YASKAWA CIMR-ACA2022, CIMR-ACA45P5, CIMR-ACA Series, CIMR-ACA2045, CIMR-ACA4022 Instruction Manual

...Page 1

YASKAWA

Varispeed AC

INSTRUCTION MANUAL

Matrix Converter for Environmentally Friendly Motor Drives

Model: CIMR-ACA

200V Class 5.5 to 45kW ( 9 to 63kVA)

400V Class 5.5 to 75kW (10 to 114kVA)

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

YASKAWA

MANUAL NO. TOEP C710636 00D

Page 2

Copyright © 2005 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

Preface

This manual is designed to ensure correct and suitable

application of the Varispeed AC-Series Matrix Converter (referred to as the “MxC”). Read this manual

before attempting to install, operate, maintain, or

inspect the MxC. This manual should be kept in a safe,

convenient location for future reference. Be sure to

have a thorough understanding of all precautions and

safety information before attempting to use this product.

General Precautions

• The diagrams and illustrations in this manual may appear without the covers or safety shields that

are normally affixed to the actual product. This is to provide the user with a better idea of how

the interior of the MxC is designed. Be sure to restore all covers or shields before operating the

MxC, and to follow the instructions described in this manual once the application is running.

• Any illustrations, photographs, or examples used in this manual are provided as examples only.

Some illustrations may not apply to certain MxC models.

• The products and specifications described in this manual or the content and presentation of the

material may be changed without notice to improve the product and/or the manual.

• To order a new copy of this manual, contact your Yaskawa representatives or the nearest

Yaskawa sales office and provide the manual number shown on the front cover.

• If nameplates become warn or damaged, order new ones from your Yaskawa representatives or

the nearest Yaskawa sales office.

i

Page 4

Safety Information

IMPORTANT

WARNING

CAUTION

The symbols below appear throughout this manual to provide precautions and warnings. Failure

to heed the precautions listed in these pages can result in damage to the product or other

devices, even serious or fatal injury.

“WARNING” indicates a safety concern that if not heeded, could possibly result in serious injury

or loss of life.

“CAUTION” indicates that if the information is not heeded, could result in relatively serious or

minor injury, damage to the product, or faulty operation.

Failure to follow information listed as CAUTION can result in serious consequences.

Indicates important information that the user must be aware of while operating the MxC.

ii

Page 5

Safety Precautions

CAUTION

CAUTION

WARNING

Confirmations upon Delivery

• Never install an MxC that is damaged or has missing components.

Failure to do so may result in injury.

Installation

• Always hold the case when carrying the MxC.

If the MxC is held by the front cover, the main body of the MxC may fall, possibly resulting in injury.

• Attach the MxC to a noncombustible material, such as a metallic surface.

Attaching the MxC to combustible material may cause a fire.

• Install a cooling fan or other cooling device when installing more than one MxC in the same enclosure so that the temperature of the air entering the MxCs is below 45°C.

Fire or other damage may result if the MxC overheats.

Wiring

• Always turn off the input power supply before wiring terminals.

• Wiring must be performed by an authorized person qualified in electrical work.

• Be sure that the ground terminal is properly grounded.

• Always check emergency stop circuits after they are wired.

• Never touch the output terminals directly with your hands or allow the output lines to come into con-

• Before turning the power on, make sure that the power LED is off. If the unit is switched on while

• If the MxC is set up for a 3-wire sequence, then be sure that the multi-function input terminals have

Failure to do so may result in electric shock or fire.

Electric shock or fire may result if an untrained individual attempts to wire the MxC.

200 V class: Ground to 100 Ω or less 400 V class: Ground to 10 Ω or less

Failure to do so may result in electric shock or fire.

Failure to verify that all emergency stops are working properly may result in serious injury. The user is responsible for

properly wiring the product.

tact with the MxC case. Never short the output circuits.

Failure to do so may result in a ground short or electric shock.

the power LED is lit, the motor will start automatically.

Failure to check the power LED may result in injury.

been set properly before wiring the control circuit.

Failure to do so will cause the motor to rotate unexpectedly, and may result in damage or personal injury.

iii

Page 6

CAUTION

• Be sure that the ground terminal is properly grounded using a wire of the recommended size.

CAUTION

WARNING

200 V class: Ground to 100 Ω or less 400 V class: Ground to 10 Ω or less

If a wire smaller than the recommended size is used, the MxC may not operate properly.

• Check to be sure that the voltage of the main AC power supply satisfies the rated voltage of the

MxC.

Injury or fire may occur if the voltage is not correct.

• Do not perform voltage tolerance tests on the MxC.

Such tests may damage semiconductor components and other devices.

• Tighten all terminal screws to the specified tightening torque.

Failure to do so may result in fire.

• Do not connect AC power to output terminals U, V, and W.

Circuitry in the MxC will be damaged if voltage is applied to the output terminals.

• Do not wire AC power lines to terminals p1, n1, r2, s2, or t2. These terminals are used for connecting peripheral devices only.

Applying voltage to these terminals will damage the MxC.

• Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits.

The MxC may be damaged and circuitry may overheat if these devices are connected.

• Do not connect electromagnetic switches or magnetic contactors to the output circuits.

If a load is connected while the MxC is operating, a power surge will trigger the overcurrent protection circuit in the MxC.

Setting Parameters

• Disconnect the load (machine, device) from the motor before performing Rotational Auto-Tuning.

The motor may turn, possibly resulting in injury or damage to equipment. Also, motor constants cannot be correctly set

with the motor attached to a load.

• Stay clear of the motor during Rotational Auto-Tuning.

The motor may start operating suddenly when stopped, possibly resulting in injury.

Te st R un

• Make sure that the front cover is properly attached before turning on the power supply.

Failure to do so may result in electric shock.

• Leave a reasonable amount of space between yourself and the application when using the fault

reset function. The machine may start moving suddenly once the alarm is cleared.

The application should be designed to ensure safety when the MxC is restarted.

Failure to do so may result in injury.

• Provide a separate emergency stop switch (the STOP key on the digital operator works only when

it has been enabled).

Failure to do so may result in injury.

• Reset alarms only after confirming that the RUN signal has been switched off.

Failure to do so may result in injury.

iv

Page 7

CAUTION

• Do not touch the cooling fins (heatsink), braking resistor, or Braking Resistor Unit. These compo-

WARNING

CAUTION

nents can become extremely hot.

These components become hot enough to cause serious burns.

• Be sure that the motor and machine is within the applicable ranges before starting operation.

Failure to do so may result in injury.

• Provide a separate holding brake if necessary.

The external sequence should be designed to ensure that the holding brake is activated in the

event of an emergency, power failure, or fault in the MxC.

Failure to do so may result in injury.

• If using an MxC with an elevator, take proper steps to ensure safety and to prevent the elevator

from falling suddenly.

Failure to observe to do so may result in injury.

• Refrain from checking relay signals while the MxC is running.

Failure to do so may result in damage to the application.

• Be careful when changing any settings in the MxC. The default settings when the MxC is first

shipped are generally set to optimal values.

Failure to do so may result in damage to the application.

Maintenance and Inspection

• Do not touch the MxC terminals. Some of the terminals carry high voltages and are extremely dangerous.

Failure to do so may result in electric shock.

• Always have the protective cover in place when power is being supplied to the MxC. When attaching the cover, always turn off power to the MxC through the MCCB.

Failure to do so may result in electric shock.

• After turning the main circuit power supply off, wait until the CHARGE display light goes out before

performing maintenance or inspections.

The capacitor will remain charged and is dangerous.

• Maintenance, inspection, and replacement of parts must be performed authorized personnel only.

Remove all metal objects, such as watches and rings, before starting work. Always use grounded tools.

Failure to heed these warning may result in electric shock.

• Customers must provide the holding brakes.

