Page 1

Solid Fuel Cooker

INSTALLATION

& OPERATING

INSTRUCTIONS

Models YM-CKWDWH-R / YM-CKWDBL-R

YM-CKWDGR-R / YM-CKWDPB-R / YM-CKWDWH-L

YM-CKWDBL-L / YM-CKWDGR-L / YM-CKWDPB-L

For use in Great Britain and Eire

This product is suitable for use in the stated countries. T

product in other countries it is essential to obtain translated

instructions and in some cases the product may require modification.

Contact Yeoman to obtain further details.

o install the

IMPORTANT

The front and top of this cooker will become hot whilst in operation, it is therefore recommended

that a suitable guard should be used for the protection of young children, the elderly or infirm.

Before installation of this product please read these instructions fully.

The installer should complete the commissioning sheet at the start of the User Instructions

PM179 Issue 1 (October 2006)

Page 2

Contents

Commissioning Data 3

Technical Specification 4

SITE REQUIREMENTS

Solid Fuel Cooker Dimensions 5

Hearth Dimensions 5

Walls adjacent to Hearths 5

PRE-INSTALLATION CHECKS

Flue or Chimney 7

Additional Ventilation 8

INSTALLATION INSTRUCTIONS

Installing the Cooker 9

Commissioning 10

USER INSTRUCTIONS

General 11

Care of the Cooker 11

Using the stove for the first time 11

ning W

Bur

ning Solid Fuel

Bur

Over Firing 13

Oven Temperature 13

Seasonal Use 13

Ash Removal 13

Recommended Fuels 14

ood

12

12

MAINTENANCE AND SERVICING

General Cleaning 15

Cleaning Glass 15

Chimney Sweeping 15

Annual Service 15

2

Page 3

FOR YOUR RECORDS

o assist us in any Guarantee claim please complete the following information:-

T

YEOMAN DEALER APPLIANCE WAS PURCHASED FROM

Name: ..................................................................................................................................................................................................

Address:...............................................................................................................................................................................................

............................................................................................................................................................................................................

.

Telephone number:

....................................................................................................................................................

ESSENTIAL INFORMATION - MUST BE COMPLETED

Date installed:......................................................................................................................................................................................

Model Description:..............................................................................................................................................................................

Serial number:

..........................................................................................................................................................

INSTALLATION ENGINEER

Company name:...................................................................................................................................................................................

Address:...............................................................................................................................................................................................

.............................................................................................................................................................................................................

Telephone number:

....................................................................................................................................................................

COMMISSIONING CHECKS (TO BE COMPLETED AND SIGNED)

Is flue system correct for the appliance

Flue swept and soundness test complete YES NO

Smoke test completed on installed appliance YES NO

Spillage test completed YES NO

Use of appliance and operation of controls explained YES NO

Instruction books handed to customer YES NO

Signature: ........................................................................................................ Print name:

YES NO

3

......................................................

