Page 1

Safety • Set-Up • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

Two-Stage Snow Thrower

READ SAFETY RULES AND iNSTRUCTiONS CAREFULLY BEFORE OPERATION

Warning: Thisunitis equippedwithan internalcombustionengineandshouldnot beusedon or nearany unimprovedforest-covered,brush-

coveredor grass-coveredlandunlesstheengine'sexhaustsystemisequippedwithasparkarrestermeetingapplicablelocalorstatelaws(if any).

If a sparkarresterisused,it shouldbemaintainedineffectiveworkingorderbythe operator.IntheStateofCaliforniatheaboveis requiredbylaw

(Section4442ofthe CaliforniaPublicResourcesCode).Otherstatesmayhavesimilarlaws.Federallawsapplyonfederallands.A sparkarrester

forthe mufflerisavailablethroughyournearestengineauthorizedservicedealeror contacttheservicedepartment,RO.Box361131Cleveland,

Ohio44136-0019.

ForUSCustomers:MTDLLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTEDIN U.S.A. ForCanadianCustomers:MTDProductsLtd.,P.O.BOX1386,KITCHENER,ONTARION2G4J1 769-03501

iMPORTANT

09/20/07

Page 2

This Operator's Manual is an important part of your new snow thrower, it will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ...................................................... 3

Safe Operation Practices ................................... 4

Setting UpYour Snow Thrower .......................... 6

Operating Your Snow Thrower ......................... 10

MakingAdjustments ......................................... 14

Finding and Recording Model Number

BEFOREYOU STARTASSEMBLING

YOURNEW EQUIPMENT,

please locatethe modelplate onthe equipmentand copythe

the modelnumber andthe serialnumbertothe sample model

plate providedto the right.You can locatethe model plate by

standing atthe operatingposition and looking downatthe

frame.

Maintaining Your Snow Thrower ...................... 16

Off-Season Storage .......................................... 19

Trouble Shooting .............................................. 20

Warranty ............................................................ 21

illustrated Parts Lists ....................................... 22

Model Number Serial Number

Num6ro de mod61e Num6ro de s6rier

XXXXXXXXXXX XXXXXXXXXXX

MTD LLC

PRODUCTS LIMITED

KITCHENER, ON N2G 4J1

USA-www.mtdproducts.com 1-800-800-7310

CAN-www.mtdcanada.com 1-800-668-1238

OH 44136

Customer Support

Please do NOTreturn the unit to the retailer from which it was purchased,

without first contacting Customer Support.

Ifyou havedifficulty assemblingthis productor haveanyquestions regardingthecontrols, operation or maintenanceof this unit,

youcan seek helpfromthe experts. Choose from the options below:

1. ForUSCustomers: Visit www.yardman.comfor many usefulsuggestions,click on CustomerSupport button.

ForCanadian Customers: Visit www.yardman.cafor manyusefulsuggestions,click on CustomerSupport button.

2. Call a CustomerSupport Representative,

ForUSCustomers: 1-330-220-4MTD (4683)or 1-800-800-7310

ForCanadianCustomers: 1-800-668-1238

3. The engine manufactureris responsiblefor allengine-relatedissueswith regardsto performance,power-rating,specifica-

tions,warranty andservice. Please referto the engine manufacturer'sOwner's/Operator's Manual,packedseparatelywith

your unit, for more information.

Pleasehaveyour unit's model number andserial numberreadywhenyou call. See previoussectionto locatethis information.

Youwill be askedto enter theserialnumber in order to processyour call.

2

Page 3

222

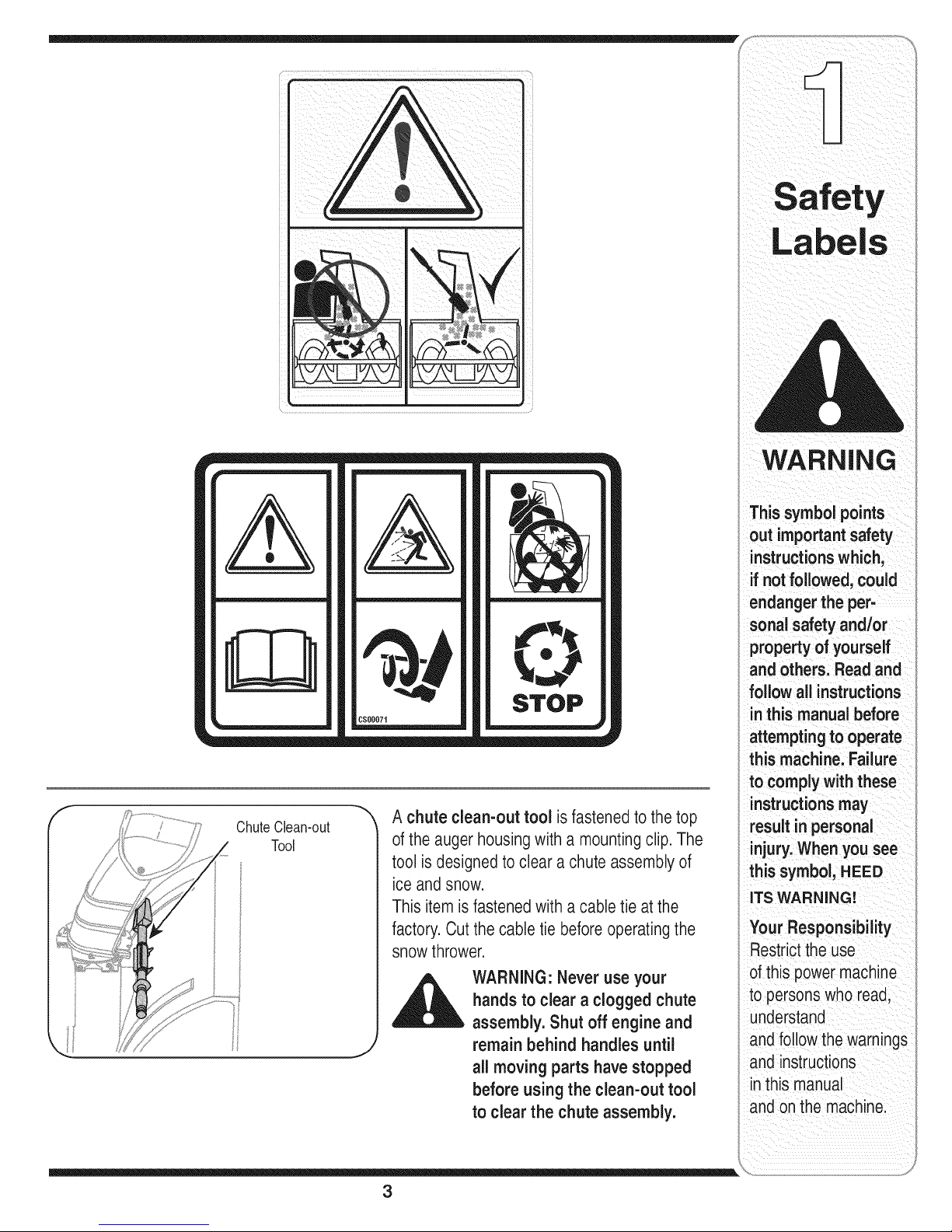

ChuteClean-out

Tool

CS00071

A chute clean-out tool isfastenedto the top

of the auger housingwith a mountingclip. The

tool isdesignedtoclear a chuteassembly of

ice and snow.

Thisitem is fastenedwitha cable tie atthe

factory.Cut the cable tie before operatingthe

snowthrower.

_ WARNING: Never use your

J

,m#

mmmmmmmmm

handsto clear a clogged chute

assembly. Shut off engine and

remain behind handles until

all moving parts havestopped

before using the clean-out tool

to clear the chute assembly.

STOP

WARNING

This symbol points

out importantsafety

instructionswhich,

ifnot followed, could

endanger the per-

sonal safety and/or

propertyof yourself

and others. Readand

follow all instructions

inthis manual before

_ttempting to operate

this machine. Failure

to comply with these

instructionsmay

result inpersonal

injury.When you see

this symbol, HEED

iTS WARNING!

four Responsibility

::restrictthe use

ofthis power machine

to persons who read,

understand

and follow thewarnings

and instructions

inthis manual

and on the machine.

3

Page 4

WARNING: EngineExhaust,some of its constituents, andcertain vehiclecompo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancer and

birth defects or other reproductiveharm.

DANGER: This machinewas builtto beoperatedaccordingto the safeoperation practices in this

manual.As with any type of powerequipment,carelessnessor error onthe part ofthe operatorcan

result in seriousinjury.This machine is capable of amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultin serious injuryordeath.

WARNING

Thissymbolpoints

outimportantsafety

instructionswhich,

ifnotfollowed, could

endangerthe per-

sonalsafetyand/or

propertyof yourself

andothers.Readand

followallinstructions

inthismanualbefore

attemptingto operate

thismachine.Failure

i to complywiththese

instructionsmay

; resultin personal

injury.Whenyou see

this symbol, HEED

iTS WARNING!

Your Responsibility

Restrictthe use

of this powermachine

to personswho read,

understand

I andfollow the warnings

and instructions

inthis manual

and on the machine.

Training

1. Read,understand,andfollowall instructionson the

machineandin themanual(s)beforeattemptingto

assembleandoperate.Keepthis manualina safe placefor

futureandregularreferenceandfor orderingreplacement

parts.

2. Befamiliarwithall controlsandtheirproperoperation.

Knowhowto stopthe machineanddisengagethemquickly.

3. Neverallowchildrenunder14yearsoldto operatethis

machine.Children14yearsold andovershouldreadand

understandtheinstructionsandsafeoperationpractices

inthismanualand onthemachineandbetrainedand

supervisedbyan adult.

4. Neverallowadultsto operatethis machinewithoutproper

instruction.

5. Thrownobjectscancauseseriouspersonalinjury.Plan

yoursnow-throwingpatternto avoiddischargeof material

towardroads,bystandersandthe like.

6. Keepbystanders,helpers,petsandchildrenat least75feet

fromthe machinewhileit isin operation.Stopmachineif

anyoneentersthearea.

7. Exercisecautiontoavoidslippingor falling,especially

whenoperatingin reverse.

Preparation

1. Thoroughlyinspectthe areawherethe equipmentisto be

used.Removealldoormats,newspapers,sleds,boards,

wiresand otherforeignobjects,whichcouldbetripped

overor thrownbythe auger/impeller.

2. Alwayswearsafetyglassesor eyeshieldsduring

operationandwhileperforminganadjustmentor repair

toprotectyoureyes.Thrownobjectswhich ricochetcan

causeseriousinjurytothe eyes.

3. Do notoperatewithoutwearingadequatewinteroutergar-

ments.Donotwearjewelry,longscarvesor otherloose

clothing,whichcouldbecomeentangledin movingparts.

Wearfootwearwhichwillimprovefootingonslippery

surfaces.

4. Useagroundedthree-wireextensioncordand receptacle

forall unitswithelectricstartengines.

5. Adjustcollectorhousingheightto cleargravel orcrushed

rocksurfaces.

6. Disengageallcontrolleversbeforestartingthe engine.

7. Neverattemptto makeanyadjustmentswhileengineis

running,exceptwherespecificallyrecommendedinthe

operator'smanual.

8. Letengineandmachineadjusttooutdoortemperature

beforestartingtoclearsnow.

Safe Handling of Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecare

in handlinggasoline.Gasolineisextremelyflammableandthe

vaporsareexplosive.Seriouspersonalinjurycanoccurwhen

gasolineisspilled onyourselfor yourclothes,whichcanignite.

