Page 1

<

"

Before

initial

operation

rte

;

read

these

instructions

s'

thoroughly

and

retain

for

future

reference

688-284

ETL

Testing

Laboratories

Certification

When

properly

installed,

operated

and

maintained,

this

equipment

will

provide

a

lifetime

of

service

.

It

is

mandatory

that

the

person

who

operates,

inspects,

or

maintains

this

equipment

thoroughly

read

and understand

this

manual,

before

proceeding

.

This

manual

applies

to

VS-616GII

Model

CIMR-H18

.5G2,

-H22G2,

-H30G2,

-H37G2,

-H45G2

.

The

VS-616GII

Drive

is

an

AC

variable

speed

drive

system

for

high-precision

variable

speed

applications

.

It

basically

consists

of a

three-phase

squirrel-

cage

induction

motor,

a

VS-616GII

controller

(VS-616GII),an

operator

control

station,

and

optional

control

units

.

This

manual

primarily

describes

VS-

616GII,

but

contains

basic

information

for

operator

control station

as

well

.

For

details

of the

operation

of

individual

units,

refer

to

their

respective

man-

uals

.

il -1

<-'r'

'

--

.RaY

Tr

r"~rc:'P

-r

"

16GII

Type

CINIR-H22G2

Page 2

CONTENTS

Page

1

.

RECEIVING

.

. . ...

. . .

. . . .

. . .

. . .

. . .

. . .

. . .

. . . .

. . .

.

.

. . . .

. . .

. .

. . .

. . . .

. . . .

. . .

. . .

. .

. . .

. .

. . . .

. .

. . . .

. .

.

. . .

. .

. . . .

. . .

. . . .

. .

. . . . .

. .

. . .

. . .

. . . .

. .

. . . . .

3

2.VS-616GI1

MAJOR

CONTROL

COMPONENT

LAYOUT

. .

. . .

. . .

. .

. . ...

. .

. . .

. .

. . . .

. . .

. . . .

. .

. . . .

. .

. . .

. . .

. . . . . ..4

3

.

INSTALLATION

.

. . . .

. . .

. . ..... . .

. . .

. . . . .

. .

. . . .

.

. .

. . .

. .

. . . .

. .

. . . . .

. . .

. . .

. .

. . . .

. .

. . .

. .

. . . . .

. .

. . .

. .

. . .

.

. . .

. . .

. .

. . . . .

. .

. . . .

. .

. . . .

. .

. . . . .

. ..4

3.1LOCATION

.

. . .

. . .

. . . .

. . .

. . .

. . .

. .

.

.

. .

. . . . .

. .

. . . . .

. .

. . .

. .

. . . .

. .

. . . . .

. .

. . . .

. .

. . . .

. .

. . .

. .

.

. .

. .

. . . . .

. .

. . .

. . .

. . . .

. .

. . . .

. .

. . . .

. . .

. . .

. . .

. . . .

. . ..4

3

.2

POSITIONING

.

. . .

. . . .

. . .

. .

.

. . .

. . .

. . .

. . . .

. . .

. . . .

. . .

. . .

. .

. . . .

. .

. . .

. . . .

. . .

. . .

. . . . . . . . ... . . .

. .

. . . . .

.

. . . .

. . .

. . .

. .

. . . . .

. .

. . . ..... . .

. .

. . . .

.

. . ..5

3.3MOUNTING

DIMENSIONS

.

. .

. . . .

.

. .

. . . .

. . .

. . . ... . . .

. . .

. . .

. . . .

. . .

. .

. . .

. .

. . . .

. .

. . .

. . .

...

.

. .

. . .

. . .

. . . .

. .

. . ...

. .

. . .

. .

. . . . .

. .

. . . . .

. .

. .

5

4

.

WIRING

.

. .

. . .

. .

. . .

. . .

. . .

. . ...

. .

. .

.

. . .

. ...

. . . .

. . .

. . .

. . .

. . .

. .

. . . .

. .

. . . . .

. .

. . .

. . .

. . .

. .

. . .

. . . ...

.

. .

. . .

. . .

. . . .

. .

. . .

. .

. . . . .

. .

. . . .

. . .

. . .

. . .

. . . . .

. .

g

4

.1

INTERCONNECTIONS

.

.

. . .

. . .

. .

. . . . .

. . . .

. . .

. .

. . .

. .

. . . .

. . .

. . . .

. . .

. . .

. .

. . . .

. .

. . . ... . . . ... . . .

. .

. . . .

. .

. . . .

. .

. . . . .

. .

. . .

. . .

. . . .

. .

. . . . .

. ..6

4.2MOLDED-CASE

CIRCUIT

BREAKER

(MCCB)

AND

POWER

SUPPLY

MAGNETIC

CONTACTOR

(MC)

. ... . . .

. .

. . . .

. .

. . .

. .

. . .

. .

. . . . .

. .

. . .

. . .

. . .

. .

. . . . .

. .

. . . ..... . .

. . .

. . . .

. . ..8

4.3SURGE

ABSORBER

.

. . .

. . .

. . .

. . .

. . . . .

. .

. . .

. ... .

. ... . . .

. . .

. . . .

. . .

. . .

. . .

. . . .

. ..... .

. . .

. .

. . . . ... . .

. . .

. . .

. . .

. .

..... . . .

. .

. . . . .

. .

. . . . .

. . ..8

4.4WIRING

INSTRUCTIONS

.

. .

. . .

. . .

. . .

. . . .

. . .

. . .

. .

. . ...

. .

. ...

. .

. .

. .

. .

. . . . . . . ..... . .

. . .

. . . .

. .

. . . .

. .

. . .

. . .

. . .

. ... . . .

. .

. . . . .

. .

. . . . .

. .

. .

9

4.4.1

Control

Circuit

.

. . .

. . .

. . .

. . .

. . .

. . .

. . . .

. .

. . . .

. . .

. . .

. .

. . .

. ... . . .

. .

. . . . .

. .

. . .

. .

. . .

. . .

. . .

. . .

. . . .

. .

. . .

. .

. . . .

. . .

. . .

. .

.

. . . .

. .

. . .

. . .

. . . . ..... .

4

.4.2Main

Circuit

Input/Output

.

.

. . . .

. . .

. . . .

. . .

. . .

. .

. . .

. . .

. . .

. . .

. . . . .

. .

.

. .

. .

. . .

. . .

. . .

. .

. . . .

. . .

. . .

. .

. . . .

. .

. . . .

. .

. . .

. .

. .

. . .

. .

. . . . .

. .

. . . .9

4.4.3

Grounding

...

. .

. . . . .

. .

. . . .

. . .

. . .

. .

. . . .

. . .

. . .

. . .

. . . .

. .

. . .

. .

. . . . .

. .

. . . . .

.

. . . ... . . .

. .

. . . .

. .

. . . . .

. .

. . .

. .

. . . ... . . . .

. .

. . . .

. . .

. .

.

. .

. . . . .

. .

. . .

.10

5.TEST

RUN

.

.

.

. . .

. .

. . . . .

. .

. . . .

. . .

. . .

. .

. . . . .

. .

. . . .

. . .

. . .

. .

. . .

. .

. . . . .

. .

. . . . .

. .

. . .

. .

. . .

. . .

. . .

. .

. . . . .

.

.

. . .

. .

. . . .

. .

. . . .

. .

. . . . .

. .

. . .

. .

. . . . ... . . .

11

5.1CHECKS

BEFORE

TEST

RUN

.

. .

. .

. . . .

. . .

. . .

. .

. . .

. .

. . . . .

. .

. . ..... . . .

. .

. . .

. . .

. . .

. .

. . . ...

. . . .

. .

. . .

. .

. . . . .

. .

. . . .

. . .

. . .

. .

. . . . .

. .

. . .

.11

5.2SIMPLE

OPERATION

USING

DIGITAL

OPERATOR

. . .

. .

. . . .

. .

. . ... . . . .

. .

. . .

. . .

. . . .

. .

. . .

. .

. . . .

. . .

. . .

. . .

. . . .

. .

. . . . .

. .

. . .

.11

5.2

. 1

Set

and

Operate

Frequency

Command

.

.

. . .

. .

. . . . .

. .

. . .

. . .

. . .

. .

. . . ... . . . .

. .

. ... .

. . . . ... . . .

. .

. . . .

. . .

. . . .

. .

. . . .

. .

. . . .

. . .

. . .

.12

5.2.2

Monitor

FunctionofDigital

Operator

.

. . . .

. . .

. .

. . . .

. . .

. . .

. .

. . . . ... . .

. .

. . . . . ... . .

. .

. . . . .

. .

. . .

. .

. . . . .

. .

. . . .

. .

. . . .

. .

. . . . .

. .

. .

.

.13

5.3ADJUSTMENT

AND

SETTING

.

.

. .

. . . .

. .

. . . .

. .

. . .

. .

. . . .

. . .

. . .

. .

. . . .

. .

. . .

. .

. . . . . ... . .

. .

. . . . ...

. . .

. .

. . . . .

. .

. . . .

. .

. . . .

. .

. . . .

. .

. . . .

.14

6.OPERATION

AT

LOAD

.

. . ... . . . .

. .

. . . . .

. .

. . .

. .

. . . .

. .

. . . ..... . . .

.

. . .

. .

. . . .

. .

. . .

. . .

. . . .

. .

. . .

. .

. . . . .

. .

. . .

. .

. . . . .

. .

. . .

. .

. . . . .

. .

. . . . .

.

17

7.MAINTENANCE

.

. . . . ... . . .

. . .

. . ... . . ... . . . . .

. .

. . .

. .

. . . .

. .

. . .

. . .

. .

. .

. .

. . .

. . .

. . .

. .

. . . ... . . . .

. .

. . . ... . .

. .

. . . . .

. .

. . . .

.

. .

. . . ... . . . .

. ... . . .

.18

8.FAILURE

INDICATION

AND

DETAILS

.

. .

.

. . .

. . .

. . . .

. .

. . . .

. .

. . ... . . .

. .

. . . . ... . .

. . .

. . . .

. .

. . .

. .

. . . . .

. .

. . ... . . . .

. . .

. . .

. . .

. .

.19

8.1DISPLAYING

THE

SEQUENCE

OF

FAILURE

OCCURRENCE

. .

. . . .

. .

. . .

. . .

. . . .

. .

. . .

. .

. . . . .

. .

. . .

. .

. . . .

. .

. . . .

. . .

. . . .

20

8.2

STORAGE

FUNCTION

AT

POWER

FAILURE

. ... . . ... . . . ... . . ... . . ... . . . .

. .

. . .

. .

. . . .

. .

. . . ... . . .

. . .

. . . .

. .

. . . .

. .

. . . .

. .

. . . .

.

21

9

.

TROUBLESHOOTING

.

.

. .

. . .

. . .

. . .

.

. .

. . . .

. .

. . . ... . . ... . . . .

. .

. . . ... . . . ... . .

. .

. . . .

. .

. . . .

. .

. . .

. .

. . . .

. .

. . . ..... . .

. .

. . . . . . . . . .

. .

. . . .

.22

9

.1

TROUBLESHOOTING

FOR

MOTOR

SYMPTOM

. .

. .

. . . ... . .

. . .

. . .

. .

. . .

. .

. . . .

. . .

. . .

. .

. . . ... . . .

. .

. . . . ... . . .

. .

. . . .

. .

. . . .

. .

.

22

APPENDIX

1

STANDARD

SPECIFICATIONS.. .

. . .

. .

. . ..... . . .

. .

. . .

. .

. . . . . . . . .

. .

. . .

. . .

. . . ... . .

. .

. . . . .

. .

