Page 1

®

360101-XTG-A-0108

TECHNICAL GUIDE

AFFINITY™ SERIES

SINGLE PACKAGE

COOLING UNITS

D2EB018 THRU 060

1.5 THRU 5 TON

8.8 - 9.4 EER

EXPORT

DESCRIPTION

These packaged cooling air conditioners are designed for

outdoor installation. Only utility and duct connections are

required at the point of installation.

Field-installed electric heater accessories are available to

provide electric heat combined with electric cooling.

STANDARD FEATURES / BENEFITS

OPERATING EFFICIENCY - All units provide high operating

efficiencies and have a minimum EER of 8.8 or above.

ON SITE FLEXIBILITY - All model sizes share a common,

compact design cabinet with a single footprint. The installer has

the flexibility of setting one curb and placing the proper tonnage

unit on that curb after the internal load has been determined.

Field convertible duct connections from side shot to down shot

allows the installer to have greater flexibility and needs to carry

less inventory.

LOWER INSTALLATION COST - Installation time and costs

are reduced by easy power and control wiring connections. The

small base dimension means less space is required on the

ground or roof, plus, the installer can fit this unit between the

wheel wells of full size pick-up tru ck. All models are well under

400 pounds.

All units are completely wired, charged with R-22 and tested

prior to shipment. Unique test stations using a new state of the

art computerized process system are used to insure product

quality. Refrigerant charge, and component part numbers are

verified via computers at installation. Vital run test statistics

such as system pressure, motor currents, air velocity and

temperature and unit vibration are monitored and recorded by

the system to insure unit performance.

Equal size, side supply and return duct connections allows easy

hook-up of ducts to match low crawl spaces without transition

pieces.

ISO 9001

Certified Quality

Management System

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

TABLE OF CONTENTS

360101-XTG-A-0108

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

STANDARD FEATURES / BENEFITS. . . . . . . . . . . . . . . . .1

FIELD-INSTALLED ACCESSORIES . . . . . . . . . . . . . . . . . .3

TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . .17

MECHANICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . .20

LIST OF FIGURES

Fig. # Pg. #

1 UNIT CUTAWAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 TYPICAL FIELD WIRING DIAGRAM . . . . . . . . . . . . . 13

3 UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 CENTER OF GRAVITY. . . . . . . . . . . . . . . . . . . . . . . . 16

5 TYPICAL SLAB ON GROUND INSTALLATION. . . . . 17

6 TYPICAL ROOF CURB INSTALLATION . . . . . . . . . . 17

7 ROOF CURB DIMENSIONS (8” ROOF CURB ALSO

AVAILABLE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8 ROOF CURB APPLICATION . . . . . . . . . . . . . . . . . . . 18

9 TYPICAL WIRING DIAGRAM (208/230-1-60 POWER

SUPPLY) DEB MODELS . . . . . . . . . . . . . . . . . . . . . . .19

LIST OF TABLES

Tbl. # Pg. #

1 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 RATINGS - ARI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 COOLING CAPACITIES - 1-1/2 TON (DEB018) . . . . . . 6

4 COOLING CAPACITIES - 2 TON (DEB024) . . . . . . . . . 7

5 COOLING CAPACITIES - 2-1/2 TON (DEB030) . . . . . . 8

6 COOLING CAPACITIES - 3 TON (DEB036) . . . . . . . . . 9

7 COOLING CAPACITIES - 3-1/2 TON (DEB042) . . . . . 10

8 COOLING CAPACITIES - 4 TON (DEB048) . . . . . . . .11

9 COOLING CAPACITIES - 5 TON (DEB060) . . . . . . . .12

10 SIDE AND BOTTOM SUPPLY AIR BLOWER

PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

11 ADDITIONAL STATIC RESISTANCE . . . . . . . . . . . . . 13

12 ELECTRICAL DATA (BASIC UNIT) . . . . . . . . . . . . . . .14

13 ELECTRICAL DATA (COOLING/ELECTRIC HEAT) . . 14

14 UNIT WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

PRODUCT CATEGORY

D = Single Package Air Conditioner

(Air Cooled)

PRODUCT GENERATION

2 = 2nd Generation

PRODUCT IDENTIFIER

EB = 10 SEER Cooling Models

D

2 E B A

20 4 0 6

NOMINAL COOLING

CAPACITY (MBH)

018 = 18,000 BTUH

024 = 24,000 BTUH

030 = 30,000 BTUH

036 = 36,000 BTUH

042 = 42,000 BTUH

048 = 48,000 BTUH

060 = 60,000 BTUH

VOLTAGE CODE

06 = 208/230-1-60

FACTORY

INSTALLED ELECTRIC HEAT

A = No Electric Heat Installed

2 Johnson Controls Unitary Products

Page 3

360101-XTG-A-0108

STANDARD FEATURES/BENEFITS (CONT.)

UTILITY CONNECTIONS MADE EASY - Electrical utility

knockouts are provided through the bottom as well as the side

of the unit. Utility connections can be made quickly and with a

minimum amount of field labor. A field supplied and field

installed electrical disconnect switch must be installed.

CONVERTIBLE AIRFLOW DESIGN - The bottom duct

openings are covered when they leave the factory ready to be

used for a side supply / side return application. If a bottom supply

/ bottom return application is desired, you simply remove the tw o

panels from the bottom of the unit and place them in the side

supply / side return duct openings. No panel cutting is required

and no accessory panel is necessary. Convertible airflow design

allows maximum field flexibility and minimum inventory.

CONDENSATE PAN - A non-corrosive, long-lasting, water-tight

pan is positioned below the evaporator coil to collect and drain

all condensate. Less collection of stagnate condensate will

build-up. The condensate pan conforms to ASHRAE 62-89

standards (Ventilation for Acceptable Indoor Air Quality).

CONDENSATE DRAIN - The heavy duty, 3/4 inch NPTI copper

connection is more tolerable during installation and is more

durable over time. The connection is rigidly mounted to assure

proper fit and leak tight seal.

DURABLE FINISH - With a heavy duty cabinet made of powderpainted, galvanized steel the neutral color blends into

surrounding areas. The powered paint, provides a better paint to

steel bond, which resists corrosion and rust creep. The special

primer formulas and glossy earth tone finish insure less fading

when exposed to sunlight and offers a more attractive on site

appearance. This paint finish exceeds ASTM-B117 standards for

750 hours salt spray rating, the highest in the industry.

FULL PERIMETER BASE RAILS - The easily removable base

rails provide a solid foundation for the entire unit and protects

the unit during shipment. The rails provide fork lift access from

all sides, and rigging holes are also provided so that an

overhead crane can be used to place the units on a roof. On

applications when the unit is placed on a pad, the base will

keep the unit off the pad to deter corrosion. On applications

where height is limited, the 2-3/8 inch high base rails may be

removed on location.

MORE ATTRACTIVE APPEARANCE - A single piece “Water

Shed” top cover containing a top discharge condenser fan

arrangement requires less square footage on installation and

provides a wider variety of installations. The one piece design

adds greater water integrity. Rounded corners with water drip

edges add to the attractive appearance. The cabinet panels

have a non-fibrous insulation that does not add insulation fibers

into conditioned area.

CONDENSER COIL GRILLE - A multi-piece totally enclosed,

rigidly mounted condenser coil grille provides protection from

objects and personal after installation and provides protection

during transit and installation.

LOW OPERATING SOUND LEVEL - The upward air flow carries

the normal operating noise up and away from the living area. The

rigid top panel effectively isolates any motor sound. Isolator

mounted compressor and the rippled fins of the condenser coil

muffle the normal fan motor and compressor operating sounds.

The unique formed base pan also aids in sound alterations with it's

“Super-Structure” design. This design strategically places

embossments in the pan for optimum strength and rigidity.

FAN SYSTEM - All models operate over a wide range of design

conditions with a 3-speed direct-drive fan motor. These units

easily match all types of applications and provides greater on

site flexibility to match comfort requirement.

SIMPLE CONTROL CIRCUIT - A low voltage printed circuit

board contains a low voltage terminal strip. The electrical

control box is not located in the compressor compartment. All

wiring internal to the unit is color/number coded.

PROTECTED COMPRESSOR - The compressor is internally

protected against high pressure and temperature. This is

accomplished by the simultaneous operation of high pressure

relief valve and a temperature sensor which protect the

compressor if undesirable operating conditions occur.

EXCLUSIVE COIL DESIGN - Grooved copper tubes and

enhanced aluminum fin construction improves heat transfer for

maximum efficiency and durability.

LOW MAINTENANCE - Long life, permanently lubricated

condenser and evaporator fan motor bearings need no annual

maintenance adding greater reliability to the unit. Blower

assembly can be easily removed for cleaning by the unique

“Slip- Track” slide-out blower assembly.

SECURED SERVICE ACCESS PORTS - Protected, externally

mounted, re-usable service access ports are provided on both

the high and low lines for ease of evacuating and charging the

system. No final field mounting required.

EASY SERVICE ACCESS - A large, single panel covers the

electrical controls and makes servicing easy. The blower

compartment has an additional large panel with a built-in

handle tab. Removing this panel will allow the blower assembly

to slide-out for easy removal for maintenance and ease of

trouble shooting.

REPLACEMENT PARTS - The installer has no need to carry

an inventory of unique parts or needs special training to replace

any of the components parts for these units. All are easily

obtained from Source 1 or other part houses.

TOP DISCHARGE - The top discharge condenser fan does not

disrupt neighboring areas and does not dry-out vegetation

surrounding the unit. The warm air from the top mounted fan is

blown up away from the structure and any landscaping. This

allows compact location on multi-unit applications.

Johnson Controls Unitary Products 3

FIELD-INSTALLED ACCESSORIES

ECONOMIZER DOWN DISCHARGE / SUPPLY KIT -

Modulating integrated economizer provides simultaneous

operation between the mechanical cooling and economizer

Page 4

360101-XTG-A-0108

operation. Independent blade design insures proper control and

less than 1% leak rate. Includes hood and mesh bird screen

filter integrated into the hood, dry bulb sensor and relief

damper. Separate field accessories of single enthalpy and dual

enthalpy are also available.

SINGLE ENTHALPY SENSOR - Sensor replaces dry bulb

sensor standard in economizer kit. Provides improved

economizer operation by sensing the dry bulb temperature from

outdoors plus the enthalpy content of the outdoor air.

DUAL ENTHALPY SENSOR - Additional sensor to single

enthalpy sensor. Sensor senses both the return air temperature

dry bulb and humidity in conjunction with the single enthalpy to

determine the most economical mix. Single Enthalpy sensor

also required.

UPGRADE SAFETY PACKAGE - Contains screw-in type High

pressure, Low Pressure/Loss of Charge switch, freeze protection

switch and lockout relay. Switches are placed onto existing

schrader ports located in the unit by furnished adapters. When

abnormal conditions are sensed through the pressure switches,

the unit will lock out preventing any further operation until reset or

problem is corrected. Package agency approved.

HAIL GUARD KIT - Kit contains protected grilles made of

expanded aluminum grilles with full perimeter inch frame.

Sloped hoods are also included to assure maximum protection..

ANTI SHORT CYCLE TIMER - Automatically prevents the

compressor from restarting for 5 minutes after cycled off. Not

required if Thermostat 2ET07700224 and 2ET04700224 are

used.

FILTER / FRAME KIT (Single Phase only) - Kit contains the

necessary hardware to field install return air filters into the base

unit. Pre-cut filter racks and appropriate cleanable standard

size filters are shipped in one kit. (1" filter is supplied) This kit is

available for single phase horizontal or vertical duct application

only. Standard in all 3 Phase models.

MOTORIZED FRESH AIR DAMPER - Designed for duct

mounted side return and unit mounted down shot return

applications. Damper capable of providing 0% thru 50% of

outdoor air (field supplied). Closes on power loss, includes

hood and screen assembly.

RECTANGLE TO ROUND ADAPTERS - Kit includes one

supply and one return air rectangle to round duct adapter.

Adapters are preformed and designed to fit over current duct

openings on the base unit. Transition is from 15” square to 14”

round.

ROOF CURBS - NRCA approved curbs provide proper fit to

base unit for rooftop installations. Curbs are designed to be

assembled through hinge pins in each corner. Kit also provides

seal strip to assure a water tight seal. Eight and 14 inch high

roof curbs are available.

MANUAL OUTDOOR DAMPER - Provides 0% thru 50%

outdoor air capability (field adjustable). Designed for duct

mounted side return and unit mounted down shot return

applications. Includes hood and screen assembly.

WALL THERMOSTAT - The units are designed to operate with

24-volt electronic and electro-mechanical thermostats. All units

can operate with single stage heat / single stage cool

thermostats - with or without the economizer.

LOW AMBIENT KIT - Kit provides necessary hardware to

convert unit to operate in cooling cycle down to 0 °F. Standard

unit operation 45 °F.

TRANSFORMER KIT - Kit provides necessary hardware to

provide single phase models from factory furnished 40 VA

transformer capability to 75 VA transformer capability.

ELECTRIC HEATERS - Each heater package provides easy

installation of electric heat strips. Slide in design with plug in

harness and agency approved. Heaters are available from 5.0

KW sizes and are designed for single point connection.