Before making any adjustments other than those done in actual operations, be sure to tighten the holding brakes by using

an external sequence.

Failure to do so may result in electric shock.

• If the MxC is used with an elevator, be sure to take safety measures to prevent the car from falling.

Failure to do so may result in electric shock.

• A CMOS IC is used in the control board. Handle the control board and CMOS IC carefully.

The CMOS IC may be destroyed by static electricity if touched directly.

• Do not change any wiring and refrain from removing connectors or the digital operator while the

MxC is operating.

Failure to do so may result in injury.

v

Page 8

Other

WARNING

CAUTION

• Do not attempt to modify or alter the MxC.

Failure to do so may result in injury or electric shock.

• Contact your Yaskawa representative if you intend to use the MxC with a non-Yaskawa motor or

any other motor not listed in Yaskawa product literature.

The MxC can be used with three-phase induction motors with 2, 4, or 6 poles. A multi-pole motor with 8 poles or more, a

PM motor, or a motor designed for use with machine tools cannot be used with the MxC.

• Install adequate branch circuit short circuit protection per applicable codes.

Failure to comply may result in damage to the MxC.

The MxC is suitable for circuits capable of delivering not more than 100,000 RMS symmetrical Amperes, 220 Vac maximum (200 V Class) and 480 Vac maximum (400 V Class).

• If disinfectants or insecticides must be used to treat packing materials such as wooden frames, pallets, or plywood, the packing materials must be treated before the product is packaged, and methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed with fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes resulting from the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or iodine can

contribute to the erosion of the capacitors.

°C for 30

vi

Page 9

Location of Warning Information

Warning

information

position

Illustration shows a CIMR-ACA4011

!

WARNING

Risk of electric shock.

yRead manual before installing.

yWait 5 minutes for capacitor discharge

after disconnecting power supply.

!

AVERTISSEMENT

Risque de décharge électrique.

yLire le manuel avant l' installation.

yAttendre 5 minutes aprés la coupure de

l' allmentation. Pour permettre la

décharge des condensateurs.

y

y

!

Warning information is printed on the MxC as indicated in the following illustration. Obey all

warnings to prevent damage and injury.

Warning Information

Read this manual before installing the MxC.

vii

Page 10

Warranty Information

Free Warranty Period and Scope

Warranty Period

This product is warranted for twelve months after delivery to the customer, or if applicable,

eighteen months from the date of shipment from the Yaskawa factory, whichever comes first.

Scope of Warranty

Inspections

Periodic inspections must be conducted by the customer. However, upon request, someone from

Yaskawa or one of Yaskawa’s Service Centers can inspect the product for a fee. In this case, if

after conferring with the customer, a Yaskawa product is found to be defective due to Yaskawa

workmanship or materials and the defect occurs during the warranty period, then this fee will be

waived and the problem remedied free of charge.

Repairs

If a Yaskawa product is found to be defective due to Yaskawa workmanship or materials and the

defect occurs during the warranty period, Yaskawa will provide a replacement, repair the defective product, and provide shipping to and from the site free of charge.

However, if the Yaskawa Authorized Service Center determines that the problem with a

Yaskawa product is not due to defects in Yaskawa’s workmanship or materials, then the customer will be responsible for the cost of any necessary repairs. Some problems that fall outside

the scope of this warranty are:

• Problems due to improper maintenance or handling, carelessness, or other reasons where the

customer is deemed responsible.

• Problems that result from any additions or modifications made to a Yaskawa product without

having consulted Yaskawa first.

• Problems due to the use of a Yaskawa product outside the operation conditions specified in

the manual.

• Problems caused by natural disaster or fire.

• Any other problems not due to defects in Yaskawa workmanship or materials.

Warranty service is only applicable in Japan.

However, after-sales service is available for customers outside of Japan for a reasonable fee.

Contact your local Yaskawa representative for more information.

Exceptions

Any inconvenience to the customer or damage to non-Yaskawa products due to a defect in a

Yaskawa product, are not covered by this warranty, whether within or outside the warranty

period.

Restrictions

• The MxC was not designed or manufactured for use with devices or systems that may directly

threaten or harm anyone in any way.

• Customers who intend to use the product described in this manual for devices or systems

relating to transportation, health care, space aviation, atomic or electric power, or underwater

use must contact their Yaskawa representatives or the nearest Yaskawa sales office beforehand.

• This product has been manufactured under strict quality-control guidelines. However, if this

product is to be installed in any location where failure of this product could involve or result

in loss of human life or in a facility where failure may cause a serious accident or physical

injury, safety devices must be installed to minimize the likelihood of any accident.

viii

Page 11

Registered Trademarks

The following registered trademarks are used in this manual:

• CC-Link is a registered trademark of CC-Link Partner Association.

• DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendors Association, Inc.).

• CANopen is a registered trademark of CiA (CAN in Automation).

ix

Page 12

Contents

Safety Information .............................................................................................................ii

Safety Precautions ...........................................................................................................iii

Location of Warning Information ......................................................................................vii

Warranty Information ...................................................................................................... viii

Registered Trademarks ....................................................................................................ix

1 MxC Physical Installation .......................................................1-1

MxC Introduction .......................................................................................... 1-2

Introducing the MxC ....................................................................................................... 1-2

MxC Models ................................................................................................................... 1-3

Confirmations upon Delivery ........................................................................ 1-4

Checks ........................................................................................................................... 1-4

Nameplate Information ................................................................................................... 1-4

Component Names ........................................................................................................ 1-6

Exterior and Mounting Dimensions .............................................................. 1-7

Checking and Controlling the Installation Site.............................................. 1-9

Installation Site ...............................................................................................................1-9

Controlling the Ambient Temperature ............................................................................. 1-9

Protecting the MxC from Foreign Matter ........................................................................ 1-9

Installation Orientation and Clearance ....................................................... 1-10

Removing and Attaching the Terminal Cover ............................................. 1-11

Removing the Terminal Cover ...................................................................................... 1-11

Attaching the Terminal Cover ....................................................................................... 1-11

Removing/Attaching the Digital Operator and Front Cover........................1-12

2 Wiring .......................................................................................2-1

Connecting Peripheral Devices....................................................................2-2

Connection Diagram .................................................................................... 2-3

Terminal Block Configuration ....................................................................... 2-5

Wiring Main Circuit Terminals.......................................................................2-6

Applicable Wire Gauges and Closed-Loop Connectors ................................................. 2-6

Main Circuit Terminal Functions..................................................................................... 2-9

Main Circuit Configurations ............................................................................................ 2-9

Standard Connection Diagrams ................................................................................... 2-10

Input and Output Wiring in the Main Circuit.................................................................. 2-11

x

Wiring Control Circuit Terminals ................................................................. 2-16

Wire Gauges and Closed-Loop Connectors................................................................. 2-16

Control Circuit Terminal Functions ............................................................................... 2-19

Page 13

Control Circuit Terminal Connections ........................................................................... 2-23

Control Circuit Wiring Precautions................................................................................2-24

Wiring Check ..............................................................................................2-25

Checks..........................................................................................................................2-25

Installing and Wiring Option Cards .............................................................2-26

Option Card Models and Specifications........................................................................2-26

Installation.....................................................................................................................2-27

PG Speed Control Card Terminals and Specifications..................................................2-28

Wiring............................................................................................................................2-30

Wiring Terminal Blocks.................................................................................................2-32

Selecting the Number of PG (Encoder) Pulses ............................................................2-33

3 Digital Operator and Modes................................................... 3-1

Digital Operator ............................................................................................3-2

Overview of the Digital Operator.....................................................................................3-2

Digital Operator Keys......................................................................................................3-2

Operation Modes ..........................................................................................3-5

MxC Modes.....................................................................................................................3-5

Switching Between Modes..............................................................................................3-6

Drive Mode .....................................................................................................................3-7

Quick Programming Mode ..............................................................................................3-9

