Page 1

TECHNICAL GUIDE

SINGLE PIECE AIR HANDLERS

FOR USE WITH SPLIT -SYSTEM

COOLING & HEAT PUMPS

MODELS: AHR18 THRU 60*

Due to continuous product improvement,

specifications are subject to change without notice.

Visit us on the web at:

www.upgnet.com and www.york.com

Additional rating information can be found at:

www.ahridirectory.org

WARRANTY

Standard 5-year limited parts warranty.

Extended 10-year limited parts warranty when product is registered online within 90 days of purchase for replacement or

closing for new home construction.

ISO 9001

Certified Quality

Management System

1055230-YTG-D-0514

DESCRIPTION

This fan coil line offers the ultimate in application flexibility. This unit

may be used for upflow, downflow, horizontal right, or horizontal left

applications.

All JCI Unitary Products air handlers and coils use a TXV to provide our

customers with the optimum performance and refrigerant control. Air

handlers are shipped with “Flex-coils” without a factory installed metering device. For added flexibility, an R-22 or R-410A TXV or orifice can

be field installed to meet your refrigerant choice.

FEATURES

Thermal Expansion Valve - Provides the ultimate refrigerant con-

trol required for today’s high efficient product. The UPG bolt-on TXV

provides the added flexibility to convert the air handler to the required

refrigerant. The UPG TXV is a true bolt-on which does not require brazing to replace or install.

Insulated Cabinet - All air handler cabinets are thermally insulated

with 3/4” foil faced insulation to prevent sweating.

Factory Sealed - Achieves 2% or less total airflow leakage rate at

duct blaster field test conditions for system airflow verification.

Durable Finish Inside and Out - Air handler casings are made of

pre-painted galvanized steel which provides a better paint to steel bond

that resists corrosion and rust creep. All internal coil sheet metal parts

are made of G60 galvanized or prepainted G30 galvanized.

Filters - All models have internal filter racks provided for use with 1”

thick standard size filters.

Electric Heat Kits - 6HK series of field installed electric heat kits are

available for installation friendly and easy service applications.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