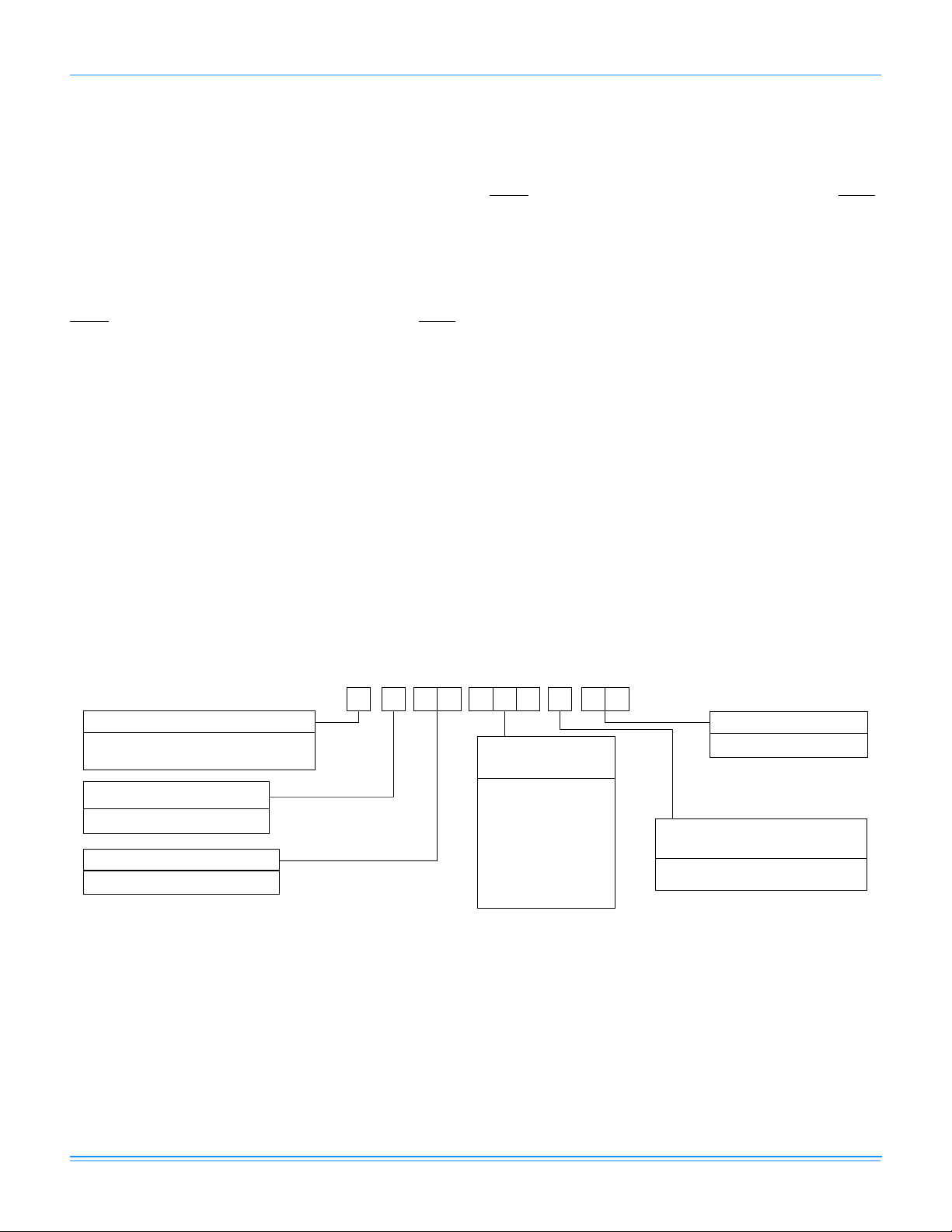

DIRECT DRIVE

CONDENSER

FAN MOTOR

HIGHLY EFFICIENT ENHANCED

BACK AND BOTTOM

RETURN AIR

AND SUPPLY AIR

DUCT OPENING

HIGH VOLTAGE

TERMINAL BLOCK

LOW VOLTAGE

TERMINAL BLOCK

LONG LASTING

POWDER PAINT

FINISH EARTH

TONE COLOR

HIGH EFFICIENCY

COMPRESSOR

RIGIDLY

MOUNTED

COPPER TUBE/ALUMINUM FIN

EVAPORATOR COIL

HIGHLY EFFICIENT

ENHANCED COPPER

TUBE/ALUMINUM FIN

CONDENSER COIL

DECORATIVE

PROTECTIVE

COIL GUARD

3-SPEED DIRECT DRIVE

BLOWER MOTOR WITH

SLIDE-OUT BLOWER ASSEMBLY

HEAVY GAUGE

REMOVABLE

BASE RAILS

FIGURE 1 - UNIT CUTAWAY

4 Johnson Controls Unitary Products

Page 5

360101-XTG-A-0108

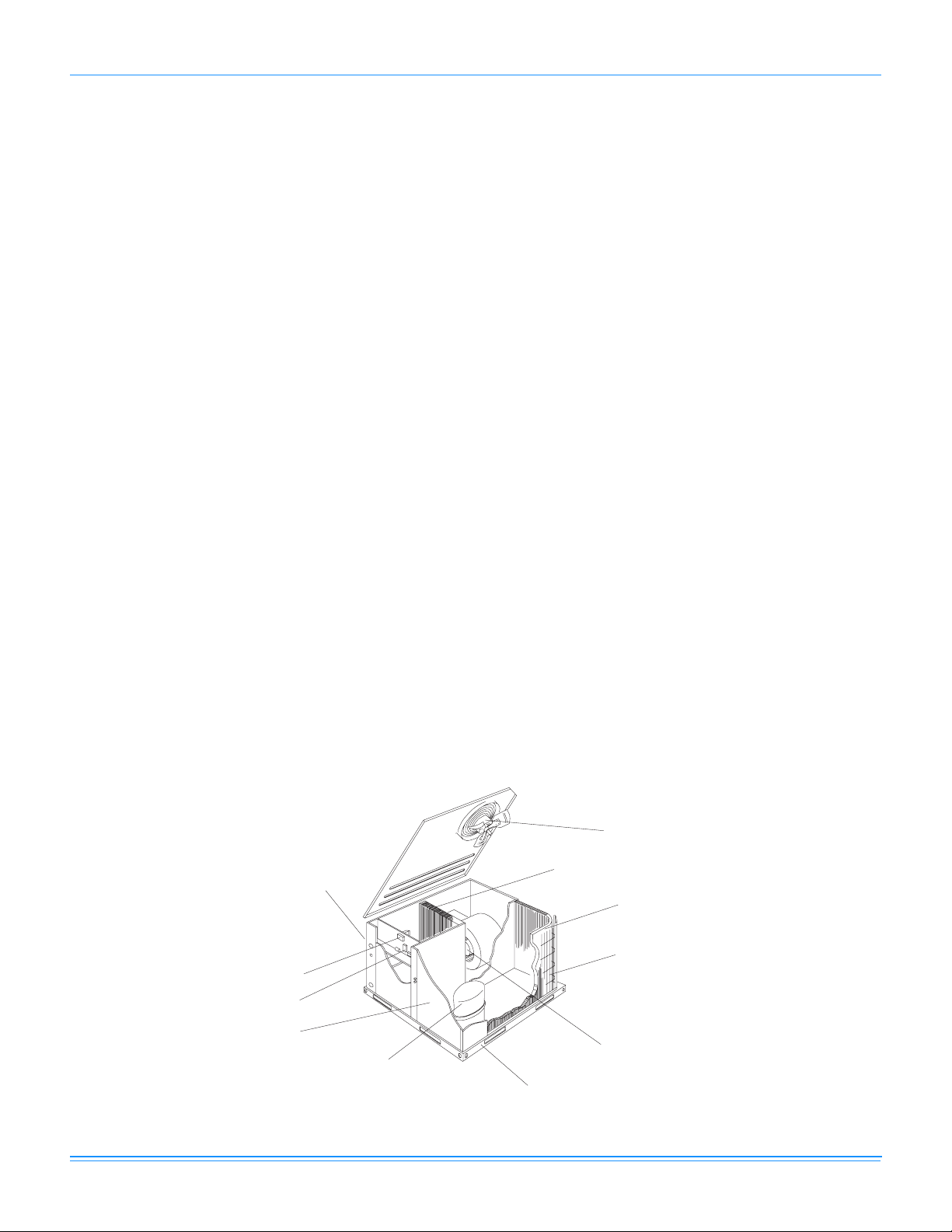

T A BLE 1: PHYSICAL DATA

DEB

3

4

3

4

3

4

EVAPORATOR

BLOWER

MODELS

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 9 X 6 10 X 8 10 X 8 10 x 8 11 X 10 11 x 10 11 x 10

FAN MOTOR HP ½ ½ ½ 1

018 024 030 036 042 048 060

ROWS DEEP 2 2 2 2 2 2 3

EVAPORATOR

COIL

FINS PER INCH 13 15 15 15 15 13 16

FACE AREA (Sq. Ft.) 2.19 2.81 4.38 4.38 4.38 5.62 5.26

PROPELLER DIA. (in.) 22 22 22 22 22 22 22

CONDENSER

FAN

FAN MOTOR HP 1/4 1/4 1/4 1/4 1/4 1/4 1/4

NOM. CFM TOTAL 1,800 2,200 2,400 2,400 2,400 2,800 2,800

ROWS DEEP 1 1 1 1 1 1 1

CONDENSER

COIL

FINS PER INCH 18 16 20 18 16 13 20

FACE AREA (Sq. Ft.) 8.3 8.3 8.3 8.3 11.7 16.4 16.4

CHARGE REFRIGERANT 22 (lbs./oz.) 3 / 4 3 / 5 3 / 13 3 / 10 4 / 8 5 / 15 5 /15

FILTER FACE AREA (Sq. Ft.) / Qty. / Size 2.14 / 2 / 14" x 22"

COMPRESSOR HERMETIC, QTY. = 1 (Type) Recip. Recip. Recip. Recip. Recip. Scroll Scroll

T ABLE 2: RATINGS - ARI

1

2

(decibels)

Model DEB

Cooling Capacity

80/67-95 °F Sound Rating

018 17.6 8.8 76 5.0, 7.5

024 23.0 9.1 76 5.0. 7.5. 10.0

030 29.0 8.9 79 5.0, 7.5, 10.0, 15.0

036 35.2 8.7 81 5.0, 7.5, 10.0, 15.0

042 40.5 9.4 83 5.0, 7.5, 10.0, 15.0

048 46.5 8.8 81 10.0, 15.0, 20.0, 25.0

060 59.0 8.8 79 10.0, 15.0, 20.0, 25.0

1. Certified in accordance with the Unitary Small Equipment certification program, which is based on ARI Standard 210/240.

2. Rated in accordance with ARI Standard 270.

SEER = Seasonal Energy Efficiency Ratio - the total cooling output in BTU's during a normal annual usage period for cooling divided by the

total electric power input in watt-hours during the same period.

Electric Heat

Nom. Capacity

KW

(single phase)MBH EER

Johnson Controls Unitary Products 5

Page 6

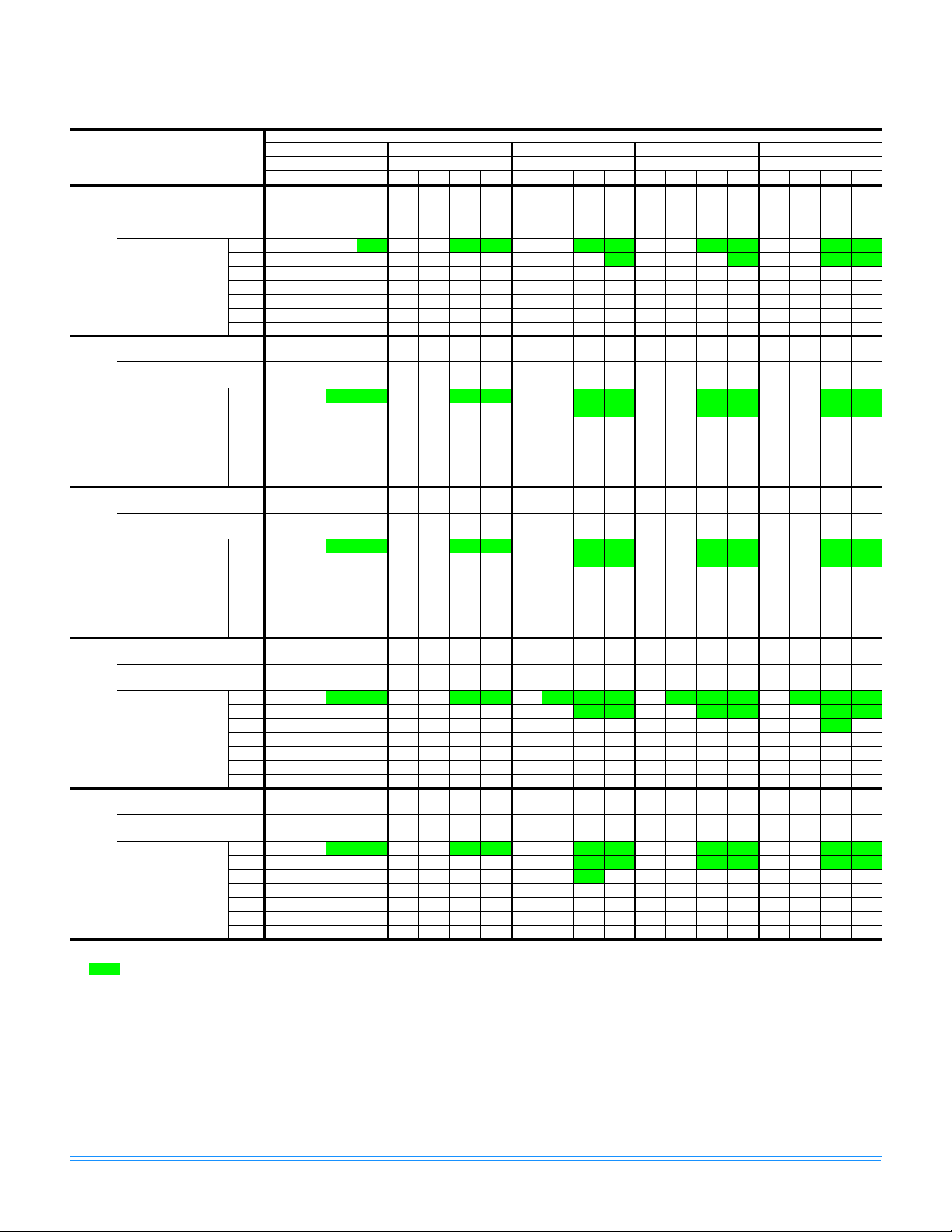

T ABLE 3: COOLING CAPACITIES - 1-1/2 TON (DEB018)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 10.1 13.1 15.9 16.3 10.8 14.0 16.1 16.4 11.5 14.8 16.2 16.5 12.3 15.7 16.8 17.1 13.1 16.7 17.4 17.7

83 8.8 11.8 14.7 16.0 9.3 12.4 15.4 16.3 9.8 13.0 16.0

80 7.5 10.6 13.4 14.7 7.8 10.9 13.8 15.2 8.0 11.3 14.3 15.7 8.3 11.7 14.9 16.3 8.7 12.2 15.5 17.0

77 6.2 9.3 12.1 13.4 6.2 9.4 12.3 13.7 6.3 9.5 12.5 14.0 6.3 9.8 12.9 14.4 6.4 10.0 13.2 14.8

74 4.9 8.0 10.8 12.1 4.7 7.9 10.8 12.2 4.5 7.8 10.8 12.2 4.4 7.8 10.9 12.4 4.2 7.7 11.0 12.5

Bulb °F

Entering Dry

71 - 6.7 9.5 10.9 - 6.4 9.3 10.7 - 6.0 9.0 10.5 - 5.8 8.9 10.4 - 5.5 8.8 10.3

68 - 5.4 8.2 9.6 - 4.9 7.8 9.1 - 4.3 7.3 8.7 - 3.8 6.9 8.4 - 3.3 6.5 8.1

86 9.1 12.6 13.7 14.1 10.2 14.1 14.3 14.8 11.3 15.5 15.0 15.5 11.9 16.2 15.1 15.6 12.5 16.8 15.3 15.8

83 7.9 11.4 13.2 13.6 8.7 12.6 14.1 14.6 9.6 13.8

80 6.6 10.1 11.9 12.3 7.2 11.0 13.1 13.5 7.8 12.0 14.3 14.7 7.9 12.2 14.4 14.9 8.1 12.3 14.6 15.1

77 5.3 8.8 10.7 11.1 5.7 9.5 11.6 12.0 6.1 10.3 12.5 13.0 6.0 10.2 12.5 12.9 5.8 10.1 12.4 12.9

74 4.0 7.5 9.4 9.8 4.2 8.0 10.1 10.5 4.3 8.5 10.8 11.2 4.0 8.2 10.5 10.9 3.6 7.9 10.2 10.7

Bulb °F

Entering Dry

71 - 6.2 8.1 8.5 - 6.5 8.6 9.0 - 6.8 9.0 9.5 - 6.2 8.5 9.0 - 5.6 7.9 8.4

68 - 4.9 6.8 7.2 - 5.0 7.0 7.5 - 5.0 7.3 7.7 - 4.2 6.5 7.0 - 3.4 5.7 6.2

86 8.7 12.0 12.7 13.2 9.8 13.4 13.3 13.8 10.9 14.8 13.9 14.3 11.6 15.4 14.1 14.6 12.3 15.9 14.4 14.9

83 7.4 10.7 12.4 12.6 8.3 11.9 13.1 13.5 9.2 13.2

80 6.2 9.4 11.1 11.3 6.8 10.4 12.2 12.5 7.4 11.4 13.4 13.6 7.6 11.7 13.7 14.0 7.8 12.0 14.1 14.4

77 4.9 8.1 9.8 10.0 5.3 8.9 10.7 10.9 5.7 9.7 11.6 11.9 5.6 9.7 11.7 12.0 5.6 9.8 11.8 12.1

74 3.6 6.9 8.5 8.7 3.8 7.4 9.2 9.4 3.9 7.9 9.9 10.1 3.7 7.7 9.8 10.0 3.4 7.5 9.6 9.9

Bulb °F

Entering Dry

71 - 5.6 7.2 7.4 - 5.9 7.7 7.9 - 6.2 8.1 8.4 - 5.7 7.8 8.0 - 5.3 7.4 7.6

68 - 4.3 5.9 6.2 - 4.3 6.2 6.4 - 4.4 6.4 6.6 - 3.7 5.8 6.0 - 3.1 5.1 5.4

86 8.3 11.3 11.8 12.2 9.4 12.8 12.3 12.7 10.5 14.2 12.8 13.2 11.3 14.6 13.2 13.6 12.1 15.0 13.5 14.0