. . ... . . . . ... . . .

. . .

. . . .

. .

.24

APPENDIX2

TERMINAL

FUNCTIONS

.

. . .

.

.

. . .

. .

. . .

. . .

. . .

. .

. . . .

. .

. . . .

. .

. . ... . . . ... . .

. . .

. . . . ... . .

. .

. . . .

. .

. . . .

. .

. . . .

. .

. . . .

. . .

. . .

. . .

.

25

A2-1Terminals

of

Main

Circuit

.

. .

. .

. . .

. ...

. . .

. .

. . .

. . .

. . .

. . .

. . .

. .

. . . .

. .

. . . ... . .

. .

. . . .

. .

. . .

. . .

. . . .

.

.

. . .

. .

. . . .

. .

. . . .

. .

. . . .

. .

. . . ... . . . .

. .

. .

25

A2-2

TerminalsofControl

Circuit

.

. . . .

. . .

. . .

. ...

.

. .

. . . .

. .

. . .

. . .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. .

. . .

. .

. . . .

. . .

. . .

. .

. . .

. . .

. . . ... . . . .

. .

. . .

. .

. . . . . ... .

25

APPENDIX

3INTERNAL

CIRCUIT

AND

INTERCONNECTION

DIAGRAMS

. ... . . .

. .

. . .

. . .

. . . ... . . . ... ...

. .

. . ... . . . .

28

A3-1

With Braking

Unit

and

Braking

Resistor

Unit

. .

. . .

. . . .

. . . .

. .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. . .

. . .

. .

. . . .

. .

. . .

. . .

. . . .

. .

. . .

. . .

. . . .

. .

. . . . . .

.28

A3-2

With

Transistor

(Open-Collector)

For

Start/

Stop

Operation

. . . ... . .

. . .

. . . ... . .

. . .

. . .

. . .

. . ..... . . .

. .

. . .

. . .

. . . .

. ...

. .

29

APPENDIX4

SYSTEM

CONSTANTS

.

. .

. . . .

. . .

. .

. . . .

. .

. . . .

. . .

. . . .

. .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. .

. . .

. . .

. . .

. . .

. . .

. . .

. . . .

. .

. . .

. . .

. . . .

. .

. . . .

. . .

30

A4-1Inverter

Capacity

Selection

(Sn-10)

. . . .

. . .

. . .

. . .

. . .

. . .

. . . .

. .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. .

. . . .

. .

. . . .

. .

. . .

. . .

. . .

. . .

. . .

. .

. . . . .

. .

. . . . .

. .

30

A4-2

SettingofV/f

Pattern

Selection

(Sn-02).. .

. . . ...

. . . .

. . .

. . .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. .

. . . .

. .

. . . .

. .

. . .

. .

. . . . .

. .

. . .

. . .

. . . .

. .

. . . . ...31

A4-3

Run

Signal

Selection

(Sn-04)

.

. .

. . . . .

. . .

. . .

. .

. . .

. . .

. .

. . . .

. . .

. . .

. . . .

. .....

. . .

. . .

. . . .

. .

. . .

. . .

. . . .

. .

. . .

. .

. . .

. .

. .

. . .

. .

. . . .

.

.

.

. . . .

. .

.32

A4-4.Protective Characteristics

Selection

(Sn-05)

. .

. .

. . . .

. . . .

. .

. . .

. . .

. . ... . . .

. .

. . .

. . .

. . .

. . .

. . . .

. .

. . .

. .

. . . .

. . .

. . .

. .

. . . . .

. .

. . . . .

.

.33

A4-5

Overtorque

Detection

(Sn-06)

.

.

. . . . . .

. .

. . .

. .

. . . .

. .

. . . .

. . .

. . .

. .

. . . .

. .

. . . ... . .

. . .

. . .

. . .

. . .

. .

. . . . ... . . .

. .

. . . . .

. .

. . .

. .

. . . .

. . .

. . ...

.

.34

A4-6

Optional

Function

Selection

(Sn-07)

.

...

. .

. . . .

. . .

. .

. . . .

. . .

. .

. . .

. ...

. .

. .

. .

.

. .

. . .

. . . .

. . .

. .

. . .

. .

. . . .

. . .

. . . .

. .

. . . .

. .

. . . .

. . .

. . ...

.

.34

A4-7

Terminal Function

(Sn-08toSn-11)

.

.

. .

. .

. . . .

. .

. . . .

. . ..... .

. . . ... . . .

. .

. . .

. .

. . .

. .

. . . . .

. .

. . .

. ...

. .

. .

. . . .

. . .

. . . .

. .

. . . .

. .

. . . .

. . .

.34

A4-8

Contact

Output

Selection

Function

(Sn-12)

... . .

. . . .

. . .

. .

. . .

. .

. . .

. . .

. . .

. .

. . .

. .

. . . . .

. .

. . .

. .

. . . .

. .

. . . .

. . .

. . .

. .

. . . . .

. .

. . . .

. . .

.40

APPENDIX5

CONTROL

CONSTANTS

.

. . .

. . .

. .

. . .

. . .

. . .

. ...

. .

. . .

. .

. . .

. . .

. . .

. . .

. .

. . .

. .

. . ...

. .

. . .

. .

. . . .

. .

.

. ... . .

. . .

. .

. . . . .

. .

. . .

. . . .

.42

APPENDIX

6

OTHER

CONSTANTS

(FUNCTIONS)

. .

. . . .

. . .

. . .

. .

. . .

. . .

. .

. . .

. . .

. .

. . . .

. .

. . . ... . . . .

. .

. . . .

. .

. . . .

. .

. . . .

. .

. . . .

. . . .

.48

A6-1

Retry

Operation

Fault

.

.

. .

. ... .

.

.

. . .

. . . .

. . .

. . .

. .

. .

. . . .

. . .

. .

. . .

. . .

. . .

. . .

. . .

. .

. . .

. . .

. . .

. .

. .

. . . .

. . .

. .

. . .

. . .

. ...

. .

. . .

. .

. . . .

. . .

. . .

. . .

. .

.

.48

A6-2

Full

Range

DC

Braking

Stop

(DB)

.

. .

.

.....

. .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. .

. . . .

. .

. .

. .

. . .

. . . .

. . .

. .

. . .

. .

. . .

. . .

. . . .

. .

. . . .

. .

. . .

.

. . .

. . .

.49

A6-3

RangetoProhibit

Frequency

Setting..

. . .

. .

. . .

. .

. . . .

. . .

. . .

. . .

. . .

. . ... . . ... . . .

. .

. . .

. . . .

. . .

. .

. . .

. .

. . .

. . .

. . . .

. .

. . . .

. .

. . .

. .

. . . . .

.50

A6-4

Stall

Prevention

during

Operation

.

. . .

. . .

. .

. . .

. . .

. .

. . . .

. . .

. . .

. . .

. . .

. .

. .

. . . ... . . . .

. .

. . .

. . .

. . .

. .

. .

. . .

. . . .

. . .

. . .

. .

. . . .

. .

. . .

. .

. . . . .

.51

A6-5

Multispeed

Setting

Method

(5-speed

operationbyinternal

constants)...... . . .

. .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. .

. . . .

. . .

. . .

62

APPENDIX7

OPTION

.

.

. .

. . . .

. .

. .

. .

. . .

. .

. . .

. . .

. . . .

. . .

. .

. . . .

. .

. . .

. .

. . . . . ... . .

. .

. ...

. ... .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. .

. . . .

. . .

. . .

. . .

. .

. . .

. ...

. .

. . .

. .

54

APPENDIX8

CHECK

FUNCTION

.

. .

. . .

. . . .

. .

. . .

. .

. ...

. .

. . .

. .

. . ...

. .

. . .

. .

. .

. . .

. ...

. .

. .

.

. . .

. . .

. .

. . .

. . .

. . .

. . .

. . .

. . .

. . .

. .

. . .

. .

. . . . ... . . .

57

APPENDIX

9

CHECKING

OF

DIODE

AND

TRANSISTOR

MODULES

. . .

. . .

. . ..... .

. .

. . .

. . .

. . .

. . .

. . . .

. .

. . .

. . .

. .

. . .

. . . .

. . .

58

APPENDIX

10

WIRE

SIZE

.

. . ... .

. . .

. . .

. . .

. . .

. . .

. . . .

. .

. . .

. .

. . .

. .

. . . .

. .

. . .

. . .

. . .

. .

. . ... . . .

. .

. . .

. .

. . . .

. .

. . .

. .

. . . .

. . .

...

.

.

. . .

. . .

. . .

. .

. . . . .

. .

.59

APPENDIX

11

RENEWAL

PARTS

.

. .

. . .

. . . .

. .

. . .

. . .

. . .

. .

. . .

. ...

. . ...

. . ... . .

. . .

. . ... . . .

. .

. . .

. .

. . . .

. .

. . .

. . .

. . .

. . .

. . .

.

.

. . .

. .

. . . ..... . .

. ...60

Page 3

DANGER

"

Do

not

touch

circuit

components

until

"CHARGE"

lamp

is

extin-

guished

after

turning

off

the

AC

main

circuit

power

supply.The

capacitors

are

still

charged

and can

be

quite

dangerous

.

"

Do

not

connect

or

disconnect

wires

and

connectors

while

power

is

applied

to

the

circuit

.

"

Do

not

check

signals

during

operation

.

IMPORTANT

"

Be

sure

to

ground

VS-616GII

using

the

ground

terminal

.See par.4.4.3

on

page

10

.

"

Never

connect

main

circuit

output

terminals

(5

(

(9)),

((@),

(5(&)

to

AC

main

circuit

power

supply

.

"

All

the

potentiometers

of

VS-616GII

have been

adjusted

at

the

factory.Do

not

change

their

settings

unnecessarily

.

"

Do

not

make

withstand

voltage

test

on

any

part of

the

VS-616GII

unit,

because

it

is

electronic

equipment

using

semi-conductors

and

vulnerable

to

high

voltage

.

"

Control

PC

board

employs

CMOS

IC's

which

are

easily

dam-

aged by

static

electricity.Take

care

not

to

touch

the

CMOS

elements

inadvertently

.

1.RECEIVING

This VS-616GII

has

been

put

through

demanding

tests

at

the

factory

before

shipment

.

After

unpacking,

check

for

the following

.

"

Verify the

part

numbers

with the

purchase

order

sheet

and/or

packing

slip

.

"

Transit

damage

.

If

any

part

of

VS-616GII

is

damaged

or

lost,

immediately

notify

the

shipper

.

Page 4

2

.

