YMGI VRFO-96VP-U2C(55)5, VRFO-240VP-U2C(55)5, VRFO-264VP-U2C(55)5, VRFO-120VP-U2C(55)5, VRFO-312VP-U2C(55)5 Installation Instructions & User Manual

...

YMGI • Your Modern Green Idea

YMGI: Engineered Comfort Products for An Efficient

and Sustainable Green World!

INSTALLATION INSTRUCTIONS & USER'S MANUAL

DC Inverter Multi Variable Refrigerant Flow (VRF) System

VRF Heat Pump Ultra Heating

8, 10 & 12 Ton Top Discharge Outdoor Unit

For Model Numbers:

VRFO-72VP-U2C(55)5

VRFO-96VP-U2C(55)5

VRFO-120VP-U2C(55)5

NOTICE

This product is designed and manufactured to be free from any defects in material and workmanship during normal use and

maintenance. Installation, operation, maintenance and repairs must follow all standards and professional practices for regular

cooling and heating equipment, such as NEC, State, or Local Codes and all related documents/manuals provided by YMGI.

Failure to follow and adhere to all codes and documentation can cause damage to equipment, property or even personal injury.

Installer: Must be currently licensed/certified HVAC technicians only. Must Read the manual and all provided documents prior

to installation. Complete and fill out all required information on the Warranty Registration Card.

User: Retain this manual and all supplied documents for your records and future reference.

Servicer: Use this manual for information concerning servicing and maintenance of this product.

SAFETY WARNING

Only qualified technicians should install and service this equipment. The installation, startup, operation and servicing of this

equipment can be hazardous and requires a HVAC professional who has been trained, licensed and certified. Installations,

adjustments or any equipment alterations done by an unqualified person could result in serious injury and even death. When

working on the equipment, observe all precautions in the provided documents, on the tags, stickers, and labels that are attached

to or placed on the equipment.

Thank you for choosing this YMGI product. Please read the user’s manual carefully before installation/operation and retain for your

records and future reference. If you need a replacement copy, please contact your local agent or visit www.ymgigroup.com to

download a current electronic version.

1

YMGI • Your Modern Green Idea

TABLE OF CONTENTS

Introduction ............................................................................................................................................. 3

Note from YMGI – Must Read ................................................................................................................ 5

Installing Technician/Contractor's Responsibilities ................................................................................. 7

Limited Product Warranty ........................................................................................................................ 8

Limited Product Warranty Registration Card ........................................................................................... 10

Why Does YMGI Group Require Installation and Service to Be Performed

100% by Currently Licensed or Certified HVAC Technicians/Contractors .............................................. 11

Suggestions to Aid You in Hiring an HVAC Contractor .......................................................................... 11

Safety Precautions ................................................................................................................................... 12

Product Information .................................................................................................................................. 13

Preparation before Installation ................................................................................................................. 14

Installation Site ......................................................................................................................................... 14

Installation Instructions ............................................................................................................................ 16

Dimensions of Outdoor Unit(s) ................................................................................................................. 16

Piping Work Requirements ...................................................................................................................... 21

Connection Pipe ........................................................................................................................................ 23

Allowable Pipe Length and Drop Height .................................................................................................. 25

Fitting Pipe between Outdoor Unit and Manifolds ................................................................................... 28

Installation of Connection Pipe ............................................................................................................... 33

Air Purging and Refrigerant Charge ........................................................................................................ 37

Electric Wiring .......................................................................................................................................... 39

System Communication .......................................................................................................................... 42

Communication Connection between IDU and Wired Controller ............................................................. 48

Check Items after Installation and Trial Run ............................................................................................ 54

Debugging ................................................................................................................................................ 56

Appendix: Judgement Reference of Normal Operational Parameters .................................................... 65

Common Malfunction and Troubleshooting ............................................................................................ 67

Error Codes .............................................................................................................................................. 68

Debugging Codes .................................................................................................................................... 70

Status Codes ............................................................................................................................................ 70

Maintenance and Care ............................................................................................................................. 71

User Notes and Installation/Service/Maintenance Notes ........................................................................ 72

2

YMGI • Your Modern Green Idea

Indicates a potentially hazardous situation which, if not avoided, could result in

serious injury or even death.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It is also used to alert against unsafe practices.

Indicates a situation that could result in equipment or property-damage only. It

can also be used to call attention to important details within this manual.

Introduction

Read this manual carefully, making sure you understand all the instructions, practices and procedures contained in

this manual. Be sure you are familiar with all the safety advisories that appear throughout this manual. Your personal

safety depends upon your observance of all precautions contained in this manual.

The 3 types of advisories are defined in the following table:

Important Environmental Concerns

Studies have shown that certain man-made chemicals can affect the earth’s stratospheric ozone layer when released

into the atmosphere. Refrigerants that contain Chlorine, Fluorine and Carbon (CFCs) and those containing Hydrogen,

Chlorine, Fluorine and Carbon (HCFCs), may affect the ozone layer. Not all refrigerants have the same potential

impact on the environment. YMGI Group advocates for the responsible handling of all refrigerants including industry

replacements for CFCs such as HCFCs and HFCs.

Responsible Refrigerant Practices

YMGI Group believes that responsible refrigerant practices are important to our customers, the HVAC/R industry and

the environment. All HVAC/R technicians who handle refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling, reclaiming, recovering and recycling of certain refrigerants,

the equipment and tools necessary to perform these service procedures. In addition, some states or municipalities

may have additional requirements that must also be adhered to for responsible management of refrigerants. HVAC/R

technicians must know the applicable laws and follow them.

Disposal Notice

Do not dispose of this product or its components as unsorted municipal waste, as they contain items that may require

special treatment. Contact your local waste management company for details.

Proper Field Wiring and Grounding Required!

Failure to follow established electrical codes can result in death, serious personal injury and property damage. All

field wiring MUST be performed by qualified personnel, such as a currently licensed electrician. Improperly installed

and grounded field wiring poses FIRE and ELECTROCUTION hazards. To avoid these hazards, you MUST follow

the requirements for field wiring installation and grounding as described in this manual, by NEC and your state/local

electrical codes.

Personal Protective Equipment (PPE) Required!

