YASKAWA CIMR-A2A0110, CIMR-A2A0138, CIMR-A2A0169, CIMR-A2A0211, CIMR-A2A0250 Quick Start Manual

...Page 1

YASKAWA AC Drive A1000

High Performance Vector Control Drive

Quick Start Guide

MANUAL NO. TOEP C710616 27D

Type: CIM R- AC A

Models:

200 V Class: 0.4 to 110 kW

400 V Class: 0.4 to 630 kW

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

Page 2

2 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Copyright © 2008 YASKAWA ELECTRIC CORPORATION.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any

means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent

liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to

improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has

been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this publication.

Page 3

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 3

Table of Contents

1 SAFETY INSTRUCTIONS AND GENERAL WARNINGS . . . . . . . . . . . . . . . . . . . . . . . 4

2 MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 ELECTRICAL INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 KEYPAD OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5 START UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 PARAMETER TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 SAFE DISABLE INPUT FUNCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 UL STANDARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Page 4

4 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

1 Safety Instructions and General Warnings

1 Safety Instructions and General Warnings

Yaskawa Electric supplies component parts for use in a wide variety of industrial applications. The selection and

application of Yaskawa products remain the responsibility of the equipment designer or end user. Yaskawa accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety control. Without exception,

all controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed

to incorporate a component part manufactured by Yaskawa must be supplied to the end user with appropriate warnings

and instructions as to the safe use and operation of that part. Any warnings provided by Yaskawa must be promptly

provided to the end user. Yaskawa offers an express warranty only as to the quality of its products in conforming to

standards and specifications published in the manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS

OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses, or claims arising from

misapplication of its products.

Applicable Documentation

The following manuals are available for A1000 series drives:

General Warnings

The following conventions are used to indicate Safety messages in this manual:

A1000 Series AC Drive Technical Manual

This manual provides detailed information on parameter settings, drive functions, and MEMOBUS/

Modbus specifications. Use this manual to expand drive functionality and to take advantage of

higher performance features.

A1000 Series AC Drive Quick Start Guide (this book)

Read this manual first. This guide is packaged together with the product. It contains basic

information required to install and wire the drive, in addition to an overview of fault diagnostics,

maintenance, and parameter settings. Use the information in this book to prepare the drive for a trial

run with the application and for basic operation.

W ARNING

• Read and understand this manual before installing, operating or servicing this drive.

• All warnings, cautions, and instructions must be followed.

• All work must be performed by qualified personnel.

• The drive must be installed according to this manual and local codes.

Heed the safety messages in this manual.

The operating company is responsible for any injuries or equipment damage resulting from failure to heed the warnings

in this manual.

W ARNING

Indicates a hazardous situation, which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates a property damage message.

CIMR-AA2A0021FAA

200V 3Phase 5.5kW/3.7kW

S/N:

危 険

据え付け、運転の前には必ず取扱説明書を読むこと。

通電中および電源遮断後5分以内はフロントカバー

を外さない事。

400V級インバータの場合は、電源の中性点が接地

されていることを確認すること。(対応)

保守・点検、配線を行う場合は、出力側開閉器を

遮断後5分待って実施してください。

けが.感電のおそれがあります。

高温注意

インバータ上部、両側面は高温になります。

触らないでください。

●

●

●

●

●

AVERTISSMENT

NPJT31470-1

Lire le manuel avant l'installation.

Attendre 5 minutes après la coupure

de l'alimentation, pour permettre

la décharge des condensateurs.

Pour répondre aux exigences , s

assurer que le neutre soit relié

à la terre, pour la série 400V.

Après avoir déconnécte la protection

entre le driver et le moteur, veuillez

patienter 5 minutes avain d’effectuer

une opération de montage ou de

câblage du variateur.

Risque de décharge électrique.

Surfaces Chaudes

Dessus et cotés du boitier Peuvent

devenir chaud. Ne Pas toucher.

WARNING

Read manual before installing.

Wait 5 minutes for capacitor

discharge after disconnecting

power supply.

To conform to requirements,

make sure to ground the supply

neutral for 400V class.

After opening the manual switch

between the drive and motor,

please wait 5 minutes before

inspecting, performing

maintenance or wiring the drive.

Risk of electric shock.

Hot surfaces

Top and Side surfaces may

become hot. Do not touch.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

LO

RE

F2F1

ESC

RUN STOP

ENTERRESET

ALM

DIGITAL OPERATOR JVOP-180

Page 5

1 Safety Instructions and General Warnings

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 5

Safety Warnings

W ARNING

Electrical Shock Hazard

Do not attempt to modify or alter the drive in any way not explained in this manual.

Yaskawa is not responsible for the damage caused by modification of the product made by the user. Failure to comply

could result in death or serious injury from operation of damaged equipment.

Do not touch any terminals before the capacitors have fully discharged.

Failure to comply could result in death or serious injury.

Before wiring terminals, disconnect all power to the equipment. The internal capacitor remains charged even after the

power supply is turned off. The charge indicator LED will extinguish when the DC bus voltage is below 50 Vdc. To

prevent electric shock, wait at least five minutes after all indicators are off and measure the DC bus voltage level to

confirm safe level.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized personnel familiar with

installation, adjustment, and maintenance of AC drives.

Do not change wiring, remove covers, connectors or options cards, or attempt to service the drive with power

applied to the drive.

Failure to comply could result in death or serious injury. Disconnect all power to the drive and check for unsafe

voltages before servicing.

Always ground the motor-side grounding terminal.

Improper equipment grounding could result in death or serious injury by contacting the motor case.

Do not perform work on the drive while wearing loose clothing, jewelry or without eye protection.

Failure to comply could result in death or serious injury.

Remove all metal objects such as watches and rings, secure loose clothing, and wear eye protection before beginning

work on the drive.

Never short the output circuits of the drive.

Do not short the output circuits of the drive. Failure to comply could result in death or serious injury.

Make sure the protective earthing conductor complies with technical standards and local safety regulations.

When an EMC filter is installed or with models CIMR-A4A0414 and larger, the leakage current exceeds 3.5 mA.

Therefore according to IEC 61800-5-1 automatic power supply interruption in case of discontinuity of the protective

earthing conductor must be provided or a protective earthing conductor with a cross section of at least 10 mm

2

(Cu) or

16 mm

2

(Al) must be used.

Use appropriate equipment for residual current monitoring/detection (RCM/RCD).

This drive can cause a residual current with a DC component in the protective earthing conductor. Where a residual

current operated protective or monitoring device is used for protection in case of direct or indirect contact, always use

an RCM or RCD of type B according to IEC 60755.

Sudden Movement Hazard

Stay clear of the motor during rotational Auto-Tuning. The motor may start operating suddenly.

During automatic starting of equipment, the machine may start moving suddenly, which could result in death or serious

injury.

System may start unexpectedly upon application of power, resulting in death or serious injury.

Clear all personnel from the drive, motor, and machine area before applying power. Secure covers, couplings, sh aft

keys, and machine loads before applying power to the drive.

Page 6

1 Safety Instructions and General Warnings

6 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Fire Hazard

Do not use an improper voltage source.

Failure to comply could result in death or serious injury by fire.

Ve rify that the rated voltage of the drive matches the voltage of the incoming power supply before applying power.

Do not use improper combustible materials in drive installation, repair or maintenance.

Failure to comply could result in death or serious injury by fire. Attach the drive or braking resistors to metal or other

noncombustible material.

Do not connect the AC power line to the output terminals of the drive.

Failure to comply could result in death or serious injury by fire as a result of drive damage from line voltage

application to output terminals.

• Do not connect AC line power to output terminals U, V, and W.

• Make sure that the power supply lines are connected to main circuit input terminals R/L1, S/L2, T/L3 (or R/L1 and S/

L2 for single-phase power).

Tighten all terminal screws to the specified tightening torque.

Loose electrical connections could result in death or serious injury by fire due to overheating of electrical connections.

Crush Hazard

Use a dedicated lifter when transporting the drive by a lifter.

Improper lifter may cause the drive to drop, resulting in serious injury.

Only allow qualified personnel to operate a crane or hoist to transport the drive.

Failure to comply could result in death or serious injury from falling equipment.

CAUTION

Crush Hazard

Do not carry the drive by the front cover.

Failure to comply may result in minor or moderate injury from the main body of the drive falling.

Burn Hazard

Do not touch the heatsink or braking resistor hardware until a powered-down cooling period has elapsed.

NOTICE

Equipment Hazard

Observe proper electrostatic discharge procedures (ESD) when handling the drive and circuit boards.

Failure to comply may result in ESD damage to the drive circuitry.

Never connect or disconnect the motor from the drive while the drive is outputting voltage.

Improper equipment sequencing could result in damage to the drive.

Do not perform a withstand voltage test on any part of the unit.

Failure to comply could result in damage to the sensitive devices within the drive. Use power off resistance checks to

determine shortcircuits.

Do not operate damaged equipment.

Failure to comply could result in further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing parts.

W ARNING

Page 7

1 Safety Instructions and General Warnings

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 7

Precautions for CE Low Voltage Directive Compliance

This drive has been tested according to European standard EN61800-5-1, and it fully complies with the Low Voltage

Directive. The following conditions must be met to maintain compliance when combining this drive with other devices:

Do not use drives in areas with pollution higher than severity 2 and overvoltage category 3 in accordance with IEC664.

Ground the neutral point of the main power supply for 400 V Class drives.

If a fuse is blown or equipment for residual current monitoring/detection (RCM/RCD) is tripped, check the

wiring and the selection of the peripheral devices.

Contact your supplier if the cause cannot be identified after checking the above.

Do not restart the drive until 5 minutes passes and CHARGE lamp is OFF or immediately operate the

peripheral devices if a fuse is blown or equipment for residual current monitoring/detection (RCM/RCD) is

tripped.

Check the wiring and the selection of peripheral devices to identify the cause.

Contact your supplier before restarting the drive or the peripheral devices if the cause cannot be identified.

For models CIMR-A4A0930 and 4A1200, make sure to install a fuse and equipment for residual current

monitoring/detection (RCM/RCD).

Failure to comply may result in serious damage to the facilities in case the drive is defected.

Do not use unshielded cable for control wiring.

Failure to comply may cause electrical interference resulting in poor system performance. Use shielded twisted-pair

wires and ground the shield to the ground terminal of the drive.

Do not carelessly connect parts or devices to the drives braking transistor terminals.

Failure to comply could result in damage to the drive or braking circuit.

Carefully review instruction manual TOBP C720600 00 when connecting a braking option to the drive.

