York 359583-YTG-B-0208 User Manual

TECHNICAL GUIDE

HIGH-EFFICIENCY

359583-YTG-B-0208

GENERAL

All Models 1/2 - 5 tons ship as factory-charged packages.

Horizontal units are designed for suspended ceiling mounting. Horizontal models are shipped with ‘straight-through’

evaporator fan discharge as standard. Fan orientation is

field convertible to side discharge. Vertical units are

designed for free-standing floor mounting. All units are

completely factory wired and pre-piped. Water supply,

water outlet, and condensate drain connections are via

female pipe thread fittings.

WATER SOURCE HEAT PUMPS

AND WATER COOLED

AIR CONDITIONERS

HORIZONTAL & VERTICAL MODELS

1/2 - 5 TONS

CABINET

All cabinets are completely constructed of 18 Ga. corrosion

resistant “Galvalume” coated steel. The horizontal units are

complete with integral hanger channels. The entire unit

interior (both evaporator and condensing section) is insulated with 1/2” thick, 2 lb. density insulation. Service panels

are equipped with lifting handles for ease of removal and

handling. All units provide excellent service access to the

reversing valve, thermal expansion valve, and compressor

with the unit remaining in location. An integral duct collar is

provided on the blower discharge opening. An optional discharge plenum is available for Vertical models.

REFRIGERANT CIRCUITS

All models utilize hermetic rotary or reciprocating type compressors. Compressors are mounted on rubber isolators to

minimize vibration transmission. Internal overload protection is provided. External high pressure and low pressure

cutout switches are included in each compressor control

circuit. Each refrigeration circuit includes an adjustable biflow thermal expansion valve (with external equalizer),

bi-flow liquid line filter drier, and service gauge ports. The

reversing valve is a pilot operated, sliding piston type with a

replaceable magnetic solenoid coil.

The refrigerant-to-air heat transfer coils are constructed of

internally enhanced copper tubes mechanically bonded to

enhanced aluminum plate fins. The evaporator coil is

employed in a draw-through configuration. Large evaporator coil face area minimizes potential water blow-off.

The coaxial refrigerant-to-water heat exchangers feature a

convoluted inner tube design for high heat transfer efficiency. Standard models feature a copper inner tube surrounded by a steel outer tube, and carry a 400 psig water

side working pressure rating.

359583-YTG-B-0208

ELECTRICAL/CONTROLS

able, complete with an alarm output contact. An

optional remote management package allows the unit

All units are completely factory wired with all necessary

to be controlled by an external source.

operating controls. A 24 volt control circuit, with oversize transformer, is provided for field connection. Units

FILTERS

are designed to operate with conventional thermostat

control interface. The reversing valve solenoid coil

shall be energized in cooling mode only. A manual

reset is provided on each compressor control circuit in

All models are shipped with 1 inch thick throw-away fil-

ters factory installed. Filters are accessible from either

side of unit.

