Page 1

TECHNICAL GUIDE

SINGLE PIECE STANDARD ECM

AIR HANDLERS

FOR USE WITH SPLIT-SYSTEM

COOLING & HEA T PUMPS

MODELS: AHE18 THRU 60*

Due to continuous product improvement,

specifications are subject to change without notice.

Visit us on the web at:

www.upgnet.com and www.york.com

Additional rating information can be found at:

www.ahridirectory.org

WARRANTY

Standard 5-year limited parts warranty.

Extended 10-year limited parts warranty when product is

registered online within 90 days of purchase for replacement or closing for new home construction.

ISO 9001

Certified Quality

Management System

1169652-YTG-A-1114

DESCRIPTION

The AHE Air Handler line offers the ultimate in comfort, sound

and application flexibility. This unit may be used for upflow,

downflow, horizontal right, or horizontal left applications. No

special kits are required to install this deluxe product.

All JCI Unitary Products air handlers and coils use a TXV to provide our customers with the optimum performance and refrigerant control. Air handlers are shipped with “Flex-coils” without a

factory installed metering device. For added flexibility, an R-22

or R-410A TXV or orifice can be field installed to meet your

refrigerant choice.

FEATURE

Thermal Expansion Valve - Provides the ultimate refrigerant

control required for today’s high efficient product. The UPG bolton TXV provides easy installation to convert the air handler to

the required refrigerant, which is a true bolt-on design that does

not require brazing to replace or install.

Insulated Cabinet - All air handler cabinets are thermally insulated with 3/4” foil faced insulation to prevent sweating.

Factory Sealed - Achieves 2% or less total airflow leakage rate

at duct blaster field test conditions for system airflow verification.

Durable Finish Inside and Out - Air handler casings are made

of pre-painted galvanized steel which provides a better paint to

steel bond that resists corrosion and rust creep. All internal coil

sheet metal parts are made of G60 galvanized or prepainted

G30 galvanized.

Filters - All models have internal filter racks provided for use

with 1” thick standard size filters.

Electric Heat Kits - 6HK series of field installed electric heat

kits are available for installation friendly and easy service applications.

High Efficiency Blowers - All models use high efficiency

brushless DC motors to provide cooling SEER rating enhancement.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

1169652-YTG-A-1114

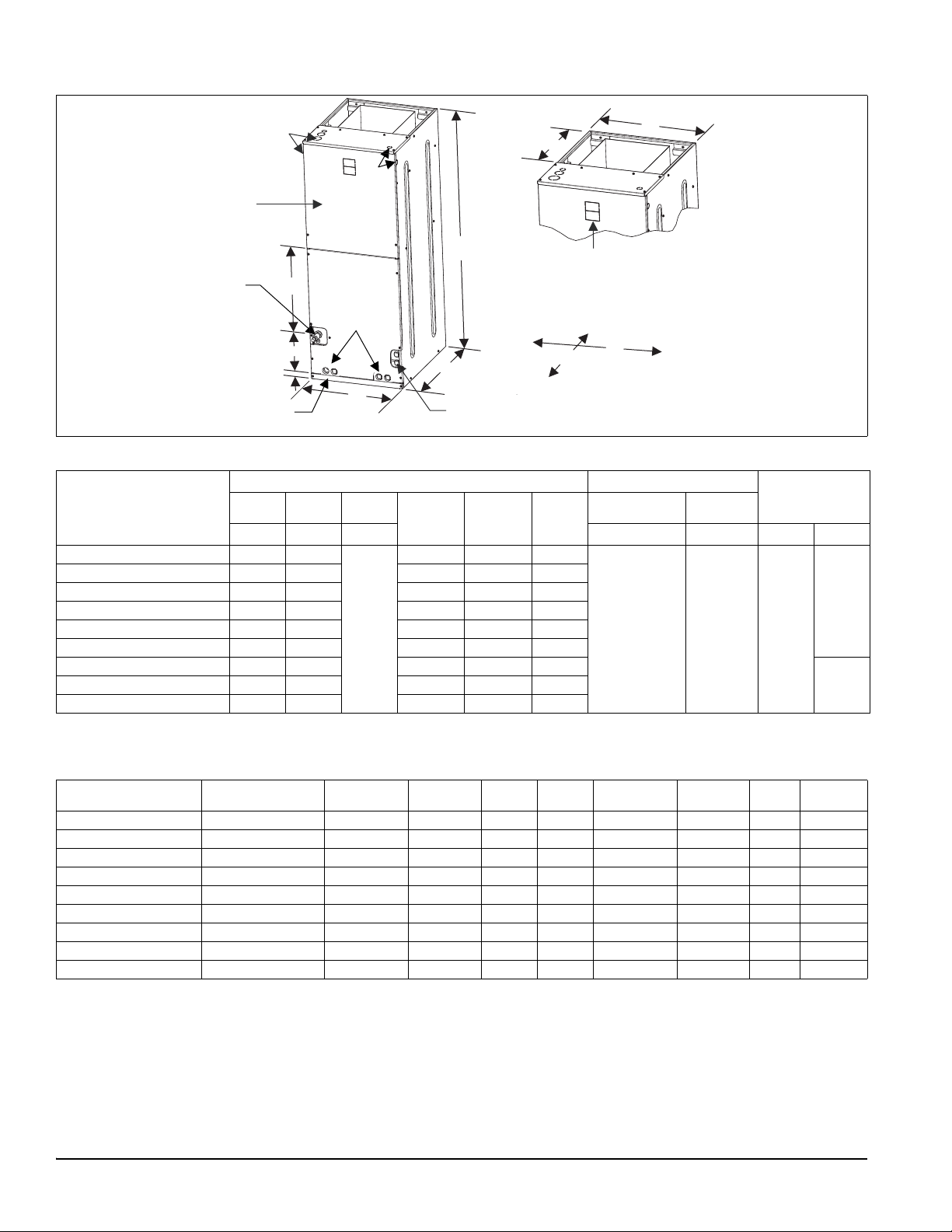

J

D

Blower

Compartment

Service

Disconnect

Panel

Drain Pan Connections

for Horizontal Applications

Refrigerant

Connections

Drain Connections

for Upflow

Applications

7-11/32”

