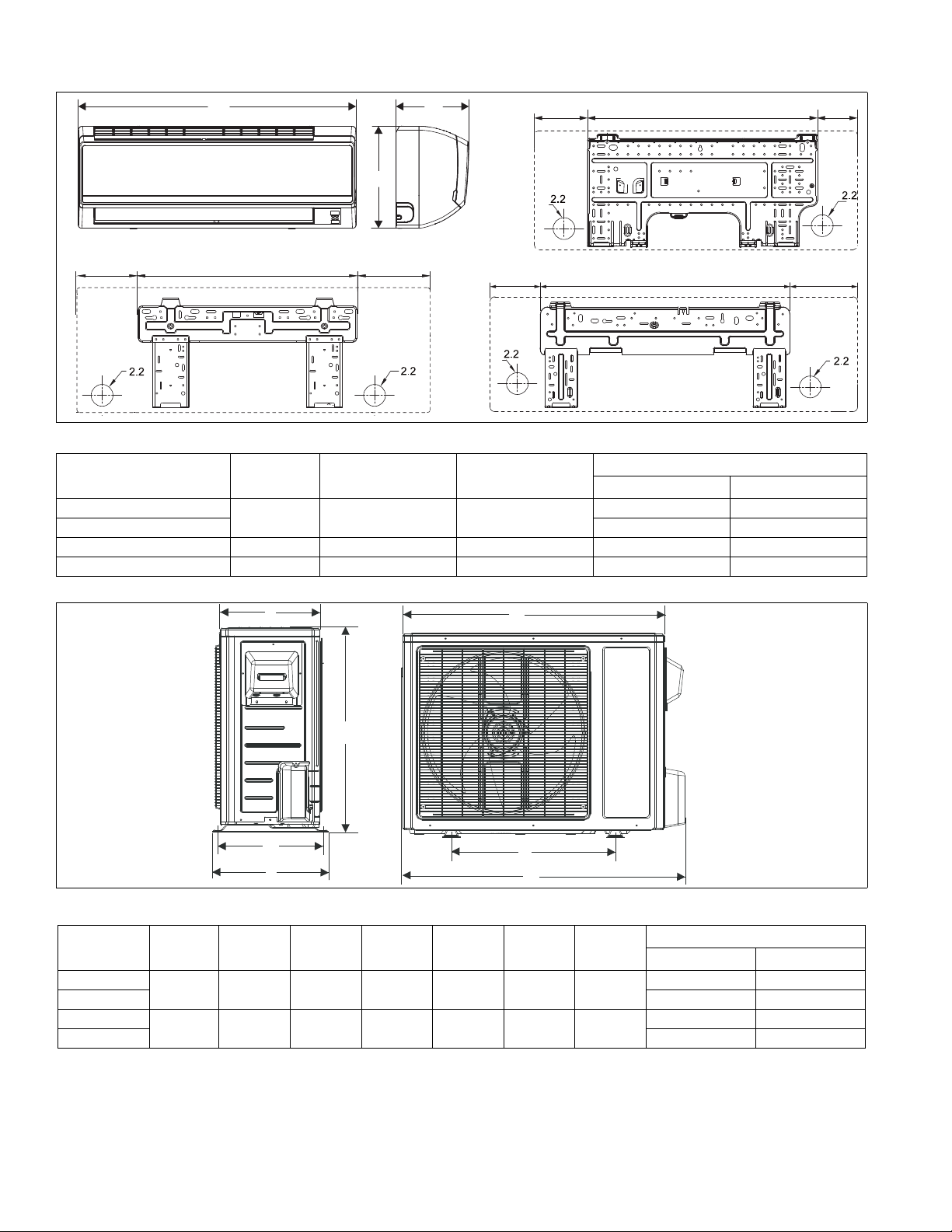

PRODUCT CONSTUCTION VIEW & DIMENSIONS

Indoor Unit Dimensions

Model Size A B C

09K

12K 27 lbs (12 kg) 27 lbs (12 kg)

18K 34.1 (866) 8.5 (216) 12.0 (305) 35 lbs (16 kg) 35 lbs (16 kg)

24K 39.7 (1008) 8.7 (221) 12.4 (315) 44 lbs (20 kg) 44 lbs (20 kg)

30.3 (770) 7.9 (201) 11.1 (282)

Unit Gross Weight

Air Conditioner Heat Pump

25 lbs (11.5 kg) 25 lbs (11.5 kg)

Outdoor Unit Dimensions

Model Size A B C D E F G

09K

12K 77 lbs (35 kg) 77 lbs (35 kg)

18K

24K 123 lbs (56 kg) 126 lbs (57 kg)

28.0 (711 ) 12.5 (318) 21.7 (551) 11.8 (300) 10.8 (274) 25.9 (658) 18.5 (470)

37.9 (963) 15.6 (396 ) 27.6 (701) 14.4 (366) 13.4 (340) 35.0 (889) 22.0 (559)

Unit Gross Weight

Air Conditioner Heat Pump

73 lbs (33 kg) 73 lbs (33 kg)

115 lbs (52 kg) 117 lbs (53 kg)

