Page 1

FLOATING RESIDUE MANAGER

INSTRUCTION MANUAL

PARTS IDENTIFICATION

2565-415_REV_A – UPDATED 03/09

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

1

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly growing

club.

For our part, we want to welcome you to the group

and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into four

major sections: Foreword, Safety Precautions,

Installation Instructions and Parts Breakdown.

This SAFETY ALERT SYMBOL indicates

important safety messages in the manual.

When you see this symbol, be alert to the

possibility of PERSONAL INJURY and carefully

read the message that follows.

The word NOTE is used to convey information that

is out of context with the manual text. It contains

special information such as specifications,

techniques and reference information of a

supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due to

improper technique or operation. Important will

apply to the same information as specified by note

only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the maintenance

schedule in the operator’s manual.

The user is responsible for inspecting his machine

and for having parts repaired or replaced when

continued use of the product would cause damage

or excessive wear to the other parts.

It is the user’s responsibility to deliver his machine

to the Yetter dealer who sold him the product for

service or replacement of defective parts, which are

covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as shall appear to be

defective after inspection. This warranty does not obligate the Company to bear cost of labor in replacement of

parts. It is the policy of the Company to make improvements without incurring obligations to add them to any

unit already sold. No warranty is made or authorized to be made, other than herein set forth. This warranty is in

effect for one year after purchase.

Dealer __________________________________________________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to equipment on

which mounted.

2

Page 3

SAFETY

A brief description of signal words that may be used in this manual:

CAUTION: Used as a general reminder of good safety practices or to direct attention to unsafe

practices.

WARNING: Denotes a specific potential hazard.

DANGER: Denotes the most serious specific potential hazard.

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions

given. Study these precautions carefully and insist that they be followed by those working with

you and for you.

Finally, remember this: an accident is usually caused by someone’s carelessness, neglect or

oversight.

WARNING

Never clean, lubricate or adjust a machine that is in motion. Always lower or block the implement

before performing service.

If machine must be serviced in the raised position, jack or block it up to prevent it from

accidentally falling and injuring someone.

Do not allow riders on the tractor or implement.

Use speeds and caution dictated by the terrain being traversed. Do not operate on any slope

steep enough to cause tipping or loss of control.

Be sure all personnel are clear of the immediate area before operating.

Read and understand the operator’s manual and require all others persons who will operate the

equipment to do the same.

Be familiar with all tractor and implement controls and be prepared to stop engine and implements

quickly in an emergency.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices.

Beware of towed implement width and allow safe clearance.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH.

3

Page 4

ASSEMBLY

2910/2995/2996 MOUNTING BRACKET

1. Remove 3/8 x 2-1/2" roll pin from end of 1-1/2" diameter shank and remove coulter.

2. 2910 Coulter-Bolt the top mount plate to the third set of holes in the mounting bracket with two

1/2 x 1-1/2" bolts, lockwashers and nuts.

2995/2996 Coulter-Bolt the top mount plate to the second set of holes in the mounting bracket

with two 1/2 x 1-1/2" bolts, lockwashers and hex nuts.

3. Slide bracket over pivot casting, reinstall coulter on shank and reinsert roll pin.

4. Install and tighten 5/8" setscrew in lock collar to 110 ft./lb. torque maximum.

5. Attach floating residue manager stem to mounting bracket with two 1/2 x 3-1/2" bolts and lock

hex nuts at desired height.

