Page 1

FAN COIL

AIR CONDITIONERS

INSTALLATION, OPERATION, & MAINTENANCE

YCW Series

2-pipe, 4-pipe

or

2-pipe, cooling with electric heat

NEW RELEASE

MODELS: YCW SERIES

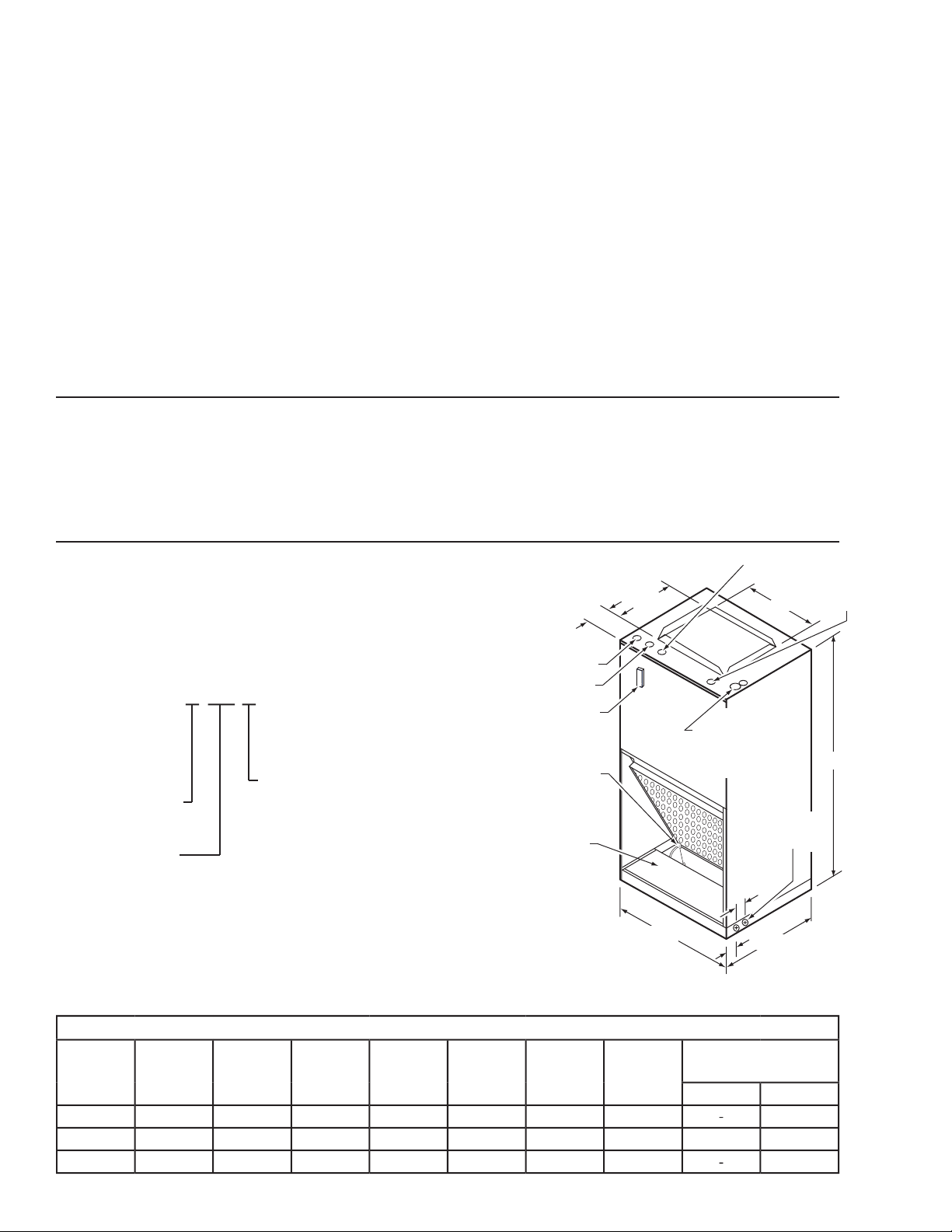

Basic YCW Series Unit

Form 115.20-NOM6 (1106)

LD11554

LD11555

YCWE with Bottom Return

Option (shown)

LD11556

Basic YCW Series with Optional

Notes:

1. For proper operation, control valve must be normally closed.

2. Aquastats provided where required.

3. Electric Heat is available as an option.

Wall Panel (shown)

***** WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER *****

Altering the product or replacing parts with non-authorized factory parts voids all warranty or

implied warranty and may result in adverse operational performance and/or a possible hazardous

safety condition to service personnel and occupants. Company employees and/or contractors are

not authorized to waive this warning.

