Page 1

INSTALLATION MANUAL

HIGH EFFICIENCY SEALED COMBUSTION

DRUM HEAT EXCHANGER SERIES

MODEL: DFAA/DFAH

(Oil and Gas Conversion Burner/

Single Stage Downflow Only)

66 - 84 MBH INPUT

(19.34 - 24.62 KW) INPUT

LIST OF SECTIONS

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OIL PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ELECTRICAL POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VENT/COMBUSTION AIR SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . 14

LIST OF FIGURES

Label Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Air Distribution Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Closet To Door Clearance - 5” or Greater . . . . . . . . . . . . . . . . . . . . . . . . . 7

Furnace To Closet Door Clearance - 1” To 5” . . . . . . . . . . . . . . . . . . . . . . 7

Furnace To Closet Door Clearance - Less Than 1” . . . . . . . . . . . . . . . . . . 7

Duct Connector Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Recommended Floor Cut-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Duct Connector Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Duct Connector Screw Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Duct Connector Tab Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Anti-Backflow Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation of Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Floor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Furnace Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

One-Pipe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Two-Pipe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Solenoid Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Line Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring for Heat Only Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring for Electronic Heat-Cool Thermostat . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring for Standard Heat-Cool Thermostat . . . . . . . . . . . . . . . . . . . . . . . 14

LIST OF TABLES

Unit Clearances to Combustibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Minimum Duct Sizing For Proper Airflow . . . . . . . . . . . . . . . . . . . . . . . 6

Round Duct Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

External Static Pressure Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Filter Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Burner Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Burner Rating at Elevation Above Sea Level, gph (l/m) . . . . . . . . . . .12

Ratings & Physical / Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Roof Jack Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Cad Cell Resistance When Sensing Flame . . . . . . . . . . . . . . . . . . . .22

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

START-UP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

WIRING DIAGRAM - OIL-FIRED FURNACE . . . . . . . . . . . . . . . . . . . .27

GAS GUN BURNER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

START-UP AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

WIRING DIAGRAM - GAS CONVERSION BURNER . . . . . . . . . . . . . . 38

Wiring for Blend Air Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Elbow Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Combustion Air Inlet Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Combustion Air Inlet Pipe Alternate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Flue Shield Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

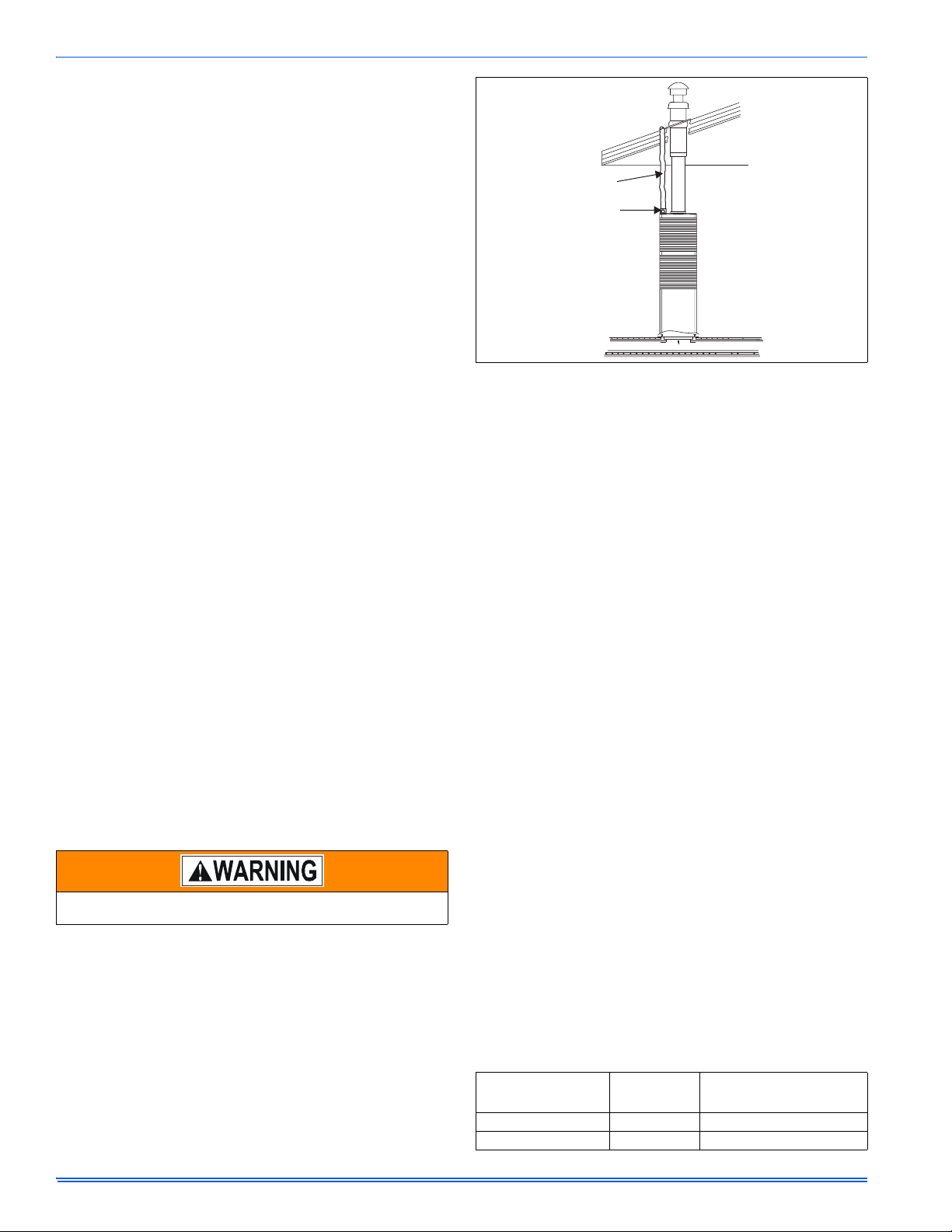

Roof Jack Attachment to Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Standard Roof Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Roof Jack With Removable Crowns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing Roof Jack Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ceiling Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Home Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Electrode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wiring Diagram for DFAA - Oil-Fired Furnace . . . . . . . . . . . . . . . . . . . . . 27

Wiring Diagram for DFAH - Oil Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Manual Shut-off Valve/Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Proper Piping Practice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Reading Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Electrode Orientation and Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Wiring Diagram for DFAA - Gas Conversion Burner . . . . . . . . . . . . . . . . . 38

Wiring Diagram for DFAH - Gas Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Timings and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Burner Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Filter Performance - Pressure Drop Inches W.C. and (kPa) . . . . . . . .24

Blower Performance CFM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Replacement Parts - Non Electrical . . . . . . . . . . . . . . . . . . . . . . . . . .26

Gas Line Piping Size and Length . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Length of Standard Pipe Threads in Inches (mm) . . . . . . . . . . . . . . .30

High Altitude Duration Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Gas Burner Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Inlet Gas Pressure Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Nominal Manifold Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

EFFICIENCY

RATING

CERTIFIED

Certified Quality

Management System

For Installation In:

1. Manufactured (Mobile) Homes

2. Recreational Vehicles & Park Models

3. Modular Homes & Buildings

ISO 9001

SECTION I: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or mo derate injury.

alert against unsafe practices and hazards involving only property damage.

.

.

It is also used to

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this manual

for assistance or for additional information, consult a qualified contractor, installer or service agency.

This product must be installed in strict compliance with the installation instructions and any applicable local, state, and national codes

including, but not limited to building, electrical, and mechanical

codes.

107272-UIM-B-1105

Page 2

107272-UIM-B-1105

SPECIFIC SAFETY RULES AND PRECAUTIONS

1. U.S.....No. 1 or No. 2 heating oil only (ASTM D396),

CANADA.....No. 1 stove oil or No. 2 furnace oil only are ap proved

for use and can be burned in this furnace. Refer to the furnace rating plate or SECTION IV of these instructions.

2. Install this furnace only in a location and position as specified in

SECTION I of these instructions.

3. An oil-fired furnace for installation in a residential garage must be

installed as specified in SECTION I of these instructions.

4. Combustion products must be discharged outdoors. The Roof

Jack vent system is the only approved vent system that can be

installed on this furnace. Install as specified in SECTION VI of

these instructions.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Read all instructions before proceeding. Follow all instructions com-

pletely. Failure to follow these instructions could result in equipment

malfunction, causing severe personal injury, death, or substantial

property damage.

5. Test for leaks in the oil line as specified in SECTION VIII of these

instructions.