Page 4

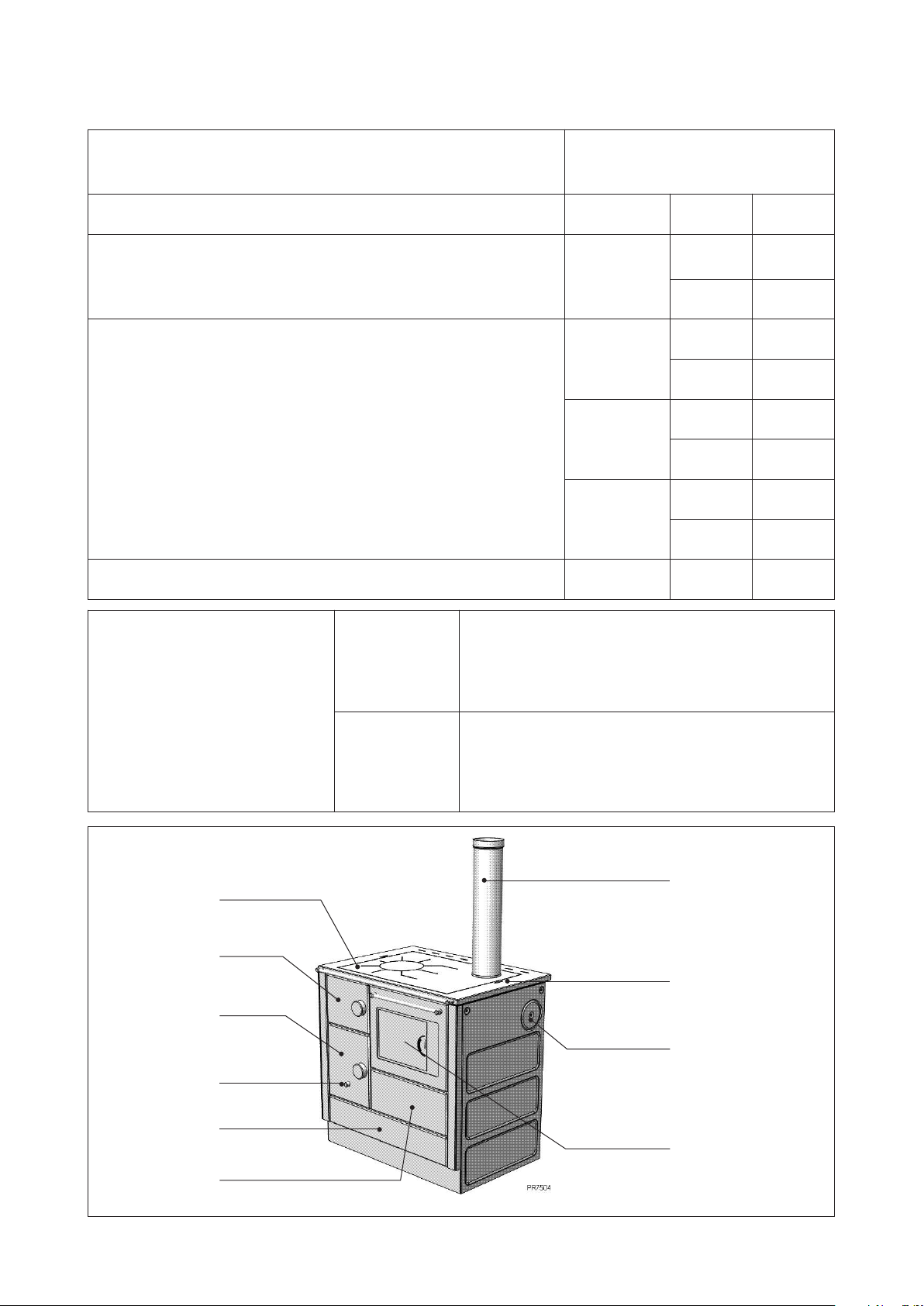

TECHNICAL SPECIFICATION

Model 3 Solid fuel cooker

Nominal heat output All fuels KW

m Wg

m

Flue draught @ nominal heat output All fuels

inch Wg

mm

To p

inch

mm

Flue outlet size

Rear

inch

mm

Side

inch

Weight Kg

Wood

Seasoned wood (less than 20% moisture content)

7.5

1.00

0.04

125

5

125

5

125

5

120

Recommended fuels

op Plate

T

Fire Door

Ash Door

Air Control

arming Drawer

W

Solid fuel

Briquetted smokeless fuel suitable for closed appliances.

(Ancit – Phurnacite – T

aybrite – Homefire ovals)

Top Flue

Flue By-pass

Side Flue

Oven

Cleaning Cover

4

Page 5

SITE REQUIREMENTS

Before installation of this product please read these

instructions fully.

It is very important to also understand the requirements of the

UK Building Regulations (England and Wales – Document J /

Scotland - Part F), along with any local regulations, and

orking practices that may apply. Should any conflict occur

w

between these instructions and these regulations then the

regulations shall apply.

All electrical connections should meet the requirements of

UK Building Regulations (England and Wales – Document P /

Scotland - Part N).

Your local Building Control Office would be happy to advise

hould questions arise, regarding the requirements of the

s

regulations.

The Solid fuel cooker should be fitted by a HETAS (GB only)

registered installer, or approved by your local building control

officer. Your Stovax dealer should be able to arrange this

service for you.

Your building insurance company may also require you to

nform them that you have installed a new heating appliance,

i

so check with your insurers that your cover is still valid after

installing the Solid fuel cooker.

When completing the installation and building works you

should comply with your responsibilities under the Health and

Safety at Work Acts, and any new regulations, which may be

introduced during the lifetime of these instructions.

faulty installation could cause danger to the inhabitants

A

and structure of the building.