B

A

K

C

1-1/2”

Top Outlet

Dimensions

Filter

Access

20-5/16”

E

Bottom Inlet

Dimensions

13”

F

A024-001

DIMENSIONS & DUCT CONNECTION DIMENSIONS

Dimensions

Dimensions Wiring Knockouts Refrigerant

Models

AHE18B3X(H,T)21 46” 17 1/2”

AHE22B3X(H,T)21 46” 17 1/2” 16 1/2” 13-29/32" 16 1/2”

AHE24B3X(H,T)21 46” 17 1/2” 16 1/2” 13-29/32" 16 1/2”

AHE30B3X(H,T)21 46” 17 1/2” 16 1/2” 13-29/32" 16 1/2”

AHE34C3X(H,T)21 52” 21” 21 1/2” 17-13/32" 20”

AHE36C3X(H,T)21 52” 21” 21 1/2” 17-13/32" 20”

AHE42D3X(H,T)21 57’ 24 1/2” 26” 20-29/32" 23-1/2”

AHE60D3X(H,T)21 57” 24 1/2” 26” 20-29/32" 23-1/2”

1. Actual size (Conduit size).

ABC

DEF

Height Width Depth Power Control Liquid Vapor

16 1/2” 13-29/32" 16 1/2”

21 1/2”

JK

7/8" (1/2")

1-3/8"(1")

1

7/8" (1/2") 3/8"

1-23/32" (1-1/4")

Connections

Line Size

3/4"

7/8"AHE48D3X(H,T)21 57” 24 1/2” 26” 20-29/32" 23-1/2”

COIL TECHNICAL DATA

Models Application

Refrig.

Conn. Types

AHE18B3X(H,T)21 Cooling /Heat Pump Sweat 3.4 2 14 (2) 14 x 17.5 1 x 0.866 3/8 Enhanced

AHE22B3X(H,T)21 Cooling /Heat Pump Sweat 3.9 2 14 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHE24B3X(H,T)21 Cooling /Heat Pump Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHE30B3X(H,T)21 Cooling /Heat Pump Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHE34C3X(H,T)21 Cooling /Heat Pump Sweat 3.9 3 12 (2) 16 x 17.5 1 x 0.866 3/8 Enhanced

AHE36C3X(H,T)21 Cooling /Heat Pump Sweat 4.9 3 12 (2) 20 x 17.5 1 x 0.866 3/8 Enhanced

AHE42D3X(H,T)21 Cooling /Heat Pump Sweat 5.4 3 12 (2) 22 x 17.5 1 x 0.866 3/8 Enhanced

AHE48D3X(H,T)21 Cooling /Heat Pump Sweat 5.8 3 11 (2) 24 x 17.5 1 x 0.866 3/8 Enhanced

AHE60D3X(H,T)21 Cooling /Heat Pump Sweat 6.8 3 12 (2) 28 x 17.5 1 x 0.866 3/8 Enhanced

2 Johnson Controls Unitary Products

Face Area

(Sq. Ft.)

Rows

Deep

Fins

Per In.

Coil Size

Tube

Geometry

Tube

Dia.