Page 2

JOHNSON CONTROLS

2

FORM 115.20-NOM6 (1106)

TABLE OF CONTENTS

http://intranet.york.com/web0003/

F

D

C

B

2

1.75

A

DRAIN

KNOCKOUTS

(BOTH SIDES)

LOW VOLTAGE

HIGH VOLTAGE

OPTIONAL

OVERFLOW

SWITCH

OPENING WITH

COVER REMOVED:

6-3/8 X 18.5

DISCONNECT

E

SUPPLY AND

RETURN CHILLED

WATER LINES

(5/8"OD COPPER

STUBOUTS)

HOT WATER RETURN

HOT WATER

SUPPLY

A

YCW

YCW-HW

YCWE

10 YCW-31

CFM (100's)

3,4,6,8,10,12

Unit Style

YCW - 2-pipe

YCWE - 2-pipe

w/EH

YCW-HW - 4-pipe

Coil Type

3 - 3 Row

4 - 4 Row

31 - 3 Row Cool,

1 Row Heat

41 - 4 Row Cool,

1 Row Heat

............................................................................................................................................................

.....................................................................................................................................................

.....................................................................................................................................................

YCW UNIT STYLE

........................................................................................................................

WIRING

................................................................................................................................................................

.................................................................................................................................................................

..................................................................................................................................................

Page 3

RECEIVING

FORM 115.20-NOM6 (1106)

INSTALLATION

Material in this shipment has been inspected at the

factory and released to the transportation agency in

good condition. When received, a visual inspection of

all cartons should be made immediately. Any evidence

of rough handling or apparent damage should be noted

on the delivery receipt and the material inspected in

the presence of the carrier’s representative.

If damage is found, a claim should be

filed against the carrier immediately.

STORAGE

If the equipment is not to be immediately installed,

store it in a dry location with the motor protected

against moisture, dust, corrosion and physical damage.

If units are to be stored for six months or longer, see

long term storage requirements (Form 50.20-NM3).

DESCRIPTION

The YCW models are available as 2-pipe cooling

(YCW), 2-pipe cooling with electric heat (YCWE)

and a 4-pipe heating/cooling (YCW-HW). All units are

provided with a 3-speed fan control in the control box

in the fan section (left side), with 24v access on the top

panel, left. Manual and auto changeover thermostats

and the T200 auto speed control thermostats can be

used with this unit. Twenty-four volt (24 v) power is

provided in the unit for thermostat operation.

The 2-pipe cooling unit is provided with a single coil

with connections on the top panel, right side.

form (platform not provided), hung on a closet wall

(use wall hanging kit option) or recessed in a wall

between wall studs (use front panel kit option).

FEATURES

Non-corrosive drain pan, installed in sloped position,

¾” female primary and secondary connections accessible from either side or bottom.

Filters provided, are 1” throwaway accessible from

the front.

Coils and fan motor/blower assemblies accessible

from the front, when installed with the optional front

panel assembly.

Front air return standard, optional bottom return available but requires bottom return option.

Options available are thermostats, wall front panels,

condensate pan overflow switch, closet hanger bracket

kit, bottom return air kit and chilled water coil valve

packages. Consult applications group @ 717-7717073 for details on ordering and availability of these

options.

Cabinet is fully insulated with 1” coated fiberglass

panels.

All units have 0” clearance to combustible surfaces,

so the units can be installed against wall studs and

drywall.

CLEARANCES

The 2-pipe cooling with electric heat is provided

with a single chilled water coil and electric heat elements; coil connections are on the top panel, right

side; electrical connections are on the top panel, left

side and the units are provided with a disconnect on

the front panel.

