Page 1

AC Servo Drives

Σ-II Series

SGM

/SGDM

USER'S MANUAL

SGMAH/SGMPH/SGMGH/SGMSH/SGMDH/SGMCS Servomotors

SGDM SERVOPACK

Outline

1

MODE/SET

YASKAWA

SERVOPACK

SGDM-

CHARGE POWER

L1C

L2C

200V

DATA/

L1

C

N

L2

3

+ 1

+ 2

C

N

1

B1

B2

U

V

C

W

N

MANUAL NO. SIEP S800000 15D

Selections

Servomotor Specifications and

Dimensional Drawings

SERVOPACK Specifications and

Dimensional Drawings

Specifications and Dimensional Drawings of

Cables and Peripheral Devices

Wiring

Digital Operator/Panel Operator

Operation

Adjustments

Upgraded Versions

Inspection, Maintenance,

and Troubleshooting

Appendix

2

3

4

5

6

7

8

9

10

11

12

Page 2

Copyright © 2003 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

About this Manual

Intended Audience

This manual is intended for the following users.

•

Those selecting Σ-II Series servo drives or peripheral devices for Σ-II Series servo drives.

•

Those wanting to know about the ratings and characteristics of Σ-II Series servo drives.

•

•

•

•

Description of Technical Terms

The terms in this manual are defined as follows:

• Servomotor or motor = Σ-II Series SGMAH, SGMPH, SGMGH, SGMSH, SGMDH, SGMCS servomo-

• SERVOPACK = Σ-II Series SGDM amplifier.

• Servo drive = A set including a servomotor and servo amplifier.

• Servo System = A servo control system that includes the combination of a servo drive with a host

• Parameter number = Numbers that the user inputs toward the SERVOPACK.

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/)

before the signal name, as shown in the following example:

• S-ON

designing Σ-II Series servo drive systems.

Those

Those installing or wiring Σ-II Series servo drives.

Those performing trial operation or adjustments of Σ-II Series servo drives.

Those maintaining or inspecting Σ-II Series servo drives.

tor.

computer and peripheral devices.

/S-ON

=

• P-CON

=

/P-CON

iii

Page 4

IMPORTANT

INFO

EXAMPLE

TERMS

Quick access to your required information

Read the chapters marked with 9 to get the information required for your purpose.

Chapter

Chapter 1

Outline

Chapter 2

Selections

Chapter 3

Servomotor Specifications

and Dimensional Drawings

Chapter 4

SERVOPACK Specifications

and Dimensional Drawings

Chapter 5

Specifications and

Dimensional Drawings of

Cables and Peripheral

Devices

Chapter 6

Wiring

Chapter 7

Digital Operator/Panel

Operator

Chapter 8

Operation

Chapter 9

Adjustments

Chapter 10

Upgraded Versions

Chapter 11

Inspection, Maintenance,

and Troubleshooting

Chapter 12

Appendix

SERVOPACKs,

Servomotors,

and Peripheral

Devices

Ratings and

Character-

istics

System

Design

Panel

Configura-tion

and Wiring

Trial Operation

and Servo

Adjustment

Inspection and

Maintenance

9

9

9999

9999

9999

99 9

99

9

9

9999

9

9999

iv

Visual Aids

■

The following aids are used to indicate certain types of information for easier reference.

• Indicates important information that should be memorized, including precautions such as alarm displays to avoid damaging the devices.

• Indicates supplemental information.

• Indicates application examples.

• Indicates definitions of difficult terms or terms that have not been previously explained in this manual.

Page 5

Related Manuals

Refer to the following manuals as required.

Manual Name Manual Number Contents

-II Series SGMH/SGDM

Σ

Digital Operator Operation Manual

Series/Σ-II Series SERVOPACKs

Σ

Personal Computer Monitoring Software

Operation Manual

TOE-S800-34 Provides detailed information on the operating method

SIE-S800-35 Describes the using and the operating methods on soft-

of JUSP-OP02A-2 type Digital Operator (option

device).

ware that changes the local personal computer into the

monitor equipment for the Σ-II Series servomotor.

v

Page 6

WARNING

CAUTION

PROHIBITED

MANDATORY

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided

in this manual can result in serious or possibly even fatal injury or damage to the products or to related equipment

and systems.

Indicates precautions that, if not heeded, could possibly result in loss of life or serious

injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if not heeded.

Indicates prohibited actions that must not be performed. For example, this symbol

would be used as follows to indicate that fire is prohibited: .

Indicates compulsory actions that must be performed. For example, this symbol would

be used as follows to indicate that grounding is compulsory: .

vi

Page 7

Notes for Safe Operation

WARNING

Read this manual thoroughly before checking products on delivery, storage and transportation, installation,

wiring, operation and inspection, and disposal of the AC servo drive.

• Never touch any rotating motor parts while the motor is running.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make sure that an emergency stop can

be applied at any time.

Failure to observe this warning may result in injury.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

• Do not touch terminals for five minutes after voltage resistance test.

Residual voltage may cause electric shock.

• Follow the procedures and instructions for trial operation precisely as described in this manual.

Malfunctions that occur after the servomotor is connected to the equipment not only damage the

equipment, but may also cause an accident resulting in death or injury.

• The multiturn limit value must be changed only for special applications.

Changing it inappropriately or unintentionally can be dangerous.

• If the Multiturn Limit Disagreement alarm (A.CC) occurs, check the setting of parameter

Pn205 in the SERVOPACK to be sure that it is correct.

If Fn013 is executed when an incorrect value is set in Pn205, an incorrect value will be set in the

encoder. The alarm will disappear even if an incorrect value is set, but incorrect positions will be

detected, resulting in a dangerous situation where the machine will move to unexpected positions.

• Do not remove the front cover, cables, connectors, or optional items while the power is ON.

Failure to observe this warning may result in electric shock.

• Installation, disassembly, or repair must be performed only by authorized personnel.

Failure to observe this warning may result in electric shock or injury.

• Do not damage, press, exert excessive force or place heavy objects on the cables.

Failure to observe this warning may result in electric shock, stopping operation of the product, or

burning.

• Provide an appropriate stopping device on the machine side to ensure safety.

A holding brake for a servomotor with brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

• Do not come close to the machine immediately after resetting momentary power loss to

avoid an unexpected restart.

Take appropriate measures to ensure safety against an unexpected restart.

Failure to observe this warning may result in injury.

• Do not modify the product.

Failure to observe this warning may result in injury or damage to the product.

• Connect the ground terminal to electrical codes (ground resistance: 100

Improper grounding may result in electric shock or fire.

or less).

Ω

vii

Page 8

CAUTION

CAUTION

Checking on Delivery

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

Storage and Transportation

• Do not store or install the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the storage or installation temperature

conditions.