Fin

Type

Page 3

1169652-YTG-A-1114

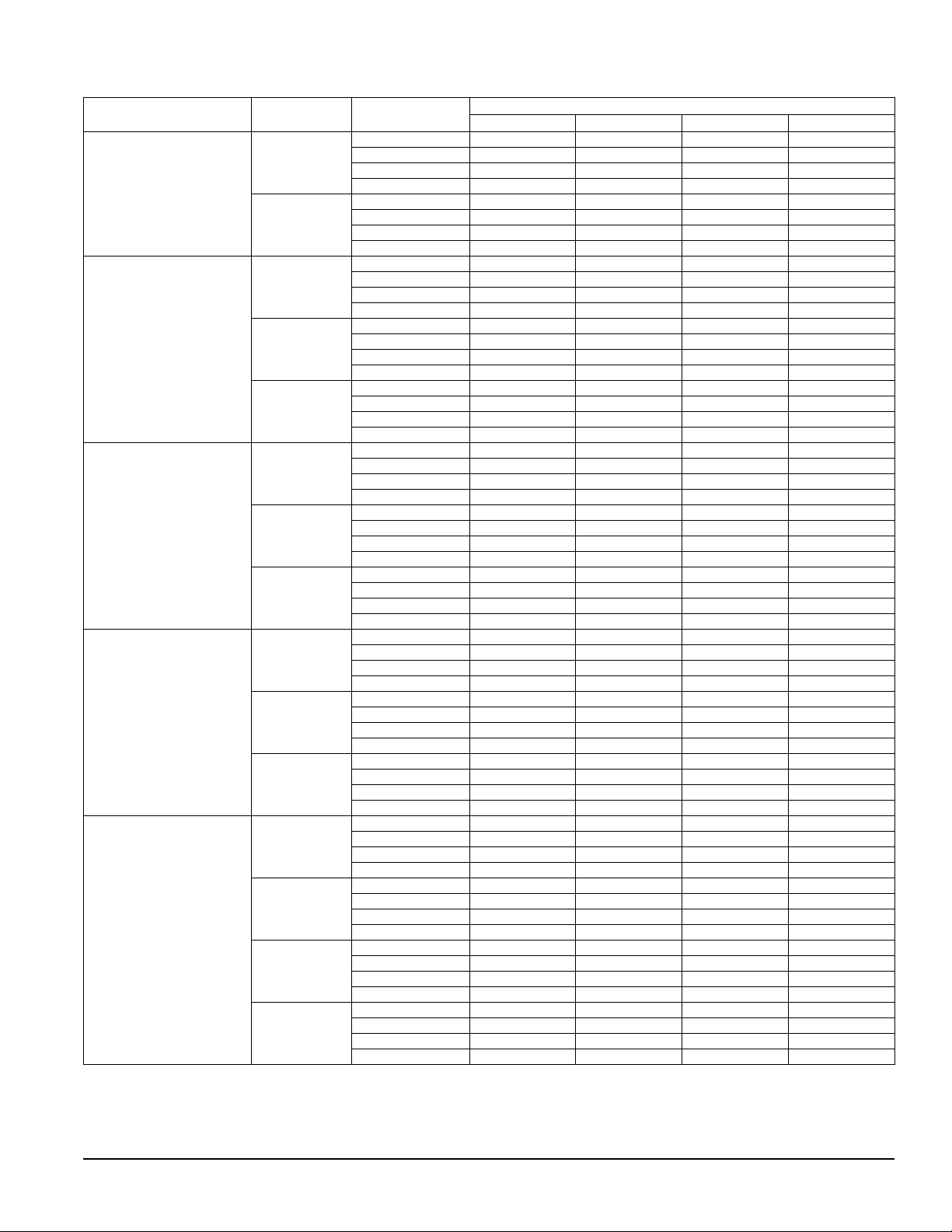

COOLING CAPACITY

Models

AHE18B

AHE22B

AHE24B

AHE30B

AHE34C

For notes see Page 4.

1

Rated CFM

610

850

585

795

985

585

795

985

585

795

985

730

855

1000

1190

Entering Air

2

Dry/Wet Bulb (°F)

MBH@ Evap. Temp. and Corresponding R-410A Pressure (°F/PSIG)

