YDIN9019

YDIN9019

2019

2019

INSTRUCTION

INSTRUCTION

MANUAL

MANUAL

1

1

WARNING

Please read this document carefully, as well as the bike-specific Installation

Guidelines, prior to assembling, installing and using the Conversion System.

4162, rue Burrill - Local A

Shawinigan, QC G9N 0C3

CANADA

TECHNICAL SUPPORT

If your dealer or distributor is unable to solve a problem related to the System, you may

contact the YETI SNOWMX support team from Monday to Friday.

E-mail: yetisnowmx@camso.co

Internet: www.yetisnowmx.ca

System Serial Number: 964__IEG

Original notice

Translations in other languages available at www.yetisnomx.ca

_______________

® and MC are trademarks of Camso inc.

All rights reserved. ©2019 Camso inc.

Printed in Canada.

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SYMBOLS AND SIGNAL WORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SERIAL NUMBER LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SOFT STRUT - ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DRIVE CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SYNCRODRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TRACK TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

WEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

YDIN9019- VERSION A

1 | YETI SNOWMX INSTRUCTION MANUAL

INTRODUCTION

Thank you for choosing the YETI SnowMX Dirt-To-

Snow bike conversion system, (hereinafter

referred to as the “System”). The YETI SnowMX is

the most advanced conversion system for off-road

motorcycle on the market. The design of its

chassis made out of light and strong carbon fiber

and its titanium components are geared towards

the needs of the most extreme riders. We went the

extra mile to offer you a quality, high-performance

conversion system that is suited to the handling

behavior of your off-road motorcycle and that will

take you to places only dreamt of while summer

riding.

SYMBOLS AND SIGNAL WORDS

This guide uses the following signal words and

symbols to emphasize particular information:

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

• This document is an integral part of the System.

Pass it along to any new System owner.

• Consult legal authorities where you drive your

motorcycle equipped with the System before

usage to ensure that you respect all applicable

laws and regulations.

• Motorcycle Conversion Systems are designed to

reduce ground pressure and increase vehicle

traction. However, during normal operating

conditions, vehicle speed should be reduced

compared to a wheeled vehicle.

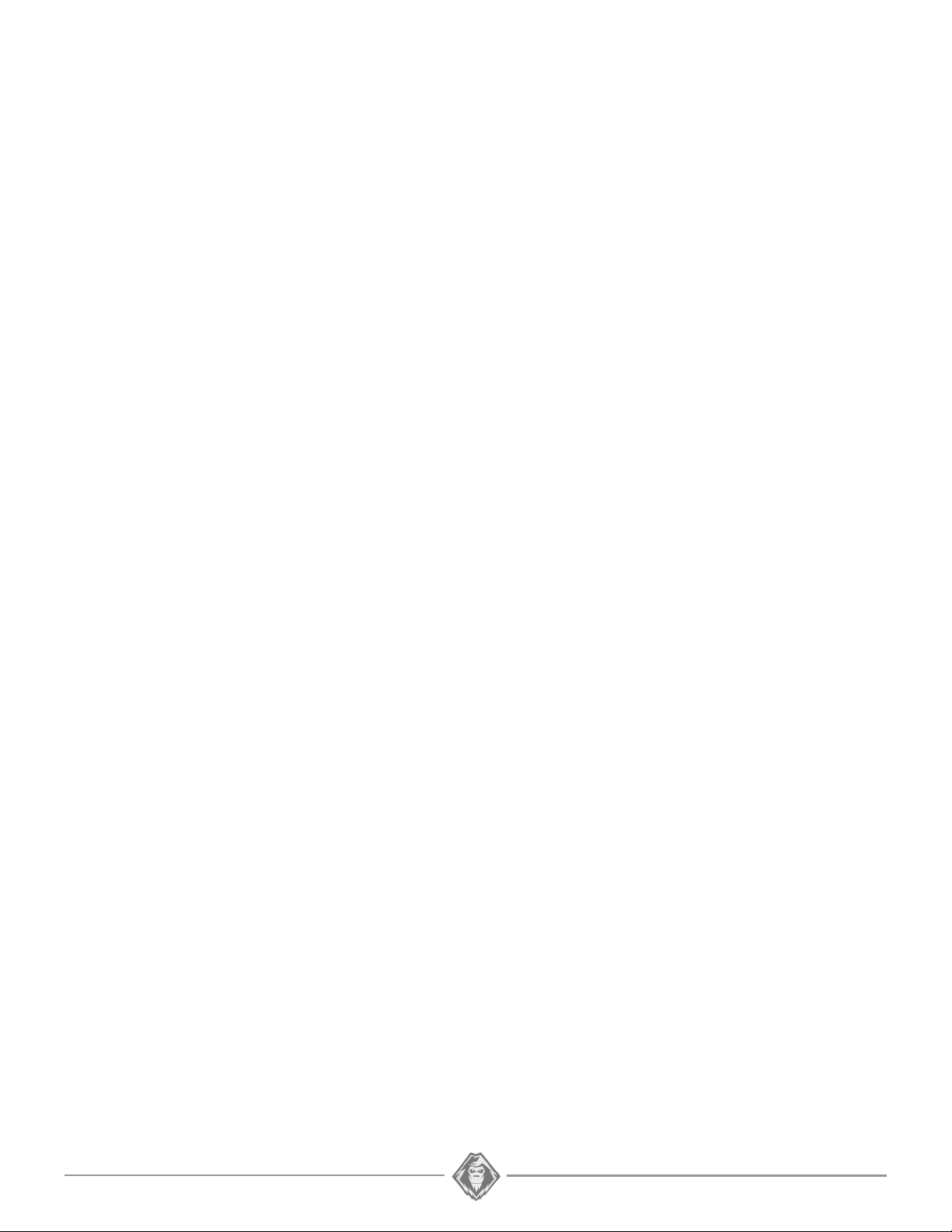

SERIAL NUMBER LOCATION

Figures below show the location of serial numbers

on the Conversion System chassis (Figure 1) and

rubber track (Figure 2).

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in damage to the

motorcycle and Conversion System components.

NOTE: Indicates supplementary information.

The Prohibition Safety Sign indicates an

action NOT to be taken in order to avoid a

hazard.

The Mandatory Action Sign indicates an

action that NEEDS to be taken to avoid a

hazard.

GENERAL INFORMATION

• All figures, information or photos presented in

this document are up to date at the time of

publication. However, they may change without

notice.

• Read and follow carefully the indications

contained in the bike’s Owner Manual. Its

content remains applicable after installation of

the System.

• This document should be read by every person

who operates a motorcycle equipped with the

System.

Figure 1

Figure 2

YETI SNOWMX INSTRUCTION MANUAL | 2

SAFETY

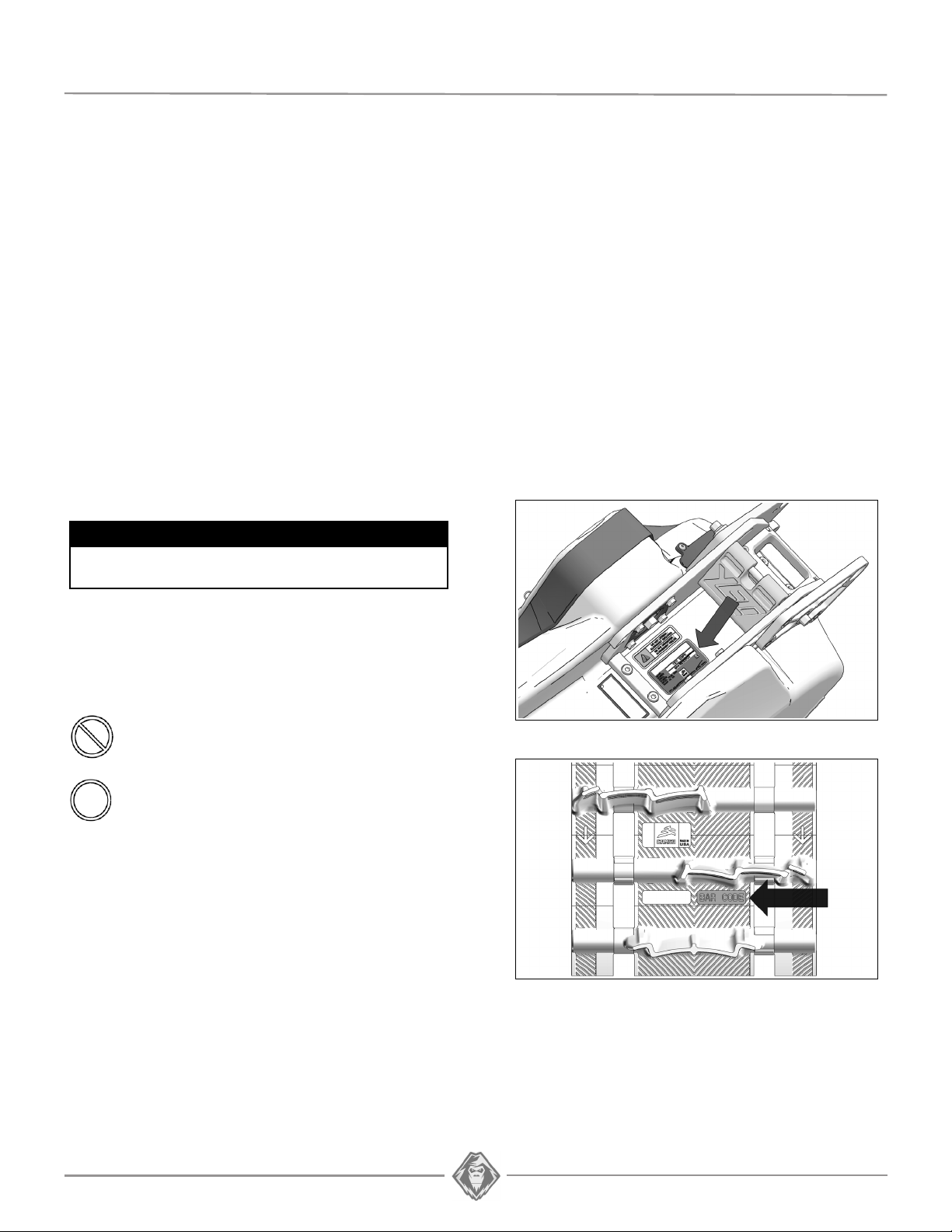

WARNING STICKERS

You will find affixed on the Conversion System the

warning stickers shown in the illustrations below.

Read the stickers carefully and understand them

before using the Conversion System. They contain

important information about safety and proper

operation of the Conversion System.

GENERAL WARNING

User Manual - Users must read the

User Manual before attempting to

operate a vehicle equipped with a

Conversion System.

If Conversion System is sold or in

any way transferred to a new user,

the User Manual must also be

transferred to the new user.

Moving Parts - Hands or fingers

caught between moving parts of the

equipment present a danger to life

or limb. Turn motor off before

servicing Conversion System.

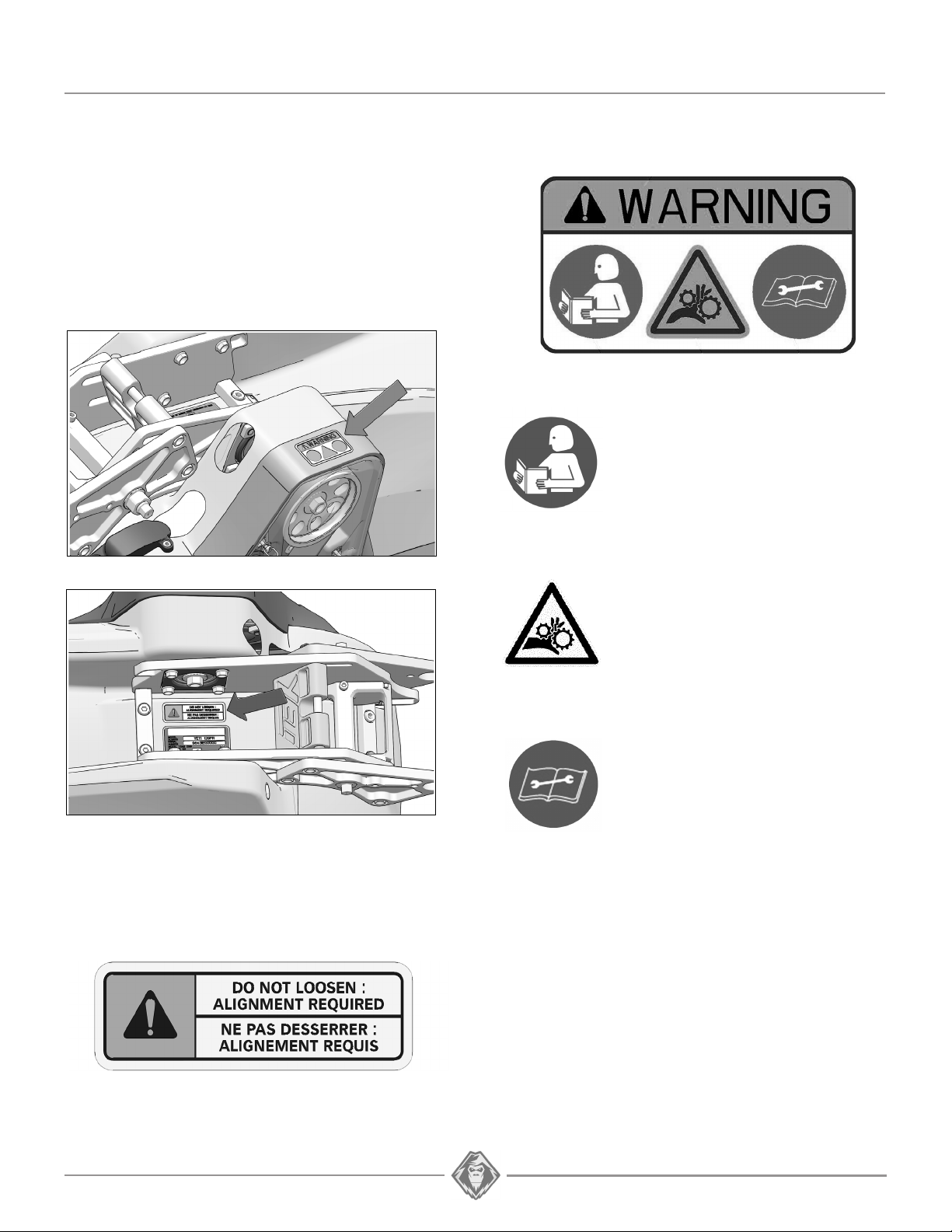

JACK SHAFT ALIGNMENT WARNING

The Jack Shaft’s bearing housing assembly bolts

must not be loosened. The Jack Shaft needs to be

realigned if these bolts are loosened.

Maintenance Schedule - Follow

the instructions contained in the

Maintenance Schedule section of

the User Manual to ensure safe and

long–lasting operation of the

Conversion System.

3 | YETI SNOWMX INSTRUCTION MANUAL

USER NOTICE AND DISCLAIMER

The YETI SnowMX Dirt-To-Snow bike conversion

System is designed to provide exceptional traction

and floatation in all winter conditions.

