Page 1

2920 SERIES

MAX SEALER PLUS™

OPERATOR’S MANUAL

PARTS IDENTIFICATION

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly

growing club.

For our part, we want to welcome you to the

group and thank you for buying a Yetter product.

We hope your new Yetter products will help you

achieve both goals-increase your productivity and

increase your efficiency so that you may generate

more profit.

This operator’s manual has been designed into

four major sections: Foreword, Safety

Precautions, Installation Instructions and Parts

Breakdown.

This SAFETY ALERT SYMBOL

indicates important safety messages in

the manual. When you see this

symbol, be alert to the possibility of

PERSONAL INJURY and carefully

read the message that follows.

The word NOTE is used to convey information

that is out of context with the manual text. It

contains special information such as

specifications, techniques and reference

information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due

to improper technique or operation. Important will

apply to the same information as specified by

note only of an immediate and urgent nature.

It is the responsibility of the user to read the

operator’s manual and comply with the safe and

correct operating procedure and to lubricate and

maintain the product according to the

maintenance schedule in the operator’s manual.

The user is responsible for inspecting his

machine and for having parts repaired or

replaced when continued use of the product

would cause damage or excessive wear to the

other parts.

It is the user’s responsibility to deliver his

machine to the Yetter dealer who sold him the

product for service or replacement of defective

parts, which are covered by the warranty policy.

If you are unable to understand or follow the

instructions provided in this publication, consult

your local Yetter dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

WARRANTY

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This

warranty being expressly limited to replacement at the factory of such parts or products as shall appear to

be defective after inspection. This warranty does not obligate the Company to bear cost of labor in

replacement of parts. It is the policy of the Company to make improvements without incurring obligations to

add them to any unit already sold. No warranty is made or authorized to be made, other than herein set

forth. This warranty is in effect for one year after purchase.

Dealer ___________________________________ ________________

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to

equipment on which mounted.

2

Page 3

SAFETY PRECAUTIONS

You can make your farm a safer place to live and work if you observe the safety precautions given. Study these

precautions carefully and insist those working with you and for you follow the precautions.

Finally, remember this an accident is usually caused by someone’s carelessness, neglect or oversight.

A brief description of signal words that may be used in this manual:

CAUTION: Used as a general reminder of good safety practices or to direct attention to unsafe practices.

WARNING: Denotes a specific potential hazard.

DANGER: Denotes the most serious specific potential hazard.

CAUTION

Consult your implement and tractor operator’s manual for correct and safe operating practices. Be aware of towed

implement width and allow safe clearance.

CAUTION: SAFETY SIGNS

Safety decals are placed on the implement to alert the operator and others to the risk of personal injury or unsafe

operation during normal operations and servicing.

1. The safety decals must be kept clean and in good condition to ensure that they are legible.

2. Safety decals must be replaced if they are missing or illegible.

3. When components are replaced during repair or servicing, check that the ne w components include the necessary

safety signs.

4. Replacement safety decals may be obtained from your local dealer.

WARNING

Read these instructions carefully to acquaint yourself with the Equ ipment. Working with unfamiliar equipment can lea d

to accidents.

Never park the equipment on a steep incline or leave the equipment running unattende d.

Never clean, lubricate or adjust a machine that is in motion.

Always check that straps are secure.

Make sure latches are in pinned position when moving equipment.

Do not allow children to operate this equipment.

Do not allow riders on the equipment, trailer and/or pick-up.

Use speed and caution dictated by the terrain being trave rsed. Do not operate on any slope steep enough to cause

tipping or loss of control.

Read and understand the operator’s manual and require a ll other persons who will operate the equipment to do the

same.

If operating on public roadways, where legal, be certain all lightin g is operating properly and observe all traffic laws.

Beware of increased stopping distances and control effort when operating with implements attached.

Be familiar with all controls and be prepared to stop equipment quickly in an emergency.

FAILURE TO HEED MAY RESULT IN PERSONAL INJURY OR DEATH.

3

Page 4

INTRODUCTION

The 2920 MAX SEALER PLUS™ disc sealer has been designed for the operators who

demand durability, longevity and performance in the field. The 2920 MAX SEALER

PLUS™ has adjustable blade pitch to match the changes in soil tilth. The unit is heavy

enough to fill the knife track and flexible enough to not cut a trench for water to start

erosion. The 2920 MAX SEALER PLUS™ has independent arms to allow the blades to

follow the roughest terrain and maintain soil flow to cover the knife track. Because each

blade is independent the sealer can handle field conditions that have large amounts of

crop residue, which keeps the toolbar productive even in less than ideal conditions.

