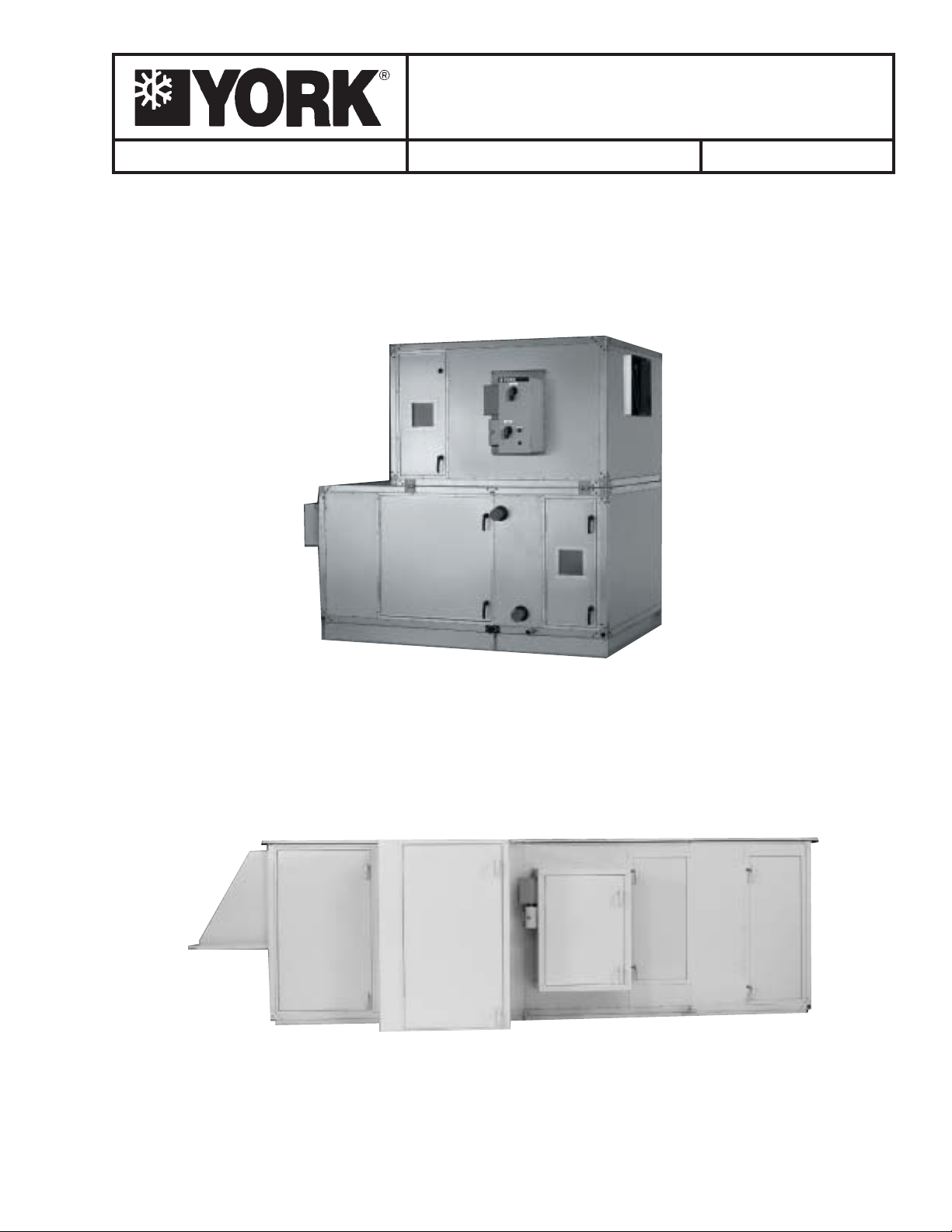

SOLUTION

AIR HANDLING UNITS

RENEWAL PARTS

Supersedes: 102.20-RP1 (504)

Form 102.20-RP1 (1104)

LDO9624

LDO9688

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

FORM 102.20-RP1(1104)

This equipment is a relatively complicated ap pa ra tus.

Dur ing installation, operation, maintenance or service,

in di vid u als may be exposed to certain com po nents or

conditions in clud ing, but not limited to: re frig er ants,

oils, materials un der pressure, rotating com po nents, and

both high and low voltage. Each of these items has the

po ten tial, if misused or handled im prop er ly, to cause

bodi ly injury or death. It is the obligation and re spon si bil i ty of operating/service per son nel to iden ti fy and

rec og nize these inherent hazards, protect them selves,

and pro ceed safely in completing their tasks. Failure

to com ply with any of these requirements could re sult

in se ri ous dam age to the equipment and the prop er ty in

which it is sit u at ed, as well as severe personal injury or

death to them selves and people at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that this in di vid u al possesses independent training that will en able

them to perform their assigned tasks properly and safe ly.

It is essential that, prior to performing any task on this

equipment, this individual shall have read and un der stood this document and any referenced materials. This

in di vid u al shall also be familiar with and comply with

all ap pli ca ble governmental standards and regulations

per tain ing to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard:

DANGER indicates an im mi nent ly

hazardous situation which, if not

avoid ed, will re sult in death or se ri ous

injury.

CAUTION identifi es a hazard which

could lead to damage to the ma chine,

damage to other equip ment and/or

en vi ron men tal pollution. Usually an

in struc tion will be given, together with

a brief ex pla na tion.

WARNING indicates a potentially

haz ard ous sit u a tion which, if not

avoid ed, could result in death or se-

NOTE is used to highlight ad di tion al

information which may be helpful to

you.

ri ous in ju ry.

External wiring, unless specifi ed as an optional connection in the man u fac tur er’s prod uct

line, is NOT to be connected inside the micro pan el cab i net. De vic es such as re lays, switch es,

transducers and controls may NOT be installed inside the mi cro pan el. NO external wiring

is al lowed to be run through the micro panel. All wir ing must be in ac cor dance with YORK’ s

pub lished spec i fi ca tions and must be per formed ONLY by qual i fi ed YORK personnel. YORK

will not be re spon si ble for dam ag es/problems re sult ing from im prop er con nec tions to the

con trols or ap pli ca tion of im prop er con trol sig nals. Failure to fol low this will void the

man u fac tur er’s warranty and cause serious dam age to property or injury to per sons.

2

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

TABLE OF CONTENTS

FASTENERS FOR SOLUTION UNITS.........................................................................................................9 - 10

GASKET/CAULK/ADHESIVE FOR SOLUTION UNITS.............................................................................11 - 12

DOOR LATCHING PARTS .........................................................................................................................13 - 14

DOOR GASKETS ..............................................................................................................................................14

THRUST RESTRAINT KIT SELECTION...........................................................................................................16

THRUST RESTRAINT KITS.......................................................................................................................17 - 18

FAN MOTORS.............................................................................................................................................22 - 26

MOTOR WIRING PARTS...................................................................................................................................27

ADJUSTABLE MOTOR BASES.................................................................................................................28 - 30

FANS AND MOTORS, SECURING....................................................................................................................32

ISOLATORS................................................................................................................................................33 - 34

SHELL COMPONENTS.....................................................................................................................................35

SPLICE & SPLIT BASERAIL KITS............................................................................................................36 - 37

WIREWAY ACCESS PLA TES.......................................................................................................... ..................41

FILTERS......................................................................................................................................................42 - 46

OA HOOD MOISTURE ELIMINATOR FILTERS (BY DAMPER SIZE).......................................................47 - 55

VISUAL CONTROL FILTER CLAMPS FOR HEPA FILTERS...........................................................................58

LIGHTING PARTS .............................................................................................................................................59

ELECTRICAL REPLACEMENT PARTS ...........................................................................................................60

WIRING-HARNESSES LIGHT ASSEMBLY - PANEL TO WIRE TRACK.........................................................61

WIRING-HARNESSES LIGHT ASSEMBLY - WIRE TRACK............................................................................62

WIRING-HARNESSES LIGHT ASSEMBLY - TIER TO TIER............................................................................63

SWITCH/RECEPTACLE ....................................................................................................................................63

TRANSFORMER PANEL...................................................................................................................................64

FILTER GAGE KITS ..........................................................................................................................................65

PART NUMBER INDEX ..............................................................................................................................67 - 89

YORK INTERNATIONAL

3

FORM 102.20-RP1(1104)

ALPHABETIZED TABLE OF CONTENTS

ADJUSTABLE MOTOR BASES.................................................................................................................28 - 30

DOOR GASKETS ..............................................................................................................................................14

DOOR LATCHING PARTS .........................................................................................................................13 - 14

ELECTRICAL REPLACEMENT PARTS ...........................................................................................................60

FANS AND MOTORS, SECURING....................................................................................................................32

FAN MOTORS.............................................................................................................................................22 - 26

FASTENERS FOR SOLUTION UNITS.........................................................................................................9 - 10

FILTERS......................................................................................................................................................42 - 46

FILTER GAGE KITS ..........................................................................................................................................65

GASKET/CAULK/ADHESIVE FOR SOLUTION UNITS.............................................................................11 - 12

ISOLATORS................................................................................................................................................33 - 34

LIGHTING PARTS .............................................................................................................................................59

MOTOR WIRING PARTS...................................................................................................................................27

OA HOOD MOISTURE ELIMINATOR FILTERS (BY DAMPER SIZE).......................................................47 - 55

PART NUMBER INDEX ..............................................................................................................................67 - 89

SHELL COMPONENTS.....................................................................................................................................35

SPLICE & SPLIT BASERAIL KITS...........................................................................................................36 - 37

SWITCH/RECEPTACLE ....................................................................................................................................63

THRUST RESTRAINT KITS.......................................................................................................................17 - 18

THRUST RESTRAINT KIT SELECTION...........................................................................................................16

TRANSFORMER PANEL...................................................................................................................................64

VISUAL CONTROL FILTER CLAMPS FOR HEPA FILTERS...........................................................................58

WIREWAY ACCESS PLA TES.......................................................................................................... ..................41

WIRING-HARNESSES LIGHT ASSEMBLY - PANEL TO WIRE TRACK.........................................................61

WIRING-HARNESSES LIGHT ASSEMBLY - TIER TO TIER............................................................................63

WIRING-HARNESSES LIGHT ASSEMBLY - WIRE TRACK............................................................................62

4

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

LIST OF FIGURES

FIG. 1 - (SEE TABLE 1) SEGMENT AVAILABILITY .........................................................................................7

FIG. 2 - DOOR LATCHING PARTS.................................................................................................................15

FIG. 3 - THRUST RESTRAINT INSTALLATION FOR COMETRI AND INDUSTRIAL FANS

DISCHARGING INTO WALLS ...........................................................................................................19

FIG. 4 - THRUST RESTRAINT INSTALLATION FOR COMEFRI AND INDUSTRIAL FANS

DISCHARGING INTO PANELS .........................................................................................................20

FIG. 5 - THRUST RESTRAINT INSTALLATION FOR PLENUM FANS WITH WALL MOUNTED INLET......21

FIG. 6 - ASSEMBLY OF CONNECTORS........................................................................................................27

FIG. 7 - MOTOR WIRE CONNECTIONS.........................................................................................................27

FIG. 8 - ADJUSTABLE MOTOR BASE...........................................................................................................30

FIG. 9 - SECURING FANS AND MOTORS .....................................................................................................31

FIG. 10 - TYPICAL, ISOLATOR.........................................................................................................................34

FIG. 11 - SPLICE & STACKING ASSEMBLIES................................................................................................38

FIG. 12 - SPLIT ASSEMBLY..............................................................................................................................39

FIG. 13 - BASERAIL & CORNER ASSEMBLIES..............................................................................................40

FIG. 14 - TYPICAL FILTERS .............................................................................................................................56

FIG. 15 - UNIVERSAL FRAME LATCH SELECTION .......................................................................................57

FIG. 16 - VISUAL CONTROL FILTER CLAMPS...............................................................................................58

FIG. 17 - EXPLODED VIEW OF LIGHT ASSEMBLIES....................................................................................59

FIG. 18 - LIGHTING SCHEMATIC.....................................................................................................................60

FIG. 19 - PANEL TO WIRETRACK....................................................................................................................61

FIG. 20 - HARNESS-WIRETRACK....................................................................................................................62

FIG. 21 - TRANSFORMER PANEL DIMENSIONS............................................................................................64

FIG. 22 - FILTER GAUGE DIAGRAMS .............................................................................................................65

FIG. 23 - TYPICAL FILTER GAUGE .................................................................................................................65

FIG. 24 - C-CHANNEL TRIM FOR:

FIELD CUT OPENINGS ...........................................................................66

FIELD MODIFICATION TO ADD DOORS................................................66

FIG. 25 - DOOR SAFETY CHAIN......................................................................................................................66

YORK INTERNATIONAL

5

FORM 102.20-RP1(1104)

GENERAL

This renewal parts list provides replacement part numbers that can be ordered from the York Parts Warehouse (Tel.

800-932-1701). Refer to the data tag on your equipment for the unit size, fan size and accessories that comprise your

unit. Compare this data tag information with the nomenclature below and on the next page to completely identify all

components in your system. Furnish this model number and the York order number on which the unit was originally

furnished when ordering replacement parts.

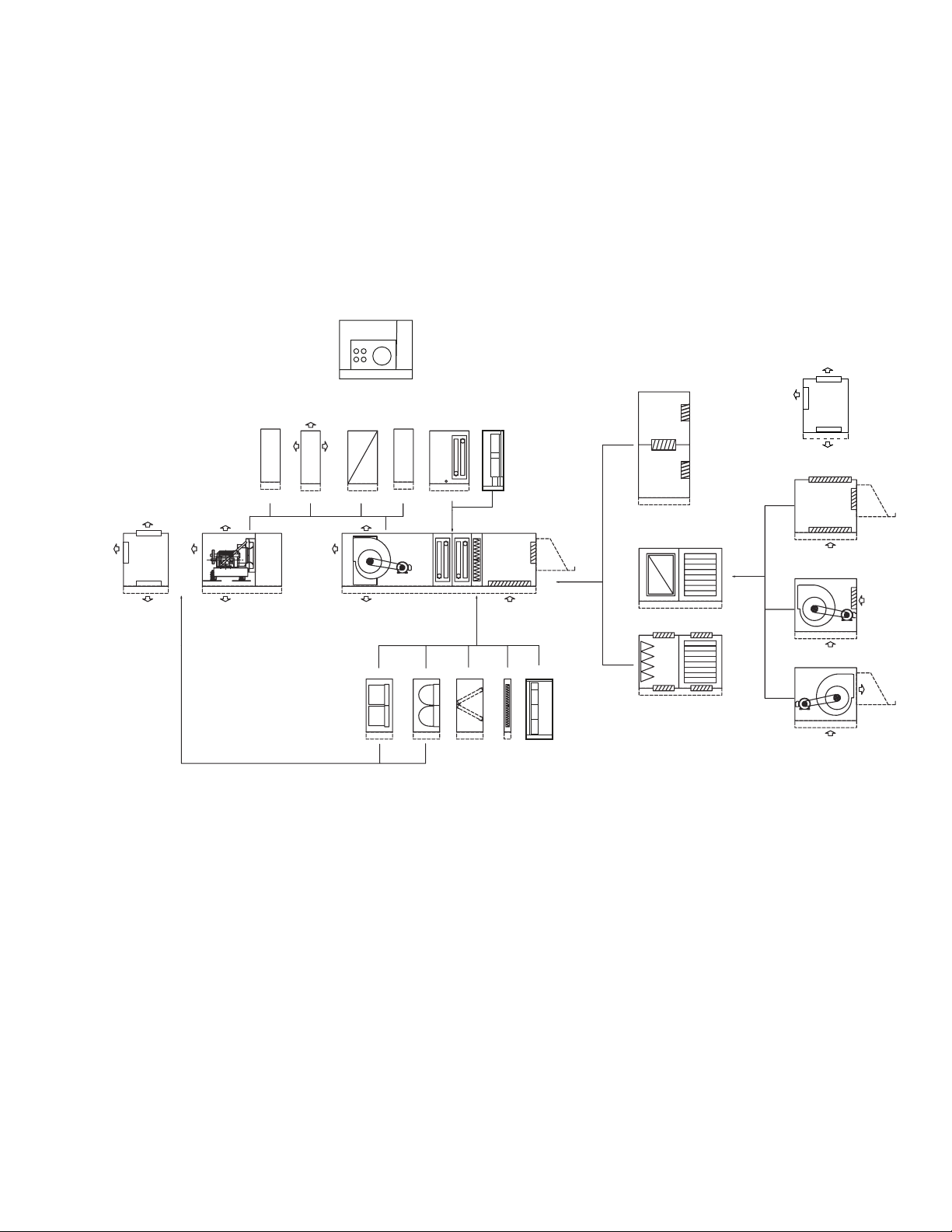

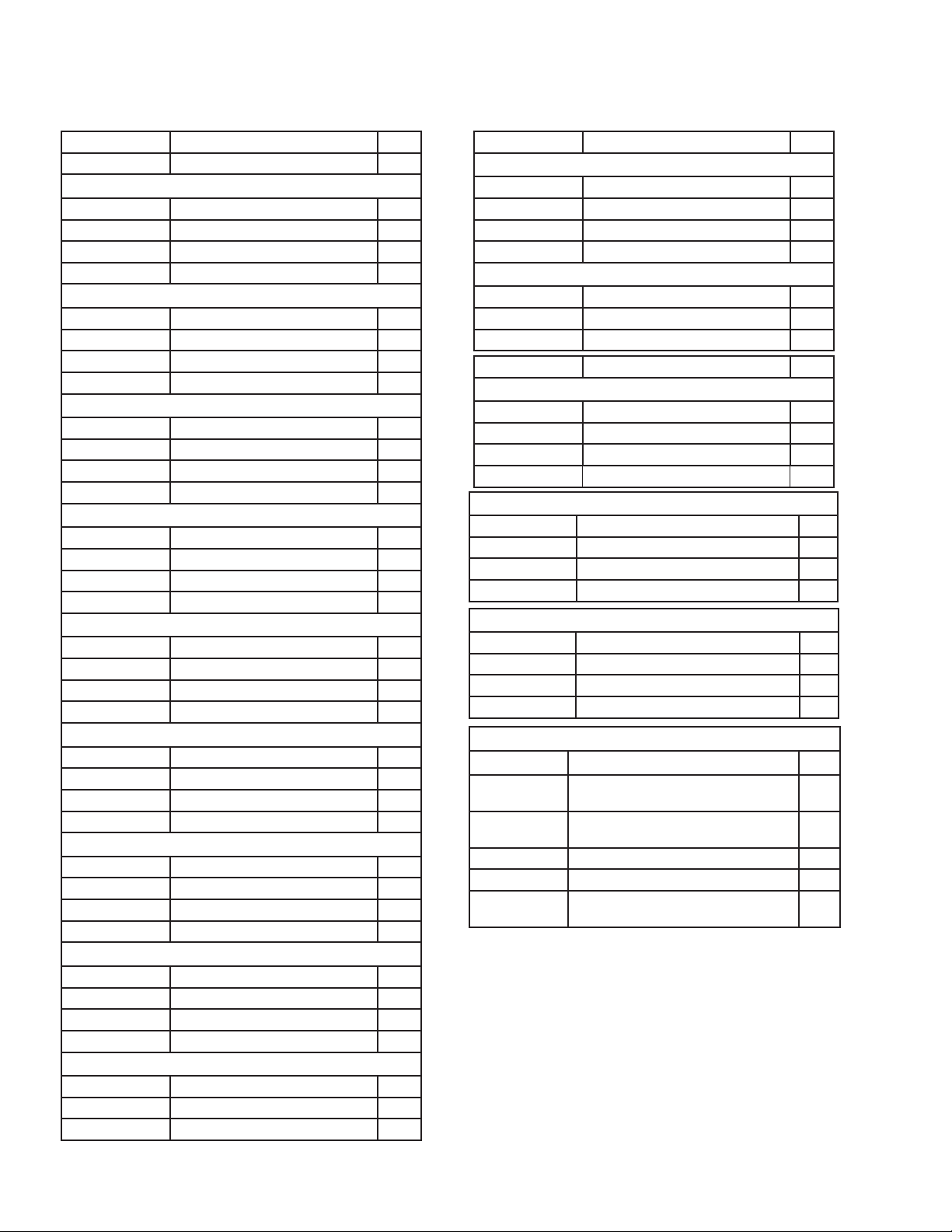

TABLE 1 – SEGMENT IDENTIFICATION (SEE FIG.1-2)

