Page 1

V

295421-YTG-B-0707

DESCRIPTION

This fan coil unit provides the flexibility for installation in any

upflow or horizontal application. These versatile models may

be used for split-system cooling or heat pump operation.

Compact cabinets along with return air options in both the

upflow and horizontal positions allow this unit to fit into tight

spaces such as attics, crawl spaces, and closets.

NOTE: For matching condensing units and performance

data, refer to condenser technical guides.

TECHNICAL GUIDE

SINGLE PIECE AIR HANDLERS

FOR USE WITH SPLIT-SYSTEM

COOLING & HEAT PUMPS

HEAT PUMP MODELS:

F*FP

VARIABLE SPEED MODEL:

F*FV

FEATURES

CABINET -The compact and sturdy cabinet is protected with

a durable, attractive finish to prevent rust. The cabinet is also

insulated to prevent cabinet sweating. F*FP and F*FV models have 3/4 inch insulation.

BLOWERS - Blowers are sized to circulate air both quietly

and efficiently. The direct-drive, multi-speed motors provide a

selection of air volume to match any application. Motor

speeds may be selected via quick connect terminal at the

motor. Slide-out blower/motor assemblies provide for easy

servicing.

COILS - Using the latest in heat transfer technology, the rifled

tube coil/aluminum fin coils produce high performance ratings

and provide long lasting quality. The coils are capable of bottom return air in the upflow position, and right or left end

return air in the horizontal position.

FACTORY INSTALLED TXV - Air handler models F*FP and

F*FV have factory installed TXV metering device.

ELECTRIC HEATERS - Models providing up to 25kw of heat

are available as field installed accessories. Electric heaters

are available in both single and three phase.

EASY INSTALLATION - These fan coil units are designed to

provide the lowest total installation cost. Accessible color

coded control wiring, top and side power wiring knockouts,

easy to install drain connections and electric heaters all combine to minimize installed cost on every job.

CONTROL BOARD - The control board is equipped with low

voltage terminal strips for easy installation. The control board

is also equipped with plug-in receptacles for the auxiliary

heaters.

ISO 9001

Certified Quality

Management System

Due to continuous product improvement, specific a t ion s

are subject to change without notice.

isit us on the web at www.york.com

Additional rating information can be foun d at

www.ari.org/aridirectory.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

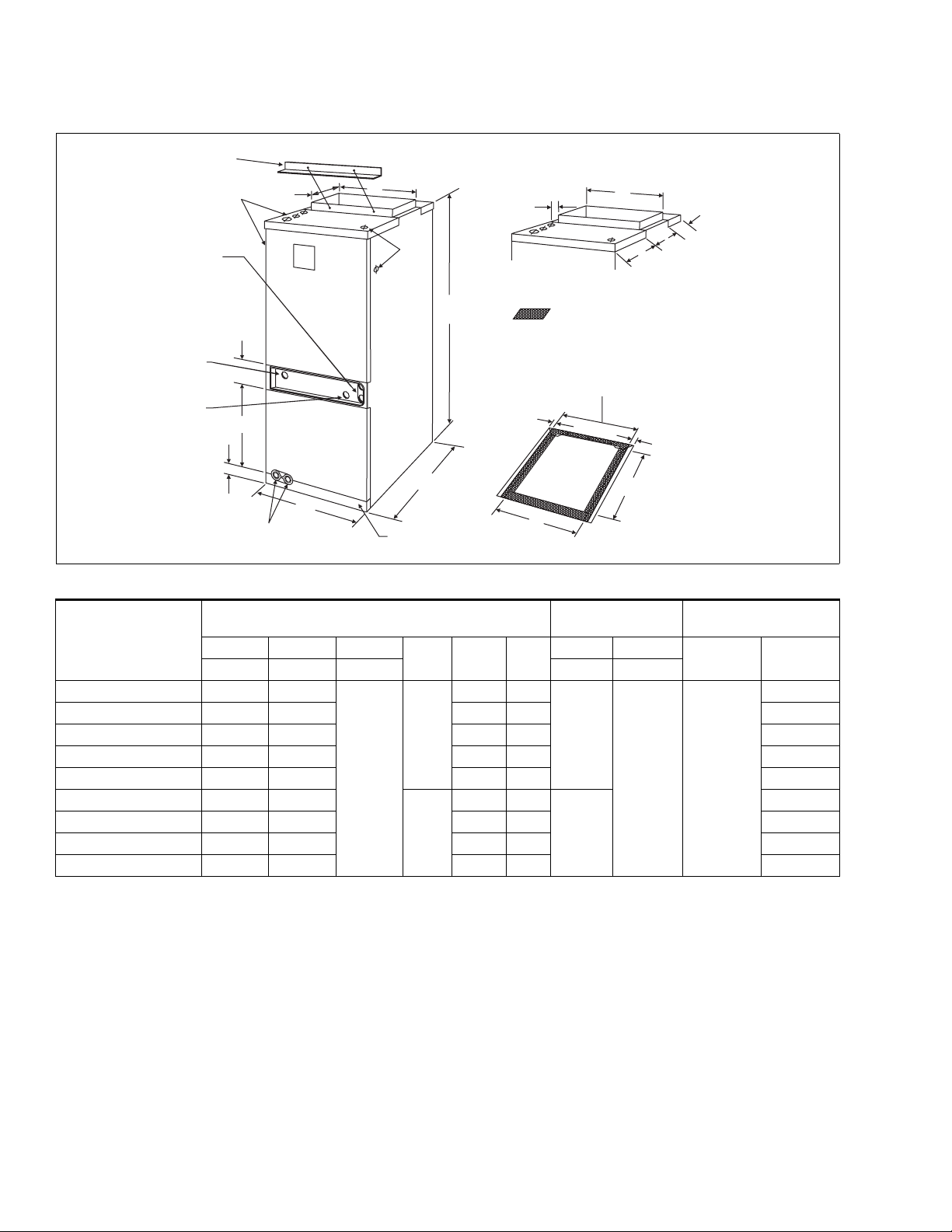

DIMENSIONS

295421-YTG-B-0707

SHIPPING BRACKET*

REMOVE PRIOR TO

INSTALLATION (2 SCREWS)

J

DRAIN CONNECTIONS

FOR HORIZONTAL

APPLICATIONS

4

VAPOR

OPENING

LIQUID

OPENING

D

2

DRAIN CONNECTIONS

FOR UPFLOW APPLICATIONS

10-3/8

ALL DIMENSIONS ARE IN INCHES. THEY ARE SUBJECT TO CHANGE

WITHOUT NOTICE. CERTIFIED DIMENSIONS WILL BE PROVIDED

F

K

C

B

FILTER

ACCESS

UPON REQUEST.

