York 36, 48, 60 User Manual

TECHNICAL GUIDE

255040-YTG-A-0506

®

DESCRIPTION

YORK Sunline 2000™ units are convertible single package

air conditioners with a common cabinet and a common roof

curb for the 3, 4, 5 and 6 ton sizes. The units were designed

for light commercial and commercial applications. They can

easily be installed on a roof curb, slab, roof jack or frame.

SINGLE PACKAGE GAS/ELECTRIC UNITS

AND SINGLE PACKAGE

AIR CONDITIONERS

D(CE, CG) 036, 048, 060 & 072

3, 4, 5 & 6 NOMINAL TONS

10.0 SEER (3, 4, & 5 Ton), 9.0 EER (6 Ton)

All units include:

• Powder Paint finish that meets ASTM-B-117 1000 hour

salt spray standards

• Permanently lubricated motors

• Bottom or side air discharge configuration capability

(field convertible)

• Manufactured under the quality standards of ISO9001

• Copper tube/aluminum fin coils

• Easy access to all components

• Rigging holes in base rails for lifting

• Fork lift slots on three sides

• Single point power connection

• Complete factory package - tested, charged and wired

• CSA agency listing on all units

WARRANTY

• Factory Limited Parts Warranty

• One-year parts warranty

• A Five-year parts warranty on the compressor and

electric heat elements.

• Ten-year parts warranty on the gas-fired heat

exchangers.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

TABLE OF CONTENTS

255040-YTG-A-0506

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . . 3

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FACTORY-INSTALLED OPTIONS . . . . . . . . . . . . . . 5

FIELD-INSTALLED ACCESSORIES . . . . . . . . . . . . 5

GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 39

LIST OF FIGURES

Fig. # Pg. #

1 UNIT CUTAWAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 TYPICAL FIELD POWER & CONTROL WIRING . . . .23

3 UNIT DIMENSIONS (3 - 6 TON COOLING ONLY/

ELECTRIC HEAT) FRONT VIEW . . . . . . . . . . . . . . . . 24

4 UNIT DIMENSIONS (3 - 6 TON COOLING/GAS HEAT)

FRONT VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5 UNIT WITH ECONOMIZER RAINHOOD . . . . . . . . . . .25

6 UNIT WITH FIXED OUTDOOR AIR/MOTORIZED

DAMPER RAINHOOD . . . . . . . . . . . . . . . . . . . . . . . . .25

7 UNIT DIMENSIONS (REAR VIEW) . . . . . . . . . . . . . . .26

8 DISCONNECT/BLOWER ACCESS LOCATION . . . . . 26

9 TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . .27

10 FOUR AND SIX POINT LOADING . . . . . . . . . . . . . . . .28

11 ROOF CURB DIMENSIONS . . . . . . . . . . . . . . . . . . . .29

12 COOLING UNIT WITH GAS HEAT CONTROL CIRCUIT

208/230V AND 460V DIAGRAM . . . . . . . . . . . . . . . . .30

13 COOLING UNIT WITH GAS HEAT CONTROL CIRCUIT

575 VOLT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . .31

14 COOLING UNIT WITH ELECTRIC HEAT CONTROL

CIRCUIT 208/230V, 460V AND 575V DIAGRAM . . . .32

15 COOLING UNIT POWER CIRCUIT 208/230-3-60

DIRECT DRIVE INDOOR BLOWER DIAGRAM . . . . .33

16 COOLING UNIT POWER CIRCUIT 208/230-3-60 BELT

DRIVE INDOOR BLOWER DIAGRAM . . . . . . . . . . . . .34

17 COOLING UNIT POWER CIRCUIT 460-3-60 DIRECT

DRIVE INDOOR BLOWER DIAGRAM . . . . . . . . . . . . .35

18 COOLING UNIT POWER CIRCUIT 460-3-60 BELT

DRIVE INDOOR BLOWER DIAGRAM . . . . . . . . . . . . .36

19 COOLING UNIT POWER CIRCUIT 575-3-60 DIRECT

DRIVE INDOOR BLOWER DIAGRAM . . . . . . . . . . . . .37

20 COOLING UNIT POWER CIRCUIT 575-3-60 BELT

DRIVE INDOOR BLOWER DIAGRAM . . . . . . . . . . . . .38

LIST OF TABLES

Tbl. # Pg. #

1 SOUND POWER RATING . . . . . . . . . . . . . . . . . . . . . . . 7

2 CAPACITY RATINGS - (ARI 210/240) . . . . . . . . . . . . . 7

3 GAS HEAT RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 D(CE, CG)036 COOLING CAPACITIES (3 TON) . . . . . 8

5 D(CE, CG)048 COOLING CAPACITIES (4 TON) . . . . . 9

6 D(CE, CG)060 COOLING CAPACITIES (5 TON) . . . . 10

7 D(CE, CG)072 COOLING CAPACITIES (6 TON) . . . . 11

8 SUPPLY AIR BLOWER PERFORMANCE (3 TON BELT

DRIVE) - SIDE DUCT APPLICATION . . . . . . . . . . . . . 12

9 SUPPLY AIR BLOWER PERFORMANCE (4 TON BELT

DRIVE) - SIDE DUCT APPLICATION . . . . . . . . . . . . . 13

10 SUPPLY AIR BLOWER PERFORMANCE (5 TON BELT

DRIVE) - SIDE DUCT APPLICATION . . . . . . . . . . . . . 14

11 SUPPLY AIR BLOWER PERFORMANCE (6 TON BELT

DRIVE) - SIDE DUCT APPLICATION . . . . . . . . . . . . . 15

12 SUPPLY AIR BLOWER PERFORMANCE (3 - 6 TON

DIRECT DRIVE) - SIDE DUCT APPLICATION . . . . . 16

13 BELT DRIVE BLOWER MOTOR AND DRIVE DATA . 16

14 STATIC RESISTANCES . . . . . . . . . . . . . . . . . . . . . . . 17

15 ELECTRIC HEATER CFM LIMITATIONS . . . . . . . . . . 17

16 ELECTRICAL DATA - D(CE, CG)036-072

DIRECT DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

17 ELECTRICAL DATA - D(CE, CG)036-072

BELT DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

18 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

19 ELECTRIC HEAT CORRECTION FACTORS . . . . . . . 22

20 VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . 22

21 UTILITIES ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

22 MINIMUM CLEARANCES . . . . . . . . . . . . . . . . . . . . . . 26

23 D(CE, CG) 4 AND 6 POINT LOADS WEIGHT

DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

24 CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . . . . . . 28

25 OPERATING WEIGHTS (LBS.) . . . . . . . . . . . . . . . . . . 29

2 Unitary Products Group

255040-YTG-A-0506

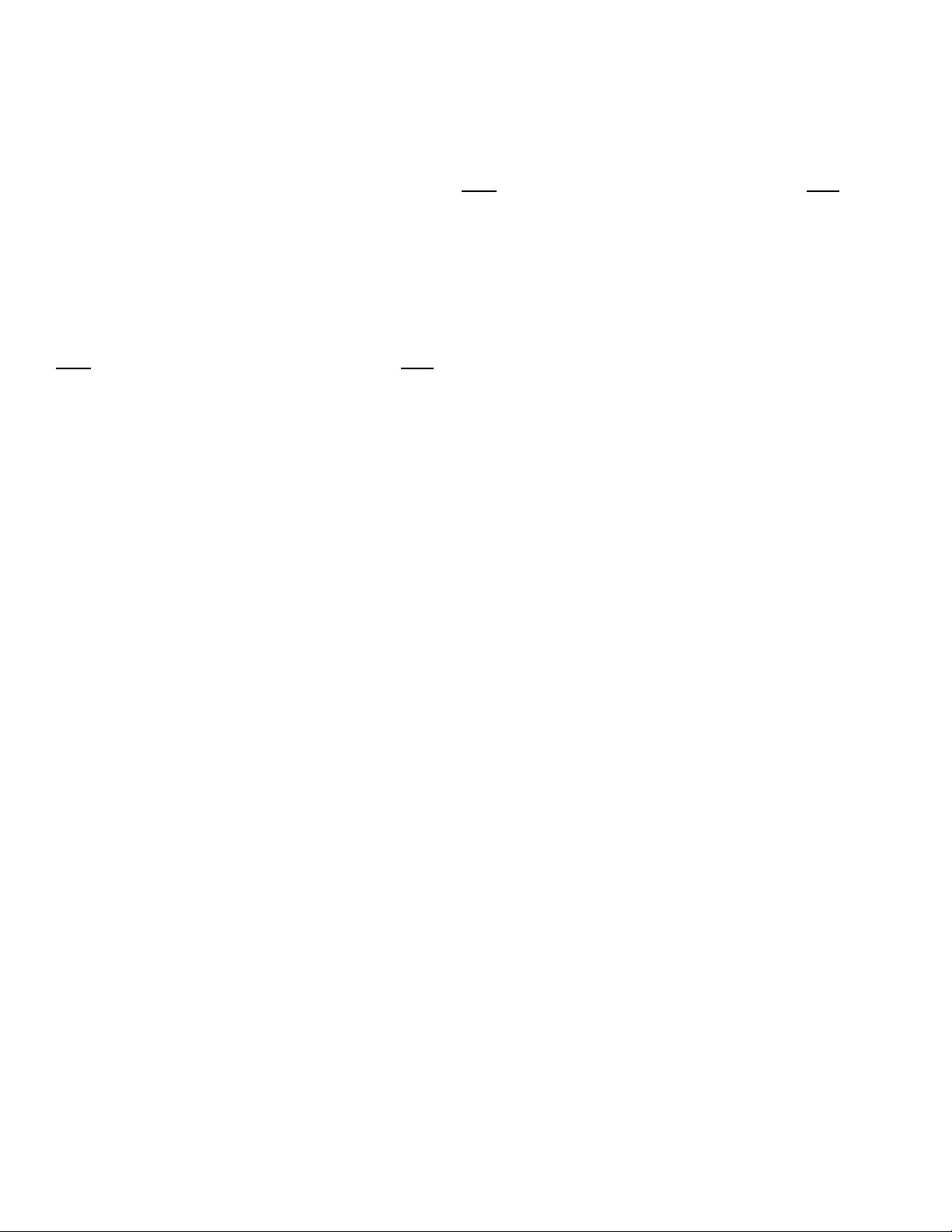

PRODUCT NOMENCLATURE

PRODUCT CATEGORY

D = Single Package Air Conditioner

(Air Cooled)