MODELS

The 2920 MAX SEALER PLUS™ is available in two models with three-blade style to

choose from.

“C” SHANK MODELS

2920-051 – 18” NOTCHED BLADE

2920-052 – 18” SMOOTH BLADE

2920-053 – 13” SHARKTOOTH

Applications include: 1” x 2” flat shank

1-1/4” square

2” edge bent shank

1-1/4” coil shank

UNIVERSAL MODELS

2920-054 – 13” SHARKTOOTH BLADE

2920-055 – 18” NOTCHED BLADE

2920-056 – 18” SMOOTH BLADE

Applications include: YETTER MAVERICK II

YETTER AVENGER

DIETRICH SLURRY INJECTOR

The 2920 MAX SEALER PLUS™ will not work with shanks that use “clamp on” style knife

plates and 1” x 3” straight shanks.

CAUTION: Frozen soil or rocks may cause damage to the 2920 MAX SEALER

PLUS™.

4

Page 5

GENERAL INFORMATION

Note: Right Hand and Left Hand designations are based on sitting in the tractor and

facing forward.

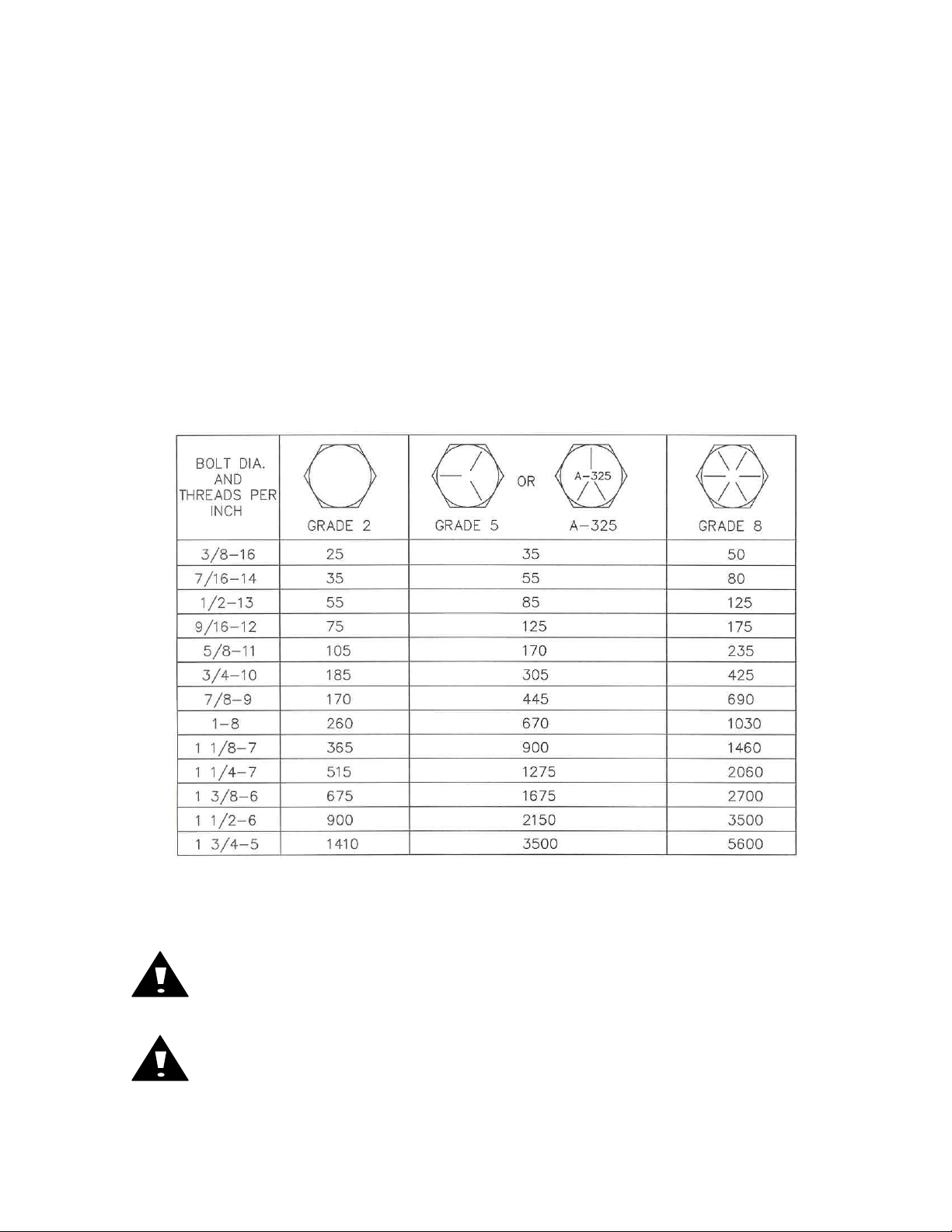

BOLT TORQUE

READ THESE INSTRUCTIONS FIRST:

1. Improperly tightened bolts will result in damage, breakage, expense, and down time.

2. Always replace bolts with the specified grade and type.

3. Torque properly before first use of the machine and every 2-4 hours of use until you are sure bolts

are staying tight.

4. The chart below is a guide for proper torque. Use it unless a specified torque is called out

elsewhere in the manual.

5. Torque is the force you apply to the wrench handle or the cheater bar, times the length of the

handle or bar.

6. Use a torque wrench whenever possible.

The following table shows torque in ft. lbs.

Lubricate all bearings and moving parts as assembled and make certain that they work freely.

WARNING: Never work around the toolbar / implement while in a raised position

without using safety lockups.

CAUTION: The 2920 MAX SEALER PLUS™ unit has sharp blades. Extra

attention should be paid to lifting techniques while handling and or maneuvering the

units during assembly. Failure to do so may lead to personal injury. Use heavy gloves

while handling the blades during assembly and any time adjustments or maintenance

operations are made to the units.

5

Page 6

ASSEMBLY

STEP 1. Attach the 2920-115 swing arm assembly to the shank/bracket using the

appropriate u-bolts, flat washers, lock washers and hex nuts or the ½” bolts and lock nuts.

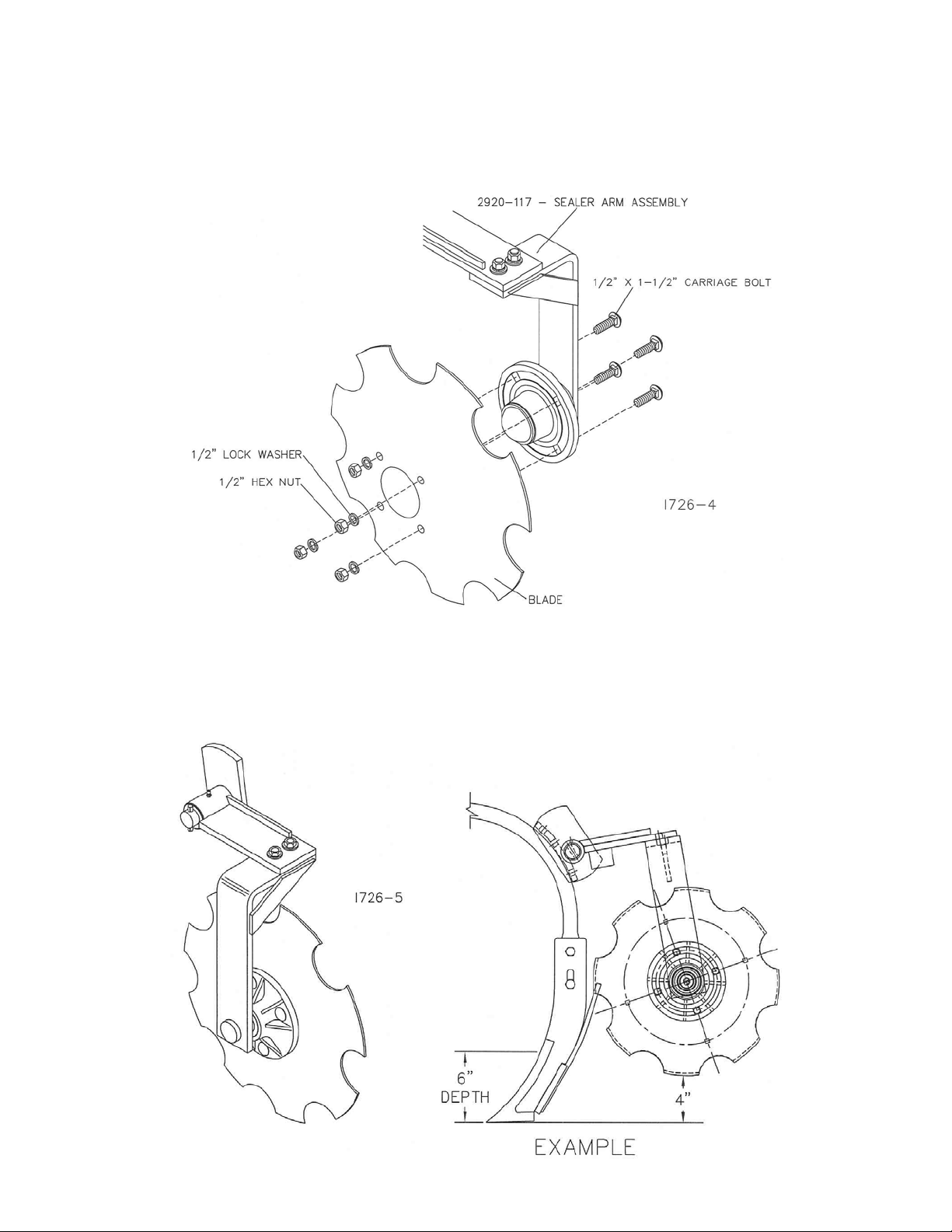

STEP 2. Attach the 2920-117 Arm Hub Assembly to the 2920-115 Swing Arm using the

½” carriage bolts, flat washers, lock washers and hex nuts.

6

Page 7

ASSEMBLY

STEP 3. Attach the blade to the 2920-117 Sealer Arm Hub Assembly using the 4) ½” x 1-

1/2” carriage bolts, lock washers and hex nuts. Curved blades can be used with the cup

“in” toward the knife for the most aggressive adjustment or with the cup “out” away from

the knife for a less aggressive adjustment.