A

3/4

TOP VIEW (ALL MODELS)

=DRAIN PAN FOOTPRINT

MAX. FILTER LENGTH

(21 INCHES)

MAX. FILTER WIDTH

(B MINUS 1-1/2 INCHES)

3/4

E

REAR

BOTTOM VIEW

F

18-3/8

7-1/2

4-1/8

10-3/8

3/4

Refrigerant Connections

1

Line Size

Liquid Vapor

5/8

Model

ABC

Height Width Depth Power Control

F4FP024H06T2* 40-3/4 18

Dimensions

DEF

14-7/8 16-1/2

Wiring K.O.s

JK

F4FP030H06T2* 40-3/4 18 14-7/8 16-1/2 3/4

F4FP036H06T2* 40-3/4 21-1/2 18-3/8 20 3/4

12-1/8

7/8 (1/2)

1-3/8 (1)

F4FP040H06T2* 40-3/4 21-1/2 18-3/8 20 7/8

F4FP042H06T2* 40-3/4 21-1/2 18-3/8 20 7/8

F4FP045H06T2* 50-3/4 24

F5FP048H06T2* 50-3/4 24 20-7/8 22-1/2 7/8

F5FP060H06T2* 50-3/4 24 20-7/8 22-1/2 7/8

F4FV060H06T2* 50-3/4 24 20-7/8 22-1/2 7/8

1. Actual conduit size is shown in parenthesis.

2. All models only available with factory installed horizontal drain pan.

22

17-3/8

20-7/8 22-1/2

7/8 (1/2)

1-3/8(1)

1-23/32

(1-1/4)

7/8 (1/2) 3/8

7/8

2 Unitary Products Group

Page 3

295421-YTG-B-0707

COIL TECHNICAL DATA

Coil

Slab Size

HW

Tube

Geometry

Tube

Dia.

Fin. Type

1 x .886 3/8 Enhanced

Models Application

F4FP024H06T2A A/C & HP

Refrigerant

Connection

Type

Face

Area

(Sq. Ft.)

Deep

Rows

Fins

Per

Inch

3.40 2 14 14 17.5

F4FP024H06T2B A/C & HP 3.40 2 14 14 17.5 TXV-2B

F4FP030H06T2A A/C & HP 3.89 2 14 16 17.5 TXV-2A

F4FP036H06T2A A/C & HP 3.40 3 12 14 17.5

F4FP040H06T2A A/C & HP 3.89 3 11 16 17.5 TXV-2A

F4FP040H06T2C A/C & HP 3.89 3 11 16 17.5 TXV-2C

F4FP042H06T2A A/C & HP 3.89 3 11 16 17.5

Sweat

F4FP042H06T2C A/C & HP 3.89 3 11 16 17.5 TXV-2C

F4FP045H06T2C A/C & HP 5.83 3 12 24 17.5 TXV-2C

F5FP048H06T2C A/C & HP 5.35 3 12 22 17.5

F5FP060H06T2C A/C & HP 5.83 3 12 24 17.5 TXV-2C

F4FV060H06T2C A/C & HP 5.83 3 12 24 17.5

COOLING CAPACITY

Blower

Model

Rated

CFM

F4FP024H06T2* 830

F4FP030H06T2* 1050

F4FP036H06T2* 1250

F4FP040H06T2* 1050

F4FP042H06T2* 1400

F4FP045H06T2* 1400

F5FP048H06T2* 1600

F5FP060H06T2* 1850

4FV060H06T2*

F

1980

Entering

Air °F

(Dry / Wet Bulb)

Upflow / Horizontal Positions Only

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

85 / 72

80 / 67

75 / 62

70 / 57

MBH @ Evaporator Temperature and Corresponding Pressure °F /

PSIG

35 / 61.5 40 / 68.5 45 / 76.0 50 / 84.0

36.3

33.4

27.4

22.2

41.5

36.2

29.1

24.1

53.4

42.8

33.4

28.7

55.3

44.2

34.5

29.6

88.4

70.8

55.2

47.4

92.7

74.2

57.8

49.7

100.5

80.4

62.7

53.9

119.9

96.0

74.8

64.3

122.0

98.1

76.9

66.4

33.0

30.2

24.3

19.3

37.8

32.4

25.3

21.5

48.6

37.8

28.1

26.5

47.5

37.1

27.5

26.0

76.0

59.4

43.9

41.5

78.1

61.3

45.3

42.8

86.4

67.5

49.9

47.2

101.0

79.2

58.6

55.4

103.1

81.3

60.7

57.5

29.5

26.7

21.0

16.2

33.7

28.6

24.0

18.7

43.4

33.1

30.6

24.5

39.6

30.2

22.4

22.4

63.3

48.4

35.8

35.8

63.4

48.4

35.7

35.7

72.0

55.0

40.7

40.7

82.0

62.6

46.2

46.2

84.1

64.7

50.3

48.3

Metering

Device

TXV-2A

TXV-2A

TXV-2A

TXV-2C

TXV-2C

25.6

23.1

17.7

12.6

29.5

24.5

19.2

15.8

38.3

28.2

22.8

22.8

31.2

23.1

18.7

18.7

50.0

37.0

29.9

29.9

48.1

35.4

28.6

28.6

56.8

42.1

34.0

34.0

62.2

45.8

37.0

37.0

64.3

47.9

39.1

39.1

Unitary Products Group 3

Page 4

295421-YTG-B-0707

ACCESSORIES

Refer to Price Manual for specific model numbers.

VERTICAL SUSPENSION KIT - The suspension kit is

designed to be used with all sizes of fan coil units whenever

the application requires vertical suspension of the unit.

ELECTRIC HEATERS - Models shown under Electrical Data

include sequencers and temperature dual limit switches for

safe, efficient operation. Circuit breakers are provided where

shown.