Failure to wear proper PPE for the job being undertaken could result in serious injury or even death. Technicians

must take the necessary precautions to protect themselves from potential electrical, mechanical, and chemical

3

YMGI • Your Modern Green Idea

hazards and MUST follow all precautions in this manual and on the tags, stickers, and labels, as well as the

instructions below:

• Before installing or servicing this unit, technicians MUST put on all PPE recommended for the work being

undertaken. ALWAYS refer to appropriate Material Safety Data Sheets (MSDS) and Occupational Safety and

Health Administration (OSHA) guidelines for proper PPE.

• When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable personal exposure levels, proper respiratory protection, and

handling recommendations. If there is a risk of arc or flash, technicians MUST put on all PPE in accordance

with NFPA 70E or other country-specific requirements for arc flash protection, PRIOR to servicing the unit.

Copyright

This document and the information contained therein are the sole property of YMGI Group and shall not be used or

reproduced in whole or in part, without the written permission of YMGI Group. YMGI Group reserves the right to

revise this manual at any time and to make changes to its content without obligation to notify anyone about any

modifications, revisions or changes.

• Instructions for installation and use of this product are provided by the manufacturer.

• Installation must be performed by authorized and licensed personnel only and in accordance with all the

requirements of this manual, the NEC, CEC and any state/local codes.

• For safe operation of this unit, please read and follow all instructions carefully.

• The total operation capacity of the indoor units should not exceed 120% of the total capacity of the outdoor units

if all indoor units must operate at their peak capacities all the time. Otherwise, the heating and cooling operation

will be diminished and less efficient which could damage the units.

• Any person responsible for system operation or system maintenance should retain this manual for reference.

• If the unit fails to operate normally, please contact your authorized system installer or HVAC professional as soon

as possible and provide the following information:

Data on the unit (model number, serial number and owner’s name).

A detailed description of the unit’s problem before and after the problem occurred.

• To avoid personal injury or property damage, do not disassemble the unit yourself. If disassembly is required to

check the unit, contact your authorized system installer or HVAC professional as they have the experience and

training necessary to perform this task.

Note: Each unit has been thoroughly tested to ensure it operates correctly before leaving the factory.

Basic Cautions and Warnings

All units shall be installed by an experienced HVAC licensed contractor or technician. Read all manuals before

installation, startup and operation.

All NEC, state, local codes and installation instructions must be followed for all units, otherwise, the unit warranty will

be void and could result in serious damage to people or property.

YMGI Group is not responsible for any damage or loss due to Do-It-Yourself (DIY), self-installation or any improper

installation, operation, service or natural disasters of any kind.

Do not connect power to the unit until all wiring, tubing and all unit inspections and tests have been completed.

Ground the unit according to the instructions and adhering to NEC, state and local codes.

All wiring connections must be correct and secure. Loose wire(s) or improper contacts may cause arcs or overheating

which can result in a fire hazard.

4

YMGI • Your Modern Green Idea

Note From YMGI – Must Read

Dear Customers, Installers, and Contractors

Thank you for choosing a YMGI product.

All YMGI's products are fully tested and have passed rigorous safety, performance and manufacturing standards

before being packed and shipped. YMGI only uses suppliers that meet our strict standards for high quality and

performance for all parts. YMGI also recognizes a quality installation is equally important therefore your system

must be installed by a licensed HVAC professional. A quality installation ensures your unit will operate at its highest

efficiency and peak performance for many years of worry free comfort; while a poor installation can result in unit

failure and cause the unit to operate inefficiently, either immediately or over time, resulting in costly repairs.

Because a quality installation is so critical, YMGI provides detailed information in our manuals which will aid the

installing technician and the owner of the unit(s).

At YMGI our goal is to ensure that your YMGI units are installed properly and correctly from the beginning.

The YMGI equipment you purchased is either a split-type or a self-contained cooling/heating system. These types of

systems require a certified and licensed HVAC professional technician for proper installation. Only a certified and

licensed HVAC professional technician will have the knowledge, experience, and attention for all required details to

perform a complete and successful installation. This equipment is different from a window or portable type air

conditioners you can purchase from local big box and retail stores which the manufacturer may not require certified

and licensed personnel to install.

Reading and following YMGI Group recommendations and requirements contained in the following pages and other

documents, is the first step to help ensure a smooth installation and proper operation of your unit for many years.

YMGI does not recommend nor allow any Do-It-Yourself (DIY) installation (partially or fully). Due to the complexity

of the installation of this product most DIY installations usually have problems, either immediate or in the near

future. These problems can cost more to fix than any upfront savings. YMGI warranty does not cover any DIY

units.

If you have any questions about your unit or if the unit has a problem, you should first check the manual. If you can’t

find a solution, then contact your local installer or service technician to schedule a service appointment. The

technician can physically inspect the unit. If at the time of inspection, the installer or service technician has any

questions about the unit, they can contact YMGI technical support division directly at:

Toll Free Number: (866)833-3138 or Email: techsp@ymgigroup.com

IMPORTANT: YMGI Group is the MEDIA AUTHORITY:

YMGI Group, located in O'Fallon, MO 63366 is the author of all media produced for its products and is the only party

able to give any additional explanation for any data, definitions and or descriptions found within any of its media,

including but not limited to YMGI product brochures, manuals, pamphlets, catalogs, and videos. YMGI's distributors,

installers, dealers, agents, customers or any other third parties will not supersede YMGI in anyway concerning YMGI

published materials and their meaning. Any concerns or questions arising from YMGI distributors, installers, dealers,

agents, customers or any other third parties, should be presented directly to YMGI. YMGI will respond to any concerns

or questions, if necessary, about any of its media in writing.

5

YMGI • Your Modern Green Idea

Be sure to only hire a certified and currently licensed HVAC Company to complete 100% of the installation so

that all details of the installation are performed correctly and completely.

Factory Warranty will be void if any portion of the installation is not performed by a licensed HVAC

contractor/technician. DIY or partial DIY will also void ALL factory warranties.

Hiring an HVAC technician that is offering their services as a "side job" rather than a licensed HVAC company

may pose possible risk. This may result in an incomplete or unsatisfactory installation, no guarantee for

workmanship, maintenance or further service to your unit.