Advanced Programming Mode .....................................................................................3-10

Verify Mode...................................................................................................................3-13

Auto-Tuning Mode ........................................................................................................3-14

4 Test Run .................................................................................. 4-1

Test Run Procedure.....................................................................................4-2

Test Run Procedures ....................................................................................4-3

Switching the Power On .................................................................................................4-3

Checking the Display Status ...........................................................................................4-3

Basic Settings .................................................................................................................4-4

Settings for the Control Methods ....................................................................................4-6

Auto-Tuning ....................................................................................................................4-8

Application Settings ......................................................................................................4-12

No-load Operation ........................................................................................................4-12

Loaded Operation .........................................................................................................4-12

Saving Parameters .......................................................................................................4-13

Notes on Tuning the MxC...........................................................................4-14

5 Parameters and Settings........................................................ 5-1

Parameter Descriptions ................................................................................5-2

Understanding Parameter Tables ...................................................................................5-2

Digital Operation Display Functions and Levels ...........................................5-3

xi

Page 14

Quick Programming Mode and Available Parameters ................................................... 5-4

Parameter Tables .........................................................................................5-7

A: Initialization ................................................................................................................ 5-7

b: Application..................................................................................................................5-9

C: Auto-Tuning ............................................................................................................. 5-16

d: Reference................................................................................................................. 5-20

E: Motor Parameter...................................................................................................... 5-25

F: Option.......................................................................................................................5-29

H: Terminal Function .................................................................................................... 5-34

L: Protection Function .................................................................................................. 5-43

n: Special Adjustments................................................................................................. 5-50

o: Digital Operator ........................................................................................................ 5-52

T: Motor Auto-Tuning ................................................................................................... 5-55

U: Monitors ................................................................................................................... 5-57

Default Settings that Change with the Control Method (A1-02) ................................... 5-64

Defaults for Various MxC Capacities (o2-04) ............................................................... 5-65

6 Parameter Settings by Function ............................................6-1

Frequency Reference................................................................................... 6-2

Selecting the Frequency Reference Source................................................................... 6-2

Using Multi-Step Speed Operation................................................................................. 6-5

Run Command ............................................................................................. 6-7

MxC Functions ............................................................................................................... 6-7

Selecting the Run Command Source ............................................................................. 6-8

Stopping Methods ...................................................................................... 6-11

Selecting the Stopping Method when a Stop Command is Sent .................................. 6-11

Using DC Injection Braking .......................................................................................... 6-15

Using an Emergency Stop (“Fast Stop”) ...................................................................... 6-16

Acceleration and Deceleration Characteristics ..........................................6-17

Setting Acceleration and Deceleration Times............................................................... 6-17

Preventing the Motor from Stalling during Acceleration (Stall Prevention during

Acceleration Function).................................................................................................. 6-20

Preventing Motor Stall during Deceleration (Stall Prevention during Deceleration

Function) ...................................................................................................................... 6-23

Adjusting Frequency References ............................................................... 6-25

Adjusting Analog Frequency References ..................................................................... 6-25

Operation Avoiding Resonance (Jump Frequency Function)....................................... 6-28

Speed Limit (Frequency Reference Limit Function) ................................... 6-30

Limiting Maximum Output Frequency........................................................................... 6-30

Limiting Minimum Frequency ....................................................................................... 6-30

xii

Improved Operating Efficiency ................................................................... 6-32

Reducing Motor Speed Fluctuation (Slip Compensation Function).............................. 6-32

Compensating for Insufficient Torque at Startup and Low-Speed Operation

(Torque Compensation) ................................................................................................ 6-34

Hunting-Prevention Function........................................................................................ 6-36

Page 15

Stabilizing Speed (Speed Feedback Detection Function) ............................................6-37

Machine Protection.....................................................................................6-38

Reducing Noise and Leakage Current..........................................................................6-38

Limiting Motor Torque (Torque Limit Function).............................................................6-40

Stall Prevention during Run ..........................................................................................6-43

Changing Stall Prevention Level during Run Using an Analog Input............................6-44

Using Frequency Detection: L4-01 to L4-05 .................................................................6-44

Detecting Motor Torque ................................................................................................6-48

Changing Overtorque and Undertorque Detection Levels Using an Analog Input ....... 6-50

Motor Overload Protection............................................................................................6-51

Setting Motor Protection Operation Time .....................................................................6-53

Motor Overheating Protection Using PTC Thermistor Inputs .......................................6-54

Limiting Motor Rotation Direction..................................................................................6-55

Continuing Operation..................................................................................6-56

Restarting Automatically after Power is Restored ........................................................6-56

Speed Search ...............................................................................................................6-59

Continue Running after Frequency Reference Loss.....................................................6-64

Restarting Operation after Transient Fault (Auto-Restart Function) .............................6-65

MxC Protection ...........................................................................................6-66

Reducing MxC Overheating Pre-Alarm Warning Levels...............................................6-66

Input Terminal Functions ............................................................................6-67

Temporarily Switching Operation between Digital Operator and Control

Circuit Terminals ...........................................................................................................6-67

Blocking MxC Outputs (Baseblock Commands) ...........................................................6-68

Stopping Acceleration and Deceleration (Accel/Decel Ramp Hold) .............................6-69

Raising and Lowering Frequency References Using Contact Signals (UP/DOWN).....6-70

Accelerating and Decelerating Parameter Frequencies in the Analog References

(+/- Speed)....................................................................................................................6-73

Hold Analog Frequency Using User-set Timing............................................................6-74

Switching Operations between a Communications Option Card and Control

Circuit Terminals ...........................................................................................................6-74

Jog Frequency Operation without Forward and Reverse Commands

(FJOG/RJOG)...............................................................................................................6-75

Stopping the MxC by Notifying Programming Device Errors to the MxC (External Fault

Function).......................................................................................................................6-76

Output Terminal Functions..........................................................................6-77

Monitor Parameters ....................................................................................6-79

Using the Analog Monitor Parameters..........................................................................6-79

Individual Functions....................................................................................6-82

Using MEMOBUS Communications .............................................................................6-82

Using the Timer Function..............................................................................................6-93

Using PID Control .........................................................................................................6-94

Setting Motor Parameters...........................................................................................6-102

Setting the V/f Pattern.................................................................................................6-104

Torque Control............................................................................................................6-108

Speed Control (ASR) Structure................................................................................... 6-115

xiii

Page 16

Increasing the Speed Reference Response (Feed Forward Control) ........................ 6-120

Droop Control Function .............................................................................................. 6-121

Zero-Servo Function................................................................................................... 6-123

Digital Operator Functions........................................................................6-125

Setting Digital Operator Functions ............................................................................. 6-125

Copying Parameters................................................................................................... 6-128

Writing Parameters from the Digital Operator ............................................................ 6-133

Setting a Password .................................................................................................... 6-133

Displaying User-Set Parameters Only........................................................................ 6-134

Options.....................................................................................................6-135

Performing Speed Control with a PG Encoder ........................................................... 6-135

Using Digital Output Cards......................................................................................... 6-138

Using an Analog Reference Card............................................................................... 6-141

Using a Digital Speed Reference Card ...................................................................... 6-142

Elevator and Hoist Type Applications....................................................... 6-146

Brake On/Off Sequence ............................................................................................. 6-146

Auto-Tuning................................................................................................................ 6-147

Momentary Power Loss Ridethrough ......................................................................... 6-148

Torque Limit................................................................................................................ 6-148

I/O Phase Loss Protection and Overtorque Detection ...............................................6-148

External Baseblock Signal.......................................................................................... 6-148

Acceleration/Deceleration Time.................................................................................. 6-148

Output Side Magnetic Contactor ................................................................................ 6-148

Control Related Adjustments......................................................................................6-149

Reducing Shock at Start/Stop and during Acceleration/Deceleration......................... 6-151