BOLT-ON THERMAL EXPANSION VALVE - TXV kits are

available for enhanced efficiency. These fan coil units have

factory installed TXV’s.

LIMITATIONS

These units must be wired and installed in accordance with

all national and local safety codes. Voltage limits are as follows:

Normal Operating voltage Range

1. Utilization range “A” in accordance with ARI Std. 110.

1

Air flow must be within the minimum and maximum limits

approved for electric heat, evaporator coils and outdoor units:

Entering Air Temperature Limits

Wet Bulb Temp. ºF Dry Bulb Temp. ºF

Min. Max. Min. Max.

57 72 65 95

187-253

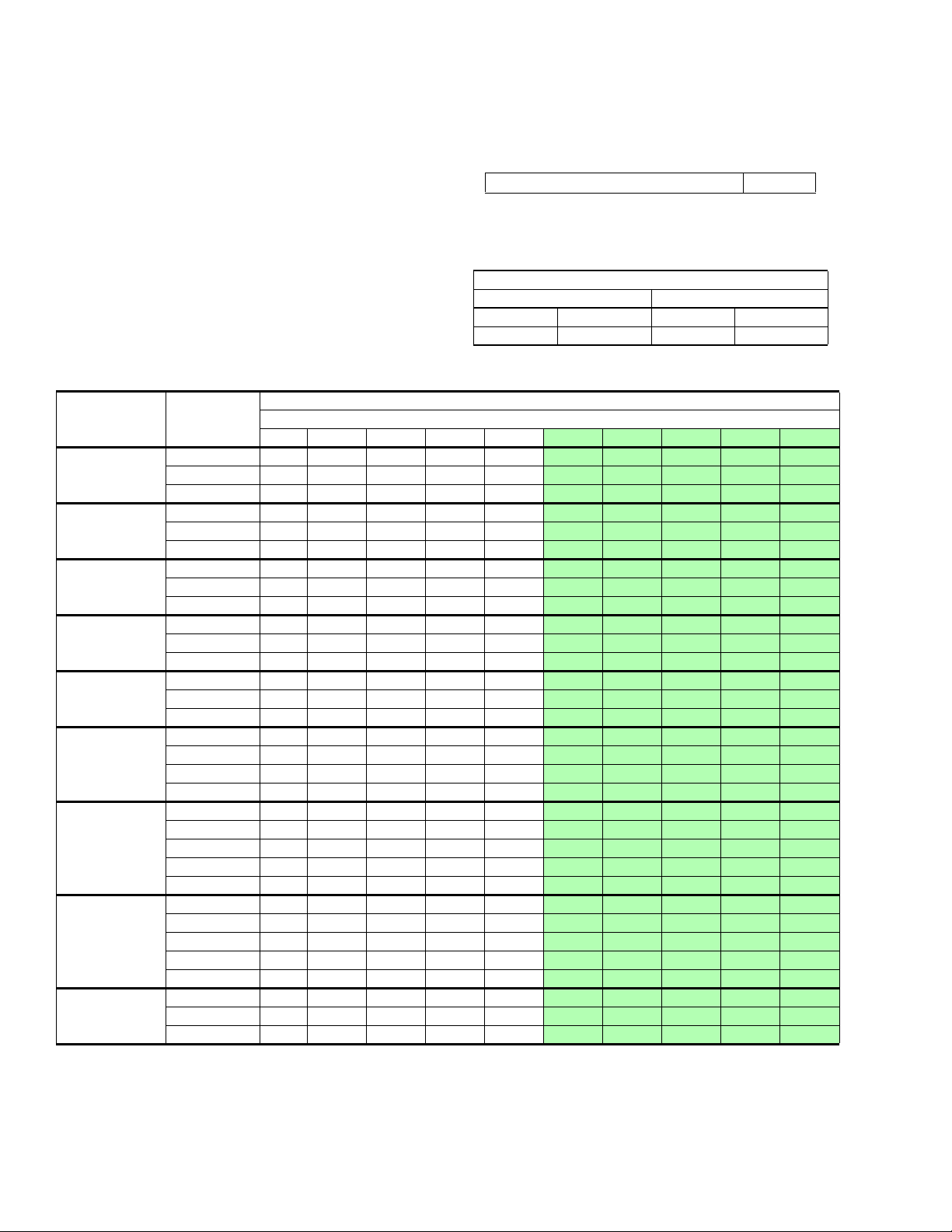

EXTENDED AIRFLOW DATA1 FOR 230 VOLT - HEAT PUMP MODELS

Models

F4FP024H06T2*

F4FP030H06T2*

F4FP036H06T2*

F4FP040H06T2*

F4FP042H06T2*

F4FP045H06T2*

F5FP048H06T2*

F5FP060H06T2*

F4FV060H06T2*

NOTE: Air flow data shown above 0.50” W.C. external static pressure is for REFERENCE ONLY. Maximum allowable external static when electric heat is used is

limited to 0.50” W.C. Maximum allowable external static pressure may also be limited by minimum CFM requirements for proper Heat Pump operation.

1. Includes Return Air Filter and Largest Electric Heater.

All F*FP series air handler units are UL Listed up to 0.50" w.c. external static pressure, including air filter, wet coil, and largest KW size heater.