83 7.0 10.1 11.5 11.5 7.9 11.3 12.1 12.4 8.8 12.5

80 5.7 8.8 10.2 10.2 6.4 9.8 11.4 11.4 7.0 10.8 12.5 12.6 7.3 11.2 13.0 13.1 7.6 11.7

77 4.4 7.5 8.9 8.9 4.9 8.3 9.9 9.9 5.3 9.0 10.8 10.8 5.3 9.2 11.0 11.1 5.4 9.4 11.3 11.3

74 3.2 6.2 7.6 7.7 3.3 6.8 8.3 8.4 3.5 7.3 9.0 9.1 3.3 7.2 9.0 9.1 3.1 7.2 9.1 9.1

Bulb °F

Entering Dry

71 - 4.9 6.4 6.4 - 5.2 6.8 6.8 - 5.5 7.3 7.3 - 5.3 7.1 7.1 - 5.0 6.8 6.9

68 - 3.6 5.1 5.1 - 3.7 5.3 5.3 - 3.8 5.5 5.6 - 3.3 5.1 5.1 - 2.7 4.6 4.6

86 7.9 10.7 10.9 11.3 9.0 12.1 11.3 11.7 10.1 13.5 11.7 12.1 11.0 13.8 12.2 12.6 11.9 14.1 12.7 13.1

83 6.6 9.4 10.6 10.4 7.5 10.7 11.1 11.3 8.4 11.9

80 5.3 8.1 9.3 9.2 6.0 9.2 10.5 10.3 6.6 10.2

77 4.0 6.9 8.1 7.9 4.5 7.6 9.0 8.8 4.9 8.4 9.9 9.7 5.0 8.8 10.3 10.1 5.2 9.1 10.7 10.6

74 2.7 5.6 6.8 6.6 2.9 6.1 7.5 7.3 3.1 6.7 8.2 8.0 3.0 6.8 8.3 8.2 2.9 6.9 8.5 8.3

Bulb °F

Entering Dry

71 - 4.3 5.5 5.3 - 4.6 6.0 5.8 - 4.9 6.4 6.2 - 4.8 6.3 6.2 - 4.6 6.3 6.1

68 - 3.0 4.2 4.0 - 3.1 4.4 4.2 - 3.2 4.7 4.5 - 2.8 4.4 4.2 - 2.4 4.0 3.9

450 CFM 525 CFM 600 CFM 675 CFM 750 CFM

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

18.1 17.3 16.0 16.3 18.2 17.4 16.1 16.4 18.4 17.5 16.2 16.5 19.0 18.2 16.8 17.1 19.7 18.8 17.4 17.7

1.77 1.75 1.74 1.72 1.82 1.81 1.79 1.78 1.87 1.86 1.85 1.83 1.91 1.90 1.88 1.87 1.95 1.94 1.92 1.91

16.2 16.1 13.7 14.1 17.0 16.8 14.3 14.8 17.8 17.6 15.0 15.5 18.0 17.8 15.1 15.6 18.1 17.9 15.3 15.8

1.88 1.89 1.84 1.84 1.94 1.95 1.90 1.89 1.99 2.00 1.95 1.95 2.02 2.03 1.98 1.97 2.04 2.05 2.00 2.00

15.2 14.6 12.7 13.2 15.9 15.2 13.3 13.8 16.6 15.9 13.9 14.3 16.9 16.2 14.1 14.6 17.2 16.5 14.4 14.9

1.99 2.00 1.96 1.94 2.05 2.06 2.02 2.00 2.11 2.12 2.08 2.06 2.14 2.15 2.10 2.09 2.16 2.17 2.13 2.11

14.3 13.1 11.8 12.2 14.8 13.6 12.3 12.7 15.4 14.2 12.8 13.2 15.9 14.6 13.2 13.6 16.3 15.0 13.5 14.0

2.10 2.11 2.07 2.04 2.17 2.17 2.14 2.11 2.23 2.24 2.21 2.18 2.26 2.27 2.23 2.20 2.28 2.29 2.26 2.22

13.3 11.6 10.9 11.3 13.7 12.0 11.3 11.7 14.2 12.4 11.7 12.1 14.8 13.0 12.2 12.6 15.4 13.5 12.7 13.1

2.2 2.2 2.2 2.1 2.3 2.3 2.3 2.2 2.4 2.4 2.3 2.3 2.4 2.4 2.4 2.3 2.4 2.4 2.4 2.3

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

16.5 10.3 13.7 16.7 17.1 10.9 14.4 17.4 17.7

15.0 15.5 9.9 14.2 15.1 15.6 10.3 14.6 15.3 15.8

13.9 14.3 9.6 13.7 14.1 14.6 10.1 14.2 14.4 14.9

12.8 13.2 9.3 13.2 13.2 13.6 9.8 13.9 13.5 14.0

11.7 12.1 9.0 12.7 12.2 12.6 9.6 13.6 12.7 13.1

11.7 11.5 7.0 10.8 12.3 12.1 7.4 11.3 13.0 12.8

360101-XTG-A-0108

13.5 13.6

6 Johnson Controls Unitary Products

Page 7

360101-XTG-A-0108

T ABLE 4: COOLING CAPACITIES - 2 TON (DEB024)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 14.8 18.5 21.2 20.7 16.2 20.1 22.0 21.5 17.5 21.7 22.8 22.3 18.6 23.0 22.9 22.4 19.7 24.2 23.0 22.5

83 13.1 16.8 20.7

80 11.4 15.1 19.0 19.6 12.1 16.1 20.2 20.9 12.9 17.1 21.5 22.1 13.3 17.6 22.2 22.3 13.8 18.2 22.9

77 9.7 13.4 17.3 17.9 10.1 14.1 18.2 18.8 10.5 14.7 19.2 19.8 10.7 15.0 19.6 19.7 10.8 15.2 20.0 19.5

74 8.0 11.7 15.6 16.2 8.1 12.0 16.2 16.8 8.2 12.4 16.8 17.5 8.0 12.3 16.9 17.0 7.8 12.3 17.0 16.5

Bulb °F

Entering Dry

71 - 10.0 13.9 14.4 - 10.0 14.2 14.8 - 10.1 14.5 15.1 - 9.7 14.2 14.3 - 9.3 14.0 13.6

68 - 8.2 12.2 12.7 - 8.0 12.2 12.8 - 7.7 12.2 12.8 - 7.0 11.6 11.7 - 6.3 11.0 10.6

86 14.2 17.6 19.7 20.2 15.7 19.4 20.4 21.0 17.2 21.1 21.2 21.8 18.3 22.2 21.3 21.9 19.4 23.2 21.4 22.0

83 12.5 15.9 19.5 19.4 13.7 17.3 20.3 20.6 14.9 18.8

80 10.8 14.2 17.7 17.7 11.7 15.3 19.1 19.1 12.5 16.4 20.5 20.5 13.0 17.1 21.0 21.2 13.5 17.7

77 9.1 12.5 16.0 16.0 9.6 13.3 17.1 17.1 10.2 14.1 18.2 18.2 10.3 14.4 18.3 18.6 10.5 14.7 18.4 19.0

74 7.4 10.8 14.3 14.3 7.6 11.3 15.1 15.0 7.9 11.8 15.9 15.8 7.7 11.8 15.6 15.9 7.5 11.7 15.4 16.0

Bulb °F

Entering Dry

71 - 9.1 12.6 12.6 - 9.3 13.1 13.0 - 9.4 13.5 13.5 - 9.1 13.0 13.3 - 8.8 12.4 13.0

68 - 7.4 10.9 10.9 - 7.2 11.1 11.0 - 7.1 11.2 11.2 - 6.4 10.3 10.6 - 5.8 9.5 10.0

86 13.4 16.7 17.9 17.9 14.9 18.3 18.7 18.7 16.4 19.8 19.6 19.5 17.5 20.4 19.6 19.6 18.6 20.9 19.7 19.7

83 11.7 15.0 17.7 17.5 12.9 16.5 18.6 18.5 14.0 18.0

80 9.9 13.3 16.0 15.9 10.8 14.5 17.4 17.3 11.7 15.7 18.8 18.7 12.2 16.3 19.3 19.2 12.6 16.9

77 8.2 11.6 14.3 14.2 8.8 12.5 15.4 15.3 9.4 13.4 16.5 16.4 9.5 13.7 16.6 16.5 9.6 13.9 16.7 16.7

74 6.5 9.9 12.6 12.5 6.8 10.5 13.4 13.3 7.0 11.0 14.2 14.1 6.9 11.0 14.0 13.9 6.7 11.0 13.8 13.7

Bulb °F

Entering Dry

71 - 8.2 10.9 10.8 - 8.4 11.3 11.2 - 8.7 11.8 11.7 - 8.3 11.3 11.2 - 8.0 10.8 10.7

68 - 6.5 9.1 9.1 - 6.4 9.3 9.2 - 6.4 9.5 9.4 - 5.7 8.6 8.6 - 5.0 7.8 7.7

86 12.5 15.9 16.1 15.5 14.0 17.2 17.0 16.4 15.6 18.5 17.9 17.2 16.7 18.6 18.0 17.3 17.7 18.7 18.1 17.3

83 10.8 14.2 15.9

80 9.1 12.4 14.2 14.1 10.0 13.7 15.7 15.5 10.9 14.9 17.1 17.0 11.3 15.5 17.6 17.1 11.8 16.1 18.1

77 7.4 10.7 12.5 12.4 8.0 11.7 13.6 13.5 8.6 12.6 14.8 14.6 8.7 12.9 14.9 14.5 8.8 13.1 15.1 14.4

74 5.7 9.0 10.8 10.7 6.0 9.7 11.6 11.5 6.2 10.3 12.4 12.3 6.0 10.2 12.3 11.8 5.8 10.2 12.1 11.4

Bulb °F

Entering Dry

71 - 7.3 9.1 9.0 - 7.6 9.6 9.5 - 7.9 10.1 10.0 - 7.6 9.6 9.2 - 7.2 9.1 8.4

68 - 5.6 7.4 7.3 - 5.6 7.6 7.4 - 5.6 7.8 7.6 - 4.9 6.9 6.5 - 4.2 6.1 5.4

86 11.6 15.0 14.4 13.2 13.2 16.1 15.3 14.0 14.8 17.2 16.3 14.9 15.8 16.8 16.3 15.0 16.9 16.4 16.4 15.0

83 9.9 13.3 14.2 13.6 11.2 14.9 15.2 14.2 12.4 16.5

80 8.2 11.6 12.5 12.3 9.2 12.9 13.9 13.8 10.1 14.2 15.4 15.2 10.5 14.8 15.9 15.1 10.9 15.3

77 6.5 9.9 10.8 10.6 7.1 10.9 11.9 11.7 7.8 11.9 13.0 12.9 7.9 12.1 13.2 12.4 7.9 12.4 13.4 12.0

74 4.8 8.2 9.1 8.9 5.1 8.8 9.9 9.7 5.4 9.5 10.7 10.5 5.2 9.5 10.6 9.8 5.0 9.4 10.4 9.1

Bulb °F

Entering Dry

71 - 6.4 7.3 7.2 - 6.8 7.9 7.7 - 7.2 8.4 8.2 - 6.8 7.9 7.1 - 6.4 7.4 6.1

68 - 4.7 5.6 5.5 - 4.8 5.8 5.7 - 4.9 6.0 5.9 - 4.1 5.2 4.5 - 3.4 4.5 3.1

600 CFM 700 CFM 800 CFM 900 CFM 1,000 CFM

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

25.1 23.0 21.2 20.7 26.1 23.9 22.0 21.5 27.0 24.8 22.8 22.3 27.2 24.9 22.9 22.4 27.3 25.0 23.0 22.5

2.33 2.34 2.30 2.26 2.39 2.40 2.35 2.31 2.44 2.45 2.40 2.36 2.57 2.58 2.53 2.49 2.71 2.72 2.66 2.62

20.7 14.2 18.1 21.8 21.5 15.2 19.4 22.8 22.3 16.0 20.3 22.9 22.4 16.7 21.2 23.0 22.5

23.8 21.4 19.7 20.2 24.7 22.2 20.4 21.0 25.7 23.0 21.2 21.8 25.8 23.1 21.3 21.9 25.9 23.2 21.4 22.0

2.49 2.46 2.44 2.39 2.54 2.51 2.49 2.44 2.59 2.56 2.54 2.49 2.74 2.71 2.68 2.63 2.89 2.86 2.83 2.77

21.5 19.0 17.9 17.9 22.5 19.9 18.7 18.7 23.5 20.8 19.6 19.5 23.6 20.8 19.6 19.6 23.7 20.9 19.7 19.7

2.61 2.58 2.55 2.51 2.67 2.64 2.60 2.56 2.72 2.69 2.65 2.62 2.87 2.84 2.79 2.76 3.01 2.98 2.93 2.90

19.2 16.7 16.1 15.5 20.2 17.6 17.0 16.4 21.3 18.5 17.9 17.2 21.4 18.6 18.0 17.3 21.4 18.7 18.1 17.3

2.74 2.70 2.65 2.63 2.80 2.76 2.71 2.69 2.86 2.82 2.77 2.75 3.00 2.96 2.91 2.88 3.14 3.10 3.04 3.02

15.5 12.0 15.7 16.9 16.4 13.2 17.3 17.9 17.2 14.0 18.0 18.0 17.3 14.8 18.7 18.1 17.3

16.9 14.3 14.4 13.2 18.0 15.3 15.3 14.0 19.1 16.2 16.3 14.9 19.2 16.3 16.3 15.0 19.2 16.4 16.4 15.0