35/107.9 40/118.9 45/130.7 50/143.3

85/72 37.9 33.7 28.3 23.3

80/67 31.8 27 22.5 17.6

75/62 26.4 21.5 16.7 11.6

70/57 20.7 18.4 15.8 13.5

85/72 49.7 43.2 36.9 28.4

80/67 42.1 35.1 28.8 22.5

75/62 33.7 28 21.4 14.7

70/57 26.5 23.8 20.3 16.9

85/72 37.9 33.8 29 24.4

80/67 31.7 27.7 23 22.8

75/62 26.4 22.1 19.5 15.8

70/57 20.2 18.4 16 13.5

85/72 47.7 42.6 35.3 30.3

80/67 40.1 34.7 28.9 22.8

75/62 32.7 27.1 24.7 19.1

70/57 25.7 23.5 20.5 17.1

85/72 55.5 47.5 41.6 34.4

80/67 45.8 40.1 32.5 22.8

75/62 38.1 31.7 28.2 23.2

70/57 29.9 27.8 23.9 20.3

85/72 38.7 34.4 30.1 24.7

80/67 33.6 28.9 23.9 18.9

75/62 27.2 22.7 17.8 12.8

70/57 21.2 18.6 16.2 13.7

85/72 50.8 45.2 38.4 32.0

80/67 43.7 36.8 31 24.0

75/62 35.7 29.5 23.1 16.1

70/57 27.9 24.5 21 17.6

85/72 64.9 54 45.6 37.8

80/67 52.3 44.6 36.9 28.4

75/62 42.2 35.2 26.8 19.3

70/57 33.6 29.6 25.4 21.4

85/72 38.7 34.4 30.1 24.7

80/67 33.6 28.9 23.9 18.9

75/62 27.2 22.7 17.8 12.8

70/57 21.2 18.6 16.2 13.7

85/72 50.8 45.2 38.4 32.0

80/67 43.7 36.8 31 24.0

75/62 35.7 29.5 23.1 16.1

70/57 27.9 24.5 21 17.6

85/72 64.9 54 45.6 37.8

80/67 52.3 44.6 36.9 28.4

75/62 42.2 35.2 26.8 19.3

70/57 33.6 29.6 25.4 21.4

85/72 49.4 44 37.6 31.3

80/67 42 36.4 29.5 22.9

75/62 34 28.4 25.1 20.2

70/57 26.6 23.9 20.7 17.5

85/72 55.5 50.4 42.1 35.2

80/67 48 40.3 33.3 26.4

75/62 38.8 32.5 28.6 23.1

70/57 30.6 28 23.8 19.9

85/72 63.3 56.3 48.3 40.1

80/67 54.2 46.4 38.3 29.8

75/62 43.8 36.3 32.9 26.4

70/57 34.4 31.7 27.4 23.0

85/72 71.3 63.5 55.1 44.8

80/67 61.3 53.1 43.5 33.7

75/62 49.8 40.3 37.5 30.2

70/57 38.8 36.5 31.5 26.7

Johnson Controls Unitary Products 3

Page 4

1169652-YTG-A-1114

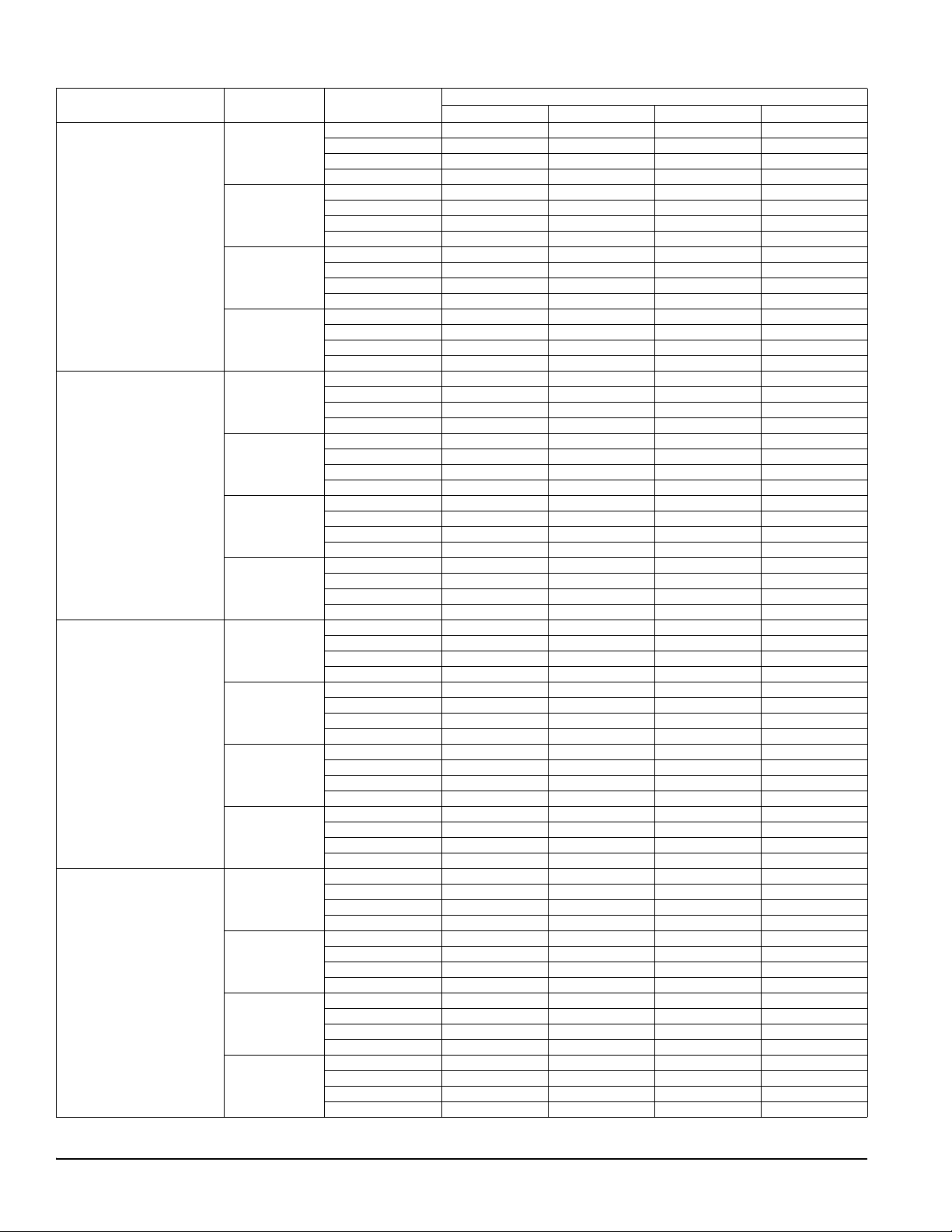

COOLING CAPACITY1 (Continued)

Entering Air

730

855

1000

1190

820

1000

1180

1385

1000

1195

1385

1600

1190

1390

1565

1835

2

Dry/Wet Bulb (°F)