• Locations subject to humidity outside the range specified in the storage or installation humidity

conditions.

• Locations subject to condensation as the result of extreme changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Failure to observe this caution may result in fire, electric shock, or damage to the product.

• Do not hold the product by the cables or motor shaft while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

• If disinfectants or insecticides must be used to treat packing materials such as wooden frames,

pallets, or plywood, the packing materials must be treated before the product is packaged, and

methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are

packed with fumigated wooden materials, the electrical components may be greatly damaged by the

gases or fumes resulting from the fumigation process. In particular, disinfectants containing halogen,

which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the capacitors.

viii

Page 9

Installation

CAUTION

CAUTION

• Never use the products in an environment subject to water, corrosive gases, inflammable gases, or

combustibles.

Failure to observe this caution may result in electric shock or fire.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

• Do not cover the inlet or outlet parts and prevent any foreign objects from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and the control panel or with other devices.

Failure to observe this caution may result in fire or malfunction.

• Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

Wiring

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminals and motor output terminals.

Failure to observe this caution may result in fire.

• Do not apply stress to connectors.

• Do not bundle or run power and signal lines together in the same duct. Keep power and signal lines

separated by at least 30 cm.

Failure to observe this caution may result in malfunction.

• Use twisted-pair shielded wires or multi-core twisted pair shielded wires for signal and encoder (PG)

feedback lines.

The maximum length is 3 m for reference input lines and is 20 m for PG feedback lines.

• Do not touch the power terminals for five minutes after turning power OFF because high voltage may still

remain in the SERVOPACK.

Make sure the charge indicator is turned OFF first before starting an inspection.

• Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than once per minute.

Since the SERVOPACK has a capacitor in the power supply, a high charging current flows for 0.2 seconds when

power is turned ON. Frequently turning power ON and OFF causes main power devices such as capacitors and fuses

to deteriorate, resulting in unexpected problems.

• Observe the following precautions when wiring main circuit terminal blocks.

• Remove the terminal block from the SERVOPACK prior to wiring.

• Insert only one wire per terminal on the terminal block.

• Make sure that the core wire is not electrically shorted to adjacent core wires.

• Do not connect the SERVOPACK for 100 V and 200 V directly to a voltage of 400 V.

The SERVOPACK will be destroyed.

ix

Page 10

CAUTION

• Install the battery at either the host controller or the SERVOPACK of the encoder.

It is dangerous to install batteries at both simultaneously, because that sets up a loop circuit between the batteries.

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Always use the specified power supply voltage.

An incorrect voltage may result in burning.

• Take appropriate measures to ensure that the input power supply is supplied within the specified voltage

fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the product.

• Connect the brake power supply properly, keeping in mind the difference of 90-V and 24-V power supplies.

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Do not modify connectors.

• Take appropriate and sufficient countermeasures for each when installing systems in the following

locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies including power supply lines.

Failure to observe this caution may result in damage to the product.

• Do not reverse the polarity of the battery when connecting it.

Failure to observe this caution may damage the battery or cause it to explode.

x

Page 11

Operation

CAUTION

CAUTION

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from machine to avoid

any unexpected accidents.

Failure to observe this caution may result in injury.

• Before starting operation with a machine connected, change the settings to match the parameters of the

machine.

Starting operation without matching the proper settings may cause the machine to run out of control or malfunction.

• Forward run prohibited (P-OT) and reverse run prohibited (N-OT) signals are not effective during zero point

search mode using parameter Fn003.

• When using the servomotor for a vertical axis, install the safety devices to prevent workpieces to fall off due

to occurrence of alarm or overtravel. Set the servomotor so that it will stop in the zero clamp state at

occurrence of overtravel.

Failure to observe this caution may cause workpieces to fall off due to overtravel.

• When not using the normal autotuning, set to the correct moment of inertia ratio.

Setting to an incorrect moment of inertia ratio may cause vibration.

• Do not touch the SERVOPACK heatsinks, regenerative resistor, or servomotor while power is ON or soon

after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• Do not make any extreme adjustments or setting changes of parameters.

Failure to observe this caution may result in injury due to unstable operation.

• When an alarm occurs, remove the cause, reset the alarm after confirming safety, and then resume

operation.

Failure to observe this caution may result in injury.

• Do not use the servo brake of the servomotor for ordinary braking.

Failure to observe this caution may result in malfunction.

• Do not turn the Servo ON or OFF unless necessary.

Failure to observe this caution may cause internal parts to deteriorate.

Maintenance and Inspection

• When replacing the SERVOPACK, transfer the previous SERVOPACK parameters to the new

SERVOPACK before resuming operation.

Failure to observe this caution may result in damage to the product.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

•

Do not disassemble the servomotor.

Failure to observe this caution may result in electric shock or injury.

xi

Page 12

CAUTION

Disposal

• When disposing of the products, treat them as ordinary industrial waste.

General Precautions

Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards. Always replace

the cover or protective guard as specified first, and then operate the products in accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

• This manual is subject to change due to product improvement, specification modification, and manual

improvement. When this manual is revised, the manual code is updated and the new manual is published as a next

edition.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the

offices listed on the back of this manual.

• Yaskawa will not take responsibility for the results of unauthorized modifications of this product. Yaskawa shall

not be liable for any damages or troubles resulting from unauthorized modification.

xii

Page 13

CONTENTS

About this Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -iii

Related Manuals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -v

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Notes for Safe Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

1 Outline

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Check Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.3 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2 Product Part Names - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.1 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.2 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.3 Examples of Servo System Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.3.1 Single-phase, 100 V and 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.3.2 Three-phase, 200 V Main Circuit- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.3.3 Connecting to SGMCS Servomotor- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.4 Applicable Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.1 North American Safety Standards (UL, CSA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.2 CE Marking- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.5 Σ-II Series SGDM SERVOPACK Upgraded Functions - - - - - - - - - - - - - - - - - - 1-12

2 Selections

2.1 Servomotor Model Designations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.1 Model SGMAH (3000 min-1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Model SGMPH (3000 min

2.1.3 Model SGMGH (1500 min

2.1.4 Model SGMGH (1000 min

2.1.5 Model SGMSH (3000 min

2.1.6 Model SGMDH (2000 min

2.1.7 Model SGMCS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-13

2.2 SERVOPACK Model Designations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-14

2.3 Σ-II Series SERVOPACKs and Applicable Servomotors - - - - - - - - - - - - - - - - - 2-15