Have the installation technician read in full the installation manual and all supplied documents for the product

model you purchased. Details within the provided documentation contributes greatly to the success and quality

of the installation. Experience with other manufacturers may not be applied fully to another manufacturer,

although there will be similarities there will also be differences. Ignoring the provided installation procedures is

an act of negligence and may cause unit failure or damage which could be permanent.

It is possible for a licensed contractor/technician to make a mistake during the installation. YMGI does not

supervise nor is able to control the contractor/technician’s installation. It is critical that the installer take each

variable into account during the initial installation. This will ensure a complete and professional

installation and that all units work properly.

The following will damage the unit and its key components resulting in loss of factory warranty:

1. Any foreign substances introduced into the system because of failure to seal the ends of the refrigeration piping

before pulling the piping through any structures at time of installation.

2. Not installing an oil P-trap in the copper suction line where the indoor unit is located 18 feet or more below the

outdoor unit.

3. Cross piping and/or cross wiring of any units including more than one single zone or a multi zone system.

4. Not conducting a positive leak check by charging the system with dry-nitrogen and performing soap bubble

testing.

5. Not conducting a negative leak check by evacuating the copper lines for 30 minutes. The vacuum must be held

at 500 microns or better for at least 5 minutes, starting a 5-minute timer after the vacuum pump is turned off.

6. Not conducting a positive leak check prior to the negative leak check.

7. Not selecting the correct size wire or circuit breaker.

8. Not answering ALL questions in the technician's checklist located inside the warranty registration form.

The following may be overlooked, ignored, or considered unimportant during your installer's installation,

but will cause your unit to underperform and may cause unit failure.

1. Any kinks in or improper bending of the copper piping.

2. Any poorly formed flares, not centering the flare with the flare nut, or not tightening all connections.

3. Not trial testing each indoor unit individually.

4. Not reading technical data (temp/time/pressure/current) after the system is stabilized (normally the compressor

needs to run at least 10 minutes before reading the data). If the data is read too early, it may lead to inaccurate

assessments about the unit.

In an effort to help protect our customers from possible faulty installations that can lead to premature unit failure,

YMGI provides the above information for you (the owner) and the technician. You can observe while your system is

being installed, even though your observation is not a guarantee your system is being or has been installed properly

and professionally. With the information provided above, you will know some things to look for and questions you can

ask. If at any time you feel there may be an issue with the installation, please have your technician contact YMGI at

(866)833-3138 x 703 with any questions, issues or concerns you may have.

6

YMGI • Your Modern Green Idea

INSTALLING TECHNICIAN/CONTRACTOR'S RESPONSIBILITIES

Discuss with the customer detailed information about the structure to be conditioned, local weather (typical design, extreme

temperature/humidity conditions, cooling and heating hours), previous and existing HVAC equipment (if any), usage and dependence

on new HVAC equipment or YMGI products.

Performing a cooling/heating load calculation by using commercially available professional programs/methods such as Right-J

(Manual J) for residential HVAC applications and Right-CommLoad (ASHRAE RTS/CLTD) for light commercial and commercial

HVAC applications.

Contact your YMGI distributor/sales department or contact YMGI directly to obtain additional information to fully understand your

YMGI products, including but not limited to product features, cooling/heating performance at standard ratings/conditions and extreme

conditions, allowed indoor and outdoor temperature and humidity ranges, installation, operation, maintenance, service, warranty,

parts and any other issues pertaining to YMGI products.

Select the correct (most suitable) YMGI product unit models and accessories necessary for your HVAC applications and list them in

the proposal/quote, in writing, on company's quotation form or letter head, based upon the information you collected from 1, 2 and 3

listed above.

List your currently valid HVAC license number and EPA number in your proposal/quote.

Make sure you are the only party to perform the entire installation and you will not sub-contract any part of the installation to any

unlicensed parties or persons. You will be solely responsible for the entire installation that you have been contracted.

Make sure you have all the materials you need to properly, completely and correctly finish the installation. The YMGI units and

accessories may be just a portion of what you will need for the project. When support issues arise, remember YMGI employees and

YMGI distributors/sales, dealers and agents are not installers and may only provide suggestions. You are the only one qualified to

determine what other materials you need to complete the installation.

When connecting electrical wires, follow all NEC, state and local codes and ensure the installation of all YMGI units and accessories

meet these requirements.

Connect the unit to a correctly sized electrical power source. If the unit is installed in an area where lightning or storms occur

frequently, a correctly sized and type of power surge protector must be installed between the outdoor unit and the power source.

Select the correct types and sizes of HVAC circuit breakers, disconnect switch boxes, wires and conduit from circuit breaker to

disconnect box and then from disconnect box to outdoor unit.

Select the proper location for installing indoor units and outdoor units with all factory requirements being followed (cooling/heating air

inlets and outlets are not blocked, or restricted, mounting structure is secure, installation for convenience is considered, allow

adequate clearance for maintenance/service and all applicable codes are met).

Cap/tape the two ends of every copper line before running them through any structure to keep any foreign substances from entering

the copper line causing contamination. Label the copper lines A-A, B-B, C-C, D-D, or any other identifying marks on each pair of

copper lines and wiring cable sets to keep from cross-piping or cross-wiring in multiple zone installations or where pipes for different

single zone systems are close to one another.

Secure the wiring cables that connect between the indoor unit and outdoor unit, following all applicable NEC, state and local codes

for your installation. If there are no special NEC, state or local codes to govern how these wires are to be installed, you can tape/cable

tie them along with insulated copper line.

Tighten all pipe and wire connections ensuring there is no leakage or false/loose connections.

Conduct a positive pressure leakage test, checking each of the inter-connecting copper lines between each indoor unit and outdoor

unit by charging with dry-nitrogen at the outdoor unit’s service port (NOTE: do not back-seat stopping valve). A liquid soap solution

shall be applied at all pipe connections to check for leakage. A 1/4” - 5/16” hose/valve adaptor may be needed if you have a 1/4”

traditional manifold hose connection.

