Page 1

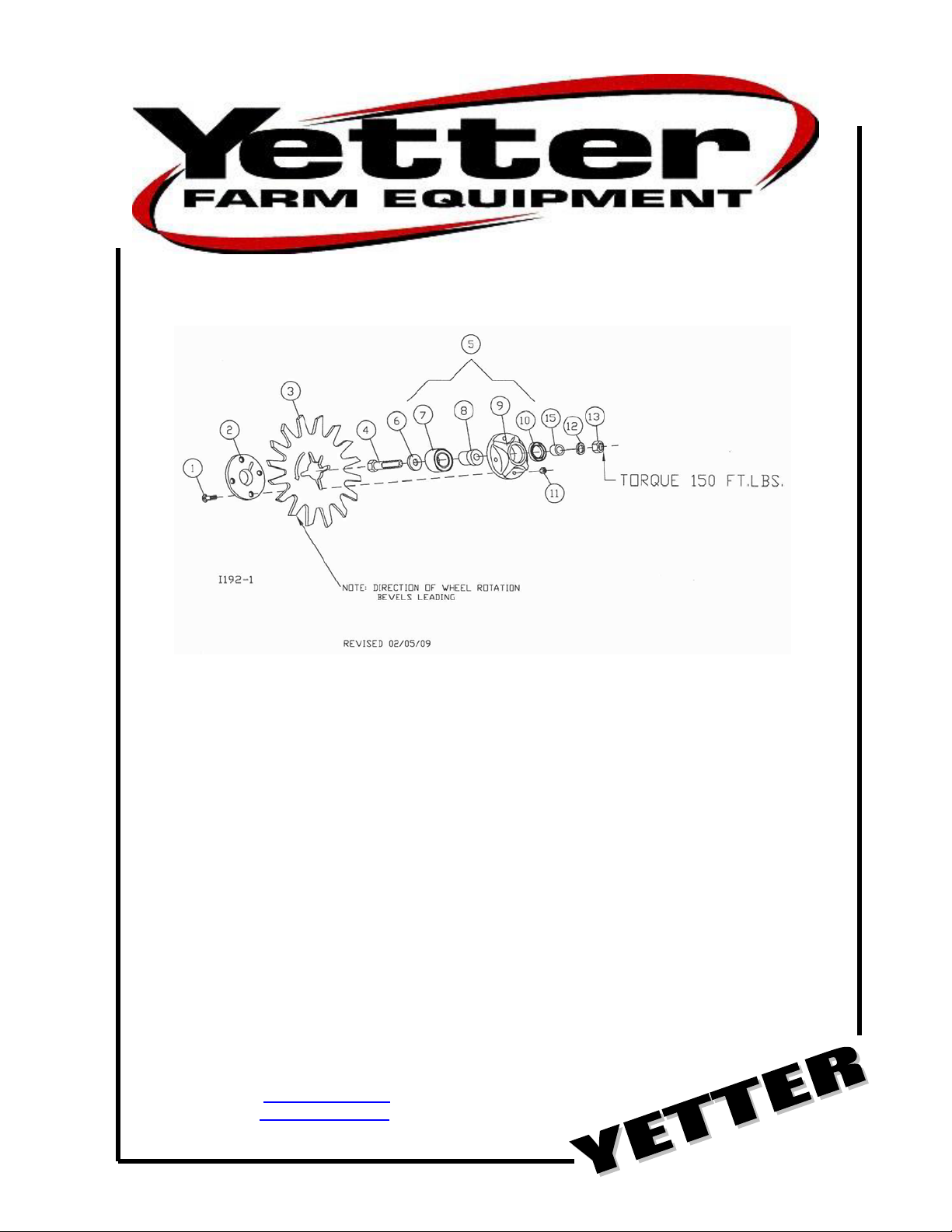

RESIDUE MANAGER WHEEL ASSEMBLY

Key Qty. Part No. Description

1 4 2505-208 5/16-18 X 1 1/2 Car. Bolt Gr. 5

2 1 2965-352 Hub Cap Casting, 4 Bolt, Black

3 1 2967-404 13” Taper Tooth Spoke Wheel

4 1 2570-742 5/8-11 X 4” ‘D’ Bolt Gr. 5 ZYD

5 1 2965-128 Hub & Bearing Assy., 4 Bolt

Includes No. 7, 8, 9 & 10

6 1 2527-530 1.5 OD X 21/32 ID 3/16 Thk Ma. Bu.

