Page 1

Operator's Manual

Riding Mower

Internal Bagging System

27.5" Cutting Deck

Model Series 320

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained ineffective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

PRINTED IN U.S.A.

MTD LLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

FORM NO. 770-10077D

(11/2001 )

Page 2

TABLEOFCONTENTS

Content Page

Important Safe Operation Practices ............................................................................ 3

Slope Gauge ............................................................................................................... 6

Assembling Your Riding Mower .................................................................................. 7

Know Your Riding Mower ............................................................................................ 9

Operating Your Riding Mower ..................................................................................... 11

Making Adjustments .................................................................................................... 13

Servicing Your Riding Mower ...................................................................................... 16

Maintaining Your Riding Mower ................................................................................... 17

Off-Season Storage .................................................................................................... 19

Troubleshootin{ .......................................................................................................... 20

Parts List ..................................................................................................................... 22

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new riding mower. Itwill help you assemble, prepare

and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space providedbelow. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

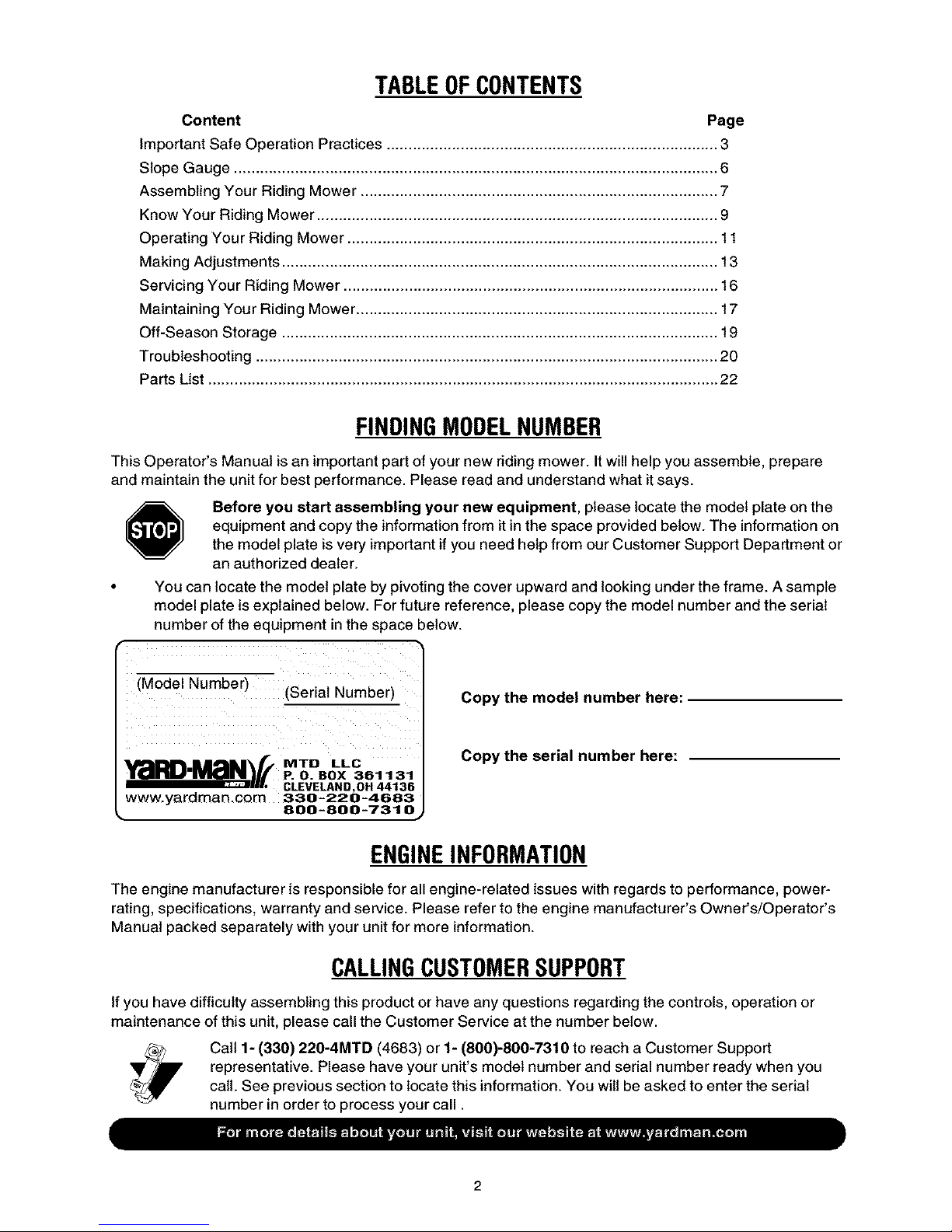

You can locate the model plate by pivoting the cover upward and looking under the frame. A sample

model plate is explained below. For future reference, please copy the model number and the serial

number of the equipment in the space below.

(Model Number) (Serial Number)

_, MTO LLC

P.O. BOX 361131

CLEVELAND,OH 44136

www.yardman,com 330-220-4683

, 800-800-7310_

Copy the model number here:

Copy the serial number here:

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-

rating, specifications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's

Manual packed separately with your unit for more information.

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Service at the number below.

Call 1- (330) 220-4MTD (4683) or 1- (800)-800-7310 to reach a Customer Support

representative. Please have your unit's model number and serial number ready when you

call. See previous section to locate this information. You will be asked to enter the serial

number in order to process your call.

Page 3

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

_hb WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all instructionsin this

manual before attempting to operate your riding mower. Failure to comply with these instructions may result

in personal injury.When you see thissymbol--heed its warning.

Your riding mower was built to be operated according to the rulesfor safe operation inthis manual. As with any type

of power equipment, carelessness or error on the part of the operator can result in serious injury. If you violate any

of these rules, you may cause serious injury to yourself or others.

_lb ARNING: Engine exhaust, some of its constituents, and certain vehicle components contain or

emit chemicals known to State of California to cause cancer and birth defects or other

reproductive harm.

GeneralOperation

• Read, understand, and follow all instructions inthe

manual and on the machine before starting. Keep

this manual in a safe place for future and regular

reference and for ordering replacement parts.

• Only allow responsible individuals familiar with the

instructions to operate the machine. Know controls

and how to stop the machine quickly.

• Do not put hands or feet under cutting deck or near

rotating parts.

• Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade. A small object may have been overlooked

and could be accidentally thrown by the mower in

any direction and cause injuryto you or a

bystander. To help avoid a thrown objects injury,

keep children, bystanders and helpers at least 75

feet from the mower while it isin operation. Always

wear safety glasses or safety goggles during

operation or while performing an adjustment or

repair, to protect eyes from foreign objects. Stop

the blade(s) when crossing gravel drives, walks or

roads.

• Be sure the area is clear of other people before

mowing. Stop machine if anyone enters the area.

Never carry passengers.

• Disengage blade(s) before shifting intoreverse and

backing up. Always look down and behind before

and while backing.

• Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not

operate the mower without either the entire grass

catcher or the chute guard in place.

• Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive

speed.

• Never leave a running machine unattended.

Always turn off blade(s), place transmission in

neutral, set park brake, stop engine and remove

key before dismounting.

• Turn off blade(s) when not mowing.

• Stop engine and wait until blade(s) comes to a

complete stop before (a) removing grass catcher or

unclogging chute, or (b) making any repairs,

adjusting or removing any grass or debris.

• Mow only in daylight or good artificial light.

• Do not operate the machine while under the

influence of alcohol or drugs.Watch for traffic when

operating near or crossing roadways.

• Use extra care when loading or unloading the

machine into a trailer or truck. This unit should not

be driven up or down a ramp onto a trailer or truck

under power, because the unit could tip over,

causing serious personal injury.The unit must be

pushed manually on a ramp to load or unload

properly.

• Never make cutting height adjustment while engine

is running, if operator must dismount to do so.

• Wear sturdy, rough-soled work shoes and close-

fitting slacks and shirts. Do not wear loose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals, or

sneakers.

• Check overhead clearance carefully before driving

under power lines, wires, bridges or low hanging

tree branches, before entering or leaving buildings,

or in any other situation where the operator may be

struck or pulled from the unit, which could result in

serious injury.

• Disengage all attachment clutches, thoroughly

depress the brake pedal, and shift into neutral

before attempting to start engine.

• Your mower isdesigned to cut normal residential

grass of a height no more than 10". Do not attempt

to mow through unusually tall, dry grass (e.g.,

pasture) or piles of dry leaves. Debris may build up

Page 4

onthemowerdeckorcontacttheengineexhaust

presentingapotentialfirehazard.

SlopeOperation

• Slopes are a major factor related to loss of control

and tip-over accidents which can result in severe

injury or death. All slopes require extra caution. If

you cannot back upthe slope or if you feel uneasy

on it, do not mow it.

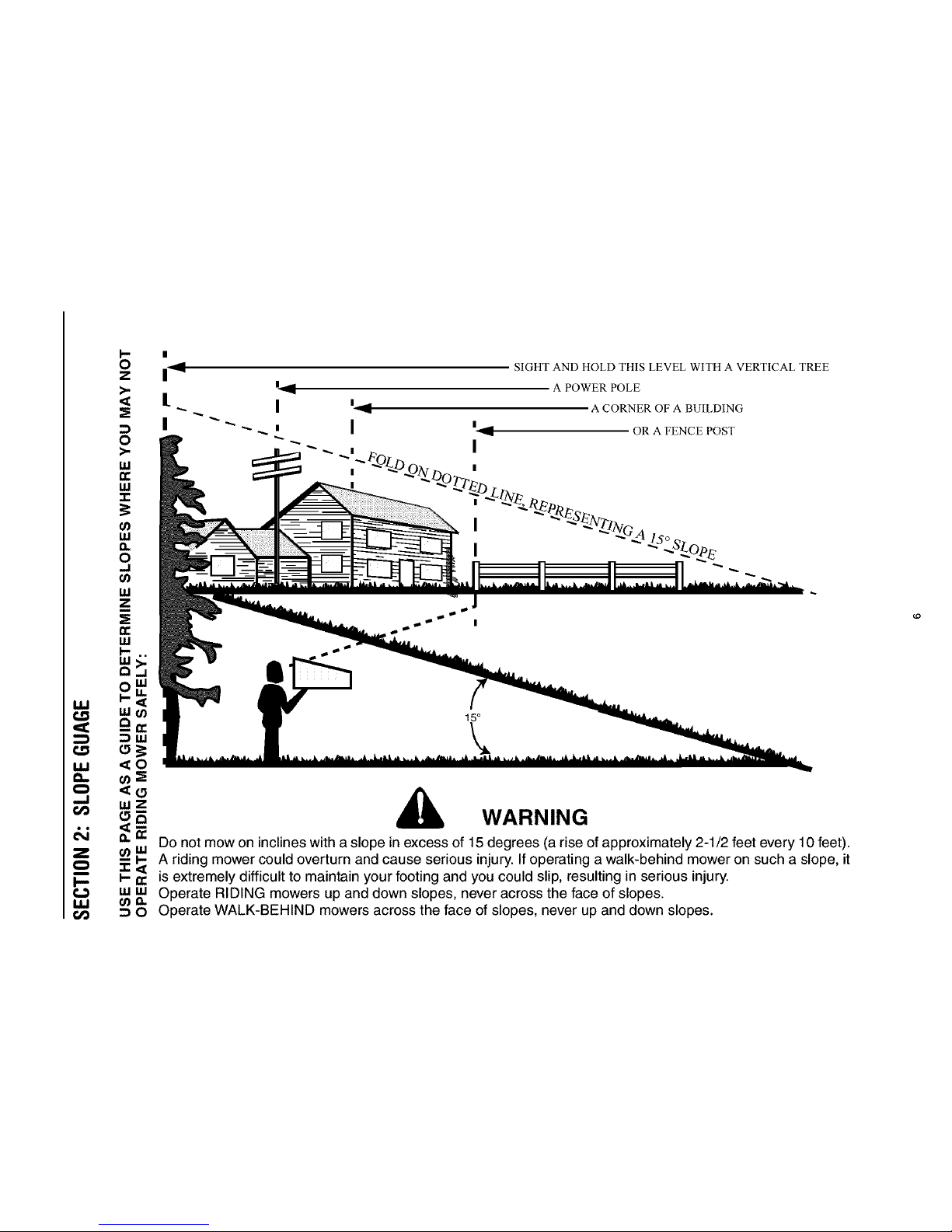

• For your safety, use the slope gauge included as

part of this manual to measure slopes before

operating this unit on a sloped or hilly area. Ifthe

slope is greater than 15° as shown on the slope

gauge, do not operate this unit in that area or

serious injury could result.

