External Dimensions Units: mm

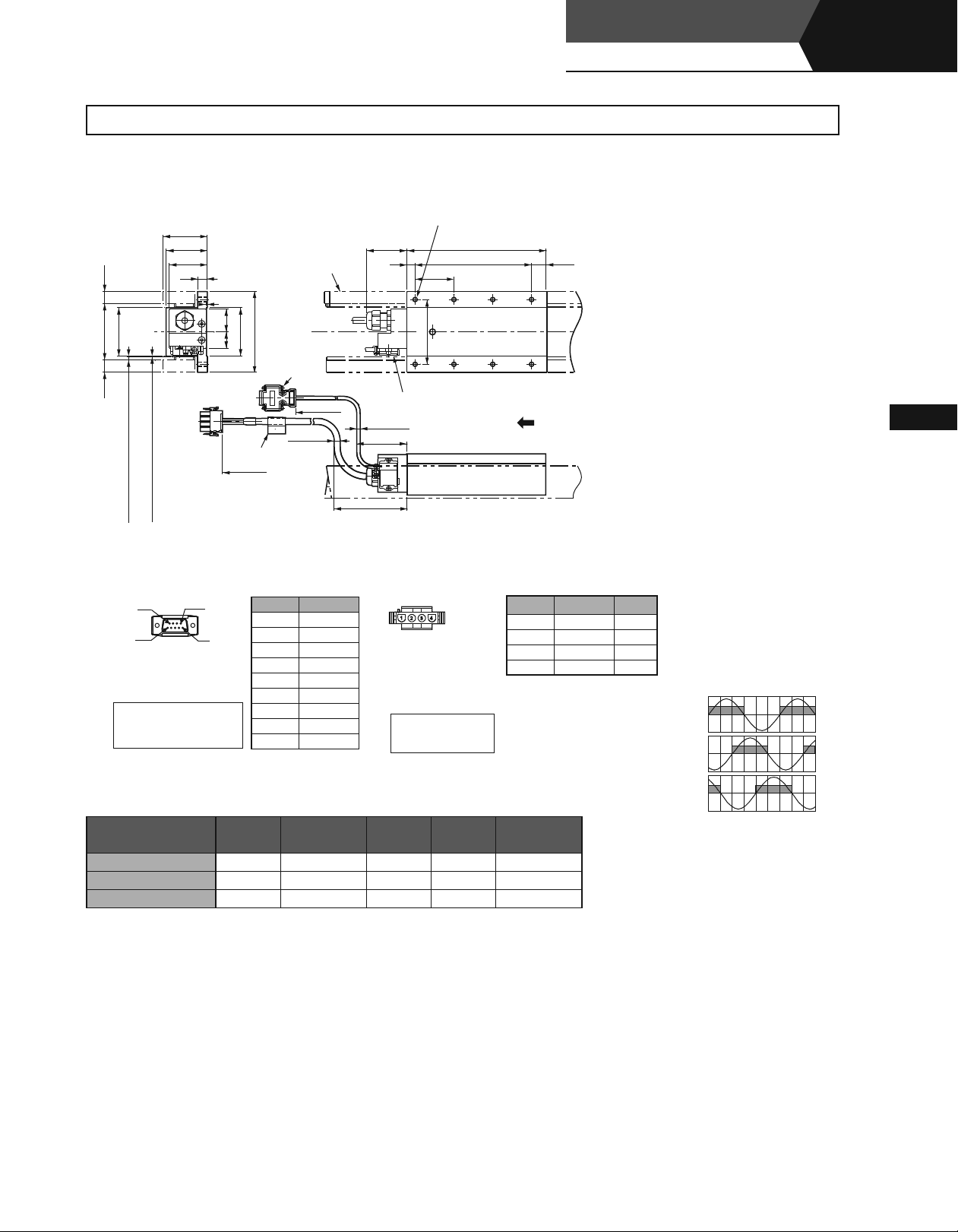

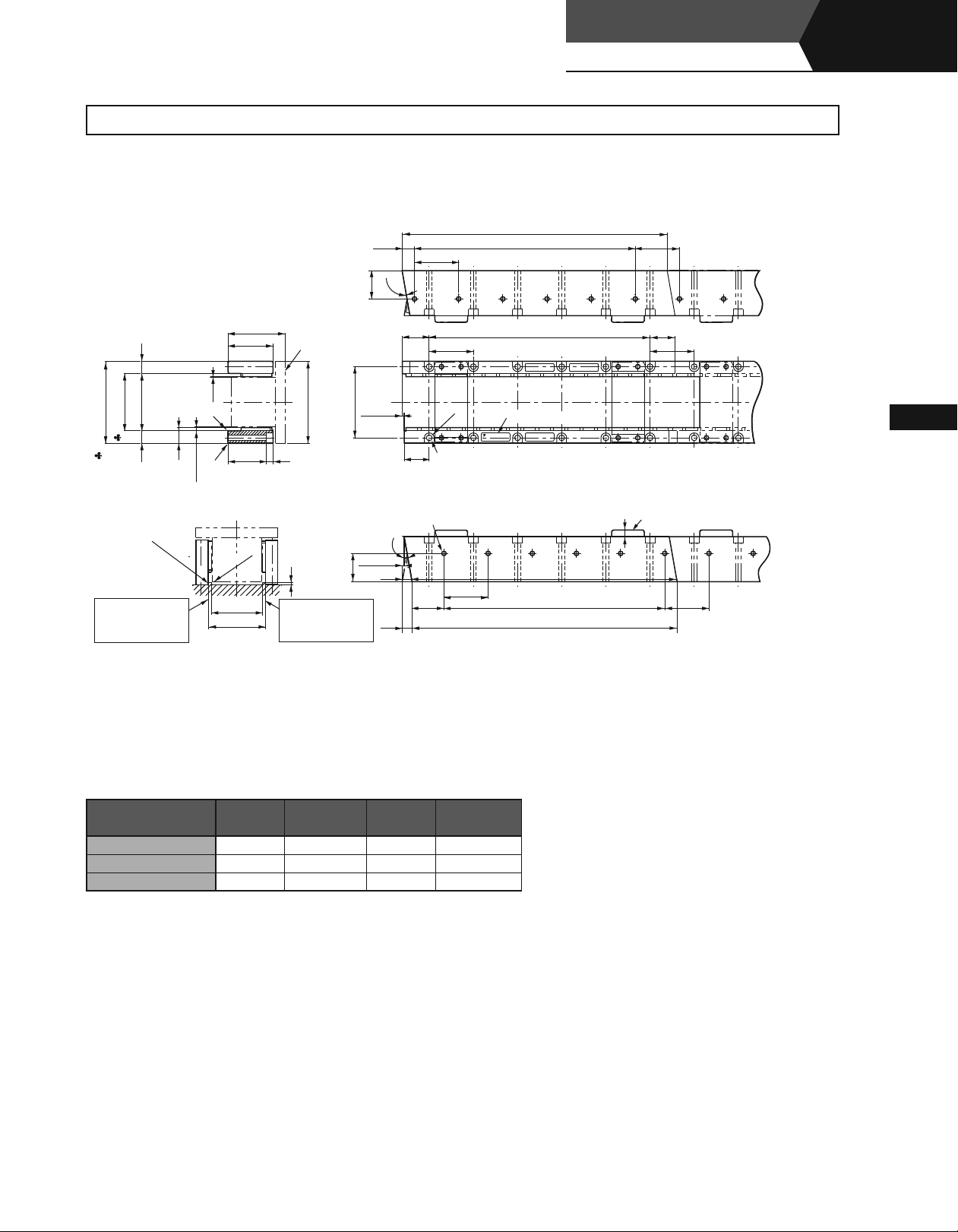

(1) Standard Type SGLTW-20SGLTW-20

Moving Coil:

3

SGLTW-20A¡¡¡A¡ (With a connector by Tyco Electronics AMP K.K.)