Blower Motor

Speed

High 950 910 865 835 775

Med 845 815 785 745 705

Low 650 630 605 575 540

High 1,270 1,210 1,150 1,085 1,015

Med 1,050 1,040 995 930 855

Low 855 820 780 735 680

High - 1,310 1,250 1,175 1,120

Med 1,200 1,150 1,100 1,040 985

Low 1,060 1,015 970 925 860

High 1,270 1,210 1,150 1,085 1,015

Med 1,050 1,040 995 930 855

Low 855 820 780 735 680

High - 1,575 1,500 1,420 1,350

Med 1,460 1,395 1,330 1,260 1,190

Low 1,250 1,200 1,155 1,100 1,050

High 1,575 1,535 1,475 1,390 1,310

Med High 1,375 1,315 1,255 1,185 1,110

Med Low 1,210 1,160 1,110 1,050 980

Low 1,035 990 940 890 825

High 2223 2158 2090 2029 1929

Med High 1948 1904 1801 1815 1777

Med 1741 1690 1649 1606 1564

Med Low 1499 1454 1415 1370 1328

Low 1286 1233 1177 1142 1092

High 2195 2145 2070 2008 1920

Med High 1938 1899 1873 1824 1791

Med 1726 1681 1641 1607 1560

Med Low 1525 1483 1441 1383 1356

Low 1306 1254 1204 1160 1114

High 2,285 2,195 2,105 2,015 1,950

Med. 2,125 2,020 1,910 1,805 1,705

Low 1,655 1,605 1,550 1,500 1,450

0.10 0.20 0.30 0.40 0.50

CFM @ External Static Pressure - IWC

230 Volt

0.60 0.70 0.80 0.90 1.00

730 662 590 502 400

654 594 524 439 344

508 450 383 285 158

946 862 769 645 502

804 714 624 494 364

624 550 447 333 190

1,053 983 894 779 645

933 879 795 711 587

809 740 661 572 453

946 802 769 645 502

804 714 624 494 364

624 550 447 333 190

1,273 1,192 1,102 996 871

1,125 1,052 960 842 695

1,001 931 851 751 631

1,245 1,147 1,030 897 735

1,040 944 848 732 606

921 844 737 640 533

770 698 616 524 432

1861 1788 1679 1594 1501

1741 1681 1618 1539 1453

1516 1476 1436 1387 1353

1269 1228 1191 1132 1093

1039 987 960 888 842

1852 1754 1663 1570 1462

1724 1679 1603 1521 1420

1517 1485 1433 1402 1349

1291 1253 1208 1169 1123

1061 1008 980 914 876

1,845 1,770 1,685 1,590 1,485

1,597 1,491 1,386 1,280 1,175

1,398 1,326 1,245 1,153 1,052

4 Unitary Products Group

Page 5

295421-YTG-B-0707

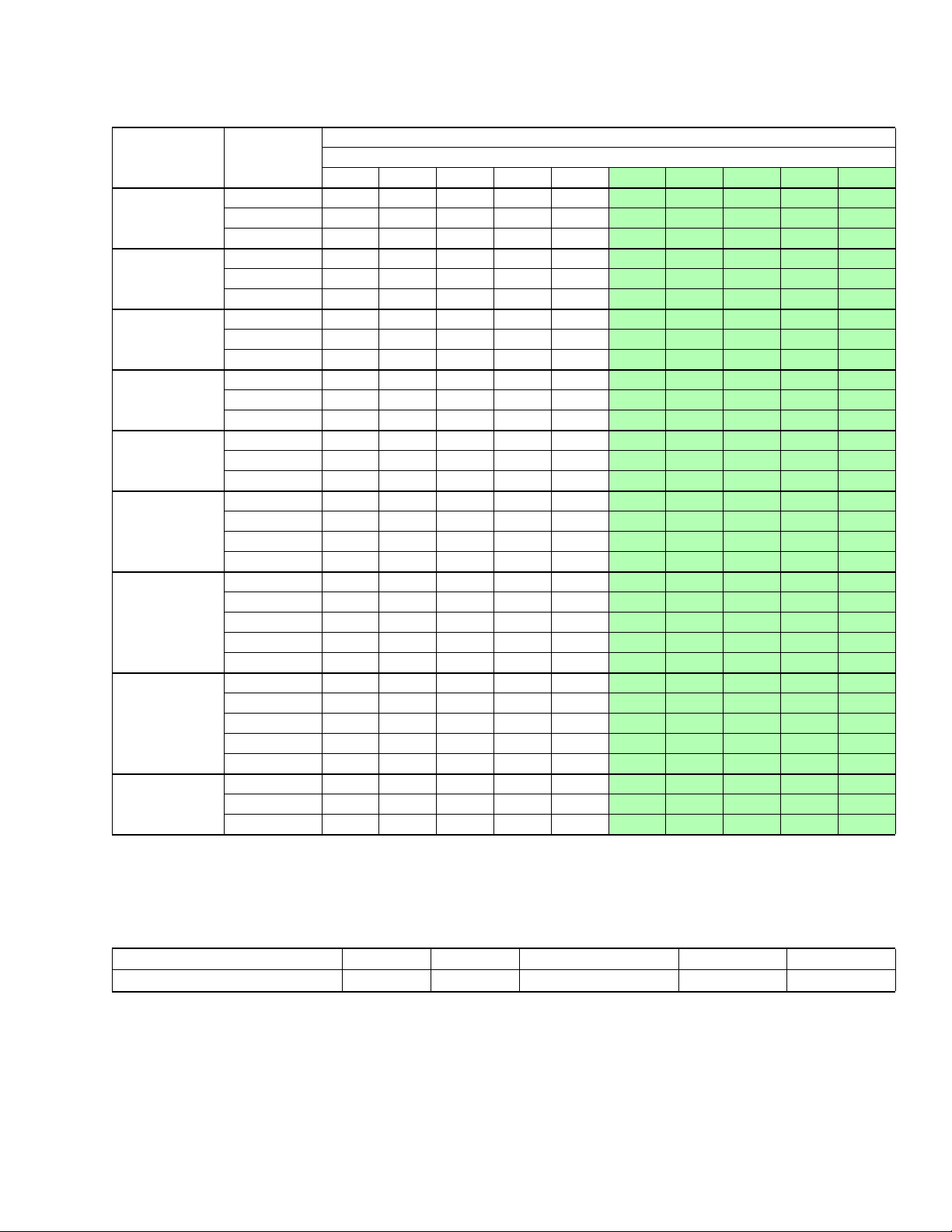

EXTENDED AIR FLOW DATA1 FOR 208 VOLT - HEAT PUMP MODELS

Models

F4FP024H06T2*

F4FP030H06T2*

F4FP036H06T2*

F4FP040H06T2*

F4FP042H06T2*

F4FP045H06T2*

F5FP048H06T2*

F5FP060H06T2*

F4FV060H06T2*

NOTE: Air flow data shown above 0.50” W.C. external static pressure is for REFERENCE ONLY. Maximum allowable external static when electric heat is used is

limited to 0.50” W.C. Maximum allowable external static pressure may also be limited by minimum CFM requirements for proper Heat Pump operation.

1. Includes Return Air Filter and Largest Electric Heater.

All F*FP series air handler units are UL Listed up to 0.50" w.c. external static pressure, including air filter, wet coil, and largest KW size heater.

