Page 1

INSTALLATION

MANUAL

SPLIT-SYSTEM HEAT PUMPS

INDOOR UNITS

Supersedes: 515.41-N2Y (692)/035-09651-000 035-09651-001-A-0304

MODELS F3EH090 & F4EH120

(50 and 60 Hz)

GENERAL

These completely assembled indoor units include a wellinsulated cabinet, a copper tube/aluminum fin coil, throw

away filters, a centrifugal blower,ablowermotor, an adjust

able V-belt drive, a blower motor contactor and a small

holding charge of an inert gas. They also include a filterdrier,anexpansion valveand adistributor that are only used

during the cooling cycle plus a check valve to provide the

proper flow of refrigerant through the coil during both the

cooling and heating cycles.

Supplementalresistanceheaters, a supplyair plenum, areturn

airgrille and abase are availableas accessories forfield instal

lation.

The units are shipped in the vertical position ready for field in

stallation. For horizontal installation, reverse the solid bottom

panel and the return air duct flange on the front of the unit.

REFERENCE

Thisinstruction coversthe installationof theindoor unit.For in

formationon theinstallation andoperation ofthe matchingout

door unit, refer to Form 035-15410-002.

Renewal Parts:

•

Refer to Parts Manual for complete listing of replacement

parts on this equipment.

All forms referenced in this instruction may be ordered from:

-

Installer should pay particular attention to the words: NOTE,

CAUTION and WARNING. Notes

make the installation easier. Cautions

equipment damage. Warnings

thatpersonal injuryand/orequipment damagemay resultifthe

installation procedure is not handled properly.

INSPECTION

As soon as a unit is received, it should be inspected for possi

ble damage during transit. If damage is evident, the extent of

thedamageshould benotedon the carrier'sfreightbill. Asepa

THIS PRODUCT MUSTBE INSTALLED IN STRICTCOMPLIANCE

WITH THE ENCLOSED INSTALLATION INSTRUCTIONS AND

ANY APPLICABLE LOCAL, STATE, AND NATIONAL CODES

-

INCLUDING, BUT NOT LIMITED TO, BUILDING, ELECTRICAL,

-

AND MECHANICAL CODES.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE INJURY OR

PROPERTY DAMAGE. REFER TO THIS MANUAL. FOR

ASSISTANCE OR ADDITIONAL INFORMATION, CONSULT A

QUALIFIED INSTALLER, SERVICE AGENCY OR THE GAS

SUPPLIER.

Standard Register

Toll Free Tel.: 877-318-9675

Toll Free Fax: 877-379-7920

are intended to clarify or

are given to prevent

are given to alert the installer

CAUTION

WARNING

-

-

Page 2

GENERAL

REFERENCE

INSPECTION

NOMENCLATURE

.............................................................................

.............................................................................

.............................................................................

......................................................................

INSTALLATION

LIMITATIONS

LOCATION

RIGGING

CLEARANCES

VERTICAL/HORIZONTALINSTALLATION

DUCT CONNECTIONS

REFRIGERANT MAINS

DRAIN CONNECTION

SUPPLYAIR BLOWER ADJUSTMENT

POWER AND CONTROL WIRING

.............................................................................

.............................................................................

.............................................................................

...........................................................................

..............................................................

..............................................................

...............................................................

.....................................

.............................................

TABLE OF CONTENTS

1

1

................................

1

2

3

3

3

3

5

5

6

6

7

9

Figure

No.

035-09651-001-A-0304

FIGURES

Description Page

1 Unit Suspension Mounting

2 Vertical & Horizontal Application

3 Electric Heater Accessory

4 Supply Air Plenum Accessory

5 Base Accessory

6 Return Air Grille Accessory

7 Recommended Drain Piping

8 Motor Mounting Assembly

9 Hole Locations for Pressure Drop

10 Pressure Drop vs Supply Air CFM

11 Field Wiring

12 Unit Dimensions & Clearances

...................................................

..........................................................

...................................

....................................

..............................

..................................

................................

....................................

............................

..........................

........................

.......................

4

5

5

5

5

6

6

7

8

8

10

11

Refer to the matching outdoor unit installation

instruction (Form 035-15410-002) for the operating

sequence of the entire system.

MAINTENANCE

INDOOR COIL

DRAIN PAN

FILTERS

LUBRICATION

BELTS ............................................................................. 12

............................................................................

.............................................................................

.............................................................................

............................................................................

12

12

12

12

TABLES

Table

No.

1 Physical Data

2 Application Data

3 Blower Motor Pulley Adjustment

4 Blower Performance (60Hz Units)

5 Blower Performance (50 Hz Units)

6 Accessory Static Resistance

7 Blower Motor & Drive Data................................... 9

8 Electrical Data...................................................... 9

Description Page

.......................................................

...................................................

..........................

........................

.......................

................................

3

4

7

8

8

9

PRODUCT NOMENCLATURE

PRODUCT CATEGORY

F = Split-System Heat Pump

Indoor

Unit

PRODUCT GENERATION

3 = 3rd Generation

4 = 4th Generation

PRODUCT IDENTIFIER

2 Unitary Products Group

F 3 E H 3 39 A

EH = Indoor Unit

0 0

NOMINAL COOLING

CAPACITY

090 = 7-1/2 Ton

120 = 10 Ton

VOLTAGE CODE

33 = 208/230/460-3-60

50 = 380/415-3-50

FACTORYINSTALLED HEAT

A = Not Applicable

Page 3

035-09651-001-A-0304

INSTALLATION

rate request for inspection by the carrier's agent should be

made in writing.