If there is no positive leaking, then conduct a negative pressure leakage test, checking all inter-connecting copper lines between each

indoor unit and outdoor unit by pulling vacuum at the outdoor unit’s service port ( NOTE: do not back-seat stopping valve) and

checking that a vacuum level of 500 Microns can be held for at least 20 minutes.

If there is no leakage found at any of the refrigeration pipe connections, flip up the indoor unit’s face panel and remove its filter,

carefully pour some clear water onto the up-right aluminum coil surface to test if the water can drain freely out of each of the indoor

unit’s without finding any leakage.

If there is water leakage found, locate the source of the leak and correct it. Only after everything is clear and all the necessary

inspections made, engage the correct electrical power to the system.

Then back-seat stopping valves of the outdoor unit to release refrigerant from the outdoor unit into the inter-connecting pipes and the

indoor unit.

Make sure both the indoor unit and outdoor unit are powered on correctly, operating the indoor unit in fan mode first. Then move on

to test cooling, dehumidifying/drying, heating and other modes.

Read refrigerant pressures and pipe/valve temperatures only after the system is stabilized (normally 10 minutes after cooling/heating

mode is started successfully). Record this data into the technician checklist in the lower half section of the Limited Product Warranty

Registration Card/Form.

Adjust refrigerant charging level (remove refrigerant if pipe is shorter, the temperature is colder; add refrigerant if pipe is longer the

temperature is warmer), following the manufacturer's instructions. If the average pipe length is shorter or longer than 25' and

pressure/temperature readings at the outdoor unit service valves are not falling into normal ranges.

Explain to the user/owner about proper unit operation and maintenance. Leave your contact information to allow them to reach you.

If the customer finds the unit does not work properly and cannot resolve the issue themselves, check the customer's

units/parts/accessories and correct the issue if there is one. Communicate with YMGI-technical support line at (866)833-3138 x 703,

if further help if necessary.

Following these requirements will aid in ensuring that the units to be installed meet general HVAC practicing standards and necessary

factory requirements. Finding any possible problems early and preventing any further damage to the unit will help to ensure a properly

working unit for many years.

7

YMGI • Your Modern Green Idea

LIMITED PRODUCT WARRANTY

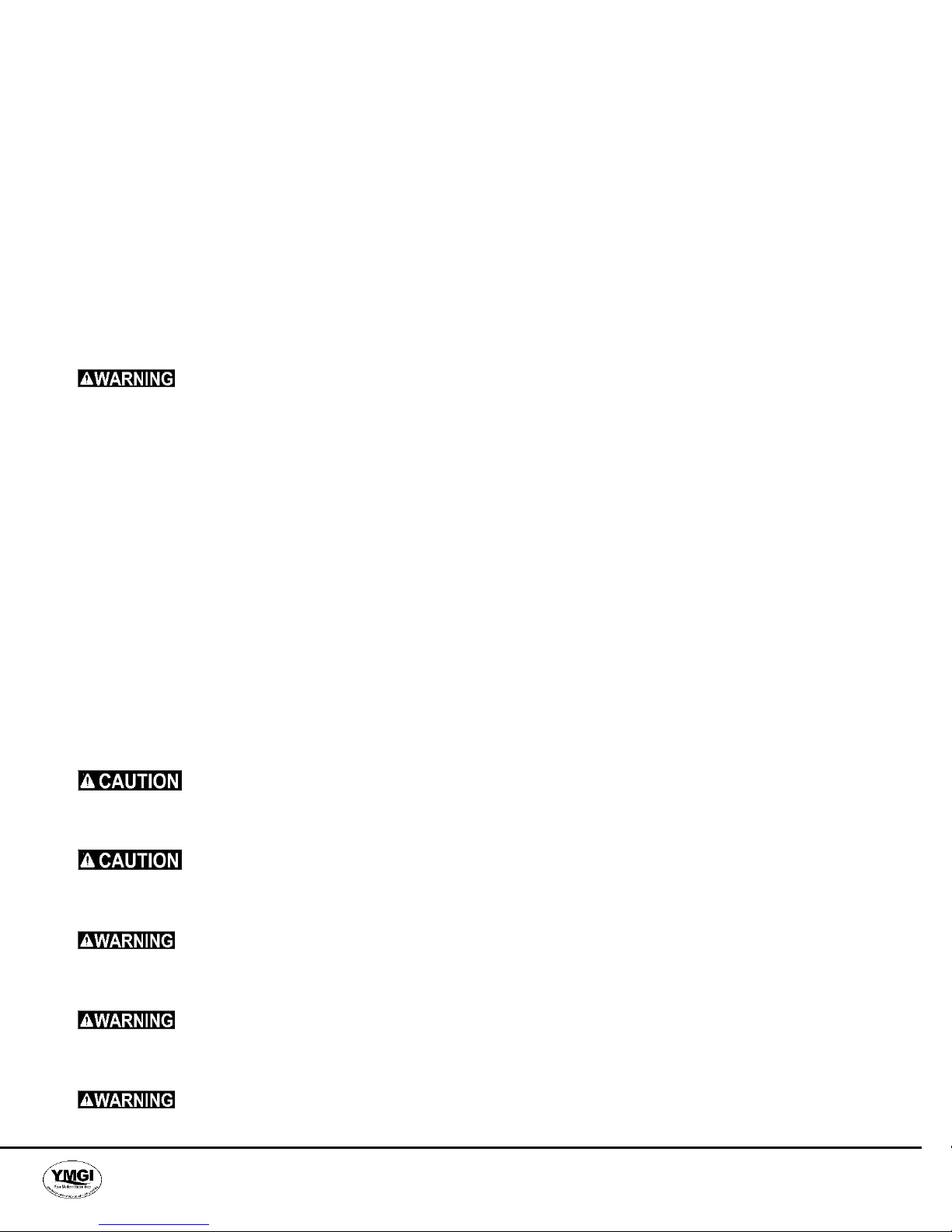

Once the installation and successful testing of the system has been completely performed by a qualified

licensed/certified HVAC technician/contractor, the registration card/form is filled out completely and correctly, mailed

and filed along with a valid installation invoice from the contractor within 7 days of the original installation, the following

standard Limited Product Warranty is qualified: 10-years on the compressor and 5-year on PARTS ONLY. There

is no labor coverage.