2.3.1 SGDM SERVOPACKs and SGMH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-15

2.3.2 SGDM SERVOPACKs and SGMCS Servomotors- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-16

-1

) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

-1

)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

-1

)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

-1

) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-10

-1

)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

2.4 Selecting Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-17

2.4.1 Cables for SGMAH and SGMPH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-17

2.4.2 Cables for SGMGH/SGMSH/SGMDH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-20

2.4.3 Cables for SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-23

2.5 Selecting Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

xiii

Page 14

2.5.1 Special Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-26

2.5.2 Molded-case Circuit Breaker and Fuse Capacity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-28

2.5.3 Noise Filters, Magnetic Conductors, Surge Absorbers and DC Reactors - - - - - - - - - - - - - - - 2-29

2.5.4 Regenerative Resistors and Brake Power Supply Units - - - - - - - - - - - - - - - - - - - - - - - - - - -2-30

3 Servomotor Specifications and Dimensional Drawings

3.1 Ratings and Specifications of SGMAH (3000 min-1) - - - - - - - - - - - - - - - - - - - - - 3-4

3.1.1 SGMAH Servomotors Without Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-4

3.1.2 SGMAH Servomotors With Standard Backlash Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-6

3.1.3 SGMAH Servomotors With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-8

3.2 Ratings and Specifications of SGMPH (3000 min-1) - - - - - - - - - - - - - - - - - - - - 3-10

3.2.1 SGMPH Servomotors Without Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-10

3.2.2 SGMPH Servomotors With Standard Backlash Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-13

3.2.3 SGMPH Servomotors With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-14

3.3 Ratings and Specifications of SGMGH (1500 min-1)- - - - - - - - - - - - - - - - - - - - 3-15

3.3.1 SGMGH Servomotors (1500 min-1) Without Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-15

3.3.2 SGMGH Servomotors (1500 min

3.3.3 SGMGH Servomotors (1500 min

-1

) With Standard Backlash Gears- - - - - - - - - - - - - - - - - - - 3-18

-1

) With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - -3-20

3.4 Ratings and Specifications of SGMGH (1000 min-1)- - - - - - - - - - - - - - - - - - - - 3-22

3.4.1 SGMGH Servomotors (1000 min-1) Without Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-22

3.4.2 SGMGH servomotors (1000 min

3.4.3 SGMGH Servomotors (1000 min

-1

) With Standard Backlash Gears - - - - - - - - - - - - - - - - - - 3-24

-1

) With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - -3-26

3.5 Ratings and Specifications of SGMSH (3000 min-1) - - - - - - - - - - - - - - - - - - - 3-27

3.5.1 SGMSH Servomotors (3000 min-1) Without Gears- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-27

3.5.2 SGMSH Servomotors (3000 min

-1

) With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - -3-29

3.6 Ratings and Specifications of SGMDH (2000 min-1) - - - - - - - - - - - - - - - - - - - 3-31

3.6.1 SGMDH Servomotors (2000 min-1) With Holding Brakes - - - - - - - - - - - - - - - - - - - - - - - - - -3-31

3.7 Ratings and Specifications of SGMCS Servomotors - - - - - - - - - - - - - - - - - - - 3-33

3.7.1 Small-capacity Series SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-33

3.7.2 Middle-capacity Series SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-36

3.8 Mechanical Specifications of SGMAH, SGMPH, SGMGH, SGMSH, and SGMDH

Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-38

3.8.1 Precautions on Servomotor Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-38

3.8.2 Mechanical Tolerance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-39

3.8.3 Direction of Servomotor Rotation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-39

3.8.4 Impact Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-40

3.8.5 Vibration Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-40

3.8.6 Vibration Class - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-40

xiv

3.9 Mechanical Specifications of SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - 3-41

3.9.1 Allowable Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-41

3.9.2 Mechanical Tolerance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-42

3.9.3 Direction of Servomotor Rotation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-42

Page 15

3.9.4 Impact Resistance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-43

3.9.5 Vibration Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-43

3.9.6 Vibration Class - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-43

3.9.7 Enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-43

3.9.8 Heating Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-43

3.10 Terms and Data for Servomotors With Gears- - - - - - - - - - - - - - - - - - - - - - - - 3-44

3.11 Servomotor Dimensional Drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-46

-1

3.12 Dimensional Drawings of SGMAH Servomotors (3000 min

) - - - - - - - - - - - - 3-47

3.12.1 SGMAH Servomotors (3000 min-1) Without Gears - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-47

3.12.2 SGMAH Servomotors (3000 min

3.12.3 SGMAH Servomotors (3000 min

3.12.4 SGMAH Servomotors (3000 min

3.12.5 SGMAH Servomotors (3000 min

-1

) Without Gears and With Brakes - - - - - - - - - - - - - - - - - 3-50

-1

) With Standard Backlash Gears - - - - - - - - - - - - - - - - - 3-53

-1

) With Standard Backlash Gears and Brakes- - - - - - - - - 3-57

-1

) With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - 3-62

3.13 Dimensional Drawings of SGMPH Servomotors (3000 min-1) - - - - - - - - - - - - 3-66

3.13.1 SGMPH Servomotors (3000 min-1) Without Gears and Brakes - - - - - - - - - - - - - - - - - - - - 3-66

3.13.2 SGMPH Servomotors (3000 min

3.13.3 SGMPH Servomotors (3000 min

and Without Brakes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-70

-1

) With Brakes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-68

-1

) With Standard Backlash Gears

3.13.4 SGMPH Servomotors (3000 min-1) With Standard Backlash Gears and Brakes- - - - - - - - - 3-73

3.13.5 SGMPH Servomotors (3000 min

-1

) With Low-backlash Gears - - - - - - - - - - - - - - - - - - - - - 3-76

3.14 Dimensional Drawing of Output Shafts With Oil Seals for SGMAH and SGMPH

Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-79

3.14.1 SGMAH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-79

3.14.2 SGMPH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-79

3.15 Dimensional Drawings of SGMGH Servomotors (1500 min-1) - - - - - - - - - - - - 3-80

3.15.1 SGMGH Servomotors (1500 min-1) Without Gears and Brakes - - - - - - - - - - - - - - - - - - - - 3-80

3.15.2 SGMGH Servomotors (1500 min

3.15.3 SGMGH Servomotors (1500 min

-1