LIMITATIONS

These units must be installed in accordance with all national

andlocal safety codes.Ifno localcodesapply,installationmust

conform with the appropriate national codes. Units are de

signedtomeetNational SafetyCodeStandards.Ifcomponents

are tobe added to aunit to meet localcodes, they are to be in

stalled at the dealer's and/or the customer's expense. See Ta

ble 2 for application limitations.

LOCATION

These indoor units are not designed for outdoor installation.

Theymustbe locatedwithinthe building structure,eitherinside

or outside the conditioned space.

The units should be located as close to the outdoor units as

practical and positioned to minimize bends in the refrigerant

piping.

Unitsbeinginstalledvertically orhorizontallycanbe setdirectly

on a floor or platform, or they can be supported by metal or

wooden beams.

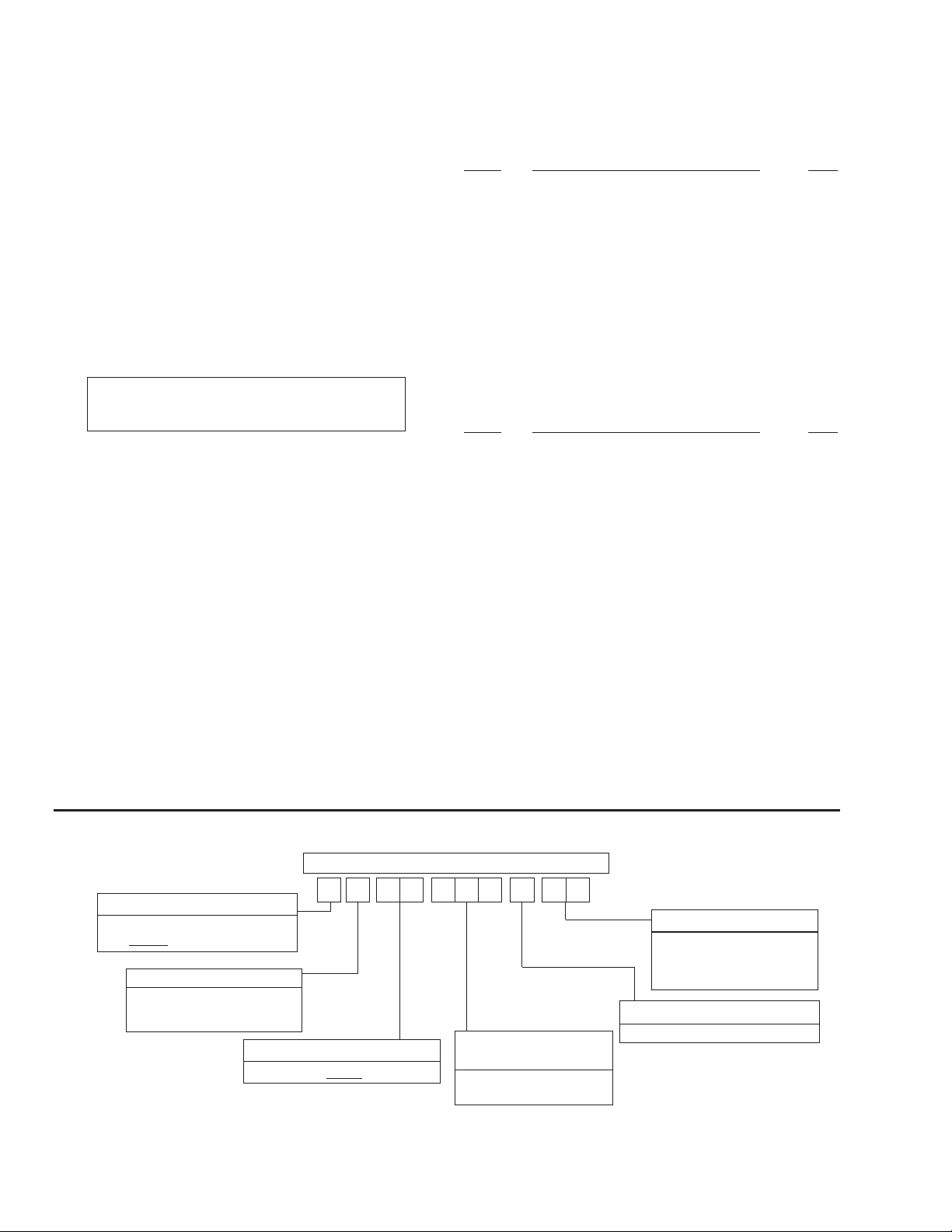

Units being installed horizontally can be suspended from

above.Four 3/8" weld nutsare provided in the unit frame to accommodate hanger rods. Knockouts must be removed from

the unit panels to expose theseweld nuts. Refer to Figure1 for

their location and the individual load on each hanger rod.

WARNING: Be careful when attaching the hanger rods. Use a

washerwith a back-upnut oneachrod andtighten

down against the cabinet so they will not be al

lowed to turn or slip.

RIGGING AND HANDLING

Exercise care when moving the unit. Do not removeany pack

aging until the unit is near the place of installation.

-

The packaging consists of a bottom wooden skid that can be

liftedwitha forktruckfrom anydirection, a cardboardcontainer

thatcovers theentire unit, andstrapping thatsecures thecard

board container to the bottom skid.

These units can be rigged with slings under the bottom skid.

CAUTION: Spreader bars should be used to prevent the

slings from crushing the unit panels and frame.

Before rigging any unit,determine itsweight from Table 1. Bef

orerigging a unitforhorizontal installation, determineitscenter

of gravity from Figure 1, and make sure that its weight will be

distributed equally.