Linear Servomotors

SGLTW

(With T-type iron core)

Linear

(55)

51

)

15

(

)

60

70

(

)

15

(

)

With Magnet Cover

:

2

.

19

(

Hall Sensor

Connector Specifications

Pin Connector:

17

JE-

by DDK Ltd.

The Mating Connector

Socket Connector:

Stud:

47.5

12

)

)

)

With Magnet Cover

Without Magnet Cover

:

8

.

:

1

0

Without Magnet Cover

:

Gap

19

Gap

(

(

(

9

5

23090-02

(D8C)

17

13090-02

JE-

17L-002

C or

17L-002C1

6

1

(D8C

1

28

20

)

60

100

2

-Screws

4-40

#

(

Nameplate

±

50

500

Pin No. Signal

1

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

Magnetic Way

UNC

±

50

500

)

7.4

Dia.

+

5VDC

50

10

80

Hall Sensor

(

)

4.2

Dia.

63

Min.

90

Min.

Linear Servomotor

Connector Specifications

350779-1

Plug:

350218-3

Pin :

350547-3

350654-1

350669-1

by Tyco Electronics AMP K.K.

The Mating Connector

350780-1

Cap :

350536-3

Socket:

350550-3

6

Tapped Holes, Depth

N-M

L

L

48

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

or

(No.1 to

)

4

(No.

or

1

2

Pin No. Signal

1 Phase U Red

2 Phase V White

3 Phase W Black

)

3

4 Ground Green

12

(

)

3

L

Linear Servomotors

Wire

Color

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

Power

(V)

Vv

Sv

Moving Coil Model

SGLTW-

20A170A¡ 170

20A320A¡ 315

20A460A¡ 460

L1 L2 (L3) N

×3)

144 (48

288 (48

432 (48

×6)

×9)

(16) 8 2.5

(17) 14 4.6

(18) 20 6.7

Approx. Mass

kg

Vw

0 180 360 540

Sw

Electrical Angle (˚

)

