York 363857-YUM-A-0208 User Manual

CONTENTS

SAFETY INFORMATION . . . . . . . . . . . . . . . . .2

FOR YOUR SAFETY. . . . . . . . . . . . . . . . . . . . . . . 2

SYSTEM OPERATION. . . . . . . . . . . . . . . . . . .2

THERMOSTATS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTERMITTENT IGNITION DEVICE. . . . . . . . . . . 2

INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . 3

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

HEATING SYSTEM INSPECTION . . . . . . . . . . . . 4

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AIR FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CONDENSER COIL. . . . . . . . . . . . . . . . . . . . . . . . 4

BLOWER ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . 4

BEFORE CALLING A SERVICE PERSON:. . . . . . 4

REPLACEMENT PARTS . . . . . . . . . . . . . . . . .5

USER’S, MAINTENANCE and

SERVICE INFORMATION

MANUAL

SINGLE PACKAGE

AIR CONDITIONER

GAS/ELECTRIC

The manufacturer recommends that the “User” read all sections of this manual and

keep the manual for future reference.

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could

result in serious injury, death, or property damage.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any

phone in your building.

•Leave the building immediately.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire

department.

- Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

363857-YUM-A-0208

363857-YUM-A-0208

SAFETY INFORMATION

FOR YOUR SAFETY

• Make sure that the furnace area is clear and free of combustible materials, gasoline and other flammable vapors

and liquids.

• Be sure the furnace is free and clear of insulating material. Examine the furnace area after installation of the furnace or the installation of additional insulation. Some

types of insulation are combustible.

• For proper operation of this furnace, air for combustion

and ventilation is required. Make sure that these openings are not obstructed.

• For lighting or shutting down this furnace, refer to the

lighting instructions provided adjacent to the burners and

also located in this manual.

• A blocked vent roll-out switch is provided in the burner

compartment. This switch is a manual reset. If the furnace fails to operate, contact a qualified service technician.

• Should the gas supply fail to shut off or if overheating

occurs, shut off the gas valve to the furnace before shutting off the electrical supply. Then call a qualified service

technician.

• Do not use this furnace if any part has been under water.

A flood-damaged furnace is extremely dangerous.

Attempts to use the furnace can result in fire or explosion. A qualified service technician should be contacted

to inspect the furnace and to replace all gas controls,

control system parts, electrical parts that have been wet

or the furnace if deemed necessary.

• Determine the integrity of the installation regarding the

flue gas vent, the return and supply air duct. Confirm the

equipment is well supported and there are no signs of

deterioration. The manufacturer recommends that main

burner, ignition device and controls are inspected by a

qualified service technician before each heating season.

SYSTEM OPERATION

THERMOSTATS

Set your thermostat for either heating or cooling then set it for

the desired temperature. DO NOT MOVE THE THERMOSTAT RAPIDLY ON AND OFF, OR BACK AND FORTH

FROM HEAT TO COOL. THIS COULD DAMAGE YOUR

EQUIPMENT.

Always allow at least 5 minutes between changes. Find the

temperature that is most comfortable to you, and then LEAVE

YOUR THERMOSTAT ALONE. (Exception is for night or

vacation “set back” to conserve energy).

Manually moving the thermostat up or down will not speed up

temperature changes in your rooms. This only causes the

thermostat switch to function at your command rather than

responding to room temperature.

Heat generated by devices other than the furnace may interfere with thermostat performance. Therefore, lamps, radios,

television sets, etc. should not be placed near the thermostat.

FIGURE 1 - TYPICAL THERMOSTAT

INTERMITTENT IGNITION DEVICE

Your unit is equipped with a cycling spark ignition device. It

has a Relight control designed to automatically light the burners each time the thermostat controller “calls” for heat.

This furnace is equipped with an intermittent spark and

automatic re-ignition system. Do Not attempt to manually

relight the pilot. Personal injury could result.