Blower Motor

Speed

High 855 819 779 752 698

Med. 760 733 706 670 634

Low 585 567 545 518 486

High 1143 1089 1035 977 914

Med. 941 936 895 837 770

Low 770 738 702 662 612

High 1235 1179 1125 1058 1008

Med. 1080 1035 990 936 887

Low 954 914 873 833 774

High 1143 1089 1035 977 914

Med. 941 936 895 837 770

Low 770 738 702 662 612

High 1400 1418 1350 1278 1215

Med. 1314 1266 1197 1135 1071

Low 1125 1080 1040 990 945

High 1418 1382 1328 1251 1179

Med-high 1238 1184 1130 1067 999

Med-low 1089 1044 999 945 882

Low 932 891 846 801 743

High 2209 2140 2093 2000 1939

Med High 1945 1906 1871 1819 1784

Med 1739 1690 1640 1602 1559

Med Low 1506 1464 1415 1369 1325

Low 1301 1248 1197 1151 1095

High 2134 2124 2052 1979 1861

Med High 1916 1875 1838 1777 1744

Med 1716 1671 1613 1569 1523

Med Low 1494 1435 1390 1341 1284

Low 1276 1223 1168 1115 1068

High 2057 1976 1895 1814 1728

Med. 1913 1818 1719 1625 1535

Low 1490 1445 1395 1350 1305

0.10 0.20 0.30 0.40 0.50

CFM @ External Static Pressure - IWC

208 Volt

0.60 0.70 0.80 0.90 1.00

657 596 531 452 360

589 535 472 395 310

457 405 344 257 142

851 776 692 581 451

724 643 562 445 328

561 495 402 300 171

947 885 804 701 580

840 791 716 640 528

728 666 595 515 408

851 776 692 581 451

724 643 562 445 328

561 495 402 300 171

1145 1073 991 897 784

1012 947 864 758 625

901 838 766 676 568

1120 1032 927 807 661

936 850 763 659 545

829 760 663 576 480

693 628 554 472 389

1864 1746 1724 1655 1587

1741 1667 1640 1595 1550

1516 1470 1431 1387 1343

1283 1238 1193 1139 1100

1054 1005 958 909 860

1756 1639 1597 1512 1427

1671 1594 1584 1537 1490

1475 1429 1384 1337 1290

1241 1194 1139 1087 1036

1009 965 902 847 792

1661 1593 1517 1431 1337

1437 1342 1247 1152 1057

1258 1194 1120 1038 946

APPLICA TION FACTORS-RELATED CFM VS. ACTUAL CFM

% Of Rated Airflow 80% 90% RATED CFM 110% 120%

Capacity Factor 0.96 0.98 1.00 1.02 1.03

Unitary Products Group 5

Page 6

EXTENDED AIR FLOW DATA - F4FV VARIABLE SPEED MODELS

295421-YTG-B-0707

CFM/TAP SELECTION - F4FV

High Speed Cooling and Heat Pump CFM

Model Jumper Setting

F4FV060H06T2* "COOL” TAP “ADJ TAP“

2100 “A” “B"

1980 "B” "B"

1860 "A” "A"

1750 "B” "A"

1675 "A” "C"

1605 "C” "B"

1575 "B” "C"

1510 "D” "B"

1420 "C” "A"

1335 "D” "A"

1280 "C” "C"

1200 "D” “C”

NOTE:

1. Both the “COOL” and the “ADJ” tap must be set for the cooling CFM.

2. Fan only CFM = 63% of high speed cooling.

3. Low speed cooling used only with two stage outdoor units.

(Speed is preset to 65% of high speed).

4. Dehumidification speed is 85% of cooling speed.

5. When operating in both heat pump and electric heat modes, the CFM will

be whichever is greater.

6. CFM indicator light flashes once for every 100 CFM (i.e., 12 Flashes is

1200 CFM).

1

ELECTRIC HEAT CFM

Model CFM Tap Selections

–"HEAT"

1860 "A"

F4FV060H06T2*

1750 "B"

1420 "C"

1335 "D"

DELAY PROFILE

"DELAY" Tap Comfort Setting

ANormal

BHumid

CDry

D Temperate

Normal

The normal setting provides a 30-second ramp-up from zero

airflow to full capacity and a 30-second ramp-down from full

capacity back to zero airflow. Whenever there is a change in

airflow mode, such as a call for cooling or a change from low

heat to high heat, the motor will take 30 seconds to ramp

from one speed to the other.

Humid

The humid setting is best-suited for installations where the

humidity is frequently very high during cooling season, such

as in the southern part of the country. On a call for cooling,

the blower will ramp up to 50% of full capacity and will stay

there for two minutes, then will ramp up to 82% of full capacity and will stay there for five minutes, and then will ramp up

to full capacity, wh ere it will stay until the wall thermostat is

satisfied. In every case, it will take the motor 30 seconds to

ramp from one speed to another.

Dry

The dry setting is best suited to parts of the country where

excessive humidity is not generally a problem, where the

summer months are usually dry. On a call for cooling the

motor will ramp up to full capacity and will stay there until the

thermostat is satisfied. At the end of the cooling cycle, the

blower will ramp down to 50% of full capacity where it will stay

for 60 seconds. Then it will ramp down to zero. In every case,

it will take the motor 30 seconds to ramp from one speed to

another.

Temperate

The temperate setting is best suited for most of the country,

where neither excessive humidity nor extremely dry conditions are the norm. On a call for cooling, the motor will ramp

up to 63% of full capacity and will stay there for 90 seconds,

then will ramp up to full capacity. At the end of the cooling

cycle, the motor will ramp down to 63% of full capacity and

will stay there for 30 seconds, then will ramp down to zero. In

every case, it will take the motor 30 seconds to ramp from

one speed to another.