164

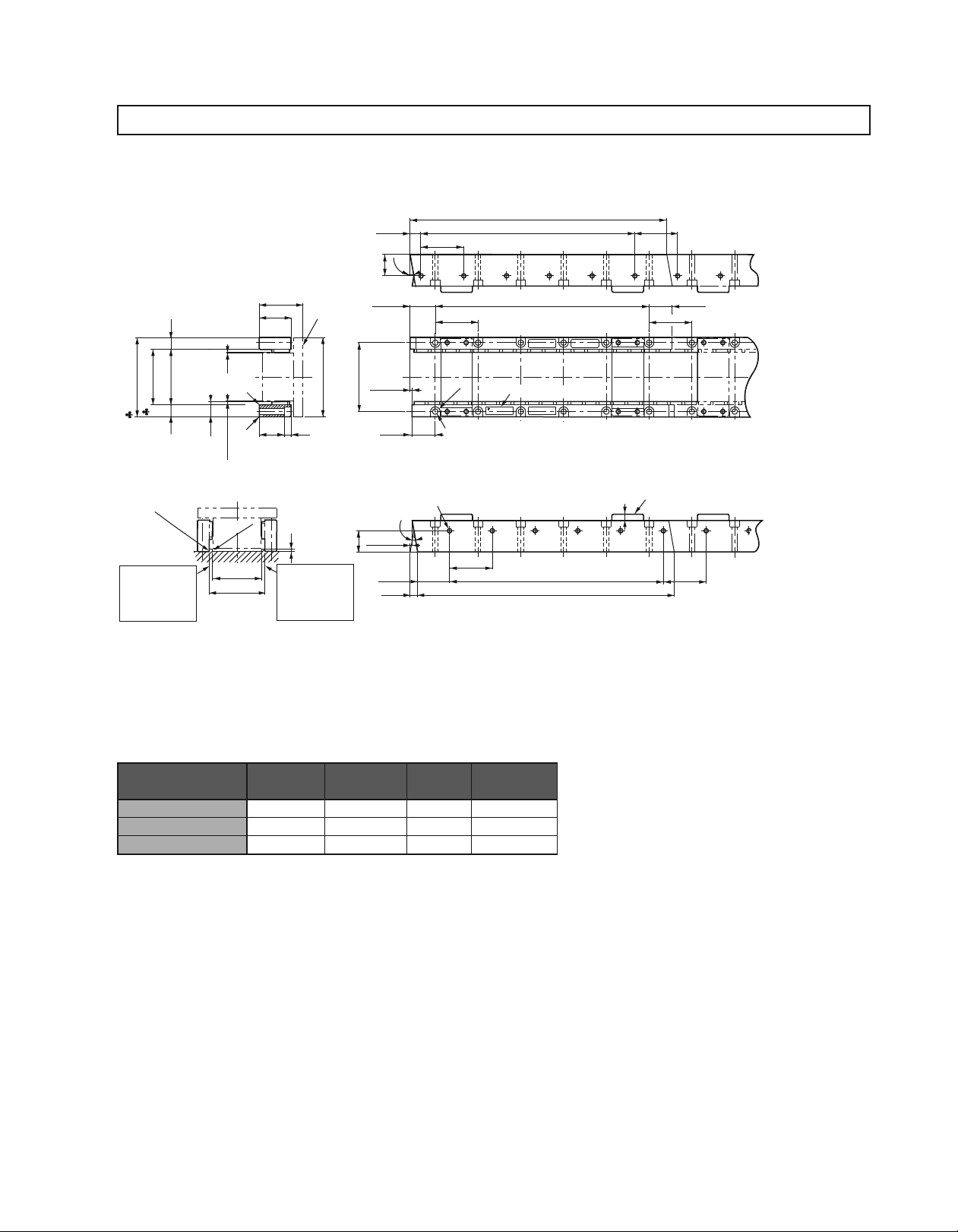

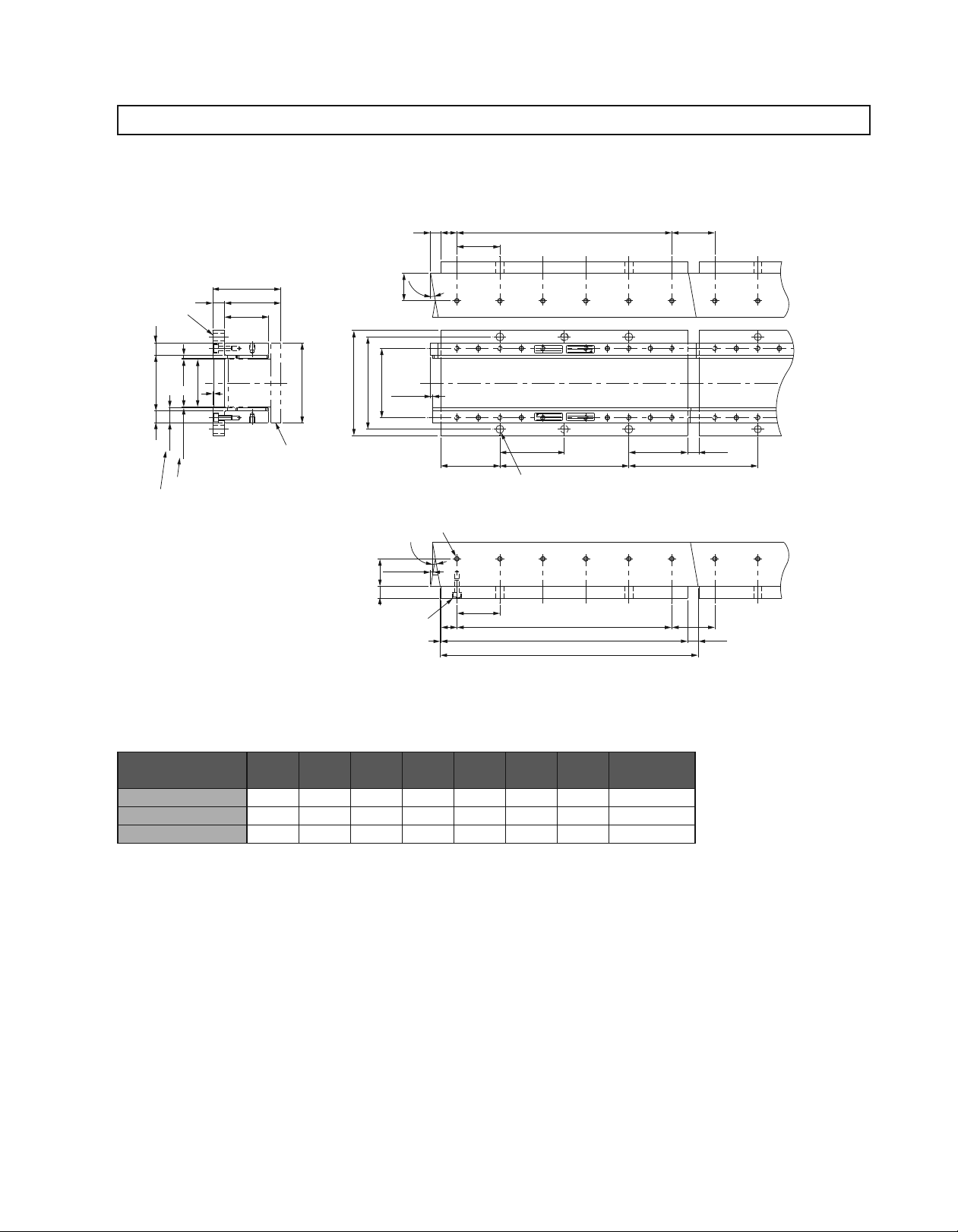

External Dimensions Units: mm

3Magnetic Way : SGLTM-20¡¡¡A¡

(

)

Max.

+

0.6

0

±

0.3

C

C

1

1

55

40

32(8

Moving Coil

)

100

(

)

3

Mount the magnetic

way so that its

corner surfaces are

flush with the inner

step.

)

15

)

Preshipment

3

(

.

0

±

Preshipment

(

1

70

±

Max.

5

*

.

71

103

15

R

0

.

5

Max.

Mount the magnetic

way so that its

corner surfaces are

flush with the inner

step.

Assembly Dimensions

)

1

(

3

.

0

±

19

1

Gap

1

R

62

*

70

0

7

13

2

.

-0.

9

.

9

27

˚

0

31.7

2

-0.

87

±

*

0.3

2.4

(

)

29.3

2

× N-M6 Screws, Depth

9.9

˚

±

*

0.3

2.4

27

0

40.3

2

-0.

(

)

9.4

1

-0.

1

L

3

-0.

2

L

)

(

54

54

(

2

L

54

6

Nameplate

R

2

× N-7 Dia. Mounting Holes (See the sectional view for the depth.

O/N

YASKAWA

TYPE:

S/N

MADE IN JAPAN

DATE

29.3

(54)

Spacers: Do not remove them until the moving coil

8

54

1

L

is mounted on the machine.

8

2

L

1

-0.

3

-0.

(54)

)

)

Notes: 1 Two magnetic ways for both ends of moving coil make one set. Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the

moving coil is mounted on a machine.

2 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

3 Two magnetic ways in a set can be connected to each other.

4 The dimensions marked with an * are the dimensions between the magnetic ways. Be sure to follow exactly the dimensions specified in the figure above. Mount magnetic ways

as shown in Assembly Dimensions. The values with a ♣ are the dimensions at preshipment.

5 Use socket headed screws of strength class 10.9 minimum for magnetic way mounting screws. Do not use stainless steel screws.

Magnetic Way Model

SGLTM-

20324A¡ 324

20540A¡ 540

20756A¡ 756

-0.1

L1

-0.3

L2 N

×5)

270 (54

486 (54

×9)

702 (54

×13)

6 3.4

10 5.7

14 7.9

Approx. Mass

kg

165

External Dimensions Units: mm

Magnetic Way with Base

3

(70)

(55)

15

Base

)

3

.

8

.

0

0

±

(

70

3

.

2

0

.

±

15 15

8

.

19

0

Gap

Includes a 0.2 thick magnet cover.

40

60

1

: SGLTM-20¡¡¡AY

)

100

(

Moving Coil

132

2

× N1-M6

Bolts, Depth

20

11.7

9

.

9

˚

27

87

116

±

0.3

2.4

2

× N1-M6 Screws, Depth

9

.

9

˚

(

±

)

0.3

2.4

2715

20

16

2.3

Linear Servomotors

Linear

SGLTW

2

54

74

8

54

L

MADE IN JAPAN

DATE

YASKAWA

TYPE:

5

L

2

× N2-10 Dia. Mounting Holes

(

See the sectional view for the depth.

TYPE:

S/N

YASKAWA

O/N

O/N

S/N

MADE IN JAPAN

DATE

74

4

L

2

L

3

L

1

-0.

1

L

3

-0.

(With T-type iron core)

(54)

(14)

(

)

162

)

(54)

(

)