10 Johnson Controls Unitary Products

Page 11

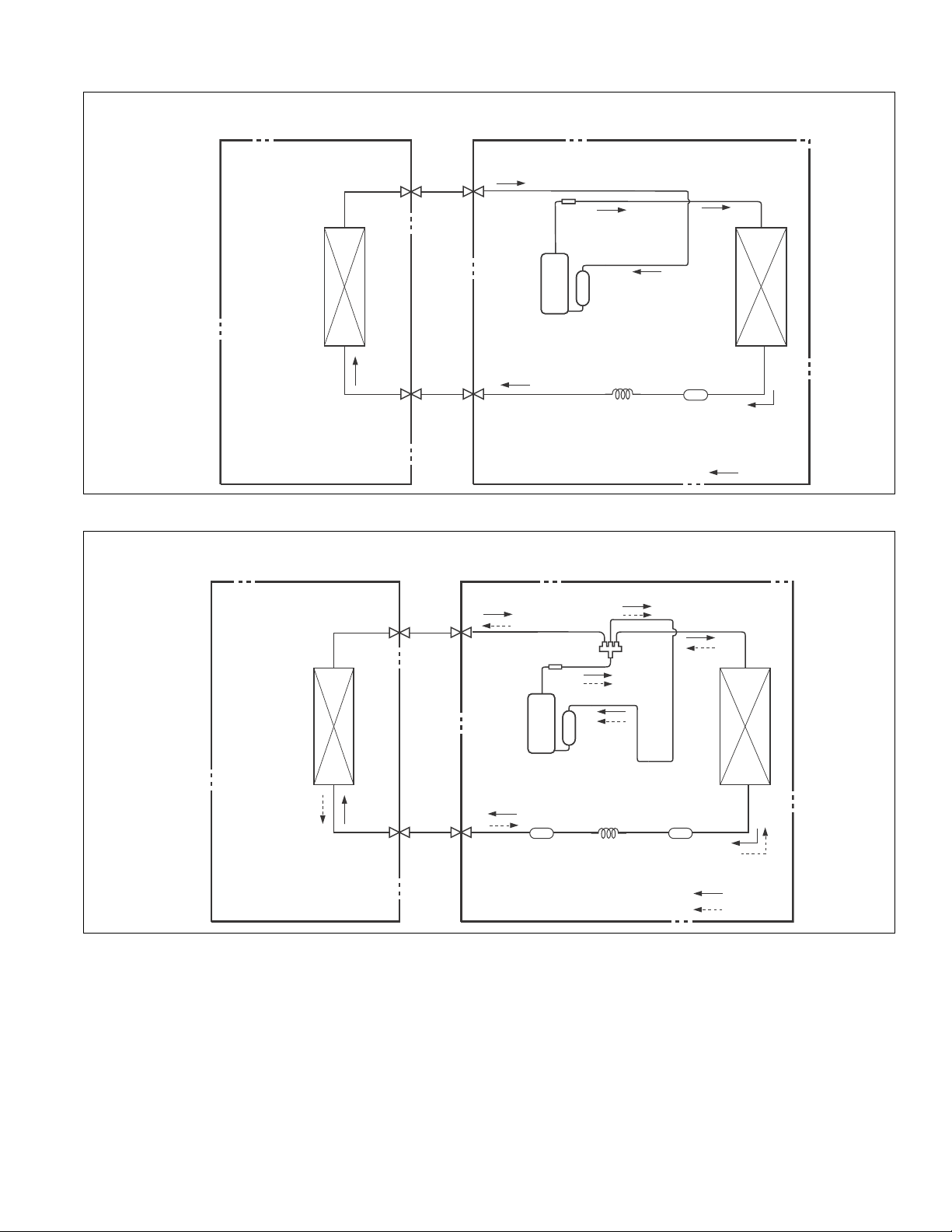

REFRIGERANT SYSTEM DIAGRAM

09K/12K/18K Cooling Only Models

09K/12K/18K Heat Pumps

INDOOR UNIT OUTDOOR UNIT

923178-UTG-B-0114

GAS SIDE

See Page 12 for notes.

3-WAY VALVE

HEAT

EXCHANGE

(EVAPORATOR)

LIQUID SIDE

2-WAY VALVE

Muffler

Discharge

Suction

Accumlator

COMPRESSOR

Capillary Strainer

INDOOR UNIT OUTDOOR UNIT

GAS SIDE

3-WAY VALVE

Muffler

HEAT

EXCHANGE

(CONDENSER)

COOLING

4-Way valve

HEAT

EXCHANGE

(EVAPORATOR)

See Page 12 for notes.

LIQUID SIDE

2-WAY VALVE

Discharge

Suction

Accumlator

COMPRESSOR

HEAT

EXCHANGE

(CONDENSER)

CapillaryStrainer Strainer

COOLING

HEATING

Johnson Controls Unitary Products 11

Page 12

923178-UTG-B-0114

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

Accumlator

Discharge

Suction

Muffler

Strainer

Electron expansion valve

24K Cooling Only Models

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

GAS SIDE

3-WAY VALVE

LIQUID SIDE

2-WAY VALVE

COOLING

HEATING

Accumlator

Discharge

Suction

Muffler

4-Way valve

Electron expansion valve

Strainer Strainer

24K Heat Pumps

See below for notes.

INDOOR UNIT OUTDOOR UNIT

NOTES:

Refrigerant pipe diameter

Liquid: 1/4” (0.24 inch)

Gas: 3/8” (0.37 inch)(09K 12K)

Gas: 1/2” (0.47 inch)(18K 24K)

INDOOR UNIT OUTDOOR UNIT

12 Johnson Controls Unitary Products

Page 13

923178-UTG-B-0114

WIRING DIAGRAM

Electrical Data

Symbol Color Symbol Symbol Color Symbol Symbol Part Name

INDOOR UNIT

BU BlUE BN BROWN PROTECTIVE EARTH

YE YELLOW GN GREEN / /

RD RED BK BLACK / /

YEGNYELLOW GREEN////

OUTDOOR UNIT

Symbol Part Name Symbol Color Symbol Symbol Color Symbol

C1 CBB61 BN BROWN WH WHITE

C2 CBB65 BU BLUE YE YELLOW

SAT OVERLOAD BK BLACK RD RED

COMP COMPRESSOR OG ORANGE YEGN YELLOW GREEN

PROTECTIVE EARTH WH WHITE / /

Electrical Wiring

09K & 12K Outdoor Air Conditioners

Johnson Controls Unitary Products 13

Page 14

923178-UTG-B-0114

09K & 12K Indoor Air Conditioners

18K & 24K Outdoor Air Conditioners

14 Johnson Controls Unitary Products

Page 15

923178-UTG-B-0114

18K & 24K Indoor Air Conditioners

09K & 12K Outdoor Heat Pumps

Johnson Controls Unitary Products 15

Page 16

923178-UTG-B-0114

09K & 12K Indoor Heat Pumps

18K & 24K Outdoor Heat Pumps

16 Johnson Controls Unitary Products

Page 17

18K

24K

Start cooling

Stop cooling

sorserpmoC

Original working state

Run

Stop

Outdoor fan

Indoor fan

T

preset

T

preset

+3.6

T

amb.

Preset fan speed

6 minutes

6 minutes

3 minutes

ºF

923178-UTG-B-0114

18K & 24K Indoor Heat Pumps

DESCRIPTION OF EACH CONTROL

OPERATION

Temperature & Current Parameters

• Indoor preset temperature (T

• Indoor ambient temperature (T

• Evaporator coil temperature (T

• Condenser coil temperature (T

• Defrost compensation temperature (T

• Outdoor ambient temperature (T

• Measured temperature of outdoor condensing coil under

cooling mode and measured temperature of indoor evaporator coil under heating mode (T

• Indoor ambient temperature (T

Basic Functions

Once energized, the compressor should never be restarted

within less than 3 minutes. In a situation where memory function is available when energized for the first time, if the compressor is at stop before de-energized, it will re-start without a

3-minute lag. If it has been in operation before de- energized,

the compressor will start with a 3-minute lag. Once started, the

compressor will not be stopped within 6 minutes regardless of

changes in room temperature.

Cooling Mode

1. Cooling Mode Operation

• When T

amb

T

fan, outdoor fan and the compressor will operate simultaneously. The indoor fan will run at preset speed.

• When T

amb

T

outdoor fan will stop with a time lag of 60 seconds, and the

indoor fan will run at preset speed.

• When T

preset

remain at its previous state.

In cooling mode, the four-way valve will be de-energized and

temperature can be set within a range from 61 to 86°F. If the

compressor stops running, the indoor fan and the swing device

will operate at original state.