6 Unitary Products Group

Page 7

295421-YTG-B-0707

Physical and Electrical Data

MODEL F4FP024H06T2* F4FP030H06T2* F4FP036H06T2* F4FP040H06T2* –

Blower - Diameter Width 10x6 10x8 10x8 10x8 –

Motor

HP 1/4 1/3 1/2 1/3

Nominal RPM 1075 1075 1075 1075 –

Voltage 208/230

AMPS

Full Load 1.6/1.4 2.5/2.2 3.3/2.9 2.5/2.2 –

Locked Rotor 3.3/2.9 6.2/5.5 7.4/6.5 6.2/5.5

Type Disposable/Permanent

Filter

1

Size 16x20x1 16x20x1 20x20x1 20x20x1 –

Permanent Type Kit

1PF0601BK 1PF0601BK 1PF0602BK 1PF0601BK –

Shipping/Operating Weight (lbs.) 98/93 105/100 115/109 121/115 –

MODEL F4FP042H06T2* F4FP045H06T2* F5FP048H06T2* F5FP060H06T2* F4FV060H06T2*

Blower - Diameter x Width 10x8 10x10 11x10 11x10 11x10

Motor

HP 3/4 1/3 1.0 1.0 1.0

Nominal RPM 1130 925 1050 1050 1200

Voltage 208/230 230

Amps

Full Load 4.4/3.8 3.0/2.7 7.6 7.6 7.8/7.0

Locked Rotor 11.9/10.3 4.8/4.1 – – –

Type Disposable/Permanent

Filter

1

Size 20x20x1 22x20x1 22x20x1 22x20x1 22x20x1

Permanent Type Kit

1PF0602BK 1PF0603BK 1PF0603BK 1PF0603BK 1PF0603BK

Shipping/Operating Weight (lbs.) 121/115 150/144 153/147 160/154 160/154

1. Field Supplied.

–

–

ELECTRICAL DATA - Cooling Only

Models

Total Motor Amps

208V 240V 208V 240V

F4FP024H06T2* 1.6 1.5 2.0 1.8 15 14

F4FP030H06T2* 2.5 2.3 3.2 2.8 15 14

F4FP036H06T2* 3.3 3.0 4.2 3.7 15 14

F4FP040H06T2* 2.5 2.3 3.2 2.8 15 14

F4FP042H06T2* 4.4 4.0 5.5 4.8 15 14

F4FP045H06T2* 3.1 2.6 3.9 3.4 15 14

F5FP048H06T2* 7.6 7.6 9.5 9.5 15 14

F5FP060H06T2* 7.6 7.6 9.5 9.5 15 14

VARIABLE SPEED MODEL

F4FV060H06T2* – – – – 15 14

1. O.C.P. = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay Fuse.

Minimum Circuit

ampacity

Max. O.C.P.1 Amps/

Type

Minimum Wire

Size A.W.G.

Unitary Products Group 7

Page 8

ELECTRICAL DATA - 1∅ - 208/230 - 1-60

1

Models

Heater

Model

2HK*6500506B

F4FP024H06T2*

2HK*6500806B Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

2HK*6501006B Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK*6500506B

F4FP030H06T2*

2HK*6500806B Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

2HK*6501006B Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK*6500506B

2HK*6500806B Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

F4FP036H06T2*

2HK*6501006B Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B Med 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK16501906B

2HK*6500506B

F4FP040H06T2*

2HK*6500806B Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

2HK*6501006B Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK*6500506B

F4FP042H06T2*

2HK*6500806B Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

2HK*6501006B Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B Low 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK*6500506B

F4FP045H06T2*

2HK*6500806B Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

2HK*6501006B Med 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK16500506B

2HK16500806B Med-Low 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

F5FP048H06T2*

2HK*6501006B Med-Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B Med-Low 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK16502006B Med-Low 15.0 20.0 51.2 68.3 3.8 5.0 11.3 10.0 15.0 20.0

2HK16502506B Med-Low 18.8 25.0 64.2 85.3 3.8 5.0 11.3 15.0 18.8 25.0

2HK*6501006B

2HK16500806B Med 5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

F5FP060H06T2*

2HK16501006B Med 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK16501506B Med 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK16502006B Med 15.0 20.0 51.2 68.3 3.8 5.0 7.5 10.0 15.0 20.0

2HK16502506B Med 18.8 25.0 64.2 85.3 3.8 5.0 11.3 15.0 18.8 25.0

2HK*6500806B

2HK*6501006B 1335 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

F4FV060H06T2*

2HK16501506B 1335 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK16502006B

2HK16502506B 1335 18.8 25.0 64.2 85.3 3.8 5.0 11.3 15.0 18.8 25.0

NOTE: All models available with factory installed horizontal drain pan.

1. 0 or as follows: 0 = No Breaker, 1 = Breaker.

2. See Conversion Table below:

3. If first stage heat or 66 is connected to W1, otherwise refer to this table.

4. 2HK16501906B only applies to F4FP036 Model.