This document holds important information

regarding driving a motorcycle equipped with the

YETI SnowMX System. It is mandatory that every

user takes the time to carefully read, understand

and then consult this reference manual and user

guide as well as the motorcycle owner's manual as

needed. When purchasing either a new or used

Conversion System, the user must obtain all

documentation related to the System, including

manuals and guides related to the motorcycle on

which the System is installed. If need be, contact

the YETI products dealer nearest to you to obtain

any additional information. You may also consult

the Yeti Web site at www.yetisnowmx.ca and

contact our technical support by email at

yetisnowmx@camso.co.

YETI believes that there are certain risks related to

the installation and use of the System. Our

experience shows that the System is safe.

However, the user must be aware of the risks

related with driving a motorcycle with the

particularities of this type of System. The

motorcycle rider must, at all times, respect all

applicable laws and regulations, the indications of

the System manufacturer and the indications from

the motorcycle manufacturer fixed by law, namely

when age restrictions exist and motorcycle base

equipment is required (headlights, flashers and

brake lights, rear view mirror, etc.). The user must

always wear adequate safety equipment, such as

a helmet, safety glasses (or visor), protective

clothing, boots and gloves. It is understood that

driving while impaired or intoxicated presents a

danger for the motorcycle user and others and is

against the law.

The System consists of many moving parts,

including transmission wheels. If an object lodges

itself or becomes jammed into the System and

blocks the track, it is mandatory to stop the engine

and the vehicle and apply the security brake

before removing said object. By avoiding to do so,

the user exposes himself to sudden movement of

the motorcycle or to breakage of a part or

component coming from the System, which could

cause severe injuries. It is also very important to

wear full length clothing and always avoid hanging

or stringy accessories.

Driving a motorcycle equipped with such a System

requires particular precautions and a knowledge of

proper driving techniques of such vehicles.

An evaluation by the user of the conditions and

terrain (state of the ground, grade of hill, density of

snow, etc.) is equally essential.

A motorcycle equipped with a System cannot

compete and/or be used to perform stunts,

acrobatics or other exploits, as these could result in

loss of control or severe injuries.

Insufficient knowledge of a motorcycle during down

hill riding, climbs and crossing of obstacles and

turns can result in tipping or roll over, and can

cause severe injuries.

Carrying a passenger, a load or attaching a tow can

cause the motorcycle to be less stable, and affect

usability. Unless otherwise prescribed by law and

by the motorcycle manufacturer, you must not carry

a passenger, loads or tow any objects.

The installation of a System:

• Increases ground clearance.

• Changes the center of gravity.

• Increases motorcycle length, width and weight.

• Reduces ground pressure.

These parameters will effectively change driving

characteristics of a motorcycle equipped with the

System.

Consequently, it is highly recommended that the

user adapt his driving style to the new

characteristics mentioned above. The rider must

always use caution when he crosses obstacles,

circulates through narrow paths, meets vehicles

coming in the opposing direction, etc.

As it was designed, the System will considerably

reduce the motorcycle top speed and can falsify

the speedometer. Generally, the System

transmission wheel diameter is less than that of the

tire. Therefore, the vehicle speed will be less than

that actually displayed. Whether the motorcycle is

equipped or not with the System, users must

always adapt the speed to actual driving

conditions. Users must never exceed speed limits

or drive faster than their capacities allow.

Excessive speed remains one of the main causes

of severe motorcycle accidents.

Camso is proud to offer dirt-to-snow motorcycle

conversion kits within its wide range of products.

Motorcycle Conversion Systems are not only

reliable, but safe. However, there are risks inherent

to riding a motorcycle equipped with the System. It

is therefore very important that the rider familiarize

himself with the proper riding techniques of a

motorcycle equipped with a System. The rider must

also adapt his riding to his experience level, and

continually evaluate operating conditions and

terrain to safely and efficiently make the best of the

YETI SnowMX motorcycle Conversion System.

OPERATING INSTRUCTIONS

HINTS AND TIPS

• Before leaving for an excursion, make sure to

bring with you the following: 13 mm, 15 mm, 16

mm wrenches and sockets; 3 mm and 6 mm

Allen keys; an axe, a shovel, a tow cable, a

container of fuel, a screwdriver type pry bar and

an adjustable wrench.

YETI SNOWMX INSTRUCTION MANUAL | 4

WARNING

Riding a motorcycle equipped with a Conversion

System is different from riding a two-wheeled

motorcycle. It is strongly recommended that the

safety guidelines provided below are followed to

prevent any accident and/or serious malfunction

that could affect the rider, the motorcycle or the

Conversion System.

• Generally, the slower you go, the better the

traction will be.

• On excursions on unknown or remote terrain,

make sure to have with you a cellular or satellite

phone, a first aid kit and spare parts.

• When riding off trails, always be cautious of

potential hidden obstacles.

• In deep snow, do not intentionally spin the track

(track spins while bike remains stationary). This

could cause the bike to get stuck.

BREAK-IN PERIOD

CAUTION: A break-in period is necessary to allow

system components to settle and adjust to each other.

During the break-in period (8 hours or 160 km),

follow these recommendations:

VERIFICATION Install. Hour 1 Hour 8

Visual Inspection x x x

Track Tension x x x

Belt Tension x x x

CAUTION: Non-compliance with the usage

recommendations can lead to a warranty claim refusal.

CAUTION: The rider is responsible for following the

recommended scheduled maintenance described in

this manual.

CAUTION: Reduce your speed at all times; a

Conversion System installed on a motorcycle does

not have the same absorption capacity as a tire.

PRE-USE VERIFICATION

CAUTION: Before each ride make sure that the

System’s wheels and moving parts are free and that

they are not frozen or stuck on the frame.

CAUTION: Verify that the motorcycle’s air intake is

well adapted to weather conditions and is not

blocked by snow accumulation.

WARNING

Jumping with a motorcycle equipped with a

Conversion System is not recommended. These

Systems were not designed for this type of

operation. A motorcycle equipped with the

System must never be used for the following

activities: races, rallies, jumps, stunts, acrobatics

or any other extreme applications.

Chain Tension x x x

Torque - fork clamp

bolts

Torque - Bolts on

System

xxx

xxx

Angle of Attack x x x

• During break-in, avoid operating in dry and clean

conditions such as icy trails, gravel, asphalt or

sand.

• A GOOD break-in period must be done in a

lubricated environment such as a groomed trail

or soft snow.

• A BAD break-in period can generate smoke,

odors of burned rubber or plastic as well as

plastic deposits on track clips.

WARNING

When travelling in groups, riders following a

motorcycle equipped with a Conversion System

should be warned of dangerous objects that can

potentially be propelled by a tracked motorcycle.

5 | YETI SNOWMX INSTRUCTION MANUAL

TORQUE SPECIFICATIONS

Refer to the exploded views at the end of the

Manual to obtain torque specifications applied to

bolts at important points on the System.

DIMENSION GRADE Nm lb-ft

M6-1.0 8.8 10 7

M8-1.25 8.8 25 18

M8-1.25 10.9 33 24

M10-1.5 8.8 50 37

M10-1.5 10.9 70 52

M12-1.75 8.8 90 66

M12-1.75 10.9 125 92

NOTE: Use a thread locker (Loctite 263 type or its

equivalent) at indicated places in the exploded

views of the system.

NOTE: Release track tension during storage period

(recommended).

NOTE: Set shock absorber springs at lowest tension

position during storage period (recommended).

ACCESSORIES

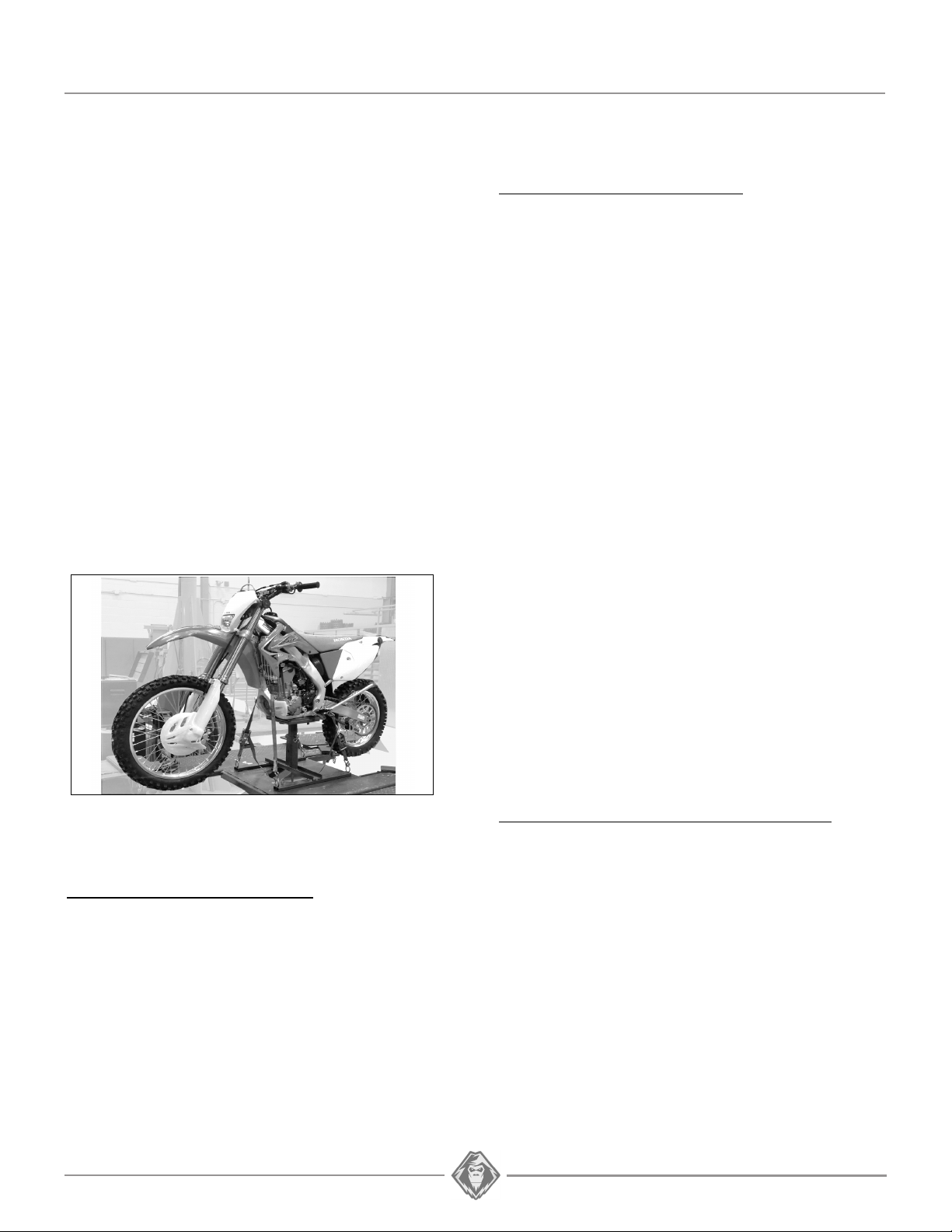

A Wheel kit is available to help move your bike

fitted with a YETI SNOWMX Conversion kit.

NOTE: The Wheel kit, shown below in Figure 4, can be

purchased through an authorized YETI dealer.

Part #YAAC1281.

WARNING

Over-tightening bolts may damage parts and

safety features may be affected.

STORAGE

CAUTION: Contaminants can alter and corrode the

moving parts of the System during storage.

Performing the prescribed maintenance before

storing the System is strongly recommended.

The best way to store the System is to lay it down

on a wood pallet, away from direct sunlight.

Figure 4

SPEED REDUCTION AND IMPACT ON

SPEEDOMETER

Installation of a YETI Conversion kit on a

motorcycle affects its speed and the way the

speedometer (if present) should be read.

Depending on the bike model, the actual speed is

lowered by 35 to 40% as compared to the

motorcycle on wheels.

Figure 3

YETI SNOWMX INSTRUCTION MANUAL | 6

INSTALLATION INSTRUCTIONS

• These installation instructions are meant to be

used in conjunction with the bike’s User Manual.

Refer to the instructions contained in your bike’s

manual for information concerning hardware,

torque specifications, and bike assembly or

disassembly procedures.

CAUTION: The warranty does not apply if

installation of the System is done by someone other

than a YETI dealer or authorized distributor.

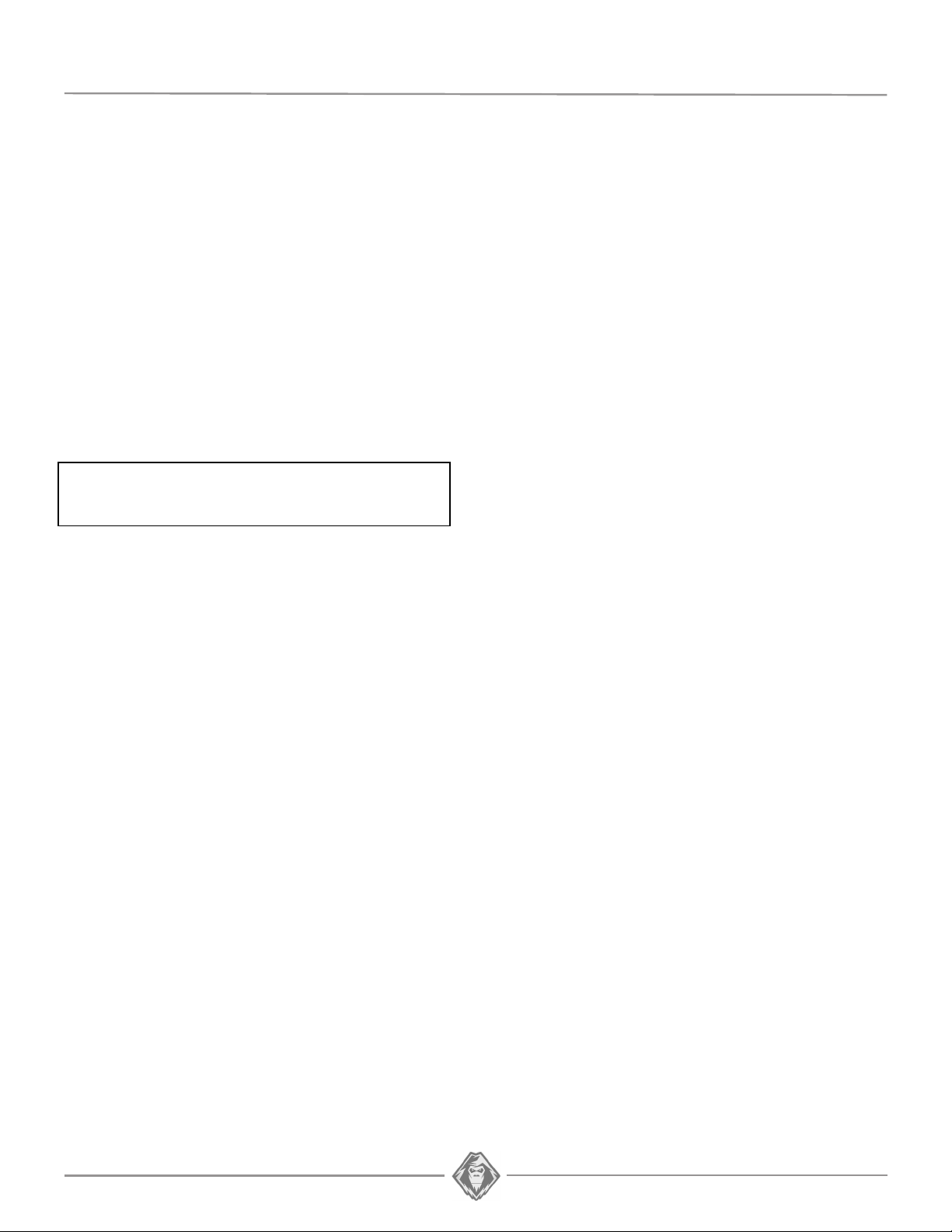

MOTORCYCLE PREPARATION

• Place the bike high enough on a solid and stable

stand so that the bike’s front and rear are not

touching the ground. Make sure that the bike is

immobilized and can be safely worked on.