VS-616G11

MAJOR

CONTROL

COMPONENT

LAYOUT

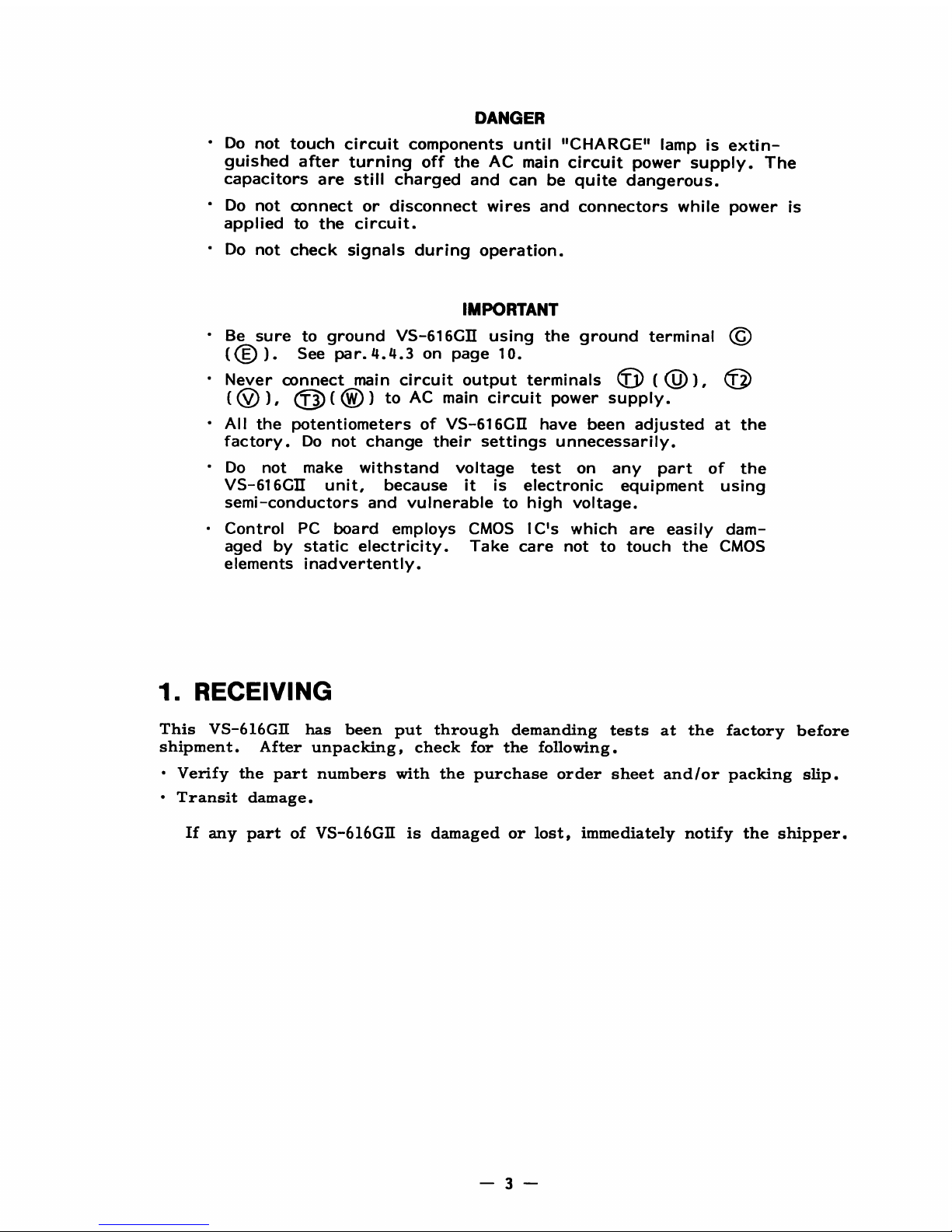

VS-616G111

major

control

component

is

shown

in

Fig.1

"

- I.-0i

111;

~

y

~

1f

~p~`. ..V

1I

I

94

Gil."100

" IIII

I

I

DIGITAL

OPERATOR

OR

DIGITAL

MONITOR

CHARGE

LAMP

CONTROL

CIRCUIT

TERMINALSt)TO

3.INSTALLATION

3

.1

LOCATION

TERMINAL

ARRANGEMENT

tt

©©©0a@®

8

~olololoTo

©

of®l@I@

~

c,a

0(©)

@(@)10

W1@(8)1@(6)1@(T)1E)10+

(®)~co)I©(®)I

Fig.1Major

Control

Component

LayoutofVS-616GII

Model

CIMR-H22G2

with

ETL

certification

Location

of

the

equipment

is

important

to

achieve

proper

performance

and

normal

operating

life.The

VS-616GII

units

should

be

installedinareas

where

the

following

conditions

exist

.

"

Ambient

temperature:-10

to

+40°C

(For

enclosed

type),

-10 to +50°C

(For

open

chassis

type)

"

Protected

from rain or

moisture

.

"

Protected

from

direct

sunlight

.

"

Protected

from

corrosive

gases

or

liquids

.

"

Free from

airborne

dust or

metallic

particles

.

"

Free

from

vibration

.

t

888-287

COVER

MTG

HOLE

BASE

DRIVEPCBOARD

CONTROLPCBOARD

CONNECTOR

TO

OPTIONS

(8CN,

9CN)

Page 5

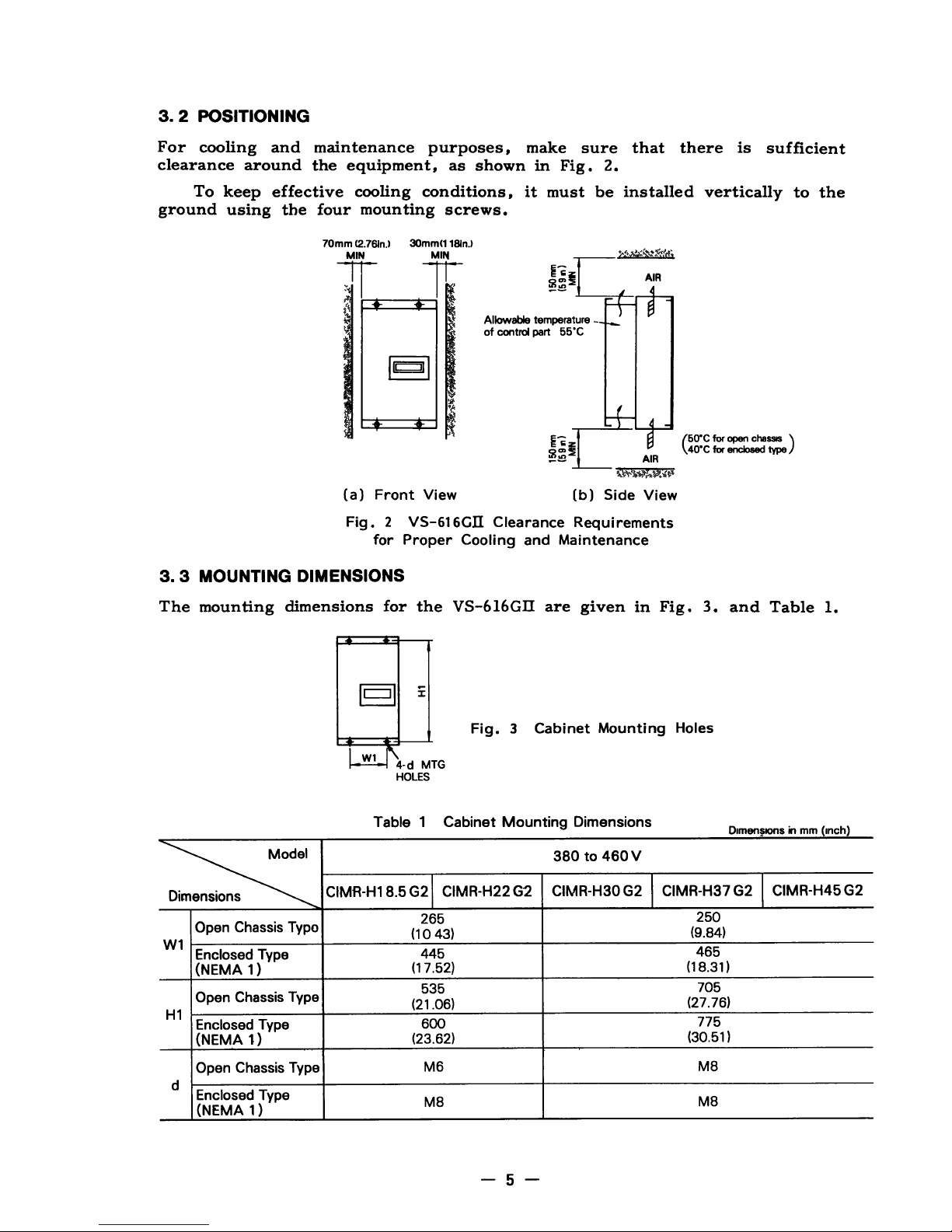

3

.2

POSITIONING

For

cooling

and

maintenance

purposes,

make

sure

that

there

is

sufficient

clearance

around

the

equipment,

as

shown

in

Fig.2

.

To

keep

effective

cooling

conditions,

it

must

be

installed

vertically to

the

ground

using

the

four

mounting

screws

.

70mm

(2

.761n

.)

30mm(1181n

.)

IN

MIN

w1

4-d

MTG

HOLES

(a)

Front

View

(b)

Side

View

Fig.2

VS-616GII

Clearance

Requirements

for

Proper

Cooling

and

Maintenance

3

.3

MOUNTING

DIMENSIONS

The

mounting

dimensions

for

the

VS-b16GII

are

given

in

Fig.3,

and

Table1.

i

Fig.3

Cabinet

Mounting

Holes

Table

1Cabinet

Mounting

Dimensions

WC

for

open

chasm

(40'C

for

enclosed type

Dimensionsinmm

(inch)

Model

380to460

V

Dimensions

CIMR-H18.5G2

CIMR-H22

G2

CIMR-H30

G2

CIMR-H37

G2

CIMR-H45

G2

Open

Chassis

Typo

265

(1043)

250

(9 .84)

W

1

Enclosed

Type

445

465

(NEMA

1)

(17

.52)

(18

.31)

Open

Chassis

Type

535

(21

.06)

705

(27

.76)

H1

Enclosed

Type

600

775

(NEMA

1)

(23

.62)

(30

.51)

Open

Chassis

Type

M6

M8

d

Enclosed

Type

M8

M8

(NEMA

1)