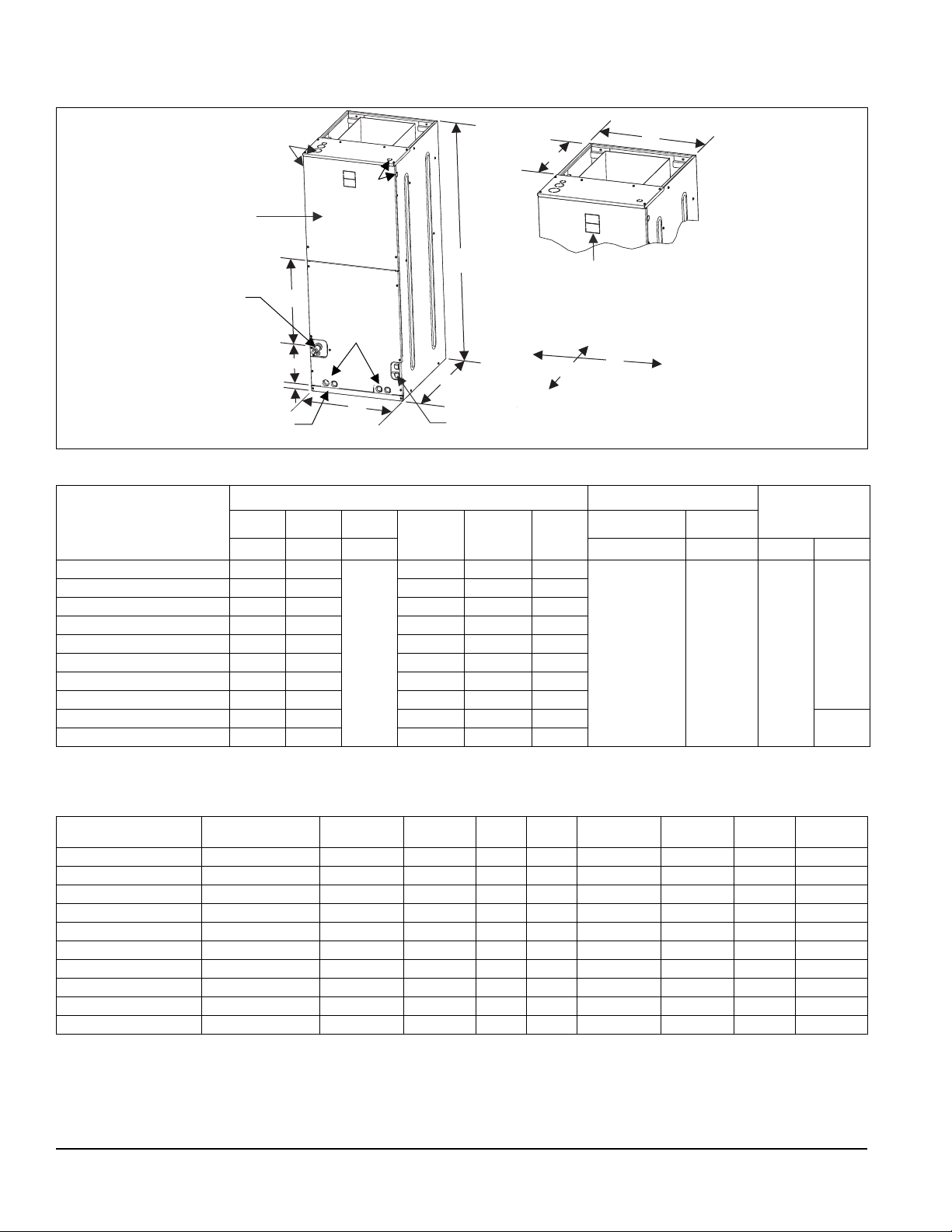

DIMENSIONS & DUCT CONNECTION DIMENSIONS

J

D

Blower

Compartment

Service

Disconnect

Panel

Drain Pan Connections

for Horizontal Applications

Refrigerant

Connections

Drain Connections

for Upflow

Applications

7-11/32”

B

A

K

C

1-1/2”

Top Outlet

Dimensions

Filter

Access

20-5/16”

E

Bottom Inlet

Dimensions

13”

F

A024-001

1055230-YTG-D-0514

Dimensions

1

Dimensions

Models

ABC

DEF

Height Width Depth Power Control Liquid Vapor

AHR18B3XH21 46 17-1/2

16-/2 13-29/32 16-1/2

AHR22B3XH21 46 17-1/2 16-/2 13-29/32 16-1/2

AHR24B3XH21 46 17-1/2 16-/2 13-29/32 16-1/2

AHR30B3XH21 46 17-1/2 16-/2 13-29/32 16-1/2

AHR36B3XH21 46 17-1/2 16-/2 13-29/32 16-1/2

AHR29C3XH21 52 21 21-1/2 17-13/32 20

21-1/2

AHR34C3XH21 52 21 21-1/2 17-13/32 20

AHR42C3XH21 52 21 21-1/2 17-13/32 20

AHR48D3XH21 57 24-1/2 26 20-29/32 23-1/2

AHR60D3XH21 57 24-1/2 26 20-29/32 23-1/2

1. All dimensions are in inches.

2. Actual size (conduit size).

COIL TECHNICAL DATA

Models Application

Refrig.

Conn. Types

AHR18B Cooling /Heat Pump Sweat 3.4 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced

AHR22B Cooling /Heat Pump Sweat 3.9 2 14 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHR24B Cooling /Heat Pump Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHR29C Cooling /Heat Pump Sweat 4.4 2 14 (2) 18 x 17.5 1 x 0.866 3/8 Enhanced

AHR30B Cooling /Heat Pump Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHR34C Cooling /Heat Pump Sweat 3.4 3 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced

AHR36B Cooling /Heat Pump Sweat 4.9 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced

AHR42C Cooling /Heat Pump Sweat 5.4 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced

AHR48D Cooling /Heat Pump Sweat 5.8 3 11 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced

AHR60D Cooling /Heat Pump Sweat 6.8 3 12 (2) 28 x 17.5 1 x 0.866 3/8 Enhanced

Face Area

(Sq. Ft.)

Rows

Deep

Fins

Per In.

Wiring Knockouts

JK

7/8 (1/2)

1-3/8(1)

7/8 (1/2) 3/8

1-23/32 (1-1/4)

Coil Size

Tube

Geometry

2

Refrigerant

Connections

Line Size

3/4

7/8

Tube

Dia.

