Page 1

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

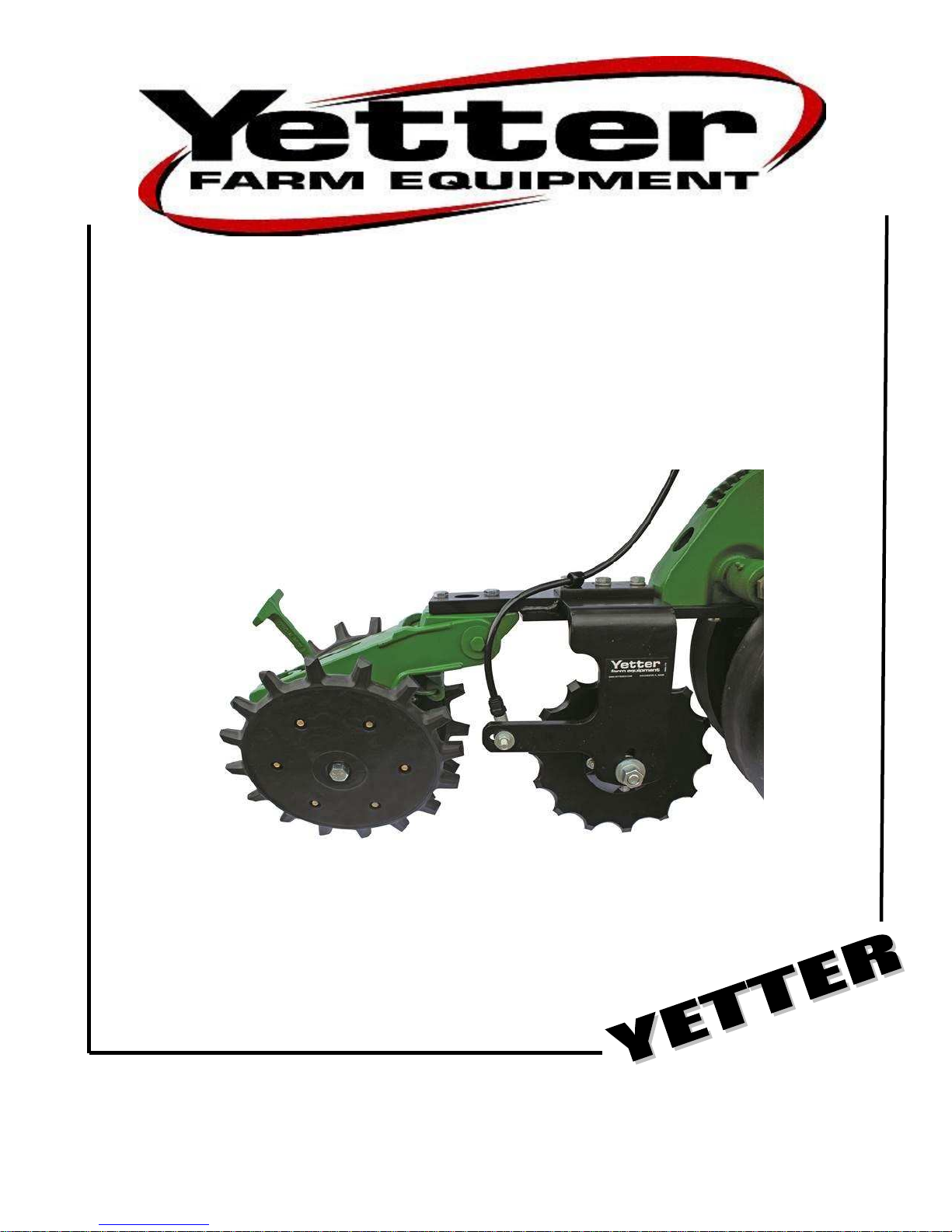

ROW UNIT MID-MOUNT

FERTILIZER INJECTION OPENER

MODELS 2968-020A, 2968-021A, 2968-026, & 2968-027 SINGLE WHEEL

MODELS 2968-040, 2968-041, 2968-044, & 2968-045 DUAL WHEEL

John Deere, Kinze, & Harvest International Row Units

SET UP & PARTS MANUAL

2565-951_REV_C – 03/2019

Page 2

FOREWORD …………………………………………………...….…............... 3

SAFETY …………………………………………………………...….................. 4

PICTORIAL PART LIST ………………………………….................... 5 – 13

INSTALLATION …………………………………………………....…..... 14 – 19

OPERATION .....………………..…………………......................... 19 – 20

MAINTENANCE …………………………….......………................. 21 – 23

PARTS IDENTIFICATION………………………………...…............ 24 – 37

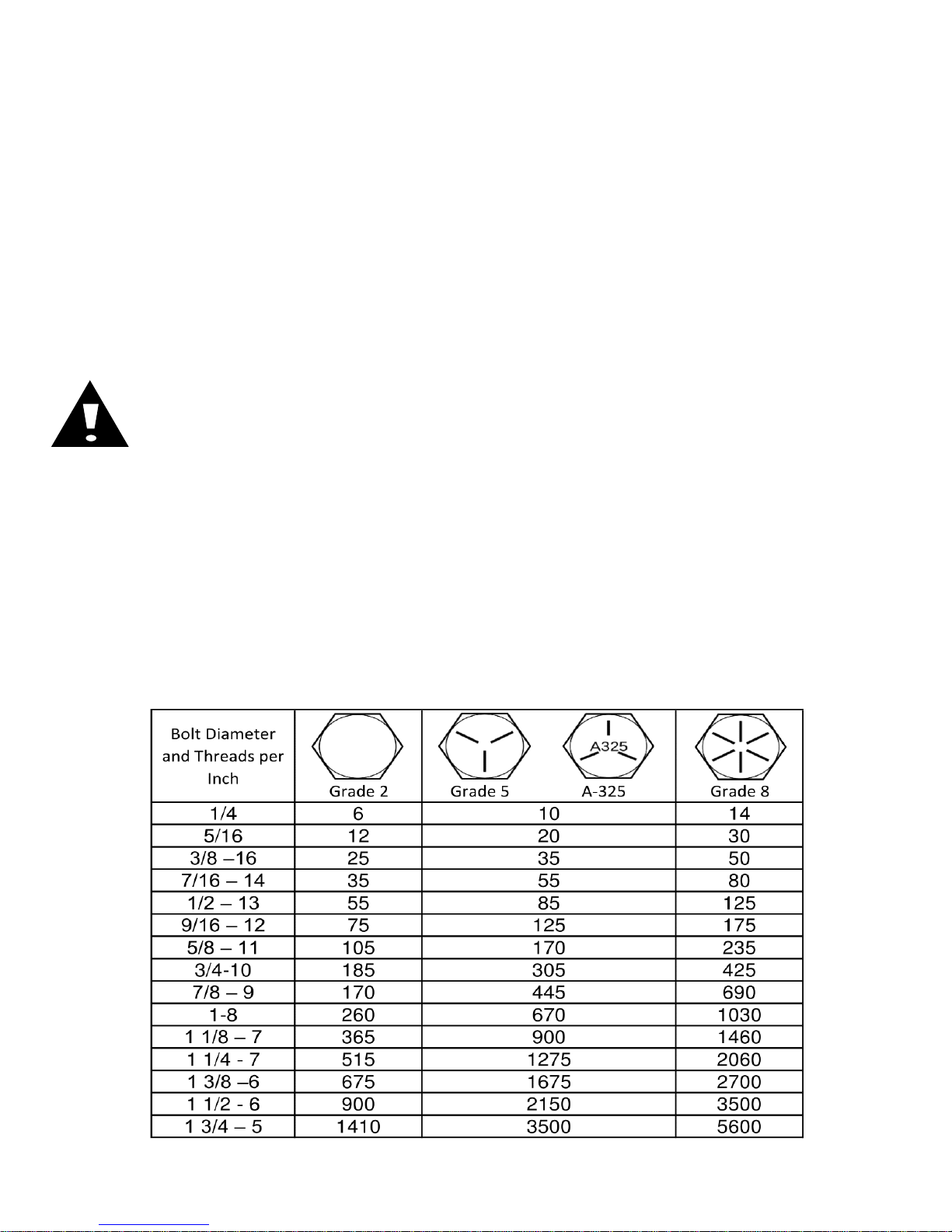

BOLT TORQUE

Important: Over-tightening hardware can cause just as much damage as under-tightening.

Tightening hardware beyond the recommended range can reduce its shock load capacity.

All hardware is either Grade 5 unless otherwise noted. Grade 5 cap screws are marked

with three radial lines on the head. Grade 8 cap screws are marked with six radial lines on the

head. If hardware must be replaced, be sure to replace it with hardware of equal size, strength

and thread type. Refer to the torque values chart when tightening hardware.

The chart below is a guide for proper torque. Use it unless a specified torque is called out

elsewhere in the manual. Torque is the force applied to the end of the handle or cheater bar,

times the length of the handle or bar. Tightening hardware beyond the recommended range can

reduce its shock load capacity.

Use a torque wrench wherever possible

The following table shows torque in ft.-lbs. for coarse thread hardware.

TABLE OF CONTENTS

2

Page 3

FOREWORD

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material.

This warranty being expressly limited to replacement at the factory of such parts or products as shall

appear to be defective after inspection. This warranty does not obligate the Company to bear cost

of labor in replacement of parts. It is the policy of the Company to make improvements without

incurring obligations to add them to any unit already sold. No warranty is made or authorized to be

made, other than herein set forth. This warranty is in effect for one year after purchase.

DEALER: ________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages

to equipment on which mounted.

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into

four major sections: Foreword, Safety

Precautions, Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL indicates

important safety messages in the manual.

When you see this symbol, be alert to the

possibility of PERSONAL INJURY and

carefully read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation.

3

Important will apply to the same information as

specified by note only of an immediate and

urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 4

BE ALERT!

YOUR SAFETY IS INVOLVED

WATCH FOR THIS SYMBOL. IT POINTS OUT IMPORTANT SAFETY

PRECAUTIONS. IT MEANS “ATTENTION – BE ALERT!”

It is your responsibility as an owner, operator, or supervision to know and instruct

everyone using this machine at the time of initial assignment and at least annually

thereafter, of the proper operation, precautions, and work hazards which exist in the

operation of the machine in accordance with OSHA regulations.

Safety Is No Accident

The following safety instructions, combined with common sense, will save your

equipment from needless damage and the operator from unnecessary exposure

to personal hazard. Pay special attention to the caution notes in the text. Review

this manual at least once a year with all operators.

1. Read and understand the operator’s manual before operating this machine. Failure to do so is

considered a misuse of the equipment.

2. Make sure equipment is secure before operating.

3. Always keep children away from equipment when operating.

4. Make sure everyone that is not directly involved with the operation is out of the work area

before beginning operation.

5. Make sure all safety devices, shields, and guards are in place and functional before beginning

operation

6. Shut off all power to adjust, service, or clean.

7. Keep hands, feet, and clothing away from moving parts. It is a good idea to remove all jewelry

before operating.