PRODUCT GENERATION

3 = 3rd Generation

5 = 5th Generation

PRODUCT IDENTIFIER

CE = Cooling

PRODUCT CATEGORY

D = Single Package Air Conditioner

(Air Cooled)

PRODUCT GENERATION

3 = 3rd Generation

8 = 8th Generation

PRODUCT IDENTIFIER

CG = Gas/Electric

D 5 C E A

D 8 C G 4N

NOMINAL COOLING

CAPACITY

036 = 3 Ton

048 = 4 Ton

060 = 5 Ton

072 = 6 Ton

30 6 2 5

NOMINAL COOLING

CAPACITY

036 = 3 Ton

048 = 4 Ton

060 = 5 Ton

072 = 6 Ton

VOLTAGE CODE

25 = 208/230-3-60

46 = 460-3-60

58 = 575-3-60

FACTORY INSTALLED

HEAT

A = Cooling Only

0 030 6 2 5

VOLTAGE CODE

25 = 208/230-3-60

46 = 460-3-60

58 = 575-3-60

NOMINAL GAS HEATING

OUTPUT CAPACITY

040 = 40 MBH

060 = 60 MBH

079 = 79 MBH

099 = 99 MBH

FACTORY I NSTALLE D

HEAT

N = Gas Heat Installed

Unitary Products Group 3

255040-YTG-A-0506

FEATURES

All units are self-contained and assembled on full perimeter

base rails with forklift holes on three sides and holes for overhead rigging. Every unit is completely piped, wired, charged

and tested at the factory to simplify the field installation and to

provide years of dependable operation.

All models (including those with an economizer) are suitable for

either bottom or horizontal duct connections. For bottom duct,

remove the sheet metal panels from the supply and return air

openings through the base of the unit. For horizontal duct,

remove the supply and return air panels on the rear of the unit.

All models are available with the “factory mounted” outdoor

air damper option:

• Single enthalpy economizer

Supply air blowers are equipped with either a direct drive or a

belt drive that can be adjusted to meet the exact requirements of the job.

All compressors are equipped with internal pressure relief.

Every refrigerant circuit includes a liquid line filter-drier, a high

pressure switch and a suction line with a freezestat and low

pressure/loss of charge switch to protect all system components.

• Control boards have standardized a number of features

previously available only as options or by utilizing additional controls.

• Low Ambient - An integrated low-ambient control

allows all units to operate in the cooling mode down

to 0ºF outdoor ambient without additional assistance. Optionally , the control board can be programmed to lockout the compressors when the

outdoor air temperature is low or when free cooling

is available.

• Anti-Short Cycle Protection - To aid compressor

life, an anti-short cycle delay is incorporated into the

standard controls. Compressor reliability is further

ensured by programmable minimum run times. For

testing, the anti short cycle delay can be temporarily

overridden with the push of a button.

• Fan Delays - Fan on and fan off delays are fully pro-

grammable and are independent of one another. All

units are programmed with default values based

upon their configuration of cooling and heat.

• Safety Monitoring - The control board monitors the

high and low-pressure switches, the freezestats, the

gas valve, if applicable, and the temperature limit

switch on gas heat units. The unit control board will

alarm on ignition failures, compressor lockouts and

repeated limit switch trips.

• Nuisance Trip Protection- To prevent nuisance

trouble calls, the control board uses a “three strikes,

you’re out” philosophy. The high and low-pressure

switches and the freezestats must trip three times

within two hours before the unit control board will

lock out the compressor.

• On Board Diagnostics - Each alarm will energize a

trouble light on the thermostat, if so equipped, and

flash an alarm code on the control board LED. Each

high and low-pressure switch alarm as well as each

freezestat alarm has its own flash code. The control

board saves the five most recent alarms in memory,

and these alarms can be reviewed at any time.

Alarms and programmed values are retained

through the loss of power.

All units have long lasting powder paint cabinets with 1000

hour salt spray test approval under ASTM-B117 procedures.

All models are CSA listed.

• Warranty - All models include a one-year limited parts

warranty on the complete unit. Compressors and electric

heater elements carry a five-year warranty. Gas heat

exchangers carry a 10-year parts warranty.

• Gas Heat Operation - All single phase models with gas

heat have minimum annual fuel utilizati on efficiency

(AFUE) of 80%. All three phase models with gas heat

have minimum steady state efficiency of 80%. Each section includes a durable heat exchanger with aluminized

steel, a redundant gas valve, spark ignition, power venting, an ignition module for 100% shut-off and all of the

safety controls required to meet the latest ANSI standards.

The gas supply piping can be routed into the heating

compartment through a hole in the base pan of the unit

or through a knockout in the piping panel on the front of

the unit.

• Electric Heat Operation - All electric heat models are

wired for a single power source and include a bank of

nickel chromium elements mounted at the discharge of

the supply air blower to provide a high velocity and uniform distribution of air across the heating elements.

Every element is fully protected against excessive temperature by thermal limit switches.

The power supply wiring can be routed into the control

box through a threaded pipe connection (field supplied)

in the base pan of the unit or through a knockout in the

wiring panel on the side of the unit.