Washyourskin andchangeclothesimmediately.

a. Useonlyanapprovedgasolinecontainer.

b. Extinguishallcigarettes,cigars,pipesandothersources

ofignition.

c. Neverfuelmachineindoors.

d. Neverremovegascap oraddfuelwhilethe engineis hot

or running.

e. Allowengineto coolat leasttwo minutesbeforerefuel-

ing.

f. Neveroverfill fueltank. Filltankto nomorethanY2inch

belowbottomoffiller neckto providespacefor fuel

expansion.

g. Replacegasolinecap andtightensecurely.

h. If gasolineis spilled,wipe itoff theengineand equip-

ment.Movemachinetoanotherarea.Wait5 minutes

beforestartingtheengine.

i. Neverstorethe machineorfuel containerinside where

there isan openflame,sparkor pilotlight(e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

j. Allowmachinetocoolat least5 minutesbeforestoring.

4

Page 5

Operation

1. Donot puthandsorfeetnearrotatingparts,inthe

auger/impellerhousingor chuteassembly.Contactwiththe

rotatingpartscanamputatehandsandfeet.

2. The auger/impellercontrolleveris asafetydevice.Never

bypassitsoperation.Doingso makesthe machineunsafe

andmaycausepersonalinjury.

3. The controlleversmustoperateeasilyin bothdirections

andautomaticallyreturntothe disengagedpositionwhen

released.

4. Neveroperatewitha missingor damagedchuteassembly.

Keepall safetydevicesinplaceandworking.

5. Neverrunan engineindoorsor in apoorlyventilatedarea.

Engineexhaustcontainscarbonmonoxide,anodorlessand

deadlygas.

6. Donotoperatemachinewhileunderthe influenceofalcohol

or drugs.

7. Mufflerandenginebecomehotandcan causea burn.Do

nottouch.

8. Exerciseextremecautionwhenoperatingonor crossing

gravelsurfaces.Stayalertfor hiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhileoperat-

ingonslopes.

10.Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageor personalinjury causedby aricochet.

11.Neverdirectdischargeatchildren,bystandersand petsor

allow anyoneinfrontofthe machine.

12.Donotoverloadmachinecapacitybyattemptingto clear

snowattoofast of arate.

13.Neveroperatethis machinewithoutgoodvisibility or light.

Alwaysbe sureofyourfootingandkeepa firmholdonthe

handles.Walk,neverrun.

14.Disengagepowerto the auger/impellerwhentransportingor

notinuse.

15.Neveroperatemachineat hightransport speedsonslippery

surfaces.Lookdownand behindandusecare when

backingup.

16.Ifthe machineshouldstartto vibrateabnormally,stopthe

engine,disconnectthesparkplugwireand groundit against

the engine.Inspectthoroughlyfordamage.Repairany

damagebeforestartingandoperating.

17.Disengageallcontrolleversandstopenginebeforeyou

leavethe operatingposition(behindthe handles).Wait

untilthe auger/impellercomestoa completestopbefore

uncloggingthe chuteassembly,makinganyadjustments,or

inspections.

18.Neverputyourhandin thedischargeor collectoropenings.

Alwaysuse theclean-outtoolprovidedtounclogthe dis-

chargeopening.Donot unclogchuteassemblywhileengine

isrunning.Shut offengineandremainbehindhandlesuntil

all movingpartshavestoppedbefore unclogging.

19.Useonly attachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

20. Ifsituationsoccurwhich arenotcoveredin thismanual,use

careand goodjudgment.Callcustomerassistanceforthe

nameof yournearestservicingdealer.

Maintenance & Storage

1. Nevertamperwithsafetydevices.Checktheir proper

operationregularly.Refertothe maintenanceandadjust-

mentsectionsofthis manual.

2. Beforecleaning,repairing,orinspectingmachinedisengage

allcontrolleversandstopthe engine.Waituntilthe

auger/impellercometo a completestop.Disconnectthe

sparkplugwireand groundagainsttheengineto prevent

unintendedstarting.

3. Checkbolts andscrewsfor propertightnessatfrequent

intervalstokeepthe machineinsafeworkingcondition.

Also,visuallyinspectmachinefor anydamage.

4. Do notchangetheenginegovernorsettingor over-speed

theengine.The governorcontrolsthemaximumsafe

operatingspeedoftheengine.

5. Snowthrowershaveplatesandskidshoesaresubjectto

wearanddamage.Foryoursafetyprotection,frequently

checkallcomponentsandreplacewith originalequipment

manufacturer's(OEM) partsonly."Useof partswhichdo

notmeetthe originalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

6. Checkcontrolsperiodicallytoverify theyengageand

disengageproperlyandadjust,if necessary.Referto the

adjustmentsectioninthis operator'smanualfor instructions.

7. Maintainor replacesafetyandinstructionlabels,as neces-

sary.

8. Observeproperdisposallawsandregulationsfor gas,oil,

etc.toprotectthe environment.

9. Priorto storing,runmachineafew minutestoclearsnow

frommachineandpreventfreezeupof auger/impeller.

10.Neverstorethemachineorfuel containerinsidewhere

thereisan openflame,sparkor pilotlightsuchas a water

heater,furnace,clothesdryeretc.

11.Alwaysreferto theoperator'smanualforproperinstructions

onoff-seasonstorage.

Do not modify engine

Toavoidseriousinjuryordeath,donot modifyengineinany

way.Tamperingwiththegovernorsettingcan leadto a runaway

engineandcauseit tooperateat unsafespeeds.Nevertamper

withfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOff RoadEquipment)

arecertifiedto operateonregularunleadedgasoline,andmay

includethefollowingemissioncontrolsystems:EngineModifica-

tion(EM)andThreeWayCatalyst(TWO)ifso equipped.

Average Useful Life

Accordingto the ConsumerProductsSafetyCommission

(CPSC)andthe U.S.EnvironmentalProtectionAgency(EPA),

thisproducthasanAverage UsefulLife ofseven(7)years,or

60hoursof operation.Attheend oftheAverage UsefulLife,

buya newmachineorhavethe machineinspectedannuallyby

anauthorizedservicedealertoensurethat all mechanicaland

safetysystemsare workingproperlyandnotwornexcessively.

Failuretodosocanresultin accidents,injuriesordeath.

WARNING

This symbol points

out important safety

instructions,which

if not followed, could

endanger the per-

sonalsafety and/or

property of yourself

and others. Read and

follow all instructions

in this rnanuai before

attempting to operate

this machine. Failure

to complywith these

instructionsmay

result in personal

injury.When you see

this symbol, HEED

IT'S WARNING!

Your Responsibility

Restrictthe use

ofthis powermachine

to personswho read,

understand

and followthe warnings

and instructions

in this manual

and on the machine.

5

Page 6

NOTE:Referencesto

rightorleftsideofthe

snowthroweraredeter-

minedfrombehindthe

unitintheoperating

position.

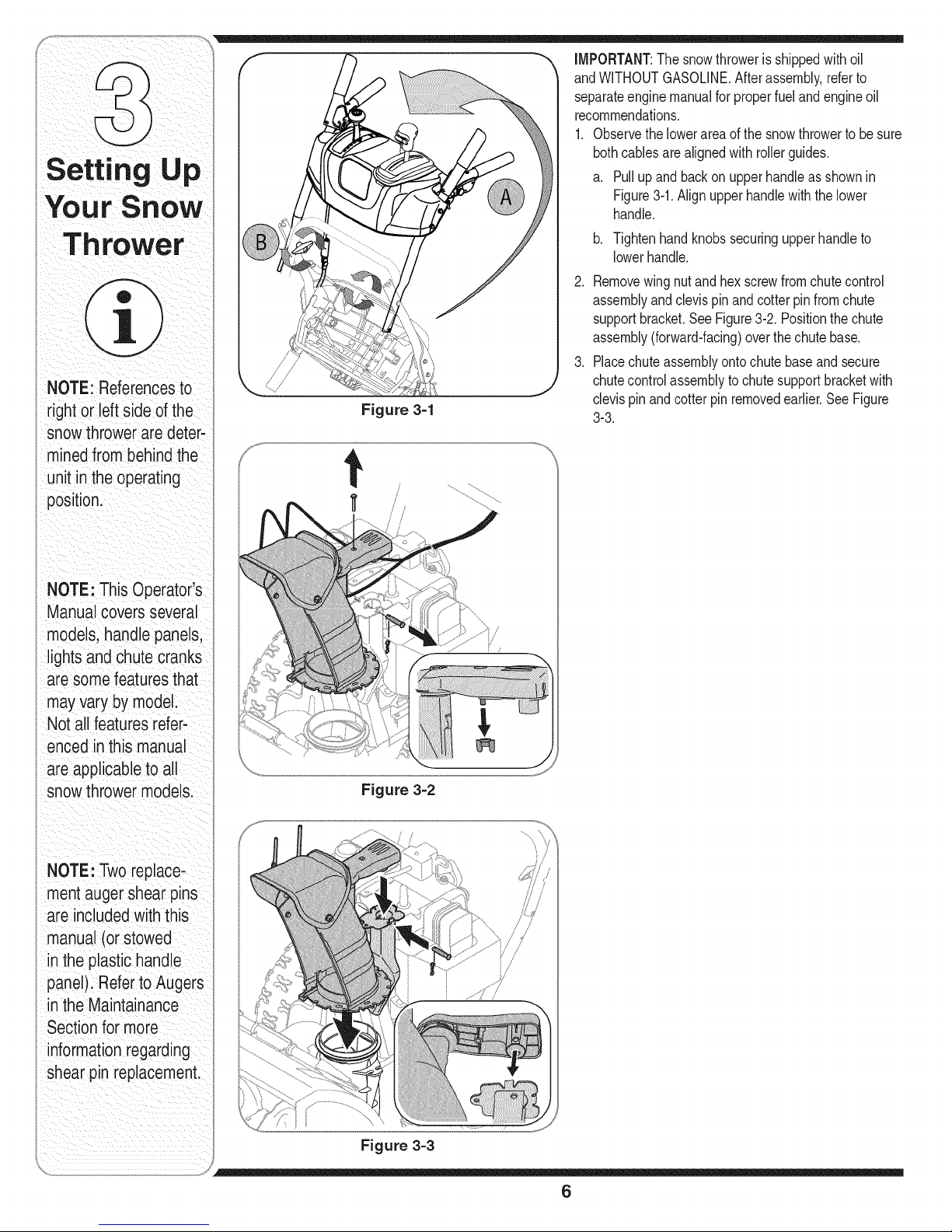

Figure 3-1

IMPORTANT:Thesnowthrowerisshippedwithoil

andWITHOUTGASOLINE.Afterassembly,referto

separateenginemanualfor properfuelandengineoil

recommendations.

1. Observethelowerareaof thesnowthrowerto be sure

bothcablesarealignedwithrollerguides.

a. Pullupand backon upperhandleas shownin

Figure3-1.Alignupperhandlewiththelower

handle.

b. Tightenhandknobssecuringupperhandleto

lowerhandle.