8. Inspect the machine periodically during operation for signs of excessive wear, loose fasteners,

and unusual noises.

BEFORE BEGINNING INSTALLATION, PLEASE GO THROUGH YOUR ORDER TO

ENSURE THAT YOU HAVE THE CORRECT PARTS AND HARDWARE, AND THAT THE

QUANTITIES ARE CORRECT. USE THE PICTORIAL PART LIST BELOW TO GUIDE YOU.

4

Page 5

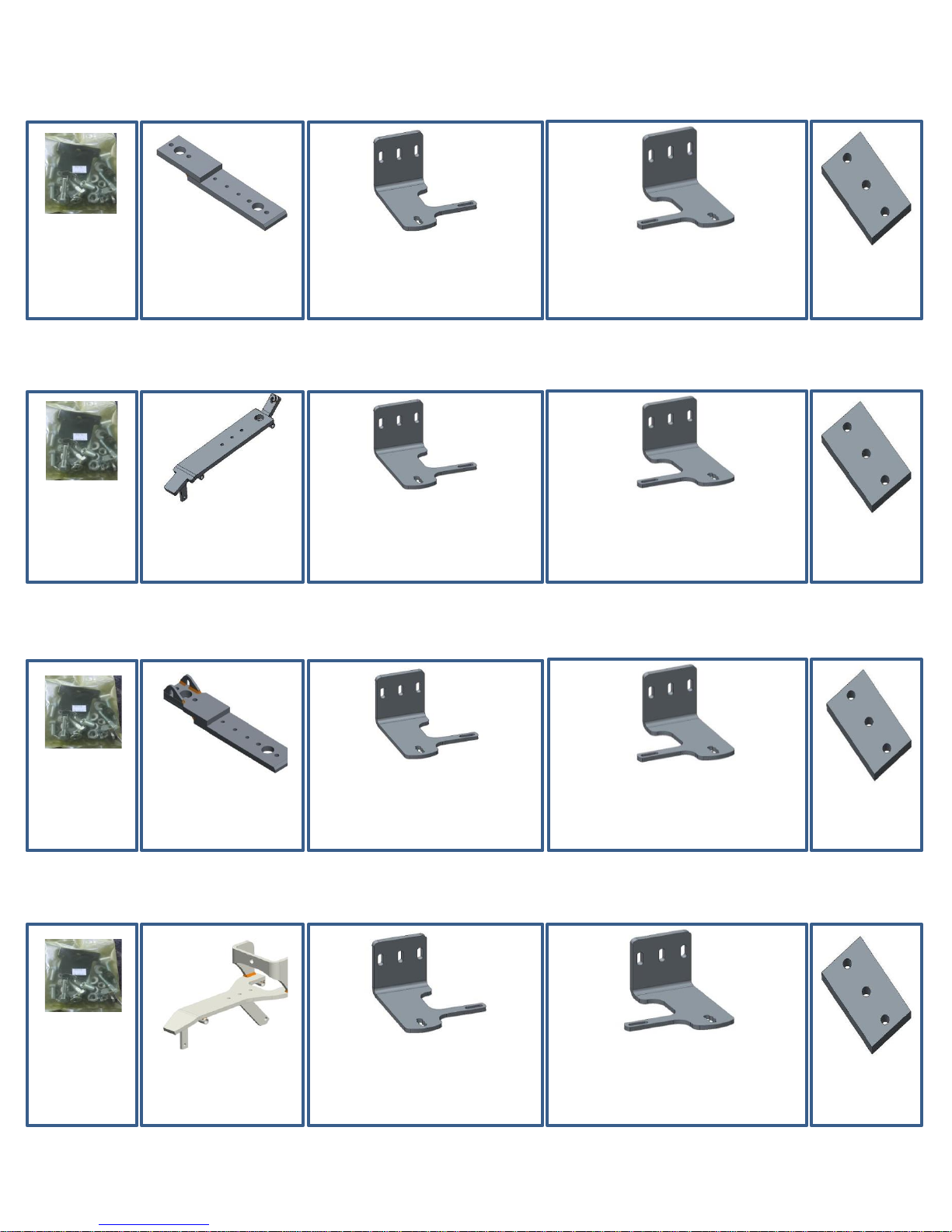

For JD 1700, 7200, & 7300 Single Disc, Left or Right Hand

2968-140

QTY 1

Bolt Bag

2968-222

QTY 1

Close Wheel Mount

Only if –LH Ordered

2968-359-LH

QTY 1

Short Fert. Wheel Mount, LH

Only if –RH Ordered

2968-359-RH

QTY 1

2968-361

QTY 1

Arm Clamp

2968-148

QTY 1

Bolt Bag

2968-223

QTY 1

Close Wheel Mount

Only if –LH Ordered

2968-359-LH

QTY 1

Short Fert. Wheel Mount, LH

Only if –RH Ordered

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-361

QTY 1

Arm Clamp

2968-140

QTY 1

Bolt Bag

2968-225

QTY 1

Close Wheel Mount

Only if –LH Ordered

2968-359-LH

QTY 1

Short Fert. Wheel Mount, LH

Only if –RH Ordered

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-361

QTY 1

Arm Clamp

2968-152

QTY 1

Bolt Bag

2968-228

QTY 1

Close Wheel Mount

Only if –LH Ordered

2968-359-LH

QTY 1

Short Fert. Wheel Mount, LH

Only if –RH Ordered

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-361

QTY 2

Arm Clamp

2968-361

QTY 1

Arm Clamp

2968-021A Pictorial Parts List

For JD 7000 & 7100, Kinze 2000 & 3000, Single Disc, Left or Right Hand

2968-020A Pictorial Parts List

2968-026 Pictorial Parts List

For Harvest International Single Disc, Left or Right Hand

2968-027 Pictorial Parts List

For Kinze 4900 Single Disc, Left or Right Hand