When the controller calls for heat, gas is supplied to the Integral Crossover Burners and at the same time, sparking

occurs to light the main burner gas. A flame sensor closes a

circuit to the ignitor control which proves that all of the burners have ignited properly.

On initial start-up, air may be in the gas lines. Several tries for

ignition may be required before the gas will carry over and

the heat sections remains lit. The ignition model has 3 trials

for ignition. If the ignition module locks out, it may be necessary to remove re-establish the call for heat W1 or W2 to continue the purging process.

When the controller is satisfied, the electrical circuit to the

gas valve is opened, closing off the flow of gas to the main

burner.

If the burners should fail to light, contact your heating contractor or gas company for service to insure that proper operating conditions are restored.

In the event that gas to the main burner has been sh ut-off,

DO NOT attempt to place the furnace into operation. Call the

appropriate service agency.

2 Johnson Controls Unitary Products

363857-YUM-A-0208

INPUT

The correct heat capacity of the furnace is regulated by the

main burner orifices and the gas pressure. The proper orifices for natural gas are furnished but the gas pressure regulator must be adjusted by the installer or gas company

service person.

OPERATING INSTRUCTIONS

TO SHUT DOWN THE FURNACE:

1. Close the main gas shutoff valve(s).

2. Turn off the electric power supply.

TO LIGHT THE FURNACE:

1. Do not attempt to light manually.

2. Open the main gas shutoff valve(s).

3. Turn on the electric p ower suppl y.

4. Initiate a call for heat.

5. If the return air temperature is below the set point of the

controller, the ventor fans will operate. After an adequate

purge time, the intermittent ignition device will light the

burners. The burners will extinguish and relight automatically upon the demand of the controller.

VENT SAFETY SYSTEM

Each gas furnace module is equipped with an automatic

reset high temperature limit and rollout switch. In the unlikely

event of a sustained main burner flame rollout, the switch will

shut off the flow of gas by closing the main gas valve. The

ignition module will also be disabled, preventing the flow of

gas to the valve. The rollout switch for each module is located

inside the gas heat section access door on the heat shield of

each module. Flame rollout can be caused by blockage of the

power vent system or improper gas pressure adjustment. If

this occurs the furnace will not operate properly, gas supply

to the furnace should be shut off and no attempt should be

made to place the furnace in operation. The system should

be inspected by a qualified service person. Refer to Figure 3

for a typical installation of vent hoods.

The ignition modules are designed such that if the furnace

fails to ignite after 3 trials for ignition after a call for heat the

flow of gas will be shut off and the ignition module will lock out

for one hour. Then the modules will retry ignition and repeat

cycle until ignition occurs, or call for heat is satisfied or power

to unit is removed. If the furnace does not light after several

tries, a service man should be called to determine the cause

of the problem.