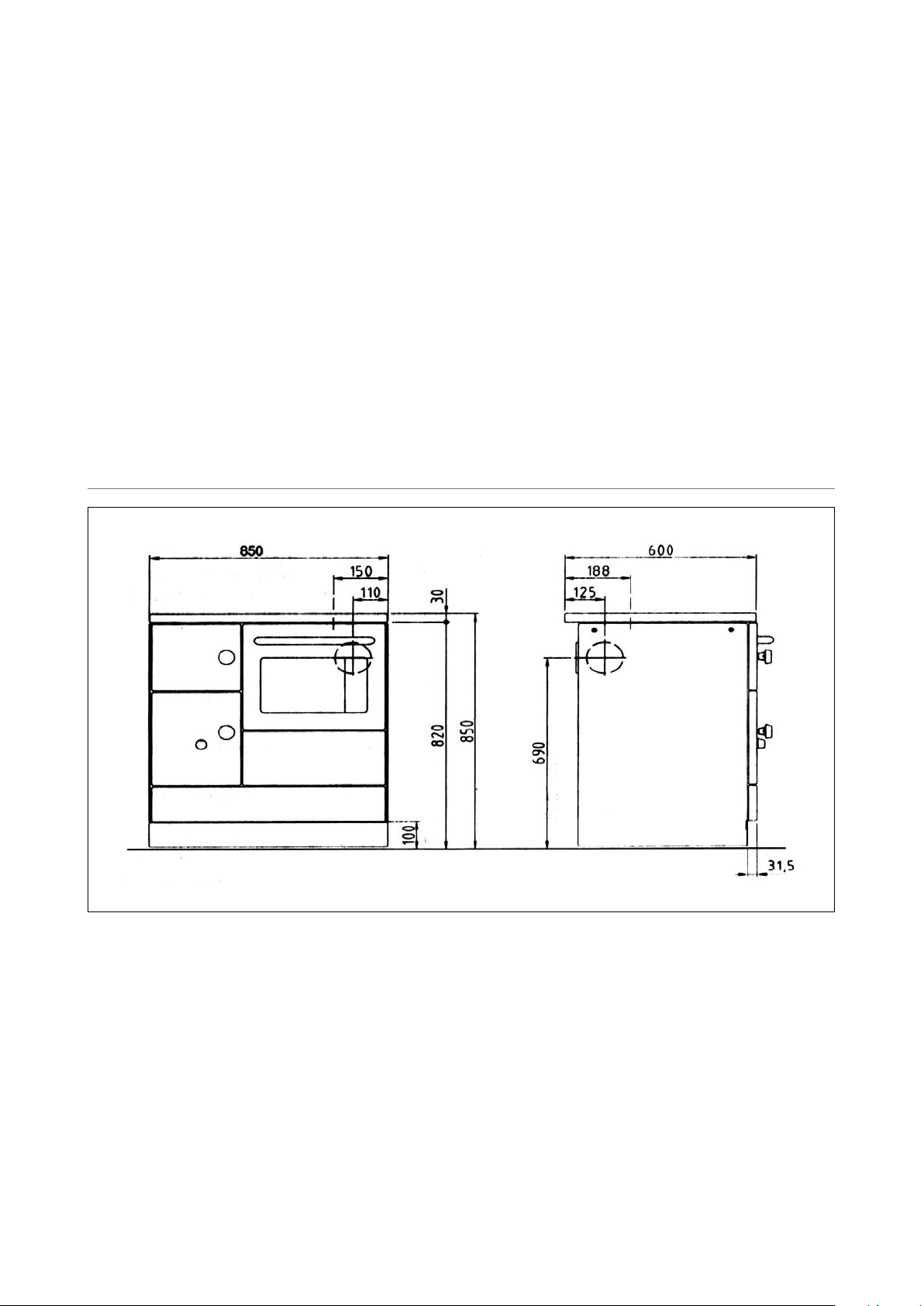

SOLID FUEL COOKER DIMENSIONS (Right hand cooker shown)

Top Flue

Additional information covering the installation the Solid fuel

cooker may be found in the following British Standard: BS8303.

Top Flue

5

Page 6

SITE REQUIREMENTS

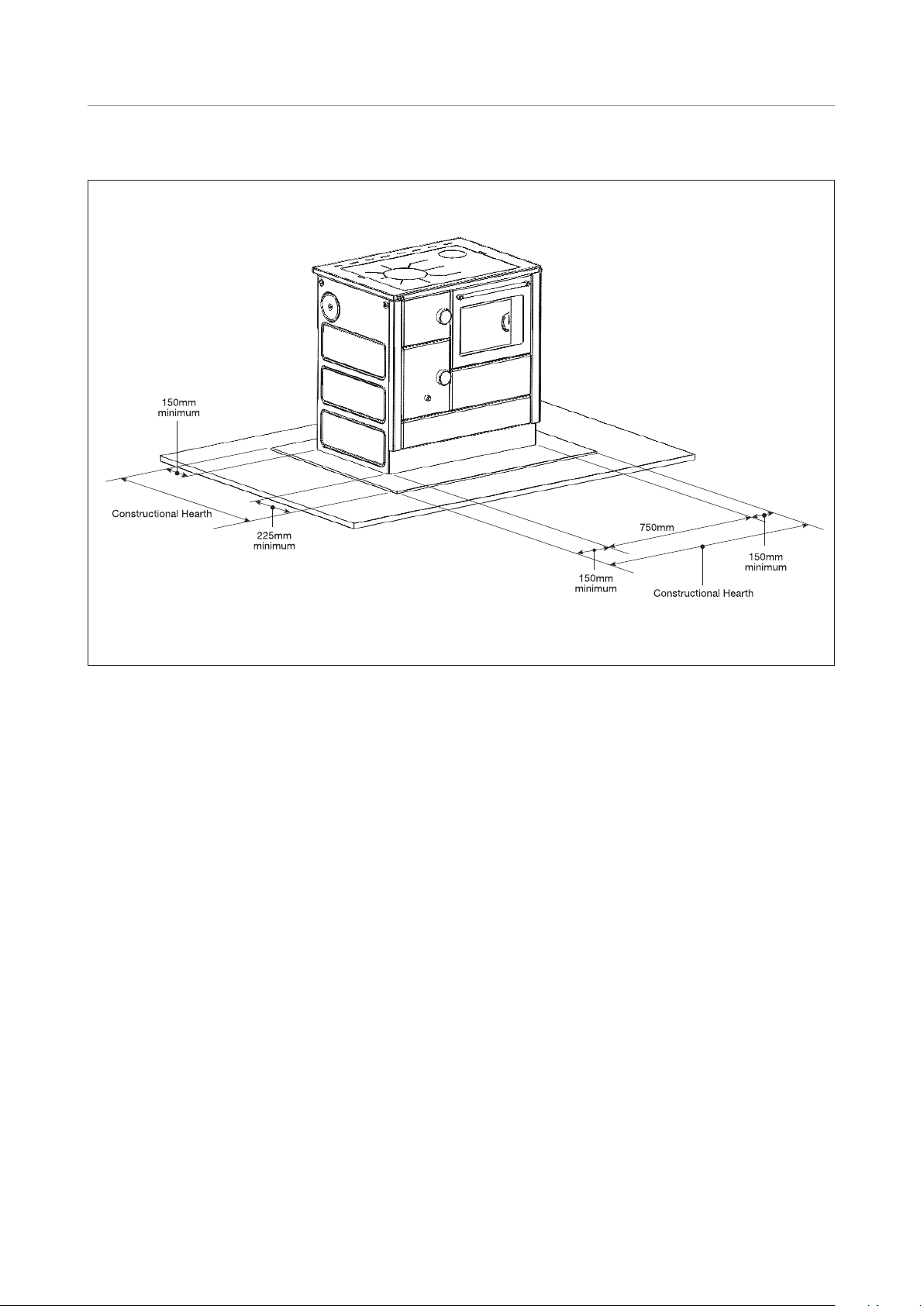

HEARTH DIMENSIONS

The appliance must stand on a constructional hearth with the

minimum dimensions as shown in diagram below.