Do:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, limbs, etc.

• Watch for holes, ruts or bumps. Uneven terrain

could overturn the machine. Tall grass can hide

obstacles.

• Use slow speed. Choose a low enough gear so that

you will not have to stop or shift while on the slope.

Always keep machine in gear when going down

slopes to take advantage of engine braking action.

• Follow the manufacturer's recommendations for

wheel weights or counterweights to improve

stability.

• Use extra care with grass catchers or other

attachments. These can change the stability of the

machine.

• Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

Rapid engagement or braking could cause the front

of the machine to lift and rapidly flip over backwards

which could cause serious injury.

• Avoid starting or stopping on a slope. Iftires lose

traction, disengage the blade(s) and proceed slowly

straight down the slope.

DoNot

• Do not turn on slopes unless necessary; then, turn

slowly and gradually downhill, if possible.

• Do not mow near drop-offs, ditches or

embankments .The mower could suddenly turn over

if a wheel is over the edge of a cliff or ditch, or if an

edge caves in.

• Do not mow on wet grass. Reduced traction could

cause sliding.

• Do not try to stabilize the machine by putting your

foot on the ground.

• Do not use grass catcher on steep slopes.

Children

• Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

• Keep children out of the mowing area and in

watchful care of an adult other than the operator.

• Be alert and turn machine off if children enter the

area.

• Before and when backing, look behind and down

for small children.

• Never carry children. They may fall off and be

seriously injured or interfere with the safe machine

operation.

• Never allow children under 14 years old to operate

the machine. Children 14 years and over should

only operate machine under close parental

supervision and proper instruction.

• Use extra care when approaching blind corners,

shrubs, trees or other objects that may obscure

your vision of a child or other hazard.

• Remove key when machine is unattended to

prevent unauthorized operation.

Service

• Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

a. Use only an approved container.

b. Never remove fuel cap or add fuel with the

engine running. Allow engine to cool at least

two minutes before refueling.

c. Replace fuel cap securely and wipe off any

spilled fuel before starting the engine as it may

cause a fire or explosion.

d. Extinguish all cigarettes, cigars, pipes and

other sources of ignition.

e. Never refuel the machine indoors because fuel

vapors will accumulate inthe area.

f. Never store the fuel container or machine

inside where there is an open flame or spark,

such as a gas hot water heater, space heater

or furnace.

• Never run a machine inside a closed area.

• To reduce fire hazard, keep the machine free of

grass, leaves or other debris build-up. Clean up oil

or fuel spillage. Allow machine to cool at least 5

minutes before storing.

• Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have

stopped. Disconnect the spark plug wire, and keep

the wire away from the spark plug to prevent

accidental starting.

• Check the blade and engine mounting bolts at

frequent intervals for proper tightness. Also,

visually inspect blade for damage (e.g., excessive

wear, bent, cracked). Replace with blade which

meets original equipment specifications.

• Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

Page 5

• Nevertamperwithsafetydevices.Checktheir

properoperationregularly.Useallguardsas

instructedinthismanual.

• Afterstrikingaforeignobject,stoptheengine,

removethewirefromthesparkplugandthoroughly

inspectthemowerforanydamage.Repairthe

damagebeforerestartingandoperatingthemower.

• Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.Foryour

safetyprotection,frequentlycheckcomponents

andreplacewithmanufacturer'srecommended

partswhennecessary.

• Mowerbladesaresharpandcancut.Wrapthe

blade(s)orwearglovesanduseextracautionwhen

servicingblade(s).

• Checkbrakeoperationfrequently.Adjustand

serviceasrequired.

• Muffler,engineandbeltguardsbecomehotduring

operationandcancauseaburn.Allowtocooldown

beforetouching.

Donotchangetheenginegovernorsettingsor

overspeedtheengine.Excessiveenginespeeds

aredangerous.

Observeproperdisposallawsandregulations.

Improperdisposaloffluidsandmaterialscanharm

theenvironmentandtheecology.

a. Priortodisposal,determinethepropermethod

todisposeofwastefromyourlocalofficeof

EnvironmentalProtectionAgency.Recycling

centersareestablishedtoproperlydisposeof

materialsinanenvironmentallysafefashion.

b. Usepropercontainerswhendrainingfluids.Do

notusefoodorbeveragecontainersthatmay

misleadsomeoneintodrinkingfromthem.

Properlydisposeofthecontainersimmediately

followingthedrainingoffluids.

c. DONOTpouroilorotherfluidsintotheground,

downadrainorintoastream,pond,lakeor

otherbodyofwater.ObserveEnvironmental

ProtectionAgencyregulationswhendisposing

ofoil,fuel,coolant,brakefluid,filters,batteries,

tiresandotherharmfulwaste.

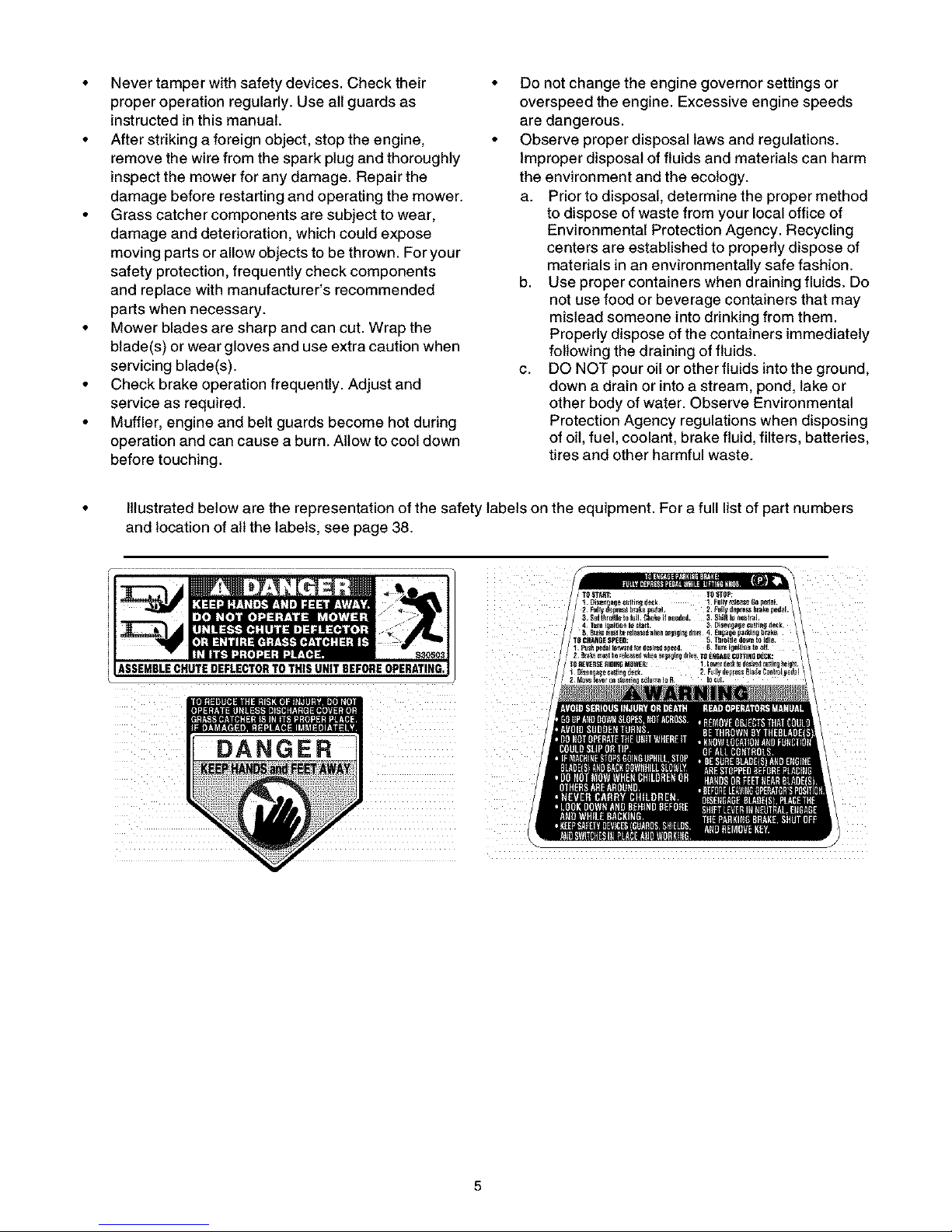

Illustratedbelowaretherepresentationofthesafetylabelsontheequipment.Forafulllistofpartnumbers

andlocationofallthelabels,seepage38.

ASSEMBLECHUTEDEFLECTORTOTHIS UNITBEFOREOPERATING,

Page 6

o .,

L _ IIq A POWER POLE

I q A CORNER OF A BUILDING

| "_ _" "_ _" _ ! OR A FENCE POST

Ill

tv

Ill

Ill

-1

Ill

_z

tv

Ill

I--

Ill

o5

€._ O3

,,, 40

.J

,,,Z

z

W mll.

SIGHT AND HOLD THIS LEVEL WITH A VERTICAL TREE

WARNING

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet).

A riding mower could overturn and cause serious injury. If operating a walk-behind mower on such a slope, it

is extremely difficult to maintain your footing and you could slip, resulting in serious injury.

Operate RIDING mowers up and down slopes, never across the face of slopes.

Operate WALK-BEHIND mowers across the face of slopes, never up and down slopes.

cO

Page 7

SECTION3: ASSEMBLINGYOURRIDINGMOWER

• Remove all screws and staples from the crate.

• Holding sides of the crate firmly, lift top of the crate

up and set it aside. Avoid tire punctures.

• Remove and discard plastic bag covering the unit.

• Lift the rear of the mower and clear the bottom of

the crate. Repeat for the front.

• Be sure the parking brake is disengaged. See

Figure 8for location of the parking brake. Roll unit

out of the crate.