85/72 49.3 45.2 38.3 31.4

80/67 43 37.3 31 24.0

75/62 34.7 28.8 22.8 16.2

70/57 26.8 23.4 20.4 16.9

85/72 59.1 51 44.1 36.5

80/67 49.3 42.4 35.4 27.6

75/62 39.9 33.1 26.1 18.2

70/57 31.1 26.9 23.5 19.7

85/72 65.2 59.5 51.2 41.3

80/67 56.4 48.3 39.9 31.3

75/62 45.8 38.1 29.7 20.8

70/57 35.7 31.2 26.9 22.6

85/72 67.5 65.9 59.8 48.7

80/67 64.9 56.7 46.2 35.7

75/62 53.5 43.2 34.1 24.0

70/57 41.4 36.6 31.5 26.2

85/72 56.6 51.1 42.8 35.6

80/67 48.6 41.1 34.8 27.6

75/62 39.4 33 26 18.3

70/57 30.5 26.6 23.1 19.6

85/72 65.7 61 52.7 42.9

80/67 58 49.6 41.1 32.1

75/62 46.7 38.9 30.4 21.8

70/57 36.4 31.6 27.6 23.3

85/72 67.9 71.4 60.2 48.8

80/67 65.6 56.9 47.1 37.1

75/62 53.8 45.2 34.7 24.6

70/57 42.2 37.1 31.9 27.0

85/72 69.4 81 68 57.2

80/67 77.1 65.4 54.1 41.6

75/62 62.1 51 39.8 28.1

70/57 48.1 42.5 36.8 30.6

85/72 69 59.8 51.3 41.5

80/67 56.5 48.2 39.7 29.9

75/62 45.1 36.8 28.3 18.9

70/57 34.4 31 26.8 22.5

85/72 79.5 69.7 59.9 48.6

80/67 65.2 55.5 45.5 34.9

75/62 52.2 42.5 32.6 21.8

70/57 40.1 36.1 31.1 26.2

85/72 90 78.1 66 54.5

80/67 73.5 62.7 51.3 38.7

75/62 59.2 48.2 36.9 24.0

70/57 45.2 41 35.4 29.7

85/72 102.2 90 74.3 60.4

80/67 83.6 70.6 57.2 43.1

75/62 66.1 54 41.2 27.0

70/57 50.7 46.1 39.8 33.4

85/72 83.6 73.7 62.9 51.6

80/67 68.2 58.4 48.4 37.1

75/62 54.9 45.3 34.8 23.9

70/57 42.2 37.3 31.9 26.9

85/72 95.9 84.1 71.9 58.8

80/67 79.2 67.4 54.4 41.6

75/62 62.4 51.2 39.7 26.9

70/57 48 42.5 36.8 30.6

85/72 106.3 94.2 78.5 63.5

80/67 87.6 73.9 60.2 45.9

75/62 69.3 56.8 43.5 29.7

70/57 53.1 46.9 40.5 34.1

85/72 122.1 107.1 90.9 72.6

80/67 100.2 85.9 69.8 51.8

75/62 79.7 65.3 49.8 32.9

70/57 60.8 54.1 46.4 38.7

Models

Rated CFM

AHE36C

AHE42D

AHE48D

AHE60D

1. Actual capacity varies with the outdoor AC or HP that is used with the system.

2. Airflow is calculated for each system tonnage.

MBH@ Evap. Temp. and Corresponding R-410A Pressure (°F/PSIG)

35/107.9 40/118.9 45/130.7 50/143.3

4 Johnson Controls Unitary Products

Page 5

1169652-YTG-A-1114

APPLICATION FACTORS - RATED CFM VS. ACTUAL CFM

% Of Rated Airflow (CFM)

Capacity Factor

80% 90% 100% 110% 120%

0.96 0.98 1.00 1.02 1.03

PHYSICAL & ELECTRICAL DATA - COOLING ONLY

Models

AHE18B

(6ELE6)

AHE22B

Blower - Diameter x Width 10 x 8 10 x 8 10 x 8 10 x 8 11 x 10 11 x 10 11 x 10 11 x 10 11 x 10

Motor

HP 1/3 HP 1/3 HP 1/3 HP 1/3 HP 1/2 HP 1/2 HP 1/2 HP 3/4 HP 3/4 HP

Nominal RPM 1050 1050 1050 1050 1050 1050 1050 1050 1050

Voltage 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Full Load Amps @230V

2.8 2.8 2.8 2.8 4.1 4.1 4.1 6.0 6.0

Type DISPOSABLE OR PERMANENT

1

Filter

Size 16 x 20 x 1 16 x 20 x 1 16 x 20 x 1 16 x 20 x 1 20 x 20 x 1 20 x 20 x 1 22 x 20 x 1 22 x 20 x 1 22 x 20 x 1

Permanent Type Kit 1PF0601BK 1PF0601BK 1PF0601BK 1PF0601BK 1PF0602BK 1PF0602BK 1PF0603BK 1PF0603BK 1PF0603BK

Shipping /

Operating Weight (lbs.)

1. Field supplied.

115/103 120/105 120/105 120/105 152/137 152/137 168/150 171/153 174/156

AHE24B

(6ELE7)

AHE30B

(6ELE8)

AHE34C

AHE36C

(6ELE9)

AHE42D

(6ELF0)

AHE48D

(6ELF1)

AHE60D

(6ELF2)

KW & MBH CONVERSIONS - FOR TOTAL POWER INPUT REQUIREMENT

For a power distribution voltage that is different than the provided nominal voltage, multiply the kW and MBH d ata from the table by

the conversion factor in the following table.

DISTRIBUTION POWER NOMINAL VOLTAGE CONVERSION FACTOR

220V 240V 0.84

ELECTRICAL DATA - COOLING ONLY

Models

AHE18B/AHE22B/

AHE24B/AHE30B

Motor FLA

1

2.8 3.5 15 14

AHE34C/AHE36C/AHE42D 4.1 5.1 15 14

AHE48D/AHE60D 6.0 7.5 15 14

1. FLA = Full Load Amps

2. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

3. 75C, copper wire only. If wire other than non-plated, 75C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

ELECTRICAL HEAT: MINIMUM FAN SPEED

Heater Kit Models

2,3

Nom. kW

@240V

1

AHE18B

6HK(0,1)6500206 2.4kW Med Low #2 Med Low #2 Low #1 Med #3 Low #1 Med Low #2 Med Low #2

6HK(0,1)6500506 4.8kW Med Low #2 Med Low #2 Med Low #2 Med Low #2 Med #3 Med #3 Med Low #2

6HK(0,1)6500806 7.7kW Med High #4 Med High #4 Med #3 Med #3 Med #3 Med #3 Med Low #2

6HK(0,1)6501006

6HK06501025

9.6kW Med High #4 Med High #4 Med High #4 Med High #4 Med High #4 Med High #4 Med #3

6HK(1,2)6501306 12.5kW - Med High #4 Med High #4 Med High #4 Med High #4 Med High #4 Med #3

6HK(1,2)6501506

6HK06501525

6HK(1,2)6501806

6HK06501825

6HK(1,2)6502006

6HK16502025

6HK(1,2)6502506

6HK16502525

1. The referenced letter in this table is for the heat jumper tap.

2. (0,1) - 0 = no circuit breaker OR 1 = with circuit breaker.

3. (1,2) - 1 = with circuit breaker, no breaker jumpe r bar OR 2 = with circuit breaker & breaker jumper bar .