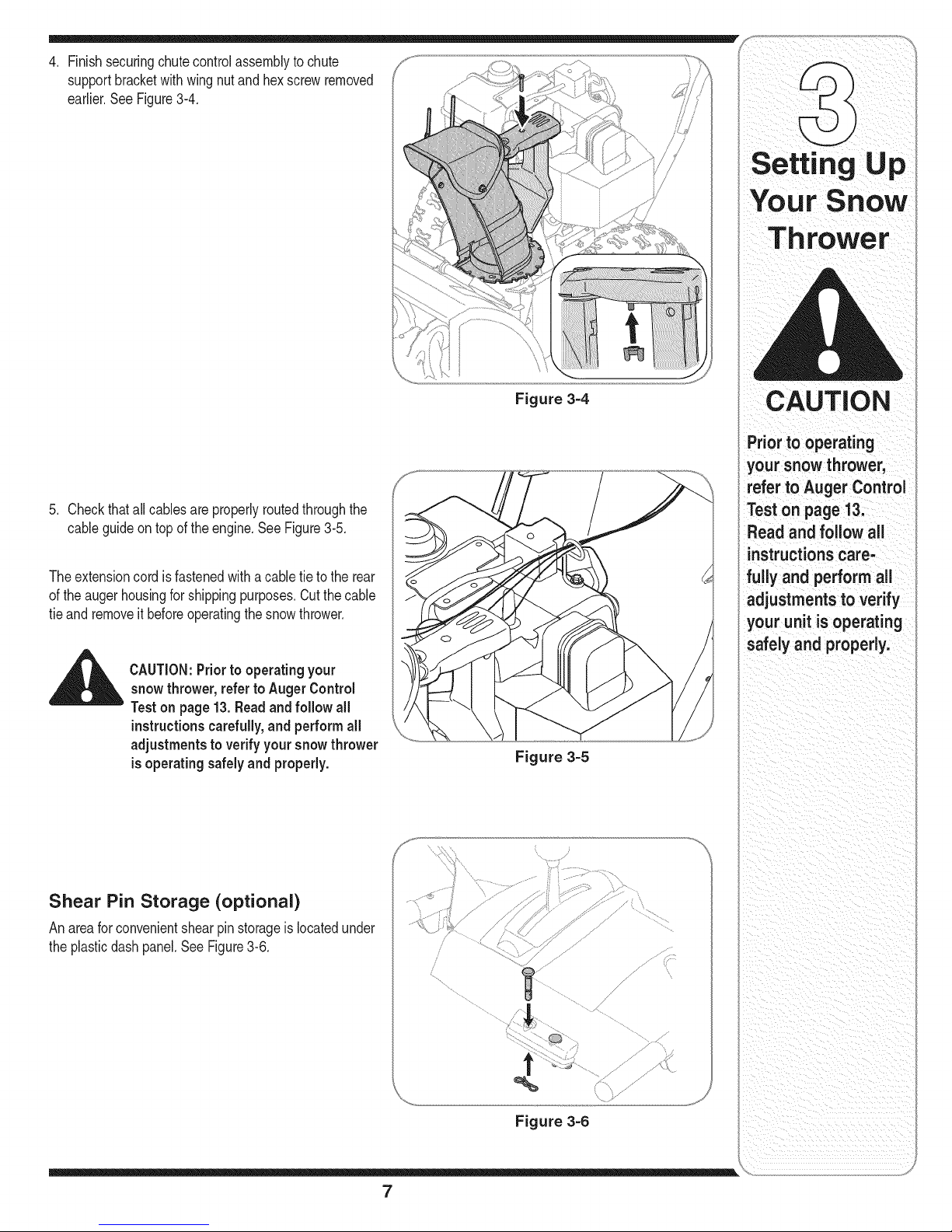

2. Removewingnutand hexscrewfromchutecontrol

assemblyandclevispinandcotter pinfromchute

supportbracket.SeeFigure3-2.Positionthechute

assembly(forward-facing)overthechutebase.

3. Placechuteassemblyontochutebaseand secure

chutecontrolassemblytochutesupportbracketwith

clevispinandcotterpin removedearlier.SeeFigure

3-3.

NOTE:ThisOperator's

Manualcoversseveral

models,handlepanels,

lightsandchutecranks

aresomefeaturesthat

mayvarybymodel.

Notallfeaturesrefer-

encedinthismanual

areapplicabletoall

snowthrowermodels.

NOTE:Tworeplace-

mentaugershearpins

areincludedwiththis

manual(orstowed

i intheplastichandle

panel).RefertoAugers

, intheMaintainance

i Sectionformore

informationregarding

shearpinreplacement.

Figure 3=2

Figure 3=3

6

Page 7

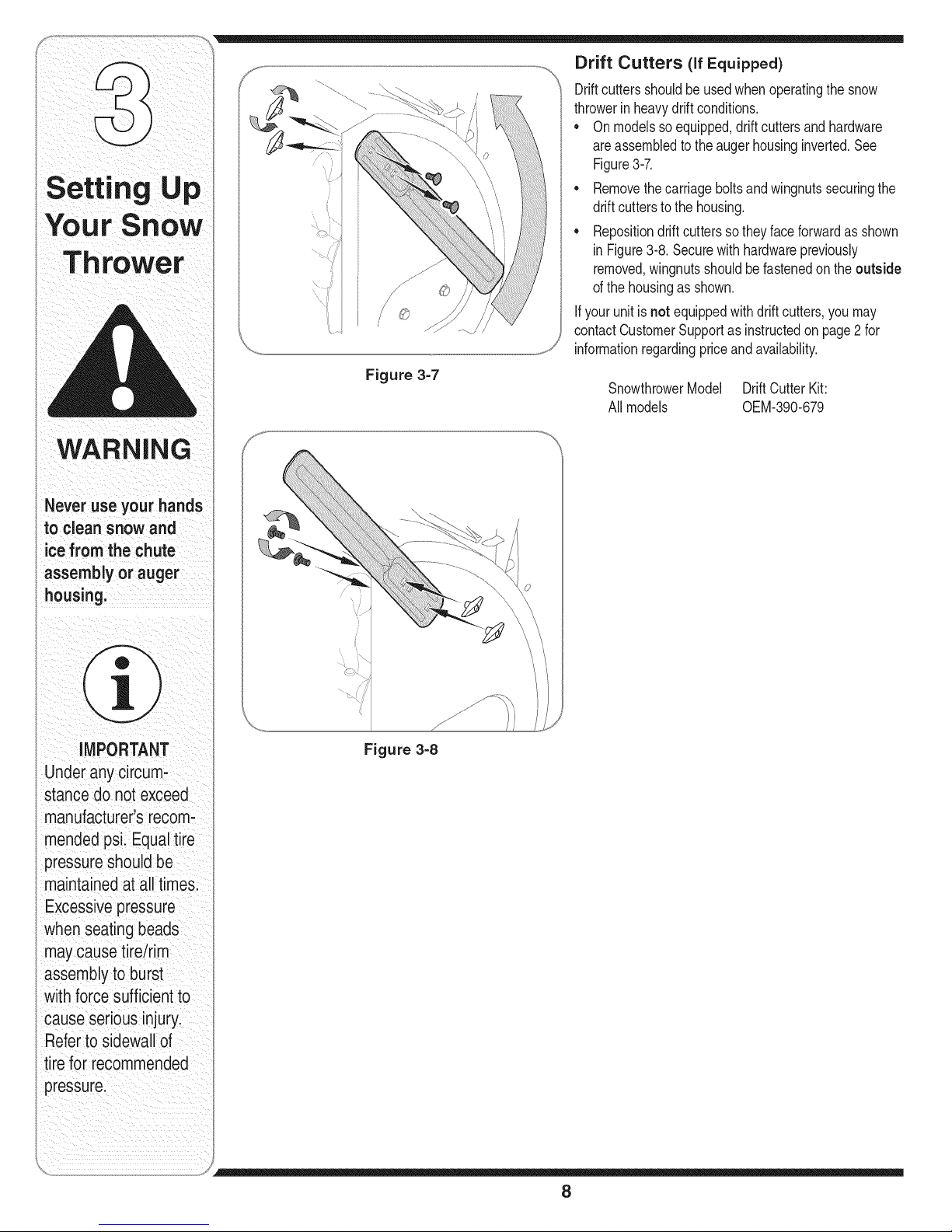

4. Finishsecuringchutecontrolassemblytochute

supportbracketwithwingnutandhexscrewremoved

earlier.SeeFigure3-4.

Setting U p

5. Checkthatall cablesareproperlyroutedthroughthe

cableguideon topofthe engine.SeeFigure3-5.

Theextensioncordis fastenedwitha cabletieto the rear

ofthe augerhousingforshippingpurposes.Cutthecable

tieand removeit beforeoperatingthesnowthrower.

CAUTION:Priorto operating your

snowthrower, referto AugerControl

Teston page13. Readand follow all

instructionscarefully,and performall

adjustments to verify your snowthrower

isoperating safely and properly.

Figure 3=4

Figure 3=5

CAUTION

Priorto operating

your snow thrower,

refer to Auger Control

Test on page 13.

Read and follow all

instructionscare-

fully and perform all

adjustments to verify

your unit is operating

safely and properly.

Shear Pin Storage (optional)

An areaforconvenientshearpin storageis locatedunder

theplasticdashpanel.SeeFigure3-6.

/

/Y

,%

Figure 3=6

7

Page 8

WARNING

Neveruseyourhands

to cleansnowand

icefromthe chute

assemblyorauger

housing.

Figure 3=7

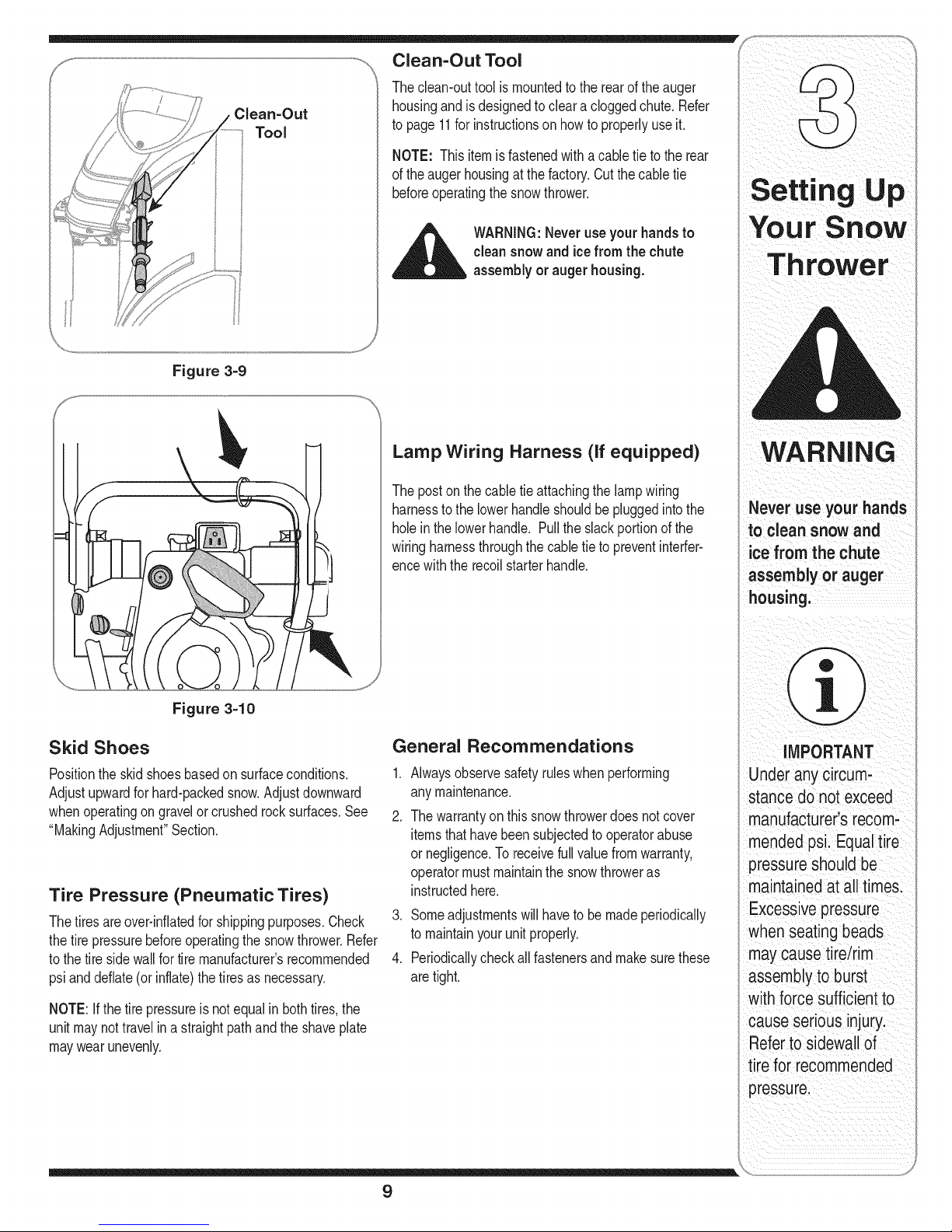

Drift Cutters (If Equipped)

Driftcuttersshouldbeusedwhenoperatingthesnow

throwerinheavydriftconditions.

Onmodelssoequipped,driftcuttersand hardware

areassembledto theaugerhousinginverted.See

Figure3-7.