the event of high/low pressure cutout. A time delay

relay for anti-short cycle protection is standard in all

units. An optional condensate overflow switch is avail-

PRODUCT NOMENCLATURE

Water Cooled Package Heat Pump and AC Model Number Nomenclature

Product Category

R = Watercooled ID Package,HP

Product Identifier

P = HP, R-22 High Efficiency

Nominal Cooling Capacity - MBH

007 = 0.5 Ton

009 = 0.75 Ton

012 = 1 Ton

018 = 1.5 Ton

024 = 2 Ton

030 = 2.5 Ton

036 = 3 Ton

048 = 4 Ton Heat Type

060 = 5 Ton C00 = No Heat Option

RP 060 C00V 2L AB 1

Voltage

1 = 208/230-1-60

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

8 = 265-1-60

V = Vertical

H = Horizontal

AA = None AG = AB + AE

AB = Insulated Water Circuit(Not available on cooling only) AH = AB + AF

AC = Cooling only (No Reversing Valve) AJ = AC = AD

AD = Cupro Nickle Heat Exchanger AK = AC = AE

AE = Condensate Overflow Switch w/ Alarm output AL = AC = AF

AF = Remote Management Relay Pkg w/ Alarm output

L = Left Hand Return

R = Right Hand Return

Airflow

Additional Options

Installation Options

Product Generation

1 = First Generation

2 Johnson Controls Unitary Products

359583-YTG-B-0208

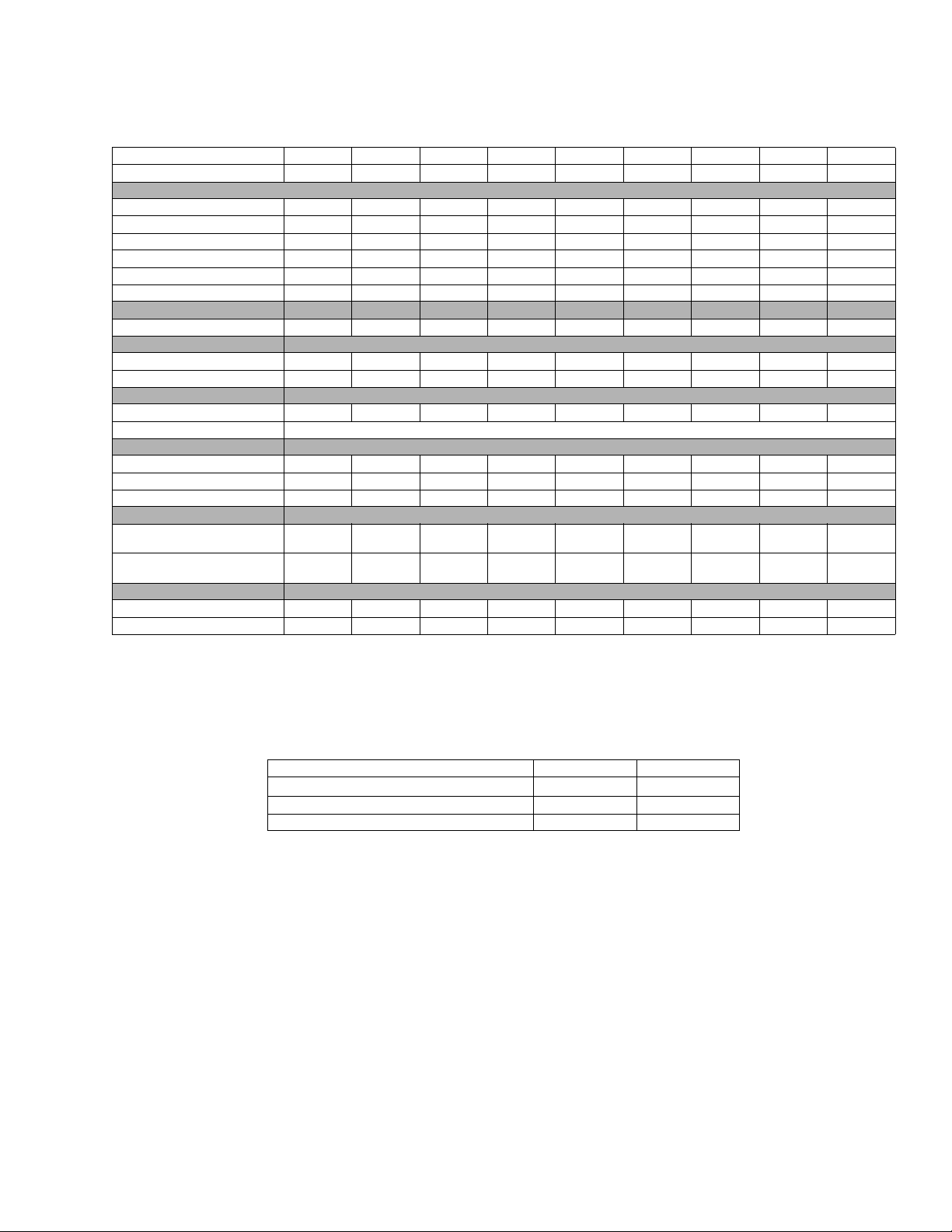

T ABLE 1: GENERAL DATA

Model Series 007 009 012 018 024 030 036 048 060

Nominal Cooling (Ton) 0.5 0.75 1.0 1.5 2.0 2.5 3.0 4.0 5.0

Cooling Performance

Cooling Capacity (BTUH) 7000 9000 12800 18100 24200 30800 36100 48200 59000

EER 12.4 13.0 12.6 14.4 14.4 13.5 14.2 14.0 12.6

Heating Capacity (BTUH) 8800 10700 14800 20900 27500 35200 41400 56000 72000

COP 4.2 4.4 4.2 4.5 4.6 4.4 4.6 4.6 4.4

Design CFM 200 300 400 600 800 1000 1200 1600 2000