6. Assemble spoke wheels (2 per row) and attach to floating residue manager stem.

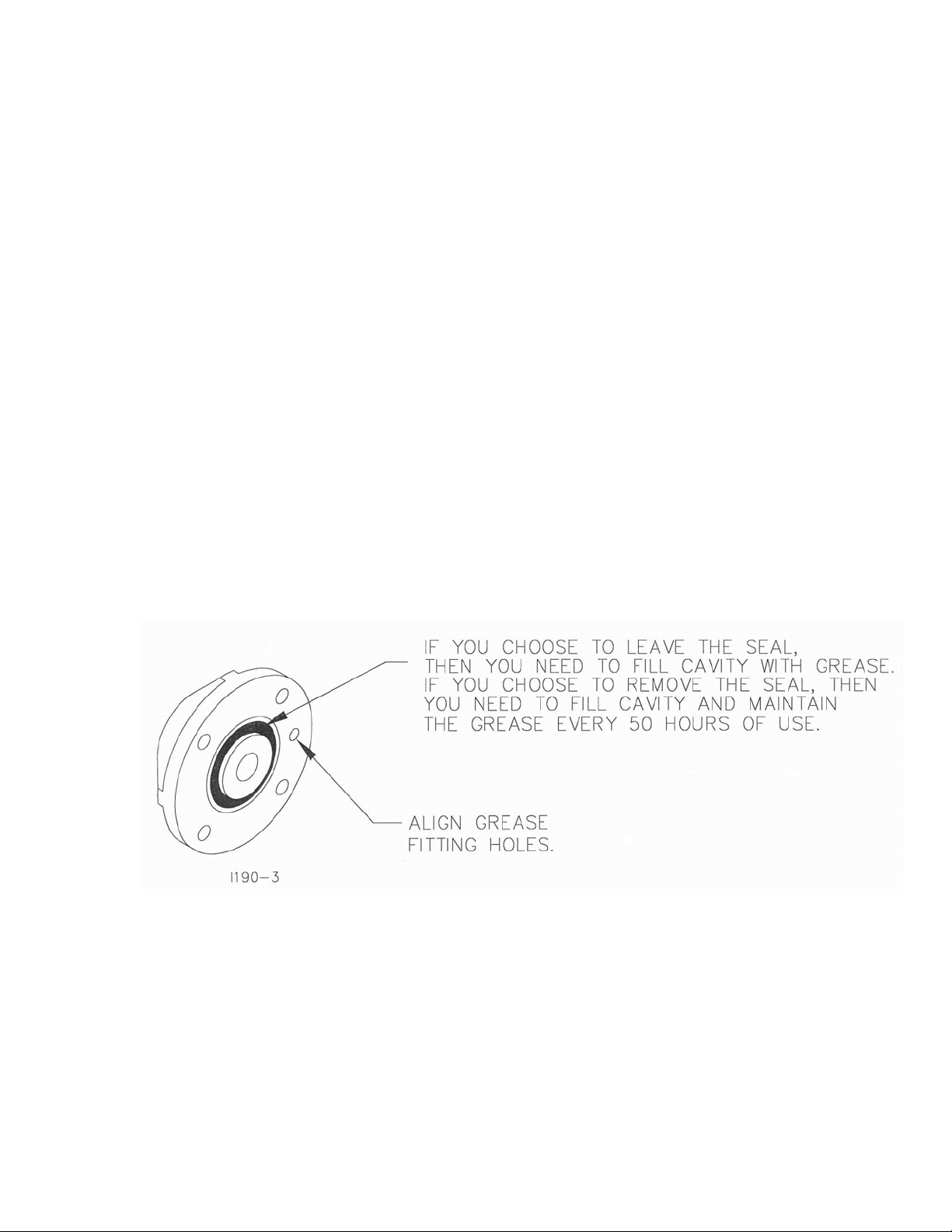

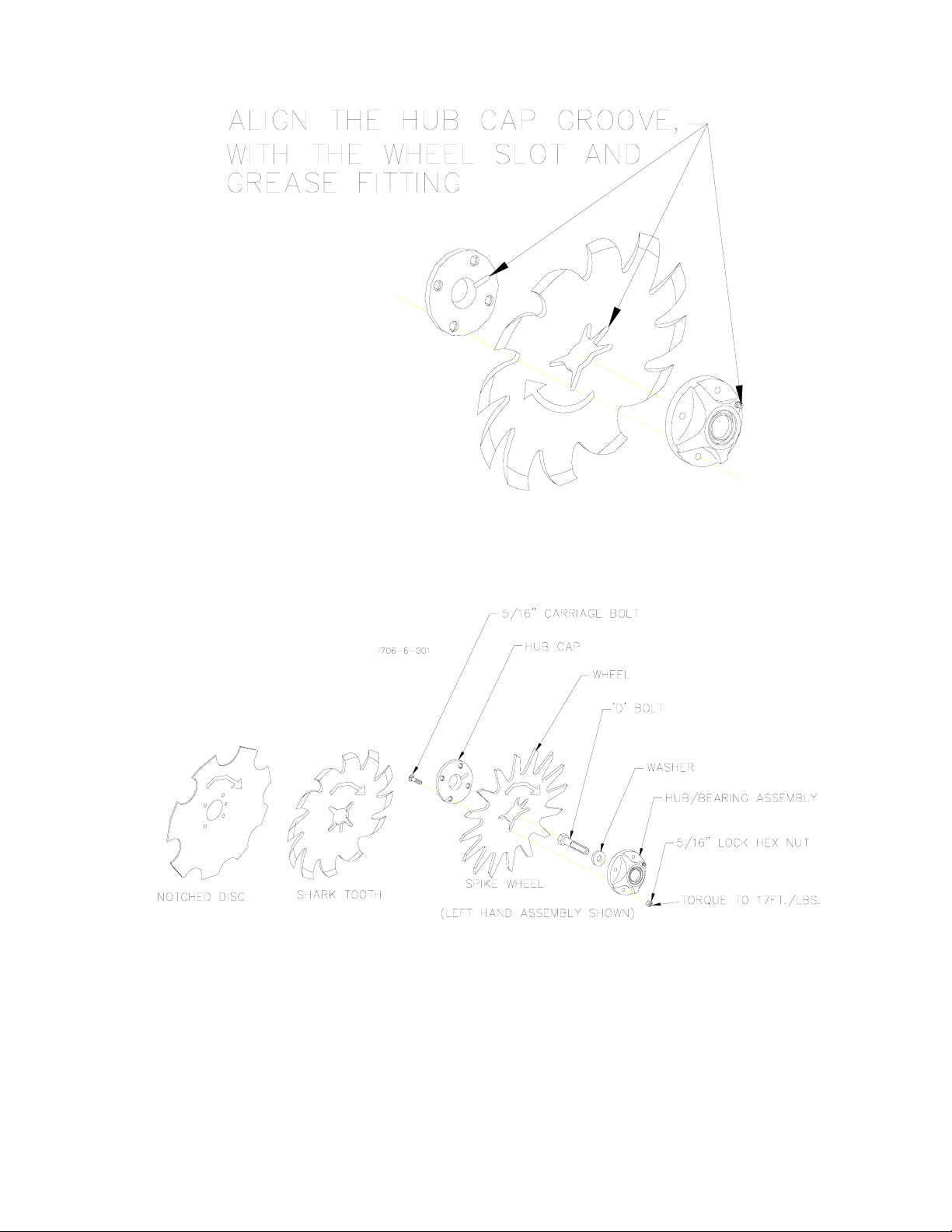

SPOKE WHEEL ASSEMBLY

1. Before assembling spoke wheel, bearing

assembly and hub cap, remove the seal

from the exposed side of the bearing in the hub and bearing

assembly if you wish touse the zerk to grease the bearing,

otherwise the bearing is sealed.

2. When assembling spoke wheel, bearing

assembly and hub cap, be sure to align the grease fitting hole with the hole in the spoke

wheel and the groove in hub cap to assure

proper greasing of wheel and hub assembly.

3. Assemble spoke wheel, bearing assembly and hub cap as shown on the parts identification

page. Be sure to install the 11/16" spacers and bearing shields. Stagger spoke wheels so

that half of the rows have a left wheel leading and half of the rows have a right wheel leading.