Fan Segments

• FS – Supply • FF – Flat Filter (2” or 4”)

o Forward Curved • AF – Angle Filter (2”)

o Airfoil • RF – High Effi ciency Filter

o Industrial Airfoil o Rigid Filter (12”)

o SWSI Plenum (Belt and Direct Drive) o Bag Filter (21”)

• FR – Return Fan • CF – Carbon Filter

o Forward Curved

o Airfoil • MB – Mixing Box

o Industrial Airfoil • FM – Filter / Mixing Box

o SWSI Plenum (Belt & Direct Drive) • EF – Filter / Economizer

• FE – Exhaust Fan • IP – Inlet Plenum

o Forward Curved

o Airfoil

o Industrial Airfoil • VP – Vertical Plenum

Coil Segments

o CC – Cooling Coil • DI – Diffuser

o HC – Heating Only Coil • XA – Access Segment

o VC – Vertical Coil • IG – Indirect-Fired Gas Furnace

o IC – Heat Only, Integral Face & Bypass Coil • ER – Energy Recovery Wheel

o IB – Internal Face & Bypass Coil • ΑB – Air Blender

Filter Segments

o Mini Pleat Filter (4”)

• ΗF – HEPA Filter

Inlet Segments

• EE – Economizer

Accessory Segments

• DP – Discharge Plenum

• TN – Turning Plenum

• FD – Face Damper

• EB – External Face & Bypass

• HM – Humidifi er

• ΑT – Sound Attenuator

6

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

IG

TN

VP

12P91

DP

FS (SWSI

plenum)

XA

DI

FS

ı

FIG. 1 - (SEE TABLE 1) SEGMENT AVAILABILITY

CC, HC

IC

IP

EE (vertical)

MB

MB

EE

FR

AF FFRF (RIGID) RF (BAG)

HF

EF

FE

HOODS ARE FOR OUTDOOR UNITS ONLY

•• •

LD08003B

ı

ı

YORK INTERNATIONAL

7

9

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

TABLE 2 – UNIT NOMENCLATURE

FORM 102.20-RP1(1104)

ENVIORNMENT

8

YORK INTERNATIONAL

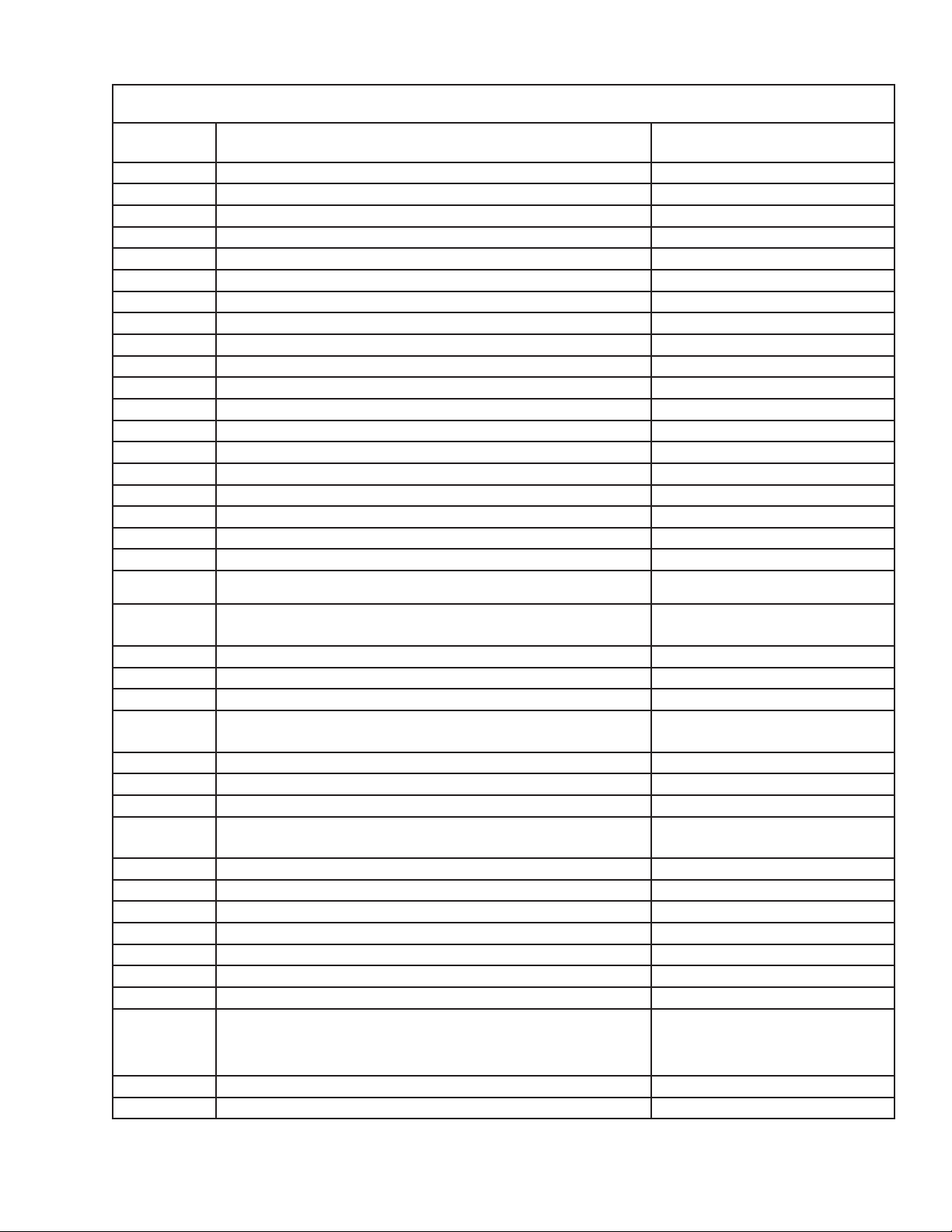

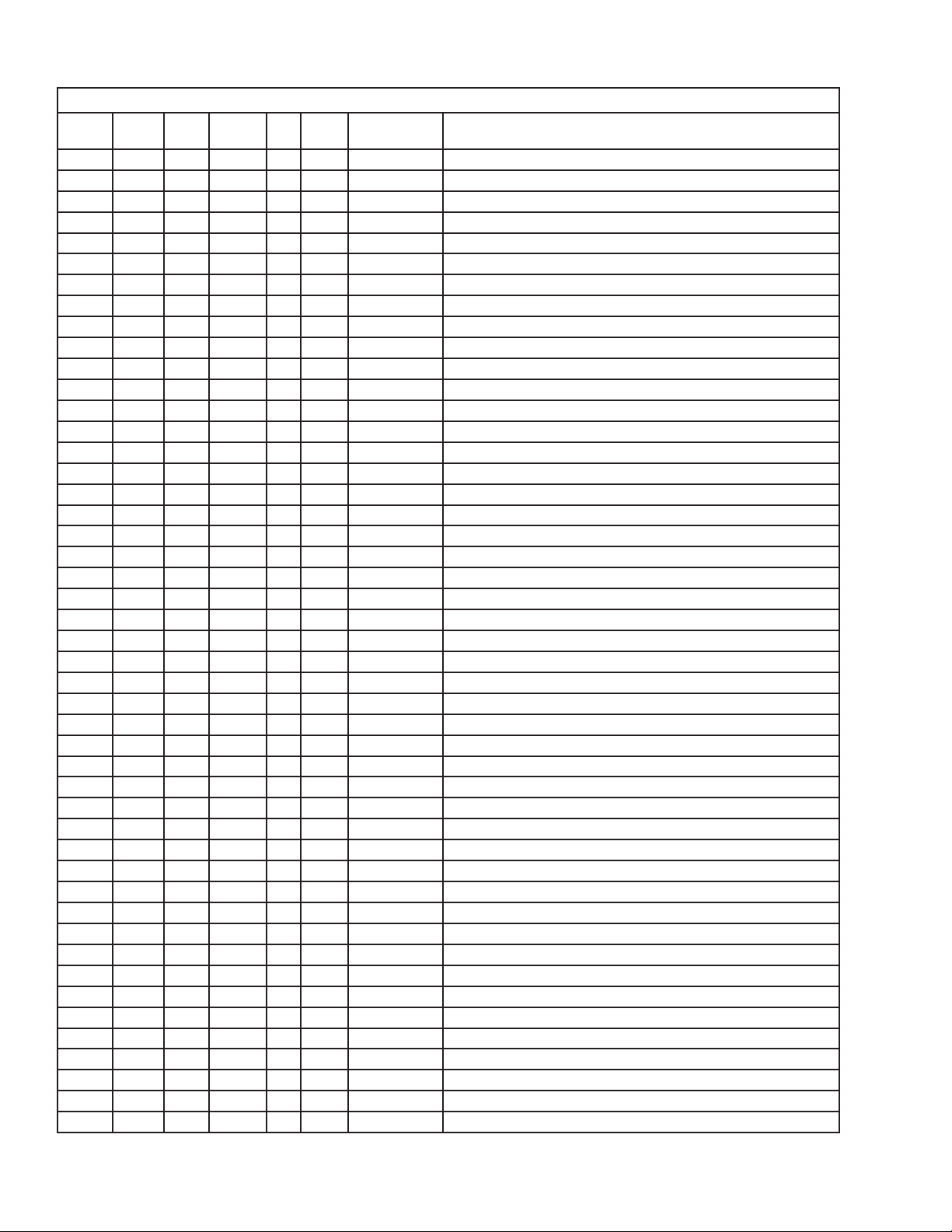

FASTENERS FOR SOLUTION UNITS

FORM 102.20-RP1(1104)

PART

DESCRIPTION WHERE USED

NUMBER

021-00331-000 BOLT, LAG HEX 3/8 X2-1/2 ZINC PLATED Tie down plate to shipping skid/wood

021-01154-000 WASH, LK TH INT 5/16 HVY,ZINC PLTD., STD. C-76 RF Filter Tracks

021-01155-000 WASH, LK TH INT 3/8 STD C-76 Fan Skid, Lifting Lugs

021-01163-000 WASH, LK TH INT 1/2 HVY STL ZINC PLTD., STD. C-76 Fan Skid, Lifi tng Lugs

021-01168-000 WASH LK TH INT 5/8 STL ZINC PLTD., STD. C-76 Blower Mounting

021-01248-000 WASHER PLAIN 5/16 ID X 3/4 OD X 0.065 NOM THK : STEEL Blower Mounting

021-01267-000 WASH FLT 7/16 ID X 1 OD X 0.083 THK STL ZINC PLTD. Snubber

021-01288-000 WASH FLT 11/16 ID X 1-3/4 OD 0.134 THK STL ZINC PLTD., STD. C-48 Blower Mounting

021-01481-000 SCR, CAP HEX 3/8 - 16 UNC - 2A X 1.0, ZINC PLATED Fan Skid

021-01499-000 SCREW, CAP HEX 3/8 - 16 UNC - 2A X 1.5, ZINC PLATED Blower Mounting

021-02523-000 NUT, HEX 5/16 - 18 UNC - 2B STL ZINC PLTD RF Filter Tracks

021- 02782- 000 Scr Hex Cap 5/16-18 X 1-1/4, 1-1/4 Lg Stl Zinc Pltd Blower Mounting

021-02794-000 SCR HEX 5/8-11UNC-2A X 2.00” SAE J429 Blower Mounting

021-02860-000 NUT, HEX 1/2-13 HVY 7/8 STL ZINC PLTD., STD. C-85 Fan Skid

021-02862-000 NUT HEX 5/8-11 HVY STL ZINC PLTD., STD. C-85 Blower Mounting

021-03749-000 SCR MACH RD PH 1/4-20UNC-2A X 1-1/4 LG STL ZINC PLTD. Blower Mounting

021-05146-000 WASH, FLT 9/16 ID X 1-3/8 OD .109 THK STL ZINC PLATED Fan Skid

021-08388-000 SCR, HEX 1/2-13UNC-2A X 1” STL ZINC PLTD, SAE J429 Fan Skid

021-08394-000 SCR, HEX CAP 5/16-18 X 3/4 LG STL ZINC PLTD RF Filter Tracks

021-08395-000 SCR, CAP HEX 3/8 - 16 UNC - 2A X 0.75, STL ZINC PLTD Secures Block To Motor Base

021-09983-000 WASH, FLT 3/8 ID X 7/8 OD 0.083 THK STL ZINC PLATED,ANSI B27.2,

STD C-48

021-10186-000 LOCK WASHER SPG HELICAL 1/4, STEEL Blower Mounting

021-11645-000 NUT, RET 3/8-16.162/.210 .162 - .210 PANEL RANGE, STD. C-77 Fan Skid

021-12656-000 NUT HEX 3/4-10 HVY STL ZINC CTD ASA B18 Blower Mounting

021-12917-000 SCR, TAP TY B HEX 5/16 X 3/4 5/16 DIA X 3/4 LG STL CD PL Fan Skid, Coil supports, Coil blockoff to

021-13291-000 NUT RET 1/4-20 0125-0.156 PANEL RANGE, STD. C-77 Economizer hatch

021-13734-000 SCR, TAP TY F PAN 1/4 X 1/2 LG STL ZINC PLTD Hood & Hood Gutter

021-13830-000 SCR HEX CAP 3/4-10 X 2-1/2, STL ZINC PLTD Blower Mounting

021-13863-000 SCR, TAP SELF DRILL 10-24 X 1/2 HD #10-24 X 1/2 LG STYLE 3 SHAKE-

PROOF # 621-100880-00-0251T,STL,ZINC PLTD

021-13911-000 SCR, TAP TYPE B HEX 3/8 X 3/4 STL ZINC PLTD. Fan Skid, Coil stacking splice

021-15802-000 WASH FLT 13/16 ID X 1-3/4 OD X 0.134 THK STL ZINC Blower Mounting

021-16151-000 LOCK WASHER SPG HELICAL 1/4, STEEL Blower Mounting

021-17212-000 SCREW,HEX HD CAP,1/4-20X1-1/2”, FULL THREAD, ZINC PLATED Blower Mounting

021-17711-000 RIVET, POP, 1/8”x1/4” GRIP Panel outer to liner

021-17717-000 NUT, HEX LK 3/8-16, ZINC PLATED Fan Skid

021-17718-000 NUT HEX 1/4 - 20 UNC - 2B Blower Mounting

021-17722-000 SCR, TAP TY A PH 14-10 1/4 X3/4 PAN HEAD, PHILLIPS (#1), TYPE A,

ZINC PLATED

RF Filter Tracks

coil casing

Control Brackets

Primary screw for inside sheet metal,

panels outside unit , damper mounting,

Shipping tie down to raceway

021-17728-000 SCR HEX 1/2-13UNC-2A X 1.75”, STL ZINC PLTD, SAE J429 Blower Mounting

021-19307-010 NUT, HEX 3/8-16, ZINC PLATED Lifting Lugs

YORK INTERNATIONAL

Continued on next page

9

FASTENERS FOR SOLUTION UNITS (CONTINUED)

FORM 102.20-RP1(1104)

PART

DESCRIPTION WHERE USED

NUMBER

021-19515-000 SCREW, SELF-DRILLING: 1/4 - 14 UN X 3/4 LG, STL ZINC PLATED Fan Discharge Flex Connection

021-19556-000 SCR, HEX 1/2-13UNC-2A X 9” STL ZINC PLTD, SAE J429, ALL THREAD,

OR EQUAL

021-19558-000 BLOCK, MOTOR BASE, 1/2-13 & 3/8-16 THRU HOLES Motor Base

021-19559-000 SCR, CAP HEX 3/8 - 16 UNC - 2A X 5.0, STL ZINC PLATED Snubber

021-19560-000 SCR,1/4-14x1,PHIL PAN SELF DRILL Self drill Screw for various locations when

021-19567-000 PLUG, STEEL FINISHING TO FIT 3/4” ID HOLE Top Corner Connector foam hole plug

021-19568-000 PLUG, STEEL FINISHING TO FIT 1-1/2” HOLE Corner Connector lifi ting hole plug

021-19570-000 SCREW, HEX SOCKET BUTTON HEAD, 3/8 -16 X 3/4, STL ZINC PLATED Lifting Lugs, Corners, Top split, stacking

021-19571-000 WASH LK TH INT 3/4 STL ZINC PLTD., STD. C-76 Blower Mounting

021-19579-000 NUT, RIVET KNURLED, #10-31, STL ZINC PLTD Mounting Kit, Small MCC Panel

021-19580-000 NUT, RIVET KNURLED, 3/8-16, STL ZINC PLTD Mounting Kit, Large MCC Panel

021-19581-000 SCR, CAP HEX 3/8 - 16 UNC - 2A X 2.5, STL ZINC PLTD Mounting Kit, 2KVA Transformer

021-19582-000 SCR, PAN HD PHLPS, MACH, #10-32 X 1/2 LG, STL ZINC PLTD, WITH

CAPTIVE INTERNAL TOOTH WASHER

021-19585-000 SCREW, 1/4”-14 X 1”, PHILLIPS PAN HD., SELF DRILLER W/WASHER,

ZINC W/EPDM .25

021-19586-000 NUT, HEX 3/8-16, ZINC PLATED Lifting Lugs

021-19587-000 RIVET, POP, 3/16”x3/8” GRIP, STL ZINC PLTD RF Front or Rear Load Filter Tracks