AIR

4

Allowable

temperature

_

of control

part

55'C

-

i

41E

AIR

Page 6

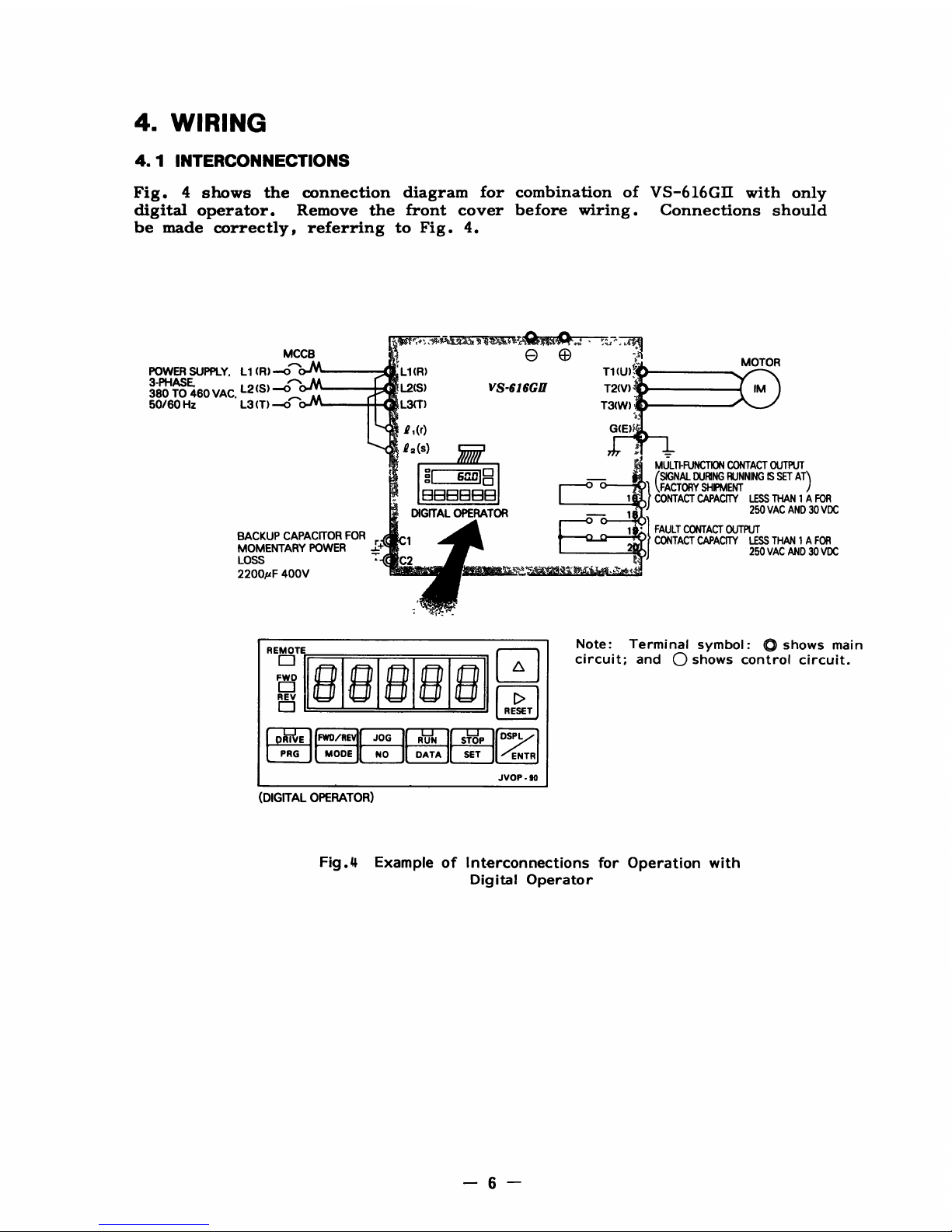

4.WIRING

4

.1

INTERCONNECTIONS

Fig

.4shows

the

connection

diagram

for

combination

of

VS-616GII

with

only

digital

operator

.

Remove

the

front

cover

before wiring

.

Connections

should

be

made

correctly,

referring

to

Fig.4

.

MCCB

POWER

SUPPLY.L1(R)

-o

L1(R)

3-PHASE'

L2(S)

L2(S)

V$-616GH

T2(V)

s

380TO460

VAC

.

-

50/80

Hz

L3

(T)

L3(T)

T3(W)

p,(r)

G(E)I

a-

12(S)

r

i

MULTI-FUNCTION

CONTACTOUTPUT

e

6^-0

C3

-

(SIGNAL

DURING

RUNNINGISSET AT)

FACTORY

SHIPMENT

16BBBE39

1CONTACT

CAPACITY

LESS

THAN1A

FOR

xDIGITAL

OPERATOR

~&

r----o

(DIGITAL

OPERATOR)

'

'

MOTOR

Note

:Terminal

symbol

:

®

shows

main

circuit;and

0

shows

control

circuit

.

T1(U)'

-

Fig

.4

Example

of

Interconnections

for

Operation

with

Digital

Operator

REMOTE

0

Fw0

II/~I

11011

I%II

ilI III

c-

1

i

REV

J

RESET

FWD/R

JOG

RUN

STOP

DS~

PRG

MODE

NO

DATA

SET

ENTR

JVOP-90

Page 7

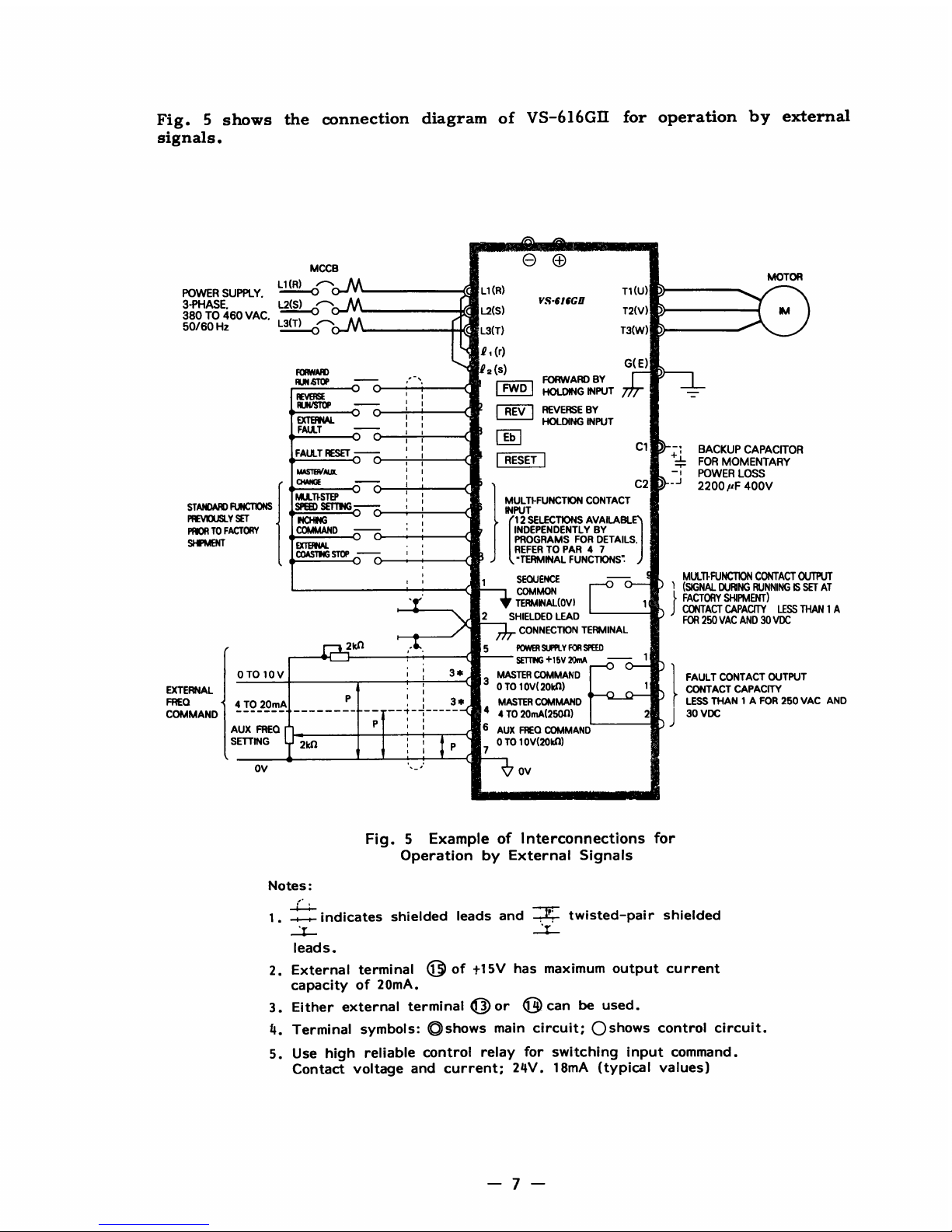

Fig.5

shows

the

connection

diagram

of

VS-616GII

for

operation

by

external

signals

.

OV

MCCB

'

Notes

:

MOTOR

b

OV

Fig.5

Example

of

Interconnections

for

Operation

by

External

Signals

1 .

-,r-indicates

shielded

leads

and

=

twisted-pair

shielded

2.External

terminal

1© oft15V

has

maximum

output

current

capacity

of

20mA

.

3.Either

external terminal03or

0

can

be

used

.

Terminal

symbols

:

®shows

main

circuit;0shows

control

circuit

.

5.Use

high

reliable

control

relay

for

switching

input

command

.

Contact

voltage

and current;24V.18mA

(typical

values)

STANDARD

PREVIOUSLY

PRIOR

TO

SHIPMW

FUNCTIONS

SET

FACTORY

MULTFSTEP

SP®

MCHNG

A6

COMMAND

jl~

I

11

.v

y

SETTNG

-

w

i

MULTI-FUNCTION

CONTACT

INPUT

12

SELECTIONS

AVAILABL

INDEPENDENTLY

BY

PROGRAMS

FOR

DETAILS

.

REFER

TOPAR

4 7

'TERMINAL

FUNCTIONS"

.

'

SEOUENCE

MULTFHJNCTIUN

GONTACT

OUTPUT

1

COMMON

(SIGNAL

DURING

RUNNINGISSET

AT

i

TERMINAL(OV)

1

FACTORY

SHIPMENT)

CONTACT

CAPACITY

LESS

THAN1A

2

SHIELDED

LEAD

FOR

250

VAC

AND

30

VDC

CONNECTION

TERMINAL

2 5 POWER

SUPPLY

FOR

SPEED

SETTNC

+15V 2OmA

1

0TO10V

3

*

3

MASTER

COMMAND

FAULT

CONTACT

OUTPUT

EXTERNAL

0TO10V(

20141)

1

CONTACT

CAPACITY

FRED

4TO20mA

3

*

MASTER

COMMAND

LESS

THAN

1

AFOR

250

VAC

AND

COMMAND

4

4TO20mA(25011)

2

30VDC

AUX

FRED

P

'

'

6

AUX

FREO

COMMAND

SETTING

2kr1

I

0

To

10V(20kf1)

P

7

POWER

SUPPLY

.

-

(R)

0

C

3-PHASE

.

L2(S)

380TO460

VAC

.

0

0-M

50/60Hz

L3(

0

0-M

L1

(R)

VS-616GH

L2(S)

L3(T)

T1(U)

T2(V)

T3(W)

IM

FORIAMAD

X2(S)

G(E)

RUNSTOP

,'

"

FORWARD

BY

O

I

FWD

BOLDING

INPUT

RUN

/STOP

O

'

'm

REV

REVERSE

BY

EXTEINAL

FAULT

Eb

FAULT

RESET

C1

-'

BACKUP

CAPACITOR

O

RESET

+

T

FOR

MOMENTARY

MKST6VNAL

POWER

LOSS

CKVQE

'

C2

' _j

2200pF

400V

Page 8

4.2MOLDED-CASE

CIRCUIT

BREAKER

(MCCB)

AND

POWER

SUPPLY

MAGNETIC

CONTACTOR

(MC)

Be

sure

to

connect

MCCBs

between

_power

supply

and

VS-616GIE

input

termi-

nals

®

T~).

Recommended

MCCBs

are

listed

in

Table2.

When

a

ground

fault

interrupter

is

used

to

prevent

malfunction,

setting

current

should

be

200mA

or

over

and

operating

time,

0.1sec

or

over

.

*Comply

with

NEMA

AB1

.

4

.3

SURGE

ABSORBER

Table

2Molded-Case

Circuit

Breakers

and

Magnetic

Contactors

For

the

surge

absorbers

to

be

connected

to

the

coils

of

relays,

magnetic

contactors,

magnetic

valves,

or

magnetic

relays,

select

types

from

the

ones

*Made

by

MARCON

Electronics

.

IMPORTANT

Lead

size

should

be

determined

considering

voltage

drop

of

leads.Refer

to

APPENDIX

10

"WIRE

SIZE"

.

ModelCIMR-

H18.5G2

H22G2

H30G2 H37G2

H45G2

VS-616GI

Capacity

kVA

34

41

54 68

82

Rated Output

Current

A

45 54

72 90

108

Mitsubishi

Molded-Case

Circuit

Breaker

Model

and

Rated

Current*

*

NF100

1

OOA

NF100

100A

NF100

100A

NF225

150A

NF225

150A

Yaskawa

Magnetic

Contactors

Model

HI-50E HI-50E HI-80E

HI-100E HI-100E

listed in

Table3.

Table 3 Surge Absorbers

Cods

of

Magnetic

Contactor

Surge

Absorber*

and

Control

Relay

Model

Specifications

CodeNo.