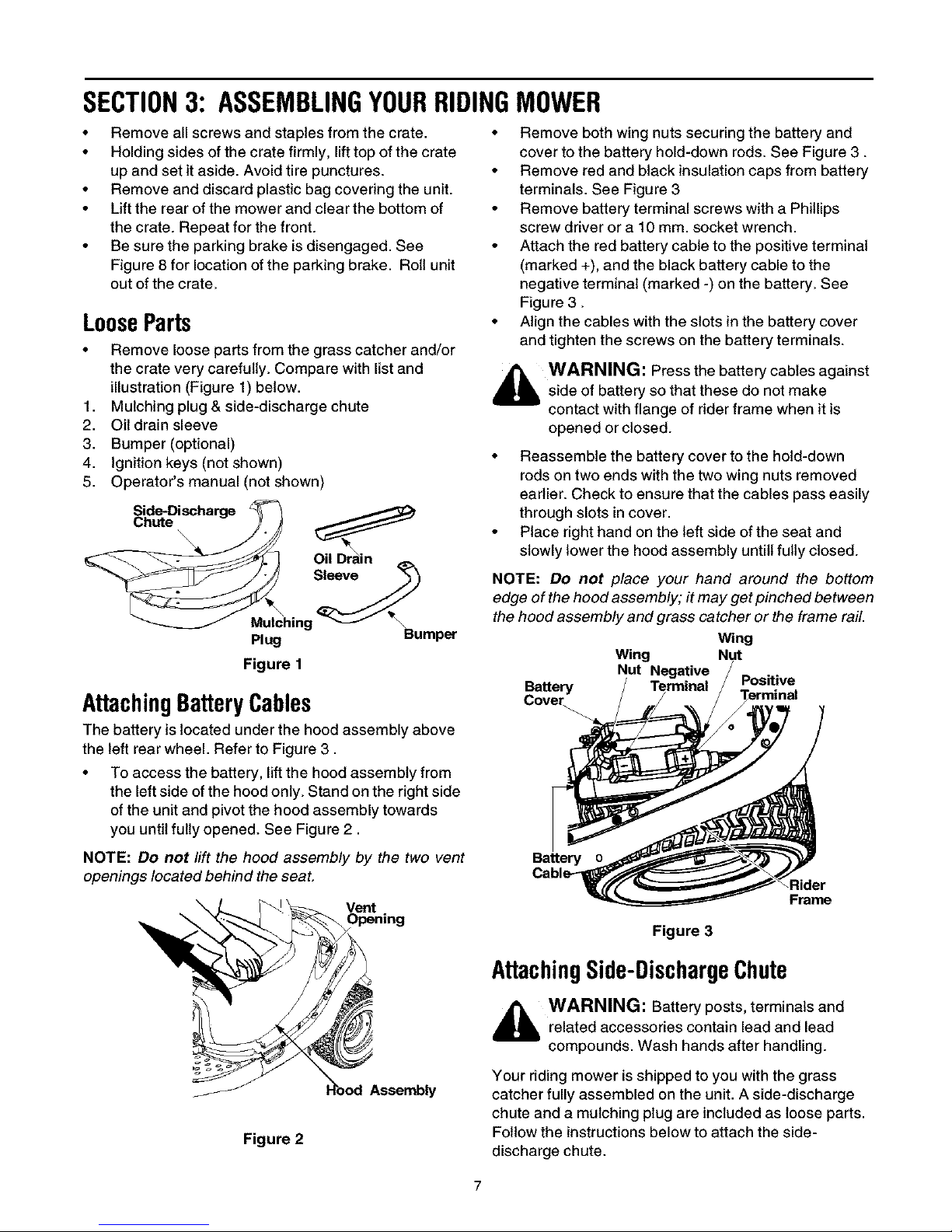

LooseParts

• Remove loose parts from the grass catcher and/or

the crate very carefully. Compare with list and

illustration (Figure 1) below.

1. Mulching plug & side-discharge chute

2. Oil drain sleeve

3. Bumper (optional)

4. Ignition keys (not shown)

5. Operator's manual (not shown)

,_ide-Discharge _

" Oil D_in

Plug Bumper

Figure 1

AttachingBatteryCables

The battery is located under the hood assembly above

the left rear wheel. Refer to Figure 3.

• To access the battery, lift the hood assembly from

the left side of the hood only. Stand on the right side

of the unit and pivot the hood assembly towards

you until fully opened. See Figure 2.

• Remove both wing nuts securing the battery and

cover to the battery hold-down rods. See Figure 3.

• Remove red and black insulation caps from battery

terminals. See Figure 3

• Remove battery terminal screws with a Phillips

screw driver or a 10 mm. socket wrench.

• Attach the red battery cable to the positive terminal

(marked +), and the black battery cable to the

negative terminal (marked -) on the battery. See

Figure 3.

• Align the cables with the slots in the battery cover

and tighten the screws on the battery terminals.

d_lb WARNING: Press the battery cables against

side of battery so that these do not make

contact with flange of rider frame when it is

opened or closed.

• Reassemble the battery cover to the hold-down

rods on two ends with the two wing nuts removed

earlier. Check to ensure that the cables pass easily

through slots in cover.

• Place right hand on the left side of the seat and

slowly lower the hood assembly until fully closed.

NOTE: Do not place your hand around the bottom

edge of the hood assembly; it may get pinched between

the hood assembly and grass ca tcher or the frame rail.

Wing

Wing Nut

Nut Negative

Battery Terminal Positive

Cover_

NOTE: Do not lift the hood assembly by the two vent

openings located behind the seat.

Battery

Frame

Figure 3

Figure 2

I_l'ood Assembly

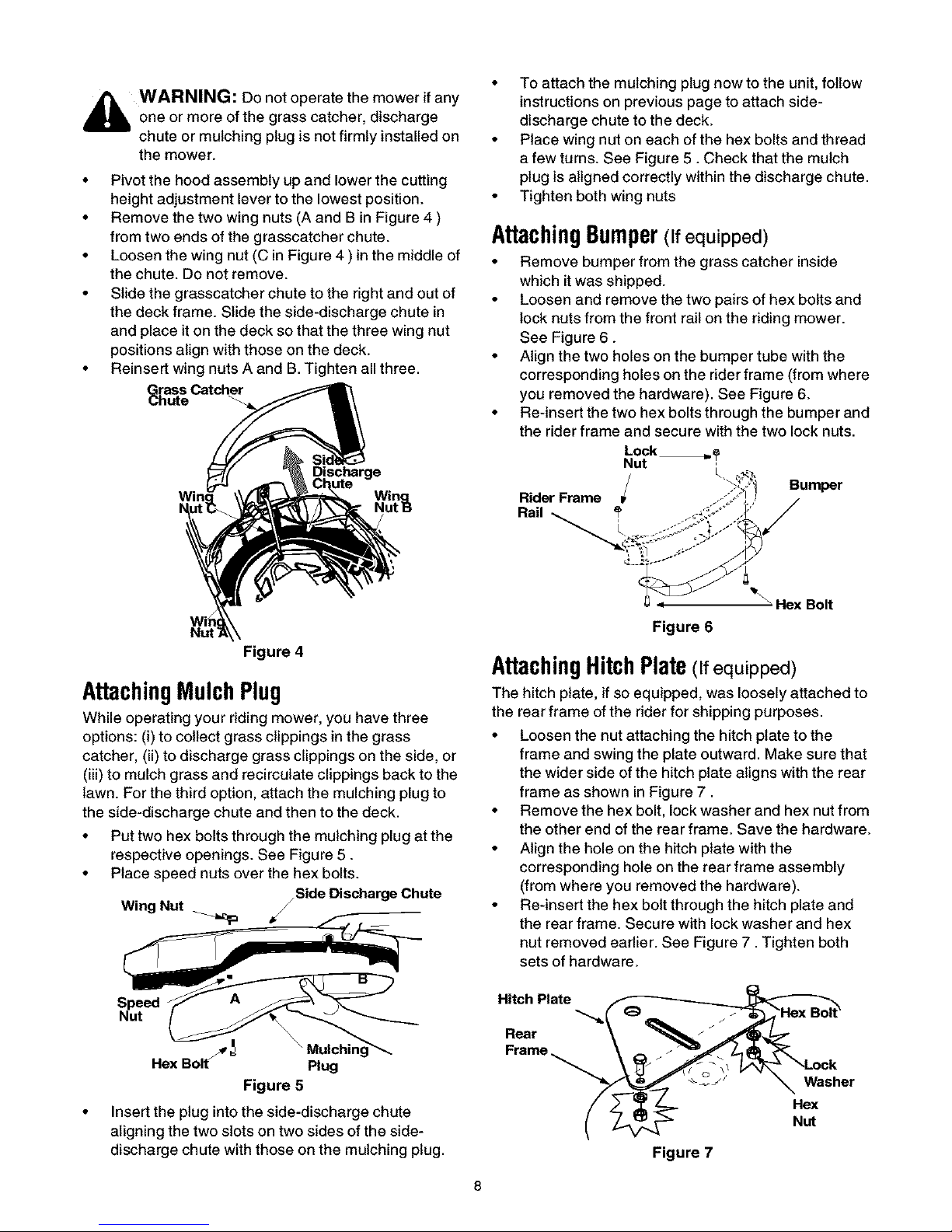

AttachingSide-DischargeChute

4_ WARNING: Battery posts, terminalsand

related accessories contain lead and lead

compounds. Wash hands after handling.

Your riding mower is shipped to you with the grass

catcher fully assembled on the unit. A side-discharge

chute and a mulching plug are included as loose parts.

Follow the instructions below to attach the side-

discharge chute.

Page 8

,_ WARNING: DO not operate the mower if any

one or more of the grass catcher, discharge

chute or mulching plug is not firmly installed on

the mower.

• Pivot the hood assembly up and lower the cutting

height adjustment lever to the lowest position.

• Remove the two wing nuts (A and B in Figure 4 )

from two ends of the grasscatcher chute.

• Loosen the wing nut (C in Figure 4 ) in the middle of

the chute. Do not remove.

• Slide the grasscatcher chute to the right and out of

the deck frame. Slide the side-discharge chute in

and place it on the deck so that the three wing nut

positions align with those on the deck.

• Reinsert wing nuts A and B. Tighten all three.

_rass Catcher

hute

• To attach the mulching plug now to the unit, follow

instructions on previous page to attach side-

discharge chute to the deck.

• Place wing nut on each of the hex bolts and thread

a few turns. See Figure 5. Check that the mulch

plug is aligned correctly within the discharge chute.

• Tighten both wing nuts

AttachingBumper(ifequipped)

• Remove bumper from the grass catcher inside

which itwas shipped.

• Loosen and remove the two pairs of hex bolts and

lock nuts from the front rail on the riding mower.

See Figure 6.

• Align the two holes on the bumper tube with the

corresponding holes on the rider frame (from where

you removed the hardware). See Figure 6.

• Re-insert the two hex bolts through the bumper and

the rider frame and secure with the two lock nuts.

Lock 4,.

Nut

L

Bumper

Rider Frame

Rail

Nut

Figure 4

AttachingMulch Plug

While operating your riding mower, you have three

options: (i) to collect grass clippings in the grass

catcher, (ii)to discharge grass clippings on the side, or

(iii) to mulch grass and recirculate clippings back to the

lawn. For the third option, attach the mulching plug to

the side-discharge chute and then to the deck.

• Put two hex bolts through the mulching plug at the

respective openings. See Figure 5.

• Place speed nuts over the hex bolts.

/Side Discharge Chute

Wing Nut

Speed A

Nut

Hex BOI_ _ Plug

Figure 5

Insert the plug into the side-discharge chute

aligning the two slots on two sides of the side-

discharge chute with those on the mulching plug.

= _ Hex Bolt

Figure 6

AttachingHitchPlate(ifequipped)

The hitch plate, ifso equipped, was loosely attached to

the rear frame of the rider for shipping purposes.

• Loosen the nut attaching the hitch plate to the

frame and swing the plate outward. Make sure that

the wider side ofthe hitch plate aligns withthe rear

frame as shown in Figure 7.