Johnson Controls Unitary Products 17

, cooling mode is activated. The indoor

preset

- 3.6,°F the compressor will stop, the

preset

- 3.6°F < T

amb

)

preset

.)

amb

)

evap

outdoor pipe

outdoor amb

tube

indoor amb)

)

compensation

).

. < T

+ 1.8°F, the unit will

preset

)

)

2. Protection – Cooling Mode

• Antifreeze protection - In cooling and dehumidification

mode, antifreeze protection is activated 6 minutes after the

compressor has started if one of followings occur:

T

35.6 °F, the compressor will operate at reduced

evap

frequency.

T

30.2 °F is detected for a duration of 3 minutes,

evap

the compressor will stop and after 60 seconds, the outdoor fan will stop. In cooling mode, the indoor fan and the

swing motor will remain at the original state.

T

42.8 °F and the compressor has remained in

evap.

OFF mode for at least 3 minutes, the compressor will

resume its original operation state.

• Total current up and freq uency down protection if the followings occur:

I

16A, the compressor frequency will start to

total

increase

I

17A, the compressor frequency will not increase

total

18A, the compressor will run at reduced frequency

I

total

20A, the compressor will immediately stop and the

I

total

outdoor fan will stop after 60 seconds

Page 18

923178-UTG-B-0114

Dehumidification Mode

1. Dehumidification Mode Operation

• When T

amb

> T

+ 1.8 °F, cooling and dehumidification

preset

mode will be activated. The compressor and th e outdoor

fan will operate while the indoor fan runs at low speed.

• When T

preset

- 3.6 °F T

amb

T

+ 1.8°F, the compres-

preset

sor remains at its original operation state.

• When T

amb

. < T

- 3.6°F, the compressor will stop, the

preset

outdoor fan will stop after 60 seconds and the indoor fan

will operate at low speed.

2. Protection – Dehumidification Mode

Protection is the same as that under cooling mode section.

Heating Mode

1. Heating Mode Operation

• When T

amb

. T

+ 3.6°F, heating mode is activated.

preset

The four-way valve, the compressor and the outdoor fan

will operate simultaneously. The indoor fan will run at preset speed defined under “cold air prevention”.

• When T

amb

. T

+ 9°F, the compressor will stop, the

preset

outdoor fan will stop after 60 seconds, and the indoor fan

will continue to run at low speed for 60 seconds more.

• When T

preset

+ 3.6°F<T

amb

.<T

+ 9°F, the unit will

preset

maintain its original operating status.

In heating mode, the four-way valve is energized an d temperature can be set within a range of 61 - 86°F. The heating symbol

and preset temperature are displayed on the indoor unit display.

2. Defrost Mode Operation

When the system has been running continuously in heating

mode for more than 45 minutes, or an accumulated heating

time of more than 90 minutes, and one of the following conditions are present, the unit will enter defrost mode after 3 minutes.

•T

outdoor amb.

• 28.4°F≤T

• 23°F≤T

• 14°F≤T

•T

outdoor amb.

outdoor amb.

door amb

outdoor amb.

≥ 41°F, T

outdoor amb.

-5.4°F);

<14°F, T

outdoor pipe

<28.4°F, T

<23°F, T

outdoor pipe-Tcompensation

≤28.4°F;

outdoor pipe

outdoor pipe

≤17.6°F;

- T

compensation

≤ (T

outdoor amb.

≤ (T

out-

5.4°F)

NOTE:

After defrost mode is energized for the first time, T

0°F. After the first time, T

densing coil temperature T

•T

outdoor pipe

•T

outdoor pipe

>35.6°F, T

≤35.6°F, T

compensation

outdoor pipe

compensation

compensation

is determined by the con of the last defrost cycle.

= 0°F;

= 5.4°F

compensation

When in defrost mode the following will occur in the order

described:

a. The indoor fan and compressor stop running

b. The outdoor fan will stop running after 60 seconds.

c. 30seconds later, the four-way valve will close.

d. After 30 seconds, the compressor’s frequency is

increased to defrost frequency.

e. When the compressor has operated in defrost mode for

10 minutes, or T

outdoor pipe

≥ 50°F, the compressor will

adjust to 46Hz.

f. After 30 seconds, the compressor will stop.

g. After another 30 seconds, the four-way valve will open.

h. After 60 seconds, the compressor and the outdoor unit fan

will start running. The indoor fan will run under preset cold

air prevention conditions. H1 will be displayed on the

indoor unit display. Defrost frequency is 70Hz.

3. Protection – Heating Mode

• Cold air prevention (Hot Heat Pump) - In heating mode,

after the compressor is energized the indoor fan is delayed

under these conditions to prevent discharging cold air:

When T

T

tube

indoor amb.

≤104°F, the indoor fan will not run. The indoor fan

<75°F if:

will start running at low speed after 2 minutes.

Within 2 minutes, if T

>104°F, the indoor fan will start

tube

running at low speed.

After 1minute of operation at low speed, the indoor fan

will run at preset speed.

Within 1-minute of low speed operation or 2-minute

non-operation, if T

>108°F, the fan will run at present

tube

speed.

When T

T

tube

indoor amb.

≤108°F, the indoor fan will run at low speed. After

≥75°F if:

one minute of operation, the indoor fan wil l run at preset speed.

Within one-minute of low speed operation, if

T

>104°F, the indoor fan will run at preset speed.

tube

Total current up and frequency down protection occurs:

When I

When I

≤16A, compressor frequency can increase

total

≥17A, compressor frequency is not allowed

total

to increase

When I

≥18A, the compressor runs at reduced fre-

total

quency

When I

≥20A, the compressor stops running and the

total

outdoor fan stops running after 60 seconds.

Fan Mode

In this mode, the indoor fan will run at preset speed. The compressor, the outdoor fan and the four-way valve will not be running.

1. In fan mode, temperature can be set within a range of 61 -

-

86°F.

AUTO Mode

1. AUTO Mode Operation

=

In AUTO mode, the default cooling setpoint temperature T

is 77°F and the default heating setpoint temperature T

68°F. Once activated, the following will occur under these con-

ditions:

• When T

• When 71.6°F< T

fan icon is displayed on the indoor unit display.

• When T

• When T

mode. The preset temperature is 77°F;

• When T

the outdoor fan stops running after 1 minute, and the indoor

fan continues to run at a preset speed.

• When T

tinues to run normally.

• When T

•T

amb.≥Tpreset

door fan stops running after 1 minute, and the indoor fan

continues to run for about 30 seconds before it stops.

≤71.6°F, heating mode is activated.

amb.

<78.8°F, fan mode is activated and the

amb.

≥78.8°F, cooling mode is activated.

amb.

amb.≥Tpreset

amb. ≤Tpreset

preset

amb.≤Tpreset

+1.8°F, the system runs in cooling

-1.8°F, the compressor stops running,

-1.8°F< T

amb.