14.4kW - High #5 High #5 Med High #4 Med High #4 Med High #4 Med #3

17.3kW - - - High #5 High #5 High #5 Med High #4

19.2kW - - - High #5 High #5 High #5 High #5

24kW------High #5

Minimum Circuit

Ampacity

AHE22B

AHE24B

AHE30B

MOP

Air Handler Models

AHE34C

AHE36C

2

Minimum Wire Size (AWG)

AHE42D AHE48D AHE60D

3

Johnson Controls Unitary Products 5

Page 6

1169652-YTG-A-1114

ELECTRIC HEAT PERFORMANCE DATA: 208/230-1-60 & 208/230-3-60

Heater

Models

1,2

Nominal kW

@240V

Total Heat

kW MBH W1 Only W1 + W2

208V 230V 208V 230V 208V 230V 208V 230V

6HK(0,1)6500206 2.4 1.8 2.2 6.2 7.5 1.8 2.2 1.8 2.2

6HK(0,1)6500506 4.8 3.6 4.4 12.3 15.0 3.6 4.4 3.6 4.4

6HK(0,1)6500806 7.7 5.8 7.1 19.7 24.1 5.8 7.1 5.8 7.1

6HK(0,1)6501006 9.6 7.2 8.8 24.6 30.1 7.2 8.8 7.2 8.8

1PH

6HK(1,2)6501306 12.5 9.4 11.5 32.0 39.2 3.1 3.8 9.4 11.5

6HK(1,2)6501506 14.4 10.8 13.2 36.9 45.1 3.6 4.4 10.8 13.2

6HK(1,2)6501806 17.3 13.0 15.9 44.3 54.2 6.5 7.9 13.0 15.9

6HK(1,2)6502006 19.2 14.4 17.6 49.2 60.2 7.2 8.8 14.4 17.6

6HK(1,2)6502506 24.0 18.0 22.0 61.5 75.2 7.2 8.8 18.0 22.0

6HK06501025 9.6 7.2 8.8 24.6 30.1 7.2 8.8 7.2 8.8

6HK06501525 14.4 10.8 13.2 36.9 45.1 10.8 13.2 10.8 13.2

3PH

6HK06501825 17.3 13.0 15.9 44.3 54.2 13.0 15.9 13.0 15.9

6HK16502025 19.2 14.4 17.6 49.2 60.2 7.2 8.8 14.4 17.6

6HK16502525 24.0 18.0 22.0 61.5 75.2 9.0 11.0 18.0 22.0

1. (0,1) - 0 = no circuit breaker OR 1 = with circuit breaker.

2. (1,2) - 1 = with circuit breaker, no breaker jumper bar OR 2 = with circuit breaker & breaker jumper bar.

3. For different power distributions, see conversion table on Page 5.

3

ELECTRICAL DATA FOR SINGLE SOURCE POWER SUPPLY: 208/230-1-60

Heater

Amps

@240V

Min. Circuit Ampacity

208V 230V 208V 230V 208V 230V

Air Handler Models

AHE18B

AHE22B

AHE24B

AHE30B

AHE34C

AHE36C

AHE42D

AHE48D

For notes see Page 7.

Heater

1,2

Models

6HK(0,1)6500206 10.0 14.3 16.0 15 20 12 12

6HK(0,1)6500506 20.0 25.2 28.5 30 30 10 10

6HK(0,1)6500806 32.0 38.2 43.5 40 45 8 8

6HK(0,1)6501006 40.0 46.8 53.5 50 60 8 6

6HK(0,1)6500206 10.0 14.3 16.0 15 20 12 12

6HK(0,1)6500506 20.0 25.2 28.5 30 30 10 10

6HK(0,1)6500806 32.0 38.2 43.5 40 45 8 8

6HK(0,1)6501006 40.0 46.8 53.5 50 60 8 6

6HK(1,2)6501306 52.0 59.8 68.5 60 70 6 4

6HK(1,2)6501506 60.0 68.5 78.5 70 80 4 4

6HK(0,1)6500206 10.0 16.0 17.6 20 20 12 12

6HK(0,1)6500506 20.0 26.8 30.1 30 35 10 10

6HK(0,1)6500806 32.0 39.8 45.1 40 50 8 8

6HK(0,1)6501006 40.0 48.5 55.1 50 60 8 6

6HK(1,2)6501306 52.0 61.5 70.1 70 80 6 4

6HK(1,2)6501506 60.0 70.1 80.1 80 90 4 4

6HK(1,2)6501806 72.0 83.1 95.1 90 100 4 3

6HK(1,2)6502006 80.0 91.8 105.1 100 110 3 2

6HK(0,1)6500206 10.0 18.3 20.0 20 20 12 12

6HK(0,1)6500506 20.0 29.2 32.5 30 35 10 8

6HK(0,1)6500806 32.0 42.2 47.5 45 50 8 8

6HK(0,1)6501006 40.0 50.8 57.5 60 60 6 6

6HK(1,2)6501306 52.0 63.8 72.5 70 80 6 4

6HK(1,2)6501506 60.0 72.5 82.5 80 90 4 4

6HK(1,2)6501806 72.0 85.5 97.5 90 100 3 3

6HK(1,2)6502006 80.0 94.2 107.5 100 110 3 2

Field Wiring

3

MOP.

kW Staging

Min Wire Size (AWG)

4

6 Johnson Controls Unitary Products

Page 7

1169652-YTG-A-1114

ELECTRICAL DATA FOR SINGLE SOURCE POWER SUPPLY: 208/230-1-60 (Continued)

Heater

Amps

@240V

Min. Circuit Ampacity

208V 230V 208V 230V 208V 230V

Air Handler Models

Heater

Models

1,2

6HK(0,1)6500206 10.0 18.3 20.0 20 20 12 12

6HK(0,1)6500506 20.0 29.2 32.5 30 35 10 8

6HK(0,1)6500806 32.0 42.2 47.5 45 50 8 8

6HK(0,1)6501006 40.0 50.8 57.5 60 60 6 6

AHE60D

6HK(1,2)6501306 52.0 63.8 72.5 70 80 6 4

6HK(1,2)6501506 60.0 72.5 82.5 80 90 4 4

6HK(1,2)6501806 72.0 85.5 97.5 90 100 3 3

6HK(1,2)6502006 80.0 94.2 107.5 100 110 3 2

6HK(1,2)6502506 100.0 115.8 132.5 125 150 1 1/0

1. (0,1) - maybe 0 (no circuit breaker) or 1 (with circuit breaker).