5

Page 6

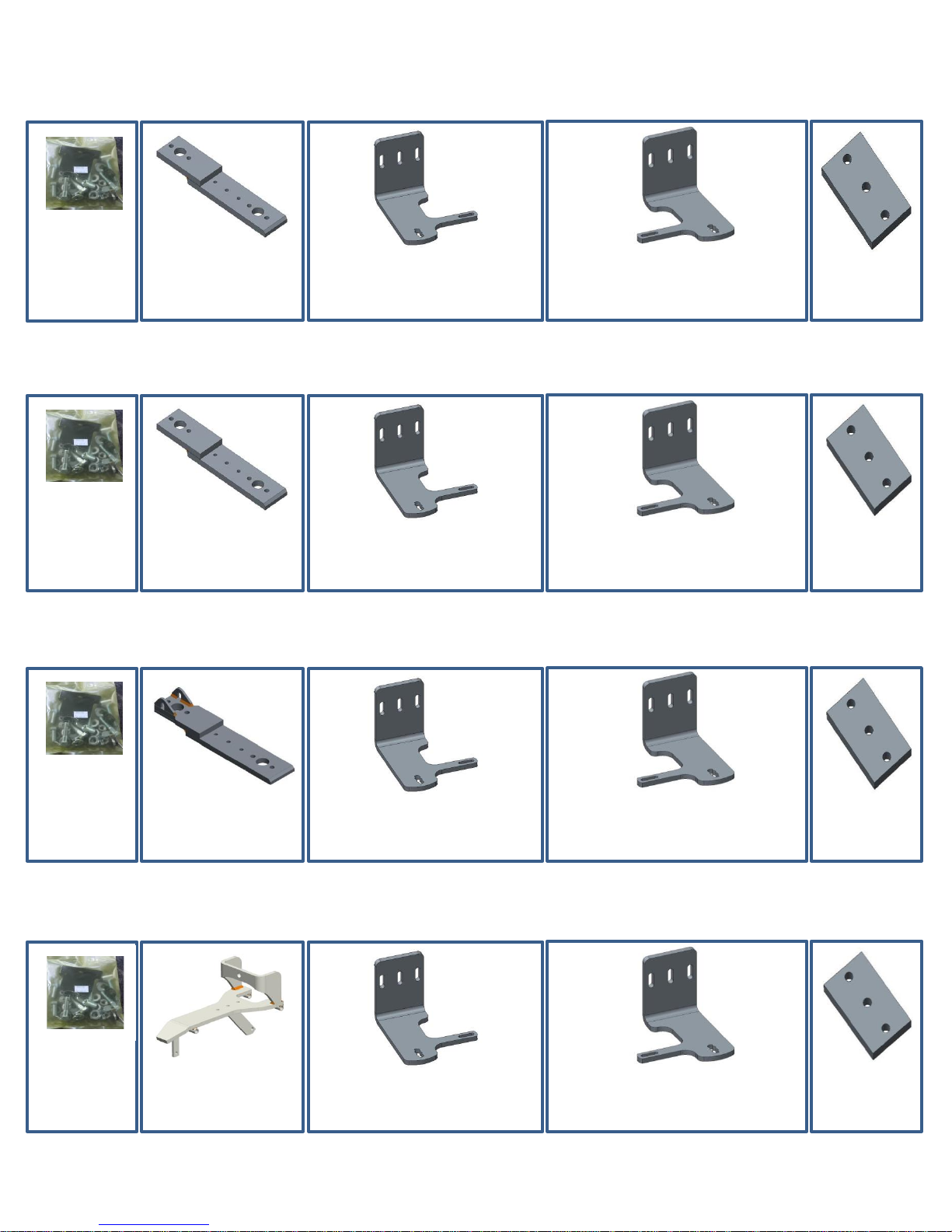

2968-040 Pictorial Parts List

2968-145

QTY 1

Bolt Bag

2968-222

QTY 1

Close Wheel Mount

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-360

QTY 1

Tall Fert. Wheel Mount

2968-361

QTY 1

Arm Clamp

2968-147

QTY 1

Bolt Bag

2968-223

QTY 1

Close Wheel Mount

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-360

QTY 1

Tall Fert. Wheel Mount

2968-361

QTY 1

Arm Clamp

2968-145

QTY 1

Bolt Bag

2968-225

QTY 1

Close Wheel Mount

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-360

QTY 1

Tall Fert. Wheel Mount

2968-361

QTY 1

Arm Clamp

2968-151

QTY 1

Bolt Bag

2968-228

QTY 1

Close Wheel Mount

2968-359-RH

QTY 1

Short Fert. Wheel Mount, RH

2968-360

QTY 1

Tall Fert. Wheel Mount

2968-361

QTY 1

Arm Clamp

For JD 1700, 7200, & 7300 Dual Disc

2968-041 Pictorial Parts List

For JD 7000 & 7100, Kinze 2000 & 3000, Dual Disc

2968-044 Pictorial Parts List

For Harvest International, Dual Disc

2968-045 Pictorial Parts List

For Kinze 4900, Dual Disc

6

Page 7

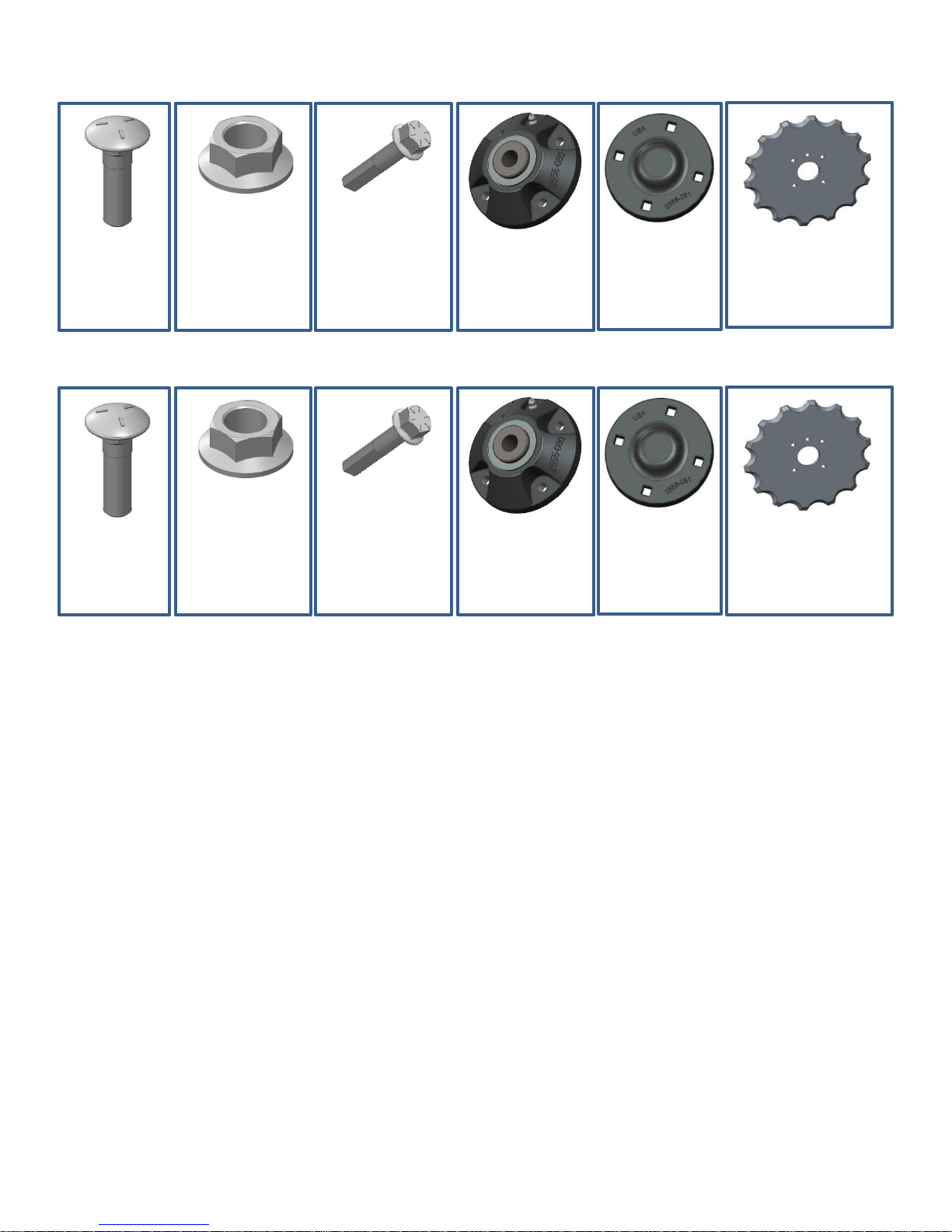

2968-132 Pictorial Parts List – 10” Fertilizer Wheel Assembly

2505-207

QTY 4

5/16 X 1 ¼

Carriage Bolt

2520-206

QTY 4

5/16 Flange

Lock Nut

2570-740

QTY 1

Flanged D-Bolt

5/8 X 2.812 GR 8

2965-128

QTY 1

Hub & Bearing

Assembly, 4 bolt

2965-352

QTY 1

Hub Cap

Casting

2968-320

QTY 1

10” Notched

Blade

2505-207

QTY 4

5/16 X 1 ¼

Carriage Bolt

2520-206

QTY 4

5/16 Flange

Lock Nut

2570-740

QTY 1

Flanged D-Bolt

5/8 X 2.812 GR 8

2965-128

QTY 1

Hub & Bearing

Assembly, 4 bolt

2965-352

QTY 1

Hub Cap

