Yetter 2968-050, 2968-051, 2968-052, 2968-053 Set-up / Parts Manual

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

ROW UNIT MID-MOUNT

FERTILIZER INJECTION OPENER

MODELS 2968-050 & 2968-052 – SINGLE WHEEL

MODELS 2968-051 & 2968-053 – DUAL WHEEL

CNH ROW UNITS

SET UP & PARTS MANUAL

2565-960 – 02/2019

FOREWORD ………………………………………………….......…............... 3

SAFETY …………………………………………………………...….................. 4

PICTORIAL PART LIST …………………...……………................... 5 – 10

INSTALLATION …………………………………………………........... 10 – 16

OPERATION .....………..……..…...…………........................... 16 – 17

MAINTENANCE ………......…..…………......………................. 18 – 20

PARTS IDENTIFICATION…...………………....……...…............ 21 – 28

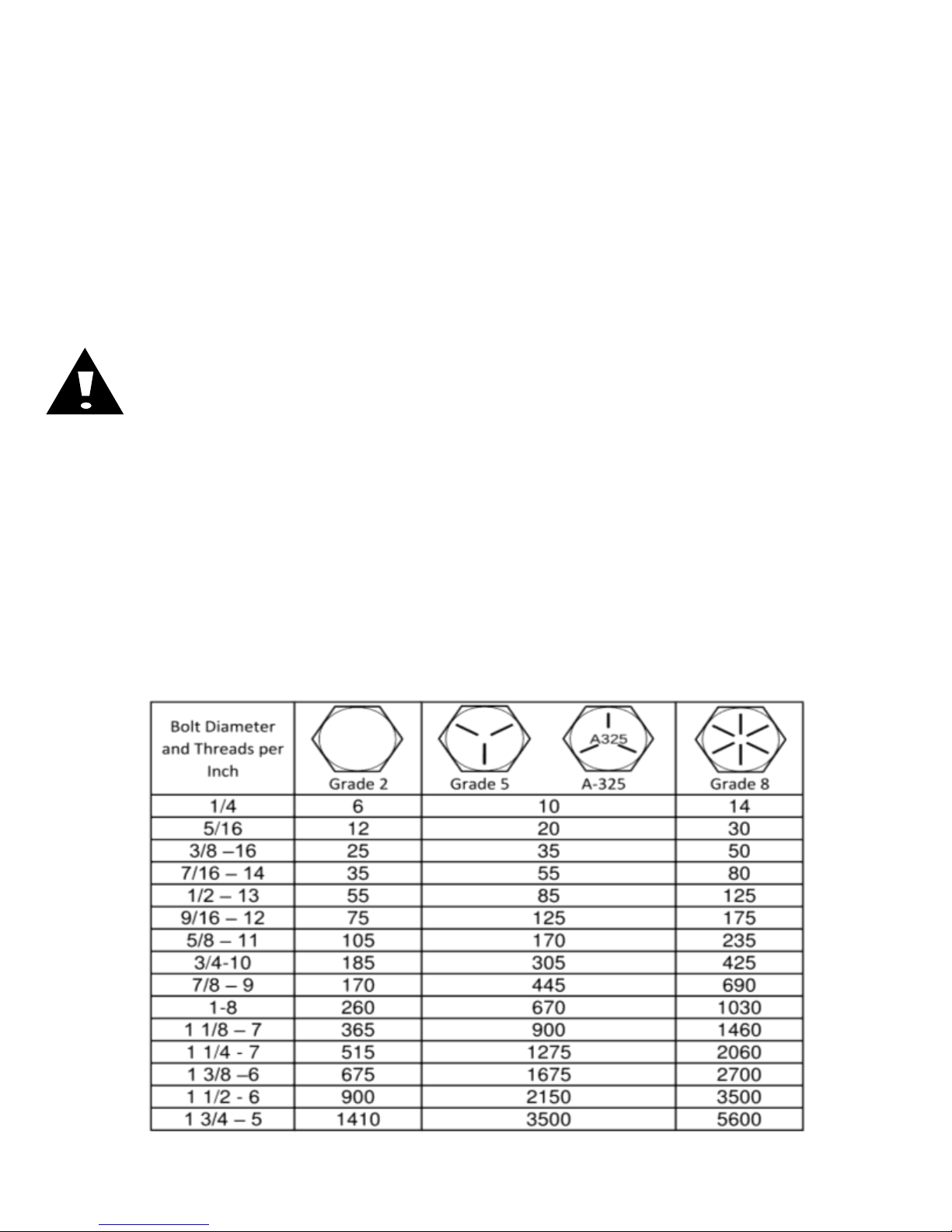

BOLT TORQUE

Important: Over-tightening hardware can cause just as much damage as under-tightening.

Tightening hardware beyond the recommended range can reduce its shock load capacity.

All hardware is either Grade 5 unless otherwise noted. Grade 5 cap screws are marked with three radial

lines on the head. Grade 8 cap screws are marked with six radial lines on the head. If hardware must be

replaced, be sure to replace it with hardware of equal size, strength and thread type. Refer to the torque

values chart when tightening hardware.

The chart below is a guide for proper torque. Use it unless a specified torque is called out elsewhere in

the manual. Torque is the force applied to the end of the handle or cheater bar, times the length of the

handle or bar. Tightening hardware beyond the recommended range can reduce its shock load capacity.

Use a torque wrench wherever possible

The following table shows torque in ft.-lbs. for coarse thread hardware.

2

TABLE OF CONTENTS

FOREWORD

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material.

This warranty being expressly limited to replacement at the factory of such parts or products as shall

appear to be defective after inspection. This warranty does not obligate the Company to bear cost

of labor in replacement of parts. It is the policy of the Company to make improvements without

incurring obligations to add them to any unit already sold. No warranty is made or authorized to be

