Yetter 10000-003-RH Magnum, 10000-001-LH Magnum, 10000-001-RH Magnum, 10000-003-LH Magnum, 10000-004-LH Magnum Assembly Instructions Manual

...Page 1

10000 SERIES MAGNUM™

FERTILIZER COULTER

YETTER MANUFACTRURING CO.

Founded 1930

Colchester, IL 62326-0358

Toll free: 800-447-5777

Fax: 309-776-3222

Website: www.yetterco.com

Email: info@yetterco.com

2565-957_Rev_D 02/2018

Page 2

FOREWORD

You’ve just joined an exclusive but rapidly growing club.

For our part, we want to welcome you to the group and

thank you for buying a Yetter product.

We hope your new Yetter products will help you achieve

both goals-increase your productivity and increase your

efficiency so that you may generate more profit.

This operator’s manual has been designed into four

major sections: Foreword, Safety Precautions,

Installation Instructions and Parts Breakdown.

This SAFETY ALERT SYMBOL indicates important

safety messages in the manual. When you see

this symbol, be alert to the possibility of

PERSONAL INJURY and carefully read the

message that follows.

The word NOTE is used to convey information that is

out of context with the manual text. It contains special

information such as specifications, techniques and

reference information of a supplementary nature.

The word IMPORTANT is used in the text when

immediate damage will occur to the machine due to

improper technique or operation. Important will apply to

the same information as specified by note only of an

immediate and urgent nature.

Yetter Manufacturing warrants all products manufactured and sold by it against defects in material. This warranty being

expressly limited to replacement at the factory of such parts or products as shall appear to be defective after inspection. This

warranty does not obligate the Company to bear cost of labor in replacement of parts. It is the policy of the Company to

make improvements without incurring obligations to add them to any unit already sold. No warranty is made or authorized to

Yetter Manufacturing warrants its own products only and cannot be responsible for damages to equipment on which

mounted.

be made, other than herein set forth. This warranty is in effect for one year after purchase.

DEALER: ________________________________________

WARRANTY

It is the responsibility of the user to read the operator’s

manual and comply with the safe and correct operating

procedure and to lubricate and maintain the product

according to the maintenance schedule in the operator’s

manual.

The user is responsible for inspecting his machine and

for having parts repaired or replaced when continued

use of the product would cause damage or excessive

wear to the other parts.

It is the user’s responsibility to deliver his machine to the

Yetter dealer who sold him the product for service or

replacement of defective parts, which are covered by the

warranty policy.

If you are unable to understand or follow the instructions

provided in this publication, consult your local Yetter

dealer or contact:

YETTER MANUFACTURING CO.

309/776-4111

800/447-5777

309/776-3222 (FAX)

Website: www.yetterco.com

E-mail: info@yetterco.com

Page 3

TABLE OF CONTENTS

Foreword ..................................................................................................... 2

Safety ........................................................................................................... 4

Torque ......................................................................................................... 5

General Information ................................................................................. 6-7

Assembly Instructions ............................................................................ 8-9

Operation .............................................................................................. 10-12

Troubleshooting ....................................................................................... 13

Maintenance ......................................................................................... 14-18

Part Identification ................................................................................ 19-44

Photo Album ........................................................................................ 45-47

3

Page 4

BE ALERT!

YOUR SAFETY IS INVOLVED.

WATCH FOR THIS SYMBOL. IT POINTS OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS “ATTENTION---BECOME ALERT!”

It is your responsibility as an owner, operator, or supervisor to know and instruct everyone using

this machine at the time of initial assignment and at least annually thereafter, of the proper

operation, precautions, and work hazards which exist in the operation of the machine in accordance

with OSHA regulations.

Safety Is No Accident

The following safety instructions, combined with common sense, will save your

equipment from needless damage and the operator from unnecessary exposure to

personal hazard. Pay special attention to the caution notes in the text. Review this

manual at least once each year with new and/or experienced operators.

1. Read and understand the operator’s manual before operating this machine. Failure

to do so is considered a misuse of the equipment.

2. Make sure equipment is secure before operating.

3. Always keep children away from equipment when operating.

4. Make sure everyone that is not directly involved with the operation is out of the

work area before beginning the operation.

5. Make sure all safety devices, shields, and guards are in place and are functional

before beginning the operation.

6. Shut off power to adjust, service, or clean.

7. Keep hands, feet, and clothing away from moving parts. It is a good idea to remove

all jewelry before starting the operation.

8.

Visually inspect the machine periodically during operation for signs of excessive

vibration, loose fasteners, and unusual noises.

WARNING: Never work around the toolbar/implement while in a raised position without

using safety lockups.

CAUTION: The 10000 Series MagnumTM coulters are very heavy. Pay extra

attention to lifting techniques when handling or maneuvering the coulter

during assembly. Failure to do so may lead to personal injury.

4

Page 5

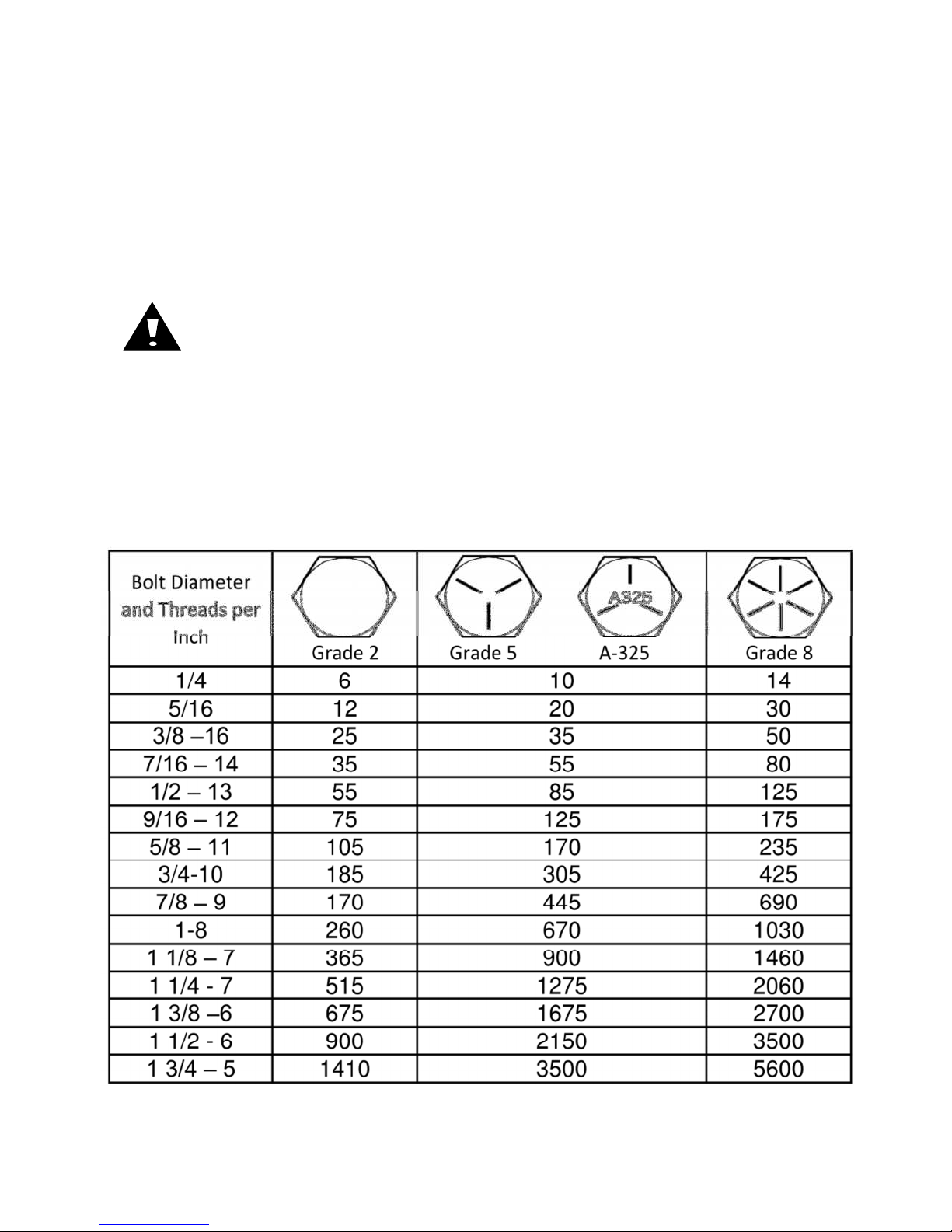

BOLT TORQUE

Before operating the 10000 Series Magnum™ for the first time, check to be sure that all

hardware is tight. Check all hardware again after approximately 50 hours of operation

and at the beginning of each planting season.