4 Unitary Products Group

255040-YTG-A-0506

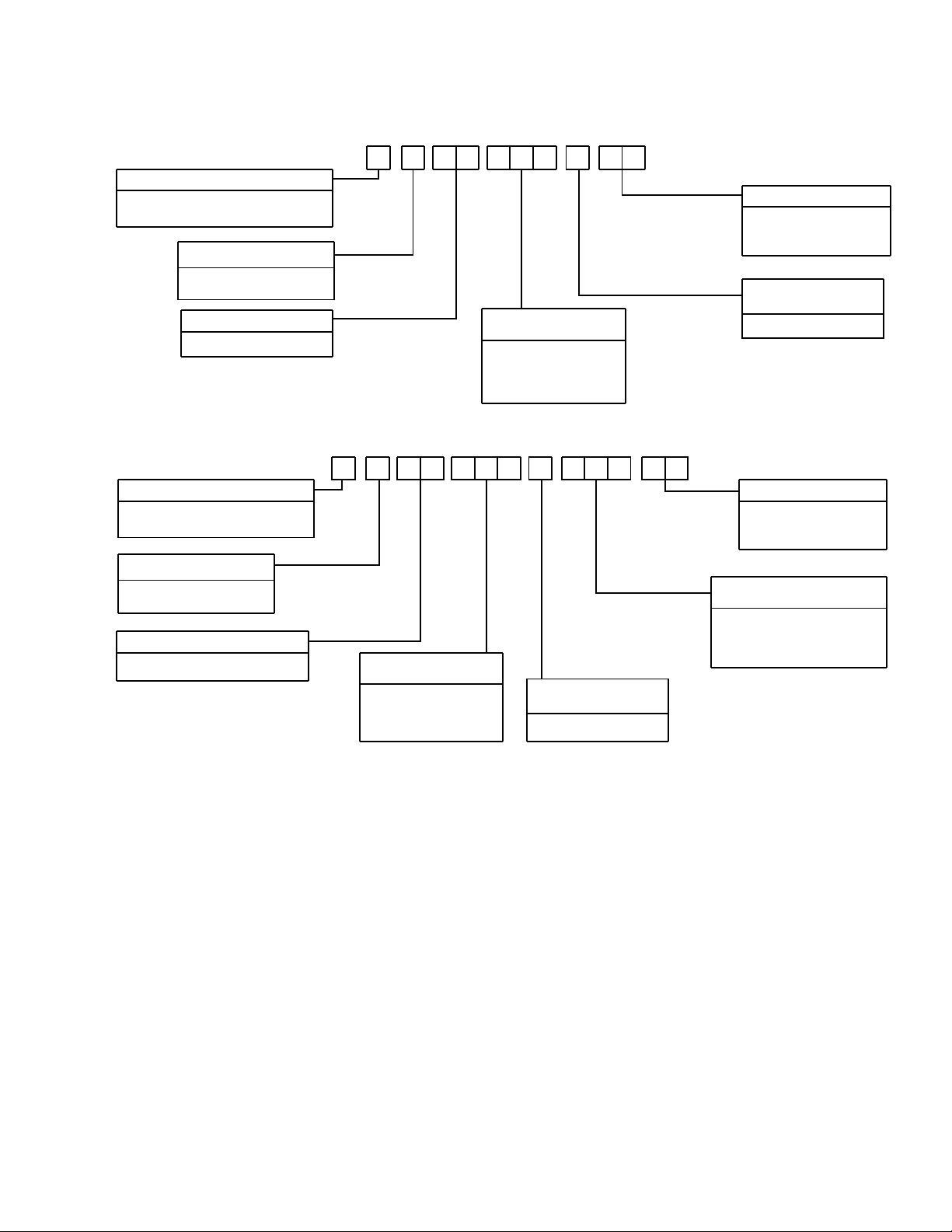

ECONOMIZER

HOOD

SLIDE-IN

ECONOMIZER

SIDE RETURN

AIR DUCT OPENING

BOTTOM

RETURN

AIR DUCT

OPENING

DIRECT OR

BELT DRIVE

BLOWER

3/4” PVC FEMALE

CONDENSATE DRAIN

KNOCKOUTS FOR

SIDE POWER AND

CONTROL ENTRY

20 GAUGE ALUMINIZED

STEEL TUBULAR HEAT

EXCHANGER

LOW VOLTAGE CONTROL

BOARD

POWER VENTOR MOTOR

WITH POST PURGE CYCLE

HIGH EFFICIENCY

COMPRESSOR

COPPER TUBE/

ALUMINUM FIN

CONDENSING

COIL

FULL PERIMETER

BASE RAILS WITH

FORKLIFT SLOTS

AND LIFTING HOLES

KNOCKOUT FOR SIDE

GAS SUPPLY ENTRY

FIGURE 1 - UNIT CUTAW AY

FACTORY-INSTALLED OPTIONS

• SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS - Includes a slide-in / plug-in damper assembly

with fully modulating spring-return motor actuator capable of introducing up to 100% outdoor air with nominal

1% leakage type dampers.

The enthalpy system contains one sensor that monitors

the outdoor air and determines when the air is cool

enough and dry enough to provide free cooling.

The rainhood is painted to match the basic unit and must

be field-assembled before installing.

• PHENOLIC COA TED CONDENS ER COILS - Special

coating process that utilizes Technicoat 10-1

cesses. Coating is applied by total immersion of the complete coil for maximum protection.

• BELT DRIVE INDOOR FAN - Includes belt drive indoor

fan and motor with unit access for belt adjustment and

service.

TM

pro-

FIELD-INSTALLED ACCESSORIES

• SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS - Includes a slide-in / plug-in damper assembly

with fully modulating spring-return motor actuator capable of introducing up to 100% outdoor air with nominal

1% leakage type dampers.

The enthalpy system contains one sensor that monitors

the outdoor air and determines when the air is cool

enough and dry enough to provide free cooling.

The rainhood is painted to match the basic unit and must

be field-assembled before installing.

• MOTORIZED OUTDOOR AIR INTAKE DAMPER -

Includes a slide-in / plug-in damper assembly with a 2position, spring return motor actuator which opens to

some pre-set position whenever the supply air blower is

operating and will drive fully closed when the blower unit

shuts down.

The rain hood is painted to match the basic unit and

must be field assembled before installing.

Unitary Products Group 5

255040-YTG-A-0506

• ELECTRIC HEA T ERS wired for single point power supply. These nickel chromium heater elements are provided with limit and automatic reset capability to prevent

operation at excessive temperatures.

• ROOF CURBS - Eight and fourteen-inch high roof curbs

provide a water-tight seal between the unit and the finished

roof. These full perimeter curbs meet the requirements of

the National Roofing Contractors Association (NRCA) and

are shipped knocked-down for field assembly .

Roof curbs are designed to fit inside the base rails of the

unit and include both a wood nailing strip and duct

hanger supports.

• HIGH ALTITUDE NATURAL GAS - Burner orifices and

pilot orifices are provided for proper furnace operation at

altitudes up to 6,000 feet.

• PROPANE - Burner orifices, pilot orifices and gas valve

parts are provided to convert a natural gas furnace to

propane.

• HIGH ALTITUDE PROPANE - Burner orifices and pilot

orifices are provided for proper furnace operation at altitudes up to 6,000 feet. This accessory supplements the

basic propane conversion kit.

• LOW NOX KIT- Required to reduce the emission of

nitrogen oxides below 40 nanograms per joule.

• POWER EXHAUST - Our single input economizer

options are available with power exhaust. Whenever the

outdoor air intake dampers are opened for free cooling,

the exhaust fan will be energized to prevent the conditioned space from being over-pressurized during economizer operation.

The power exhaust option can only be used on bottom duct configurations.

• BAROMETRIC RELIEF DAMPER - This damper accessory can be used to relieve internal building air pressure

on units with an economizer without power exhaust. This

accessory includes a rain hood, a bird screen and a fully

assembled damper. With bottom duct connections, the

damper should be mounted over the opening in the

return air panel. With horizontal ductwork, the accessory

should be mounted on the return air duct.

• ENTHALPY ACCESSORY CONTROL KIT - This kit

contains the required components to convert a single

enthalpy economizer to dual enthalpy.

• BURGLAR BARS - Mount in the supply and return

openings to prevent entry into the duct work.

• FLUE EXHAUST EXTENSION KIT - In locations with

wind or weather conditions which may interfere with

proper exhausting of furnace combustion products, this

kit can be installed to prevent the flue exhaust from

entering nearby fresh air intakes.

• COIL GUARD - Customers can purchase a coil guard kit

to protect the condenser coil from damage. This is not a

hail guard kit.

• HAIL GUARD -Hail Guard Kit is available to prevent unit

from hail damage. This is a sloped hood that fits above

the condenser coil.

• GAS PIPING KIT - This kit supplies all necessary fittings

and shut off valve.

6 Unitary Products Group

255040-YTG-A-0506

TABLE 1: SOUND POWER RATING

UNIT

SIZE

CFM

ESP BLOWER

IWG SPEED KW 63 125 250 500 1,000 2,000 4,000 8,000

1

SOUND POWER (db 10

Octave Band Centerline Frequency (Hz)

-12

Watts)

SWL

dB(A)

dB(A)

@

10Ft.

036 1,200 0.6 LOW 0.60 84 84 74 67 69 62 57 52 74 41

048 1,600 0.55 HIGH 0.80 85 85 75 68 70 63 58 53 75 42

060 2,000 0.45 HIGH 1.00 86 86 76 69 71 64 59 54 76 43

072 2,2000.3HIGH1.3587877770726560557744

1. These values have been accessed using a model of sound propagation from a point source into the hemispheric\free field. The

dBA values provided are to be used for reference only. Calculation of dBA values cover matters of system design and the fan

manufacture has no way of knowing the details of each system. This constitutes and expectation to any specification or guarantee requiring a dBA value or sound data in any other form than sound power level ratings.

2. At a distance of 10 feet from the blower.

TABLE 2: CAPACITY RATINGS - (ARI 210/240)

MODEL MBH

D(CE, CG)036

D(CE, CG)048

D(CE, CG)060

D(CE, CG)072

36.0 9.1 10.0

47.4 9.0 10.0

59.0 9.1 10.0

72.0 9.0 -

1. 80/67°F Indoor and 95°F outdoor.

2. EER = Energy Efficiency Ratio at full load - the cooling

capacity in Btu’s per hour (Btuh) divided by the power

input in watts, expressed in Btuh per watt (Btuh/watt).