Confirming Start Up Current and Reducing Carrier Frequency.................................. 6-154

Maintenance Timer Display Function ....................................................... 6-155

Settings Required to Enable the Maintenance Timer Display Function ..................... 6-155

Settings Required After Replacement of Cooling Fan or Capacitors on PCB Board . 6-156

7 Troubleshooting ......................................................................7-1

Protective and Diagnostic Functions............................................................7-2

Fault Detection ............................................................................................................... 7-2

Alarm Detection............................................................................................................ 7-10

Operation Errors........................................................................................................... 7-14

Errors During Auto-Tuning .......................................................................................... 7-15

Errors when Using the Digital Operator Copy Function................................................ 7-16

Troubleshooting.......................................................................................... 7-17

Trouble Setting Parameters.......................................................................................... 7-17

If the Motor Does Not Operate ..................................................................................... 7-18

Direction of the Motor Rotation is Reversed................................................................. 7-20

Motor Does Not Produce Torque or Acceleration is Slow ............................................ 7-20

Motor Operates Faster than the Frequency Reference................................................ 7-20

Slip Compensation Function has Low Speed Precision ............................................... 7-21

xiv

Page 17

Low Speed Control Accuracy at High-Speed Rotation in Open Loop Vector Control

Method..........................................................................................................................7-21

Motor Deceleration is Too Slow ....................................................................................7-21

Motor Overheat.............................................................................................................7-22

Noise is Produced from an AM Radio or when the MxC is Started ..............................7-23

Ground Fault Interrupter Operates while the MxC is Running......................................7-23

Mechanical Oscillation ..................................................................................................7-23

Torque Generated for the Motor is Insufficient (Insufficient Power)..............................7-24

Motor Rotates Even When MxC Output is Stopped......................................................7-24

OV or OC is Detected when the Fan is Started or Stalls ..............................................7-25

Output Frequency does not Reach the Specified Frequency Reference......................7-25

8 Maintenance and Inspection.................................................. 8-1

Maintenance and Inspection.........................................................................8-2

Limited Warranty.............................................................................................................8-2

Daily Inspection ..............................................................................................................8-2

Periodic Inspection .........................................................................................................8-2

Periodic Maintenance of Parts........................................................................................8-3

Precautions when Replacing the Control Board (1PCB) ................................................8-3

Types and Number of Cooling Fans Used in the MxC....................................................8-4

How to Replace the Cooling Fan ....................................................................................8-4

How to Remove or Install the Control-Circuit Terminal Board ......................................8-11

9 Specifications ......................................................................... 9-1

Standard MxC Specifications........................................................................9-2

Specifications by Model ..................................................................................................9-2

Common Specifications ..................................................................................................9-3

Specifications for Options and Peripheral Devices.......................................9-5

10 Appendix ............................................................................... 10-1

MxC Control Methods.................................................................................10-2

Control Methods and Features .....................................................................................10-2

Control Methods and Applications ................................................................................10-4

MxC Application Precautions......................................................................10-5

Selection .......................................................................................................................10-5

Installation.....................................................................................................................10-8

Settings.........................................................................................................................10-8

Handling........................................................................................................................10-8

Motor Application Precautions..................................................................10-10

Using the MxC to Run an Existing Standard Motor ....................................................10-10

Using the MxC for Motors other than Standard Yaskawa Motors ............................... 10-11

Power Transmission Mechanism (Speed Reducers, Belts, and Chains).................... 10-11

Wiring Examples.......................................................................................10-12

xv

Page 18

Using a VS Operator .................................................................................................. 10-12

Using Transistors for Input Signals and a 0 V Common in Sinking Mode with an Internal

Power Supply ............................................................................................................. 10-13

Using Transistors for Input Signals and a +24 V Common in Sourcing Mode ........... 10-14

Using Transistors for Input Signals and a 0 V Common in Sink Mode with an External

Power Supply ............................................................................................................. 10-15

Using Contact and Open Collector Outputs ............................................................... 10-16

Parameters............................................................................................... 10-17

Index

Revision History

xvi

Page 19

MxC Physical Installation

This chapter describes the requirements for receiving and installing the MxC.

MxC Introduction...........................................................1-2

Confirmations upon Delivery......................................... 1-4

Exterior and Mounting Dimensions...............................1-7

Checking and Controlling the Installation Site .............. 1-9

Installation Orientation and Clearance........................ 1-10

Removing and Attaching the Terminal Cover ............. 1-11

Removing/Attaching the Digital Operator and Front

Cover ..........................................................................1-12

Page 20

MxC Introduction

Reactor

Input current,

high harmonics

Braking resistor:

Emits regenerated power as heat

Regenerated

power

Braking unit

PWM inverter

Regenerated

power

Regenerated

power

Electric

power

Electric power

Power

Motor

PWM inverterPWM converter

AC filter

Regenerated

power

Electric

power

Regenerated

power

Electric

power

Power

Input current,

low harmonics

Motor

Introducing the MxC

The design of the MxC is simpler and more efficient than a conventional inverter. The MxC uses a different

mechanism to generate AC voltage, and relies on nine bi-directional switches to adjust AC output power to the

motor directly from an AC line power input.

The MxC has no rectifying diodes and no DC bus capacitors commonly used in inverters.

New Type: Varispeed AC (uses the MxC circuit, with no external devices)

Regenerated

Power

power

Input current,

low harmonics

Electric

power

MxC

Built-in AC filter

Regenerated

power

: Bi-directional

switches

Electric

power

Motor

Conventional Type: Requires a regenerative resistor discharging system and two external devices

1-2

Conventional Type: Harmonic filter and power regeneration system with two external devices