MAX. STATIC

& MIN. CFM

Static Tap 208V 240V 208V 240V 208V 240V 208V 240V 208V 240V

Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

4

High 13.2 17.6 45.1 60.1 2.8 3.8 10.4 13.8 13.2 17.6

Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

Med-Low 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

Med 3.8 5.0 13.0 17.1 3.8 5.0 3.8 5.0 3.8 5.0

0.5

1335

0.5

1335 15.0 20.0 51.2 68.3 3.8 5.0 7.5 10.0 15.0 20.0

295421-YTG-B-0707

Total Heat

2

KW Staging

KW MBH W1 Only W2 Only W1 + W2

5.6 7.5 19.1 25.6 3.8 5.0 5.6 7.5 5.6 7.5

3

KW & MBH CONVERSIONS - FOR TOTAL POWER INPUT REQUIREMENT

FOR 230V OPERATION MULTIPLY 240V TABULATED KW & MBH BY .918

8 Unitary Products Group

Page 9

295421-YTG-B-0707

ELECTRICAL DATA - 1∅ (SINGLE SOURCE POWER SUPPLY) - COPPER WIRE

Models

Heater

Model

1

Heater

Amps

240V

Min. Circuit

Ampacity

208V 240V 208V 240V 208V 240V

2HK*6500506B 20.8 24.7 27.7 25 30 10 10

F4FP024H06T2*

2HK*6500806B 31.3 35.5 40.7 40 45 8 8

2HK*6501006B 41.7 46.9 53.7 50 60 8 6

2HK*6500506B 20.8 25.8 28.7 30 30 10 10

F4FP030H06T2*

2HK*6500806B 31.3 36.7 41.7 40 45 8 8

2HK*6501006B 41.7 48.1 54.7 50 60 8 6

2HK16501506B 62.5 70.9 80.8 80 90 4 3

2HK*6500506B 20.8 26.8 29.5 30 30 10 10

2HK*6500806B 31.3 37.7 42.6 40 45 8 8

F4FP036H06T2*

2HK*6501006B 41.7 49.1 55.6 50 60 8 6

2HK16501506B 62.5 71.9 81.6 80 90 4 3

3

2HK16501906B

73.3 83.3 95.2 90 100 3 3

2HK*6500506B 20.8 25.8 28.7 30 30 10 10

F4FP040H06T2*

2HK*6500806B 31.3 36.7 41.7 40 45 8 8

2HK*6501006B 41.7 48.1 54.7 50 60 8 6

2HK16501506B 62.5 70.9 80.8 80 90 4 3

2HK*6500506B 20.8 28.1 30.5 30 35 10 8

F4FP042H06T2*

2HK*6500806B 31.3 38.9 43.6 40 45 8 8

2HK*6501006B 41.7 50.3 56.6 60 60 6 6

2HK16501506B 62.5 73.2 82.6 80 90 4 3

2HK*6500506B 20.8 26.6 29.3 30 30 10 10

F4FP045H06T2*

2HK*6500806B 31.3 37.4 42.3 40 45 8 8

2HK*6501006B 41.7 48.8 55.3 50 60 8 6

2HK16501506B 62.5 71.7 81.4 80 90 4 3

2HK16500506B 20.8 32.8 35.6 35 40 8 8

2HK*6500806B 31.3 43.0 48.4 45 50 8 8

F5FP048H06T2*

2HK*6501006B 41.7 55.3 61.5 60 70 6 4

2HK16501506B 62.5 77.3 87.8 80 90 4 3

2HK16502006B 83.3 101.0 113.8 110 125 2 1

2HK16502506B 104.2 124.3 139.9 125 150 1 1/0

2HK*6500506B 20.8 32.8 35.6 35 40 8 8

2HK*6500806B 31.3 42.9 48.3 45 50 8 8

F5FP060H06T2*

2HK*6501006B 41.7 55.3 61.6 60 70 6 4

2HK16501506B 62.5 78.5 87.8 80 90 4 3

2HK16502006B 83.3 101.0 113.8 110 125 2 1

2HK16502506B 104.2 122.2 139.5 125 150 1 1/0

2HK*6500806B 31.3 43.8 47.8 45 50 8 8

2HK*6501006B 41.7 55.2 60.8 60 70 6 4

F4FV060H06T2*

2HK16501506B 62.5 78.0 86.9 80 90 4 3

2HK16502006B 83.3 100.3 112.9 110 125 2 1

2HK16502506B 104.2 123.1 139.0 125 150 1 1/0

1. 0 or 1 as follows: 0 = No Breaker, 1 = Breaker

2. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

3. 2HK16501906B only applies to F4FP036 Model.

Field Wiring

Max. O.C.P.

Amps/Type

2

75°C Wire

Size - AWG

Unitary Products Group 9

Page 10

295421-YTG-B-0707

ELECTRICAL DATA - 1 Ø (MULTI-SOURCE POWER SUPPLY) - COPPER WIRE

Models Heater Model

Min. Circuit Ampacity

Circuit Circuit Circuit

1st 2nd 3rd 1st 2nd 3rd 1st 2nd 3rd

Max. O.C.P.1 Amps/Type

208/240V 208/240V 208/240V 208/240V 208/240V 208/240V 208/240V 208/240V 208/240V

F4FP030H06T2* 2HK16501506B 25.8/28.7 45.1/52.1 — 30/30 50/60 — 10/10 8/6 —

F4FP036H06T2*

2HK16501506B 26.8/29.5 45.1/52.1 — 30/30 50/60 — 10/10 8/6 —

2

2HK16501906B

38.3/42.6 45.7/52.6 — 40/45 50/60 — 8/8 8/6 —

F4FP040H06T2* 2HK16501506B 25.8/28.7 45.1/52.1 — 30/30 50/60 — 10/10 8/6 —

F4FP042H06T2* 2HK16501506B 28.1/30.5 45.1/52.1 — 30/35 50/60 — 10/8 8/6 —

F4FP045H06T2* 2HK16501506B 26.6/29.3 45.1/52.1 — 30/30 50/60 — 10/10 8/6 —

2HK16501506B 32.8/35.6 45.1/52.1 — 35/40 50/60 — 8/8 8/6 —

F5FP048H06T2*

2HK16502006B 55.3/61.6 45.1/52.1 — 60/70 50/60 — 6/4 8/6 —

2HK16502506B 32.8/35.6 45.1/52.1 45.1/52.1 35/40 50/60 50/60 8/8 8/6 8/6

2HK16501506B 32.8/35.6 45.1/52.1 — 35/40 50/60 — 8/8 8/6 —

F5FP060H06T2*

2HK16502006B 55.3/61.6 45.1/52.1 — 60/70 50/60 — 6/4 8/6 —

2HK16502506B 33.8/35.6 45.1/52.1 45.1/52.1 35/40 50/60 50/60 8/8 8/6 8/6

2HK16501506B 33.0/34.8 45.1/52.1 — 35/35 50/60 — 8/8 8/6 —

F4FV060H06T2*

2HK16502006B 55.2/60.8 45.1/52.1 — 60/70 50/60 — 6/4 8/6 —

2HK16502506B 33.0/34.8 45.1/52.1 45.1/52.1 35/35 50/60 50/60 8/8 8/6 8/6

1. OCP = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

2. 2HK16501906B only applies to F4FP036 Model.