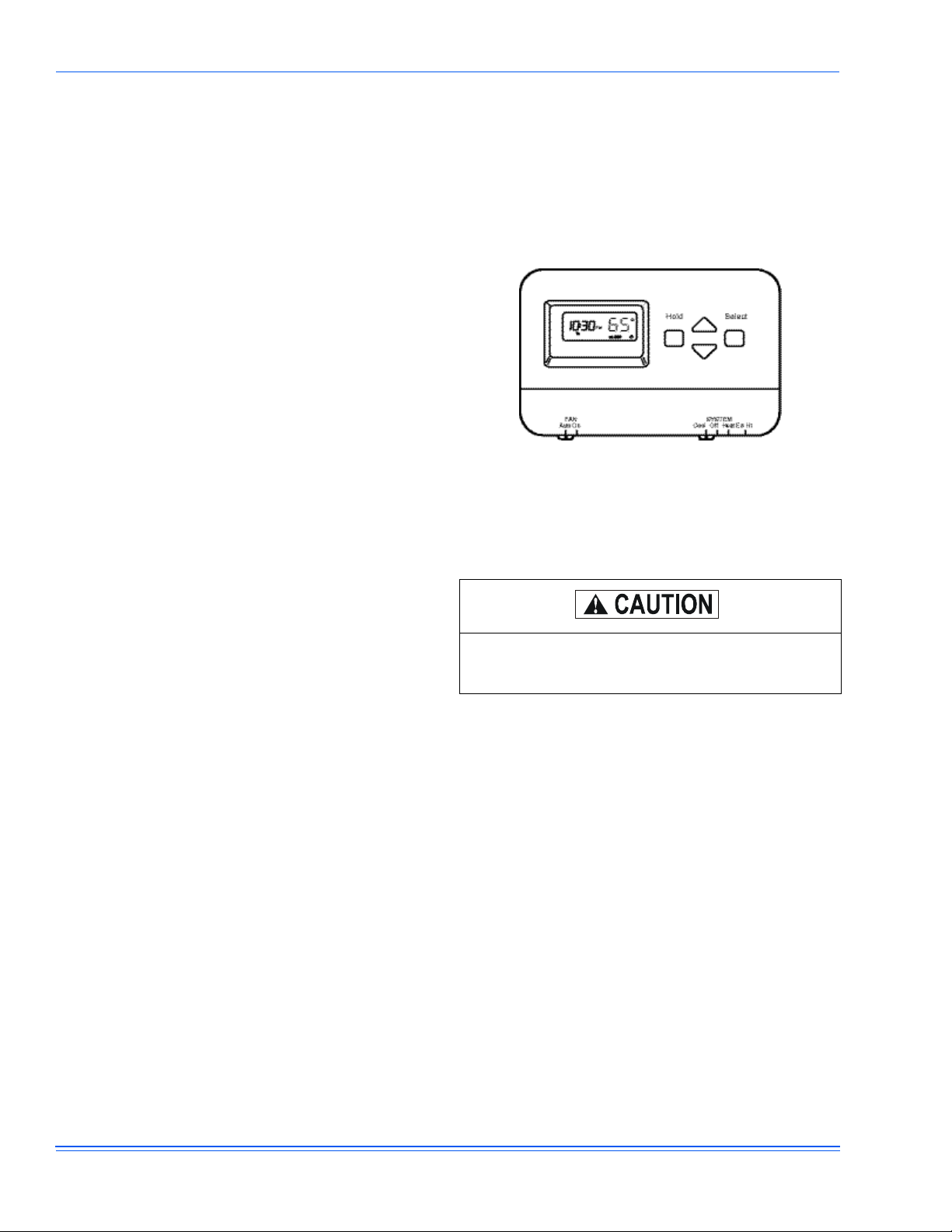

HEAT EXCHANGER TUBE

GAS

SUPPLY

PIPE

BURNER

BURNER BRACKET

BURNER FLAME

(BLUE ONLY)

IGNITOR

FIGURE 2 - TYPICAL FLAME APPEARANCE

EXHAUST VENT OUTLET

SHIPPING LABELS

(REMOVE SHIPPING

LABELS PRIOR TO

VENT INSTALLATION)

VENT FLUE ASSY.

COMBUSTION AIR INLET

HEAT SECTION DOOR

FIGURE 3 - FLUE VENT ASSEMBLY

This furnace is equipped with a blocked vented shut-off system (air proving switch). The purpose of the switch is to prove

that there is combustion air being drawn through the heat

section. The ignition control will not operate if this switch is

not made in the pre-purge time of the vent assembly. In the

event that the furnace fails to operate due to the pressure

switch, a qualified service agency should be contacted.

Determine that external vent is in place (field installed) and

clear and free of obstructions.