Casting

2968-364

QTY 1

11” Notched

Blade

2968-133 Pictorial Parts List – 11” Fertilizer Wheel Assembly

7

Page 8

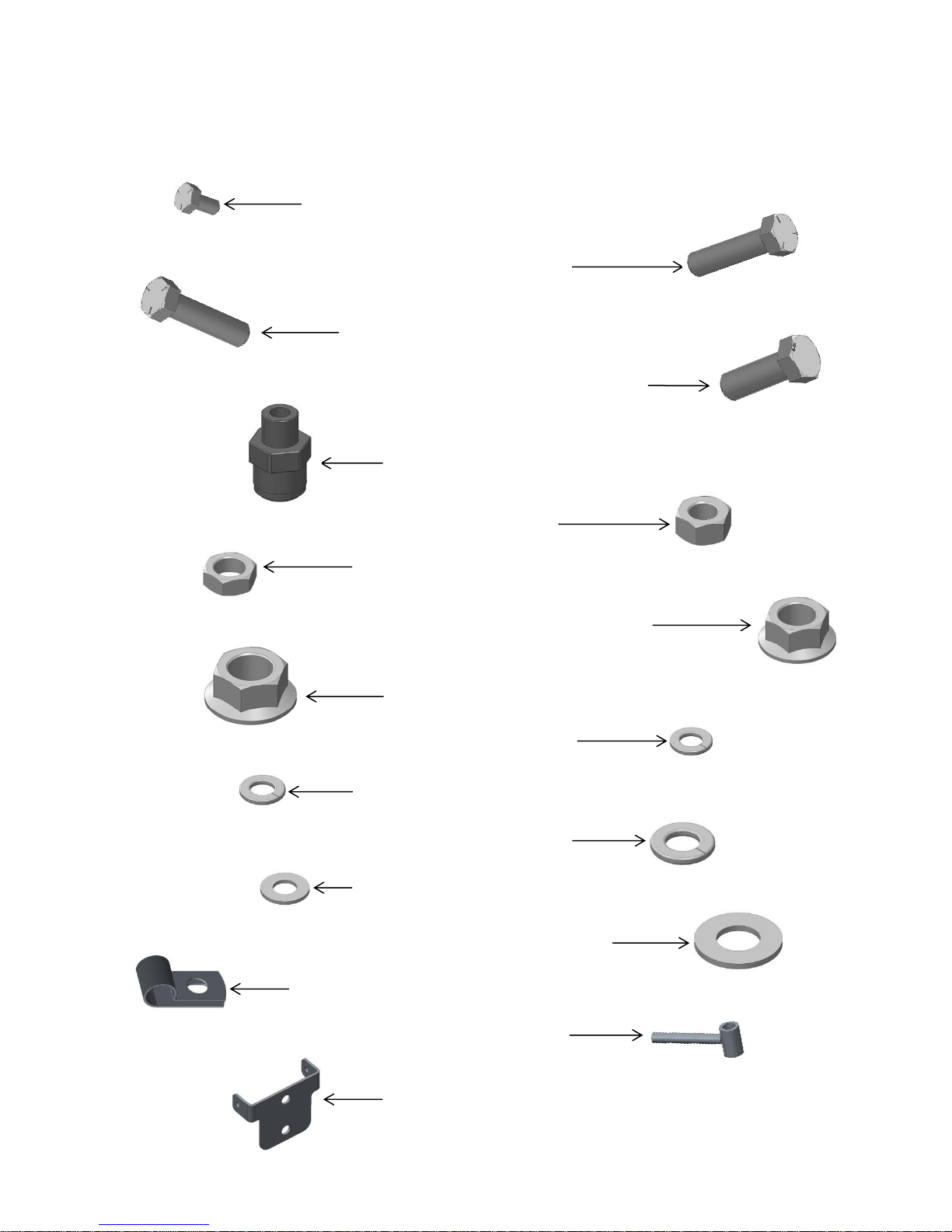

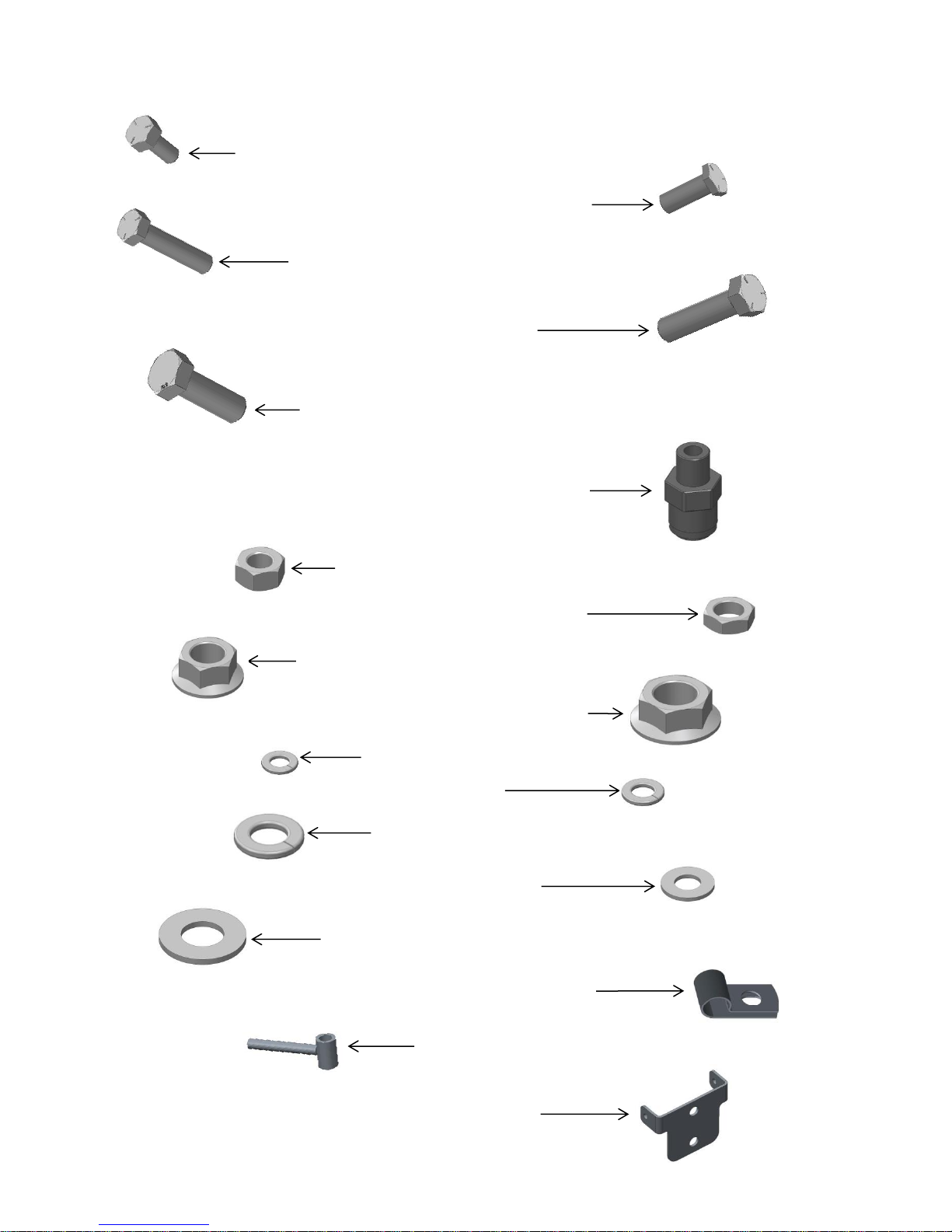

2968-140 Pictorial Parts List – Bolt Bag for 2968-020A & 2968-026

2502-104 -1/4-20 X 1/2 HHCS GR. 5 ZYD.– QTY 2

2502-351 -1/2-13 X 2 HHCS GR.5 ZP– QTY 5

2502-379 -M12 X 1.75 X 35 GRD 10.9 ZYD– QTY 2

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 1

2520-151 -1/4-20 HEX NUT, GR 2, ZP– QTY 2

2520-253 -3/8-16 JAM HEX NUT, GR 2, ZP– QTY 2

2520-361 -1/2-13FLANGE WHZLCK HXNT, GR 5, ZP – QTY 2

2520-464 -5/8-11 WHIZLOCK ZP, GR 8– QTY 1

2525-151 - 1/4 MED. LOCKWASHER ZP – QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 1

2525-352 - 1/2 MED LOCKWASHER ZP – QTY 5

2526-253 - 3/8 SAE FLATWASHER ZP – QTY 2

2526-454 - 5/8SAE FLATWASHER HRD'ND ZP – QTY 1

2570-724 - 3/8 HOSE P-CLIP W/ VINYL CUSHION – QTY 1

2968-218 - INJECTOR HOLDER W.A. – QTY 1

2968-363 - HOSE HOLDER, FORMED – QTY 1

2502-293 – ½ - 13 X 1 ¼ HHCS GR. 5 ZYD.– QTY 2

8

Page 9

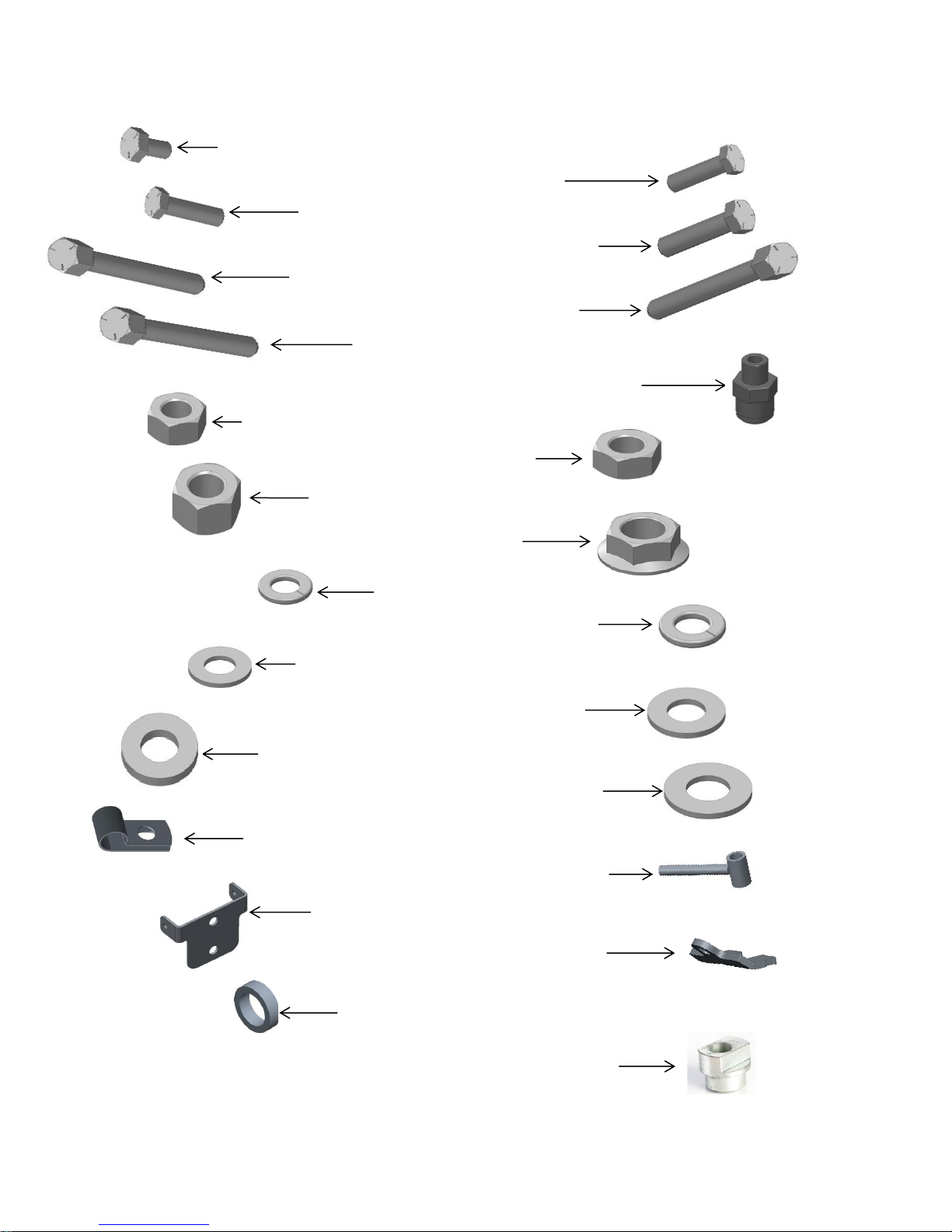

2968-145 Pictorial Parts List – Bolt Bag for 2968-040A & 2968-044

2502-104 -1/4-20 X 1/2 HHCS GR. 5 ZYD.– QTY 2

2502-351 -1/2-13 X 2 HHCS GR.5 ZP– QTY 2

2502-379 -M12 X 1.75 X 35 GRD 10.9 ZYD– QTY 2

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 2

2520-151 -1/4-20 HEX NUT, GR 2, ZP– QTY 2

2520-253 -3/8-16 JAM HEX NUT, GR 2, ZP– QTY 4

2520-361 -1/2-13FLANGE WHZLCK HXNT, GR 5, ZP – QTY 2

2520-464 -5/8-11 WHIZLOCK ZP, GR 8– QTY 2

2525-151 - 1/4 MED. LOCKWASHER ZP – QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 2