All hardware used on the 10000 Series Magnum™ is Grade 5 unless otherwise

specified. Grade 5 cap screws are marked with three radial lines on the head. If

hardware must be replaced, be sure to replace it with hardware of equal size, strength

and thread type. Refer to the torque table below when tightening hardware.

Important: Over tightening hardware can cause as much damage as when

under tightening. Tightening hardware beyond the recommended range can

reduce its shock load capacity.

The chart below is a guide for proper torque. Use it unless a specified torque is called out

elsewhere in the manual.

Torque is the force you apply to the wrench handle or the cheater bar, times the length of the

handle or bar.

Use a torque wrench whenever possible.

The following table shows torque in ft. lbs. for coarse thread hardware.

5

Page 6

GENERAL INFORMATION

Model No.

Description

Est. Wt. (lbs)

Model No.

Description

Est. Wt. (lbs)

Model No.

Description

Est. Wt. (lbs)

Model No.

Description

Est. Wt. (lbs)

10000 Series MagnumTM Fertilizer Coulter

STANDARD FEATURES FOR ALL MODELS

• High application speeds with minimal soil disturbance for fall, pre-

plant, and side-dressing applications

• Tube kits for applying liquid, dry, or anhydrous

• All cast design

• Spring loaded knife with carbide tip for extended wear

• 22.6” blade set at 4° angle.

• Fits 4x4, 4x6, 5x7, 6x4, and 7x7 toolbar sizes

• Sharktooth® Wheel Closer standard

ORDER from SECTIONS: A, B, and C

Section A:

10000-001-LH LH Magnum, w/ Walking Tandem, fits toolbars 4,5,6,7 wide univ. mount 380

10000-001-RH RH Magnum, w/ Walking Tandem, fits toolbars 4,5,6,7 wide univ. mount 380

10000-002-LH LH Magnum, w/ Walking Tandem, fits toolbars 4” wide, Short mount 375

10000-002-RH RH Magnum, w/ Walking Tandem, fits toolbars 4” wide, Short mount 375

10000-003-LH LH Magnum, w/o Walking Tandem, fits toolbars 4,5,6,7 wide univ. mount 355

10000-003-RH RH Magnum, w/o Walking Tandem, fits toolbars 4,5,6,7 wide univ. mount 355

10000-004-LH LH Magnum, w/o Walking Tandem, fits toolbars 4” wide, Short mount 345

10000-004-LH RH Magnum, w/o Walking Tandem, fits toolbars 4” wide, Short mount 345

Section B:

2987-040-L LH NH3 (3/8”) Tube Kit .395

2987-040-R RH NH3 (3/8”) Tube Kit .395

2987-041-L LH NH3 w/ Liquid (3/8” Dual) Tube Kit .697

2987-041-R RH NH3 w/ Liquid (3/8” Dual) Tube Kit .697

2987-042-L LH NH3 w/ Vapor (3/8” and 3/4”) Tube Kit .954

2987-042-R RH NH3 w/ Vapor (3/8” and 3/4”) Tube Kit .954

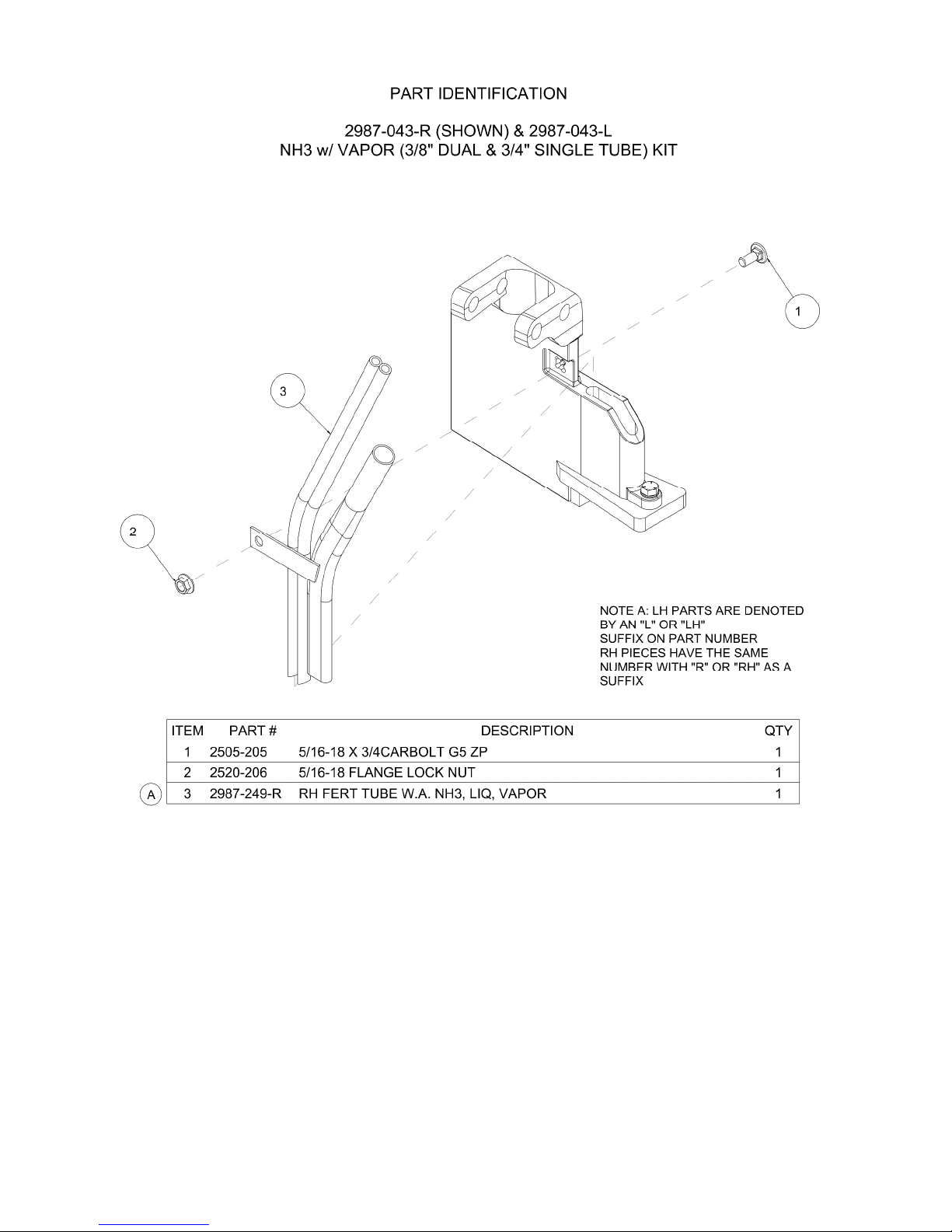

2987-043-L LH NH3 w/ Liquid and Vapor (3/8” Dual and 3/4” Single) Tube Kit 1.044

2987-043-R RH NH3 w/ Liquid and Vapor (3/8” Dual and 3/4” Single) Tube Kit 1.044

2987-044-L LH Vapor Only (3/4”) Tube Kit .455

2987-044-R RH Vapor Only (3/4”) Tube Kit .455

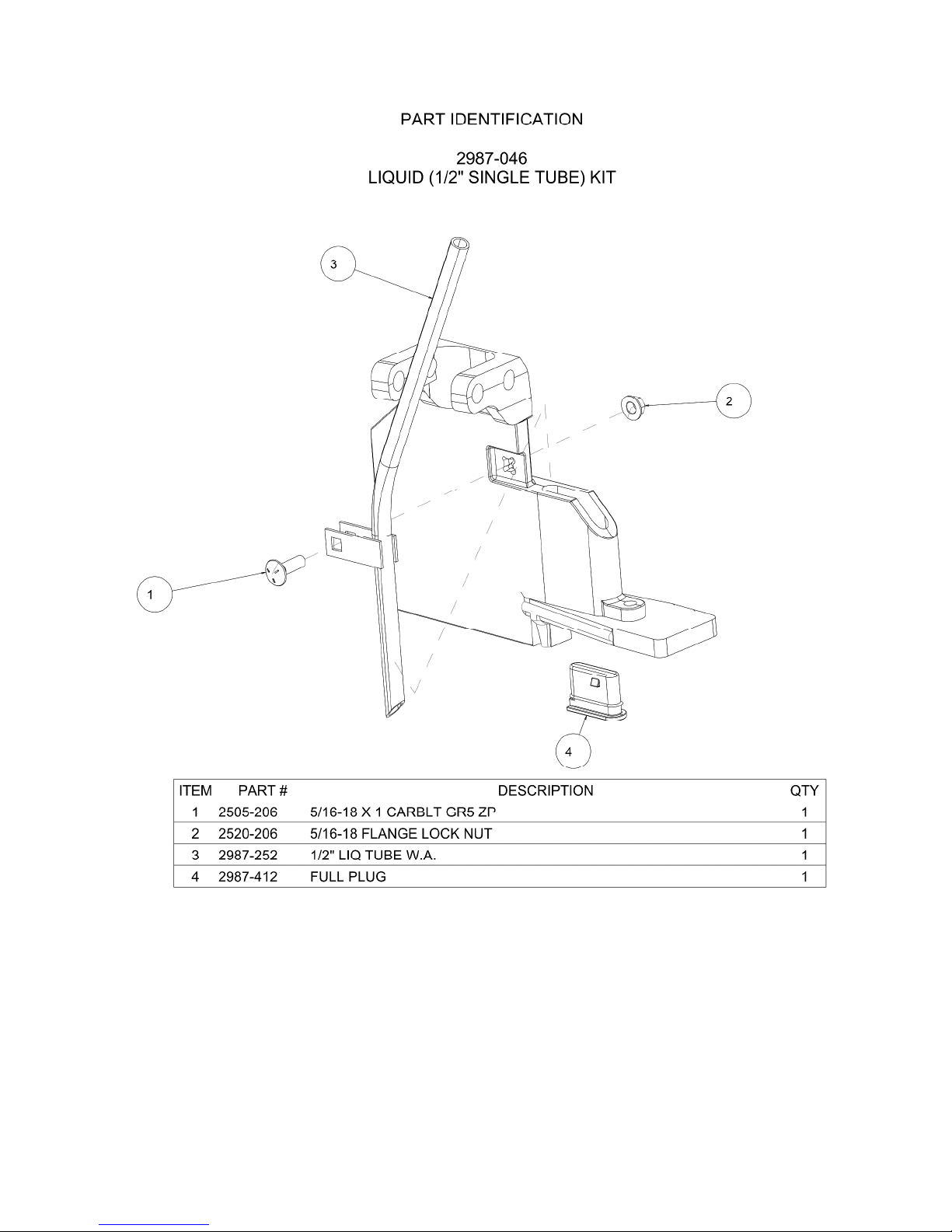

2987-046 Liquid (1/2” Single) Tube Kit .425

2987-047 Liquid (1/2” Dual) Tube Kit .850

10000-050-LH LH Magnum Dry Tube Assembly Kit 1.500

10000-050-RH RH Magnum Dry Tube Assembly Kit 1.500

Section C:

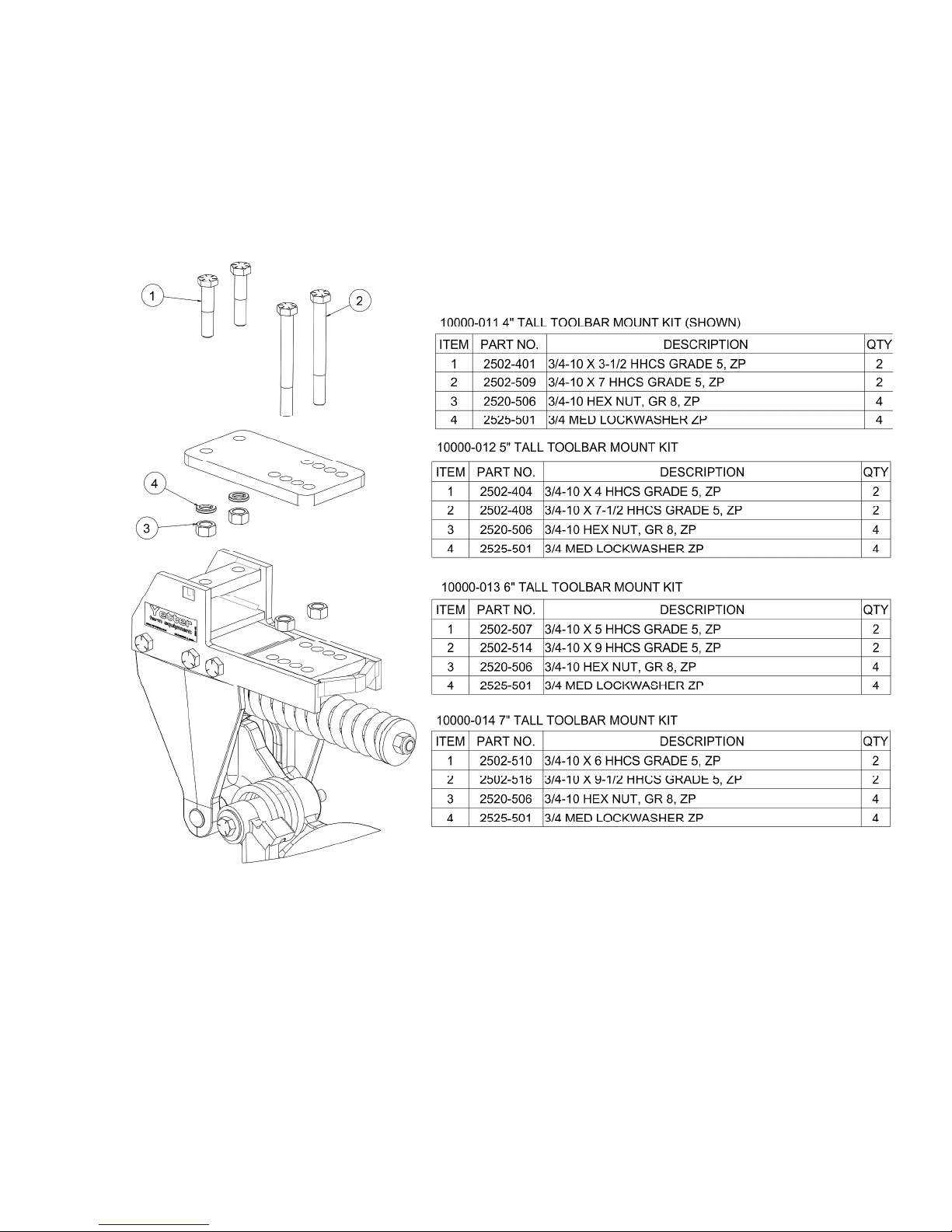

10000-011 4” Tall Toolbar Mount Hardware Kit 4

10000-012 5” Tall Toolbar Mount Hardware Kit 4.1

10000-013 6” Tall Toolbar Mount Hardware Kit 4.3

10000-014 7” Tall Toolbar Mount Hardware Kit 4.5

Optional Equipment:

10000-020-LH LH Walking Tandem Wheel Conversion Kit 28.5

10000-020-RH RH Walking Tandem Wheel Conversion Kit 28.5

10000-099 2” Drop Down Kit (For Wheel Tracks) 16.4

6

Page 7

GENERAL INFORMATION

10000 Magnum

TM

Fertilizer Coulter

7

Page 8

ASSEMBLY INSTRUCTIONS

WARNING: Never work under the toolbar while in a raised position without

using safety lockups.

WARNING: Use extreme caution, the blade is sharp and may cause bodily

injury. The coulter can be mounted to the toolbar using different techniques.

One way is to mount the main arm assembly to the toolbar and then attach

the components one at a time. Another way is to completely assemble the coulter

before attaching to the toolbar frame.

CAUTION: 10000 MagnumTM Fertilizer Coulter and its components are very

heavy. Extra attention to lifting techniques while handling and or maneuvering

the coulter during assembly is very important. Failure to do so may lead to

personal injury or death.

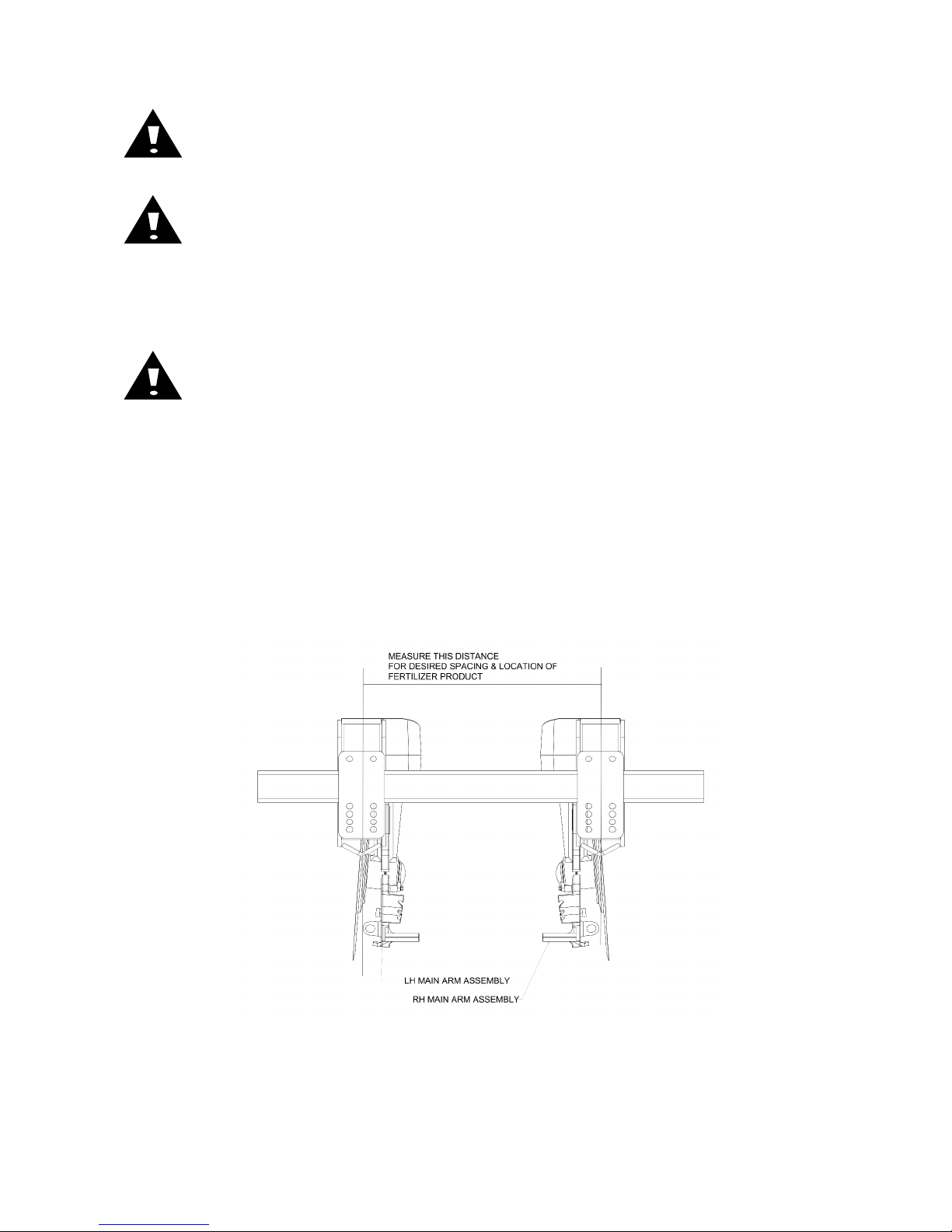

STEP 1: Mark the toolbar frame as to the location that each coulter is to be mounted.

IMPORTANT: Install an equal quantity of right hand and left hand coulters to each

section of the toolbar. Example: A 30’ – 3 section toolbar with 12 coulters (6R & 6L)

will need to install 2R and 2L coulters on each section of the toolbar. If any questions

concerning assembly of coulters, then please contact Yetter Farm Equipment for

recommendations at 800-447-5777.

Note: The coulter blade is in line with the center of the mount bracket. Measure from left

edge to left edge or from right edge to right edge to ensure the coulters are mounted at

the desired spacing.

8

Page 9

ASSEMBLY INSTRUCTIONS

STEP 2: Attach the 10000 Series MagnumTM to the toolbar using the appropriate clamp

and hardware.

