Page 1

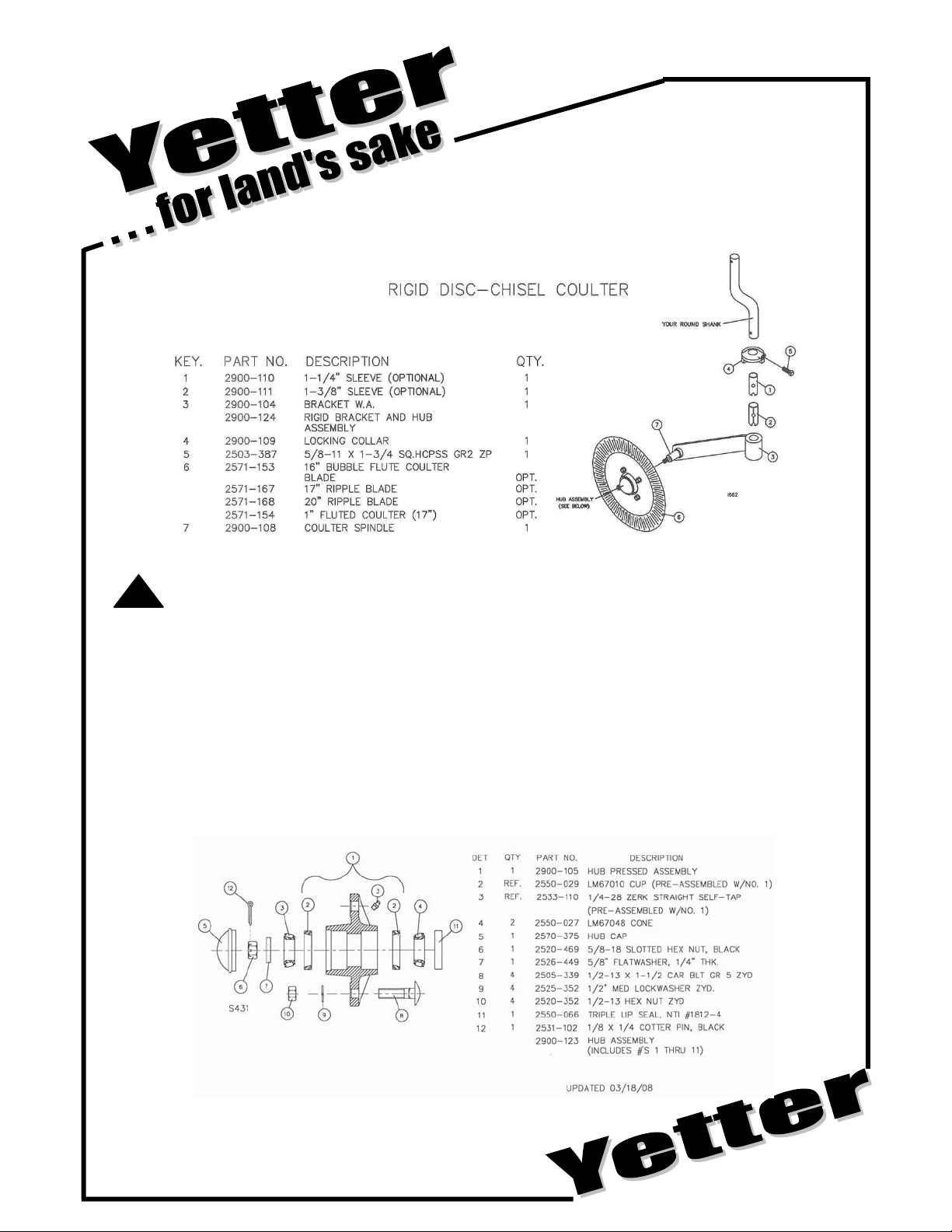

2900 SERIES RIGID PLOW COULTER

PARTS & INSTALLATION

INSTALLATION AND OPERATING INSTRUCTIONS

Caution: COULTER BLADE HAS SHARP EDGE.

USE CARE WHEN WORKING WITH OR CLOSE TO BLADES

The 2900 series coulter comes to you partially assembled. Remove any burrs from the lower end of your round shank and install

any sleeves needed to fit shank tube into shank. (Shank tube is designed to fit 1-1/2” SHANK. Sleeve number 2900-111 is to be used

for 1-3/8” shanks and numbers 2900-110 and 2900-111 both must be used on 1-1/4” shanks. Shank sleeves are not included in the

units above. Please order sleeves separately.)

NOTE: Sleeves or shank tube must fit above retainer pin or cotter key in your shank. If none exists in your shank, drill a 5/16” or

larger hole in your shank to accommodate a cotter key.

Place the coulter and locking collar over the shank (and sleeves, if used) then insert pin through the retainer hole. After aligning

coulter for proper position, tighten setscrew in locking collar in center of slot in hinge casting for maximum swivel.

The Yetter coulter is equipped with automotive type tapered bearings; and are pre-lubricated during assembly. Grease the hub

assembly periodically during use.

PERIODICALLY CHECK NUTS TO BE SURE THEY ARE TIGHT.