Motor Base

required

plate

Mounting Kit, 500VA / 150VA Control

Transformer & Mounting Kit, Small MCC

Panel

Outdoor Unit Roof

10

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

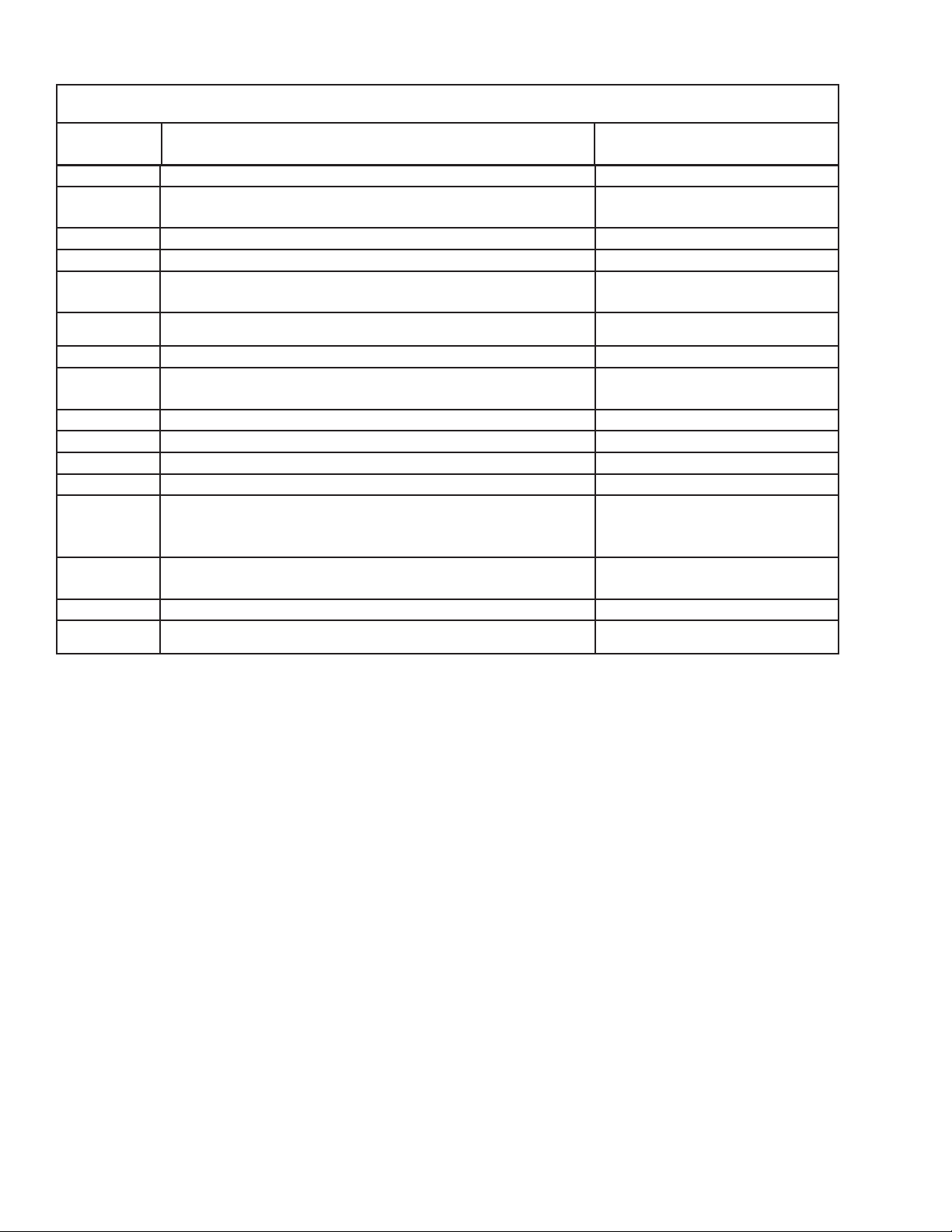

GASKET/CAULK/ADHESIVE FOR SOLUTION UNITS

PART

NUMBER

010-01017-010 Caulk, Sikafl ex, 221 SF, Sika Corp or Equal Corner connectors & raceway; inside corners where

010-02917-000 Ins Therm 1/8 x 1-1/2 x 50 Lg, Ind. Rolls C3-

241-DC 221 White Ethafoam, W/psa, Std

R749 DTD 10/8/90 Marriage Tape

013-02966-011 Caulk, Manus-bond,75-am, Manus Products,

or Equal

013-02976-010 Tape, Butyl, 0.75W x .19THK, TC-49 Xl 121,

Manus Products, or Equal

013-02977-010 Tape, Butyl, 1.5W x .13THK, TC-49 Xl 121,

Manus Products, or Equal

013-02978-010 Tape, Butyl, 0.5W x .13THK, TC-49 Xl 121,

Manus Products, or Equal

013-02979-010 Tape, Butyl, 0.5W x .25THK, TC-49 Xl 121,

Manus Products, or Equal

013-03317-010 Caulk, Solvent Free, Pace Gray or Equal,

Sikafl ex 221 SF or Manus-bond 75-AM

013-22013-010 Adhesive, Super Fast,#74, 3M or Equal Fan fl ex connection

028-11778-010 Gasket, Neoprene, Closed Cell, B/G, 1.25W x

0.25THK, Scott Mfg or Equal

028-11791-010 Gasket, Polyurethane, Open Cell, B/G, 1.0W x

1.0THK, Scott Mfg or Equal

028-11861-000 GROMMET, SUPPLY/RETURN

COIL HEADER, 1/8” PVC, For 3.00”

CONNECTIONS

028-11861-000 GROMMET, SUPPLY/RETURN COIL

HEADER, 1/8” PVC

028-11864-010 Gasket, Neoprene, Closed Cell, B/G, 0.75W x

0.5THK, Scott Mfg or Equal

028-11865-010 Foam, #2 Polyester, Open Cell, 2W x 2THK,

4LG, Scott Mfg or Equal

028-11865-010 Gasket, Neoprene, Closed Cell, B/G, 1.0W x

2.0THK, Scott Mfg or Equal

028-11866-001 Tape, Polyethylene, Double, 0.375W x

0.032THK, 5,184 In / Roll, or Equal

028-11866-002 Tape, Polyethylene, Double, 0.375W x

0.032THK, Spool, 60,000 In / Spool, or Equal

028-11866-010 Tape, Polyethylene, Double Sided, .38W x

0.13THK, Acrylic, Adhesive

028-11867-010 Gasket, Neoprene, Closed Cell, B/G, 1.25W x

.50THK, Scott Mfg or Equal

028-11871-000 Grommet, Supply/Return Coil Header, 1/8”

PVC, for 2.50” And 2.00” Connections

028-11872-000 Grommet, Supply/return Coil HEADER, 1/8”

PVC, for 1.50”, 1.25” And 1.00” Connections

DESCRIPTION WHERE USED

corner connector, raceway and panels meet; wireway and

bulkhead seal

Coil seal, bulk head seal

Corner connectors & raceway; inside corners where

corner connector, raceway and panels meet; wireway and

bulkhead seal

Outdoor units, between raceway 0.688 Flanges and

panels/ roof/drain pan/pipe chase/control enclosure,

panel to panel (vertical)

Outdoor units, between top raceways & along roof sides

& between bottom raceways & curb rest

Outdoor unit doors along sides when door is between two

panels

Outdoor units, between raceway 0.688 Flanges and roof

Corner connectors & raceway; inside corners where

corner connector, raceway and panels meet; wireway and

bulkhead seal

Split, bottom, sides, top panel to panel ends butt to butt

Filters

Coil Header Panel, For 3.00” Connections

Coil Header Panel

Between vertical bulkheads and panel

Wireway at pressure transitions.

Wireway at pressure transitions.

Between raceway double fl ange, between the liner

fl anges and out fl anges of panels

Between raceway double fl ange, between the liner

fl anges and out fl anges of panels

Between raceway double fl ange, between the liner

fl anges and out fl anges of panels

Between roof panels, type 8 fi lter tracks under the

bulkhead

Coil header panel, for 2.50” And 2.00” Connections

Coil header panel, for 1.50”, 1.25” And 1.00” Connections

YORK INTERNATIONAL

Continued on next page

11

GASKET/CAULK/ADHESIVE FOR SOLUTION UNITS (CONT.)

PART

NUMBER

028-11873-010 Gasket, Neoprene, Closed Cell, Grey, .75W X

.25THK, Scott Mfg or Equal

028-11875-010 Gasket, Ethafoam 221,Closed Cell, White,

1.5W X .13THK, Scott Mfg or Equal

044-02912-000 Ultra Flex Elastomeric, #2260-0100(White)

Coating: *an Expiration Date Required on This

Product (Drain Pan)

044-02912-010 Coating, Ultra Flex Elastomeric, Mastic

Coating for Drain Pan

1620 Gasket, Door, ____" High x ____" Wide Door (see example below)

TAC01494 Standard Touchup Spray Paint, Dessert Sand Outdoor unit exterior

Example For Ordering Door Gasket:

Door Is 35-1/2" High by 21-1/2" Wide

Order P/N 1620 35-1/2" High X 21-1/2" Wide.

DESCRIPTION WHERE USED

Panel to panel (vertical)

Coil seal, bulk head seal

Mastic coating for drain pan

Mastic coating for drain pan

FORM 102.20-RP1(1104)

12

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

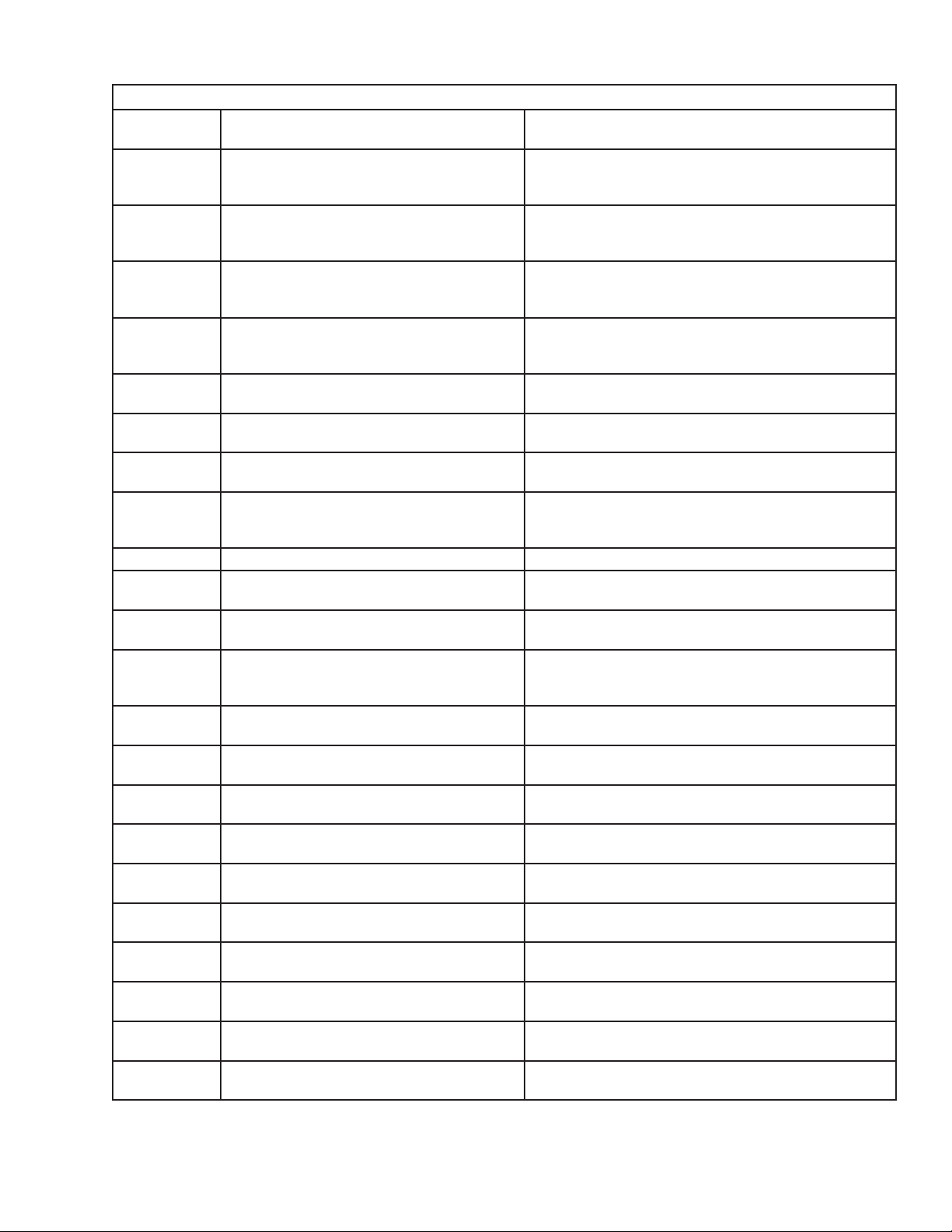

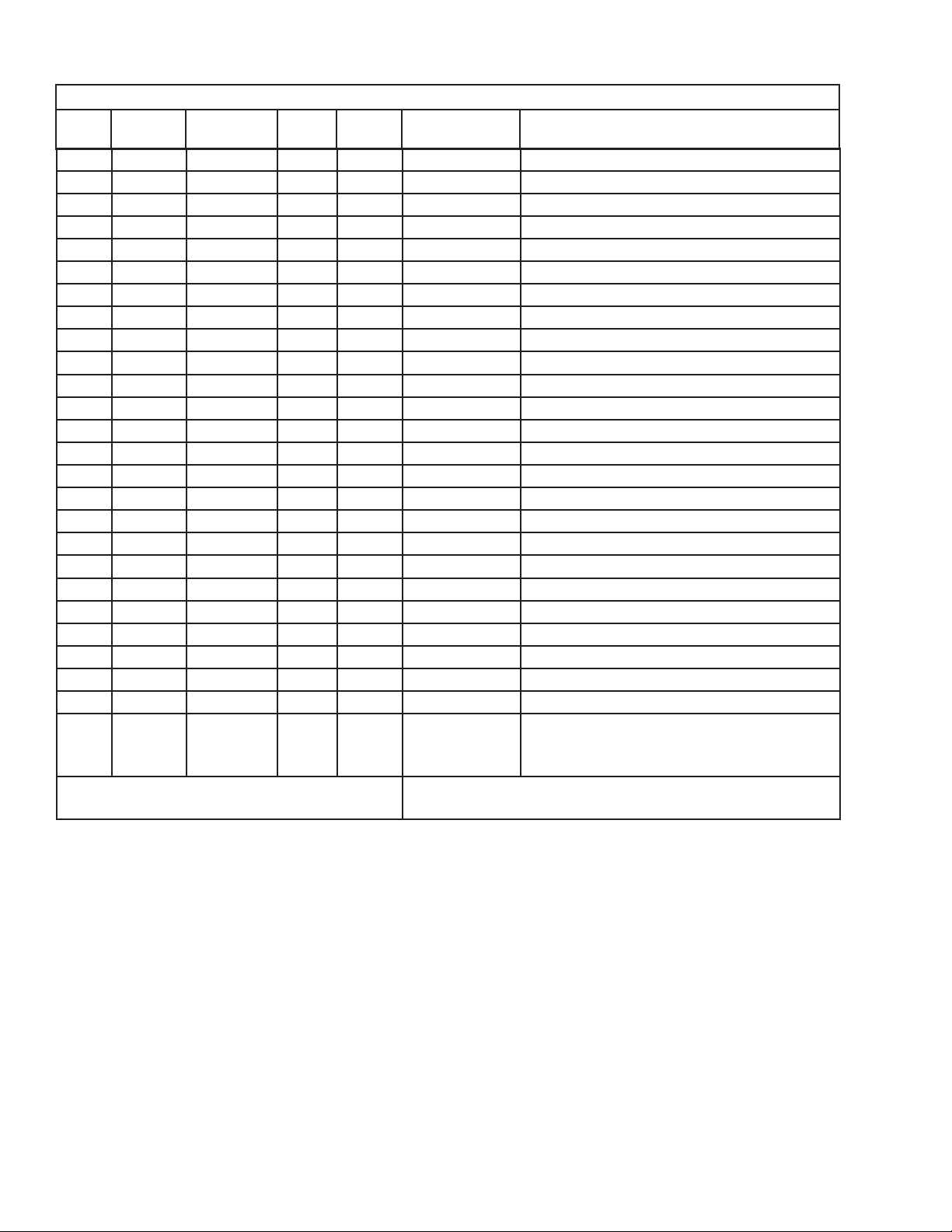

DOOR LATCHING PARTS

REF # DOOR

HT*

1SHORT

OR T ALL

1SHORT

OR T ALL

1SHORT

OR T ALL

1SHORT

OR T ALL

1SHORT

OR T ALL

1SHORT

OR T ALL

1SHORT

OR T ALL

2 SHORT

OR

TALL

3 SHORT

OR

TALL

4 SHORT OUT N/A N/A 034-12002-011 Single Point Roller Cam, Snub Nose Outswing

5 SHORT

OR

TALL

6 SHORT

OR

TALL

7 SHORT

OR

TALL

8 20.88 SINGLE N/A N/A 086-02023-001 Rod 0.315” Dia 10” Long Zinc Plated

8 23.88 SINGLE N/A N/A 086-02023-002 Rod 0.315” Dia 13” Long Zinc Plated

8 26.88 SINGLE N/A N/A 086-02023-003 Rod 0.315” Dia 16” Long Zinc Plated

8 29.88 SINGLE N/A N/A 086-02023-004 Rod 0.315” Dia 19” Long Zinc Plated

8 32.88 SINGLE N/A N/A 086-02023-005 Rod 0.315” Dia 22” Long Zinc Plated

8 35.88 SINGLE N/A N/A 086-02023-006 Rod 0.315” Dia 25” Long Zinc Plated

8 38.88 SINGLE N/A N/A 086-02023-007 Rod 0.315” Dia 28” Long Zinc Plated

8 41.88 SINGLE N/A N/A 086-02023-008 Rod 0.315” Dia 31” Long Zinc Plated

8 44.88 SINGLE N/A N/A 086-02023-009 Rod 0.315” Dia 34” Long Zinc Plated

8 47.88 SINGLE N/A N/A 086-02023-010 Rod 0.315” Dia 37” Long Zinc Plated

8 50.88 SINGLE N/A N/A 086-02023-011 Rod 0.315” Dia 40” Long Zinc Plated

8 53.88 SINGLE N/A N/A 086-02023-012 Rod 0.315” Dia 43” Long Zinc Plated

HANDLE** LOCK SWING PART NUMBER DESCRIPTION

STD OR

SINGLE

STD OR

SINGLE

STD OR

SINGLE

STD OR

SINGLE

STD OR

SINGLE

STD OR

SINGLE

SINGLE KEY

N/A N/A N/A 034-12002-001 Mechanism, Latching,Includes Bushing, Lock

N/A N/A N/A 034-12002-009 3/8 Sae Flat Washer

SINGLE N/A N/A 034-12002-010 Linkage Adapter For 8 Mm (0.315”) Dia Rods

STD OR

SINGLE

SINGLE N/A OUT 034-12002-007 Cover Plug For Latching Mechanism For Single

STD OUT 034-12001-001 Handle,Type_L,Lock_Non,Out-Swg,Roller_

Straight,W/Screw & Cover Plug.

STD IN 034-12001-006 Handle,Type_L,Lock_Non,In-Swg ,Roller_Off-

Set,W/Screw & Cover Plug.

KEY OUT 034-12001-007 Handle,Type_L,Lock_Key,Out-Swg,Roller_

Straight,W/Screw & Cover Plug, Key The

Same,York Std.

KEY IN 034-12001-010 Handle,Type_L,Lock_Key,In-Swg , Roller_Off-

Set,W/Screw & Cover Plug, Key The Same,York

Std.

PAD OUT 034-12001-011 Handle,Type_L,Lock_Pad,Out-Swg, Roller_

Straight,W/Screw & Cover Plug.

PAD IN 034-12001-012 Handle,Type_L,Lock_Pad,In-Swg ,Roller_Off-

Set,W/Screw & Cover Plug.