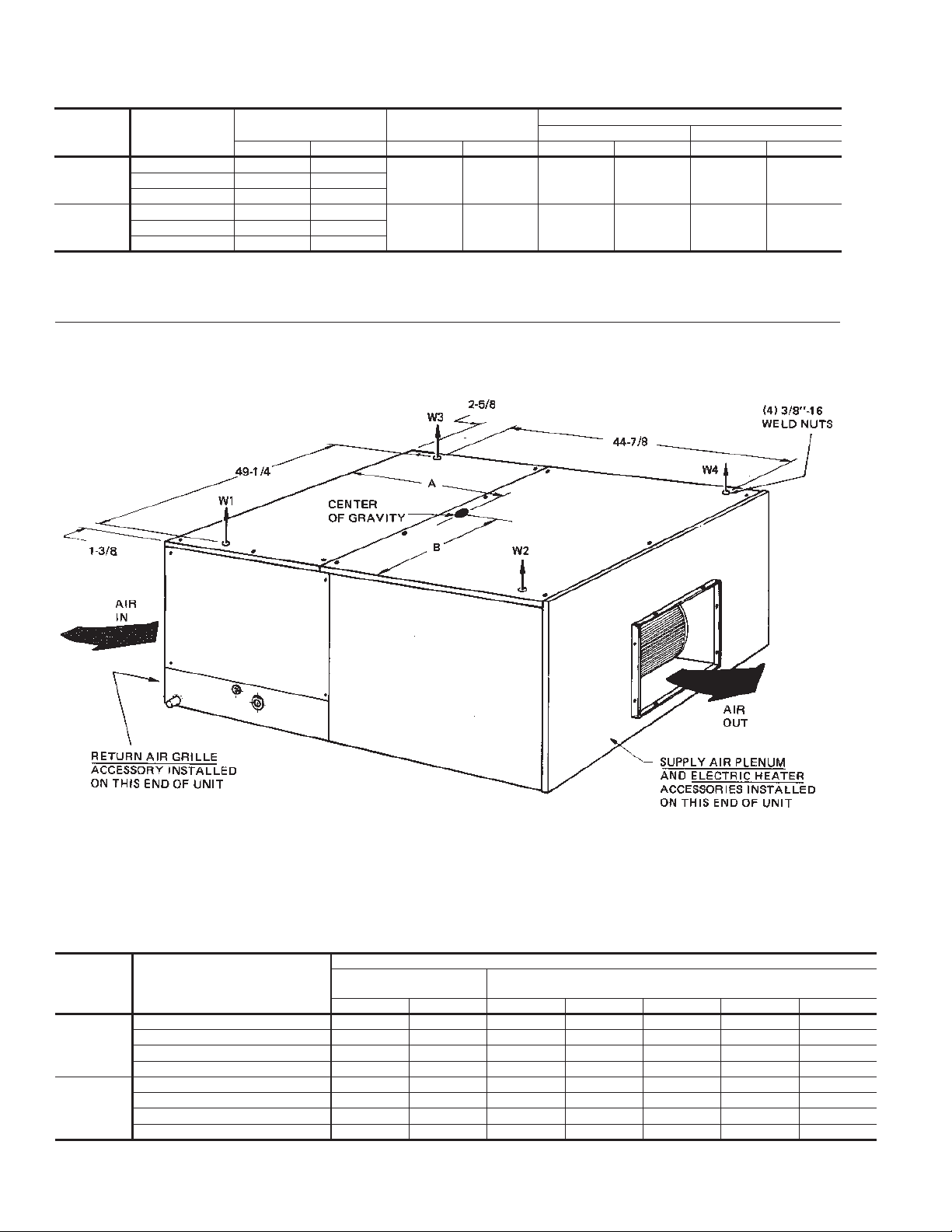

CLEARANCES

All unitsrequire certain minimum clearances for proper operation and service. Refer to Figure 12 for these clearances.

