Page 1

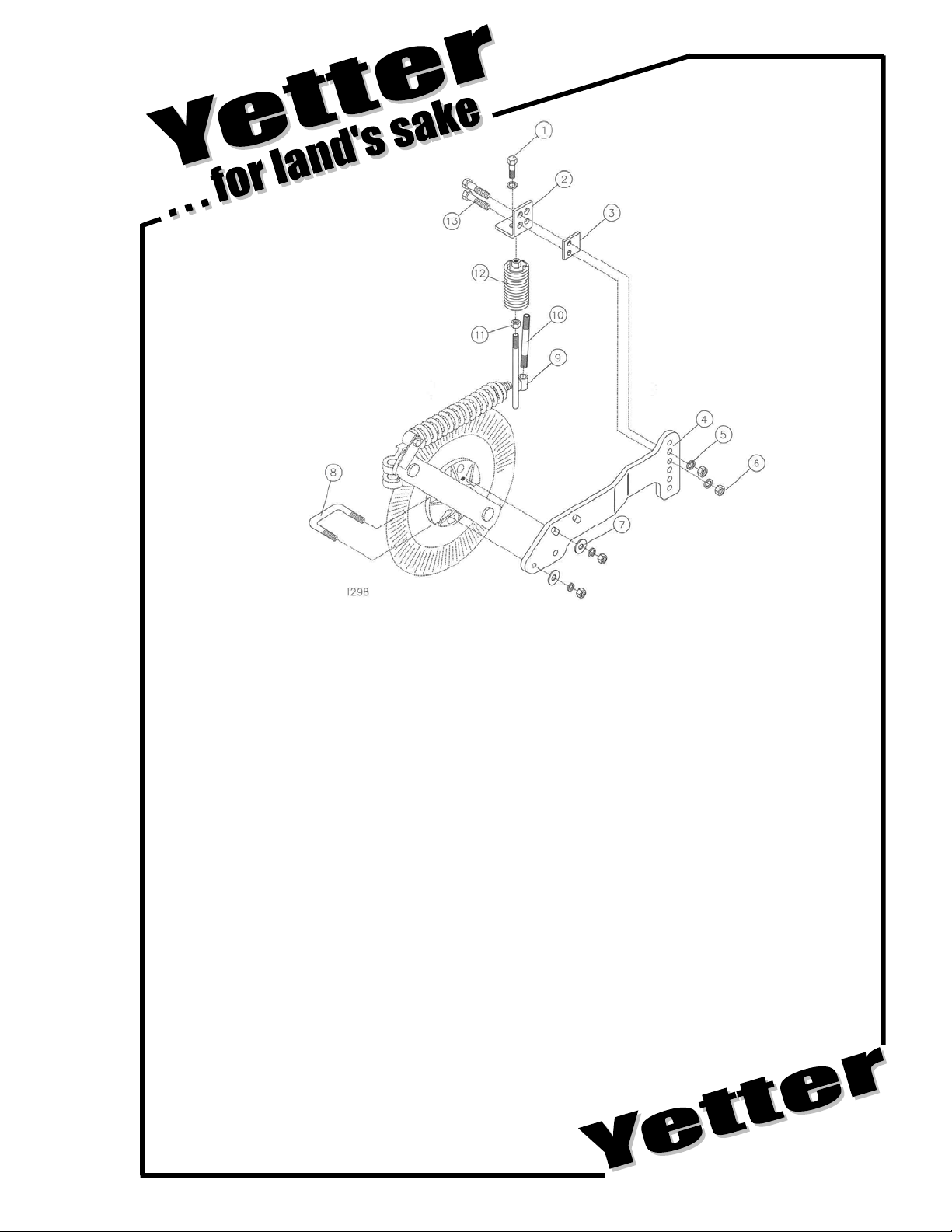

2910-114 HD LIQUID FERT. KIT, 2910

Key Qty. Part No. Description

1 1 2502-292 1/2-13 X 1 HHCS Gr. 5 ZP

2 1 2995-301 Injector Mount Plate

3 1 2995-320 Spacer, Injector

4 1 2910-321 HD Injector Arm 2910

5 5 2525-352 1/2 Med. Lockwasher ZP

6 4 2520-352 1/2-13 Hex Nut ZP

7 2 2526-351 1/2 Std. Flatwasher ZP

8 1 2570-736 1/2 X 3-1/8 X 2-1/4 U-Bolt ZP

9 1 2995-212 Injector Rod W.A., 1/2-13

10 1 2515-311 3” Nipple, 1/4 NPT Stainless Steel

11 1 2520-356 1/2-13 Jam Hex Nut

12 1 2995-131 Injector Spring Assembly

13 2 2502-317 1/2-13 X 1-3/4 HHCS Gr. 5 ZP

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 2

2910-114 HD LIQUID FERTILIZER KIT

1. Mount HD injector arm (#4) to the coulter arm using a 1/2 x 3-1/8" x 2-1/4" u-bolt, two flatwashers,

lockwashers and nuts as shown. Location of the u-bolt on the coulter arm will effect the depth that the

injector rod w.a. operates.

2. Assemble the 3" stainless steel nipple (#10) to the injector rod w.a. (#9).

NOTE: A female hose barb (not supplied) will be required. Also a straight stream nozzle 1/4 NPT

male thread will be required (not supplied). A check valve may be installed to minimize fertilizer

waste.

3. Thread a 1/2" hex jam nut onto the injector rod w.a. with at least 3/4" threads showing. Now thread the

injector spring assembly (#12) onto the injector rod. Now jam lock the injector rod to the spring

assembly using the 1/2" jam hex nut.

4. Install the injector rod/spring assembly to the injector mount plate (#2) using a 1/2 x 1" bolt and one

1/2" lockwasher.

NOTE: The injector rod assembly is to be installed so that the stream nozzle is on the trailing or rear

side of the injector rod.

5. Bolt injector assembly to HD injector arm with one spacer (#3), two 1/2 x 1-3/4" bolts, lockwashers

and nuts.

6. Operating depth is adjusted by selecting different holes vertically in the HD injector arm.

7. For exact alignment of the injector rod to the coulter blade, a spacer (#3) is included.

8. Securely tighten all hardware.

9. Inspect the assembly after four hours of use for loose hardware.

2565-391Great River Printing10/00

Loading...

Loading...