• Removethecarriageboltsandwingnutssecuringthe

driftcutterstothe housing.

• Repositiondriftcutterssotheyfaceforwardas shown

in Figure3-8.Securewithhardwarepreviously

removed,wingnutsshouldbefastenedon theoutside

ofthe housingasshown.

If yourunit isnot equippedwithdrift cutters,youmay

contactCustomerSupportas instructedonpage2 for

informationregardingpriceand availability.

SnowthrowerModel Drift CutterKit:

Allmodels 0EM-390-679

iMPORTANT

Underany circum-

stance do not exceed

manufacturer'srecom-

mendedpsi. Equaltire

pressureshouldbe

maintainedat all times.

i Excessivepressure

whenseatingbeads

maycausetire/rim

assemblyto burst

with forcesufficientto

cause seriousinjury

Referto sidewallof

tirefor recommended

pressure.

Figure 3=8

8

Page 9

Clean=Out

Tool

Clean-Out Tool

Theclean-outtool ismountedtotherearof theauger

housingandis designedtocleara cloggedchute.Refer

topage11for instructionson howtoproperlyuseit.

NOTE: This itemisfastenedwithacabletie to therear

ofthe augerhousingatthefactory.Cutthecabletie

beforeoperatingthesnowthrower.

Figure 3-9

_ ARNING:Neveruse yourhandsto

_jJ_

clean snowand ice from the chute

assembly or auger housing.

Lamp Wiring Harness (If equipped)

Theposton the cabletie attachingthelampwiring

harnessto the lowerhandleshouldbe pluggedintothe

holeinthelowerhandle. Pullthe slackportionofthe

wiringharnessthroughthecabletieto preventinterfer-

encewiththe recoilstarterhandle.

ThrOWer

WARNING

Never use your hands

to clean snow and

ice from the chute

assembly or auger

housing,

Figure 3-10

Skid Shoes

Positiontheskidshoesbasedon surfaceconditions. 1.

Adjustupwardforhard-packedsnow.Adjustdownward

whenoperatingon gravelorcrushedrocksurfaces.See 2.

"MakingAdjustment"Section.

Tire Pressure (Pneumatic Tires)

Thetiresareover-inflatedforshippingpurposes.Check

thetire pressurebeforeoperatingthesnowthrower.Refer

tothe tiresidewallfor tiremanufacturer'srecommended

psianddeflate(or inflate)thetiresas necessary.

NOTE:Ifthetire pressureisnot equalinbothtires, the

unitmaynottravelina straightpathandtheshaveplate

maywearunevenly.

General Recommendations

Alwaysobservesafetyruleswhenperforming

anymaintenance.

Thewarrantyon thissnowthrowerdoesnotcover

itemsthathavebeensubjectedtooperatorabuse

or negligence.Toreceivefullvaluefromwarranty,

operatormustmaintainthe snowthroweras

instructedhere.

3. Someadjustmentswillhaveto bemadeperiodically

tomaintainyourunitproperly.

4. Periodicallycheckall fastenersand makesurethese

aretight.

i _ i i i

iMPORTANT

Underanycircum:

stance do not exceed

manufactureCs recom_

mended psL EqUaltire

pressure shouldbe

maintainedat alltimes:

Excessive pressure

when seating beads

may causetireirim

assembly toburSt

with forcesufficientto

cause seriousinjuryl

Refer tosidewallof

tire for rec0mmended

pressure:

9

Page 10

ThrOWer

WARNING

Read,understand,

andfollow allinstruc-

tions andwarnings

onthe machineand

inthis manualbefore

operating.

Useextreme care

hen handling

gasoline.Gasoline is

extremelyflammable

andthe vapors are

explosive.Neverfuel

the machineindoors

or while the engine

is hot or running.

Extinguishcigarettes,

cigars,pipes and

other sourcesof

ignition.

HeatedHandles

Switch (en option)l-

Headlight_ WheelSteering

Electric Start

GasCa

Oil EngineControls

]ool

1 If Equipped Shoe Control

Figure 4-1

Nowthatyouhavesetup yoursnowthrowerfor opera-

tion,getacquaintedwithits controlsandfeatures.These

aredescribedbelowandillustrated in Figure4-1.This

knowledgewillallow youto useyournewequipmentto

itsfullestpotential.

NOTE: Fordetailedstartinginstructionsandmore

informationonall enginecontrols,refertothe separate

enginemanualpackedwithyour unit.

Shift Lever

Theshiftleveris locatedon therightside

ofthe handlepanel.Placetheshift lever

intoany ofeightpositionstocontrolthe 4,

directionof travelandgroundspeed.

Forward 3

Yoursnowthrowerhassixforward(F)

speeds,withpositionnumberone (1) t 2

beingtheslowestspeed.

Reverse 1

Yoursnowthrowerhastwo reverse(R)

speeds,withpositionnumberone (1) R 1

beingtheslowerspeed.

6

Choke Control

Thechokecontrolis foundonthe rearofthe engineand

isactivatedby rotatingtheknobclockwise.Activatingthe

chokecontrolclosesthe chokeplateon thecarburetor

andaidsinstartingtheengine.

Throttle Control

Thethrottlecontrolis locatedonthe engine.

it regulatesthespeedof theengineand

willshutoff the enginewhenpusheddown

completely.

Primer

Depressingthe primerforcesfueldirectly

intothe engine'scarburetortoaidin cold-

weatherstarting.

Oil Fill

Engineoil levelcanbecheckedandoil

addedthroughtheoil fill.

R2

Drive Control

.Shift Lever

Four-Way

Chute ControlTM

uger Control

Control 1

RecoilStarter

Handle

ElectricStarterOutlet

Ignition

Key

X

Choke

Control

Throttle

• J

III

10

Page 11

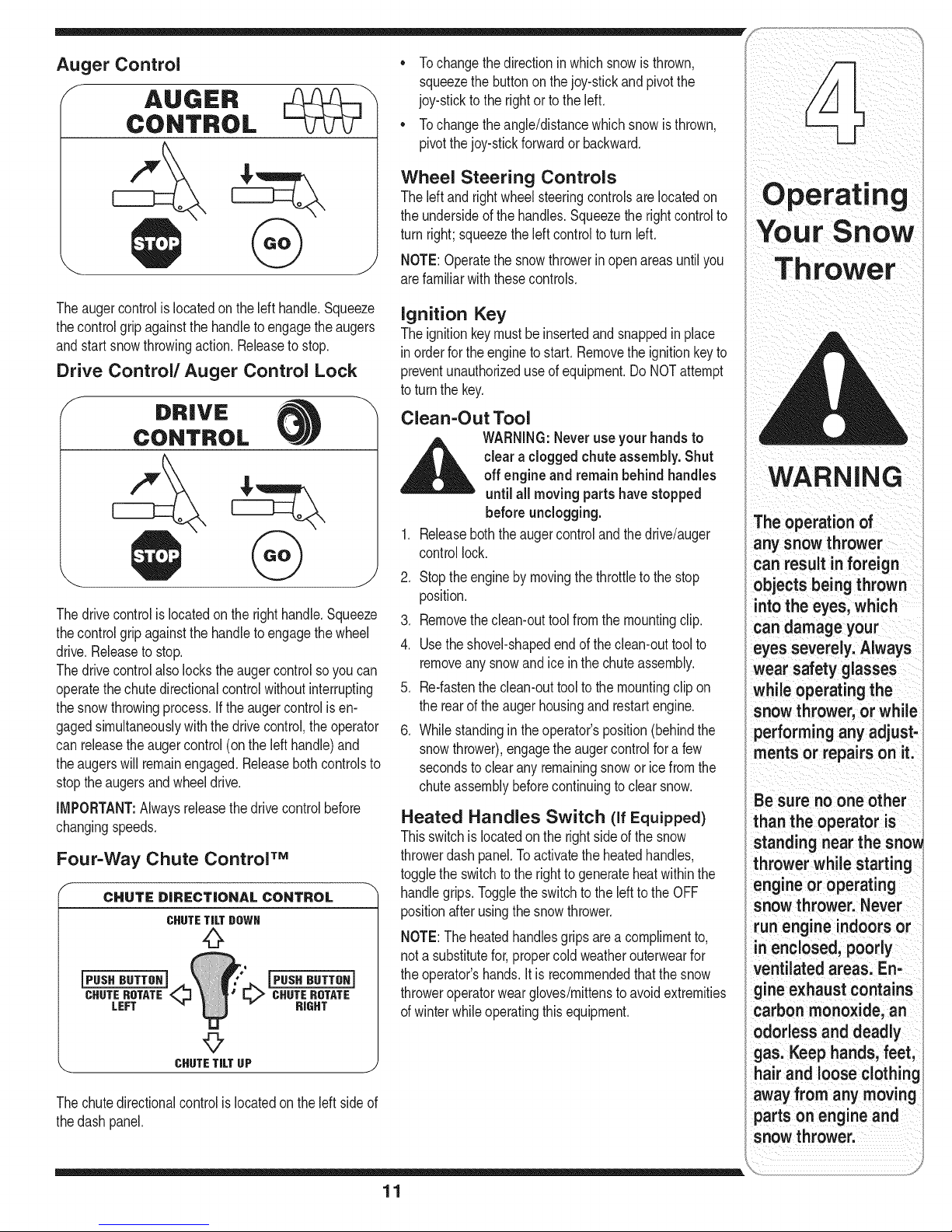

Auger Control

f

* Tochangethedirectioninwhichsnowis thrown,

squeezethe buttononthejoy-stickandpivotthe

joy-stickto the rightorto theleft.

* Tochangetheangle/distancewhichsnowisthrown,

pivotthejoy-stickforwardor backward.

Wheel Steering Controls

Theleftand rightwheelsteeringcontrolsare locatedon

theundersideofthe handles.Squeezetherightcontrolto

turnright;squeezetheleftcontroltoturnleft.

NOTE:Operatethesnowthrowerinopenareas untilyou

arefamiliarwiththesecontrols.

Operating

Snow

Throwe r

Theaugercontrolis locatedontheleft handle.Squeeze

thecontrolgripagainstthe handletoengagetheaugers

andstartsnowthrowingaction.Releasetostop.

Drive Control/Auger Control Lock

f DRIVE -X

CONTROL

Thedrivecontrolislocatedonthe righthandle.Squeeze

thecontrolgripagainstthe handletoengagethewheel

drive.Releasetostop.

Thedrivecontrolalsolockstheaugercontrolsoyoucan

operatethechutedirectionalcontrolwithoutinterrupting

thesnowthrowingprocess.Ifthe augercontrolisen-

gagedsimultaneouslywiththedrivecontrol,theoperator

canreleasetheaugercontrol(onthe lefthandle)and

theaugerswillremainengaged.Releasebothcontrolsto

stoptheaugersandwheeldrive.

iMPORTANT:Alwaysreleasethedrivecontrolbefore

changingspeeds.

Four-Way Chute Control TM

f

CHUTE DiRECTiONAL CONTROL

CHUTETILTDOWN

jPUSH BUTTOHi

CHUTEROTATE

RIGHT

CHUTETiLTUP j

Thechutedirectionalcontrolislocatedon theleftside of

thedash panel.

Ignition Key

Theignitionkeymustbe insertedandsnappedinplace

inorderforthe enginetostart. Removetheignitionkeyto

preventunauthorizeduseof equipment.DoNOTattempt

toturn thekey.

Clean-Out Tool

WARNING:Neveruseyour handsto

clear aclogged chute assembly.Shut

off engine and remain behind handles

until ail moving partshavestopped

before unclogging.

1.

Releaseboththe augercontroland thedrive/auger

controllock.

2.

Stoptheenginebymovingthethrottleto thestop

position.

3.

Removethe clean-outtoolfromthe mountingclip.

4.

Usetheshovel-shapedendofthe clean-outtoolto

removeanysnowandice inthechuteassembly.

5.

Re-fastentheclean-outtoolto themountingclipon

therearof theaugerhousingand restartengine.

6.