Nominal Waterflow (gpm) 1.5 2.25 3.0 4.5 6.0 7.5 9.0 12.0 15.0

Compressor-Type Rotary Rotary Rotary Recip. Recip. Recip. Recip. Recip. Recip.

Number Used 111111111

Air Coil- Type Enhanced Copper Tubes, Enhanced Aluminum Fins

Face Area (sq. Ft.) 1.00 1.00 1.00 1.51 2.56 2.56 2.88 4.38 5.00

Rows/FPI 2/14 2/14 3/14 3/14 3/14 3/14 3/14 3/14 3/14

Water Coil - Type Co-Axial

Water Connection Size 1/2” FPT 1/2” FPT 1/2” FPT 3/4” FPT 3/4” FPT 3/4” FPT 3/4” FPT 3/4” FPT 1” FPT

Drain Connection Size 3/4” FPT

Direct Drive Fan-Type Centrifugal, Forward Curved

Number Used 111111111

Diameter x Width (in) 9x4 9x4 9x4 9x6 9x7 9x7 9x7 10x9 10x9

Motor HP /Speed 0.10/3 0.10/3 0.17/3 0.25/3 0.25/3 0.33/3 0.50/3 0.75/3 1.0/3

Filters

Horizontal Model - Qty. Size 1-14x16x1 1-14x16x1 1-14x16x1 1-16x20x1 1-18x25x1 1-18x25x1 1-20x25x1 2-20x20x1 1-20x20x1

Vertical Models - Qty. Size 1-14x16x1 1-14x16x1 1-14x16x1 1-16x20x1 1-18x25x1 1-18x25x1 1-20x25x1 1-16x25x1

1-14x25x1

Weight

Operating 130 135 155 180 215 235 260 325 345

Shipping 145 150 170 195 230 255 280 345 365

1-20x25x1

1-18x25x1

1-16x25x1

NOTE:

1. Performance calculated in accordance with ARI/ISO Standard 13256-1 for Water Loop Application.

2. Cooling capacities are rated at entering air conditions of 80.6ºF db / 66.2ºF wb. 86ºF entering water temperature.

3. Heating capacities are rated at entering air conditions of 68ºF db / 59ºF wb, 68ºF entering water temperature.

OPERATING LIMITS - WATER LOOP APPLICATION

Cooling Heating

Min. Entering Water 50ºF

Max. Entering Water 110ºF 80ºF

Normal Entering Water 60-90ºF 50-70ºF

*.

Heating operation below 55ºF requires insulated water circuit.