2.9 2.8 2.8 2.8 2.9 2.9 2.8 2.8 3.0 3.0 2.9 2.9 3.1 3.1 3.0 3.0 3.3 3.2 3.1 3.1

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

21.2 21.8 15.7 19.7 21.3 21.9 16.5 20.7 21.4 22.0

19.6 19.5 14.8 18.8 19.6 19.6 15.6 19.7 19.7 19.7

16.3 14.9 13.2 17.1 16.3 15.0 13.9 17.6 16.4 15.0

22.5

21.4 22.0

19.7 19.7

17.3

16.4 15.0

Johnson Controls Unitary Products 7

Page 8

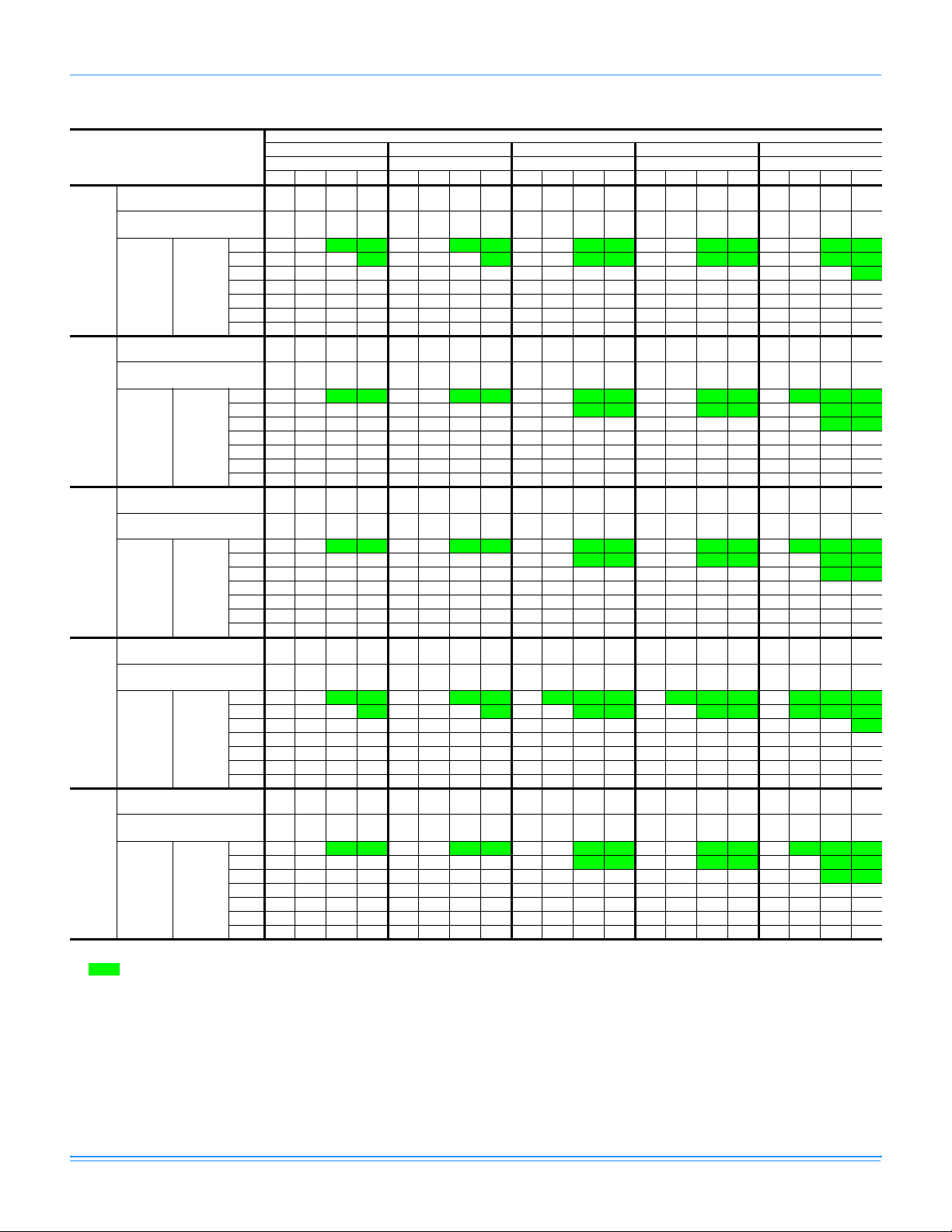

T ABLE 5: COOLING CAPACITIES - 2-1/2 TON (DEB030)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 18.2 23.6 27.5 28.1 20.1 25.8 27.8 28.4 21.9 28.0 28.1 28.7 23.3 29.6 28.4 29.1 24.8 31.3 28.8 29.5

83 16.1 21.4 25.5 26.3 17.5 23.3 26.8 27.5 19.0 25.1

80 14.0 19.3 23.3 24.1 15.0 20.7 25.1 25.9 16.0 22.2 26.8 27.7 16.7 23.1 27.8 28.6 17.3 24.0

77 11.8 17.2 21.2 22.0 12.5 18.2 22.5 23.4 13.1 19.3 23.9 24.8 13.4 19.7 24.5 25.3 13.6 20.2 25.1 25.8

74 9.7 15.0 19.1 19.9 10.0 15.7 20.0 20.9 10.2 16.3 21.0 21.9 10.1 16.4 21.2 22.0 9.9 16.5 21.4 22.1

Bulb °F

Entering Dry

71 - 12.9 16.9 17.7 - 13.2 17.5 18.3 - 13.4 18.0 19.0 - 13.1 17.9 18.7 - 12.8 17.7 18.4

68 - 10.8 14.8 15.6 - 10.6 15.0 15.8 - 10.5 15.1 16.1 - 9.8 14.5 15.3 - 9.1 13.9 14.6

86 17.5 22.2 24.4 24.8 19.5 24.7 25.3 25.7 21.6 27.2 26.2 26.7 23.1 28.1 25.9 26.4 24.6 28.9 25.6 26.0

83 15.4 20.1 24.1 23.9 17.0 22.2 25.2 25.3 18.7 24.3

80 13.2 18.0 22.0 21.8 14.5 19.7 24.1 23.8 15.8 21.4

77 11.1 15.8 19.9 19.6 12.0 17.2 21.6 21.3 12.8 18.5 23.3 23.0 13.1 19.0 22.6 22.6 13.4 19.6 21.8 22.3

74 9.0 13.7 17.7 17.5 9.4 14.6 19.1 18.8 9.9 15.6 20.4 20.1 9.8 15.7 19.2 19.3 9.7 15.9 18.1 18.6

Bulb °F

Entering Dry

71 - 11.6 15.6 15.3 - 12.1 16.5 16.3 - 12.7 17.5 17.2 - 12.4 15.9 16.0 - 12.1 14.4 14.8

68 - 9.4 13.5 13.2 - 9.6 14.0 13.7 - 9.7 14.6 14.3 - 9.1 12.6 12.7 - 8.4 10.6 11.1

86 16.5 21.3 22.2 22.3 18.5 23.4 23.1 23.2 20.5 25.6 24.0 24.1 22.0 25.9 23.7 23.9 23.5 26.3 23.5 23.6

83 14.4 19.2 22.0 21.8 16.0 21.2 23.0 22.9 17.6 23.3

80 12.3 17.0 19.8 19.6 13.5 18.7 21.8 21.6 14.7 20.4 23.8 23.5 15.4 21.3 23.6 23.6 16.0 22.2

77 10.1 14.9 17.7 17.5 10.9 16.2 19.3 19.0 11.8 17.5 20.9 20.6 12.0 18.0 20.3 20.3 12.3 18.5 19.8 19.9

74 8.0 12.7 15.6 15.3 8.4 13.7 16.8 16.5 8.9 14.6 17.9 17.7 8.7 14.7 17.0 16.9 8.6 14.8 16.0 16.2

Bulb °F

Entering Dry

71 - 10.6 13.4 13.2 - 11.1 14.2 14.0 - 11.7 15.0 14.8 - 11.4 13.7 13.6 - 11.0 12.3 12.5

68 - 8.5 11.3 11.1 - 8.6 11.7 11.5 - 8.7 12.1 11.9 - 8.0 10.3 10.3 - 7.3 8.6 8.7

86 15.6 20.3 20.0 19.8 17.5 22.1 20.8 20.7 19.5 23.9 21.7 21.5 20.9 23.7 21.6 21.4 22.3 23.6 21.4 21.3

83 13.4 18.2 19.8 19.6 15.0 20.3 20.7 20.6 16.5 22.3

80 11.3 16.1 17.7 17.5 12.5 17.7 19.5 19.3 13.6 19.4 21.3 21.1 14.2 20.3 21.4 21.2 14.9 21.1

77 9.1 13.9 15.5 15.3 9.9 15.2 17.0 16.8 10.7 16.5 18.4 18.2 10.9 16.9 18.1 17.9 11.1 17.4 17.7 17.6

74 7.0 11.8 13.4 13.2 7.4 12.7 14.4 14.2 7.8 13.6 15.5 15.3 7.6 13.6 14.7 14.6 7.4 13.7 14.0 13.8

Bulb °F

Entering Dry

71 - 9.6 11.2 11.1 - 10.1 11.9 11.7 - 10.6 12.6 12.4 - 10.3 11.4 11.2 - 10.0 10.2 10.1

68 - 7.5 9.1 8.9 - 7.6 9.4 9.2 - 7.7 9.7 9.5 - 7.0 8.1 7.9 - 6.2 6.5 6.4

86 14.6 19.4 17.8 17.4 16.5 20.8 18.6 18.2 18.4 22.2 19.4 19.0 19.8 21.6 19.4 18.9 21.2 20.9 19.4 18.9

83 12.5 17.2 17.6 17.5 14.0 19.3 18.5

80 10.3 15.1 15.5 15.3 11.4 16.7 17.2 17.0 12.6 18.4 18.9 18.7 13.1 19.2 19.1 18.8 13.7 20.1

77 8.2 13.0 13.3 13.2 8.9 14.2 14.7 14.5 9.6 15.5 16.0 15.8 9.8 15.9 15.8 15.5 10.0 16.3 15.6 15.2

74 6.0 10.8 11.2 11.1 6.4 11.7 12.1 12.0 6.7 12.6 13.1 12.9 6.5 12.6 12.5 12.2 6.3 12.6 11.9 11.5

Bulb °F

Entering Dry

71 - 8.7 9.1 8.9 - 9.2 9.6 9.4 - 9.6 10.1 10.0 - 9.3 9.2 8.9 - 8.9 8.2 7.7

68 - 6.5 6.9 6.8 - 6.6 7.1 6.9 - 6.7 7.2 7.0 - 5.9 5.8 5.5 - 5.2 4.5 4.0

750 CFM 875 CFM 1,000 CFM 1,125 CFM 1,250 CFM

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

32.3 29.8 27.5 28.1 32.6 30.1 27.8 28.4 33.0 30.4 28.1 28.7 33.5 30.9 28.4 29.1 33.9 31.3 28.8 29.5

2.94 2.92 2.83 2.81 3.02 3.00 2.90 2.88 3.10 3.08 2.98 2.96 3.20 3.18 3.08 3.06 3.31 3.28 3.18 3.16

29.1 27.5 24.4 24.8 30.2 28.6 25.3 25.7 31.3 29.7 26.2 26.7 30.9 29.3 25.9 26.4 30.5 28.9 25.6 26.0

3.17 3.11 3.04 3.03 3.24 3.17 3.10 3.09 3.30 3.23 3.16 3.15 3.43 3.36 3.29 3.27 3.56 3.49 3.41 3.39

26.7 24.8 22.2 22.3 27.8 25.8 23.1 23.2 28.9 26.8 24.0 24.1 28.6 26.5 23.7 23.9 28.3 26.3 23.5 23.6

3.38 3.28 3.22 3.22 3.45 3.35 3.29 3.28 3.52 3.42 3.36 3.35 3.66 3.55 3.49 3.48 3.79 3.68 3.62 3.61

24.3 22.0 20.0 19.8 25.4 22.9 20.8 20.7 26.4 23.9 21.7 21.5 26.2 23.7 21.6 21.4 26.1 23.6 21.4 21.3

3.58 3.45 3.41 3.41 3.66 3.52 3.48 3.48 3.74 3.60 3.56 3.56 3.89 3.74 3.69 3.69 4.03 3.87 3.83 3.83

21.9 19.2 17.8 17.4 22.9 20.1 18.6 18.2 23.9 21.0 19.4 19.0 23.9 21.0 19.4 18.9 23.9 20.9 19.4 18.9

3.8 3.6 3.6 3.6 3.9 3.7 3.7 3.7 4.0 3.8 3.8 3.8 4.1 3.9 3.9 3.9 4.3 4.1 4.0 4.0

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

28.1 28.7 20.0 26.4 28.4 29.1 21.1 27.7 28.8 29.5

26.2 26.7 19.8 25.7 25.9 26.4 20.9 27.0 25.6 26.0

26.2 25.9 16.5 22.4 25.9 26.0 17.2 23.3 25.6 26.0

24.0 24.1 18.7 24.3 23.7 23.9 19.7 25.3 23.5 23.6

21.7 21.5 17.6 23.0 21.6 21.4 18.6 23.6 21.4 21.3

18.2 15.5 21.3 19.4 19.0 16.5 21.6 19.4 18.9 17.4 21.9 19.4 18.9

360101-XTG-A-0108

28.8 29.5

23.5 23.6

21.4 21.3

19.4 18.9

8 Johnson Controls Unitary Products

Page 9

360101-XTG-A-0108

T ABLE 6: COOLING CAPACITIES - 3 TON (DEB036)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 19.7 25.4 28.5 28.4 22.2 28.5 30.3 30.1 24.6 31.5 32.1 31.9 26.3 33.5 32.7 32.6 28.0 35.5 33.4 33.2

83 17.2 22.9 26.7

80 14.6 20.3 24.2 26.0 16.1 22.4 26.7 28.7 17.6 24.5 29.2 31.4 18.4 25.6 30.4 32.3 19.1 26.6 31.6

77 12.0 17.7 21.6 23.4 13.1 19.4 23.7 25.6 14.1 21.0 25.7 27.9 14.4 21.6 26.4 28.3 14.6 22.1 27.2 28.8

74 9.5 15.2 19.1 20.8 10.1 16.4 20.6 22.6 10.6 17.5 22.2 24.4 10.4 17.6 22.5 24.3 10.2 17.6 22.7 24.3

Bulb °F

Entering Dry

71 - 12.6 16.5 18.3 - 13.3 17.6 19.6 - 14.1 18.7 20.9 - 13.6 18.5 20.4 - 13.2 18.2 19.8

68 - 10.0 13.9 15.7 - 10.3 14.6 16.5 - 10.6 15.2 17.4 - 9.6 14.5 16.4 - 8.7 13.7 15.4

86 18.5 24.3 27.8 26.8 21.0 27.4 29.4 28.4 23.4 30.5 31.0 29.9 24.8 32.0 31.8 30.7 26.1 33.4 32.6 31.5

83 16.0 21.7 25.7 26.6 18.0 24.4 28.4 28.2 19.9 27.0

80 13.4 19.2 23.2 24.0 14.9 21.3 25.8 26.7 16.4 23.5 28.4 29.4 16.8 24.0 29.0 30.0 17.1 24.5 29.6 30.7

77 10.8 16.6 20.6 21.4 11.9 18.3 22.8 23.7 12.9 20.0 24.9 25.9 12.8 20.0 25.0 26.1 12.7 20.0 25.1 26.2

74 8.3 14.0 18.0 18.9 8.9 15.3 19.7 20.6 9.4 16.5 21.4 22.4 8.8 16.0 21.0 22.1 8.2 15.5 20.7 21.7

Bulb °F

Entering Dry

71 - 11.5 15.5 16.3 - 12.2 16.7 17.6 - 13.0 17.9 18.9 - 12.0 17.1 18.1 - 11.1 16.2 17.3

68 - 8.9 12.9 13.7 - 9.2 13.7 14.6 - 9.5 14.4 15.4 - 8.1 13.1 14.1 - 6.6 11.7 12.8

86 17.5 23.3 25.0 24.4 19.9 26.3 26.6 26.0 22.3 29.2 28.2 27.6 23.6 30.3 28.9 28.3 24.8 31.4 29.6 29.0

83 15.0 20.7 24.0 24.3 16.9 23.3 26.1 25.9 18.8 25.9

80 12.4 18.1 21.4 21.7 13.9 20.3 23.9 24.3 15.3 22.4 26.5 26.8 15.6 22.8 26.9 27.3 15.8 23.1 27.3 27.7

77 9.8 15.6 18.8 19.1 10.8 17.3 20.9 21.2 11.8 18.9 23.0 23.3 11.6 18.8 22.9 23.3 11.4 18.7 22.8 23.2

74 7.3 13.0 16.3 16.6 7.8 14.2 17.9 18.2 8.3 15.4 19.5 19.8 7.6 14.8 18.9 19.3 6.9 14.2 18.4 18.8

Bulb °F

Entering Dry

71 - 10.4 13.7 14.0 - 11.2 14.8 15.2 - 11.9 16.0 16.3 - 10.8 14.9 15.3 - 9.7 13.9 14.3

68 - 7.9 11.1 11.4 - 8.2 11.8 12.1 - 8.4 12.5 12.8 - 6.9 10.9 11.3 - 5.3 9.4 9.8

86 16.5 22.2 22.2 22.0 18.9 25.1 23.8 23.6 21.2 28.0 25.5 25.2 22.4 28.6 26.1 25.8 23.5 29.3 26.7 26.4

83 14.0 19.7

80 11.4 17.1 19.6 19.4 12.8 19.2 22.1 21.8 14.2 21.4 24.5 24.3 14.4 21.6 24.8 24.5 14.5 21.8 25.0 24.7

77 8.8 14.5 17.1 16.9 9.8 16.2 19.0 18.8 10.7 17.9 21.0 20.8 10.4 17.6 20.8 20.5 10.1 17.3 20.5 20.3

74 6.3 12.0 14.5 14.3 6.8 13.2 16.0 15.8 7.2 14.4 17.5 17.3 6.4 13.6 16.8 16.5 5.6 12.9 16.1 15.8