Do not modify the drive circuitry.

Failure to comply could result in damage to the drive and will void warranty.

Yaskawa is not responsible for modification of the product mad e by the user. This product must not be modified.

Check all the wiring to ensure that all connections are correct after installing the drive and connecting other

devices.

Failure to comply could result in damage to the drive.

Improper application of devices on drive output circuits can damage the drive

Do not connect unapproved LC or RC interference suppression filters, capacitors, ground fault circuits, or overvoltage

protection devices to the drive.

Fire Hazard

Install adequate branch circuit short circuit protection per applicable codes.

The drive is suitable for circuits capable of delivering not more than 100,000 RMS symmetrical Amperes, 240 Vac

maximum (200 V Class) and 480 Vac maximum (400V Class). Inadequate branch short circuit protection damage or

serious injury by fire.

NOTICE

Page 8

8 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

2 Mechanical Installation

2 Mechanical Installation

Upon Receipt

Perform the following tasks after receiving the drive:

• Inspect the drive for damage. If the drive appears damaged upon receipt, contact your supplier.

• Verify receipt of the correct model by checking the information on the nameplate. If you have received the wrong

model, contact your supplier.

Installation Environment

For optimum performance life of the drive, install the drive in an environment that meets the conditions listed below.

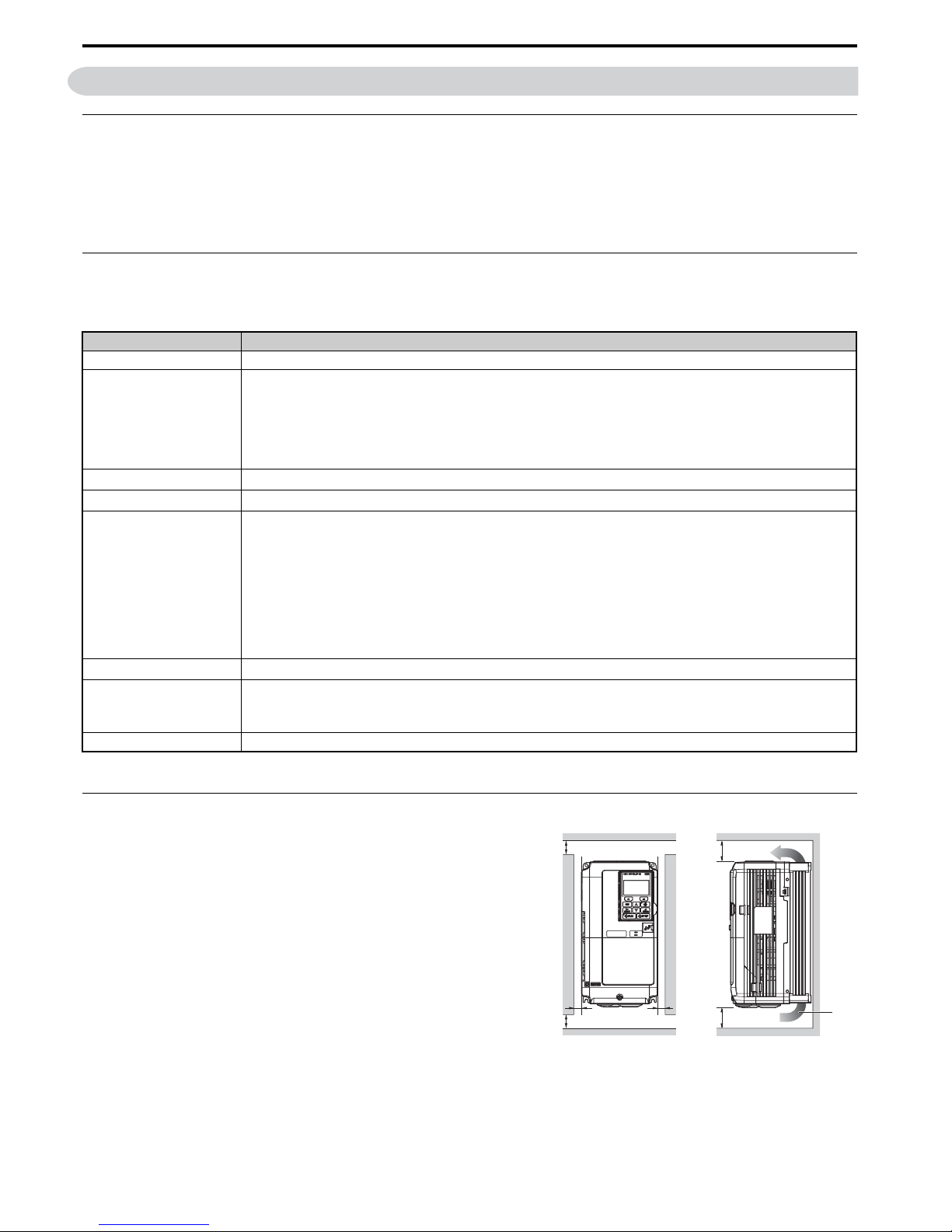

Installation Orientation and Spacing

Always install the drive in an upright position. Leave space around

the unit for proper cooling as shown in the figure on the right.

Note: Several units can be installed closer together than shown in the figure by

using “Side-by-Side” mounting. For details refer to the Technical Manual.

Environment Conditions

Installation Area

<1> Models CIMR-A4A0930 and 4A1200 are rated at 5.9 m/s

2

.

Indoors

Ambient Temperature

-10°C to +40°C (IP20/NEMA Type 1 Enclosure)

-10°C to +50°C (IP00 Enclosure)

Drive reliability improves in environments without wide temperature fluctuations.

When using the drive in an enclosure panel, install a cooling fan or air conditioner in the area to ensure that the air

temperature inside the enclosure does not exceed the specified levels.

Do not allow ice to develop on the drive.

Humidity

95% RH or less and free of condensation

Storage Temperature

-20 to +60°C

Surrounding Area

Install the drive in an area free from:

• oil mist and dust

• metal shavings, oil, water or other foreign materials

• radioactive materials

• combustible materials (e.g., wood)

• harmful gases and liquids

• excessive vibration

• chlorides

• direct sunlight

Altitude

1000 m, up to 3000 m with derating (for details, refer to the Technical Manual)

Vibration

10 to 20 Hz at 9.8 m/s2 <1>

20 to 55 Hz at 5.9 m/s2 (Models CIMR-2A0004 to 2A0211 and 4A0002 to 4A0165) or,

2.0 m/s

2

(Models CIMR-A2A0250 to 2A0415 and 4A0208 to 4A1200)

Orientation Install the drive vertically to maintain maximum cooling effects.

50 mm

50 mm

30 mm 30 mm

120 mm

120 mm

Ai

r

Page 9

2 Mechanical Installation

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 9

Instructions on Installation of Models CIMR-A4A0930 and 4A1200

Read the following precautions and instructions before installing the largest-capacity models, 4A0930 and 4A1200.

WARNING! Be sure to observe the following instructions and precautions. Failure to comply could result in minor or moderate injury

and damage to the drive from falling equipment.

• Vertical suspension of the drive should be used only for temporarily lifting the drive for installation in the enclosure

panel. Do not vertically suspend for transportation of the drive.

• Before vertical suspension, make sure that the drive front cover, terminal blocks and other drive components are

securely fixed with screws.

• Do not subject the drive to vibration or impact greater than 1.96 m/s

2

(0.2 G) while it is suspended by the wires.

• Do not overturn the drive.

• Do not leave the drive for a long time while it is suspended by the wires

Procedure for Vertical Wire Suspension of the Drive

• Use the wire of a length that ensures a 50 degree or wider suspending angle, as illustrated in the figure below. The

maximum allowable load of the eye bolts for suspension cannot be guaranteed when the drive is suspended with the

wires at an angle less than 50 degrees.

• When lifting the drive with a crane after wires are passed to hold it, make sure to follow the procedure described below.

1. Remove the four eye bolts from the drive side panels, and fix them securely on the top panel (See the figure

below.).

2. Pass wire through the holes of all the four eye bolts (See the figure below).

3. Take up the slack in the wires gradually with a crane, and when the wires are confirmed to have stretched tight,

hoist the drive.

4. When ready to install the drive in the enclosure panel, lower the drive. Halt lowing once when the drive has

reached near the floor, and then lower the drive again very slowly.

Eye bolt

Eye bolt

Wires

Suspending angle:

50 degree or greater

Page 10

2 Mechanical Installation

10 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

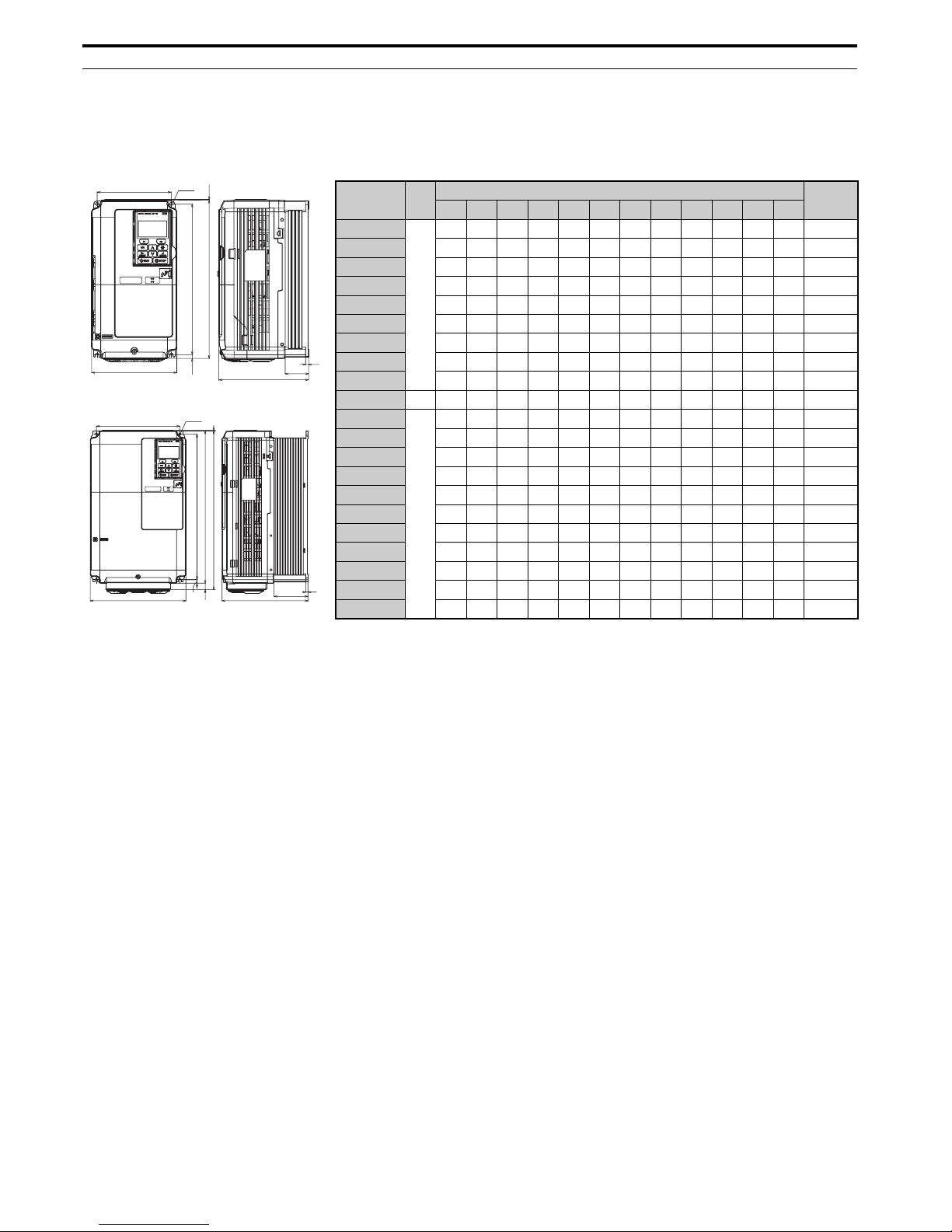

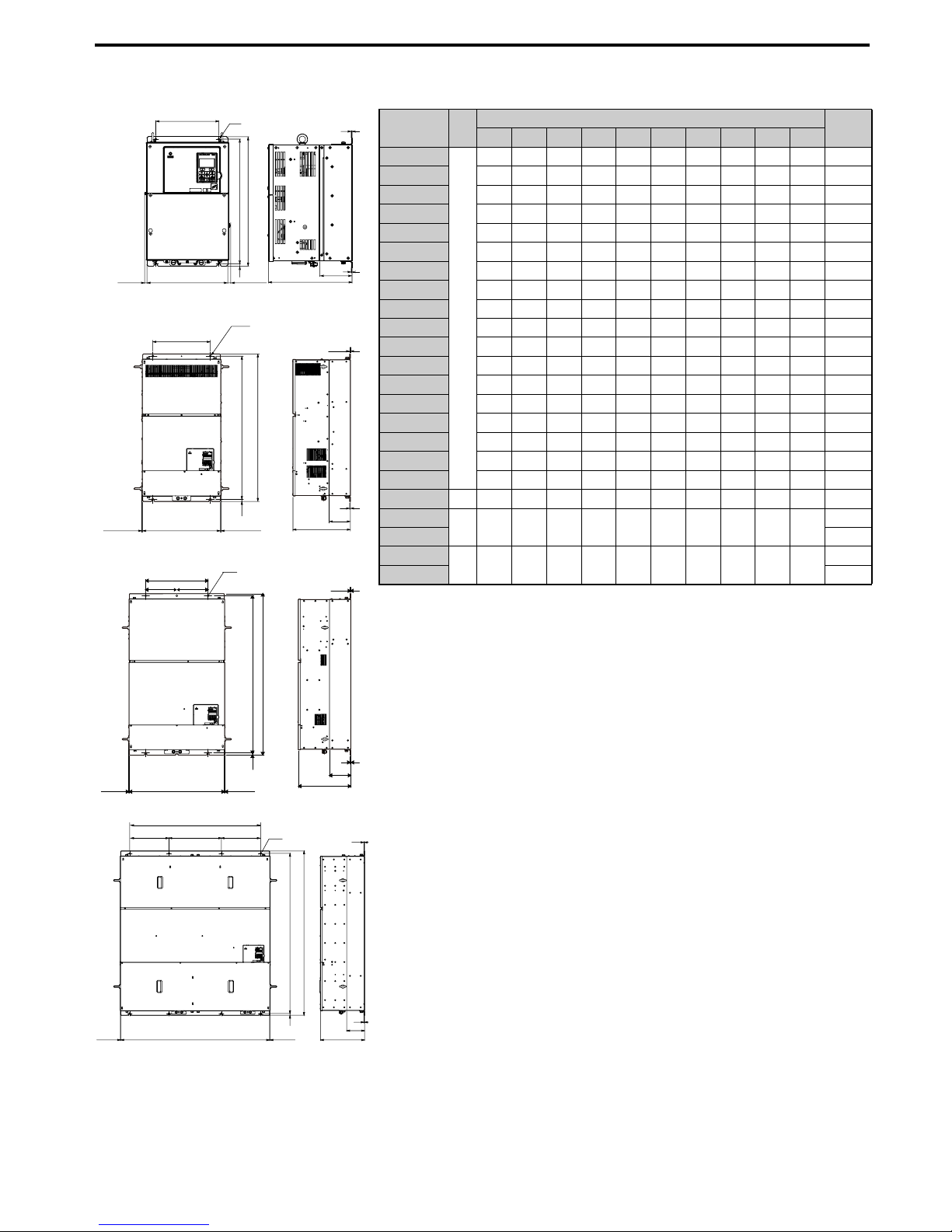

Dimensions

IP20/NEMA Type 1 Enclosure Drives

Note: IP20/NEMA Type 1 Enclosure drives are equipped with a top protective cover. Removing this cover voids NEMA Type 1

protection but still keeps IP20 conformity.

Model

CIMR-A

Fig.

Dimensions (mm)

Weight

(kg)

W H D W1 H0 H1 H2 H3 D1 t1 t2 d

2A0004

1

140 260 147 122 – 248 6 – 38 5 – M5 3.1

2A0006 140 260 147 122 – 248 6 – 38 5 – M5 3.1

2A0010 140 260 147 122 – 248 6 – 38 5 – M5 3.2

2A0012 140 260 147 122 – 248 6 – 38 5 – M5 3.2

2A0021 140 260 164 122 – 248 6 – 55 5 – M5 3.5

2A0030 140 260 167 122 – 248 6 – 55 5 – M5 4.0

2A0040 140 260 167 122 – 248 6 – 55 5 – M5 4.0

2A0056 180 300 187 160 – 284 8 – 75 5 – M5 5.6

2A0069 220 350 197 192 – 335 8 – 78 5 – M6 8.7

2A0081 2 220 365 197 192 350 335 8 15 78 5 – M6 9.7

4A0002

1

140 260 147 122 – 248 6 – 38 5 – M5 3.2

4A0004 140 260 147 122 – 248 6 – 38 5 – M5 3.2

4A0005 140 260 147 122 – 248 6 – 38 5 – M5 3.2

4A0007 140 260 164 122 – 248 6 – 55 5 – M5 3.4

4A0009 140 260 164 122 – 248 6 – 55 5 – M5 3.5

4A0011 140 260 164 122 – 248 6 – 55 5 – M5 3.5

4A0018 140 260 167 122 – 248 6 – 55 5 – M5 3.9

4A0023 140 260 167 122 – 248 6 – 55 5 – M5 3.9

4A0031 180 300 167 160 – 284 8 – 55 5 – M5 5.4

4A0038 180 300 187 160 – 284 8 – 75 5 – M5 5.7

4A0044 220 350 197 192 – 335 8 – 78 5 – M6 8.3

W1

1.5

H

H1

H2

W

D

D1

t1

H2

W1

1.5

H

H0

H1

W

D1

D

t1

H3

Figure 1

Figure 2

4-d

4-d

Page 11

2 Mechanical Installation

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 11

IP00 Enclosure Drives

Model

CIMR-A

Fig.

Dimensions (mm)

Weight

(kg)