11.7

Linear Servomotors

Notes: 1 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

2 Two magnetic ways in a set can be connected to each other.

3 The characteristics of the magnetic way with base are the same as of the magnetic way without base (SGLTM-20¡¡¡A).

Magnetic Way Model

SGLTM-

L1 L2 L3 L4 L5 N1 N2

Approx. Mass

20324AY 324 270 310 162 162 6 2 5.1

Y 540 486

20540A

526 378 189 10 3 8.5

20756AY 756 702 742 594 198 14 4 12

kg

166

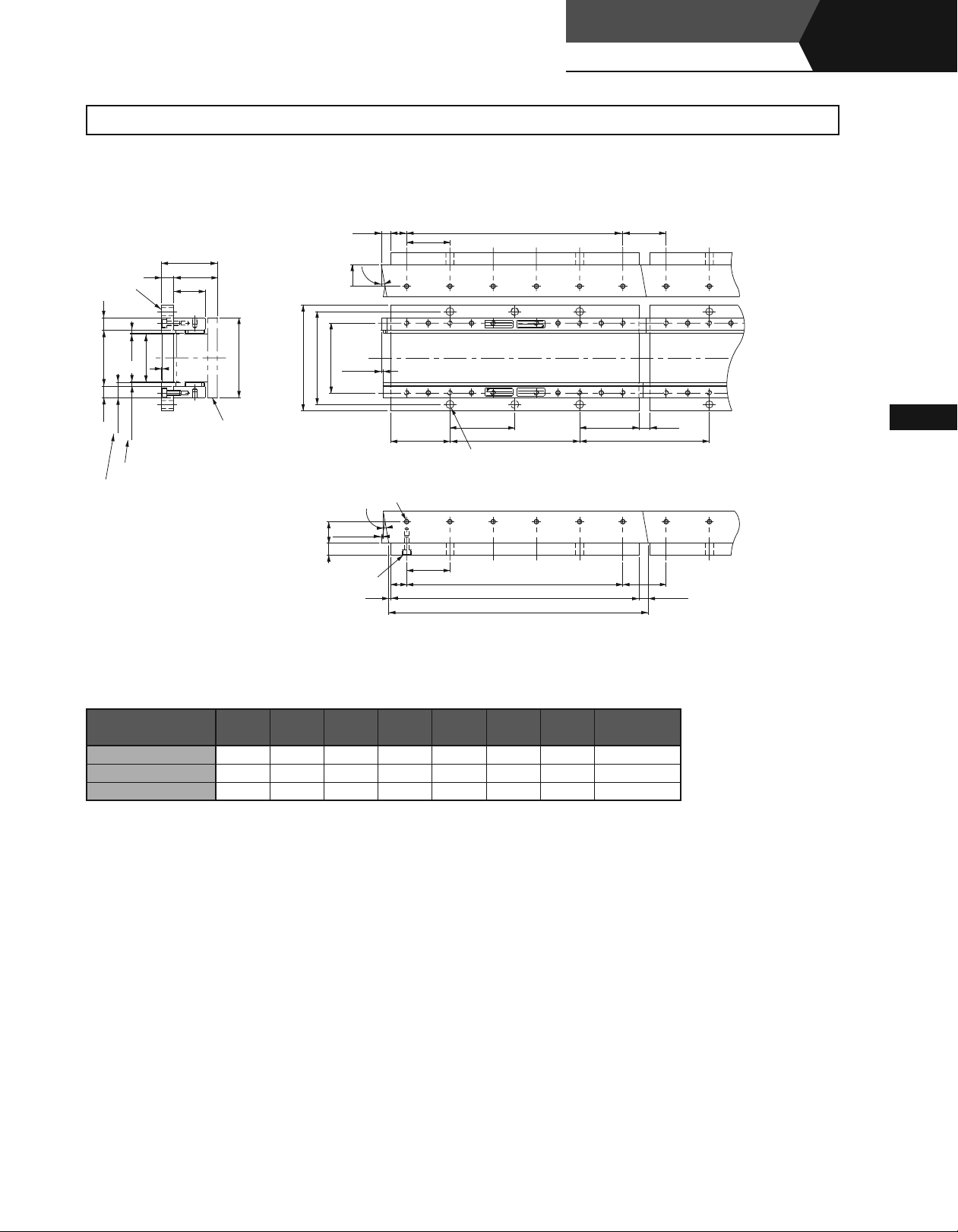

External Dimensions Units: mm

(2) Standard Type SGLTW-35ASGLTW-35A

3Moving Coil: SGLTW-35A¡¡¡A¡ (With a connector by Tyco Electronics AMP K.K.)

(70)

66

)

15

(

)

60

70

(

)

)

)

15

(

With Magnet Cover

:

Without Magnet Cover

2

.

:

19

19

(

(

Hall Sensor

Connector Specifications

9

5

Pin Connector:

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector:

17

JE-

17L-002

Stud:

17L-002C1

55

12

)

)

With Magnet Cover

:

8

Without Magnet Cover

.

:

0

1

Gap

Gap

(

(

6

1

(D8C)

13090-02

(D8C

C or

1

28

20

Nameplate

500

)

Magnetic Way

60

100

2

-Screws

4-40

UNC

#

±

50

500

(

)

8.4

Dia.

±

50

Pin No. Signal

1

+

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

5VDC

50

10

Hall Sensor

(

4.2

Dia.

63

Min.

100

Min.

Linear Servomotor

Connector Specifications

Plug:

Pin :

by Tyco Electronics AMP K.K.

The Mating Connector

Cap :

Socket:

48

80

)

350779-1

350218-3

350547-3

350654-1

350669-1

350780-1

350536-3

350550-3

6

Tapped Holes, Depth

N-M

or

(No.1 to

(No.

1

L

2

L

)

3

)

4

or

12

(

)

3

L

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

Pin No. Signal

1 Phase U Red

2 Phase V White

3 Phase W Black

4 Ground Green

Wire

Color

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Inverse

Power

(V)

Vu

Su

Vv

Sv

167

Moving Coil Model

SGLTW-

35A170A¡ 170

35A320A¡ 315

35A460A¡ 460

L1 L2 (L3) N

×3)

144 (48

288 (48

432 (48

×6)

×9)

(16) 8 3.7

(17) 14 6.8

(18) 20 10

Approx. Mass

kg

Vw

0 180 360 540

Sw

Electrical Angle (˚

)

External Dimensions Units: mm

3Magnetic Way: SGLTM-35¡¡¡A¡

)

(

70

)

15

)

3

.

0

Preshipment

±

Preshipment

(

(

1

.

0

70

±

*

5

.

71

Max.

103

15

R

0

.

5

Max.

Mount the magnetic

way so that its corner

surfaces are flush with

the inner step.

3

.

0

19

±

1

Gap

Assembly Dimensions

55

)

1

(

C

1

1

C

47

Max.

1

R

6

+0.

62

0

±

*

0.3

70

Moving Coil

)

100

(

(8)

3

Mount the magnetic

way so that its corner

surfaces are flush with

the inner step.

0

15

2

-0.

5

9

.

.

9

˚

34

0

33

-0.

87

±

*

0.3

2.4

(

30.6

2

× N-M6 Screws, Depth

9.9

˚

5

±

*

0.3

2.4

.

34

39

(12)

Linear Servomotors

SGLTW

1

-0.

1

L

3

-0.

2

Nameplate

YASKAWA

TYPE:

8

L

O/N

S/N

MADE IN JAPAN

2

L

DATE

Spacers: Do not remove them until the moving

coil is mounted on the machine.

2

L

1

-0.

1

L

3

-0.

54

2

54

6

R

2

× N-7 Dia. Mounting Holes (See the sectional view for the depth.

)

54

0

2

-0.

(With T-type iron core)

(

)

54

(

)

30.6

(54)

4

(54)

Linear

)

Linear Servomotors

Notes: 1 Two magnetic ways for both ends of moving coil make one set. Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the

moving coil is mounted on a machine.

2 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

3 Two magnetic ways in a set can be connected to each other.

4 The dimensions marked with an * are the dimensions between the magnetic ways. Be sure to follow exactly the dimensions specified in the figure above. Mount magnetic ways

as shown in Assembly Dimensions. The values with a ♣ are the dimensions at preshipment.

5 Use socket headed screws of strength class 10.9 minimum for magnetic way mounting screws. Do not use stainless steel screws.

Magnetic Way Model

SGLTM-

35324A¡ 324

35540A¡ 540

35756A¡ 756

-0.1

L1

-0.3

L2 N

×5)

270 (54

486 (54

×9)

702 (54

×13)

6 4.8

10 8

14 11

Approx. Mass

kg

168

External Dimensions Units: mm

Magnetic Way with Base

3

(85)

(

15

Base

)

3

.

8

.

0

±

0

(

70

3

.

2

0

.

±

15 15

8

.

19

0

Gap

Includes a 0.2 thick magnet cover.

55

60

1

: SGLTM-35¡¡¡AY

)

70

)

100

(

Moving Coil

132

20

13

2

L

(54)

54

5

9

.

.

9

˚

34

MADE IN JAPAN

DATE

87

116

±

0.3

2.4

YASKAWA

TYPE:

5

L

74

2

× N2-10 Dia.

Mounting Holes (See the sectional view for the depth.

TYPE:

S/N

YASKAWA

O/N

O/N

S/N

DATE

MADE IN JAPAN

4

74

L

(14)

(

)

162

)

2

× N1-M6 Screws, Depth

9

.

9

˚

515

(

±

)

0.3

2.4

.

34

2

× N1-M6

Bolts, Depth

20

16

1

Notes: 1 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

2 Two magnetic ways in a set can be connected to each other.

3 The characteristics of the magnetic way with base are the same as of the magnetic way without base (SGLTM-35¡¡¡A).

Magnetic Way Model

SGLTM-

L1 L2 L3 L4 L5 N1 N2

8

54

2

L

3

L

1

-0.

1

L

3

-0.