Bulb °F

Entering Dry

71 - 9.4 11.9 11.7 - 10.1 13.0 12.7 - 10.9 14.0 13.8 - 9.6 12.8 12.5 - 8.4 11.6 11.3

68 - 6.8 9.4 9.2 - 7.1 9.9 9.7 - 7.4 10.5 10.3 - 5.6 8.8 8.6 - 3.9 7.1 6.9

86 15.5 21.2 19.4 19.6 17.8 24.0 21.1 21.3 20.1 26.7 22.7 22.9 21.2 27.0 23.2 23.4 22.2 27.2 23.7 23.9

83 13.0 18.6 20.4 19.7 14.8 21.2 21.6

80 10.4 16.1 17.9 17.1 11.8 18.2 20.2 19.4 13.1 20.3 22.6 21.7 13.2 20.4 22.6 21.7 13.2 20.4 22.7 21.8

77 7.8 13.5 15.3 14.6 8.7 15.2 17.2 16.4 9.6 16.8 19.1 18.2 9.2 16.4 18.7 17.7 8.8 16.0 18.2 17.3

74 5.3 10.9 12.7 12.0 5.7 12.1 14.2 13.3 6.1 13.3 15.6 14.7 5.2 12.4 14.7 13.8 4.3 11.5 13.8 12.8

Bulb °F

Entering Dry

71 - 8.4 10.2 9.4 - 9.1 11.1 10.3 - 9.8 12.1 11.2 - 8.4 10.7 9.8 - 7.0 9.3 8.4

68 - 5.8 7.6 6.9 - 6.1 8.1 7.3 - 6.3 8.6 7.7 - 4.4 6.7 5.8 - 2.6 4.8 3.9

900 CFM 1,050 1,200 1,350 1,500

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

34.7 32.3 28.5 28.4 36.9 34.3 30.3 30.1 39.0 36.4 32.1 31.9 39.9 37.1 32.7 32.6 40.7 37.9 33.4 33.2

3.61 3.52 3.46 3.46 3.62 3.53 3.47 3.47 3.63 3.55 3.48 3.48 3.70 3.61 3.55 3.55 3.77 3.68 3.61 3.61

28.4 19.2 25.5 29.4 30.1 21.1 28.0 32.1 31.9 22.4 29.5 32.7 32.6 23.6 31.0 33.4 33.2

32.5 30.4 27.8 26.8 34.4 32.2 29.4 28.4 36.3 34.0 31.0 29.9 37.2 34.8 31.8 30.7 38.1 35.7 32.6 31.5

3.85 3.74 3.70 3.68 3.85 3.75 3.71 3.68 3.86 3.75 3.71 3.69 3.93 3.82 3.78 3.76 4.01 3.90 3.86 3.83

29.5 27.4 25.0 24.4 31.4 29.2 26.6 26.0 33.3 31.0 28.2 27.6 34.1 31.7 28.9 28.3 35.0 32.5 29.6 29.0

4.05 3.92 3.93 3.85 4.07 3.94 3.95 3.87 4.09 3.96 3.97 3.89 4.15 4.02 4.02 3.95 4.21 4.08 4.08 4.00

26.5 24.4 22.2 22.0 28.4 26.2 23.8 23.6 30.4 28.0 25.5 25.2 31.1 28.6 26.1 25.8 31.8 29.3 26.7 26.4

4.25 4.11 4.16 4.03 4.28 4.14 4.19 4.06 4.31 4.17 4.22 4.09 4.36 4.21 4.27 4.13 4.40 4.25 4.31 4.17

22.2 22.0 15.9 22.3 23.8 23.6 17.7 24.9 25.5 25.2 18.4 25.6 26.1 25.8 19.0 26.3 26.7 26.4

23.5 21.4 19.4 19.6 25.4 23.2 21.1 21.3 27.4 25.0 22.7 22.9 28.0 25.5 23.2 23.4 28.6 26.1 23.7 23.9

4.5 4.3 4.4 4.2 4.5 4.3 4.4 4.2 4.5 4.4 4.5 4.3 4.6 4.4 4.5 4.3 4.6 4.4 4.5 4.3

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

31.0 29.9 20.8 28.0 31.8 30.7 21.6 29.0 32.6 31.5

28.2 27.6 19.6 26.8 28.9 28.3 20.3 27.6 29.6 29.0

21.3 16.6 23.8 22.7 22.9 17.2 24.4 23.2 23.4 17.7 24.9 23.7 23.9

33.2

Johnson Controls Unitary Products 9

Page 10

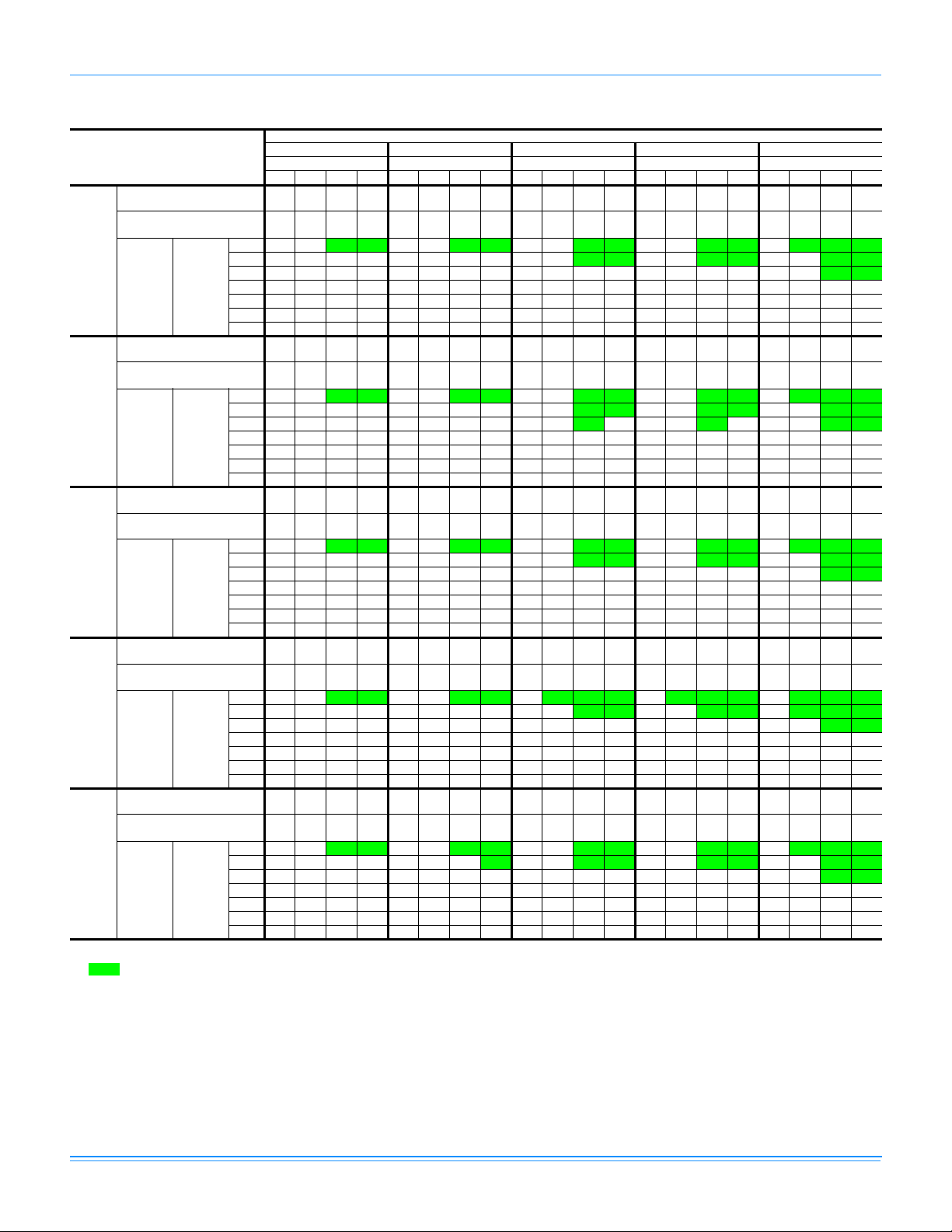

T ABLE 7: COOLING CAPACITIES - 3-1/2 TON (DEB042)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 23.8 31.3 36.5 34.1 26.1 34.2 37.7 35.2 28.5 37.0 38.8 36.3 30.5 39.4 39.3 36.8 32.6 41.9 39.8 37.2

83 20.8 28.3 34.6

80 17.8 25.4 31.6 31.9 19.1 27.1 33.8 34.1 20.3 28.8 36.0

77 14.9 22.4 28.6 28.9 15.5 23.6 30.3 30.6 16.2 24.7 31.9 32.2 16.6 25.5 32.9 32.1 16.9 26.2 34.0 32.0

74 11.9 19.4 25.6 26.0 12.0 20.0 26.7 27.0 12.1 20.7 27.8 28.1 11.9 20.8 28.3 27.5 11.7 21.0 28.8 26.8

Bulb °F

Entering Dry

71 - 16.4 22.7 23.0 - 16.5 23.2 23.5 - 16.6 23.7 24.1 - 16.2 23.6 22.8 - 15.8 23.6 21.6

68 - 13.4 19.7 20.0 - 12.9 19.6 20.0 - 12.5 19.6 20.0 - 11.5 19.0 18.2 - 10.6 18.3 16.4

86 23.0 30.4 34.0 32.7 25.4 33.3 35.2 33.9 27.8 36.3 36.5 35.2 29.9 38.3 36.9 35.6 32.0 40.3 37.4 36.0

83 20.0 27.4 33.2

80 17.0 24.4 30.3 30.4 18.3 26.3 32.6 32.8 19.7 28.2 35.0

77 14.0 21.4 27.3 27.5 14.8 22.7 29.1 29.3 15.6 24.1 30.9 31.1 15.9 24.8 31.5 30.9 16.3 25.6 32.1 30.8

74 11.0 18.4 24.3 24.5 11.3 19.2 25.5 25.7 11.5 20.0 26.8 27.0 11.3 20.2 26.9 26.3 11.1 20.4 26.9 25.5

Bulb °F

Entering Dry

71 - 15.4 21.3 21.5 - 15.6 22.0 22.2 - 15.9 22.7 22.9 - 15.5 22.2 21.6 - 15.2 21.7 20.3

68 - 12.4 18.3 18.5 - 12.1 18.4 18.7 - 11.8 18.6 18.8 - 10.9 17.6 17.0 - 10.0 16.5 15.1

86 22.4 29.3 30.8 31.2 24.8 32.1 32.0 32.4 27.3 34.9 33.1 33.6 29.3 36.1 33.5 34.0 31.4 37.3 33.9 34.4

83 19.4 26.3 30.5

80 16.4 23.3 27.8 28.8 17.7 25.3 30.1 31.2 19.1 27.2 32.4

77 13.4 20.3 24.8 25.8 14.2 21.7 26.5 27.6 15.0 23.1 28.3 29.5 15.4 23.9 28.5 29.3 15.8 24.7 28.7 29.1

74 10.4 17.3 21.8 22.8 10.7 18.2 23.0 24.1 10.9 19.0 24.2 25.4 10.7 19.3 23.8 24.7 10.6 19.5 23.5 23.9

Bulb °F

Entering Dry

71 - 14.3 18.8 19.8 - 14.7 19.4 20.6 - 15.0 20.1 21.3 - 14.6 19.2 20.0 - 14.3 18.3 18.7

68 - 11.4 15.8 16.8 - 11.1 15.9 17.0 - 10.9 16.0 17.2 - 10.0 14.5 15.4 - 9.1 13.1 13.5

86 21.7 28.3 27.7 29.8 24.2 30.8 28.8 30.9 26.7 33.4 29.8 32.0 28.8 33.8 30.1 32.3 30.9 34.2 30.5 32.7

83 18.7 25.3

80 15.7 22.3 25.3 27.1 17.1 24.3 27.5 29.5 18.5 26.3

77 12.7 19.3 22.3 24.1 13.6 20.7 24.0 26.0 14.4 22.2 25.7 27.9 14.9 23.0 25.5 27.7 15.3 23.8 25.3 27.5

74 9.7 16.3 19.3 21.1 10.0 17.2 20.4 22.5 10.3 18.1 21.6 23.8 10.2 18.4 20.8 23.0 10.1 18.6 20.1 22.3

Bulb °F

Entering Dry

71 - 13.3 16.3 18.1 - 13.7 16.9 18.9 - 14.0 17.5 19.7 - 13.7 16.2 18.4 - 13.4 14.8 17.1

68 - 10.3 13.3 15.2 - 10.1 13.4 15.4 - 9.9 13.4 15.6 - 9.1 11.5 13.7 - 8.2 9.6 11.9

86 21.1 27.2 24.6 28.3 23.6 29.6 25.5 29.3 26.1 31.9 26.4 30.3 28.3 31.5 26.7 30.7 30.4 31.1 27.1 31.1

83 18.1 24.2 25.0

80 15.1 21.3 22.8 25.5 16.5 23.3 25.0 27.9 17.9 25.3 27.2

77 12.1 18.3 19.8 22.5 13.0 19.7 21.4 24.4 13.9 21.2 23.1 26.3 14.3 22.1 22.5 26.1 14.8 23.0 21.9 25.9

74 9.1 15.3 16.8 19.5 9.4 16.2 17.9 20.8 9.8 17.1 19.0 22.2 9.7 17.4 17.8 21.4 9.5 17.7 16.6 20.7

Bulb °F

Entering Dry

71 - 12.3 13.8 16.5 - 12.7 14.4 17.3 - 13.1 14.9 18.1 - 12.8 13.2 16.8 - 12.5 11.4 15.5

68 - 9.3 10.8 13.5 - 9.1 10.8 13.8 - 9.0 10.8 14.0 - 8.1 8.5 12.1 - 7.3 6.2 10.2

1,050 CFM 1,225 1,400 1,575 1,750

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

40.7 39.0 36.5 34.1 42.0 40.3 37.7 35.2 43.3 41.6 38.8 36.3 43.9 42.1 39.3 36.8 44.4 42.6 39.8 37.2

4.09 3.82 3.77 3.75 4.16 3.89 3.83 3.81 4.23 3.95 3.90 3.88 4.38 4.10 4.04 4.02 4.54 4.25 4.18 4.16

34.1 22.6 30.6 36.7 35.2 24.4 32.9 38.8 36.3 25.9 34.8 39.3 36.8 27.3 36.6 39.8 37.2

38.7 36.7 34.0 32.7 40.1 38.1 35.2 33.9 41.6 39.4 36.5 35.2 42.1 39.9 36.9 35.6 42.6 40.3 37.4 36.0

4.16 4.06 3.96 3.98 4.23 4.13 4.03 4.05 4.30 4.19 4.10 4.11 4.44 4.33 4.23 4.25 4.59 4.47 4.37 4.39

32.7 21.9 29.8 34.9 33.9 23.7 32.2 36.5 35.2 25.2 34.1 36.9 35.6 26.7 36.0 37.4 36.0

36.2 33.9 30.8 31.2 37.6 35.1 32.0 32.4 38.9 36.4 33.1 33.6 39.4 36.8 33.5 34.0 39.9 37.3 33.9 34.4

4.40 4.28 4.20 4.22 4.47 4.35 4.27 4.29 4.54 4.42 4.34 4.35 4.69 4.57 4.48 4.50 4.84 4.71 4.63 4.64

31.2 21.3 28.8 31.8 32.4 23.2 31.3 33.1 33.6 24.7 33.2 33.5 34.0 26.2 35.1 33.9 34.4

33.8 31.1 27.7 29.8 35.0 32.2 28.8 30.9 36.3 33.4 29.8 32.0 36.7 33.8 30.1 32.3 37.2 34.2 30.5 32.7

4.64 4.51 4.44 4.46 4.71 4.58 4.51 4.53 4.78 4.65 4.58 4.59 4.94 4.80 4.73 4.75 5.09 4.96 4.88 4.90