Fin

Type

2 Johnson Controls Unitary Products

Page 3

1055230-YTG-D-0514

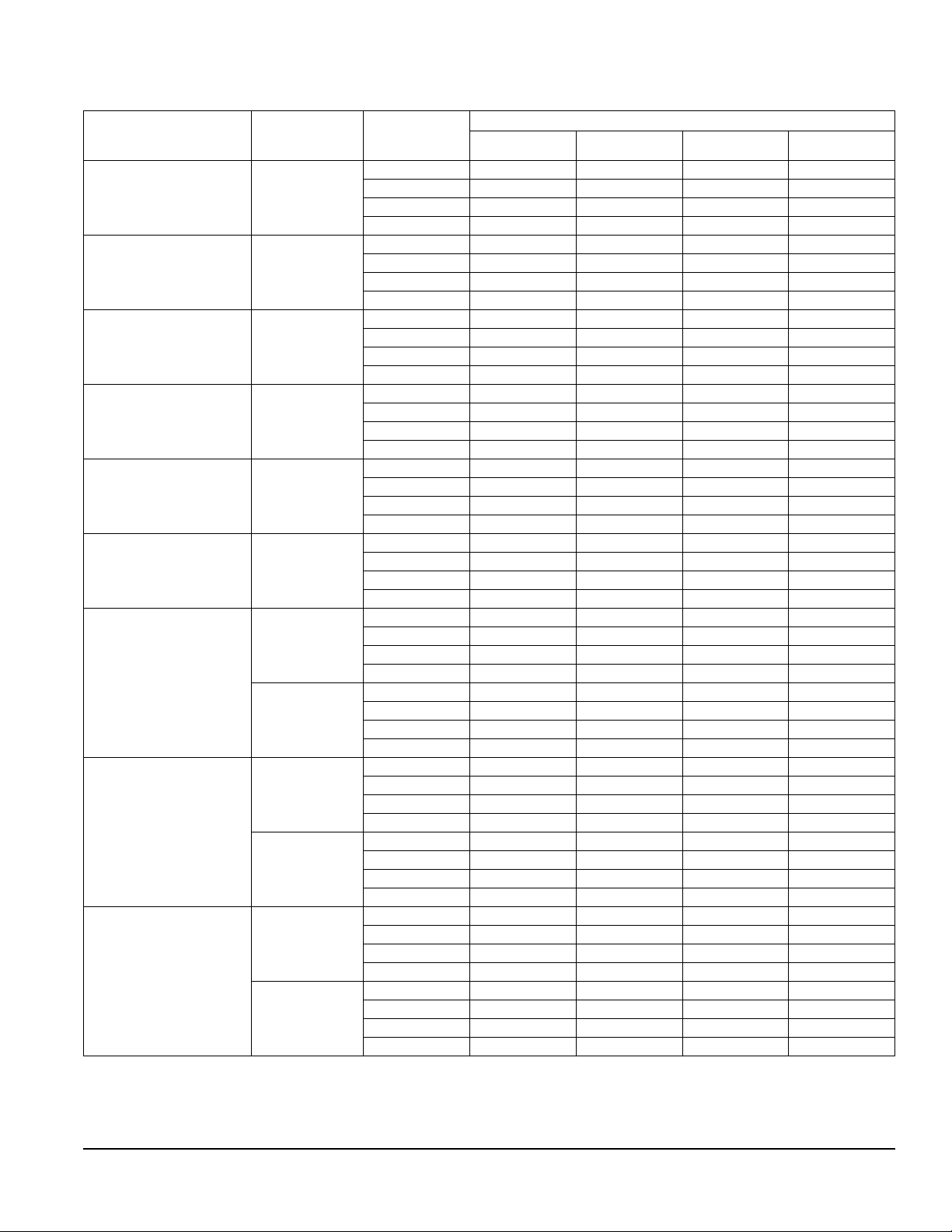

COOLING CAPACITY

Models

AHR18B 665

AHR22B 800

AHR24B 740

AHR29C 1000

AHR30B 1115

AHR34C 1000

AHR36B

AHR42C

AHR48D

(For notes see page 4.)

1

Rated CFM

1060

1245

1230

1485

1320

1610

2

Entering Air

Dry/Wet Bulb

(°F)

85/72 40.7 35.6 30.5 24.1

80/67 35.0 29.5 23.9 18.6

75/62 27.9 22.7 18.1 12.4

70/57 22.1 19.8 16.9 14.1

85/72 47.7 42.6 35.3 30.3

80/67 40.1 34.7 28.9 22.8

75/62 32.7 27.1 24.7 19.1

70/57 25.7 23.5 20.5 17.1

85/72 47.9 42.4 36.8 29.9

80/67 40.9 35.2 29.0 22.6

75/62 33.6 28.0 21.7 15.5

70/57 26.2 23.0 19.9 16.9

85/72 38.9 35.4 31.6 27.6

80/67 33.9 30.3 26.8 23.0

75/62 27.3 23.7 22.5 18.0

70/57 22.6 20.1 17.5 14.8

85/72 65.8 60.4 50.7 41.5

80/67 58.0 49.5 39.9 31.2

75/62 47.1 38.9 30.4 21.1

70/57 37.1 33.1 28.2 23.9

85/72 35.0 31.8 28.4 24.7

80/67 32.2 29.1 25.7 22.3

75/62 26.4 23.4 21.0 17.1

70/57 21.4 18.6 20.2 12.1

85/72 71.1 62.4 51.5 44.3

80/67 59.2 51.0 42.0 32.7

75/62 48.0 39.6 30.8 21.8

70/57 37.3 32.8 28.3 24.0

85/72 83.2 66.7 60.1 48.9

80/67 66.0 59.5 47.8 37.1

75/62 55.0 45.2 35.5 24.8

70/57 42.9 38.1 32.6 27.6

85/72 68.2 72.9 62.8 51.6

80/67 66.3 59.7 48.6 38.4

75/62 56.4 45.4 36.1 25.5

70/57 43.7 38.3 33.3 28.3

85/72 69.8 86.0 74.0 59.1

80/67 68.5 69.5 56.6 44.2

75/62 65.3 54.1 42.0 29.8

70/57 51.0 45.4 39.1 32.8

85/72 87.5 75.9 64.4 51.7

80/67 71.2 59.9 49.8 37.2

75/62 56.5 46.6 35.4 23.3

70/57 43.5 39.5 34.0 28.4

85/72 102.3 90.1 76.1 60.5

80/67 83.7 71.5 57.3 43.6

75/62 67.0 54.0 41.2 27.0

70/57 50.9 46.6 39.8 33.4

MBH@ Evap. Temp. and Corresponding R-410A Pressure (°F/PSIG)

35/107.9 40/118.9 45/130.7 50/143.3

Johnson Controls Unitary Products 3

Page 4

COOLING CAPACITY1 (Continued)

Entering Air

2

Models

AHR60D

1. Actual capacity varies with the outdoor AC or HP that is used with the system.

2. Airflow is calculated for each system tonnage.

Rated CFM

1350

1620

1870

Dry/Wet Bulb

(°F)