) 200-V Specifications Without Gears and With Brakes - 3-82

-1

) With Standard Backlash Gears and Without Brakes

(Foot-mounted Type)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-84

3.15.4 SGMGH Servomotors (1500 min

-1

) With Standard Backlash Gears and Without Brakes

(Flange-mounted Type) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-89

3.15.5 SGMGH Servomotors (1500 min-1) With Low-backlash Gears and Without Brakes

(Flange-mounted Type) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-95

3.16 Dimensional Drawings of SGMGH Servomotors (1000 min-1) - - - - - - - - - - - - 3-98

3.16.1 SGMGH Servomotors (1000 min-1) Without Gears and Brakes - - - - - - - - - - - - - - - - - - - - 3-98

3.16.2 SGMGH Servomotors (1000 min

3.16.3 SGMGH Servomotors (1000 min

(Foot-mounted Type)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-103

3.16.4 SGMGH Servomotors (1000 min

(Flange-mounted Type) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-108

-1

) Without Gears and With Brakes - - - - - - - - - - - - - - - 3-100

-1

) With Standard Backlash Gears and Without Brakes

-1

) With Standard Backlash Gears and Without Brakes

3.16.5 SGMGH Servomotors (1000 min-1) With Low-backlash Gears and Without Brakes

(Flange-mounted Type) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-113

xv

Page 16

3.17 Dimensional Drawings of SGMSH Servomotors (3000 min-1) - - - - - - - - - - - 3-116

3.17.1 SGMSH Servomotors (3000 min-1) Without Gears and Without Brakes - - - - - - - - - - - - - - 3-116

3.17.2 SGMSH Servomotors (3000 min

3.17.3 SGMSH Servomotors (3000 min

mounted Type)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-120

-1

) 200-V Specifications Without Gears and With Brakes - 3-118

-1

) With Low-backlash Gears and Without Brakes (Flange-

3.18 Dimensional Drawings of SGMDH Servomotors (2000 min-1) - - - - - - - - - - - 3-124

3.18.1 SGMDH Servomotors (2000 min-1) Without Gears and With/Without Brakes - - - - - - - - - - 3-124

3.19 Dimensional Drawings of SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - 3-126

3.19.1 SGMCS Servomotors φ135 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-126

3.19.2 SGMCS Servomotors φ175 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-127

3.19.3 SGMCS Servomotors φ230 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-128

3.19.4 SGMCS Servomotors φ290 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-129

3.19.5 SGMCS Servomotors φ280 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-130

3.19.6 SGMCS Servomotors φ360 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-131

3.20 Shaft End Specifications for SGMGH, SGMSH and SGMDH Servomotors - 3-135

3.20.1 SGMGH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-136

3.20.2 SGMSH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-137

3.20.3 SGMDH Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-138

4 SERVOPACK Specifications and Dimensional Drawings

4.1 SERVOPACK Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.1.1 Single-phase 100 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-3

4.1.2 Single-phase/Three-phase 200 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-3

4.1.3 SERVOPACK Ratings and Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-4

4.2 SERVOPACK Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

4.3 SERVOPACK Internal Block Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-8

4.3.1 Single-phase 200 V, 30 W to 400 W, and 100 V, 30 W to 200 W Models - - - - - - - - - - - - - - - -4-8

4.3.2 Three-phase 200 V, 500 W to 1.5 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-8

4.3.3 Three-phase 200 V, 2.0 kW to 5.0 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-9

4.3.4 Three-phase 200 V, 6.0 kW to 15 kW Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-9

4.4 SERVOPACK’s Power Supply Capacities and Power Losses - - - - - - - - - - - - - 4-10

4.5 SERVOPACK Overload Characteristics and Allowable Load Moment of Inertia 4-11

4.5.1 Overload Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-11

4.5.2 Starting and Stopping Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-12

4.5.3 Load Moment of Inertia - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-12

xvi

4.6 SERVOPACK Dimensional Drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

4.7 Dimensional Drawings of Base-mounted SERVOPACK Model - - - - - - - - - - - - 4-16

4.7.1 Single-phase 100 V: 30 W to 100 W (A3BD to 01BD, A3BDA to 01BDA)

Single-phase 200 V: 30 W to 200 W (A3AD to 02AD, A3ADA to 02ADA) - - - - - - - - - - - - - - -4-16

4.7.2 Single-phase 100 V: 200 W (02BD, 02BDA)

Single-phase 200 V: 400 W (04AD, 04ADA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-17

4.7.3 Three-phase 200 V: 500 W/750 W/1.0 kW (05AD to 10AD, 05ADA to 10ADA) - - - - - - - - - - -4-18

4.7.4 Three-phase 200 V: 1.5 kW (15AD, 15ADA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-19

Page 17

4.7.5 Three-phase 200 V: 2.0 kW/3.0 kW (20AD to 30AD, 20ADA to 30ADA) - - - - - - - - - - - - - - - 4-20

4.7.6 Three-phase 200 V: 5.0 kW (50ADA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-21

4.7.7 Three-phase 200 V: 6.0 kW/7.5 kW (60ADA to 75ADA) - - - - - - - - - - - - - - - - - - - - - - - - - - 4-22

4.7.8 Three-phase 200 V: 11.0 kW/15.0 kW (1AADA to 1EADA) - - - - - - - - - - - - - - - - - - - - - - - - 4-23

4.8 Dimensional Drawings of Rack-mounted SERVOPACK Model - - - - - - - - - - - - 4-24

4.8.1 Single-phase 100 V: 30 W/50 W/100 W

(A3BD-R to 01BD-R, A3BDA-R to 01BDA-R)

Single-phase 200 V: 30 W/50 W/100 W/200 W

(A3AD-R to 02AD-R, A3ADA-R to 02ADA-R) - - - - - - - - - - - - - - - - - - - 4-24

4.8.2 Single-phase 100 V: 200 W (02BD-R, 02BDA-R)

Single-phase 200 V: 400 W (04AD-R, 04ADA-R) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-25

4.8.3 Three-phase 200 V: 500 W/750 W/1.0 kW

(05AD-R to 10AD-R, 05ADA-R to 10ADA-R) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-26

4.8.4 Three-phase 200 V: 1.5 kW (15AD-R, 15ADA-R) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-27

4.8.5 Three-phase 200 V: 2.0 kW/3.0 kW

(20AD-R to 30AD-R, 20ADA-R to 30ADA-R) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-28

4.8.6 Three-phase 200 V: 5.0 kW (50ADA-R)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-29

4.9 Dimensional Drawings of Duct-ventilated SERVOPACK Model - - - - - - - - - - - - 4-30

4.9.1 Three-phase 200 V: 6.0 kW/7.5 kW (60ADA-P to 75ADA-P) - - - - - - - - - - - - - - - - - - - - - - - 4-30

4.9.2 Three-phase 200 V: 11.0 kW/15.0 kW (1AADA-P/1EADA-P) - - - - - - - - - - - - - - - - - - - - - - - 4-31

5 Specifications and Dimensional Drawings of Cables and Peripheral Devices

5.1 Specifications and Dimensional Drawings of Servomotor Main

Circuit Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.1.1 Cables for SGMAH and SGMPH Servomotors Without Brakes - - - - - - - - - - - - - - - - - - - - - - 5-3

5.1.2 Cables for SGMAH and SGMPH Servomotors With Brakes- - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.1.3 Flexible Cables for SGMAH and SGMPH Servomotors Without Brakes - - - - - - - - - - - - - - - - 5-4