6. Always install the furnace to operate within the furnace’s intended

temperature rise range. Only connect the furnace to a duct system

which has an external static pressure within the allowable range,

as specified on the furnace rating plate.

7. The return air duct system is not required by the furnace manufacturer. This furnace utilizes a sealed combustion air and vent system referred to as a roof jack. The Roof Jack must be installed as

specified in these instructions and must conform with state, local,

or regional codes.

8. It is permitted to use the furnace for heating of buildings or structures under construction. Installation must comply with all manufacturer’s installation instructions including:

• Proper vent installation;

• Furnace operating under thermostatic control;

• Return air filter door must be sealed to the furnace;

• Air filters in place;

• Set furnace input rate and temperature rise per rating plate

marking;

• Means for providing outdoor air required for combustion;

• Return air temperature maintained between 55ºF (13ºC) and

80ºF (27ºC);

• The air filter must be replaced or thoroughly cleaned upon sub-

stantial completion of the construction process;

• Clean furnace, duct work and components upon substantial

completion of the construction process, and verify furnace

operating conditions including ignition, input rate, temperature

rise and venting, according to the manufacturer’s instructions.

The following requirements to be met:

a. Clean, outside combustion air is provided to the furnace to

minimize the impact of corrosive adhesives, sealants, and

other construction materials. Drywall dust is a major concern

during construction, which can be pulled into the combustion

air path, leading to plugged heat exchangers, burners, and

inducer assemblies.

b. Filter must be installed in the furnace as specified in the

installation instructions, and must be replaced or thoroughly

cleaned prior to occupancy of the home. Again, drywall dust

is the key issue, as that dust can be pulled into the circulating

blower motor, plugging the motor vents, coating the rotors

and stators, etc. which can lead to a potential fire hazard.

c. The temperature of the retu rn air to the furnace must not be

less than 55° F (13° C), with no evening setback or furnace

shutdown, to prevent condensation in the primary heat

exchangers.

d. The air temperature rise must be within the stated rise range

as indicated on the furnace rating plate, and the firing input

rate must be set to the unit nameplate value.

e. The external static pressure of the air distribution system

ductwork must be set for heating operation to be at least 0.12

(.03 kPA) to 0.30 (0.7 kPA) inches water column, based on

the input rate of the furnace, with the lower value for input

rates at 66,000 btu/hr and the upper value for units with input

rates at 84,000 btu/hr.

f. The furnace and ductwork should be thoroughly and com-

pletely cleaned prior to occupancy of the dwelling to insure

the proper operation of the furnace and to avoid potential

health concerns.

9. In Canada refer to the Oil-fired Central Furnace Installation code,

CANCSA B139 When installed in a Manufactured (Mobile) Home,

combustion air shall not be supplied from occupied spaces.

10. The size of the unit should be based on an acceptable heat loss

calculation for the structure. ACCA, Manual J or other approved

methods may be used.

11. Manufactured (Mobile) Home and Modular Home Installation:

This appliance must be installed in a (sealed combustion) configuration using a roof jack vent system. A roof jack is the only

approved vent system that can be used to vent this appliance.

12. Modular Home Definition: Factory-built home constructed to the

state, local, or regional code where the house will be located. The

home is transported in one or more modules and joined at the

home site.

13. Manufactured (Mobile) Home Definition: Factory-built home

constructed, transported and installed under the federal building

code administered by the U.S. Department of Housing and Urban

Development (HUD Code), rather than to building codes at their

destination. The house is built, transported and installed on a nonremovable chassis.

14. This furnace is approved for installation in trailers or recreational

vehicles.

SAFETY REQUIREMENTS

• Never attempt to alter or modify this furnace or any of its components.

• Never attempt to repair damaged or inoperable components.

Such action could cause unsafe operation, explosion, fire and/

or asphyxiation.

• If a malfunction has occurred, or if you feel that the furnace is

not operating as it should, contact a qualified service agency or

oil supplier for assistance.

• A manufactured (mobile) home installation must conform with the

Manufactured Home Construction and Safety Standard, Title 24

CFR, Part 3280, Federal Manufactured Home Construction &

Safety Standard (H.U.D., Title 24, Part 3280) or when such standard is not applicable, the standard for Manufactured Home

Installations (Manufactured Home Sites, Communities, and Setups) NFPA 31 Installation of Oil-Burning Equipment, CAN/CSA

B139 Installation Codes). This furnace has been certified to the

latest edition of standard UL 727 Standard for Safety for Oil-Burning Equipment, and for Oil-Fired Central Furnaces (Latest Edition), CSA B140.10 (Latest Edition), and all local codes and

ordinances.

• Refer to the unit rating plate for the furnace model number, and

then see the dimensions page of these instructions for return air

door dimensions in Figure 2. The filter(s) must be installed

according to the instructions.

2 Unitary Products Group

Page 3

107272-UIM-B-1105

• Provide clearances from combustible materials as listed under

Furnace Locations and Clearances.

• Provide clearances for servicing, ensuring that service access is

allowed for both the burners and blower.

• These models are ETL listed and ap proved for installation into a

Modular Home or a Manufactured (Mobile) Home.

• Failure to carefully read and follow all instructions in this

manual can result in furnace malfunction, death, personal

injury and/or property damage.

• Furnaces for installation on combustible flooring shall not be

installed directly on carpeting, tile or other combustible material

other than wood flooring.

• Check the rating plate and power supply to be sure that the electrical characteristics match. All models use nominal 115 VAC, 1

Phase, 60-Hertz power supply. DO NOT CONNECT THIS APPLIANCE TO A 50 HZ POWER SUPPLY OR A VOLTAGE ABOVE

130 VOLTS.

• Furnace shall be installed so the electrical components are protected from water.

• Installing and servicing heating equipment can be hazardous due

to the electrical components and the oil fired components. Only

trained and qualified personnel should install, repair, or service oil

heating equipment. Untrained service personnel can perform

basic maintenance functions such as cleaning and replacing the

air filters. When working on heating equipment, observe precautions in the manuals and on the labels attached to the unit and

other safety precautions that may apply.

NOTICE SPECIAL REQIREMENTS

This equipment must be installed, adjusted, and started only by a

qualified service agency - an individual or agency, licensed and

experienced with all codes and ordinances, who is responsible for

the installation and adjustment of the equipment. The installation

must comply with all local codes and ordinances and with the latest

revision of the National Fire Protection Association Standard

NFPA31 (or CSA B139).

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances these

instructions exceed certain local codes and ordinances, especially

those who have not kept up with changing Modular Home and Manufactured (Mobile) Home construction practices. These instructions are

required as a minimum for a safe installation.

COMBUSTION AIR QUALITY

(LIST OF CONTAMINANTS)

The furnace will require OUTDOOR AIR for combustion when the furnace is located in any of the following environments.

• Restricted Environments

• Commercial buildings

• Buildings with indoor pools

• Laundry rooms

• Hobby or craft rooms

• Near chemical storage areas

• Chemical exposure

The furnace will require OUTDOOR AIR for combustion when the furnace is located in an area where the furnace is being exposed to the following substances and / or chemicals.

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

When outdoor air is used for combustion, the combustion air intake duct

system termination must be located external to the building and in an

area where there will be no exposure to the substances listed above.

The furnace area must not be used as a broom closet or for any

other storage purposes, as a fire hazard may be created. Never

store items, such as the following, on, near or in contact with the

furnace.

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning compounds; plastic items or

3. Containers, gasoline, kerosene, cigarette lighter fluid, dry

cleaning fluids or other volatile fluid.

4. Paint thinners and other painting compounds.

5. Paper bags, boxes or other paper products

Never operate the furnace with the blower door removed. To

do so could result in serious personal injury and/or equipment

damage.

INSPECTION

As soon as the furnace and/or accessories are received, it should be

inspected for damage during transit. If damage is evident, the extent of

the damage should be noted on the carrier’s freight bill. A separate

request for inspection by the carrier’s agent should be made in writing.

Also, before installation, the furnace and/or accessories should be

checked for screws or bolts which have loosened in transit, or shipping

and spacer brackets that need to be removed.

CONCEALED DAMAGE - If you discover damage to the burner or

controls during unpacking, notify carrier at once and file the appropriate claim.

WHEN CONTACTING BECKETT FOR SERVICE INFORMATION Please record the burner serial number (and have available when

calling or writing). You will find the serial number on the Underwriters Laboratories label, located on the left rear of the burner, or

cover mounting plate. See Figure 1.