85/72 93.7 82.0 70.0 57.4

80/67 76.5 65.5 54.1 41.4

75/62 60.9 50.3 38.4 26.2

70/57 46.6 41.6 35.5 29.8

85/72 70.8 96.4 82.4 66.2

80/67 89.9 76.0 62.8 47.3

75/62 71.4 58.3 44.8 29.9

70/57 55.0 48.4 41.9 34.9

85/72 126.4 110.6 92.8 74.5

80/67 102.1 86.3 70.0 53.1

75/62 81.5 65.6 50.0 34.1

70/57 62.1 55.3 47.1 39.4

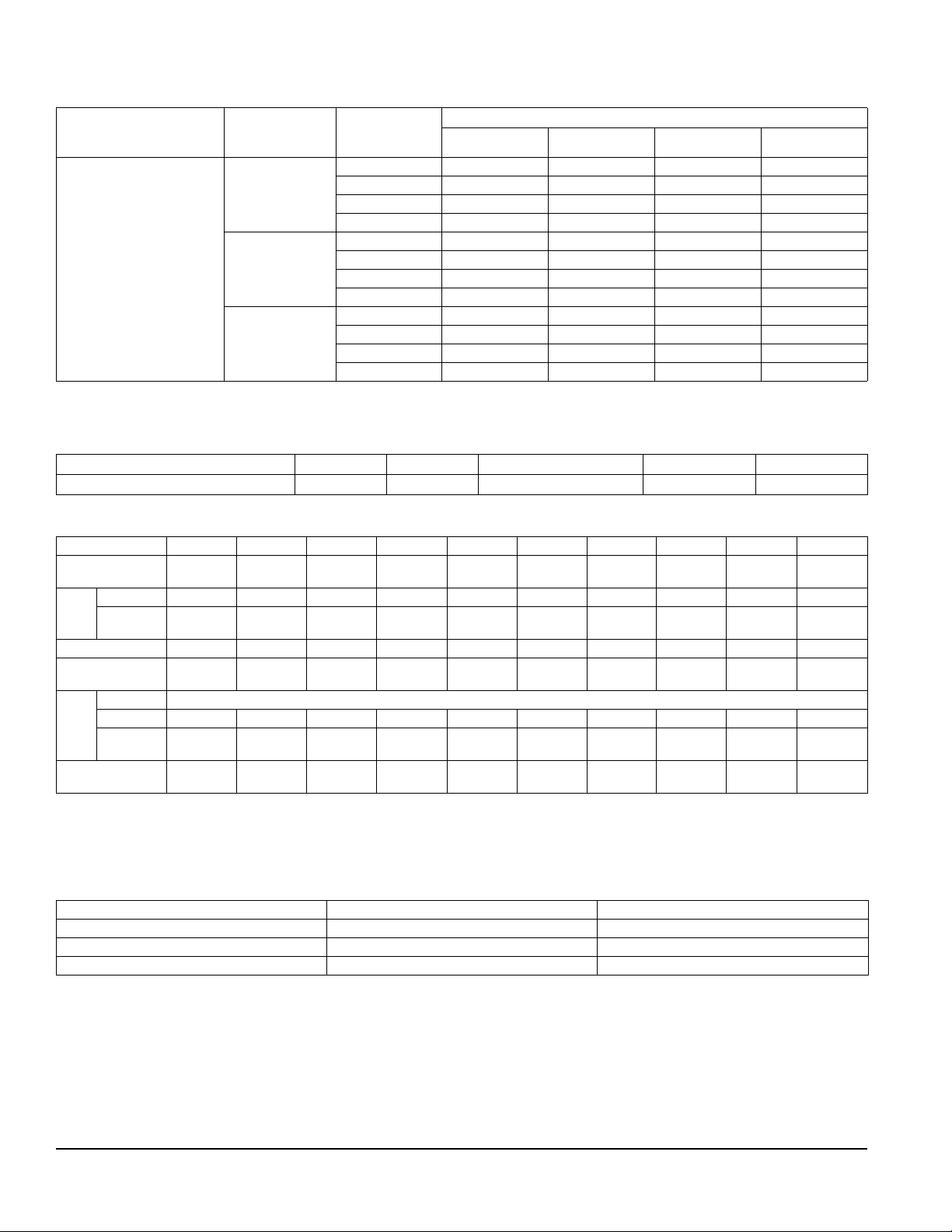

APPLICATION FACTORS - RATED CFM VS. ACTUAL CFM

% Of Rated Airflow (CFM)

Capacity Factor

80% 90% 100% 110% 120%

0.96 0.98 1.00 1.02 1.03

1055230-YTG-D-0514

MBH@ Evap. Temp. and Corresponding R-410A Pressure (°F/PSIG)

35/107.9 40/118.9 45/130.7 50/143.3

PHYSICAL & ELECTRICAL DATA - COOLING ONLY

Models AHR18B AHR22B AHR24B AHR29C AHR30B AHR34C AHR36B AHR42C AHR48D AHR60D

Blower - Diameter x

Width

HP 1/4 HP 1/3 HP 1/4 HP 1/2 HP 3/4 HP 1/2 HP 3/4 HP 3/4 HP 3/4 HP 3/4 HP

Motor

Filter

Shipping / Operat-

Nominal

RPM

Voltage 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Full Load Amps

@230V

Type DISPOSABLE OR PERMANENT

Size 16 x 20 x 1 16 x 20 x 1 16 x 20 x 1 20 x 20 x 1 16 x 20 x 1 20 x 20 x 1 16 x 20 x 1 20 x 20 x 1 22 x 20 x 1 22 x 20 x 1

1

Permanent

Type Kit

ing Weight (lbs.)