3. SEER = Seasonal Energy Efficiency Ratio.

EER

2

1

3

SEER

TABLE 3: GAS HEAT RATINGS

MODEL

DCG036N040

DCG036N079

DCG048N060

DCG048N099

DCG060N079

DCG060N099

DCG072N079

DCG072N099

MBH

INPUT

50

100

75

125

100

125

100

125

1

MBH

OUTPUT

40

80

60

100

80

100

80

100

AFUE

(%)

80.9

80.5

80.9

80.3

80.5

80.3

80.5

80.3

TEMP

RISE ºF

15 - 45

40 - 70

25 - 55

45 - 75

25 - 55

35 - 65

25 - 55

35 - 65

1. All units are single-stage heating.

2

Unitary Products Group 7

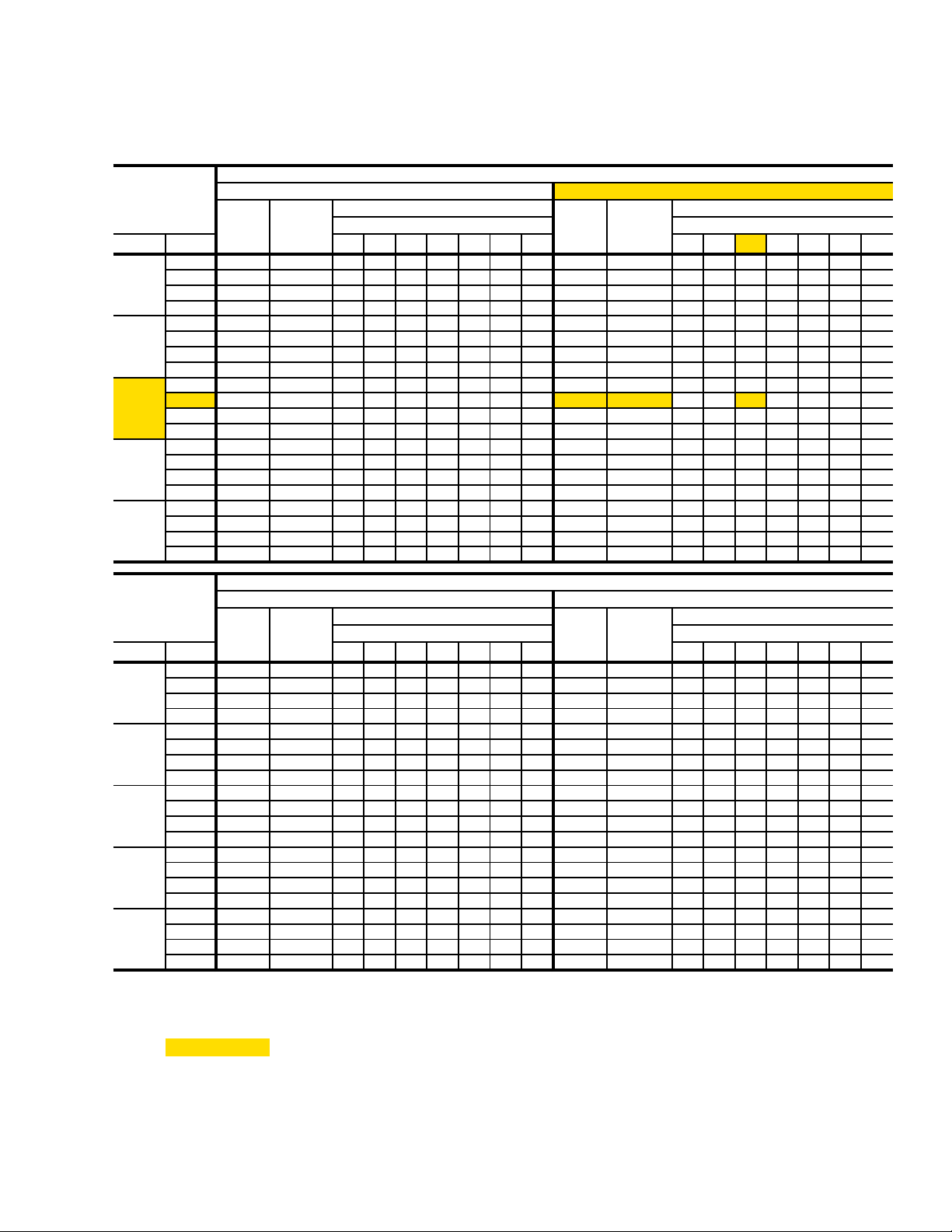

TABLE 4: D(CE, CG)036 COOLING CAPACITIES (3 TON)