CAUTION: Do not expose any part of your body

under the vehicle unless the motorcycle is installed

on a secure stand.

• Disassemble and remove fork protectors (if

applicable).

FRONT BRAKING SYSTEM REMOVAL

Proceed as follows:

• Loosen and remove front brake caliper assembly

bolts.

• Squeeze brake lever down to the handlebar and

maintain in place with zip-tie.

• Remove banjo bolt securing brake hose to

master-cylinder. Keep crush washers.

• Install rubber grommet, supplied in YETI parts

box, on banjo bolt. Reinstall and finger tighten

banjo bolt in master-cylinder.

NOTE: Rubber grommet will keep brake fluid from

leaking out of master-cylinder while Conversion

System is being assembled to bike.

• Remove assembled brake hose and caliper from

bike.

Figure 5

FRONT WHEEL

FRONT WHEEL ASSEMBLY REMOVAL

Proceed as follows:

• Loosen front fork axle pinch bolts.

• Loose and remove the front wheel axle nut.

• Remove front wheel axle.

• Remove the motorcycle’s front wheel.

NOTE: Bleed brake fluid out of brake hose and caliper

before storing them.

NOTE: Re-use the Conversion System’s Parts box to

store the disassembled parts during the periods

the Conversion System is used.

REAR WHEEL

To prepare the bike for rear system installation,

perform the following disassembly steps:

WHEEL/REAR SUSPENSION ASSEMBLY REMOVAL

• Loosen the rear suspension swing-arm nut.

• Lower chain tension to its minimum setting.

• Disassemble brake pedal and rear mastercylinder from the motorcycle’s frame.

NOTE: Do not remove the brake hose from the caliper.

The braking system needs only to be decoupled

from the motorcycle frame.

• Remove chain guard, guide rollers, and chain

from motorcycle.

NOTE: The nut and wheel axle will be reused to install

the ski assembly on the motorcycle.

• Disassemble and remove upper shock absorber

mounting bolt.

7 | YETI SNOWMX INSTRUCTION MANUAL

• Unbolt from the frame the linkage between the

swingarm and the shock absorber.

NOTE: There is no lower linkage between swingarm

and shock absorber on KTM PDS models.

NOTE: On certain bike models, some components

(muffler, seat, plastic side panels or rear frame

extension) have to be temporarily removed to

allow removal of shock absorber.

• Remove rear suspension swingarm pivot shaft.

• Remove the complete swingarm/rear

suspension assembly from the motorcycle.

NOTE: The swingarm/rear suspension assembly should

separate completely from the motorcycle.

• Remove mud deflector from rear part of frame.

Bikes equipped with a kick stand.

• Disassemble and remove the kickstand.

SPECIAL INSTRUCTION

DISASSEMBLED PARTS

Some of the components removed from the bike

will be re-used for the Conversion System

installation:

• Front wheel axle and nut.

• Rear swingarm axle and nut.

• Upper shock absorber bolt and nut.

• Crankcase Chain cover and bolts.

NOTE: All other components can be stored. Re-use the

Conversion System parts box to store the

disassembled parts when the Conversion

system is in use.

CAUTION: Some bike models (Honda & Yamaha) are

equipped with a kickstand / footpeg unit used to

support the bike when not in use. This stand

interferes with the rear conversion system and

should be removed. The kickstand and footpeg

make up one unit; so removing the kickstand

means removing the footpeg as well and therefore

the bike becomes unusable

Two options are available:

- Remove the footpeg / kickstand unit and replace

it by a footpeg without kickstand available from

the OEM (best option).

- Cut away the kickstand portion of the unit and

render it unusable.

YETI SNOWMX INSTRUCTION MANUAL | 8

SPINDLE INSTALLATION

FORK CLAMP VERIFICATION

Verify that the fork clamps received in the

installation kit are the right size and fit perfectly on

the bike’s forks.

CAUTION: A clamp that is too loose on the fork tube

does not allow for rigid assembly with the ski and

may damage the fork tube.

INSERTION OF SPINDLE BETWEEN FORK

TUBES

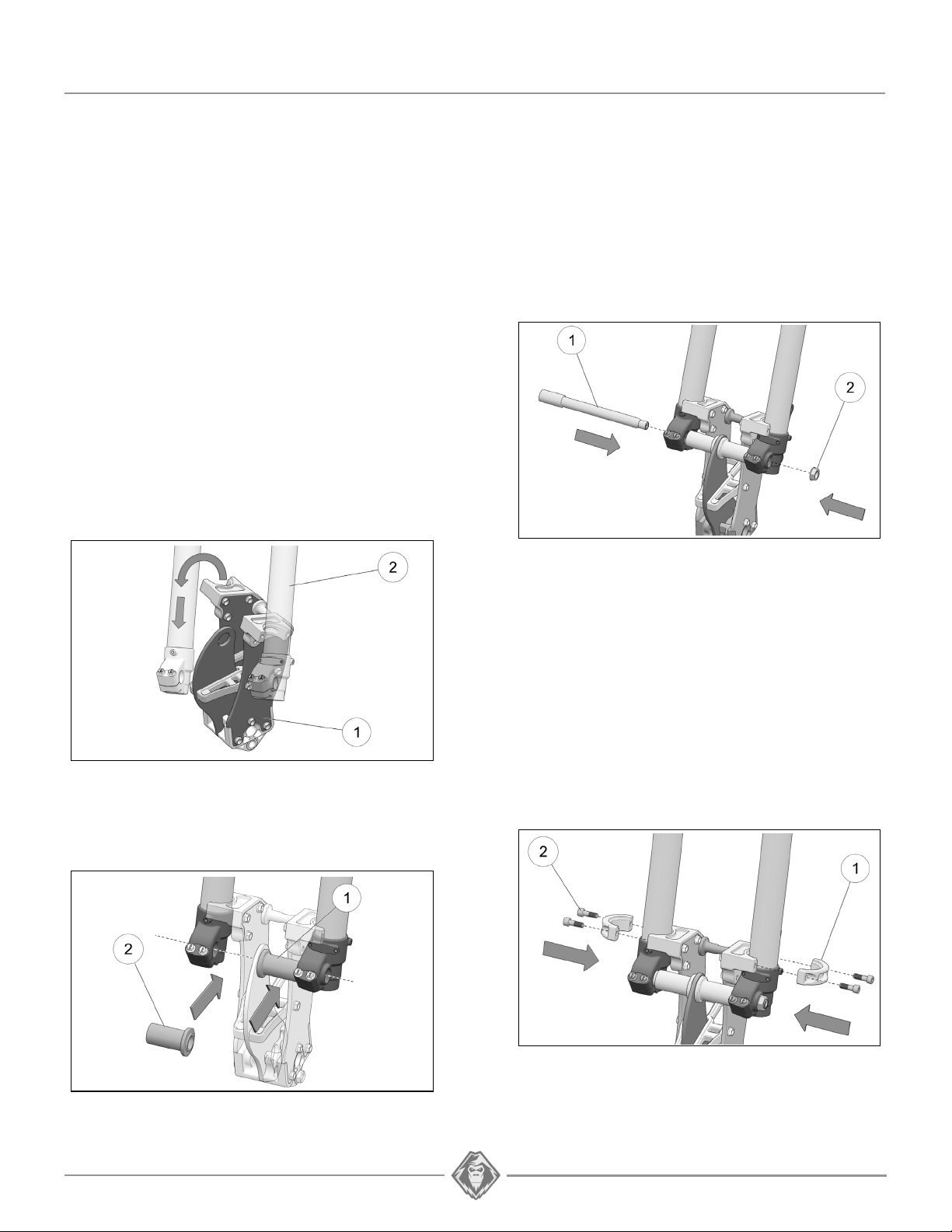

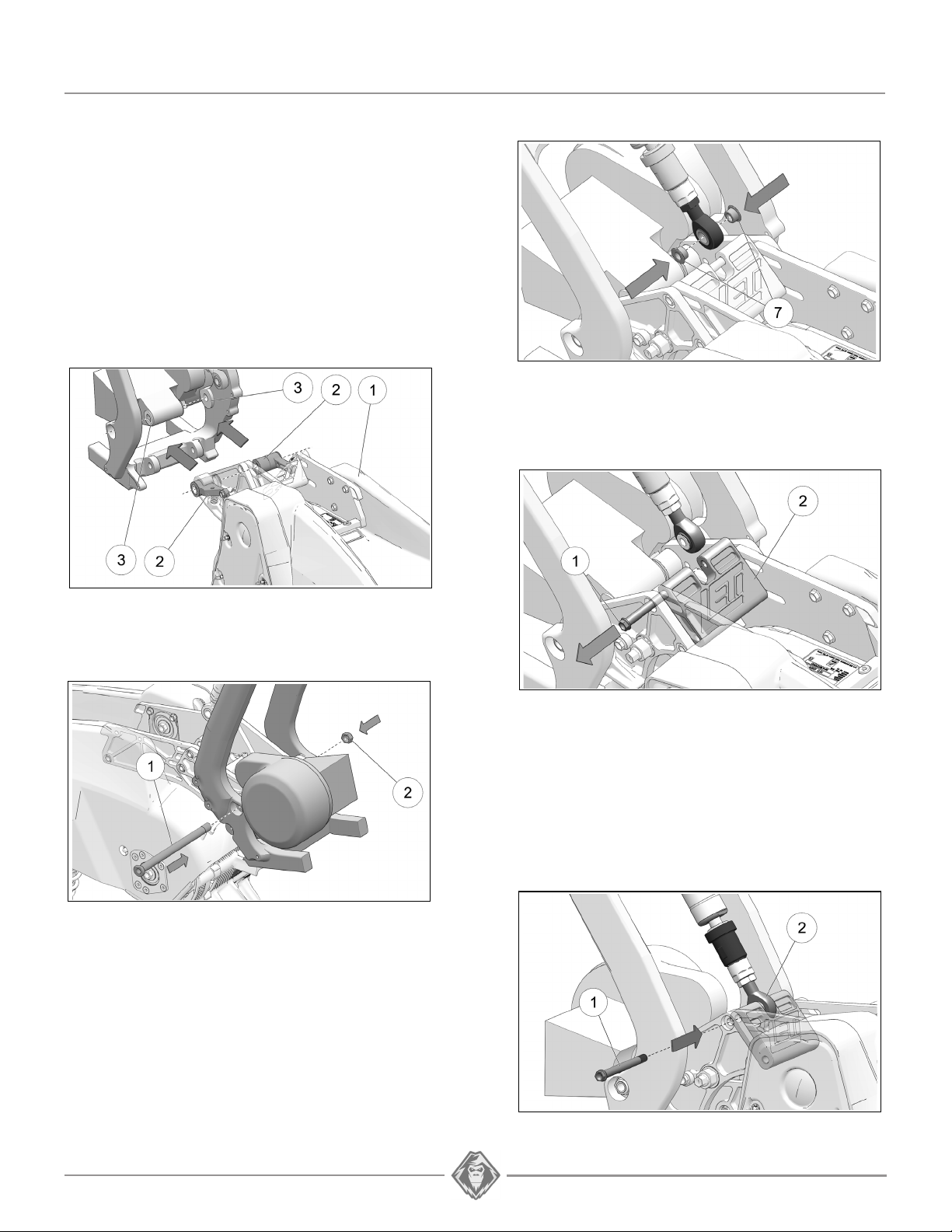

Proceed as follows:

NOTE: Center carbon blade must be positioned toward

the bike’s front.

• Install the complete spindle (1) between the two

lower fork tubes (2). Twist and slide spindle

down to position it between the fork tubes. See

Figure 6.

NOTE: Depending on bike model, the left and right axle

spacers on each side of the carbon blade may

be the same or different. If you are uncertain

about their position, consult the YETIVERTER

tool on YETISNOWMX.CA

NOTE: Make sure axle spacer locater collar is through

the center carbon blade.

• Insert front wheel axle (1) through forks and axle

spacers to secure spindle assembly. Install axle

nut (2) and tighten temporarily by hand. Figure 8.

NOTE: Lube wheel axle before assembly.

Figure 8

Figure 6

• Position left (1) and right (2) axle spacers on

each side of the spindle’s center carbon blade.

See Figure 7.

• Set the outer fork clamps (1) in their position at

the bottom of the forks. The small machined

diameter in the fork clamps is used as clearance

for fork seals and so must be positioned up.

Insert clamp assembly bolts (2); do not tighten at

this point. See Figure 9.

CAUTION: Observe installation direction for outer

fork clamps. A clamp assembled in the wrong

direction could damage the fork if the front

suspension travels all the way down.

NOTE: Apply a thread locker product (e. g. Blue Loctite

242) to Fork clamp assembly bolts.

Figure 7

Figure 9

NOTE: Depending on bike model, the left and right fork

clamps may be the same or different. If you are

uncertain about their position, consult the

YETIVERTER tool on YETISNOWMX.CA

9 | YETI SNOWMX INSTRUCTION MANUAL

CAUTION: Clamps must be straight and aligned

before final tightening. Clamp misalignment can

hinder normal operation of forks.

• Tighten clamp bolts to 25 Nm [18 lb-ft] of torque.

See Figure 9.

NOTE: Use an alternate tightening sequence between

the 4 clamp bolts to distribute force equally.

• Tighten, in sequence, the front wheel axle nut (1)

and then the pinch bolts (2) at the bottom of the

forks to the torque specifications recommended

by the manufacturer of the bike. Figure 10.

Figure 12

REAR SYSTEM PREPARATION

VERIFICATION OF ADAPTERS AND BUSHINGS

Check that the mount adapters and bushings

received match your bike’s model. These parts are

identified by a number inscribed on each one;

consult the YETIVERTER tool on

YETISNOWMX.CA to confirm the parts and identify

their installation position.