2525-352 - 1/2 MED LOCKWASHER ZP – QTY 5

2502-314 -1/2-13 X 2-1/4" GRADE 5 HHCS ZYD – QTY 3

2526-454 - 5/8SAE FLATWASHER HRD'ND ZP – QTY 3

2570-724 - 3/8 HOSE P-CLIP W/ VINYL CUSHION – QTY 2

2968-218 - INJECTOR HOLDER W.A. – QTY 2

2968-363 - HOSE HOLDER, FORMED – QTY 1

2526-253 - 3/8 SAE FLATWASHER ZP – QTY 4

2502-293 -1/2-13 X 1 ¼” GRADE 5 HHCS ZYD – QTY 2

9

Page 10

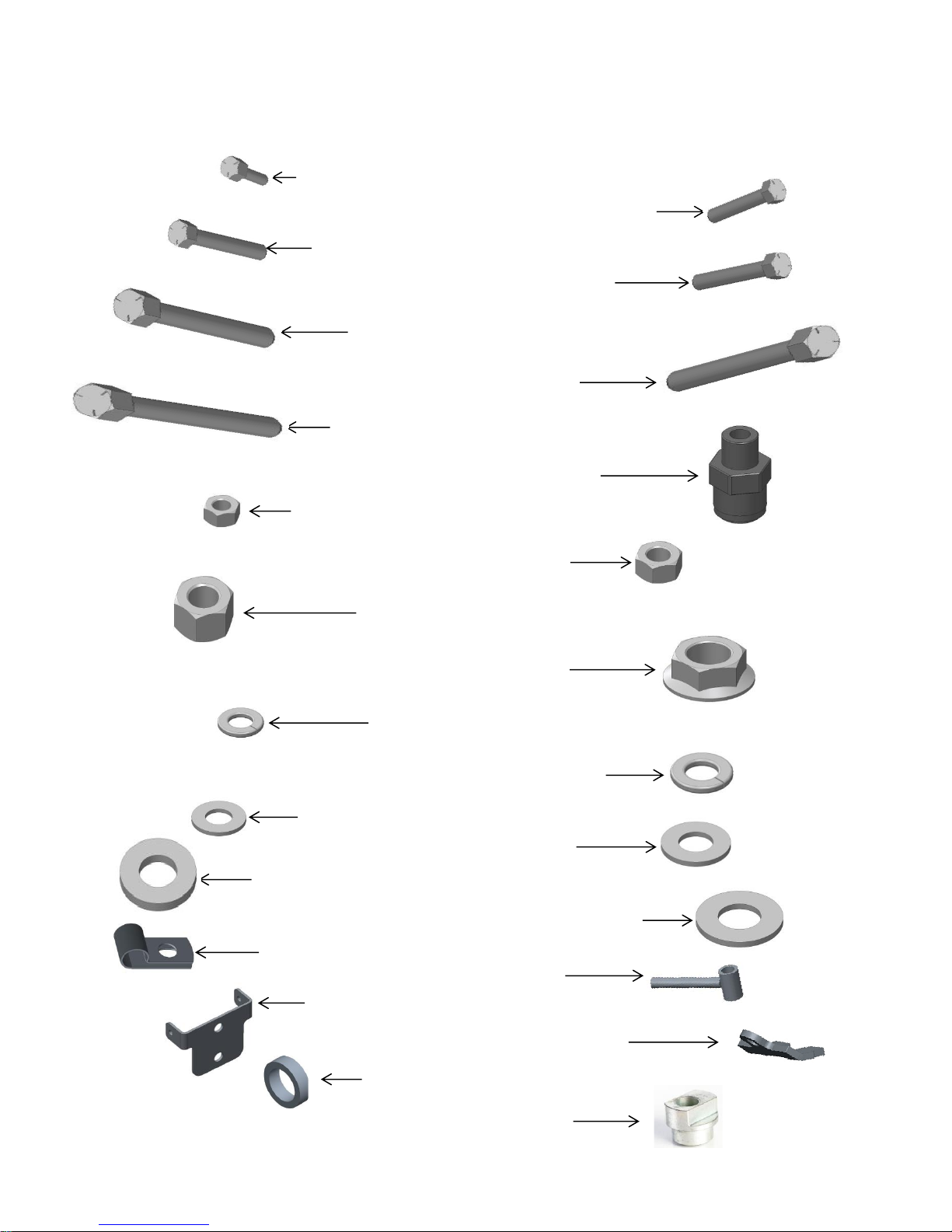

2968-147 Pictorial Parts List – Bolt Bag for 2968-041

2502-104 -1/4-20 X 1/2 HHCS GR. 5 ZYD – QTY 2

2502-245 - 3/8-16 X 1 ¾ HHCS GR 5 ZP – QTY 1

2502-362 -1/2-13 X 5 HHCS GR. 5 ZP – QTY 1

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 2

2520-151 -1/4-20 HEX NUT, GR 2, ZP– QTY 2

2502-368 -1/2-13 X 5-1/2 HHCS GR5 ZP – QTY 1

2502-372 -1/2-13 X 6-1/2 HHCS GR5 ZP – QTY 1

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 2

2525-352 - 1/2 MED LOCKWASHER ZP – QTY 3

2502-314 -1/2-13 X 2-1/4" GRADE 5 HHCS ZYD – QTY 3

2520-253 3/8 JAM HEX NUT – QTY 4

2520-464 5/8 WHIZ LOCK– QTY 2

2526-454 - 5/8SAE FLATWASHER HRD'ND ZP – QTY 2

2570-724 - 3/8 HOSE P-CLIP W/ VINYL CUSHION – QTY 2

2526-253 - 3/8 SAE FLATWASHER ZP – QTY 8

2526-352 - 1/2 SAE FLATWASHER ZP – QTY 4

2968-218 - INJECTOR HOLDER W.A. – QTY 2

2968-363 - HOSE HOLDER, FORMED – QTY 1

2968-370 – GAUGE WHEEL ARM STOP – QTY 1

6000-523 – ECCENTRIC BUSHING CLOSE WHEEL– QTY 2

2968-373 – SPACER – QTY 2

2526-402 – 9/16ID X 1 3/4OD X 1/4MB ZP – QTY 2

2502-232 – 3/8-16 X 1 ½ HHCS GR 5 ZP – QTY – 1

10

Page 11

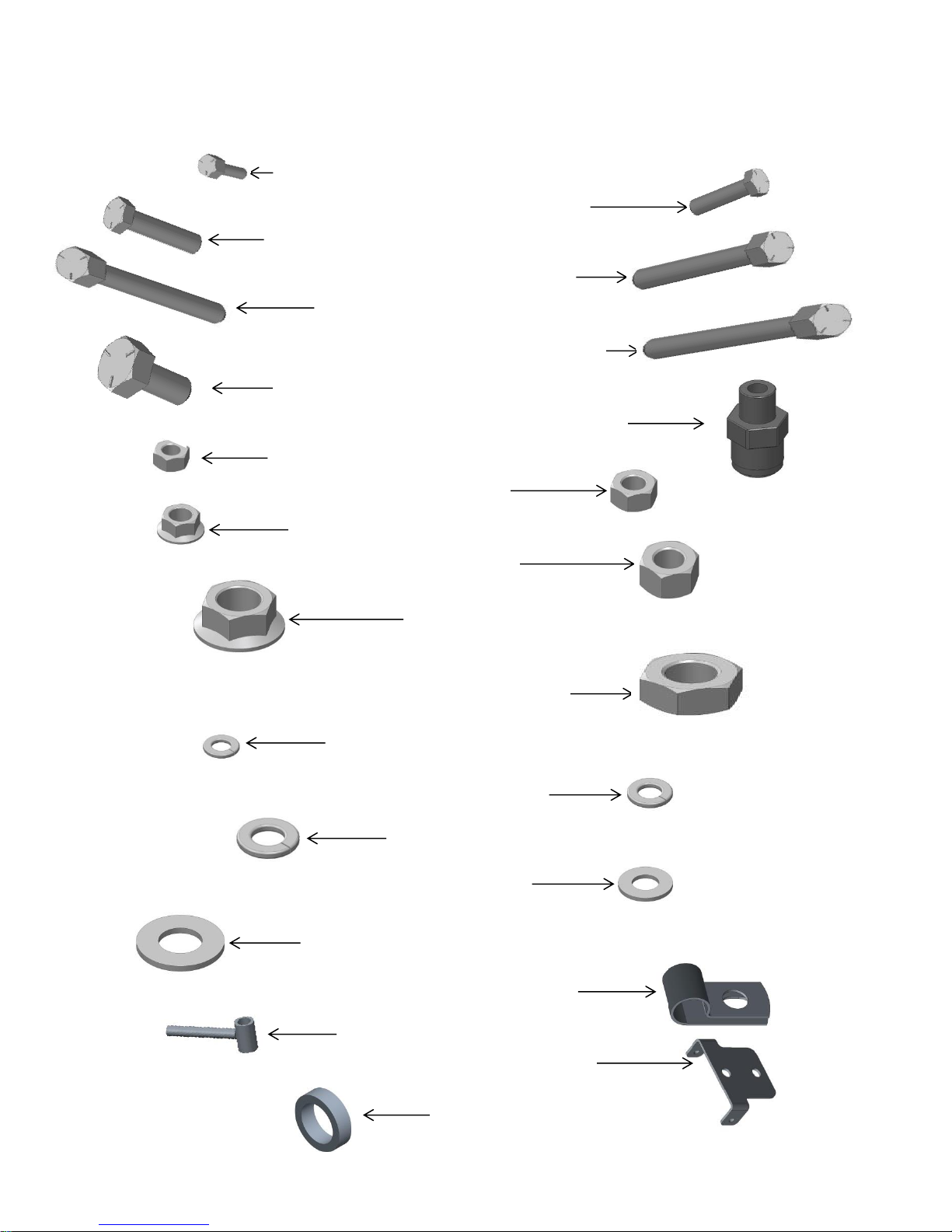

2502-104 -1/4-20 X 1/2 HHCS GR. 5 ZYD.– QTY 1

2502-232 – 3/8 – 16 X 1 ½ HHCS GR 5 ZP – QTY 1

2502-362 -1/2-13 X 5 HHCS GR. 5 ZP – QTY 1

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 1

2520-151 -1/4-20 HEX NUT, GR 2, ZP– QTY 1

2502-368 -1/2-13 X 5-1/2 HHCS GR5 ZP – QTY 1

2502-372 -1/2-13 X 6-1/2 HHCS GR5 ZP – QTY 1

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 1

2525-352 - 1/2 MED LOCKWASHER ZP – QTY 3

2502-245 - 3/8-16 X 1-3/4 HHCS GR 5 ZP – QTY 1

2520-253 3/8 JAM HEX NUT – QTY 2

2520-464 5/8 WHIZ LOCK– QTY 1

2526-454 - 5/8 SAE FLATWASHER HRD'ND ZP – QTY 1

2570-724 - 3/8 HOSE P-CLIP W/ VINYL CUSHION – QTY 1

2968-218 - INJECTOR HOLDER W.A. – QTY 1

2526-253 - 3/8 SAE FLATWASHER ZP – QTY 6

2526-352 - 1/2 SAE FLATWASHER ZP – QTY 4

2968-363 - HOSE HOLDER, FORMED – QTY 1

2968-370 – GAUGE WHEEL ARM STOP – QTY 1

2502-351 -1/2-13 X 2" GRADE 5 HHCS – QTY 3

2968-373 – SPACER – QTY 2

2526-402 – 9/16ID X 1 3/4OD X 1/4MB ZP – QTY 2

2968-148 Pictorial Parts List – Bolt Bag for 2968-021A

11

Page 12

2502-104 -1/4-20 X 1/2 HHCS GR. 5 ZYD.– QTY 2

2502-266 – 7/16 – 14 X 1 ½ HHCS GR 5 ZP – QTY 1

2502-368 -1/2-13 X 5-1/2 HHCS GR5 ZP – QTY 1

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 2

2520-151 -1/4-20 HEX NUT, GR 2, ZP– QTY 2

2502-372 -1/2-13 X 6-1/2 HHCS GR5 ZP – QTY 1

2502-375 – ½ - 13 X 8 ½ HHCS GR 5 ZP – QTY 1

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 2

2525-352 - 1/2 MED LOCKWASHER ZP – QTY 3

2502-314 -1/2-13 X 2 ¼” GRADE 5 HHCS – QTY 3

2520-253 3/8 JAM HEX NUT – QTY 4

2520-464 5/8 WHIZ LOCK– QTY 2

2526-454 - 5/8 SAE FLATWASHER HRD'ND ZP – QTY 2

2570-724 - 3/8 HOSE P-CLIP W/ VINYL CUSHION – QTY 2

2968-218 - INJECTOR HOLDER W.A. – QTY 2

2526-253 - 3/8 SAE FLATWASHER ZP – QTY 4

2968-363 - HOSE HOLDER, FORMED – QTY 1

2968-373 – SPACER – QTY 2

2520-502 – ¾ - 10 HEX JAM NUT GR 2 ZP– QTY 1

2520-307 – 7/16 – 14 FLANGE WHIZ LOCK GR 2 – QTY 1

2502-501 – ¾ - 10 X 1 ½ HHCS GR 5 ZP – QTY 1

2525-151 – ¼ MED LOCK WASHER ZP – QTY 2

2968-151 Pictorial Parts List – Bolt Bag for 2968-045

12

Page 13

2968-152 Pictorial Parts List – Bolt Bag for 2968-027

2502-104 -1/4-20 X 1/2 HHCS GR. 5 ZYD.– QTY 1

2502-266 – 7/16 – 14 X 1 ½ HHCS GR 5 ZP – QTY 1

2502-368 -1/2-13 X 5-1/2 HHCS GR5 ZP – QTY 1

2515-846 -MALE CONNECTOR - 3/8 X 1/4 NPTF– QTY 1

2520-151 -1/4-20 HEX NUT, GR 2, ZP– QTY 1

2502-372 -1/2-13 X 6-1/2 HHCS GR5 ZP – QTY 1

2502-375 – ½ - 13 X 8 ½ HHCS GR 5 ZP – QYT 1

2520-357 1/2-13 LOCK HEX NUT, GR A, ZP– QTY 2

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 1

2525-352 - 1/2 MED LOCKWASHER ZP – QTY 3

2502-351 -1/2-13 X 2” GRADE 5 HHCS – QTY 3

2520-253 3/8 JAM HEX NUT – QTY 2

2520-464 5/8 WHIZ LOCK– QTY 1

2526-454 - 5/8 SAE FLATWASHER HRD'ND ZP – QTY 1

2570-724 - 3/8 HOSE P-CLIP W/ VINYL CUSHION – QTY 1

2968-218 - INJECTOR HOLDER W.A. – QTY 1

2526-253 - 3/8 SAE FLATWASHER ZP – QTY 2

2968-363 - HOSE HOLDER, FORMED – QTY 1

2968-373 – SPACER – QTY 2

2520-502 – ¾ - 10 HEX JAM NUT GR 2 ZP– QTY 1

2520-307 – 7/16 – 14 FLANGE WHIZ LOCK GR 2 – QTY 1

2502-501 – ¾ - 10 X 1 ½ HHCS GR 5 ZP – QTY 1

2525-251 -3/8 MED. LOCKWASHER ZP – QTY 1

13

Page 14

INSTALLATION INSTRUCTIONS

Step 1: Remove the V-Closing Wheel Tail Piece from the row unit.