W H D W1 H1 H2 D1 t1 t2 d

2A0110

3

250 400 258 195 385 7.5 100 2.3 2.3 M6 21

2A0138 275 450 258 220 435 7.5 100 2.3 2.3 M6 25

2A0169 325 550 283 260 535 7.5 110 2.3 2.3 M6 37

2A0211 325 550 283 260 535 7.5 110 2.3 2.3 M6 38

2A0250 450 705 330 325 680 12.5 130 3.2 3.2 M10 76

2A0312 450 705 330 325 680 12.5 130 3.2 3.2 M10 80

2A0360 500 800 350 370 773 13 130 4.5 4.5 M12 98

2A0415 500 800 350 370 773 13 130 4.5 4.5 M12 99

4A0058 250 400 258 195 385 7.5 100 2.3 2.3 M6 21

4A0072 275 450 258 220 435 7.5 100 2.3 2.3 M6 25

4A0088 325 510 258 260 495 7.5 105 2.3 3.2 M6 36

4A0103 325 510 258 260 495 7.5 105 2.3 3.2 M6 36

4A0139 325 550 283 260 535 7.5 110 2.3 2.3 M6 41

4A0165 325 550 283 260 535 7.5 110 2.3 2.3 M6 42

4A0208 450 705 330 325 680 12.5 130 3.2 3.2 M10 79

4A0250 500 800 350 370 773 13 130 4.5 4.5 M12 96

4A0296 500 800 350 370 773 13 130 4.5 4.5 M12 102

4A0362 500 800 350 370 773 13 130 4.5 4.5 M12 107

4A0414 4 500 950 370 370 923 13 135 4.5 4.5 M12 125

4A0515

5 670 1140 370 440 1110 15 150 4.5 4.5 M12

216

4A0675 221

4A0930

6 1250 1380 370 1110 1345 15 150 4.5 4.5 M12

545

4A1200 555

D

Figure 6

D1

D

t2

H1

H2

H

4-d

W1

W

Max 7.7Max 7.7

t1

W1

4-d

H1

H

H2

Max 10 Max 10

W

t2

t1

D1

D

Figure 3

Figure 4

Figure 5

D1

W

H1

H2

H

Max 6Max 6

4-d

t2

t1

W1

220 220

330 330

8-d

440

W1

H1

H

W

H2

D

Max 6Max 6

D1

t1

t2

Page 12

12 YA SKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

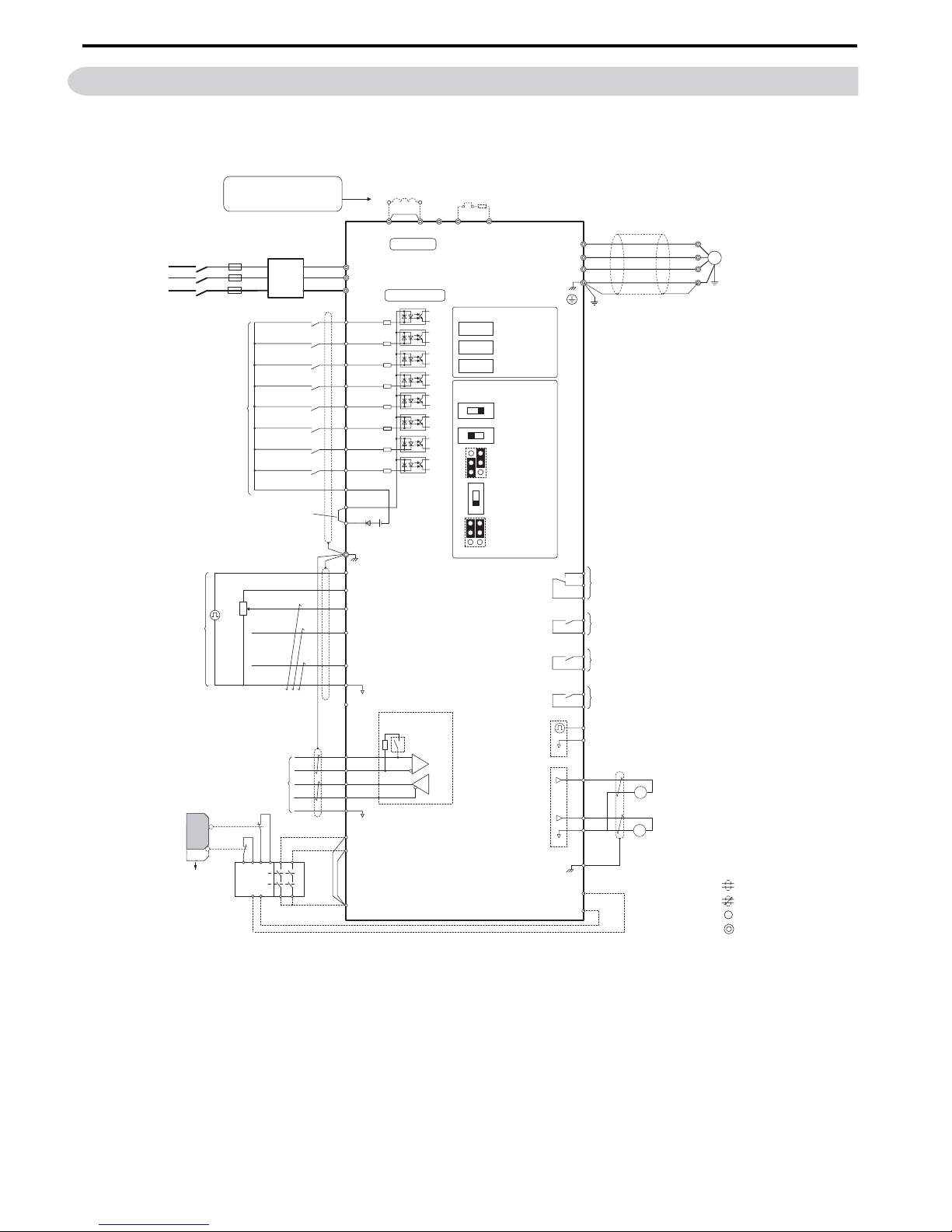

3 Electrical Installation

3 Electrical Installation

The figure below shows the main and control circuit wiring.

<1> Remove the jumper when installing a DC reactor. Models CIMR-A2A110 through 0415 and 4A0058 through 1200 come with a built-in DC

reactor.

<2> Never short terminals SP and SN as doing so will damage the drive.

<3> Disconnect the wire jumper between H1 - HC and H2 - HC when utilizing the Safe Disable input.

Three-phase

power supply

200 to 400 V

50/60 Hz

R/L1

S/L2

T/L3

Main

Switch

Fuse

EMC

Filter

+

−

+

+

++

M

U/T

1

V/T2

W/T

U

V

W

3

Ground

Terminals -, +1, +2, B1, B2 are

for connection options. Never

connect power supply lines to

these terminals

DC reactor

(option)

UX

Thermal relay

(option)

+

−

+

+

++

+

−

UX

S

1

S2

S3

S4

S5

S6

S7

MP

DM

DM

RP

A

1

A2

A3

0

V

AC

R

R

S

S

IG

H

1

H2

HC

Drive

B112

B2

2 kΩ

S8

SC

0 V

0 V

AC

FM

AM

AC

E (G)

S

1

S2

<1>

<3>

−

+24 V

+V

MA

M

1

M2

MB

MC

Jumper

Braking resistor

(option)

Forward Run / Stop

Reverse Run / Stop

External fault

Fault reset

Multi-speed step 1

Multi-speed step 2

External Baseblock

Jog speed

Multi-function

digtial inputs

(default setting)

Sink / Source mode

selection wire link

(default: Sink)

CN5-C

CN5-B

CN5-A

Option card connectors

Pulse Train Input (max 32 kHz)

Shield ground terminal

Multi-function

analog/ pulse

train inputs

Power supply +10.5 Vdc, max. 20 mA

Analog Input 1 (Frequency Reference Bias)

-10 to +10 Vdc (20 kΩ)

Analog Input 2 (Frequency Reference Bias)

-10 to +10 Vdc (20 kΩ)

0 or 4 to 20 mA (250 Ω)

Analog Input 3 / PTC Input

(Aux. frequency reference)

-10 to +10 Vdc (20 kΩ)

−V

Power supply, -10.5 Vdc, max. 20 mA

Safety

switch

MEMOBUS/Modbus

comm. RS485/422

max. 115.2 kBps

Safe Disable inputs

Wire

jumper

Open

Safety relay /

controller

Termination resistor

(120 Ω, 1/2 W)

DIP

Switch S2

Fault relay output

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function relay output (During Run)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function pulse train output

(Output frequency)

0 to 32 kHz (2.2 kΩ)

Multi-function analog output 1

(Output frequency)

-10 to +10 Vdc (2mA) or 4 to 20 mA

Multi-function analog output 2

(Output current)

-10 to +10 Vdc (2mA) or 4 to 20 mA

EDM (Safety Electronic Device Monitor)

Main Circuit

Control Circuit

shielded line

twisted-pair shielded line

main circuit terminal

control circuit terminal

R/L1

S/L2

T/L3

Motor

Shielded

Cable

M3

M4

Multi-function relay output (Zero Speed)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

M5

M6

Multi-function relay output (Speed Agree 1)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

SP

SN

AM

FM

V

I

V

I

DIP Switch S1

A2 Volt/Curr. Sel

DIP Switch S4

A3 Analog/PTC

Input Sel

PTC

AI

Off

On

DIP Switch S2

Term. Res. On/Off

Jumper S3

H1, H2

Sink/Source Sel.

Jumper S5

FM/AM Volt./Curr.

Selection

Terminal board

jumpers and switches

FM

+

−

AM

<2>

Page 13

3 Electrical Installation

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 13

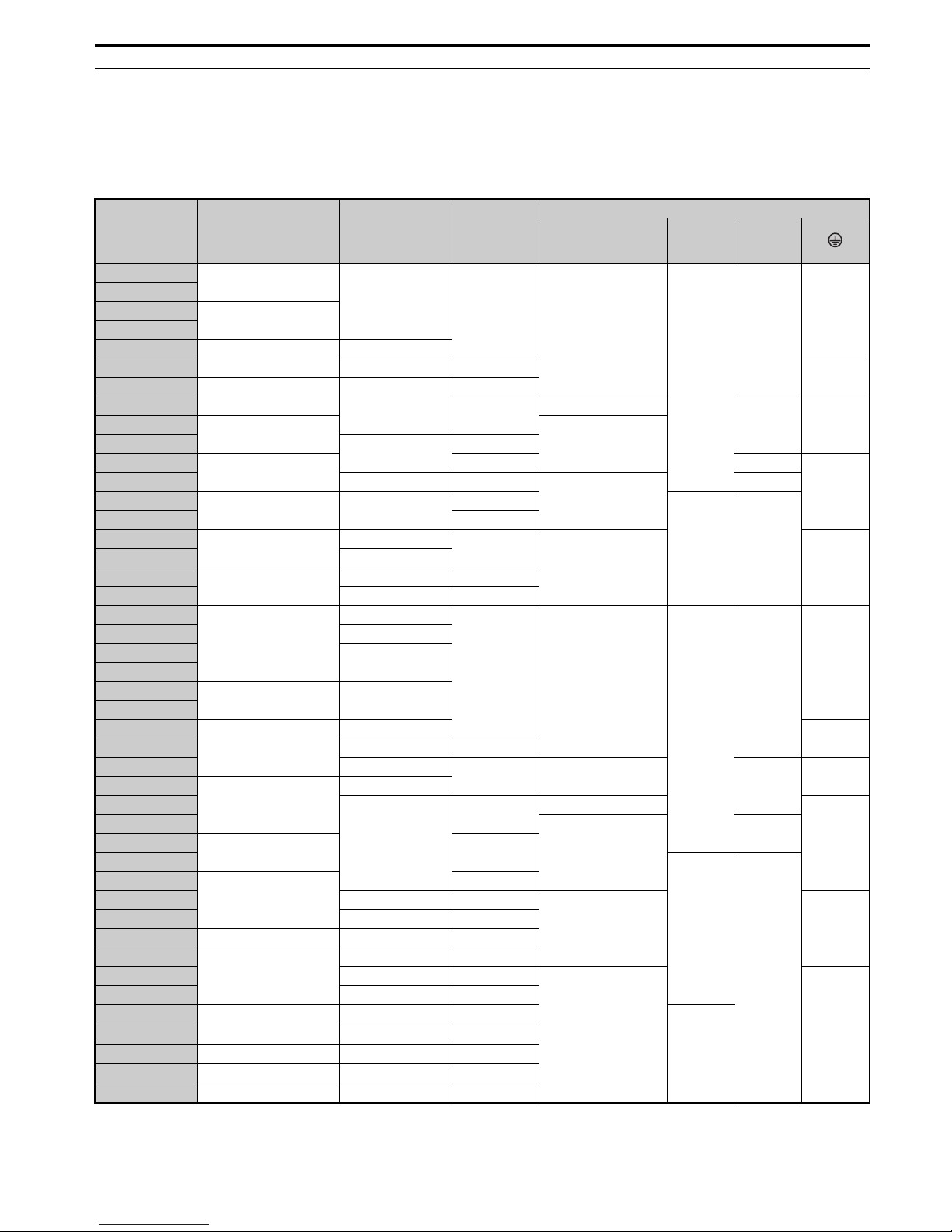

Wiring Specification

Main Circuit

Use the fuses and line filters listed in the table below when wiring the main circuit. Make sure not to exceed the given

tightening torque values.