-

-

-

-

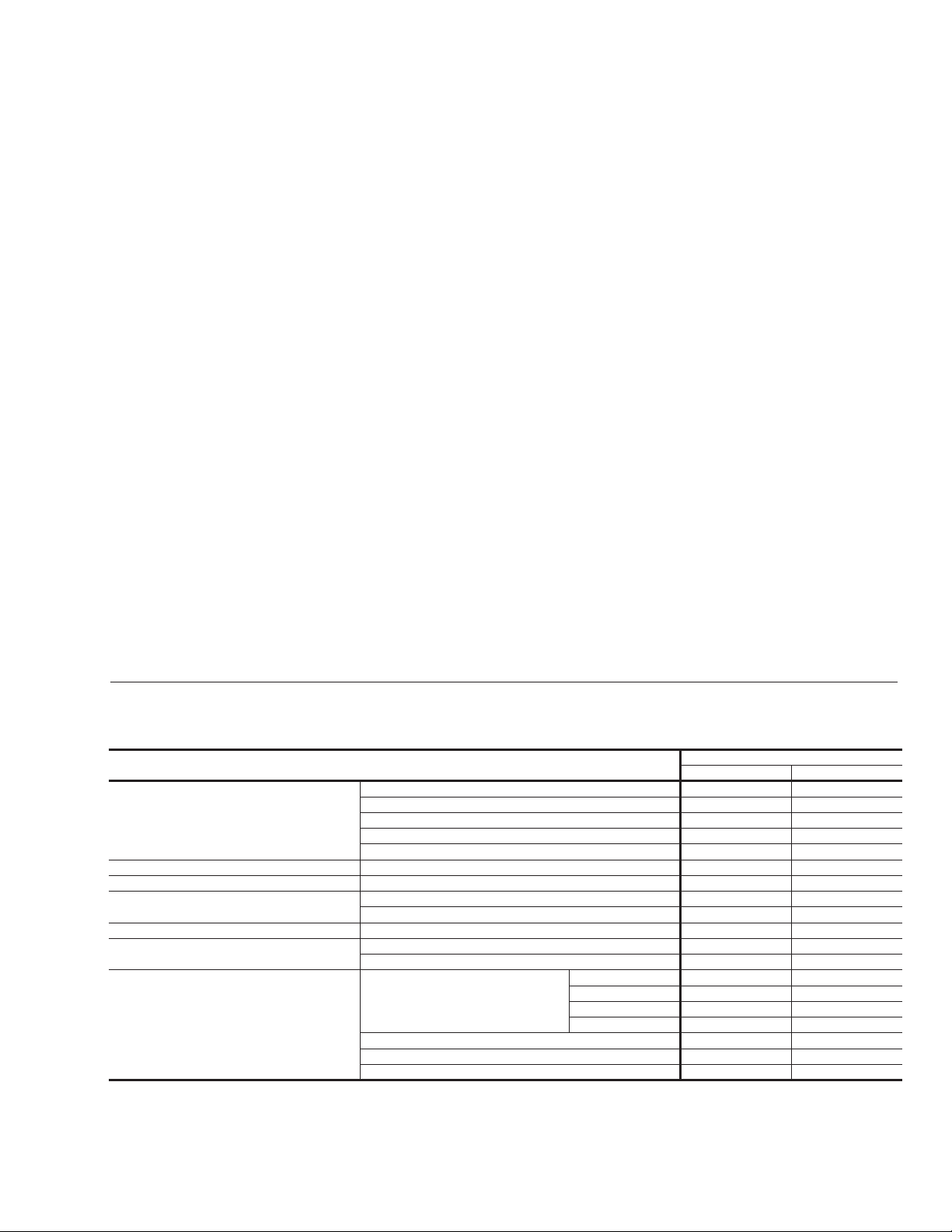

TABLE 1 - PHYSICAL DATA

DESCRIPTION

Rows Deep x Rows High 3 x 24 4 x 32

Finned Length - inches 45.5 45.5

Coil

Centrifugal Blower (Forward Curve) Diameter x Width - inches 15 X 15 15 X 15

Blower Motor

Filters (Throwaway)

Refrigerant-22 (Lbs.)

Unit Weight (lbs.)

Accessory Operating Weights (Lbs.)

1

All of these 1750 RPM motors have a solid base, a 56 frame, a 1.15 service factor, inherent protection & permanently lubricated ball bearings. Refer to page 6 for additional motor & drive data.

2

Refer to Form 035-15410-002 for system charge.

Unitary Products Group 3

1

2

Face Area - square feet 7.6 10.1

Tube (Copper) OD - inches 3/8 3/8

Fins (Aluminum) per inch 13 13

Nominal Rating - HP 1-1/2 2

Quantity Per Unit - 16" x 25" x 1" 4 4

Total Face Area - square feet 11.1 11.1

Pumpdown Capacity 12.0 22.0

Shipping 405 440

Operating 365 400

10 KW 63 63

Electric Heaters

Supply Air Plenum 102 102

Base 60 60

Return Air Grille 15 15

16 KW 66 66

26 KW 71 71

36 KW 74 74

UNIT MODEL

F3EH090 F4EH120

Page 4

TABLE 2 - APPLICATION DATA

Model

Power

Supply

Voltage Variation

Min. Max. Min. Max. Min. Max. Min. Max.

1

208/230-3-60 187 252

F3EH090

380/415-3-50 342 456

208/230-3-60 187 252

F4EH120

1

Utilization Range “A” in accordance with ARI Standard 110.

2

The system may operate below 50°F for a short period of time when warming up the conditioned space after a long shutdown.

380/415-3-50 342 456

Supply Air CFM

2400 3600 57 72 50

3200 4800 57 72 50

035-09651-001-A-0304

Entering Air Temperatures, °F

Cooling - wb Heating - db

2

2

80460-3-60 414 506

80460-3-60 414 506

FIG. 1 - UNIT SUSPENSION MOUNTING

(Horizontal Application)

Based on a Standard Blower Motor

Model Accessory

Center of Gravity

Dimensions, In.

Weight

Distribution, Lbs.

A B W1 W2 W3 W4 Total

Basic Unit Only 25-5/8 23-1/4 99 104 79 83 365

F3EH090

Unit with Electric Heat 30-3/4 23-3/8 90 150 72 121 433

Unit with Plenum 35-1/8 23-1/2 71 186 58 152 467

Unit with Electric Heat & Plenum 38 23-5/8 62 232 51 190 535

Basic Unit Only 24-1/8 23-1/4 116 106 93 85 400

F4EH120

Unit with Electric Heat 29-1/4 23-3/8 103 155 84 126 468

Unit with Plenum 33-3/8 23-1/2 88 190 70 154 502

Unit with Electric Heat & Plenum 36-5/8 23-5/8 76 236 63 195 570

NOTE: Unit weights (with electric heat accessory) are based on an average heater weight of 68 lbs.

4 Unitary Products Group

Page 5

035-09651-001-A-0304

WARNING: Do notpermit overhanging structures or shrubs to

obstruct air discharge.

Additional height may be required for snow clearance if winter

operation is expected.

Thereturn airduct flangeis factory-mountedon thefront ofthe

unit, but it can bereversed with the solid bottom panel forhori

zontal applications.

A supply air plenum (Fig. 4), a base (Fig. 5) and a return air

grille (Fig. 6) are available as field-installed accessories, and

one ofthe following respective instructions will be packed with

each.