1. Field Supplied.

10 x 8 10 x 8 10 x 8 10 x 10 10 x 8 10 x 10 10 x 8 10 x 10 10X10 10X10

1075 1039 1075 1075 1075 1075 1075 1075 1075 1075

1.4 2.2 1.4 2.3 3.0 2.3 3.0 3.0 3.0 3.0

1PF0601BK 1PF0601BK 1PF0601BK 1PF0602BK 1PF0601BK1PF0602BK 1PF0601BK1PF0602BK 1PF0603BK 1PF0603BK

112/100 112/100 117/102 131/116 117/105 132/117 122/110 148/133 165/147 168/150

KW & MBH CONVERSIONS - FOR TOTAL POWER INPUT REQUIREMENT

For a power distribution voltage that is different than the provided nominal voltage, multiply the kW and MBH data from the table by

the conversion factor in the following table.

DISTRIBUTION POWER NOMINAL VOLTAGE CONVERSION FACTOR

208V 240V 0.75

220V 240V 0.84

230V 240V 0.92

4 Johnson Controls Unitary Products

Page 5

1055230-YTG-D-0514

ELECTRICAL DATA - COOLING ONLY

Models

Motor FLA

1

AHR18B / AHR24B 1.4 1.8 15 14

AHR22B 2.2 2.8 15 14

AHR29C/AHR34C 2.3 2.9 15 14

AHR30B / AHR36B /

AHR42C / AHR48D /

3.0 3.8 15 14

AHR60D

1. FLA = Full Load Amps

2. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

3. 75C, copper wire only. If wire other than non-plated, 75C ambien t, copper wire is used, consult applicable tables of the NEC and local codes.

Minimum Circuit

Ampacity

MOP

2

Minimum Wire Size (AWG)

ELECTRICAL HEAT: MINIMUM FAN SPEED

Nom. kW

Heater Kit Models

1,2

@240V

AHR18B AHR22B AHR24B AHR29C AHR30B AHR34C AHR36B AHR42C AHR48D AHR60D

6HK(0,1)6500206 2.4kW Low Med Low Med Low Med Low Low Low Low

6HK(0,1)6500506 4.8kW Med Med Low Med Low Med Low Low Low Low

6HK(0,1)6500806 7.7kW Med High Med High Med Med Med Med Low Low

6HK(0,1)6501006

6HK06501025

9.6kW Med High High High Med High High Med Med Med

6HK(1,2)6501306 12.5kW – High High High High High High High Med Med

6HK(1,2)6501506

6HK06501525

6HK(1,2)6501806

6HK06501825

6HK(1,2)6502006

6HK16502025

6HK(1,2)6502506

6HK16502525

1. (0,1) - 0 = no circuit breaker OR 1 = with circuit breaker.

2. (1,2) - 1 = with circuit breaker, no breaker jumper bar OR 2 = with circuit breaker & breaker jumper bar.

14.4kW – High High High High High High High Med Med

17.3kW––––––High–MedMed

19.2kW––––––High–HighHigh

24kW–––––––––High

Air Handler Models

ELECTRIC HEAT PERFORMANCE DATA: 208/230-1-60 & 208/230-3-60

Heater

Models

1,2

Nominal kW

@240V

Total Heat

kW MBH W1 Only W1 + W2

3

208V 230V 208V 230V 208V 230V 208V 230V

6HK(0,1)6500206 2.4 1.8 2.2 6.2 7.5 1.8 2.2 1.8 2.2

6HK(0,1)6500506 4.8 3.6 4.4 12.3 15.0 3.6 4.4 3.6 4.4

6HK(0,1)6500806 7.7 5.8 7.1 19.7 24.1 5.8 7.1 5.8 7.1

6HK(0,1)6501006 9.6 7.2 8.8 24.6 30.1 7.2 8.8 7.2 8.8

1PH

6HK(1,2)6501306 12.5 9.4 11.5 32.0 39.2 3.1 3.8 9.4 11.5

6HK(1,2)6501506 14.4 10.8 13.2 36.9 45.1 3.6 4.4 10.8 13.2

6HK(1,2)6501806 17.3 13.0 15.9 44.3 54.2 6.5 7.9 13.0 15.9

6HK(1,2)6502006 19.2 14.4 17.6 49.2 60.2 7.2 8.8 14.4 17.6

6HK(1,2)6502506 24.0 18.0 22.0 61.5 75.2 7.2 8.8 18.0 22.0

6HK06501025 9.6 7.2 8.8 24.6 30.1 7.2 8.8 7.2 8.8

6HK06501525 14.4 10.8 13.2 36.9 45.1 10.8 13.2 10.8 13.2

3PH

6HK06501825 17.3 13.0 15.9 44.3 54.2 13.0 15.9 13.0 15.9

6HK16502025 19.2 14.4 17.6 49.2 60.2 7.2 8.8 14.4 17.6

6HK16502525 24.0 18.0 22.0 61.5 75.2 9.0 11.0 18.0 22.0

1. (0,1) - 0 = no circuit breaker OR 1 = with circuit breaker.