• Remove the hex bolt, lockwasher and hex nut from

the other end of the rear frame. Save the hardware.

• Align the hole on the hitchplate with the

corresponding hole on the rear frame assembly

(from where you removed the hardware).

• Re-insert the hex bolt through the hitch plate and

the rear frame. Secure with lock washer and hex

nut removed earlier. See Figure 7. Tighten both

sets of hardware.

Hitch Plate

Rear

Washer

Hex

N_

Figure 7

Page 9

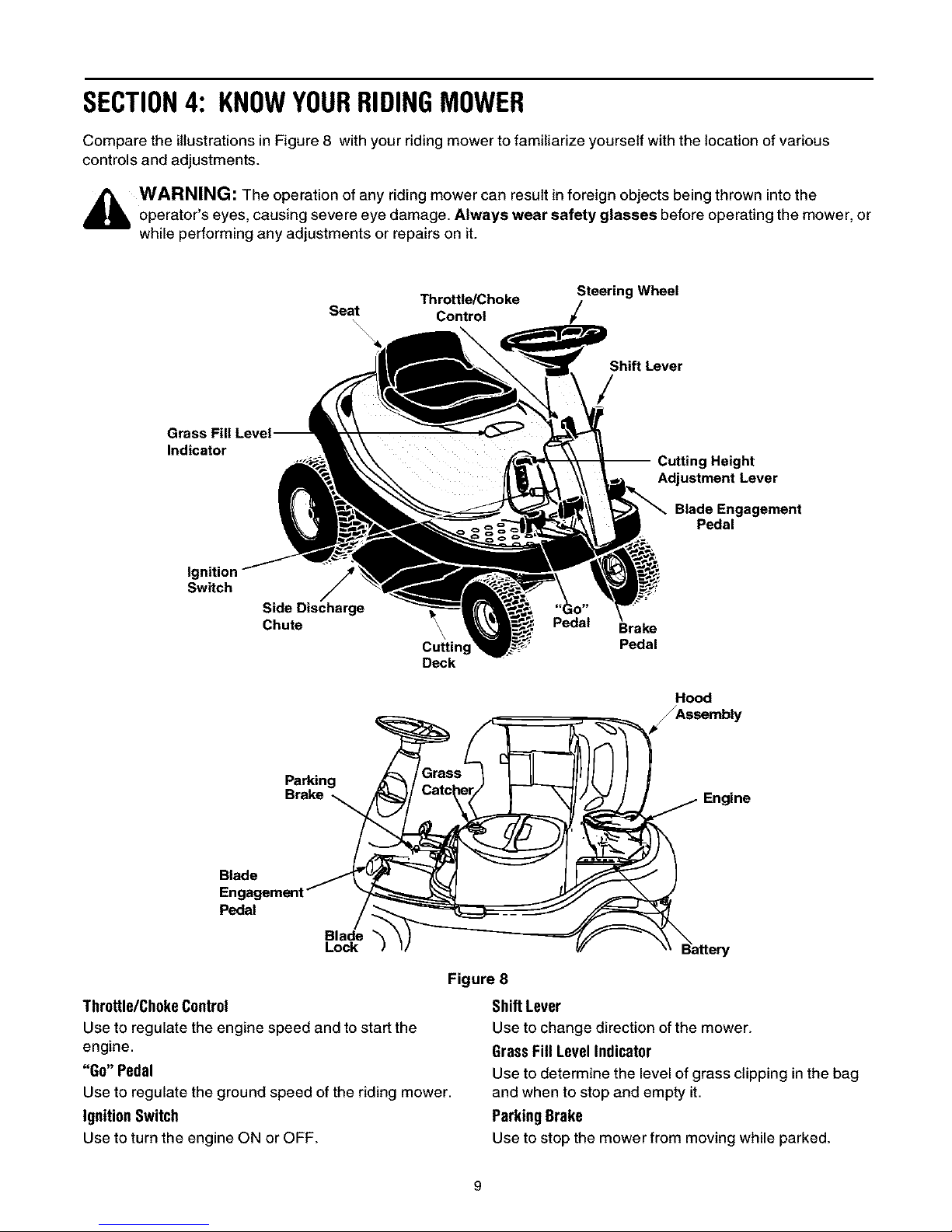

SECTION4: KNOWYOURRIDINGMOWER

Compare the illustrations in Figure 8 with your riding mower to familiarize yourself with the location of various

controls and adjustments.

_ WARNING: The operation of any riding mower can result in foreign objects being thrown into the

operator's eyes, causing severe eye damage. Always wear safety glasses before operating the mower, or

while performing any adjustments or repairs on it.

Throttle/Choke

Seat Control

Steering Wheel

Shift Lever

Indicator

-- Cutting Height

Adjustment Lever

Blade Engagement

Pedal

Ignition

Switch

Side Discharge

Chute

Pedal Brake

\\

Cutting Pedal

Deck

Hood

_Assembly

Parking

Engine

Blade

Engagement

Pedal

Blade

Lock

Throttle/ChokeControl

Use to regulate the engine speed and to start the

engine.

"Go" Pedal

Use to regulate the ground speed of the riding mower.

IgnitionSwitch

Use to turn the engine ON or OFF.

Figure 8

ShiftLever

Use to change direction ofthe mower.

Grass Fill Level Indicator

Use to determine the level ofgrass clipping in the bag

and when to stop and empty it.

Parking Brake

Use to stop the mower from moving while parked.

Page 10

BladeEngagementPedal

Use to engage or disengage the blade.

BladeLock

Use to lock blade at the engaged position.

CuttingHeightAdjustmentLever

Use to raise and lower the cutting deck which

determines the cutting height.

BrakePedal

Use to stop the mower's forward or reverse motion.

StoppingMower

• Release blade engagement pedal all the way.

• Release the "Go" Pedal and depress the brake

pedal.

• When the mower comes to a complete stop, place

the shift lever in neutral.

• Engage the parking brake by pulling up onthe

parking brake knob.

• Turn the ignition key to OFF position and remove

the key.

SafetyInterlock

This unit is equipped with a safety interlock system for

your protection. The interlock safety switches are

connected to the brake pedal, the blade engagement

pedal, the shift lever, and the seat.

The purpose of the safety interlock system is threefold:

a. to prevent the engine from starting unless the

brake pedal is depressed and the blade

engagement pedal is disengaged;

b. to shut off the engine if the blade pedal is not

disengaged when the shift lever is put into

reverse; and

c. to shut the engine off when the operator leaves

the seat without engaging the parking brake.

,_ WARNING: To avoid the risk of serious

injury, do not operate the riding mower ifthe

interlock system is malfunctioning.

• Remove objects that could be thrown by the

blade(s).

• Know location and function of all controls.

• Be sure blade(s) and engine are stopped before

placing hands or feet near blade(s).

• Before leaving operator's position, disengage

blade(s), place the shift lever in neutral, engage

parking brake, shut engine off and remove key.

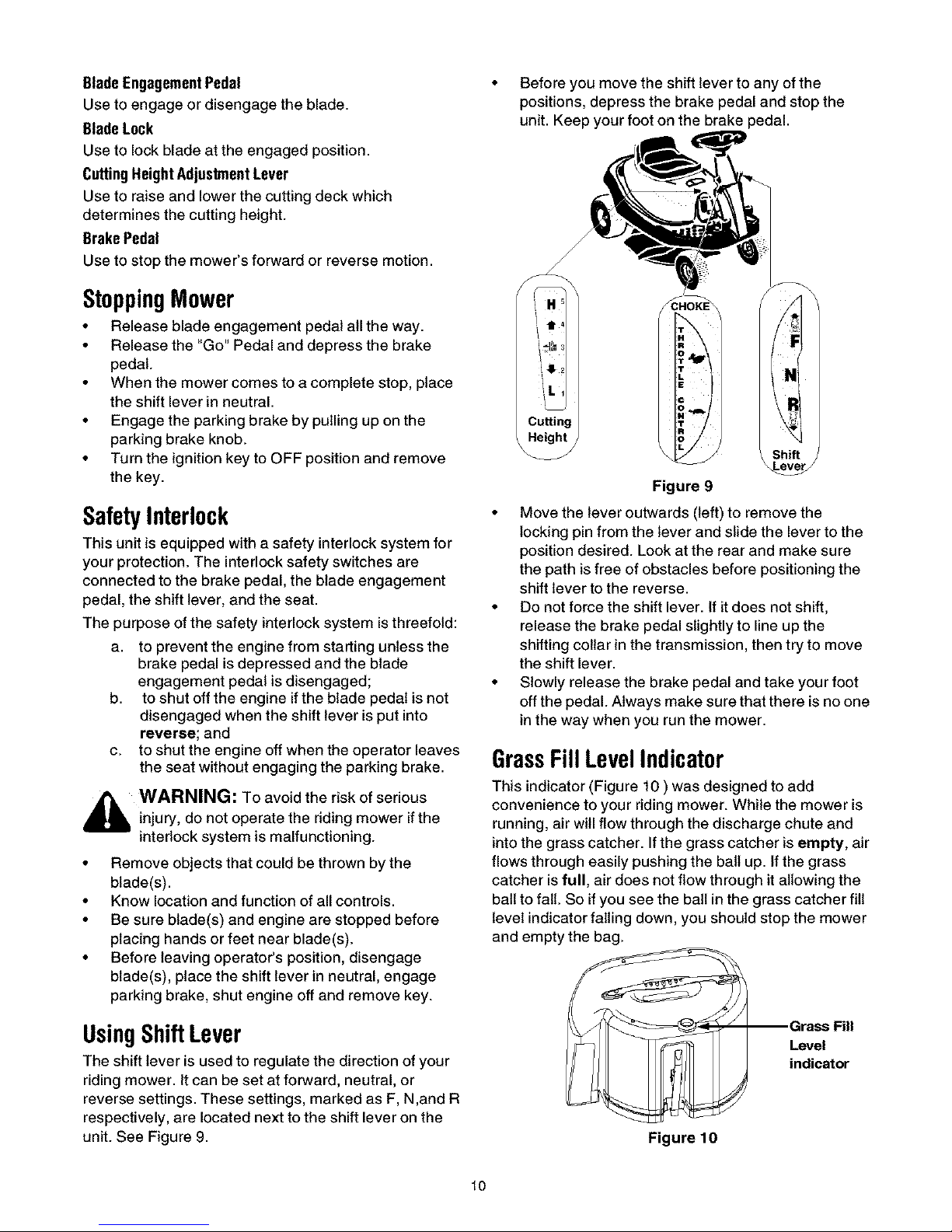

UsingShiftLever

The shift lever is used to regulate the direction of your

riding mower. Itcan be set at forward, neutral, or

reverse settings. These settings, marked as F, N,and R

respectively, are located next to the shift lever on the

unit. See Figure 9.

• Before you move the shift lever to any of the

positions, depress the brake pedal and stop the

unit. Keep your foot on the brake pedal.

Figure 9

• Move the lever outwards (left) to remove the

locking pin from the lever and slide the lever to the

position desired. Look at the rear and make sure

the path is free of obstacles before positioning the

shift lever to the reverse.

• Do not force the shift lever. Ifit does not shift,

release the brake pedal slightly to line up the

shifting collar in the transmission, then try to move

the shift lever.

• Slowly release the brake pedal and take your foot

off the pedal. Always make sure that there is no one

in the way when you run the mower.