made, other than herein set forth. This warranty is in effect for one year after purchase.

DEALER: ________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages

to equipment on which mounted.

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into

four major sections: Foreword, Safety

Precautions, Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL indicates

important safety messages in the manual.

When you see this symbol, be alert to the

possibility of PERSONAL INJURY and

carefully read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation.

3

Important will apply to the same information as

specified by note only of an immediate and

urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

BE ALERT!

YOUR SAFETY IS INVOLVED

WATCH FOR THIS SYMBOL. IT POINTS OUT IMPORTANT SAFETY

PRECAUTIONS. IT MEANS “ATTENTION – BE ALERT!”

It is your responsibility as an owner, operator, or supervision to know and instruct

everyone using this machine at the time of initial assignment and at least annually

thereafter, of the proper operation, precautions, and work hazards which exist in the

operation of the machine in accordance with OSHA regulations.

Safety Is No Accident

The following safety instructions, combined with

common sense, will save your equipment from needless

damage and the operator from unnecessary exposure

to personal hazard. Pay special attention to the

caution notes in the text. Review this manual at least once a year with all

operators.

1. Read and understand the operator’s manual before operating this machine. Failure to do so is

considered a misuse of the equipment.

2. Make sure equipment is secure before operating.

3. Always keep children away from equipment when operating.

4. Make sure everyone that is not directly involved with the operation is out of the work area before

beginning operation.

5. Make sure all safety devices, shields, and guards are in place and functional before beginning

operation

6. Shut off all power to adjust, service, or clean.

7. Keep hands, feet, and clothing away from moving parts. It is a good idea to remove all jewelry

before operating.

8. Inspect the machine periodically during operation for signs of excessive wear, loose fasteners,

and unusual noises.