Figure 10

SKI INSTALLATION

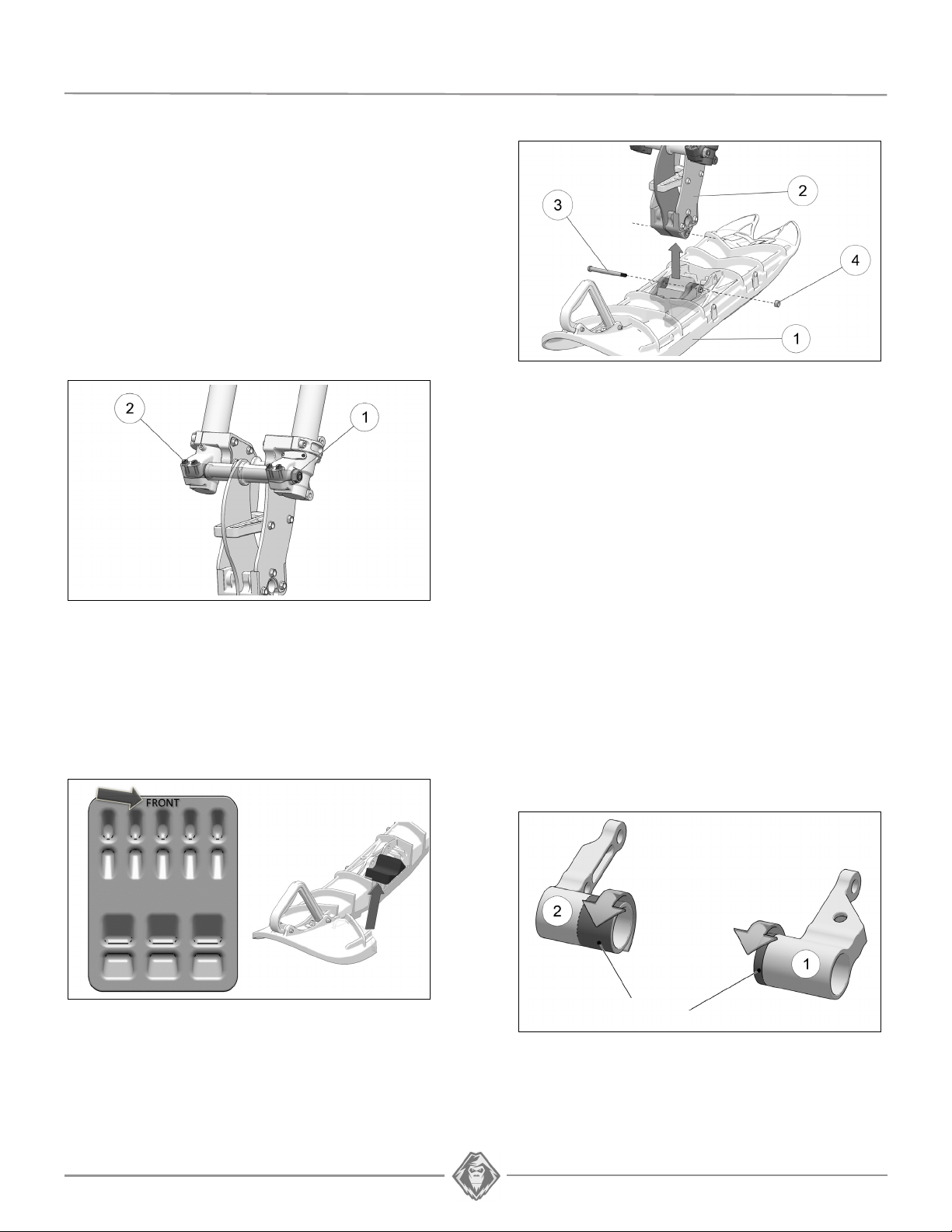

Assemble ski to spindle as follows:

• Check if «FRONT» marking under ski rubber is

positioned towards front of ski. Figure 11.

Figure 11

• Position ski (1) to spindle (2) and align holes in

ski’s base with mounting hole in spindle. Insert

M10x110mm bolt (3) and secure with M10

locking nut (4). Tighten assembly to 55 Nm

[38lb-ft] of torque. See Figure 12.

MOUNT ADAPTER INSTALLATION

Assemble mount adapters to Bike Mount as

follows:

NOTE: Make sure to assemble the correct adapters on

the Bike Mount’s left (1) and right (2) sides.

• Apply lube on the portion of adapters inserted in

Bike Mount. Figure 13.

LUBE

Figure 13

• Place mount adapters (1) in position outside of

Bike Mount (2). Finger tighten the temporary

M8x25mm assembly bolts (3) provided, at the

small end of the adapters. See Figure 14.

Figure 14

• Using the provided Mount adapter insertion tool

(1) and the M8x25mm bolts (2), rotate and

alternate between the tool’s nut (3) and bolt (2)

to insert mount adapters on both sides of the

Bike Mount. See Figure 15.

NOTE: Rotate slowly and alternate a few times to avoid

jamming the adapter during insertion.

YETI SNOWMX INSTRUCTION MANUAL | 10

Figure 16

CAUTION: To ensure adequate assembly, the

M8x25mm bolts used to insert the adapters must be

relocated to the Bike Mount’s front inside M8 holes.

• Insert bushings in mount adapters. Make sure to

match the bushings to the correct adapters.

NOTE: Depending on your bike model, the left and right

adapter bushings are the same or differ. If you

are uncertain about their position, consult the

YETIVERTER tool on YETISNOWMX.CA

AUTOMATIC CHAIN TENSIONER

INSTALLATION

Figure 15

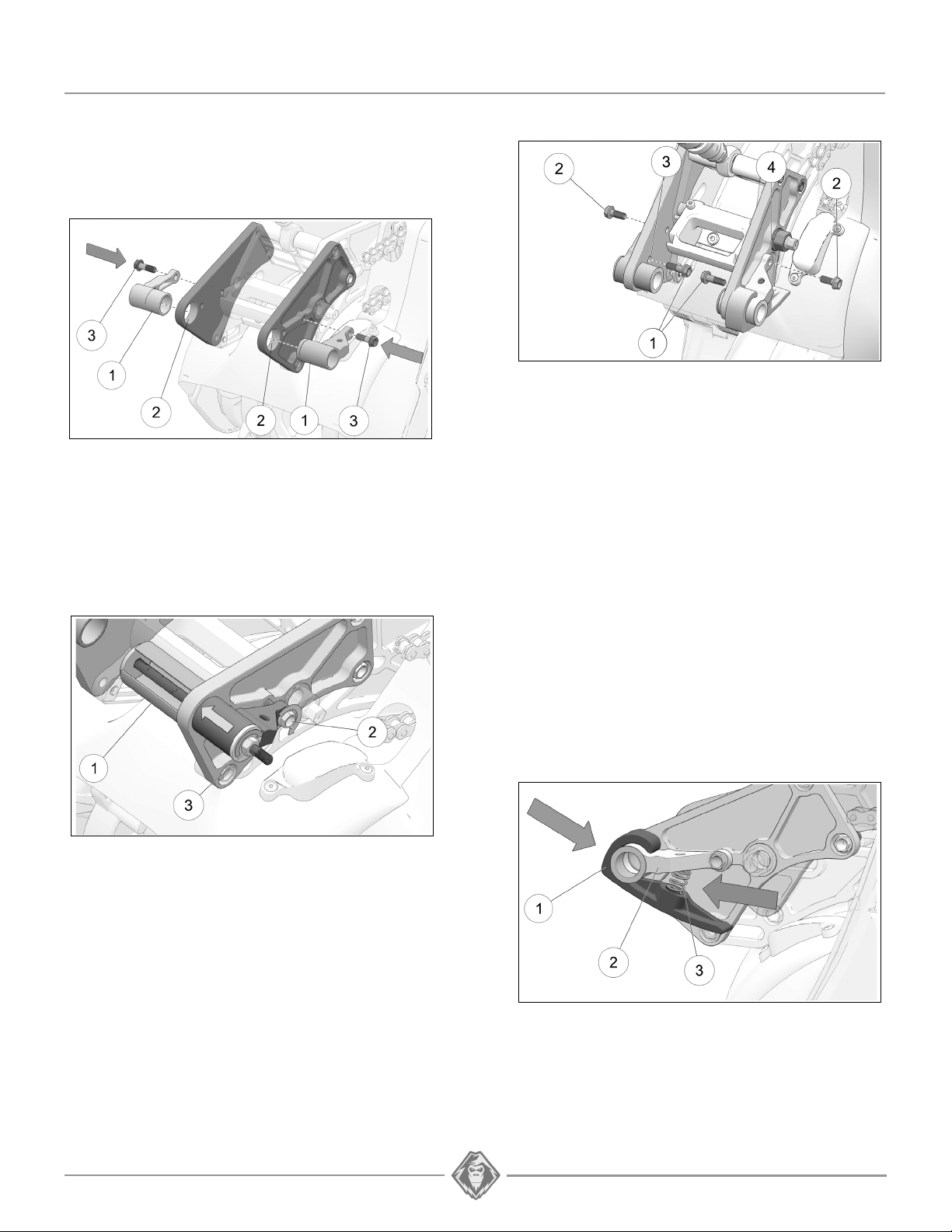

• Remove M8x25mm bolt used to insert Bike

Mount adapter.

NOTE: Apply a thread locker product (e. g. Blue Loctite

242) to Mount adapter assembly bolts.

• Secure adapters to Bike Mount with the longer

M8x25mm bolts (1) installed inside (3) and the

shorter M8x20mm bolts (2) on the outside (4).

Tighten bolts to 25 Nm [18 lb-ft]. See Figure 16.

• Insert Chain tensioner (1) on mount adapter (2)

installed on left side of Bike mount. Apply

pressure to insert guard on larger part of adapter.

Next, insert the chain tensioner spring (3) in its

seats, in the Chain tensioner and mount adapter.

See Figure 17.

Figure 17

11 | YETI SNOWMX INSTRUCTION MANUAL

BIKE MOUNT ADJUSTMENT

Before mounting the rear system to the bike, the

Bike mount must be extended out at its farthest

point. Proceed as follows:

• Loosen nut on eccentric bolt (1) and the Bike

mount M8 adjustment bolts (2).

• Using a 12mm socket, rotate eccentric bolt to

move the Bike mount out. See Figure 18.

Figure 18

• Insert spacer bushings (6) and o-rings (5) in both

sides of Soft Strut’s upper eye.

• Set aside the 2 spacer bushings (7); they will be

installed later.

NOTE: For KTM models with PDS suspension, the Soft

Strut assembly differs from the one illustrated in

Figure 19.

SOFT STRUT INSTALLATION

• Position the Soft Strut’s upper eye to the bike’s

shock absorber upper mount.

IMPORTANT: Spacer bushings (6) and o-rings (5)

must be installed and positioned correctly in upper

eye of Soft Strut.

• Assemble Soft Strut (1) using the bike’s shock

absorber assembly bolt (2). See Figure 20

SOFT STRUT PREPARATION

Before installing Soft Strut on your bike, the strut

components must be assembled as shown in

Figure 19. Proceed as follows:

Figure 19

• Assemble rod end connector (1) to strut body(2).

Tighten connector adequately to body.

• Thread lock nut (3) on rod end (4).

• Assemble the rod end w/nut to strut connector.

Figure 20

• Tighten shock assembly bolt (2) to

manufacturer’s recommended torque

specification. Figure 20.

NOTE: Apply threadlocker product on bolt as per the

manufacturer’s specification.

• Slip one o-ring (5) on each spacer bushing (6).

REAR SYSTEM INSTALLATION

NOTE: The YETI’s bike mount adapters have the same

dimensions as your swing arm bushings. You

might have to wiggle or slightly pry to open the

gap to install the YETI in the bike’s frame.

• Assemble the rear system to the bike as follows:

• Slide the YETI Conversion System (1) into

position to align Bike mount adapters (2) where

your bike’s swing arm (3) used to be. See Figure

21.

YETI SNOWMX INSTRUCTION MANUAL | 12

Figure 23

• Loosen and remove bike mount bolt (1) to install

the Soft Strut’s rod end in the Strut block (2). See

Figure 24.

Figure 21

• Attach YETI to bike by reinstalling swing arm

assembly bolt (1) and nut (2). See Figure 22.

Figure 22

• Tighten bolt to the bike manufacturer’s

recommended specification.

• Insert the 2 remaining spacer bushings (7) in the

Soft Strut’s rod end. See Figure 23.

Figure 24

• Raise rear of YETI System and align the Soft

Strut rod end and Strut block in Bike mount.

IMPORTANT: Make sure Spacer bushings are

correctly positioned in Soft Strut rod end.

• Re-insert assembly bolt (1) to attach Soft Strut

(2) to Bike mount. Do not tighten the bolt

completely at this point. See Figure 25.

Figure 25

13 | YETI SNOWMX INSTRUCTION MANUAL

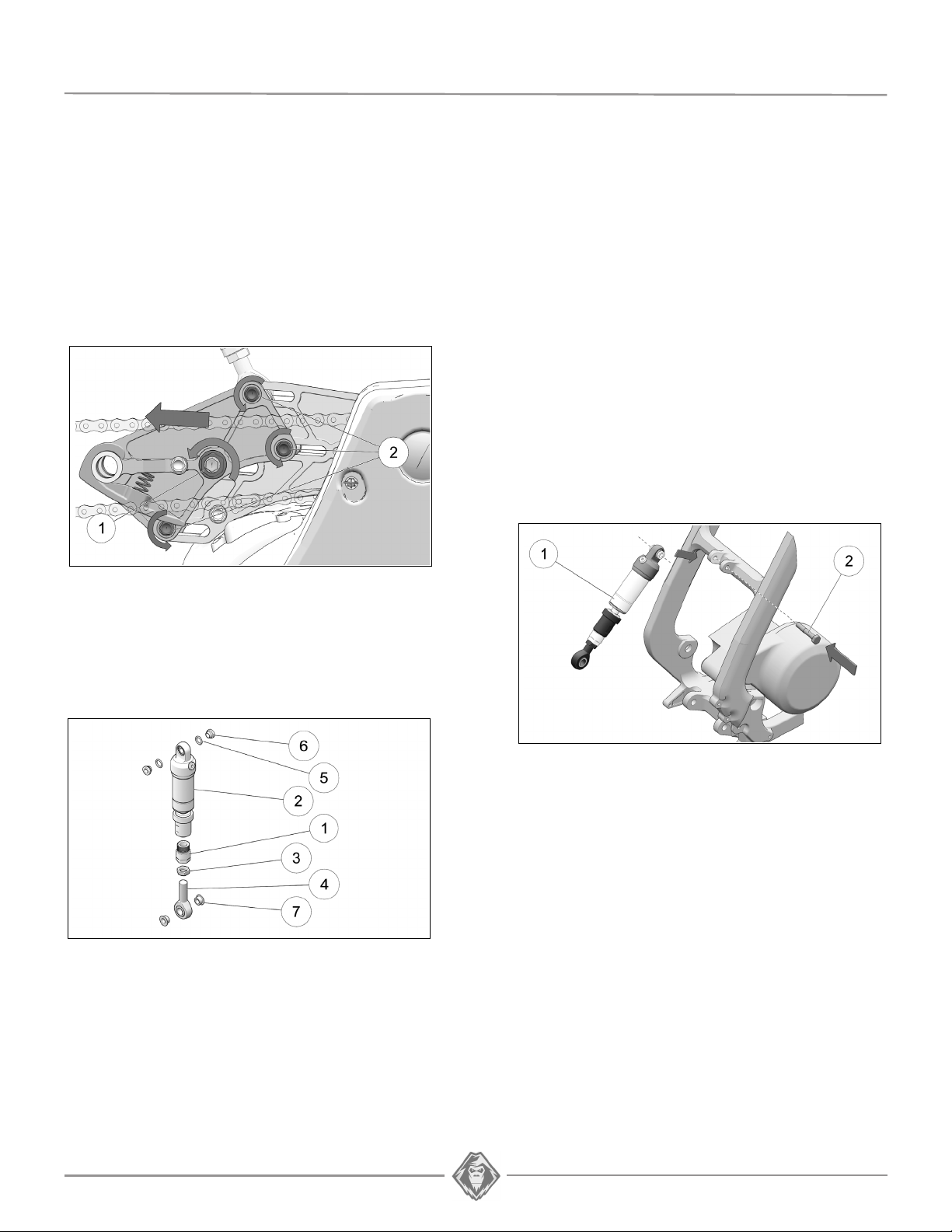

CHAIN INSTALLATION

Before installing the chain, the Bike mount should

be retracted as much as possible.