Unitary Products Group 3

Page 4

107272-UIM-B-1105

General Model

Information

Serial Number,

Including Date Code

Rating Information

Approval Agency

Symbols

Primary Group

and Fuel Oil

Model "AFEVC"

Series Oil Burner

SERIAL NUMBER

020923-49038

Firing Rng:0.50-0.75 GPH

120V/60Hz 5.8A

R

OIL BURNER NO. PI-100001

R.W.BeckettCorp.

Elyria, Ohio

Made inthe U.S.A.

For usewith Group 1 or 2

primary safety controls&

#1 or#2 fuel oil

MP 1192 EVC201 R00

LISTED

MFR'S SETTINGS

AF36YHHS

ATC:

FIRING RNG:

0.5-1.10 GPH

F3

HEAD:

3-3/8U

STCPLT:

NOZZLE: 0.65 X 70A DLVNHLW

PUMP PRS: 100PSI

EVC201 R00

020923-49038

026-37357-000

DEPT.

Comm. ofMass. -

CS

I

A

L

B

F

U

E

P

T

Y

OFFICEOF

THESTATE

State FireMarshall

FIRE

MARSHAL

Approval #BEC-88-01

Approval July1, 1988

Accepted N.Y.C.MEA. 213-83-E

R. W. Beckett

Manufacturer’s Settings

R. W. Beckett Specification

Number and Revision

Can be Customized by

Individual Specification

State and Local Approvals

RWB

ELYRIA

OHIOU.S.A.

MFR'SSETTINGS

Model"AF "

AF65XNATC:

SeriesOilBurner

FIRINGRNG:

0.75-1.35GPH

HEAD:

F3

SERIALNUMBER

STCPLT:

2-3/4U

1.0X80BDLVN

NOZZLE:

000405-62736

100PSI

PUMPPRS:

BJB3001R00

0.50-3.00GPH,120V/60HZ5.8A

000405-62736

4ULTESTSPEC

5ULTESTSPEC

R

LISTED

R

6ULTESTSPEC

7ULTESTSPEC

OILBURNER NO.PI-100001

8ULTESTSPEC

9ULTESTSPEC

R.W.BeckettCorp.

Elyria,Ohio

MadeintheU.S.A.

DEPT.

Comm.ofMass.-

CS

I

A

L

B

F

U

E

P

T

Y

OFFICEOF

THESTATE

StateFireMarshall

FIRE

ForusewithGroup1or 2

MARSHAL

Approval#BEC-88-01

primarysaftycontrols&

ApprovalJuly1,1988

#1or#2fueloil

AcceptedN.Y.C.MEA.213-83-E

ApprovalJuly1,1988

MP1192BJB3001 R00

FIGURE 1: Label Location

CHECK CERTIFICATIONS / APPROVALS

• Underwriters Laboratories has certified this burner to comply with

ANSI/UL 296 and has listed it for use with #1 or #2 fuel oil as

specified in ASTM D396. Low sulfur #1 and #2 fuel oils reduce

2. Do not allow return air temperature to be below 55º F (13° C) for

extended periods. To do so may cause condensation to occur in

the main heat exchanger, leading to premature heat exchanger

failure.

heat exchanger deposits with all burners compared to the standard fuels. Reduced deposits may extend the service interval for

cleaning and improve the efficiency of the appliance over time.

Low sulfur fuels reduce particulate and oxides of nitrogen emissions as well. The Oil Heat Manufacturers’ Association recommends these fuels as the preferred fuels for this burner.

• State and local approvals are shown on burner rating label (See

Figure 1).

• All oil burners must be installed in accordance with the regulations of the latest revision of the National Fire Protection Association Standard NFPA 31 and in complete accordance with all local

codes and authorities having jurisdiction. Regulation of these

authorities take precedence over the general instructions provided in this installation manual.

FURNACE LOCATION AND CLEARANCES

The furnace shall be located using the following guidelines:

1. The furnace should be located where the roof jack can be installed

without major modifications to the roof of the structure.

2. As centralized with the air distribution as possible.

3. Where there is access to fresh air particularly when the blend air

accessory will be installed.

Installation in an ambient below 32ºF (0.0° C) could create a hazard, resulting in damage, injury or death.

3. If this furnace is installed in an unconditioned space and an

extended power failure occurs, there will be potential damage to

the internal components. Following a power failure situation, do

not operate the unit until inspection and repairs are performed.

Clearances for access:

Ample clearances should be provided to permit easy access to the unit.

The following minimum clearances are recommended:

1. Twenty-four (24) inches (61 cm) between the front of the furnace

and an adjacent wall or another appliance, when access is

required for servicing and cleaning.

2. Twenty-four (24) inches (61 cm) at the side where access is

required for passage to the front when servicing or for inspection

or replacement of flue/vent connections.

In all cases, accessibility clearances shall take precedence over clearances for combustible materials where accessibility clearances are

greater.

4. Where it will not interfere with proper air circulation in the confined

space.

5. Where the outdoor section of the roof jack will not be blocked or

restricted. Refer to “VENT CLEARANCES” located in SECTION VI

of these instructions. These minimum clearances must be maintained throughout the installation.

6. Where the unit will be installed in a level position with no more than

1/4” (0.64 cm) slope side-to-side and front-to-back to provide a

proper roof jack connection and seal.

Installation in freezing temperatures:

1. Furnace shall be installed in an area where ventilation facilities

provide for safe limits of ambient temperature under normal operating conditions. Ambient temperatures below 32º F (0º C) may

Check the rating plate and power supply to be sure that the electrical characteristics match. All models use nominal 115 VAC, 1

Phase 60Hz power supply.

Furnace shall be installed so the electrical components are protected from water.

Installation in a residential garage:

1. An oil-fired furnace for installation in a residential garage must be

installed so the burner(s) and the ignition source are located not

less than 18 inches (46 cm) above the floor, and the furnace must

be located or protected to avoid physical damage by vehicles.

result in the vent temperature falling below 260º F (127º C) at any

point in the vent pipe. Vent temperatures below 260º F (127º C)

will cause the flue products in the vent pipe to condense causing

the vent pipe to deteriorate rapidly.

TABLE 1:

Unit Clearances to Combustibles

APPLICATION

TOP FRONT BACK SIDES

AIR INLET

PIPING

ROOF JACK

DUCT

1

In. (cm) In. (cm) In. (cm) In. (cm) In. (cm) In. (cm) In. (cm)

CLOSET 2 (5.08) 6 (15.24) 0 (0.0) 0 (0.0) 0 (0.0) 3 (7.62) 0 (0.0) 0 (0.0)

ALCOVE 2 (5.08) 24 (60.96) 0 (0.0) 0 (0.0) 0 (0.0) 3 (7.62) 0 (0.0) 0 (0.0)

1. Approved Duct Connector must be used. Refer to Section II - Ductwork.

FLOOR/BOTTOM

4 Unitary Products Group

Page 5

107272-UIM-B-1105

Inches

A

59-1/2”

B

C

D

E

F

G

A

DFAH Series

76”

C

24.3/4”

D

23”

E

19-1/2”

F

9-3/4”

G

12”

FIGURE 2: Dimensions

SECTION II: DUCTWORK

DUCTWORK GENERAL INFORMATION

The duct system’s design and installation must:

1. Handle an air volume appropriate for the served space and within

the operating parameters of the furnace specifications.

2. Be installed in accordance with standards of NFPA (National Fire

Protection Association) as outlined in NFPA pamphlets 90A and

90B (latest editions), in Canada CAN/CSA-B139, Installation Code

for Oil-Burning Equipment, or applicable national, provincial, or

state, and local fire and safety codes.

3. For Manufactured (Mobile) Home and Modular Home Return

Duct System Installations:

A return air duct and the return air plenum cannot be installed on

this furnace. The return air is drawn through the louvers on the

blower door. The vent system is a Sealed Combustion Direct Roof

Jack Vent System. This is the ONLY vent system approved for use

on this furnace.

4. Complete a path for heated or cooled air to circulate through the

air conditioning and heating equipment and from the conditioned

space.

5. Consideration should be given to the heating capacity required

and also to the air quantity (CFM) required. These factors can be

determined by calculating the heat loss and heat gain of the home

or structure. If these calculations are not performed and the furnace is over-sized, the following may result:

a. Short cycling of the furnace.

b. Wide temperature fluctuations from the thermostat setting.

c. Reduced overall operating efficiency of the furnace.

On DFAA furnaces, the cooling coil must be installed in the bottom

of the casing. DFAH furnaces must have the cooling coil installed

downstream of the furnace. Cooled air may not be passed over the

heat exchanger.