7 1 2570-594 Bearing, 2 Row NTN# DF0654L

8 1 2570-715 Bearing Insert, Trash master

9 1 2965-351 Hub Casting, Mach., 4 Bolt

10 1 2550-052 Seal, CR#13548

11 4 2520-205 5/16-18 Lock Hex Nut ZP

12 1 2525-451 5/8 Med. Lock washer ZP

13 1 2520-452 5/8-11 Hex Nut ZP

14 1 2533-110 ¼” Self Tap Grease Zerk (Not Shown)

15 1 2967-302 Spacer, 3/4”, ZYD

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 2

MAINTENANCE

BEARING ASSEMBLY AND LUBRICATION

Practice Safety

Understand and practice safe service procedures before doing work. Follow ALL the

operating, maintenance and safety information in the equipment operator manual. Clear

the area of bystanders, especially small children, when performing any maintenance or

adjustments. Keep work area clean and dry. Use adequate lighting for the job. Use only

tools, jacks and hoists of sufficient capacity for the job.

Never lubricate, service, or adjust machine while it is moving. Keep hands, feet, and

clothing from power-driven moving and rotating parts. Disengage all power and operate

controls to relieve pressure. Lower equipment to the ground and stop the engine. Remove

the key. Wait for all moving parts to stop before servicing, adjusting, repairing or

unplugging.

Securely support any machine elements with blocks or safety stands that must be raised

for service work.

Keep all parts in good condition and properly installed. Fix damaged equipment

immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris.

Make sure all guards are in place and properly secured when maintenance work is

completed.

Assembly

2

Page 3

MAINTENANCE

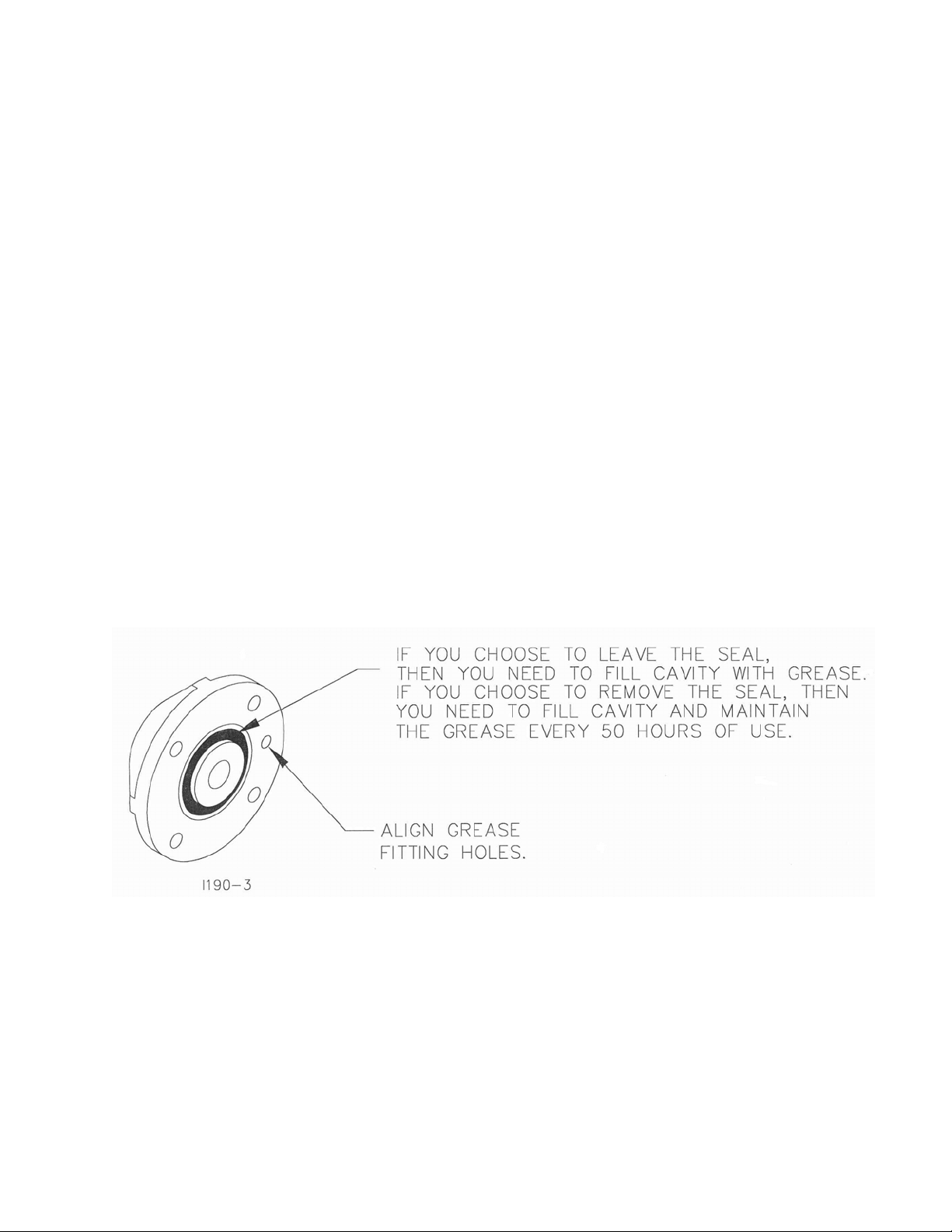

NOTE: Be certain to align the grease fitting with the slot in the wheel and the

hubcap so that the grease can flow freely.