NOTE: For the next step, the bike should be raised

slightly so that the track is off the ground and

can be rotated.

• Insert chain (1) in upper opening at the front of

the system and feed it over jack shaft drive

sprocket (2). See

Figure 26

• Slowly rotate the YETI’s track to advance chain

links on the sprocket. Use a hook or magnet to

extract the chain out of the chassis through the

lower opening at the front. See Figure 27.

Figure 26.

CAUTION: The chain has the right length and does

not need to be shortened.

CAUTION: Observe direction of insertion for master

link locking clip.

CAUTION: Do not remove grease applied on master

link pins.

Figure 28

IMPORTANT: Chain adjustment is not done at

installation but will be done later. Leave play in the

chain to allow for other necessary adjustments to

be done first. Soft Strut adjustments impact chain

tension and therefore must be done before

adjusting chain tension.

NOTE: For further details on adjustments to be

performed on the Conversion System, see the

section entitled “Adjustments”.

Figure 27

• Install the provided chain on the engine sprocket

and join the ends using the master link. See

Figure 28.

NOTE: If the Soft Strut is adjusted too long, it could

make the chain too short to assemble.

Shortening the Soft Strut or raising the rear of

the System should help you join the ends of the

chain.

BRAKE SYSTEM

IMPORTANT: YETI SnowMX recommends that

assembly, preparation and brake system setting

steps be performed by a YETI SnowMX dealer.

WARNING

The braking system is an important safety feature

of your YETI conversion system and must be

kept in good running order. It is the operator’s

responsibility to keep the Conversion System in

optimal running order. Failure to perform

maintenance or verifications before use of

Braking system could result in a loss of control

that could cause serious injury or death.

BRAKE LINE ROUTING

Two options are available to route the brake line:

- Route brake line along the chassis up to the

handlebars without removing any bodywork

component.

- Disassemble bodywork components to enable

easy routing of line and master-cylinder up to

handlebars.

No matter the chosen method, observe the

following recommendations:

• Follow existing line and cable routing.

• Re-use existing ties and clips to secure brake

line. Add more ties if needed.

• Do not position the brake line against sharp

edges in the Bike’s chassis.

• Maintain large radiuses in brake line to avoid

pinches.

• Keep line away from heat sources that can

damage it or overheat hydraulic fluid.

• Keep enough play in Brake line between

handlebars and chassis, to ensure that turning

radius is not reduced.

CAUTION: Presence of an important heat source

near the line, such as an exhaust pipe, or the

engine, can overheat the Braking system’s

hydraulic fluid and render it less effective. Route

the Brake line to bypass such heat sources.

YETI SNOWMX INSTRUCTION MANUAL | 14

WARNING

Do not mix brake fluid types or grades. Some are

not compatible. Using the wrong type or mixing

incompatible fluids may cause loss or

inadequate breaking which may result in serious

injury or even death.

• Insert the clear plastic tube at the end of the

medical syringe. These two items are included in

the common parts box shipped with your YETI.

• Open the brake caliper’s bleeder check valve

about ½ turn and push the other end of the

plastic tube on the bleeder valve.

• Position the new fluid bottle securely at

handlebar level. Submerge end of brake line in

brake fluid.

NOTE: There must not be any loop in the brake line.

Keep it in an uphill position during the next step.

IMPORTANT: In the next step, the brake line end

must be submerged continuously in fluid.

• Pull on the syringe to fill the line and brake

caliper.

• Once brake fluid has started filling the syringe,

give it a pull to fill it completely. Then close the

bleeder check valve on the brake caliper.

• Remove end of plastic tube from bleeder valve.

NOTE: Squeeze the new brake fluid contained in the

syringe back into the brake fluid bottle.

• Re-assemble all motorcycle components

removed during the Conversion’s System

installation and routing of the brake line (rear

frame section, exhaust, plastic side panels, tank,

seat, etc.). Observe the manufacturer’s torque

specifications when tightening bolts.

CAUTION: Be sure to apply the bike manufacturer

requirements at reassembly of components.

BRAKE LINE HOOKUP & BLEEDING

IMPORTANT: To perform the following steps, use a

new bottle of brake fluid that meets the bike

manufacturer’s specifications.

• Remove end of brake line from brake fluid bottle.

and keep it in an upward position.

IMPORTANT: During the next steps, keep the end

of the brake line in an upward position to avoid

formation of air pockets in your primed brake line.

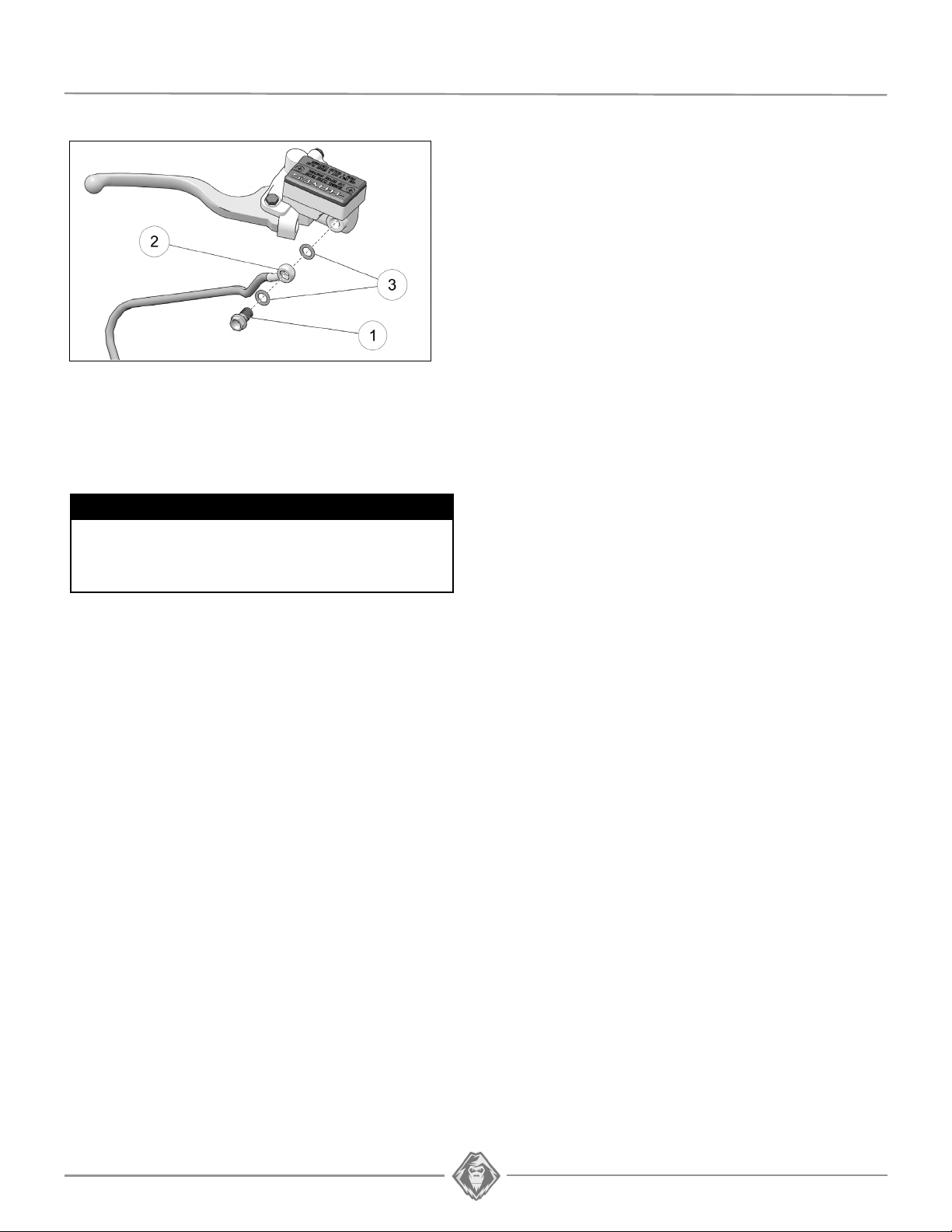

• Remove banjo bolt and rubber grommet inserted

temporarily during front brake disassembly.

• Insert banjo bolt (1) in end of brake line (2)

making sure to install the copper crush washers

(3) against both sides of the brake line banjo end.

See Figure 29.

15 | YETI SNOWMX INSTRUCTION MANUAL

IMPORTANT: It is important to OVER FILL the

reservoir before putting the cover back on to

prevent air from entering the braking system if you

happen to tip the bike upside down while riding.

BRAKING SYSTEM VALIDATION

Perform the following test after assembly and

bleeding of the braking system.

• Pump the brake lever a few times and tie it in the

closed position during 24 hours.

Figure 29

• Engage by hand banjo bolt - brake line - crush

washers assembly in the bike’s master cylinder.

Then tighten banjo bolt to the manufacturer’s

torque specifications.

WARNING

Apply the recommended torque to banjo bolt in

master cylinder. Inadequate tightening of banjo

bolt may cause loss or faulty breaking which may

result in serious injury or even death.

• Cut the zip tie that was installed temporarily on

the brake lever during the front brake

disassembly. Remove the master cylinder cover.

• Top off master cylinder reservoir with the same

new fluid used to prime your brake line.

• SLOWLY wiggle front brake lever in small

increments of ¼ - ½ lever travel at first. Pull lever

until there are no more air bubbles in brake fluid.

NOTE: Use a zip tie if the master cylinder does not have

a brake lever lock.

- If the system maintains pressure after 24 hours,

it is bled correctly.

- If the lever is even more closed after 24 hours,

check for fluid leaks in the braking system. if a

leak is detected, disassemble the braking system

and repair the leak.

- If there are no leaks and the lever is abnormally

closed, re-bleed the braking system.

• Reconnect plastic tube to brake caliper bleeder

valve. Open bleeder valve about ½ turn.

IMPORTANT: In the next step, check fluid level in

master cylinder reservoir and keep it full at all

times.

• Pump the brake lever fully. Check for air bubbles

in the fluid leaving the braking system and going

in the syringe. When there are no more air

bubbles, close caliper bleeder valve.

• Tighten bleeder valve to 5 Nm (44 lb-in).

Reinstall rubber dust cap on bleeder valve.

• Fill master cylinder reservoir to the rim. Reinstall

reservoir cover and tighten cover screws

according to manufacturer’s recommendations.

YETI SNOWMX INSTRUCTION MANUAL | 16

ADJUSTMENTS

CAUTION: Adjustment settings on your YETI must

be verified after first use on the bike. Soft Strut

setting, rubber track tension, Syncro belt tension

and chain tension must be re-checked. Incorrect

adjustments can decrease system performance and

produce premature wear on certain components.

SOFT STRUT - ADJUSTMENT

Adjustment of the Soft Strut has a direct impact on

the bike’s handling. Modifying the Strut adjustment

according to the changing snow conditions has a

radical effect on ski behavior.

• Place bike on ground, supported on ski skag and

rubber track.

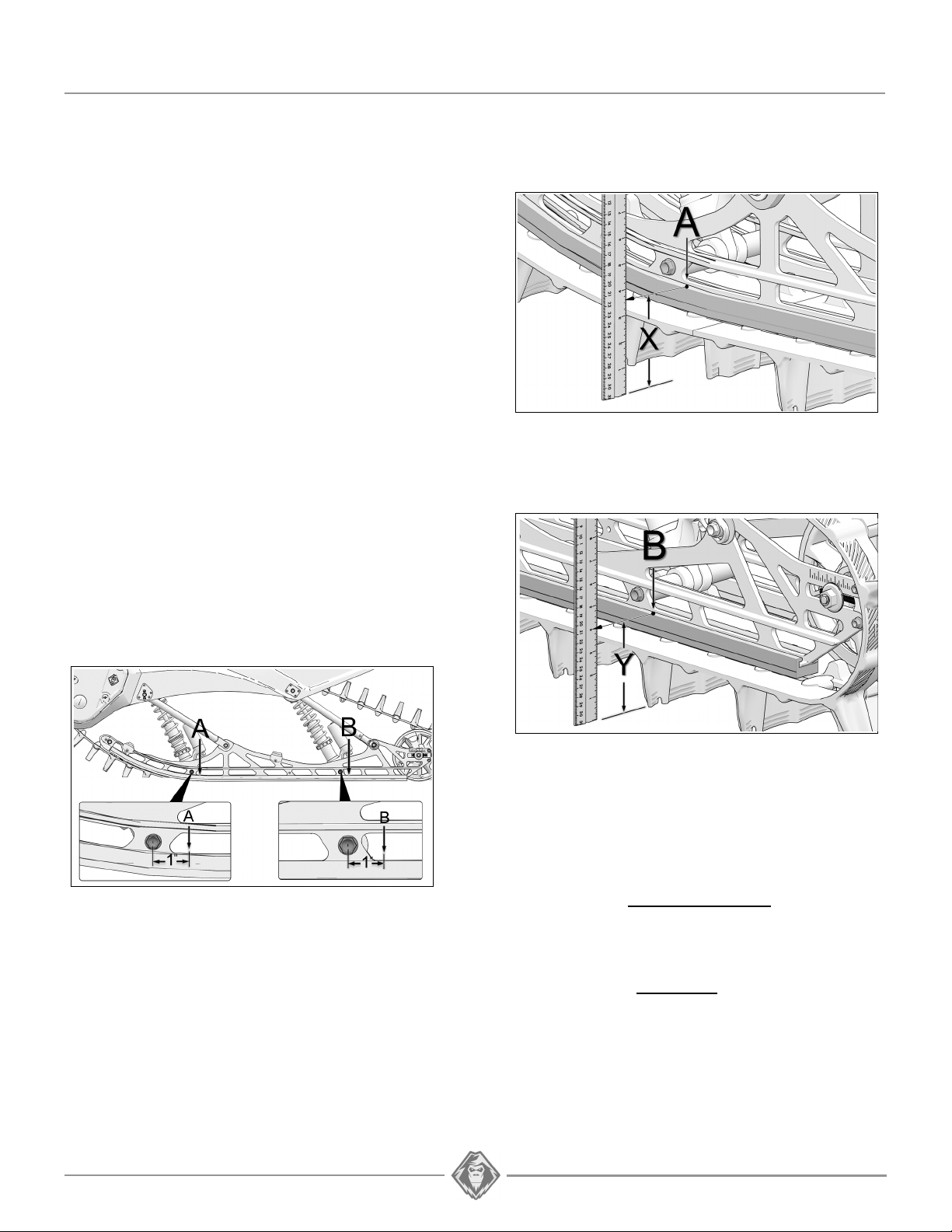

Front Measurement Point (A): Measure distance

between top of rail slide and the ground, at 1.00”

(25mm) back of front shock lower mounting bolt.