JD 1700/7200/7300 Kinze/JD 7000/7100 Harvest International

Step 2: Install the Fertilizer Mount Plate for the Yetter 2968 unit.

JD 1700/7200/7300 Kinze 2000 & 3000/JD 7000/7100

Harvest International Kinze 4900

14

Page 15

INSTALLATION INSTRUCTIONS

Step 3: Attach V-Closing Wheel Tail Piece to the Fertilizer Mount Plate. Reattach the spring.

JD 1700/7200/7300 All Kinze/JD 7000/7100 Harvest International

(2968-020A, 2968-021A, 2968-026A, & 2968-027A MODELS, SINGLE DISC)

(IF INSTALLING 2968-040, 2968-041, 2968-044, OR 2968-045 DUAL DISC, SKIP TO 4B)

Step 4A: Install the 2968-359-LH or 2968-359-RH L-Mount bracket, Arm Clamp, & Formed Hose Holder to the

Fertilizer Mount Plate using 3) ½” X 2” Bolts & 3) ½” Lock Washers.

NOTE: DO NOT tighten the 3) ½” X 2” Bolts until after the wheel are installed.

JD 1700/7200/7300 Kinze/JD 7000/7100

Harvest International Kinze 4900

15

Page 16

INSTALLATION INSTRUCTIONS

(2968-040A, 2968-041A, 2968-044A, & 2968-045 MODELS, DUAL DISC)

Step 4B: Install the 2968-359-RH L-Mount bracket, 2968-360 Tall L-Mount Bracket, Arm Clamp, &

Formed Hose Holder to Fertilizer Mount Plate using 3) ½” X 2 ¼” Bolts & 3) ½” Lock Washers.

NOTE: DO NOT tighten the 3) ½” X 2 ¼” Bolts until after the wheel are installed.

JD 1700/7200/7300 Kinze/JD 7000/7100

Harvest International Kinze 4900

16

Page 17

INSTALLATION INSTRUCTIONS

NOTE: If installing 2968-090 Rear Knife Option, use that manual to finish installation from this point.

Step 5: Place a 5/8 flat washer over the D-bolt & install the Fertilizer Wheel Assembly to the

Fertilizer Wheel Mount Plate & tighten 5/8flange whiz lock nut. See page 19 to determine

which D-bolt hole to install the wheel assembly to achieve your desired depth.

SINGLE WHEEL (RH Shown) DUAL WHEEL

Step 6: Set each Fertilizer Wheel Assembly to the desired spacing off the row (2” – 3”) & then

tighten the 3) ½” bolts from STEP 4.

SINGLE WHEEL DUAL WHEEL WHEEL ADJUSTMENT

17

Page 18

INSTALLATION INSTRUCTIONS

STEP 7: Install each P-Clip to the Formed Hose Holder using ¼” X ½” bolts, ¼” lock washers, & ¼” hex nuts. A

P-Clip should be placed on the side with blade for single wheel placement & on both sides for dual wheel

placement.

SINGLE WHEEL DUAL WHEEL

STEP 8: Install each Injector Holder behind each blade. Thread a 3/8” hex jam nut on the threaded rod roughly 2”,

place a 3/8” lock washer & 3/8” flat washer over the threaded rod against the hex jam nut. Slide the

threaded rod through the horizontal slotted hole on the fertilizer wheel mount so that the threaded rod

end is on the outside of the fertilizer wheel mount. Place a 3/8” flat washer over the end & thread another

3/8” hex jam nut. Before tightening, center the coupler behind the blade & point the bottom of the

coupler slightly forward. Install the push connect fitting on the top side of the coupler if you wish to use it.

18

Page 19

INSTALLATION INSTRUCTIONS

POSITION

DEPTH (USING 10” NOTCHED BLADE)

1

¾” BELOW DOUBLE DISC OPENERS

2

½” BELOW DOUBLE DISC OPENERS

3

¼” BELOW DOUBLE DISC OPENERS

4

EVEN WITH DOUBLE DISC OPENERS

5

¼” ABOVE DOUBLE DISC OPENERS

POSITION

DEPTH (USING 11” NOTCHED BLADE)

1

1 ¼” BELOW DOUBLE DISC OPENERS

2

1” BELOW DOUBLE DISC OPENERS

3

¾” BELOW DOUBLE DISC OPENERS

4

½” BELOW DOUBLE DISC OPENERS

5

¼” BELOW DOUBLE DISC OPENERS

- On dual fertilizer placement, the wheels are staggered front to back

to keep the soil from heaving.

- Fertilizer can be placed 2” – 3” off the seed furrow. Please see your

agronomist to determine best spacing on the rate that’s being applied.

- Blade replacement is necessary when the depth cannot be achieved or

the blade struggles to penetrate the ground.

- If there is buildup of damp soil on the planter gauge wheels or opener disks,

then conditions are less than ideal & some problems may also be

encountered with the fertilizer wheel.

- Seed depth will need rechecked after fertilizer unit installation.

- More row unit down force will be needed to maintain fertilizer wheel depth.

STEP 9: Assemble nozzle tip (not supplied) to each 2968-218 injector holder. Injector tips can be ordered through

fertilizer equipment dealer. Calibrate the fertilizer pump and tips to maximum recommended pressure

of 30PSI and minimum 20PSI at the tip. Attach the fertilizer hose to the top side of each coupler.

OPERATION

19

Page 20

OPERATION

TIP #

LIQUID

PRESSURE IN PSI

CAPACITY 1 NOZZLE

IN GPM

4 MPH

H2O

5 MPH

H20

5.5 MPH

H2O

6 MPH

H2O

7 MPH

H2O

8MPH

H2O

#00015

20

25

30

40

50

60

0.11

0.12

0.13

0.15

0.17

0.18

5.45

5.94

6.44

7.43

8.42

8.91

4.36

4.75

5.15

5.94

6.73

7.13

3.96

4.32

4.68

5.40

6.12

6.48

3.63

3.96

4.29

4.95

5.61

5.94

3.11

3.39

3.68

4.24

4.81

5.09

2.72

2.97

3.22

3.71

4.21

4.46

#0002

20

25

30

40

50

60

0.14

0.16

0.17

0.20

0.23

0.25

6.93

7.92

8.42

9.90

11.39

12.38

5.54

6.34

6.73

7.92

9.11

9.90

5.04

5.76

6.12

7.20

8.28

9.00

4.62

5.28

5.61

6.60

7.59

8.25

3.96

4.53

4.81

5.66

6.51

7.07

3.47

3.96

4.21

4.95

5.69

6.19

#0003

20

25

30

40

50

60

0.21

0.24

0.26

0.30

0.34

0.37

10.40

11.88

12.87

14.85

16.83

18.32

8.32

9.50

10.30

11.88

13.46

14.65

7.56

8.64

9.36

10.80

12.24

13.32

6.93

7.92

8.58

9.90

11.22

12.21

5.94

6.79

7.35

8.49

9.62

10.47

5.20

5.94

6.44

7.43

8.42

9.16

#0004

20

25

30

40

50

60

0.28

0.32

0.35

0.40

0.45

0.49

13.86

15.84

17.33

19.80

22.28

24.26

11.09

12.67

13.86

15.84

17.82

19.40

10.08

11.52

12.60

14.40

16.20

17.64

9.24

10.56

11.55

13.20

14.85

16.17

7.92

9.05

9.90

11.31

12.73

13.86

6.93

7.92

8.66

9.90

11.14

12.13

#0005

20

25

30

40

50

60

0.35

0.40

0.43

0.50

0.56

0.61

17.33

19.80

21.29

24.75

27.72

30.20

13.86

15.84

17.03

19.80

22.18

24.16

12.60

14.40

15.48

18.00

20.16

21.96

11.55

13.20

14.19

16.50

18.48

20.13

9.90

11.31

12.16

14.14

15.84

17.25

8.66

9.90

10.64

12.38

13.86

15.10

#0006

20

25

30

40

50

60

0.42

0.47

0.52

0.60

0.67

0.74

20.79

23.27

25.74

29.70

33.17

36.63

16.63

18.61

20.59

23.76

26.53

29.30

15.12

16.92

18.72

21.60

24.12

26364

13.86

15.51

17.16

19.80

22.11

24.42

11.88

13.29

14.71

16.97

18.95

20.93

10.40

11.63

12.87

14.85

16.58

18.32

#0008

20

25

30

40

50

60

0.57

0.63

0.69

0.80

0.89

0.98

28.22

31.19

34.16

39.60

44.06

48.51

22.57

24.95

27.32

31.68

35.24

38.81

20.52

22.68

24.84

28.80

32.04

35.28

18.81

20.79

22.77

26.40

29.37

32.34

16.12

17.82

19.52

22.63

25.17

27.72

14.11

15.59

17.08

19.80

22.03

24.26

#0010

20

25

30

40

50

60

0.71

0.79

087

1.00

1.12

1.23

35.15

39.11

43.07

49.50

55.44

60.89

28.12

31.28

34.45

39.60

44.35

48.71

25.56

28.44

31.32

36.00

40.32

44.28

23.43

26.07

28.71

33.00

36.96

40.59

20.08

22.35

24.61

28.29

31.68

34.79

17.57

19.55

21.53

24.75

27.72

30.44

#0015

20

25

30

40

50

60

1.06

1.19

1.30

1.50

1.68

1.81

52.47

58.91

64.35

74.25

83.16

89.60

41.98

47.12

51.48

59.40

66.53

71.68

38.16

42.84

46.80

54.00

60.48

65.16

34.98

39.27

42.90

49.50

55.44

59.73

29.98

33.66

36.77

42.43

47.52

51.20

26.24

29.45

32.18

37.13

41.58

44.80

Row Spacing Multiplier

10” X 3.3

15” X 2.0

20” X 1.5

36” X .83

38” X .79

40” X .75

GALLONS PER ACRE (USING WATER)

LIQUID FERTILIZER APPLICATION RATE & PRESSURE CHART – TABLES BASED ON 30” NOZZLE SPACING

20

Page 21

MAINTENANCE

IMPORTANT: If seal is removed from hub/bearing assembly, grease bearing

Every 50 hours. If seal is left assembled, 2-3 pumps of grease twice a year,

depending on acres, is sufficient.

IMPORTANT: For proper operation, the planter frame must operate level

(fore, aft & side to side) and at the correct height, typically 20”-22”.

21

Page 22

MAINTENANCE

Grease must fill this

Hubcap cavity.

NOTE: BE CERTAIN TO ALIGN THE GREASE FITTING WITH THE SLOT IN THE WHEEL & HUBCAP SO THAT THE GREASE

CAN FLOW FREELY.