IN OR

OR

STD

N/A N/A 034-12001-005 Inside Handle W/ Red Plastic Grip

OUT

034-12002-007 Plug, Cover For Latch Mechanism

nut, & Jam Nut.

Doors Only

Point To Cover Outside Latching Mech.

YORK INTERNATIONAL

Continued on next page

13

FORM 102.20-RP1(1104)

DOOR LATCHING PARTS (CONTINUED)

REF # DOOR

HT*

8 56.88 SINGLE N/A N/A 086-02023-013 Rod 0.315” Dia 46” Long Zinc Plated

8 59.88 SINGLE N/A N/A 086-02023-014 Rod 0.315” Dia 49” Long Zinc Plated

8 62.88 SINGLE N/A N/A 086-02023-015 Rod 0.315” Dia 52” Long Zinc Plated

8 65.88 SINGLE N/A N/A 086-02023-016 Rod 0.315” Dia 55” Long Zinc Plated

8 68.88 SINGLE N/A N/A 086-02023-017 Rod 0.315” Dia 58” Long Zinc Plated

8 71.88 SINGLE N/A N/A 086-02023-018 Rod 0.315” Dia 61” Long Zinc Plated

8 74.88 SINGLE N/A N/A 086-02023-019 Rod 0.315” Dia 64” Long Zinc Plated

8 77.88 SINGLE N/A N/A 086-02023-020 Rod 0.315” Dia 67” Long Zinc Plated

8 80.88 SINGLE N/A N/A 086-02023-021 Rod 0.315” Dia 70” Long Zinc Plated

8 83.88 SINGLE N/A N/A 086-02023-022 Rod 0.315” Dia 73” Long Zinc Plated

8 86.88 SINGLE N/A N/A 086-02023-023 Rod 0.315” Dia 76” Long Zinc Plated

8 89.88 SINGLE N/A N/A 086-02023-024 Rod 0.315” Dia 79” Long Zinc Plated

8 92.88 SINGLE N/A N/A 086-02023-025 Rod 0.315” Dia 82” Long Zinc Plated

8 95.88 SINGLE N/A N/A 086-02023-026 Rod 0.315” Dia 85” Long Zinc Plated

8 98.88 SINGLE N/A N/A 086-02023-027 Rod 0.315” Dia 88” Long Zinc Plated

8 101.88 SINGLE N/A N/A 086-02023-028 Rod 0.315” Dia 91” Long Zinc Plated

8 104.88 SINGLE N/A N/A 086-02023-029 Rod 0.315” Dia 94” Long Zinc Plated

8 107.88 SINGLE N/A N/A 086-02023-030 Rod 0.315” Dia 97” Long Zinc Plated

8 110.88 SINGLE N/A N/A 086-02023-031 Rod 0.315” Dia 100” Long Zinc Plated

8 113.88 SINGLE N/A N/A 086-02023-032 Rod 0.315” Dia 103” Long Zinc Plated

8 116.88 SINGLE N/A N/A 086-02023-033 Rod 0.315” Dia 106” Long Zinc Plated

8 119.88 SINGLE N/A N/A 086-02023-034 Rod 0.315” Dia 109” Long Zinc Plated

8 122.88 SINGLE N/A N/A 086-02023-035 Rod 0.315” Dia 112” Long Zinc Plated

8 125.88 SINGLE N/A N/A 086-02023-036 Rod 0.315” Dia 115” Long Zinc Plated

8 128.88 SINGLE N/A N/A 086-02023-037 Rod 0.315” Dia 118” Long Zinc Plated

9 SHORT

OR

TALL

* Short door heights - 20.88” through 68.88” Tall door

heights - 71.88” through 128.88”

HANDLE** LOCK SWING PART NUMBER DESCRIPTION

STD OR

SINGLE

N/A N/A 386-02177-000 Kit, Latching Mechanism, Door , (Includes Ref. 2)

(Order 2 Kits For Short Doors And 3 Kits For Tall

Doors)

** - Single is for “Single point multi-latch system”. Standard is a

complete latch and handle for each latching point.

DOOR GASKETS

Measure door dimensions to special order door gasket made with welded corners. See example in Table "GASKET/CAULK/

ADHESIVE FOR SOLUTION UNITS" in this manual.

14

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

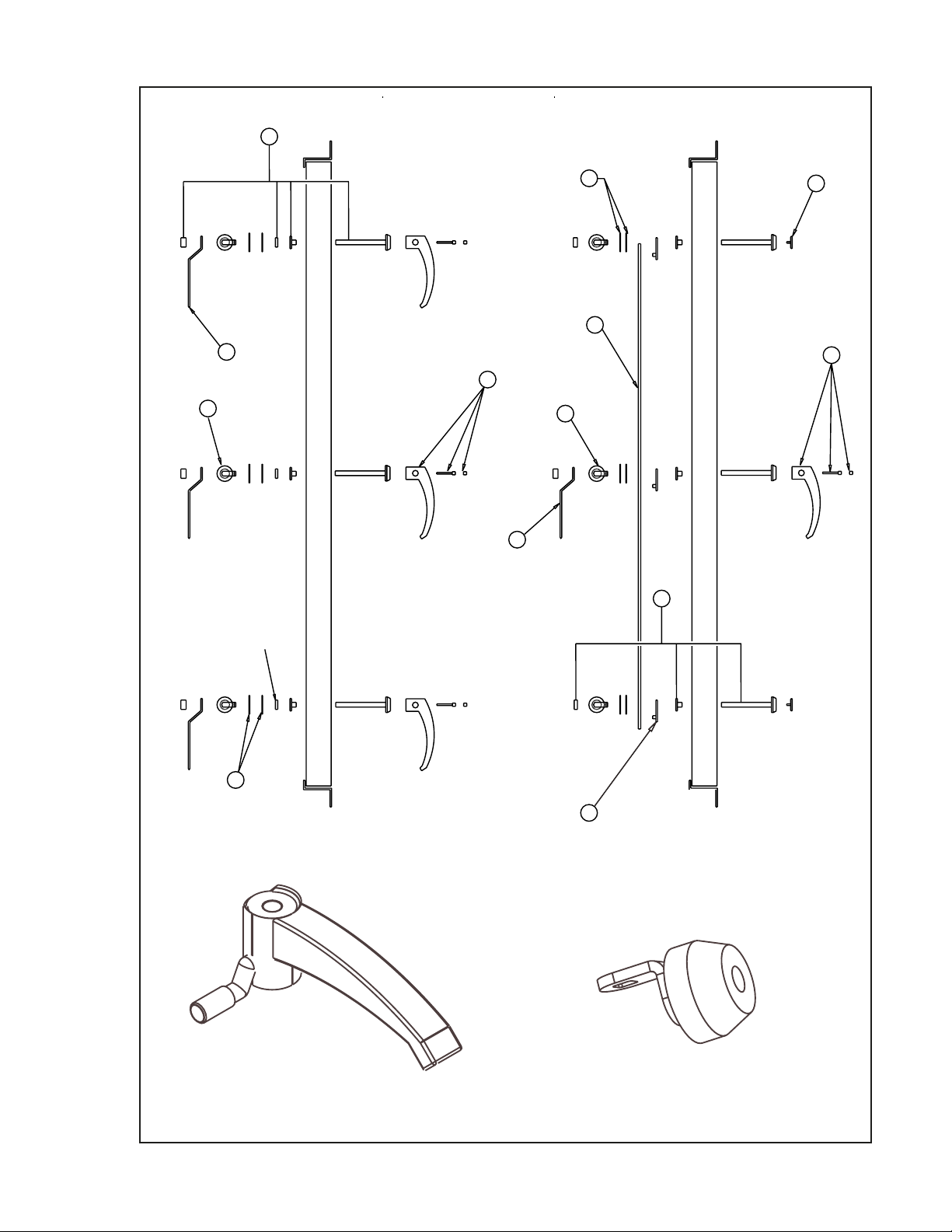

STANDARD DOOR

MULTI - PT LATCH

STANDARD DOOR

OUTSIDE UNIT

INSIDE UNIT

OUTSIDE UNIT

INSIDE UNIT

2

(3 Washers On

In Swing)

3

7

6

(Out Swing Only)

(See Detail B)

4

(Out Swing Only)

(In Swing Offset

Shown)

(See Detail A)

1

6

8

(Out Swing Only)

(See Detail B)

4

(In Swing Offset Shown)

(See Detail A)

2

1

3

(Out Swing Only)

DETAIL A

HANDLE W/OFFSET ROLLER

(In Swing Only) (Out Swing Only)

FIG. 2 - DOOR LATCHING PARTS

YORK INTERNATIONAL

5

DETAIL B

CAM ROLLER SNUB NOSE

LDO9694

15

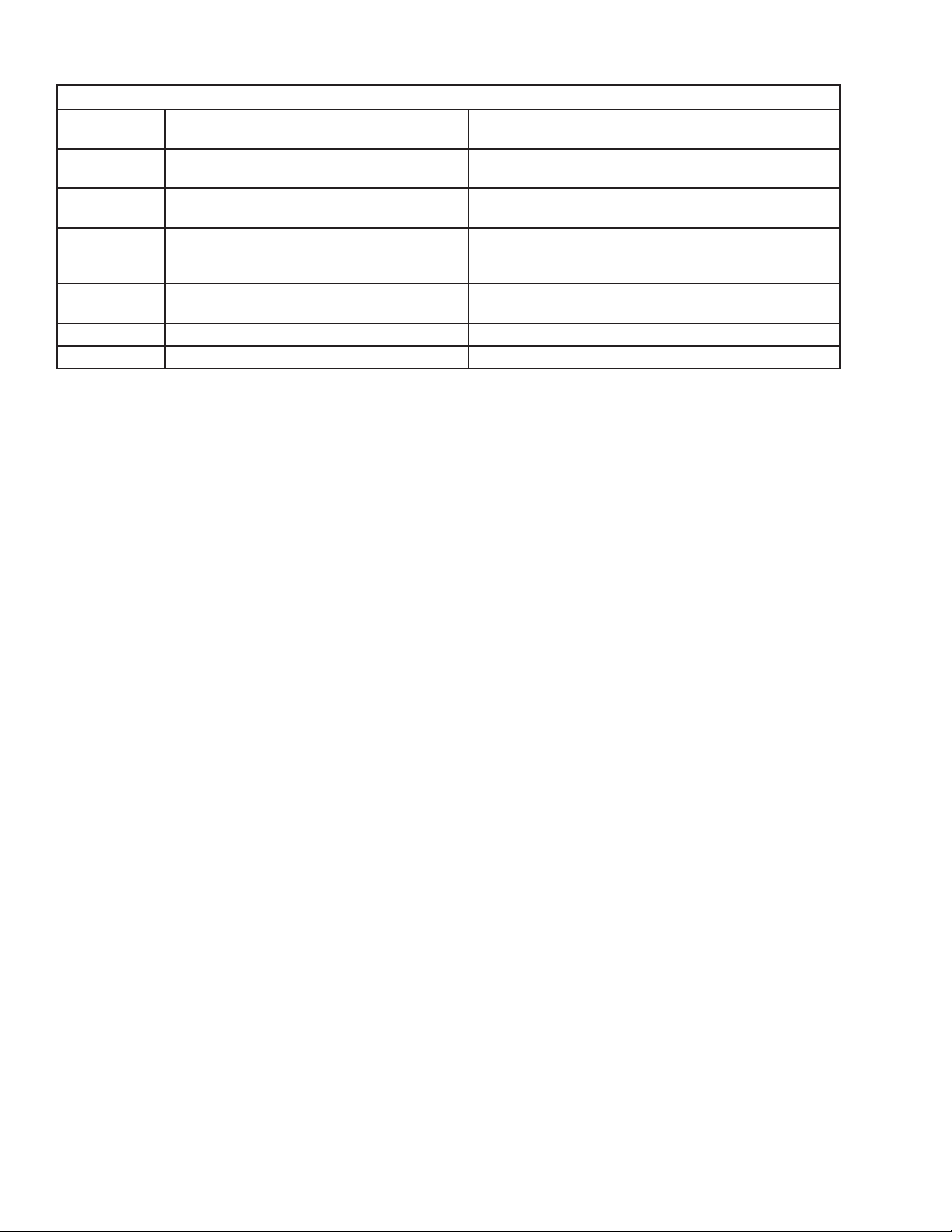

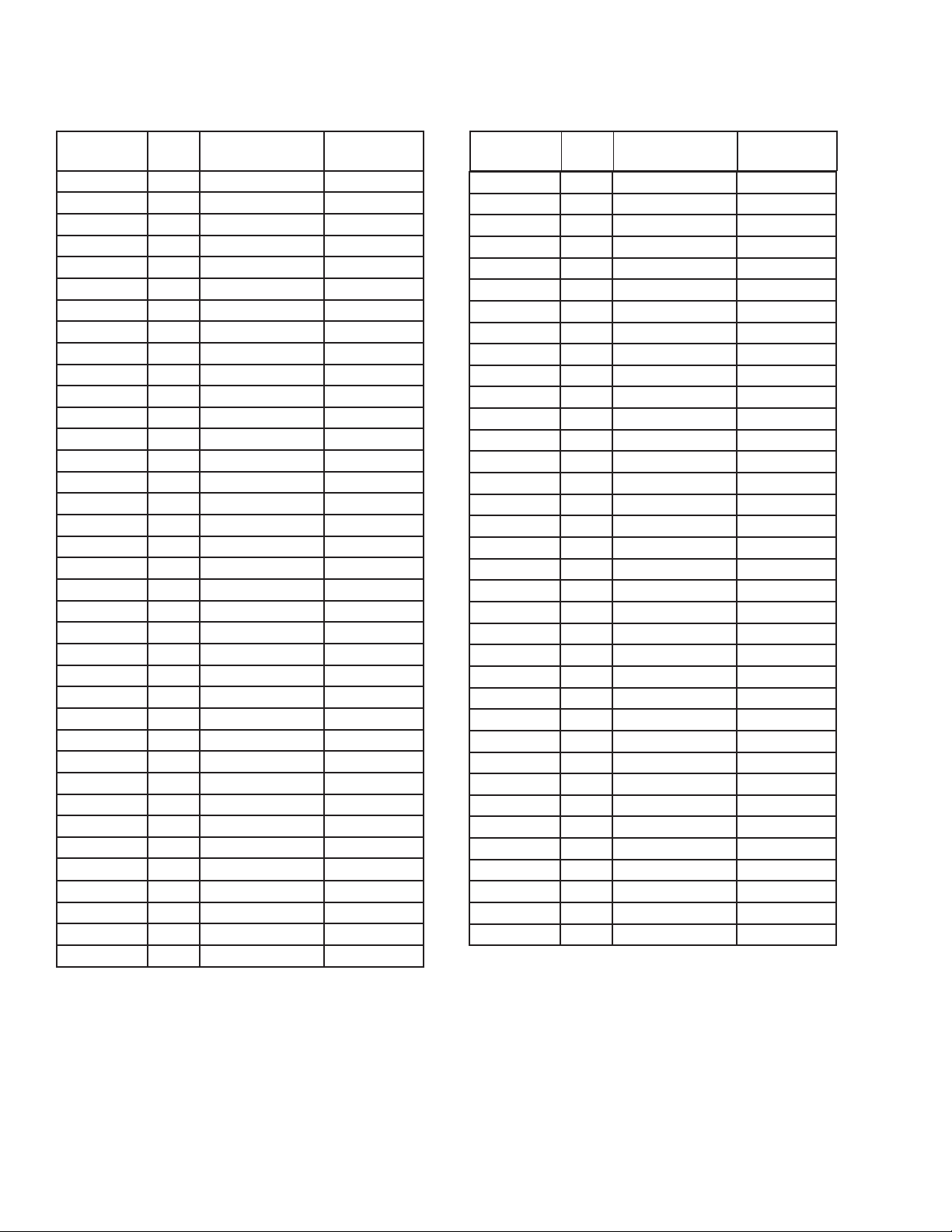

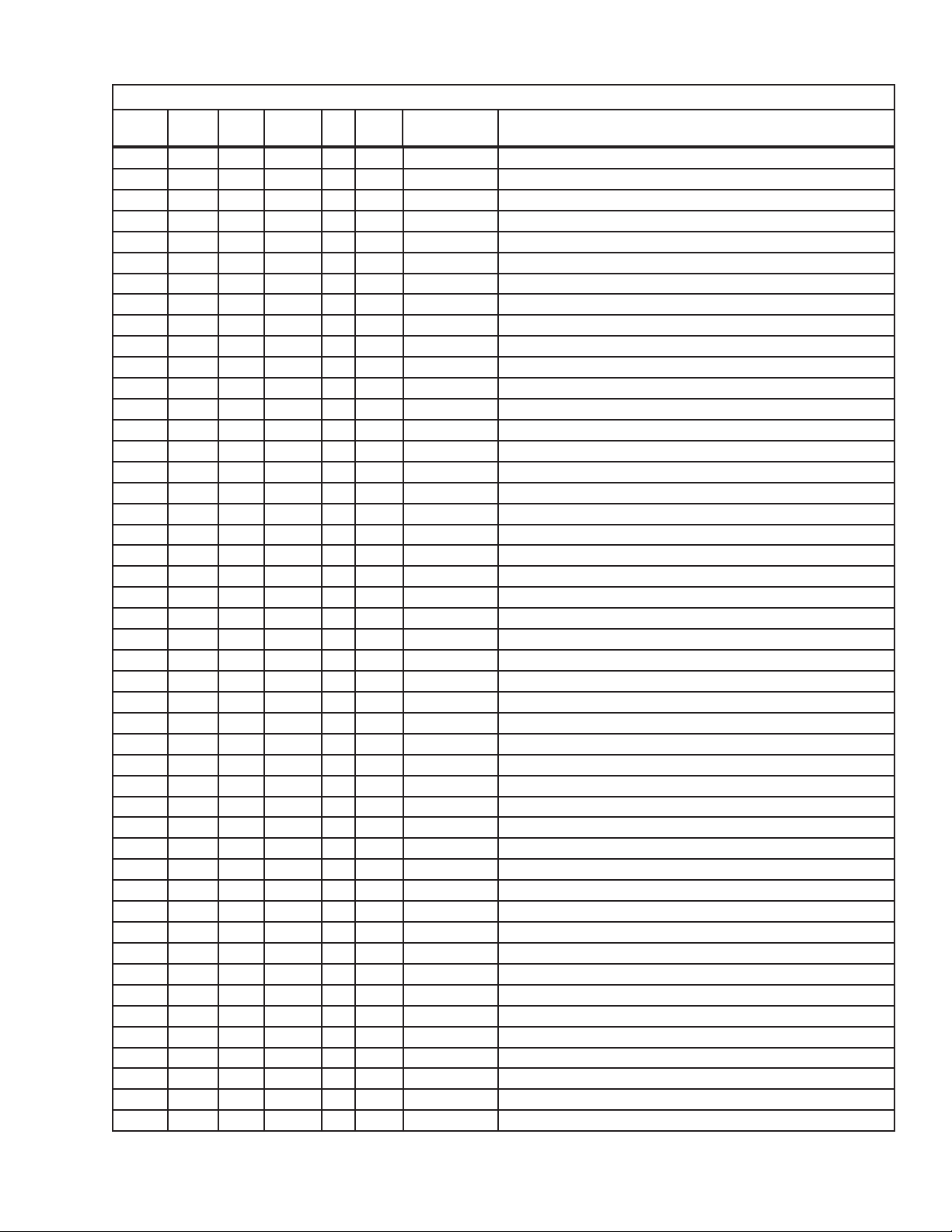

THRUST RESTRAINT KIT SELECTION

FORM 102.20-RP1(1104)