If you are fitting the appliance into an existing hearth setting

check that it complies with the current construction

regulations and is the minimum sizes shown.

If you have no e

construct a suitable non-combustible housing and hearth

setting. However this should be constructed to comply with

the requirements of both current national and local

regulations with the design approved by your local building

xisting fireplace or chimney, it is possible to

control officer. Masonry chimney systems built with clay or

concrete liners or pre-fabricated block systems should be

constructed in accordance with BS 6461 : Part 1. Factory

made insulated systems should comply with BS 4543 : Part 2

and be installed to BS 7566 : Parts 1 to 4.

Remember that any new chimney added to your property may

also require planning permission.

6

Page 7

SITE REQUIREMENTS

WALLS ADJACENT TO HEARTHS

Location of hearth or Solid fuel

cooker

Where the hearth abuts a wall and the solid

fuel cooker is not more than 50mm from the

wall

Where the hearth abuts a wall and the

appliance is more than 50mm but not more

than 300mm from the wall

Where the hearth does not abut a wall and

is no more than 150mm from the wallSee

note below

Note: there is no requirement for protection the wall where C is more than 150mm

Solid, non combustible material

Thickness (W) height (A)

At least 300mm above the solid fuel

200mm

75mm

75mm At least 300mm above the hearth

cooker and 1200mm above the

hearth(Use the largest value)

At least 300mm above the solid fuel

cooker and 1200mm above the hearth

(Use the largest value)

7

Page 8

PRE-INSTALLATION CHECKS

t is important that adequate ventilation exists and the Flue or

I

himney system that is to be used is in good working

C

condition. Products of combustion that enter the room could

be a serious health risk. Before installation of this product the

Flue or Chimney system and Ventilation requirements are

inspected by a competent person, and passed as suitable for

use with the appliance to be fitted. In particular the following

should be checked: -

1. Flue or Chimney

The construction of the Flue or Chimney system should meet

the requirements of the Building Regulations with sizes as

shown: -

.3 A flexible flue liner system may be used, if it is

1

ndependently certified for use with Solidfuel systems,

i

nd is installed according to the manufacturer’s

a

instructions and the requirements of Building

Regulations. If an appliance is been replaced on an

existing flexible flue liner system, the liner system

should be replaced, unless it can be proved to be

recently installed and can be seen to be in good

condition.

.4 The flue exit from the building should be positioned to

1

omply with the requirements of the Building

c

Regulations.

1.5 Any existing flue should be confirmed as suitable for the

new intended use, as defined in the Building

Regulations.

Model Solid fuel cooker

mm 150

Without liner system

Round (diameter)

inch 6

Flue / Chimney

size

Flue / Chimney

minimum

height *

*When measured from the top of the cooker to the top of

the flue, with no horizontal sections and a maximum of 4

An, approved, factory made system suitable for Solidfuel

1.1

use, complying with BS 4543: Part 2, may be used when

installed to the requirements of BS 7566: Parts 1 to 4,

the manufacturer’s instructions and the requirements of

Building Regulations.

New masonry chimney systems built with clay or

1.2

concrete liners or pre-fabricated block systems should

be constructed in accordance with BS 6461: Part 1, and

the requirements of Building Regulations, may be used.

Without liner system

(square) minimum

dimension

With liner or factory

made system (diameter)

installed in accordance

with manufactures

instructions

bends with angles of less than 45°

mm 135

inch 51/2

mm 150

inch 6

m 4

feet 13

1.6 Any existing flue or chimney system must be inspected

and swept by a NACS registered (UK only) chimney

sweep, to confirm that the system is structurally sound

and free from any obstructions.

1.7 Suitable access should be provided to enable the

collection and removal of debris.

1.8 Provision should be made to sweep and inspect the flue

when the appliance is installed.

1.9 No other heating appliances should be connected to, or

share, the same Flue or Chimney system.

1.10 Check the flue draught. This should be done with all

windows and doors closed and any extraction fans in

this or adjoining rooms running at maximum speed.

(See next section for additional ventilation

requirements)

Note: A guide containing general information on

Chimneys and Flues is obtainable from: -

The British Flue & Chimney Manufacturers’

Association,

FETA

2 Waltham court

Milley lane

Hare hatch

Reading

Bucks

RG10 9TH

Tel : - 01189403416 e-mail :- info@feta.co.uk

8

Page 9

PRE-INSTALLATION CHECKS

1.11 Where a hearth, fireplace, flue or chimney is provided

r extended (including cases where a flue is provided as

o

art of refurbishment work), information essential to

p

he correct appliance and use of these should be

t

permanently posted in the building, to meet

Requirement J4 of the Building Regulations (England

and Wales), F3.12 (Scotland).