< T

+1.8°F, the system con-

preset

+3.6°F, heating mode is activated.

+9°F, the compressor stops running, the out-

preset

preset

is

18 Johnson Controls Unitary Products

Page 19

923178-UTG-B-0114

• When T

preset

+3.6°F< T

amb.

< T

+41°F, the system con-

preset

tinues to run normally

• When 71.6°F<T

<78.8°F, the system continues to run

amb.

normally.

2. Protection – Auto Mode

• When the system is running in cooling mode, the protections described in “Protection - Cooling Mode” apply.

• When the system is running in heating mode, the protections described in “Protection – Heating Mode” apply.

• When the ambient temperature changes, operation mode

will switch back and forth. Once the compressor is ene rgized, it will keep running for a minimum of 6 minutes.

COMMON PROTECTION FUNCTIONS AND

FAULT DISPLAY UNDER COOL, HEAT, DRY

AND AUTO MODES

1. Overload Protection

• Cooling Overload

When T

When T

allowed to increase.

When T

quency.

When T

the indoor fan will continue to run at preset speed.

Heating Overload

When T

When T

allowed to increase.

When T

quency.

≤ 126⁰F, the system operates normally.

tube

≥ 131⁰F, compressor frequency is not

tube

≥ 136⁰F, compressor will run at reduced fre-

tube

≥ 144⁰F, compressor is de-energized and

tube

≤ 126⁰F, the system operates normally.

tube

≥ 131⁰F, compressor frequency is not

tube

≥ 136⁰F, compressor will run at reduced fre-

tube

When T

≥ 144⁰F, compressor is de-energized and

tube

the indoor fan will continue to run for about 30 seconds

and stops.

2. High Discharge Temperature Compressor Protection

• When compressor discharge temperature is ≥ 208 ⁰F, compressor frequency is not allowed to increase.

• When compressor discharge temperature is ≥ 217 ⁰F, compressor will run at reduced frequency.

• When compressor discharge temperature is ≥ 230 ⁰F, t he

compressor will stop.

• When compressor discharge temperature is ≤ 194 ⁰F and

the compressor has been idle for at least 3 minutes, it will

resume its operation.

3. Communication Fault

If the system fails to receive communication signals for more

than 3 minutes, its operation will stop.

4. Module Protection

• Under module protection mode, the compressor will stop.

• If the compressor remains idle for at least 3 minutes, it will

resume its operation.

• If module protection occurs six consecutive times, the compressor will not be allowed to start again.

5. Overload Protection

• If the overload temperature is over 239 ⁰F, the compressor

will stop and the outdoor fan will stop after 30 seconds.

• If the overload temperature drops below 203 ⁰F, t h e c om pressor overload protection is reset.

• If voltage on the DC bus is below 150V or over 420V, the

compressor will stop and the outdoor fan will stop after 30

seconds.

• When voltage on the DC bus returns to its normal value

and the compressor has been idle for at least 3 minutes,

the compressor will resume its operation.

6. Temperature Sensors Faults.

Designation of Sensors Faults

Indoor ambient temperature The sensor is detected to be open-circuited or short-circuited for a continuous 30 seconds.

Indoor tube temperature The sensor is detected to be open-circuited or short-circuited for a continuous 30 seconds.

Outdoor ambient temperature The sensor is detected to be open-circuited or short-circuited for a continuous 30 seconds.

Outdoor tube temperature

Exhaust

Overload

The sensor is detected to be open-circuited or short-circuited for a continuous 30 seconds and no detection is

performed within 10 minutes after defrost begins.

After the compressor has operated for 3minutes, the sensor is detected to be open-circuited or short-circuited for a

continuous 30 seconds.

After the compressor has operated for 3minutes, the sensor is detected to be open-circuited or short-circuited for a

continuous 30 seconds.

Johnson Controls Unitary Products 19

Page 20

923178-UTG-B-0114

RESISTANCE TABLES

Resistance Table of Ambient Temperature Sensor for Indoor and Outdoor Units (15K)

Temp. (°F) Resistance (k) Temp. (°F) Resistance (k) Temp. (°F) Resistance (k) Temp. (°F) Resistance (k)

-2.2 138.1 68 18.75 138.2 3.848 208.4 1.071

-0.4 128.6 69.8 17.93 140 3.711 210.2 1.039

1.4 121.6 71.6 17.14 141.8 3.579 212 1.009

3.2 115 73.4 16.3 9 143.6 3.454 213.8 0.98

5 108.7 75.2 15.68 145.4 3.333 215.6 0.952

6.8 102.9 77 15 147.2 3.217 217.4 0.925

8.6 97.4 78.8 14.36 149 3.105 219.2 0.898

10.4 92.22 80.6 13.74 150.8 2.998 221 0.873

12.2 87.35 82.4 13.16 152.6 2.896 222.8 0.848

14 82.75 84.2 12.6 154.4 2.797 224.6 0.825

15.8 78.43 86 12.07 156.2 2.702 226.4 0.802

17.6 74.35 87.8 11.57 158 2.611 228.2 0.779

19.4 70.5 89.6 11.09 159.8 2.523 230 0.758

21.2 66.88 91.4 10.63 161.6 2.439 231.8 0.737

23 63.46 93.2 10.2 163.4 2.358 233.6 0.717

24.8 60.23 95 9.779 165.2 2.28 235.4 0.697

26.6 57.18 96.8 9.382 167 2.206 237.2 0.678

28.4 54.31 98.6 9.003 168.8 2.133 239 0.66

30.2 51.59 100.4 8.642 170.6 2.064 240.8 0.642

32 49.02 102.2 8.297 172.4 1.997 242.6 0.625

33.8 46.6 104 7.967 174.2 1.933 244.4 0.608

35.6 44.31 105.8 7.653 176 1.871 246.2 0.592

37.4 42.14 107.6 7.352 177.8 1.811 248 0.577

39.2 40.09 109.4 7.065 179.6 1.754 249.8 0.561

41 38.15 111.2 6.791 181.4 1.699 251.6 0.547

42.8 36.32 113 6.529 183.2 1.645 253.4 0.532

44.6 34.58 114.8 6.278 185 1.594 255.2 0.519

46.4 32.94 116.6 6.038 186.8 1.544 257 0.505

48.2 31.38 118.4 5.809 188.6 1.497 258.8 0.492

50 29.9 120.2 5.589 190.4 1.451 260.6 0.48

51.8 28.51 122 5.379 192.2 1.408 262.4 0.467

53.6 27.18 123.8 5.197 194 1.363 264.2 0.456

55.4 25.92 125.6 4.986 195.8 1.322 266 0.444

57.2 24.73 127.4 4.802 197.6 1.282 267.8 0.433

59 23.6 129.2 4.625 199.4 1.244 269.6 0.422

60.8 22.53 131 4.456 201.2 1.207 271.4 0.412

62.6 21.51 132.8 4.294 203 1.171 273.2 0.401

64.4 20.54 134.6 4.139 204.8 1.136 275 0.391

66.2 19.63 136.4 3.99 206.6 1.103 276.8 0.382

20 Johnson Controls Unitary Products

Page 21

923178-UTG-B-0114

Resistance Table of Outdoor and Indoor T u be Temperature Sensors (20K)