Whilestandingin theoperator'sposition(behindthe

snowthrower),engagethe augercontrolfora few

secondsto clearanyremainingsnoworicefromthe

chuteassemblybeforecontinuingtoclearsnow.

Heated Handles Switch (if Equipped)

Thisswitchis locatedonthe rightside ofthe snow

throwerdashpanel.Toactivatethe heatedhandles,

togglethe switchtothe rightto generateheatwithinthe

handlegrips.Toggletheswitchtothe lefttothe OFF

positionafterusingthe snowthrower.

NOTE:Theheatedhandlesgripsarea complimentto,

nota substitutefor,propercoldweatherouterwearfor

theoperator'shands.Itis recommendedthatthesnow

throweroperatorweargloves/mittensto avoidextremities

ofwinterwhile operatingthis equipment.

WARNING

The operation of

any snow thrower

can result inforeign

objects being thrown

intothe eyes, which

can damage your

eyes severely. Always

wear safety glasses

while operating the

snow thrower, or while

performing any adjust-

ments or repairs on it.

Besure no oneother

than the operator is

standing near the sno_

thrower while starting

engine or operating

snow thrower. Never

run engine indoors or

in enclosed, poorly

ventilated areas. En-

gine exhaust contains

carbon monoxide, an

odorless and deadly

gas. Keep hands, feet,

hair and loose clothing

away from any moving

parts on engine and

snow thrower.

11

Page 12

WARNING

Gas & Oil Fill-Up

Servicetheenginewithgasolineandoil asinstructedin

theseparateenginemanualpackedwithyourunit.Read

instructionscarefully.

Starting The Engine

1. Attachsparkplugwireto sparkplug.Makecertainthe

metalloopon theendof thesparkplugwire (inside

therubberboot)isfastenedsecurelyoverthe metal

tiponthe sparkplug.

2. Makecertainboththeaugercontrolanddrivecontrol

arein thedisengaged(released)position.

3. Movethrottlecontrolupto FASTposition.Insert

ignitionkeyinto slot.Makesureitsnapsintoplace.

Donotattempttoturn thekey.

7. Whendisconnectingtheextensioncord,always

unplugtheendat thethree-prongwalloutletbefore

unpluggingtheoppositeendfromthe snowthrower.

Recoil Starter

1. Rotatechokecontrolto FULLchokeposition(cold

enginestart).

NOTE:If theengineis alreadywarm,placechokecontrol

intheOFFpositioninsteadof FULL.

2. Pushthe primertwoor threetimesforcoldengine

start,makingsureto coverventholeinthecenterof

theprimerwhenpushing.

NOTE:DO NOTuseprimerto restarta warmengine

aftera shortshutdown.

Read, understand,

and follow all instruc-

tions and warnings

on the machineand

inthis manual before

operating.

Useextreme care

when handling

gasoline.Gasoline is

extremelyflammable

and the vapors are

explosive.Neverfuel

the machine indoors

or while the engine

is hot or running.

Extinguishciga-

rettes, cigars, pipes

and other sources of

ignition.

Ifyour home'swiring

systemis not a

three-wire grounded

system,do not use

this electric starter

under any condi-

tions.

If your home

electricalsystem

is grounded,

but a three-hole

receptacleis not

available, do not use

yoursnow throweCs

electricstarter.

NOTE:The enginecannotstartunlessthe keyis

insertedintoignitionswitch.

Electric Starter

1. Determinethatyourhome'swiringis a three-wire

groundedsystem.Ask a licensedelectricianifyouare

notcertain.

WARNING:Theoptional electricstarter

isequippedwith a grounded three-wirepowercordand plug,and is designed

to operate on 120voltAC household

current.It must beused with a properly

grounded three-prong receptacle atall

times to avoidthe possibilityof electric

shock.Followall instructionscarefully

priorto operating the electric starter,

ifyouhavea groundedthree-prongreceptacle,proceed

asfollows:

1. Plugtheextensioncordintothe outletlocatedon the

engine'ssurface.Plugtheotherendofextensioncord

intoa three-prong120-volt,grounded,ACoutletina

well-ventilatedarea.

2. RotatechokecontroltoFULLchokeposition(fora

coldenginestart).

NOTE:Ifthe engineisalreadywarm,placechokecontrol

inthe OFFpositioninsteadofFULL.

3. Pushtheprimertwoor threetimesforcoldengine

start,makingsureto coverventholein thecenterof

theprimerwhenpushing.

NOTE:DONOTuseprimertorestartawarmengine

aftera shortshutdown.

4. Pushstarterbuttonto startengine.

5. Oncetheenginestarts,immediatelyreleasestarter

button.

6. As theenginewarms,slowlyrotatethechokecontrol

tothe OFFposition.Ifthe enginefalters,quickly

rotatethechokecontrolbackto FULLand thenslowly

intothe OFFpositionagain.

NOTE:Additionalprimingmaybe necessaryifthe

temperatureis below150Fahrenheit.

3. Graspthe recoilstarterhandleandslowlypullthe

ropeout.Atthe pointwhereitbecomesslightlyharder

topullthe rope,slowlyallowthe ropeto recoil.

4. Pullthe starterhandlewithafirm,rapidstroke.Donot

releasethehandleandallowitto snapback.Keepa

firmholdon thestarterhandleandallowitto slowly

recoil.

.

Asthe enginewarms,slowlyrotatethe chokecontrol

tothe OFFposition.Ifthe enginefalters,quicklyrotate

thechokecontrolbackto the FULLpositionandthen

slowlyintotheOFFpositionagain.

NOTE:Allowtheengineto warmup fora few minutes

afterstarting.Theenginewill notdevelopfull poweruntil

itreachesoperatingtemperatures.

Stopping The Engine

Runenginefor a fewminutesbeforestoppingtohelpdry

offanymoistureontheengine.

Tohelppreventpossiblestarterfreeze-up,proceedas

follows:

Electric Starter (if Equipped)

1. Connectextensioncordtothe electricstarteroutlet

ontheengine,thento 120voltACoutlet.

2. Withthe enginerunning,pushthestarterbuttonand

allowthe starterforspinfor severalseconds.The

noisemadebythe starteris normal.Theengine's

starteris notbeingharmed.

3. Whendisconnectingtheextensioncord,always

unplugtheendat thethree-prongwalloutletbefore

unpluggingtheoppositeendfromthe snowthrower.

4. MovethrottlecontroltoSTOPposition.

5. Removetheignitionkey(Donotturnkey)to prevent

unauthorizeduseof equipment.

6. Wipeallsnowandmoisturefromtheareaaroundthe

engineaswell asthe areainandaroundthedrive

controlandaugercontrol.Also,engageandrelease

bothcontrolsseveraltimes.

12

Page 13

NOTE:Keepthe keyin a safeplace.Theenginecannot

startwithouttheignitionkey.

Recoil Starter

1. Withenginerunning,pullstarterropewitha rapid,

continuousfull armstrokethreeor fourtimes.Pulling

thestarterropewillproducea loudclatteringsound,

whichisnotharmfultoengine.

2. MovethrottlecontroltoSTOPposition.

3. Removethe ignitionkey(Donotturnkey)to prevent

unauthorizeduseof equipment.

NOTE:Keepthe keyin a safeplace.Theenginecannot

startwithouttheignitionkey.

4. Wipeall snowandmoisturefromtheareaaroundthe

engineaswellasthe areain andaroundthedrive

controlandaugercontrol.Also,engageand release

bothcontrolsseveraltimes.

To Engage Drive

Withtheenginerunningneartop speed,move

shiftleverto oneof sixFORWARDpositionsor two

REVERSEpositions.Selecta speedappropriatefor

thesnowconditionsthatexist.

2. Squeezedrivecontrolagainstthe righthandleand

thesnowthrowerwill move.Releaseitandthedrive

motionwillstop.

3. Toturnthe unitleftorright,squeezetherespective

wheelsteeringcontrol.SeeFigure4-1.

2. Ina well-ventilatedarea,startthesnowthrower

engineasinstructedonthe previouspage.Makesure

thethrottleissetin the FASTposition.

3. Whilestandingin theoperator'sposition(behindthe

snowthrower),engagethe auger.

4. Allowtheaugerto remainengagedforapproximately

ten(10)secondsbeforereleasingtheaugercontrol.

Repeatthisseveraltimes.

5. Withthe throttlecontrolin the FAST(rabbit)position

andtheaugercontrolinthe disengaged"up"position,

walktothe frontofthe machine.

6. Confirmthattheaugerhascompletelystopped

rotatingandshowsNOsignsofmotion.Iftheauger

showsANYsignsofrotating,immediatelyreturnto

theoperator'spositionandshutofftheengine.Wait

forALLmovingpartsto stopbeforere-adjustingthe

augercontrol.

7. To readjustthecontrolcable,loosentheupperhex

nutonthe augercablebracket.

8. Positionthebracketupwardtoprovidemoreslack(or

downwardtoincreasecabletension).SeeFigure4-2.

9. Retightentheupperhex nut.

10.RepeatAugerControlTesttoverifyproperadjustment

hasbeenachieved.

WARNING

Never use your hands

tocleansnowand

ice from the chute

assembly orauger

The muffler, engine

and surrounding

areas become hot

and can cause a

burn, Do not touch,

To Engage Augers

1. Toengageaugersandstartsnowthrowing,squeeze

thelefthandaugercontrolagainstthe left handle.

Releaseto stopaugers.

2. Whiletheaugercontrolis engaged,squeezethe drive

controltomove,releasetostop.Donotshiftspeeds

whilethe driveis engaged.

NOTE:Thissameleveralsolocksaugercontrolsoyou

canturn thechutecontrolwithoutinterruptingthesnow

throwingprocess.

3. Releasetheaugercontrol;the interlockmechanism

shouldkeeptheaugercontrolengageduntilthedrive

controlis released.

.

Releasethedrivecontrolto stopboththeaugersand

thewheeldrive.Tostoptheauger,bothleversmust

be released.

Auger Control Test

Performthefollowingtestbeforeoperatingyoursnow

throwerforthe firsttimeandat thestartofeachwinter.

Checktheadjustmentofthe augercontrolasfollows:

1. Whentheaugercontrolis releasedandinthe

disengaged"up"position,thecableshouldhavevery

littleslack.It shouldNOTbetight.

When selecting a

Drive Speed, usethe

slower speeds until

!ou are comfortable

and familiar with the

operation of the snow

thrower.

Figure 4=2

NEVERreposition the

shift lever(change

speeds or direction

of travel) without first

releasing the drive

control and bringing

the snow thrower

to a complete stop.

Doingso will result in

_remature wear to the

snow thrower's drive

system.

13

Page 14

Shift Cable

If thefull rangeofspeeds(forwardandreverse)cannot

beachieved,refertothe figureto theleftandadjustthe

shiftcable asfollows:

1. Placetheshiftleverin the fastest forwardspeed

position.

2. Loosenthehex nuton the shiftcableindexbracket.

SeeFigure5-1.

3. Pivotthe bracketdownwardtotakeupslackinthe

cable.

4. Retightenthehex nut.

5. Checkforcorrectadjustmentbeforeoperatingthe

snowthrower.

WARNING

Read, understand,

and follow all instruc-

tions and warnings

on the machine and

inthis manual before

operating.

i Never attempt to

make any adjust-

i merits whilethe

engine is running,

i exceptwhere speci-

fied in operator's

' manual.

Figure 5=1

Figure 5=2

Figure 5=3

Chute Control

Oncea seasonorevery25hoursofoperation,whichever

isearlier,checkwhetherthe four-waychutecontroFM

cableshaveslackened,ifthechutedoesnotrotate

fullyor itspitchcannotbe movedupordown,the chute

controlcableswillhavetobeadjusted.

Toadjustthesecables,proceedasfollows:

1. Totightencable,loosenthetopnutand tightenthe

bottomnuton thecable.

2. Adjustequallyon bothsidesby workingonboth

cables.SeeFigure5-2.

Drive Control & Shift Lever

Whenthedrivecontrolis releasedandin thedisengaged

"up"position,thecableshouldhaveverylittleslack.It

shouldNOTbetight.