2. Additional Ventilation

.1 Additional ventilation will be required to comply with

2

he requirements of the Building Regulations. This

t

should be provided using a permanently open air vent,

of the size listed, which is positioned so that it is not

liable to be blocked both inside and outside the

building.

Model Solid fuel cooker

2

mm

Additional

ventilation

2.2 Extractor fans or cooker hoods should not be placed in

the same room or space as the appliance.

If any of these checks reveal problems do not

2.3

proceed with the fitting of the appliance until they

have been rectified.

2

cm

sq. inch 2.125

1375

13.75

9

Page 10

INSTALLATION INSTRUCTIONS

ecause each installation is unique to the property, it is not

B

possible to give full details to suit every setting. However the

installation should comply with the requirements of the

Building Regulations and be made using “best practice”

construction methods.

Remember that many fireplace openings will have a

upporting lintel. Do not remove this without making

s

rovision to support the remaining structure of the building.

p

he Solid fuel cooker must not form any part of the

T

supporting structure.

1. INSTALLING THE COOKER

1.1 Remove all packing and temporary transportation

fixings from the Solid fuel cooker, check that no parts

have been left inside the cooker.

1.2 Take care handling the cooker as it is possible damage

the enamel finish. The hot plate area may be removed

to reduce the weight, but take care not to damage any

seals, and beware of any sharp edges when handling the

cooker or any parts.

1.5 Decide it the installation is to be top, rear or side flue

exit, and fit and seal, with fire cement, the flue collar

and blanking plate to suit. The flue collar attaches to

the cooker backplate or top plate with fixings supplied.

The blanking plates are fixed to the unused flue outlets

with fixings supplied.

1.6 Lift the cooker into position on the prepared hearth

area, taking care not to damage the hearth finish.

1.3 If the cooker is to be placed between combustible work

surfaces and cupboards the optional, insulating, side

panels must be fitted.

Stovax Part No. Description

YM-CKSPWH Yeoman SF Cooker Insulation

Panel 5cm White

YM-CKSPBL Yeoman SF Cooker Insulation

Panel 5cm Blue

YM-CKSPGR Yeoman SF Cooker Insulation

P

anel 5cm Green

CKSPPB Yeoman SF Cooker Insulation

YM-

anel 5cm P

P

YM-CKSPINT Yeoman SF Cooker Integral

Insulation Panel

1.4 The clearance to any side wall and the firebox side of

the cooker should be a minimum of 50mm, to allow the

firedoor to open fully.

ebble

1.7 Level cooker using adjustable feet.

1.8 Connect the cooker to the chimney system, using

Stovax enamelled flue pipe and seal the connecting

joints. Typical top, rear or side flue connections are

shown.

1.9 Provision must be made to clean the flue/chimney after

the cooker is installed, as it is not possible to clean

through the cook

1.10 Provision should be made for flue debris collection and

cleaning when the cooker is installed.

er when it is installed.

10

Page 11

INSTALLATION INSTRUCTIONS

.11 Rear or side flue pipe installation

1

5” Flue Pipe

Stovax Part No. 4501)

(

5” Tee

(Stovax Part No. 4516)

1.12 Connect a tee (Stovax part no 4516 (5” pipe)) by

inserting it into the flue spigot and sealing using fire

cement. The cap supplied with the tee is used as the

cleaning access.

1.13 Side flue installation will require the use of an extension

flue pipe to enable correct fitting of tee (Stovax part

No. YM-CKADAP).

1.14 Top flue pipe installation

5” Flue Pipe

(Stovax Part No. 4501)

.15 Connect a flue pipe 612mm long (Stovax part no 4501

1

5” pipe)) by inserting it into the flue spigot and sealing

(

using fire cement.

2. COMMISSIONING

2.1 Before lighting the Solid fuel cooker, check the

following items:

) Fit of internal parts (firegrate, firebricks, baffles,

a

nd log retainer).

a

b) Door alignment, seals and catch operation.

c) Operation of air controls.

d) Operation of riddling grate system.

e) Check no items have been left in the warming

drawer, oven, firebox and ashpan.

2.2 If there are any problems with the fit or operation of

any of these items this should be corrected before

continuing with the commissioning of the Solid fuel

cooker.

2.3 Carry out a final smoke draw test, by first warming the

flue with a blowlamp, or similar, for about 10 minutes.

Then place a smoke pellet on the centre of the grate,

with the air controls open, and close the door. Smoke

should now be drawn up the flue and be seen to exit

from the flue terminal. This test should be completed

with all doors and windows in the room where the

Cooker is fitted closed. Should this test fail the

suitability of the flue system and ventilation should be

re-checked.

Light the appliance and gently allow the temperature to

2.4

increase slowly to operating levels. Check that no

combustion products are entering the room. When the

Cooker has reached a steady operating condition open

the main firedoor and carry out a spillage test with a

smoke match or pellet around the door opening.

2.5 If excessive spillage does occur allow the appliance to

cool and re-check the suitability of the flue system and

ventilation.

2.6 Explain the safe operation of the cooker and the use of

the controls to the user, along with the need to only use

suitable fuels. Also explain the cleaning and routine

maintenance requirements.

Explain the requirements to use a suitable protection

2.7

when children, elderly or infirm persons may be near

the appliance.

Record dealer/supplier details and installer details in

2.8

user instructions.

11

Page 12

INSTALLATION INSTRUCTIONS

2.9 Record serial number in user instructions. This

number will be required when ordering spare parts and

making warranty claims.

2.10

Give the copy of the user instructions to the

customer

.