27.7 29.8 20.7 27.8 28.8 30.9 22.6 30.3 29.8 32.0 24.2 32.3 30.1 32.3 25.7 34.2 30.5 32.7

31.4 28.3 24.6 28.3 32.5 29.3 25.5 29.3 33.6 30.4 26.4 30.3 34.0 30.7 26.7 30.7 34.5 31.1 27.1 31.1

4.9 4.7 4.7 4.7 4.9 4.8 4.7 4.8 5.0 4.9 4.8 4.8 5.2 5.0 5.0 5.0 5.3 5.2 5.1 5.2

28.3 20.0 26.8 25.7 29.3 22.0 29.4 26.4 30.3 23.6 31.3 26.7 30.7 25.2 33.3 27.1 31.1

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

36.3 21.2 30.1 37.6 36.8 22.1 31.4 39.2 37.2

35.2 20.6 29.5 36.2 35.6 21.5 30.8 37.4 36.0

33.6 20.0 28.6 33.1 34.0 21.0 29.9 33.9 34.4

29.8 32.0 19.5 27.7 30.1 32.3 20.5 29.1 30.5 32.7

30.3 19.0 26.7 27.1 30.7 20.0 28.2 27.1 31.1

360101-XTG-A-0108

10 Johnson Controls Unitary Products

Page 11

360101-XTG-A-0108

T ABLE 8: COOLING CAPACITIES - 4 TON (DEB048)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 28.3 35.7 41.3 41.3 31.5 39.6 42.7 42.5 34.7 43.5 44.1 43.7 37.1 46.3 44.7 44.2 39.5 49.1 45.2 44.8

83 24.9 32.3 37.8 39.5 27.4 35.6 41.0 41.6 30.0 38.9

80 21.4 28.9 34.4 36.1 23.4 31.6 37.6 39.4 25.4 34.2 40.7 42.7 26.5 35.7 42.5 43.8 27.6 37.2 44.3

77 18.0 25.5 31.0 32.7 19.4 27.5 33.5 35.4 20.7 29.5 36.1 38.1 21.2 30.4 37.2 38.5 21.6 31.2 38.3 38.9

74 14.6 22.1 27.6 29.3 15.3 23.5 29.5 31.3 16.0 24.9 31.4 33.4 15.8 25.1 31.9 33.1 15.7 25.3 32.4 32.9

Bulb °F

Entering Dry

71 - 18.6 24.2 25.8 - 19.4 25.4 27.3 - 20.2 26.7 28.7 - 19.8 26.6 27.8 - 19.3 26.4 26.9

68 - 15.2 20.7 22.4 - 15.4 21.4 23.2 - 15.5 22.1 24.1 - 14.4 21.3 22.5 - 13.4 20.4 21.0

86 27.7 34.7 39.3 38.8 30.6 38.3 40.5 40.0 33.6 41.9 41.7 41.1 35.3 42.9 40.8 40.2 37.0 44.0 39.9 39.3.

83 24.2 31.3 36.5 37.9 26.6 34.2 39.1 39.5 28.9 37.2

80 20.8 27.9 33.0 34.5 22.5 30.2 35.8 37.4 24.3 32.5 38.5 40.2 24.7 33.0 39.1 39.8 25.0 33.5 39.7

77 17.4 24.5 29.6 31.1 18.5 26.2 31.7 33.3 19.6 27.9 33.9 35.6 19.3 27.7 33.8 34.5 19.1 27.6 33.8 33.3

74 14.0 21.0 26.2 27.7 14.5 22.1 27.7 29.3 14.9 23.2 29.2 30.9 14.0 22.4 28.5 29.1 13.1 21.6 27.8 27.4

Bulb °F

Entering Dry

71 - 17.6 22.8 24.2 - 18.1 23.7 25.2 - 18.5 24.5 26.2 - 17.1 23.2 23.8 - 15.7 21.9 21.4

68 - 14.2 19.4 20.8 - 14.0 19.6 21.2 - 13.9 19.9 21.6 - 11.8 17.9 18.5 - 9.7 15.9 15.5

86 27.0 33.2 37.8 37.4 29.6 36.1 38.3 37.9 32.3 39.1 38.8 38.3 34.3 39.7 38.5 38.0 36.4 40.4 38.2 37.7

83 23.6 29.8 35.7 36.3 25.6 32.2 37.3 37.3 37.6 34.7

80 20.1 26.4 32.3 32.9 21.5 28.2 34.6 35.2 22.9 30.0 36.8 37.5 23.7 31.0 37.5 37.6 24.5 32.0 38.1

77 16.7 22.9 28.9 29.5 17.5 24.2 30.5 31.2 18.3 25.4 32.1 32.8 18.4 25.7 32.1 32.3 18.5 26.0 32.1 31.8

74 13.3 19.5 25.5 26.1 13.5 20.1 26.5 27.1 13.6 20.7 27.5 28.2 13.1 20.4 26.8 27.0 12.5 20.1 26.2 25.8

Bulb °F

Entering Dry

71 - 16.1 22.0 22.7 - 16.1 22.4 23.1 - 16.0 22.8 23.5 - 15.1 21.5 21.7 - 14.1 20.2 19.8

68 - 12.7 18.6 19.2 - 12.0 18.4 19.0 - 11.6 18.1 18.8 - 9.8 16.2 16.4 - 8.1 14.3 13.9

86 26.3 31.7 36.3 36.0 28.6 34.0 36.1 35.8 30.9 36.3 35.8 35.5 33.4 36.6 36.2 35.8 35.8 36.9 36.5 36.2

83 22.9 28.3 35.0 34.8 24.6 30.2 35.4 35.1 26.3 32.2

80 19.5 24.8 31.6 31.3 20.5 26.2 33.3 33.1 21.6 27.6 35.1 34.8 22.7 29.0 35.8 35.5 23.9 30.5

77 16.1 21.4 28.2 27.9 16.5 22.2 29.3 29.0 17.0 22.9 30.4 30.1 17.4 23.7 30.4 30.2 17.9 24.5 30.5 30.2

74 12.6 18.0 24.7 24.5 12.5 18.1 25.2 25.0 12.3 18.2 25.7 25.4 12.1 18.4 25.1 24.8 12.0 18.5 24.5 24.2

Bulb °F

Entering Dry

71 - 14.6 21.3 21.1 - 14.1 21.2 20.9 - 13.6 21.1 20.8 - 13.1 19.8 19.5 - 12.6 18.6 18.3

68 - 11.1 17.9 17.6 - 10.0 17.1 16.9 - 8.9 16.4 16.1 - 7.8 14.5 14.2 - 6.6 12.6 12.3

86 25.6 30.1 34.8 34.6 27.6 31.8 33.8 33.7 29.6 31.4 32.9 32.7 32.4 32.4 33.8 33.7 35.2 33.4 34.8 34.6

83 22.2 26.7 34.3 33.2 23.6 28.2 33.6 32.9 25.0 29.8

80 18.8 23.3 30.8 29.8 19.5 24.2 32.1 30.9 20.3 25.1

77 15.4 19.9 27.4 26.3 15.5 20.2 28.0 26.9 15.6 20.4 28.6 27.4 16.5 21.7 28.8 28.0 17.3 22.9 28.9 28.6

74 12.0 16.5 24.0 22.9 11.5 16.1 24.0 22.8 11.0 15.8 24.0 22.7 11.2 16.4 23.4 22.7 11.4 17.0 22.9 22.7

Bulb °F

Entering Dry

71 - 13.0 20.6 19.5 - 12.1 19.9 18.8 - 11.1 19.3 18.1 - 11.1 18.1 17.4 - 11.0 17.0 16.7

68 - 9.6 17.2 16.1 - 8.0 15.9 14.7 - 6.4 14.6 13.4 - 5.7 12.8 12.1 - 5.1 11.0 10.7

1200 CFM 1400 CFM 1600 CFM 1800 CFM 2000 CFM

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

49.2 46.1 41.6 41.3 50.6 47.4 42.9 42.5 52.1 48.8 44.1 43.7 52.8 49.4 44.7 44.2 53.4 50.1 45.2 44.8

4.47 4.44 4.35 4.33 4.59 4.57 4.47 4.45 4.72 4.69 4.59 4.57 4.78 4.76 4.66 4.63 4.85 4.83 4.72 4.70

47.2 43.4 39.3 38.8 48.6 44.7 40.5 40.0 50.0 46.0 41.7 41.1 48.9 45.0 40.8 40.2 47.8 44.0 39.9 39.3

4.88 4.85 4.74 4.74 5.00 4.97 4.86 4.86 5.13 5.09 4.98 4.98 5.23 5.20 5.09 5.08 5.34 5.31 5.19 5.19

45.5 40.1 37.8 37.4 46.1 40.6 38.3 37.9 46.7 41.1 38.8 38.3 46.3 40.8 38.5 38.0 46.0 40.4 38.2 37.7

5.37 5.30 5.21 5.21 5.49 5.43 5.34 5.33 5.62 5.55 5.46 5.45 5.72 5.66 5.56 5.55 5.83 5.76 5.66 5.65

43.9 36.7 36.3 36.0 43.6 36.5 36.1 35.8 43.3 36.3 35.8 35.5 43.7 36.6 36.2 35.8 44.1 36.9 36.5 36.2

5.86 5.76 5.69 5.67 5.98 5.88 5.81 5.80 6.11 6.01 5.94 5.92 6.22 6.11 6.04 6.02 6.32 6.21 6.14 6.12

42.2 33.4 34.8 34.6 41.1 32.4 33.8 33.7 40.0 31.4 32.9 32.7 41.1 32.4 33.8 33.7 42.2 33.4 34.8 34.6

6.3 6.2 6.2 6.1 6.5 6.3 6.3 6.3 6.6 6.5 6.4 6.4 6.7 6.6 6.5 6.5 6.8 6.7 6.6 6.6

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

44.1 43.7 31.8 41.0 44.7 44.2 33.5 43.2 45.2 44.8

41.7 41.1 30.0 38.3 40.8 40.2 31.0 39.5 39.9 39.3

38.8 38.3 29.0 36.3 38.5 38.0 30.4 38.0 38.2 37.7

35.8 35.5 28.1 34.3 36.2 35.8 29.8 36.4 36.5 36.2

32.9 32.7 27.1 32.3 33.8 33.7 29.3 33.4 34.8 34.6

32.9 32.1 21.8 27.0 33.8 33.3 23.3 28.9 34.8 34.6

44.8

39.3

37.7

36.5 36.2

Johnson Controls Unitary Products 11

Page 12

T ABLE 9: COOLING CAPACITIES - 5 TON (DEB060)

TEMPERATURE

OF AIR ON

OUTDOOR COIL

Net Cap

MBH

Total Power

Input kW

85 °F

95 °F

105 °F

115 °F

125 °F

1. These are net capacity ratings. The indoor blower motor heat has already been subtracted from the gross cooling capacity

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Total Power

1

MBH

Sensible Capacity

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

Net Cap

MBH

Input kW

86 37.9 46.9 52.9 53.4 41.7 51.4 54.5 55.1 45.6 56.0 56.2 56.7 49.1 60.1 57.1 57.6 52.6 64.2 58.0 58.6

83 33.6 42.6 50.2 51.9 36.7 46.4 53.2 54.3 39.8 50.1

80 29.3 38.3 45.9 47.6 31.6 41.3 49.5 51.3 33.9 44.3 53.1 55.0 35.8 46.8 55.6 56.8 37.7 49.3

77 25.1 34.0 41.7 43.3 26.6 36.3 44.5 46.2 28.1 38.5 47.3 49.2 29.2 40.2 48.9 50.2 30.3 41.8 50.6 51.1

74 20.8 29.8 37.4 39.0 21.5 31.2 39.4 41.2 22.3 32.7 41.5 43.4 22.5 33.5 42.3 43.5 22.8 34.4 43.1 43.7

Bulb °F

Entering Dry

71 - 25.5 33.1 34.7 - 26.2 34.4 36.1 - 26.8 35.6 37.5 - 26.9 35.6 36.9 - 26.9 35.7 36.2

68 - 21.2 28.8 30.5 - 21.1 29.3 31.1 - 21.0 29.8 31.7 - 20.2 29.0 30.2 - 19.5 28.2 28.8

86 35.5 44.5 48.7 49.4 39.4 49.2 50.7 51.3 43.3 53.9 52.6 53.3 47.0 57.2 53.3 54.0 50.8 60.6 53.9 54.6

83 31.2 40.2 47.6 48.7 34.4 44.1 50.1 51.0 37.5 48.0

80 27.0 35.9 43.3 44.4 39.3 39.1 47.1 48.2 31.7 42.2 50.9 52.1 33.8 45.0 52.4 53.4 35.9 47.8

77 22.7 31.7 39.0 40.1 24.3 34.0 42.0 43.2 25.8 36.4 45.0 46.3 27.1 38.4 45.7 46.7 28.4 40.4 46.4 47.2

74 18.4 27.4 34.8 35.8 19.2 29.0 37.0 38.1 20.0 30.5 39.2 40.4 20.5 31.7 39.1 40.1 21.0 32.9 39.0 39.7

Bulb °F

Entering Dry

71 - 23.1 30.5 31.5 - 23.9 31.9 33.1 - 24.7 33.4 34.6 - 25.1 32.5 33.4 - 25.5 31.5 32.3

68 - 18.8 26.2 27.3 - 18.9 26.9 28.0 - 18.9 27.5 28.8 - 18.4 25.8 26.8 - 18.0 24.1 24.8

86 33.5 42.4 45.0 45.3 37.5 47.1 46.9 47.2 41.4 51.8 48.8 49.1 44.9 53.7 49.3 49.7 48.3 55.6 49.9 50.2

83 29.2 38.1 44.0 44.5 32.4 42.2 46.4 46.8 35.6 46.3

80 24.9 33.8 39.8 40.2 27.4 37.1 43.6 44.2 29.8 40.5 47.5 48.1 31.6 42.9 48.7 49.2 33.4 45.3 49.9 50.2

77 20.6 29.6 35.5 36.0 22.3 32.1 38.6 39.1 24.0 34.6 41.7 42.3 24.9 36.3 42.1 42.5 25.9 37.9 42.4 42.8

74 16.4 25.3 31.2 31.7 17.2 27.0 33.5 34.1 18.1 28.8 35.9 36.4 18.3 29.6 35.4 35.9 18.5 30.4 35.0 35.3

Bulb °F

Entering Dry

71 - 21.0 26.9 27.4 - 22.0 28.5 29.0 - 23.0 30.0 30.6 - 23.0 28.8 29.2 - 23.0 27.5 27.9

68 - 16.7 22.7 23.1 - 16.9 23.4 23.9 - 17.1 24.2 24.8 - 16.3 22.1 22.6 - 15.5 20.1 20.4

86 31.4 40.3 41.3 41.3 35.5 45.0 43.1 43.1 39.6 49.6 45.0 44.9 42.7 50.2 45.4 45.4 45.8 50.7 45.9 45.8

83 27.2 36.0 40.5 40.4 30.5 40.3 42.7 42.7 33.7 44.5

80 22.9 31.7 36.2 36.1 25.4 35.2 40.2 40.1 27.9 38.7 44.2 44.1 29.4 40.8 45.0 45.0 30.9 42.9

77 18.6 27.5 32.0 31.8 20.3 30.2 35.2 35.0 22.1 32.9 38.4 38.2 22.8 34.1 38.4 38.3 23.5 35.4 38.4 38.4

74 14.3 23.2 27.7 27.6 15.3 25.1 30.1 30.0 16.2 27.0 32.5 32.4 16.1 27.5 31.8 31.7 16.0 27.9 31.0 30.9

Bulb °F

Entering Dry

71 - 18.9 23.4 23.3 - 20.1 25.0 24.9 - 21.2 26.7 26.6 - 20.9 25.1 25.0 - 20.5 23.5 23.5