The 4-pipe heating/cooling unit is provided with 2

coils with single end sheets – cooling connections are

on the top panel, right side and the hot water connections are on the top panel, middle front.

This unit is designed to be installed vertically in the

upflow position and can be installed on a closet plat-

JOHNSON CONTROLS

Clearance required in front of the unit to provide

access to coils, electrical controls and motor/blower

assembly. This clearance should be equal to the depth

of the cabinet.

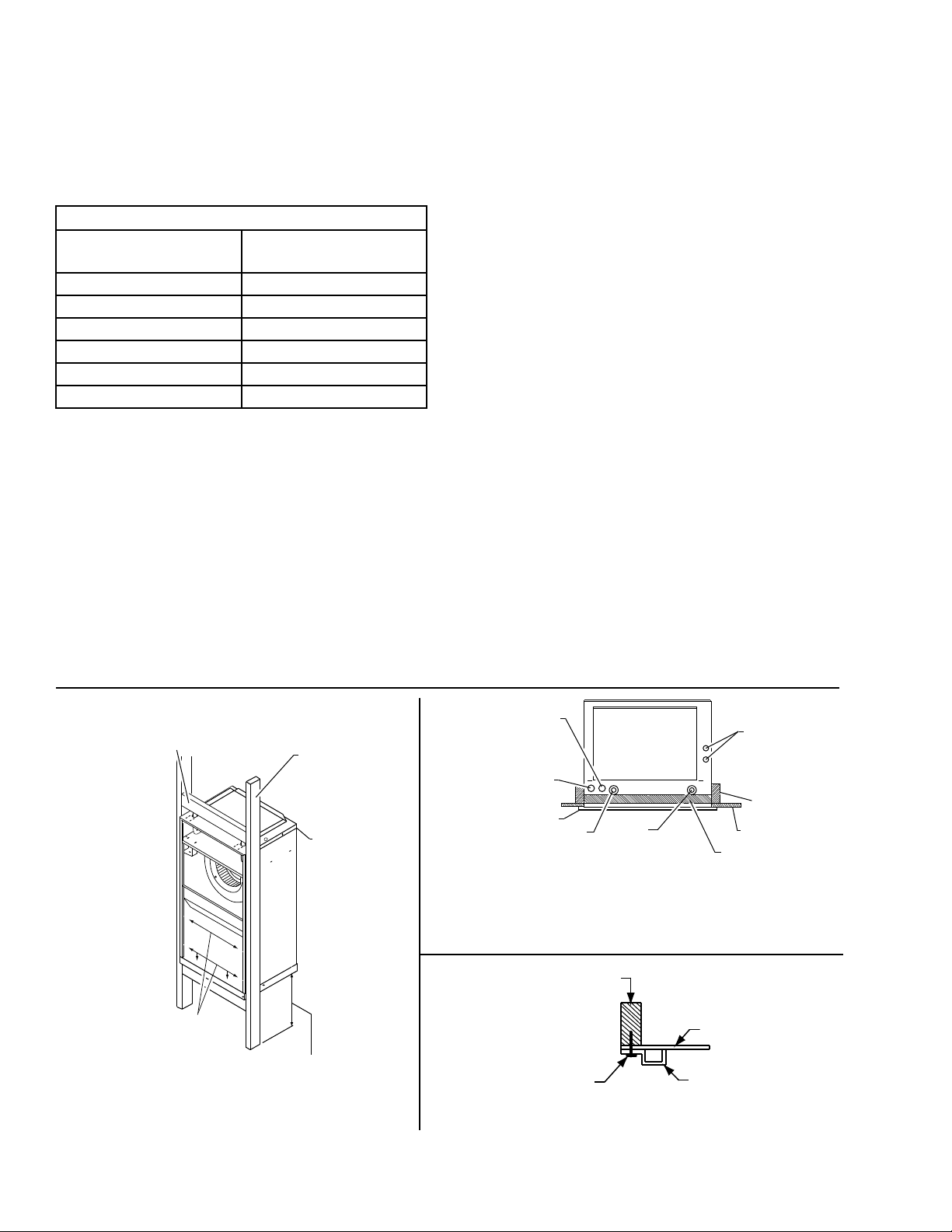

MOUNTING - YCW UNIT STYLE

Recessed In Wall

All units must be installed level to insure proper drainage and operation.