12

Page 13

USER INSTRUCTIONS

1. GENERAL

.1 This cooker is designed for domestic use and should

1

only be used for this purpose, and in accordance with

the manufacturers operating instructions.

1.2 It should be installed by a competent installer (HETAS

registered UK only), in accordance with all local

regulations, including those referring to national and

uropean standards.

E

1.3 The cooker should only be used to burn approved fuels

and should not be used with liquid fuels or used as an

incinerator.

1.4 As with all cookers the surfaces will become very hot

when in use, therefore due care should be taken when

near the cooker. If it is to be used in the presence of

young children, elderly or infirm persons a suitable

fireguard should be used. Care should also be taken with

the placement of combustible items near the cooker as

conducted and radiated heat could cause a fire hazard.

1.5 Stovax offer a hearthgate system designed to offer full

protection for cookers and fireplaces. Your Stovax dealer

can advise you on these products.

1.6 The additional ventilation required for the safe use of

this cooker should be kept free of any obstructions, both

inside and outside the building, at all times.

1.7 Your Stovax product should be serviced annually by a

competent service engineer, and if repairs are required

use only Stovax approved spare parts.

1.8 Do not make unauthorised modifications or changes to

the cooker.

SERIAL NUMBER

1.9

.4 Use hot soapy water and a cloth to clean the enamel

2

urfaces and finish with a soft dry cloth to avoid

s

streaking.

2.5 We recommend you allow your cooker to cool fully

before cleaning and carrying out any maintenance

work.

.6

ITREOUS ENAMEL FINISH

2

V

he coloured surfaces of the cooker are finished in

T

vitreous enamel. Care should be taken as this finish can

be damaged by dropping objects onto surfaces or

cleaning with metal scrapers or wire wool. Burnt-on

food may be removed by carefully using a plastic scraper

or plastic cleaning pad when the cooker is cool.

2.7 CLEANING THE HOTPLATE

Some natural discolouration and marking of the hot

plate will occur during use of the cooker.

Burnt-on food may be removed by carefully using a

plastic scraper or plastic cleaning pad when the cooker

is cool.

Use hot soapy water and a cloth to clean and finish

with a soft dry cloth. Some light surface rust may

occasionally appear on the hot plate, this may be

removed by using a cleaning pad and polishing with a

small amount of cooking oil.

2.8 CLEANING THE OVEN

The internal surfaces of the oven are finished with

vitreous enamel. These may be cleaned using a nonabrasive oven cleaner and any burnt-on food may be

removed by carefully using a plastic scraper or plastic

cleaning pad when the cooker is cool.

This number will be required when ordering spare parts

or making warranty claims.

2. CARE OF THE COOKER

2.1 IMPORTANT

NEVER use caustic, citric or abrasive cleaning products

on your cooker because these may scratch or damage its

surfaces.

2.2 ALWAYS try to wipe up spillages when they happen.

2.3 You will get better results if you clean your cooker when

it is cool.

The door glass may be cleaned by using Stovax glass

cleaner and a soft cloth. Then wipe with warm soapy

water and a cloth, to neutralise any remaining cleaner

and finish with a soft dry cloth.

3. USING THE COOKER

FOR THE FIRST TIME

3.1 When new, it is best to burn the cooker at a low output

for the first few days of use. This will allow the

construction to settle and all fixing glues and paint to

fully cure.

void touching any painted finish during the first

A

3.2

period of use.

13

,

Page 14

.3 During this time the cooker may give off some

3

npleasant odours, and we recommend that you keep

u

the room well ventilated during this period to avoid a

build-up of fumes.

4. BURNING WOOD

USER INSTRUCTIONS

.9 Allow the new logs to burn at high output for a few

4

inutes before adjusting the burn rate, with the

m

control

and often to maintain clean and efficient burning.

4.10 The ideal control settings to suit the particular

installation and personal preferences will be established

by experience in using the cooker.

ir

a

, to the desired setting. It is best to refuel little

(min)

(max)

CLOSED

OPEN

4.1 Open the air control to maximum.

Air Control

Flue By-pass

To back

To front

.11 It is not recommended to load large amounts of logs and

4

urn with the

b

periods of time. This will cause large a build-up of tars

and creosotes in the cooker and flue system, possibly

resulting in a chimney fire.

4.12

Do not burn kiln-dried, painted, impregnated wood

or manufactured board products. As the high

combustion temperatures generated by these products

could cause permanent damage to the internal parts

of the cooker.

ir controlon low settings for long

a

5. BURNING SOLID FUEL

(min)

(max)

Air Control

4.2 Open flue by-pass control using tool.

Place some pieces of firelighter or dry crumpled paper

4.3

on the grate and cover with some small pieces of dry

kindling wood. Light the paper or firelighters.

4.4 As the fire becomes established add larger pieces of

Do not leave the firedoor open as this could

wood.

over-fire the cooker and cause permanent damage

As the fire becomes established adjust the

4.5

give the oven temperature you require.

4.6 Close flue by-pass control.

4.7 To burn wood efficiently it is best to allow a bed of ash

to build-up on the grate.

4.8 Before re-fuelling the cooker it is advisable to first rake

the embers evenly over the firebed then open the air

control fully for a few minutes, to establish a glowing

bed before adding new logs.

air control to

.