Torque 150 ft.lbs.

4. Fill hub and bearing with general purpose grease if seal was removed from bearing in step 1.

4

Page 5

MAINTENANCE

BEARING ASSEMBLY AND LUBRICATION

Practice Safety

Understand and practice safe service procedures before doing work. Follow ALL the

operating, maintenance and safety information in the equipment operator manual.

Clear the area of bystanders, especially small children, when performing any

maintenance or adjustments. Keep work area clean and dry. Use adequate lighting

for the job. Use only tools, jacks and hoists of sufficient capacity for the job.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet, and

clothing from power-driven moving and rotating parts. Disengage all power and

operate controls to relieve pressure. Lower equipment to the ground and stop the

engine. Remove the key. Wait for all moving parts to stop before servicing,

adjusting, repairing or unplugging.

Securely support any machine elements with blocks or safety stands that must be

raised for service work.

Keep all parts in good condition and properly installed. Fix damaged equipment

immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or

debris.

Make sure all guards are in place and properly secured when maintenance work is

completed.

Assembly

5

Page 6

MAINTENANCE

NOTE: Be certain to align the grease fitting with the slot in the wheel and the

hubcap so that the grease can flow freely.

6

IMPORTANT: THE 2527-530 WASHER MUST BE INSTALLED OR THE WHEEL

AND HUB ASSEMBLY WILL FALL OFF DURING USE.

Page 7

MAINTENANCE

Grease must fill this

Hubcap cavity.

7

Page 8

MAINTENANCE

Lubrication

CAUTION: To help prevent serious injury or death to you or others caused

by unexpected movement, service machine on a level surface. Lower

machine to ground or sufficiently lock or block raised machine before

servicing. If machine is connected to tractor, engage parking brake and

place transmission in "PARK", shut off engine and remove key. If machine

is detached from tractor, block wheels and use shop stands to prevent

movement.

CAUTION: Do not clean, lubricate, or adjust machine while in motion.

Use grease based on NLGI consistency numbers and the expected air temperature

range during the service interval.

Use a multi-purpose lithium, water resistant, moderate speed, and NLGI grade

#2 grease.

Other greases may be used if they meet the following NLGI Performance

Classification: GC-LB

IMPORTANT: Some types of grease thickener are not compatible with others.

Consult your grease supplier before mixing different types of grease.

Alternative Lubricants

Conditions in certain geographical areas may require special lubricants and

lubrication practices which do not appear in the operator's manual. If there are any

questions, consult Yetter Manufacturing Co. to obtain latest information and

recommendation.

PART #

2967-404 13” TAPER TOOTH R.M. WHEEL 1.12 OZ

2967-602 13” SHARK TOOTH R.M. WHEEL 1.12 OZ

2967-186 FLOATER WHEEL KIT W/R.M. WHEEL 2.08 OZ

2967-596 HEAVY DUTY OR BEVEL R.M. WHEEL

W/ FLOATER WHEEL KIT

DESCRIPTION

OUNCES OF GREASE

2.40 OZ

Storing Lubricants

Your machine can operate at top efficiency only if clean lubricants are used.

Use clean containers to handle all lubricants.

Store them in an area protected from dust, moisture and other contaminants.

8

Page 9

MAINTENANCE

Lubrication Symbols

Lubricate with grease at hourly interval indicated on symbol.

Lubrication Intervals

IMPORTANT: The recommended service intervals are based on normal

conditions; severe or unusual conditions may require more frequent

lubrication.

Perform each lubrication and service procedure at the beginning and end of each

season.

Clean grease fittings before using grease gun, to avoid injecting dirt and grit into the

bearing. Replace any lost or broken fittings immediately. If a fitting fails to take

grease, remove and clean thoroughly, replace fitting if necessary. Also check for

failure of adjoining parts.

BEARING REPLACEMENT INSTALLATION

1. If you wish to be able to grease the bearings in the hubs, remove the seal

from one side of the bearings as illustrated before assembly. Otherwise the

bearings may be left “sealed for life”.