40ºF

*

Johnson Controls Unitary Products 3

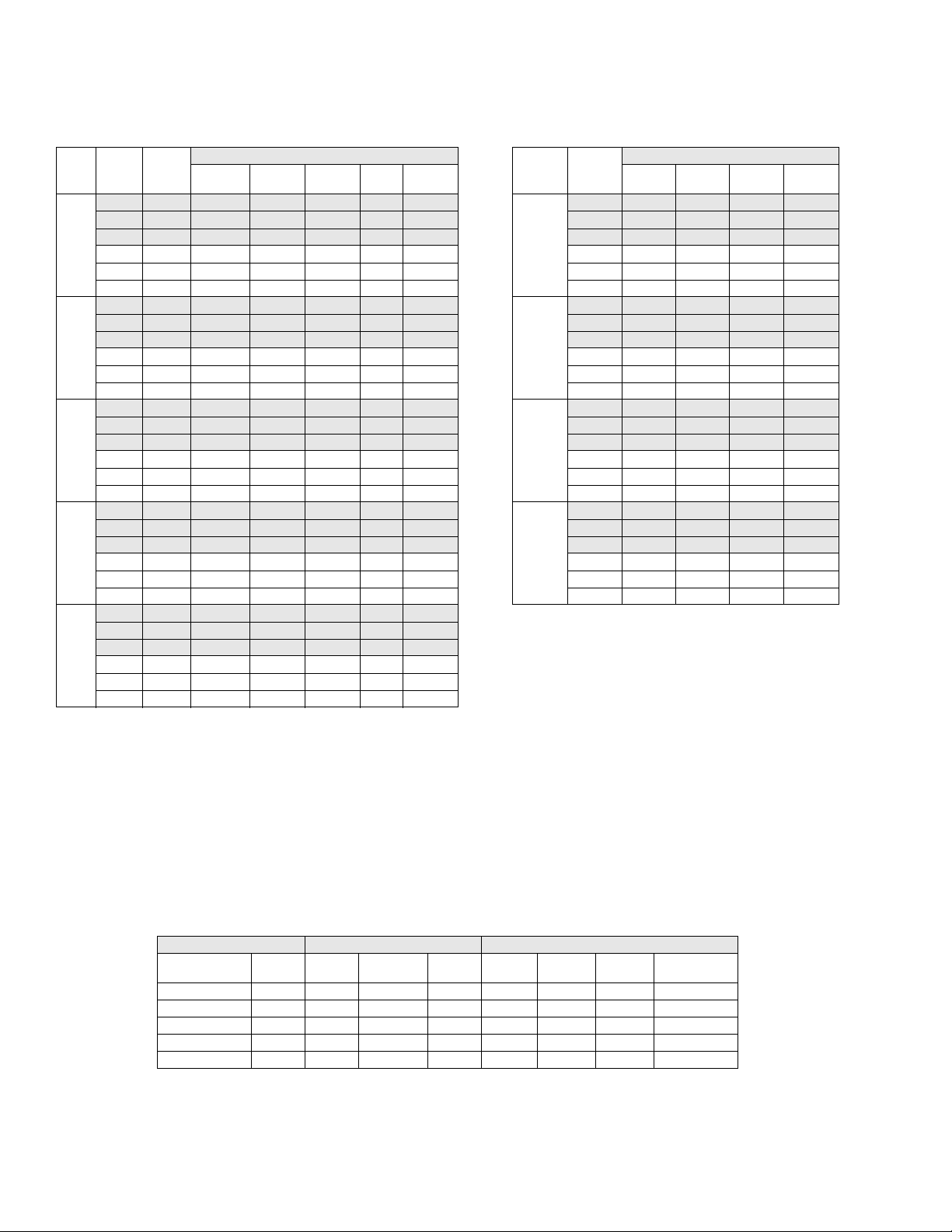

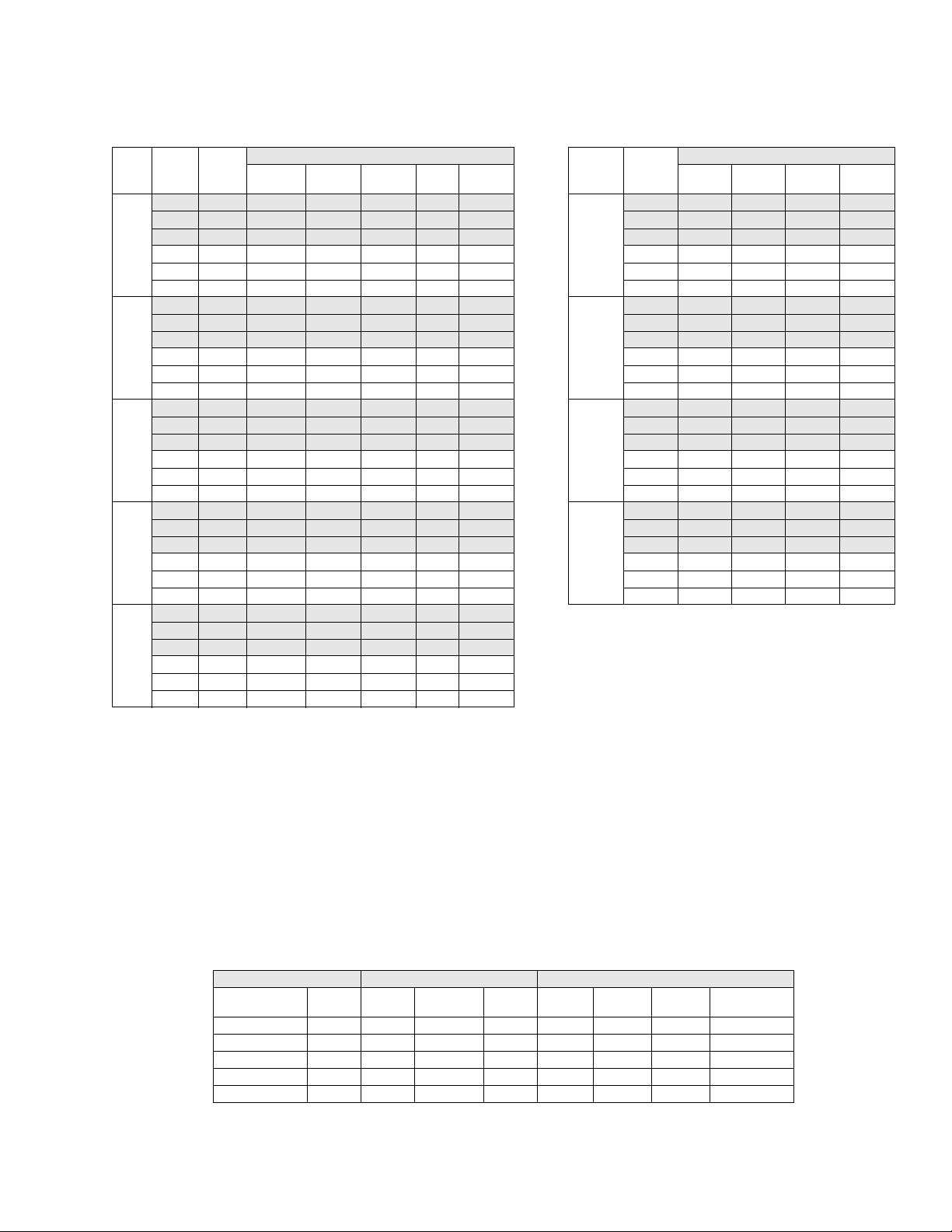

TABLE 2: RP 007 @200 CFM NOMINAL AIRFLOW VERTICAL AND HORIZONTAL MODELS

EWT

GPM

(ºF)

50

60

70

85

100

NOTE: All capacity data shown is NET - includes motor power/heat at design

CFM and HI fan speed. Tabulated kW values do not include allowance for

external pumping power.