YMGI products are designed and manufactured free from defects in workmanship, and materials for normal use.

However, if for any reason, including occasionally transporting between YMGI factories/warehouses and your delivery

location, you discover the unit has issues, YMGI Group will help field a solution by following YMGI’s established

warranty procedures:

Compressor: YMGI will warrant the compressor of a YMGI-validated and approved warranty filing, for a period of 10

years from the date of successful installation at its original installation location.

Parts: YMGI will warrant parts of a YMGI-validated and approved warranty filing, for 5 years from the date of

successful installation at original installation location.

All warranty compressors and parts replaced will become the sole property of YMGI Group and must be returned

upon request. Warranty parts may be new or refurbished. All parts are tested and approved before shipping. At no

time does YMGI Group warrant labor cost of any type. Warranty will start from the date of a successful

installation at the original installation location, or 90 days as of original shipping date from YMGI Group,

whichever comes first.

This is a standard limited liability warranty and DOES NOT cover the following:

• Any damage or repairs to properties, or persons as an incident of or consequence of improper faulty

transportation, installation, operation, maintenance or service.

• Any damage caused by frozen or broken water hoses or refrigeration pipes in the event of equipment failure.

• Any damage due to floods, fire, wind, lightening, accidents, corrosive atmosphere.

• Any damage due to interruption or inadequate electrical service to equipment.

• Any products that are installed outside the US or Canada.

• Any unit that has been moved from its original installation address.

• Any labor costs associated with the installation or service of the unit.

• Poor unit performance due to improper unit selection (SEER, Unit size).

To validate the above warranties, ALL of the following conditions must all be fulfilled:

1. The unit was fully (100%) and successfully installed by a licensed or certified HVAC technician.

2. The unit was installed following all NEC, state and local codes.

3. The unit was installed following all the information within the Instructions and User Manuals provided by YMGI

Group.

4. ALL fields, especially the technician-checklist, of the Limited Warranty Registration Card/Form were filled out

completely by the installing technician and signed by both the installing company’s technician and the unit owner.

5. The Limited Warranty Registration Card/Form and a copy of the original installing company's invoice have been

received by YMGI Group-Warranty Dept., POB 1559, O'Fallon, MO 63366, within 7 days of successful installation.

No warranty filing will be validated or approved, if any one of the above conditions are not

met. Product registration does not guarantee the validity of this limited warranty statement.

8

YMGI • Your Modern Green Idea

Steps to follow for warranty part replacement:

1. The installing or service technician must contact YMGI tech support at 1-866-833-3138 ext. 703 from the

installation location to check and confirm with YMGI Technical support the exact part(s) needed to fix the

problem(s).

2. YMGI will check the customer's warranty filing. There will be no charge for Parts with a validated and approved

warranty. Any Parts needed for warranties that have not been validated and approved or have an invalid

warranty filing (resulting in an unapproved warranty request), will be charged accordingly.

3. YMGI will ground ship the parts ASAP. Expedited shipping is available at the customer's expense.

4. Replacement parts that have an approved warranty registration are to be warrantied for the remainder of the

5year on parts and a 10-year compressor warranty. Purchasing of replacement parts without a valid warranty

filing or unapproved warranty request, will be sold as is and are not covered by any warranty.

5. YMGI is continually improving products with various engineering changes and these changes are made without

prior notice. Such improvements or changes include but are not limited to product specification, appearance,

functionality, size, packaging, etc. These improvements or changes will not void the limited warranty stated

herein. YMGI is the final authority concerning this warranty policy.

9

YMGI • Your Modern Green Idea

10

YMGI • Your Modern Green Idea

WHY DOES YMGI GROUP REQUIRE INSTALLATION AND SERVICE TO BE PERFORMED

100% BY CURRENTLY LICENSED OR CERTIFIED HVAC TECHNICIANS/CONTRACTORS?

Expertise and Safety:

They have the training and experience to accurately and safely install and service your equipment. The equipment

runs with high-pressure refrigerant, oil and electrical current. The copper lines must be installed properly to prevent

leakage and foreign substances from contaminating the refrigerant system.

You will save money in the long run:

If any problem occurs with the unit that has been fully installed by a currently licensed or certified

technician/contractor, contact the original licensed or certified HVAC technician to evaluate the unit as they have

the training and experience to correct the problem quickly and efficiently. A technician may be unwilling to repair

an issue on a unit that they did not install. If you do find a technician willing to perform this service, there is an

increased possibility of higher service fees, increased service visits, or delayed service from that technician.

It's the law!

The federal, state and/or local government and authorities have various governing laws or regulations, guidelines,

ordinances, etc. These laws may require only licensed or certified professionals can install and service this type

of high pressure HVAC equipment.

SUGGESTIONS TO AID YOU IN HIRING AN HVAC CONTRACTOR:

Hire a currently practicing, licensed/certified HVAC professional technician/contractor. Technicians, who are no

longer practicing (retired, etc.) in this field, may not have current technical knowledge or may lack experience on

the equipment you have purchased.

Hiring a licensed technician to install your unit as a "side job" rather than a licensed HVAC company may pose

possible risk. This may result in an incomplete or unsatisfactory installation, no guarantee for workmanship and

lack of maintenance and further service to your unit.

Hire a technician/contractor who services customers in your local area and one you are familiar with. Local

contractors have a faster response time and it will be easier for you to determine if they are reputable.

Use only a reputable licensed/certified HVAC installation professional to prevent any unexpected charges

because of unethical business practices.

Check their references, verify they provide professional service for their customers. N.A.T.E or A.C.C.A certified

technicians are strongly recommended.

Some contractors/technicians may not feel comfortable installing equipment that has been purchased by

someone other than themselves. You can contact YMGI directly to check and see if there are contractors in your

area who have installed our products or any similar products.

Ask for a detailed quote for the complete installation project. A flat rate quote is the safest contract for both you

and the contractor.

Local HVAC technicians may charge you on a project basis or on an hourly basis. It has been our general

experience; a full single head installation normally can cost $800 to $1500. These costs are estimates, and

your actual costs may differ due to your specific job requirements and installation location.

Number of hours can vary depending upon each individual situation, some factors are, but not limited to:

Difficulty or complexity of securely installing the indoor unit.