C

c.m.

151.0

193.0

62.9

58.4

49.5

24.8

30.5

D

E

F

G

B

DFAA Series

When the furnace is used in conjunction with a cooling coil, the coil

must be installed parallel with, or in the supply air side of the furnace to

avoid condensation in the primary heat exchanger. When a parallel flow

arrangement is used, dampers or other means used to control airflow

must be adequate to prevent chilled air from entering the furnace. If

manually operated, the damper must be equipped with means to prevent the furnace or the air conditioner from operating unless the damper

is in full heat or cool position.

The duct system must be properly sized to obtain the correct airflow

for the furnace size that is being installed.

Refer to Table 8 and the furnace rating plate for the correct rise

range and Table 4 for static pressures.

If the ducts are undersized, the result will be high duct static pressures and/or high temperature rises which can result in a heat

exchanger OVERHEATING CONDITION. This condition can result

in premature heat exchanger failure, which can result in personal

injury, property damage, or death.

HAZARD OF ASPHYXIATION, DO NOT COVER OR RESTRICT

FLOOR OPENING.

The duct system is a very important part of the installation. If the duct

system is improperly sized, the furnace will not operate properly.

The ducts attached to the furnace duct connector should be of sufficient

size so that the furnace operates at the specified external static pressure and within the air temperature rise specified on the nameplate.

IMPORTANT: Fabricate and install an inspection door in the plenum

base below the unit to allow an annual inspection of the heat exchangers. The inspection door can be fabricated by following method.

1. Cut a rectangular opening in the plenum base.

2. A Sheet metal plate can be made that completely covers the opening in the base.

3. The plate must be secured with screws.

4. This plate must be sealed to prevent leaks.

Table 2 is a guide for determining whether the rectangular duct system

that the furnace is being connected to, is of sufficient size for proper furnace operation.

Unitary Products Group 5

Page 6

107272-UIM-B-1105

Use the example below to help you in calculating the duct area to determine whether the ducts have sufficient area so that the furnace operates at the specified external static pressure and within the air

temperature rise specified on the nameplate.

Example: The furnace input is 80,000 BTUH, (23.4 kW) 1,200 CFM

3

(34.0 m

in x 14 in (20.3 cm x 35.6 cm) rectangular ducts attached to the plenum

and there are two 7 inch (722 cm

1. Take 8 in x 14 in (20.3 cm x 35.6 cm), which equals 112 inch

). The recommended duct area is 280 inch2 (1, there are two 8

2

) round ducts attached to the furnace.

(35.6 cm x 2), which equals 224 inch

2

(1445 cm2) then go to round

2

X 2

2. The square inch area for 7 inch (17.8 cm) round pipe is 38.4, multiply by 2 for two round ducts which equals 76.8 inch

2

3. Then take the 224 inch

add it to the 76.8 inch

inch of duct attached to the furnace plenum is 300.8 inch

2

cm

). This exceeds the recommended 280 inch2 (1,806 cm2) of

(1445 cm2) from the rectangular duct and

2

(495 cm2) of round duct. The total square

2

(495 cm2).

2

(1,940

duct.

In this example, the duct system attached to the plenum has a sufficient

area so that the furnace operates at the specified external static pressure and within the air temperature rise specified on the nameplate.

duct size located in Table 3.

TABLE 2:

Minimum Duct Sizing For Proper Airflow

Input Airflow

Return

1

Rectangular

2

Round

2

Supply

3

Rectangular

2

Round

2

BTU/H (kW) CFM(m³) In² (cm²) in. x in.(cm x cm) in. (cm) dia In² (cm²) in. x in. (cm x cm) in. (cm) dia.

66000 (19.34) 1,050 (29.73) 280 (711) 14 x 20 (35.6 x 50.8) 18(45.7) 216(549) 12 x 18 (30.5 x 45.7) 16 (40.6)

84000 (24.62) 1,250 (35.40) 360 (914) 18 x 20 (45.7 x 50.8) 22(55.8) 280(711) 14 x 20 (35.6 x 50.8) 18 (45.7)

NOTE: This chart does not replace proper duct sizing calculations or take into account static pressure drop for run length and fittings. Watch out for the temperature rise

and static pressures.

3

1. Maximum return air velocity in rigid duct @ 700 feet per minute (19.82 m

2. Example return main trunk duct minimum dimensions.

3. Maximum supply air velocity in rigid duct @ 900 feet per minute (25.49 m

TABLE 3:

Round Duct Size

Round Duct Size Calculated Area For Each Round Duct Size

Inches (cm)

Sq. Inch (cm

2

)

5 (13) 19.8 (126)

6 (15) 28.2 (182)

7 (18) 38.4 (248)

8 (20) 50.2 (324)

9 (23) 63.6 (410)

10 (25) 78.5 (506)

11 (28) 95.0 (613)

12 (30) 113.1 (730)

13 (33) 132.7 (856)

14 (36) 153.9 (993)

1. The Air Temperature Rise is determined by subtracting the Return

Air Temperature Reading from the Supply Air Temperature Reading.

2. The External Static Pressure is determined by the Supply Duct

Static Pressure reading.

TABLES 2 and 3 are to be used as a guide only to help the installer

determine if the duct sizes are large enough to obtain the proper air flow

(CFM) through the furnace. TABLES 2 and 3 ARE NOT to be used to

design ductwork for the building where the furnace is being installed.

There are several variables associated with proper duct sizing that are

not included in the tables. To properly design the ductwork for the building, Refer to the ASHRAE Fundamentals Handbook, Chapter on

“DUCT DESIGN” or a company that specializes in Residential and Modular Home duct designs.

/ minute).

3

/ minute).

DUCKWORK INSTALLATION

Air Distribution Systems

For proper air distribution, the supply duct system shall be designed so

that the static pressure does not exceed the listed static pressure rating

on the furnace rating plate.

Three typical distribution systems are illustrated in Figure 3.

Location, size and number of registers should be selected on the basis

of best air distribution and floor plan of the home.

The Air Temperature Rise is to be adjusted to obtain a temperature rise

within the range(s) specified on the furnace rating plate.

DUCT DESIGN - CANADA

Supply duct design shall be in accordance with the latest HRA Digest,

the ASHRAE Handbook Fundamentals, or other good engineering principles.

NOTE: Refer to HRA Digest Residential Air System Design Manual,

Sections 5 and 6, the requirements of which are summarized as follows:

1. The kilowatt output of each duct register shall not exceed 2.35 kW.

2. The furnace output should not be more than 20% greater than the

calculated heat loss of the home. If a larger furnace is used, the

duct system shall be capable of the increased air volumes neces-

sary to maintain a maximum air temperature rise of 50

air passes over the furnace heat exchanger.

3. At least one warm air supply outlet shall be provided in each room.

4. When rooms are located adjacent to the exterior walls, warm air

outlets shall be located so as to bathe at least one exterior wall

and, where practical, a window area with warm air, except for bathrooms or kitchens where this might not be practical.

o

C as the

5. Where practical, outlets shall be provided near the exterior doors

of the home.

The supply air temperature MUST NEVER exceed the Maximum

Supply Air Temperature, specified on the nameplate.

Operating the furnace above the maximum supply air temperature

will cause the heat exchanger to overheat, causing premature heat

exchanger failure. Improper duct sizing, dirty air filters, incorrect oil

pump pressure, incorrect oil orifice and/or a faulty limit switch can

CLEARANCE REQUIREMENTS - CANADA

Supply air ducts from warm air furnaces having a specified minimum

plenum clearance shall maintain this clearance from combustible material for at least the distance specified in CSA Standards CAN/CSA

B139, B14.0, B140.10.

cause the furnace to operate above the maximum supply air temperature. Refer to SECTIONS II, III and VIII for additional information on correcting the problem.

6 Unitary Products Group

Page 7

A

Single trunk duct

Dual trunk duct with crossover connector

B*

1

Transition Duct with Branches

C

Transition duct

107272-UIM-B-1105

Dual trunk duct

1. Crossover Duct must be centered directly under furnace.

2. Use 12” (30.5 cm) Diameter Round or insulated Flex-duct only.

3. Terminate Flex-duct (opposite furnace) in the center of the trunk duct.

4. Flex-duct material must be pulled tight — No Loops or unnecessary dips — Air Flow may be impeded.

Crossover

4

FIGURE 3: Air Distribution Systems

Return Air Grille Part No.