WPD

(PSI)

1.0 0.8 80/67 7.7 5.0 0.53 9.5 1.0 70 7.2 0.63 5.0

1.5 2.0 80/67 8.1 5.2 0.48 9.7 1.5 70 7.4 0.64 5.2

1.0 0.7 80/67 7.5 5.0 0.57 9.4 1.0 70 8.0 0.66 5.7

1.5 1.9 80/67 7.9 5.1 0.54 9.7 1.5 70 8.3 0.67 6.0

1.0 0.7 80/67 7.2 4.8 0.63 9.3 1.0 70 9.1 0.69 6.7

1.5 1.8 80/67 7.6 5.0 0.59 9.6 1.5 70 9.4 0.70 7.0

1.0 0.7 80/67 6.7 4.7 0.72 9.1 1.0 70 10.0 0.72 7.5

1.5 1.7 80/67 7.1 4.8 0.67 9.4 1.5 70 10.3 0.73 7.8

1.0 0.6 80/67 6.3 4.5 0.80 9.0

1.5 1.6 80/67 6.6 4.6 0.76 9.2

EAT

(db/wb)TC(MBH)SC(MBH)

75/62 7.1 5.1 0.51 8.8

85/72 8.3 4.9 0.55 10.2 80 7.1 0.67 4.8

75/62 7.3 5.2 0.46 8.9 60 7.5 0.60 5.4

85/72 8.8 5.1 0.50 10.5 80 7.3 0.68 5.0

75/62 6.9 5.0 0.56 8.8

85/72 8.0 4.8 0.60 10.0 80 7.9 0.70 5.5

75/62 7.1 5.1 0.52 8.9 60 8.4 0.63 6.2

85/72 8.6 5.0 0.56 10.5 80 8.2 0.71 5.8

75/62 6.6 4.9 0.61 8.7

85/72 7.7 4.7 0.66 9.9 80 9.0 0.73 6.5

75/62 6.8 5.0 0.57 8.7 60 9.5 0.66 7.3

85/72 8.3 4.9 0.62 10.4 80 9.3 0.74 6.7

75/62 6.2 4.7 0.70 8.6

85/72 7.2 4.5 0.75 9.7 80 9.8 0.76 7.2

75/62 6.4 4.8 0.65 8.6 60 10.5 0.69 8.1

85/72 7.8 4.7 0.70 10.2 80 10.2 0.77 7.5

75/62 5.8 4.6 0.77 8.4

85/72 6.7 4.3 0.84 9.6

75/62 6.0 4.6 0.73 8.5

85/72 7.2 4.5 0.80 9.9

Cooling

KW

THR

(MBH)

EWT(ºF) GPM

50

60

70

80

359583-YTG-B-0208

Heating

EAT

(db)HC(MBH)

60 7.2 0.59 5.2

60 8.1 0.62 5.9

60 9.2 0.65 7.0

60 10.1 0.68 7.8

KW

H Absrp.

(MBH)

TC = TOTAL COOLING CAPACI TY

SC = SENSIBLE COOLING CAPACITY

THR = TOTAL HEAT REJECTION

HC = TOTAL HEATING CAPACITY

WPD = WATER PRESSURE DROP

AIR FLOW CORRECTION FACTORS

AIRFLOW HEATING COOLING

OF

%

Nominal

80 160 0.986 1.058 0.969 0.966 0.893 0.992 0.971

90 180 0.993 1.029 0.985 0.983 0.947 0.996 0.986

100 200 1.000 1.000 1.000 1.000 1.000 1.000 1.000

110 220 1.007 0.977 1.014 1.011 1.049 1.004 1.011

115 230 1.010 0.965 1.021 1.017 1.074 1.006 1.016

CFM HC

Input

Power

4 Johnson Controls Unitary Products

Heat

Absrp.

TC SC

Input

Power

THR

359583-YTG-B-0208

TABLE 3: RP 009 @ 300 CFM NOMINAL AIRFLOW VERTICAL AND HORIZONTAL MODELS

EWT

GPM

(ºF)

50

60

70

85

100

NOTE: All capacity data shown is NET - includes motor power/heat at design

CFM and HI fan speed. Tabulated kW values do not include allowance for

external pumping power.