22

Page 23

MAINTENANCE

PART #

DESCRIPTION

OUNCES OF GREASE

2968-320

10” FERTILIZER WHEEL

1.12 OZ

2968-364

11” FERTILIZER WHEEL

1.12 OZ

CAUTION: To help prevent serious injury/death to you or others caused by unexpected movement, service machine

on a level surface. Lower machine to ground or sufficiently lock or block raised machine before servicing.

If machine is connected to tractor, engage parking brake & place transmission in “PARK”, shut off engine,

& remove key. If machine is detached from tractor, block wheels & use shop stands to prevent movement.

CAUTION: DO NOT CLEAN, LUBRICATE, OR ADJUST MACHINE WHILE IN MOTION

Use grease based on NLGI consistency numbers & the expected air temperature range during the service interval.

Use a multi-purpose polyurea, water resistant, moderate speed, & NLGI grade #2 grease. Other greases may be used

if they meet the following NLGI Perfomance.

IMPORTANT: Some types of grease thickener are not compatible with others. Consult your grease supplier before

mixing different types of greases.

Alternative Lubricants

Conditions in certain geographical areas may require special lubricants & lubrication practices which do not appear in

the operator’s manual. If there are any questions, consult Yetter Manufacturing Co. to obtain latest information &

recommendation.

Storing Lubricants

Your machine can operate at top efficiency only if clean lubricants are used. Use clean containers to handle all

lubricants. Store them in an area protected from dust, moisture and other contaminants

LUBRICATION SYMBOLS

Lubricate with grease at hourly interval indicated on symbol if Lubrication Intervals

seal has been removed. If seal is left installed on hub/beairng

assembly, apply 2 – 3 pumps of grease to each hub twice a

season to keep cavity full.

IMPORTANT: The recommended service intervals are based on normal conditions; severe or unusual conditions may

require more frequent lubrication. Perform each lubrication and service procedure at the beginning

& end of each season. Clean grease fittings before using grease gun, to avoid injecting dirt & grit into

the bearing. Replace any lost or broken fittings immediately. If a fitting fails to take grease, remove &

clean thoroughly, replace fitting if necessary. Also check for failure of adjoining parts.

BEARING REPLACEMENT INSTALLATION

1. When assembling the spoke wheels, bearing assembly and hubcap, be sure to align the grease transfer hole

in the spoke wheel with the groove in the hubcap and hole in the hub to allow grease passage.

2. Assemble the wheels, hubs and caps.

3. Grease the wheel/hub/bearing assembly.

23

Page 24

2968-020A-L-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1

2

2502-351

½ - 13 X 2 HHCS GR 5 ZP

5 3 2502-379

M12 X 1.75 X 35 GRD 10.9 ZYD

2 4 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 5 2520-151

¼ - 20 HEX NUT ZP

1 6 2520-253

3/8 – 16 JAM HEX NUT ZP

2 7 2520-361

½ - 13 FLANGE WHIZ LOCK HEX NUT, GR 5, ZP

2 8 2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1 9 2525-151

¼ MEDIUM LOCK WASHER ZP

1

10

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

11

2525-352

½ MEDIUM LOCK WASHER ZP

5

12

2526-253

3/8 SAE FLAT WASHER ZP

2

13

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

14

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

15

2968-218

INJECTOR HOLDER W.A.

1

16

2968-222

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

17

2968-361

ARM CLAMP

1

18

2968-363

FORMED HOSE HOLDER

1

19

2968-359-LH

LH SHORT FERTILIZER WHEEL MOUNT

1

FOR JD 1700, 7200, & 7300

24

Page 25

2968-020A-R-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-351

½ - 13 X 2 HHCS GR 5 ZP

5 3 2502-379

M12 X 1.75 X 35 GRD 10.9 ZYD

2 4 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 5 2520-151

¼ - 20 HEX NUT ZP

1 6 2520-253

3/8 – 16 JAM HEX NUT ZP

2 7 2520-361

½ - 13 FLANGE WHIZ LOCK HEX NUT, GR 5, ZP

2

8

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

9

2525-151

¼ MEDIUM LOCK WASHER ZP

1

10

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

11

2525-352

½ MEDIUM LOCK WASHER ZP

5

12

2526-253

3/8 SAE FLAT WASHER ZP

2

13

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

14

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

15

2968-218

INJECTOR HOLDER W.A.

1

16

2968-222

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

17

2968-361

ARM CLAMP

1

18

2968-363

FORMED HOSE HOLDER

1

19

2968-359-RH

RH SHORT FERTILIZER WHEEL MOUNT

1

FOR JD 1700, 7200, & 7300

25

Page 26

2968-021A-L-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY

1

2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-232

3/8 – 16 X 1 ½ HHCS GR 5 ZYD (USED ON KINZE 3000)

1

2502-245

3/8 – 16 1 ¾ HHCS GR 5 ZP (USED ON JD 7000 & 7100, KINZE 2000)

1 3 2502-351

½ - 13 X 2 HHCS GR 5 ZP

3

4

2502-362

½ - 13 X 5 HHCS GR 5 ZP

1 5 2502-368

½ - 13 X 5 ½ HHCS GR 5 ZP

1 6 2502-372

½ - 13 X 6 ½ HHCS GR 5 ZP

1 7 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 8 2520-151

¼ - 20 HEX NUT ZP

1 9 2520-253

3/8 – 16 JAM HEX NUT ZP

2

10

2520-357

½ - 13 LOCK HEX NUT, GR A, ZP

2

11

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

12

2525-151

¼ MEDIUM LOCK WASHER ZP

1

13

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

14

2525-352

½ MEDIUM LOCK WASHER ZP

3

15

2526-253

3/8 SAE FLAT WASHER ZP

3

16

2526-352

½ SAE FLAT WASHER ZP

4

17

2526-402

9/16ID X 1 ¾OD X 1/4MB ZP

2

18

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

19

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

20

2968-218

INJECTOR HOLDER W.A.

1

21

2968-223

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

22

2968-359-LH

LH SHORT FERTILIZER WHEEL MOUNT

1

23

2968-361

ARM CLAMP

1

24

2968-363

FORMED HOSE HOLDER

1

25

2968-370

GAUGE WHEEL ARM STOP(ONLY USED ON JD 7000 & 7100, KINZE 2000)

1

26

2968-373

SPACER

2

27

6000-523

ECCENTRIC BUSHING CLOSE WHEEL

2

FOR JD 7000 & 7100, KINZE 2000 & 3000

26

Page 27

2968-021A-R-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY

1

2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-232

3/8 – 16 X 1 ½ HHCS GR 5 ZYD (USED ON KINZE 3000)

1

2502-245

3/8 – 16 1 ¾ HHCS GR 5 ZP (USED ON JD 7000 & 7100, KINZE 2000)

1 3 2502-351

½ - 13 X 2 HHCS GR 5 ZP

3

4

2502-362

½ - 13 X 5 HHCS GR 5 ZP

1 5 2502-368

½ - 13 X 5 ½ HHCS GR 5 ZP

1 6 2502-372

½ - 13 X 6 ½ HHCS GR 5 ZP

1 7 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 8 2520-151

¼ - 20 HEX NUT ZP

1 9 2520-253

3/8 – 16 JAM HEX NUT ZP

2

10

2520-357

½ - 13 LOCK HEX NUT, GR A, ZP

2

11

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

12

2525-151

¼ MEDIUM LOCK WASHER ZP

1

13

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

14

2525-352

½ MEDIUM LOCK WASHER ZP

3

15

2526-253

3/8 SAE FLAT WASHER ZP

3

16

2526-352

½ SAE FLAT WASHER ZP

4

17

2526-402

9/16ID X 1 ¾OD X 1/4MB ZP

2

18

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

19

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

20

2968-218

INJECTOR HOLDER W.A.

1

21

2968-223

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

22

2968-361

ARM CLAMP

1

23

2968-363

FORMED HOSE HOLDER

1

24

2968-370

GAUGE WHEEL ARM STOP(ONLY USED ON JD 7000 & 7100, KINZE 2000)

1

25

2968-373

SPACER

2

26

2968-359-RH

RH SHORT FERTILIZER WHEEL MOUNT

1

27

6000-523

ECCENTRIC BUSHING CLOSE WHEEL

2

FOR JD 7000 & 7100, KINZE 2000 & 3000

27

Page 28

2968-026A-L-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-293

½ - 13 X 1 ¼ HHCS GR 5 ZP

2 3 2502-351

½ - 13 X 2 HHCS GR 5 ZP

5 4 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 5 2520-151

¼ - 20 HEX NUT ZP

1 6 2520-253

3/8 – 16 JAM HEX NUT ZP

2 7 2520-361

½ - 13 FLANGE WHIZ LOCK HEX NUT, GR 5, ZP

2

8

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

9

2525-151

¼ MEDIUM LOCK WASHER ZP

1

10

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

11

2525-352

½ MEDIUM LOCK WASHER ZP

5

12

2526-253

3/8 SAE FLAT WASHER ZP

2

13

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

14

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

15

2968-218

INJECTOR HOLDER W.A.

1

16

2968-225

FERTILIZER CLOSE WHEEL MOUNT W.A., HARVEST INTL

1

17

2968-361

ARM CLAMP

1

18

2968-363

FORMED HOSE HOLDER

1

19

2968-359-LH

LH SHORT FERTILIZER WHEEL MOUNT

1

HARVEST INTERNATIONAL

28

Page 29

2968-026A-R-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-293

½ - 13 X 1 ¼ HHCS GR 5 ZP

2 3 2502-351

½ - 13 X 2 HHCS GR 5 ZP

5 4 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 5 2520-151

¼ - 20 HEX NUT ZP

1 6 2520-253

3/8 – 16 JAM HEX NUT ZP

2 7 2520-361

½ - 13 FLANGE WHIZ LOCK HEX NUT, GR 5, ZP

2

8

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

9

2525-151

¼ MEDIUM LOCK WASHER ZP

1

10

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

11

2525-352

½ MEDIUM LOCK WASHER ZP

5

12

2526-253

3/8 SAE FLAT WASHER ZP

2

13

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

14

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

15

2968-218

INJECTOR HOLDER W.A.