5.1.4 Flexible Cables for SGMAH and SGMPH Servomotors With Brakes - - - - - - - - - - - - - - - - - - 5-4

5.1.5 Cables for SGMAH and SGMPH Servomotors With Waterproof Connector- - - - - - - - - - - - - - 5-5

5.1.6 Cables for SGMCS-B, C, D, and E Servomotors- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.2 Servomotor Main Circuit Wire Size and Connectors- - - - - - - - - - - - - - - - - - - - - 5-7

5.2.1 Wire Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-7

5.2.2 SGMAH and SGMPH Servomotor Connectors for Standard Environments - - - - - - - - - - - - - - 5-9

5.2.3 SGMGH, SGMSH, and SGMDH Servomotor Connector Configurations - - - - - - - - - - - - - - - 5-12

-1

5.2.4 SGMGH Servomotor (1500 min

5.2.5 SGMGH Servomotor (1000 min

5.2.6 SGMSH Servomotor (3000 min

5.2.7 SGMDH Servomotor (2000 min

5.2.8 SGMGH Servomotor (1500 min

European Safety Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-20

) Connectors for Standard Environments - - - - - - - - - - - - - 5-13

-1

) Connectors for Standard Environments - - - - - - - - - - - - - 5-15

-1

) Connectors for Standard Environments - - - - - - - - - - - - - 5-17

-1

) Connectors for Standard Environments - - - - - - - - - - - - - 5-19

-1

) Connectors Conforming to IP67 and

5.2.9 SGMGH Servomotor (1000 min-1) Connectors Conforming to IP67 and

European Safety Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-23

5.2.10 SGMSH Servomotors (3000 min-1) Connectors Conforming to IP67 and

European Safety Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-26

5.2.11 SGMDH Servomotors (2000 min-1) Connectors Conforming to IP67 and

European Safety Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-28

xvii

Page 18

5.2.12 Connectors for SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-29

5.2.13 Connector Dimensional Drawings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-31

5.3 SERVOPACK Main Circuit Wire Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-37

5.3.1 Cable Types- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-37

5.3.2 Single-phase 100 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-37

5.3.3 Single-phase 200 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-38

5.3.4 Three-phase 200 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-38

5.4 Encoder Cables for CN2 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

5.4.1 Encoder Cable With Connectors on Both Ends for SGMAH and SGMPH

Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

5.4.2 Encoder Cable With Connectors on Both Ends for SGMGH, SGMSH, and SGMDH

Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

5.4.3 Cable with Loose Wire at Encoder End for SGMAH and SGMPH Servomotors - - - - - - - - - - 5-40

5.4.4 Cable with Loose Wire at Encoder End for SGMGH, SGMSH, and SGMDH Servomotors - - -5-41

5.4.5 Encoder Flexible Cables for SGMAH and SGMPH Servomotors - - - - - - - - - - - - - - - - - - - - -5-43

5.4.6 Encoder Flexible Cables for SGMGH, SGMSH, and SGMDH Servomotors - - - - - - - - - - - - -5-45

5.4.7 Encoder Cable With a Waterproof Connector for SGMAH and SGMPH

Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-47

5.4.8 Encoder Cables for SGMCS Servomotors- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-48

5.5 Connectors and Cables for Encoder Signals - - - - - - - - - - - - - - - - - - - - - - - - - 5-50

5.5.1 Connectors and Cables for SGMAH and SGMPH Servomotors - - - - - - - - - - - - - - - - - - - - -5-50

5.5.2 Connectors and Cables for SGMGH, SGMSH, and SGMDH Servomotors - - - - - - - - - - - - - - 5-52

5.5.3 Connectors and Cables for SGMCS Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-54

5.6 Flexible Cables- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-55

5.7 I/O Signal Cables for CN1 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-56

5.7.1 Standard Cables- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-56

5.7.2 Connector Type and Cable Size- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-56

5.7.3 Connection Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-58

5.8 Peripheral Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-59

5.8.1 Cables for Connecting Personal Computers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-59

5.8.2 Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-60

5.8.3 Cables for Analog Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-61

5.8.4 Connector Terminal Block Converter Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-62

5.8.5 Brake Power Supply Unit- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-63

5.8.6 External Regenerative Resistor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-65

5.8.7 Regenerative Resistor Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-68

5.8.8 Absolute Encoder Battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-69

5.8.9 Molded-case Circuit Breaker (MCCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-70

5.8.10 Noise Filter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-71

5.8.11 Magnetic Contactor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-75

5.8.12 Surge Absorber (for switching surge) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-77

5.8.13 Surge Absorber (for lightning surge) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-79

5.8.14 DC Reactor for Harmonic Suppression - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-80

5.8.15 Variable Resistor for Speed and Torque Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-81

5.8.16 Encoder Signal Converter Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-82

xviii

Page 19

6 Wiring

6.1 Wiring Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Names and Functions of Main Circuit Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.2 Wiring Main Circuit Power Supply Connector (Spring Type) - - - - - - - - - - - - - - - - - - - - - - - - 6-4

6.1.3 Typical Main Circuit Wiring Examples - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-5

6.2 Wiring Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-7

6.2.1 Connecting an Encoder (CN2) and Output Signals from the SERVOPACK (CN1) - - - - - - - - - 6-7

6.2.2 Encoder Connector (CN2) Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-8

6.3 Examples of I/O Signal Connections- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-9

6.3.1 Speed Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-9

6.3.2 Position Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-10

6.3.3 Torque Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-11

6.3.4 I/O Signal Connector (CN1) Terminal Layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-12

6.3.5 I/O Signal (CN1) Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-13

6.3.6 Interface Circuit- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-15

6.4 Others - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-18

6.4.1 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-18

6.4.2 Wiring for Noise Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-19

6.4.3 Installation Conditions of EMC Directives- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-22

6.4.4 Installation Conditions of UL Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-24

6.4.5 Using More Than One SERVOPACK- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-25

6.4.6 Extending Encoder Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-26

6.4.7 Operating Conditions on 400-V Power Supply Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-28

6.4.8 DC Reactor for Harmonic Suppression - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-29

6.5 Connecting Regenerative Resistors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-30

6.5.1 Regenerative Power and Regenerative Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-30

6.5.2 Connecting External Regenerative Resistors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-30

7 Digital Operator/Panel Operator

7.1 Functions on Digital Operator/Panel Operator - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.1 Connecting the Digital Operator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.2 Key Names and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.1.3 Basic Mode Selection and Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.1.4 Status Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-5

7.2 Operation in Utility Function Mode (Fn) - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.2.1 List of Utility Function Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.2.2 Alarm Traceback Data Display (Fn000) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-8

7.2.3 Zero-point Search Mode (Fn003) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.2.4 Parameter Settings Initialization (Fn005) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-10