Flue By-pass

CLOSED

OPEN

5.1 Open the air control to maximum.

5.2 Open flueby-pass control using tool.

Place some pieces of firelighter or dry crumpled paper

5.3

on the grate and cover with some small pieces of dry

kindling wood. Light the paper or firelighters.

5.4 As the fire becomes established add larger pieces of

Do not leave the firedoor open as this could

wood.

over-fire the cooker and cause permanent damage.

To back

To front

14

Page 15

USER INSTRUCTIONS

.5 As the fire becomes established adjust the air controlto

5

ive the oven temperature you require.

g

5.6 Close flue by-pass control.

5.7 Before re-fuelling the cooker it is advisable to first deash the firebed, using the riddling grate system or a

suitable poker.

iddling system or using a poker to clear the firebed.

r

.8 Then open the air controlfully for a few minutes, to

5

establish a glowing bed before adding new fuel. Allow

the new fuel to burn at high output for a few minutes

before adjusting the burn rate with the

the desired setting

maintain clean and efficient burning.

5.9 The ideal control settings to suit the particular

installation and personal preferences will be established

by experience in using the cooker.

5.10

Do not burn bituminous coal, ‘petro-coke’ or other

petroleum based fuels, as this will invalidate and

product guarantee.

Do not use bare hands to operate the

air control to

. It is best to refuel little and often to

7. OVEN TEMPERATURE

.1 The oven temperature may be adjusted by changing the

7

burn rate by turning the air control on the ashdoor, or

adding fuel to increase the temperature. As with all

solid fuel cookers the response to changes in control

settings may be slow, and the ideal method of operation

will be determined by experience.

Oven

Temperature

°C

8. SEASONAL USE

6. OVER-FIRING

6.1 Do not use the cooker at maximum output for

prolonged periods of time, or over fill the firebox with

fuel, as this could result in over-firing. If the connecting

fluepipe, appliance flue collar or top plate glow red with

heat the appliance is been over-fired and the air

controls should be closed to reduce the output.

If a chimney fire occurs shut all air controls immediately

6.2

to close the appliance down, and evacuate all persons

from the building before calling the fire brigade. Do not

re-enter the building until it is confirmed safe to do so.

6.3 Following a chimney fire do not use the appliance until

it is inspected, by a HETAS (GB only) registered

installer, to confirm that the appliance is safe to use, or

make any repairs required before re-use. Only genuine

Stovax replacement parts are to be used to k

appliance in safe and efficient working order

6.4 After any chimney fire it is recommended that the

chimney system be inspected and swept by a NACS

registered (UK only) chimney sweep, to confirm that

the system is structurally sound and free from any

obstructions before re

-use.

eep your

.

8.1 If the cooker is not to be used during the warmer

periods of the year it is recommended to clean and

service the cooker, as detailed.

8.2 The air controls should be set in the 50% position to

keep the appliance ventilated, and stop the build-up of

any moisture inside.

8.3 Before re-lighting the cooker clear any debris that may

have accumulated and check the flue is clear of any

blockages.

9. ASH REMOVAL

9.1 The burning of any fuel will produce ash, which will

have to be removed after a period of use. This time will

depend on the fuel used. Before removing the ash from

the cook

low level, or even go out completely

removed from the cooker after opening the ashdoor.

er it is advisable to let the fire burn down to a

. The ashpan can be

15

Page 16

USER INSTRUCTIONS

9.2 De-ash the firebed using the operating tool to riddle the

grate and clear ash.

9.3 As heat can remain in the ash for a long period after

use care must be taken when removing and carrying the

full ashpan. We suggest that the ashpan be carried using

gloved hands, or the ash is placed directly in to a

Stovax ash caddie.

9.4 When burning wood the amount of ash will be smaller

and may only need removal once every week. To do

this, allow the fire to burn out and cool. It is best to

leave a layer of ash in the cooker to form a bed for the

new fire.

he symptoms of poor performance related to wet wood

T

nclude: -

i

• difficulty getting a fire going and keeping it burning

well,

• smoky fires with little flame,

• dirty glass,

• rapid creosote build-up in the chimney,

low heat output,

•

Short burn times, excessive fuel consumption and

•

lue/grey smoke from the chimney.

b

10.3 It is not recommended to load large amounts of logs

and burn with the air control on low settings for long

periods of time. This will cause large a build-up of tars

and creosotes in the cooker and flue system, possibly

resulting in a chimney fire, The use of Stovax Protector

chimney cleaner will also help to reduce this problem.

10.4

Solid fuel: - Burn manufactured smokeless fuels, listed

as suitable for use with closed heating appliances.

not burn bituminous coal,

petroleum based fuels, as this will invalidate and

product guarantee.

10.5 If you require advice on suitable solid fuels contact your

local Approved Coal Merchant. Details can be obtained

by ringing the Solid fuel Association advice line on

Freephone 0800 600 000. Or their web site at

www.solifuel.co.uk

‘petro-coke’ or other

Do

9.5 Do not place ash in a bin made from plastic or any

other combustible material.

10. RECOMMENDED FUELS

10.1 Wood:- Burn only seasoned timber, with a moisture

content of less than 20%. In most cases, this would

require drying cut wood for at least 12 to 18 months

before use. Poor quality timber could cause low

combustion efficiency, produce large amounts of

harmful condensation, which could reduce the

effectiveness of the combustion system, and ultimately

the life of the cooker

Do not burn kiln-dried, painted, impregnated wood

10.2

or manufactured board products. As the high

combustion temperatures generated by these

products could cause permanent damage to the

internal parts of the cooker.