4

2968-050 Pictorial Parts List

2968-150

QTY 1

Bolt Bag

2968-227

QTY 1

Close Wheel Mount

ONLY IF –LH ORDERED

2968-359-LH

QTY 1

Short Fert. Wheel Mount, LH

ONLY IF –RH ORDERED

2968-359-RH

QTY 1

2968-149

QTY 1

Bolt Bag

2968-227

QTY 1

Close Wheel

Mount

ONLY IF –L ORDERED

2968-359-LH

QTY 1

Short Fert.

Wheel Mount, LH

ONLY IF –L ORDERED

2968-360-RH

QTY 1

Tall Fert.

Wheel Mount, RH

2968-113

QTY 1

Bolt Bag

2968-226

QTY 1

Close Wheel Mount

2968-384

QTY 1

Short Fert. Wheel Mount, LH

2968-385

QTY 1

Short Fert. Wheel Mount, RH

2968-113

QTY 1

Bolt Bag

2968-226

QTY 1

Close Wheel Mount

ONLY IF –LH ORDERED

2968-384

QTY 1

Short Fert. Wheel Mount, LH

ONLY IF –RH ORDERED

2968-385

QTY 1

Short Fert. Wheel Mount, RH

ONLY IF –R ORDERED

2968-359-RH

QTY 1

Short Fert.

Wheel Mount, RH

ONLY IF –R ORDERED

2968-360-LH

QTY 1

Tall Fert.