2. (1,2) maybe 1 (with circuit breaker, no breaker jumper bar) or 2 (with circuit breaker & breaker jumper bar).

3. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

4. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

Field Wiring

3

MOP.

Min Wire Size (AWG)

ELECTRICAL DATA FOR SINGLE SOURCE POWER SUPPLY - 208/230-3-60

Heater

Amps

@ 240V

Min. Circuit Ampacity

208V 230V 208V 230V 208V 230V

Air Handler Models

AHE22B

AHE24B

AHE30B

Heater

Models

6HK06501025 23.1 28.5 32.4 30 35 10 8

6HK06501525 34.6 41.0 46.8 45 50 8 8

6HK06501025 23.1 30.2 34.0 30 35 10 8

AHE34C

AHE36C

AHE42D

6HK06501525 34.6 42.6 48.4 45 50 8 8

6HK06501825 41.6 50.2 57.1 60 60 6 6

6HK16502025

3

46.255.262.9 60 70 6 6

6HK06501025 23.1 32.5 36.4 35 40 8 8

AHE48D

6HK06501525 34.6 45.0 50.8 45 60 8 6

6HK06501825 41.6 52.6 59.5 60 60 6 6

6HK16502025

3

46.257.665.3 60 70 6 4

6HK06501025 23.1 32.5 36.4 35 40 8 8

6HK06501525 34.6 45.0 50.8 45 60 8 6

AHE60D

1. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

2. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and local codes.

3. The 20kW and 25kW heater models (6HK16502025 and 6HK16502525 ) come with circu it breakers st andard. Single sour ce power MCA and MOP req uirement s are

given here only for reference if used with field installed single point power modification.

6HK06501825 41.6 52.6 59.5 60 60 6 6

6HK16502025

6HK16502525

3

3

46.257.665.3 60 70 6 4

57.770.079.6 70 80 4 4

Field Wiring

1

MOP

Min. Wire Size (AWG)

4

2

Johnson Controls Unitary Products 7

Page 8

1169652-YTG-A-1114

UPFLOW

HORIZONTAL RIGHT

HORIZONTAL LEFT

HEAT

HEAT

HEAT

DOWNFLOW

HEAT

ELECTRICAL DATA FOR MULTI-SOURCE POWER SUPPLY: 208/230-1-60

MOP

1

1st

3

2nd 3rd

Min. Wire Size (AWG)

3

2nd 3rd

1st

1st

Air

Handlers

Models

AHE22B

AHE24B

AHE30B

AHE34C

AHE36C

AHE42D

Min. Circuit Ampacity

208V 230V 208V 230V 208V 230V

Circuit Circuit Circuit

1st

3

2nd 3rd

1st

3

2nd 3rd

1st

3

2nd 3rd

Heater

Models

Total

Heater

Amps

@240V

6HK16501306 52.0 22.2 37.6 – 24.6 43.3 – 25 40 – 25 45 – 10 8 – 10 8 –

6HK16501506 60.0 25.1 43.3 – 27.9 50.0 – 30 45 – 30 50 – 10 8 – 10 8 –

6HK16501306 52.0 23.3 37.6 – 25.7 43.3 – 25 40 – 30 45 – 10 8 – 10 8 –

6HK16501506 60.0 26.2 43.3 – 29.0 50.0 – 30 45 – 30 50 – 10 8 – 10 8 –

6HK16501806 72.0 43.5 39.0 – 49.0 45.0 – 45 40 – 50 45 –88–88–

6HK16502006 80.0 47.8 43.3 – 54.0 50.0 – 50 45 – 60 50 –88–68–

6HK16501306 52.0 25.4 37.6 – 27.8 43.3 – 30 40 – 30 45 – 10 8 – 10 8 –

AHE48D

6HK16501506 60.0 28.3 43.3 – 31.1 50.0 – 30 45 – 35 50 – 10 8–88–

6HK16501806 72.0 45.6 39.0 – 51.1 45.0 – 50 40 – 60 45 –88–68–

6HK16502006 80.0 49.9 43.3 – 56.1 50.0 – 50 45 – 60 50 –88–68–

6HK16501306 52.0 25.4 37.6 – 27.8 43.3 – 30 40 – 30 45 – 10 8 – 10 8 –

6HK16501506 60.0 28.3 43.3 – 31.1 50.0 – 30 45 – 35 50 – 10 8–88–

AHE60D

6HK16501806 72.0 45.6 39.0 – 51.1 45.0 – 50 40 – 60 45 –88–68–

6HK16502006 80.0 49.9 43.3 – 56.1 50.0 – 50 45 – 60 50 –88–68–

6HK16502506 100.0 49.9 43.3 21.7 56.1 50.0 25.0 50 45 25 60 50 25 8 8 10 6 8 10

1. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

2. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and loca l codes.

3. 1st Circuit includes the blower motor amps.