7.2.5 Alarm Traceback Data Clear (Fn006) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-11

7.2.6 Manual Zero-adjustment of Analog Monitor Output (Fn00C) - - - - - - - - - - - - - - - - - - - - - - - 7-12

7.2.7 Manual Gain-adjustment of Analog Monitor Output (Fn00D) - - - - - - - - - - - - - - - - - - - - - - - 7-13

7.2.8 Automatic Offset-adjustment of Motor Current Detection Signal (Fn00E) - - - - - - - - - - - - - - 7-14

7.2.9 Manual Offset-adjustment of Motor Current Detection Signal (Fn00F) - - - - - - - - - - - - - - - - 7-15

7.2.10 Password Setting (Protects Parameters from Being Changed) (Fn010) - - - - - - - - - - - - - - 7-16

xix

Page 20

7.2.11 Motor Models Display (Fn011) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-17

7.2.12 Software Version Display (Fn012) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-18

7.3 Operation in Parameter Setting Mode (Pn)- - - - - - - - - - - - - - - - - - - - - - 7-19

7.3.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-19

7.3.2 Input Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-23

7.3.3 Output Circuit Signal Allocation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-26

7.4 Operation in Monitor Mode (Un) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-28

7.4.1 List of Monitor Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-28

8 Operation

8.1 Trial Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-4

Trial Operation for Servomotor without Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-6

8.1.1

8.1.2 Trial Operation for Servomotor without Load from Host Reference - - - - - - - - - - - - - - - - - - - -8-9

Trial Operation with the Servomotor Connected to the Machine

8.1.3

8.1.4 Servomotor with Brakes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-16

8.1.5 Position Control by Host Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-16

- - - - - - - - - - - - - - - - - - - - -8-15

8.2 Control Mode Selection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-17

8.3 Setting Common Basic Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-18

8.3.1 Setting the Servo ON Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-18

8.3.2 Switching the Servomotor Rotation Direction- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-19

8.3.3 Setting the Overtravel Limit Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-20

8.3.4 Setting for Holding Brakes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-22

8.3.5 Selecting the Stopping Method After Servo OFF - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-27

8.3.6 Instantaneous Power Loss Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-28

8.4 Absolute Encoders - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-29

8.4.1 Interface Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-30

8.4.2 Selecting an Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-31

8.4.3 Handling Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-31

8.4.4 Replacing Batteries- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-32

8.4.5 Absolute Encoder Setup (Fn008) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-32

8.4.6 Absolute Encoder Reception Sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-34

8.4.7 Multiturn Limit Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-37

8.4.8 Multiturn Limit Setting When Multiturn Limit Disagreement (A.CC) Occurred - - - - - - - - - - - -8-38

8.5 Operating Using Speed Control with Analog Reference - - - - - - - - - - - - - - - - - 8-39

8.5.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-39

8.5.2 Setting Input Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-40

8.5.3 Adjusting Offset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-41

8.5.4 Soft Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-44

8.5.5 Speed Reference Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-44

8.5.6 Using the Zero Clamp Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-44

8.5.7 Encoder Signal Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-46

8.5.8 Speed Coincidence Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-48

xx

8.6 Operating Using Position Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-49

8.6.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-49

8.6.2 Setting the Electronic Gear - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-51

Page 21

8.6.3 Position Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-54

8.6.4 Smoothing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-57

8.6.5 Positioning Completed Output Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-58

8.6.6 Positioning Near Signal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-59

8.6.7 Reference Pulse Inhibit Function (INHIBIT) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-60

8.7 Operating Using Torque Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-61

8.7.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-61

8.7.2 Torque Reference Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-61

8.7.3 Adjusting the Reference Offset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-62

8.7.4 Limiting Servomotor Speed during Torque Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-64

8.8 Operating Using Speed Control with an Internally Set Speed - - - - - - - - - - - - - 8-66

8.8.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-66

8.8.2 Input Signal Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-66

8.8.3 Operating Using an Internally Set Speed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-67

8.9 Limiting Torque- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-69

8.9.1 Internal Torque Limit (Limiting Maximum Output Torque) - - - - - - - - - - - - - - - - - - - - - - - - - - 8-69

8.9.2 External Torque Limit (Output Torque Limiting by Input Signals)- - - - - - - - - - - - - - - - - - - - - 8-70

8.9.3 Torque Limiting Using an Analog Voltage Reference- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-71

8.9.4 Torque Limiting Using an External Torque Limit and Analog Voltage Reference- - - - - - - - - - 8-72

8.9.5 Checking Output Torque Limiting during Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-73

8.10 Control Mode Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-74

8.10.1 Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-74

8.10.2 Switching the Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-74

8.11 Other Output Signals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-75

8.11.1 Servo Alarm Output (ALM) and Alarm Code Output (ALO1, ALO2, ALO3)- - - - - - - - - - - - - 8-75

8.11.2 Warning Output (/WARN) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-76

8.11.3 Running Output Signal (/TGON) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-76

8.11.4 Servo Ready (/S-RDY) Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-77

9 Adjustments

9.1 Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.1.1 Servo Gain Adjustment Methods- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.1.2 List of Servo Adjustment Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

9.2 Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-5

9.2.1 Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-5

9.2.2 Online Autotuning Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-6

9.2.3 Selecting the Online Autotuning Execution Method- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

9.2.4 Machine Rigidity Setting for Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-7

9.2.5 Method for Changing the Machine Rigidity Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-8

9.2.6 Saving the Results of Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-9

9.2.7 Procedure for Saving the Results of Online Autotuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-9

9.3 Manual Tuning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.3.1 Explanation of Servo Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.3.2 Servo Gain Manual Tuning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-11

9.3.3 Position Loop Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-11

xxi

Page 22

9.3.4 Speed Loop Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-12

9.3.5 Speed Loop Integral Time Constant - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-12

9.4 Servo Gain Adjustment Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-13

9.4.1 Feed-forward Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-13

9.4.2 Torque Feed-forward- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-13

9.4.3 Speed Feed-forward - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-14

9.4.4 Proportional Control Operation (Proportional Operation Reference)- - - - - - - - - - - - - - - - - - - 9-15

9.4.5 Using the Mode Switch (P/PI Switching) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-16

9.4.6 Setting the Speed Bias - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-19

9.4.7 Speed Feedback Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-19

9.4.8 Speed Feedback Compensation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-19

9.4.9 Switching Gain Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-21

9.4.10 Torque Reference Filter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-22

9.5 Analog Monitor- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-24

10 Upgraded Versions

10.1 Upgraded Versions for SGDM SERVOPACK- - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.2 Upgraded Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-3