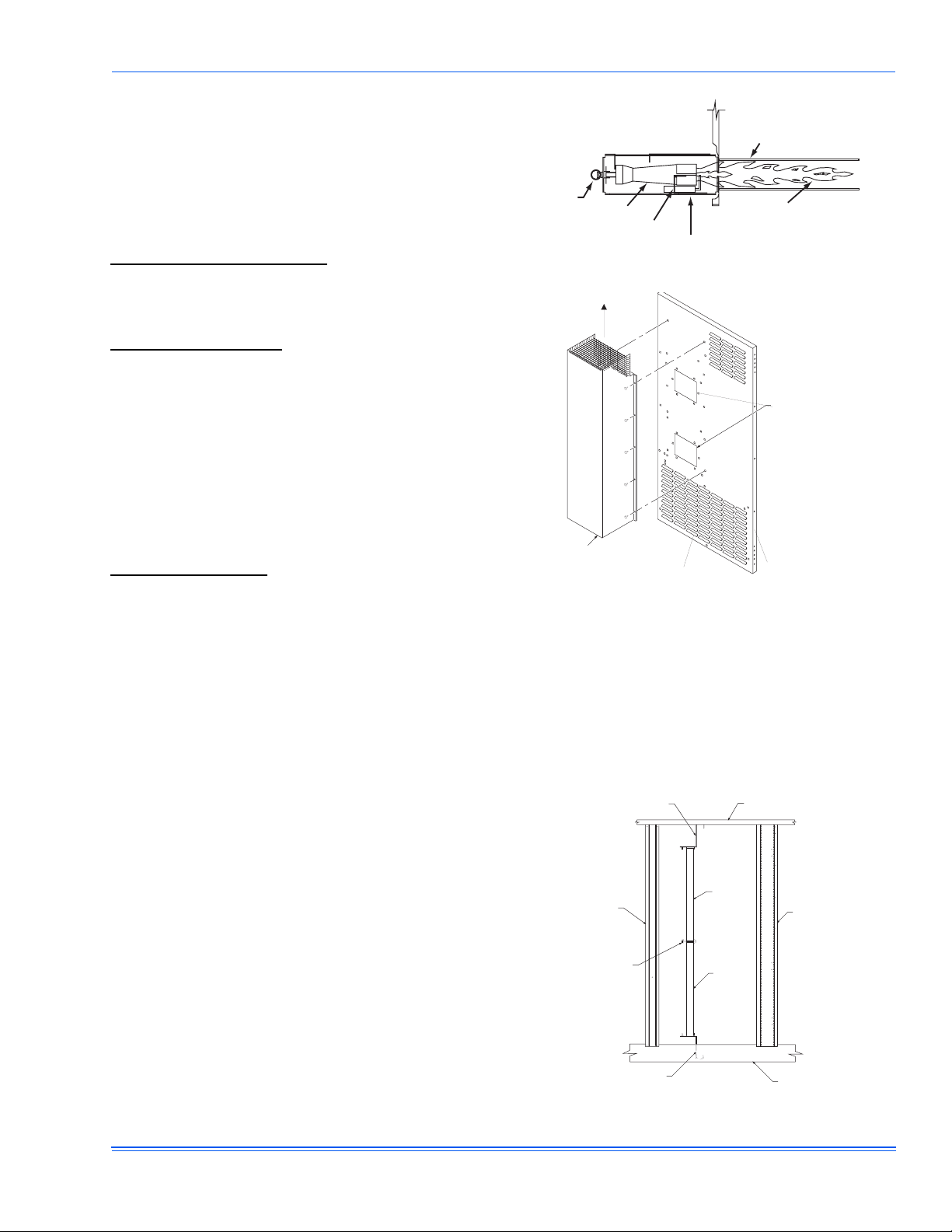

EXTERNAL

UPRIGHT

BRACKET

FILTER CHANNEL

FILTER

FILTERS

FILTERS

PERIMETER FRAME

EXTERNAL

UPRIGHT

FILTER CHANNEL

BASE RAIL

FIGURE 4 - FILTER ACCESS

Johnson Controls Unitary Products 3

Loading...

Loading...