Checktheadjustmentofthe drivecontrolas follows:

1. Withthe drivecontrolreleased,pushthesnowthrower

gentlyforward.Theunitshouldrollfreely.

2. Engagethedrivecontrolandgentlyattemptto push

thesnowthrowerforward.Thewheelsshouldnotturn.

Theunit shouldnot rollfreely.

3. Withthe drivecontrolreleased,movetheshiftlever

backandforthbetweentheR2 positionandtheF6

positionseveraltimes.Thereshouldbeno resistance

in theshift lever.

4. If anyofthe abovetestsfailed,thedrivecable isin

needofadjustment.Proceedasfollows:

5. Loosenthelowerhexnutonthedrivecablebracket.

SeeFigure5-3.

6. Positionthebracketupwardtoprovidemoreslack(or

downwardto increasecabletension).

7. Retightenthelowerhexnut.

Youcanalsocheckthe adjustmentasfollows:

1. Withthe snowthrowertippedforward(becertainto

draingasolineorplace plasticfilmunderthe gascap if

thesnowthrowerhasalreadybeenoperated),remove

theframecoverunderneaththesnowthrowerby

J

removingtheself-tappingscrews. SeeFigure6-5on

page17.

14

Page 15

2. Withthe drivecontrolreleased,theremustbe 1/8"

clearancebetweenthefrictionwheelandthe drive

pulleyin all positionsof theshiftlever.

3. Withthe drivecontrolengaged,thefrictionwheelmust

contactthedrive pulley.SeeFigure6-8.

4. Ifadjustmentisnecessary,loosenthelowerhexnut

on thedrivecableindexbracketandpivotthe bracket

upwardordownwardasnecessary.Referto Figure

5-3.Tightenthe lowerhexnutto securethebracket

whencorrectadjustmentisreached.

5. Reassembletheframecoverandreturntheunitback

to itsoperatingposition.

NOTE:if youplacedplasticunderthe gascap,becertain

to removeit now.

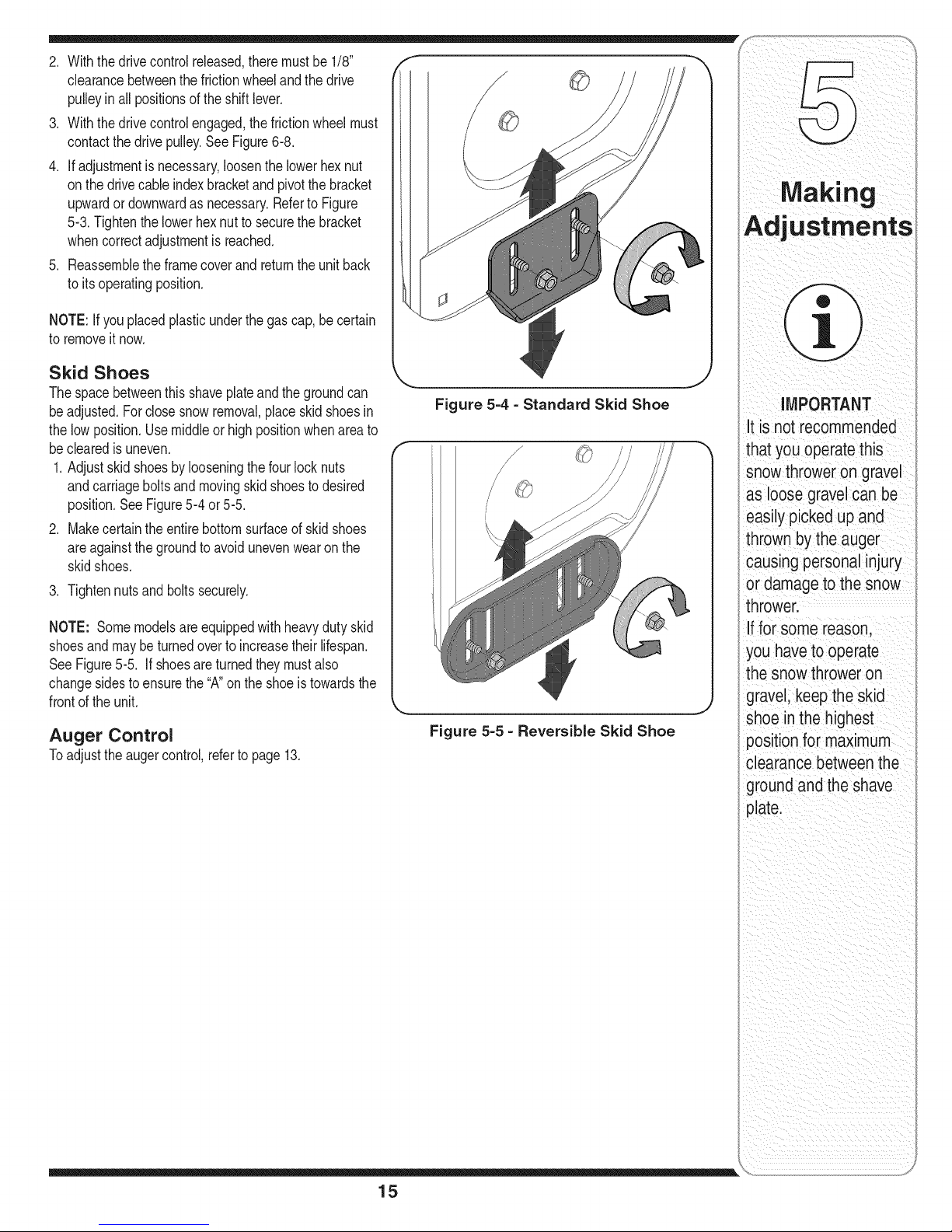

Skid Shoes

Thespacebetweenthisshaveplateandthegroundcan

be adjusted.Forclosesnowremoval,placeskidshoesin

thelowposition.Usemiddleorhighpositionwhenareato

be clearedis uneven.

1.Adjustskidshoesby looseningthefourlocknuts

andcarriageboltsand movingskidshoesto desired

position.SeeFigure5-4 or5-5.

2. Makecertainthe entirebottomsurfaceofskidshoes

areagainstthegroundto avoidunevenwearon the

skidshoes.

3. Tightennutsandboltssecurely.

NOTE: Somemodelsareequippedwith heavydutyskid

shoesandmaybeturnedoverto increasetheirlifespan.

See Figure5-5. If shoesareturnedtheymustalso

changesidesto ensurethe "A"onthe shoeis towardsthe

frontofthe unit.

Auger Control

Toadjustthe augercontrol,referto page13.

Figure 5-4 - Standard Skid Shoe

Figure 5-5 - Reversible Skid Shoe

Mak ng

i

AdjuStments

IMPORTANT

It is not recommended

that you operatethis

snowthrower on gravel

as loose gravelcan be

easilypicked up and

thrownby the auger

causingpersonal injury

ordamageto thesnow

thrower,

Iffor some reason.

you haveto operate

the snowthroweron

gravel,keepthe skid

shoe inthe highest

positionfor maximum

clearance betweenthe

groundand the shave

plate.

15

Page 16

Maintainin,

Engine

Refertothe separateenginemanualpackedwithyour

unitfor all enginemaintenance.

Lubrication

Engine

Refertothe separateenginemanualpackedwithyour

unitfor all enginelubricationinstructions.

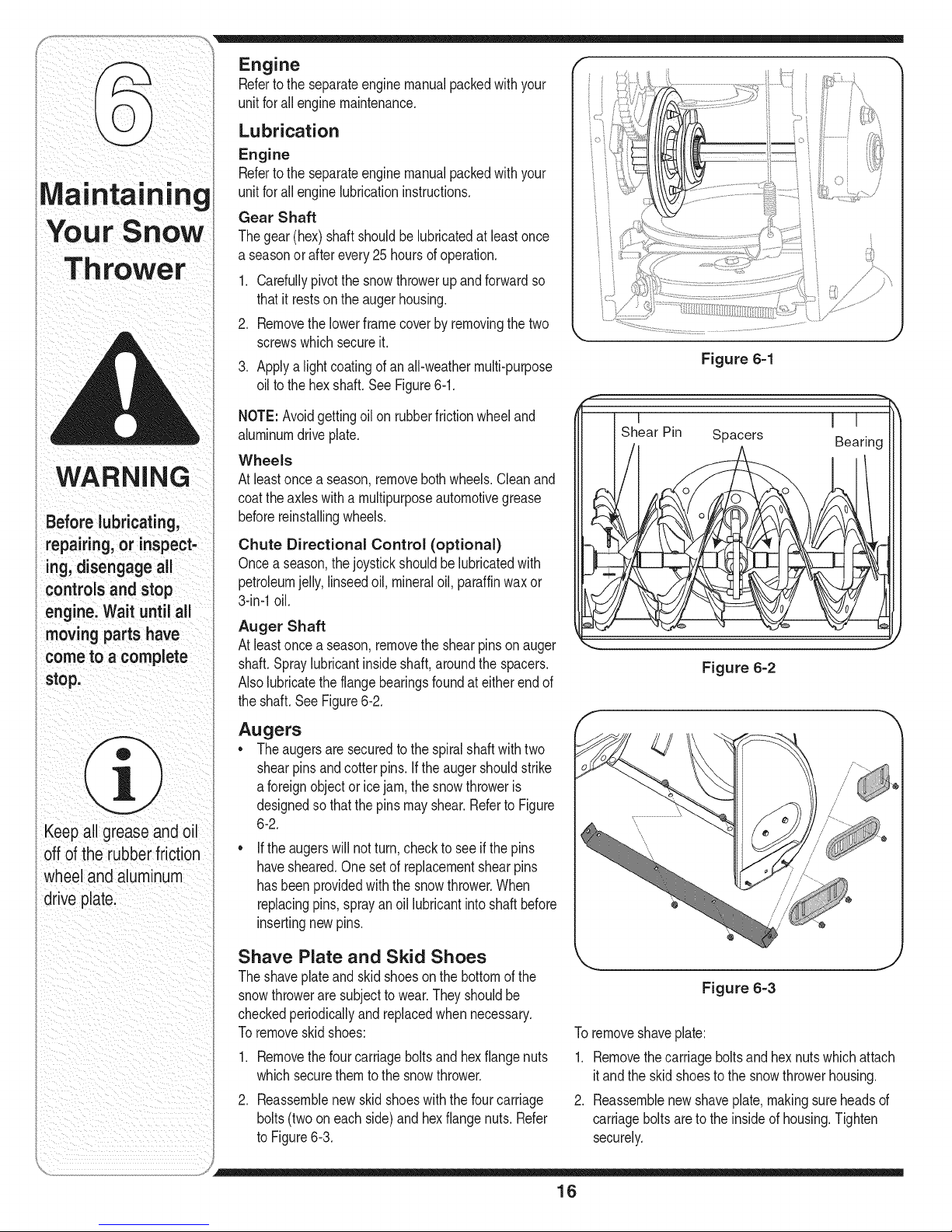

Gear Shaft

Thegear(hex) shaftshouldbelubricatedatleastonce

a seasonor afterevery25 hoursof operation.

1. Carefullypivotthesnowthrowerupand forwardso

thatit restson theaugerhousing.

2. Removethelowerframecoverbyremovingthetwo

screwswhichsecureit.

3.

Applya lightcoatingofan all-weathermulti-purpose

oilto thehexshaft.SeeFigure6-1.

NOTE:Avoidgettingoil on rubberfrictionwheeland

aluminumdriveplate.

Wheels

Atleastonce a season,removeboth wheels.Cleanand

coattheaxleswitha multipurposeautomotivegrease

beforereinstallingwheels.

=,

Figure 6-1

Keepall greaseandoil

Offof therubber friction

wheeland aluminum

drive ,

i

Chute Directional Control (optional)

Oncea season,thejoystickshouldbelubricatedwith

petroleumjelly,linseedoil, mineraloil,paraffinwaxor

3-in-1oil.