-

FIG. 2 - VERTICAL AND HORIZONTAL APPLICATIONS

VERTICAL / HORIZONTAL INSTALLATION

Theseindoor units are shipped forvertical installationwith ver

tical air discharge as shown in Figure 2(A) but may be con

verted for horizontal installation as shown in Figure 2(B) by

interchanging the solid bottom panel and the return air duct

flange.

-

-

DUCT CONNECTIONS

Design and install all ducts in accordance with all national

and/or local codes.

Ducts should be sized no smaller than the duct flanges on the

unitor theelectric heater(if used).Refer tothe unitdimensions

(Fig. 12) and the heater detail (Fig. 3) for these sizes. Refer to

Form035-16602-002 for installationinstructionson theelectric

heater.

FIG. 3 - ELECTRIC HEATER ACCESSORY

(Vertical Arrangement Shown)

Plenum should be field mounted on the supply air end of indoor

units for either vertical or horizontal application. For rear discharge,

rotate plenum 180°. For horizontal discharge on a horizontal unit,

the grille panel and the top panel will be arranged differently. Refer

to Form 035-16650-001 for installation and assembly instructions.

FIG. 4 - SUPPLY AIR PLENUM ACCESSORY

(Vertical Arrangement Shown)

Useflexible fiber glass or plasticcloth collarsor other nonflam

-

mable material at the unit duct connections to minimize the

transmission of noise and vibration.

Insulate all ductwork running through unconditioned areas to

prevent moisture condensation and to provide more economi

cal operation.

Unitary Products Group 5

-

FIG. 5 - BASE ACCESSORY

(For Vertical Arrangement Shown)

Page 6

FIG. 6 - RETURN AIR GRILLE ACCESSORY

(Vertical Arrangement Shown)

Form 035-16650-001 – Supply Air Plenum

Form 035-16621-001 – Return Air Grille

Form 035-16632-001 – Base

035-09651-001-A-0304

INSTALLING REFRIGERANT MAINS

WARNING: Provisions for recovering refrigerant releases

must be available during allphases of installation,

leak testing and charging. Do NOT release refrig

erant into the atmosphere.

The units are evacuated and dehydrated at the factory and

shipped with a holding charge of aninert gas suchas Nitrogen

or Helium. The vapor and liquid connections are sealed with

copper discs.

If the unit has already lost its holding charge, it should be leak

tested and the necessary repairs should be made. If the unit

has maintained its holding charge, you can assume that it has

no leaks and proceed with the installation.

The temperature required to make or break a brazed joint is

sufficientlyhightocauseoxidation of thecopperunlessaninert

atmosphere is provided.

-

Thesupplyair plenumandthereturn airgrilleshouldbe usedin

lieuof ductworkonly whena free blow/free return applicationis

practical.

REFRIGERANT MAINS

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system and

by using procedures and materials that conform with established standards.

Useharddrawn copper tubingwherenoappreciable amountof

bending around pipes or other obstructions is necessary. Use

long radius ells wherever possible with one exception - small

radius ells for any traps in a vapor riser.If soft copper is used,

care should be taken toavoid sharp bends whichmay cause a

restriction.

Fiber glass insulation and a sealing material such as perma

gum should be packed around refrigerant lines where they

penetrate a wall to reduce vibration and to retain some flexibil

ity.

Support all refrigerant lines at minimum intervals with suitable

hangers, brackets or clamps.

Braze all copper to copper joints with Sil-Fos 5 or equivalent

brazing material. DO NOT USE SOFT SOLDER.

Drilla small holethrough thediscsto preventanyinternal pres

surefrom blowing themoff and to allowthe flow of dry nitrogen

through the connections when unbrazing the closures.

The liquid and vapor connections must be piped outside the

unit. Refer to the unit drawing for the locations and the dimensions of these connections.

Before brazing the refrigerant lines to these connections, remove the short panel from the unit frame and slide the grommets onto the refrigerant lines. After the brazed joints have

cooled, slide the grommets back into place and secure the

panel to the unit frame.

NOTE: Thesecoilscan only bepipedfromonesideof the unit.

DRAIN CONNECTION

The drain line MUSTbe trapped becausethe coil islocated on

the negative side of the supply air blower,and it must be pro

tected from freezing temperatures.

-

-

Never braze or solder the liquid and vapor lines together. The

completevaporline should beinsulatedwithminimum 1/2" AR

-

MAFLEX or equivalent.

If it is desirable to tape or wire these lines together for support

purposes, they must be completely insulated, one from the

other.

Refer to the installation instruction (Form 035-15410-002) for

the matching outdoor unit for piping limitations, line sizes, and

other design considerations.

6 Unitary Products Group

FIG. 7 - RECOMMENDED DRAIN PIPING

Page 7

035-09651-001-A-0304

A7/8" OD drain connection extends through right hand side of

cabinet. Refer to Fig. 7 for recommended drain piping.

The drain connection is located on the sameside of theunit as

therefrigerantconnections. The lineshouldbe insulated where

moisturedrippagewillbe objectionable orcausedamagetothe

area.

The 3" dimension must equal or exceed the negative static

pressure developed by the supply air blower. If it does not, the

condensate will not drain properly and may overflow the drain

pan. The trap must be at least 2-1/2" deep to maintain a water

seal under all operating conditions, especially during blower

start-up.

NOTE: The unit may have to be raised off the floor to allow

enough height for the trap.

FIG. 8 - TYPICAL MOTOR MOUNTING ASSEMBLY

NOTE: Never loosen the two nuts (C).