Wheel Mount, LH

For CNH 2000 Row Units, Single Disc, Left or Right Hand

2968-051-L & 2968-051-R Pictorial Parts List

For CNH 2000 Row Units, Dual Disc

2968-052 Pictorial Parts List

For CNH 1200 Row Units, Single Disc, Left or Right Hand

2968-053 Pictorial Parts List

For CNH 1200 Row Units, Dual Disc

5

2968-054 Pictorial Parts List

2502-807

QTY 8

M16X2X80 Bolt

2520-477

QTY 1

M16X2 Hex Nut

2968-374

QTY 2

Box Mount Bracket

2968-375

QTY 4

Box Mount Spacer

2505-207

QTY 4

5/16 X 1 ¼

Carriage Bolt

2520-206

QTY 4

5/16 Flange

Lock Nut

2570-740

QTY 1

Flanged D-Bolt

5/8 X 2.812 GR 8

2965-128

QTY 1

Hub & Bearing

Assembly, 4 bolt

2965-352

QTY 1

Hub Cap

Casting

2968-320

QTY 1

10” Notched

Blade

2968-364

QTY 1

11” Notched

Blade

2505-207

QTY 4

5/16 X 1 ¼

Carriage Bolt

2520-206

QTY 4

5/16 Flange

Lock Nut

2570-740

QTY 1

Flanged D-Bolt

5/8 X 2.812 GR 8

2965-128