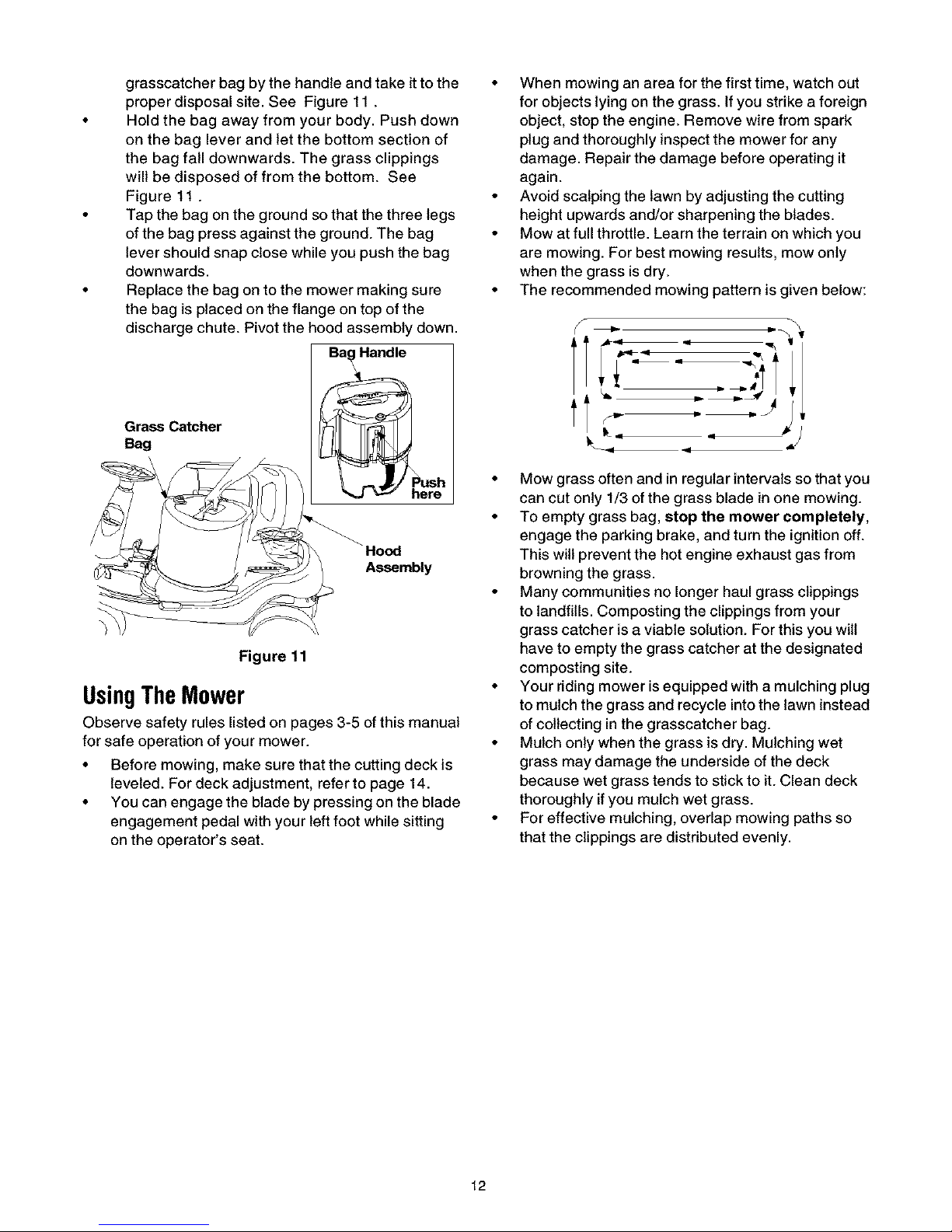

GrassFillLevelIndicator

This indicator (Figure 10 ) was designed to add

convenience to your riding mower. While the mower is

running, air will flow through the discharge chute and

into the grass catcher. If the grass catcher is empty, air

flows through easily pushing the ball up. If the grass

catcher is full, air does not flow through it allowing the

ball to fall. So ifyou see the ball in the grass catcher fill

level indicator falling down, you should stop the mower

and empty the bag.

Figure 10

Fill

Level

indicator

10

Page 11

SECTION5: OPERATINGYOURRIDINGMOWER

UsingThrottle/ChokeControl

The throttle/choke control is used to increase or

decrease the speed of the engine.The FAST and the

SLOW positions are marked with illustrations of a rabbit

and a turtle respectively. See Figure 9.

• For normal operation and when using a grass

catcher, move the throttle/choke control to the

FAST position.

• For maximum charging of the battery and also for a

cooler engine while running, move the throttle/

choke control to the FAST position.

• For transport and to tow pull-behind attachments,

move the throttle/choke control to the SLOW

position.

• Do not adjust the governor to increase or decrease

the engine speed. The governor is set at the factory

for maximum engine performance, and should not

be altered.

UsingParkingBrake

To engageparkingbrake

• Completely push the brake pedal down and stop

the unit.

• With your right foot on the brake pedal, move the

shift lever to the neutral position.

• Continuing to hold down the brake pedal with your

right foot, pull up the parking brake knob. Make

sure the parking brake holds the unit.

• Release the brake pedal. Stop the engine and

remove the ignition key. Now your riding mower is

parked.

To releasethe parkingbrake

• Depress the brake pedal. The parking brake will be

automatically disengaged.

BeforeStarting

Service the engine with gasoline as described in the

engine manual. Check the oil level.

,_ WARNING: Never fill fuel tank indoors, or

when engine is running or hot. Do not smoke

while filling up the gasoline tank.

StartingEngine

• Attach the wire to the spark plug.

• Depress the brake pedal with your right foot.

• Set throttle/choke control in the CHOKE position

(all the way forward).

• Place the shift lever in the NEUTRAL position.

• Turn the ignition key to the START position. As

soon as the engine starts, let the key return to the

ON position.

• Move throttle/choke control out of CHOKE position

and into FAST throttle position.

StartingMower

• Depress the brake pedal so that the parking brake

is disengaged.

• Place the shift lever in either the FORWARD or the

REVERSE position as you desire. Look to the rear

and check before backing up.

• Release the brake pedal.

• Depress the "Go" Pedal.

• To stop, release the "Go" Pedal and depress the

brake pedal.

• Press the blade engagement pedal downward until

the blades are turning.The blades can be engaged

either while the mower is in motion or while it is

standing.

NOTE: Your riding mower is equipped with a blade lock

to keep the blade engaged without the operator having

to depress the blade pedal continuously. See Figure 8.

To engage the blade lock: While pressing down

on the blade pedal, push the blade lock down with

your heel. It should click into the "blade engaged"

position. To disengage the blade lock, simply push

down on the blade pedal and release the lock.

,_ WARNING: When the blades are engaged,

keep hands and feet away from the discharge

opening, the blades or any part of the deck.

StoppingMower

• Release blade engagement pedal all the way.

• Release the "Go" Pedal and depress the brake

pedal.

• When the mower comes to a complete stop, place

the shift lever in neutral.

• Engage the parking brake by pulling up on the

parking brake knob.

• Turn ignition key to OFF position and remove key.

NOTE: Do not leave the key in the ON position when

you are not operating the mower. Such action will drain

the battery dead.

ToEmptyGrassCatcher

• Stop the mower completely, pull up on the

parking brake knob and take the ignition key out.

Get off the operator's seat.

• Pivot the hood assembly up. Pull up the

11

Page 12

grasscatcher bag by the handle and take it to the

proper disposal site. See Figure 11 .

Hold the bag away from your body. Push down

on the bag lever and let the bottom section of

the bag fall downwards. The grass clippings

will be disposed of from the bottom. See

Figure 11.

Tap the bag on the ground so that the three legs

of the bag press against the ground. The bag

lever should snap close while you push the bag

downwards.

Replace the bag on to the mower making sure

the bag is placed on the flange on top of the

discharge chute. Pivot the hood assembly down.

• When mowing an area for the first time, watch out

for objects lying on the grass. If you strike a foreign

object, stop the engine. Remove wire from spark

plug and thoroughly inspect the mower for any

damage. Repair the damage before operating it

again.

• Avoid scalping the lawn by adjusting the cutting

height upwards and/or sharpening the blades.

• Mow at full throttle. Learn the terrain on which you

are mowing. For best mowing results, mow only

when the grass is dry.

• The recommended mowing pattern is given below:

S

Grass Catcher

Bag

Assembly

Figure 11

UsingTheMower

Observe safety rules listed on pages 3-5 of this manual

for safe operation of your mower.

• Before mowing, make sure that the cutting deck is

leveled. For deck adjustment, refer to page 14.

• You can engage the blade by pressing on the blade

engagement pedal with your left foot while sitting

on the operator's seat.

• Mow grass often and in regular intervals so that you

can cut only 1/3 of the grass blade in one mowing.

• To empty grass bag, stop the mower completely,

engage the parking brake, and turn the ignition off.

This will prevent the hot engine exhaust gas from

browning the grass.

• Many communities no longer haul grass clippings

to landfills. Composting the clippings from your

grass catcher is a viable solution. For this you will

have to empty the grass catcher at the designated

composting site.

• Your riding mower is equipped with a mulching plug

to mulch the grass and recycle into the lawn instead

of collecting in the grasscatcher bag.

• Mulch only when the grass is dry. Mulching wet

grass may damage the underside of the deck

because wet grass tends to stick to it. Clean deck

thoroughly if you mulch wet grass.

• For effective mulching, overlap mowing paths so

that the clippings are distributed evenly.

12

Page 13

SECTION6: MAKINGADJUSTMENTS

,_ WARNING: DO not at any time make any

adjustment to the mower without first stopping

engine and disconnecting spark plug wire.

BrakePedal

During normal operation of the riding mower, the brake

is subject to wear and tear. Check the brake

periodically by carrying out the following test:

• Release the parking brake and place the riding

mower in neutral. Depress the brake pedal and try

to roll the riding mower. The tractor should not

move. Ifthe tractor moves, adjust the brake.

,_ WARNING: Do not adjust the brake while

the engine is running. Be sure to block the

wheels of the riding mower before making any

adjustments on the brake cable.

Adjustment to the brake pedal is made at the cable end.

See Figure 12.

• Set the parking brake and turn ignition key off.

• Shift the cutting height lever to the lowest position.

• Pivot the hood assembly up and remove the

grasscatcher bag and the side-discharge chute or

the mulching plug from the mower.

• Disconnect wire from the spark plug.

• Locate the brake cable on the right side under the

front housing. See Figure 12.

• Using a pair of 1/2" wrenches, loosen the jam nuts

and back the cable out to tighten or thread inward

to loosen. See Figure 12 inset.

• Retighten the jam nuts when proper tension is

reached.

• Unlock parking brake and repeat the test described

above. Readjust if necessary.

"Go" Pedal

Adjustment to the "Go" Pedal is made at the cable end.

See Figure 12.

• Set the parking brake and turn ignition key off.

• Shift the cutting height lever to the lowest position.

• Pivot the hood assembly up and remove the

grasscatcher bag and the side-discharge chute or

the mulching plug from the mower.

• Disconnect wire from the spark plug.

• Locate the speed control cable under the front

housing. See Figure 12.

• Loosen the jam nuts and back the cable out to

tighten or thread inward to loosen as shown.

• Retighten the jam nuts when proper tension is

reached.

• Reconnect the spark plug wire and pivot the hood

assembly down.

CuttingHeight

The deck cutting height adjustment lever is located on

the hood assembly. For a representation of the cutting

height positions, refer to Figure 9.

• Pull the lever out of the slot and slide it upward or

downward to the desired cutting height.

• Lower the cutting height to mow close to the

ground.