10.2.1 Additional Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-3

10.2.2 Improved Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-3

10.3 Additional Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-4

10.3.1 SGMCS Direct-drive Motor Supporting Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-4

10.3.2 Improvement of Dividing Output Resolution- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-7

10.3.3 Reference Pulse Input Multiplication Switching Function- - - - - - - - - - - - - - - - - - - - - - - - - - 10-9

10.3.4 Second Stage Notch Filter and Changeable Q Value - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-11

10.3.5 Automatic Gain Switching Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-13

10.4 Improved Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-15

10.4.1 Moment of Inertia Ratio Setting Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-15

10.4.2 Adaptation to Single-turn Data Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-15

10.4.3 Serial Number and Manufactured Data Reading Function- - - - - - - - - - - - - - - - - - - - - - - - 10-17

10.5 Additional and Improved Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-18

10.5.1 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-18

10.5.2 Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-19

10.5.3 Input Signal Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-19

10.5.4 Output Signal Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-20

10.5.5 Utility Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-20

10.5.6 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10-21

xxii

11 Inspection, Maintenance, and Troubleshooting

11.1 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-2

11.1.1 Alarm Display Table- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-2

11.1.2 Warning Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-4

11.1.3 Troubleshooting of Alarm and Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-5

11.1.4 Troubleshooting for Malfunction without Alarm Display - - - - - - - - - - - - - - - - - - - - - - - - - - 11-14

Page 23

11.2 Inspection and Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11-18

11.2.1 Servomotor Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-18

11.2.2 SERVOPACK Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-18

11.2.3 SERVOPACK’s Parts Replacement Schedule- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11-19

12 Appendix

12.1 Servomotor Capacity Selection Examples - - - - - - - - - - - - - - - - - - - - - - - - - - 12-2

12.1.1 Selection Example for Speed Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-2

12.1.2 Selection Example for Position Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-4

12.1.3 Calculating the Required Capacity of Regenerative Resistors - - - - - - - - - - - - - - - - - - - - - 12-7

12.2 Connection to Host Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-15

12.2.1 Example of Connection to MP920 4-axes Analog Module SVA-01 - - - - - - - - - - - - - - - - - 12-15

12.2.2 Example of Connection to CP-9200SH Servo Controller Module SVA

(SERVOPACK in Speed Control Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-16

12.2.3 Example of Connection to MEMOCON GL120/130 Series Motion Module MC20- - - - - - - 12-17

12.2.4 Example of Connection to MEMOCON GL60/70 Series Positioning Module B2813

(SERVOPACK in Position Control Mode)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-18

12.2.5 Example of Connection to OMRON’s Motion Control Unit - - - - - - - - - - - - - - - - - - - - - - - 12-19

12.2.6 Example of Connection to OMRON’s Position Control Unit - - - - - - - - - - - - - - - - - - - - - - 12-20

12.2.7 Example of Connection to OMRON’s Position Control Unit C500-NC221 (SERVOPACK in

Speed Control Mode)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-21

12.2.8 Example of Connection to OMRON’s Position Control Unit C500-NC112 (SERVOPACK in

Position Control Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-22

12.2.9 Example of Connection to MITSUBISHI’s AD72 Positioning Unit

(SERVOPACK in Speed Control Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-23

12.2.10 Example of Connection to MITSUBISHI’s AD75 Positioning Unit

(SERVOPACK in Position Control Mode)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-24

12.3 List of Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-25

12.3.1 Utility Functions List- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-25

12.3.2 List of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-26

12.3.3 Monitor Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-43

12.4 Parameter Recording Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12-44

INDEX

Revision History

xxiii

Page 24

1

Outline

1

Outline

1.1 Checking Products - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.1.1 Check Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.3 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

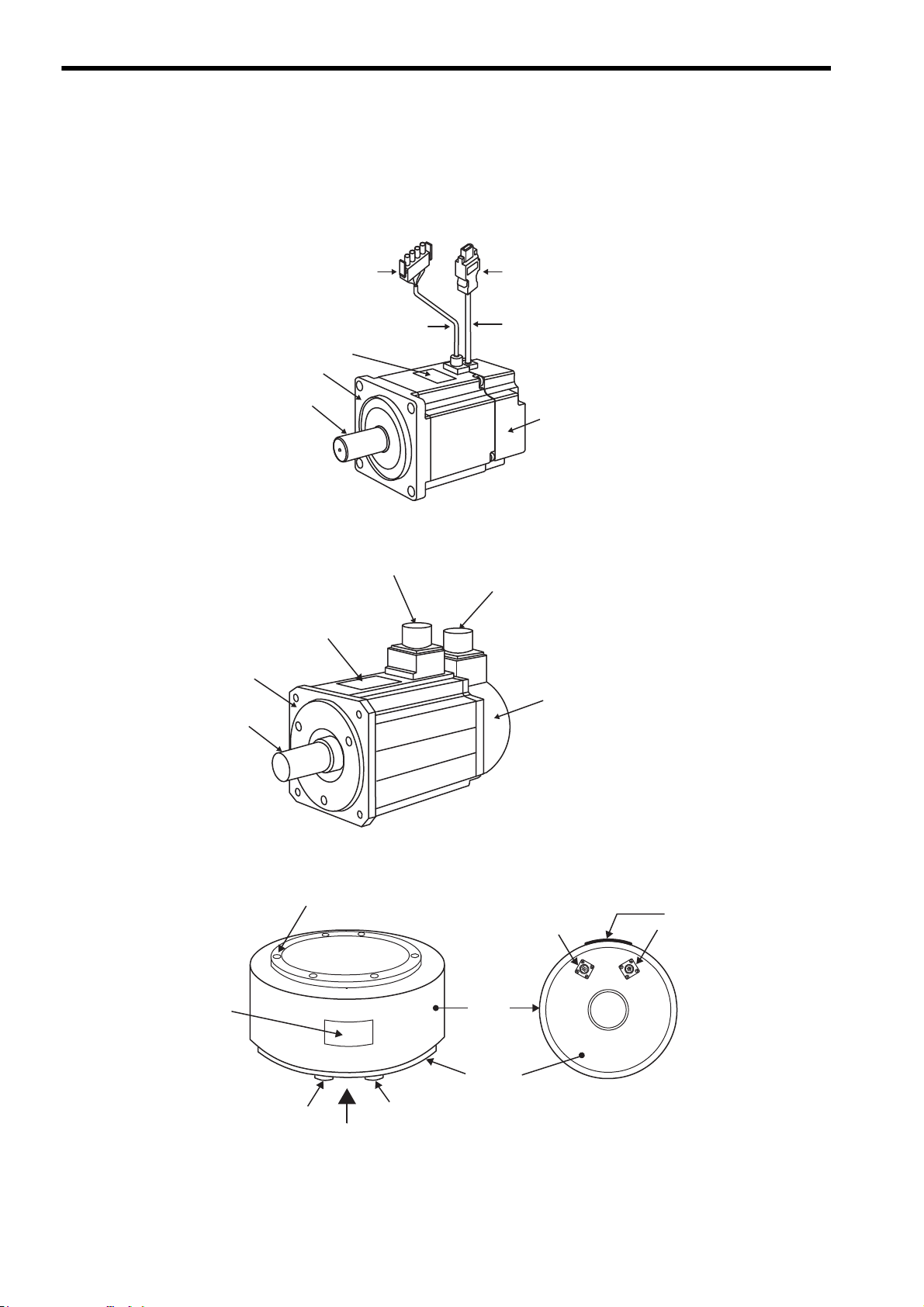

1.2 Product Part Names - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.2.1 Servomotors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.2.2 SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.3 Examples of Servo System Configurations - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.3.1 Single-phase, 100 V and 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.3.2 Three-phase, 200 V Main Circuit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.3.3 Connecting to SGMCS Servomotor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.4 Applicable Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.1 North American Safety Standards (UL, CSA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.4.2 CE Marking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1.5 Σ-II Series SGDM SERVOPACK Upgraded Functions - - - - - - - - - - - - - - 1-12