1. Frame the unit as required so the front panel

of the wall unit will be flush with the drywall

surface when installed (see Fig. 3).

3

Page 4

INSTALLATION

VERTICAL 2X 4

WALL STUDS

CLOSET MOUNT:

BRACKET

PLACEMENT

FOR HANGING

MOUNT UNIT

FLUSH WITH

DRY WALL (1/2"

MIN. IN FRONT

OF WALL STUD)

LEAVE SUFFICIENT SPACE

FOR DRAIN PIPING 10" TO 12"

MIN. RECOMMENDED

ATTACH UNIT TO FRAMING

USING SIX SCREWS/NAILS

IN CABINET LOCATIONS

SHOWN

CROSS MEMBER - TOP &

BOTTOM (PLACE UPPER CROSS

MEMBER 3" ABOVE UC UNIT)

SUPPORT FRAMING

RECESSED WALL UNIT TOP VIEW

THERMOSTAT

WIRING

POWER SUPPLY

WIRING

WALL PANEL FRAME

HOT

WATER

OUTLET

HOT

WATER

INLET

DRY WALL

2 X 4 WALL

STUD

CW UNITS:

CHILLED WATER

CONNECTION

Note: Front edge of unit to

be flush with dry wall.

CROSS MEMBER

(ON EDGE)

2 X 4 WALL STUD

WALL PANEL FRAME

SCREW

DETAIL OF WALL PANEL FRAME INSTALLATION

DRY WALL

FORM 115.20-NOM6 (1106)

2. Frame around the perimeter of the unit as

required for securing the drywall. See Table 1

below for drywall openings.

TABLE 1 - DRYWALL OPENINGS

MODEL NUMBER

3YWC 28 x 42

4YWC 28 x 50

6YWC 28 x 58

8YWC 28 x 66

10YWC 28 x 74

12YWC 28 x 82

DRYWALL CUTOUT DIM

HT x WD

3. Mount the unit in its permanent location, making

sure it is level to insure proper drainage and

operation (two 1/2” holes have been provided

on each end of the unit for securing the unit to

the wall studs).

4. After the drywall has been installed, recheck to

make sure the unit’s front panel is flush with the

exterior drywall surface. Shimming of the unit

may be required to get a seal between the unit

and panel.

5. Install the wall panel to the front of the unit using

the 1/4-20 x 1-1/2” long, painted, Phillips head

screws (four on unit sizes 3, 4, 6 and 8; six on

unit sizes 10 and 12) (1/4” cage nuts are located

in the slotted front panel of the unit).

6. Remove the lower return air grille to get access

to the filter.

7. See Fig. 2 for unit details and dimensions.

Hung on a Closet Wall

Unit can be mounted in a closet using the bracket

support option 90PK3.

These brackets mount to the top, back of the cabinet.

See Fig 3 for location.

The unit should be isolated from the wall to be sure

sound is not transferred from the unit to the wall.

Platform Mounted in a Closet

Unit can be set on a platform (provided by others) in

a closet.

Be sure to allow for sufficient space below the platform

for drain piping.

FIG. 3 – CW-HW RECESSED WALL and CLOSET

MOUNTING

4

LD11695A

JOHNSON CONTROLS

Page 5

DUCTWORK

FORM 115.20-NOM6 (1106)

INSTALLATION

Ductwork recommendations are as follows:

• Insulat e to pr event condensa tion during

cooling.

• Size to th e unit op enings ar e general ly

acceptable but are determined by the engineering

drawings.

• Be sure units are ducted per local codes or

national codes, as applicable.

WIRING

Units are provided with wiring diagrams and nameplate data to provide information required for necessary field wiring. All wiring must comply with local

and national code requirements.

Refer to Fig. 3 for access locations.

These units are provided with a class 2 transformer

for 24-volt control circuits. Should any add-on equipment also have a class 2 transformer furnished, care

must be taken to prevent interconnecting outputs of

the two transformers by using a thermostat with isolating contacts. These units are supplied with a 3-speed

control board.