HARDWARE KITS

PART IDENTIFICATION

9

Page 10

OPERATION INSTRUCTIONS

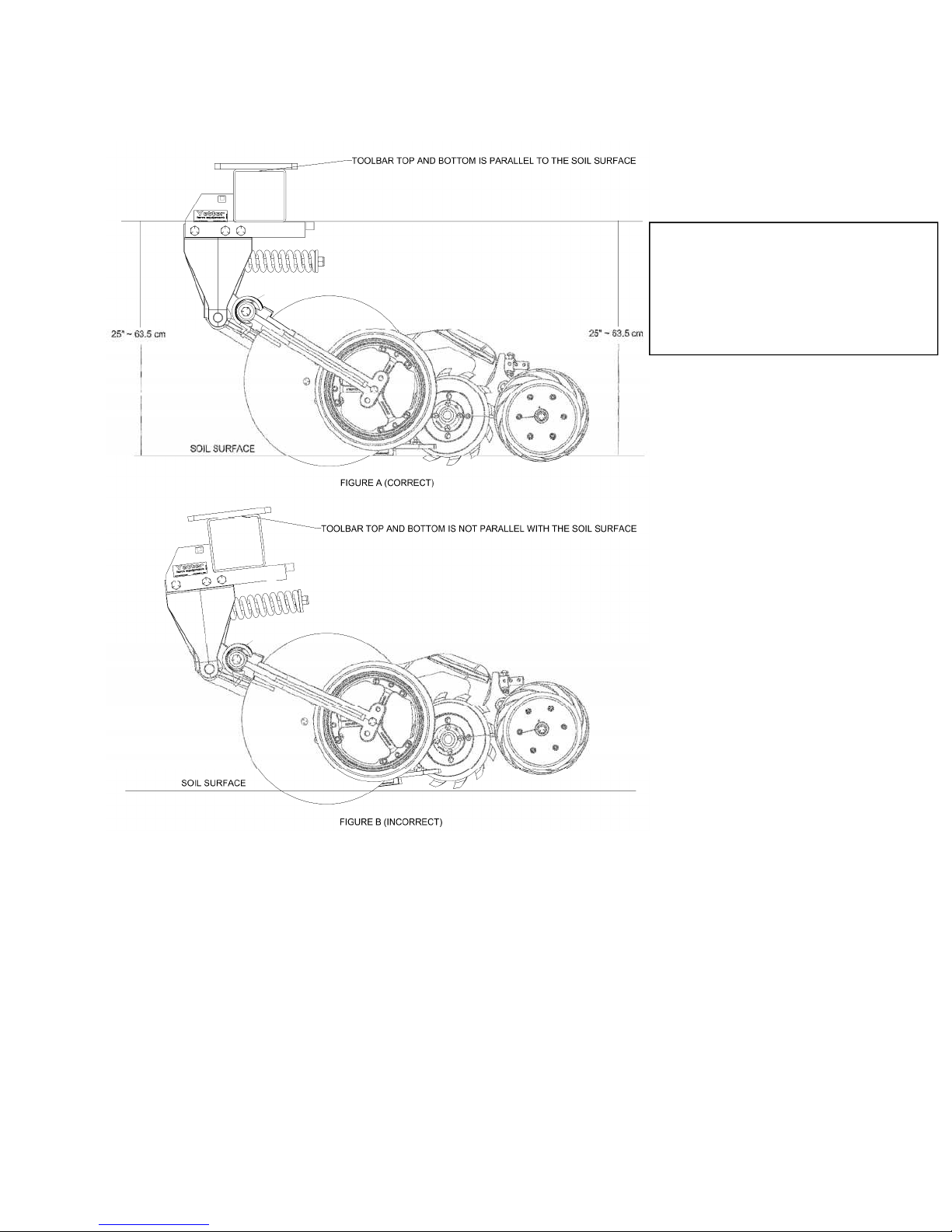

Adjusting Opener Depth:

TOOLBAR FRAME HEIGHT ADJUSTMENT

-Raise toolbar frame for shallow

application

-Lower toolbar frame for deeper

application

Figure A: The toolbar height is set to 25” above the soil surface. To ensure that frame

heights are correct, it is important measurements are taken before use.

Figure B: The hitch is set too low while the toolbar is not parallel with the soil surface.

Note: The illustrations are intended to show that the settings are critical. Tool frame