Auger Shaft

Atleastonce a season,removethe shearpinson auger

shaft.Spraylubricantinsideshaft,aroundthe spacers.

Alsolubricatethe flangebearingsfoundat eitherendof

theshaft.SeeFigure6-2.

Augers

• Theaugersaresecuredtothespiralshaftwithtwo

shearpinsandcotterpins.If the augershouldstrike

a foreignobjector icejam,thesnowthroweris

designedsothatthepinsmayshear.RefertoFigure

6-2.

If theaugerswillnotturn,checkto seeif thepins

havesheared.Onesetof replacementshearpins

hasbeenprovidedwiththesnowthrower.When

replacingpins,sprayanoil lubricantintoshaftbefore

insertingnewpins.

Shave Plate and Skid Shoes

Theshaveplateand skidshoesonthebottomofthe

snowthroweraresubjectto wear.Theyshouldbe

checkedperiodicallyandreplacedwhennecessary.

Toremoveskidshoes:

.

Removethefourcarriageboltsandhexflangenuts

whichsecurethemtothe snowthrower.

2.

Reassemblenewskidshoeswiththe fourcarriage

bolts(twooneachside)andhexflange nuts.Refer

toFigure6-3.

Figure 6=2

J

Figure 6=3

Toremoveshaveplate:

1. Removethecarriageboltsand hexnutswhichattach

itandthe skidshoesto the snowthrowerhousing.

2. Reassemblenewshaveplate,makingsureheadsof

carriageboltsareto theinsideof housing.Tighten

securely.

16

Page 17

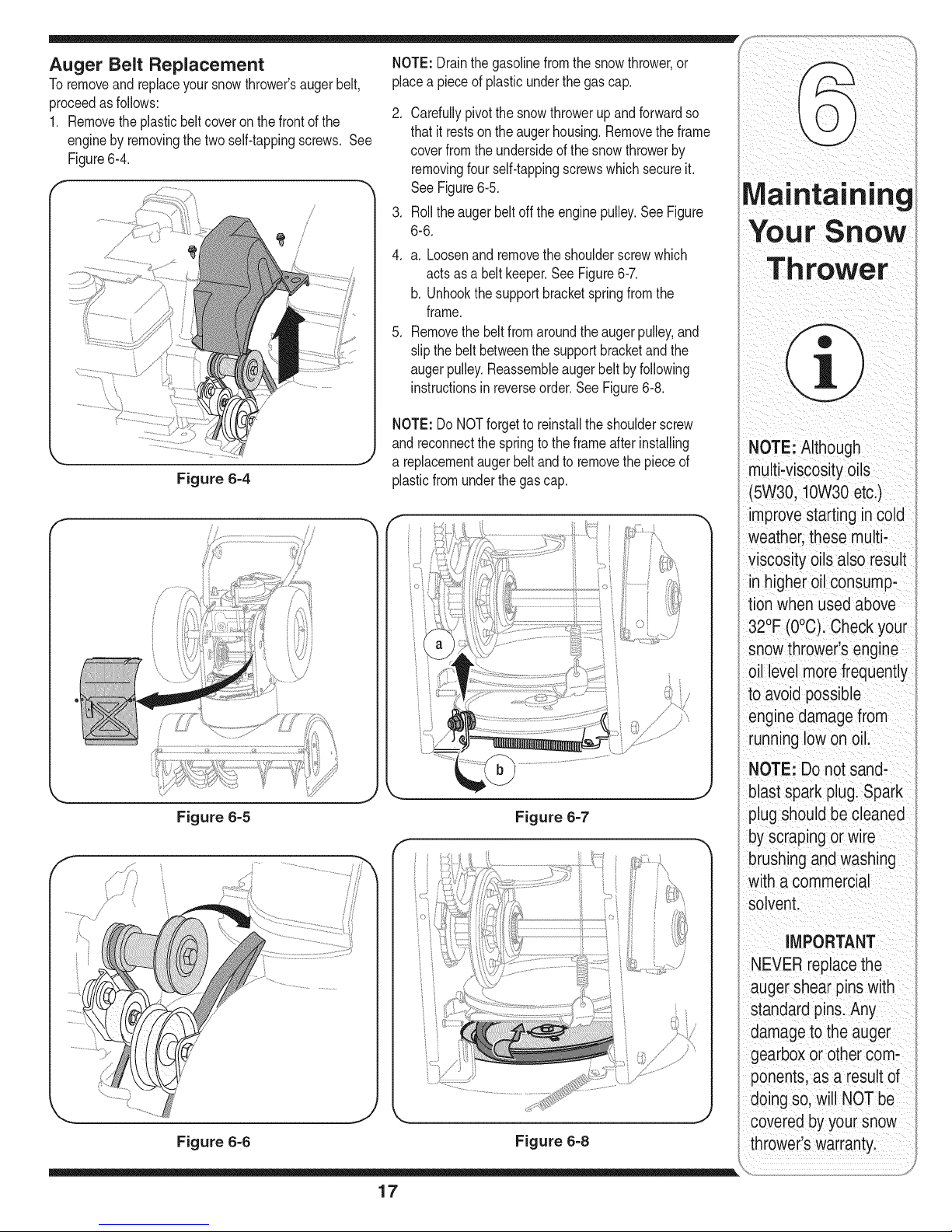

Auger Belt Replacement

Toremoveandreplaceyoursnowthrower'saugerbelt,

proceedasfollows:

1. Removetheplasticbeltcoveronthe frontofthe

enginebyremovingthe two self-tappingscrews. See

Figure6-4.

/

Figure 6-4

i

NOTE:Drainthegasolinefromthesnowthrower,or

placea pieceofplasticunderthegas cap.

.

Carefullypivotthesnowthrowerup andforwardso

thatit restson theaugerhousing.Removetheframe

coverfromtheundersideofthe snowthrowerby

removingfourself-tappingscrewswhichsecureit.

SeeFigure6-5.

.

Rollthe augerbeltoff the enginepulley.SeeFigure

6-6.

4.

a. Loosenand removetheshoulderscrewwhich

actsas a beltkeeper.SeeFigure6-7.

b. Unhookthesupportbracketspringfromthe

frame.

.

Removethe beltfromaroundtheaugerpulley,and

slipthe beltbetweenthe supportbracketandthe

augerpulley.Reassembleaugerbeltby following

instructionsin reverseorder.SeeFigure6-8.

NOTE:Do NOTforgettoreinstallthe shoulderscrew

andreconnectthespringtotheframeafterinstalling

a replacementaugerbeltandto removethepieceof

plasticfromunderthe gascap.

i _ ii i

Maintaining

You rSnow

Th rower

NOTE: Although

multi-viscosityoils

(5W30, 10W30etc.)

improvestarting incold

weather,these multi-

viscosity oils also result

in higher oil consump-

tion when usedabove

32°F (O°C).Check your

snowthrower's engine

oil levelmorefrequently

to avoidpossible

enginedamagefrom

runninglow onoil.

Figure 6-5

\

Figure 6-6

17

Figure 6-7

Figure 6-8

NOTE: Do notsand-

blastspark plug. Spark

plugshould be cleaned

by scraping or wire

brushingand washing

with a commercial

solvent.

IMPORTANT

NEVERreplacethe

auger shear pins with

standardpins.Any

damageto the auger

gearboxor othercom-

ponents as a resultof

(Jongso,wil NOTbe

J

covered byyoursnow

thrower'swarranty.

Page 18

NEVER replacethe

auger shear pinswith

standardhex pins.

Anydamage to the

auger gearboxor

other components

as a resultd failing

to do sowill NOT be

coveredby your snow

thrower'swarranty.

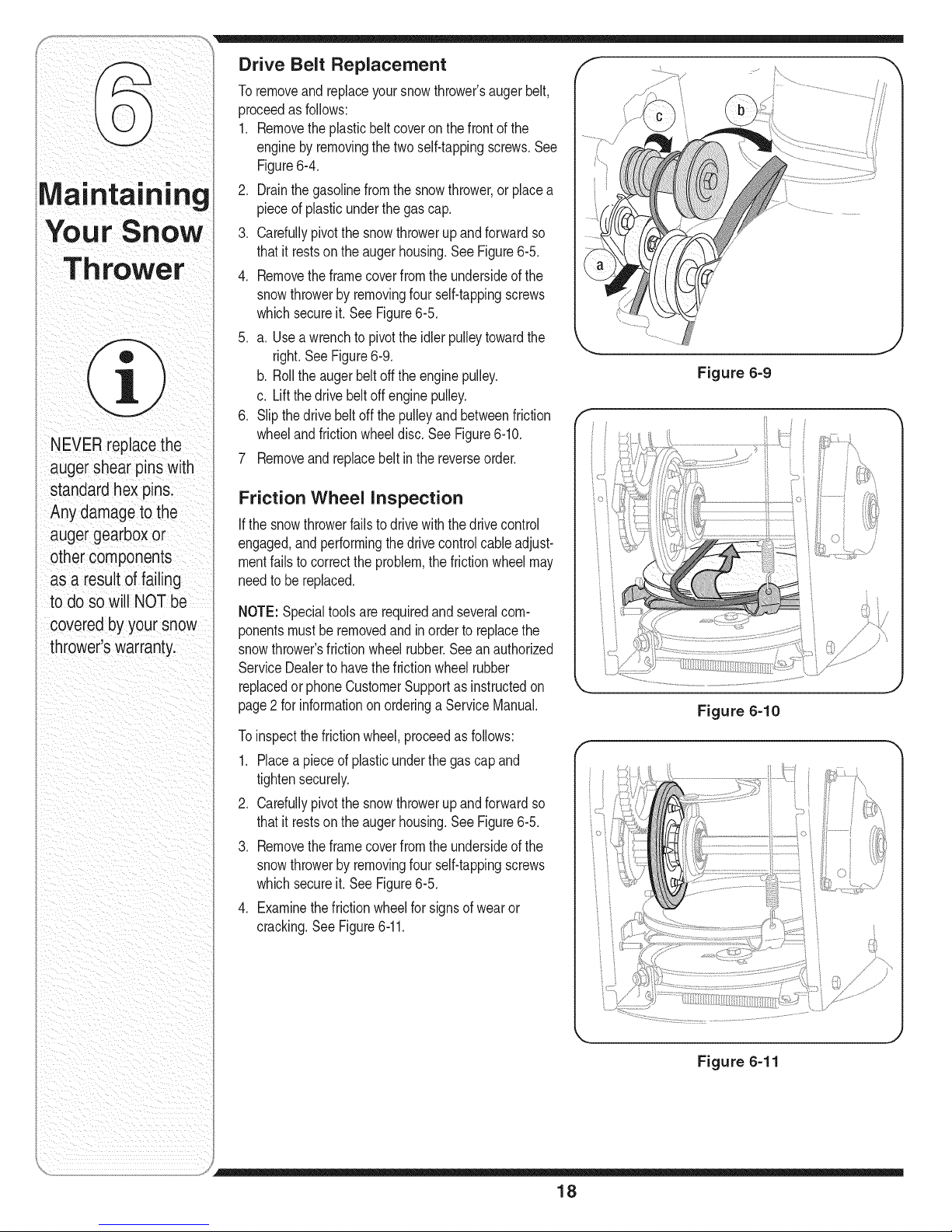

Drive Belt Replacement

Toremoveandreplaceyoursnowthrower'saugerbelt,

proceedasfollows:

1. Removetheplasticbeltcoveron thefrontofthe

enginebyremovingthetwoself-tappingscrews.See

Figure6-4.

2. Drainthegasolinefromthe snowthrower,or placea

pieceof plasticunderthe gascap.

3. Carefullypivotthesnowthrowerupand forwardso

thatit restson theaugerhousing.SeeFigure6-5.

4. Removetheframecoverfromthe undersideofthe

snowthrowerbyremovingfourself-tappingscrews

whichsecureit.See Figure6-5.

5. a. Useawrenchtopivottheidlerpulleytowardthe

right.SeeFigure6-9.

b. Rolltheaugerbeltoff theenginepulley.

c. Liftthedrivebeltoffenginepulley.