Large-size

Magnetic

DCR250A22E

I

250

VAC

0.5pF+

200

El

C002417

Contactors

Control

Relay

LY-2,-3(OMRON)

DC132-

I

250

VAC

C002482

HH-22.-23

(Fuji)

10A25C

0

.1pF

+

100(l

MM-2.-4

(OMRON)

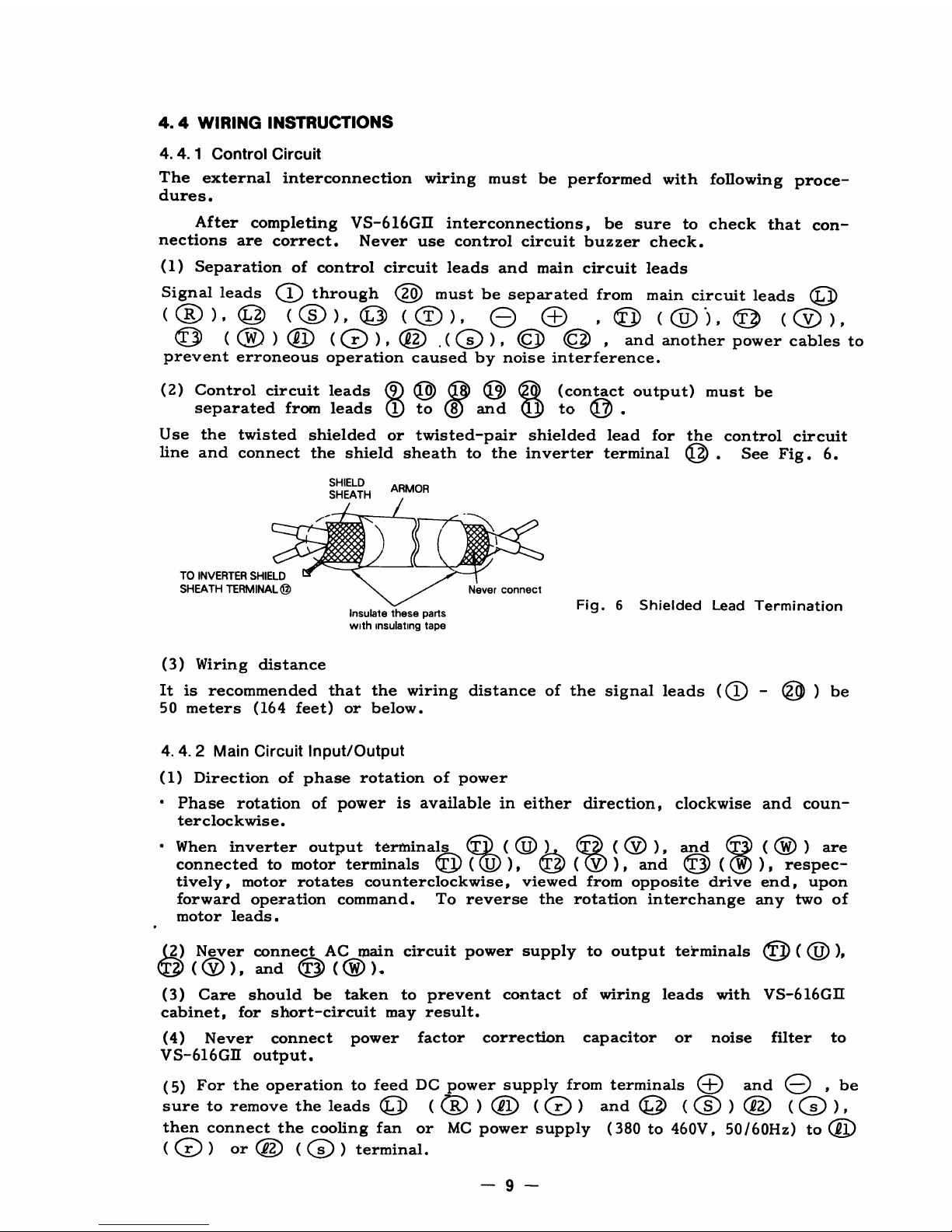

Page 9

4

.4

WIRINGINSTRUCTIONS

4.4.1Control

Circuit

The

external

interconnection wiring

must

be

performed

with

following

proce-

dures

.

After

completing

VS-616GII

interconnections,

be

sure

to

check

that

con-

nections

are

correct.Never

use

control

circuit

buzzer

check

.

(1)

Separation

of

control

circuit

leads

and

main

circuit

leads

Signal leads

Ol

through

20

must be

separatedfrom main

circuit

leads

c

tT

IN

®),

Q

c0),

~

c0),

~

~+,

©

cQo,

©

c0),

©

(

Q

)

0

((D),

©2

J(D)

,

©©

,

and

another

power

cables

to

prevent

erroneous

operation

caused

by

noise

interference

.

(2)

Control

circuit

leads

9

00

®

a

(contact

output)

must

be

separated

from leads

1

to

8

and

to

©

.

Use

the

twisted shielded

or

twisted-pair

shielded

lead

for

the

control

circuit

line

and

connect

the

shield

sheath

to

the

inverter

terminal

©

.

See

Fig.6

.

(3)

Wiring

distance

It

is

recommended

that

the

wiring

distance

of

the

signal

leads

(~

-

®)

be

50

meters

(164

feet)

or

below

.

4.4.2 Main

Circuit

Input/Output

(1)

Direction

of

phase

rotation

of

power

"

Phase

rotation

of

power

is

available

in either direction,

clockwise

and

coun-

terclockwise

.

"

When

inverter

output

terminals

(

QU

)

(

~

V),

and

(QW

)

are

connected

to

motor

terminals©(U

)

,

(V),and

(

),respec-

tively,

motor

rotates

counterclockwise,

viewed

from

opposite

drive

end,

upon

forward

operation

command

.

To

reverse

the

rotation

interchange

any

two

of

motor

leads

.

(3)

Care

should

be

taken

to

prevent

contact

of

wiring

leads

with

VS-616GII

cabinet,

for

short-circuit

may

result

.

(4)

Never

connect

power

factor

correction

capacitor

or

noise

filter

to

VS-616GH

output

.

(5)

For

the

operationtofeed

DC

power

supply

from

terminals

0

and

0

,

be

sure

to

remove

the

leads

©

(~R)Ql(

(D)

and

©

(S)Q2

(

(s) ,

then

connect

the

cooling

fan

or

MC

power

supply

(380

to

460V, 50/60Hz)

to

or

Q2(

Os

)

terminal

.

2)Never

connect

AC

main

circuit

power

supply

to

output

terminals

8

©(O

),

(O),

and

Q

(O)

.

Insulate

these

parts

with

insulating

tape

Fig.6

Shielded

Lead

Termination

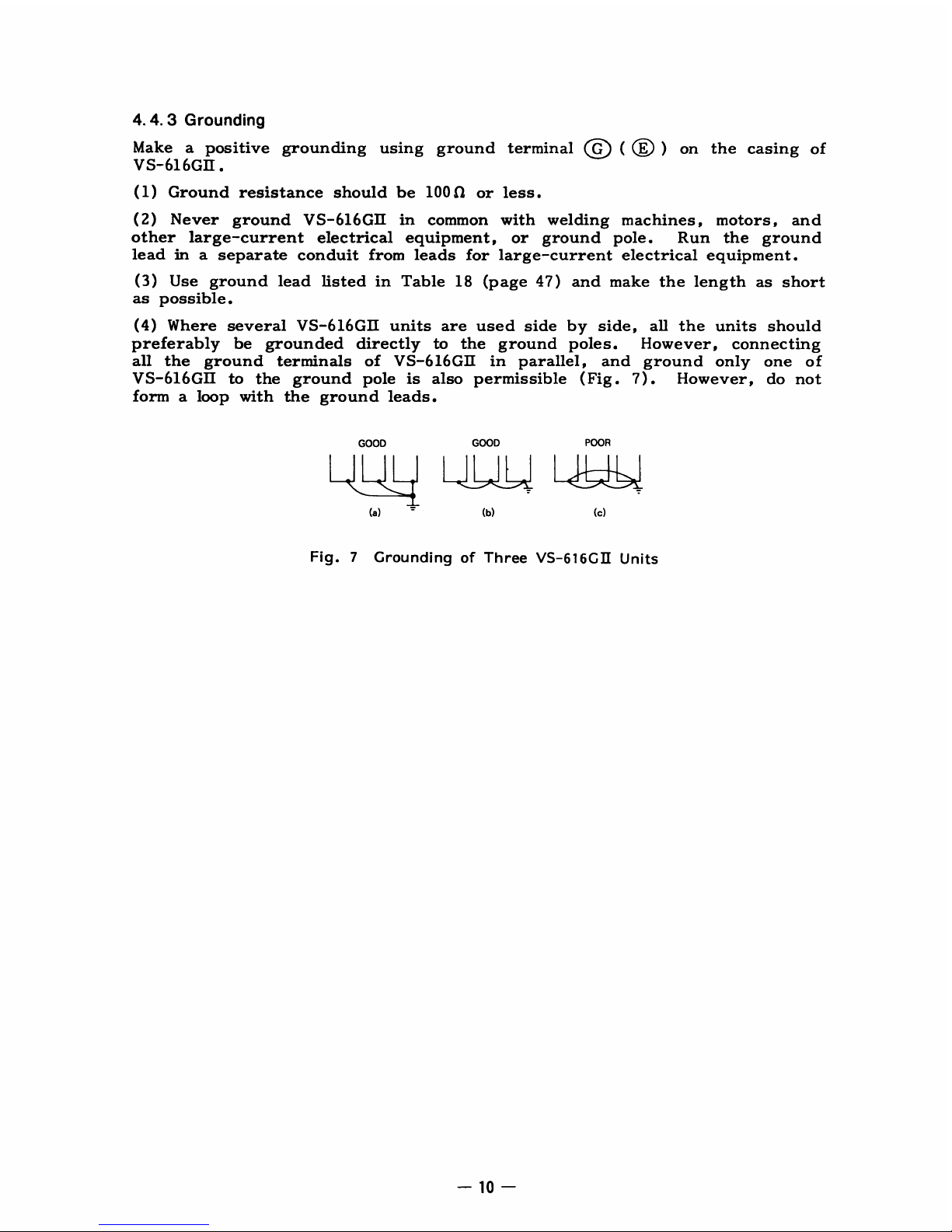

Page 10

4

.4

.3

Grounding

Make

a

positive

grounding

using

ground

terminal

O

()

on

the

casing

of

V

S-616GII

.

(1)

Ground

resistance

should

be

10013

or

less

.

(2)

Never

ground

VS-616GII

in

common

with

welding

machines,

motors,

and

other

large-current

electrical

equipment,

or

ground

pole

.

Run

the

ground

lead

in

a separate

conduit

from

leads

for

large-current

electrical

equipment

.

(3)

Use ground

lead

listedinTable

18

(page

47)

and

make

the length

as

short

as

possible

.

(4)

Where

several

VS-616GII

units are

used

side

by

side,

all

the

units

should

preferably

be

grounded

directly

to

the

ground

poles.However,

connecting

all

the

ground

terminals

of

VS-616GII

in

parallel,

and

ground

only

one

of

V

S-616GII

to

the

ground

pole

is

also

permissible

(Fig

.

7)

.

However,

do

not

formaloop with

the

ground

leads

.

4

1

(a)

GOOD GOOD

POOR

Fig.7

Grounding

of

Three

VS-616GII

Units

Page 11

5.TEST

RUN

5

.1

CHECKS

BEFORE

TEST

RUN

After

mounting

and

connection

are

completed,

check

for

:

"

Correct

connections

"

Short-circuit

conditions

"

Loose

screw

terminals

(Check

especially

for

loose

wire

clippings

.)