Approx. Mass

35324AY 324 270 310 162 162 6 2 6.4

Y 540 486

35540A

526 378 189 10 3 11

35756AY 756 702 742 594 198 14 4 15

(54)

(13)

kg

169

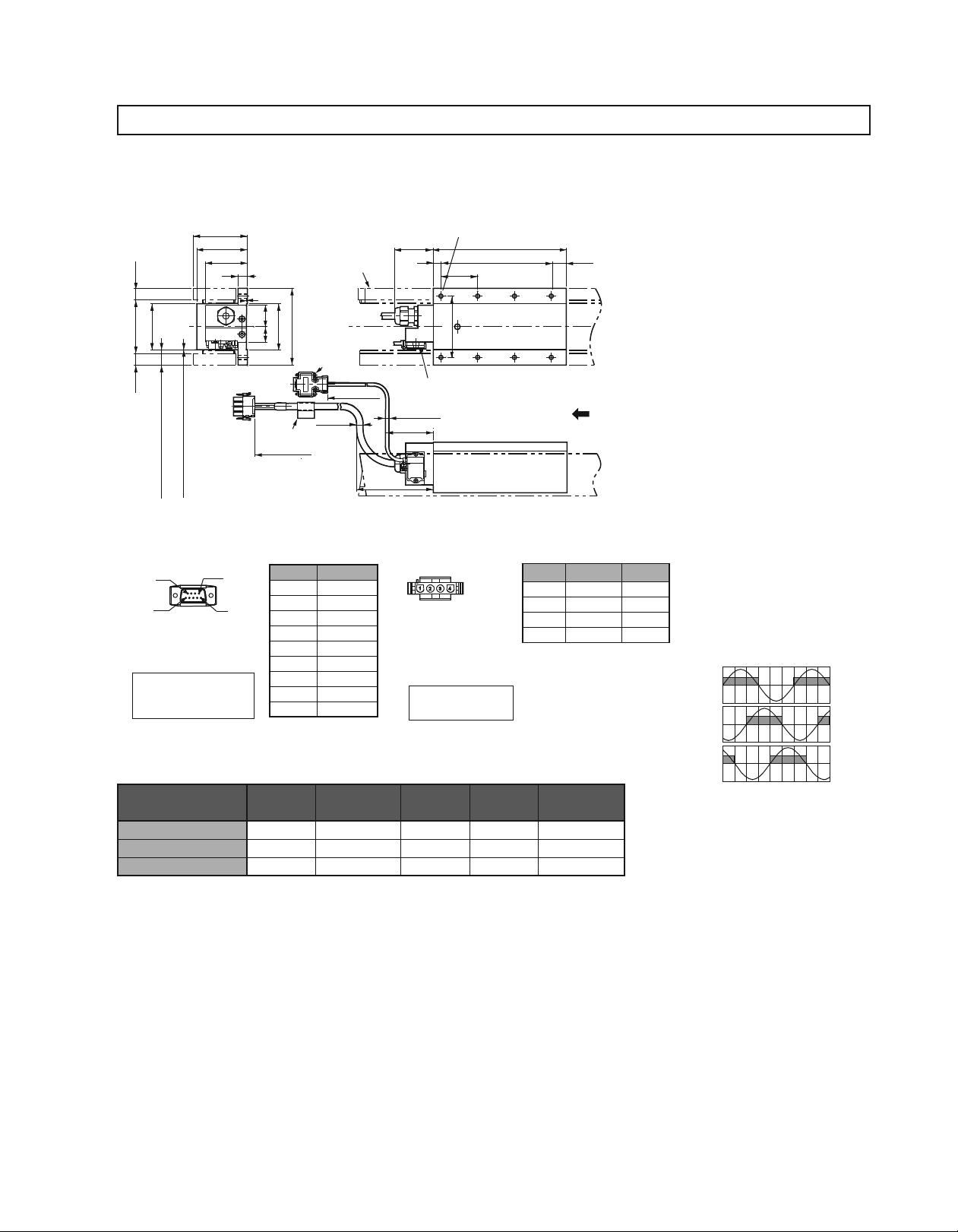

External Dimensions Units: mm

(3) Standard Type SGLTW-40

Moving Coil: SGLTW-40

3

(83)

)

1

.

19

(

78

75

16

¡¡¡¡B¡

Hall Sensor

Receptacle

Magnetic Way

(With an MS connector)

8

Tapped Holes, Depth

N-M

63

20

40 60

Linear Servomotors

Linear

SGLTW

16

1

L

2

L

(With T-type iron core)

(

)

3

L

)

8

.

97

111

(

)

1

.

19

(

Hall Sensor

Connector Specifications

)

)

)

)

With Magnet Cover

Without Magnet Cover

:

:

2

4

.

.

1

1

With Magnet Cover

Without Magnet Cover

:

:

3

1

.

.

Gap

Gap

25

25

(

(

(

(

9

5

Pin Connector:

17JE-23090-02 (D8C)

by DDK Ltd.

The Mating Connector

Socket Connector:

17JE-13090-02 (D8C)

Stud: 17L-002C or

17L-002C1

1

30 38

98

2

-Screws

4-40

#

150

UNC

)

Dia.

2

.

4

64

Min.

(

±

50500

O/N

S/N

W

A

YASKAWA ELECTRIC

N

V

ins.

DATE

m/s

124

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

TYPE

Linear SERVO MOTOR

MADE IN JAPAN

Nameplate

Linear Servomotor

Connector Specifications

6

1

Pin No. Signal

1

+

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

5VDC

Receptacle type: MS3102A-22-22P

by DDK Ltd.

The Mating Connector

L-shaped plug type : MS3108B22-22S

Straight plug type : MS3106B22-22S

Cable clamp type : MS3057-12A

Pin No. Signal

A Phase U

B Phase V

C Phase W

D Ground

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Linear Servomotors

Inverse

Power

(V)

Vv

Sv

Moving Coil Model

SGLTW-

40¡400B¡ 395

L1 L2 (L3) N

360(60×6) (15)

14 15

40¡600B¡ 575 540(60 ×9) (15) 20 22

Approx. Mass

kg

Vw

0 180 360 540

Electrical Angle (˚

Sw

)

170

External Dimensions Units: mm

3Magnetic Way : SGLTM-40¡¡¡A¡

(

)

83

63

)

4

.

1

(

C

1

(15)

48

4

6

+0.

0

±

0.3

Mount the magnetic

way so that its

corner surfaces are

flush with the inner

step.

)

)

Preshipment

(

Preshipment

(

1

Max.

113

♣

153

♣

R

0

.

5

Max.

Mount the magnetic

way so that its

corner surfaces are

flush with the inner

step.

1

.

19

8

.

111

1

.

25

R

3

.

0

4

.

1

Gap

Max.

1

3

.

0

*

1

.

19

100

*

111.8

Assembly Dimensions

Moving Coil

)

150

(

2

0

15

2

-0.

5

.

6

39

°

0

37.5

2

-0.

131

0.3

1.4

)

(

36.1

×

N-M8 Screws, Depth

°

5.6

*

±

0.3

1.4

39

0

52.5

2

-0.

(

)

7.6

67

.

2

10

5

67

5

.

×

N-9 Dia.

Nameplate

YASKAWA

TYPE:

67

.

1

-0.

1

L

3

-0.

2

L

DATE

MADE IN JAPAN

S/N

O/N

2

L

(

)

67.5

TYPE:

YASKAWA

(

67.5

Mounting Holes (See the sectional view for the depth.

Spacers: Do not remove them until the moving coil

is mounted on the machine.

6

O/N

S/N

MADE IN JAPAN

5

2

L

1

-0.

1

L

3

-0.

(

(

36.1

)

67.5

)

)

O/N

YASKAWA

TYPE:

S/N

MADE I

)

Notes: 1 Two magnetic ways for both ends of moving coil make one set. Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the

moving coil is mounted on a machine.

2 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

3 Two magnetic ways in a set can be connected to each other.

4 The dimensions marked with an * are the dimensions between the magnetic ways. Be sure to follow exactly the dimensions specified in the figure above. Mount magnetic ways

as shown in Assembly Dimensions. The values with a ♣ are the dimensions at preshipment.