WPD

(PSI)

1.35 1.4 80/67 10.0 6.9 0.56 11.9 1.35 70 8.1 0.66 5.8

2.25 3.5 80/67 10.2 7.0 0.54 12.0 2.25 70 8.5 0.68 6.2

1.35 1.4 80/67 9.7 6.8 0.62 11.8 1.35 70 8.7 0.69 6.3

2.25 3.5 80/67 9.9 6.8 0.59 11.9 2.25 70 9.6 0.72 7.1

1.35 1.4 80/67 9.3 6.6 0.67 11.6 1.35 70 10.4 0.76 7.8

2.25 3.5 80/67 9.5 6.7 0.65 11.7 2.25 70 11.1 0.79 8.4

1.35 1.4 80/67 8.8 6.4 0.75 11.3 1.35 70 11.6 0.81 8.8

2.25 3.5 80/67 9.0 6.5 0.74 11.5 2.25 70 12.1 0.83 9.3

1.35 1.4 80/67 8.3 6.2 0.84 11.2

2.25 3.5 80/67 8.4 6.3 0.83 11.2

EAT

(db/wb)TC(MBH)SC(MBH)

75/62 9.1 7.0 0.55 11.0

85/72 10.8 6.7 0.57 12.7 80 8.0 0.70 5.6

75/62 9.2 7.0 0.53 11.0 60 8.6 0.64 6.5

85/72 11.1 6.8 0.56 13.0 80 8.4 0.72 6.0

75/62 8.8 6.8 0.61 10.9

85/72 10.5 6.6 0.64 12.7 80 8.6 0.73 6.1

75/62 8.9 6.9 0.58 10.9 60 9.7 0.68 7.4

85/72 10.7 6.7 0.61 12.8 80 9.4 0.76 6.8

75/62 8.5 6.7 0.66 10.7

85/72 10.1 6.5 0.69 12.4 80 10.3 0.81 7.5

75/62 8.6 6.8 0.64 10.8 60 11.3 0.74 8.7

85/72 10.4 6.6 0.66 12.6 80 11.0 0.84 8.1

75/62 8.0 6.5 0.74 10.5

85/72 9.6 6.3 0.78 12.3 80 11.4 0.86 8.5

75/62 8.1 6.5 0.73 10.6 60 12.3 0.78 9.7

85/72 9.8 6.4 0.77 12.4 80 12.0 0.88 9.0

75/62 7.5 6.3 0.82 10.3

85/72 9.0 6.1 0.87 12.0

75/62 7.6 6.3 0.81 10.4

85/72 9.1 6.2 0.86 12.0

Cooling

KW

THR

(MBH)

EWT(ºF) GPM

50

60

70

80

EAT

(db)HC(MBH)

60 8.2 0.62 6.0

60 8.8 0.65 6.6

60 10.6 0.71 8.1

60 11.8 0.76 9.2

Heating

KW

H Absrp.

(MBH)

TC = TOTAL COOLING CAPACI TY

SC = SENSIBLE COOLING CAPACITY

THR = TOTAL HEAT REJECTION

HC = TOTAL HEATING CAPACITY

WPD = WATER PRESSURE DROP

AIR FLOW CORRECTION FACTORS

AIRFLOW HEATING COOLING

% OF

Nominal

80 240 0.986 1.058 0.969 0.966 0.893 0.992 0.971

90 270 0.993 1.029 0.985 0.983 0.947 0.996 0.986

100 300 1.000 1.000 1.000 1.000 1.000 1.000 1.000

110 330 1.007 0.977 1.014 1.011 1.049 1.004 1.011

115 345 1.010 0.965 1.021 1.017 1.074 1.006 1.016

CFM HC

Input

Power

Johnson Controls Unitary Products 5

Heat

Absrp.

TC SC

Input

Power

THR

Loading...

Loading...