STEP 4. “Barn Yard Setting” – set the sealer blade to 2” closer to the bottom of the knife

than the depth that the knife will be used at. Example: knife at 6” depth, set the blades to

4” above the bottom of the knife. Adjust the blade pitch as needed to cover the knife track

with soil. Tighten all hardware to the recommended amount of torque unless otherwise

stated.

7

Page 8

MAINTENANCE

Lubrication: Use #2 multi-purpose lithium grease.

To insure longevity and reliability of the MAX SEALER PLUS™ the recommended lubrication schedule

should be followed.

BEARING ADJUSTMENT

Tighten the slotted nut to 10 to 15 ft/lbs. or until a definite drag is felt when the blade is turned by hand.

Tighten the nut one slot position to align the slot with the hole in the spindle shaft. Secure the nut with a

new cotter pin. Install the hubcap.

BEARING REPLACEMENT

1. Raise the toolbar until the blade is clear of the ground. Place a safety stand under the toolbar. Remove the

blade from the hub assembly. Remove the hubcap, cotter pin, slotted nut and washer from the hub assembly.

2. Remove bearing cones and seal from the hub.

3. Wash the old grease from the hub, bearing cups, spindle, seals and bearing cones. Inspect the conditio n of

bearing cups, cones and seals. Replace if necessary.

4. Apply #2 multi-purpose lithium grease on each bearing. Make sure the space aroun d each roller is filled.

Lubricate the bearing cups.

5. Position the bearing in the cup and install the seal. Lubricate the seal lips and proce ed with re-assembly of the

removed parts including the blade. Blade bolt torque is 90 to 96 ft/lbs.

6. Tighten the slotted nut to 10 to 15 ft/lbs. or until a definite drag is felt when blade is turned by hand. Tighten

the nut one slot position to line up the cotter pin hole with a slot. Secure the nut with a new cotter pin. Install

the hubcap.