FAN

TYPE

AF 12-12 WALL 386-17791-002

AF 12-12 INSULATED PANEL 386-17791-010

AF 15-15 WALL 386-17791-002

AF 15-15 INSULATED PANEL 386-17791-011

AF 18-18 WALL 386-17791-002

AF 18-18 INSULATED PANEL 386-17791-012

AF 20-20 WALL 386-17791-002

AF 20-20 INSULATED PANEL 386-17791-013

AF 22-22 WALL 386-17791-007

AF 22-22 INSULATED PANEL 386-17791-014

AF 25-25 WALL 386-17791-007

AF 25-25 INSULATED PANEL 386-17791-015

AF 28-28 WALL 386-17791-008

AF 28-28 INSULATED PANEL 386-17791-016

AF 32-32 WALL 386-17791-008

AF 32-32 INSULATED PANEL 386-17791-017

AF 36-36 WALL 386-17791-009

AF 36-36 INSULATED PANEL 386-17791-018

AF 40-40 WALL 386-17791-006

AF 40-40 INSULATED PANEL 386-17791-019

IND 122 WALL 386-17791-002

IND 122 INSULATED PANEL 386-17791-020

IND 135 WALL 386-17791-002

IND 135 INSULATED PANEL 386-17791-021

IND 150 WALL 386-17791-002

IND 150 INSULATED PANEL 386-17791-022

IND 165 WALL 386-17791-002

IND 165 INSULATED PANEL 386-17791-023

IND 182 WALL 386-17791-002

IND 182 INSULATED PANEL 386-17791-024

IND 200 WALL 386-17791-002

IND 200 INSULATED PANEL 386-17791-025

IND 222 WALL 386-17791-007

IND 222 INSULATED PANEL 386-17791-026

IND 245 WALL 386-17791-007

IND 245 INSULATED PANEL 386-17791-027

IND 270 WALL 386-17791-008

FAN

SIZE

DISCHARGE KIT PART

NUMBER

FAN

TYPE

IND 270 INSULATED PANEL 386-17791-028

IND 300 WALL 386-17791-008

IND 300 INSULATED PANEL 386-17791-029

IND 330 WALL 386-17791-008

IND 330 INSULATED PANEL 386-17791-030

IND 365 WALL 386-17791-009

IND 365 INSULATED PANEL 386-17791-031

IND 402 WALL 386-17791-006

IND 402 INSULATED PANEL 386-17791-032

IND 445 WALL 386-17791-006

IND 445 INSULATED PANEL 386-17791-033

PLENUM 121 WALL 386-17791-001

PLENUM 141 WALL 386-17791-001

PLENUM 161 WALL 386-17791-001

PLENUM 181 WALL 386-17791-001

PLENUM 201 WALL 386-17791-001

PLENUM 221 WALL 386-17791-001

PLENUM 251 WALL 386-17791-001

PLENUM 281 WALL 386-17791-001

PLENUM 321 WALL 386-17791-001

PLENUM 351 WALL 386-17791-001

PLENUM 391 WALL 386-17791-003

PLENUM 441 WALL 386-17791-003

PLENUM 491 WALL 386-17791-004

PLENUM 551 WALL 386-17791-005

PLENUMDD 181 WALL 386-17791-001

PLENUMDD 201 WALL 386-17791-001

PLENUMDD 221 WALL 386-17791-001

PLENUMDD 251 WALL 386-17791-001

PLENUMDD 281 WALL 386-17791-001

PLENUMDD 321 WALL 386-17791-001

PLENUMDD 351 WALL 386-17791-001

PLENUMDD 391 WALL 386-17791-003

PLENUMDD 441 WALL 386-17791-003

PLENUMDD 491 WALL 386-17791-004

PLENUMDD 551 WALL 386-17791-005

FAN

SIZE

DISCHARGE KIT PART

NUMBER

16

YORK INTERNATIONAL

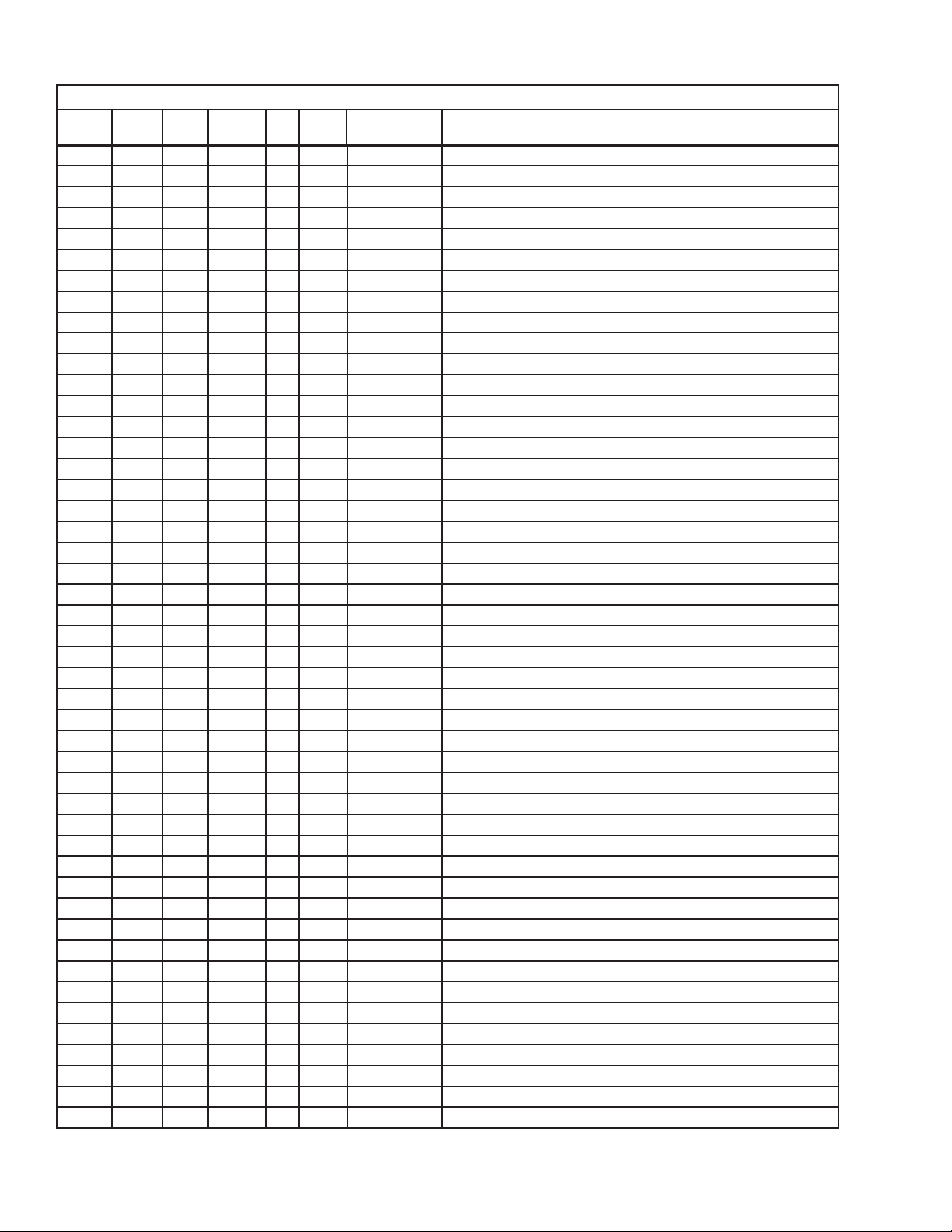

THRUST RESTRAINT KITS

FORM 102.20-RP1(1104)

P/N - 386-17791-001

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-002

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01322-002 THRUST RESTRAINT SST PLATE 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-003

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-004

P/N DESCRIPTION QTY

029-21364-003 RESTRAINT THRUST 750LBS/PR 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-005

P/N DESCRIPTION QTY

029-21364-004

086-01320-001 SMALL THRUST REST BRKT 2

RESTRAINT THRUST 1500LBS/

PR 2

P/N - 386-17791-006

P/N DESCRIPTION QTY

029-21364-004

086-01322-002 THRUST RESTRAINT SST PLATE 2

086-01320-002 LARGE THRUST REST BRKT 2

RESTRAINT THRUST 1500LBS/

PR 2

P/N - 386-17791-007

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01322-002 THRUST RESTRAINT SST PLATE 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-008

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01322-002 THRUST RESTRAINT SST PLATE 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-009

P/N DESCRIPTION QTY

029-21364-003 RESTRAINT THRUST 750LBS/PR 2

086-01322-002 THRUST RESTRAINT SST PLATE 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-010

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-001 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-011

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-002 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-012

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-003 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-013

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-004 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-014

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-005 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-015

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-006 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-016

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01321-007 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-017

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01321-008 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-018

P/N DESCRIPTION QTY

029-21364-003 RESTRAINT THRUST 750LBS/PR 2

086-01321-009 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-019

P/N DESCRIPTION QTY

029-21364-004

RESTRAINT THRUST 1500LBS/

PR 2

Continued on next page

YORK INTERNATIONAL

17

THRUST RESTRAINT KITS (CONTINUED)

FORM 102.20-RP1(1104)

086-01321-010 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-020

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-011 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-021

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-012 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-022

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-013 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-023

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-014 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-024

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-015 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-025

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-016 THRUST REST SUPPORT 2

086-01320-001 SMALL THRUST REST BRKT 2

P/N - 386-17791-026

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-017 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-027

P/N DESCRIPTION QTY

029-21364-001 RESTRAINT THRUST 350LBS/PR 2

086-01321-018 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-028

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01321-019 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-029

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01321-020 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-030

P/N DESCRIPTION QTY

029-21364-002 RESTRAINT THRUST 550LBS/PR 2

086-01321-021 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-031

P/N DESCRIPTION QTY

029-21364-003 RESTRAINT THRUST 750LBS/PR 2

086-01321-022 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-032

P/N DESCRIPTION QTY

029-21364-004 RESTRAINT THRUST 1500LBS/PR 2

086-01321-023 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

P/N - 386-17791-033

P/N DESCRIPTION QTY

029-21364-004 RESTRAINT THRUST 1500LBS/PR 2

086-01321-024 THRUST REST SUPPORT 2

086-01320-002 LARGE THRUST REST BRKT 2

HARDWARE INCLUDED IN ALL KITS

P/N DESCRIPTION QTY.

021-01481-000 SCR, CAP HEX 3/8 - 16 UNC - 2A X

1.0, ZINC PLATED

021-01267-000 WASH FLT 7/16 ID X 1 OD X 0.083

THK STL ZINC PLTD.

021-01155-000 WASH, LK TH INT 3/8 STD C-76 4

021-19307-000 NUT, HEX LK 3/8-16 ZINC PLATED 4

021-19515-000 SCREW, SELF-DRILLING: 1/4 - 14 UN

X 3/4 LG, ZINC PLATED

4

8

16

18

YORK INTERNATIONAL

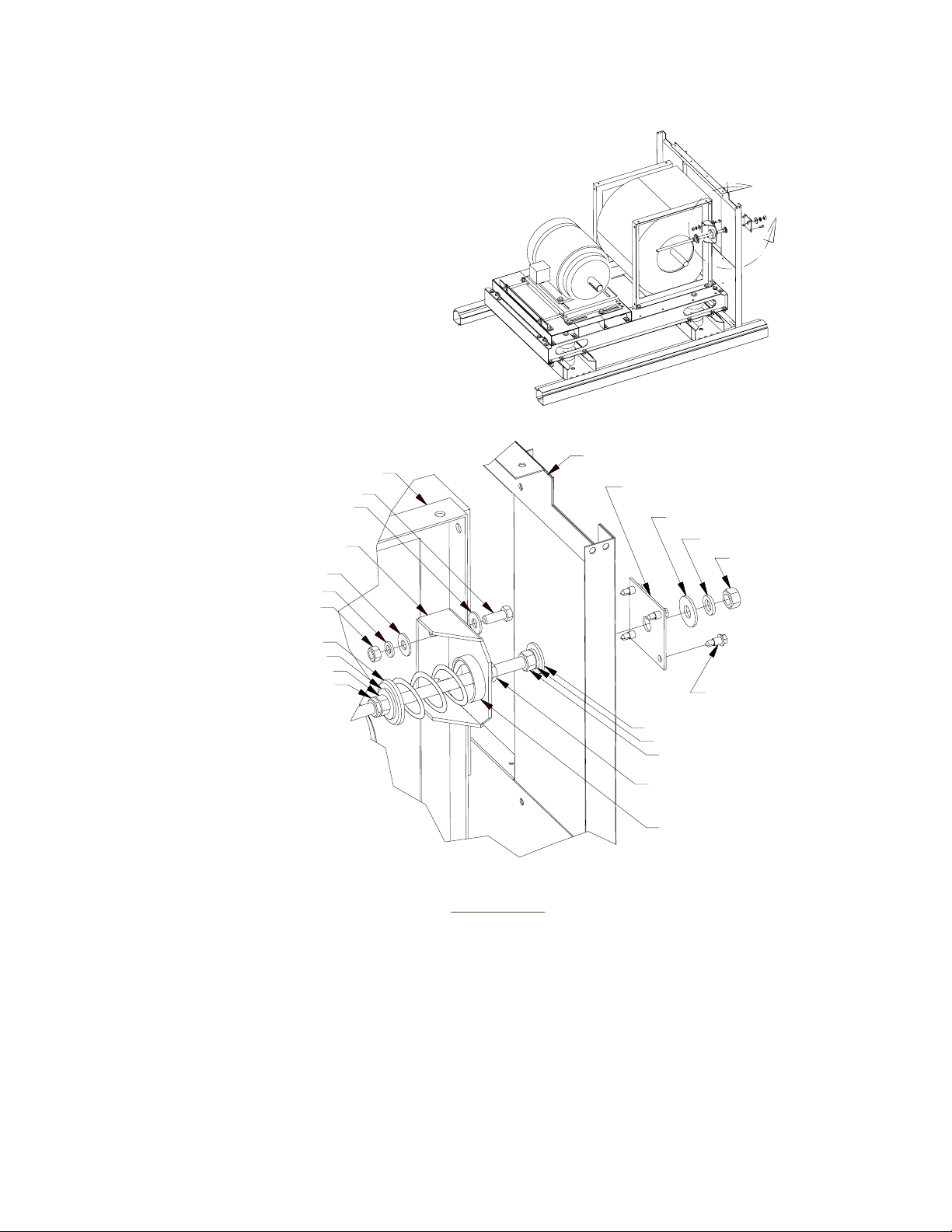

021-01481-000

021-01267-000

THRUST REST BRKT

021-01267-000

021-01155-000

021-19307-000

FAN

WALL ASSY

086-00105-152

TH REST PLATE

FLAT WASH

LOCK WASH

FORM 102.20-RP1(1104)

A

HEX NUT

STEEL CUP

FLAT WASH

HEX NUT

LOCK NUT

FLAT WASH

LOCK WASHER

HEX NUT

LOCK NUT

HEX NUT

FLAT WASH

NEOPRENE CUP

LDO9700-2

DETAIL A

FIG. 3 - THRUST RESTRAINT INSTALLATION FOR

COMEFRI AND INDUSTRIAL FANS DISCHARGING INTO WALLS

021- 19515-000

YORK INTERNATIONAL

19

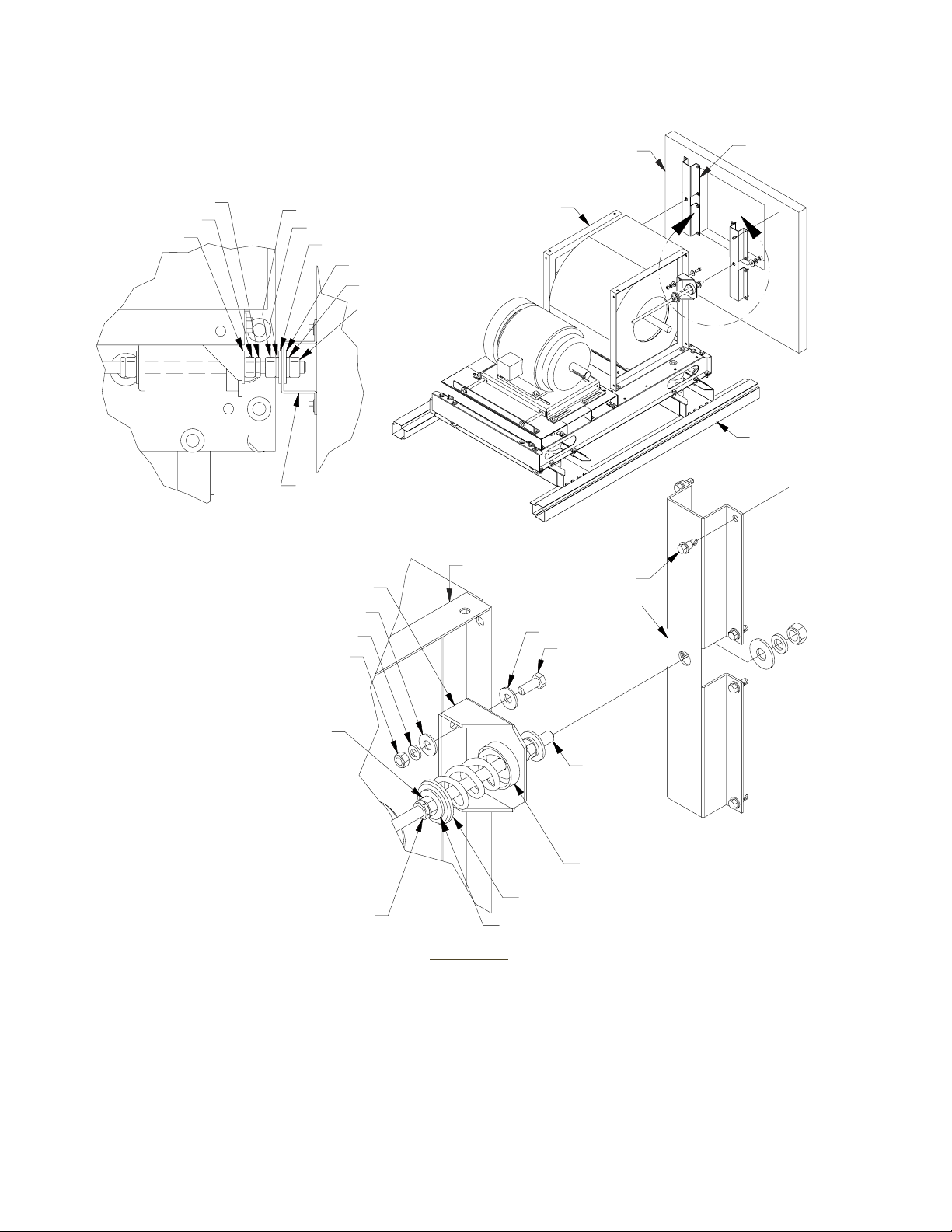

FORM 102.20-RP1(1104)