IMPORTANT: THE 2527-530 WASHER MUST BE INSTALLED OR THE WHEEL

AND HUB ASSEMBLY WILL FALL OFF DURING USE.

3

Page 4

MAINTENANCE

Grease must fill this

Hubcap cavity.

4

Page 5

MAINTENANCE

Lubrication

CAUTION: To help prevent serious injury or death to you or others caused by

unexpected movement, service machine on a level surface. Lower machine to

ground or sufficiently lock or block raised machine before servicing. If machine

is connected to tractor, engage parking brake and place transmission in

"PARK", shut off engine and remove key. If machine is detached from tractor,

block wheels and use shop stands to prevent movement.

CAUTION: Do not clean, lubricate, or adjust machine while in motion.

Use grease based on NLGI consistency numbers and the expected air temperature range

during the service interval.

Use a multi-purpose lithium, water resistant, moderate speed, and NLGI grade #2

grease.

Other greases may be used if they meet the following NLGI Performance

Classification: GC-LB

IMPORTANT: Some types of grease thickener are not compatible with others.

Consult your grease supplier before mixing different types of grease.

Alternative Lubricants

Conditions in certain geographical areas may require special lubricants and lubrication

practices which do not appear in the operator's manual. If there are any questions,

consult Yetter Manufacturing Co. to obtain latest information and recommendation.

PART # DESCRIPTION OUNCES OF GREASE

2967-404 13” TAPER TOOTH R.M. WHEEL 1.12 OZ

2967-602 13” SHARK TOOTH R.M. WHEEL 1.12 OZ

2967-186 FLOATER WHEEL KIT W/R.M. WHEEL 2.08 OZ

2967-596 HEAVY DUTY OR BEVEL R.M. WHEEL W/

FLOATER WHEEL KIT

2.40 OZ

Storing Lubricants

Your machine can operate at top efficiency only if clean lubricants are used.

Use clean containers to handle all lubricants.

Store them in an area protected from dust, moisture and other contaminants.

5

Page 6

MAINTENANCE

Lubrication Symbols

Lubricate with grease at hourly interval indicated on symbol.

Lubrication Intervals

IMPORTANT: The recommended service intervals are based on normal conditions;

severe or unusual conditions may require more frequent lubrication.

Perform each lubrication and service procedure at the beginning and end of each season.

Clean grease fittings before using grease gun, to avoid injecting dirt and grit into the

bearing. Replace any lost or broken fittings immediately. If a fitting fails to take grease,

remove and clean thoroughly, replace fitting if necessary. Also check for failure of

adjoining parts.

BEARING REPLACEMENT INSTALLATION

1. If you wish to be able to grease the bearings in the hubs, remove the seal from one

side of the bearings as illustrated before assembly. Otherwise the bearings may

be left “sealed for life”.

2. When assembling the spoke wheels, bearing assembly and hubcap, be sure to

align the grease transfer hole in the spoke wheel with the groove in the hubcap

and hole in the hub to allow grease passage.

3. Install/assemble the wheels, hubs and caps. IMPORTANT: THE 2527-530

WASHER MUST BE INSTALLED OR THE WHEEL AND HUB ASSEMBLY WILL

FALL OFF DURING USE.

4. Grease the wheel/hub/bearing assembly.

6

Page 7

MAINTENANCE

Storing the Equipment

Store the machine in an area away from human activity

Store machine in RAISED position.

Install service locks on all wheel cylinders.

At the end of the season, the machine should be thoroughly inspected and prepared for

storage. Repair or replace any worn or damaged components to prevent down time at the

start of the next season. Store machine under cover with all parts in operating condition.

• Clean machine thoroughly to remove all dirt, debris and crop residue, which would

hold moisture and cause rusting.

• Inspect machine for worn or broken parts. See your Yetter Farm Equipment dealer

during the off-season so that parts or service can be acquired when machine is not

needed in the field.

• Lubricate bearings as outlined in the Lubrication section

• Paint all parts which are chipped or worn and require repainting.

• Store machine in a clean, dry place with the planting unit out of the sun.

• If the machine cannot be stored inside, cover with a waterproof tarpaulin and tie

securely in place.

• Do not allow children to play on or around the machine

7

Page 8

2565-367_REV_A • 03/09

8

Loading...

Loading...