2910 AND 2900 SERIES HUB ASSEMBLIES

Page 2

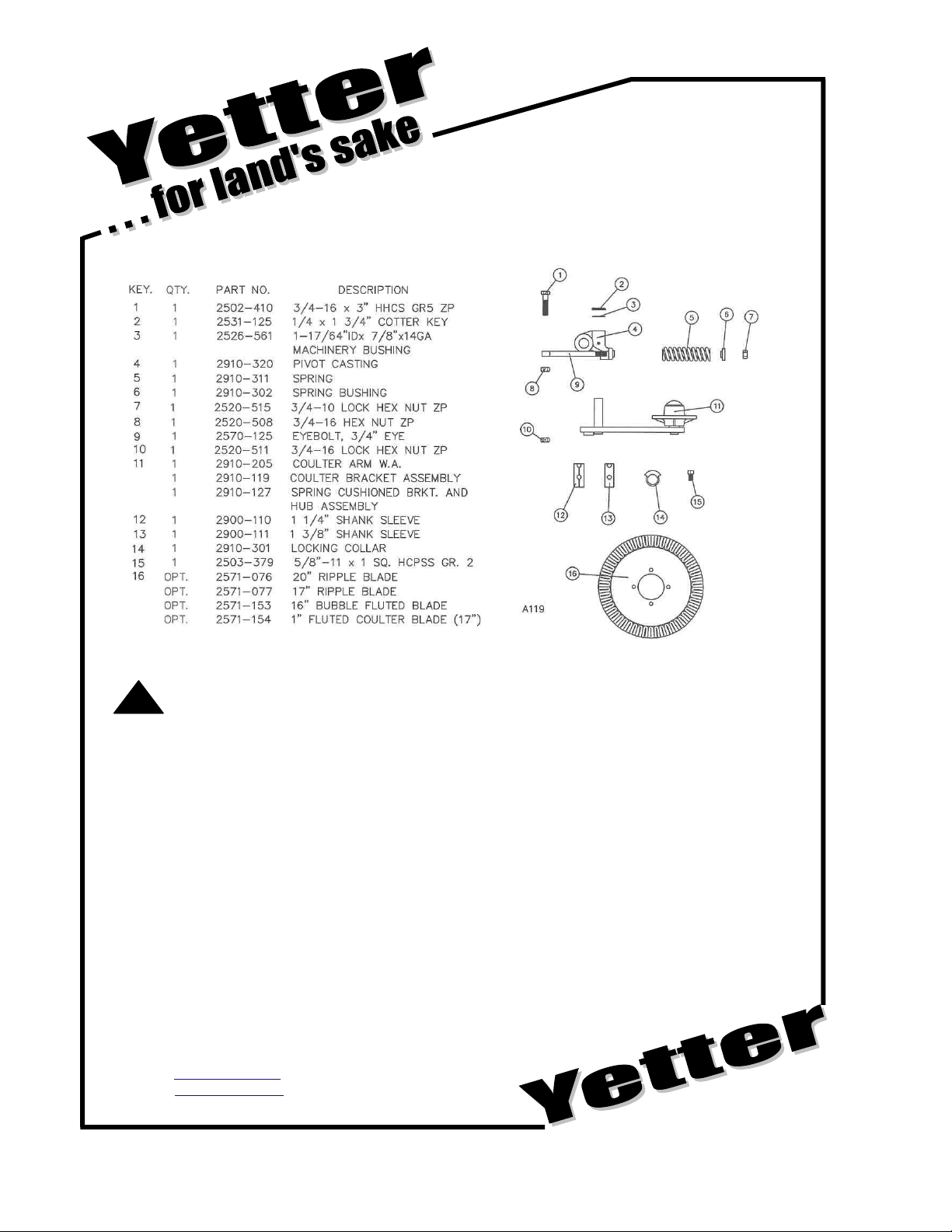

2910 SERIES SPRING CUSHIONED

PLOW COULTER

PARTS & INSTALLATION

INSTALLATION AND OPERATING INSTRUCTIONS

Caution: COULTER BLADE HAS SHARP EDGE.

USE CARE WHEN WORKING WITH OR CLOSE TO BLADES

The 2910 series coulter comes to you partially assembled. Remove any burrs from the lower end of your round shank

and install any sleeves need to fit shank tube into shank. (Shank tube is designed to fit 1-1/2” shank. Sleeve number 2900111 must be used for 1-3/8” shanks and part numbers 2900-110 and 2900-111 are both used on 1-1/4” shanks. Shank

sleeves are not included in the units above. Please order sleeves separately.)

NOTE: Sleeves or shank tube must fit above retainer pin or cotter key in your shank. If none exists in your shank, drill a

5/16” or larger hole in your shank to accommodate a cotter key.

Place the coulter and locking collar (2900-301) over the shank (and sleeves, if used) then insert pin through the retainer

hole. After aligning coulter for proper position, tighten setscrew in locking collar (make sure the set screw is through the notch

in the sleeves and seated in your round shank). When tightening setscrew, align locking collar in center of slot in hinge casting

for maximum swivel.

The Yetter coulter is equipped with automotive type tapered bearings; and are pre-lubricated during assembly. Grease

the zerk on the hinge casting (2910-320) prior to using the coulters then grease the hinge casting and hub assembly on a

periodic basis. Before going to the field, check the springs to be sure they have been given a preload tension. If the spring

can be rotated on the push rod by hand, it is too loose and must be tightened. Failure to do so may result in lost parts or

excessive wear. Approximately one inch of threads on the end of the push rod should be exposed when the spring is properly

preloaded.

PERIODICALLY CHECK ALL NUTS TO BE SURE THEY ARE TIGHT.

YETTER MANUFACTURING CO.

FOUNDED 1930

Colchester, IL 62326-0358

Toll free: 800/447-5777

309/776-3222 (Fax)

Website: www.yetterco.com

E-mail: info@yetterco.com

2565-184 03/08 Great River Printing, Hamilton, IL

Loading...

Loading...