TABLE 3 - SUPPLY AIR BLOWER MOTOR

PULLEY ADJUSTMENT

TURNS

OPEN*

5 655 RPM 542 RPM 700RPM 581 RPM

4 760 580 750 622

3 745 618 800 663

2 790 656 850 704

1 835 694 900 745

0 880 732 950 786

*Pulleys can be adjusted in half-turn increments.

F3EH090

60 Hz

F3EH090

50 Hz

MODEL

F4EH120

60 Hz

F4EH120

50 Hz

SUPPLY AIR BLOWER ADJUSTMENT

The RPM of the supply air blower will depend on the required

CFM,theunitaccessories andthestaticresistancesofboth the

supply and the return air duct systems. With this information,

the RPM for the supply air blower can be determined from the

blower performance in Table 4.

Knowing the required blower RPM and the blower motor HP,

the setting (turns open) for the supply air motor pulley can be

determined from Table 3.

Each motor pulley has:

1. Athreaded barrel with two flats (or notched recesses) 180

degrees apart.

2. A movable flange with one set screw.

After the movable flange has been rotated to the proper

number of “turns open”, the set screw should be tightened

againsttheflat on thebarreltolock the movableflangeinplace.

If the pulley includesa locking collar, thelocking collar mustbe

loosened to adjust the setting of the movable flange.

Note the following:

1. The supply air CFM mustbe within the limitations shown in

Table 2.

2. All pulleys can be adjusted in half turn increments.

3. The tension on the belt should be adjusted for a deflection

of 3/16 of an inch per footof belt spanwith an applied force

of 2 to 3 pounds. This adjustment is made by moving the

blowermotor mounting plate.Refer toFigure8. Turningthe

adjustment bolt (B) moves the motor mounting plate up or

down.

Unitary Products Group 7

Twohex nuts (A) have to be loosened to move the mount

ingplate and retightenedafter the mountingplate hasbeen

moved to the proper position.

4. All pulleys are factory aligned.

5. All supply air motor pulleys are factory set 3 “turns open”.

After thesupply air blower motoris operating, adjust the resis

tances in both the supply and the return duct systems to bal

ancethe air distributionthroughout theconditioned space. The

job specifications may require that this balancing be done by

someone other than the equipment installer.

Tocheckthe supply airCFMafter the initialbalancinghas been

completed:

1. Drill two 5/16 inch holes in the side panel as shown in Figure 9.

2. Insert atleast 6" of 1/4 inch tubing into each of these holes

for sufficient penetration into the air flow on both sides of

the indoor coil.

NOTE: The tubes must be inserted and heldin a position

perpendicular tothe air flow so thatvelocity pres

sure will not affect the static pressure readings.

3. Usingan inclined manometer,determinethepressuredrop

across a dry indoor coil. Since moisture on the coil may

varygreatly,measuringthe pressuredrop acrossa wet coil

underfield conditions would be inaccurate. To assure a dry

coil, the heat pump system should be de-activated while

the test is being run.

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curve in

Figure 10.

Ifthe CFM is above orbelow thespecified value, the supply air

motor pulley may have to be readjusted. After one hour of op

eration,checkthebeltand pulleys fortightnessandalignment.

WARNING: Failure to properly adjust the total system CFM

can result in extensive blower damage.

Afterreadings havebeen obtained,remove thetubes and seal

up the drilled holes in the side panel. Dot plugs (5/16" - P/N

029-13880-000) are available through normal parts ordering

procedures.

NOTE: Shut down the heat pump system before taking any

test measurements to assure a dry indoor coil.

-

-

-

-

-

Page 8

0.5

035-09651-001-A-0304

PRESSURE DROP

ACROSS DRY INDOOR COIL

FIG. 9 - HOLE LOCATIONS FOR PRESSURE

DROP READINGS

TABLE 4 - SUPPLY AIR BLOWER PERFORMANCE

RPM

ESP

2

BHP KW ESP2BHP KW ESP2BHP KW ESP2BHP KW ESP2BHP KW

0.4

0.3

0.2

PRESSURE DROP (IWG)

0.1

2000 2400 2800 3200 3600 4000 4400 4800 5200

FEH090

SUPPLY AIR CFM

FIG. 10 - PRESSURE DROP ACROSS A DRY

INDOOR COIL VS. SUPPLYAIR CFM

1,3

(60 Hz Units)

CFM

FEH120

F3EH090 (60 Hz)

2400 2700 3000 3300 3600

600 0.30 0.62 0.79 0.21 0.70 0.76 0.09 0.78 0.89 -----655 0.43 0.70 0.86 0.39 0.78 0.83 0.26 0.87 0.97 0.11 0.96 1.07 - - 700 0.52 0.77 0.93 0.48 0.85 0.90 0.40 0.95 1.06 0.28 1.06 1.16 0.14 1.17 1.26

800 0.82 0.97 1.10 0.81 1.06 1.07 0.74 1.18 1.27 0.63 1.30 1.38 0.51 1.42 1.49

880 1.10 1.11 1.24 1.09 1.24 1.21 1.02 1.37 1.45 0.91 1.50 1.55 0.78 1.64 1.70

900 1.15 1.15 1.27 1.14 1.28 1.24 1.07 1.42 1.49 0.97 1.55 1.60 0.87 1.70 1.74

1000 1.49 1.35 1.46 1.47 1.48 1.43 1.42 1.63 1.65 1.35 1.81 1.82 1.27 2.02 2.02

F4EH120 (60 Hz)