7900-287P/A * White

A

22

250 IN. (161 cm )

MINIMUM

FREE AREA

22

50 IN. (322 cm )

MINIMUM

FREE AREA

FIGURE 4: Closet To Door Clearance - 5” or Greater

2

Branches

3

Furnace to Closet Door Clearance —

B

22

250 IN. (161 cm )

MINIMUM

FREE AREA

5 Inches (12.7 cm) or more

The closet door have a minimum of

of free area in the upper half of the door.

If opening for return air is located in the floor or sidewalls and

below the top of the furnace casing:

6 inches (15.2 cm) minimum clearance must be provided on side

1.

where return is located, and

6 inches (15.2 cm) minimum clearance must be maintained from

2.

the front of furnace.

CLOSET

FURNACE

DOOR

MUST 250 Inches (1613 cm )

5 in (12.7 cm) or greater * Closet

to Door Clearance

Return Air Closet Door Part No.

7900-7771/C* White

22

22

250 IN. (161 cm )

MINIMUM

FREE AREA

22

50 IN. (322 cm )

MINIMUM

FREE AREA

As an option to the lower grill,

an undercut of 2-1/2" will provide

50 inches (322 cm ) of free area.

22

FIGURE 5: Furnace To Closet Door Clearance - 1” To 5”

250 IN. (161 cm )

MINIMUM

FREE AREA

50 IN. (322 cm )

MINIMUM

FREE AREA

B

250 IN. (161cm )

MINIMUM

FREE AREA

22

22

Furnace to Closet Door Clearance —

Greater than 1 Inch (2.54 cm) and Up to 5 (12.7 cm) Inches

1.

The closet door have a minimum of (1613 cm f free

area in the upper half of the door and a minimum of (322 cm ) of

free area in the lower area of the door.

omitted if an undercut of 2-1/2 inches (16.1 cm) is provided in the door.

2.

A fully louvered closet door have a minimum of

250 Inches

22

Furnace to Closet Door Clearance —

Less than 1 Inch (2.54 cm)

MUST 250 Inches

The lower closet door grille may be

22

(1613 cm )

MUST

of free area in the upper half of the door.

The closet door MUST have three return air grilles. The total free area of the

two upper grilles must be minimum of (1613 cm ) . The total

free area of the lower grille MUST be a minimum of .

The grilles MUST BE ALIGNED directly opposite the return air grille of

the furnace door.

250 Inches

22

50 Inches

22

50 Inches (322 cm )

)o

22

22

FIGURE 6: Furnace To Closet Door Clearance - Less Than 1”

Unitary Products Group 7

Page 8

107272-UIM-B-1105

DUCT CONNECTORS

18-3/4 (47.6 cm)

2-3/8

(6.0 cm)

14 (35.6 cm)

13

(33.0 cm)

(27.9 cm

11

DUCT CONNECTOR DIMENSIONS

DUCT CONNECTOR

PART NUMBER

7990-6011

7990-6021

7990-6041

7990-6061

7990-6071

7990-6081

7990-6101

7990-6121

FIGURE 7: Duct Connector Dimensions

Rear Wall

2-3/4 (7.0 cm)

Min.

9-7/8

(25.1 cm

of Enclosure

2-3/8

(6.0 cm)

12

(30.5 cm)

18-3/4

(47.6 cm)

4-3/8

(11.1 cm)

DUCT CONNECTOR

DEPTH

1” (2.5 cm)

2” (5.7 cm)

4-1/2” (11.4 cm

6-1-2” (16.5 cm)

7-1/2” (19.0 cm)

8-1/2” (21.6 cm)

10-1/4” (26.0 cm)

12-1/4” (21.1 cm)

Ceiling Cut-Out

For Roof Jack

Floor Cut-Out

For Duct

Connector

SEE

CHART

Furnace

Outline

2-3/8

(6.0 cm)

DUCT CONNECTOR DIMENSIONS

DUCT CONNECTOR

PART NUMBER

7990-6211

7990-6221

7990-6241

7990-6261

7990-6271

7990-6281

7990-6301

7990-6321

18-3/4 (47.6 cm)

14 (35.6 cm)

13

(33.0 cm)

11

(27.9 cm

Locator Bracket

2-3/8

(6.0 cm)

12

(30.5 cm)

18-3/4

(47.6 cm)

4-3/8

(11.1 cm)

DUCT CONNECTOR

DEPTH

1” (2.5 cm)

2” (5.7 cm)

4-1/2” (11.4 cm

6-1-2” (16.5 cm)

7-1/2” (19.0 cm)

8-1/2” (21.6 cm)

10-1/4” (26.0 cm)

12-1/4” (21.1 cm)

Nails, Flat Head Screws

or Staples

Screws

SEE

CHART

Floor

23-1/4 (59.1 cm)

20-1/2 (52.1 cm)

2-1/8 (5.4 cm)

1

1-3/8

(3.5 cm)

Future

Refrigerant

Line Entrance

15

(38.1 cm)

6-3/8

(16.2 cm)

9-3/4

24.8 cm)

15

(38.1 cm)

20

(50.8 cm)

(8.3 cm)

FIGURE 8: Recommended Floor Cut-out

Duct Connector

Depth

Supply Duct

FIGURE 9: Duct Connector Depth

3-1/4

Floor

1-1/8

(2.9 cm)

Floor

Optional Gas

or Electric

Entrance

Front Panel

of Furnace

Floor

Joist

Supply Duct

FIGURE 10: Duct Connector Screw Attachment

INSTALLATION OF SCREW ATTACHMENT DUCT

CONNECTOR

1. Make floor cut out as shown in Figure 8.

2. Determine the depth of the floor cavity from the surface of the floor

to the top of the supply air duct and select the appropriate duct

connector from the chart.

3. Place locating bracket (supplied with the duct connector) to the

back edge of the floor opening. See Figure 10.

4. Apply a water based duct sealant to the 1/2 in (1.3 cm) supply duct

attachment flange of the duct connector.

5. Determine which of the four positions the duct connector best centers over the supply duct and insert it through the floor cut-out.

6. When properly aligned with the supply duct, secure the duct connector to the floor with nails, flat head screws or staples.

7. Use screws as required to secure the duct connector to the supply

duct.

8. Cut out the opening to the supply duct. If sealant was not used, the

installer should tape the mating flanges to provide a good air seal.

NOTE: Duct sealant and tape must be classified as meeting HUD Standard 3280.715, U.L. Standard 181A.

If tape is used to provide a better air seal, it should be a type approved

by the applicable national or local codes.

8 Unitary Products Group

Page 9

107272-UIM-B-1105

Locator Bracket

Nails, Flat Head Screws

or Staples

Bend Tabs Under Duct

Opening to Secure to the

Supply Duct

Floor

Supply Duct

FIGURE 11: Duct Connector Tab Attachment

INSTALLATION OF TAB ATTACHMENT DUCT

CONNECTORS

1. Make floor cut out as shown in Figure 8.

2. Determine the depth of the floor cavity from the surface of the floor

to the top of the supply air duct and select the appropriate duct

connector from the chart.

3. Place locating bracket (supplied with the duct connector) to the

rear of the floor area for the furnace. See Figure 11.

4. Determine which of the four positions the duct connector best centers over the supply duct and insert it through the floor cut-out.

5. Mark cut-out location on the supply duct and remove the duct connector.

6. Cut out the opening to the supply duct.

7. Bend tabs down through and back up under the supply duct.

8. Secure the duct connector to the floor with nails, flat head screws

or staples.

The duct connector is designed for use on ducts down to 12 in (30.5

cm) width. When using the connector on smaller width ducts, there will

not be sufficient clearance to bend the tabs on two sides of the duct

connector.

In such cases the tabs may be attached to the sides of the duct by

using sheet metal screws or other suitable fasteners. Holes for sheet

metal screws are provided in three (3) tabs on each side of the duct

connector. If more than 3 tabs need to be used to provide a more

secure and air tight connection, the remaining tabs can also be fastened to the duct with screws after drilling the required screw hole.

TABLE 4:

External Static Pressure Range

Input Output

Nominal

Air Flow

Ext. Static Pressure

1

Minimum Maximum

MBH kW MBH kW CFM cmm In.W.C kPa In.W.C kPa

66000 19.34 53000 15.55 1050 29.73 .12 .03 .30 .07

84000 24.62 67000 19.63 1250 35.40 .12 .03 .30 .07

1. Std. Blower-High Speed-No Coil.

IMPORTANT: The air temperature rise should be taken only after the

furnace has been operating for at least 15 minutes. Temperatures

should be taken 6" (15.2 cm) past the first bend from the furnace in the

supply duct. The return air temperature must be taken at the return air

louvered door. Return static pressures can be taken by pushing probe

through the air filter on the louvered door.