Page 21

MxC Introduction

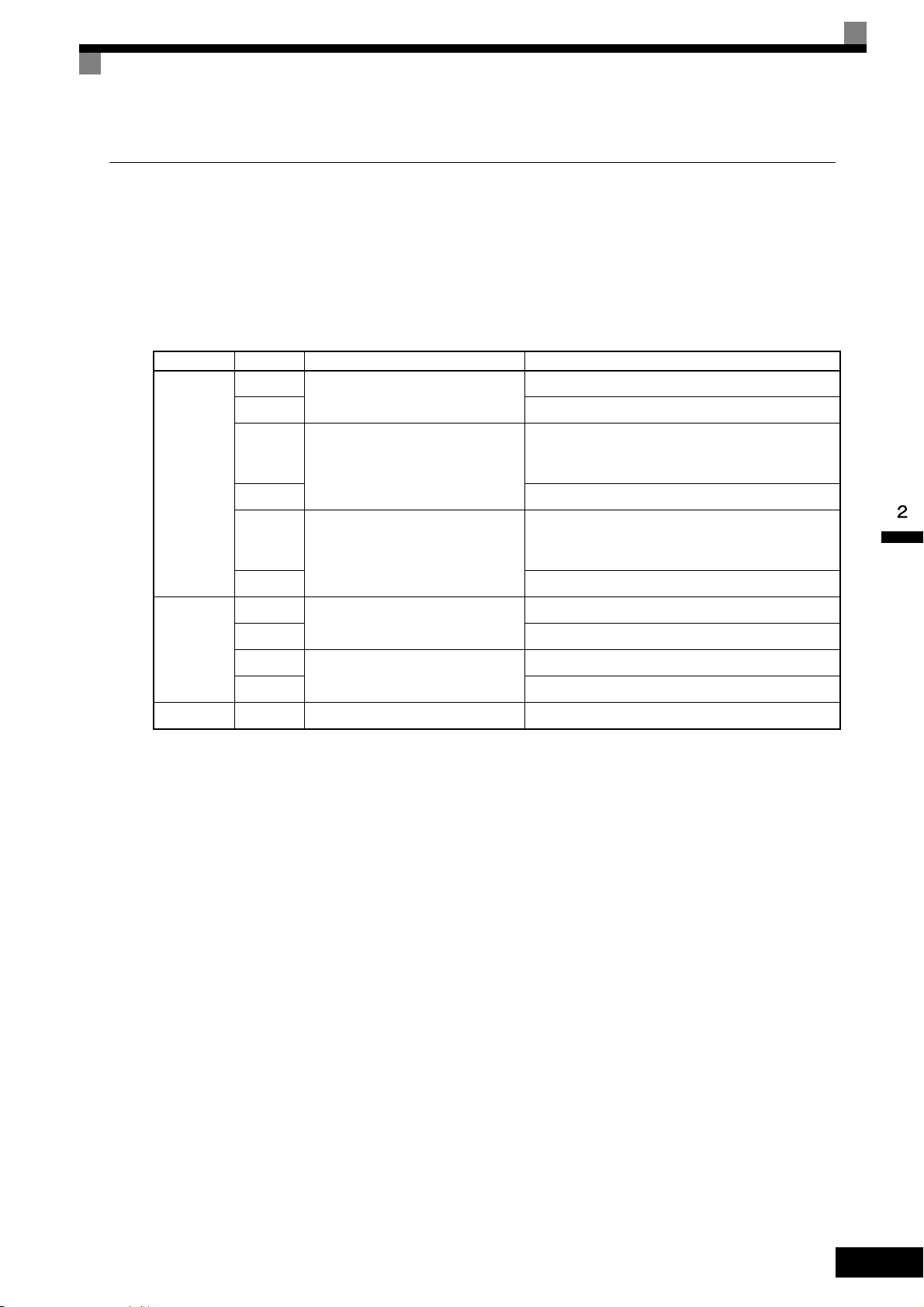

MxC Models

The various models of the MxC are separated into two voltage classes: 200 V and 400 V. Maximum motor capacities

vary from 5.5 to 75 kW to create a total of nine different models.

Table 1.1 MxC Models

Protection Specifications

Voltage

Class

200 V class

400 V class

* Under development.

Maximum

Motor

Capacity

kW

5.5 9 CIMR-ACA25P5 25P50 25P51

11 17 CIMR-ACA2011 20110 20111

22 33 CIMR-ACA2022 20220 20221

45 63 CIMR-ACA2045 20450 20451

5.5 10 CIMR-ACA45P5 45P50 45P51

11 19 CIMR-ACA4011 40110 40111

22 36 CIMR-ACA4022 40220 40221

45

*

75

Output

Capacity

kVA

67 CIMR-ACA4045 40450 40451

114 CIMR-ACA4075 40750 40750

MxC

Basic Model Number

(Always specify the protective design

required when placing an order)

Open Chassis

(IEC IP00)

CIMR-ACA

Enclosed Wall-mounted

[IEC IP20, NEMA 1 (Type 1)]

CIMR-ACA

1-3

Page 22

Confirmations upon Delivery

MxC model

Software version

Input specifications

Output specifications

Lot number

Serial number

MxC specifications

Weight

UL file number *

(+.'01'

/1&'.%+/4#%#

+0276#%2*8*\#

176276#%2*8*\#M8#

52'%

+2;#5-#9#'.'%64+%%14214#6+10

/#&'+0,#2#0

10 /#55MI

24)

50

* Pending for CIMR-ACA4045, and -4075.

Checks

Check the following items as soon as you have received the MxC.

Table 1.2 Checks

Item Method

Has the correct model of MxC been delivered?

Check the model number on the nameplate attached to the side of the MxC.

Is the MxC damaged in any way?

Are any screws or other components

loose?

Inspect the entire exterior of the MxC to see if there are any scratches or

other damage as a result of shipping.

Use a screwdriver to make sure that all screws are properly fastened.

If you find any irregularities with the items listed above, contact the agency from which the MxC was purchased, or your Yaskawa representative immediately.

Nameplate Information

An information nameplate appears on the right side of each MxC. The nameplate shows the model number,

specifications, lot number, serial number, and other information on the MxC.

Example Nameplate

The following nameplate is an example of a standard MxC: 3-phase, 400 Vac, 11 kW, IEC IP00 design.

1-4

Fig 1.1 Nameplate

Page 23

Confirmations upon Delivery

TERMS

4 011 1 A

No.

0

1

Open chassis (IEC IP00)

Enclosed wall-mounted

[IEC IP20, NEMA 1 (Type 1)]

Protective Structure

No.

2

4

AC input, 3-phase, 200 V

AC input, 3-phase, 400 V

Voltage Class

No.

5P5

011

022

5.5 kW

22 kW

045

45 kW

075

75 kW

11 kW

Max. Motor Capacity

"P" indicates the decimal point.

No.

A to Z

Design revision order (A to Z)

Revision

MxC Model Numbers

The model number of the MxC on the nameplate indicates the specification, voltage class, and maximum

motor capacity of the MxC in alphanumeric code.

CIMR - AC A 4 011

MxC

No.

A

No.

2

4

Specification

Standard model

Voltage Class

AC input, 3-phase, 200 V

AC input, 3-phase, 400 V

Max. Motor Capacity

No.

5P5

011

022

045

075

"P" indicates the decimal point.

5.5 kW

11 k W

22 kW

45 kW

75 kW

Fig 1.2 MxC Model Numbers

MxC Specifications

The MxC specifications (“SPEC”) on the nameplate indicate the voltage class, maximum motor capacity, the

protective structure, and the version of the MxC.

Fig 1.3 MxC Specifications

Open Chassis Type (IEC IP00)

Protected so that no one can come in direct contact with electrically charged parts from the front when the

MxC is mounted in a control panel.

Enclosed Wall-Mounted Type [IEC IP20, NEMA 1 (Type 1)]

The MxC is structured so that the MxC is shielded from the exterior, and can thus be mounted to the interior

wall of a standard building (not necessarily enclosed in a control panel). The protective structure conforms to

the standards of NEMA 1 (Type 1) in the USA. The protective covers are required for an IEC IP20 or NEMA 1

(Type 1) protective structure.

1-5

Page 24

Component Names

Front cover

Controller cover

Digital operator

Terminal cover

Nameplate

Cooling fan

Mounting holes

T

U

VRP

4. 5. 6.

76 86

96

Charge indicator

Control circuit terminals

Main circuit terminals

Ground terminal

The exterior of the MxC and its components are shown in Fig 1.4. Fig 1.5 shows the MxC with the terminal

cover removed.

Fig 1.4 MxC Exterior (Model: CIMR-ACA4011)

1-6

Fig 1.5 Terminal Arrangement (Model: CIMR-ACA4011)

Page 25

Exterior and Mounting Dimensions

W

W3

W3

W1

T1

D1

D

(5)

H1

H0

H2

H3

H

4-d

W2

Figure 1.6 shows the exterior of the open-chassis type (IP00).

W2

W1

4-d

H1

H

Exterior and Mounting Dimensions

T1

D1

W3

H2

W

W3

(5)

D

Fig 1.6 Exterior of Open Chassis MxCs

Table 1.3 Dimensions (mm) and Approx Weight (kg) of MxC

Voltage

Class

200 V

(3-phase)

400 V

(3-phase)

* Under development.

Max Applicable

Motor Output (kW)

WH DW1W2W3H1H2D1T1d

5.5 300 530 290 210 392 5 514 8 85 2.3 M6 28

11 300 530 290 210 392 5 514 8 85 2.3 M6 30

22 360 560 300 260 452 5 545 7.5 130 2.3 M6 45

45 480 865 403 310 592 6 841 12 170 4.5 M10 130

5.5 300 530 290 210 392 5 514 8 85 2.3 M6 29

11 300 530 290 210 392 5 514 8 85 2.3 M6 30

22 360 560 300 260 452 5 545 7.5 130 2.3 M6 45

45

*

75

480 865 403 310 592 6 841 12 170 4.5 M10 130

480 865 403 310 592 6 841 12 170 4.5 M10 135

Dimensions (mm) Approx.