3200 3600 4000 4400 4800

700 0.30 1.01 1.17 0.15 1.17 1.27 --------800 0.66 1.25 1.38 0.52 1.42 1.51 0.31 1.60 1.64 0.08 1.80 1.78 - - 900 0.99 1.48 1.60 0.87 1.70 1.77 0.69 1.92 1.93 0.47 2.18 2.09 0.19 2.45 2.23

950 1.20 1.61 1.71 1.08 1.86 1.90 0.90 2.12 2.07 0.72 2.39 2.23 0.41 2.67 2.42

1000 1.37 1.75 1.83 1.27 2.02 2.02 1.11 2.30 2.20 0.92 2.60 2.39 0.63 2.90 2.59

1,3

TABLE 5 - SUPPLY AIR BLOWER PERFORMANCE

RPM

ESP

2

BHP KW ESP2BHP KW ESP2BHP KW ESP2BHP KW ESP2BHP KW

(50 Hz Units)

CFM

F3EH090 (50 Hz)

2000 2250 2500 2750 3000

500 0.22 0.43 0.41 0.16 0.48 0.46 0.08 0.53 0.50 -----542 0.30 0.47 0.45 0.25 0.53 0.50 0.18 0.58 0.55 0.10 0.63 0.60 - - 550 0.32 0.48 0.46 0.27 0.54 0.51 0.20 0.59 0.56 0.12 0.64 0.61 0.01 0.70 0.66

600 0.42 0.54 0.51 0.38 0.60 0.57 0.32 0.66 0.62 0.23 0.72 0.68 0.13 0.78 0.73

650 0.54 0.60 0.57 0.50 0.66 0.62 0.45 0.73 0.68 0.37 0.79 0.74 0.28 0.85 0.80

700 0.67 0.67 0.63 0.63 0.73 0.69 0.58 0.80 0.75 0.52 0.87 0.82 0.43 0.95 0.89

732 0.77 0.71 0.67 0.73 0.77 0.72 0.68 0.84 0.79 0.62 0.93 0.87 0.54 1.02 0.96

750 0.83 0.74 0.69 0.79 0.80 0.75 0.73 0.87 0.82 0.68 0.97 0.91 0.60 1.07 1.00

F4EH120 (50 Hz)

2800 3150 3500 3850 4200

550 0.14 0.65 0.60 -----------581 0.21 0.70 0.64 0.05 0.77 0.70 --------600 0.26 0.73 0.67 0.10 0.80 0.73 --------650 0.40 0.81 0.74 0.25 0.89 0.82 0.11 0.98 0.91 -----700 0.54 0.90 0.83 0.41 1.00 0.93 0.27 1.11 1.03 0.10 1.25 1.16 - 1.40 1.29

750 0.70 0.99 0.92 0.58 1.12 1.04 0.45 1.25 1.16 0.29 1.40 1.29 0.10 1.55 1.43

786 0.81 1.06 0.98 0.71 1.21 1.13 0.59 1.36 1.26 0.43 1.51 1.39 0.24 1.66 1.54

800 0.86 1.09 1.01 0.76 1.25 1.16 0.64 1.41 1.30 0.49 1.55 1.43 0.30 1.71 1.58

1

Unit resistance is based on a wet indoor coil and clean filters.

2

Available static pressure in IWG to overcome the resistance of the duct system and any accessories added to the unit. Refer to the Tables 6 & 7 for the resistance of these accessories and for

additional motor and drive data .

3

Motors can be selected to operate into the service factor because they are located in the moving air stream, upstream of any heating device.

RPM range for the standard drive components.

Exceeds the BHP limitations of the standard blower motor.

8 Unitary Products Group

Page 9

035-09651-001-A-0304

TABLE 6 - ACCESSORY STATIC RESISTANCE (IWG)

(To be included with Duct System Static Resistance)

Model Accessory Static Resistance, IWG

BLOWER CFM 2400 2700 3000 3300 3600

10 KW 0.01 0.01 0.01 0.02 0.02

16 KW 0.01 0.02 0.02 0.03 0.04

26 KW 0.03 0.04 0.05 0.06 0.07

36 KW 0.05 0.07 0.08 0.10 0.11

F3EH090

Electric

Heat

Supply Air Plenum 0.03 0.03 0.04 0.05 0.06

Return Air Grille 0.02 0.03 0.04 0.05 0.06

BLOWER CFM 3200 3600 4000 4400 4800

10 KW 0.02 0.02 0.03 0.03 0.04

16 KW 0.03 0.04 0.05 0.06 0.07

26 KW 0.06 0.07 0.09 0.11 0.13

36 KW 0.09 0.11 0.14 0.17 0.20

F4EH120

Electric

Heat

Supply Air Plenum 0.05 0.06 0.07 0.08 0.10

Return Air Grille 0.05 0.06 0.07 0.08 0.10

TABLE 7 - BLOWER MOTOR AND DRIVE DATA

Model Motor HP* Blower RPM

60 Hz

50 Hz

*These factory-mounted motors are wired for a 460V power supply. Refer to the wiring diagram inside the motor terminal box when reconnecting the motor leads for a

208 or 230 volt power supply.

F3EH090 1-1/2 655 - 880

F4EH120 2 700 - 950 7.0

F3EH090 1-1/2 542 - 732 7.5

F4EH120 2 581 - 786 7.0

Adjustable Motor Pulley Fixed Blower Pulley Belt

Pitch Dia.

(Inches)

Bore

(Inches)

Pitch Dia.

(Inches)

Bore

(Inches)

Designation

7.5

2.8 - 3.8 7/8

1 A36 37.3

Pitch Lg.