levelness and height adjustment are very important settings for correct

performance of the 10000 MagnumTM Coulter

10

Page 11

OPERATION INSTRUCTIONS

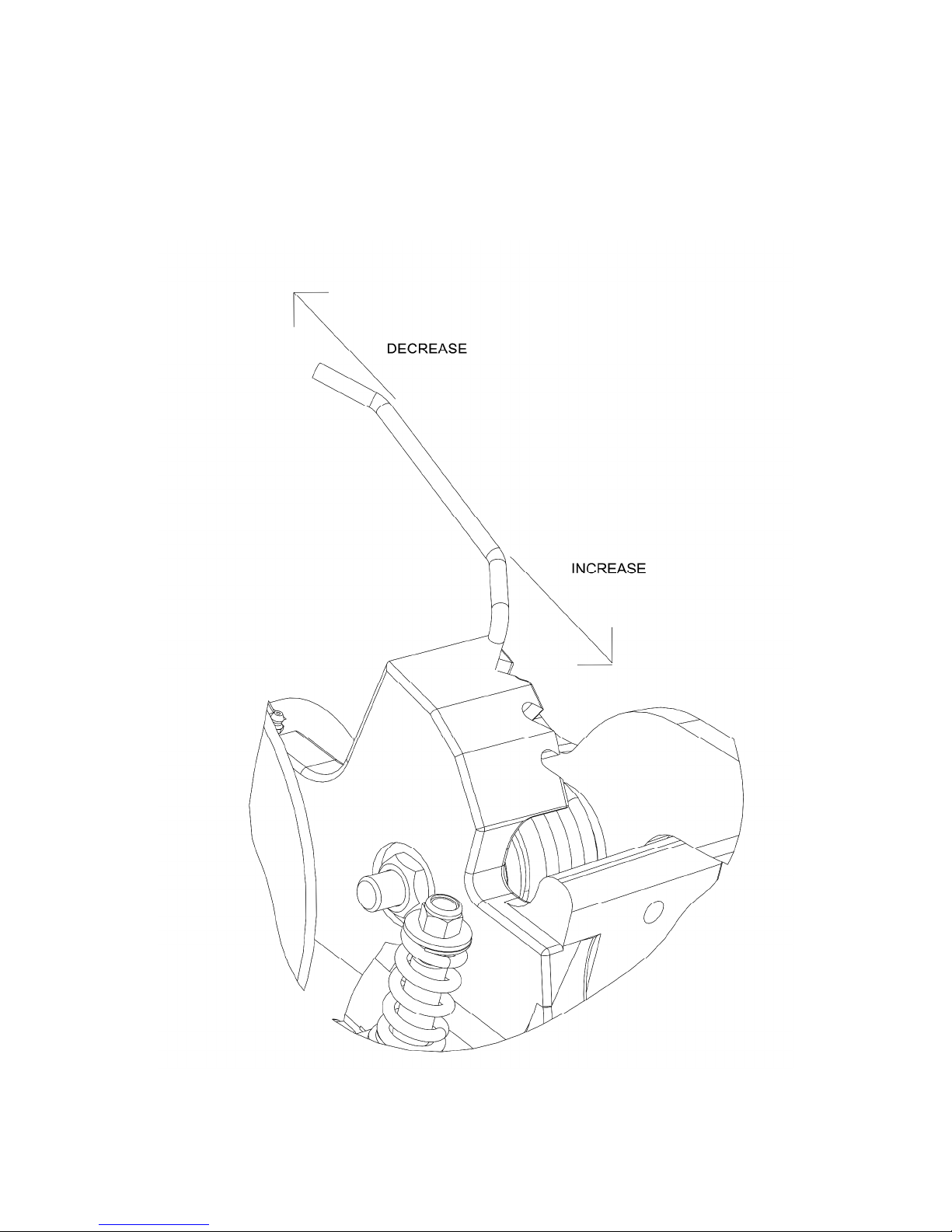

10000 MAGNUMTM CLOSING WHEEL DOWNFORCE

ADJUSTMENT

11

Page 12

OPERATION INSTRUCTIONS

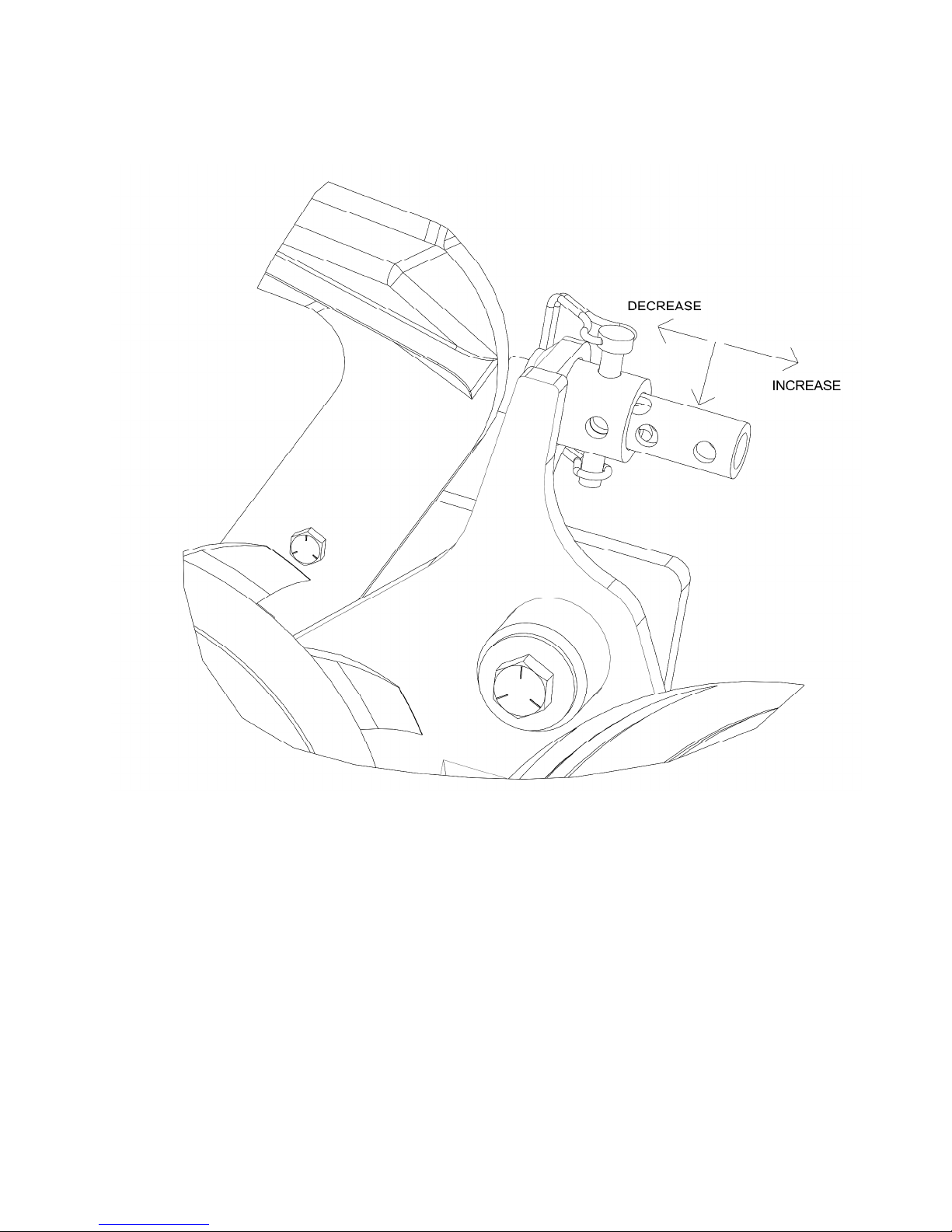

10000 MAGNUMTM WHEEL SEALER DEPTH ADJUSTMENT

12

Page 13

OPERATION INSTRUCTIONS

Symptom

Problem

Solution

Troubleshooting the 10000 Series MagnumTM Coulter

Mud builds up on press

wheels and wheels stop

turning

Poor opener penetration

Furrow not closing

Soil freezes to blade

Residue buildup in front of

openers

Uneven depth

Too much down pressure

Field is too wet

Hard ground conditions

Residue laying in bunches

Excessive residue

Dull disk openers

Disk opener worn too small

Field is too wet or overly

hard ground conditions

Raise toolbar when

Residue wedged between

scraper and disk opener

Residue laying in bunches

In adequate down pressure

Remove spring pressure

from press wheels

Wait until field dries before

running

Add weights to toolbar

frame

Spread residue evenly

across the field

Adjust toolbar for deeper

operation

Sharpen or replace opener

disks

Replace disk opener

Adjust closing wheel spring

pressure

stopping to prevent

anhydrous ammonia from

contacting and freezing soil

to blade

Verify adjustment bolt is

properly adjusted to hold

scraper against blade

Spread residue evenly

across field

Increase down pressure or

install weights

13

Page 14

MAINTENANCE

Practice Safety

Understand and practice safe service procedures before doing work. Follow ALL the

operating, maintenance, and safety information in the equipment operator’s manual.

Clear the area of bystanders, especially small children, when performing any

maintenance or adjustments. Keep work area clean and dry. Use adequate lighting for

the job. Use only tools, jacks, and hoists of sufficient capacity for the job.

Never lubricate, service, or adjust a machine while it is moving. Keep hands, feet, and

clothing free from power-driven moving parts. Disengage all power and operate controls

to relieve pressure. Lower equipment to the ground and stop the engine. Remove the

key. Wait for all moving parts to stop before servicing, adjusting, repairing, or

unplugging.

Securely support any machine elements with blocks or safety stands that must be

raised for service work.

Keep all parts in good condition and properly installed. Fix damaged equipment

immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or

debris from the equipment.

Make sure all guards and in place and properly secured when maintenance work is

completed.

14

Page 15

MAINTENANCE

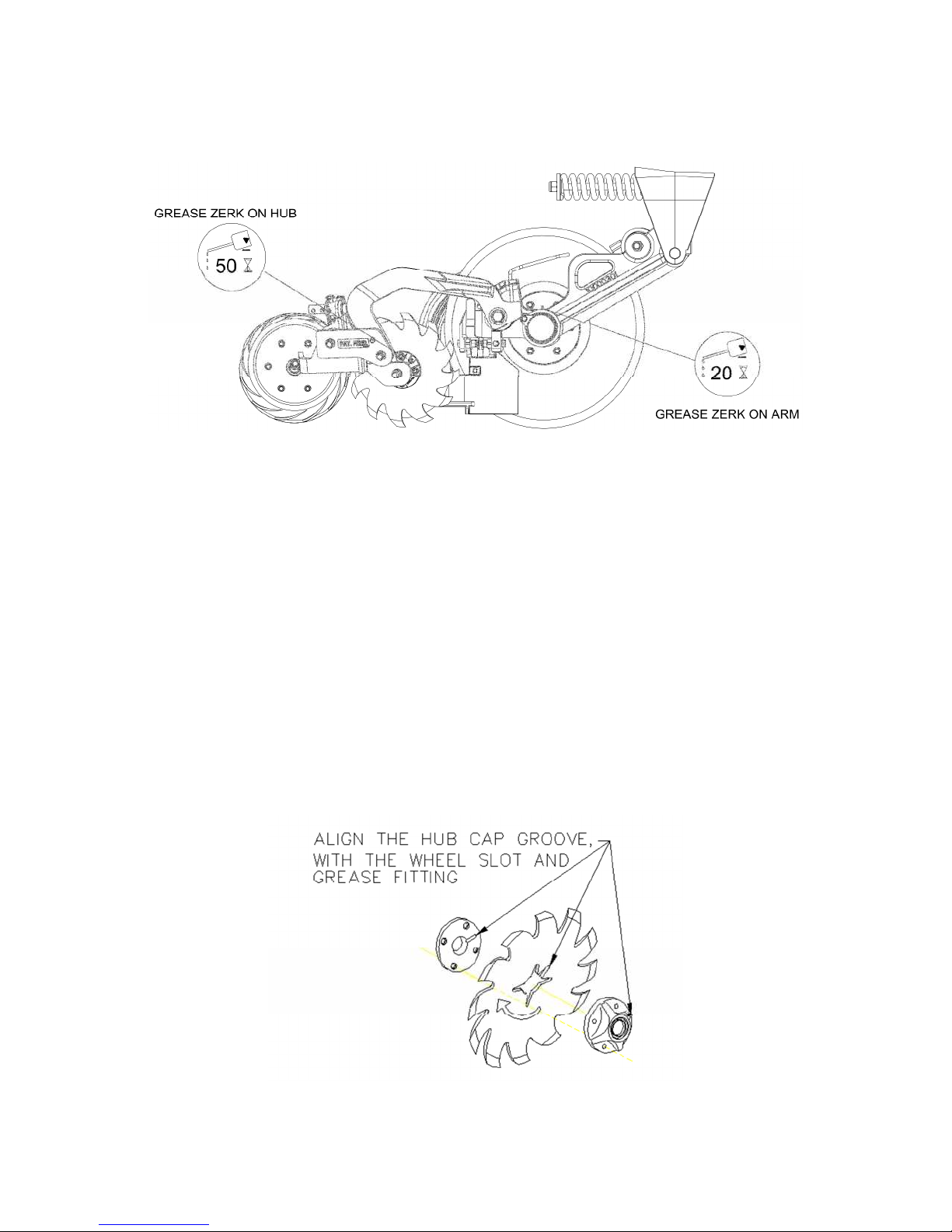

Lubrication Intervals

Lubricate with grease at hourly interval indicated on symbol.