2. (1,2) - 1 = with circuit breaker, no breaker jumper bar OR 2 = with circuit breaker & breaker jumper bar.

3. For different power distributions, see conversion table on Page 4.

kW Staging

3

Johnson Controls Unitary Products 5

Page 6

1055230-YTG-D-0514

ELECTRICAL DATA FOR SINGLE SOURCE POWER SUPPLY: 208/230-1-60

Air Handler Models

Heater

Models

1,2

Heater

Amps

@240V

Min. Circuit Ampacity

208V 230V 208V 230V 208V 230V

6HK(0,1)6500206 10.0 12.6 14.3 15 15 12 12

AHR18B

6HK(0,1)6500506 20.0 23.4 26.8 25 30 10 10

6HK(0,1)6500806 32.0 36.4 41.8 40 45 8 8

6HK(0,1)6501006 40.0 45.1 51.8 50 60 8 6

6HK(0,1)6500206 10 13.5 15.3 15 20 12 12

6HK(0,1)6500506 20 24.3 27.8 25 30 10 10

AHR22B

6HK(0,1)6500806 32 37.3 42.8 40 45 8 8

6HK(0,1)6501006 40 46.0 52.8 50 60 6 6

6HK(1,2)6501306 52 59.0 67.8 60 70 6 4

6HK(1,2)6501506 60 67.7 77.8 70 80 4 4

6HK(0,1)6500206 10.0 12.6 14.3 15 15 12 12

6HK(0,1)6500506 20.0 23.4 26.8 25 30 10 10

AHR24B

6HK(0,1)6500806 32.0 36.4 41.8 40 45 8 8

6HK(0,1)6501006 40.0 45.1 51.8 50 60 8 6

6HK(1,2)6501306 52.0 58.1 66.8 60 70 6 4

6HK(1,2)6501506 60.0 66.8 76.8 70 80 4 4

6HK(0,1)6500206 10.0 13.8 15.4 15 20 12 12

6HK(0,1)6500506 20.0 24.6 27.9 25 30 10 10

AHR29C

AHR34C

6HK(0,1)6500806 32.0 37.6 42.9 40 45 8 8

6HK(0,1)6501006 40.0 46.3 52.9 50 60 6 6

6HK(1,2)6501306 52.0 59.3 67.9 60 70 6 4

6HK(1,2)6501506 60.0 68.0 77.9 70 80 4 4

6HK(0,1)6500206 10.0 14.6 16.3 15 20 12 12

6HK(0,1)6500506 20.0 25.4 28.8 30 30 10 10

AHR30B

AHR42C

6HK(0,1)6500806 32.0 38.4 43.8 40 45 8 8

6HK(0,1)6501006 40.0 47.1 53.8 50 60 6 6

6HK(1,2)6501306 52.0 60.1 68.8 70 70 6 4

6HK(1,2)6501506 60.0 68.8 78.8 70 80 4 4

6HK(0,1)6500206 10.0 14.6 16.3 15 20 12 12

6HK(0,1)6500506 20.0 25.4 28.8 30 30 10 10

6HK(0,1)6500806 32.0 38.4 43.8 40 45 8 8

AHR36B

AHR48D

6HK(0,1)6501006 40.0 47.1 53.8 50 60 8 6

6HK(1,2)6501306 52.0 60.1 68.8 70 70 6 4

6HK(1,2)6501506 60.0 68.8 78.8 70 80 4 4

6HK(1,2)6501806 72.0 81.8 93.8 90 100 4 3

6HK(1,2)6502006 80.0 90.4 103.8 100 110 3 2

6HK(0,1)6500206 10.0 14.6 16.3 15 20 12 12

6HK(0,1)6500506 20.0 25.4 28.8 30 30 10 10

6HK(0,1)6500806 32.0 38.4 43.8 40 45 8 8

6HK(0,1)6501006 40.0 47.1 53.8 50 60 8 6

AHR60D

6HK(1,2)6501306 52.0 60.1 68.8 70 70 6 4

6HK(1,2)6501506 60.0 68.8 78.8 70 80 4 4

6HK(1,2)6501806 72.0 81.8 93.8 90 100 4 3

6HK(1,2)6502006 80.0 90.4 103.8 100 110 3 2

6HK(1,2)6502506 100.0 112.1 128.8 125 150 2 1

1. (0,1) - maybe 0 (no circuit breaker) or 1 (with circuit breaker).

2. (1,2) maybe 1 (with circuit breaker, no breaker jumper bar) or 2 (with circuit breaker & breaker jumper bar).

3. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

4. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

Field Wiring

3

MOP.