255040-YTG-A-0506

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

85°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1

72 45 3.1 35 30 26 21 17 - - 43 3.3 35 30 26 21 17 - -

1750

67 43 3.0 43 38 34 29 25 20 16 41 3.3 41 38 34 29 25 21 16

62 39 3.0 39 39 39 34 30 25 21 36 3.3 36 36 36 32 27 23 18

57 40 2.9 40 40 40 35 31 26 22 38 3.2 38 38 38 33 29 24 20

72 44 3.1 31 28 24 20 16 - - 42 3.3 31 27 23 20 16 - -

1475

67 41 3.0 39 35 31 27 23 19 16 39 3.3 37 35 31 27 23 19 15

62 38 3.0 38 38 37 33 29 25 21 36 3.3 36 36 35 31 27 23 19

57 39 2.9 39 39 39 35 31 27 23 37 3.2 37 37 36 32 28 25 21

72 42 3.1 28 25 22 18 15 - - 41 3.3 28 24 21 18 14 - -

1200

67 40 3.0 35 32 28 25 22 18 15 38 3.2 34 31 28 25 21 18 15

62 36 3.0 36 36 35 31 28 25 21 35 3.3 35 35 34 30 27 24 20

57 37 2.9 37 37 37 34 31 27 24 36 3.2 36 36 35 32 28 25 22

72 41 3.1 26 23 20 17 14 - - 39 3.2 26 23 20 17 14 - -

1050

67 38 3.0 32 30 27 24 21 18 15 37 3.2 32 29 26 23 20 17 14

62 35 3.0 35 35 33 30 27 24 21 33 3.2 33 33 31 28 25 22 20

57 36 2.9 36 36 35 32 29 26 23 34 3.2 34 34 32 30 27 24 21

72 39 3.1 24 21 19 16 14 - - 38 3.2 23 21 18 16 13 - -

900

67 37 3.0 30 27 25 22 20 17 15 36 3.2 29 26 24 21 19 16 14

62 34 3.0 34 33 30 28 25 23 20 32 3.2 32 31 29 26 24 21 19

57 34 2.9 34 34 33 30 27 25 22 33 3.1 33 33 30 27 25 22 20

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

SENSIBLE CAPACITY

1

72 41 3.7 34 29 25 20 16 - - 39 4.1 33 28 24 19 15 - -

1750

67 38 3.7 38 37 33 28 24 19 15 36 4.0 36 36 32 27 23 18 14

62 34 3.7 34 34 34 30 25 21 16 32 4.0 32 32 32 27 23 18 14

57 35 3.6 35 35 35 31 26 22 17 33 4.0 33 33 33 28 24 19 15

72 40 3.7 30 26 23 19 15 - - 38 4.1 30 26 22 18 14 - -

1475

67 37 3.6 36 34 30 26 22 18 14 35 4.0 34 33 29 25 21 17 13

62 33 3.7 33 33 33 29 25 21 17 31 4.0 31 31 31 27 23 19 15

57 34 3.6 34 34 34 30 26 22 18 32 4.0 32 32 32 28 24 20 16

72 39 3.7 27 24 20 17 14 - - 37 4.1 26 23 20 16 13 - -

1200

67 36 3.6 34 30 27 24 20 17 14 34 4.0 33 30 26 23 20 16 13

62 32 3.6 32 32 32 29 25 22 19 30 4.0 30 30 30 27 24 20 17

57 33 3.6 33 33 33 29 26 23 19 31 3.9 31 31 31 27 24 21 17

72 37 3.6 25 22 19 16 13 - - 36 4.1 24 21 18 15 12 - -

1050

67 35 3.6 31 28 25 22 19 16 13 32 4.0 30 27 24 21 18 15 12

62 31 3.6 31 31 29 27 24 21 18 29 4.0 29 29 28 25 22 19 16

57 32 3.5 32 32 30 27 24 21 18 30 3.9 30 29 28 25 22 19 16

72 36 3.6 22 20 17 15 12 - - 34 4.0 21 19 16 14 11 - -

900

67 33 3.6 28 25 23 20 18 15 13 31 4.0 27 24 22 19 17 14 11

62 30 3.6 30 29 27 24 22 19 17 28 4.0 28 28 25 22 20 17 15

57 31 3.5 31 30 28 25 22 20 17 28 3.9 28 28 25 23 20 17 15

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

8 Unitary Products Group

255040-YTG-A-0506

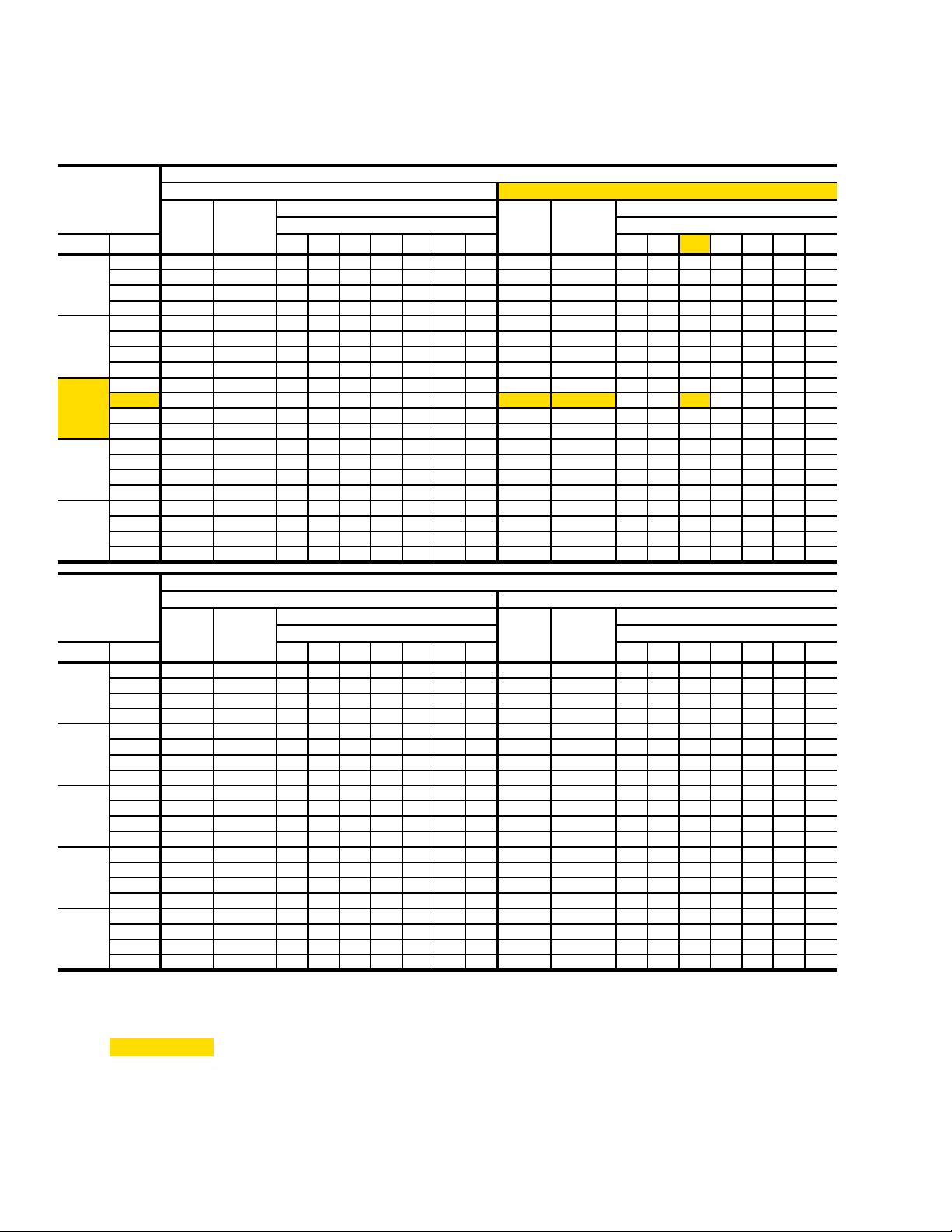

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 60 4.1 44 39 33 28 23 - - 60 4.5 44 39 33 28 23 - 67 55 4.1 53 48 42 37 32 26 21 52 4.5 52 47 42 36 31 25 20

62 51 4.0 51 51 51 45 40 34 29 48 4.4 48 48 48 42 37 32 26

57 49 3.9 49 49 49 44 39 33 28 47 4.3 47 47 47 42 36 31 26

72 58 4.1 41 36 31 26 21 - - 57 4.5 41 36 31 26 21 - 67 53 4.1 49 45 40 35 30 25 20 50 4.5 49 44 39 34 29 24 19

62 49 4.0 49 49 48 43 38 33 28 46 4.4 46 46 46 41 36 31 26

57 47 3.9 47 47 47 43 38 33 28 45 4.3 45 45 45 40 36 31 26

72 56 4.1 38 34 29 25 20 - - 55 4.6 38 33 29 24 20 - 67 51 4.1 46 41 37 32 28 24 19 48 4.5 45 40 36 31 27 23 18

62 47 4.0 47 47 45 41 36 32 27 44 4.4 44 44 44 40 35 31 26

57 46 3.9 46 46 46 41 37 32 28 44 4.4 44 44 44 39 35 30 26

72 54 4.1 35 31 27 23 19 - - 53 4.5 35 31 27 23 19 - 67 49 4.1 42 38 34 30 26 22 19 47 4.5 41 38 34 30 26 22 18

62 45 4.0 45 45 42 38 34 30 26 43 4.4 43 43 41 37 33 29 25

57 44 3.9 44 44 43 39 35 31 27 42 4.3 42 42 41 37 33 29 25

72 52 4.1 32 29 25 22 18 - - 51 4.5 32 28 25 21 18 - 67 47 4.1 39 35 32 28 25 21 18 45 4.4 38 35 31 28 24 21 17

62 43 4.0 43 43 39 36 32 29 25 41 4.3 41 41 38 35 31 28 24

57 42 3.9 42 42 39 36 32 29 25 41 4.3 41 41 38 34 31 27 24

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 56 5.1 42 37 31 26 21 - - 53 5.6 40 35 29 24 19 - 67 49 5.0 49 46 40 35 29 24 19 46 5.5 46 44 39 33 28 23 17

62 45 4.9 45 45 45 39 34 28 23 41 5.4 41 41 41 36 30 25 20

57 44 4.9 44 44 44 39 33 28 22 41 5.4 41 41 41 35 30 25 19

72 55 5.0 39 34 29 24 20 - - 52 5.5 38 33 28 23 18 - 67 48 5.0 47 43 38 33 28 23 18 45 5.4 45 42 37 32 27 22 17

62 43 4.9 43 43 43 38 33 28 23 40 5.4 40 40 40 35 30 26 21

57 43 4.9 43 43 43 38 33 28 23 40 5.4 40 40 40 35 30 25 20

72 53 5.0 36 32 28 23 19 - - 51 5.5 35 31 26 22 17 - 67 46 4.9 44 40 35 31 26 22 17 44 5.4 44 39 35 30 26 21 17

62 42 4.9 42 42 42 37 33 28 24 39 5.3 39 39 39 35 30 26 21

57 41 4.8 41 41 41 37 32 28 23 39 5.3 39 39 39 34 30 25 21

72 51 5.0 33 29 26 22 18 - - 48 5.5 32 28 24 20 16 - 67 44 4.9 41 37 33 29 25 21 17 42 5.3 40 36 32 28 24 20 16

62 40 4.8 40 40 39 35 31 27 23 37 5.3 37 37 36 32 28 24 20

57 40 4.8 40 40 38 34 30 26 22 37 5.3 37 37 36 32 28 24 20

72 49 4.9 30 27 23 20 16 - - 46 5.4 29 26 22 19 15 - 67 42 4.9 37 34 30 27 23 20 16 39 5.3 36 33 29 26 22 19 15

62 38 4.8 38 38 36 32 29 25 22 35 5.3 35 35 33 29 26 22 19

57 38 4.8 38 38 35 32 28 25 21 35 5.3 35 35 33 29 26 22 19

NOMINAL RATING

1200

1400

85°F

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

1

ENTERING DRY BULB, °F

2000

1800

1600

SENSIBLE CAPACITY

1

ENTERING DRY BULB, °F

AIR ON

EVAPORATOR

COIL

TEMPERATURE OF AIR ON CONDENSER COIL

1400

POWER

INPUT

2

kW

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

AIR ON

EVAPORATOR

COIL

TEMPERATURE OF AIR ON CONDENSER COIL

105°F 115°F

SENSIBLE CAPACITY

1

SENSIBLE CAPACITY

1

1200

TOTAL

CAP.

1

MBH

POWER

INPUT

2

kW

TOTAL

CAP.

1

MBH

TOTAL

CAP.

1

MBH

POWER

INPUT

2

kW

TOTAL

CAP.

1

MBH

2000

1800

1600

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

TABLE 5: D(CE, CG)048 COOLING CAPACITIES (4 TON)

Unitary Products Group 9

TABLE 6: D(CE, CG)060 COOLING CAPACITIES (5 TON)