"

Proper

load

condition

"

Proper

power

voltage

selection

Select

the

proper

position

by

AC

main

circuit

power

voltage value

as

shown

in

right

figure,

and

set

the

connector

toit.

The

voltage

is

preset

to the

posi-

tion of

460V

prior

to

factory

shipment

.

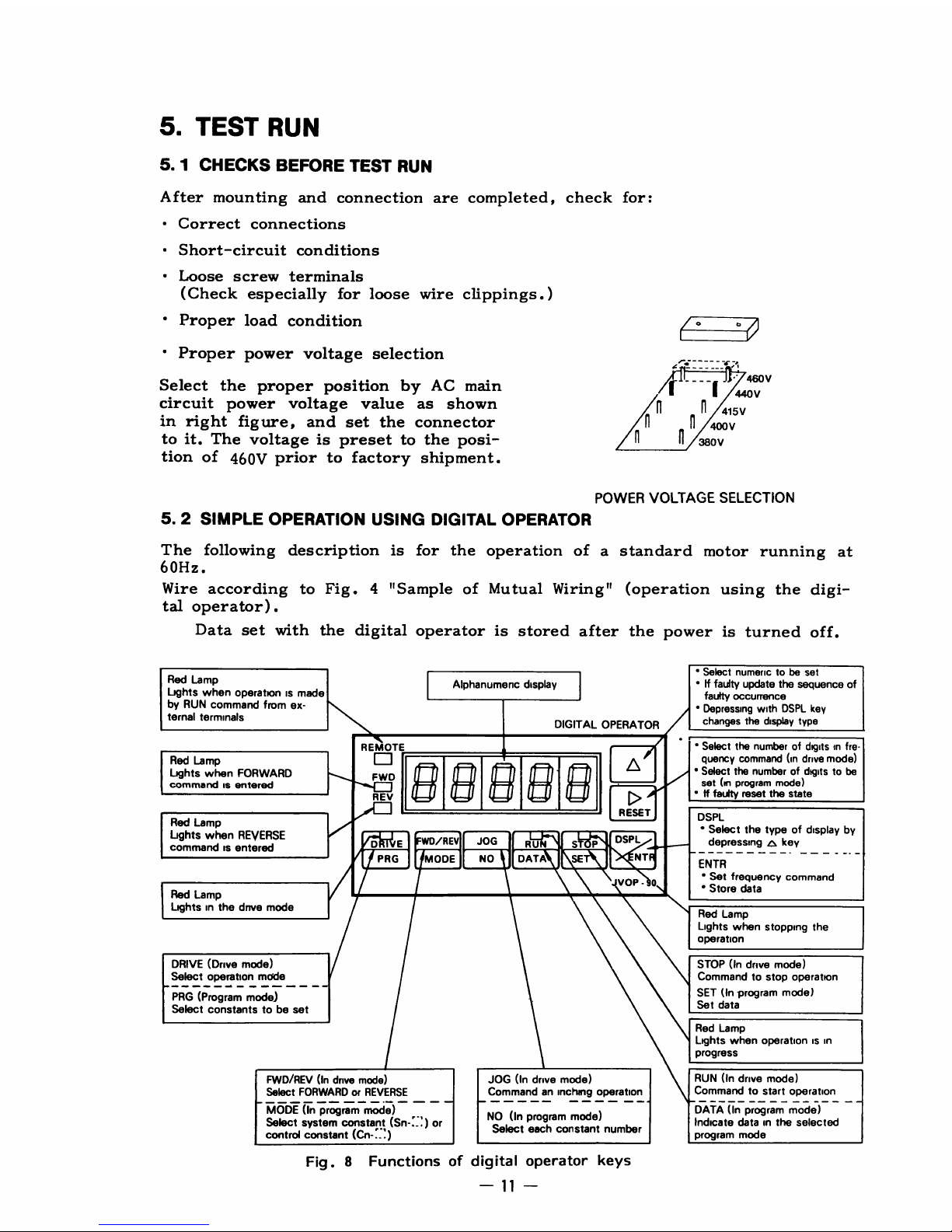

5

.2

SIMPLE

OPERATION

USING

DIGITAL

OPERATOR

The

following

description

is

for the

operation

of a

standard

motor

running

at

60Hz

.

Wire

according

to

Fig.4

"Sample

of

Mutual

Wiring" (operation

using

the

digi-

tal

operator)

.

Data

set

with

the

digital

operator

is

stored

after

the

power

is

turned

off

.

Red

Lamp

Lights

when

operationismade

by

RUN

command

from

ex-

ternal

terminals

Red

Lamp

Lights

when

FORWARD

command

is

entered

Red

Lamp

Lights

when

REVERSE

commandisentered

Red

Lamp

Lightsinthe

drive

mode

DRIVE

(Drive

mode)

Select

operation

mode

PRG

(Program

mode)

Select

constantstobe

set

k

J

FWD/REV

(In

drive

mode)

Select

FORWARDorREVERSE

MODE

(In

program

mode)

Select

system

constant

(Sri-

:_ :)

or

control

constant

(Cn-'_'

)

Alphanumenc

display

POWER

VOLTAGE

SELECTION

JOG

(In

drive

mode)

Commandaninching

operation

NO

(In

program

mode)

Select

each

constant

number

DIGITAL

OPERATOR

Fig.8 Functions

of

digital

operator

keys

/--

----

-7

l

V

4MV

440V

415V

400V

380V

'

Select

numerictobe

set

"Iffaulty

update

the

sequence

of

faulty

occurrence

'

Depressing

with

DSPL

key

changes

the

display

type

"

Select

the

numberofdigitsmfre-

quency

command

(in

drive

mode)

"

Select the

numberofdigitstobe

set(mprogram

mode)

' If

faulty

reset the state

DSPL

"

Select

the

typeofdisplay

by

depressing

p

key--

-

ENTR

'

Set

frequency

command

"

Store

data

Red

Lamp

Lights

when

stopping

the

operation

STOP

(In

drive

mode)

Commandtostop

operation

SET

(In

program

mode)

Set

data

Red

Lamp

Lights

when

operation

is in

progress

RUN

(In

drive

mode)

Command

to

start

operation

DATA

(In

program

mode)

Indicate

datainthe

selected

program

mode

w

REMOTE

0

FWD

Q

/

REV

RESET

D

F

G

E

WD/REV

JOG

RU

1

S

P

3

~

DSPL

~NT

VOP-

0

Page 12

5.2.1Set and

Operate

Frequency

Command

DRIVE

Set

frequency

command

in

drive

mode

(

PRc

Setting

DsP~

"

(1)

Depress

1n

while

depressing

then

the

frequency

command

appears

.

When

thisisrepeated,

the

display

changes

as

follows.See

(3) for

details

.

F~OUENCYC

OMMAND

OUTPUTFREQUENCY

}---~

OUTPUT

CURRENT

F--~

CONTENTOFBAST

FALURE

uuu.

u

FREQUENCY

COMMAND

IN

THE

LASTTIME

,

(2)

Using

RESET

flash

can

be

moved

to

the

digittobe

set,

and

the

numeric

set

with

[7o

key

.

(3)

Depress

DSP

NTR

to

store

the

frequency

command

value

.

(Stored

data

is

maintained

when

the

power

is

off

.)

DSP~L

(4)

Depress

17o

while

depressing

~NTR

to

select

the

output

frequency

to

be

indicated

.

Operation

FWD/REV

(5)

Depress

MODE

to

select

the

motor

rotating direction

.

RUN

(6)

Depress

DATA

to

give

run

command.The

motor

accelerates

acoording

to

the

specified

acceleration

time

(10

s)

and

holds

the

speed

at

the

specified

frequency

.

Stop

operation

STOP

(7)

Depress

SET

to

stop

the

motor.The

motor

decelerates

according

to

the

specified

deceleration

time

(10s).

Page 13

5.2.2

Monitor

Function'of

Digital

Operator

(a)

Output

freuency

display

The

output

frequencyappears

in

units

of0.1

Hz

.

7l

1~

1-11-

1

_I

0

1.1,1

.1

(-)

appears

for

reverse

rotation

(b)

Frequency

command

display

The

following

display

appears

in

units

of

0

.1Hz,

depending

on

the

operation

performed

with

the

frequency

command

either

from

the

external

terminal

or

digital

operator

.

(1)

Operation

by frequency

command

from

the

external

terminal

The

frequency

command

specified

from

the

external

terminal

appears

.

1

C

_I

1_I1_I

,1_I

Indicates

frequency

commandisappearing

(2)

Operation

by

frequency

command

from

the

digital

operator

.

The

frequency

command

specified

from

the

digital

operator

appears

.

The

digit

which

is

flashing

can

be

changed

.

A

frequency

command

can

also

be

set

.

1=

=1

1=

1~1

r1

1

IT

---

Flashing

L

Indicates

frequency

commandisappearing

(c)

Output

current

display

The

inverter

output

current

appears

in

units

of 0.1A

.

:I

1

0

1,

1_I

1

1

Indicates

currentisflowing

Page 14

5

.3

ADJUSTMENT

AND

SETTING

The

VS-616GIIhas

the

following

two

constants

to

select the

function

and

change

the

characteristics

.

Before

starting

operation,

set

these

constants

to

meet

the

operation

condition

.

"

System

constants

(Sn-O1

to

Sn-12)

:

Mainly

used

to

select

V/f

and

the

function

of

external

terminals

(Table

4)

.

"

Control

constants

(Cn-O1

to

Cn-30)

:

Mainly

used

to

change

characteristics

(Table

5)

.

Table

4

System

Constants

(S

n

Swill

.

Name

Function

Setting

Value

at

Factca

"

ent

SI

WA

selection

Sets

printed

circuit

board

constants

commonly

Used

for

multiple

inverters

Already

set

pare

pan

needs

01

S

ew

setting

16

V/f

patterns

are

available

for

use so

that

the

operation

suitedtothe

motor

4cxty

1

02

V/f

pattern

type load

characteristics.and

operation

condition

canbeperformed

selection

15

types

V/f

patternisScllectahln

try

snitinq0toE(See

lirule

29)

Z

1

type

V/f

pativrii

caii

tic

:

chancled by

sottirul

F

60Hr

03

-

-

0000

0

1

0011

1st

ControlledbyFregviwy

coniniarut ControlledbyFrequencycommaiicf

Operation

from

the

external

terminal

from the

digital

operator

04

signal

2nd

ControlledbyRun

corriniand

front

CctFOlled

by RIIn

Cnnlriland

from hK7i1

QiQq

selection

the

external

terminal

the

digital

operator

3rd

2nd

Main

speed

frequency

command

Main

speed

frequency

command

drq-1

r1Q1

3rd

0

.10V/0-100%

4-20mA/0100%

0

10V/100-096

4-20niA/100

0%

Reverse

allowed

/Controlledbydigital

4th

No

reverse

allowed

operator

1st

Operation stopsata

momentary

Operation

continuesata

power

failure

momentary

power

failure

Protection

2nd

Operation

stalls

during Operation

will

not

stall

chirinq

05

deceleration

deceleration

characteristics

3

rd

The

electronic

thermal

motor

The

electronic

thermal

motor

not

0000

selection

protected protected

4th

The

electronic

thermal

protector

The

electronic

thermal

protector

(reduced

torque)

(constant

torque)

1st

Overtoique not

detected

Oveitorque

detected

2nd

Overtorque

detected

during

speed

Overtorque

always

detected

06

Overlorque

synchronization

detection

3rdOperation

continues

Coasting

stop

0000

4th

I

1st

Used

when

the

pulse

monitor

(model

JOGB-C01)isinstalled

07

Optional

2nd

function

0000

selection

3rd

Used

when

the

interface

(model

JOGB-CO4)isinstalled

input

4th

08

xternalterminal05Select

terminal5functioninaccordance

with

table15(Page

351

0

09

I

terminalf3Select

terminal6functionnaccordance

with

table15(Page

35)

3

10

I

telminal7Select

terminal

7

function

in

accordance

with

table15(Page

35)

5

11

External

terminal

1.0Select

terminal8functioninaccordance

with

table15(Page

35)

6

12G_.~:-"

s~nrra

Select

contact output

function

in

accordance

with

table

17

(Page 40)

0

Termmai

Select

terminal(7functionofthe

output

interfaceinaccordance

with

table

0

13

Output

C~

17

(Page

401

interlace

model

terminal

Select

terminal(Dfunctionofthe

output

interfaceinaccordance

with

table

0

14

(

j0Ga

)

20

17

(Page

40)

terminal

Select

terminal

(1)

functionofthe

output

interfaceinaccordance

with

table

0

15

Open

ootleotor

p

O

17

(Page 40)

--

output

temanai

Select

terminal@functionofthe

output

interfaceinaccordance

with

table

0

16

O

17

(Page

40)

Page 15

Table

5

Control

Constants

(`nr

Control

ConstantNo.