• Raise the deck height to the highest position when

you ride on a sidewalk or a road.

• To mow tall or thick grass, move the cutting height

adjustment lever to the highest position and cut.

Then move the lever to a lower position and cut

again.

Brake

Cable

Conkol

Cable* m

Jam Nuts

jhten

Loosen

*Same type of adjustment on both cables

(on{y one shown here)

Figure 12

13

Page 14

SeatPosition

The seat position on the riding mower can be adjusted

to maximize the operator's convenience.

• Stop the mower completely and engage the parking

brake. Turn ignition off.

• Pivot the hood assembly up.

• Loosen the four self-tapping screws on the bottom

of the seat.

• Slide the seat forward or backward in the slot, and

position it as desired. Retighten the four screws.

BladeBrake/PTO

The blade engagement pedal should be adjusted so

that if you depress it about 3/4" from the front of the slot,

it should start engaging the deck belt. The PTO (power

take off) switch is located in the blade brake slot on the

left side of the upper frame. See Figure 13. The brake

engagement pedal needs to make contact with the PTO

switch for the engine to start.

Under normal operation, the blade engagement pedal

should not require frequent adjustment. However,

perform the following test periodically and make sure

that it is in fine working condition.

• Pivot the hood assembly up and check if there is

enough slack on the deck engagement cable.

• Depress the blade engagement pedal (about 3/4

inch) and check ifthe belt is engaging.

• If the cable is tight or too loose or the belt is not

engaging, adjust the deck engagement cable.

NOTE: The deck engagement cable will be correctly

adjusted when the cable moves approximately 1/2" off

center line in both directions.

Adjustment to the blade brake will have to be made at

the cable end. See Figure 13.

Deck Hex

Engagement Nut

Cable

Blade Engagement

Pedal

S itch

Figure 13

• If the belt is slipping when you depress the blade

engagement pedal about 3/4", loosen the two hex

nuts on the cable. See Figure 13.

• If the belt is engaging sooner than when the blade

engagement pedal is 3/4" from the PTO switch,

tighten both hex nuts on the cable. See Figure 13.

• Repeat the blade engagement test and readjust if

necessary.

• Pivot the hood assembly back.

WheelAlignment

The front wheels should toe-in 1/16-5/16 inch. To adjust

toe-in, follow these steps:

• Remove the 3/8" hex nut and lock washer which

holds the ball joint to the steering segment. See

Figure 14.

• Adjust the ball joint in or out until the wheels toe-in

approximately 1/16-5/16" (Dimension "B" should

be approximately 1/16-5/16" less than dimension

"A"). See Figure 14.

• Replace the ball joint into the steering segment,

and replace the 3/8" hex nut and the lock washer.

Hex Nut

Steerin Washer

Rod

Segment Ball

Joint

Figure 14

L/16_5/16" _ess than /

AdjustingtheDeck

There are three tests for checking deck levelling on the

riding mower. The results of each test will determine

what kind of levelling, if at all, the equipment needs.

IMPORTANT: Perform adjustments to the deck on a flat,

level surface. Before continuing with deck adjustment,

check air pressure in all four tires. Recommended air

pressure is 12 psi. Please note that the valve stems on

this riding mower are on the inside of the front wheels

and on the outside of the rear wheels.

Test1:CheckingRear DeckHeightAdjustment

• Lift the hood assembly and remove grass catcher

from the riding mower. Place the deck in the highest

position.

14

Page 15

• Inspect rear of deck. If the deck is contacting the

cable bracket on the front of the transmission, you

will have to adjust the rear deck height.

Test2:CheckingFrontto Rear Levelling

• Place the deck in the highest position.

• Wearing a pair of heavy work gloves to prevent

injury, rotate the cutting blade so that it is pointed

front to back and parallel to the rider. Depress and

lock the deck engagement pedal.

• Measure the distance from the front and the rear

tips of the blade to the ground.The front should be

approximately 1/4" to 3/8" lower than the rear.

• If the distance is higher, level the deck front to rear.

Test3:CheckingSideto Side Levelling

• Place the deck in the highest position.

• Wearing a pair of heavy work gloves to prevent

injury, rotate the cutting blade so that it is pointed

side to side and perpendicular to the rider. Depress

and lock the deck engagement pedal.

LOOsenhex nuts

to adjust

not adjust hex nut

• Measure the distance from the tips of the blade to

the ground.

• If the two distances are unequal, level the deck

side to side.

AdjustingRearDeck Height

• Completely loosen, but do not remove, the top hex

nut out of the three hex nuts that hold the hex bolt

and the ferrule on the deck hanger link assembly.

See Figure 15.

IMPORTANT: Do not try to loosen/tighten the bottom

nut.

• Thread the middle nut as far down as possible.

• Locate the lower links at the rear of the deck.

Working on one side at a time, disconnect the

helper springs from them.

• Remove each lower link by removing both hair pin

clip and washers.

• Reattach the lower links as shown in Figure 15

inset.

Helper

Spri

Remove Hairpin Clips

and Washers

Lever

"Hanger

Link

Figure 15

Frontto RearLevelling •

• Place the deck in the highest position.

• Wearing a pair of heavy work gloves to prevent •

injury, rotate the cutting blade so that it is pointed

front to back and parallel to the rider. Depress and

lock the deck engagement pedal.

• Completely loosen, but do not remove, the top hex

nut out of the three hex nuts that hold the hex bolt

and the ferrule on the deck hanger link assembly.

See Figure 15.

IMPORTANT: Do not try to loosen/tighten bottom nut.

• Thread the middle nut as far down as possible.

• Keeping an equal number of threads above each of

the nuts, thread the upper nut down until the front

tip of the blade is 1/4" to 3/8" lower than the rear tip

of the blade. Note that threading this nut down will

raise the front of the deck.

Thread the middle nut up against the base of the

ferrule. See Figure 15.

Tighten the upper nut against the top of the ferrule

to lock adjustment.

Sideto SideLevelling

• Place the deck in the highest position.

• Wearing heavy work gloves to prevent injury,rotate

the cutting blade so that it is pointed side to side

and perpendicular to the rider. Depress and lock

the deck engagement pedal.

• Loosen the middle hex nut.

• Thread the top hex nut up or down in order to set

both tips of the blade at an equal height from the

ground. Remember to thread the nut down to raise

the deck, and thread up to lower the deck.

• Once the deck is level, thread the middle hex nut to

tighten against the ferrule. Make sure the cut is

even and the lift lever moves to all cutting heights.

15

Page 16

SECTION7: SERVICINGYOURRIDINGMOWER

FuseReplacement

Imaginary

The fuse islocated next to the spark plug under the rear Belt Line

frame. Fuses seldom fail without a reason. Ifthe fuse Keeper '

blows, the source problem must be corrected or the

new fuse wilt blow again. Cover_

• Check for loose connections in the fuse holder and

replace holder ifnecessary. Adead short may be in

the cranking or charging circuit where insulation

may have rubbed through and exposed bare wire.

• Replace the wire or repair with electrician's tape if

the wire strands have not been damaged. Also look

for a wire pinched between body panels, burned by

the exhaust pipe or muffler, or rubbed against a

moving part.

• Stop the riding mower and engage the parking

brake. Remove ignitionkey.

• Pivot the hood assembly up. Disconnect the spark

plug wire and ground it.

• Pull the fuse out of the lead wire. Screw

• Replace with new automotive fuse.

• Make sure to reconnect the spark plug wire before Pulley

pivoting the hood assembly back.

BeltReplacement

There are two drive belts and one deck belt in your

riding mower; follow the description below to identify

the belts.

1. Lower drive belt goes from the variable speed

pulley to the transmission pulley.

2. Upper drive belt goes from the variable speed

pulley to the upper sheave of engine pulley.

3. Deck pelt goes from the deck pulley to the

lower sheave in engine pulley.

• Periodically check to see if these belts are too loose

or damaged through wear and tear. If so, replace

with new belt.

DeckBelt

• Engage the parking brake and turn the ignition off.

Pivot the hood assembly up and remove the grass

catcher. Remove the spark plug wire.

• Put the deck at the lowest cutting height by

adjusting the cutting height adjustment lever to the

lowest position.

• Using a 1/2" socket wrench, remove two self-

tapping screws, lock washer and hex nut that hold

the deck belt cover to the deck. See Figure 16. For

this, you will have to work from the top left side of

the mower. Remove the belt cover.

• Using a 9/16" wrench, loosen the hex nut on the

idler pulley. See Figure 16.

Belt

Keeper "A"

Pulley

Figure 16

• Remove belt from around deck pulley, idler pulley,

and the engine pulley.

• Place the new belt around the deck pulley and the

engine pulley making sure that the belt is routed

inside the belt keepers. There are two belt keepers

under the grass catcher, one on the idler and the

other under the deck belt cover. See Figure 16.

• Reinstall deck belt cover and secure withtwo self-

tapping screws, lock washer and hex nut.

NOTE: Belt keeper ",4"must be mounted on the outside

of the bell

• Make sure to align the belt keeper in line with the

frame. See Figure 16.

NOTE: An imaginary line between the belt keeper and

idler pulley should be parallel to frame. See Figure 16.

• Replace the grass catcher and pivot the hood

assembly back.

LowerVariableSpeedBelt

• Remove the rear deck belt guard following first five

steps for deck belt removal. Remove belt from the

engine pulley.

• Push the spring loaded idler, located onthe left side

of the transmission, to the right. Remove belt from

around the idler and then the transmission pulley.

See Figure 17.

16

Page 17

Using a 9/16" socket, remove bolt, spacer and the

flat washer from the variable speed pulley. See

Figure 17.

Variable Speed Pulley

Spring

Spring Loaded

Idler

• Drop the pulley down and remove the belt.

• Replace new belt and reassemble.

• Make sure that the belt is routed inside of belt

keeper, and the belt keeper is reassembled in the

same location from where it was removed.

UpperVariableSpeedBelt

• Remove the engine pulley using a 5/8" socket

wrench with a 6" extension. The engine pulley is

located in front of the transmission.

• Drop the engine pulley down and remove the belt

from around it.

• Push the idler bracket to the right and remove the

belt. See Figure 17.

• Replace belt and reassemble.

Transmission

Pulley

Engine Pulley

Figure 17

SECTION8: MAINTAININGYOURRIDINGMOWER

GeneralRecommendations

• Always observe safety rules when performing any

maintenance.

• The warranty on this riding mower does not cover

items that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, operator must maintain the riding mower

as instructed in this manual.

• We do not recommend the use of pressure

washers or garden hose to clean your unit. These

may cause damage to electrical components,

spindles, pulleys, bearings or the engine. The use

of water may shorten life of your riding mower and

reduce its serviceability.

,_ WARNING: Always stop engine and

disconnect spark plug wire before any

maintenance or adjustments.

CuttingBlade

,i_ WARNING: Protect your hands by wearing

heavy gloves or using a rag to grasp the cutting

blade. Avoid personal injury.

Removal

• Remove the 5/8" hex flange nut which holds the

blade tothe blade spindle.

Remove blade from the spindle. See Figure 18.

De

Spindle

Blade

Figure 18

Sharpening

• When sharpening the blade, follow the original

angle of grind as a guide. Itisextremely important

that each cutting edge receives an equal amount of

grinding to prevent an unbalanced blade. An

unbalanced blade will cause excessive vibration

when rotatingat high speeds, may cause damage

to the mower and/or cause personal injury.

17

Page 18

• The blade can be tested for balance by balancing it

on a round shaft screwdriver. Remove metal from

the heavy side until it balances evenly.