LOCK NUT

HEX NUT

FLAT WASH

TOP VIEW OF DETAIL A

THRUST REST BRKT

021-19307-000

HEX NUT

LOCK WASH

FLAT WASH

FLAT WASH

TH REST SUPPORT

021-01267-000

021-01155-000

LOCK WASH

HEX NUT

FAN

DISCH PANEL

FAN

021- 19515-000

TH REST SUPPORT

021-01267-000

021-01481-000

NOTE 1

A

RACEWAY

HEX NUT

STEEL ROD

NEOPRENE CUP

STEEL CUP

LOCK NUT

FLAT WASHER

DETAIL A

1. TH REST SUPPORT FLANGE IS TO BE FLUSH WITH PANEL OPENING.

FIG. 4 - THRUST RESTRAINT INSTALLATION FOR

COMEFRI AND INDUSTRIAL FANS DISCHARGING INTO PANELS

LDO9701-1

20

YORK INTERNATIONAL

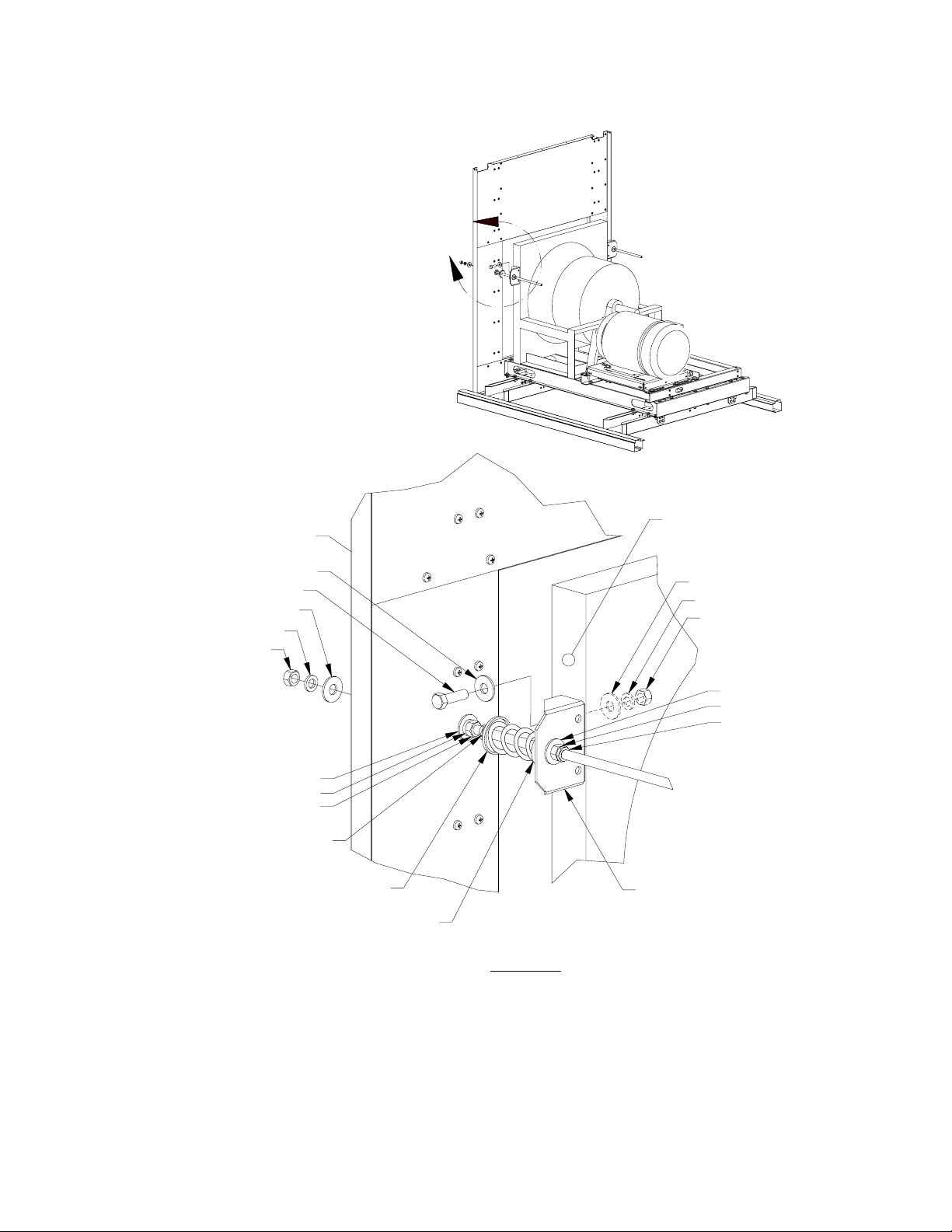

A

FORM 102.20-RP1(1104)

WALL ASSY

021-01267-000

021-01481-000

FLAT WASH

LOCK WASH

HEX NUT

FLAT WASH

LOCK WASH

HEX NUT

LOCK NUT

HEX NUT

FLAT WASH

STEEL CUP

NEOPRENE CUP

FAN INLET COVER

021-01267-000

021-01155-000

021-19307-000

FLAT WASH

HEX NUT

LOCK NUT

THRUST REST BRKT

LDO9702A

DETAIL A

YORK INTERNATIONAL

FIG. 5 - THRUST RESTRAINT INSTALLA-

TION FOR PLENUM FANS WITH

WALL MOUNTED INLET

21

FORM 102.20-RP1(1104)

FAN MOTORS

HERTZ EFF TYPE VOLT. HP

60 HIGH ODP 200 50 1800 024-14920-000 MTR 50HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2543T-8

60 HIGH ODP 200 1.5 1800 024-23174-000 MTR 1.5HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3154T-8

60 HIGH ODP 230/460 2 1800 024-23189-000 MTR 2HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3157T

60 HIGH ODP 230/460 30 1800 024-23191-000 MTR 30HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2535T

60 HIGH ODP 230/460 40 1800 024-23195-000 MTR 40HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2539T

60 HIGH ODP 230/460 50 1800 024-23196-000 MTR 50HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2543T

60 HIGH ODP 230/460 60 1800 024-23197-000 MTR 60HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2547T

60 HIGH TEFC 230/460 3 1800 024-23914-000 MTR 3HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3611T

60 HIGH TEFC 230/460 5 1800 024-23915-000 MTR 5HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3615T

60 HIGH TEFC 230/460 7.5 1800 024-23916-000 MTR 7.5HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3710T

60 HIGH TEFC 230/460 10 1800 024-23917-000 MTR 10HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3714T

60 HIGH TEFC 230/460 15 1800 024-23918-000 MTR 15HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M2333T

60 HIGH TEFC 230/460 20 1800 024-23919-000 MTR 20HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M2334T

60 HIGH TEFC 230/460 25 1800 024-23920-000 MTR 25HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4103T

60 HIGH TEFC 200 3 1800 024-23921-000 MTR 3HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3611T-8

60 HIGH TEFC 200 5 1800 024-23922-000 MTR 5HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3615T-8

60 HIGH TEFC 200 7.5 1800 024-23923-000 MTR 7.5HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3710T-8

60 HIGH TEFC 200 10 1800 024-23924-000 MTR 10HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3714T-8

60 HIGH TEFC 200 15 1800 024-23925-000 MTR 15HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M2333T-8

60 HIGH ODP 230/460 3 1800 024-23928-000 MTR 3HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3211T

60 HIGH ODP 230/460 5 1800 024-23929-000 MTR 5HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3218T

60 HIGH ODP 230/460 7.5 1800 024-23930-000 MTR 7.5HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3311T

60 HIGH ODP 230/460 10 1800 024-23931-000 MTR 10HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3313T

60 HIGH ODP 230/460 15 1800 024-23932-000 MTR 15HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2513T

60 HIGH ODP 230/460 20 1800 024-23933-000 MTR 20HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2515T

60 HIGH ODP 230/460 25 1800 024-23934-000 MTR 25HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2531T

60 HIGH ODP 200 3 1800 024-23935-000 MTR 3HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3211T-8

60 HIGH ODP 200 5 1800 024-23936-000 MTR 5HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3218T-8

60 HIGH ODP 200 7.5 1800 024-23937-000 MTR 7.5HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3311T-8

60 HIGH ODP 200 10 1800 024-23938-000 MTR 10HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3313T-8

60 HIGH ODP 200 15 1800 024-23939-000 MTR 15HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2513T-8

60 HIGH ODP 200 20 1800 024-23940-000 MTR 20HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2515T-8

60 HIGH ODP 200 25 1800 024-23941-000 MTR 25HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2531T-8

50 HIGH ODP 380 3 1500 024-26203-000 MTR 3HP 380-3-50 ODP HIGH 1500RPM BALDOR M3211T-50

50 HIGH ODP 380 5 1500 024-26204-000 MTR 5HP 380-3-50 ODP HIGH 1500RPM BALDOR M3218T-50

50 HIGH ODP 380 7.5 1500 024-26205-000 MTR 7.5HP 380-3-50 ODP HIGH 1500RPM BALDOR M3311T-50

50 HIGH TEFC 380 10 1500 024-26221-000 MTR 10HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3714T-50

50 HIGH TEFC 380 15 1500 024-26252-000 MTR 15HP 380-3-50 TEFC HIGH 1500RPM BALDOR M2333T-50

60 HIGH ODP 200 1 1800 024-26261-000 MTR 1HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3116T-8

60 HIGH ODP 230/460 1 1800 024-26262-000 MTR 1HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3116T

60 HIGH ODP 230/460 1.5 1800 024-26263-000 MTR 1.5HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M3154T

60 HIGH ODP 200 2 1800 024-26264-000 MTR 2HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M3157T-8

60 HIGH ODP 200 30 1800 024-26265-000 MTR 30HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2535T-8

60 HIGH ODP 200 40 1800 024-26266-000 MTR 40HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2539T-8

60 HIGH ODP 230/460 75 1800 024-26267-000 MTR 75HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2551T

60 HIGH ODP 230/460 100 1800 024-26268-000 MTR 100HP 230/460-3-60 ODP HIGH 1800RPM BALDOR M2555T

60 HIGH TEFC 200 30 1800 024-26271-000 MTR 30HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M4104T-8

RPM

NOM-

PART

NUMBER DESCRIPTION

22

Continued on next page

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

FAN MOTORS (CONTINUED)

HERTZ EFF TYPE VOLT. HP

60 HIGH TEFC 200 1 1800 024-26276-000 MTR 1HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3546T-8

60 HIGH TEFC 230/460 1 1800 024-26277-000 MTR 1HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3546T

60 HIGH TEFC 200 1.5 1800 024-26278-000 MTR 1.5HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3554T-8

60 HIGH TEFC 230/460 1.5 1800 024-26279-000 MTR 1.5HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3554T

60 HIGH TEFC 200 2 1800 024-26280-000 MTR 2HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M3558T-8

60 HIGH TEFC 230/460 2 1800 024-26281-000 MTR 2HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M3558T

60 HIGH TEFC 230/460 30 1800 024-26282-000 MTR 30HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4104T

60 HIGH TEFC 230/460 40 1800 024-26283-000 MTR 40HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4110T

60 HIGH TEFC 230/460 50 1800 024-26284-000 MTR 50HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4115T

60 HIGH TEFC 230/460 60 1800 024-26285-000 MTR 60HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4314T

60 HIGH TEFC 230/460 75 1800 024-26286-000 MTR 75HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4316T

60 HIGH TEFC 230/460 100 1800 024-26287-000 MTR 100HP 230/460-3-60 TEFC HIGH 1800RPM BALDOR M4400T

60 HIGH ODP 575 1 1800 024-27005-000 MTR 1HP 575-3-60 ODP HIGH 1800RPM BALDOR M3116T-5

60 HIGH ODP 575 1.5 1800 024-27006-000 MTR 1.5HP 575-3-60 ODP HIGH 1800RPM BALDOR M3154T-5

60 HIGH ODP 575 2 1800 024-27007-000 MTR 2HP 575-3-60 ODP HIGH 1800RPM BALDOR M3157T-5

60 HIGH ODP 575 3 1800 024-27008-000 MTR 3HP 575-3-60 ODP HIGH 1800RPM BALDOR M3211T-5

60 HIGH ODP 575 5 1800 024-27009-000 MTR 5HP 575-3-60 ODP HIGH 1800RPM BALDOR M3218T-5

60 HIGH ODP 575 7.5 1800 024-27010-000 MTR 7.5HP 575-3-60 ODP HIGH 1800RPM BALDOR M3311T-5

60 HIGH ODP 575 10 1800 024-27011-000 MTR 10HP 575-3-60 ODP HIGH 1800RPM BALDOR M3313T-5

60 HIGH ODP 575 15 1800 024-27012-000 MTR 15HP 575-3-60 ODP HIGH 1800RPM BALDOR M2513T-5

60 HIGH ODP 575 20 1800 024-27013-000 MTR 20HP 575-3-60 ODP HIGH 1800RPM BALDOR M2515T-5

60 HIGH ODP 575 25 1800 024-27014-000 MTR 25HP 575-3-60 ODP HIGH 1800RPM BALDOR M2531T-5

60 HIGH ODP 575 30 1800 024-27015-000 MTR 30HP 575-3-60 ODP HIGH 1800RPM BALDOR M2535T-5

60 HIGH ODP 575 40 1800 024-27016-000 MTR 40HP 575-3-60 ODP HIGH 1800RPM BALDOR M2539T-5

60 HIGH ODP 575 50 1800 024-27017-000 MTR 50HP 575-3-60 ODP HIGH 1800RPM BALDOR M2543T-5

60 HIGH ODP 575 60 1800 024-27018-000 MTR 60HP 575-3-60 ODP HIGH 1800RPM BALDOR M2547T-5

60 HIGH ODP 575 75 1800 024-27019-000 MTR 75HP 575-3-60 ODP HIGH 1800RPM BALDOR M2551T-5

60 HIGH ODP 575 100 1800 024-27020-000 MTR 100HP 575-3-60 ODP HIGH 1800RPM BALDOR M2555T-5

60 HIGH TEFC 575 1 1800 024-27037-000 MTR 1HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3546T-5

60 HIGH TEFC 575 1.5 1800 024-27038-000 MTR 1.5HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3554T-5

60 HIGH TEFC 575 2 1800 024-27039-000 MTR 2HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3558T-5

60 HIGH TEFC 575 3 1800 024-27040-000 MTR 3HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3611T-5

60 HIGH TEFC 575 5 1800 024-27041-000 MTR 5HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3615T-5

60 HIGH TEFC 575 7.5 1800 024-27042-000 MTR 7.5HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3710T-5

60 HIGH TEFC 575 10 1800 024-27043-000 MTR 10HP 575-3-60 TEFC HIGH 1800RPM BALDOR M3714T-5

60 HIGH TEFC 575 15 1800 024-27044-000 MTR 15HP 575-3-60 TEFC HIGH 1800RPM BALDOR M2333T-5

60 HIGH TEFC 575 20 1800 024-27045-000 MTR 20HP 575-3-60 TEFC HIGH 1800RPM BALDOR M2334T-5

60 HIGH TEFC 575 25 1800 024-27046-000 MTR 25HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4103T-5

60 HIGH TEFC 575 30 1800 024-27047-000 MTR 30HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4104T-5

60 HIGH TEFC 575 40 1800 024-27048-000 MTR 40HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4110T-5

60 HIGH TEFC 575 50 1800 024-27049-000 MTR 50HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4115T-5

60 HIGH TEFC 575 60 1800 024-27050-000 MTR 60HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4314T-5

60 HIGH TEFC 575 75 1800 024-27051-000 MTR 75HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4316T-5

60 HIGH TEFC 575 100 1800 024-27052-000 MTR 100HP 575-3-60 TEFC HIGH 1800RPM BALDOR M4400T-5

60 PREM ODP 200 3 1800 024-27054-000 MTR 3HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3211T-8

60 PREM ODP 460 3 1800 024-27055-000 MTR 3HP 460-3-60 ODP PREM 1800RPM BALDOR EM3211T

60 PREM ODP 230/460 3 1800 024-27055-000 MTR 3HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3211T

RPM

NOM

PART

NUMBER DESCRIPTION

YORK INTERNATIONAL

Continued on next page

23

FORM 102.20-RP1(1104)

FAN MOTORS (CONTINUED)

HERTZ EFF TYPE VOLT. HP

60 PREM ODP 200 5 1800 024-27056-000 MTR 5HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3218T-8

60 PREM ODP 230/460 5 1800 024-27057-000 MTR 5HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3218T

60 PREM ODP 200 7.5 1800 024-27058-000 MTR 7.5HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3311T-8

60 PREM ODP 230/460 7.5 1800 024-27059-000 MTR 7.5HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3311T

60 PREM ODP 200 10 1800 024-27060-000 MTR 10HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3313T-8

60 PREM ODP 230/460 10 1800 024-27062-000 MTR 10HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3313T

60 PREM ODP 200 15 1800 024-27063-000 MTR 15HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2513T-8

60 PREM ODP 230/460 15 1800 024-27064-000 MTR 15HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2513T

60 PREM ODP 200 20 1800 024-27065-000 MTR 20HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2515T-8

60 PREM ODP 230/460 20 1800 024-27066-000 MTR 20HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2515T

60 PREM ODP 200 25 1800 024-27067-000 MTR 25HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2531T-8

60 PREM ODP 230/460 25 1800 024-27068-000 MTR 25HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2531T

60 PREM ODP 200 30 1800 024-27069-000 MTR 30HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2535T-8

60 PREM ODP 230/460 30 1800 024-27070-000 MTR 30HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2535T

60 PREM ODP 200 40 1800 024-27071-000 MTR 40HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2539T-8

60 PREM ODP 230/460 40 1800 024-27072-000 MTR 40HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2539T

60 PREM ODP 200 50 1800 024-27073-000 MTR 50HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2543T-8

60 PREM ODP 230/460 50 1800 024-27074-000 MTR 50HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2543T

60 PREM ODP 200 60 1800 024-27075-000 MTR 60HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2547T-8

60 PREM ODP 230/460 60 1800 024-27076-000 MTR 60HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2547T

60 PREM ODP 200 75 1800 024-27077-000 MTR 75HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2551T-8

60 PREM ODP 230/460 75 1800 024-27078-000 MTR 75HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM2551T

60 PREM ODP 200 100 1800 024-27079-000 MTR 100HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM2555T-8

60 PREM ODP 460 100 1800 024-27080-000 MTR 100HP 460-3-60 ODP PREM 1800RPM BALDOR EM2555T-4

60 PREM TEFC 200 3 1800 024-27081-000 MTR 3HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3661T-8

60 PREM TEFC 230/460 3 1800 024-27082-000 MTR 3HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3611T

60 PREM TEFC 200 5 1800 024-27083-000 MTR 5HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3665T-8

60 PREM TEFC 230/460 5 1800 024-27084-000 MTR 5HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3615T

60 PREM TEFC 200 7.5 1800 024-27085-000 MTR 7.5HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3770T-8

60 PREM TEFC 230/460 7.5 1800 024-27086-000 MTR 7.5HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3710T

60 PREM TEFC 200 10 1800 024-27087-000 MTR 10HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3774T-8

60 PREM TEFC 230/460 10 1800 024-27088-000 MTR 10HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3714T

60 PREM TEFC 200 15 1800 024-27089-000 MTR 15HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM2333T-8

60 PREM TEFC 230/460 15 1800 024-27090-000 MTR 15HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM2333T

60 PREM TEFC 200 20 1800 024-27097-000 MTR 20HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM2334T-8

60 PREM TEFC 230/460 20 1800 024-27098-000 MTR 20HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM2334T

60 PREM TEFC 200 25 1800 024-27099-000 MTR 25HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM4103T-8

60 PREM TEFC 230/460 25 1800 024-27300-000 MTR 25HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM4103T

60 PREM TEFC 230/460 30 1800 024-27301-000 MTR 30HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM4104T

60 PREM TEFC 230/460 40 1800 024-27302-000 MTR 40HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM4110T

60 PREM TEFC 230/460 50 1800 024-27303-000 MTR 50HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM4115T

60 PREM TEFC 230/460 60 1800 024-27304-000 MTR 60HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM4314T

60 PREM TEFC 230/460 75 1800 024-27305-000 MTR 75HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM4316T

60 PREM TEFC 460 100 1800 024-27306-000 MTR 100HP 460-3-60 TEFC PREM 1800RPM BALDOR ECP4400T-4

60 PREM TEFC 575 1 1800 024-27307-000 MTR 1HP 575-3-60 TEFC PREM 1800RPM BALDOR EM3546T-5

60 PREM TEFC 575 1.5 1800 024-27308-000 MTR 1.5HP 575-3-60 TEFC PREM 1800RPM BALDOR EM3554T-5

60 PREM TEFC 575 2 1800 024-27309-000 MTR 2HP 575-3-60 TEFC PREM 1800RPM BALDOR EM3558T-5

RPM

NOM

PART

NUMBER DESCRIPTION

24

Continued on next page

YORK INTERNATIONAL

FORM 102.20-RP1(1104)