The YCW units (2-pipe cooling) are provided as

standard 120 volt power wired to a disconnect/terminal

block and a ground lug. Fan motor hi, med and low

speed leads are wired to the control board. There may

be an unused motor lead from the motor – it needs to

be capped off. The board is also wired to handle either

24v or 120v control wiring. To use 24v, remove jumpers on the control board. To use a 24v chilled water

control valve, wire the valve in series with the “Y”

connection from the control box, max of 20va.

For 24v wiring using a T420 manual C/O, T421 auto

C/O or the T200 speed control thermostats, you will

need a 6-wire thermostat cable minimum.

The YCW-HW units (4-pipe heating/cooling) are

provided as standard 120 volt power wired to a disconnect/terminal block and a ground lug. Fan motor

hi, med and low speed leads are wired to the control

board. There may be an unused motor lead from the

motor – its needs to be capped off. The board is also

wired to handle either 24v or 120v control wiring. To

use 24v, remove jumpers on the control board. For

your 24v hot water control valve, wire it in series

with the “W” connection. For your 24v chilled water

control valve, wire it in series with the “Y” connection.

For 24v wiring using a T420 manual C/O, T421 auto

C/O or the T200 speed control thermostats, you will

need a 7-wire thermostat cable minimum.

The YCWE units (2-pipe cooling w/electric heat)

are provided as standard 208/240 volt power wired

to a disconnect switch with a ground lug. Fan motor

hi, med and low speed leads are wired to the control

board. There may be an unused motor lead from the

motor – its needs to be capped off. The board is also

wired to handle either 24v or 120v control wiring.

To use 24v, remove jumpers on the control board.

The transformer in the control box is 208/240v with

a common terminal, one for 208v and one for 240v.

Transformer is wired 240v from factory; for 208v application, move the ORG wire on the transformer to

the 208v terminal. For your 24v chilled water control

valve, wire it in series with the “Y” connection. When

using a T420 manual C/O, T421 auto C/O or the T200

speed control thermostats, you will need a 7-wire

thermostat cable minimum. See Table 2 for MCA and

MFS for each unit size/electric heat KW size.

Any devices such as fan switches or

thermostats that have been furnished

by the factory for field installation

must be wired in strict accordance with

the wiring diagram that is supplied

with the unit. Failure to do so could

result in damage or injury.

JOHNSON CONTROLS

5

Page 6

Table 2 - ELECTRICAL DATA

UNIT MODEL

240V 208V 240V 208V 240V 208V 240V 208V

0 0 0.0 1.1 N/A N/A N/A N/A N/A

1 1 0.8 5.3 4.7 7 6 15 15

4CWE

6CWE

8CWE

10CWE

2 2 1.5 9.4 8.3 12 11 15 15

3 3 2.3 13.6 11.9 17 15 20 15

4 4 3.0 17.8 15.5 23 20 25 20

0 0 0.0 1.1 N/A N/A N/A N/A N/A

2 2 1.5 9.4 8.3 12 11 15 15

3 3 2.3 13.6 11.9 17 15 20 15

4 4 3.0 17.8 15.5 23 20 25 20

5 5 3.8 21.9 19.1 28 24 30 25

6 6 4.5 26.1 22.7 33 29 35 30

0 0 0.0 1.7 N/A N/A N/A N/A N/A

3 3 2.3 14.2 12.5 18 16 20 20

4 4 3.0 18.4 16.1 23 21 25 25

5 5 3.8 22.5 19.7 29 25 30 25

6 6 4.5 26.7 23.5 34 30 35 30

8 8 6.0 35.0 30.5 44 39 50 40

0 0 0.0 2.7 N/A N/A N/A N/A N/A

3 3 2.3 15.2 13.5 19 17 20 20

5 5 3.8 23.5 20.7 30 26 30 30

6 6 4.5 27.7 24.3 35 31 35 35

8 8 6.0 36 31.5 45 40 50 40

10 10 7.5 44.4 38.8 56 49 60 50

KW TOTAL AMPS MIN. CIR. AMPACITY

FORM 115.20-NOM6 (1106)

MAX.OVERCURRENT

PROTECTION

6

JOHNSON CONTROLS

Page 7

PIPING

FORM 115.20-NOM6 (1106)

INSTALLATION

All piping connections are 5/8" OD copper tubing

(see Fig.4).