Furnace and Air Conditioner Installations

If an air conditioner is installed which does not use the blower for air distribution and operates completely independent of the furnace, the thermostat system must have an interlock to prevent the furnace and air

conditioner from operating at the same time. This interlock system usu ally contains a heat-cool switch which must be turned to either HEAT or

COOL to activate either heating or cooling operation, or a positive OFF

switch on the cooling thermostat.

When used in connection with a cooling unit the furnace shall be

installed parallel with or on the upstream side of the cooling unit to avoid

condensation in the heat exchanger.

For installations with a parallel flow arrangement, the furnace must be

equipped with a damper to prevent cold air from being discharged up

around the heat exchanger. Cold air causes condensation inside the

exchanger and can cause it to rust out which can allow products of

combustion to be circulated into the living area by the furnace blower

resulting in possible asphyxiation. An air flow activated automatic

damper, is available from furnace manufacturer. See Figure 12.

NOTE: See label on coil panel for conversion and lighting instructions.

Obtain a temperature rise within the ranges specified on the name

plate.

All installations must have a filter installed.

Automatic

Damper

Supply Duct

Furnace

Base

NOTE: FOR BEST AIR DELIVERY INSTALL DAMPER

WITH BLADES PARALLEL TO SUPPLY DUCT.

Opening

Duct

Connector

FIGURE 12: Anti-Backflow Damper

INSTALLATION OF THE FURNACE

1. Remove the front panels and set the furnace onto the duct connector. Slide it back until the rear of the unit engages the locator

bracket.

2. Secure the front of the furnace with two screws at the mounting

holes provided. See Figure 13.

Furnace Seated

Against the

Locator Bracket

Secure Furnace to

Floor with Two Nails

or Screws.

FIGURE 13: Installation of Furnace

3. Secure the top of the furnace to a structural member using screw

through the strap at the back of the furnace. Strap may be moved

to any of the holes located along the top back of the furnace.

Installer may provide an equivalent method, such as screws

through the casing side.

Unitary Products Group 9

Page 10

107272-UIM-B-1105

DFAH Furnaces:

If a matching cooling coil is used, it may be placed directly on the furnace outlet and sealed to prevent leakage. Follow the coil instructions

for installing the supply plenum. On all installations without a coil, a

removable access panel is recommended in the outlet duct such that

smoke or reflected light would be observable inside the casing to indicate the presence of leaks in the heat exchanger. This access cover

shall be attached in such a manner as to prevent leaks.

RETURN AIR REQUIREMENTS

Closet Installations

Additional Requirements

Additional requirements for floor and ceiling return system for closet

installed sealed combustion heating appliances are given in the next

paragraph.

Floor or Ceiling Return Air System

Listed in the next paragraph are the conditions to be met by Manufactured Home Manufacturers to have U.L. acceptance of in-floor or ceiling

return air systems of closet installed direct vent forced air heating appliances for Manufactured Homes to be sold in the United States.

1. The return air opening into the closet, regardless of location, is to

be sized not less than 16” X 24” (40.6 cm x 101.6 cm).

2. If the return air opening is located on the floor of the closet (versus

the vertical front or side wall), the opening is to be provided with

means to prevent its inadvertent closure by a flat object placed

over the opening.

3. The cross sectional area of the return duct system (when located

in the floor or ceiling of the manufactured home) leading into the

closet is to be not less than 16” X 24” (40.6 cm x 101.6 cm).

4. At least one register is to be located where likelihood of its being

covered by carpeting, boxes, and other objects is minimized.

5. Materials located in the return duct system have a flame spread

classification of 200 or less.

6. Non-combustible pans having 1” (2.5 cm) upturned flanges are

located beneath openings in the floor return duct system.

7. Wiring materials located in the return duct system conform to Article 300-22 (B&C) of the National Electrical Code (NFPA-70).

8. Fuel piping is not run in or through the return duct system.

9. The negative pressure in the closet as determined by test with the

air circulating fan operating at high heating speed and the closet

door closed is to be not more negative than minus 0.05 inches (1.2

kPa) water column.

10. For floor return systems, the manufactured home manufacturer or

installer shall affix a prominent marking on or near the appliance

where it is easily read when the closet door is open. The marking

shall read:

HAZARD OF ASPHYXIATION, DO NOT COVER OR RESTRICT

FLOOR OPENING.

BLEND AIR INSTALLATIONS

If a blend air ventilation system is installed, the 5” (12.7 cm) diameter

knockout in the top cover must be removed. The blend air damper is to

be placed on the top cover and secured with screws as shown in Figure

14. The power wires for the Blend Air Damper are inserted through the

7/8” (2.22 cm) hole in the top cover. The wires to the Blend Air Damper

will be connected as shown in Figure 24. Refer to the Blend Air Installation Manual to complete the installation.

Blend Air

Flex Duct

Blend Air

Damper

WARM AIR DUCT

DUCT CONNECTOR

Floor

FIGURE 14: Floor Installation

SECTION III: FILTERS

FILTER INSTALLATION

All applications require the use of a filter. A standard air filter is located

in the return filter rack on the louvered door. The air filter(s) must be

replaced with air filter(s) that are the same size and same type.

Replacement filter size is shown in Table 5.

Downflow Filters:

There are two types of downflow filter racks.

1. FURNACE FILTER RACK: A return filter rack is with two standard

throwaway type filters are supplied on all models. The return filter

rack is located on the inside of the louvered door. This type of filter

rack is designed for two standard air filters only. Pleated Media or

Washable Filters cannot be used in this filter rack because they

cause too much pressure drop causing a reduction in airflow.

2. EXTERNAL RETURN FILTER GRILLE: The second type is an

external return air filter grille that can only be used in applica-

tions where the furnace is installed in a closet. This type of filter grille is typically installed in a closet door or wall with the filters

located within 12" (30.5 cm) of the return air opening of the furnace. There must be a minimum clearance of 6" (15.2 cm)

between the front of the furnace and the closet door and/or the furnace and the filter grille to prevent the return air flow from being

obstructed. Refer to Table 1 Unit Clearances to Combustibles.

a. If the standard throwaway filter are used the external filter

grille must have a minimum area of 540 in² (3483 cm²) which

would equal a 15" X 36" (38.1 cm x 91.4 cm) filter grille.

b. If the Pleated Media or Washable Filters are used the exter-

nal filter grille must have a minimum area of 684 in² (4413

cm²) which would equal a 18" X 38" (38.1 cm x 91.4 cm) filter

grille. The increased area is to reduce the pressure drop

across the air filter.

c. Consideration should be given when locating the return filter

grille for maintenance.

d. Any filter that has a large pressure drop should be checked to

be sure the pressure drop caused by the air filter will not prevent the furnace from operating within the rise range, specified on the rating plate and in Table 8. If the furnace does not

operate within the specified rise range then a larger air filter

or an air filter that has a lower pressure drop must be

installed.

TABLE 5:

66 / 53 (19.34 / 15.53) 1050 (29.73) (2) 14 x 20 (35.56 x 50.8)

84 / 67 (24.62 / 19.64) 1250 (35.40) (2) 14 x 20 (35.56 x 50.8)

Filter Sizes

Input / Output

BTU/H (kW)

(m

CFM

3

/mm)

Top Return

Filter In. (cm)

10 Unitary Products Group

Page 11

107272-UIM-B-1105

IMPORTANT: Air velocity through throwaway type filters must not

exceed 300 feet per minute (1.52 m/m).

.

All installations must have a filter installed.

Air Filters Can Be

Found On The Inside

Of This Access Panel

FIGURE 15: Furnace Air Filters

.

SECTION IV: OIL PIPING

OIL SAFETY

IMPORTANT INFORMATION: Long or oversized inlet lines may require

the pump to operate dry during initial bleeding period. In such cases,

the priming may be assisted by injecting fuel oil in the pump gearset.

Under lift conditions, lines and fittings must be air tight. To assure this,

“Pipe Dope” may be applied to both the used and unused inlet and both

return fittings. DO NOT USE TEFLON TAPE! DO NOT USE COMPRESSION FITTINGS!

VACUUM CHECK: A vacuum gauge may be installed in either of the 1/

4” NPT inlet ports. The Beckett CleanCut pump should be used where

the vacuum does not exceed 6” hg. (20.3 kPa) single pipe and 12” hg.