Figure 30.

Back Measurement Point (B): Measure distance

between top of rail slide and the ground, at 1.00”

(25mm) back of back shock lower mounting bolt.

Figure 30.

• At the front measurement point (A), measure

distance (X) between the top of the rail slide and

the ground. See Figure 31.

Figure 31

• At the rear measurement point (B), measure

distance (Y) between the top of the rail slide and

the ground. See Figure 32.

Figure 30

Recommended setting: The rear measurement

must be 0.300 to 0.500” (7,6 to 12,7 mm) higher

than the front measurement with the suspension

on the ground.

Figure 32

• Calculate the difference between the rear and

front measurement points.

Rear (Y) - Front (X) = 0.3 to 0.5” (7,6 to 12,7 mm)

Reaction to Soft Strut adjustment:

- One complete

counterclockwise rotation of the

Soft Strut shortens it by 0.050” (1,27 mm). The

rear measurement (Y) will then increase 0.050”

per rotation.

- One complete

clockwise rotation of the Soft

Strut lengthens it by 0.050” (1,27 mm). The front

measurement (X) will then increase 0.050” per

rotation.

17 | YETI SNOWMX INSTRUCTION MANUAL

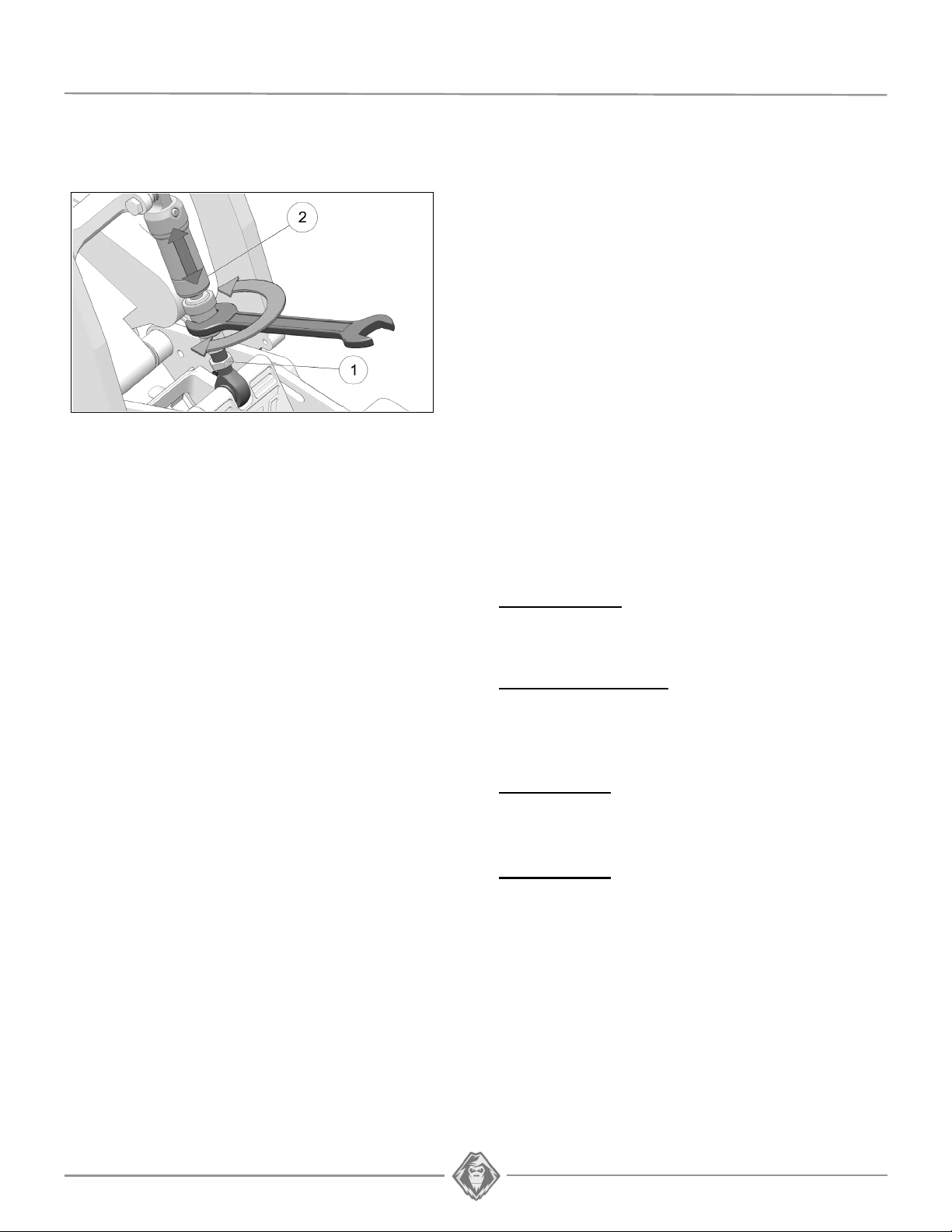

• Loosen the rod end lock nut (1). Adjust length of

rod end by rotating the Soft Strut (2) using a 31mm wrench. See

Figure 33

NOTE: Each time Soft Strut adjustment is checked,

raise bike’s rear and lower it back down slowly.

Figure 33.

• Adjust length of Soft Strut until the rear

measurement point is 0.300 to 0.500'' higher

than the front measurement point.

• Once the Soft Strut adjustment is completed,

tighten the lock nut (1) back to 40 Nm [30 lb-ft].

An adjustment above 0.500” at the rear

measurement point:

- lowers ski pressure;

- shortens the bike’s virtual wheelbase;

- produces more skittish handling on trails;

- produces better handling at low speeds.

CAUTION: An adjustment above 0.750” at the rear

measurement point is not recommended. The bike

then becomes hard to handle and unpredictable.

SHOCK ABSORBER ADJUSTMENT

Four (4) shock absorber combination options are

available for YETI SnowMX 2019 models:

Option1: RAPTOR Res/clicker front & Mono rear

Option 2: ELKA Stage 3, front & rear

Option 3: RAPTOR Res/clicker, front & rear

Option 4: ELKA Stage 5, front & rear

RAPTOR Mono (rear option 1)

Basic Tuning

An adjustment of under 0.300” or 0.000” (Flat)

at the rear measurement point produces:

- a better angle of attack for hill climbing;

- better handling in deep or powder snow;

- greater ski pressure;

- more stability at higher speeds.

An adjustment of between 0.300” and 0.500”

higher at the rear measurement point is:

- the recommended adjustment for all conditions;

- the best compromise suited for various uses

and snow conditions.

Only the spring preload can be adjusted on this

shock absorber model.

RAPTOR Res/clicker (front option 1, front & rear

option 3)

Spring preload and compression can be adjusted

on these shock absorber models.

ELKA Stage 3 (front & rear option 2)

Spring preload and compression can be adjusted

on these shock absorber models.

ELKA Stage 5 (front & rear option 4)

Spring preload, compression and rebound can be

adjusted on these shock absorber models.

Spring Preload

The shock absorbers are factory set for a 180-lbs

rider. Spring preload on shock absorbers can be

adjusted to take into account a rider’s weight and

riding style.

YETI SNOWMX INSTRUCTION MANUAL | 18

Proceed as follows:

• Loosen the spring preload adjustment ring

locking screw a few turns. Use a 3-mm Allen

key.

• Rotate adjustment ring to raise or lower shock

absorber spring preload. Use the provided tool.

NOTE: Rotating ring clockwise lowers spring preload.

NOTE: Rotating ring counterclockwise raises spring

preload.

• Once adjustment is completed, tighten

adjustment ring locking screw.

IMPORTANT: Modification of Shock absorber

spring preload impacts Soft Strut adjustment. Soft

Strut adjustment must absolutely re-checked if the

shock absorber spring preload is modified.

CAUTION: Spring preload must be set at a level

sufficient to keep the spring seated solidly in place.

Damage to components could occur if spring

preload is too low.

Compression and Rebound

Following the option chosen at purchase of your

YETI SnowMX, shock absorbers can be adjusted

in compression and rebound.

ELKA shock absorbers

DRIVE CHAIN

IMPORTANT: Soft Strut adjustment must be

completed before adjusting the drive chain tension.

• Position the bike level on the ground

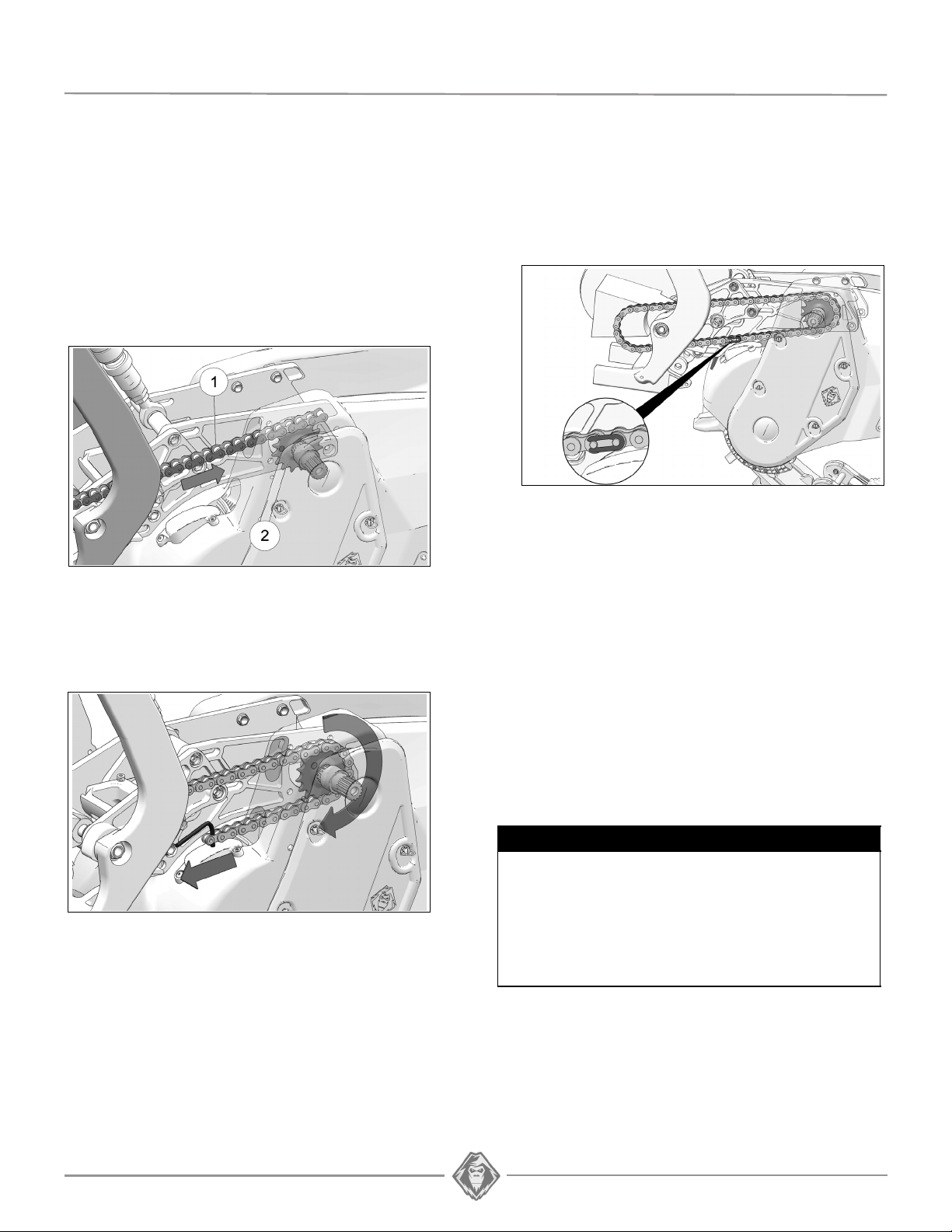

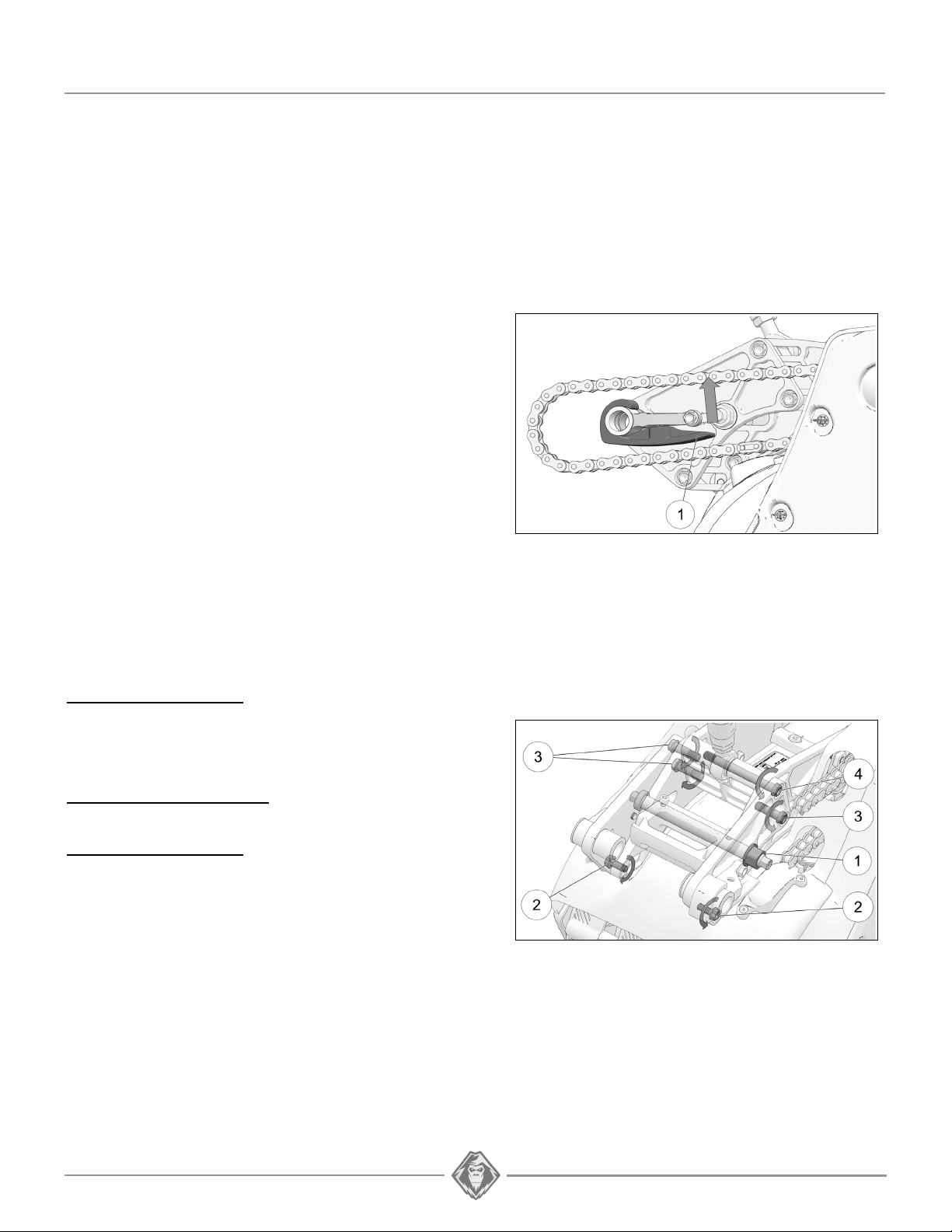

• Lift automatic chain tensioner (1) off the chain

and keep it up (e. g. with a zip tie) to avoid

adding tension to the chain during adjustment.