Reassembly

• Before reassembling the blade to the unit, lubricate

the spindle with light oil (or engine oil).

• Be sure to properly align "star" fitting on blade with

"star" on spindle.

• When replacing the blade, be sure to install the

blade with the side of the blade marked "Bottom" (or

with part number) facing the ground when the

mower is in the operating position.

• Blade Mounting Torque: 70/90 foot-pounds

maximum.

NOTE: To ensure safe operation, all nuts and bolts

must be checked periodically for correct tightness.

OilDrainSleeve

Your riding mower has a plastic oil drain sleeve, packed

with the loose parts, for draining oil from the crankcase.

• To drain the oil, snap small end of the oil drain

sleeve onto oil sump. See Figure 19.

• Remove drain plug and drain oil into a suitable

container.

Oil Drain

Sleeve

Figure 19

Engine

Refer to the separate engine manual for engine

maintenance instructions.

• Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and

follow instructions carefully.

• Poor engine performance and flooding usually

indicates that the air cleaner should be serviced.

Service air cleaner as per the engine manual.

Clean frequently under extremely dusty conditions.

• The spark plug should be cleaned and the gap

reset once a season. Spark plug replacement is

recommended at the start of each mowing season.

Check engine manual for correct plug type and gap

specifications.

Lubrication

See Figure 20 for an illustration of the lube points

described below.

kube

Lube

Lube

Viewed from the bottom

Lube

(before

reassemby)

Figure 20: Lubrication Chart

BladeAssembly

• Lubricate blade assembly and deck spindle only

while reassembling the blade either after

sharpening or replacement.

PivotPoints

• Lubricate pivot points with light oil once a season.

SteeringShaftandGear

• Lubricate steering shaft and spline at least once a

season with light oil.

18

Page 19

• Lubricate teeth of the external steering gears with

automotive multi-purpose grease every 25 hours of

operation or once a season.

Linkage

• Lubricate all deck linkage and height adjustment

linkage with a light oil.

FrontWheels

• Lubricate at least once a season with automotive

multi-purpose grease.

Engine

• Maintain the engine as recommended in the

separate engine manual.

CleaningEngine

• Promptly wipe off any fuel or oil spilled on the

machine with clean cloth.

• Clean the underside of the blade housing after

each mowing. Do not let clippings or debris

accumulate around the blade which may cause rust

on the deck.

• Using a brush or cloth, remove grass, chaff or

debris from the finger guard on the engine daily to

prevent overheating of the engine. Do not clean

with a forceful spray of water since water

contaminates the fuel system.

• Keep the governor linkage, springs and controls

free of debris.

• If engine muffler is equipped with spark arrester

screen, remove and clean the screen regularly.

Replace if damaged or plugged with debris.Clean

muffler area and remove any grass or other debris

before operating the unit.

FuelFilter

Your unit isequipped with a replaceable in-line fuel

filter. Replace filter whenever contamination or

discoloration is noticed. Order replacement filter

through your engine authorized service dealer.

SECTION9: OFF-SEASONSTORAGE

If the machine is to be inoperative for a period longer

than 30 days, prepare for storage as follows.

RidingMower

• Clean the engine and the entire unit thoroughly.

• Lubricate all pivot points. Wipe the entire

machine with an oiled rag to protect the surfaces.

• Store unit in a clean, dry area. Do not store next

to corrosive materials, such as fertilizer.

• When storing any type of power equipment in an

unventilated or metal storage shed, care should

be taken to rustproof the equipment. Using a light

oil or silicone, coat the equipment, especially any

chains, springs, bearings and cables.

Battery

• Charge battery fully. The battery loses some of

its charge each day when the unit is not used.

NEVER store battery without afull charge.

Recharge battery before returning to service or

every two months, whichever occurs first.

When storing unit for extended periods,

disconnect battery cables and remove the battery

from the unit.

Clean dirt and chaff from cylinder, cylinder head

fins, blower housing, rotating screen and muffler

area.

Engine

• Refer to the engine manual for storage

instructions. Make sure to store the engine

properly so that your equipment can work

smoothly afterwards.

19

Page 20

SECTION10: TROUBLE-SHOOTING

Trouble Possible Cause Remedial Action

Excessive vibration 1. Bent ordamaged blade 1.

Mower wilt not

discharge grass or

leaves uncut strips

Broken Belt

Belt comes off

Belt shreds

2. Bent blade.

1. Engine speed low.

2. Speed selection.

3. Cutting height set too low.

4. Blades short or dull.

1. Sudden stop or shock load to belt

2.

3.

4.

1.

2.

1.

2.

3.

Incorrect belt used

Belt engaged abruptly

Defective or damaged belt

Belt too loose; stretched

Broken or weak idler spring

Belt guides or guards incorrectlyadjusted

Pulleys not aligned

Pulley rusted or in otherwise bad condition;

frozen bearing

Stop engine immediately. Check all

pulleys, blade adapters, keys and bolts

for tightness and spindle damage.

Tighten or replace any damaged parts

2. Stop engine immediately. Replace

damaged blade. Only use original

equipment blades.

1. Throttle must be set at full throttle.

2. Use lower ground speed. Slower the

ground speed, better the quality of cut.

3. Raise the deck.

4. Sharpen or replace blades (uncut strip

problem only).

1. Inspect rider for cause such as foreign

objects stuck in between deck and

frame or belt path. Remove

obstruction and check for damage.

Replace belt if needed.

2. Replace with proper belt. Check Parts

list inthis manual for correct part

number.

3. Engage belt slowly by depressing the

blade engagement pedal slowly.

4. Replace with proper belt. Follow

instructions on page 16.

1. Readjust belt. Replace if needed.

Follow instructionsfor belt

replacement on page 16.

2. Replace. Order with correct part

number from Parts List in this manual.

1. Adjust belt guides and guards so that

these are approximately 1/16 to 1/8

inch from belt when engaged.

2. Realign pulleys to be within

approximately 1/16 inch of each other.

Check with straight edge. Make sure

fastening hardware is tight.

3. Replace pulleys. Order with correct

part number from the Parts List in this

manual. Adjust new pulleys to 1/16 ".

2O

Page 21

Trouble

Engine will not crank

Engine cranks but

will not start

Possible Cause

1. Safety switch button not depressed

2. Battery installed incorrectly

3. Battery dead or weak.

4. Blown fuse or circuit breaker

5. Engine ground wire loose.

1. Throttle/choke not in starting position.

2. No fuel to the carburetor

3. Fuel line or in-line fuel filter plugged

4. No spark to spark plug

5. Faulty spark plug

6. Dirty air cleaner

Engine smokes 1. Engine oil has been overfilled 1.

2. Dipstick not seated or broken 2.

3. Engine loses crankcase vacuum 3.

Remedial Action

1.

There are two switches inthe starting

circuit of your unit. Make sure that the

actuator is fully depressing both switch

buttons. Brake pedal must be

depressed and blade engagement

pedal disengaged.

2. Install the battery with negative

terminal attached to the black ground

wire. Attach the positive terminal to the

red wire which goes to the solenoid.

Charge the battery fully before

installation.

3. Check fluid level in battery. If fluid level

is low, fill to just below split rings with

water. Charge with 6 Amp. charger

until fully charged. Ifthis does not

work, replace battery.

4. Replace fuse following instructions on

page 16.

5. Make sure the black ground wire runs

from engine to frame or mounting bolt.

1. Check owner's guide for correct

position for throttle control/choke for

starting.

2. Gasoline tank empty. Fill with

gasoline.

3. Remove and clean fuel line. Replace

filter if necessary.

4. Spark plug lead disconnected.

Connect lead. Hold spark plug lead

away from engine block about 1/8".

Crank engine. There should be a

spark. If not, have engine repaired at

authorized engine service dealer.

5. To test, remove spark plug. Attach

spark plug lead to spark plug. Ground

the spark plug body against the engine

block. Crank the engine. The spark

plug should fire at the electrode.

Replace if it does not.

6. If the air cleaner is dirty, the engine

may not start. Clean or replace as

recommended by the engine

manufacturer.

Check oil level.

Replace defective part.

Engine breather defective. Replace.

For repairs beyond those listed in the Trouble-Shooting chart above, please contact an authorized

service dealer or call Yard-Man Customer Service at 1- (800)-800-7310.

21

Page 22

SECTION11:PARTSLISTFORSERIES320

27

48

z24

26

_8

25 _ "_"

12

47

13

I

4O

15

22

Page 23

Model320 Series

Ref. No. Part No.

1. 17962

2. 650-0007

3. 683-0033A

4. 683-0178A

5. 683-0179A

6. 710-0224

7. 710-0459A

8. 710-0643

9. 710-0689

10. 710-0837

11. 710-0958

12. 710-1017

13. 710-1611B

14. 710-3008

15. 712-0116

16. 712-0206

17. 712-0241

18. 712-0267

19. 712-0324

20. 712-0411

21. 712-0711

22. 714-0470

23. 723-0156

24. 726-3046

Description Ref. No. Part No.

Switch Plate 25. 731-0511

Steering Tube Assembly 26. 735-0674

Steering Support Bracket 27. 735-0266A

Front Axle Assembly: RH 28. 736-0105

Front AxleAssembly: LH 29. 736-0119

Hex Screw AB 30. 736-0160

Hex Screw 3/8-24 x 1.5" Gr.5 Sp. 31. 736-0169

Lock Screw 5/16-18 x 1.0" Gr.5 32. 736-0187

Hex Screw 1/2-13 x 0.75" 33. 736-0196

Oval C-Sunk Screw #10-16 x 0.625" 34. 736-0242

Hex Screw 1/4-20 x 1.25 Gr.5 Sp. 35. 736-0272

AB Screw 1/4-14 x 0.625" 36. 736-0320

Self-Tapping Screw 5/16-18 x 0.75" 37. 736-3078

Hex Screw 5/16-18 x 0.75" 38. 737-3007

Lock Nut 3/8-24 39. 738-0541

Hex Nut 1/2-13 40. 738-3089A

Hex Nut 41. 741-0225

Hex Nut 42. 741-0356

Lock Nut 1/4-20 43. 747-0955

Description

Trim Strip

Floor Pad: LH

Floor Pad: RH

Bell Washer

Lock Washer

Flat Washer

Lock Washer

Flat Washer

Flat Washer

Belleville Washer

Flat Washer

Flat Washer

Flat Washer

Grease

Spacer

Steering Adapter

Hex Flange Rearing

Bearing: Steering Column

Tie Rod

Lock Nut 44. 748-0290

Jam Nut 45. 750-0532

Cotter Pin 46. 783-0411

Ball Joint 47. 783-0565C

Ratchet Clip 48. 783-1013

Pinion Gear

Spacer

Gear: Steering Segment

Upper Frame Cover

Lift Plate

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever

needed, to the part number to order a replacement part. For instance, if a part numbered 700-xxxx is painted Yard-Man

Green, the part number to order would be 700-xxxx-0665.

Yard-Man Green: 0665

Yard-Man Yellow: 0674

Powder Black: 0637

23

Page 24

Model320 Series

14

22

44

J

/

/

f

27

10

11

42 52

29

28

_10

28 40

7

41

12

28

4O

34

40

31

24

Page 25

Model320 Series

Ref. No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

Part No.

683-0155A

683-0161

683-0275A

683-0310A

710-1017

711-0701

711-1156

712-0287

712-0324

712-3017

714-0104

714-0111

714-0470

720-0166

726-0100

726-0450

731-0405

731-1913

732-0815A

732-0865

735-o261

735-0262

735-0263

736-0117

736-0133

736-0159

736-0169

Description

Brake Pedal Assembly

Shift Cam Assembly

Deck Pedal Assembly

Variable Pedal Assembly

Ab Screw 1/4-14 X .625

Ref. No.