Temp. (°F) Resistance (k) Temp. (°F) Resistance (k) Temp. (°F) Resistance (k) Temp. (°F) Resistance (k)

-2.2 181.4 68 25.01 138.2 5.13 208.4 1.427

-0.4 171.4 69.8 23.9 140 4.948 210.2 1.386

1.4 162.1 71.6 22.85 141.8 4.773 212 1.346

3.2 153.3 73.4 21.85 143.6 4.605 213.8 1.307

5 145 75.2 20.9 145.4 4.443 215.6 1.269

6.8 137.2 77 20 147.2 4.289 217.4 1.233

8.6 129.9 78.8 19.14 149 4.14 219.2 1.198

10.4 123 80.6 18.13 150.8 3.998 221 1.164

12.2 116.5 82.4 17.55 152.6 3.861 222.8 1.131

14 110.3 84.2 16.8 154.4 3.729 224.6 1.099

15.8 104.6 86 16.1 156.2 3.603 226.4 1.069

17.6 99.13 87.8 15.43 158 3.481 228.2 1.039

19.4 94 89.6 14.79 159.8 3.364 230 1.01

21.2 89.17 91.4 14.18 161.6 3.252 231.8 0.983

23 84.61 93.2 13.59 163.4 3.144 233.6 0.956

24.8 80.31 95 13.04 165.2 3.04 235.4 0.93

26.6 76.24 96.8 12.51 167 2.94 237.2 0.904

28.4 72.41 98.6 12 168.8 2.844 239 0.88

30.2 68.79 100.4 11.52 170.6 2.752 240.8 0.856

32 65.37 102.2 11.06 172.4 2.663 242.6 0.833

33.8 62.13 104 10.62 174.2 2.577 244.4 0.811

35.6 59.08 105.8 10.2 176 2.495 246.2 0.77

37.4 56.19 107.6 9.803 177.8 2.415 248 0.769

39.2 53.46 109.4 9.42 179.6 2.339 249.8 0.746

41 50.87 111.2 9.054 181.4 2.265 251.6 0.729

42.8 48.42 113 8.705 183.2 2.194 253.4 0.71

44.6 46.11 114.8 8.37 185 2.125 255.2 0.692

46.4 43.92 116.6 8.051 186.8 2.059 257 0.674

48.2 41.84 118.4 7.745 188.6 1.996 258.8 0.658

50 39.87 120.2 7.453 190.4 1.934 260.6 0.64

51.8 38.01 122 7.173 192.2 1.875 262.4 0.623

53.6 36.24 123.8 6.905 194 1.818 264.2 0.607

55.4 34.57 125.6 6.648 195.8 1.736 266 0.592

57.2 32.98 127.4 6.403 197.6 1.71 267.8 0.577

59 31.47 129.2 6.167 199.4 1.658 269.6 0.563

60.8 30.04 131 5.942 201.2 1.609 271.4 0.549

62.6 28.68 132.8 5.726 203 1.561 273.2 0.535

64.4 27.39 134.6 5.519 204.8 1.515 275 0.521

66.2 26.17 136.4 5.32 206.6 1.47 276.8 0.509

Johnson Controls Unitary Products 21

Page 22

923178-UTG-B-0114

Resistance Table of Outdoor Discharge Temperature Sensor (50K)

Temp. (°F) Resistance (k) Temp. (°F) Resistance (k) Temp. (°F) Resistance (k) Temp. (°F) Resistance (k)

-20.2 853.5 50 98 120.2 18.34 190.4 4.754

-18.4 799.8 51.8 93.42 122 17.65 192.2 4.609

-16.6 750 53.6 89.07 123.8 16.99 194 4.469

-14.8 703.8 55.4 84.95 125.6 16.36 195.8 4.334

-13 660.8 57.2 81.05 127.4 15.75 197.6 4.204

-11.2 620.8 59 77.35 129.2 15.17 199.4 4.079

-9.4 580.6 60.8 73.83 131 14.62 201.2 3.958

-7.6 548.9 62.6 70.5 132.8 14.09 203 3.841

-5.8 516.6 64.4 67.34 134.6 13.58 204.8 3.728

-4 486.5 66.2 64.33 136.4 13.09 206.6 3.619

-2.2 458.3 68 61.48 138.2 12.62 208.4 3.514

-0.4 432 69.8 58.77 140 12.17 210.2 3.413

1.4 407.4 71.6 56.19 141.8 11.74 212 3.315

3.2 384.5 73.4 53.74 143.6 11.32 213.8 3.22

5 362.9 75.2 51.41 145.4 10.93 215.6 3.129

6.8 342.8 77 49.19 147.2 10.54 217.4 3.04

8.6 323.9 78.8 47.08 149 10.18 219.2 2.955

10.4 306.2 80.6 45.07 150.8 9.827 221 2.872

12.2 289.6 82.4 43.16 152.6 9.489 222.8 2.792

14 274 84.2 41.34 154.4 9.165 224.6 2.715

15.8 259.3 86 39.61 156.2 8.854 226.4 2.64

17.6 245.6 87.8 37.96 158 8.555 228.2 2.568

19.4 232.6 89.6 36.38 159.8 8.268 230 2.498

21.2 220.5 91.4 34.88 161.6 7.991 231.8 2.431

23 209 93.2 33.45 163.4 7.726 233.6 2.365

24.8 198.3 95 32.09 165.2 7.47 235.4 2.302

26.6 199.1 96.8 30.79 167 7.224 237.2 2.241

28.4 178.5 98.6 29.54 168.8 6.998 239 2.182

30.2 169.5 100.4 28.36 170.6 6.761 240.8 2.124

32 161 102.2 27.23 172.4 6.542 242.6 2.069

33.8 153 104 26.15 174.2 6.331 244.4 2.015

35.6 145.4 105.8 25.11 176 6.129 246.2 1.963

37.4 138.3 107.6 24.13 177.8 5.933 248 1.912

39.2 131.5 109.4 23.19 179.6 5.746 249.8 1.863

41 125.1 111.2 22.29 181.4 5.565 251.6 1.816

42.8 119.1 113 21.43 183.2 5.39 253.4 1.77

44.6 113.4 114.8 20.6 185 5.222 255.2 1.725

46.4 108 116.6 19.81 186.8 5.06 257 1.682

48.2 102.8 118.4 19.06 188.6 4.904 258.8 1.64

22 Johnson Controls Unitary Products

Page 23

REMOVAL PROCEDURE

Axonometric drawing for the

complete unit.

panel

clasps

filter

a. Open the panel.

b. Loosen the clasps

on the filter.

c. Draw out two

pieces of filter.