Figure 34

• Loosen eccentric bolt nut (1) a little using the

special socket provided in your YETI SnowMX

parts kit. Figure 35.

• Loosen slightly, the two M8 bolts (2), and the

four M10 bolts (3-4) on each side of the Bike

Mount so that the Bike Mount assembly can

slide. Figure 35.

Consult the ELKA owner’s manual provided with

your YETI for more details relative to compression

and rebound settings (if applicable).

RAPTOR shock absorbers

Consult the « Shock Service » section on

www.raptorshocks.com for more details relative to

compression and rebound settings (if applicable).

Figure 35

NOTE: Be careful to not loosen the two bolts (2) too

much; T-nuts could fall out and be lost.

• Rotate eccentric bolt (7) to adjust chain tension

as required. Use a 12-mm socket. Figure 36.

19 | YETI SNOWMX INSTRUCTION MANUAL

Figure 36

IMPORTANT: Remove all play in the chain without

over-tensioning it. The chain must be tensioned

before tightening Bike mount bolts and locking it in

place.

• Tighten in sequence: the eccentric bolt nut (1) to

61 Nm (45 lb-ft); the four M10 bolts (3-4) of the

Strut block to 41 Nm (30 lb-ft); and the two M8

bolts (2) at the front of the Bike Mount to 25 Nm

(18 lb-ft). See Figure 37.

Figure 37

• Release the automatic chain tensioner back

onto the chain.

SYNCRODRIVE BELT

IMPORTANT: Verify belt tension after 1 or 2

kilometers, and 3 or 4 times on your first outing. If

you notice a significant change in belt tension, readjust tension.

Figure 38

• With your thumbs, apply pressure to the belt (1),

where the tension gauge (2) sits, toward the

tensioner pulley (3). See Figure 39.

Figure 39

• Recommended setting: Required belt tension

is 11 mm (7/16'') of play, which corresponds to

the width of the red tension gauge in the

tensioner mechanism. See Figure 40.

SLIDE TENSION GAUGE TO

BELT OUTER EDGE. PUSH BELT

WITH THUMBS THE WIDTH

OF THE TENSION GAUGE

Figure 40

Syncrodrive Belt Tension Verification

• Slide the red tension gauge (1), incorporated in

tensioner mechanism, to the outer edge of the

Syncrodrive belt. See Figure 38.

Syncrodrive Belt Tension Adjustment

• Loosen tensioner pulley nut (1) ½ to ¾ turn. See

Figure 41.

IMPORTANT: Do not loosen tensioner pulley nut

(1) more than ½ to ¾ turn. If the nut is too loose

during the adjustment process, the belt tension

could increase when the nut is tightened back.

• Loosen lock nut (2) on Belt Tensioner adjusting

bolt. See Figure 41.

YETI SNOWMX INSTRUCTION MANUAL | 20

• Rotate Belt Tensioner adjusting bolt (3) to raise

or lower belt tension. See Figure 41.

Figure 41

• Tighten tensioner pulley nut (1) back to 55 Nm

(38 lb-ft) of torque. See Figure 41.

• Verify tension adjustment. Repeat previous

steps if tension is found insufficient.

TRACK TENSION

CAUTION: The two rear wheel assembly axle nuts

(1) must be loosened before adjusting Track

tension. See Figure 42.

Figure 42

• Rotate the right and left rear wheel axle

adjusting bolts (2) an equal number of turns,

clockwise or counterclockwise, to set the Track

to the recommended tension. See Figure 43.

Figure 43

CAUTION: Use a ruler to verify how long the

adjusting bolts are engaged in the axle. A

misaligned rear axle can cause premature wear of

suspension components.

• The table below shows the force applied and the

deflection which must/ occur when track tension

is correctly set. Refer also to Figure 44.

FORCE DEFLECTION

6,8 kg (15 lb) 19 mm (¾ in.)

21 | YETI SNOWMX INSTRUCTION MANUAL

BASIC TUNING

• A higher rubber track tension reduces drive

“ratcheting”.

NOTE: Track tension set too high could cause

premature wear on system components.

• A lower rubber track tension provides better

traction, a smoother ride and better fuel

economy.

• Check Track tension at mid-point between the

two lower shock absorber mount shafts. Figure

44.

DEFLECTION = 19 mm

Figure 44

[¾ in.]

• Tighten the two rear wheel axle nuts (1) back to

55 Nm (38 lb-ft) of torque. Figure 42

NOTE: The track tension testing tool shown below in

Figure 45 can be purchased through an

authorized YETI dealer. The part number is

2000-00-3125.

Figure 45

Final Check

Ride your bike at slow speed on a distance of

about 1.5 km [1 mile]. Re–adjust as required.

YETI SNOWMX INSTRUCTION MANUAL | 22

MAINTENANCE

can result in premature wear and important

breakage on the System that will not be covered

under the warranty. The user is responsible to

WARNING

Do not insert hands or feet into or near the

System unless the engine is off, the vehicle is

stopped and the security brake is engaged.

follow the maintenance schedule provided by the

manufacturer.

The maintenance schedule is provided for optimum

durability of your System. The type and conditions

of usage of the System have a direct bearing on

CAUTION: Regular inspection, adjustment and

lubrication of the System is essential to its good

running order and safe operation. Users have the

responsibility to perform maintenance and regularly

adjust their System. The “Maintenance” section

provides the necessary information to perform

adequate maintenance on the System.

CAUTION: Failure to do regular maintenance at the

prescribed intervals and perform the preventive

adjustments indicated in the maintenance schedule

the frequency of maintenance actions to perform.

After inspection of your System, you will be able to

determine if the recommended maintenance

intervals are correct and adjust them as needed.

For optimum performance and maximum durability,

please refer to the maintenance chart below.

For more details, consult the Maintenance

specifications on page 23 and page 24.

INITIAL INTERVALS

MAINTENANCE

FIRST USE EVERY 25 HRS EVERY 50 HRS

SYSTEM - VISUAL INSPECT CLEAN / INSPECT CLEAN / INSPECT CLEAN / INSPECT

SYSTEM - ADJUSTMENTS ADJUST INSPECT / ADJUST INSPECT / ADJUST

SYSTEM - BOLT TORQUE INSPECT INSPECT / ADJUST

SYSTEM - SPROCKETS / CHAIN /

MASTER LINK

SYSTEM - BRAKE INSPECT INSPECT INSPECT / REPLACE

SYSTEM - CHAIN GUARD

SYSTEM - SYNCRO DRIVE BELT

SYSTEM - BEARINGS, DRIVESHAFT

SYSTEM - CRACKS INSPECT

BIKE MOUNT - LUBE INSPECT / LUBE

TRACK- TENSION ADJUST INSPECT / ADJUST INSPECT / ADJUST

TRACK - WEAR INSPECT

WHEELS - WEAR INSPECT

WHEELS - BEARINGS INSPECT INSPECT / REPLACE

SUSPENSION - GUIDE WEAR INSPECT INSPECT

SUSPENSION - LUBRICATION INSPECT / LUBE INSPECT / LUBE

SUSPENSION - NYLON BUSHINGS INSPECT

SUSPENSION - SPROCKETS INSPECT

SUSPENSION - RUBBER DAMPER INSPECT INSPECT / REPLACE

SKI - SKAG INSPECT INSPECT / REPLACE

SKI - SIDE RUNNERS INSPECT INSPECT / REPLACE

SKI - RUBBER DAMPER INSPECT INSPECT / REPLACE

SPINDLE - NYLON BUSHINGS INSPECT INSPECT / REPLACE

STRUT ROD - ROD END INSPECT INSPECT / REPLACE

ADJUST ADJUST / INSPECT / LUBE ADJUST / REPLACE

INSPECT INSPECT / REPLACE

ADJUST INSPECT / ADJUST INSPECT / ADJUST

INSPECT INSPECT / REPLACE

EVERY 100 HRS /

ANNUAL

23 | YETI SNOWMX INSTRUCTION MANUAL

MAINTENANCE - TASKS

• Inspect: Component(s) must be examined with

care. If an anomaly is noticed, the

malfunctioning component(s) must be repaired

or replaced.

• Clean: Component(s) must be cleaned of any

dirt, dust or contaminant liable to impair the

proper operation of the Conversion System.

•

Adjust: Component(s) must be adjusted or re-

adjusted according to the manufacturer’s

adjustment recommendations. Refer to the

relevant section of the User Manual.

•

Lubricate: Component(s) need to be lubricated

according to the manufacturer’s

recommendations. Refer to the relevant section

of the User Manual.

•

Replace: Component(s) must be replaced to

avoid serious breakage.

MAINTENANCE - SPECIFICATIONS

System

• Visual Inspection: Visually inspect the

System’s components to detect any defect or

anomaly that can impair its proper functioning.

•

Adjustment: Perform or verify angle of attack

adjustment on the suspension according to the

manufacturer’s recommendations. Refer to the

Adjustments section on page 16.

Chain - Wear: Verify wear and general condition

•

of chain in drive mechanism. Refer to “Wear” in

the Maintenance section on page 28. Replace

chain if wear is too great.

• Master link - Lubrication: Remove the chain’s

master link and grease the two pins according to

the maintenance chart recommendations. Refer

to “Lubrication” in the Maintenance section on

page 27.

•

Chain - Lubrication: Lubricate the System’s

drive chain according to the maintenance chart.

Refer to “Lubrication” in the Maintenance section

on page 26.

CAUTION: If a chain needs to be replaced, its

sprockets should be replaced at the same time.

Assembly of new and used parts can speed up wear

of new components installed on drive system.

• Brake Pads - Wear: Verify wear on brake pads.

Refer to “Wear” in the Maintenance section on

page 28. Replace brake pads if wear is too

great.

•

Brake - Oil Level: With the vehicle upright and

on a level surface, check the oil level to make

sure that it is over the indicator mark on the

brake’s master cylinder sight glass. Add oil if

needed.

•

Brake - Hydraulic pressure: Check brake lever

pressure. Bleed brake system if lever feels

spongy or ends its travel too close to the

handlebar. Refer to the Brake Line Bleeding

section on page 14.

•

Bolt Torque: Check the torque of critical bolts

identified in the exploded views of the System.

Refer to the central pages of the User Manual.

CAUTION: Comply with tightening torque

recommendations and use a thread locker product

if you come across a bolt that is not tightened to the

manufacturer’s specifications.

• Chain - Adjustment: Perform or verify tension

adjustment on the System’s drive chain

according to the manufacturer’s

recommendations. Refer to the Adjustments

section on page 18.

•

Sprockets - Wear: Verify wear and general

condition of sprockets in chain drive

mechanism. Refer to “Wear” in the Maintenance

section on page 28. Replace sprockets if wear is

too great.

•

Chain Guard - Wear: Verify wear and general

condition of Chain guard. Refer to “Wear” in the

Maintenance section on page 28.

•

Syncro Drive Belt - Wear: Verify wear and

general condition of Syncro Drive Belt. Refer to

“Wear” in the Maintenance section on page 29.

•

Drive Shaft Bearings: Check Drive Shaft

bearings for restriction, noise or abnormal play in

rotation. Bearings must absolutely be replaced if

they present a defect.

•

Cracks: Visually inspect the System’s frame and

Bike Mount for presence of cracks or defects

that can impair proper operation of the System.

•

Bike Mount - Lubrication: Lube the Bike

Mount’s moving parts. Refer to “Lubrication” in

the Maintenance section on page 27.

Track

• Tension: Set or check track tension on the

System according to the manufacturer’s

recommendations. Refer to “Rubber Track

Tension” in the Adjustments section on page 20.

•

Wear: Verify wear and overall condition of the

System’s rubber track. Refer to “Wear” in the

Maintenance section on page 29.

CAUTION: A damaged track can result in premature

wear on suspension components.

Wheels

• Wear: Verify general condition of wheels and

inspect for wear on the outside diameter or

deformation. Refer to “Wear” in the Maintenance

section on page 29. Replace wheel(s) if a defect

is present.

•

Bearings: Check wheel bearings for restriction,

noise or abnormal play in rotation. Replace

wheel bearing if it shows any one of these

defects.

YETI SNOWMX INSTRUCTION MANUAL | 24

Rubber Dampers: Check general condition of

•

rubber dampers on suspension rails. Refer to

“Wear” in the Maintenance section on page 30.

Replace dampers if they are severely deformed

or cracked.

Ski

• Ski Skag: Inspect general condition of Skag.

Refer to “Wear” in the Maintenance section on

page 31. Replace Skag if it shows signs of

damage or deformation.

Side Runners: Inspect general condition of the

•

ski’s Side Runners. Refer to “Wear” in the

Maintenance section on page 31. Replace Side

Runners if they show signs too much wear or

deformation.

Rubber Damper: Inspect general condition of

•

the Rubber Damper located on the ski. Replace

damper if it is deformed, cracked or shows

severe wear. Refer to “Wear” in the Maintenance

section on page 31.

Strut Rod

Suspension

• Track Guides - Wear: Inspect for wear on

Suspension Guide rails. Refer to “Wear” in the

Maintenance section on page 30. Replace guide

rails if wear is too great.

•

Front Suspension Arm - Lubrication: Lube

the front suspension arm’s upper pivot shaft and

lower nylon bushings as per the maintenance

chart. Refer to “Lubrication” in the Maintenance

section on page 26.