Difficulty or length of the inter-connecting pipes and wires to be installed.

A successful installation is dependent on all these suggestions and necessary steps are followed.

If the contractor(s)/technician(s) are experienced with the systems/brands you purchased. You might save on

the installation cost but remember to always ask for and verify references.

The contracts should list and detail all work to be performed and the standards they will follow. Some contractors

are willing to include a 1-year installation/service warranty at no extra charge. Check to see if this is an available

option. If available, make sure it is included in the contract.

Verify and confirm the installation is completed and all the unit functions have been tested and working properly.

All items on the checklist should be checked and clearly marked in the warranty registration card/form, prior to

paying the contractor in full.

The cost of not having your unit professionally installed can be more expensive than the additional cost of hiring a

certified contractor. Protect your investment and warranty eligibility by doing it right the first time.

11

YMGI • Your Modern Green Idea

Safety Precautions

Follow these instructions to complete the necessary installation process. Carefully read this manual before

installation and unit startup or servicing.

Wire size of power cord should be properly sized to meet the required electrical loads. Should the power cord get

damaged, the power cord should be replaced with a manufacturer approved cable.

After connecting the power cord, attach the electric box cover and secure properly.

Always meet the nitrogen charge requirements when welding pipes.

Never short-circuit or cancel the pressure switch as this will result in damage to the unit.

Connect the wired controller before energizing, otherwise the wired controller cannot be used.

Before using the unit, verify the piping and wiring are correct. This will avoid water leakage, refrigerant leakage,

electric shock, fire, etc.

Do not insert fingers or objects into the air outlet or inlet grille.

Open a door or window for ventilation for allowing fresh air to enter the room to avoid depleting the oxygen while

gas/oil supplied heating equipment is used during the installation.

Never start up or shut off the unit by means of directly plugging into or unplugging the power cord from the power

outlet.

Turn off the unit after it runs at least five minutes, otherwise it will influence the oil return of the compressor.

Do not allow children to operate this unit.

Do not operate this unit with wet hands.

Turn off the unit or disconnect the power supply before cleaning the unit. This will avoid possible electric shock

or personnel injury.

Never spray or splash water towards the unit. This can cause a malfunction in the unit or can result in electric

shock.

Do not expose the unit to moist or corrosive environments.

While operating in cooling mode, do not set the indoor unit room temperature too low. Keeping the temperature

difference between indoor and outdoor unit within 41℉ (5℃).

YMGI Group recommends that only properly trained and authorized personnel be allowed to repair or service the

unit. Improper repairs or servicing can result in electric shock or fire hazards. Please contact YMGI Group if you

need help locating a qualified repair or service technician.

Before installation, check the power supply to ensure it is sufficient to meet and is in accordance with the

requirements specified on the nameplate of the unit. Ensure the power overload is functioning correctly and make

sure it is properly maintained.

Installation must be performed only by an authorized installer or HVAC professional in accordance with the

requirements set by the NEC and CEC. Do not attempt to install the unit yourself. Improper handling may result

in water leakage, electric shock, fire, and voiding of the warranty.

Be sure to use only approved accessories and parts to prevent water leakage, electric shock and fire.

Make sure the unit is grounded properly prior to connecting to power source, to avoid electric shock. Do not

connect the ground wire to a gas pipe, water pipe, lightning rod or telephone line.

Energize the unit for 8 hours before operation. Turn off or disconnect the power within 24 hours to prevent

shortcycling (to protect the compressor).

If refrigerant leakage happens in a confined space during installation, ventilate immediately. Poisonous gases

can occur if the refrigerant gas is exposed to fire.

Volatile liquids, (such as paint thinners or solvents) if exposed to the unit’s surface will damage to the surface

finish. Only use a soft cloth along with a mild non-abrasive detergent to clean the outer casing of the unit.

If the unit does not operate normally or if you notice any type of burning odor, power off the unit and turn off the

main power supply, then immediately contact your YMGI authorized repair service center or HVAC professional.