Figure 1.7 shows the exterior of a wall-mounted enclosed MxC [IP20, NEMA1 (Type 1)].

Weight

(kg)

Cool-

ing

Method

Fan

Fig 1.7 Exterior of enclosed, wall-mounted MxCs

1-7

Page 26

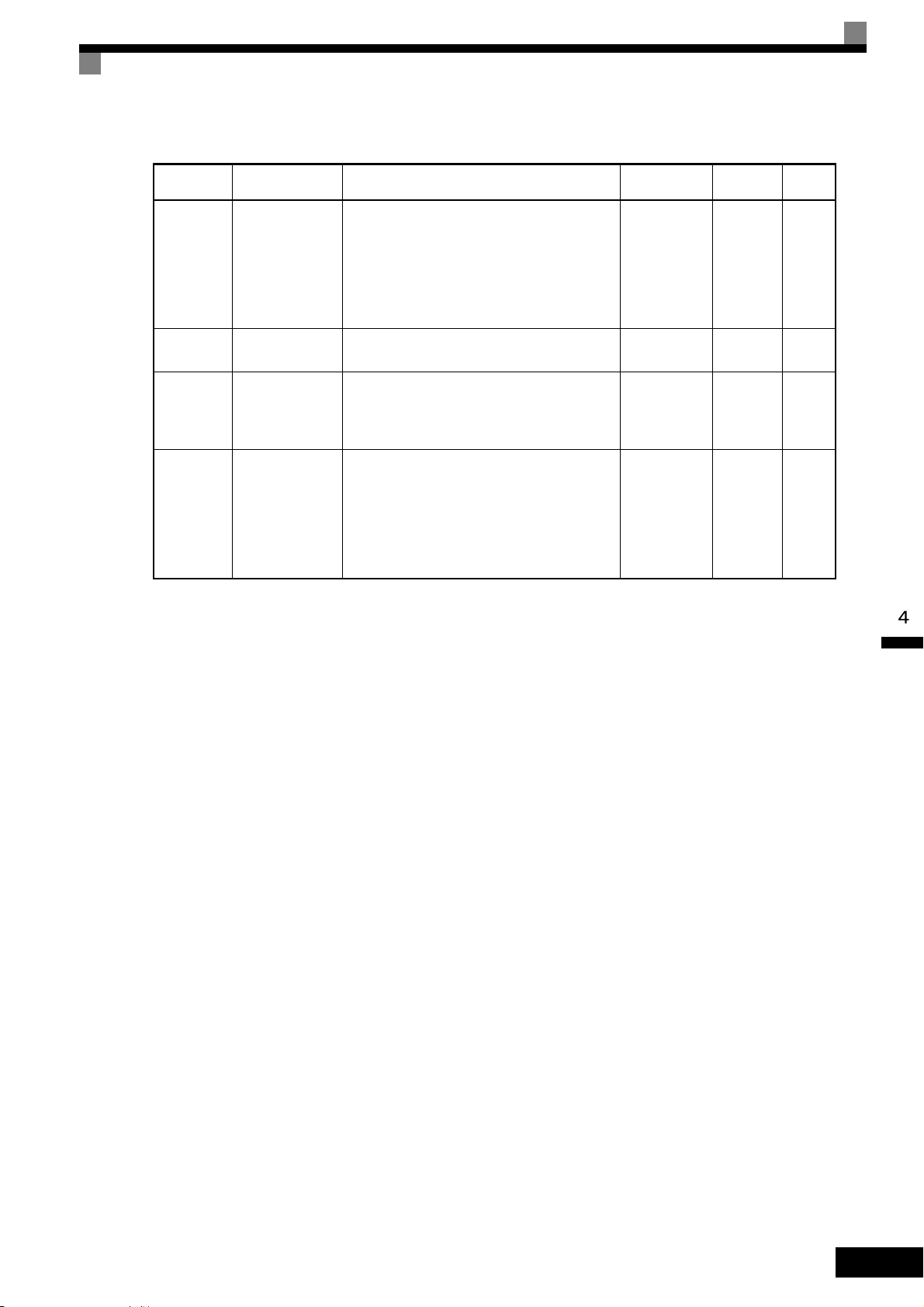

Voltage

Class

200 V

(3-phase)

400 V

(3-phase)

* Under development.

Max Applicable

Motor Output (kW)

Table 1.4 External Dimensions (mm) and Approx Weight (kg) of MxCs

External Dimensions (mm) Approx.

W H D W1W2W3H0H1H2H3D1T1 d

5.5 300 564 290 210 392 7 530 514 8 34 85 2.3 M6 30

11 300 564 290 210 392 7 530 514 8 34 85 2.3 M6 32

22 360 725 300 260 452 7 560 545 7.5 165 130 2.3 M6 48

45 480 1272 403 310 592 8.5 872 841 12 400 170 4.5 M10 140

5.5 300 564 290 210 392 7 530 514 8 34 85 2.3 M6 31

11 300 564 290 210 392 7 530 514 8 34 85 2.3 M6 32

22 360 725 300 260 452 7 560 545 7.5 165 130 2.3 M6 48

45

*

75

480 1272 403 310 592 8.5 872 841 12 400 170 4.5 M10 140

480 1272 403 310 592 8.5 872 841 12 400 170 4.5 M10 145

Weight

(kg)

Cooling

Method

Fan

1-8

Page 27

Checking and Controlling the Installation Site

Checking and Controlling the Installation Site

The MxC must be installed and used in an area that complies with the conditions listed below. Maintain

the conditions of the area for proper performance life.

Installation Site

Install the MxC under the following conditions, making sure that the area complies with Pollution Level 2 or

less (as defined by UL standards).

Table 1.5 Installation Site

Type Ambient Operating Temperature Humidity

Enclosed wall-mounted -10 to + 40 °C 95% RH or less (no condensation)

Open chassis -10 to + 45 °C 95% RH or less (no condensation)

The MxC should be installed:

• in a clean location free from oil mist and dust.

• in an environment where metal shavings, oil, water, or other foreign materials do not get into the MxC.

• in a location free from radioactive materials and combustible materials (e.g. wood).

• in a location free from harmful gases and liquids.

• in a location free from excessive oscillation.

• in a location free from chlorides.

• in a location away from direct sunlight.

Controlling the Ambient Temperature

To get optimum performance and full product life, the MxC should be installed in an environment free of

extreme temperature changes. If the MxC is installed in an enclosed environment such as a box or enclosure

panel, use a cooling fan or air conditioner to keep the internal air temperature below 45°C.

Protecting the MxC from Foreign Matter

Place a cover over the MxC during installation to shield it from exposure to metal particles when drilling.

Always remove the cover from the MxC after completing installation. Failing to do so will reduce ventilation

and possibly cause the MxC to overheat.

1-9

Page 28

Installation Orientation and Clearance

IMPORTANT

Install the MxC vertically so as not to reduce the cooling effect. When installing the MxC, always provide

the following installation space to allow normal heat dissipation.

50 mm min.

120 mm min.

50 mm min.

30

mm

min.

30

mm

min.

50 mm min.

Air

50 mm min.

Horizontal Space

120 mm min.

Vertical Space

Air

Fig 1.8 MxC Installation Orientation and Clearance

1. The same space is required horizontally and vertically for both Open Chassis (IP00) and Enclosed Wallmounted [IP20, NEMA 1 (Type 1)] designs.

2. Always provide enough space for suspension eye bolts and the main circuit lines when installing a MxC in

a panel.

1-10

Page 29

Removing and Attaching the Terminal Cover

#

Removing and Attaching the Terminal Cover

Remove the terminal cover to wire cables to the control circuit and main circuit terminals.