(Inches)

TABLE 8 - ELECTRICAL DATA

Blower

Motor

HP

Power

Supply

FLA

Max. Fuse

Size,

AMPS

F3EH090

208-3-60 5.3 10 207

230-3-60 5.8 10 209

1-1/2

460-3-60 2.7 5 897

380-3-50 3.3 5 606

415-3-50 4.0 5 546

F4EH120

208-3-60 7.5 10 146

230-3-60 6.8 10 178

2

460-3-60 3.4 5 712

380-3-50 4.0 5 500

415-3-50 4.5 5 485

NOTE: Refer to Form 550.13-N10.1 for electrical data on units equipped with an electric

heat accessory.

1

Dual element, time delay fuses.

2

Based on three 60°C, 14 AWG, insulated copper conductors in steel conduit, a 3% voltage

drop.

1

Max. Wire

Length

(Ft.)

2

#19 Solid 130

#18 Solid 170

#18 Stranded 180

#16 Stranded 270

#14 Stranded 455

#12 Stranded 730

To determine the total circuit length, add the following distances:

1 - Outdoor Unit to Indoor Unit ___________

2 - Indoor Unit to Thermostat ____________

3 - Thermostat to Indoor Unit ____________

4 - Indoor Unit to Outdoor Unit ___________

5 - Outdoor Unit to Elec. Heater __________

CONTROL WIRE SIZING

Wire Size

Total Circuit Length __________

Maximum Total

Circuit Length

(Feet)

Unitary Products Group 9

Page 10

POWER AND CONTROL WIRING

Install electrical wiring in accordance with the latest National

Electrical Code (NFPA Standard No. 70) and/or local regula

tions. The unit should be grounded in accordance with these

codes.

Routethe powerwiresinto theunit throughthe1-3/8” knockout

in the rear panel, and connect them to the terminals on blower

motor contactor 10M. Route the control wires into the unit

throughthe 7/8"hole inthe rear panel,and connectthem to the

terminals on block 4TB. Refer to the unit drawing in Fig. 12 for

the locations of these knockouts.

If the unit includes an electric heat accessory, route the power

wires intoheater control box in lieu of the unit. Referto electric

035-09651-001-A-0304

heatinstruction Form035-16602-002 foradditional installation

information.

-

NOTE: Motors are wiredfor a460V power supply.Refertothe

wiring diagram inside the motor terminal box when re

connecting motor leads for a 208 or 230 volt power

supply.

RefertoTable6 to sizethedisconnectswitch, the powerwiring,

the fuses and the control wiring. Refer to Fig. 11for field wiring

diagram.

If the supply air blower rotates in the wrong direction,

reversetwoof the motorleadsatblower motor contactor

10M.

-

NOTE: For thermostat to be used on these units refer to form #036-13335-003.

Refer to electric heat instruction 035-16602-002 for additional

NOTE:

power and control wire requirements if the indoor unit is

equipped with an electric heat accessory.

FIG. 11 - FIELD WIRING

10 Unitary Products Group

Page 11

035-09651-001-A-0304

All dimensions are in inches. They are

subject to change without notice. Certified

dimensions will be provided upon request.

ACCESSORIES

•

ELECTRIC HEATER - Add 14-1/4" to unit height when used.

•

SUPPLY AIR PLENUM - Add 27-1/2" to unit height when used.

•

BASE - Add 20" to unit height when used.

FIG.12 - UNIT DIMENSIONS & CLEARANCES (F3EH090 & F4EH120)

CLEARANCES

Side with RETURN AIR opening 24"

Side with SUPPLYAIR opening 24"

Side with PIPING CONNECTIONS 52"

Side opposite PIPING CONNECTIONS 12"

Side with access for both POWER & CONTROL WIRING

Bottom –

Unitary Products Group 11

1

2

3

–

4

1

Overall dimension of the unit will vary if an electric heater, a

supply air plenum or a base is used.

2

This dimension is required for removal of the coil. Only 26" is

required for normal servicing.

3

Although no clearance is required for service and operation,

some clearance may be required for routing the power wiring

and the control wiring.

4

Allow enough clearance to trap the condensate drain line.

Page 12

SECUREOWNER'SAPPROVAL:Whenthesystem isfunctioning properly,securethe owner'sapproval.Show himthe

location of all disconnect switches and the thermostat. Teach him how to start and stop the unit, how to adjust temperature

settings within the limitations of the system, how the defrost cycle is controlled and how the anti-cycle timer operates.

MAINTENANCE

INDOOR COIL

Do not allow dirt to accumulate on the indoor coil or other parts

of the supply/return air circuit. Clean as often as necessary to

assure good system performance. Use a brush, vacuum

cleaner attachment or other suitable means.

If the coil becomes extremely dirty,it may be necessary to use

anindustrialgrade detergent andahoseto clean thefinnedsur

faces.This isrecommended to preventany lossin capacity and

efficiency.

DRAIN PAN

The condensate drain pan should be inspected regularly to as

sure proper drainage.

FILTERS

The filters must be replaced as often as necessary to assure

good air flow and filtering action. Clean filters will prevent any

loss in capacity and efficiency.

Refer to the unit drawing in Fig. 12 for the location of the filter

access panel.

LUBRICATION

Thebearings fortheblower shaftandthe blowermotor areper

manentlylubricated and shouldnot require anyadditional lubri

cant.

BELTS

-

Maintain belt tension to extend belt life. Replace when signs of

failure begin to appear.

-

-

Unitary

Products

Group

Subject to change without notice. Printed in U.S.A.

by York International Corporation 2004 All rights reserved.

Copyright

5005

York

Drive

Norman,

Oklahoma

73069

Supersedes: 515.41-N2Y (692) / 035-09651-000

035-09651-001-A-0304

Loading...

Loading...