Min Wire Size (AWG)

4

6 Johnson Controls Unitary Products

Page 7

1055230-YTG-D-0514

d

ELECTRICAL DATA FOR MULTI-SOURCE POWER SUPPLY: 208/230-1-60

MOP

1

1st

3

2nd 3rd

Min. Wire Size (AWG)

3

2nd 3rd

1st

1st

Air

Handlers

Models

AHR22B

AHR24B

AHR29C

AHR34C

AHR30B

AHR42C

Min. Circuit Ampacity

208V230V208V230V208V230V

Circuit Circuit Circuit

1st

3

2nd 3rd

1st

3

2nd 3rd

1st

3

2nd 3rd

Heater

Models

Total

Heater

Amps

@240V

6HK16501306 52 21.2 37.6 – 24.4 43.3 – 25 40 – 25 45 – 10 8 – 10 8 –

6HK16501506 60 22.8 43.3 – 27.8 50.0 – 25 45 – 30 50 – 10 8 – 10 8 –

6HK16501306 52.0 20.6 37.6 – 23.4 43.3 – 25 40 – 25 45 – 10 8 – 10 8 –

6HK16501506 60.0 23.5 43.3 – 26.8 50.0 – 25 45 – 30 50 – 10 8 – 10 8 –

6HK16501306 52.0 21.3 37.6 – 24.5 43.3 – 25 40 – 25 45 – 10 8 – 10 8 –

6HK16501506 60.0 24.2 43.3 – 27.9 50.0 – 25 45 – 30 50 – 10 8 – 10 8 –

6HK16501306 52.0 22.6 37.6 – 25.4 43.3 – 25 40 – 30 45 – 10 8 – 10 8 –

6HK16501506 60.0 25.5 43.3 – 28.8 50.0 – 30 45 – 30 50 – 10 8 – 10 8 –

6HK16501306 52.0 22.6 37.6 – 25.4 43.3 – 25 40 – 30 45 – 10 8 – 10 8 –

AHR36B

AHR48D

6HK16501506 60.0 25.5 43.3 – 28.8 50.0 – 30 45 – 30 50 – 10 8 – 10 8 –

6HK16501806 72.0 42.8 39.0 – 48.8 45.0 – 45 40 – 50 45 –88–88–

6HK16502006 80.0 47.1 43.3 – 53.8 50.0 – 50 45 – 60 50 –88–68–

6HK16501306 52.0 22.6 37.6 – 25.4 43.3 – 25 40 – 30 45 – 10 8 – 10 8 –

6HK16501506 60.0 25.5 43.3 – 28.8 50.0 – 30 45 – 30 50 – 10 8 – 10 8 –

AHR60D

6HK16501806 72.0 42.8 39.0 – 48.8 45.0 – 45 40 – 50 45 –88–88–

6HK16502006 80.0 47.1 43.3 – 53.8 50.0 – 50 45 – 60 50 –88–68–

6HK16502506 100 47.1 43.3 21.7 53.8 50.0 25.0 50 45 25 60 50 25 6 6 10 6 8 10

1. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

2. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

3. 1st Circuit includes the blower motor amps.

ELECTRICAL DATA FOR SINGLE SOURCE POWER SUPPLY - 208/230-3-60

Field Wiring

1

MOP

Min. Wire Size (AWG)

Air Handler Models

Heater

Models

Heater

Amps

@ 240V

Min. Circuit Ampacity

208V 230V 208V 230V 208V 230V

AHR18B 6HK06501025 23.1 26.8 30.7 30 35 10 10

AHR24B

AHR30B

AHR42C

6HK06501025 23.1 26.8 30.7 30 35 10 10

6HK06501525 34.6 39.2 45.0 40 45 8 8

6HK06501025 23.1 28.8 32.7 30 35 10 8

6HK06501525 34.6 41.2 47.0 45 50 8 8

6HK06501025 23.1 28.8 32.7 30 35 10 8

AHR36B

AHR48D

6HK06501525 34.6 41.2 47.0 45 50 8 8

6HK06501825 41.6 48.8 55.8 50 60 8 6

6HK16502025

3

46.2 53.8 61.5 60 70 6 6

6HK06501025 23.1 28.8 32.7 30 35 10 8

6HK06501525 34.6 41.2 47.0 45 50 8 8

AHR60D

1. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

2. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

3. The 20kW and 25kW heater models (6HK16502025 and 6HK165025 25) come with circuit breakers stan dard. Single so urce power MCA and MOP requirement s are

given here only for reference if used with field installed single point power modification.

6HK06501825 41.6 48.8 55.8 50 60 8 6

6HK16502025

6HK16502525

3

3

46.2 53.8 61.5 60 70 6 6

57.7 66.3 75.9 70 80 4 4

3

2nd 3rd

2

2

Johnson Controls Unitary Products 7

Page 8

1055230-YTG-D-0514

UPFLOW

HORIZONTAL RIGHT

HORIZONTAL LEFT

HEAT

HEAT

HEAT

DOWNFLOW

HEAT

ELECTRICAL DATA FOR MULTI-SOURCE POWER SUPPLY: 208/230-3-60

2nd

MOP

1

1st

Min. Wire Size (AWG)

3

2nd

1st

3

2nd

1st

3

Min. Circuit Ampacity

Air Handler Models

AHR36B

AHR48D

AHR60D

1. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

2. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

3. 1st Circuit includes the blower motor amps.

Heater

Models

6HK16502025 46.2 28.8 25.0 32.6 28.9 30 25 35 30 10 10 8 10

6HK16502025 46.2 28.8 25.0 32.6 28.9 30 25 35 30 10 10 8 10

6HK16502525 57.7 35.0 31.3 39.8 36.1 35 35 40 40 8888

Total Heater

Amps

@ 240V

208V 230V 208V 230V 208V 230V

Circuit Circuit Circuit

1st

3

2nd

1st

3

2nd

1st

3

TYPICAL APPLICATIONS ACCESSORIES

Refer to Price Manual for specific model numbers.