.

16

Page 17

MAINTENANCE and SERVICING

1. GENERAL CLEANING

.1 We would recommend that your Solid fuel cooker be

1

cleaned fully on a regular basis, according to the level of

use. Attention should be given to cleaning the flueways

and removing ash. Regular cleaning and preventive

maintenance will help give many years of safe use.

1.2 Flue ways under the oven may be cleaned by removing

overs as shown.

c

.2 This can be done as follows. Allow the Solid fuel cooker

2

o cool fully, never attempt to clean hot glass. Any

t

deposits can be removed using a soft cloth and Stovax

Glass Cleaner. Then wipe with warm soapy water and a

cloth, to neutralise any remaining cleaner, and finish

with a soft dry cloth.

2.3 Before re-lighting the appliance, dry the glass fully.

.4

2

o not use abrasive cleaner or cleaning pads

D

.

Inner Cleaning Cover

Outer Cleaning Cover

fter removing the outer cover by pulling free from the

A

sprung retaining clips the inner cover can be removed

after unscrewing the two, wingnut fixings. Care should

be taken not to damage any seals. If seals are damaged

they should be replaced before cooker is re-used.

3. CHIMNEY SWEEPING

3.1 We would recommend that to maintain the safe and

efficient use of the appliance the flue / chimney is

inspected and swept at least once a year, by a NACS

registered (UK only) chimney sweep, to confirm that

the system is clean, structurally sound and free from any

obstructions.

4. ANNUAL SERVICE

4.1 Once a year it is recommended to inspect and clean the

cooker as detailed: -

4.2 Carefully remove all of the following internal parts.

Complete grate and ashpan, and vacuum clean any

remaining ash and debris from the inside of the cooker.

4.3 The coloured surfaces of the cooker are finished in

vitreous enamel. Care should be taken as this finish can

be damaged by cleaning with metal scrapers or wire

wool. Burnt-on food may be removed by carefully using

a plastic scraper or plastic cleaning pad. Use hot soapy

water and a cloth to clean and finish with a soft dry

cloth.

The internal surfaces of the oven are finished with

4.4

vitreous enamel. These may be cleaned using a nonabrasive oven cleaner and any burnt-on food may be

removed by carefully using a plastic scraper or plastic

cleaning pad. Use hot soapy water and a cloth to clean

and finish with a soft dry cloth.

1.3 The external finish may be cleaned using warm soapy

water and a soft clean cloth. Wipe dry with a soft clean

cloth before re

, as this may cause rust.

drying

-lighting

. Do not leave unit without

2. CLEANING GLASS

While the correct use will generally keep the glass clean

2.1

when the appliance is used you may sometimes need to

clean the glass.

4.5 The door glass may be cleaned by using Stovax glass

cleaner and a soft cloth. Then wipe with warm soapy

water and a cloth, to neutralise any remaining cleaner

and finish with a soft dry cloth.

4.6 Clean the Grate parts with a wire brush, check for any

damage and replace any damaged parts as required.

4.7 Check and clean, with a soft brush the Firebricks.

Replace any broken bricks. It is normal for some surface

damage to occur during use.

-fit cleaned internal parts.

Re

4.8

17

,

Page 18

MAINTENANCE and SERVICING

.9 Lightly oil the door catch mechanism and hinge pins.

4

void getting oil on to the door seals, glass and enamel.

A

4.10 To refresh painted finishes it is possible to re-paint using

Stovax Thermolac paint.

4.11 Use only genuine Stovax replacement parts to keep your

appliance in safe and efficient working order. Your local

tovax dealer will be able to provide you with the parts

S

ou require.

y

4.12 This is a list of the maintenance products you may need

to use.

ask

T

Glass cleaning

Preventing build-up of creosote in flue

Sealing flue pipe joints

Re-painting hot plate

Protecting your hands Heat resistant leather gloves 4008

4.13 These products, all available from you local Stovax

dealer, along with regular maintenance and use of the

correct fuels, will help you to keep your cooker in the

best possible condition.

4.14 Your Solid fuel cooker will have contained a brochure

illustrating all Stovax group products. If this is mislaid,

or you require more information about Stovax group

products visit our web site www.stovax.com.

Stove glass cleaner (500ml wipe on)

Stove glass cleaner (500ml spray on)

Thermolac Black (400ml aerosol)

Thermolac Black (200ml brush-on)

roduct name

P

Protector (15 sachets)

Protector (1kg tub)

Fire Cement (500g tub)

ire Cement (600g cartridge)

F

tovax Code number

S

4111

4130

7002

7025

2020

2021

2019

2057

4.15 When using the cooker for the first time again it is best

to burn the fire at a low output for the first day of use.

This will allow the new seals to settle and all new fixing

glues and paint to fully cure.

4.16 During this time, the cooker may give off some

unpleasant odours, and we recommend that you keep

the room well ventilated during this period to avoid a

build-up of fumes.

If you require help, your local Stovax dealer will be able

4.17

to carryout all of your service and maintenance

requirements for a reasonable cost.

18

Page 19

NOTES

19

Page 20

YEOMAN STOVES

A division of Stovax Ltd

Falcon Road, Sowton Industrial Estate, Exeter, EX2 7LF

Tel 01392 . 474500 Fax 01392 . 219932

www.yeoman-stoves.co.uk

Email: yeoman@stovax.com

Loading...

Loading...