1

16

2968-225

FERTILIZER CLOSE WHEEL MOUNT W.A., HARVEST INTL

1

17

2968-361

ARM CLAMP

1

18

2968-363

FORMED HOSE HOLDER

1

19

2968-359-RH

RH SHORT FERTILIZER WHEEL MOUNT

1

HARVEST INTERNATIONAL

29

Page 30

2968-027A-L-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY

1

2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-266

7/16 – 14 X 1 ½ HHCS GR 5 ZP

1

3

2502-351

½ - 13 X 2 HHCS GR 5 ZP

3 4 2502-368

½ - 13 X 5 ½ HHCS GR 5 ZP

1

5

2502-372

½ - 13 X 6 ½ HHCS GR 5 ZP

1 6 2502-375

½ - 13 X 8 ½ HHCS GR 5 ZP

1 7 2502-501

¾ - 10 X 1 ½ HHCS GR 5 ZP

1 8 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 9 2520-151

¼ - 20 HEX NUT ZP

1

10

2520-253

3/8 – 16 JAM HEX NUT ZP

2

11

2520-307

7/16 – 14 FLANGE LOCK NUT

1

12

2520-357

½ - 13 LOCK HEX NUT, GR A, ZP

2

13

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

14

2520-502

¾ - 10 HEX JAM NUT, GR 2, ZP

1

15

2525-151

¼ MEDIUM LOCK WASHER ZP

1

16

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

17

2525-352

½ MEDIUM LOCK WASHER ZP

3

18

2526-253

3/8 SAE FLAT WASHER ZP

2

19

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

20

2565-179

YETTER DECAL

1

21

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

22

2968-218

INJECTOR HOLDER W.A.

1

23

2968-228

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

24

2968-359-LH

LH SHORT FERTILIZER WHEEL MOUNT

1

25

2968-361

ARM CLAMP

1

26

2968-363

FORMED HOSE HOLDER

1

27

2968-373

SPACER

2

KINZE 4900

30

Page 31

2968-027-R-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY

1

2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-266

7/16 – 14 X 1 ½ HHCS GR 5 ZP

1 3 2502-351

½ - 13 X 2 HHCS GR 5 ZP

3 4 2502-368

½ - 13 X 5 ½ HHCS GR 5 ZP

1 5 2502-372

½ - 13 X 6 ½ HHCS GR 5 ZP

1

6

2502-375

½ - 13 X 8 ½ HHCS GR 5 ZP

1 7 2502-501

¾ - 10 X 1 ½ HHCS GR 5 ZP

1 8 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1

9

2520-151

¼ - 20 HEX NUT ZP

1

10

2520-253

3/8 – 16 JAM HEX NUT ZP

2

11

2520-307

7/16 – 14 FLANGE LOCK NUT

1

12

2520-357

½ - 13 LOCK HEX NUT, GR A, ZP

2

13

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

14

2520-502

¾ - 10 HEX JAM NUT, GR 2, ZP

1

15

2525-151

¼ MEDIUM LOCK WASHER ZP

1

16

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

17

2525-352

½ MEDIUM LOCK WASHER ZP

3

18

2526-253

3/8 SAE FLAT WASHER ZP

2

19

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

20

2565-179

YETTER DECAL

1

21

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

22

2968-218

INJECTOR HOLDER W.A.

1

23

2968-228

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

24

2968-359-LH

LH SHORT FERTILIZER WHEEL MOUNT

1

25

2968-361

ARM CLAMP

1

26

2968-363

FORMED HOSE HOLDER

1

27

2968-373

SPACER

2

KINZE 4900

31

Page 32

2968-040-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1

2

2502-314

½ - 13 X 2 ¼ HHCS GR 5 ZP

3 3 2502-351

½ - 13 X 2 HHCS GR 5 ZP

2 4 2502-379

M12 X 1.75 X 35 GRD 10.9 ZYD

2 5 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

2 6 2520-151

¼ - 20 HEX NUT ZP

2 7 2520-253

3/8 – 16 JAM HEX NUT ZP

4 8 2520-361

½ - 13 FLANGE WHIZ LOCK HEX NUT, GR 5, ZP

2 9 2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

2

10

2525-151

¼ MEDIUM LOCK WASHER ZP

2

11

2525-251

3/8 MEDIUM LOCK WASHER ZP

2

12

2525-352

½ MEDIUM LOCK WASHER ZP

5

13

2526-253

3/8 SAE FLAT WASHER ZP

4

14

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

2

15

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

2

16

2968-218

INJECTOR HOLDER W.A.

2

17

2968-222

FERTILIZER CLOSE WHEEL MOUNT W.A.

2

18

2968-359-RH

RH SHORT FERTILIZER WHEEL MOUNT

1

19

2968-360

TALL FERT. WHEEL MOUNT

1

20

2968-361

ARM CLAMP

1

21

2968-363

FORMED HOSE HOLDER

2

FOR JD 1700, 7200, & 7300

32

Page 33

2968-041-LB PARTS IDENTIFICATION

FOR JD 7000 & 7100, KINZE 2000 & 3000

33

Page 34

2968-041-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

2 2 2502-245

3/8 – 16 1 ¾ HHCS GR 5 ZP

1 3 2502-314

½ - 13 X 2 ¼ HHCS GR 5 ZP

3 4 2502-362

½ - 13 X 5 HHCS GR 5 ZP

1 5 2502-368

½ - 13 X 5 ½ HHCS GR 5 ZP

1 6 2502-372

½ - 13 X 6 ½ HHCS GR 5 ZP

1 7 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

2 8 2520-151

¼ - 20 HEX NUT ZP

2 9 2520-253

3/8 – 16 JAM HEX NUT ZP

4

10

2520-357

½ - 13 LOCK HEX NUT, GR A, ZP

2

11

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

2

12

2525-151

¼ MEDIUM LOCK WASHER ZP

1

13

2525-251

3/8 MEDIUM LOCK WASHER ZP

2

14

2525-352

½ MEDIUM LOCK WASHER ZP

3

15

2526-253

3/8 SAE FLAT WASHER ZP

5

16

2526-352

½ SAE FLAT WASHER ZP

4

17

2526-402

9/16ID X 1 ¾OD X 1/4MB ZP

2

18

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

19

2565-179

YETTER DECAL

2

20

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

21

2968-218

INJECTOR HOLDER W.A.

1

22

2968-223

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

23

2968-359-RH

RH SHORT FERTILIZER WHEEL

1

24

2968-360

TALL FERTILIZER WHEEL MOUNT

1

25

2968-361

ARM CLAMP

1

26

2968-363

FORMED HOSE HOLDER

1

27

2968-370

GAUGE WHEEL ARM STOP (ONLY USED ON JD 7000 & 7100, KINZE 2000)

1

28

2968-373

SPACER

2

29

6000-523

ECCENTRIC BUSHING CLOSE WHEEL MOUNT

2

FOR JD 7000 & 7100, KINZE 2000 & 3000

34

Page 35

2968-044-R-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY 1 2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

2 2 2502-293

½ - 13 X 1 ¼ HHCS GR 5 ZP

2 3 2502-314

½ - 13 2 ¼ HHCS GR 5 ZP

3 4 2502-351

½ - 13 X 2 HHCS GR 5 ZP

2 5 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

2 6 2520-151

¼ - 20 HEX NUT ZP

2 7 2520-253

3/8 – 16 JAM HEX NUT ZP

4

8

2520-361

½ - 13 FLANGE WHIZ LOCK HEX NUT, GR 5, ZP

2

9

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

2

10

2525-151

¼ MEDIUM LOCK WASHER ZP

2

11

2525-251

3/8 MEDIUM LOCK WASHER ZP

2

12

2525-352

½ MEDIUM LOCK WASHER ZP

5

13

2526-253

3/8 SAE FLAT WASHER ZP

4

14

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

2

15

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

2

16

2968-218

INJECTOR HOLDER W.A.

2

17

2968-225

FERTILIZER CLOSE WHEEL MOUNT W.A., HARVEST INTL

1

18

2968-360

TALL FERTILIZER WHEEL MOUNT

1

19

2968-361

ARM CLAMP

1

20

2968-363

FORMED HOSE HOLDER

1

21

2968-359-RH

RH SHORT FERTILIZER WHEEL MOUNT

1

HARVEST INTERNATIONAL

35

Page 36

2968-045-LB PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY

1

2502-104

¼ - 20 X ½ HHCS GR 5 ZYD

1 2 2502-266

7/16 – 14 X 1 ½ HHCS GR 5 ZP

1

3

2502-351

½ - 13 X 2 HHCS GR 5 ZP

3 4 2502-368

½ - 13 X 5 ½ HHCS GR 5 ZP

1

5

2502-372

½ - 13 X 6 ½ HHCS GR 5 ZP

1 6 2502-375

½ - 13 X 8 ½ HHCS GR 5 ZP

1 7 2502-501

¾ - 10 X 1 ½ HHCS GR 5 ZP

1 8 2515-846

MALE CONNECTOR – 3/8 X ¼ NPTF

1 9 2520-151

¼ - 20 HEX NUT ZP

1

10

2520-253

3/8 – 16 JAM HEX NUT ZP

2

11

2520-307

7/16 – 14 FLANGE LOCK NUT

1

12

2520-357

½ - 13 LOCK HEX NUT, GR A, ZP

2

13

2520-464

5/8 – 11 WHIZ LOCK HEX NUT, GR 2, ZP

1

14

2520-502

¾ - 10 HEX JAM NUT, GR 2, ZP

1

15

2525-151

¼ MEDIUM LOCK WASHER ZP

1

16

2525-251

3/8 MEDIUM LOCK WASHER ZP

1

17

2525-352

½ MEDIUM LOCK WASHER ZP

3

18

2526-253

3/8 SAE FLAT WASHER ZP

2

19

2526-454

5/8 SAE FLAT WASHER HARDENED ZP

1

20

2565-179

YETTER DECAL

1

21

2570-724

3/8 HOSE P-CLIP WITH VINYL CUSHION

1

22

2968-218

INJECTOR HOLDER W.A.

1

23

2968-228

FERTILIZER CLOSE WHEEL MOUNT W.A.

1

24

2968-359-LH

LH SHORT FERTILIZER WHEEL MOUNT

1

25

2968-360

TALL FERTILIZER WHEEL MOUNT

1

26

2968-361

ARM CLAMP

1

27

2968-363

FORMED HOSE HOLDER

1

28

2968-373

SPACER

2

KINZE 4900

36

Page 37

PARTS IDENTIFICATION

ITEM

PART #

DESCRIPTION

QTY

1

2505-207

5/16 – 18 X 1 ¼ CARRIAGE BOLT GR 5 ZP

4 2 2520-206

5/16 – 18 FLANGE LOCK NUT

4 3 2570-740

D-BOLT, FLANGED, 5/8 – 11 X 2.812 GR 8

1 4 2965-128

HUB & BEARING, 4 BOLT

1 5 2965-352

HUB CAP, 4 BOLT, BLACK

1

6

2968-320

10.05 X .256 FERTILIZER WHEEL (SHOWN)

1 2968-364

11.05 X .256 FERTILIZER WHEEL

1

ITEM

PART #

DESCRIPTION

QTY

1

2550-069

TRIPLE LIP SEAL, NTI# 1812-5

1 2 2570-594

BEARING, 2 ROW

1

3

2570-715

BEARING INSERT

1

4

2965-351

HUB CASTING, MACHINED, 4 BOLT

1

5

2533-110

¼ - 28 SELF-TAP ZERK, STRAIGHT

1

2968-132 (SHOWN) 10” WHEEL ASSEMBLY

2968-133 11” WHEEL ASSEMBLY

37

Page 38

38

Page 39

39

Page 40

2565-951_REV_C – 03/2019

40

Loading...

Loading...