•

Shock Absorbers Upper & Lower Mounting

Points - Lubrication: Lube the shock

absorbers’ upper and lower mounting points as

per the maintenance chart. Refer to

“Lubrication” in the Maintenance section on

page 26.

•

Nylon Bushings - Wear: Verify play and extent

of wear of nylon bushings on front and rear

suspension arm. Refer to “Wear” in the

Maintenance section page 30. Replace

bushings if play or wear is too great.

• Rod End: Check the Strut Rod’s rod end for

wear or excessive play. Refer to “Wear” in the

Maintenance section on page 31. Replace rod

end if it shows one of these defects.

Spindle

• Nylon Bushings - Wear: Verify play and extent

of wear of nylon bushings on bolt securing ski to

spindle. Refer to “Wear” in the Maintenance

section on page 32. Replace bushings if play or

wear is too great.

•

Drive Sprockets - Wear: Inspect for wear on

the sprockets driving the rubber track. Refer to

“Wear” in the Maintenance section on page 29.

Replace the sprockets if wear is too great.

25 | YETI SNOWMX INSTRUCTION MANUAL

LUBRICATION

A Front suspension arm - Upper shaft

B Shock absorbers - Lower shaft

C Rear shock absorber - Upper shaft

D Adjustment bolts - Rear axle

E Front suspension arm - Lwr bushings

F Circular slots - Eccentric cam

G Slots - T-nuts

H Adjustment bolt - Belt tensioner

Chain & Master link

i

YETI SNOWMX INSTRUCTION MANUAL | 26

LUBRICATION

The maintenance chart on page 22 contains

lubrication maintenance to be performed on the

System. Refer to the following

recommendations for optimal lubrication.

NOTE: Use a good quality translucent synthetic grease.

NOTE: Components might have to be removed to

access some of the lubrication points.

REFERENCE “A”

FRONT SUSPENSION ARM - UPPER SHAFT

Apply 3-4 cc of grease evenly all around and over

the entire length of the front suspension arm’s

upper shaft (A).

REFERENCE “C”

REAR SHOCK ABSORBER - UPPER MOUNT

Apply 1-2 cc of grease evenly around mid-point of

rear shock absorber’s upper support shaft (C).

REFERENCE “D”

CHAINS

Apply 1 cc of grease on threads of track tension

adjustment bolts (D).

REFERENCE “B”

SHOCK ABSORBERS - LOWER SHAFT

Apply 1-2 cc of grease evenly all around the midpoint of the shock absorbers’ lower support shafts

(B).

REFERENCE “E”

FRONT SUSPENSION ARM - LOWER MOUNTS

Apply 1-2 cc of grease evenly around front

suspension arm’s lower bushings (E).

27 | YETI SNOWMX INSTRUCTION MANUAL

REFERENCE “F”

ECCENTRIC CAM - SLOTS

Apply 1-2 cc of grease to circular slots (F) on each

side of Bike Mount eccentric cam.

REFERENCE “H”

SYNCRO DRIVE BELT - TENSION

ADJUSTMENT BOLT

Apply 1 cc of grease to threads of belt tension

adjustment bolt (H).

REFERENCE “i”

REFERENCE “G”

T-NUTS - SLOTS

Apply 1 cc of grease to Bike Mount T-slots (G).

CHAIN & MASTER LINK

Spray grease on the System’s drive chain (i).

Remove master link from primary chain and apply

a small quantity of grease to the link’s pins.

YETI SNOWMX INSTRUCTION MANUAL | 28

WEAR

Chain Drive Sprockets

Inspect the chain drive sprockets (A) for wear. If

the chain is set to the required tension (3-6 mm [1/

8-1/4 in.] deflection) but misses or skips over some

of the driving teeth, the sprockets must be

replaced. See Figure 46.

CAUTION: If a chain is replaced, the sprockets

should be replaced at the same time. Assembly of

new and used parts can speed up wear of the new

components installed on the drive system.

Check wear on the primary chain’s master link

pins. If abnormal wear is present, replace the

master link. See Figure 48.

Figure 48

Brake pads

Inspect brake pads (A) for wear. If pad thickness is

under 1.6 mm (1/16 in.), replace the parts. See

Figure 49.

Figure 46

Chain

If the chain is adjusted to the highest tension

setting (A) and the required 3 - 6 mm amount of

play (1/8-1/4 in.) cannot be obtained at mid-point

(B) between the sprockets, the chain should be

replaced. See Figure 47.

Figure 47

CAUTION: If the chain is replaced, the sprockets

should be replaced at the same time. Assembly of

new and used parts can speed up wear of the new

components installed on the drive system.

Figure 49

Chain guard

Verify wear on Chain guard (A). Replace guard if

wear reaches the part number molded at the front.

See Figure 50.

REPLACE

Figure 50

29 | YETI SNOWMX INSTRUCTION MANUAL

Chain guard spring

Verify that the Chain guard spring (A) is functional

and not damaged. Replace if defective. Figure 51.

Figure 51

Syncro Drive belt

Check the general condition of the Syncro Drive

belt (A). If you notice cracks or missing teeth, if

cord is showing or there is abnormal wear, replace

the belt. Figure 52.

CAUTION: Verify Jack Shaft alignment if repeated

wear problems occur on the belt.

Track

Verify wear on Track by inspecting the internal (A)

and external (B) condition of the Track's carcass

rolling path, driving lugs (C), the profile (D). Make

sure that the Track’s internal structure is not visible

at cuts or in worn areas. Make sure the steel clips (E)

are not abnormally worn. See Figure 53.

Figure 53

Wheels

Verify the general condition of wheels. If they show

important wear or missing fragments, replace the

wheel. Check wheel bearings for restriction, noise

or abnormal play in rotation. Replace wheel or

wheel bearing if they present any one of these

defects. Figure 54.

Figure 52

Track Drive Sprockets

Inspect the Sprockets that drive the Track. If the

Track is set to the required tension (19 mm

deflection for an applied force of 6.8 kg) and that

the sprockets miss or skip over some of the driving

lugs, the sprockets must be replaced.

Figure 54

YETI SNOWMX INSTRUCTION MANUAL | 30

Track Guides

Inspect the Track Guides for wear. If a guide is less

than 15 mm thick (22 mm - when new), anywhere

along the entire length, replace the part.

Figure 55

Figure 55

Verify if the guide is thick enough to cover the

assembly bolt head at the front. Thickness should

be over 20 mm. See Figure 56.

See

NOTE: YETI 120SS or 129SS shown.

LOWER FRONT ARM NYLON BUSHINGS

Figure 57

UPPER FRONT ARM NYLON BUSHINGS

Figure 56

Nylon bushings - suspension

Verify play and extent of wear on the suspension’s

nylon bushings (A). If there is abnormal play in the

bushings, replace them. See Figure 57, Figure 58

and Figure 59.

Figure 58

UPPER REAR ARM NYLON BUSHINGS

Figure 59

Rubber Dampers (suspension)

Verify general condition of rubber dampers installed

on the suspension rails.

replaced if they show cracks or are excessively

worn or deformed

. See Figure 60.

The dampers should be

31 | YETI SNOWMX INSTRUCTION MANUAL

Figure 60

Ski Skag

If the ski lacks support through turns on ice, check

condition of the skag (A). If the blades (B) show

deformations or are less than 4mm in height (8mm

when new), they do not provide enough support.

The skag should be replaced. See Figure 61.

Rubber Damper (ski)

Inspect Rubber Damper mounted on ski. Replace

damper if it shows cracks or is excessively worn or

deformed. A deformed Rubber Damper does not

provide adequate support to the ski and affects the

bike’s steering behavior. See Figure 63.

Figure 63

CAUTION: Rubber damper must be correctly seated

in position. An improperly seated rubber damper

can result in ice accumulating underneath and

difficult steering.

Figure 61

Side Runners

Verify the Side runners (A) mounted on the ski. If

they show rounded edges, they should be resharpened. Replace part if the height of a runner is

under 19 mm (25mm when new). See Figure 62.

Ball Joint - Strut Rod

Inspect ball joint on Strut rod. Make sure that it is

not seized or too loose. Figure 64.

CAUTION: A damaged ball joint can make the System

difficult to adjust and result in damages if not

replaced.

Figure 64

Figure 62

Nylon bushings - Ski & Spindle assembly

Verify play and extent of wear on the nylon

bushings (A) guiding the assembly bolt that

secures the ski to the spindle. If there is abnormal

play in the bushings, replace them. See Figure 65.

Figure 65

YETI SNOWMX INSTRUCTION MANUAL | 32

33 | YETI SNOWMX INSTRUCTION MANUAL

2-YEAR LIMITED WARRANTY

Camso guarantees that the new, unused YETI

SNOWMX System (System) installed by an

authorized dealer or distributor is free from any

defects in materials and workmanship during the

period and in conditions described below. When

operating a new YETI SNOWMX System, the user

agrees that the present form is applicable and

exclusive, that they have been signified and that

they have been accepted by him/her at the time of

purchase.

The YETI SNOWMX Dirt-To-Snow bike conversion

System is covered by a manufacturer warranty

(warranty). The warranty covers manufacturing

defects related with materials and workmanship.

The installation and maintenance of the System is

always the responsibility of the owner.

PERIOD OF COVERAGE

The warranty is valid for a period of twenty-four

(24) months following the date of purchase. This

warranty does not apply to normal maintenance.

The warranty applies exclusively to parts and

components of the conversion System. All paint

defects on the System (frames and components)

are not covered.

The warranty is not valid if the System is not

installed by an authorized YETI network dealer or

distributor.

This warranty specifically excludes any damage or

breakage to the motorcycle and related defects on

the motorcycle, whether or not these were caused

or believed to be caused by the System.

The manufacturer is not responsible for damages,

injuries or loss caused at the time of or after

installing of the System on the motorcycle.

For a warranty to be valid, the System owner must

comply with manufacturer notices and warnings. In

addition, all claims must be accompanied by a

proof of purchase (original receipt or sale contract)

and work or repairs must be performed by an

authorized YETI dealer. All claims not previously

approved and authorized by Camso will be

rejected.

The following situations and items are not

under any circumstances covered by the

warranty:

1) Any and all consequential damages, including,

but not limited to, indirect costs, such as towing,

storage, phone calls, renting, transportation,

inconveniences, insurance coverage,

reimbursement of loss, loss of time and loss of

revenue, etc.

2) Damage resulting from faulty installation.

3) Damage resulting from normal parts wear or

progressive deterioration owing to the distance

covered with a vehicle on which the System is

installed.

4) Damage resulting in non-compliance with the

user manual and with maintenance instructions

recommended in the user’s manual and other

technical documents.

5) Damage resulting in abusive use, abnormal use,

negligence or even a use which does not comply

with recommendations of the manual, excess

weight or loading, including excessive number of

passengers.

6) Labor costs, parts and materials related any and

all maintenance costs.

7) Damage resulting from faulty repairs, improper

maintenance or any unauthorized changes made

to the System other than those specified by the

manufacturer or from the installation of non-original

or unauthorized parts that were not produced or

approved by Camso.

8) Damage resulting from an accident, incident,

robbery, vandalism, war or unforeseen event or act

of God.

9) Regardless of cause, damage resulting from

inexperience, driving errors, accident or other

incident.

10) The use of the System on a motorcycle used

for public rental, including by a previous owner, will

render this warranty null and void.

11) The use of the System in races, rallies or other

competitive events/activities of this type, at any

time, including from a previous owner or in

conditions that do not comply with those described

by the manufacturer will render the warranty null

and void.

YETI SNOWMX INSTRUCTION MANUAL | 34

Any repaired or replaced components or parts are

guaranteed only to the extent of the original

warranty. in other words: if a warranted part was

replaced after nine (9) months, the new

replacement part will only be guaranteed for fifteen

(15) months, for a total of twenty–four (24) months.

Any claim for a track will be established according

to its residual value, 100% during the first 12

months, 75% between 12 and 18 months and 50%

between 18 and 24 months. The residual value will

have to be applied in the form of reduction to the

purchase of a track of replacement at regular

price. In no event shall the warranty extend

beyond a total of twenty-four (24) months from the

date of original System purchase.

In all cases, the warranty is limited to a maximum

of the original purchase price or the fair market

value of the System. Camso will have final

authority in determining the fair market value of a

used System. The warranty is applicable within the

limits and conditions initially contracted. If the

System is determined to be unusable due to

accident or improper repair, the warranty will be

considered null and void without further recourse

available to the System owner.

The manufacturer, the retailer and/or the repair

shop shall not be held responsible for any delays

caused by material, parts or components

availability or backorder.

*Shipping and handling costs, as well as any fees

related with shipping or transportation of the

System to the dealer location are the responsibility

of the System owner.

ELKASHOCKS

CANADA:

ELKA FACTORY SERVICE DEPT

1585-M De Coulomb, Boucherville, Québec,

Canada J4B 8J7

Phone: 1-800-557-0552

U.S.A:

IMPACT SOLUTIONS LLC.

655 Hocking Rd., Little Hocking, OH 45742

Phone: 740-989-2026

www.impactsolutionsatv.com

www.elkasuspension.com

RAPTOR SHOCKS

CANADA:

RAPTOR PERFORMANCE SHOCKS

PO Box 191

Sprague, Manitoba

R0A 1Z0

U.S.A:

RAPTOR PERFORMANCE SHOCKS

36778 County Rd 13

Warroad, MN 56763

info@raptorshocks.com

Camso reserves its sole and exclusive right to

update or modify this warranty without impact on

end users. All previous terms and conditions of the

warranty at time of purchase will be respected.

SHOCK ABSORBERS

Camso guarantees that the ELKA or RAPTOR

shock absorbers are free from any defects in

materials and workmanship during a period of

twelve (12) months. All subsequent support,

maintenance or repair requests should be sent to

the appropriate ELKA or RAPTOR Authorized

Service Center.

35 | YETI SNOWMX INSTRUCTION MANUAL

TROUBLESHOOTING

Break any ice under the front or back of the

upright (around rubber location) check if ski

can move 15-20° up and 5-10° down

Replace Ski damper if ski can move more

than 20° up or 10° down

Break any ice under the front or back of the

upright (around rubber location) check if ski

can move 15-20° up and 5-10° down

Adjust track tension, inspect parts, replace if

needed

Adjust chain tension. Inspect parts, replace if

needed

Replace parts as a set, adjust & lubricate to

manual specification (frequency)

Verify and realign drive track drive shaft

assembly

Verify if cover is properly seated, skin cover

must be inserted in the side panel openings

Incorrect angle of attack adjustment Re-adjust the suspension’s angle of attack

Ski mount is iced up & does not move

PROBLEM CAUSE SOLUTION

Unstable ski / handling too loose

Suspension preload too high Lower spring preload

Broken Suspension Limiter Strap Replace Limiter Strap

Limiter Strap is adjusted to long position Adjust Limiter Strap to a shorter position

Sagged, damaged ski damper

Compound too soft Replace rubber damper on ski

Ice build-up

Ski washout / Understeering