Removing the Terminal Cover

Loosen the screws on the left and right top of the terminal cover. Pull out the terminal cover in the direction of

arrow 1 and then lift up on the terminal in the direction of arrow 2.

Note: For 45 kW and 75 kW MxCs, an additional screw is located in position A as indicated below.

Fig 1.9 Removing the Terminal Cover (Model: CIMR-ACA4011)

Attaching the Terminal Cover

Once wiring the terminal block has been completed, attach the terminal cover by reversing the removal procedure.

1-11

Page 30

Removing/Attaching the Digital Operator and

Front Cover

This section demonstrates how the digital operator and front cover are removed.

Remove the terminal cover and then use the following procedures to remove the digital operator and front

cover.

Removing the Digital Operator

Press the lever on the side of the digital operator in the direction of arrow 1 to unlock the digital operator and

lift the digital operator in the direction of arrow 2 to remove the digital operator as shown in the following

illustration.

Fig 1.10 Removing the Digital Operator (Model: CIMR-ACA4011)

Removing the Front Cover

Pull the bottom of the front cover in the direction as shown by arrow 2 while pushing both sides of the cover in

the direction shown by arrow 1.

Fig 1.11 Removing the Front Cover (Model: CIMR-ACA4011)

1-12

Page 31

Removing/Attaching the Digital Operator and Front Cover

A

B

Attaching the Front Cover

After completing required work (i.e., installing an option card, setting the control circuit terminal board, etc.),

attach the front cover by reversing the procedure to remove it.

1. Make sure that the digital operator is not mounted on the front cover. Contact faults can occur if the cover

is attached while the digital operator is still connected.

2. Insert the tab on the top of the front cover into the slot on the MxC and press in on the cover until it clicks

into place on the MxC.

Attaching the Digital Operator

After attaching the front cover, plug the digital operator key pad into the front of the unit as follows:

1. Hook the digital operator at point A (two locations) on the front cover in the direction of arrow 1 as shown

in the illustration below.

2. Press the digital operator in the direction of arrow 2 until it snaps in place at B (two locations).

Fig 1.12 Mounting the Digital Operator (Model: CIMR-ACA4011)

1-13

Page 32

Wiring

This chapter describes wiring terminals, main circuit terminal connections, main circuit termi-

nal wiring specifications, control circuit terminals, and control circuit wiring specifications.

Connecting Peripheral Devices ....................................2-2

Connection Diagram ..................................................... 2-3

Terminal Block Configuration ........................................ 2-5

Wiring Main Circuit Terminals .......................................2-6

Wiring Control Circuit Terminals .................................2-16

Wiring Check ..............................................................2-24

Installing and Wiring Option Cards ............................. 2-25

Page 33

Connecting Peripheral Devices

Power supply

Molded-case

circuit breaker

or ground fault

interrupter

Magnetic contactor

(MC)

Motor

Ground

Input noise filter

Output noise filter

MxC

Ground

Zero-phase reactor

Zero-phase reactor

Examples of connections between the MxC and typical peripheral devices are shown in Fig 2.1.

2-2

Fig 2.1 Example Connections to Peripheral Devices

Page 34

Connection Diagram

IMPORTANT

1

IG

R

IM

IM

2

PG

SA

SA

SA

S

T

1MCCB

MC

2MCCB

r1

s1

t1

r2 s2 t2

*2

*2

*2

p1 n1

*1

*1

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

U

V

W

r1

s1

t1

PG-B2

TA1

3

4

5

6

TA3

TA2

1

2

3

4

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

SC

E(G)

+24V

8mA

+V

A1

A2

A3

AC

0V

-V (-15V 20mA)

R+

R-

S+

S-

+24V

AM

FM

AC

MA

MC

E(G)

MA

MB

MC

M1

M2

P1

P2

PC

P3

C3

MC

On

MC

Off

THRX

2MCCB

THRX

TRX

MC

TRX

MA

MC

FU

FV

FW

-

+

-

+

1

2

3

C

H

B

G

A

F

D

P4

C4

3-phase power

200 V to 220 V

50/60 Hz

Motor

Cooling fan

Pulse monitor output

Wiring distance:

30 m max

Shielded twisted-pair

wires

Pulse B

Pulse A

(Ground to 100 max)

(optional)

MxC

CIMR-ACA2011

CN5 (NPN setting)

Multi-function analog output 1

FM

-10 to 10 V 2 mA

Default: Output frequency

0 to +10 V

Default: Output curren

0 to +10 V

-10 to 10 V 2 mA

Multi-function analog output 2

Ammeter adjustment

20 kΩ

Ammeter adjustment

20 kΩ

AM

Error contact output

250 VAC, 10 mA min. 1 A max

30 VAC, 10 mA min. 1 A max

Multi-function contact oputput

250 VAC, 10 mA min. 1 A max

30 VAC, 10 mA min. 1 A max

Default: Running

signal

Open collector 1

Open collector 2

Open collector 3

Open collector 4

Multi-function

open-collector

outputs

48 VDC

50 mA max

Default: Frequency

agree signal

Default: Zero

speed

Default:

Minor fault

Default:

MxC operation ready

MEMOBUS

communications

RS-485/422

Shield wire

connection terminal

Master speed

pulse train

Frequency setting power

Master speed reference

Multi-function anlog input

Master speed reference

4 to 20 mA (250

Ω)

[0 to 10 V (20 k

Ω

) input]

+15 V, 20 mA

0 to 10 V (20 kΩ)

0 to 10 V (20 kΩ)

Terminating

resistance

Default:

Auxiliary frequency

command

0 to 32 kHz (3 kΩ)

High level: 3.5 to 13.2 V input

P

P

4 to 20 mA

0 to 10 V

0 to 10 V

Frequency

Frequency

setting

adjustment

setter

External

frequency

references

2k

Ω

2k

Ω

(Main speed switching)

External

baseblock command

Multi-step speed

reference 3

Multi-step speed

reference 4

Acc/dec time 1

Emergency stop (NO)

Forward Run/Stop

Reverse Run/Stop

External fault

Fault reset

Multi-step speed

reference 1

Multi-step speed

reference 2

Jog frequency

selection

contact inputs

Multi-function

(Default)

Fault contact

Thermal overload relay

(trip contact) for cooling fan

30 mA max

The connection diagram of the MxC is shown in Fig 2.2.

When using the digital operator, the motor can be operated by wiring only the main circuits.

Connection Diagram

* 1. Connect to the momentary power loss compensation unit. Do not connect power lines to these terminals.

* 2. Normally not used. Do not connect power lines to these terminals.

Fig 2.2 Connection Diagram (Model: CIMR-ACA2011)

2-3

Page 35

IMPORTANT

1. Control circuit terminals are arranged as shown below.

A3 -V

S8

S9

S10

S11

S12

P3

C3 P4 C4

2. The output current capacity of the +V terminal is 20 mA. Do not create a short between the +V, -V, and AC

control-circuit terminals. This may cause the MxC to fault out or malfunction.

3. Main circuit terminals are indicated with double circles and control circuit terminals are indicated with single

circles.

4. The wiring for a motor with a cooling fan is not required for self-cooling motors.

5. PG circuit wiring (i.e., wiring to the PG-B2 Card) is not required for control without a PG.

6. Sequence input signals S1 to S12 are labeled for sequence connections (0 V common and Sinking Mode)

for no-voltage contacts or NPN transistors. These are the default settings.

For PNP transistor sequence connections (+24V common and Sourcing Mode) or to provide a 24 V external power supply, refer to Table 2.10.

7. The master speed frequency reference can be input from a voltage signal (terminal A1) or current signal

(terminal A2) by changing the setting of parameter H3-13. The default setting is for a voltage reference

input.

8. The multi-function analog output is a dedicated meter output for an analog frequency meter, ammeter, voltmeter, wattmeter, etc. Do not use this output for feedback control or for any other control purpose.