Display

Remove 2 screws fixing display,

and then remove the filter.

Removal Procedure of Indoor Unit

Be sure to wait for a minimum of 10 minutes after turning off all power supplies before disassembly.

STEPS PROCEDURES

1. Before disassembly of the unit

923178-UTG-B-0114

2. Remove filter

3. Remove display

Johnson Controls Unitary Products 23

Page 24

923178-UTG-B-0114

horizontal louver

Remove the axial bush on the

horizontal louver, and then

remove the horizontal louver.

Screw

Top cover of electric box

a. Remove screws fixing the

top cover of electric box.

b. Remove the top cover of

electric box.

STEPS PROCEDURES

Pull the clasps at both sides slightly,

4. Remove panel

5. Remove horizontal louver

and then remove the panel.

Panel

Clasp

6. Remove top cover of electric box

24 Johnson Controls Unitary Products

Page 25

STEPS PROCEDURES

Screw Cap

Screw

Front Case

a. Remove the screw caps on front case.

b. Remove screws connecting

the front case.

c. Remove the front case.

screw

Remove earthing screws, and

then remove the earthing wire.

Clasp

Clasp

electric box cover

a. Loosen clasps at the left side of

electric box.

b. Loosen clasps on the right side of

electric box.

c. Remove electric box cover.

7. Remove front case

923178-UTG-B-0114

8. Remove earthing wire

9. Remove electric box cover

Johnson Controls Unitary Products 25

Page 26

923178-UTG-B-0114

STEPS PROCEDURES

10. Remove temperature sensor

11. Remove electric box

Pull out the indoor temperature sensor.

a. Pull out 6 sockets on PCB board.

b. Pull out two screws on electric box.

temperature sensor

Screw

Electric

Box

c. Remove the electric box.

Water Tray

12. Remove water tray

13. Remove connection pipe between

indoor and outdoor units

Pull the water tray upwards,

and then remove the water tray.

Separate the connection pipe

between indoor and outdoor units.

Connection position for indoor and

outdoor units' connection pipe

26 Johnson Controls Unitary Products

Page 27

STEPS PROCEDURES

Pipe-Stopping Plate

Screw

Remove two screws on pipe-stopping

plate for indoor unit, and then remove

the pipe-stopping

Screw

Damping

Board

Remove 2 screws on

damping board, and then

remove the damping board.

Screw

Evaporator

a. Remove screws between

evaporator and bottom case.

b. Turn over the indoor unit

and adjust the pipe line to

the position as shown by

the broken line.

c. Lift up the evaporator, and

then remove the evaporator.

Screw

Remove 2 screws on fixing

plate of motor, and then

remove the fixing pate of

motor.

14. Remove pipe-stopping plate

15. Remove damping board

923178-UTG-B-0114

16. Remove evaporator

17. Remove the fixing plate of motor

Johnson Controls Unitary Products 27

Page 28

923178-UTG-B-0114

STEPS PROCEDURES

a. Remove screws fixing cross

flow blade and motor.

18. Remove cross flow blade and motor

Blade

Motor

19. Remove cushion rubber

b. Remove the motor sub-assy.

c. Separate two cross flow blade.

a. Remove the cushion rubber

on cross flow blade.

Cushion Rubber

b. Remove the cushion rubber

from the base.

28 Johnson Controls Unitary Products

Page 29

Removal Procedure of Outdoor Unit

a. Use the screwdriver to remove

the screws connecting the top

panel and panel and side panels.

Remove the top panel. Loosen the

screws fixing the valve cover and

then remove the valve cover.

Top Panel

Valve Cover

b. Loosen the screws connecting the front

side panel and mask and chassis.

Remove the front side panel.

Front Side Plate

Twist off the screws connecting the grille

and panel, and then remove the grille.

Grille

Twist off the screws connecting the panel,

chassis and motor support with screwd-river,

and then remove the panel.

Panel

Be sure to wait for a minimum of 10 minutes after turning off all power supplies before disassembly.

STEPS PROCEDURES

1. Remove top cover and front side plate

923178-UTG-B-0114

2. Remove grille

3. Remove panel

Johnson Controls Unitary Products 29

Page 30

923178-UTG-B-0114

STEPS PROCEDURES

Twist off the screws fixing the guard grille

4. Remove guard grille

and then remove the guard grille.

Twist off the screws fixing the handle

5. Remove handle

and then remove the handle.

Guard Grille

Handle

6. Remove right side plate

7. Remove electric box

Right

Side Plate

Twist off the screws connecting the right

side plate and chassis, valve support and

condenser, and then remove the right

side plate.

Electric Box

Cover

a. Twist off the screws on electric box

cover with screwdriver, and then

remove the electric box cover.

30 Johnson Controls Unitary Products

Page 31

STEPS PROCEDURES

b. Twist off the screws on electric box,

cut off the tieline with scissors or pliers,

pull out the wiring terminal, pull it upwards

to remove the electric box.

Electric Box

Electric Box 1

c. Twist off the screws between electric box 1

and left side plate with screwdriver,

pull it upwards to remove the electric box 1.

Left Side Plate

Twist off the screws connecting the

left side plate and chassis with

screwdriver, and then remove the

left side plate.

Axial Flow Blade

Twist off the nuts on blade

with wrench and then remove

the axial flow blade.

7. Remove electric box (Continued)

923178-UTG-B-0114

8. Remove left side plate

9. Remove axial flow blade

Johnson Controls Unitary Products 31

Page 32

923178-UTG-B-0114

STEPS PROCEDURES

a. Twist off the tapping screws fixing the

motor, pull out the pin of leading wire

for motor and then remove the motor.

Motor

10. Remove motor and motor support

11. Remove 4-way valve

Motor

Support

b. Twist off the tapping screws fixing the

motor support, pull it upwards and

then remove the motor support.

4-Way Valve

Unsolder the pipeline between

compressor, condenser, gas and

liquid valve, and then remove the

4-way valve. (note: release all

refrigerant before unsoldering).

Twist off the 2 bolts fixing the

valve sub-assy. Unsolder the

soldering joint between gas valve

and air-return pipe and then

remove the gas valve.

(note: when unsoldering

12. Remove gas valve and liquid valve

the soldering joint, wrap the

gas valve with wet cloth

completely to avoid the damage

to valve, and release all

Gas

Valve

refrigerant completely at first).

Unsolder the soldering joint

between liquid valve and connection

pipe of liquid valve, and then remove the liquid valve.

Liquid Valve

32 Johnson Controls Unitary Products

Page 33

STEPS PROCEDURES

Compressor

Twist off the 3 foot nuts on

compressor and then remove

the compressor.

Isolation

Sheet

Twist off the screws connecting

isolation sheet and end plate of

condenser and chassis, and then

remove the isolation sheet.