12

YMGI • Your Modern Green Idea

Product Introduction

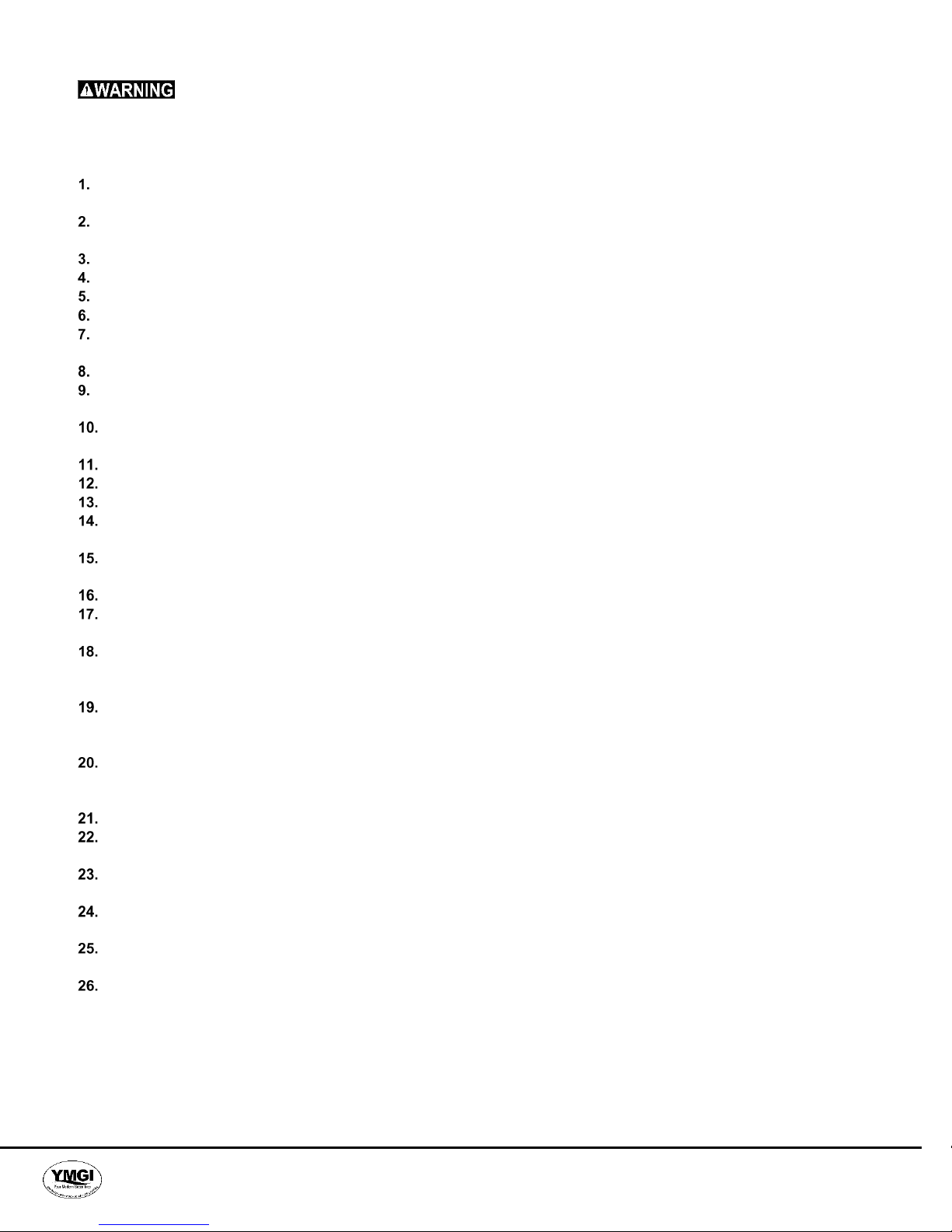

No. 1 2 3 4

5

Name

Fan, Motor

Electric Box

Assembly

Valve interface

Power cord

through-hole

Communication

code through-hole

Model (Single)

VRFO-144VP-U2C(55)5

VRFO-168VP-U2C(55)5

VRFO-192VP-U2C(55)5

Model

(Combined)

VRFO-72VP-U2C(55)5

+ VRFO-72VP-U2C(55)5

VRFO-72VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

VRFO-96VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

Model (Single)

VRFO-216VP-U2C(55)5

VRFO-240VP-U2C(55)5

VRFO-264VP-U2C(55)5

Model

(Combined)

VRFO-96VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

VRFO-120VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

VRFO-72VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

Model (Single)

VRFO-288VP-U2C(55)5

VRFO-312VP-U2C(55)5

VRFO-336VP-U2C(55)5

Model

(Combined)

VRFO-96VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

VRFO-96VP-U2C(55)5

+ VRFO-96VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

VRFO-96VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

Model (Single)

VRFO-360VP-U2C(55)5

Model

(Combined)

VRFO-120VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

+ VRFO-120VP-U2C(55)5

YMGI Multi VRF Modular System adopts inverter compressor technology. According to changes in the displacement of

the compressor, stepless capacity regulation within range of 10%-100% can be realized. Various product configurations

are provided with capacity range from 72kBtu/h to 360kBtu/h, which can be widely used in working area and especially

applicable to the place with variable load change. YMGI air conditioners are your best choice.

Names of Main Parts

Combinations of Outdoor Units

Fig.1

13

YMGI • Your Modern Green Idea

Combinations of Indoor and Outdoor Units

Model

Max number of

connectable IDU

(unit)

ODU Model

Max number of

connectable IDU

(unit)

VRFO-72VP-U2C(55)5

12

VRFO-240VP-U2C(55)5

41

VRFO-96VP-U2C(55)5

16

VRFO-264VP-U2C(55)5

45

VRFO-120VP-U2C(55)5

20

VRFO-288VP-U2C(55)5

49

VRFO-144VP-U2C(55)5

25

VRFO-312VP-U2C(55)5

53

VRFO-168VP-U2C(55)5

29

VRFO-336VP-U2C(55)5

58

VRFO-192VP-U2C(55)5

33

VRFO-360VP-U2C(55)5

61

VRFO-216VP-U2C(55)5

37

Cooling

Ambient temperature: -5ºC(23ºF)~52ºC(125.6ºF)

Heating

Ambient temperature: -20ºC (-4ºF)~24ºC (75.2ºF)

The total capacity of indoor units should be within 50%~135% of that of outdoor units.

Fig.2

Fig.2 is the combination view of the ODU of Modular DC Inverter Multi VRF System and the IDU of Multi VRF System.

IDU can be cassette type, one-way cassette type, wall-mounted type, duct type, etc. When any one IDU receives

operation signal, ODU will start to work according to the capacity; when all IDUs stop, ODU will also stop.

The Range of Production Working Temperature

Running this system outside of the working temperature range may damage the unit and will invalidate the

warranty.

14

YMGI • Your Modern Green Idea

Number

Name

Picture

Remarks

1

Owner's Manual

2

Wiring (match with resistance)

Must be connected to the last

IDU of communication

connection

3

Mark (Master )

Attach on the wired controller

of master IDU or on the front

panel

Preparation before Installation

The picture is only used for reference and the actual product prevails. Unit: mm (in.).

Standard Parts

Please use the following standard parts supplied by YMGI.

Installation Site

1. Install the unit in a location where the floor is adequate and can withstand the weight of the unit, and ensure the

unit will not shake or fall off.

2. Never expose the unit under direct sunshine and rainfall. Install the unit at a place where it is protected against

dust, typhoons and earthquakes.

3. Try to keep the unit away from combustible, flammable, and corrosive gas or exhaust gas.

4. Leave some space for heat exchanging and servicing so as to guarantee unit normal operation.

5. Keep the indoor and outdoor units close to each other as much as possible so as to decrease the pipe length

and bends.