Model

CIMR-A

EMC Filter

[Schaffner]

Main Fuse

[Bussmann]

Recom.

Motor cable

(mm2)

Main Circuit Terminal Sizes

R/L1,S/L2,T/L3,

U/T1,V/T2,W/T3,

– , +1, +2

+3 B1, B2

2A0004

<1> Connect two of the same filters in parallel. Refer to the Technical Manual for details.

FS5972-10-07

FWH-70B

2.5

M4

–

M4

M4

2A0006

2A0010

FS5972-18-07

2A0012

2A0021

FS5972-35-07

FWH-90B

2A0030 FWH-100B 6

M5

2A0040

FS5972-60-07

FWH-200B

10

2A0056

16

M6

M5 M6

2A0069

FS5972-100-35

M8

2A0081

FWH-300A

25

2A0110

FS5972-170-40

35 M8

M8

2A0138 FWH-350A 50

M10

M10

2A0169

FS5972-250-37 FWH-400A

70

M10 –

2A0211 95

2A0250

FS5972-410-99

FWH-600A

95 × 2P

M12 M12

2A0312 FWH-700A

2A0360

FS5972-600-99

FWH-800A 240

2A0415 FWH-1000A 300

4A0002

FS5972-10-07

FWH-40B

2.5

M4

–

M4

M4

4A0004 FWH-50B

4A0005

FWH-70B

4A0007

4A0009

FS5972-18-07 FWH-90B

4A0011

4A0018

FS5972-35-07

FWH-80B

M5

4A0023 FWH-100B 4

4A0031 FWH-125B

6M5

M5

M6

4A0038

FS5972-60-07

FWH-200B

4A0044

FWH-250A

16

M6

M8

4A0058

M8

M8

4A0072

FS5972-100-35 25

4A0088

M10

–

4A0103

FS5972-170-40

35

4A0139 FWH-350A 50

M10 M10

4A0165 FWH-400A 70

4A0208 FS5972-250-37 FWH-500A 95

4A0250

FS5972-410-99

FWH-600A 120

4A0296 FWH-700A 185

M12 M12

4A0362 FWH-800A 240

4A0414

FS5972-600-99

FWH-800A 95 × 2P

M12

4A0515 FWH-1000A 150 × 2P

4A0675 FS5972-800-99 FWH-1200A 95 × 4P

4A0930 FS5972-600-99 <1> FWH-1200A 120 × 4P

4A1200 FS5972-800-99 <1> FWH-1600A (95 × 4P) × 2

Page 14

3 Electrical Installation

14 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Tightening Torque Values

Tighten the main circuit terminals using the torque values provided by the table below.

Control Circuit

The control terminal board is equipped with screwless terminals. Always use wires within the specification listed below .

For safe wiring it is recommended to use solid wires or flexible wires with ferrules. The stripping length respecti vely

ferrule length should be 8 mm.

EMC Filter Installation

This drive has been tested in accordance with European standards EN61800-3. In order to comply to the EMC standards,

wire the main circuit as described below.

1. Install an appropriate EMC noise filter to the input side. See the table in Main Circuit on page 13 or refer to the

Technical Manual for details.

2. Place the drive and EMC noise filter in the same enclosure.

3. Use braided shield cable for the drive and motor wiring.

4. Remove any paint or dirt from ground connections for minimal ground impedance.

5. Install an DC reactor at drives smaller than 1 kW for compliance with the EN61000-3-2. Refer to the Technical

Manual or contact your supplier for details.

Terminal Size M4 M5 M6 M8 M10 M12

Tightening Torque (N"m) 1.2 to 1.5 2.0 to 2.5 4.0 to 6.0 9.0 to 11.0 18.0 to 23.0 32.0 to 40.0

Wire Type Wire size (mm2)

Solid 0.2 to 1.5

Flexible 0.2 to 1.0

Flexible with ferrule 0.25 to 0.5

L3L3L2L2L1L1L3 L2 L1

E

L3

L2

L1

PE

Make sure the ground wire is grounded

Enclosure panel

Metal plate

Grounding surface

(remove any paint or sealant)

Drive

Grounding surface

(remove any paint or sealant)

Motor cable (braided shield cable, max. 10 m)

Cable clamp

Ground plate

(scrape off any visible paint)

EMC noise filter

Motor

Ground the cable shield

Page 15

3 Electrical Installation

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 15

Main and Control Circuit Wiring

Wiring the Main Circuit Input

Consider the following precautions for the main circuit input.

• Use fuses recommended in Main Circuit on page 13 only.

• If using a ground fault circuit breaker, make sure that it can detect both DC and high frequency current.

• If using an input switch is used, make sure that the switch does not operate not more than once every 30 minutes.

• Use insulation caps when wiring the drive with crimp terminals. Take particular care to ensure that wiring does not

touch neighboring terminals or the surrounding case.

• Insulation barriers are packaged with drive models CIMR-A4A0414 through 1200 to provide added protection

between terminals. Yaskawa recommends using the insulation barriers provided to ensure proper wiring.

• Use a DC reac tor or AC reactor on the input side of the drive:

–To suppress harmonic current.

–To improve the power factor on the power supply side.

–When using an advancing capacitor switch.

–With a large capacity power supply transformer (over 600 kVA).

Wiring the Main Circuit Output

Consider the following precautions for the output circuit wiring.

• Do not connect any other load than a 3 phase motor to the drives output.

• Never connect a power source to the drives output.

• Never short or ground the output terminals.

• Do not use phase correction capacitors.

• If using a contactor between the drive and motor, it should never be operated when the drive is outputting a voltage.

Operating while there is voltage output can cause large peak currents, thus tripping the over current detection or

damage the drive.

Ground Connection

Take the following precautions when grounding the drive.

• Never share the ground wire with other devices such as welding machines, etc.

• Always use a ground wire, that complies with electrical equipment technical standards. Keep ground wires as short as

possible. Leakage current is caused by the drive. Therefore, if the distance between the ground electrode and the

ground terminal is too long, potential on the ground terminal of the drive will become unstable.

• When using more than one drive, do not loop the ground wire.

Control Circuit Wiring Precautions

Consider the following precautions for wiring the control circuits.

• Separate control circuit wiring from main circuit wiring and other high-power lines.

• Separate wiring for control circuit terminals M1-M2, M3-M4, M5-M6, MA, MB, MC (contact output) from wiring to

other control circuit terminals.

• For external control pow er supply use a UL Listed Class 2 power supply.

• Use twisted-pair or shielded twisted-pair cables for control circuits to prevent operating faults.

• Ground the cable shields with the maximum contact area of the shield and ground.

• Cable shields should be grounded on both cable ends.

• If flexible wires with ferrules are connected they might fit tightly into the terminals. To disconnect them, grasp the wire

end with a pair of pliers, release the terminal using a straight-edge screw driver, turn the wire for about 45°, and pull it

gently out of the terminal. For details, refer to the Technical Manual. Use this procedure for removing the wire link

between HC, H1 and H2 when the Safe Disable function is utilized.

Page 16

3 Electrical Installation

16 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Main Circuit Terminals

Note: Confirm the following when wiring models CIMR-A4A0930 and 4A1200:

" Remove the jumpers shorting terminals R/L1-R1/L11, S/L2-S1/L21, and T/L3-T1/L31 when operating with 12-phase

rectification. Refer to the Technical Manual for more information.

" When operating without 12-phase rectification, properly wire terminals R1/L11, S1/L21, and T1/L31 in addition to terminals

R1/L1, S1/L2, and T1/L3.

Control Circuit Terminals

The figure below shows the control circuit terminal arrangement. The drive is equipped with screwless terminals.

There are three DIP switches and two jumpers, S1 to S5, located on the terminal board.

Terminal Type

Function200 V Class

Model

CIMR-A

2A0004 to 2A0081 2A0110 to 2A0138 2A0169 to 2A0415 –

400 V Class 4A0002 to 4A0044 4A0058 to 4A0072 4A0088 to 4A0675 4A0930, 4A1200

R/L1, S/L2, T/L3

Main circuit power supply input

Main circuit power

supply input

Connects line power to

the drive

R1/L11, S1/L21, T1/L31 not available

U/T1, V/T2, W/T3

Drive output Connects to the motor

B1, B2

Braking resistor not available

Available for connecting

a braking resistor or a

braking resistor unit

option

+2

• DC reactor

connection (+1, +2)

(remove the

shorting bar

between +1 and +2)

• DC power supply

input (+1, −)

not available

For connection

• of the drive to a DC

power supply

(terminals +1 and – are

not CE or UL

approved)

• of braking options

• connection of a DC

reactor

+1, –

• DC power supply

input

(+1, −)

• DC power supply input (+1, −)

• Braking transistor connection (+3, −)

+3

not available

− Grounding terminal

S1 Terminal A2 Signal Selection

S2 RS422/485 Termination Resistor

S3

Safe Disable Input

Sink/Source/External Supply Selection

S4 Termin al A3 Analog/PTC Input Selection

MA MB MC

M1 M2 M5

M3 M6 M4

E(G)

HC H1 H2 DM+DM- IG R+ R- S+ S-

S1 S2 S3 S4 S5 S6 S7 S8 SN SC SP

V+ AC V- A1 A2 A3 FM AM AC MP RP AC

Use a straight-edge screwdriver

with a blade width of max 2.5 mm

and a thickness of max 0.6 mm to

release the terminals

S2

S3

S1

S4

S5

V

I

V

I

Current Voltage

Off

On

Source Sink

External 24 Vdc

Power Supply

A

nalog Input PTC Input

PTC

AI

PTC

AI

Page 17

3 Electrical Installation

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 17

Control Circuit Terminal Functions

S5 Terminal FM/AM Signal Selection

Type No. Terminal Name (Function) Function (Signal Level) Default Setting

Multi-Function

Digital Inputs

S1

Multi-function input 1 (Closed: Forward run,

Open: Stop)

Photocoupler

24 Vdc, 8 mA

Use the wire link between terminals SC and SN or SC and SP to select

between sinking, sourcing mode, and the power supply.

S2

Multi-function input 2 (Closed: Reverse run,

Open: Stop)

S3

Multi-function input 3 (External fault, N.O.)