FAN MOTORS (CONTINUED)

HERTZ EFF TYPE VOLT. HP

60 PREM TEFC 575 3 1800 024-27310-000 MTR 3HP 575-3-60 TEFC PREM 1800RPM BALDOR EM3611T-5

60 PREM TEFC 575 5 1800 024-27311-000 MTR 5HP 575-3-60 TEFC PREM 1800RPM BALDOR EM3615T-5

60 PREM TEFC 575 7.5 1800 024-27312-000 MTR 7.5HP 575-3-60 TEFC PREM 1800RPM BALDOR EM3710T-5

60 PREM TEFC 575 10 1800 024-27313-000 MTR 10HP 575-3-60 TEFC PREM 1800RPM BALDOR. EM3714T-5

60 PREM TEFC 575 15 1800 024-27314-000 MTR 15HP 575-3-60 TEFC PREM 1800RPM BALDOR EM2333T-5

60 PREM TEFC 575 25 1800 024-27316-000 MTR 25HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4103T-5

60 PREM ODP 230/460 1 1800 024-34400-000 MTR 1HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3116T

60 PREM ODP 575 1 1800 024-34402-000 MTR 1HP 575-3-60 ODP PREM 1800RPM BALDOR EM3116T-5

60 PREM ODP 200 1 1800 024-34403-000 MTR 1HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3116T-8

60 PREM TEFC 230/460 1 1800 024-34404-000 MTR 1HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3546T

60 PREM TEFC 200 1 1800 024-34406-000 MTR 1HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3546T-8

60 PREM ODP 230/460 2 1800 024-34407-000 MTR 2HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3157T

60 PREM ODP 575 2 1800 024-34409-000 MTR 2HP 575-3-60 ODP PREM 1800RPM BALDOR EM3157T-5

60 PREM ODP 200 2 1800 024-34410-000 MTR 2HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3157T-8

60 PREM TEFC 230/460 2 1800 024-34411-000 MTR 2HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3558T

60 PREM TEFC 200 2 1800 024-34413-000 MTR 2HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3558T-8

60 PREM ODP 575 3 1800 024-34414-000 MTR 3HP 575-3-60 ODP PREM 1800RPM BALDOR EM3211T-5

60 PREM ODP 575 5 1800 024-34415-000 MTR 5HP 575-3-60 ODP PREM 1800RPM BALDOR EM3218T-5

60 PREM ODP 575 7.5 1800 024-34416-000 MTR 7.5HP 575-3-60 ODP PREM 1800RPM BALDOR EM3311T-5

60 PREM ODP 575 10 1800 024-34417-000 MTR 10HP 575-3-60 ODP PREM 1800RPM BALDOR EM3313T-5

60 PREM ODP 230/460 1.5 1800 024-34419-000 MTR 1.5HP 230/460-3-60 ODP PREM 1800RPM BALDOR EM3154T

60 PREM ODP 575 1.5 1800 024-34420-000 MTR 1.5HP 575-3-60 ODP PREM 1800RPM BALDOR EM3154T-5

60 PREM ODP 200 1.5 1800 024-34421-000 MTR 1.5HP 200/208-3-60 ODP PREM 1800RPM BALDOR EM3154T-8

60 PREM TEFC 230/460 1.5 1800 024-34423-000 MTR 1.5HP 230/460-3-60 TEFC PREM 1800RPM BALDOR EM3554T

60 PREM TEFC 200 1.5 1800 024-34424-000 MTR 1.5HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM3554T-8

60 PREM ODP 575 15 1800 024-34425-000 MTR 15HP 575-3-60 ODP PREM 1800RPM BALDOR EM2513T-5

60 HIGH TEFC 200 20 1800 024-34426-000 MTR 20HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M2334T-8

60 PREM ODP 575 20 1800 024-34427-000 MTR 20HP 575-3-60 ODP PREM 1800RPM BALDOR EM2515T-5

60 PREM TEFC 575 20 1800 024-34428-000 MTR 20HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP2334T-5

60 HIGH TEFC 200 25 1800 024-34429-000 MTR 25HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M4103T-8

60 PREM ODP 575 25 1800 024-34430-000 MTR 25HP 575-3-60 ODP PREM 1800RPM BALDOR EM2531T-5

60 PREM ODP 575 30 1800 024-34431-000 MTR 30HP 575-3-60 ODP PREM 1800RPM BALDOR EM2535T-5

60 PREM TEFC 575 30 1800 024-34432-000 MTR 30HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4104T-5

60 PREM TEFC 200 30 1800 024-34433-000 MTR 30HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM4104T-8

60 HIGH TEFC 200 40 1800 024-34434-000 MTR 40HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M4110T-8

60 PREM ODP 575 40 1800 024-34435-000 MTR 40HP 575-3-60 ODP PREM 1800RPM BALDOR EM2539T-5

60 PREM TEFC 575 40 1800 024-34436-000 MTR 40HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4110T-5

60 PREM TEFC 200 40 1800 024-34437-000 MTR 40HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM4110T-8

60 HIGH TEFC 200 50 1800 024-34438-000 MTR 50HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR M4115T-8

60 PREM ODP 575 50 1800 024-34439-000 MTR 50HP 575-3-60 ODP PREM 1800RPM BALDOR EM2543T-5

60 PREM TEFC 575 50 1800 024-34440-000 MTR 50HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4115T-5

60 PREM TEFC 200 50 1800 024-34441-000 MTR 50HP 200/208-3-60 TEFC PREM 1800RPM BALDOR EM4115T-8

60 HIGH ODP 200 60 1800 024-34442-000 MTR 60HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2547T-8

60 HIGH TEFC 200 60 1800 024-34443-000 MTR 60HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR CUSTOM

60 PREM ODP 575 60 1800 024-34444-000 MTR 60HP 575-3-60 ODP PREM 1800RPM BALDOR EM2547T-5

60 PREM TEFC 200 60 1800 024-34445-000 MTR 60HP 200/208-3-60 TEFC PREM 1800RPM BALDOR CUSTOM

60 PREM TEFC 575 60 1800 024-34446-000 MTR 60HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4314T-5

RPM

NOM

PART

NUMBER DESCRIPTION

YORK INTERNATIONAL

Continued on next page

25

FORM 102.20-RP1(1104)

FAN MOTORS (CONTINUED)

HERTZ EFF TYPE VOLT. HP

60 HIGH ODP 200 75 1800 024-34447-000 MTR 75HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2551T-8

60 HIGH TEFC 200 75 1800 024-34448-000 MTR 75HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR CUSTOM

60 PREM ODP 575 75 1800 024-34449-000 MTR 75HP 575-3-60 ODP PREM 1800RPM BALDOR 44WGW126

60 PREM TEFC 200 75 1800 024-34450-000 MTR 75HP 200/208-3-60 TEFC PREM 1800RPM BALDOR CUSTOM

60 PREM TEFC 575 75 1800 024-34451-000 MTR 75HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4316T-5

60 HIGH ODP 200 100 1800 024-34452-000 MTR 100HP 200/208-3-60 ODP HIGH 1800RPM BALDOR M2555T-8

60 HIGH TEFC 200 100 1800 024-34453-000 MTR 100HP 200/208-3-60 TEFC HIGH 1800RPM BALDOR CUSTOM

60 PREM ODP 230/460 100 1800 024-34454-000 MTR 100HP 230/460-3-60 ODP PREM 1800RPM BALDOR 16WGW559

60 PREM ODP 575 100 1800 024-34455-000 MTR 100HP 575-3-60 ODP PREM 1800RPM BALDOR 16WGW614

60 PREM TEFC 200 100 1800 024-34456-000 MTR 100HP 200/208-3-60 TEFC PREM 1800RPM BALDOR CUSTOM

60 PREM TEFC 230/460 100 1800 024-34457-000 MTR 100HP 230/460-3-60 TEFC PREM 1800RPM BALDOR CUSTOM

60 PREM TEFC 575 100 1800 024-34458-000 MTR 100HP 575-3-60 TEFC PREM 1800RPM BALDOR ECP4400T-5

50 HIGH TEFC 380 1 1500 024-34459-000 MTR 1HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3546T-50

50 HIGH ODP 380 1 1500 024-34460-000 MTR 1HP 380-3-50 ODP HIGH 1500RPM BALDOR M3116T-50

50 HIGH ODP 380 1.5 1500 024-34461-000 MTR 1.5HP 380-3-50 ODP HIGH 1500RPM BALDOR M3154T-50

50 HIGH ODP 380 2 1500 024-34462-000 MTR 2HP 380-3-50 ODP HIGH 1500RPM BALDOR M3157T-50

50 HIGH TEFC 380 5 1500 024-34463-000 MTR 5HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3615T-50

50 HIGH TEFC 380 7.5 1500 024-34464-000 MTR 7.5HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3710T-50

50 HIGH ODP 380 10 1500 024-34466-000 MTR 10HP 380-3-50 ODP HIGH 1500RPM BALDOR M3313T-50

50 HIGH ODP 380 15 1500 024-34467-000 MTR 15HP 380-3-50 ODP HIGH 1500RPM BALDOR M2513T-50

50 HIGH ODP 380 20 1500 024-34468-000 MTR 20HP 380-3-50 ODP HIGH 1500RPM BALDOR M2515T-50

50 HIGH ODP 380 25 1500 024-34469-000 MTR 25HP 380-3-50 ODP HIGH 1500RPM BALDOR 39X214

50 HIGH ODP 380 30 1500 024-34470-000 MTR 30HP 380-3-50 ODP HIGH 1500RPM BALDOR 40W989

50 HIGH ODP 380 40 1500 024-34471-000 MTR 40HP 380-3-50 ODP HIGH 1500RPM BALDOR 40W473

50 HIGH ODP 380 50 1500 024-34472-000 MTR 50HP 380-3-50 ODP HIGH 1500RPM BALDOR 40W565

50 HIGH ODP 380 60 1500 024-34473-000 MTR 60HP 380-3-50 ODP HIGH 1500RPM BALDOR 42W598

50 HIGH ODP 380 75 1500 024-34474-000 MTR 75HP 380-3-50 ODP HIGH 1500RPM BALDOR 42W502

50 HIGH ODP 380 100 1500 024-34475-000 MTR 100HP 380-3-50 ODP HIGH 1500RPM BALDOR 44W096

50 HIGH TEFC 380 1.5 1500 024-34819-000 MTR 1.5HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3554T-50

50 HIGH TEFC 380 2 1500 024-34820-000 MTR 2HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3558T-50

50 HIGH TEFC 380 3 1500 024-34821-000 MTR 3HP 380-3-50 TEFC HIGH 1500RPM BALDOR M3611T-50

50 HIGH TEFC 380 20 1500 024-34822-000 MTR 20HP 380-3-50 TEFC HIGH 1500RPM BALDOR M2334T-50

50 HIGH TEFC 380 25 1500 024-34823-000 MTR 25HP 380-3-50 TEFC HIGH 1500RPM BALDOR M4103T-50

50 HIGH TEFC 380 30 1500 024-34824-000 MTR 30HP 380-3-50 TEFC HIGH 1500RPM BALDOR M4104T-50

50 HIGH TEFC 380 40 1500 024-34825-000 MTR 40HP 380-3-50 TEFC HIGH 1500RPM BALDOR M4110T-50

50 HIGH TEFC 380 50 1500 024-34826-000 MTR 50HP 380-3-50 TEFC HIGH 1500RPM BALDOR M4115T-50

50 HIGH TEFC 380 60 1500 024-34827-000 MTR 60HP 380-3-50 TEFC HIGH 1500RPM BALDOR M4314T-50

50 HIGH TEFC 380 75 1500 024-34828-000 MTR 75HP 380-3-50 TEFC HIGH 1500RPM BALDOR 14X116

50 HIGH TEFC 380 100 1500 024-34829-000 MTR 100HP 380-3-50 TEFC HIGH 1500RPM BALDOR 16W740

RPM

NOM

PART

NUMBER DESCRIPTION

26

YORK INTERNATIONAL

MOTOR WIRING PARTS

FORM 102.20-RP1(1104)