Support Plate

of Condenser

Twist off the screws connecting

the support plate of condenser

and condenser with screwdriver,

and then remove the support

plate of condenser.

Condenser

Chassis

Pull it upwards to separate

the chassis and condenser.

13. Remove compressor

14. Remove isolation sheet

923178-UTG-B-0114

15. Remove support plate of condenser

16. Remove chassis and condenser

Johnson Controls Unitary Products 33

Page 34

ACCESSORIES

PART NUMBER DESCRIPTION

OTHER ACCESSORIES

S1-DL30510050 Remote Control

S1-DL26150003 Remote Control Holder

S1-DL112005 11 Catechin Filter

S1-230-DL16 5/8" Drain Line

MOUNTING ACCESSORIES

S1-1836-2 PAD,UNIT,ECOPAD,18X36X2 (M50)

S1-ACP1836-2 PAD,UNIT,DURAGRID,18X36X2 (M50)

S1-EL1838-3 PAD,UNIT,ELITE PLASTIC,18X38X3 (M16)

S1-UC1636-2 PAD,UNIT,ULTRALITE,16X36X2 (M20)

S1-UC1636-3 PAD,UNIT,ULTRALITE,16X36X3 (M15)

S1-230-MB14W BLOCK,MOUNTING,MINISPLIT,14",PK OF 2(M6)

S1-230-MB17W BLOCK,MOUNTING,MINISPLIT,17",PK OF 2(M6)

S1-230-MB36W BLOCK,MOUNTING,MINISPLIT,36",PK OF 2(M6)

S1-230-MBCW CAP,END,MTG BLOCK,MINISPLIT,4/PACK (M25)

S1-WBB300 BRACKET,WALL,MINISPLIT,300-LB

S1-CNG STAND,CONDENSER

S1-PR-351N-M RISER,CONDENSER,4"H X 18"L (M20)

S1-NP-R410 10PK CAP,REFRIG,LOCKING,NOVENT,PINK,R-410

S1-NP-R410 2PK CAP,REFRIG,LOCKING,NOVENT,PINK,R-410

S1-NP-R410 SDT SCREWDRIVER/KEY,CAP,REFRIG,LOCKING,R-410

CONDENSATE HANDLING

S1-ASP-MA-UNI KIT,PUMP,CONDS,MINISPLIT,100-250V,AQUA

S1-ASP-MAXO-230 KIT,PUMP,CONDS,MINISPLIT,230V,ORANGE

S1-ASP-MLF-UNI KIT,PUMP,CONDS,MINISPLIT,100-250V,LIME

S1-ASP-MW-UNI KIT,PUMP,CONDS,MINISPLIT,100-250V,WHITE

S1-CVMINI PUMP, CONDS,MINISPLIT,120/230V (M6)

S1-IQP-KUBE PUMP,CONDS,0-15 FT,115V,MINISPLIT (M6)

S1-IQP-KUBE-SHROUD PUMP,CONDS,0-15 FT,1 15V,MINI,W/SHRD (M6)

S1-553676 PUMP,CONDS,46',230V,MINISPLIT,TPR (M4)

S1-553712 PUMP,CONDS,29',230V,MSPLIT,EC-OP-K (M4)

S1-EZT-180 TRAP,CONDENSATE,WATERLESS,5/8" (M10)

S1-SS610E SWITCH,CONDS,MINISPLIT,W/DIAG DISP (M12)

S1-230-DPML PAN,CONDS,OUTDOOR,MINISPLIT,LARGE

S1-230-DPMM PAN,CONDS,OUTDOOR,MINISPLIT,MEDIUM

S1-230-DPPL PAN,CONDS,OUTDOOR,MINISPLIT,LARGE

S1-230-DPPM PAN,CONDS,OUTDOOR,MINISPLIT,MEDIUM

S1-DH-16S HOSE,DRAIN,16MM (5/8") X 20' (M5)

S1-230-DL16 LINE,DRAIN,MINISPLIT,5/8" ID X 160'

S1-230-DL20 LINE,DRAIN,MINISPLIT,3/4" ID X 160'

S1-230-DLF16 ADAPTER,DRAIN,MINISPLIT,16MM (M10)

S1-230-DLF18 ADAPTER,DRAIN,MINISPLIT,18MM (M10)

S1-230-DLF20 ADAPTER,DRAIN,MINISPLIT,20MM (M10)

S1-230-DLF25 ADAPTER,DRAIN,MINISPLIT,25MM (M10)

S1-230-DLF32 ADAPTER,DRAIN,MINISPLIT,32MM (M10)

S1-230-DLFY Y,DRAIN,MINISPLIT (M10)

LINESET COVERS AND FITTINGS

S1-LDK-122-W KIT,LINESET COVER,4.5" X 12',WHITE

S1-LDK-92-W KIT,LINESET COVER,3.5" X 12',WHITE

S1-NFP-75 SLEEVE,WALL,ADJUSTABLE,3"DIA (M10)

S1-230-CP3 CPLG, UNION,SPEEDICHANNEL,3" (M10)

S1-230-CP4 CPLG, UNION,SPEEDICHANNEL,4" (M10)

S1-230-CP6 CPLG, UNION,SPEEDICHANNEL,6" (M10)

S1-230-D3 COVER,LINESET,SPEEDICHANNEL,3" (M6)

S1-230-D4 COVER,LINESET,SPEEDICHANNEL,4" (M6)

S1-230-D6 COVER,LINESET,SPEEDICHANNEL,6" (M5)

S1-230-DC3 CAP,END,SPEEDICHANNEL,3" (M10)

S1-230-DC4 CAP,END,SPEEDICHANNEL,4" (M10)

S1-230-DC6 CAP,END,SPEEDICHANNEL,6" (M10)

S1-230-DCLIP CLIP,SPEEDICHANNEL,PK OF 50

S1-230-DE3 END,DUCT,SPEEDICHANNEL,3" (M10)

S1-230-DE4 END,DUCT,SPEEDICHANNEL,4" (M10)

S1-230-DE6 END,DUCT,SPEEDICHANNEL,6" (M10)

S1-230-DSCREW SCREW,SPEEDICHANNEL,PK OF 100

S1-230-EB3 ELBOW,INSIDE,90DEG,SPEEDICHANNEL,3"(M10)

S1-230-EB4 ELBOW,INSIDE,90DEG,SPEEDICHANNEL,4"(M10)

S1-230-EB6 ELBOW,INSIDE,90DEG,SPEEDICHANNEL,6"(M10)

PART NUMBER DESCRIPTION

S1-230-EIN3 ELBOW,OUTSD,90DEG,SPEEDICHANNEL,3"(M10)

S1-230-EIN4 ELBOW,OUTSD,90DEG,SPEEDICHANNEL,4"(M10)