S4

Multi-function input 4 (Fault reset)

S5

Multi-function input 5 (Multi-step speed

reference 1)

S6

Multi-function input 6 (Multi-step speed

reference 2)

S7

Multi-function input 7 (Jog reference)

S8

Multi-function input 8 (External baseblock)

SC

Multi-function input common –

SN Multi-function input 0 V 24 Vdc power supply for digital inputs, 150 mA max (if no digital

input option DI-A3 is used)

Never short terminals SP and SN as doing so will damage the drive.

SP Multi-function input 24 Vdc

Safe Disable

Inputs

H1

Safe Disable input 1

24 Vdc, 8 mA

One or both open: Drive output disabled

Both closed: Normal operation

Internal impedance: 3.3 kΩ

Off time of at least 1 ms

Disconnect the wire jumpers shorting terminals H1, H2, and HC to

use the Safe Disable inputs. Set the S3 jumper to select between

sinking, sourcing mode, and the power supply.

H2

Safe Disable input 2

HC

Safe Disable function common Safe disable function common

Analog Inputs /

Pulse Train

Input

RP

Multi-function pulse train input (Frequency

reference)

Input frequency range: 0 to 32 kHz

Signal Duty Cycle: 30 to 70%

High level: 3.5 to 13.2 Vdc, low level: 0.0 to 0.8 Vdc

Input impedance: 3 kΩ

+V

Power supply for analog inputs 10.5 Vdc (max allowable cur rent 20 mA)

-V

Power supply for analog inputs -10.5 Vdc (max allowable current 20 mA)

A1

Multi-function analog input 1 (Frequency

reference bias)

-10 to 10 Vdc, 0 to 10 Vdc (input impedance: 20 kΩ)

A2

Multi-function analog input 2 (Frequency

reference bias)

-10 to 10 Vdc, 0 to 10 Vdc (input impedance: 20 kΩ)

4 to 20 mA, 0 to 20 mA (input impedance: 250

Ω)

Voltage or current input must be selected by DIP switch S1 and H3-09

A3

Multi-function analog input 3 / PTC Input

(Auxiliary frequency reference)

-10 to 10 Vdc, 0 to 10 Vdc (input impedance: 20 kΩ)

Use switch S4 on the control terminal board to select between analog

input or PTC input. If PTC is selected, set H3-06 = E.

AC

Frequency reference common 0 V

E (G)

Ground for shielded lines and option cards –

Fault Relay

MA

N.O.

30 Vdc, 10 mA to 1 A; 250 Vac, 10 mA to 1 A

Minimum load: 5 Vdc, 10 mA

MB

N.C. output

MC

Fault output common

AM

FM

V

I

V

I

AM

FM

FM/AM: Voltage Output FM: Current Output

AM: Voltage Output

...

Page 18

3 Electrical Installation

18 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

NOTICE: The terminals HC, H1, H2 are used for the Safe Disable function. Do not remove the wire link between HC, H1, or H2 unless

the Safe Disable function is used. Refer to Safe Disable Input Function on page 35 when using this function.

NOTICE: The wiring length to the terminals HC, H1 and H2 should not exceed 30 m.

Multi-Function

Digital Output

M1

Multi-function digital output (During run)

30 Vdc, 10 mA to 1 A; 250 Vac, 10 mA to 1 A

Minimum load: 5 Vdc, 10 mA

M2

M3

Multi-function digital output (Zero speed)

30 Vdc, 10 mA to 1 A; 250 Vac, 10 mA to 1 A

Minimum load: 5 Vdc, 10 mA

M4

M5

Multi-function digital output (Speed agree 1)

30 Vdc, 10 mA to 1 A; 250 Vac, 10 mA to 1 A

Minimum load: 5 Vdc, 10 mA

M6

Monitor Output

MP

Pulse train output (Output frequency) 32 kHz (max)

FM

Analog monitor output 1 (Output frequency)

-10 to +10 Vdc, 0 to +10 Vdc, or 4 to 20 mA

Use jumper S5 on the control terminal board to select between voltage

or current output at terminals AM and FM. Set parameters H4-07 and

H4-08 accordingly when changing the jumper setting.

AM

Analog monitor output 2 (Output current)

AC

Monitor common 0 V

Safety Monitor

Output

DM+

Safety monitor output

Outputs status of Safe Disable function. Closed when both Safe

Disable channels are closed. Up to +48 Vdc 50 mA

DM-

Safety monitor output common

Type No. Terminal Name (Function) Function (Signal Level) Default Setting

Page 19

4 Keypad Operation

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 19

4 Keypad Operation

Digital Operator and Keys

The digital operator is used to program the drive, to start/stop it, and to display fault

information. The LEDs indicate the drive status.

Keys and Functions

Key Name Function

Function Key

(F1, F2)

The functions assigned to F1 and F2 vary depending on the menu that is currently displayed. The

name of each function appears in the lower half of the display window.

ESC Key

• Returns to the previous display.

• Moves the cursor one space to the left.

• Pressing and holding this button will return to the Frequency Reference display.

RESET Key

• Moves the cursor to the right.

• Resets the drive to clear a fault situation.

RUN Key

Starts the drive in the LOCAL mode.

The Run LED

• is on, when the drive is operating the motor.

• flashes during deceleration to stop or when the frequency reference is 0.

• flashes quickly the drive is disabled by a DI, the drive was stopped using a fast stop DI or a run

command was active during power up.

Up Arrow Key Scrolls up to display the next item, sel ects parameter numbers and increments setting values.

Down Arrow Key

Scrolls down to display the previous item, selects parameter numbers and decrements setting

values.

STOP Key Stops drive operation.

ENTER Key

• Enters parameter values and settings.

• Selects a menu item to move between displays.

LO/RE Selection

Key

Switches drive control between the operator (LOCAL) and the control circuit terminals

(REMOTE). The LED is on when the drive is in the LOCAL mode (operation from keypad).

ALM LED Light

On: When the drive detects a fault.

Flashing:

• When an alarm occurs.

• When oPE is detected.

• When a fault or error occurs during Auto-Tuning.

LO

RE

F2F1

ESC

RUN STOP

ENTERRESET

ALM

DIGITAL OPERATOR JVOP-180

F1

F2

ESC

RESET

RUN

STOP

ENTER

LO

RE

ALM

Page 20

4 Keypad Operation

20 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Menu Structure and Modes

The following illustration explains the operator keypad menu structure.

Figure 1.1

<1> Pressing will start the motor.

<2> Drive cannot operate the motor.

<3> Flashing characters are shown as .

<4> X characters are shown in this manual. The LCD Operator will display the actual setting values.

<5> The Frequency Reference appears after the initial display which shows the product name.

<6> The information that appears on the display will vary depending on the drive.

- MODE -

U1-01= 0.00Hz

U1-02= 0.00Hz

U1-03= 0.00A

DRV

FREF (OPR)

Rdy

-MONITR-

FREF (d1-01)

U1-01= 000.00Hz

<3>

<4>

㧔0.00㨪50.00㧕

0.00Hz

DRV

←→

FWD

Rdy

- MODE -

U1-01= 0.00Hz

U1-02= 0.00Hz

U1-03= 0.00A

DRV

Monitor Menu

Rdy

- MODE - PRG

Modified Consts

HELP

HELP

DATA

- MODE - PRG

Quick Setting

DATA

HELP

- MODE - PRG Rdy

Auto-Tuning

DATA

HELP

- MODE - PRG

DATA

Programming

AUTO

-MONITR-

U1 -01= 0.00Hz

U1-02= 0.00Hz

U1-03= 0.00A

DRV

Monitor

JOG FWD FWD/REV

Rdy

-MONITR-

U1- 01 = 0.00Hz

U1-02= 0.00Hz

U1-03= 0.00A

DRV

Frequency Ref

JOG FWD FWD/REV

Rdy

-MONITR-

U1- 02 = 0.00Hz

U1-03= 0.00A

U1-04= 0

DRV

Output Freq

JOG FWD FWD/REV

Rdy

-MONITR-

U2 -01= oC

U2-02= oPr

U2-03= 0.00Hz

DRV

Fault Trace

JOG FWD FWD/REV

Rdy

JOG FWD FWD/REV

JOG FWD

FWD

FWD

FWD

FWD

FWD/REV

Modified

X Parameters

LSEQ

LREF

LSEQ

LREF

LSEQ

LREF

LSEQ

LREF

LSEQ

LREF

LSEQ

LREF

YAS K A WA

A1000

A1000

XXXVX.X/X.XkW

XX.XX/XX.XXA

<XXXXXXXXX>

Initial Display <5>

<6>

Programming Mode <2> Drive Mode <1>

RUN

0

Page 21

5 Start Up

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 21

5Start Up

Drive Setup Procedure

The illustration below shows the basic setup procedure. Each step is explained more detailed on the following pages.

Power On

Before turning on the power supply,

• Make sure all wires are connected properly.

• Make sure no screws, loose wire ends or tools are left in the drive.

• After turning the power on, the drive mode display should appear and no fault or alarm should be displayed.

Control Mode Selection (A1-02)

There are three control modes available. Select the control mode that best suits the application the drive will control.

Control Mode Parameter Main Applications

V/f Control for Induction

Motors

A1-02 = 0

(default)

• General variable speed applications, particularly useful for running multiple motors from a

single drive.

• When replacing a drive in which parameter settings are unknown.

V/f Control with PG Speed

Feedback

A1-02 = 1

• For general-purpose applications that do not require high dynamic response but high speed

accuracy.

• This mode should be used if the motor parameters are unknown and Auto-Tuning cannot be

performed.

Open Loop V ector Contr ol A1-02 = 2

• General variable speed applications

• Applications requiring high precision, high speed control

Closed Loop Vector

Control

<1>

A1-02 = 3

• For general, variable-speed applications that requiring precise speed control down to zero

speed, fast torque response, or precise torque control.

• A speed feedback signal from the motor is required.

Install and wire the drive as explained.

Turn the power on.

Set the control mode.

Set/check the basic parameters:

* b1-01, b1-02 for frequency reference and RUN command source

* H1-, H2-, H3-, H4-, H6- to configure the I/Os

* Frequency reference values

* C1-, C2- for Acceleration/Deceleration times and S-curves

Run the motor without load, check the operation and verify, if the

upper controller (e.g. PLC,...) commands to the drive work as

desired.

Connect the load, run the motor and check the operation

Fine tune and set application parameters (e.g. PID,...) if necessary.

Final check the operation and verify the settings.

Drive is ready to run the application

START

Perform Auto-Tuning or set the motor data manually.

Initialize the drive if necessary using parameter A1-01.