28.

29.

30.

31.

32.

Part No.

736-0187

736-0262

736-0272

736-0300

736-O329

Description

Flat Washer

Flat Washer

Flat Washer.510 X 1.oo X .o60

Flat Washer

Lock Washer

Clevis Pin

Shaft

Hex Nut 1/4-20

Lock Nut 1/4-20

Hex Nut 3/8-16

Internal Cotter Pin

Hairpin Clip

Hairpin Clip

Ball Knob

Push Cap

Plug Cap

Snap-on Bushing

Stop Lever

Extension Spring

Torsion Spring

Drive Pad

Deck Pad

Brake Pad

Flat Washer 3/8 X .620 X .033

FlatWasher.411 x 1.25"x .100

5/16 Washer

Lock Washer

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

736-0608

736-3000

736-3019

736-3020

738-0255

738-0373

738-0974

741-0591

746-0935A

746-0936

746-0937

746-0940

746-0964

747-0963A

747-0964

750-0736

783-0473

783-0525

783-0593A

783-0794

726-0157

Spring Washer

Flat Washer

Flat Washer ,531 X 1.062 X ,134

Flat Washer ,271 X ,630 X .o65

Shoulder Screw ,375 Dia X .18

Shoulder Screw

Shoulder Screw .375 X ,380 X 1/4-20

Flange Bearing

Shift Cable

Variable Drive Cable

Brake Cable

Deck Cable

Throttle Choke Cable: 67"

Brake Rod

Brake Lock Out Rod

Shoulder Spacer

Brake Lock Out Bracket

Self-Propelled Pedal Link

Shift Lever

Bracket: Lock-Out Pedal

Cable Tie

NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever

needed, to the part number to order a replacement part. For instance, if a part numbered 700-xxxx is painted Yard-Man

Green, the part number to order would be 700-xxxx-0665.

Yard-Man Green: 0665

Yard-Man Yellow: 0674

Powder Black: 0637

25

Page 26

Model320 Series

5

27

26

0

21

22

3

21

13

24

29

17

16

6

15

2

20

9

Ref.No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Part No.

683-0152

683-0194A

710-0376

710-3230

711-0332

711-1120

711-3319

712-0266

712-3008

712-3010

712-3048

714-0104

714-0147

714-3010

720-0298

Description Ref. No. Part No.

Pivot Link Assembly 16. 732-0829

Lift Arm Assembly 17. 732-0837

Hex Screw 5/16-18 X 1.00 Gr.5 18. 736-0119

Hex Bolt 1/2-13 X 2.75 Gr.5 Spec. 19. 736-0140

Lift Bracket Pin 20. 736-0169

Lift Rod 21. 736-0257

Ferrule 22. 736-0275

Jam Nut 23. 736-3019

Jam Nut 3/8-16 Gr. 5 24. 738-0145

Hex Nut 5/16-16 25. 738-0183

Jam Nut 26. 738-0958

Cotter Pin 27. 783-0435

Cotter Pin 28. 783-0437

Cotter Pin 29. 783-0440

Handle Grip

Description

Extension Spring

Torsion Spring

Lock Washer 5/16

Flat Washer .385 LD. x .620 O.D.

Lock Washer

Flat Washer

Flat Washer 5/16

Flat Washer

Shoulder Screw

Shoulder Screw

Shoulder Spacer

Upper Deck Link

Axle Bracket: Rear

_ower Link

26

Page 27

Model320 Series

2

lO

11

13

1

5

2

NOTE: For painted parts, please refer to the list of

color codes below. _lease add the applicable color

code. wherever needed, to the part number to order a

replacement part. For instance, if a part numbered

700-xxxx is painted Yard-Man Green. the part number

toorder would be 700-xxxx-0665.

Yard-Man Green: 0665

Yard-Man Yellow: 0674

Powder Black: 0637

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Part No. Description

629-0865

710-1208

710-0227

710-0805

710-0642

712-3010

714-0115

726-0320

736-0289

736-0119

736-3000

750-1064

783-0591

783-0433A

Harness Assembly Adapter

Hex TT Screw 5/16-18 x 3.50

Hex Washer Head Self-Tap.Scew

Hex Screw 5/16q 8 x 1.5 Gr. 5

Thd. Forming Scr. 1/4-20x .75

Hex Nut 5/16-18

Cotter Pin

Insulator Nut Plate

Shoulder Bushing

Lock Washer 5/16

FiatWasher

Spacer

Tranaaxle Bracket

Shift Lever

27

Page 28

Model320 Series

15_

32

2

\\\

26

12

Ref. No.

1

2

3

4

5.

6.

7

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

J

13

17

24

11

4_

23

26

7 @ 15

9

Part No,

683-0147A

710-0191

710-0314

710-0902

710-1611B

710-3096

712-0116

712-0241

712-3017

712-3035

714-0114

717-0884

732- 0814

732-0815A

736-0169

736-0171

736-0219

Descript_o_

Idler Bracket Assembly

Hex Screw (Special)

Hex Screw 7/16-20 x 1.0"

Hex Screw 3/8-24 x3.75"

TT Screw

Hex Screw 3/8-16 x2.0"

Jam Lock Nut

Hex Nut 3/8-24

Hex Nut 3/8-16

Jam Nut 9/16-18

Sq. Key

Variable Speed Pulley Assembly

Extension Spring

Extension Spring

Lock Washer

Lock Washer

Bell Washer

lO

31 25

3

Ref. No.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

Part No.

736-0247

736-0427

737-0167

737-0288

738-0968

741-0405

750-0705

754-0453

756-0116

756-0650

756-0658

756-0981A

783-0528

783-0529

683-0149B

Description

Flat Washer

Beleville Washer

Grease

Grease

Shoulder Spacer

Thrust Bearing

Slv. Spacer

V-Belt

Idler Pulley

Transmission Pulley

Engine Pulley

Flat Idler Pulley

Idler Bracket: Variable Speed

Cable Bracket

Frame Assembly

28

Page 29

Model320 Series

3d

30

%

31 34

18

15

21

17

33

25

35

28

4

R_. No. Put No.

1 783-0605

3 783-0564A

4 783-0811

5 683-0264A

6 783-0554

8 783-0414A

9 783-0413

10 783-0412B

11 747-0985

12 736-3019

14 736-0275

15 736-0187

16 736-0101

17 735-0271

18 735-0199A

19 732-0829

32

Description

Ref. No. Part No.

Deck Stabilizing Bracket 20 726-0272

Front Frame: Upper 21 725-0157

Steering Gear Cover 22 714-0470

Front Channel Assembly 23 714-0147

Cam Bracket 25 714-0104

Frame Rail: Rear 26 712-0271

Frame RaiI--L.H. 27 712-0265

Frame RaiI--R.H. 28 711-1165

Deck Rod 29 711-0332

Flat Washer .531 X 1.062 X .134 30 710-1611B

Flat Washer 5/16 31 710-1017

Flat Washer .64 I.D. X 1.24 X .06 32 710-0599

Flat Washer 3/8 X 1.00 X .030 33 683-0163A

Rubber Bumper 34 683-0160

Description

Clamp: 9/16 dia.

Cable Tie

Hairpin Clip

Hairpin Clip

Hairpin Clip

Hex Nut

Hex Nut 1/4-20

Clevis Pin

Lift Bracket Pin

TT Screw 5/16-18 x .75

Torx Mach. AB Scr. 1/4-14 x 0.625 _

Hex TT Screw 1/4-20

Steering Support Bracket

Pivot Bracket Assembly: Hood

Rubber Bumper 35 683-0142 Pivot Bar Assembly

Extension Spring

29

Page 30

Model320 Series

45

41

11

41

22

23

38

13

35

43

41

5 4

7

2 25

22

12

3O

3O

Page 31

Model320 Series

Ref. No. Part No.

1. 683-0149B

2. 683-0190A

3. 683-0191A

4. 683-0192

5. 710-0148

6. 710-0157

7. 710-0599

8. 710-0654A

9. 710-0751

10. 710-0871

11. 710-1237

12. 710-1611B

13. 710-1653

14. 710-3008

15. 711-0222A

16. 712-0267

17. 712-0271

18. 712-0291

19. 712-0397

20. 712-3017

21. 725-0157

22. 726-0205

23. 726-02O9

24. 731-0708

Description Ref. No. Part No.

Frame Assembly 25. 731-1682A

Frame Rail Support: RH 26. 731-1945A

Frame Rail Suppod: LH 27. 732-3080A

Muffler Pipe Extension 28. 735-0273

Hex Fl. Screw #8-32 x 0.375 29. 736-0119

Hex Screw 5/16-24 x .75" Gr.5 30. 736-0123

Self-Tapping Screw 31. 736-0169

TT Screw 3/8-16 x 1.0" 32. 736-0188

Hex Screw 1/4-20 x 0.5" 33. 736-0222

Hex Slot Sems Screw #10-32 x 0.38 34. 736-0329

TT Screw #10-32 x 0.625" 35. 736-0400

TT Screw 5/16-18 x 0.75" 36. 736-0607

Machine Screw #10-32 x 0.5" 37. 737-0169

Hex Screw 5/16-18 x 0.75" 38. 738-0960

Battery Hold-Down Rod 39. 741-0516

Hex Nut 5/16-18 40. 751 B213146

Hex Sems Nut 1/4-20 41. 751-0535

Lock Nut 1/4-20 42. 751-0656

Wing Nut with Bell Washer 43. 783-0561

Hex Nut 44. 783-0624

Cable Tie 45. 783-0630C

Hose Clamp 46. 783-0809B

Cable Tie 47 725-1698

Battery Cover

Description

Oil Drain Sleeve

Engine Duct

Compression Spring

Rubber Washer

Lock Washer

Flat Washer

Lock Washer

Flat Washer

Lock Washer

Lock Washer

Flat Washer

Lock Washer

Motor Oil

Shoulder Screw

Flange Bearing

Throttle Casing Clamp

Fuel Line Hose

Fuel Tank

Hitch Plate

Battery Bracket

Fuel Tank Bracket

Transaxle Suppor_ Bracket

Battery (not shown)

@

5

\\\\

\\\\

11

10

6

3

\ Part No.

634-0139

634-0169A

734-1727

734-1382

734-0255

737-0211A

741-0353

634-0138

734-1455A

710-0627

736-0242

714-0115

736-0285

736-0156

731-0484A

Description

Rear Wheel Cempl.

Front Wheel Cempl.

Rear Tire

Front Tire

Valve: Tubeless Air

Grease Fitting

Flange Bearing

Rim Assembly

Rim Assembly

Hex Bolt 5/16-24 x .75"

Beleville Washer

Cotter Pin

Flat Washer

Flat Washer

Hub Cap (not shown)

31

Page 32

Model320 Series

16

/

NOTE: For painted parts, please refer to the list of color

codes below. Please add the applicable color code,

wherever needed, to the part number to oraer a

replacement part. For instance if a part numbered 700-

xxxx _s paintec Yard-Man Green the part number to

order would be 700-xxxx-0665.

Yard-Man Green: 0665

Yard-Man Yellow: 0674

Powder Black: 0637

14

\

I

/

/.4-'

3'

Ref. No.

1.

2.

3.

4.

5.

6.

7.

8.

Part No.

710-0599

710-0870

710-1017

720-0238

731-0511

73f-f69fA

783-0410

783-0445