9. The minimum load of a multi-function contact output and an error contact output is 10 mA. Use a multifunction open-collector output for a load less than 10 mA.

10. Do not ground the AC terminal of the control circuit. This may cause the MxC to fault out or malfunction.

2-4

Page 36

Terminal Block Configuration

Main circuit terminals

Control circuit terminals

Charge indicator

Ground terminal

T

U

VRP

4. 5. 6.

76 86

96

Control circuit terminals

Main circuit terminals

Ground terminal

Charge indicator

The following figures show the terminal arrangements for MxC. Refer to Fig. 2.3 for 5.5 kW and 11 kW

MxCs, Fig. 2.4 for a 22 kW MxC, and Fig.2.5 for 45 kW and 75 kW MxCs.

Fig 2.3 Terminal Arrangement (Model: CIMR-ACA4011)

Terminal Block Configuration

Charge indicator

Control circuit terminals

Main circuit terminals

Ground terminal

Fig 2.4 Terminal Arrangement (Model: CIMR-ACA4022)

Fig 2.5 Terminal Arrangement (Model: CIMR-ACA2045)

2-5

Page 37

Wiring Main Circuit Terminals

Applicable Wire Gauges and Closed-Loop Connectors

Select the appropriate wires and crimp terminals listed in Table 2.1 through Table 2.3.

Table 2.1 200 V Class Wire Gauges

MxC Model

CIMR-

Terminal Symbol

Ter m in a l

Screws

Tightening

To rq u e

(N•m)

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M5 2 to 2.4 Nm

ACA25P5

r2*2, s2*2, t2*2, p1*1, n1*

1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M5 2 to 2.4 Nm

ACA2011

2

, s2*2, t2*2, p1*1, n1*

r2*

1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M8 9 to 10 Nm

ACA2022

2

, s2*2, t2*2, p1*1, n1*

r2*

1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M10 18 to 23 Nm

ACA2045

*2

, s2*2, t2*2, p1*1, n1

r2

*1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

* 1. Connect the momentary power loss compensation unit. Do not connect the power to these terminals.

* 2. Normally not used. Do not connect the power to these terminals.

Possible

Wire

Gauges

2

(AWG)

mm

8 to 14

(8 to 6)

(14 to 12)

8 to 22

(8 to 4)

14

(6)

(14 to 12)

14 to 22

(6 to 4)

38 to 60

(1 to 1/0)

(14 to 12)

22 to 38

(4 to 2)

100

(4/0)

(14 to 12)

5 to 60

(1 to 1/0)

Recommended

Wire Gauge

2

(AWG)

mm

8

(8)

2

(14)

8

(8)

14

(6)

2

(14)

14

(6)

38

(1)

2

(14)

22

(4)

100

(4/0)

2

(14)

50

(1)

Wire Type

Power cables,

e.g., 600 V

vinyl power

cables

2-6

Page 38

Table 2.2 400 V Class Wire Gauges

MxC Model

CIMR-

Terminal Symbol

Terminal

Screws

Tightening

Torque

(N•m)

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M5 2 to 2.4 Nm

ACA45P5

r2*2, s2*2, t2*2, p1*1, n1*

1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M5 2 to 2.4 Nm

ACA4011

2

r2*

, s2*2, t2*2, p1*1, n1*

1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M8 9 to 10 Nm

ACA4022

2

r2*

, s2*2, t2*2, p1*1, n1*

1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M8 9 to 10 Nm

ACA4045

*2

r2

, s2*2, t2*2, p1*1, n1

*1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3 M10 18 to 23 Nm

ACA4075

*2

*3

r2

, s2*2, t2*2, p1*1, n1

*1

M4

1.3 to 1.4 Nm2 to 3.5

M8 9 to 10 Nm

* 1. Connect the Momentary Power Loss compensation unit. Do not connect power to these terminals.

* 2. Normally not used. Do not connect power to these terminals.

* 3. Under development.

Wiring Main Circuit Terminals

Possible

Wire

Gauges

2

mm

3.5 to 14

(12 to 6)

(AWG)

Recommended

Wire Gauge

2

(AWG)

mm

3.5

(12)

2

(14 to 12)

3.5 to 22

(12 to 4)

8 to 14

(8 to 6)

(14)

3.5

(12)

8

(8)

2

(14 to 12)

8 to 22

(8 to 4)

14 to 60

(6 to 1/0)

(14)

8

(8)

14

(6)

2

(14 to 12)

14 to 38

(6 to 2)

38 to 60

(1 to 1/0)

(14)

14

(6)

38

(2)

2

(14 to 12)

22 to 60

(4 to 1/0)

100

(4/0)

(14)

22

(4)

100

(4/0)

2

(14 to 12)

50 to 60

(1 to 1/0)

(14)

50

(1)

Wire Type

power cables,

e.g., 600 V

vinyl power

cables

2-7

Page 39

Table 2.3 Closed-Loop Connector Sizes (JIS C2805) (200 V class and 400 V class)

IMPORTANT

3

Wire Thickness (mm

2

)

Terminal Screws Size

M3.5 1.25 to 3.5

0.5

M4 1.25 to 4

M3.5 1.25 to 3.5

0.75

M4 1.25 to 4

1.25

M3.5 1.25 to 3.5

M4 1.25 to 4

M3.5 2 to 3.5

M4 2 to 4

2

M5 2 to 5

M6 2 to 6

M8 2 to 8

M4 5.5 to 4

M5 5.5 to 5

3.5/5.5

M6 5.5 to 6

M8 5.5 to 8

M5 8 to 5

8

M6 8 to 6

M8 8 to 8

M6 14 to 6

14

M8 14 to 8

M6 22 to 6

22

M8 22 to 8

30/38 M8 38 to 8

M8 60 to 8

50/60

M10 60 to 10

80

80 to 10

M10

100 100 to 10

2-8

100

150 150 to 12

M12

100 to 12

200 200 to 12

M12 x 2 325 to 12

325

M16 325 to 16

Determine the wire gauge for the main circuit so that line voltage drop is within 2% of the rated voltage. Line

voltage drop is calculated as follows:

Line voltage drop (V) =

× wire resistance (W/km) × wire length (m) × current (A) × 10

-3

Page 40

Wiring Main Circuit Terminals

Main Circuit Terminal Functions

Main circuit terminal functions are summarized according to terminal symbols in Table 2.4. Wire the terminals

correctly for the desired purpose.

Table 2.4 Main Circuit Terminal Functions

(200 V class and 400 V class)

Purpose Terminal symbols

Main circuit power input R/L1, S/L2, T/L3

MxC output U/T1, V/T2, W/T3

Ground

Connection to optional devices

* 1. Connect the momentary power loss compensation unit. Do not connect power to these terminals.

* 2. Normally not used. Do not connect power to these terminals.

r2*2, s2*2, t2*2, p1*1, n1

*1

Main Circuit Configurations

The main circuit configurations of the MxC are shown in Fig 2.6.

CIMR-ACA25P5 to 2045, 45P5 to 4075

∗1

p1

∗1

n1

∗2

r2

∗2

s2

∗2

t2

R/L1

S/L2

T/L3

* 1. Connect the momentary power loss compensation unit. Do not connect power to these terminals.

* 2. Normally not used. Do not connect power to these terminals.

Note: 1. Control power is supplied internally from the main circuit power supply for all MxC models.

2. 400 V class MxC for 75 kW is under development.

Input filter

Fig 2.6 MxC Main Circuit Configurations

Power supply

Control

circuit

U/T1

V/T2

W/T3

2-9

Page 41

Standard Connection Diagrams

3-phase 200 VAC

(400 VAC)

U/T1

V/T2

W/T3

t2

∗2

R/L1

S/L2

T/L3

r2

∗2

s2

∗2

IM

p1

∗1

n1

∗1