Name

Unit

Setting

Range

Setting

Value

Prior

to

Factory

Shipment

rl

-01

Max

Frequency

(F

MAX)

01Hz

500

-

4000Hz

60Hz

02

Max

Voltage

(V

MAX)

0

1

V

00-4600V

400

V

03

Max

Voltage

Freq

(F

A)

01Hz

00-4000Hz

60

Hz

04

V/f

Constant

(F B)

01Hz

00

-

4000Hz 3

Hz

05

V/f

Constant(VC)

01V

00-

4600V

26V

06

Min

Output

Freq

(F

MIN)

01Hz 00-

4000Hz

1

5

Hz

07

Min

Output

Freq

Voltage

(V

MIN)

01V

00-

460

0V

14

V

08

Accel

Time

0

1

s

0

1

-18000S

100s

09

Decel

Time

01s

01-18000S

100s

10

DC

Injection

Braking

Voltage

01V

0

0-

2000

V

15V

1 1

DC

Injection

Braking

Timeatstop

0

1

s

00-1000S

05s

12

DC

Injection

Braking

Time

at start

01s

00-255s

00s

13

Freq

Command

Gain

001

001

-255

100

14

Freq

Command

Bias

01%

00-255%

00

1

5

Freq

Command

Upper

Limit

1

%

0-110%

100

16

Freq

Command

Lower

Limit

1

%

0-110%

0

1

7

Setting

Prohibited

Freq

1

01Hz

00

-

40001-1z

00

Hz

18

Setting

Prohibited

Freq

2

01Hz 00-

4000Hz

0

0 Hz

19

Setting

Prohibited

Freq

3

01Hz 00-

4000Hz

0

0 Hz

20

Motor

Rated

Current

01A

01-

3600A

See

Table12.

21

Carrier

Freq

Lower

1

Hz

380-2500Hz

380

Hz

22

Torque

Compensation

Gain

0

1

00-99

1

0

23

Over Torque

Detecting

Level

1

%

30-200%

160%

24

Freq

Monitor

Gain

001 001

-200

100

25

Current

Monitor

Gain

001

001

-200

100

26

Inching

Freq

01Hz

00-4000Hz

60Hz

27

Freq.Command

1

for

Multi-step

Run

01Hz

00-

40001-1z

1

00

Hz

28

Freq

Command

2

for

Multi-step

Run

01Hz

00-

4000Hz

1

0

0 Hz

29

Accel/Decel

Time

01s

01-18000S

100s

30

Save

Energy

Gain

1

%

0-120%

80%

31

Slip

Compensation

Gain

0

1

00-99

00

32

Speed

Display

(Freq,

RPM, Speed%.

etc)

1

0-39999

0

33

Optional

Speed

Agreed

Frequency

01Hz

00-

4000

Hz

00

Hz

Page 16

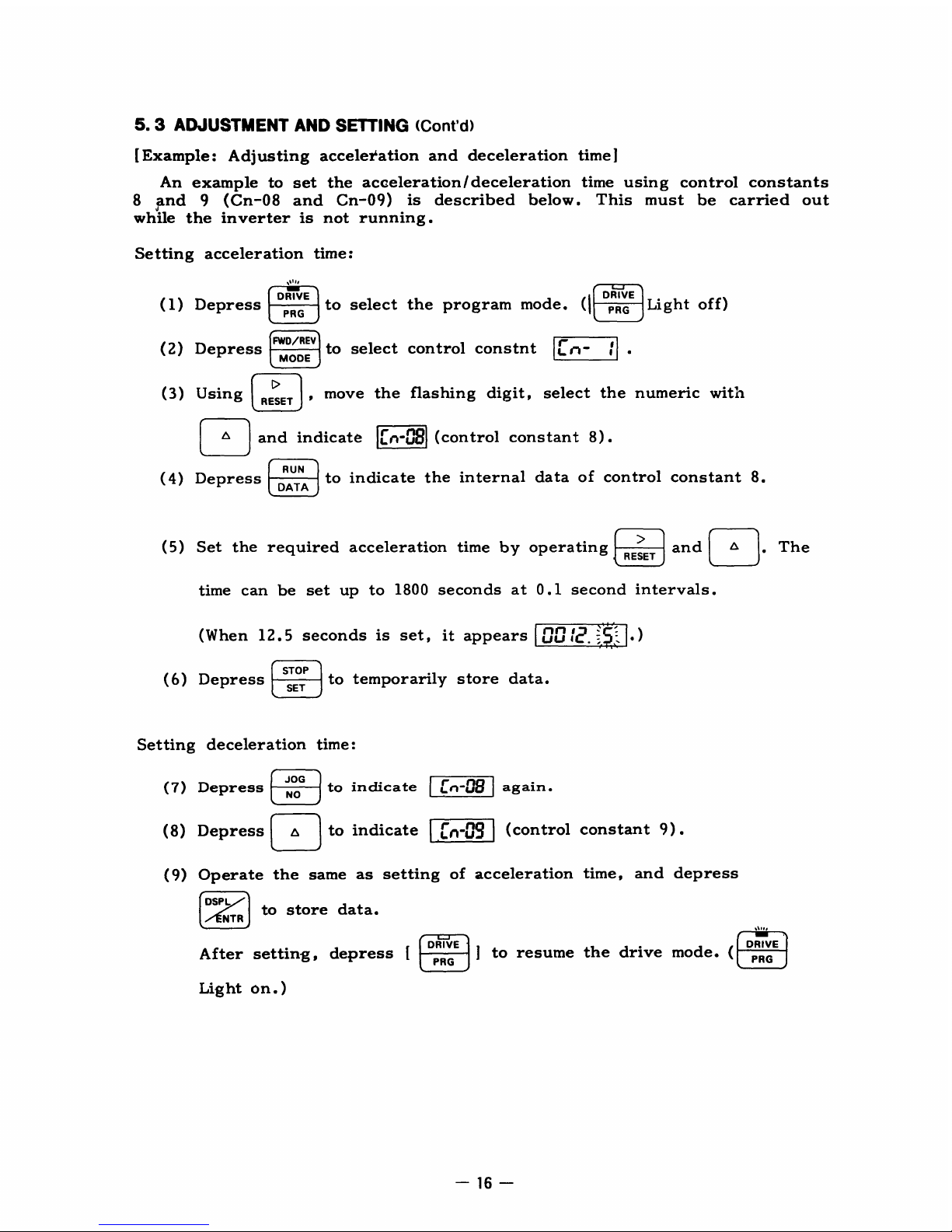

5

.3

ADJUSTMENT

AND

SETTING

(Cont'd)

[Example:Adjusting

acceleration

and

deceleration

time]

An

example

to

set

the

acceleration/

deceleration

time

using

control

constants

8

and

9

(Cn-08

and

Cn-09)

is

described

below.This

must be

carried

out

while

the inverter

is

not

running

.

Setting

acceleration

time

:

(1)

Depress

DRIVE

PRG

DRIVE

to select

the

program

mode

.

(I

PRG

Light

off)

(2)

Depress

FWD/REV

MODE

to

select

control

constnt

n-

;

(3)

Usin

g

I

RESET

I

move

the

flashing

digit,

select

the

numeric

with

with

and

indicate

ff

n

-

u

^

$

(control

constant

8)

.

(4)

Depress

DATA

to

indicate

the

internal

data

of

control

constant8.

(5)

Set

the

required

acceleration

time

by

operating

and

L-AI

.

The

RESET

time

can

be

set

up

to

1800

seconds

at0.1

second

intervals

.

(When

12.5seconds

is

set,

it

appears

UU;

.

)

STOP

(6)

Depress

SET

to

temporarily

store

data

.

Setting

deceleration time

(7)

Depress

JOG

ND

to

indicate

FL

F

n

-

u^$

again

.

(8)

Depress

1o

to

indicate

~n-n

(control

constant

9)

.

(9)

Operate

the

same

as

setting

of

acceleration

time,

and

depress

DSPL

to

store

data

.

NTR

DRIVE

After

setting,

depress

[

PRG

]

to

resume

the

drive

mode

.

Lighton. )

a1"

-77

DRIVE

,

PRG

Page 17

6.OPERATION

AT

LOAD

After

the

no-load

operation,

turn

off

the

AC

main

circuit

power,

and

connect

the

driven

machine

to

the

motor

.

Make

sure

that

the

driven

machine

is

in

running

condition,

and

that

proper

safety precaution

are

followed,

then

run

the

motor

under

load

in

exactly

the

same

way

as

the

test

run

.

For

preset

starting

(one-touch

operation

after setting

the

frequency)

Per-

form the

following

beforehand

:

(1)

Set

the

frequency

and

depress

onTn

to

accelerate

the

motor

in

the deter-

mined

time,

as

described

earlier,

and

to

maintain

the

rpm

at

the

preset

fre-

quency

.

If

the

acceleration

time

is

set

short

relative

to

the

load

and

if

the

rpm

of

the

accelerating

motor

is

not

smooth

(anti-stalling

function

during

acceleration

is

functioning)

;

or

if

trouble

is

displayed

on

the

digital

operator,

set

the

acceleration

time

longer

.

(2)

To

decelerate

the

motor

in

the preset

time

and

to

stop

it,

depress

STOP

T

T

while

the

motor

is

rotating

.

If

the

deceleration

time

is

set

short

relative to

the

load

and

if

the

rpm

of

the

decelerating

motor

is

not

smooth

(anti-stalling

function

during

deceleration

is

functioning);or

if

trouble

is

displayed

on

the

digital

operator,

set

the

deceleration

time

longer

.

(1)

Start

the

motor

after

making

sure

that

the

motor

is

stopped

.

If

the operation

is

started

during

motor

coasting,

use

the

control

constant

(Cn-12)

DC

Injection

Braking

Time

at

startintable5.

(2)

When

a

standard

motor

is

driven

with

the

inverter,

there

isalittle

increase

in

motor

temperature,

noise,

and

vibration

as

compared

to

the operation

from

the

commercial

power

sup-

ply

PRECAUTION

(3)

The

motor

cooling

effect

lowers

during

low-speed

run-

ning

.

The

torque

needs

to

be

reduced

in

accordance

with

the

frequency

.

(For the

reduction

ratio,

refer

to

the

cat-

alog

or

technical

sheet

.)