5 Use socket headed screws of strength class 10.9 minimum for magnetic way mounting screws. Do not use stainless steel screws.

Magnetic Way Model

SGLTM-

40405A¡ 405

40675A¡ 675

40945A¡ 945

-0.1

L1

-0.3

L2 N

337.5 (67.5

607.5 (67.5

877.5 (67.5

×5)

×9)

×13)

69

10 15

14 21

Approx. Mass

kg

171

External Dimensions Units: mm

Magnetic Way with Base

3

: SGLTM-40¡¡¡AY

Linear Servomotors

SGLTW

(With T-type iron core)

Linear

(

)

103

1

.

19

3

.

0

±

8

.

111

1

.

19

3

.

25

Base

)

2

.

1

(

3

.

0

±

2

.

1

20

90

(83)

63

1

Moving Coil

Gap

Includes a 0.2 thick magnet cover.

)

150

(

2

190

× N1-M8 Bolts, Depth

12.525

5

.

6

39

゚

170

131

±

0.3

1.4

2

× N1 - M8 Screws, Depth

(

1.4±0.3

39

5

.

6

゚

)

20

25

25

5

92.5

67.5

67.5

(

)

2

L

MADE IN JAPAN

DATE

TYPE:

S/N

YASKAWA

O/N

O/N

YASKAWA

S/N

TYPE:

DATE

MADE IN JAPAN

592

L

4

L

2

× N2 -12 Dia. Mounting Holes

(

10

See the sectional view for the depth.

67.5

(

)

17.5

)

5

.

(

202.5

)

Linear Servomotors

(

2

L

3

L

1

-0.

1

L

3

-0.

(

12.5

67.5

)

)

Notes: 1 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

2 Two magnetic ways in a set can be connected to each other.

3 The characteristics of the magnetic way with base are the same as of the magnetic way without base (SGLTM-40¡¡¡A).

Magnetic Way Model

SGLTM-

L1 L2 L3 L4 L5 N1 N2

Approx. Mass

40405AY 405 337.5 387.5 202.5 202.5 6 2 13

Y 675 607.5

40675A

657.5 472.5 236.25 10 3 21

40945AY 945 877.5 927.5 742.5 247.5 14 4 30

kg

172

External Dimensions Units: mm

(4) Standard Type SGLTW-80

Moving Coil: SGLTW-80

3

(

)

120

)

1

.

19

(

115

75

Magnetic Way

16

¡¡¡¡B¡

Hall Sensor

Receptacle

(With an MS connector)

N-M8 Tapped Holes, Depth

63

20

6040

16

1

L

2

L

(

)

3

L

)

8

.

97

111

(

)

)

)

)

1

.

19

(

With Magnet Cover

:

2

.

With Magnet Cover

1

Without Magnet Cover

:

:

3

1

.

.

Gap

25

25

(

(

(

Hall Sensor

Connector Specifications

9

5

Pin Connector:

17JE-23090-02 (D8C)

by DDK Ltd.

The Mating Connector

Socket Connector:

17JE-13090-02 (D8C)

Stud: 17L-002C or

17L-002C1

1

38

98

150

30

)

2

-Screws

4-40

#

Without Magnet Cover

:

4

.

1

Gap

(

UNC

6

1

)

Dia.

2

64

.

4

(

±

50

500

Nameplate

Pin No. Signal

1

+

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

5VDC

Min.

O/N

S/N

Y

A

SKA

WA ELECTRIC

DATE

124

TYPE

Linear SERVO MOTOR

W

A

V

MADE IN JAPAN

ins.

m/s

Linear Servomotor

Connector Specifications

Receptacle type: MS3102A-22-22P

by DDK Ltd.

The Mating Connector

L-shaped plug type : MS3108B22-22S

Straight plug type : MS3106B22-22S

Cable clamp type : MS3057-12A

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

Pin No. Signal

A Phase U

B Phase V

C Phase W

D Ground

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

Power

(V)

Vv

Sv

Moving Coil Model

SGLTW-

80¡400B¡ 395

L1 L2 L3 N

360(60×6) (15)

14 24

80¡600B¡ 575 540(60×9) (15) 20 35

Approx. Mass

kg

Vw

0 180 360 540

Electrical Angle (˚

Sw

)

173

Linear Servomotors

SGLTW

(With T-type iron core)

External Dimensions Units: mm

3Magnetic Way : SGLTM-80¡¡¡A¡

1

-0.

1

L

3

0

16.9

2

-0.

57

)

(

1

.

19

)

)

)

3

.

4

3

.

0

±

8

Preshipment

.

Preshipment

(

(

1

±

111

*

113

Max.

♣

153

1

.

♣

19

R

0

.

5

Max.

Mount the magnetic

way so that its

corner surfaces are

flush with the inner

step.

Notes: 1 Two magnetic ways for both ends of moving coil make one set. Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the

moving coil is mounted on a machine.

2 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

3 Two magnetic ways in a set can be connected to each other.

4 The dimensions marked with an * are the dimensions between the magnetic ways. Be sure to follow exactly the dimensions specified in the figure above. Mount magnetic ways

as shown in Assembly Dimensions. The values with a ♣ are the dimensions at preshipment.

5 Use socket headed screws of strength class 10.9 minimum for magnetic way mounting screws. Do not use stainless steel screws.

0

.

±

1

(

4

.

1

Gap

1

.

25

Max.

1

R

+0.

100

*

111.8

Assembly Dimensions

120

100

Moving Coil

)

C

1

1

85

C

(

(15)

2

× N1-M8 Screws, Depth

4

6

0

±

0.3

Mount the magnetic

way so that its

corner surfaces are

flush with the inner

step.

150

39.4

-0.

*

1.5

131

(

37.9

5.6

*

±

0.3

1.5

57

50.6

(

11.3

0

±

°

0

-0.

5

.

6

2

0.3

)

2

)

°

67

5

.

75

33

.

7

R

×

2

N2-9 Dia. Mounting Holes (See the sectional view for the depth.

Nameplate

10

O/N

YASKAWA

S/N

TYPE:

MADE IN JAPAN

67

5

.

-0.

2

L

DATE

3

L

DATE

2

L

1

-0.

1

L

3

-0.

(

)

67.5

MADE IN JAPAN

TYPE:

S/N

YASKAWA

O/N

(

)

37.9

(

)

67.5

O/N

S/N

MADE IN JAPAN

)

Spacers: Do not remove them until the moving coil

6

is mounted on the machine.

YASKAWA

TYPE:

(

)

67.5

Linear

Linear Servomotors

Magnetic Way Model

SGLTM-

80405A¡ 405

80675A¡ 675

80945A¡ 945

-0.1

L1

-0.3

L2 L3 N1 N2

337.5(67.5

×5)

607.5(67.5×9)

877.5(67.5×13)

337.5(33.75

607.5(33.75

887.5(33.75

×

10)

×

18)

×

26)

611 14

10 19 24

14 27 34

Approx. Mass

kg

174

External Dimensions Units: mm

Magnetic Way with Base

3

20

Base

1

.

)

3

2

.

.

0

1

±

(

8

90

.

111

119

.

19

1

3

.

0

3

.

±

2

25

.

1

: SGLTM-80¡¡¡AY

(

)

140

(

)

120

100

Moving Coil

)

150

(

190

170

131

1.5

(

)

22514.4

67.5

33.75

5

.

57

6

゚

±

0.3

L

MADE IN JAPAN

DATE

TYPE:

S/N

YASKAWA

O/N

2

× N2 - 12 Dia. Mounting Holes

(

See the sectional view for the depth.