Select Normal / Heavy Duty

Page 22

5 Start Up

22 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Normal / Heavy Duty Selection (C6-01)

The drive supports two ratings, Normal Duty and Heavy Duty. Both have different output current ratings (refer to the

catalog or the Technical Manual). Set the Duty mode in accordance with the application.

Auto-Tuning (T1-)

Auto-Tuning automatically sets up the motor data relevant drive parameters. Three different modes are supported.

Open Loop Vector Control

for PM <1>

A1-02 = 5

Derated torque-load applications employing permanent magnet motors (SPM, IPM) and energy

savings.

Advanced Open Loop

Vector Control for PM <1>

A1-02 = 6 This control mode can be used to operate an IPM motor for constant torque applications.

Closed Loop Vector

Control for PM

<1>

A1-02 = 7

• This mode can be used for high precision control of a PM motor in constant torque or variable

torque applications.

• A speed feedback signal is required.

<1> For explanations of these control modes, refer to the Technical Manual.

Mode Heavy Duty Rating (HD) Normal Duty Rating (ND)

C6-01 01

Application

Applications with a constant torque like extruders,

conveyors and cranes. High overload capability

might be needed.

Applications where the torque increases with the speed

like fans or pumps. High overload tolerance is normally

not needed.

Overload capability (OL2) 150% of drive rated current for 60 s 120% of drive rated current for 60 s

L3-02 Stall Prevention during

Acceleration

150% 120%

L3-06 Stall Prevention during

Run

150% 120%

Default carrier frequency 2 kHz 2 kHz Swing PWM

Type Setting Application Conditions and Benefits

Control Mode (A1-02)

V/f (0)

V/f w/PG

(1)

OLV (2) CLV (3)

Rotational Auto-

Tuning

T1-01 = 0

• Motor can be decoupled from the load and rotate freely

while Auto-Tuning is performed.

• Motor and load can not be decoupled but the motor load

is below 30%.

• Rotational Auto-Tuning gives the most accurate results,

and is therefore highly recommended if possible.

N/A N/A YES YES

Stationary Auto-

Tuning 1

T1-01 = 1

• Motor and load can not be decoupled and the load is

higher than 30%.

• A motor test report listing motor data is not available.

• Automatically calculates motor parameters needed for

vector control.

N/A N/A YES YES

Stationary Auto-

Tuning 2

T1-01 = 4

• Motor and load can not be decoupled and the load is

higher than 30%.

• A motor test report is available. Once the no- load current

and the rated slip have been entered, the drive calculates

and sets all other motor-related parameters.

N/A N/A YES YES

Stationary Auto-

Tuning for Line-to-

Line Resistance

T1-01 = 2

• The drive is used in V/f Control and other Auto-Tuning

selections not possible.

• Drive and motor capacities differ.

• Tunes the drive after the cable between the drive and

motor has been replaced with a cable over 50 m long.

Assumes Auto-Tuning has already been performed.

• Should not be used for any vector control modes unless

the motor cable has changed.

YES YES YES YES

Control Mode Parameter Main Applications

Page 23

5 Start Up

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 23

For Auto-Tuning enter the Auto-Tuning menu and perform the steps shown in the figure below. The number of name

plate data to be entered depends on the selected typ e of Auto-Tuning. This example shows Rotational Auto-Tuning.

If Auto-Tuning can not be performed for some reason (no-load operation impossible etc.), then set up the maximum

frequency and voltage in the E1- parameters and enter the motor data manually into the E2- parameters.

NOTICE: The Safe Disable inputs must be closed during Auto-Tuning.

External Reference Selection and Acceleration/ Deceleration Times

Frequency Reference Selection (b1-01)

Set parameter b1-01 according to the frequency reference used.

Rotational Auto-

Tuning for V/f

Control

T1-01 = 3

• Recommended for applications using Speed Estimation

Speed Search or using the Energy Saving function in V/f

Control.

• Assumes motor can rotate while Auto-Tuning is

executed. Increases accuracy for certain functions like

torque compensation, slip compensation, Energy Saving,

and Speed Search.

YES YES N/A N/A

CAUTION

Do not touch the motor until the Auto-Tuning is finished.

Failure to comply may result in minor or moderate injury. Voltage is still applied to the motor during the tuning

process, even thought the motor may not be rotating.

b1-01 Reference source Frequency reference input

0 Operator keypad

Set the frequency references in the d1- parameters and use digital inputs to switch over between

different reference values.

1 Analog input Apply the frequency reference signal to terminal A1, A2, or A3.

2 Serial Comm. Serial Communications using the RS422/485 port

3 Option Card Communications option card

4 Pulse input Set the frequency reference at terminal RP using a pulse train signal.

Type Setting Application Conditions and Benefits

Control Mode (A1-02)

V/f (0)

V/f w/PG

(1)

OLV (2) CLV (3)

- MODE -

End

Tune Successful

DRV

FWD RESET

Enter the Auto-

Tuning Mode

Select the tuning

method

Set up all name

plate data

The tuning start

display appears

During the tuning the

display flashes

After successful tuning

“End” is displayed

Drive mode

display

- A.TUNE -

T1-01= 0

∗0∗

Standard Tuning

PRG

Entry Accepted

Tuning Mode Sel

FWD

- A.TUNE -

T1-01= 0

∗0∗

Standard Tuning

PRG

Tuning Mode Sel

ESC FWD DATA

- MODE -

U1-01= 0.00Hz

U1-02= 0.00Hz

U1-03= 0.00A

DRV

FREF (OPR)

Rdy

JOG FWD FWD/REV

LSEQ

LREF

HELP

- MODE - PRG

Auto-Tuning

DATA

AUTO

FWD

“0”

- A.TUNE -

T1-07= 1450RPM

(0 ~ 24000)

PRG

Rated Speed

ESC FWD DATA

“1750RPM”

- A.TUNE -

T1-02= X.XXkW

(0.00 ~ 650.00)

PRG

Mtr Rated Power

ESC FWD DATA

“X.XXkW”

- A.TUNE -

0.00 Hz/ 0.00A

Tuning Ready ?

DRV

Auto-Tuning

ESC FWD

Press RUN key

- A.TUNE -

X.XX Hz/ X.XXA

DRV

Tune Proceeding

FWD

RUN

Page 24

5 Start Up

24 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

Run Command Selection (b1-02)

Set parameter b1-02 according to the run command used.

Acceleration/ Deceleration Times and S-Curves

There are four sets of acceleration and deceleration times which can be set in the C1- parameters. The default

activated accel/decel times are C1-01/02. Adjust these times to the appropriate values required by the application. If

necessary S-curves can be activated in the C2- parameters for softer accel/decel start and end.

Reference and Run Source

The drive has a LOCAL and a REMOTE mode.

If the drive is operated in the REMOTE mode, make sure that the correct sources for the frequency reference and run

command are set in parameters b1-01/02 and that the drive is in the REMOTE mode.

The LED in the LO/RE key indicates where the Run command is input from.

I/O Setup

Note: The default setting functions can be seen in the connection diagram on page 12.

Multi-Function Digital Inputs (H1-)

The function of each digital input can be assigned in the H1- parameters.

Multi-Function Digital Outputs (H2-)

The function of each digital output can be assigned in the H2- parameters. The setting value of these parameters

consist of 3 digits, where the middle and right digit set the function and the left digit sets the output characteristics (0:

Output as selected; 1: Inverse output).

Multi-Function Analog Inputs (H3-)

The function of each analog input can be assigned in the H3- parameters. Input A1 and A3 are set for -10 to +10 Vdc

input. A2 is set for 4-20 mA input.

NOTICE: If the input signal level of input A2 is switched between voltage and current, make sure that DIP switch S1 is in the correct

position and parameter H3-09 is set up correctly.

NOTICE: When using analog input A3 as PTC input, set DIP switch S4 to PTC and parameter H3-06 = E.

Multi-Function Analog Outputs (H4-)

Use the H4- parameters to set up the output value of the analog monitor outputs and to adjust the output signal

levels. When changing signal levels in parameter H4-07/08, make sure jumper S5 is set accordingly.

b1-02 Reference source Run command input

0 Operator keypad RUN and STOP keys on the operator

1 Multi-Function digital input Multi-Function digital input

2 Serial Comm. Serial Communications using the RS422/485 port

3 Option Card Communications option card

Status Description

LOCAL The Run/ Stop command and the frequency reference are entered at the operator keypad.

REMOTE

The Run command source entered in parameter b1-02 and the frequency reference source entered in parameter

b1-01 are used.

LO/RE LED Description

ON Run command is issued from operator.

OFF Run command is issued from a different source than the operator.

Page 25

5 Start Up

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 25

Test Run

Perform the following steps to start up the machine after all parameter settings have been done.

1.

Run the motor without load and check if all input, outputs and the sequence work as desired.

2. Connect the load to the motor.

3. Run the motor with load and make sure that there is no vibrations, hunting or motor stalling occurs.

After taking the steps listed above, the drive should be ready to run the application and perform the basic functions. For

special setups like PID control etc. refer to the Technical Manual.

Page 26

26 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

6 Parameter Table

6 Parameter Table

This parameter table shows the most important parameters.

Default settings are bold type. Refer to the Technical

Manual for a complete list of parameters.

No. Name Description

Initialization Parameters

A1-01

Access Level

Selection

0: View and set A1-01 and A1-04. U-

parameters can also be viewed.

1: User Parameters (access to a set of

parameters selected by the user, A2-01 to

A2-32)

2: Advanced Access (access to view and

set all parameters)

A1-02

Control

Method

Selection

0: V/f Control

1: V/f Control with PG

2: Open Loop Vector Control

3: Closed Loop Vector Control

5: Open Loop Vector Control for PM

6: Advanced Open Loop Vector Control for

PM

7: Closed Loop Vector Control for PM

A1-03

Initialize

Parameters

0: No initialization

1110: User Initialize (parameter values must

be stored using parameter o2-03)

2220: 2-wire initialization

3330: 3-wire initialization

5550: oPE04 error reset

Operation Mode Selection

b1-01

Frequency

Reference

Selection 1

0: Digital operator

1: Analog input terminals

2: MEMOBUS/Modbus communications

3: Option PCB

4: Pulse input (terminal RP)

b1-02

Run

Command

Selection 1

0: Digital operator

1: Digital input terminals

2: MEMOBUS/Modbus communications

3: Option PCB

b1-03

Stopping

Method

Selection

0: Ramp to stop

1: Coast to stop

2: DC Injection Braking to stop

3: Coast with timer

9: Simple Positioning Stop

b1-04

Reverse

Operation

Selection

0: Reverse enabled.