(4)

Even

with

small load,

never

use

a

motor

whose

current

exceeds

the

inverter

rating

.

(5)

When

two

or

more

motors

are

operated,

check

to

be

sure

that

the

total

motor

current

is

not

larger

than

inverter

rat-

ing

.

(6)

When

starting

and

stopping

the motor,

be

sure

to

use

the operation

signals

(FWD/REV),

not

the

magnetic

contactor

on

the

power

supply

side

.

Page 18

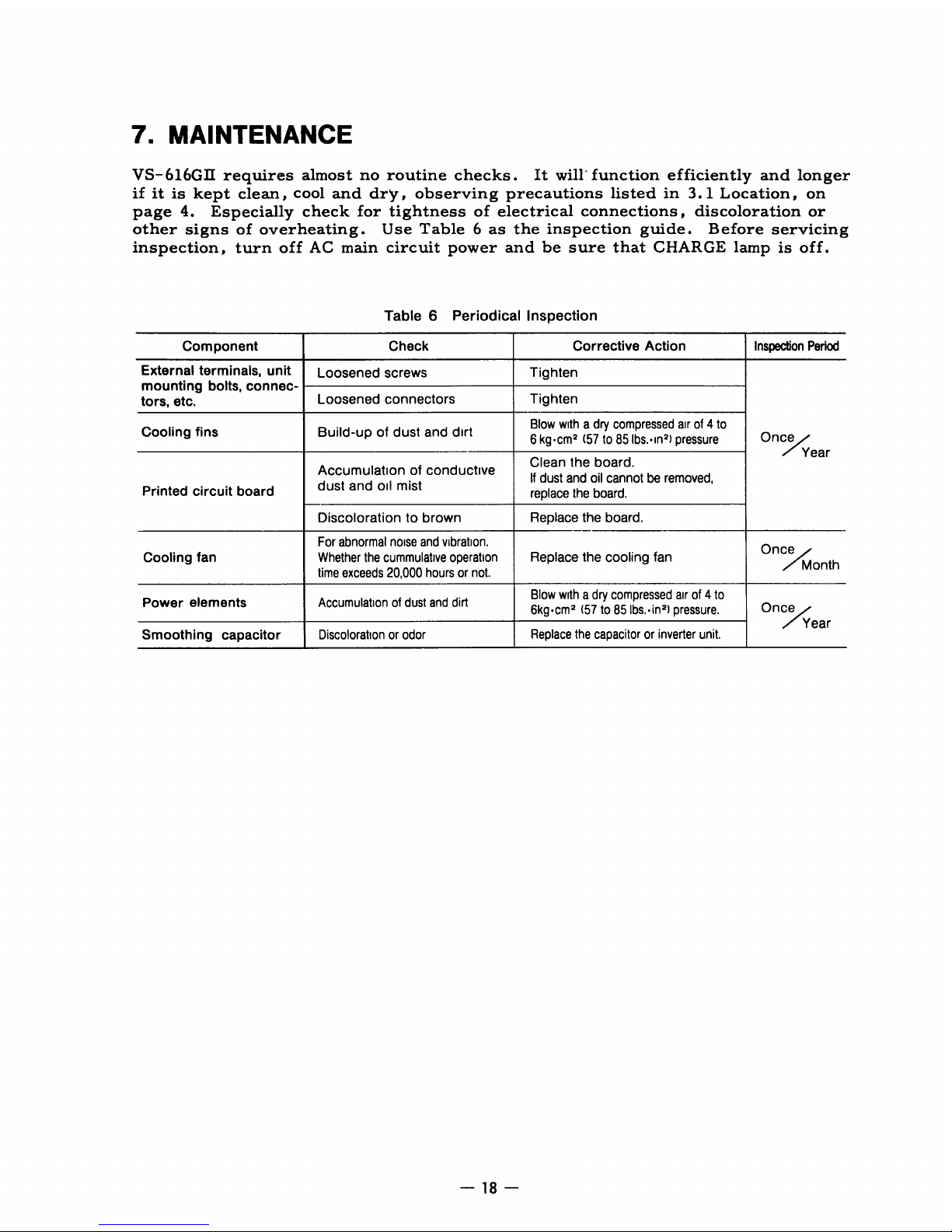

7.MAINTENANCE

VS-616GII

requires

almost

no

routine

checks

.It

will'

function

efficiently

and

longer

if

itiskept

clean,

cool

and

dry,

observing

precautions

listedin3.1Location,

on

page4.

Especially

check

for tightness of

electrical

connections,

discoloration

or

other

signs

of

overheating.Use

Table6as

the

inspection

guide.Before

servicing

inspection,

turn

off

AC

main

circuit

power

and

be

sure

that

CHARGE

lamp

is

off

.

Table

6

Periodical

Inspection

Component

Check

Corrective

Action

Inspection

Period

External

terminals,

unit

Loosened

screws

Tighten

mounting

bolts,

connec-

tors,

etc

.

Loosened

connectors

Tighten

Cooling

fins

Build-up

of

dust

and

dirt

Blow

withadry

compressed

airof4

to

Once

6kgcm

(57to85

lbs

.-in)

pressure

Year

Accumulation

of

conductive

Clean

the

board

.

dust

and

oil

mist

If

dust

and

oil

cannotberemoved,

Printed

circuit

board

replace

the

board

.

Discolorationtobrown

Replace

the

board

.

For

abnormal

noise

and

vibration

.

OnceOnce

Cooling

fan Whether

the

cummulative

operation

Replace

the cooling fan

time

exceeds

20,000

hoursornot

.

Power

elements

Accumulationofdust

and

dirt

Blow

with

a dry

compressed

airof4

to

Once

6kgcm2(57to85

Ibs..in

2)pressure

.

ear

Smoothing

capacitor

Discolorationorodor

Replace

the capacitororinverter

unit

.

Page 19

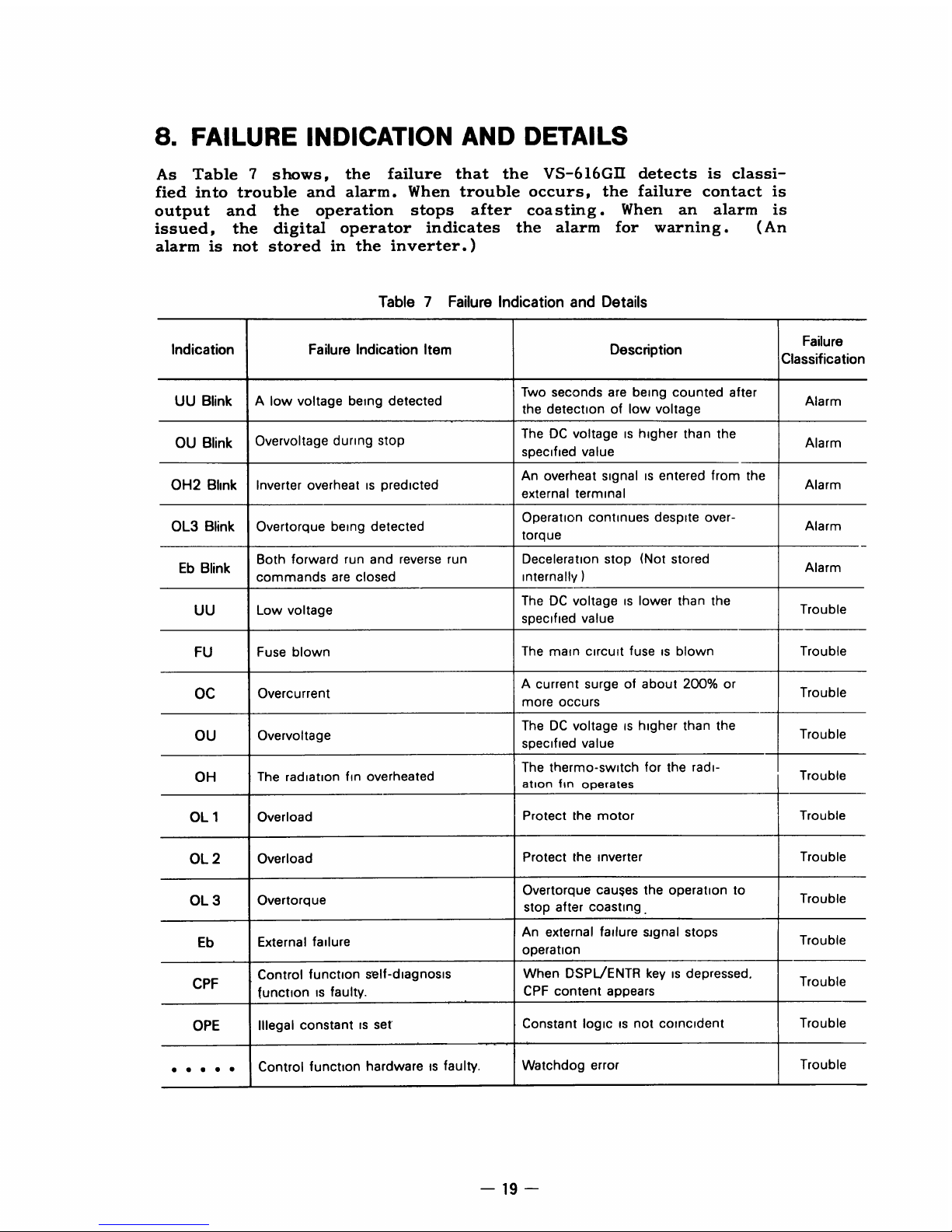

8.FAILURE

INDICATION

AND

DETAILS

As

Table

7

shows,

the

failure

that

the

VS-616GII

detects

is

classi-

fied

into

trouble

and

alarm.When

trouble occurs,

the

failure

contact

is

output

and

the

operation

stops

after

coasting

.

When

an

alarm

is

issued, the

digital

operator

indicates

the

alarm

for

warning

.

(An

alarm

is

not stored

in

the inverter

.)

Table

7Failure

Indication

and

Details

Indication

Failure

Indication

Item

Description

Failure

Classification

UU

Blink

A

low

voltage

being

detected

Two

seconds

are

being

counted

after

Alarm

the

detectionoflow

voltage

OU

Blink

Overvoltage

during

stop

TheDCvoltageishigher than

the

Alarm

specified

value

An

overheat

signalisentered

from

the

OH2

Blink

Inverter

overheatispredicted

Alarm

external

terminal

OL3

Blink

Overtorque being

detected

Operation

continues

despite

over-

Alarm

torque

Eb

Blink

Both

forward

run

and

reverse

run

Deceleration stop (Not

stored

Alarm

commands

are

closed

internally

)

TheDCvoltageislower

than

the

UU

Low

voltage

specified

value

Trouble

FU

Fuse

blown

The

main

circuit

fuseisblown

Trouble

OC

Overcurrent

A

current

surgeofabout 200°

or

Trouble

more

occurs

TheDCvoltageishigher

than

the

OU

Overvoltage

specified

value

Trouble

The

thermo-switch

for

the

radi-

OH

The

radiation

fin

overheated

fin

Trouble

ation

operates

OL

1

Overload

Protect

the

motor

Trouble

OL

2

Overload

Protect

the

inverter

Trouble

OL

3

Overtorque

Overtorque

cau$es

the operation

to

Trouble

stop

after

coasting

.

An

external

failure

signal

stops

Eb

External

failure

Trouble

operation

CPF

Control

function

self-diagnosis

When

DSPL/ENTR

keyisdepressed

.

Trouble

functionisfaulty

.

CPF

content appears

OPE

Illegal

constantisset"

Constant

logicisnot

coincident

Trouble

. ... .

Control

function

hardwareisfaulty

.

Watchdog