O/N

YASKAWA

S/N

TYPE:

DATE

MADE IN JAPAN

5

L

492.5

L

67.5

)

(

)

(

202.5

)

17.5

92

5

.

2

Gap

× N1-M8 Screws, Depth

Includes a 0.2 thick magnet cover.

2

× N3-M8 Bolts, Depth

Notes: 1 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

2 Two magnetic ways in a set can be connected to each other.

3 The characteristics of the magnetic way with base are the same as of the magnetic way without base (SGLTM-80¡¡¡A).

Magnetic Way Model

SGLTM-

L1 L2 L3 L4 L5 N1 N2 N3

10

(

1.5±0.3

20 57

5

.

6

゚

)

33.75

67

5

25

3

1

.

.

25

2

L

3

L

1

-0.

1

L

3

-0.

80405AY 405 337.5 387.5 202.5 202.5 6 2 11 18

Y 675 607.5

80675A

657.5 472.5 236.25 10 3 19 31

80945AY 945 877.5 927.5 742.5 247.5 14 4 27 43

Approx. Mass

kg

(

14.4

(

67.5

)

)

175

Linear Servomotors

SGLTW

External Dimensions Units: mm

(5) High-efficiency Type SGLTW-35A¡¡¡H¡

3Moving Coil: SGLTW-35A¡¡¡H¡ (With a connector by Tyco Electronics AMP K.K.)

(With T-type iron core)

Linear

(70)

28

30

)

:Without Magnet Cover

0

.

1

Gap

(

1

(D8C

66

62.5

Magnetic Way

12

S/N

YASKAWA ELECTRICMADE IN JAPAN

W

AV

DATE

ins.

m/sN

0

±

60

120

1

.

1

Linear SERVO MOTOR

TYPE

O/N

Nameplate

2

-Screws

4-40

UNC

#

Cable

,

20276

UL

)

28

AWG

Pin No. Signal

1 +5VDC

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

L1 L2 (L3) N

144 (48

288 (48

1

.

0

)

±

15

20

05

.

)(

0

±

90

(

80

30

)

)

)

)(

15

:With Magnet Cover

:With Magnet Cover

8

2

.

.

:Without Magnet Cover

0

19

(

19

(

Gap

(

Hall Sensor

Connector Specifications

96

5

Pin Connector:

17

23090-02

JE-

by DDK Ltd.

The Mating Connector

Socket Connector:

Stud:

17

13090-02

JE-

17L-002

17L-002C1

(D8C)

C or

Moving Coil Model

SGLTW-

35A170H¡ 170

35A320H¡ 315

Hall Sensor

)

Dia.

2

.

4

(

±

50

500

×3)

×6)

N-M6 Screws, Depth

1

30

10

±

0.15

48

20

15

.

0

±

L

2

L

100

Protective Tube

The moving coil moves in the direction

indicated by the arrow when current flows

50

±

in the order of phase U, V, and W.

500

35

43

63

Min.

Lead Specifications of Moving Coil

・

If this cable is bent repetitively, the cable

will disconnect.

Phase V

Phase W

(

View from Top of Moving Coil

Name Color Code

Phase U

Phase V V

Phase W W

Ground Green – 2 mm

Phase U

Ground

)

U

Black

Approx. Mass

(16) 8 4.7

(17) 14 8.8

kg

Wire

Size

2 mm

12

(

)

3

L

Linear Servomotors

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

2

Power

Vv

(V)

2

Vw

Sv

Sw

0 180 360 540

Electrical Angle (˚

)

176

External Dimensions Units: mm

Moving Coil: SGLTW-35D

3

¡¡¡H¡

(70)

28

30

)

66

62.5

12

Linear SERVO MOTOR

TYPE

O/N

S/N

YASKAWA ELECTRICMADE IN JAPAN

W

AV

DATE

ins.

m/sN

Nameplate

1

.

1

0

±

60

120

1

.

0

)

±

15

20

05

.

0

)(

±

90

(

80

30

)(

)

)

15

)

500

2

-Screws

4-40

#

20276

,AWG

Pin No. Signal

UNC

28

1

+

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

:With Magnet Cover

2

.

19

(

Hall Sensor

Connector Specifications

:Without Magnet Cover

19

(

8

.

0

Gap

(

0

.

1

Gap

(

:Without Magnet Cover

:With Magnet Cover

96

5

Pin Connector:

17JE-23090-02 (D8C)

by DDK Ltd.

The Mating Connector

Socket Connector:

17JE-13090-02 (D8C)

Stud: 17L-002C or

17L-002C1

1

Cable

UL

D (With a connector by Interconnectron GmbH)

N-M6 Screws, Depth

Magnetic Way

Hall Sensor

±

50

)

Dia.

2

.

4

(

500±50

5VDC

30

10

48±0.15

20

15

.

0

±

100

Protective tube

35

43

63

Min.

Linear Servomotor

Connector Specifications

6

5

1

4

Extension : ARRA06AMRPN182

Pin : 021.279.1020

by Interconnectron GmbH

The Mating Connector

Plug : APRA06BFRDN170

Socket : 020.105.1020

2

1

L

2

L

Pin No. Signal

1 Phase U

2 Phase V

4 Phase W

5 Not used

6 Not used

12

(

)

3

L

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Ground

Vu

Su

Inverse

Power

(V)

Vv

Sv

177

Moving Coil Model

SGLTW-

35D170H¡D

L1 L2 (L3) N

170 144(48× 3)

(16) 8 4.7

Approx. Mass

35D320H¡D 315 288(48×6) (17) 14 8.8

Vw

0 180 360 540

kg

Electrical Angle (˚

Sw

)

External Dimensions Units: mm

3Magnetic Way: SGLTM-35¡¡¡H¡

Linear Servomotors

Linear

SGLTW

1

-0.

3

-0.

1

0

2

-0.

54

9

5

.

.

9

˚

34

L

215

L

(With T-type iron core)

(54)

1

.

0

±

)

15

)

3

.

0

±

Preshipment

(

Preshipment

(

90

1

*

±

5

.

Max.

91

123

1

.

0

±

15

)

8

.

0

(

3

1

.

.

0

0

±

±

8

2

.

.

0

4

(70)

55

Moving Coil

0

33

2

-0.

2

L

54

MADE IN JAPAN DATE

TYPE:

S/N

YASKAWA

O/N

(

30.6

(54)

)

)

±

3

0

.

*

4

2

107

.

R

(

)

2

30.6

120

C

1

1

C

47

(

(8)

Model

Nameplate

6

O/N

YASKAWA

S/N

TYPE:

MADE IN JAPAN DATE

× N-7 Dia. Mounting Holes (See the sectional view for the depth.

)

Gap

0.2

6

+0.

0

±

0.3

90

thick magnet cover.

N-M6 Screws, Depth 8

2

×

3

Mount the magnetic

way so that its corner

surfaces are flush with

the inner step.

Spacer: Do not remove them until the moving

)

coil is mounted on the machine.

4

9

.

9

˚

5

±

*

0.3

2.4

.

34

54

0

39

2

-0.

(12)

2

L

1

-0.

1

L

3

-0.

(

(54)

R

0

.

5

Max.

Mount the magnetic

way so that its corner

surfaces are flush with

the inner step.

Includes a

Max.

1

R

82

*

Assembly Dimensions

Notes: 1 Two magnetic ways for both ends of moving coil make one set. Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the

moving coil is mounted on a machine.

2 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

3 Two magnetic ways in a set can be connected to each other.

4 The dimensions marked with an * are the dimensions between the magnetic ways. Be sure to follow exactly the dimensions specified in the figure above. Mount magnetic ways

as shown in Assembly Dimensions. The values with a ♣ are the dimensions at preshipment.

5 Use socket headed screws of strength class 10.9 minimum for magnetic way mounting screws. Do not use stainless steel screws.