2. When assembling the spoke wheels, bearing assembly and hubcap, be sure

to align the grease transfer hole in the spoke wheel with the groove in the

hubcap and hole in the hub to allow grease passage.

3. Install/assemble the wheels, hubs and caps. IMPORTANT: THE 2527-530

WASHER MUST BE INSTALLED OR THE WHEEL AND HUB ASSEMBLY

WILL FALL OFF DURING USE.

4. Grease the wheel/hub/bearing assembly.

9

Page 10

MAINTENANCE

Storing the Equipment

Store the machine in an area away from human activity

Store machine in RAISED position.

Install service locks on all wheel cylinders.

At the end of the season, the machine should be thoroughly inspected and prepared

for storage. Repair or replace any worn or damaged components to prevent down

time at the start of the next season. Store machine under cover with all parts in

operating condition.

• Clean machine thoroughly to remove all dirt, debris and crop residue, which

would hold moisture and cause rusting.

• Inspect machine for worn or broken parts. See your Yetter Farm Equipment

dealer during the off-season so that parts or service can be acquired when

machine is not needed in the field.

• Lubricate bearings as outlined in the Lubrication section

• Paint all parts which are chipped or worn and require repainting.

• Store machine in a clean, dry place with the planting unit out of the sun.

• If the machine cannot be stored inside, cover with a waterproof tarpaulin and

tie securely in place.

• Do not allow children to play on or around the machine

10

Page 11

Problem

Overall settings

Cannot set shallow

enough.

Spoke wheels not turning

continuously.

TROUBLESHOOTING

Cause

Planter not set correctly.

Planter not set correctly.

Spoke wheels not

engaging residue.

Solution

Ensure that in operation

the planter frame is at

correct height (20-22")

and level the tool bar.

See above.

Lower wheels to ensure

rotation at all times, DO

NOT engage solid part of

wheel in dirt.

11

Page 12

PARTS IDENTIFICATION

2967-113 - FLOATING RESIDUE MANAGER STEM

Key Qty Part No. Description

1 1 2967-241 Pivot Arm W.A.

2 1 2967-242 Adjustment Tube W.A.

3 1 2967-425 Inside Bushing ZYD

4 1 2502-296 1/2-13 x 2-1/2 HHCS Gr. 5 ZP

5 1 2520-357 1/2-13 Lock Hex Nut ZP

6 1 2960-359 Spring Adjustment Pin ZP

7 1 2570-448 1/8 Std. Hairpin Cotter ZP

8 1 2550-750 Spring, Floating R.M.

OPTIONAL EQUIPMENT

07-97 TO 05-08

12

Page 13

PARTS IDENTIFICATION

2967-113 - FLOATING RESIDUE MANAGER STEM

Key Qty Part No. Description

1 1 2967-241 Pivot Arm W.A.

2 1 2967-242 Adjustment Tube W.A.

3 1 2967-425 Inside Bushing ZYD

4 1 2502-296 1/2-13 x 2-1/2 HHCS Gr. 5 ZP

5 1 2520-357 1/2-13 Lock Hex Nut ZP

6 1 2960-359 Spring Adjustment Pin ZP

7 1 2570-448 1/8 Std. Hairpin Cotter ZP

8 1 2550-750 Spring, Floating R.M

13

05-08 TO PRESENT

Page 14

14

PARTS IDENTIFICATION

07-97 TO 05-08

Page 15

PARTS IDENTIFICATION

05-08 TO PRESENT

15

Page 16

16

PARTS IDENTIFICATION

07-97 TO 05-08

Page 17

PARTS IDENTIFICATION

05-08 TO PRESENT

17

Page 18

PARTS IDENTIFICATION

07-97 TO 05-08

18

Page 19

19

PARTS IDENTIFICATION

05-08 TO PRESENT

Page 20

2565-415_REV_A

03/09

20

Loading...

Loading...