1-1

Page 25

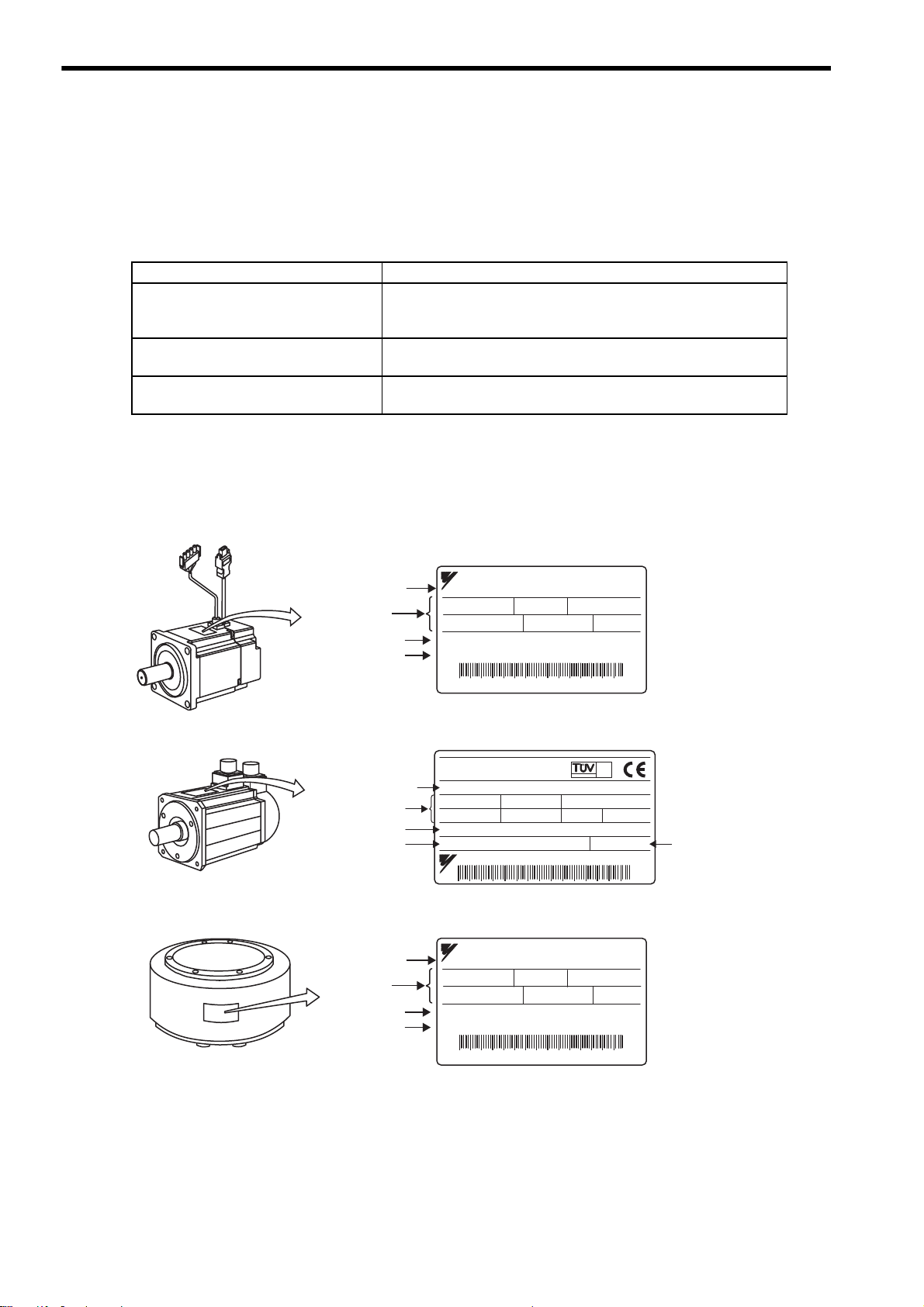

1 Outline

AC SERVO MOTOR

YASKAWA ELECTRIC MADE IN JAPAN

TYPE SGMSH-10ACA21

O/N 9W0774 002A

S/N BB2 753000039 DATE 0002

-039

1000 W

5.7

A

3.18 N m

200 V CONT ins F

3000 min

-1

Manufacturing

date

PURODUCT SERVICE

Bauart

gepruft

..

SGMAH and SGMPH

SGMGH / SGMSH / SGMDH

AC SERVO MOTOR

SGMCS-04C3C11

84

200

2.1

W

V

A

NO

200

A

4.0

min

Ins.

O/N 9271316-1

S/N DD 9964567890012

YASKAWA ELECTRIC CORPORATION JAPAN

Nameplate

-1

SGMCS (Small-capacity series)

AC SERVO MOTOR

SGMAH-02AAA21

200

200

2.1

W

V

A

NO

3000

B

0.637

min

Ins.

O/N 9271316-1

S/N DD 9964567890012

YASKAWA ELECTRIC CORPORATION JAPAN

Servomotor model

Ratings

Serial number

Nameplate

-1

Order number

Servomotor model

Ratings

Order number

Serial number

Servomotor model

Ratings

Order number

Serial number

1.1.1 Check Items

1.1 Checking Products

The following procedure is used to check the AC servo drives of Σ-ΙΙ Series products on delivery.

1.1.1 Check Items

Check the following items when Σ-ΙΙ Series products are delivered.

Check Items Comments

Are the delivered products the ones

that were ordered?

Does the servomotor shaft rotate

smoothly?

Is there any damage?

If any of the above items are faulty or incorrect, contact your Yaskawa representative or the dealer from whom

you purchased the products.

1.1.2 Servomotors

Check the model numbers marked on the nameplates on the servomotor and SERVOPACK. (Refer to the descriptions of model numbers in

the following section.)

The servomotor shaft is normal if it can be turned smoothly by hand.

Servomotors with brakes, however, cannot be turned manually.

Check the overall appearance, and check for damage or scratches that

may have occurred during shipping.

1-2

Page 26

1

Outline

1.1.3 SERVOPACKs