Linear Servomotors

Magnetic Way Model

SGLTM-

35324H¡ 324

35540H¡ 540

35756H¡ 756

-0.1

L1

-0.3

L2 N

×5)

270 (54

486 (54

×9)

702 (54

×13)

10 8

14 11

Approx. Mass

kg

6 4.8

178

External Dimensions Units: mm

(6) High-efficiency Type SGLTW-50

3Moving Coil: SGLTW-50A¡¡¡H¡ (With a connector by Tyco Electronics AMP K.K.)

)

1

.

1

.

0

±

19

(

20

05

)

.

0

±

90

(

80

)

1

.

19

(

Hall Sensor

Connector Specifications

Pin Connector:

17

JE-

by DDK Ltd.

The Mating Connector

Socket Connector:

Stud:

2830

)

)

: With Magnet Cover

3

.

23

(

)

)

: With Magnet Cover

: Without Magnet Cover

: Without Magnet Cover

8

0

1

.

.

.

0

1

23

(

Gap

Gap

(

(

96

(D8C)

13090-02

C or

1

(D8C

5

23090-02

17

JE-

17L-002

17L-002C1

Moving Coil Model

SGLTW-

50A170H¡ 170

50A320□ 315

(85)

81

5

62

.

12

Linear SERVO MOTOR

TYPE

O/N

S/N

YASKAWA ELECTRICMADE IN JAPAN

W

AV

DATE

ins.

m/sN

Nameplate

2

-Screws

4-40

#

1

UNC

Magnetic Way

)

1

.

4

(

1

.

0

±

60

120

Hall Sensor

±

50

500

)

Dia.

2

.

4

(

Hall Sensor

End Connector

Cable

,

UL

)

20276

28

AWG

Pin No. Signal

1 +5VDC

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

L1 L2 (L3) N

×3)

144 (48

288 (48

×6)

N-M6 Screws, Depth

30

10

±

0.15

48

20

15

.

0

±

1

L

2

L

100

Protective Tube

50

±

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

500

35

43

63

Min.

Lead Specifications of Moving Coil

• If this cable is bent repetitively, the cable

will disconnect.

Phase V

Phase W

(

View from Top of Moving Coil

Name Color Code

Phase U

Phase V V

Phase W W

Ground Green – 2 mm

Phase U

Ground

U

Black

Approx. Mass

(16) 8 6

(17) 14 11

kg

Wire

Size

2 mm

12

(

)

3

L

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

)

Vu

Su

Inverse

Power

2

2

Vv

(V)

Vw

0 180 360 540

Electrical Angle (˚

Sv

Sw

)

179

External Dimensions Units: mm

Linear Servomotors

SGLTW

(With T-type iron core)

Linear

Moving Coil: SGLTW-50D

3

1

.

)

0

1

.

±

19

20

(

05

.

0

)

±

90

(

80

)

1

.

19

(

Hall Sensor

Connector Specifications

)

:With Magnet Cover

3

.

23

(

)

:Without Magnet Cover

1

.

23

(

2830

)

)

:With Magnet Cover

:Without Magnet Cover

0

8

.

.

1

0

Gap

(

Gap

(

96

5

Pin Connector:

17JE-23090-02 (D8C)

by DDK Ltd.

The Mating Connector

Socket Connector:

17JE-13090-02 (D8C)

Stud: 17L-002C or

17L-002C1

1

(85)

81

5

62

.

12

Linear SERVO MOTOR

TYPE

O/N

S/N

YASKAWA ELECTRICMADE IN JAPAN

W

AV

DATE

ins.

m/sN

Nameplate

2

-Screws

4-40

#

Cable

20276

UL

¡¡¡H¡

)

1

.

4

(

1

.

1

0

±

60

120

500

UNC

500±50

28

,AWG

Pin No. Signal

1

+

2 Phase U

3 Phase V

4 Phase W

50V

6 Not used

7 Not used

8 Not used

9 Not used

5VDC

D (With a connector by Interconnectron GmbH)

N-M6 Screws, Depth

1

L

2

L

The moving coil moves in the direction

indicated by the arrow when current flows

in the order of phase U, V, and W.

Pin No. Signal

1 Phase U

2 Phase V

4 Phase W

5 Not used

6 Not used

Magnetic Way

Hall Sensor

±

50

)

Dia.

2

.

4

(

30

10

48±0.15

20

15

.

0

±

100

Protective tube

35

43

63

Min.

Linear Servomotor

Connector Specifications

6

5

1

4

Extension : ARRA06AMRPN182

Pin : 021.279.1020

by Interconnectron GmbH

The Mating Connector

Plug : APRA06BFRDN170

Socket : 020.105.1020

2

12

Ground

(

)

3

L

Hall Sensor Output Signals

When the moving coil moves in the

direction indicated by the arrow in the

figure, the relationship between the hall

sensor output signals Su, Sv, Sw and the

inverse power of each motor phase Vu,

Vv, Vw becomes as shown in the figure

below.

Vu

Su

Inverse

Power

(V)

Vv

Sv

Linear Servomotors

Moving Coil Model

SGLTW-

50D170H¡D

L1 L2 (L3) N

170 144(48×3)

(16) 8 6

Approx. Mass

50D320H¡D 315 288(48×6) (17) 14 11

Vw

0 180 360 540

kg

Electrical Angle (˚

Sw

)

180

External Dimensions Units: mm

3Magnetic Way: SGLTM-50¡¡¡H¡

1

.

0

±

1

.

)

19

)

3

.

0

±

Preshipment

(

Preshipment

90

(

*

1

±

5

.

Max.

91

131

1

.

0

±

1

.

19

)

8

.

0

(

1

3

.

.

0

0

±

±

2

8

.

.

4

0

Gap

Includes a

(85)

70

C

1

1

C

62

0.2

thick magnet cover.

(8)

0

9

2

-0.

42

0

27

2

)

1

.

4

-0.

)(

120

(

112

Moving Coil

1

-0.

1

L

3

-0.

2

L

54

2

L

54

MADE IN JAPAN DATE

S/N

O/N

Model

Nameplate

Dia.

12

2

× N-7 Dia. Mounting Holes

(

See the sectional view for the depth.

O/N

YASKAWA

S/N

MADE IN JAPAN DATE

TYPE:

)

(

54

(27)

(54)

TYPE:

YASKAWA

)

Spacers: Do not remove them until the moving

coil is mounted on the machine.

)

4

(

R

0

.

5

Max.

Mount the magnetic

way so that its corner

surfaces are flush with

the inner step.

R

Max.

1

*

3

2

× N-M6 Screws, Depth

6

+0.

82

0

±

0.3

90

Mount the magnetic

way so that its corner

surfaces are flush with

the inner step.

42

8

54

0

45

2

-0.

2

L

1

-0.

1

3

-0.

L

(54)

Assembly Dimensions

Notes: 1 Two magnetic ways for both ends of moving coil make one set. Spacers are mounted on magnetic ways for safety during transportation. Do not remove the spacers until the

moving coil is mounted on a machine.

2 If you have a pacemaker or any other electronic medical device, do not go near the magnetic way of the linear servomotor.

3 Two magnetic ways in a set can be connected to each other.

4 The dimensions marked with an * are the dimensions between the magnetic ways. Be sure to follow exactly the dimensions specified in the figure above. Mount magnetic ways

as shown in Assembly Dimensions. The values with a ♣ are the dimensions at preshipment.

5 Use socket headed screws of strength class 10.9 minimum for magnetic way mounting screws. Do not use stainless steel screws.

Magnetic Way Model

SGLTM-

50324H¡ 324

50540H¡ 540

50756H¡ 756

-0.1

L1

-0.3

L2 N

×5)

270 (54

486 (54

×9)

702 (54

×13)

68

10 13

14 18

Approx. Mass

kg

181

Loading...

Loading...