68 - 14.6 19.1 19.0 - 15.0 20.0 19.9 - 15.4 20.9 20.7 - 14.2 18.5 18.4 - 13.0 16.1 16.0

86 29.4 38.2 37.7 37.3 33.6 42.9 39.4 39.0 37.7 44.9 41.1 40.7 40.5 45.3 41.5 41.1 43.3 45.7 41.9 41.5

83 25.1 33.9 37.0 36.3 28.5 38.3 39.0 38.5 31.9 42.8

80 20.8 29.6 32.7 32.0 23.4 33.3 36.8 36.0 26.0 36.9 40.9 40.0 27.2 38.7 41.4 40.7 28.4 40.4

77 16.6 25.3 28.4 27.7 18.4 28.2 31.7 31.0 20.2 31.1 35.0 34.2 20.6 32.0 34.7 34.1 21.0 32.9 34.4 34.0

74 12.3 21.1 24.1 23.4 13.3 23.2 26.7 25.9 14.4 25.3 29.2 28.4 14.0 25.4 28.1 27.5 13.5 25.5 27.0 26.6

Bulb °F

Entering Dry

71 - 16.8 19.9 19.2 - 18.1 21.6 20.8 - 19.5 23.4 22.5 - 18.7 21.5 20.8 - 18.0 19.5 19.1

68 - 12.5 15.6 14.9 - 13.1 16.6 15.8 - 13.6 17.5 16.7 - 12.1 14.8 14.2 - 10.6 12.1 11.7

1200 CFM 1400 CFM 1600 CFM 1800 CFM 2000 CFM

WB °F WB °F WB °F WB °F WB °F

72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57 72 67 62 57

65.2 59.2 52.9 53.4 67.2 61.1 54.5 55.1 69.2 62.9 56.2 56.7 70.3 63.9 57.1 57.6 71.4 64.9 58.0 58.6

5.68 5.60 4.45 5.41 5.87 5.79 5.63 5.59 6.06 5.98 5.82 5.77 6.25 6.16 6.00 5.95 6.43 6.35 6.18 6.13

60.1 54.7 48.7 49.4 62.5 56.9 50.7 51.3 64.9 59.1 52.6 53.3 65.7 59.9 53.3 54.0 66.5 60.6 53.9 54.6

6.25 6.13 6.02 5.97 6.42 6.30 6.19 6.13 6.59 6.47 6.35 6.30 6.78 6.66 6.54 6.48 6.97 6.84 6.72 6.66

55.5 50.2 45.0 45.3 57.9 52.3 46.9 47.2 60.2 54.4 48.8 49.1 60.9 55.0 49.3 49.7 61.6 55.6 49.9 50.2

6.90 6.73 6.63 6.58 7.07 6.90 6.79 6.75 7.25 7.06 6.96 6.91 7.47 7.28 7.17 7.12 7.69 7.50 7.38 7.33

51.0 45.7 41.3 41.3 53.2 47.6 43.1 43.1 55.5 49.6 45.0 44.9 56.0 50.2 45.4 45.4 56.6 50.7 45.9 45.8

7.56 7.33 7.23 7.20 7.73 7.50 7.39 7.36 7.90 7.66 7.56 7.52 8.15 7.90 7.80 7.76 8.40 8.15 8.04 8.00

46.5 41.1 37.7 37.3 48.6 43.0 39.4 39.0 50.7 44.9 41.1 40.7 51.2 45.3 41.5 41.1 51.7 45.7 41.9 41.5

8.2 7.9 7.8 7.8 8.4 8.1 8.0 8.0 8.5 8.3 8.2 8.1 8.8 8.5 8.4 8.4 9.1 8.8 8.7 8.7

ALL SENSIBLE CAPACITIES

AIR ON INDOOR COIL

56.2 56.7 42.5 53.4 57.1 57.6 45.2 56.7 58.0 58.6

52.6 53.3 40.4 51.7 53.3 54.0 43.3 55.3 53.9 54.6

48.8 49.1 38.2 49.5 49.3 49.7 40.8 52.8 49.9 50.2

45.0 44.9 36.1 47.4 45.4 45.4 38.4 50.3 45.9 45.8

41.1 40.7 33.9 45.3 41.5 41.1 35.9 45.7 41.9 41.5

360101-XTG-A-0108

58.0 58.6

53.9 54.6

45.9 45.8

41.9 41.5

12 Johnson Controls Unitary Products

Page 13

360101-XTG-A-0108

TABLE 10: SIDE AND BOTTOM SUPPLY AIR BLOWER PERFORMANCE

Model No.

DEB

018

(1.5)

024

(2.0)

030

(2.5)

036

(3.0)

042

(3.5)

048

(4.0)

060

(5.0)

Blower

Speed

Setting

High --------689374593361497347-------Medium------690231659210487188---------Low 741226686212632198577185453165-- - - -------High ------------990468888456786444684432-Medium- - - -961331902321841305781290720274660257-----Low 810261765250720238675227627212-- - - -------High --------11715041080486990468888456786444---Medium 1080 351 1021 341 961 331 902 321 841 305 781 290 - - - - - ----Low 810261765240-----------------High - - - - 1440 605 1361 581 1273 555 1185 530 1097 504 1004 480 912 456 - - - Medium 1465 531 1395 512 1325 492 1255 473 1167 446 1079 419 992 392 - - - ----Low 1316 473 1260 455 1204 438 1148 420 1069 396 990 372 911 348 - - - ----High - - - - 1728 725 1633 697 1527 666 1422 635 1317 605 1205 576 1094 547 - - - Medium - - 1674 614 1590 590 1506 567 1400 535 1295 502 1190 470 1063 428 - ----Low 1579 567 1512 546 1444 525 1377 504 1282 476 1188 447 1093 418 - - - ----High - - 1985 870 1939 850 1897 830 1813 800 1728 770 1644 740 1559 707 1474 673 1389 640 - Medium 1694 690 1662 673 1629 657 1597 640 1542 623 1486 607 1431 590 1336 563 1240 537 - - - Low 1385 520 1349 510 1312 500 1276 490 1235 480 - - - - -------High - - - - 2450 1213 2366 1165 2282 1117 2198 1068 2114 1020 1989 993 1864 967 1739 940 - Medium 2339 1170 2275 1118 2211 1067 2147 1015 2083 963 2019 912 1955 860 1854 824 1753 788 1652 752 - Low 1929 940 1877 903 1824 867 1772 830 1720 793 1667 757 1615 720 1586 706 1557 691 1528 677 - -

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1

CFM W CFM W CFM W CFM W CFM W CFM W CFM W CFM W CFM W CFM W CFM W

External Static Pressure (Inches Water Gauge)

TABLE 11: ADDITIONAL STATIC RESISTANCE

Resistance, IWG

Description

500 600 700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600

Wet Evaporator Coil .01 .01 .01 .02 .03 .04 .05 .06 .07 .08 .09 .09

Economizer .00 .00 .00 .01 .01 .01 .01 .02 .03 .04 .05 .06

Filter/Frame Kit .01 .02 .02 .02 .02 .02 .03 .03 .03 .03 .04 .05

Electric Heat .02 .03 .03 .03 .04 .04 .05 .06 .07 .08 .09 .10

Note:1. Deduct these resistance values from the available external static pressure shown in the respective Blower Performance Table.

2. The pressure thru the economizer is greater for 100% outdoor air then for 100% return air. If the resistance of the return air duct

system is less then 0.25 IWG, the unit will deliver less CFM during full economizer operation.

CFM

THERMOSTAT

** = Minimum wire size of 18 AWG

wire should be used for all field

installed 24 volt wire.

PROGRAMMABLE

THERMOSTAT ONLY

* = Only required on units with

supplemental electric heat.

CONTROL WIRING

REFER TO ELECTRICAL

POWER WIRING

FIGURE 2 - TYPICAL FIELD WIRING DIAGRAM

UNIT TERMINAL STRIP

**

*

DATA TABLES TO SIZE

THE DISCONNECT

CAUTION: Label all wires prior to discon

24 VOLT

TRANSFORMER

nection when servicing con

trols. Wiring errors can cause

improper and dangerous op

eration. Verify proper operation

after servicing.

NOTE:

HEAT ANTICIPATOR

SHOULD BE SET AT 0.25

AMPS FOR ALL MODELS.

-

-

-

Johnson Controls Unitary Products 13

Page 14

360101-XTG-A-0108

TABLE 12: ELECTRICAL DATA (BASIC UNIT)

Cond.

Model

DEB

018 208/230-1-60 187 253 9.0 48.0 1.1 2.6 14.9 20 20 .96 40

024 208/230-1-60 187 253 11.5 60.0 1.1 2.6 18.1 25 25 .96 40

030 208/230-1-60 187 253 14.7 73.0 1.1 2.6 22.1 30 30 .96 40

036 208/230-1-60 187 253 17.3 94.0 1.1 3.5 26.2 35 35 .96 40

042 208/230-1-60 187 253 15.5 86.0 1.1 3.5 23.9 30 30 .96 40

048 208/230-1-60 187 253 24.4 140.0 1.3 4.0 35.8 45 45 .96 40

060 208/230-1-60 187 253 28.9 165.0 1.3 4.0 44.4 60 60 .96 40

Volt

Voltage

Limitations

Min. Max. RLA LRA FLA FLA

Compressors

1

Fan

Motors

Supply Air

Blower

Motor

MCA

(Amps)

Max

Fuse

Size

(Amps)

1. Rated in accordance with ARI Standard 110, utilization range “A”.

2. Dual element, time delay type

2

Max HACR/

Breaker

Size

(Amps)

Power

Factory

Unit

Transformer

Size

(VA)

ELECTRIC HEAT

CORRECTION

FACTORS

NOMINAL VOLTAGE VOLTAGE

240

208 .75

230 .92

TABLE 13: ELECTRICAL DATA (COOLING/ELECTRIC HEAT)

Model

DEB

Power

Supply

Compressor

RLA LRA Model No. Stage KW

Cond..

Fan

Motor

FLA

Supply

Air Blower

Motor

FLA

018 208/230-1-60 9.0 48.0 1.1 2.6

024 208/230-1-60 11.2 60.0 1.1 2.6

030 208/230-1-60 12.0 73.0 1.1 2.6

036 208/230-1-60 17.3 94.0 1.1 3.5

042 208/230-1-60 15.5 86.0 1.1 3.5

048 208/230-1-60 24.4 140.0 1.3 4.0

060 208/230-1-60 28.9 165.0 1.3 7.0

1. Dual element, time delay type.

2. Standard circuit breakers may be used in Canada and on applications over 60 amps where the heaters are separately fused.

* KW listed is for 240 volts, use table at top of page for 208 or 230 volts.

ELECTRIC HEAT ACCESSORY

Total

AMPS

Min.

Circuit

Ampacity

(Amps)

2NH04500506 1 3.8/5.0* 18.1/20.8 25.8/29.3 30/30 30/30

2NH04500706 2 5.6/7.5* 27.1/31.3 37.1/42.3 40/45 40/45

2NH04500506 1 3.8/5.0* 18.1/20.8 25.8/29.3 30/30 30/30

2NH04500706 2 5.6/7.5* 27.1/31.3 37.1/42.3 40/45 40/45

2NH04501006 2 7.5/10.0* 36.1/41.7 48.4/55.3 50/60 50/60

2NH04500506 1 3.8/5.0* 18.1/20.8 25.8/29.3 30/30 30/30

2NH04500706 2 5.6/7.5* 27.3/31.3 37.1/42.3 40/45 40/45

2NH04501006 2 7.5/10.0* 36.1/41.7 48.4/55.3 50/60 50/60

2NH04501506 2 11.3/15.0* 54.2/62.5 71.0/81.4 80/90 80/90

2NH04501006 2 7.5/10.0* 36.1/41.7 49.5/56.5 50/60 50/60

2NH04501506 2 11.3/15.0* 54.2/62.5 72.1/82.5 80/90 80/90

2NH04500506 1 3.8/5.0* 18.1/20.8 26.9/30.4 35/35 35/35

2NH04500706 2 5.6/7.5* 27.1/31.3 38.2/43.4 40/45 40/45

2NH04501006 2 7.5/10.0* 36.1/41.7 49.5/56.5 50/60 50/60

2NH04501506 2 11.3/15.0* 54.2/62.5 72.1/82.5 80/90 80/90

2NH04501006 2 7.5/10.0* 36.1/41.7 50.1/57.1 60/60 60/60

2NH04501506 2 11.3/15.0* 54.2/62.5 72.1/83.1 80/90 80/90

2NH04502006 2 15.0/20.0* 72.2/83.3 95.3/109.2 100/110 100/110

2NH04502506 2 18.8/25.0* 90.3/104.2 117.8/135.2 125/150 125/150

2NH04501006 2 7.5/10.0* 36.1/41.7 53.9/60.8 70/70 70/70

2NH04501506 2 11.3/15.0* 54.2/62.5 76.5/86.9 80/90 80/90

2NH04502006 2 15.0/20.0* 72.2/83.3 99.0/112.9 100/125 100/125

2NH04502506 2 18.8/25.0* 90.3/104.2 121.6/139.0 125/150 125/150

KW CAP.

MULTIPLIER

Max.

Fuse

1

SizE

(Amps)

Max.

HACR

Breaker

Size

(Amps)

2

14 Johnson Controls Unitary Products

Page 15

360101-XTG-A-0108

HIGH VO L TAGE CONN.

" DIA. KNOCKOUT

HIGH VO

L TAGE CONN.

" DIA. KNOCKOUT

LOW VO L TAGE CONN.

“ DIA. KNOCKOUT

SIDE SUPP

AIR OPENING

LOW VO L TAGE CONN.

L Y

SIDE RETURN

AIR OPENING

“ DIA. KNOCKOUT

(OVERALL)

FRONT

2

1

4

HIGH VO L TAGE

CONN.

“ x " DIA.

KNOCKOUT

FRONT

“A”

(OVERALL)

2

COMPRESSOR

R VICE ACCESS

SE

P A R TMEN T P ANEL

COM

UNI

0 18 - 042

048 - 060

REFRIGERANT

CONNECTIONS

HIGH VO L TAGE CONN.

(OVERALL)

UNI T CONDENS A TE

CONNECTION

(TRA

“ NPTI

P REQUIRED)

All dimensions are in inches. They are

subject to change without notice. Certified

dimensions will be provided upon request.

DIMENSION

T SIZE

“A”

33

41

ELECTRICAL/FILTER

R VICE ACCESS

SE

P A R TMEN T P ANEL

COM

" DIA. KNOCKOUT

6

CONDENS A TE

“ NPTI

DRAIN

BOT T OM SUPP L Y

CLEARANCES

(Minimum)

Fron t 12"

Bac

k 0"

Left Side (Filter Access ) 24"

Right Sid e 24"

Below Unit

Above Unit

1

Units may be installed on combustible floors made from wood or class A,

B or C roof covering material.

2

Units must be installed outdoors. Overhanging structures or shrubs

should not obstruct outdoor air discharge outlet.

1

2

0"

36" (For Condenser

Air Discharge)

CONDENSER

COIL

AIR OPENING

1

15

15

SIDE SUPP L Y

AIR OPENING

BACK

SIDE RETURN

AIR OPENING

2

15

1

1

4

BOT T OM RETURN

AIR OPENING

FIGURE 3 - UNIT DIMENSIONS

Johnson Controls Unitary Products 15

Page 16

TABLE 14: UNIT WEIGHTS

Unit Size

Shipping

Weight

Operating

Weight

ABCD

Corner Weights

018 318 313 86 76 73 83

024 324 319 88 77 75 85

030 333 328 85 81 82 86

036 338 333 91 80 78 88

042 347 342 94 83 80 91

048 368 363 92 88 92 97

060 376 371 105 100 84 87

CENTER OF GRAVITY

D

FRONT

OF

UNIT

A

B

26

C

FIGURE 4 - CENTER OF GRAVITY

360101-XTG-A-0108

Economizer

(lbs.)