75°C Wire Size - AWG

ELECTRICAL DATA - 3∅ - 208/230-3-60

1

KW Staging

Models Heater Model

MAX. STATIC

& MIN. CFM

Total Heat

KW MBH W1 Only W2 Only W1 + W2

Static Tap 208V 240V 208V 240V 208V 240V 208V 240V 208V 240V

F4FP024H06T2* 2HK06501025B 0.5 Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

F4FP030H06T2*

F4FP036H06T2*

F4FP040H06T2*

F4FP042H06T2*

F4FP045H06T2*

F5FP048H06T2*

F5FP060H06T2*

F4FV060H06T2*

1. See Conversion Table below.

2. If first stage heat is connected to W1/66, otherwise refe r to Table below.

2HK06501025B 0.5 Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 Low 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 Med 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 High 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 Med Low 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 Med Low 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 Med 7.5 10.0 25.6 34.1 3.8 5.0 7.5 5.0 7.5 10.0

2HK06501525B 0.5 Med 11.3 15.0 38.6 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2HK06501025B 0.5 1335 7.5 10.0 25.6 34.1 3.8 5.0 7.5 10.0 7.5 10.0

2HK06501525B 0.5 1335 11.3 15.0 38.8 51.2 3.8 5.0 7.5 10.0 11.3 15.0

2

KW & MBH CONVERSIONS - FOR TOTAL POWER INPUT REQUIREMENT

FOR 230V OPERATION MULTIPLY 240V TABULATED KW & MBH BY .918

10 Unitary Products Group

Page 11

295421-YTG-B-0707

ELECTRICAL DATA - 3∅ - (SINGLE SOURCE POWERSUPPLY) - COPPER WIRE

Field Wiring

Models Heater Models

F4FP024H06T2* 2HK06501025B 41.2 46.5 45 50 8 8

F4FP030H06T2*

F4FP036H06T2*

F4FP040H06T2*

F4FP042H06T2*

F4FP045H06T2*

F5FP048H06T2*

F5FP060H06T2*

F4FV060H06T2*

1. O.C.P. = Over Current Protection device, must be HACR type Circuit Breaker or Time Delay fuse.

2HK06501025B 42.2 47.4 45 50 8 8

2HK06501525B 42.2 47.4 45 50 8 8

2HK06501025B 43.1 48.2 45 50 8 8

2HK06501525B 43.1 48.2 45 50 8 8

2HK06501025B 42.2 47.4 45 50 8 8

2HK06501525B 42.2 47.4 45 50 8 8

2HK06501025B 44.2 49.1 45 50 8 8

2HK06501525B 44.2 49.1 45 50 8 8

2HK06501025B 42.8 47.9 45 50 8 8

2HK06501525B 42.8 47.9 45 50 8 8

2HK06501025B 48.3 53.9 50 60 8 6

2HK06501525B 48.3 53.9 50 60 8 6

2HK06501025B 48.3 53.9 50 60 8 6

2HK06501525B 48.3 53.9 50 60 8 6

2HK06501025B 48.6 52.9 50 60 8 6

2HK06501525B 48.6 52.9 50 60 8 6

Min. Circuit Ampacity

Max. O.C.P.1 Amps

208V 240V 208V 240V 208V 240V

75°C Wire Size - AWG

FIELD WIRING CONNECTION - COOLING ONLY FIELD WIRING CONNECTION - WITH HEATER KIT

OUTDOOR

UNIT

THERMOSTAT

R

Y

G

W

FAN

COIL

UNIT

OUTDOOR

UNIT

G

Y

W2 W1 O C

R

THERMOSTAT

R

Y

G

W

FAN

COIL

UNIT

*

G

Y

W2 W1 O C

*

NOTREQUIREDON2OR5KW

R

Unitary Products Group 11

Page 12

FIELD WIRING CONNECTIONS - COOLING MODELS WITH ELECTRIC HEAT WIRING

F* SERIES F* SERIES

Air Handler Control Wiring

Typical A/C - Cooling only Applications

THERMOSTAT

RR

Y

G

W1

W2

C

AIR HANDLER

BOARD

Y

G

W1

W2

O

C

AIR CONDITIONING

1-STAGE

Y

C

HUMIDISTAT

THERMOSTAT

1

Air Handler Control Wiring

Typical A/C with Electric Heat Applications

AIR HANDLER

BOARD

RR

Y

G

W1

W2

C

Y

G

W1

W2

O

C

1-STAGE

AIR CONDITIONING

Y

Field

Installed

Jumper If Required

C

295421-YTG-B-0707

HUMIDISTAT

1

CFM selection

board only on

F4FV model

HUM

X

Y1

Y2

1

NOTE:

Dehumidification

control connection

(”Humidistat” jumper on

CFM selection board

CFM selection

board only on

F4FV model

FIELD WIRING CONNECTIONS - SINGLE STAGE HEAT PUMP

AIR HANDLER

THERMOSTAT

R

Y

G

E

W2

O

C

L

W1

CFM selection board

only on F4FV model

BOARD

R

Y

G

W1

W2

O

C

HUM

X

Y1

Y2

1

HUM

1

NOTE:

Dehumidification

control connection

(”Humidistat” jumper on

CFM selection board

HEAT PUMP

R

Y

W1 Out

O

C

X/L

W

HUMIDISTAT

X

Y1

Y2

1

NOTE:

Dehumidification control connection

(”Humidistat” jumper on CFM selection

board must be removed)

NOTES:

1. “Y” Terminal on Air Handler Control Board must be connected for full CFM and applications requiring 60 second Blower Off Delay

for SEER enhancement.

1

Optional Dehumidification Humidistat contacts open on rise.

2.

3. For F4FV model - Remove Humidistat Jumper on CFM Selection Board - if used.

4. For F4FV model - For Heat Pump Applications - Remove Heat Pump Jumper on CFM Selection Board.

5. To change quantity of heat during HP defrost cycle - Reverse connections at W1 and W2 on Air Handler Control Board.

12 Unitary Products Group

Page 13

295421-YTG-B-0707

TYPICAL INSTALLATION

POWERWIRING

TOMAIN

POWERSOURCE

REFRIGERANT

LINES

TO

CONDENSATE

DRAIN

SUPPLY

AIR

POWERWIRING

ELECTRICHOTWATERHEATER

(Mustcomplywithwaterheaterinstallationinstructions)

CONTROL

WIRING

THERMOSTAT

FILTER

ACCESS

LOUVERED

TYPICAL APPLICA T IONS

UPFLOW

HORIZONTAL

RIGHTHANDAPPLICATION

LEFTHANDAPPLICATION

Unitary Products Group 13

Page 14

NOTES

295421-YTG-B-0707

14 Unitary Products Group

Page 15

295421-YTG-B-0707

NOTES

Unitary Products Group 15

Page 16

NOTES

Subject to change without notice. Printed in U.S.A. 295421-YTG-B-0707

Copyright © by York International Corp. 2007. All rights reserved. Supersedes: 295421-YTG-A-0507

Unitary 5005 Norman

Products York OK

Group Drive 73069

Loading...

Loading...