WIRE CONNECTORS

PART NUMBER MOTOR

VOLTAGE

025-39042-001 200/208V 1,2,3 3

230/240V 1,2,3 4

460V 1,2,3,5,7.5 6

025-39042-003 200/208V 5 3

230/240V 5,7.5,10 4

460V 10,15 6

025-39043-001 200/208V 7.5,10 4

200/208V 15,20 3

230/240V 15,20,25 3

460V 20,25,30,40,50 6

025-39043-002 460V 60,75 6

025-39043-003 460V 100 6

025-39044-001 230/240V 10 3

025-39044-002 200/208V 25,30,40 3

230/240V 30,40,50 3

HP QTY

FLEXIBLE CABLE SLEEVES

PART NUMBER MOTOR

VOLTAGE

025-39049-001 200/208V 7.5,10,15 3

230/240V 10 3

230/240V 15 6

460V 20,25,30,40 3

025-39049-002 200/208V 20 6

200/208V 25 9

230/240V 20,25 6

460V 50 12

025-39049-003 200/208V 30 3

230/240V 30 9

230/240V 40 12

460V 60,75 12

025-39049-004 200/208V 40 9

230/240V 50 12

460V 100 12

HP QTY

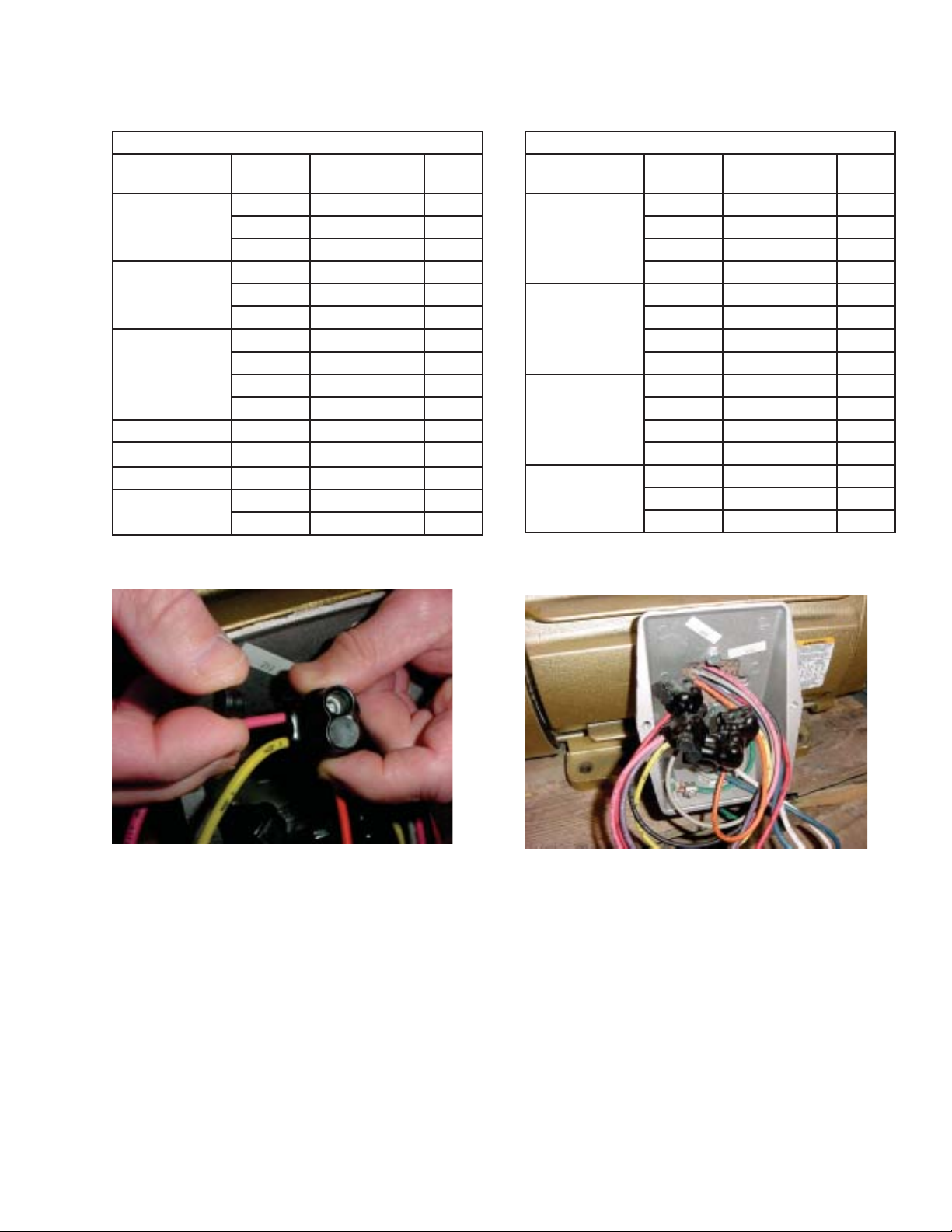

FIG. 6 - ASSEMBLY OF CONNECTORS

YORK INTERNATIONAL

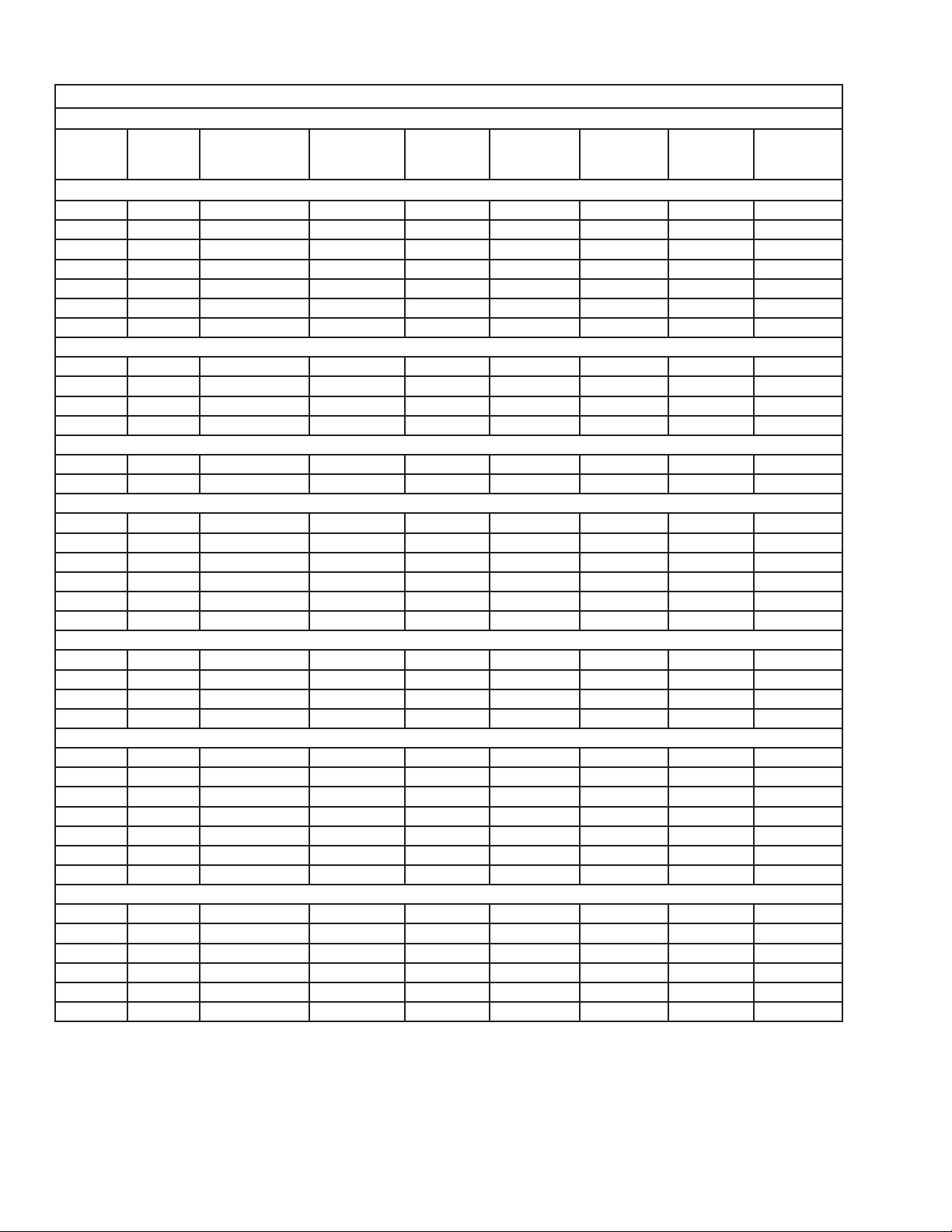

FIG. 7 - MOTOR WIRE CONNECTIONS

27

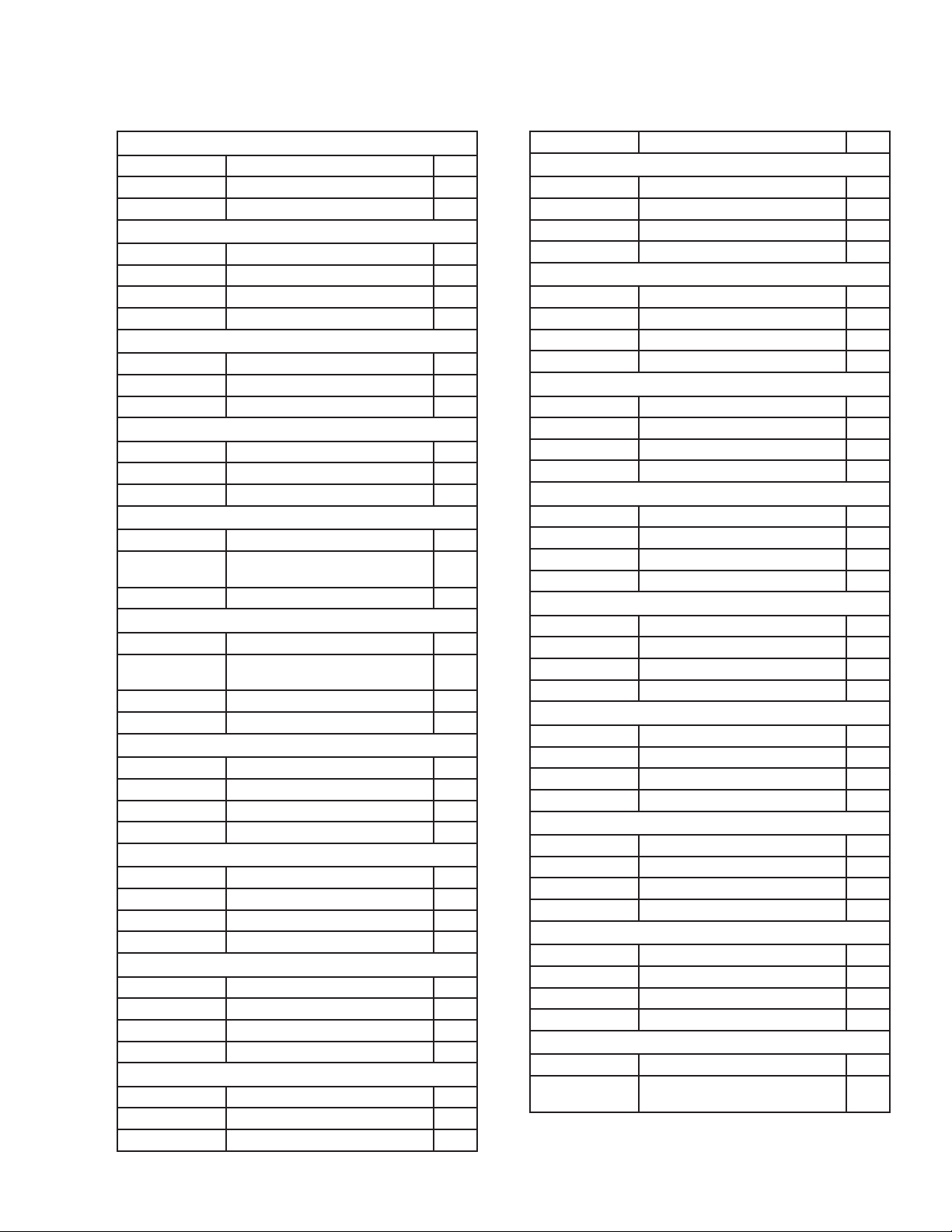

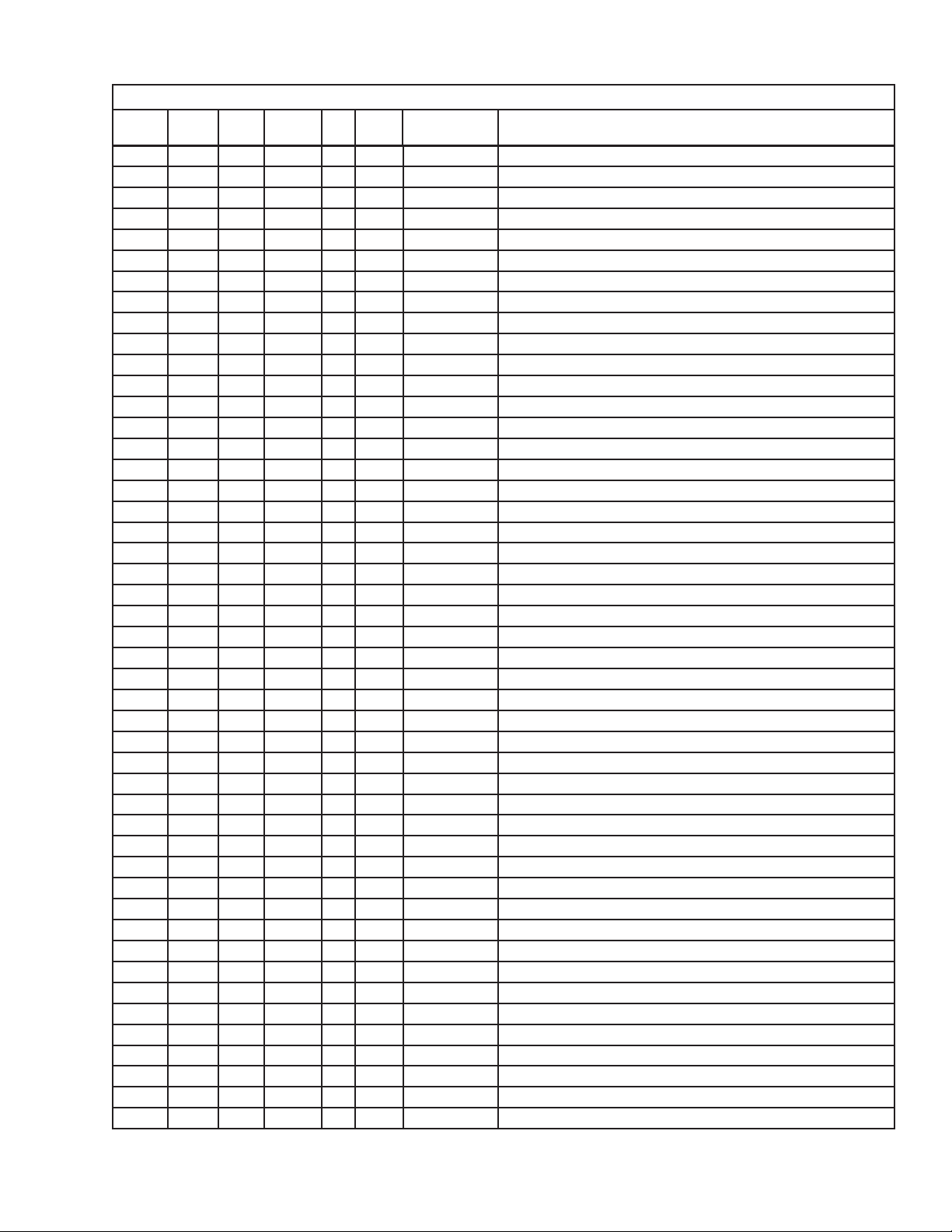

ADJUSTABLE MOTOR BASES

FORM 102.20-RP1(1104)

Frame

Size

143T 1 386-23937-001 FC7-7 FC9-6 FC10-7 PL121

145T 2 386-23937-001 FC7-7 FC9-6 FC10-7 PL121

182T 3 386-23937-001 FC7-7 FC9-6 FC10-7 PL121

184T 5 386-23937-001 FC7-7 FC9-6 FC10-7 PL121

182T 3 386-23940-001 FC9-9 FC10-10 FC12-9 PL141 PL161

184T 5 386-23940-001 FC9-9 FC10-10 FC12-9 PL141 PL161

143T 1 386-23943-001 FC9-9 FC10-10 FC12-9 PL141 PL161

145T 2 386-23943-001 FC9-9 FC10-10 FC12-9 PL141 PL161

213T 7.5 386-23943-001 FC9-9 FC10-10 FC12-9 PL141 PL161

215T 10 386-23943-001 PL161

213T 7.5 386-23946-001 AF-FC12-12 FC15-11 AF-FC15-15 FC18-13 AF-FC18-18 BAF122

215T 10 386-23946-001 AF-FC12-12 FC15-11 AF-FC15-15 FC18-13 AF-FC18-18 BAF122

143T 1 386-23949-001 AF-FC12-12 FC15-11 AF-FC15-15 BAF122

145T 2 386-23949-001 AF-FC12-12 FC15-11 AF-FC15-15 FC18-13 AF-FC18-18 BAF122

182T 3 386-23949-001 AF-FC12-12 FC15-11 AF-FC15-15 FC18-13 AF-FC18-18 BAF122

184T 5 386-23949-001 AF-FC12-12 FC15-11 AF-FC15-15 FC18-13 AF-FC18-18 BAF122

254T 15 386-23949-001 AF-FC12-12 FC15-11 AF-FC15-15 FC18-13 AF-FC18-18 BAF122

256T 20 386-23949-001 AF-FC18-18

MotorHPAssembly Base

P/N

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

213T 7.5 386-23952-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

215T 10 386-23952-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

284T 25 386-23952-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

286T 30 386-23952-001 AF-FC20-20 BAF200 BAF222 BAF245

143T 1 386-23956-001

145T 2 386-23956-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

182T 3 386-23956-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

184T 5 386-23956-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

254T 15 386-23956-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

256T 20 386-23956-001 FC20-15 AF-FC20-20 BAF182 BAF200 BAF222 BAF245

324T 40 386-23956-001 BAF222 BAF245

213T 7.5 386-23960-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

215T 10 386-23960-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

284T 25 386-23960-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

286T 30 386-23960-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

364T 60 386-23960-001 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

365T 75 386-23960-001 AF-FC32-32 AF-FC36-36 AF-FC40-40

28

Continued on next page

YORK INTERNATIONAL

ADJUSTABLE MOTOR BASES (CONTINUED)

FORM 102.20-RP1(1104)

Frame

Size

143T 1 386-23965-001 AF-FC28-28 AF-FC32-32

145T 2 386-23965-001 AF-FC28-28 AF-FC32-32

182T 3 386-23965-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32

184T 5 386-23965-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

254T 15 386-23965-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

256T 20 386-23965-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

324T 40 386-23965-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

326T 50 386-23965-001 AF-FC22-22 AF-FC25-25 AF-FC28-28 AF-FC32-32 AF-FC36-36 AF-FC40-40

404T 100 386-23965-001 AF-FC40-40

405T 125 386-23965-001

213T 7.5 386-23946-001 BAF135 BAF150 BAF165 PL181 PL201

215T 10 386-23946-001 BAF135 BAF150 BAF165 PL181 PL201

143T 1 386-23949-001 BAF135 BAF150 BAF165 PL181

145T 2 386-23949-001 BAF135 BAF150 BAF165 PL181 PL201

182T 3 386-23949-001 BAF135 BAF150 BAF165 PL181 PL201

184T 5 386-23949-001 BAF135 BAF150 BAF165 PL181 PL201

254T 15 386-23949-001 BAF135 BAF150 BAF165 PL181 PL201

256T 20 386-23949-001 BAF150 BAF165 PL181 PL201

MotorHPAssembly Base

P/N

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

213T 7.5 386-23952-001 BAF270 PL221 PL251 PL281

215T 10 386-23952-001 BAF270 PL221 PL251 PL281

284T 25 386-23952-001 BAF270 PL221 PL251 PL281

286T 30 386-23952-001 BAF270 PL251 PL281

143T 1 386-23956-001 PL251 PL281

145T 2 386-23956-001 PL221 PL251 PL281

182T 3 386-23956-001 BAF270 PL221 PL251 PL281

184T 5 386-23956-001 BAF270 PL221 PL251 PL281

254T 15 386-23956-001 BAF270 PL221 PL251 PL281

256T 20 386-23956-001 BAF270 PL221 PL251 PL281

324T 40 386-23956-001 BAF270 PL251 PL281

326T 50 386-23956-001 BAF270 PL281

213T 7.5 386-23960-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

215T 10 386-23960-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

284T 25 386-23960-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

286T 30 386-23960-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

364T 60 386-23960-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

365T 75 386-23960-001 BAF330 BAF365 BAF402 BAF445

YORK INTERNATIONAL

Continued on next page

29

ADJUSTABLE MOTOR BASES (CONTINUED)

FORM 102.20-RP1(1104)

Frame

Size

143T 1 386-23965-001

145T 2 386-23965-001 PL321

182T 3 386-23965-001 BAF300 BAF330 BAF365 BAF402 PL321

184T 5 386-23965-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

254T 15 386-23965-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

256T 20 386-23965-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

324T 40 386-23965-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

326T 50 386-23965-001 BAF300 BAF330 BAF365 BAF402 BAF445 PL321

404T 100 386-23965-001 BAF365 BAF402 BAF445

405T 125 386-23965-001

213T 7.5 386-23960-001 PL351

215T 10 386-23960-001 PL351 PL391 PL441 PL491 PL551

284T 25 386-23960-001 PL351 PL391 PL441 PL491 PL551

286T 30 386-23960-001 PL351 PL391 PL441 PL491 PL551

364T 60 386-23960-001 PL351 PL391 PL441 PL491 PL551

365T 75 386-23960-001 PL351 PL391 PL441 PL491 PL551

143T 1 386-23965-001 PL351 PL391

145T 2 386-23965-001 PL351 PL391 PL441

182T 3 386-23965-001 PL351 PL391 PL441

184T 5 386-23965-001 PL351 PL391 PL441 PL491 PL551

254T 15 386-23965-001 PL351 PL391 PL441 PL491 PL551

256T 20 386-23965-001 PL351 PL391 PL441 PL491 PL551

324T 40 386-23965-001 PL351 PL391 PL441 PL491 PL551

326T 50 386-23965-001 PL351 PL391 PL441 PL491 PL551

404T 100 386-23965-001 PL391 PL441 PL491 PL551

405T 125 386-23965-001

MotorHPAssembly Base

P/N

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

Fan

Size/Type

See Fig. 9 "Securing Fans and Motors"

for proper hardware.

HOLD DOWN

BOLT ASSEMBLY

FIG. 8 - ADJUSTABLE MOTOR BASE

30

DRIVE BOLT ASSEMBLY

LDO9693

YORK INTERNATIONAL

COMEFRI FAN

DIRECTION OF AIR FLOW FOR: R, RI

(OPP. DIRECTION FOR F, FI)

FORM 102.20-RP1(1104)

INDUSTRIAL FAN

B

(SEE TABLES5&6) A

NOTES:

1. SECURING FANS:

COMEFRI FAN 7-7 - SEE TABLE 1.

COMEFRI FANS 9-6 TO 32-32 - SEE TABLE 2.

INDUSTRIAL FANS 122 TO 182 - SEE TABLE 2.

INDUSTRIAL FANS 200 TO 330 - SEE TABLE 3.

2. SECURING MOTOR BASES:

BASES USED WITH COMEFRI FANS 7-7 TO 12-9 - SEE TABLE 2.

ALL OTHER BASES - SEE TABLE 3.

DIRECTION OF AIRFLOW FOR

PLENUM FAN

MOTOR

NOTE 3

FRONT INLET

DRIVE

NOTE 1

B (SEETABLES5&6)

NOTE 2

MBS RL

ISO RL WITH STIFF

Spring RL

3. SECURING MOTORS:

1H.P.TO2H.P.MOTORS-SEETABLE1.

3 H.P. THROUGH 10 H.P. MOTORS - SEE TABLE 2.

15 H.P. MOTORS AND UP - SEE TABLE 3.

4. DIMENSION "A" IS THE DISTANCE FROM THE INSIDE EDGE OF

THE RAIL TO THE SIDE OF THE MOTOR BASE RAIL.

DIMENSION "B" IS THE DISTANCE FROM THE FAN'S FRAME TO

THE INSIDE EDGE OF THE END RAIL.

END RL