40

Roof Curb

(lbs.)

8" - 70

14" - 75

16 Johnson Controls Unitary Products

Page 17

360101-XTG-A-0108

TYPICAL APPLICATIONS

SUPPLY AIR

RETURN AIR

DUCT

FIELD SUPPLIED

DISCONNECT SWITCH

LOCATED TO REAR OF UNIT

TO POWER SUPPLY

FIGURE 5 - TYPICAL SLAB ON GROUND INSTALLATION

DUCT

CONTROL WIRING

TO INDOOR

THERMOSTAT

FIELD SUPPLIED

DISCONNECT SWITCH

MOUNTED ON UNIT

TO POWER SUPPLY

ROOF CURB

INSTALLATION

REAR DUCT

CONTROL WIRING

TO INDOOR THERMOSTAT

ROOF CURB

INSTALLATION

BOTTOM DUCT

SLAB ON GROUND

INSTALLATION

RETURN AIR

DUCT

SUPPLY AIR

DUCT

FIGURE 6 - TYPICAL ROOF CURB INSTALLATION

Johnson Controls Unitary Products 17

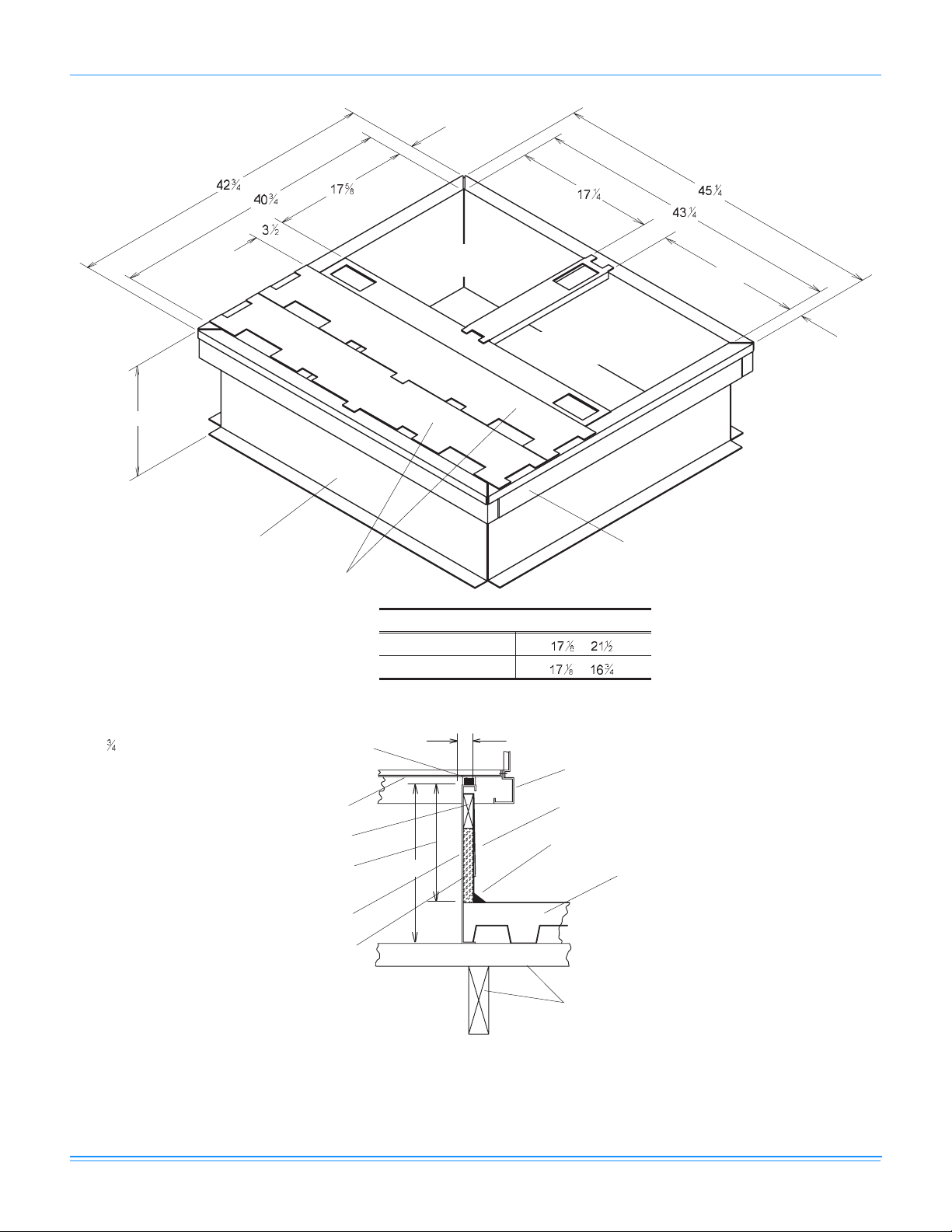

Page 18

1

OPENING FOR

RETURN AIR DUCT

360101-XTG-A-0108

4

22

14

FRONT

INSULATED

PANELS

RECOMMENDED DUCT SIZE

SUPPLY AIR DUCT

RETURN AIR DUCT

FIGURE 7 - ROOF CURB DIMENSIONS (8” Roof curb also available)

" x 1" WIDE GASKETING FOR CURB FRAME

AND ALL DUCT SUPPORT SURFACES

1"

OPENING FOR

SUPPLY AIR DUCT

WOOD NAILER

" x "

" x "

UNIT BASE RAIL

1

UNIT BASE

WOOD NAILER

8" MIN. ABOVE FINISHED ROOF

CURB FRAME

INSULATION

14"

COUNTERFLASHING

CANT STRIP

INSULATION AND ROOFING MATERIAL

ROOF DECK AND ROOFING MATERIAL

FIGURE 8 - ROOF CURB APPLICATION

18 Johnson Controls Unitary Products

Page 19

360101-XTG-A-0108

OPTIONAL CCH

S / P CONFIGURATION

CCH

BLK

BLK

D / P CONFIGURATION

CCH

BLK

BLK

M1 - 2

T2

DETAIL "A"

L1

T1

2

L

SEE

DETAIL

"A"

L1

2

L

15695BASH0301

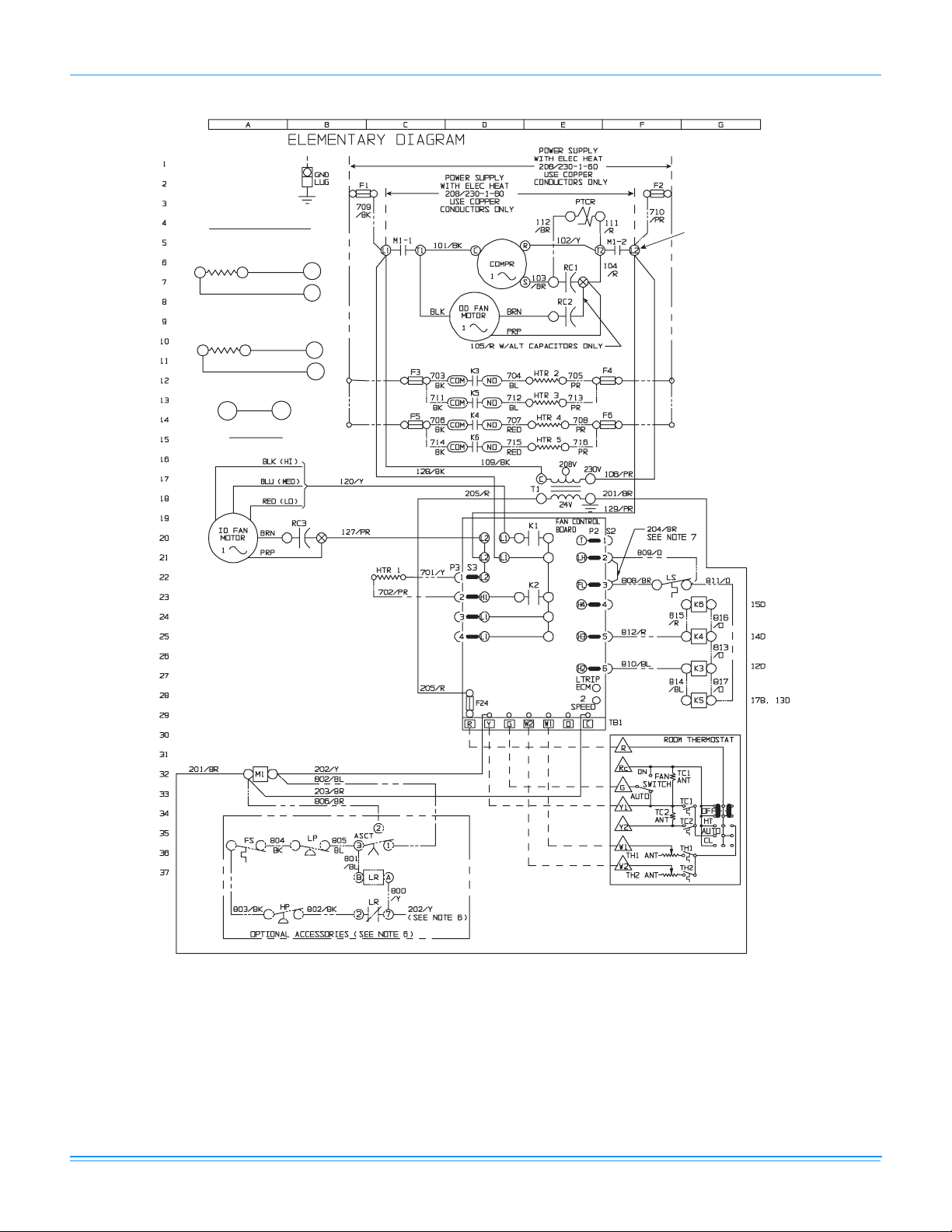

FIGURE 9 - TYPICAL WIRIN G DIAGRAM (208/230-1-60 POWER SUPPLY) DEB MODELS

Johnson Controls Unitary Products 19

Page 20

360101-XTG-A-0108

MECHANICAL SPECIFICATIONS

GENERAL DESCRIPTION

Units shall be factory-assembled, single packaged, Electric

Cooling units, designed for outdoor mounted installation. They

shall have built in, equal size, field convertible duct connections

for down discharge supply/return or horizontal discharge

supply/return.

The units shall be factory wired, piped, charged with R-22

refrigerant and factory tested prior to shipment. All unit wiring

shall be both numbered and color coded.

All units shall be manufactured in a facility certified to ISO 9001

standards, and the cooling performance shall be tested in

accordance with ARI test procedures. Units shall be certified to

UL 1995/CAN/CSA C22.2 No. 236 standards.

UNIT CABINET

1. Unit cabinet shall be constructed of a combination of G60

and G90 galvanized steel, with exterior surfaces coated

with a non-chalking, powdered paint finish, certified at

750 hours salt spray test per ASTMB117 standards.

2. The unit top shall be a single piece “Water Shed” design,

with drip edges and no-seam corners to provide optimum

water integrity

3. Unit shall have a rigidly mounted condenser coil guard to

provide protection from objects and personnel after

installation.

4. Indoor blower section shall be insulated with up to 3/4”

thick, aluminum, foil faced insulation, fastened to prevent

insulation from entering the air stream.

5. Cabinet panels shall be “large” size, easily removable for

servicing and maintenance, with built-in lift handles.

6. Unit shall be built on a formed, “Super-Structure ” design

base pan, with embossments at critical points to add

strength, rigidity and aid in minimizing sound.

7. Full perimeter base rails shall be provided to assure

reliable transit of equipment, overhead rigging, fork truck

access and proper sealing on roof curb applications. Base

rails shall be removable, when required, to lower unit

height.

8. Filters shall be furnished and be accessible through a

removable access door, sealed air tight. (Single phase

models - accessory kit available. Three phase models standard from factory.)

9. Units vertical discharge and return duct configuration sha ll

be designed to fit between standard 24” O.C. beams

without modification to building structure, duct work and

base unit.

10. Condensate pan shall be internally sloped and conform to

ASHRAE 62-89 self-draining standards, with 3/4” NPTI

copper, ridged mount connection.

INDOOR (EVAPORATOR) FAN ASSEMBLY

1. Fan shall be direct drive, multi-speed design. Job site

selected (BHP) brake horse power shall not exceed the

motors nameplate horse power rating.

2. Fan wheel shall be double-inlet type with forward-curved

blades, dynamically balanced to operate smoothly

throughout the entire range of operation. Airflow design

shall be constant air volume.

3. Bearings shall be sealed and permanently lubricated for

longer life and no maintenance.

4. Fan assembly shall be “Slip Track” (slide-out) design for

easy removal and cleaning.

OUTDOOR (CONDENSER) FAN ASSEMBLY

1. The outdoor fan shall be of the direct-driven propeller type,

discharge air vertically, have aluminum blades riveted to

corrosion resistant steel spider bracket and shall be

statically balanced for smooth operation.

2. The outdoor fan motor shall be totally enclosed with

permanently lubricated bearings and internally protected

against overload conditions.

REFRIGERANT COMPONENTS

1. Compressors:

a. Shall be fully hermetic reciprocating type, direct drive,

internally protected with internal high-pressure relief and

over temperature protection. The hermetic motor shall be

suction gas cooled and have a voltage range of + or 10% of the unit nameplate voltage.

b Shall have internal isolation and sound muffling to

minimize vibration and noise, and be externally isolated

on a dedicated, independent mounting.

2. Coils:

a. Evaporator and condenser coils shall have aluminum

plate fins mechanically bonded to seamless internallyenhanced copper tubes with all joints brazed.

b Evaporator and Condenser coils shall be of the direct

expansion, draw-thru design.

3. Refrigerant Circuit and Refrigerant Safety Components

shall include:

a. Independent fixed-orifice expansion devices.

b. Filter/strainer to eliminate any foreign matter.

c. Accessible service gauge connections on both suction

and discharge lines to charge, evacuate, and measure

refrigerant pressure during any necessary servicing or

troubleshooting, without losing charge and without

disrupting condenser or evaporator air flow.

d The refrigeration system shall provide at least 10° F of

liquid sub-cooling at design conditions.

20 Johnson Controls Unitary Products

Page 21

360101-XTG-A-0108

4. Unit Controls:

a. Unit shall contain a large, low voltage Termi nal Bo ard for

easy connection of field low voltage wiring.

b. Controls shall be mounted in a large control bo x with tilt-

out, hinged access door, allowing easy access for trouble

shooting and maintenance without affecting the normal

system operation pressures.

c. Unit shall have large, easily removable panels, covering

electrical controls and compressor, allowing ea sy access

for any necessary maintenance or servicing.

ELECTRIC HEATING SECTION

1. An electric heating section, with nickel chromium elements,

shall be provided in a range of 5 thru 25 KW, offering two

stages of capacity - 7 KW and above on single phase

heaters, and 20 KW and above on three phase heaters.

2. The heating section shall have a primary limit control(s)

and automatic reset, to prevent the heating element

system from operating at an excessive temperature.

3. The heating section assembl y shall slide out of the unit for

easy maintenance and service.

4. Units with electric heating sections shal l be wired for a

single point power supply, with branch circuit fusing (where

required).

UNIT OPERATING CHARACTERISTICS

1. Unit shall be capable of starting and running at 125° F

outdoor temperature, exceeding maximum load criteria of

ARI Standard 210/240.

2. The compressor, with standard controls, shall be capable

of operation down to 45° F outdoor temperature. Accessory

low ambient kit shall be available for operation to 0° F.

ELECTRICAL REQUIREMENTS

All unit power wiring shall enter unit cabinet at a single factory

provided location and be capable of side or bottom entry, to

minimize roof penetrations and avoid unit field modifications.

Separate side and bottom openings shall be provided for the

control wiring.

Johnson Controls Unitary Products 21

Page 22

360101-XTG-A-0108

22 Johnson Controls Unitary Products

Page 23

360101-XTG-A-0108

Johnson Controls Unitary Products 23

Page 24