3

2nd 3rd

2

ELECTRICAL DATA FOR MULTI-SOURCE POWER SUPPLY: 208/230-3-60

2nd

MOP

1

1st

Min. Wire Size (AWG)

3

2nd

1st

3

2nd

1st

3

2nd

Min. Circuit Ampacity

Air Handler

Models

Heater

Models

Total Heater

Amps

@ 240V

208V 230V 208V 230V 208V 230V

Circuit Circuit Circuit

1st

3

2nd

1st

3

2nd

1st

3

AHE34C, AHE36C, AHE42D 6HK16502025 46.2 30.2 25.0 34.0 28.9 35 25 35 30 8 10 8 10

AHE48D 6HK16502025 46.2 32.5 25.0 36.4 28.9 35 25 40 30 8 10 8 10

AHE60D

1. MOP = Maximum Overcurrent Protection device; must be HACR type circuit breaker or time delay fuse.

2. Stated sizes are for 75°C, copper wire only. If wire other than non-plated, 75°C ambient, copper wire is used, consult applicable tables of the NEC and loca l codes.

3. 1st Circuit includes the fan motor.

TYPICAL APPLICATIONS

6HK16502025 46.2 32.5 25.0 36.4 28.9 35 25 40 30 8 10 8 10

6HK16502525 57.7 38.8 31.3 43.6 36.1 40 35 45 40 8888

TXV Kits - TXV kits are available for “Flex-coil” applications and

converting R-22 to R-410A or as a service replac ement. All ki ts

are bolt-on and require no brazing to install.

Electric Heaters - 6HK models shown under electrical data

include sequential operation and temperature dual limit

switches for safe, efficient operation. Circuit breakers are provided where shown.

LIMITATIONS

These units must be wired and installed in acco rdance with all

national and local safety codes.

Voltage limits are as follows:

2

ACCESSORIES

Refer to Price Manual for specific model numbers where not

shown.

Air Handler Voltage Voltage code

Normal Operating

Voltage Range

208/230-1-60 06 187-253

1. Rated in accordance with ARI Standard 110, utilization range “A”.

Airflow must be within the minimum and maximum limits

approved for electric heat, evaporator coils and outdoor units.

8 Johnson Controls Unitary Products

1

Page 9

1169652-YTG-A-1114

AIR FLOW DATA (CFM)

Models

1

Blower

Motor Speed

External Static Pressure (in. wc.)

0.10 0.20 0.30 0.40 0.50 0.60 0.70

High #5 1075 1041 1003 970 930 885 842

Med High #4 895 845 808 767 709 647 561

AHE18B

Med #3 663 618 557 490 348 267 192

Med Low #2 629 468 356 197 175 68 23

Low #1 629 468 356 197 175 68 23

High #5 1156 1120 1093 1056 1014 951 862

AHE22B

AHE24B

AHE30B

Med High #4 1021 987 952 918 873 836 787

Med #3 829 789 754 698 654 585 532

Med Low #2 681 621 575 496 435 336 262

Low #1 598 503 437 340 259 203 74

High #5 1471 1429 1387 1337 1289 1233 1172

Med High #4 1301 1248 1198 1147 1008 999 927

AHE34C

Med #3 1097 1044 972 906 815 748 680

Med Low #2 943 868 768 689 617 566 520

Low #1 869 668 515 424 365 287 NA

High #5 1465 1415 1360 1307 1246 1183 1118

Med High #4 1260 1204 1142 1075 1008 946 876

AHE36C

Med #3 1088 1022 939 862 782 721 626

Med Low #2 998 810 717 630 562 493 444

Low #1 903 707 411 323 265 152 NA

High #5 1632 1589 1542 1494 1446 1391 1335

Med High #4 1430 1390 1346 1294 1238 1168 960

AHE42D

Med #3 1238 1198 1145 1082 993 908 805

Med Low #2 1118 1020 947 851 734 666 563

Low #1 998 772 477 418 349 NA NA

High #5 1861 1823 1787 1750 1708 1666 1620

Med High #4 1674 1640 1599 1562 1516 1472 1432

AHE48D

Med #3 1442 1405 1358 1311 1262 1197 1108

Med Low #2 1257 1220 1163 1103 1031 942 864

Low #1 1153 1031 967 867 764 718 633

High #5 2091 2053 2016 1975 1937 1906 1869

Med High #4 1903 1868 1832 1791 1748 1703 1660

AHE60D

Med #3 1634 1598 1562 1516 1468 1422 1350

Med Low #2 1447 1404 1361 1318 1257 1164 1092

Low #1 1268 1203 1148 1073 978 907 839

1. Air handler units have been tested to UL 1995 / CSA 22.2 st andards up to 0.30" wc. external static pressure.

Dry coil conditions only, tested without filters.

For optimal performance, external static pressures of 0.2" to 0.5" are recommended. Applications above 0.6" are not recommended.

Airflow data shown is from testing performed at 230V. AHE units use a X13 motor, and there is minimal variation of airflow at other distribution voltage values. The

above data can be used for airflow at other distribution voltages.

Johnson Controls Unitary Products 9

Page 10

1169652-YTG-A-1114

TYPICAL THERMOSTAT CONNECTION

10 Johnson Controls Unitary Products

Page 11

1169652-YTG-A-1114

A001-001

NOTICE

WIRING FOR BLOWER MOTOR

MAY REQUIRE FIELD ADJUSTMENT,

DEPENDING ON MATCHUP OF

SYSTEM UNITS. REFER TO

THE AIR FLOW DATA (CFM) TABLE IN

THE TECHNICAL GUIDE FOR DETAILS.

BLK -SPD (Y1 / W1)

TYPICAL THERMOSTAT WIRING FOR 2-STAGE HEAT PUMP WITH ECM BLOWER MOTOR

Johnson Controls Unitary Products 11

Page 12

NOTES

Subject to change without notice. Published in U.S.A. 1169652-YTG-A-1114

Copyright © 2014 by Johnson Controls, Inc. All rights reserved. Supersedes: 697887-YTG-H-0514

York International Corp.

5005 York Drive

Norman, OK 73069

Loading...

Loading...