(40.6 kPa) two pipe. Remember, running vacuum is the total of all pressure drops (∆P) in the system from tank to inlet of pump.

PRESSURE CHECK: When a pressure check is made, use either the

BLEED PORT OR NOZZLE PORT.

CUTOFF CHECK: To check cut-off pressure, dead head a pressure

gauge in nozzle port. Run burner for short period of time. Shut burner

off. The pressure will drop and hold above zero

.

Pressurized or gravity feed installations must not exceed 3 P.S.I.

20.7 kPa) on inlet line or return line at the pump per NFPA 31. A

pressure greater than 10 P.S.I. (69.0 kPa) may cause damage to

the shaft seal.

TABLE 6:

Furnace Model Burner Spec ATC Head

DFAA084BBTA

DFAH084BBSA

DFAA066BBTA

DFAH066BBSA

Burner Specifications

EVC - 201 AF36YHHS F3

EVC - 202 AF36YHHS F3

Static Plate Nozzle Pump Pressure Air Boot Setting

3-3/8 U 0.65 x 70° A

Delavan

3-3/8 U 0.50 x 70° A

Delavan

100 psi

(689.5 kPa)

100 psi

(689.5 kPa)

4.0

3.0

The burner fuel unit is shipped without the bypass plug installed.

You must install this plug on two-pipe oil systems. DO NOT install

the plug in the fuel unit if connected to a one-pipe oil system. Failure to comply could cause fuel unit seal failure, oil leakage, and

potential fire and injury hazard.

Fuel Supply Level With or Above Burner

The burner may be equipped with a single-stage fuel unit for these

installations. Connect the fuel supply to the burner with a single supply

line if you want a one-pipe system (making sure the bypass plug is NOT

installed in the fuel unit). Manual venting of the fuel unit is required on

initial start-up. If connecting a two-pipe fuel supply, install the fuel unit

bypass plug.

The oil supply inlet pressure to the fuel unit cannot exceed 3 psi.

(20.7 kPa) Install a pressure-limiting device in accordance with

NFPA 31.

Fuel Supply Below the Level of the Burner

When the fuel supply is below the level of the burner, a two-pipe fuel

supply system is required. Depending on the fuel line diameter and horizontal and vertical length, the installation may also require a two-stage

pump. Consult the fuel unit manufacturer’s literature for lift and vacuum

capability.

Fuel Line Installation

• Continuous lengths of heavy wall copper tubing are recommended. Always use flare fittings. Never use compression fit-

tings.

• Always install fittings in accessible locations. Fuel lines should

not run against the appliance or the ceiling joists (to avoid vibration noise).

CONNECT FUEL LINES

Carefully follow the fuel unit manufacturer’s literature and the latest edition of NFPA 31 for oil supply system specifications. If this information is

unavailable, use the following basic guidelines.

Never use Teflon tape on any fuel fitting. Tape fragments can lodge

in fuel line components and the fuel unit, damaging the equipment

and preventing proper operation.

Fuel Line Valve and Filter

Install two high quality shut-off valves in accessible locations on the oil

supply line. Locate one close to the tank and the other close to the

Fuel units with automatic bypass do not require a bypass plug.

burner, upstream of the filter.

Some states require these valves to be fusible-handle design for

Burners equipped with a Beckett CleanCut pump must have a control system that provides a valve-on delay (prepurge).

protection in the event of fire. We recommend this as good industry

practice for all installations.

Install a generous capacity filter inside the building between the fuel

tank shut-off valve and the burner, locating both the filter and the valve

close to the burner for ease of servicing. The filter should be rated for

50 microns 50 micrometers) or less.

Unitary Products Group 11

Page 12

107272-UIM-B-1105

NOTICE SPECIAL REQUIREMENTS

This equipment must be installed, adjusted, and started only by a

qualified service technician, an individual or agency, licensed and

experienced with all codes and ordinances, who is responsible for

the installation and adjustment of the equipment. The installation

must comply with all local codes and ordinances and with the

National Fire Protection Standard for Liquid Fuel Equipment, NFPA

31 (or in Canada the installation must comply with CSA B139).

This pump must be used with a control system that provides a valve

on delay (pre-purge).

This furnace is designed to operate on #1 FUEL-OIL or #2 FUELOIL ONLY. Do Not burn any other fuel in this furnace. Burning any

fuel except #1 FUEL-OIL or #2 FUEL-OIL in this furnace can cause

premature heat exchanger burnout, high levels of carbon monoxide, excessive sooting, a fire hazard, personal injury, property damage, and/or death.

In Canada, the furnace is designed to operate on #1 STOVE OIL or

#2 FURNACE OIL ONLY.

THE EFFECT OF ELEVATION ON OIL BURNER

FIRING

The elevation of the installation of a modern high-speed flame retention

oil burner affects the performance of the burner. Allowance for elevation

must be taken into consideration when choosing an oil burner and operating it above 2000 ft. (610m).

It is especially important in high elevation installations to adjust air settings to match the burner nozzle firing rate. As elevation increases

above sea level, the ambient air contains less oxygen. Because there is

less available oxygen per cubic foot of air, the burner must deliver a

greater volume flow (cfm) of air to provide the proper amount of oxygen

for the amount of oil being burned. This is the reason that an increase in

the burner air setting may be required.

It is also important in high elevation installations to consider the maximum firing rate of the burner, so that the heat input as required by the

application is maintained. Regardless of elevation, the oil burner has a

maximum volume flow of air that it can deliver. As a result, the maximum firing rate of the oil burner decreases as the elevation increases,

because the combustion air contains less oxygen. An increase in the

size of a fixed-type retention head, or even the use of an oil burner with

a higher maximum firing rate may be necessary.

The effect of elevation up to 2000 ft. (610 m) is minimal, so no re-rate is

necessary up to 2000 ft. (610 m) elevation. Above 2000 ft. (610 m), for

every 1000 ft. (305 m) above sea level (including the first 2000 ft. (610

m), there is a 1.84% rate reduction of the burner. To assist you, we have

included the following chart and some examples: Refer to Table 7.

The pressure regulator on the fuel pump must not be adjusted in

excess of 100 PSIG (689 kPa).

Pressures exceeding 100 PSIG (689 kPa) may cause an overheating condition which can lead to premature heat exchanger failure,

resulting in a fire or explosion, or cause damage to the furnace of

some of its components that will result in property damage and loss

of life. Refer to Figure 16 for Pressure Regulator Location.

TABLE 7:

(Above Sea Level)

Burner Rating at Elevation Above Sea Level, gph (l/m)

Elevation

Nozzle Size

0.50 1.892706 0.65 2.460518

ft m gph l/h gph l/h

500 152 0.50 1.89 0.65 2.46

1,000 305 0.50 1.89 0.65 2.46

1,500 457 0.50 1.89 0.65 2.46

2,000 610 0.50 1.89 0.65 2.46

2,500 762 0.49 1.86 0.65 2.46

3,000 914 0.48 1.82 0.64 2.42

3,500 1,067 0.48 1.82 0.64 2.42

4,000 1,219 0.47 1.79 0.63 2.37

4,500 1,372 0.47 1.79 0.63 2.37

5,000 1,527 0.46 1.76 0.61 2.33

5,500 1,676 0.46 1.76 0.61 2.33

6,000 1,829 0.46 1.72 0.60 2.28

6,500 1,981 0.46 1.72 0.60 2.28

7,000 2,134 0.45 1.69 0.59 2.24

7,500 2,286 0.45 1.69 0.59 2.24

8,000 2,438 0.44 1.66 0.58 2.20

9,000 2,743 0.43 1.63 0.57 2.16

10,000 3,048 0.42 1.60 0.56 2.12

Note: All examples are for 7000 ft. elevation.

1.84% x 7 (for 7000 ft.) = 12.9% → 100% - 12.9% = 87.1%

ft = feet

m = meters

gph = gallons per hour

l/h = liters per hour

EXAMPLE 1:

Re-Rating of the Maximum Firing Rate for Burners @ 7000 ft.

Burner

Model

Maximum Firing

Rate of Burner

@ Sea Level

Elevation

X

Re-rate Factor

@ 7000 ft.

=

Adjusted

Maximum

Firing Rate

AFG 3.00 gph (11.4 L/h) X 87.1% = 2.61 gph (9.83 Lh)

AF 3.00 gph (11.4 L/h) X 87.1% = 2.61 gph (9.83 Lh)

.