IMPORTANT: The recommended service intervals are based on normal oberating

conditions. Severe or unusual conditions may requre more frequent lubrication.

Perform each lubrication and service procedure at the beginning and each of

each season. Clean grease fittings before using grease gun to avoid injecting dirt

and grit into the bearing. Replace and lost or broken fittings immediately. If a

fitting fails to take grease, remove and clean thoroughly, replace if necessary.

Also check for failure of adjoining parts.

Bearing Replacement Installation

1. When assembling the spoke wheels, bearing assembly, and hubcap, be sure to

align the grease transfer hole in the spoke wheel with the grove in the hubcap

and hole in the hub to allow grease passage.

2. Assembly the wheels, hubs, and caps.

3. Grease the wheel/hub/bearing assembly.

15

Page 16

MAINTENANCE

Lubrication

CAUTION: To help prevent serious injury or death to you or others, service

machinery on a level surface. Lower machine to ground or sufficiently

lock or block raised machine before servicing. If machine is connected

to tractor, engage parking brake and place transmission in “PARK”,

shut off engine and remove key. If machine is detached from tractor, block

wheels and use jack stands to prevent movement.

CAUTION: Do not clean, lubricate, or adjust machine while in motion.

Use grease based on NLGI consistency number and the expected air temperature

range during operation.

Use a multi-purpose polyurea, water resistant, moderate speed, and NLGI grade

#2 grease. Other greases may be used if they meet the NLGI performance standard.

IMPORTANT: Some types of grease thickener are not compatible with others. Consult

your grease supplier before mixing different types of grease.

Alternative Lubricants

Conditions in certain geographical areas may require special lubricants and lubrication

practices which do not appear in the operator’s manual. If there are any questions,

consult Yetter Manufacturing Co. to obtain the latest information and reccomendations.

Part # Description Ounces of Grease

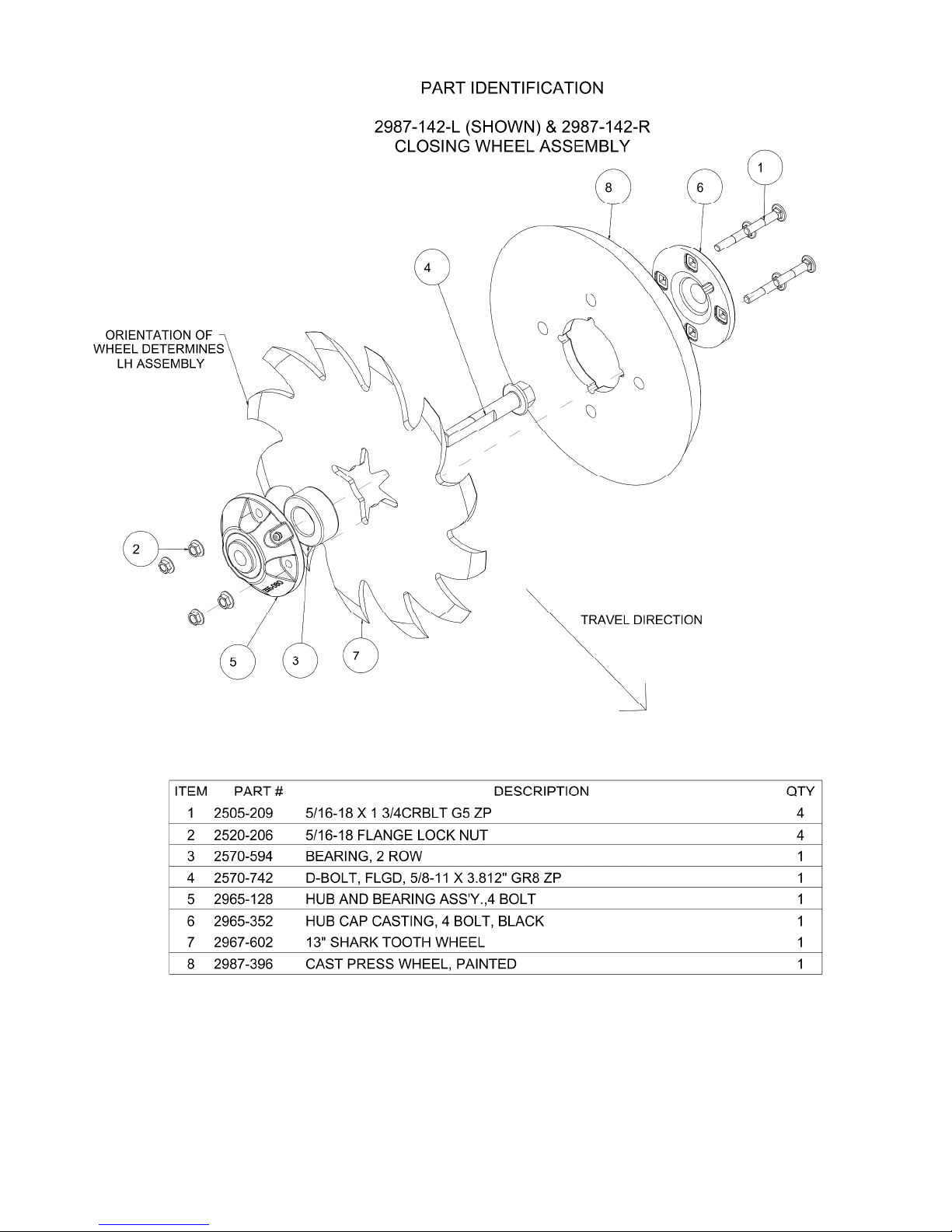

2987-142-L

Cast closer with SharkTooth Wheel 1 oz.

2987-142-R

10000-111-LH

Main Arm, Magnum Assembly 18 oz

10000-111-RH

Storing Lubricants

Your machine can operate at top efficiency only if clean lubricants are used.

Use clean containers to handle all lubricants.

Store them in an area protected from dust, moisture, and other contaminants.

16

Page 17

MAINTENANCE

Storing the Equipment

Store the machine in an area away from human activity.

Store the machine in a RAISED position.

Install service locks on all wheel cylinders.

At the end of the season the machine should be thoroughly inspected and prepared for

storage. Repair or replace any worn or damaged components to prevent down time at

the beginning of the following season. Store machine under cover with all parts in

operating condition.

• Clean machine thoroughly to remove all dirt, debris, and crop residue.

• Inspect machine for worn or broken parts. See your Yetter Farm Equipment

dealer during the off-season so parts and service can be acquired when the

machine is not needed in the field.

• Lubricate bearings as outlined in the lubrication section.

• Paint all parts which are chipped or worn to prevent rust.

• Store machine in a clean, dry location with the unit out of the sun.