8

Page 9

PARTS IDENTIFICATION

9

Page 10

PARTS IDENTIFICATION

10

Page 11

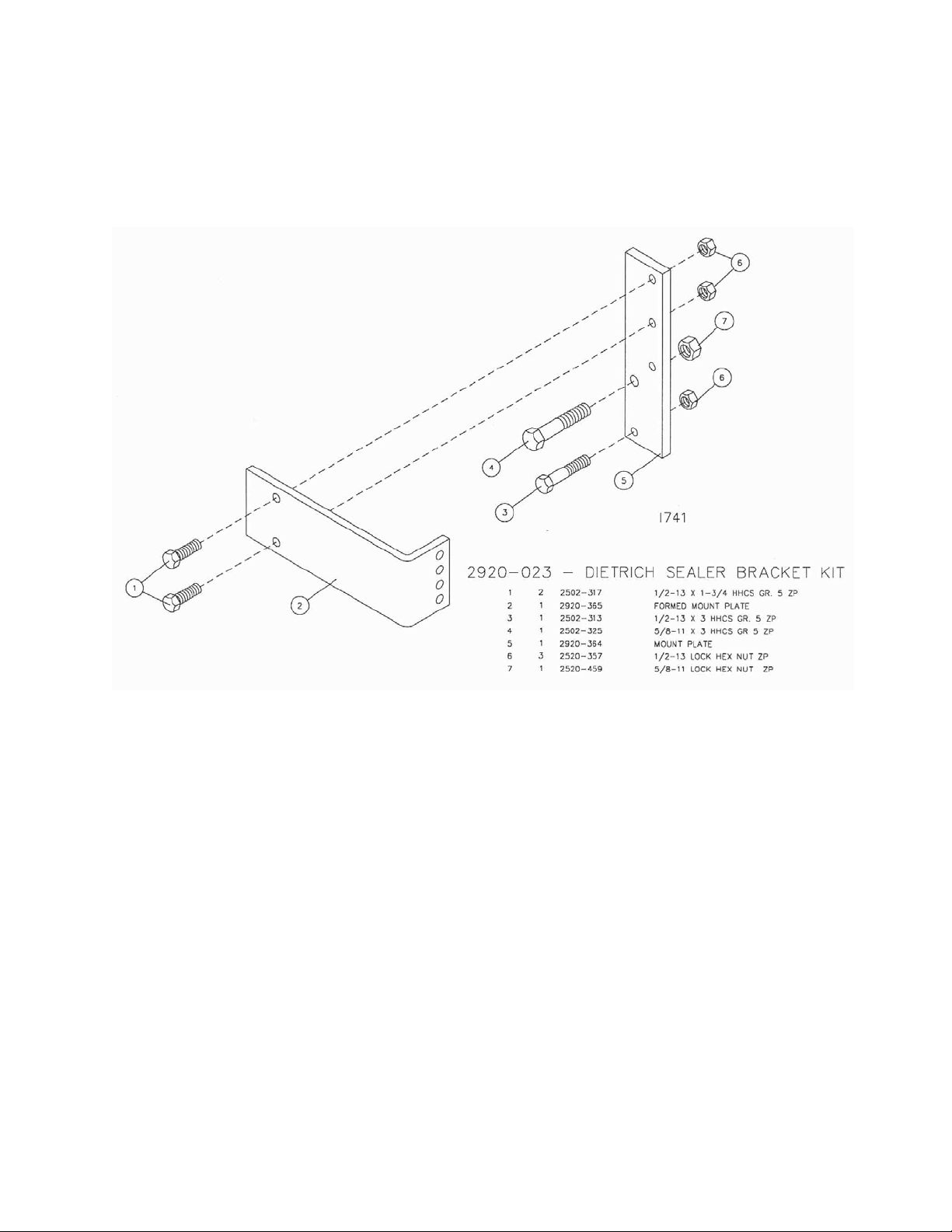

PARTS IDENTIFICATION

11

Page 12

PARTS IDENTIFICATION

12

Page 13

PARTS IDENTIFICATION

13

Page 14

PARTS IDENTIFICATION

14

Page 15

Problem

Poor overall performance.

Max Sealer Plus not creating

a mound or too small of a

mound.

Max Sealer Plus is not closing

the knife track.

TROUBLESHOOTING

Cause

Toolbar not adjusted correctly

Speed too slow.

Blades are not set

aggressively enough

Toolbar is not level-probably

nose down

Blades are not set aggressive

enough.

Solution

Adjust the toolbar so that

during operation it is level.

Operate at 5mph min.

Increase the angle of the front

edge of blade to the row.

Level toolbar.

Curved blades the “cup”

should be in toward the knife.

Increase the angle of the front

edge of the blade.

15

Page 16

Our name

Is getting known

Just a few years ago, Yetter products were sold primarily to the

Midwest only. Then we embarked on a program of expansion and

moved into the East, the South, the West and now north into Canada.

We’re even getting orders from as far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a name that’s

recognized. A name that’s known and respected. A name that’s

become a part of American agriculture and has become synonymous

with quality and satisfaction in the field of conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

Colchester, IL 62326-0358 • 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: WWW.YETTERCO.COM

E-MAIL: INFO@YETTERCO.COM

2565-727_REV_A • 12/09

16

Loading...

Loading...