S1-230-EIN6 ELBOW,OUTSD,90DEG,SPEEDICHANNEL,6"(M10)

S1-230-FB3 BEND,FLAT,90 DEG,SPEEDICHANNEL,3" (M10)

S1-230-FB4 BEND,FLAT,90 DEG,SPEEDICHANNEL,4" (M10)

S1-230-FB453 BEND,FLAT,45 DEG,SPEEDICHANNEL,3" (M10)

S1-230-FB454 BEND,FLAT,45 DEG,SPEEDICHANNEL,4" (M10)

S1-230-FB456 BEND,FLAT,45 DEG,SPEEDICHANNEL,6" (M10)

S1-230-FB6 BEND,FLAT,90 DEG,SPEEDICHANNEL,6" (M10)

S1-230-FJ3 JOINT,FLEX.SPEEDICHANNEL,3" (M10)

S1-230-FJ4 JOINT,FLEX.SPEEDICHANNEL,4" (M10)

S1-230-FR3 ESCUTCH,FLAT,WALL,SPEEDICHANNEL,3" (M10)

S1-230-FR4 ESCUTCH,FLAT,WALL,SPEEDICHANNEL,4" (M10)

S1-230-FR6 ESCUTCH,FLAT,WALL,SPEEDICHANNEL,6" (M10)

S1-230-LFB3 BEND,FLAT,LGRAD,90DEG,SPEEDICHNL,3"(M10)

S1-230-LFB4 BEND,FLAT,LGRAD,90DEG,SPEEDICHNL,4"(M10)

S1-230-LFB6 BEND,FLAT,LGRAD,90DEG,SPEEDICHNL,6"(M10)

S1-230-TC34 CPLG,REDUCER,SPEEDICHANNEL,3"X4" (M10)

S1-230-TC46 CPLG,REDUCER,SPEEDICHANNEL,4"X6" (M10)

S1-230-TJ4 TEE,SPEEDICHANNEL,4" (M10)

S1-230-TJ6 TEE,SPEEDICHANNEL,6" (M10)

S1-230-WC3 CVR,WALL PEN,SPEEDICHANNEL,3" (M10)

S1-230-WC4 CVR,WALL PEN,SPEEDICHANNEL,4" (M10)

S1-230-WC6 CVR,WALL PEN,SPEEDICHANNEL,6" (M10)

S1-230-WR3 ESCUTCHEON,WALL,SPEEDICHANNEL,3" (M10)

S1-230-WR4 ESCUTCHEON,WALL,SPEEDICHANNEL,4" (M10)

S1-230-WR6 ESCUTCHEON,WALL,SPEEDICHANNEL,6" (M10)

S1-230-WS2 SLV,WALL PEN,SPEEDICHANNEL,2-1/2" (M10)

MINISPLIT LINESETS (BOTH LINES INSULATED WITH FLARE NUTS)

S1-52642437015 LINEST,MINISPLIT,1/4LX3/8SX15',3/8(M8)

S1-52642437020 LINEST,MINISPLIT,1/4LX3/8SX20',3/8(M8)

S1-52642437025 LINEST,MINISPLIT,1/4LX3/8SX25',3/8(M8)

S1-52642437030 LINEST,MINISPLIT,1/4LX3/8SX30',3/8(M8)

S1-52642437035 LINEST,MINISPLIT,1/4LX3/8SX35',3/8(M8)

S1-52642437050 LINEST,MINISPLIT,1/4LX3/8SX50',3/8(M8)

S1-52642438015 LINEST,MINISPLIT,1/4LX1/2SX15',3/8(M8)

S1-52642438020 LINEST,MINISPLIT,1/4LX1/2SX20',3/8(M8)

S1-52642438025 LINEST,MINISPLIT,1/4LX1/2SX25',3/8(M8)

S1-52642438030 LINEST,MINISPLIT,1/4LX1/2SX30',3/8(M8)

S1-52642438035 LINEST,MINISPLIT,1/4LX1/2SX35',3/8(M8)

S1-52642438050 LINESET,MINISPLIT,1/4LX1/2SX50',3/8(M8)

S1-52642439015 LINESET,MINISPLIT,1/4LX5/8SX15',3/8(M8)

S1-52642439020 LINESET,MINISPLIT,1/4LX5/8SX20',3/8(M8)

S1-52642439025 LINESET,MINISPLIT,1/4LX5/8SX25',3/8(M8)

S1-52642439030 LINESET,MINISPLIT,1/4LX5/8SX30',3/8(M8)

S1-52642439035 LINESET,MINISPLIT,1/4LX5/8SX35',3/8(M8)

S1-52642439050 LINESET,MINISPLIT,1/4LX5/8SX50',3/8(M6)

S1-52642440015 LINESET,MINISPLIT,1/4LX3/4SX15',3/8(M8)

S1-52642440020 LINESET,MINISPLIT,1/4LX3/4SX20',3/8(M8)

S1-52642440025 LINESET,MINISPLIT,1/4LX3/4SX25',3/8(M8)

S1-52642440030 LINESET,MINISPLIT,1/4LX3/4SX30',3/8(M8)

S1-52642440035 LINESET,MINISPLIT,1/4LX3/4SX35',3/8(M8)

S1-52642440050 LINESET,MINISPLIT,1/4LX3/4SX50',3/8(M6)

S1-52642441015 LINESET,MINISPLIT,3/8LX5/8SX15',3/8(M8)

S1-52642441020 LINESET,MINISPLIT,3/8LX5/8SX20',3/8(M8)

S1-52642441025 LINESET,MINISPLIT,3/8LX5/8SX25',3/8(M8)

S1-52642441030 LINESET,MINISPLIT,3/8LX5/8SX30',3/8(M8)

S1-52642441035 LINESET,MINISPLIT,3/8LX5/8SX35',3/8(M8)

S1-52642441050 LINESET,MINISPLIT,3/8LX5/8SX50',3/8(M6)

S1-52642442015 LINESET,MINISPLIT,3/8LX3/4SX15',3/8(M8)

S1-52642442020 LINESET,MINISPLIT,3/8LX3/4SX20',3/8(M8)

S1-52642442025 LINESET,MINISPLIT,3/8LX3/4SX25',3/8(M8)

S1-52642442030 LINESET,MINISPLIT,3/8LX3/4SX30',3/8(M8)

S1-52642442035 LINESET,MINISPLIT,3/8LX3/4SX35',3/8(M8)

S1-52642442050 LINESET,MINISPLIT,3/8LX3/4SX50',3/8(M6)

S1-52642443015 LINESET,MINISPLIT,3/8LX7/8SX15',3/8(M8)

S1-52642443025 LINESET,MINISPLIT,3/8LX7/8SX25',3/8INS

Subject to change without notice. Published in U.S.A. 923178-UTG-B-0114

Copyright © 2014 by Johnson Controls, Inc. All rights reserved. Supersedes: 923178-UTG-A-1112

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...