• If the machine cannot be stored inside, cover with a waterproof tarpaulin and tie

securely in place

• Do not allow children to play on or around the machine

17

Page 18

MAINTENANCE

BEARING ADJUSTMENT:

1. Raise the toolbar until the blade is clear of the ground. Place a safety stand

under the toolbar. Remove the blade. Remove the hub cap, cotter pin, slotted

nut, washer and spacer from the spindle shaft assembly.

2. Pull the coulter spindle shaft assembly from the hub. Remove bearing cones and

seal.

3. Wash the old grease from the hub, bearing cups, coulter spindle shaft, seal and

bearing cones. Inspect the condition of bearing cups, cones and seal. Replace if

necessary.

4. Apply #2 multi-purpose polyurea grease on each bearing. Make sure the space

around each roller is filled. Lubricate the bearing cups.

5. Position the bearing in the cup and install the seal. Lubricate the seal lips and

proceed with re-assembly of the removed parts including the blade. Blade bolt

torque is 90 to 96 ft/lbs.

6. Tighten the slotted nut to 10 to 15 ft/lbs. or until a definite drag is felt when the

blade is turned by hand. Back off the nut one slot position to line up the cotter

pin hole with a slot. Secure the nut with a new cotter pin.

KNIFE WEAR:

The lower portion of the scraper and tube are subject to wear during operation. The

rate of wear will depend on a variety of factors and in abrasive hard soil conditions the

wear will be more rapid.

NOTE: In certain areas, replacement knives should be kept in stock, replacing worn

knives as needed.

ADJUST KNIFE TO BLADE CONTACT on each opener so the blade will turn by

hand with slight resistance, but will not coast or freewheel. In loose soil the knife

adjustment is critical. If adjustment is not maintained, soil or residue may wedge

between knife and blade, resulting in the blade not turning. Because of blade run

out, rotate the blade one full revolution after adjustment. Re-adjust knife as

needed. Never strike the knife with a heavy object or damage may occur.

To adjust, use shims or adjust knife mounting out.

18

Page 19

19

Page 20

20

Page 21

21

Page 22

22

Page 23

23

Page 24

MANUFACTURED 7/2016 – 2/2018

24

Page 25

MANUFACTURED 7/2016 – 2/2018

25

Page 26

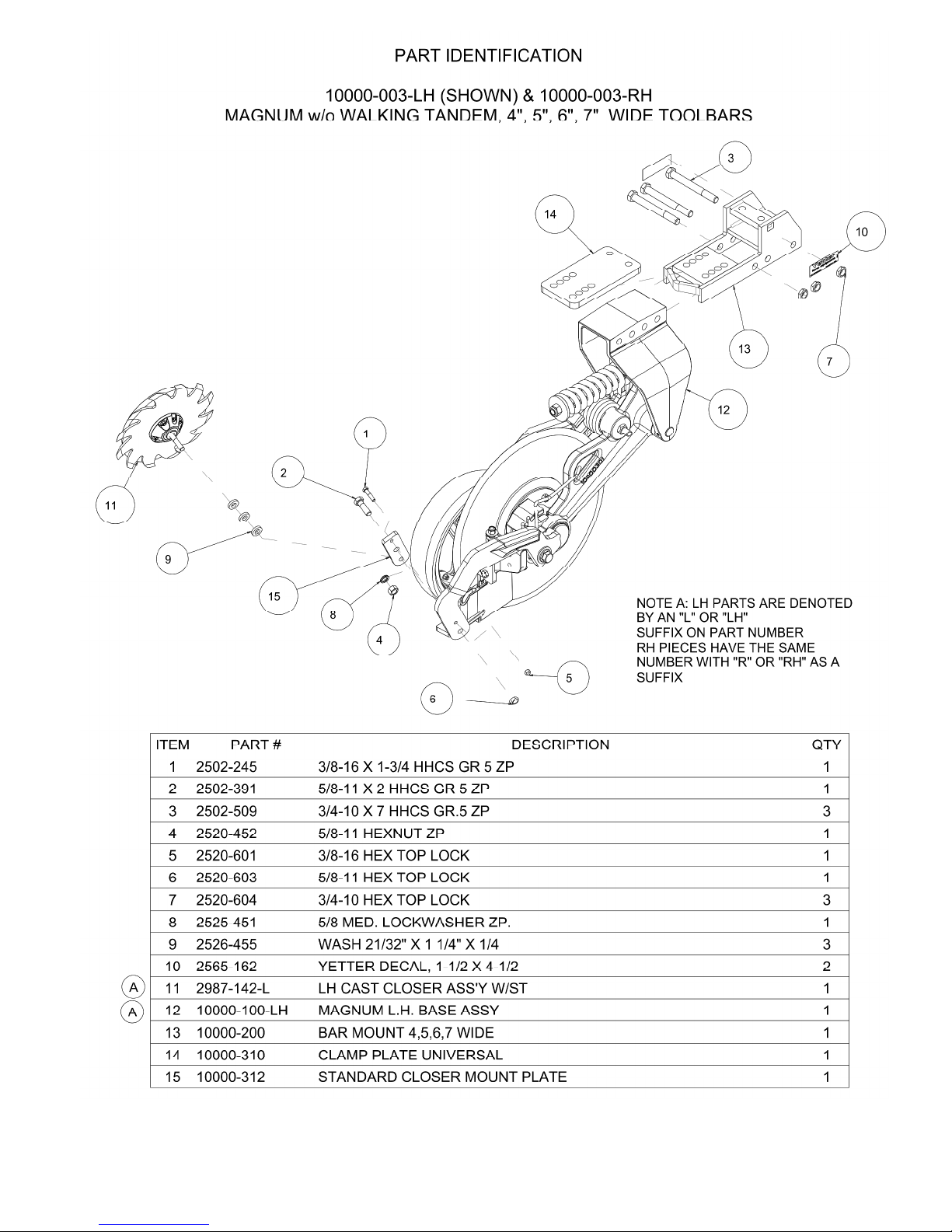

PART IDENTIFICATION

10000-100-LH

MANUFACTURED 3/2018 - PRESENT

26

Page 27

PART IDENTIFICATION

10000-100-LH

MANUFACTURED 3/2018 - PRESENT

27

Page 28

PART IDENTIFICATION

10000-100-RH

MANUFACTURED 3/2018 - PRESENT

28

Page 29

PART IDENTIFICATION

10000-100-RH

MANUFACTURED 3/2018 - PRESENT

29

Page 30

30

Page 31

31

Page 32

32

Page 33

33

Page 34

34

Page 35

35

Page 36

36

Page 37

37

Page 38

38

Page 39

39

Page 40

40

Page 41

41

Page 42

42

Page 43

43

Page 44

44

Page 45

10000 MAGNUM

TM

RH ST SEALER

45

Page 46

10000 MAGNUM

TM

RH KNIFE

46

Page 47

10000 MAGNUM

TM

RH

TANDEM WHEEL SEALER

47

Page 48

Our name

Is getting known

Just a few years ago, Yetter products were sold primarily to the Midwest

only. Then we embarked on a program of expansion and moved into the East,

the South, the West and now north into Canada. We’re even getting orders

from as far away as Australia and Africa.

So, when you buy Yetter products . . .you’re buying a name that’s

recognized. A name that’s known and respected. A name that’s become a

part of American agriculture and has become synonymous with quality and

satisfaction in the field of conservation tillage.

Thank you.

YETTER MANUFACTURING CO.

48

Colchester, IL 62326-0358 • 309/776-4111

Toll Free 800/447-5777

Fax 309/776-3222

Website: WWW.YETTERCO.COM

E-MAIL: INFO@YETTERCO.COM

2565-957_Rev_D 02/2018

Loading...

Loading...