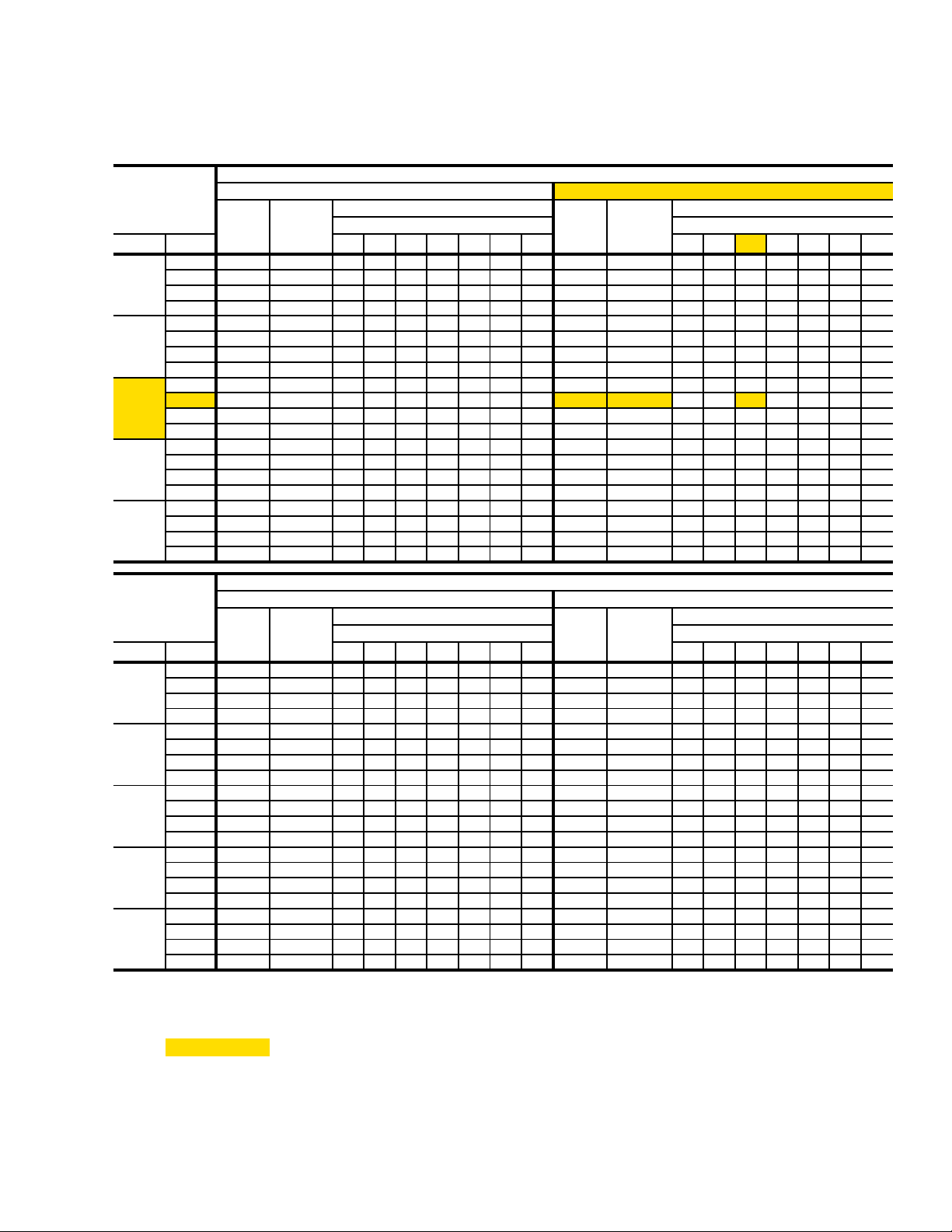

255040-YTG-A-0506

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

85°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1

72 68 4.9 50 44 38 32 25 - - 65 5.6 50 43 37 31 24 - -

2500

67 62 4.8 62 56 50 43 37 31 24 60 5.3 60 54 48 42 35 29 23

62 57 4.7 57 57 57 51 44 38 32 53 5.3 53 53 53 47 41 34 28

57 55 4.7 55 55 55 48 42 36 29 51 5.4 51 51 51 44 38 32 25

72 67 4.9 48 42 36 30 24 - - 65 5.4 47 41 35 29 23 - -

2250

67 62 4.8 59 53 47 41 35 30 24 59 5.2 57 51 45 40 34 28 22

62 56 4.7 56 56 56 50 45 39 33 53 5.2 53 53 53 47 41 35 29

57 54 4.7 54 54 54 48 42 36 31 50 5.3 50 50 50 44 39 33 27

72 66 4.9 45 39 34 29 23 - - 64 5.3 44 39 33 28 22 - -

2000

67 61 4.8 55 50 44 39 34 28 23 58 5.1 54 48 43 38 32 27 22

62 55 4.7 55 55 55 50 45 39 34 52 5.1 52 52 52 47 42 36 31

57 53 4.6 53 53 53 48 42 37 32 50 5.2 50 50 50 44 39 34 28

72 63 4.8 41 36 31 27 22 - - 61 5.4 40 35 31 26 21 - -

1750

67 58 4.7 51 46 41 36 32 27 22 56 5.1 49 44 39 35 30 25 21

62 53 4.6 53 53 51 47 42 37 32 50 5.2 50 50 48 43 39 34 29

57 51 4.6 51 51 49 44 40 35 30 47 5.2 47 47 46 41 36 32 27

72 60 4.8 37 33 29 25 21 - - 58 5.4 36 32 28 24 20 - -

1500

67 56 4.7 46 42 38 34 30 26 21 53 5.2 44 40 36 32 28 24 20

62 51 4.6 51 51 47 43 39 35 31 47 5.2 47 47 44 40 36 32 27

57 49 4.6 49 49 45 41 37 33 29 45 5.3 45 45 42 38 34 29 25

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

SENSIBLE CAPACITY

1

72 61 6.1 48 41 35 29 22 - - 57 6.7 46 39 33 27 20 - -

2500

67 55 5.9 55 52 46 39 33 27 20 50 6.6 50 50 43 37 31 24 18

62 49 5.9 49 49 49 42 36 30 23 44 6.5 44 44 44 38 31 25 19

57 47 5.9 47 47 47 40 34 28 21 42 6.5 42 42 42 36 30 23 17

72 61 6.0 45 39 33 28 22 - - 57 6.6 43 38 32 26 20 - -

2250

67 54 5.9 53 49 44 38 32 26 20 50 6.5 50 47 42 36 30 24 18

62 48 5.8 48 48 48 42 37 31 25 44 6.4 44 44 44 38 32 26 20

57 46 5.8 46 46 46 40 35 29 23 42 6.4 42 42 42 36 31 25 19

72 60 6.0 42 37 32 26 21 - - 57 6.6 41 36 30 25 20 - -

2000

67 54 5.8 52 47 41 36 31 25 20 50 6.5 50 45 40 34 29 24 18

62 48 5.7 48 48 48 43 37 32 27 44 6.4 44 44 44 38 33 28 22

57 46 5.8 46 46 46 41 35 30 25 42 6.3 42 42 42 37 32 26 21

72 57 6.0 38 34 29 24 19 - - 53 6.5 37 32 27 23 18 - -

1750

67 51 5.8 47 42 38 33 28 24 19 46 6.4 45 41 36 31 26 22 17

62 45 5.7 45 45 44 39 34 30 25 41 6.3 41 41 39 35 30 25 21

57 43 5.8 43 43 42 37 32 28 23 39 6.3 39 39 38 33 29 24 19

72 54 6.0 34 30 26 22 18 - - 49 6.5 33 28 24 20 16 - -

1500

67 48 5.8 42 38 34 30 26 22 18 43 6.4 40 36 32 28 24 20 16

62 43 5.7 43 43 39 35 31 27 23 38 6.3 38 38 35 31 27 23 19

57 41 5.8 41 41 38 34 30 26 21 37 6.2 37 37 34 30 26 22 18

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

10 Unitary Products Group

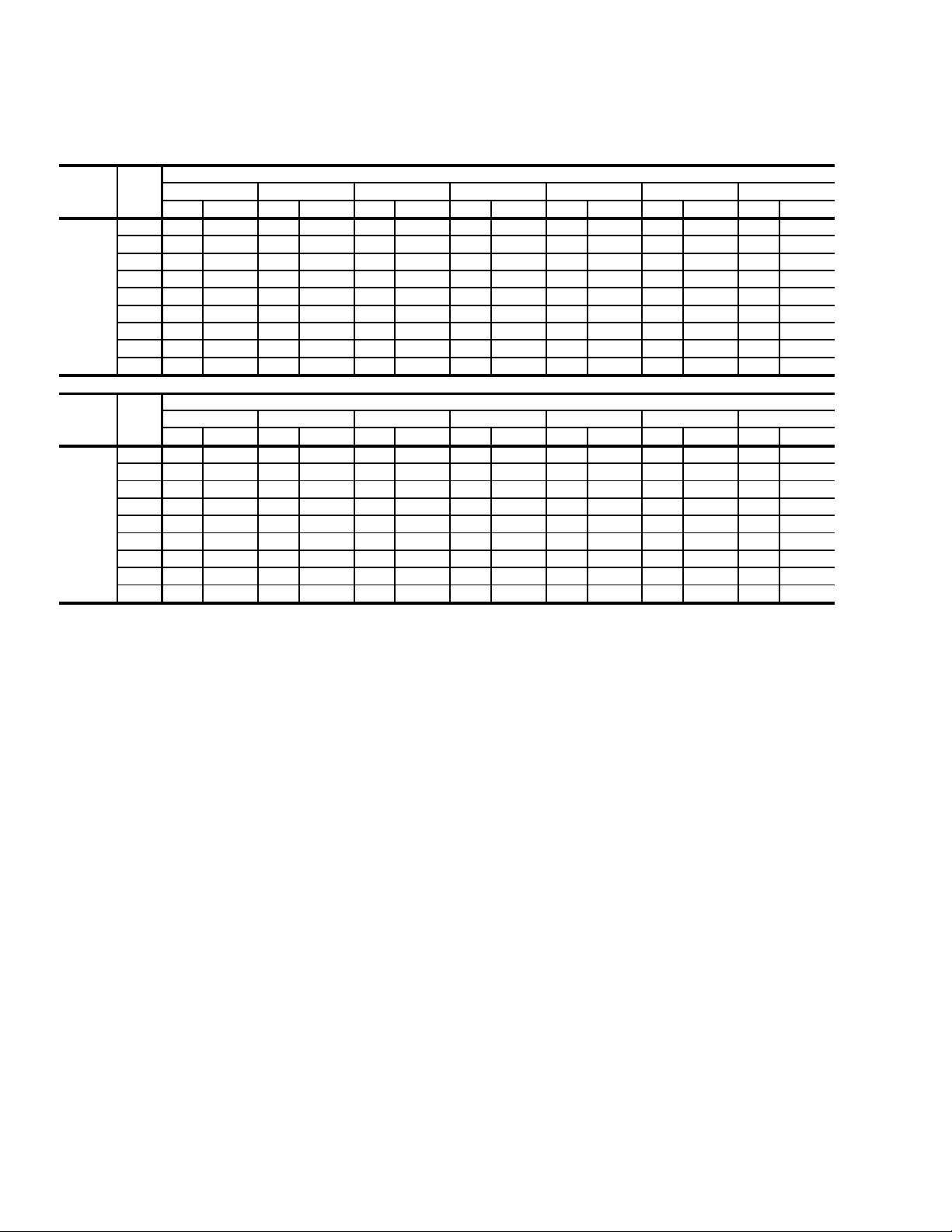

255040-YTG-A-0506

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 80 5.7 63 55 47 40 32 - - 77 6.3 63 55 47 40 32 - 67 80 5.7 76 68 60 53 45 37 30 77 6.3 75 68 60 53 45 37 30