QTY 1

Hub & Bearing

Assembly, 4 bolt

2965-352

QTY 1

Hub Cap

Casting

Box Mount Kit For CNH 1200 Row Units, Dual Disc

2968-132 Pictorial Parts List – 10” Fertilizer Wheel Assembly

2968-133 Pictorial Parts List – 11” Fertilizer Wheel Assembly

6

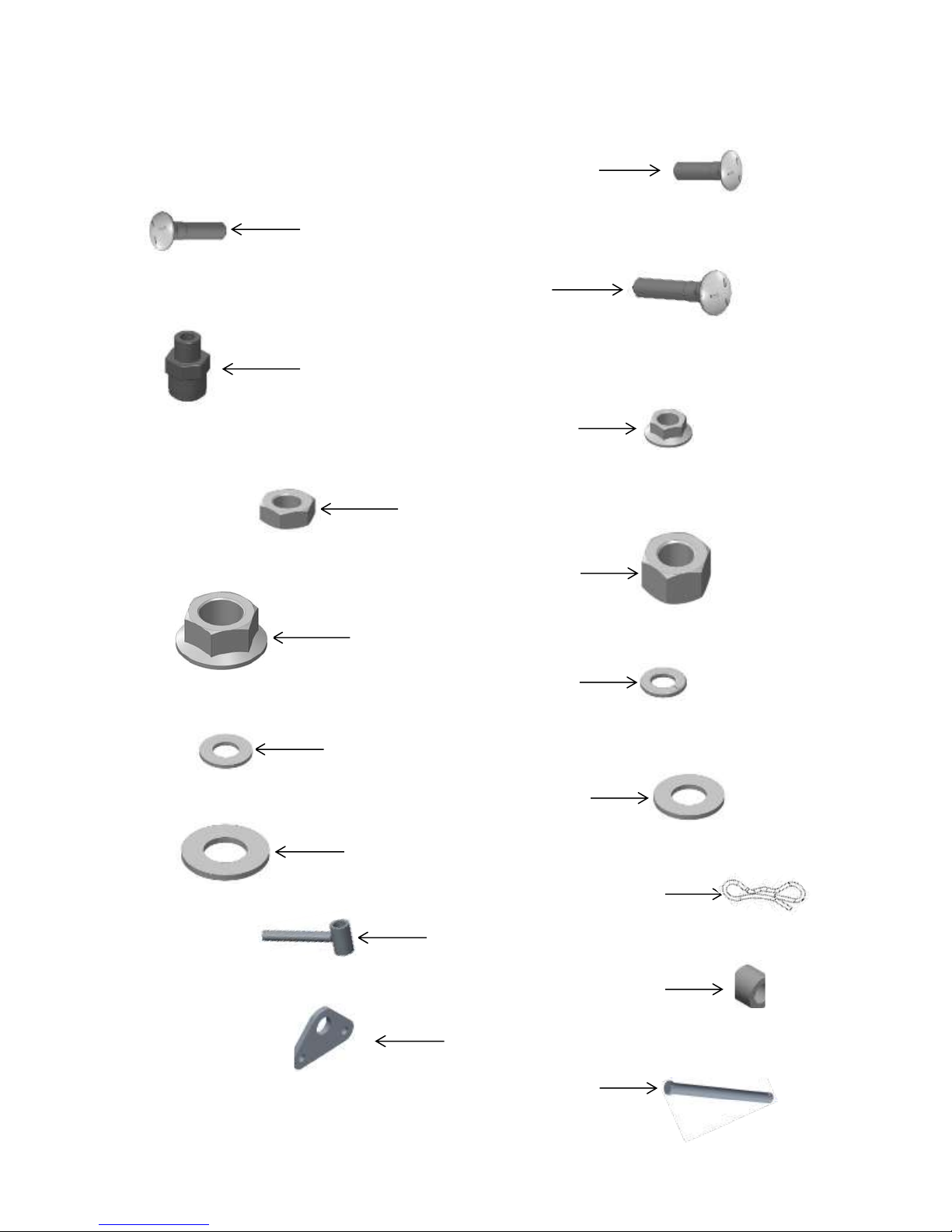

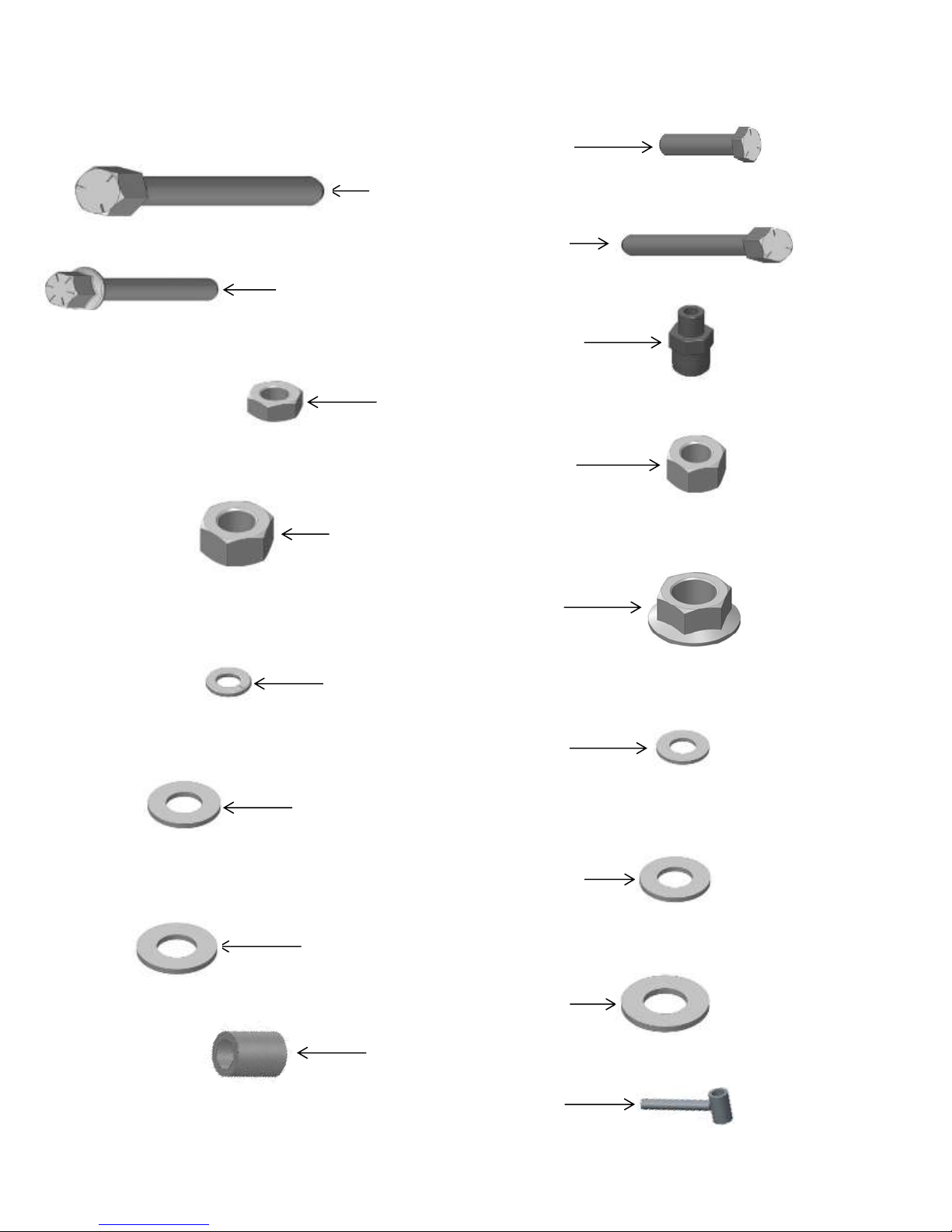

2968-113 Pictorial Parts List

2505-207 – 5/16 – 18 X 1 ¾ CARRIAGE BOLT – QTY 4

2505-208 – 5/16 – 18 X 1 ½ CARRIAGE BOLT – QTY 4

2505-345 – ½ – 13 X 2 CARRIAGE BOLT – QTY 3

2520-206 – 5/16 FLANGE LOCK NUT – QTY 8

2968-386 – TRIANGULAR MOUNT – QTY 2

2984-497 – AIR CYLINDER ROD PIN – QTY 1

2968-218 - INJECTOR HOLDER W.A. – QTY 1

2570-448 - .120 BOWTIE LOCKING COTTER ZP – QTY - 1

2526-454 - 5/8 SAE FLATWASHER HRD'ND ZP – QTY 1

2526-355 – ½ FLAT WASHER HRD'ND ZP – QTY 3

2526-253 – 3/8 SAE FLAT WASHER ZP – QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 1