The supply and return piping must be adequately

sized to meet the design water flow requirements as

specified for the specific installation. All chilled water

piping must be insulated to prevent condensation. It

is also recommended that all piping be insulated to

prevent freezing when piping is run in an unconditioned space.

Coil freeze protection is recommended

for applications where the fan coil is

located in ambient air locations (attics,

crawl spaces, etc.) or within structures

that may be unoccupied during freezing conditions. Consult the factory for

additional information.

Piping Precautions

• Flush all piping prior to connection to remove

all debris.

• Use wet cotton rags to cool valve bodies when

soldering.

• Open all valves (midway for hand valves,

manually open on motorized valves) prior to

soldering.

• When soldering to bronze or brass, heat the piping

while in the socket/cup and begin introducing the

solder when the flux boils rapidly. Avoid direct

flame into the solder joint.

• Heat can only be applied to the cup of the valve

body for a minimal time before damage occurs

(even with the use of wet rags).

• Avoid rapid quenching of solder joints, as this

will produce joints of inferior quality.

• Connect all piping per accepted industry

standards and observe all regulations governing

installation of piping systems. When all

connections are complete, the system must be

pressure tested. Repair any solder joint leaks and

gently tighten any leaking valve packing nuts

and piping accessories as required. Hydronic

systems are not designed to hold pressurized air

and should only be tested with water.

When connecting piping or valve

kits to fan coil units, do not bend or

reposition the coil header tubing for

alignment purposes. This could cause

a tubing fracture resulting in a water

leak when water pressure is applied

to the system

JOHNSON CONTROLS

LD12277A

FIG. 4 – CW-HW SERIES UPFLOW WALL / CLOSET FAN COILS

4-Pipe Chilled Water-Hot Water (190 - 1085 CFM)

7

Page 8

INSTALLATION

CONDENSATE DRAIN CONNECTIONS

(With drain cover removed)

(Thermoplastic pan shown)

Drain Piping

Condensate drain lines must be installed with adequate

slope away from the unit to assure positive drainage.

Since the drain pan is located on the suction side of

the blower, a negative pressure exists at the drain pan

and a minimum trap of 1-1/2" must be provided in the

drain line to assure proper drainage.

Drain connections, primary and secondary, are 3/4"

MPT (see Fig. 5 for details).

FORM 115.20-NOM6 (1106)

On units with plastic drain pans the

drain connections must be made hand

tight only.

LD12278

FIG. 5 – CWE SERIES WALL / CLOSET FAN COILS

Chilled Water with Electric Heat

8

JOHNSON CONTROLS

Page 9

SEQUENCE OF OPERATION

YCW With a Chilled Water Coil

The unit will respond to a cooling command from

the thermostat by powering a water control valve

open. The fan will operate at the speed selected at the

thermostat. When the space reaches the temperature

setpoint at the thermostat, the cooling valve will close

and the fan will continue to operate.

When using the T420 manual C/O thermostat and the

TB3-3/TB2-5 jumper is in place, the fan will continue to operate at the fan speed selected. Removing

the jumper will cause the fan to shut down when the

thermostat is satisfied.

When using the T200 thermostat, the stat will automatically regulate the fan speed based on the difference between the space temp and setpoint - @ 4˚F off

setpoint, the fan will run @ HI; @ 3˚F off setpoint, the

fan will run @ MED; @ 2˚F off setpoint, the fan will

run @ LO. When the thermostat is satisfied, the water

valve will be deenergized and the fan will revert to

LO speed.

FORM 115.20-NOM6 (1106)

When using the T200 thermostat, the stat will automatically regulate the fan speed based on the difference between the space temp and setpoint - @ 4˚F off

setpoint, the fan will run @ HI; @ 3˚F off setpoint, the

fan will run @ MED; @ 2˚F off setpoint, the fan will

run @ LO. When the thermostat is satisfied, the water

valve will be deenergized and the fan will revert to

LO speed.

The YCWE With Both a Chilled Water Coil and

Electric Heating Coil.