6. Never allow children to approach to the unit and take measures to prevent children touching the unit.

15

YMGI • Your Modern Green Idea

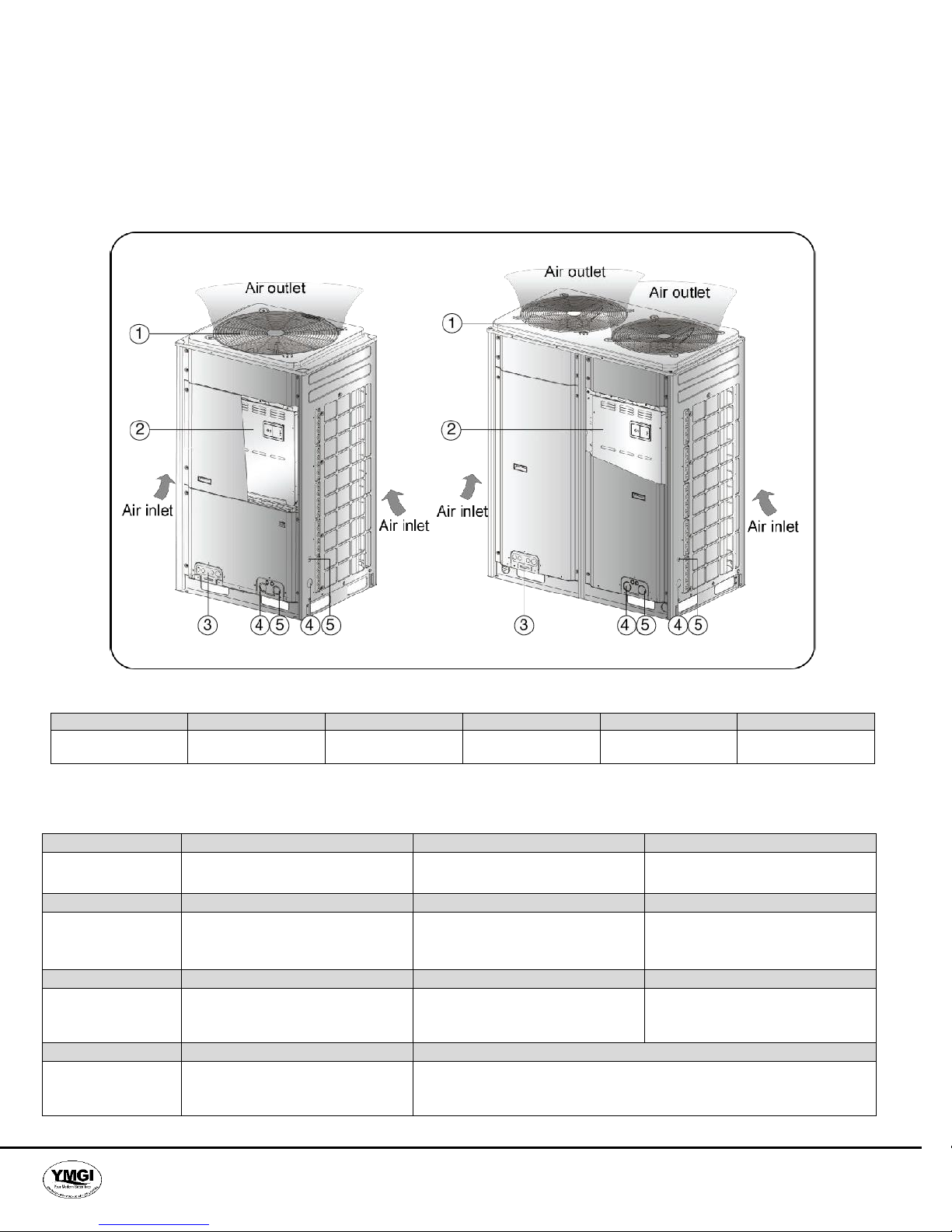

When the outdoor unit is totally surrounded by walls, please refer to following figures for

space dimension.

Space dimension for single-module unit

Space dimension for dual-module unit

Fig.3

Fig.4

16

YMGI • Your Modern Green Idea

Space dimension for three-module unit

Fig.5

When there is a wall (or similar obstruction) above the unit, keep the distance between the unit top and the wall at least

3000mm (118-1/8in.) or above. When the unit is located in a totally open space with no obstructions in four directions,

keep the distance between the unit top and wall at least 1500mm (59in.) or above (See Fig.6). When space is limited

within 1500mm (59in.) or the unit is not set in an open space, air return pipe is required to be installed in order to keep

good ventilation (See Fig.7).

17

YMGI • Your Modern Green Idea

Fig.6

Fig.7

Space dimension for multiple-module unit

To ensure good ventilation, make sure there is no obstruction above the unit. When the unit is located in a half-open

space (front and left/right side is open), install the unit as per the same or opposite direction.

Fig.8

18

YMGI • Your Modern Green Idea

Fig.9

Considering the seasonal wind in outdoor unit installation

Anti-monsoon installation requirements for unit not connecting exhaust duct

Fig.10

Fig.11

19

YMGI • Your Modern Green Idea

Anti-monsoon installation requirement for unit connecting exhaust duct

Fig. 12

Considering snow in outdoor unit installation

Fig. 13

20

YMGI • Your Modern Green Idea

Piping Work Requirements

R410A Refrigerant System

Outer Diameter mm(in.)

Wall Thickness mm(in.)

Type

Φ6.35mm (1/4”)

≥0.8mm (1/32”)

0

Φ9.52mm (3/8”)

≥0.8mm (1/32”)

0

Φ12.7mm (1/2”)

≥0.8mm (1/32”)

0

Φ15.9mm (5/8”)

≥1.0mm (3/76”)

0

Φ19.05mm (3/4”)

≥1.0mm (3/76”)

1/2H

Φ22.2mm (7/8”)

≥1.2mm (1/21”)

1/2H

Φ28.6mm (1-1/8”)

≥1.2mm (1/21”)

1/2H

Φ34.9mm (1-3/8”)

≥1.3mm (2/39”)

1/2H

Φ41.3mm (1-5/8”)

≥1.5mm (1/17”)

1/2H

There should be no fall among outdoor modules. Refer to the table below for piping work requirements.

Installation Instructions

Physical Dimension of the Outdoor Unit and Mounting Hole

Outline and Physical Dimensions of VRFO-72VP-U2C(55)5.

Fig. 14

21

YMGI • Your Modern Green Idea

Outline and Physical Dimension of VRFO-96VP-U2C(55)5 and VRFO-120VP-U2C(55)5 unit.

Fig. 15

22

YMGI • Your Modern Green Idea

Connection Pipes

Fig. 16

23

Loading...

Loading...