62 70 5.5 70 70 70 62 55 47 39 71 6.3 71 71 71 63 56 48 40

57 68 5.6 68 68 68 60 52 45 37 71 6.3 71 71 71 63 56 48 40

72 82 5.7 60 53 46 38 31 - - 76 6.3 60 53 46 39 31 - 67 82 5.7 73 65 58 51 43 36 29 76 6.3 73 66 58 51 44 36 29

62 71 5.5 71 71 70 62 55 48 41 70 6.3 70 70 69 62 55 48 40

57 69 5.6 69 69 69 62 55 47 40 70 6.3 70 70 70 62 55 48 40

72 83 5.7 58 51 44 37 30 - - 75 6.3 58 51 44 37 30 - 67 83 5.7 70 63 56 49 42 35 28 75 6.3 70 64 57 50 43 36 29

62 73 5.5 73 73 70 63 56 49 42 69 6.3 69 69 68 61 54 47 40

57 71 5.6 71 71 71 64 57 50 43 69 6.3 69 69 68 61 54 47 40

72 79 5.7 54 48 41 35 29 - - 73 6.3 53 47 41 35 29 - 67 79 5.7 65 59 53 47 40 34 28 73 6.3 65 59 52 46 40 34 28

62 69 5.5 69 69 66 60 54 47 41 67 6.3 67 66 63 57 51 45 38

57 67 5.6 67 67 67 61 54 48 42 67 6.3 67 66 63 57 51 45 39

72 74 5.6 50 44 39 34 28 - - 71 6.3 49 43 38 33 27 - 67 74 5.6 60 55 50 44 39 34 28 71 6.3 59 54 48 43 38 32 27

62 65 5.4 65 65 62 57 51 46 41 65 6.2 65 63 58 53 47 42 37

57 63 5.5 63 63 63 58 52 47 42 65 6.3 65 63 58 53 47 42 37

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 76 7.1 61 53 45 38 30 - - 75 7.9 59 51 43 36 28 - 67 71 7.1 70 66 58 50 43 35 27 65 7.8 65 64 56 48 41 33 25

62 64 7.0 64 64 64 56 49 41 34 57 7.8 57 57 57 50 42 34 27

57 64 7.0 64 64 64 56 49 41 34 57 7.7 57 57 57 50 42 34 27

72 76 7.1 59 51 44 37 29 - - 76 7.9 57 49 42 35 27 - 67 71 7.1 69 64 56 49 42 34 27 66 7.9 66 61 54 47 40 32 25

62 64 7.0 64 64 64 56 49 42 35 58 7.8 58 58 58 51 43 36 29

57 64 7.0 64 64 64 56 49 42 34 58 7.7 58 58 58 50 43 36 29

72 75 7.1 56 49 43 36 29 - - 76 8.0 55 48 41 34 27 - 67 70 7.1 68 61 54 48 41 34 27 66 7.9 66 59 52 45 38 32 25

62 64 7.0 64 64 63 56 49 42 35 59 7.8 59 59 59 52 45 38 31

57 64 7.0 64 64 63 56 49 42 35 59 7.7 59 59 58 51 44 37 30

72 73 7.1 52 45 39 33 27 - - 73 7.9 50 44 37 31 25 - 67 68 7.1 63 56 50 44 38 32 26 63 7.8 61 54 48 42 36 30 24

62 61 7.0 61 61 58 52 46 40 34 56 7.7 56 56 54 48 42 35 29

57 61 7.0 61 61 58 52 46 40 34 56 7.7 56 56 53 47 41 35 29

72 70 7.1 47 41 36 31 25 - - 69 7.8 45 40 34 29 23 - 67 65 7.0 57 51 46 41 35 30 25 60 7.8 55 49 44 39 33 28 23

62 59 7.0 59 58 54 48 43 38 32 53 7.7 53 53 49 44 39 33 28

57 59 6.9 59 58 53 48 43 37 32 53 7.6 53 53 49 44 38 33 27

NOMINAL RATING

1800

2100

85°F

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

1

ENTERING DRY BULB, °F

2700

2550

2400

SENSIBLE CAPACITY

1

ENTERING DRY BULB, °F

AIR ON

EVAPORATOR

COIL

TEMPERATURE OF AIR ON CONDENSER COIL

2100

POWER

INPUT

2

kW

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

AIR ON

EVAPORATOR

COIL

TEMPERATURE OF AIR ON CONDENSER COIL

105°F 115°F

SENSIBLE CAPACITY

1

SENSIBLE CAPACITY

1

1800

TOTAL

CAP.

1

MBH

POWER

INPUT

2

kW

TOTAL

CAP.

1

MBH

TOTAL

CAP.

1

MBH

POWER

INPUT

2

kW

TOTAL

CAP.

1

MBH

2700

2550

2400

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

TABLE 7: D(CE, CG)072 COOLING CAPACITIES (6 TON)

Unitary Products Group 11

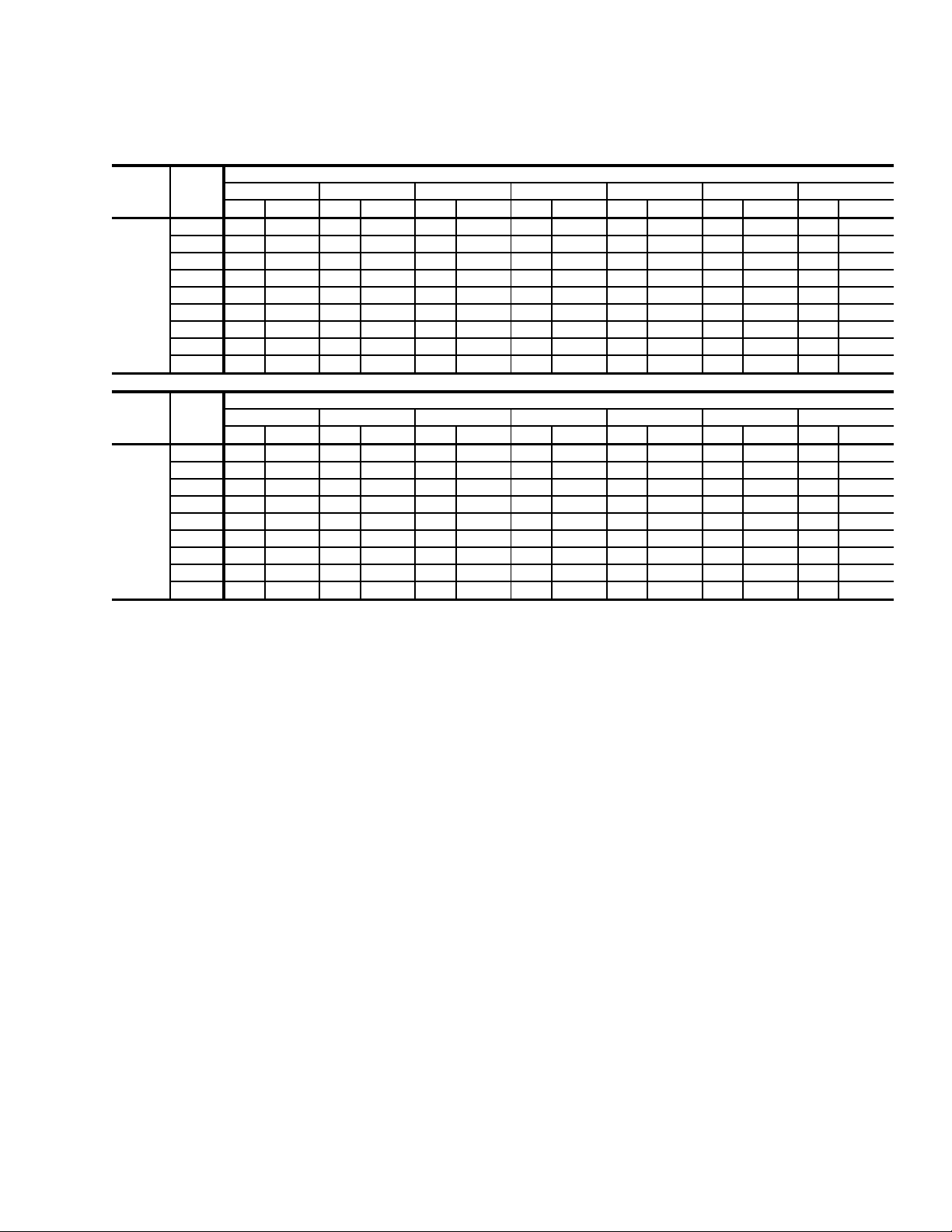

T ABLE 8: SUPPLY AIR BLOWER PERFORMANCE (3 TON BELT DRIVE) - SIDE DUCT APPLICATION

pp

255040-YTG-A-0506

UNIT

TONNAGE

1,2

3

UNIT

TONNAGE

1, 2

3

AIR

FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.20 0.30 0.40 0.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