The unit control thermostat, on a call for heating, will

energize the heater contactor(s). When the thermostat

is set for cooling, it will energize the chilled water

valve on a call for cooling. The fan will operate at

the speed selected at the thermostat. When the space

reaches the temperature setpoint at the thermostat,

the cooling valve will close (on cooling) or the heating contactors will open (on heating) and the fan will

continue to operate.

The YCW-HW with Both a Chilled Water Coil and a

Hot Water Coil.

The unit control thermostat, on a call for heating, will

energize the hot water control valve. When the thermostat is set for cooling, it will energize the chilled

water valve on a call for cooling. The fan will operate

at the speed selected at the thermostat. When the space

reaches the temperature setpoint at the thermostat, the

cooling valve will close (on cooling) or the heating

valve will close (on heating) and the fan will continue

to operate.

When using the T420 manual C/O thermostat and the

TB3-3/TB2-5 jumper is in place, the fan will continue to operate at the fan speed selected. Removing

the jumper will cause the fan to shut down when the

thermostat is satisfied.

When using the T421 auto C/O thermostat and the

TB3-3/TB2-5 jumper is in place, the fan will continue to operate at the fan speed selected. Removing

the jumper will cause the fan to shut down when the

thermostat is satisfied.

When using the T420 manual C/O thermostat and the

TB3-3/TB2-5 jumper is in place, the fan will continue to operate at the fan speed selected. Removing

the jumper will cause the fan to shut down when the

thermostat is satisfied.

When using the T421 auto C/O thermostat and the

TB3-3/TB2-5 jumper is in place, the fan will continue to operate at the fan speed selected. Removing

the jumper will cause the fan to shut down when the

thermostat is satisfied.

When using the T200 thermostat, the stat will automatically regulate the fan speed based on the difference between the space temp and setpoint - @ 4˚F off

setpoint, the fan will run @ HI; @ 3˚F off setpoint, the

fan will run @ MED; @ 2˚F off setpoint, the fan will

run @ LO. When the thermostat is satisfied, the water

valve will be deenergized (on cooling) or the heating

contactor will open (on heating) and the fan will revert

to LO speed.

JOHNSON CONTROLS

9

Page 10

MOTOR

FORM 115.20-NOM6 (1106)

MAINTENANCE

The blower motor should be cleaned annually and if it

has oiling ports, it should be oiled with a good grade

of SAE 20 oil. Normally a few drops of oil in each

bearing is sufficient.

COIL

The coil must be kept clean by any of the following

methods.

1. Cleaning with low-pressure compressed air.

2. Flushing or rinsing with water (a detergent is

advisable for greasy surfaces).

FILTERS

Clean or replace air filters regularly

The intervals at which filters require replacement

depend on local conditions.

Because of dust and lint in the room, room-air filters

load up much more rapidly than outdoor-air filters.

Under normal conditions, the room air filter requires

replacement every six to eight weeks.

To ensure proper maintenance of the filters, it is best

to follow an organized maintenance procedure. The

following one is recommended:

Divide the total number of units on the job into six

equal groups. Each week inspect, clean or replace

the filters in each group, in rotation. This insures

a uniform servicing interval. The interval may be

lengthened or shortened as determined by experience.

If inspection shows only the room-air filter to be dirty,

this one alone should be replaced.

Dirty filters reduce the air and heating

capacities of the unit. When the filters

are excessively dirty, the unit heating

capacity will be so reduced that it is ineffective for heating the room. When

a room fails to heat, always check the

filters.

CLEAN UNIT INTERIOR

Once a year clean the fans and coils of the unit thoroughly. Remove the access panel as necessary.

Wipe the interior of the unit clean with a rag. Wipe

the motor and inside and outside of the fan housings.

(In cooling units, clean out the drain pan.)

10

JOHNSON CONTROLS

Page 11

FORM 115.20-NOM6 (1106)

This Page Intentionally Left Blank

JOHNSON CONTROLS

11

Page 12

www.York.com

www.York.com

air fi lters are clean, installed properly and secured. Use the di rec tion al ar rows or oth er information on the fi lter to

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑ Ensure

❑ Ensure

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

Loading...

Loading...