1: Reverse disabled.

b1-14

Phase Order

Selection

0: Standard

1: Switch phase order (reverses the direction

of the motor)

DC Injection Braking

b2-01

DC Injection

Braking Start

Frequency

Sets the frequency at which DC Injection

Braking starts when “Ramp to stop” (b1-03

= 0) is selected.

b2-02

DC Injection

Braking

Current

Sets the DC Injection Braking current as a

percentage of the drive rated current.

b2-03

DC Injection

Braking Time

at Start

Sets DC Injection Braking (Zero Speed

Control when in CLV/PM) time at start.

Disabled when set to 0.00 seconds.

b2-04

DC Injection

Braking Time

at Stop

Sets DC Injection Braking time at stop.

Acceleration/ Deceleration

C1-01

Acceleration

Time 1

Sets the time to accelerate from 0 to

maximum frequency.

C1-02

Deceleration

Time 1

Sets the time to decelerate from maximum

frequency to 0.

C1-03 to

C1-08

Acceleration/

Deceleration

Time 2 to 4

Set the accel/decel times 2 to 4 (set like C101/02).

C2-01

S-Curve

Characteristic

at Accel Start

S-curve at acceleration start.

C2-02

S-Curve

Characteristic

at Accel End

S-curve at acceleration end.

C2-03

S-Curve

Characteristic

at Decel Start

S-curve at deceleration start.

C2-04

S-Curve

Characteristic

at Decel End

S-curve at deceleration end.

Slip Compensation

C3-01

Slip

Compensation

Gain

Sets the gain for the motor slip

compensation function used for motor 1.

C3-02

Slip

Compensation

Primary Delay

Time

Adjusts the slip compensation function

delay time used for motor 1.

Torque Compensation

C4-01

Torque

Compensation

Gain

Sets the gain for the automatic torque

(voltage) boost function and helps to

produce better starting torque. Used for

motor 1.

C4-02

Torque

Compensation

Primary Delay

Time

Sets the torque compensation filter time.

Carrier Frequency

C6-01

Drive Duty

Selection

0: Heavy Duty (HD) for constant torque

applications.

1: Normal Duty (ND) for variable torque

applications.

C6-02

Carrier

Frequency

Selection

1: 2.0 kHz

2: 5.0 kHz

3: 8.0 kHz

4: 10.0 kHz

5: 12.5 kHz

6: 15.0 kHz

7: Swing PWM1 (Audible sound 1)

8: Swing PWM2 (Audible sound 2)

9: Swing PWM3 (Audible sound 3)

A: Swing PWM4 (Audible sound 4)

B to E: No setting possible

F: User defined (determined by C6-03

through C6-05)

Frequency Reference

d1-01 to

d1-16

Frequency

Reference

1 to 16

Sets the frequency reference for the drive.

Setting units are determined by parameter

o1-03.

No. Name Description

Page 27

6 Parameter Table

YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide 27

d1-17

Jog Frequency

Reference

Sets the Jog frequency reference. Setting

units are determined by parameter o1-03.

V/f Pattern for Motor 1

E1-01

Input Voltage

Setting

This parameter must be set to the power

supply voltage.

WARNING! Drive input voltage (not motor

voltage) must be set in E1-01 for the

protective features of the drive to function

properly. Fa ilure to do so may result in

equipment damage and/or death or personal

injury.

E1-04

Maximum

Output

Frequency

These parameters are only applicable when

E1-03 is set to F.

To set li nea r V/f chara cteristics, set the

same values for E1-07 and E1-09. In this

case, the setting for E1-08 will be

disregarded. Ensure that the four

frequencies are set according to these rules:

E1-09 ≤ E1-07 < E1-06 ≤ Ε1−11 ≤ E1-04

Note: Some parameters may not be

available depending on the control mode.

• E1-07, E1-08 and E-10 are available only

in the following control modes: V/f

Control, V/f with PG, Open Loop Vector.

• E1-11, E1-12 and E-13 are available only

in the following control modes: V/f

Control, V/f with PG, Open Loop Vector,

Closed Loop Vector.

E1-05

Maximum

Volt ag e

E1-06

Base

Frequency

E1-07

Middle Output

Frequency

E1-08

Middle Output

Frequency

Volt ag e

E1-09

Minimum

Output

Frequency

E1-10

Minimum

Output

Frequency

Volt ag e

E1-13 Base Voltage

Motor 1 Parameters

E2-01

Motor Rated

Current

Sets the motor nameplate full load current in

Amps. Automatically set during

Auto-Tuning.

E2-02

Motor Rated

Slip

Sets the motor rated slip. Automatically set

during Auto-Tuning.

E2-03

Motor

No-Load

Current

Sets the no-load current for the motor.

Automatically set during Auto-Tuning.

E2-04

Number of

Motor Poles

Sets the number of motor poles.

Automatically set during Auto-Tuning.

E2-05

Motor

Line-to-Line

Resistance

Sets the phase-to-phase motor resistance.

Automatically set during Auto-Tuning.

E2-06

Motor Leakage

Inductance

Sets the voltage drop due to motor leakage

inductance as a percentage of motor rated

voltage. Automatically set during

Auto-Tuning.

Multi-Function Digital Inputs

H1-01 to

H1-08

Multi-Function

Digital Input

Terminal S1 to

S8 Function

Selection

Selects the function of terminals S1 to S8.

Note: Major functions are listed at the end of the table.

No. Name Description

Output Voltage (V)

Frequency (Hz)

E1-05

E1-12

E1-13

E1-08

E1-10

E1-09 E1-07 E1-06 E1-11 E1-04

Multi-Function Digital Outputs

H2-01

Terminal M1M2 function

selection

Set the function for the relay output M1M2.

H2-02

Terminal M3M4 function

selection

Sets the function for the relay output M3M4.

H2-03

Terminal M5M6 function

selection

Sets the function for the relay output M5M6.

H2-06

Watt Hour

Output Unit

Selection

Outputs a 200 ms pulse signal when the

watt-hour counter increases by the units

selected.

0: 0.1 kWh units

1: 1 kWh units

2: 10 kWh units

3: 100 kWh units

4: 1000 kWh units

Note: Major functions are listed at the end of the table.

Multi-Function Analog Inputs

H3-01

Terminal A1

Signal Level

Selection

0: 0 to 10 V

1: –10 to 10 V

H3-02

Terminal A1

Function

Selection

Sets the function of terminal A1.

H3-03

Terminal A1

Gain Setting

Sets the level of the input value selected in

H3-02 when 10 V is input at terminal A1.

H3-04

Terminal A1

Bias Setting

Sets the level of the input value selected in

H3-02 when 0 V is input at terminal A1.

H3-05

Terminal A3

Signal Level

Selection

0: 0 to 10 V

1: –10 to 10 V

H3-06

Terminal A3

Function

Selection

Sets the function of terminal A3.

H3-07

Terminal A3

Gain Setting

Sets the level of the input value selected in

H3-06 when 10 V is input at terminal A3.

H3-08

Terminal A3

Bias Setting

Sets the level of the input value selected in

H3-06 when 0 V is input at terminal A3.

H3-09

Terminal A2

Signal Level

Selection

0: 0 to 10 V

1: –10 to 10 V

2: 4 to 20 mA

3: 0 to 20 mA

Note: Use DIP switch S1 to set input

terminal A2 for a current or a voltage input

signal.

H3-10

Terminal A2

Function

Selection

Sets the function of terminal A2.

H3-11

Terminal A2

Gain Setting

Sets the level of the input value selected in

H3-10 when 10 V (20 mA) is input at

terminal A2.

H3-12

Terminal A2

Bias Setting

Sets the level of the input value selected in

H3-10 when 0 V (0 or 4 mA) is input at

terminal A2.

H3-13

Analog Input

Filter Time

Constant

Sets a primary delay filter time constant for

terminals A1, A2, and A3. Used for noise

filtering.

No. Name Description

Page 28

6 Parameter Table

28 YASKAWA ELECTRIC TOEP C710616 27D YASKAWA AC Drive - A1000 Quick Start Guide

H3-14

Analog Input

Terminal

Enable

Selection

Determines which of the analog input

terminals will be enabled when a digital

input programmed for “Analog input

enable” (H1- = C) is activated.

1: Terminal A1 only

2: Terminal A2 only

3: Terminals A1 and A2 only

4: Terminal A3 only

5: Terminals A1 and A3

6: Terminals A2 and A3

7: All terminals enabled

Multi-Function Analog Inputs

H4-01

Multi-Function

Analog Output

Terminal FM

Monitor

Selection

Selects the data to be output through multifunction analog output terminal FM.

Set the desired monitor parameter to the

digits available in U-. For example,

enter “103” for U1-03.

H4-02

Multi-Function

Analog Output

Terminal FM

Gain

Sets the signal level at terminal FM that is

equal to 100% of the selected monitor

value.

H4-03

Multi-Function

Analog Output

Terminal FM

Bias

Sets the signal level at terminal FM that is

equal to 0% of the selected monitor value.

H4-04

Multi-Function

Analog Output

Terminal AM

Monitor

Selection

Selects the data to be output through multifunction analog output terminal AM.

Set the desired monitor parameter to the

digits available in U-. For example,

enter “103” for U1-03.

H4-05

Multi-Function

Analog Output

Terminal AM

Gain

Sets the signal level at terminal AM that is

equal to 0% of the selected monitor value.

H4-06

Multi-Function

Analog Output

Terminal AM

Bias

Sets the bias value added to the terminal

AM output signal.

H4-07

Multi-Function

Analog Output

Terminal FM

Signal Level

Selection

0: 0 to 10 V

1: -10 to 10 V

2: 4 to 20 mA

H4-08

Multi-Function

Analog Output

Terminal AM

Signal Level

Selection

0: 0 to 10 V

1: -10 to 10 V

2: 4 to 20 mA

Pulse Input Setting (Freq.)

H6-02

Pulse Train

Input Scaling

Sets the terminal RP input signal frequency

that is equal to 100% of the value selected

in H6-01.

H6-03

Pulse Train

Input Gain

Sets the level of the value selected in H6-01

when a frequency with the value set in H602 is input.

H6-04

Pulse Train

Input Bias

Sets the level of the value selected in H6-01

when 0 Hz is input.

Pulse Output Setting

H6-06

Pulse Train

Monitor

Selection

Select the pulse train monitor output

function (value of the - part of

U-).

Example: To select U5-01, set 501.

No. Name Description

H6-07

Pulse Train

Monitor

Scaling

Sets the terminal MP output signal

frequency when the monitor value is 100%.