Nozzle Port

3/16 Flare

Fittting

USEONLY WITH

VALVE ONDELAY

4GPH 100-150 P SI 3450 RPM

NO.2 & LIGHTERFUEL

3GPH 150-200 P SI 3450 RPM

INLET

Inlet Port

1/4 NPTF

(0.64 cm)

Beckett

CLEANCUT

A2EA-6520

NO.2FUEL

MadebyS untec

ExclusivelyforBe ckett

By Pass

Solenoid

Valve

INLET

BY-PASS

Cordset

Bleed &

Gauge Port

Return Port

Install 1/16” by Pass Pipe

Plug For Two-Pipe System Only

(Use 5/32” Allen Wrench)

Inlet Port

1/4 NPTF

Pressure

Adjustment

Screw

FIGURE 16: Oil Pump

INSTALLATION AND CHECKING OF OIL PIPING

Location and installation of oil tanks and oil piping must comply with

local codes and regulations. In absence of such codes, follow NFPA 31:

Standard Floor Installation of Oil Burner Equipment.

12 Unitary Products Group

Page 13

107272-UIM-B-1105

Follow information provided with the burner, the fuel pump, or the calculation below to determine pipe size and length.

L = Line Length in feet

H = Head in feet

Q = Firing rate in GPH

3/8” (0.95 cm) line L = (6 - 0.75 x H) / 0.0086 x Q)

1/2” (1.27 cm) line L = (6 - 0.75 x H) / (0.00218 x Q)

If tank is above the oil pump, then use the following calculation:

3/8” (0.95 cm) line L = (6 + 0.75 x H) / (0.0086 x Q)

The return line must terminate 3” to 4” above supply line in the oil tank.

Failure to do this may introduce air into the system and could result in

the loss of the prime. Refer to Figure 18.

Fill

Pipe

Outside Tank Fuel Unit

Above Bottom of Tank

Air

Vent

Fuel

Unit

Primary

Filter

L=H+R

Inlet

1/2” (1.27 cm) line L = (6 + 0.75 x H) / (0.00218 x Q)

IMPORTANT: The recommended piping configuration is a single or two

“H”

pipe system that is inserted into the top of the tank as shown in Figure

17 or 18. The two pipe system should be used in applications where the

oil tank is considerably lower than the burner and the oil pump keeps

losing its prime. The oil line should never be connected to the bottom of

the oil tank if the oil tank is outdoors. Water in the bottom of the oil will

freeze in the winter causing the oil line to freeze.

ONE PIPE SYSTEM

DO NOT INSTALL BY-PASS PLUG! Connect inlet line to pump inlet.

Start burner. Arrange primary burner control for continuous operation

during the purging. Place a clear plastic tube on bleed valve. Open

bleed valve 1 turn counterclock wise. Bleed until all air bubbles disappear. Tighten bleed valve securely. Hurried bleeding will impair efficient

operation of unit. Refer to Figures 16 and 17.

L=H+R

Maximum

One Pipe (H)

Lift: 8 Ft

Vent

Fill

Pipe

Shut-Off

Valve

Primary

Filter

Air

Oil

Tank

Fuel Unit

Inlet

“R”

FIGURE 17: One-Pipe System

TWO PIPE SYSTEM

Remove 1/16” (0.16 cm) pipe by-pass plug from plastic bag attached to

the unit. Remove 1/4” (0.635 cm) plug from return port. Insert by-pass

plug into the return port of the oil pump. The oil pump return por t location is shown in Figure 16.

FIGURE 18: Two-Pipe System

SOLENOID WIRING

DISCONNECT THE POWER SUPPLY BEFORE WIRING TO PREVENT ELECTRICAL SHOCK OR EQUIPMENT DAMAGE.

Lead wires on these devices are long enough to reach the junction box

on most burner installations. Refer to Figure 19.

NOTE: Check the burner manufacturer’s installation sheets for the correct solenoid wiring. All electrical wiring must be done in accordance

with the local codes.

NOTE: Solenoid power requirements: 115 VAC, 0.1 Amp, 60 Hz

FIGURE 19: Solenoid Wiring

SECTION V: ELECTRICAL POWER

Electrical Power Connections

Field wiring to the unit must be grounded. Electric wires that are field

installed shall conform to the temperature limitation for 63°F (35°C) rise

wire when installed in accordance with instructions. Refer to Table 8 in

these instructions for specific furnace electrical data.

Oil

Tank

To Power

Control

“R”

Bypass

Solenoid

Valve

Violet

White

3”-4”

Use Protective Plastic

Tubing in Concrete or as

Local Codes Require

Insert a 1/4” MPT x flare adaptor into the by-pass port and the inlet port.

Attach the return and inlet copper lines that go to the oil tank. Start the

burner. DO NOT open the bleed valve. The air in the oil lines will bleed

automatically.

Use copper conductors only.

TABLE 8: Ratings & Physical / Electrical Data

Input Output Nominal Burner Air Temp. Rise

MBH (kW) MBH (kW) CFM (cm) Amps HP RPM Rotation °F (°C) GPH (Liter / H)

AFUE

Input Rate

66 (19.3) 53 (15.5) 1050 (29.7) 2.1 1/7 3450 CCW 45 - 75 (28 - 47) 80 0.50 (1.9)

84 (24.6) 67 (19.6) 1250 (35.4) 2.1 1/7 3450 CCW 45 - 75 (28 - 47) 80 0.65 (2.5)

Input

Max. Outlet

Air Temp

Blower

MBH (kW) °F (°C) Hp Amps Amps In. (cm) LBS/Kg LBS/Kg

Max Over-current

Size (awg) @

75 ft. protect

Total

Unit

Min. Wire

One Way

Blower Size

DFAA

Operation Wgt.

DFAH

Operation Wgt.

66 (19.3) 165 (74) 1/6 8.0 15 8.3 14 10 x 8 (25.4 x 20.3) 175/79.4 158/71.7

84 (24.6) 165 (74) 1/4 5.9 15 7.8 14 10 x 8 (25.4 x 20.3) 175/79.4 158/71.7

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

The furnace shall be installed so that the electrical components are protected from water.

Rotation when facing shaft end.

Unitary Products Group 13

Page 14

107272-UIM-B-1105

NOTE: A burner with an electronic igniter or a PSC motor will have a

lower operating current. The actual load should be determined by a current meter.

NOTE: See appliance manufacturer’s burner specifications for required

outlet pressure. Pressure is 100 psig (689 kPa) unless otherwise noted.

SUPPLY VOLTAGE CONNECTIONS

1. Provide a power supply separate from all other circuits. Install

overcurrent protection and disconnect switch per local/national

electrical codes. With the control box switch in the OFF position,

check all wiring against the unit wiring label. Refer to the wiring

diagram in this instruction.

2. Remove the screws retaining the wiring box cover. Route the

power wiring through the opening in the unit into the junction box

with a conduit connector or other proper connection. In the junction

box there will be two wires, a Black Wire, a White Wire and a

Green Screw. Connect the power supply as shown on the unit-wiring label on the coil compartment panel on the DFAA or the onside

of the burner door on the DFAH or the wiring schematic in this section. The black furnace lead must be connected to the L1 (hot) wire

from the power supply. The white furnace lead must be connected

to neutral. Connect the green furnace lead (equipment ground) to

the power supply ground screw.

3. The furnace's control system requires correct polarity of the power

supply and a proper ground connection. Refer to Figure 20.

BLK

WHT

GRN

BLK (Hot)

WHT (Neutral)

GRN

Nominal

120 Volt

FIGURE 20: Line Wiring Connections

LOW VOLTAGE CONTROL WIRING CONNECTIONS

1. Insert 24 volt wires through the small plastic bushing just above

the control panel.

2. Connect the thermostat wires to the furnace low voltage pigtails.

See Figure 21 (heating only) and Figure 22 or 23 (heating and

cooling).

3. Connect low-voltage circuit to the wall thermostat pigtails.

NOTE: Five-conductor thermostat cable is recommended for all installations to allow easy installation of an air conditioning system at a later

time.

Eighteen gauge thermostat wire is highly recommended.

Smaller gauge thermostat wire may be used only if the guideline below

is followed.

Thermostat Wire Length

(Furnace to Thermostat)

0 - 45 feet 22

0 - 70 feet 18

Do not use the thermostat wire smaller than 22 gauge. If thermostat

wire small than 18 gauge is used, pay particular attention that the connections between the difference wire sizes are tight.

Operational problems may be caused by loose connections or by the

use of thermostat wire that is too small to carry the required load. Any