2520-464 -5/8-11 WHIZLOCK ZP, GR 8– QTY 1

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 3

2520-253 3/8 JAM HEX NUT – QTY 2

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 1

Bolt Bag for 2968-052

7

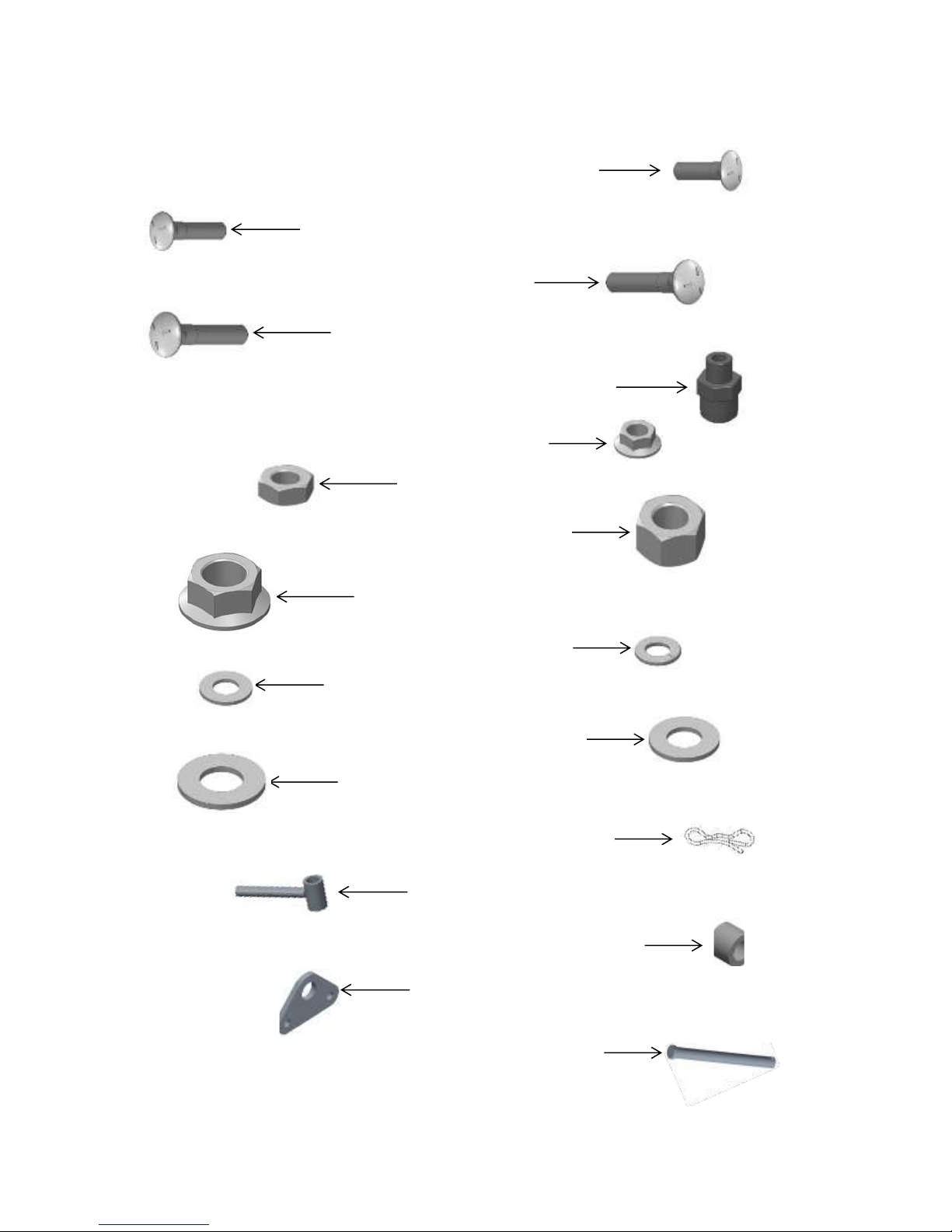

2968-114 Pictorial Parts List

2505-207 – 5/16 – 18 X 1 ¾ CARRIAGE BOLT – QTY 4

2505-208 – 5/16 – 18 X 1 ½ CARRIAGE BOLT – QTY 4

2505-345 – ½ – 13 X 2 CARRIAGE BOLT – QTY 3

2520-206 – 5/16 FLANGE LOCK NUT – QTY 8

2968-386 – TRIANGULAR MOUNT – QTY 2

2984-497 – AIR CYLINDER ROD PIN – QTY 1

2968-218 - INJECTOR HOLDER W.A. – QTY 2

2570-448 - .120 BOWTIE LOCKING COTTER ZP – QTY - 1

2526-454 - 5/8SAE FLATWASHER HRD'ND ZP – QTY 2

2526-355 – ½ FLAT WASHER HRD'ND ZP – QTY 3

2526-253 – 3/8 SAE FLAT WASHER ZP – QTY 4

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 2

2520-464 -5/8-11 WHIZLOCK ZP, GR 8– QTY 2

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 3

2520-253 3/8 JAM HEX NUT – QTY 4

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 2

2505-343 – ½ – 13 X 2 ½ CARRIAGE BOLT – QTY 3

Bolt Bag for 2968-053

8

2968-149 Pictorial Parts List – Bolt Bag for 2968-051

2502-314 – 1/2-13 X 2-1/4" HHCS GR 5 ZYD – QTY 3

2502-333 –5/8 – 11 X 9 HHCS GR 5 ZP – QTY 1

2502-373 – ½ – 13 X 6 HHCS GR 5 ZP – QTY 1

2502-808 – M16 X 40MM SERRATED HEX FLANGE ZP – QTY 4

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 4