0.60 0.70 0.80

1700 835 705 880 745 923 795 969 860 1013 970 ----

1600 811 655 854 695 898 740 942 790 986 840 1029 900 - -

1500 782 610 827 650 871 685 917 730 960 775 1003 825 1046 905

1400 - - 798 595 844 640 889 680 932 720 975 765 1018 790

1300 ----816590862635907675951715995750

1200 ------834585881630927665970705

1100 ------809550855590900625942665

1000 ------782510829545872858919625

900--------797500843540890580

AIR

FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

1700 --------------

1600 --------------

1500 --------------

1400 1055 875 ------------

1300 1036 780 1066 850 ----------

1200 1011 735 1047 765 1075 800 --------

1100 987 690 1028 720 1060 750 1084 775 ------

1000 963 655 1005 680 1040 695 1068 715 1089 735 ----

900 936 615 980 645 1020 660 1050 670 1053 680 1090 690 - -

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table

for resistance values on a

lications other than gas / electric units with side duct airflows.

12 Unitary Products Group

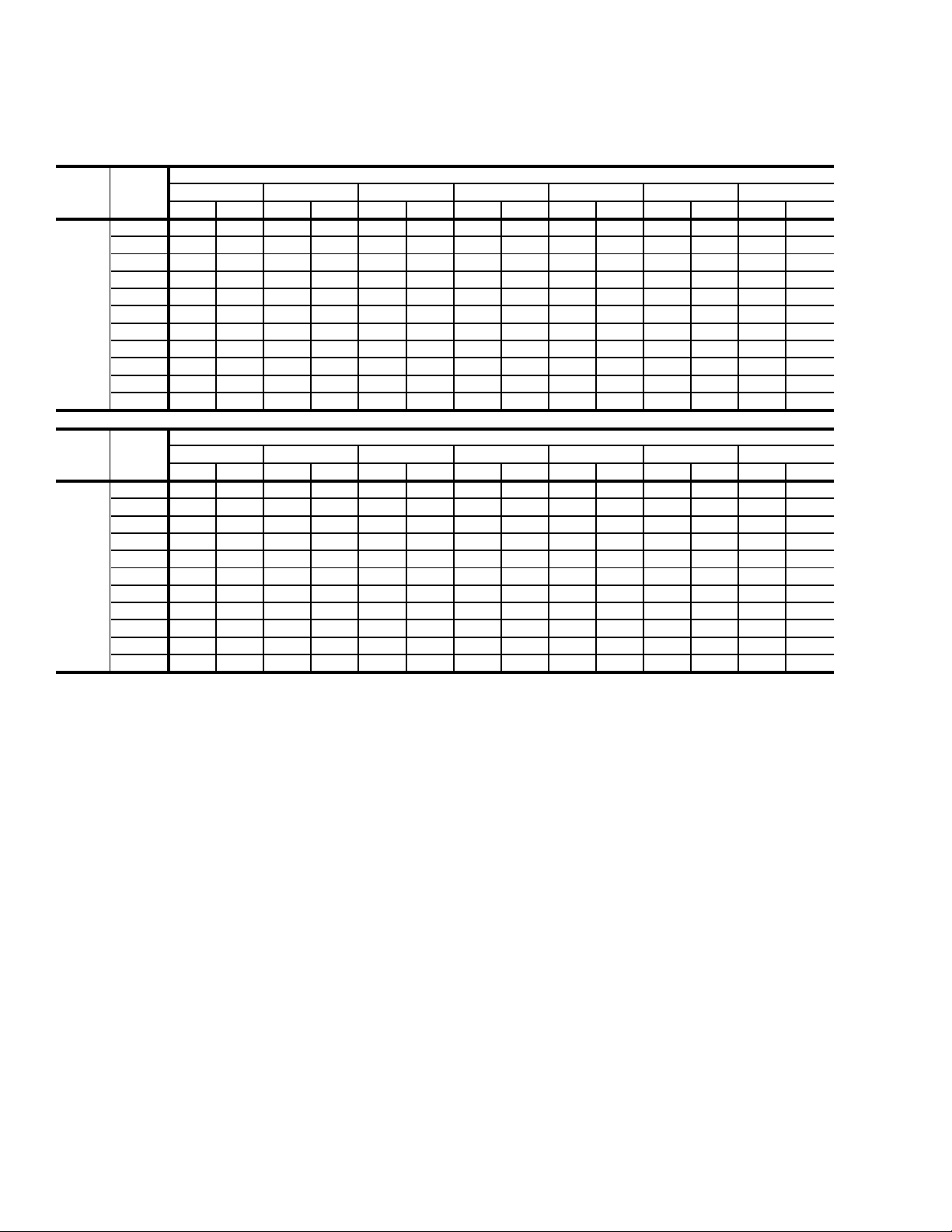

255040-YTG-A-0506

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

2000 843 860 880 925 919 1005 956 1065 993 1145 1030 1195 1067 1235

1900 817 775 854 850 893 920 930 995 970 1065 1008 1125 1046 1170

1800 790 700 828 760 867 840 906 905 944 980 985 1040 1025 1100

1700 - - 802 670 840 745 881 815 920 900 961 970 1001 1030

1600 ----818665858740898820940890980950

1500 ------842695882755922835962895

1400 ------833650867705904765942820

1300 --------858665893725932785

1200 --------847640880680916730

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

2000 1103 1270 ------------

1900 1085 1210 ------------

1800 1064 1145 1102 1180 ----------

1700 1040 1075 1081 1115 1121 1140 --------

1600 1020 1005 1060 1050 1100 1085 --------

1500 1003 945 1044 995 1086 1035 --------

1400 982 880 1024 920 1067 965 1107 1000 ------

1300 970 835 1010 870 1053 920 1099 960 ------

1200 953 780 992 815 1034 855 1080 905 ------

0.60 0.70 0.80

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

3

0.20 0.30 0.40 0.50

UNIT

TONNAGE

AIR

FLOW

CFM

4

1, 2

UNIT

TONNAGE

AIR

FLOW

CFM

4

1, 2

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

3

0.90 1.00 1.10 1.20 1.30 1.40 1.50

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table for

resistance values on applications other than gas / electric units with side duct airflows.

T ABLE 9: SUPPLY AIR BLOWER PERFORMANCE (4 TON BELT DRIVE) - SIDE DUCT APPLICATION

Unitary Products Group 13

TABLE 10: SUPPLY AIR BLOWER PERFORMANCE (5 TON BELT DRIVE) - SIDE DUCT APPLICATION

255040-YTG-A-0506

UNIT

ONNAGE

1, 2

5

UNIT

ONNAGE

1, 2

5

AIR FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.20 0.30 0.40 0.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

0.60 0.70 0.80

2500 1059 1560 1077 1590 1095 1630 1114 1650 1134 1660 1158 1685 1181 1720

2400 1032 1405 1054 1470 1074 1525 1094 1560 1116 1595 1140 1620 1167 1640

2300 1005 1260 1024 1275 1049 1370 1069 1440 1090 1475 1116 1505 1142 1535

2200 980 1160 1002 1170 1022 1190 1044 1250 1066 1350 1090 1410 1117 1440

2100 930 1060 957 1070 983 1080 1010 1100 1039 1160 1064 1260 1092 1340

2000 877 950 908 975 941 1000 976 1020 1009 1050 1040 1100 1070 1225

1900 ----8948859409409809801014 1020 1047 1095

1800 ----8558159038609509059889401022 970

1700 ------8848159258509648801001 910

1600 ------864770908805948835987870

1500 --------882740926780965830

AIR FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

2500 --------------

2400 1193 1665 ------------

2300 1170 1580 1202 1620 ----------

2200 1148 1480 1180 1530 ----------

2100 1121 1385 1155 1425 1190 1475 --------

2000 1100 1285 1133 1340 1169 1385 1205 1445 ------

1900 1079 1180 1110 1240 1143 1280 1178 1330 1222 1375 ----

1800 1058 1060 1090 1135 1122 1190 1158 1240 1196 1295 ----

1700 1035 960 1071 1030 1103 1100 1134 1140 1164 1175 1197 1205 - -

1600 1020 900 1056 965 1088 1035 1118 1065 1145 1105 1170 1130 1198 1150

1500 1004 860 1038 880 1070 925 1101 980 1130 1045 1158 1075 1184 1110

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table for

resistance values on applications other than gas / electric units with side duct airflows.

14 Unitary Products Group

Loading...

Loading...