TXV Kits - TXV kits are available for “Flex-coil” applications and con-

verting R22 to R410A or as a service replacement. All kits are bolt-on

and require no brazing to install.

Electric Heaters - 6HK models shown under electrical data include

sequential operation and temperature dual limit switches for safe, efficient operation. Circuit breakers are provided where shown.

LIMITATIONS

These units must be wired and installed in accordance with all national

and local safety codes.

Voltage limits are as follows:

Air Handler

Voltage

Voltage

code

208/230-1-60 06 187-253

1. Rated in accordance with ARI Standard 110, utilization range “A”.

Airflow must be within the minimum and maximum limits approved for

electric heat, evaporator coils and outdoor units.

Normal Operating

Voltage Range

1

2

2nd

8 Johnson Controls Unitary Products

Page 9

1055230-YTG-D-0514

TYPICAL THERMOSTAT CONNECTIONS

Johnson Controls Unitary Products 9

Page 10

1055230-YTG-D-0514

AIR FLOW DA TA (CFM)

Models

AHR18B

AHR22B

AHR24B

AHR29C

AHR30B

AHR34C

AHR36B

AHR42C

AHR48D

AHR60D

AHR18B

AHR22B

AHR24B

AHR29C

AHR30B

AHR34C

AHR36B

(For notes see page 11.)

1

Motor Speed

Blower

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

Medium

Low

External Static Pressure (in. wc.)

0.10 0.20 0.30 0.40 0.50 0.60 0.70

208 Volt

1024 1000 970 930 860 810 NA

756 731 700 670 620 550 NA

557 531 495 445 375 315 195

1214 1177 1136 1071 1019 951 828

705 684 661 592 548 404 266

534 512 460 394 261 167 125

995 970 935 900 925 795 645

820 810 780 745 695 545 485

715 695 640 405 370 375 220

1605 1548 1486 1420 1356 1159 913

981 960 921 815 756 697 614

769 717 654 561 510 451 389

1380 1315 1245 1160 1075 990 885

1060 1040 1005 955 890 860 820

1035 980 910 825 770 685 485

1496 1423 1328 1217 1105 1041 942

976 907 843 815 742 686 582

729 687 647 602 498 447 366

1410 1335 1270 1190 1110 990 820

1215 1170 1115 1050 935 850 740

950 935 895 855 NA NA NA

1800 1725 1645 1545 1360 1200 1050

1535 1480 1415 1280 1155 1010 870

1225 1195 1095 1025 925 825 680

1890 1830 1755 1650 1565 1450 1285

1515 1480 1450 1380 1295 1115 985

1170 1165 1140 1100 965 860 745

1911 1841 1757 1668 1564 1439 1233

1556 1507 1450 1388 1266 1246 989

1211 1181 1151 1062 992 911 827

230 Volt

1145 1100 1055 1005 930 845 725

755 750 725 665 605 485 435

680 655 625 585 540 395 300

1294 1254 1189 1133 1064 996 907

803 785 763 729 645 585 422

615 600 566 492 447 284 183

1305 1285 1225 1175 920 915 835

930 920 890 845 705 760 505

735 730 700 670 545 470 NA

1711 1665 1598 1513 1435 1309 1088

1134 1111 1068 998 909 813 735

887 861 792 695 649 576 486

1450 1380 1300 1215 1130 1030 910

1330 1280 1205 1135 1050 975 780

1160 1120 1065 1005 930 825 635

1579 1511 1399 1273 1145 1068 978

1108 1057 987 924 849 770 703

849 802 756 712 630 527 170

1470 1390 1325 1245 1155 1045 880

1325 1265 1205 1125 1025 965 840

1115 1075 1025 950 NA NA NA

10 Johnson Controls Unitary Products

Page 11

1055230-YTG-D-0514

AIR FLOW DA TA (CFM)1 (Continued)

Models

Blower

Motor Speed

0.10 0.20 0.30 0.40 0.50 0.60 0.70

230 Volt

High

AHR42C

Medium

Low

High

AHR48D

Medium

Low

High

AHR60D

Medium

Low

1. Air handler units have been tested to UL 1995 / CSA 22.2 standards up to 0.30" wc. external static pressure.

Dry coil conditions only, tested without filters.

For optimal performance, external static pressures of 0.2" to 0.5" are recommended. Applications above 0.6" are not recommended.

Airflow data shown is from testing performed at 230V. AHE units use a X13 motor, and there is minimal variation of airflow at other distribut ion voltage values. The

above data can be used for airflow at other distribution voltages.

1750 1670 1570 1477 1260 1125 935

1590 1520 1435 1277 1150 1010 870

1330 1280 1200 1083 980 850 NA

2005 1940 1850 1755 1650 1530 1405

1705 1665 1605 1510 1425 1340 1185

1355 1330 1300 1245 1170 990 980

2034 1955 1858 1753 1640 1522 1296

1733 1672 1609 1527 1431 1272 1220

1388 1359 1313 1255 1133 1004 912

External Static Pressure (in. wc.)

Johnson Controls Unitary Products 11

Page 12

NOTES

Subject to change without notice. Published in U.S.A. 1055230-YTG-D-0514

Copyright © 2014 by Johnson Controls, Inc. All rights reserved. Supersedes: 1055230-YTG-C-0214

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...