2520-459 5/8 – 11 LOCK HEX NUT GR A ZP – QTY – 1

2526-351 – ½ STANDARD FLAT WASHER ZP – QTY – 5

2526-451 - 5/8 STANDARD FLATWASHER ZP – QTY 2

2967-567 – PIVOT BUSHING – QTY – 2

2526-454 - 5/8SAE FLATWASHER HRD'ND ZP – QTY 2

2526-355 – ½ FLAT WASHER HRD'ND ZP – QTY 5

2526-253 – 3/8 SAE FLAT WASHER ZP – QTY 4

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 2

2520-464 -5/8-11 WHIZLOCK ZP, GR 8– QTY 2

2520-253 3/8 JAM HEX NUT – QTY 4

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 2

2968-218 - INJECTOR HOLDER W.A. – QTY 2

9

2502-317 – 1/2-13 X 1 ¾" HHCS GR 5 ZYD – QTY 3

2502-333 –5/8 – 11 X 9 HHCS GR 5 ZP – QTY 1

2502-373 – ½ – 13 X 6 HHCS GR 5 ZP – QTY 1

2502-808 – M16 X 40MM SERRATED HEX FLANGE ZP – QTY 4

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 4

2520-459 5/8 – 11 LOCK HEX NUT GR A ZP – QTY – 1

2526-351 – ½ STANDARD FLAT WASHER ZP – QTY – 5

2526-451 - 5/8 STANDARD FLATWASHER ZP – QTY 2

2967-567 – PIVOT BUSHING – QTY – 2

2526-454 - 5/8SAE FLATWASHER HRD'ND ZP – QTY 1

2526-355 – ½ FLAT WASHER HRD'ND ZP – QTY 5

2526-253 – 3/8 SAE FLAT WASHER ZP – QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 1

2520-464 -5/8-11 WHIZLOCK ZP, GR 8– QTY 1

2520-253 3/8 JAM HEX NUT – QTY 2

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 1

2968-218 - INJECTOR HOLDER W.A. – QTY 1

2968-150 Pictorial Parts List – Bolt Bag for 2968-050

10

Loading...

Loading...