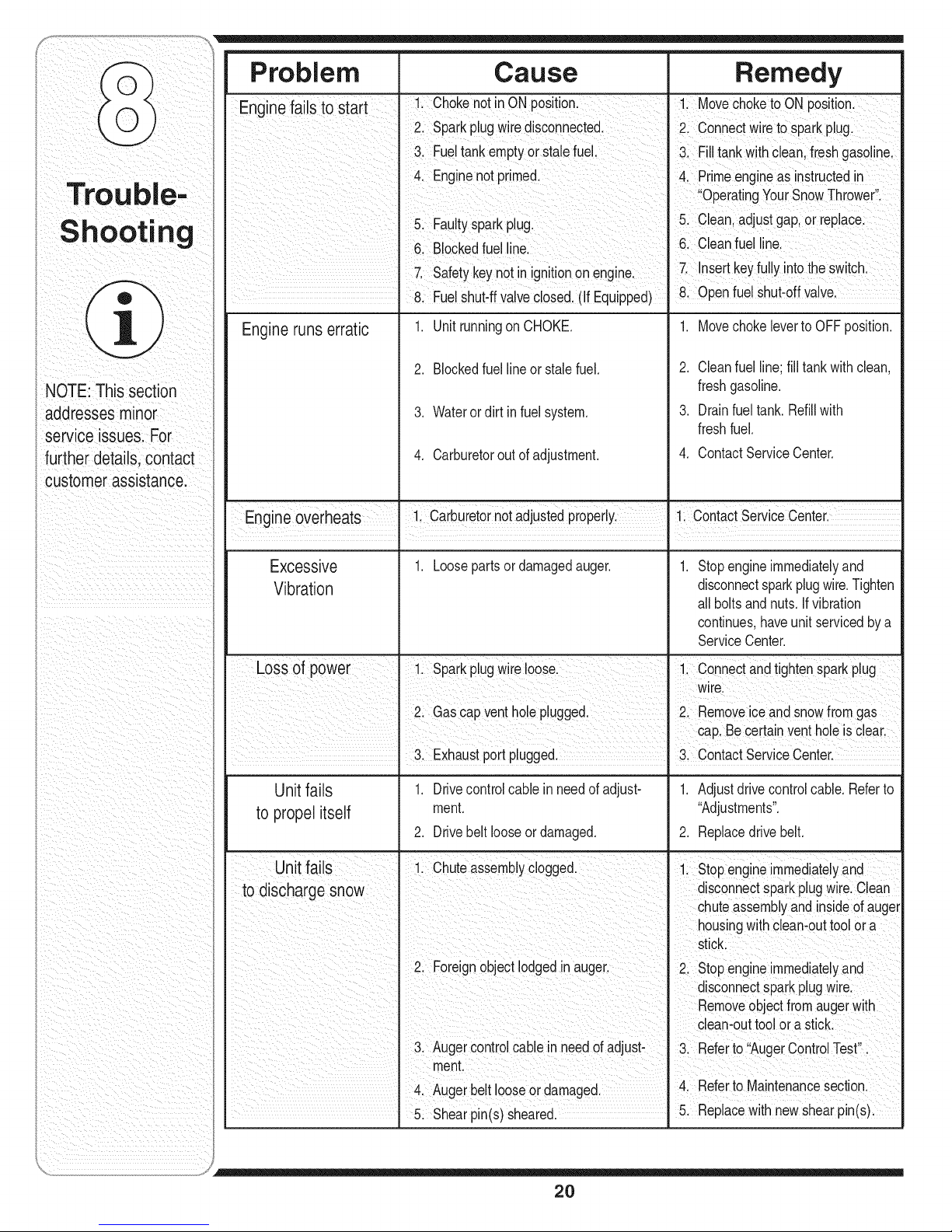

6. Slipthe drivebeltoff thepulleyandbetweenfriction

wheelandfrictionwheeldisc.SeeFigure6-10.

7 Removeandreplacebeltinthe reverseorder.

Friction Wheel Inspection

If thesnowthrowerfailsto drivewiththedrivecontrol

engaged,andperformingthedrivecontrolcableadjust-

mentfailstocorrecttheproblem,thefrictionwheelmay

needtobereplaced.

NOTE:Specialtoolsarerequiredand severalcom-

ponentsmustberemovedandinorderto replacethe

snowthrower'sfrictionwheelrubber.Seeanauthorized

ServiceDealerto havethefrictionwheel rubber

replacedorphoneCustomerSupportasinstructedon

page2 forinformationon orderinga ServiceManual.

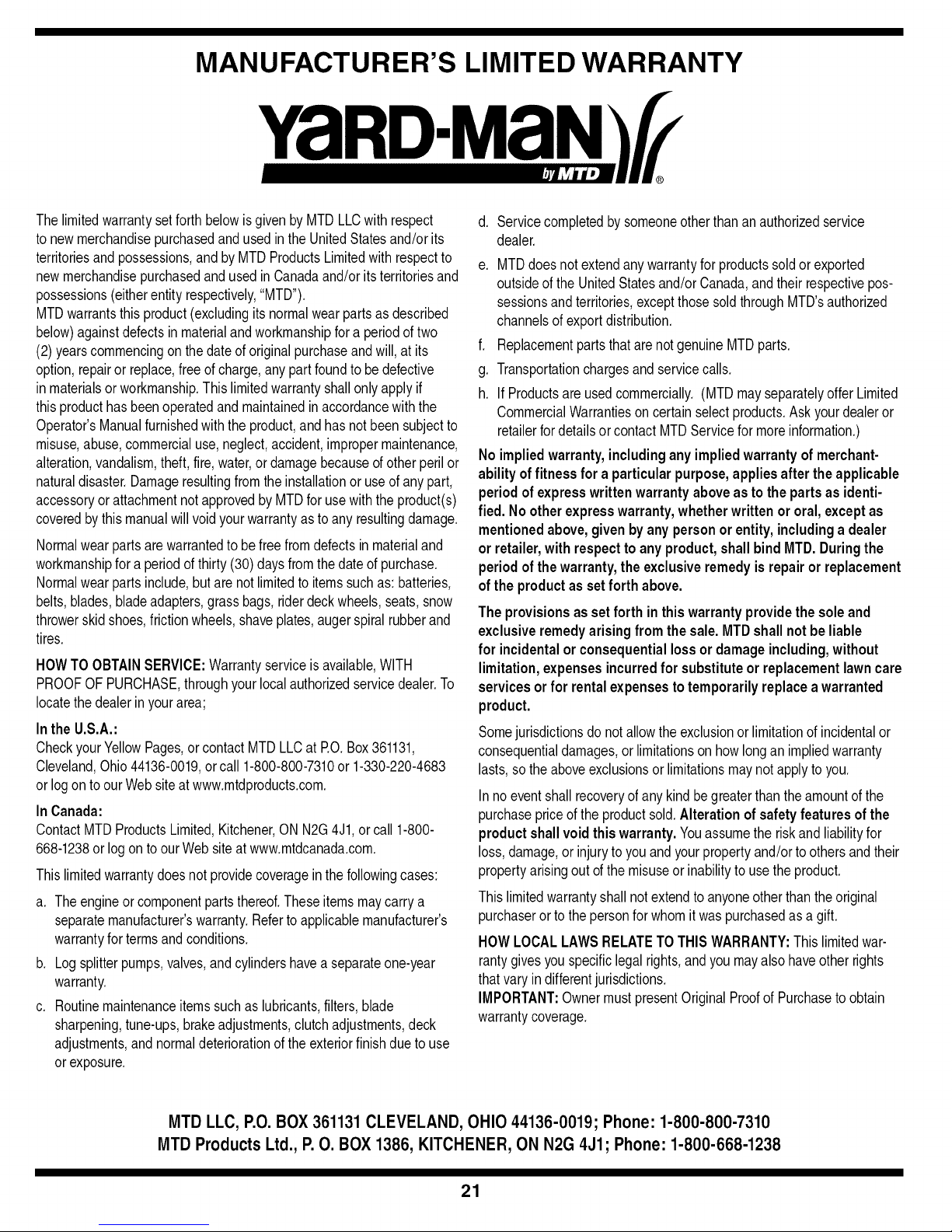

Toinspectthefrictionwheel,proceedasfollows:

1. Placea pieceof plasticunderthe gascapand

tightensecurely.

2. Carefullypivotthesnowthrowerupand forwardso

thatit restson theaugerhousing.SeeFigure6-5.

3. Removetheframecoverfromthe undersideofthe

snowthrowerbyremovingfourself-tappingscrews

whichsecureit.See Figure6-5.

4. Examinethefrictionwheelforsignsof wearor

cracking.See Figure6-11.

Figure 6=9

Figure 6=10

Figure 6=11

18

Page 19

Observethefollowing,whenpreparingyoursnowthrower

foroff-seasonstorage:

* Drainfuelintoanapprovedcontaineroutdoors,away

fromanyopenflame.Allowengineto cool.Extinguish

cigarettes,cigars,pipesandothersourcesofignition

priortodrainingfuel.Fuelleft inengineduringwarm

weatherdeterioratesand willcauseseriousstarting

problems.

* Ifunitistobestoredover30days,prepareforstorage

asinstructedinthe separateenginemanualpacked

withyourunit.

* Runengineuntilfueltankisemptyandenginestops

dueto lackof fuel.

* Removegasolinefromcarburetorandfueltankto

preventgumdepositsfromformingonthesepartsand

causingpossiblemalfunctionofengine.

* Draincarburetorbypressingupwardonbowldrain,

locatedbelowthe carburetorcover.

* Fuelstabilizers,suchas STA-BIL®,are anacceptable

alternativeinminimizingtheformationoffuel gum

depositsduringstorage.Donotdraincarburetorif

usinga fuel stabilizer.

* Wipeequipmentwithan oiledragto preventrust.

* Removesparkplugandpouroneounceofengineoil

throughsparkplugholeintocylinder.Coversparkplug

holewith rag.Crankengineseveraltimestodistribute

oil. Replacesparkplug.

* Followthelubricationrecommendationsfoundinthe

MaintenanceSection.

* Alwaysstorethe snowthrowerin aclean,dryarea.

WARNING

Never store snow

thrower with fuel

in tank indoorsor

in poorly ventilated

areas, where fuel

fumes may reach an

open flame, spark

or pilot light as on a

furnace, water heater,

clothes dryer or gas

appliance.

Drain fuel intoan

approved container

outdoors, away from

any open flame. Be

certain engine is

cool. Donot smoke.

Fuel left in engine

during warm weather

deteriorates and wiii

cause serious

starting problems.

Do not drain

carburetor if

usingfuel stabilizer.

Never use engine or

carburetor cleaning

products in the fuel

tank or permanent

damage mayoccur.

19

Page 20

I

Problem Cause Remedy

Enr,inefails to start - 1. ChokenotinONposition. 1 MovechoketoONpost on

3. Fueltankemptyorstalefuel. 3. Filltankwithclean freshgasoline.

2. Sparkplugwiredisconnected, 2. Connectwireto sparkplug.

4. Enginenot primed. 4. Primeengineasinstructedin

Ible-

_,.w, L,__hOo_lr_n 5 Clean,adjustgap,orreplace

Engineruns erratic 1. UnitrunningonCHOKE. 1. MovechokelevertoOFFposition.

NOTE:This section freshgasoline.

addressesminor 3. Waterordirt infuelsystem. 3. Drainfueltank.Refillwith

service issues. For freshfuel.

further details,contact 4. Carburetoroutofadjustment. 4. ContactServiceCenter.

customerassistance.

5. Fauty sparkpug. • •

6. Blockedfuelline, 6, Cleanfuelline.

7. Safetykeynotin ignitionon engine. 7. Insertkeyfully intotheswitch.

I 8. Fuelshut-ffvalveclosed,(If Equipped) 8. Openfuelshut-offvalve.

2. Blockedfuellineor stalefuel. 2. Cleanfuelline;fill tankwithclean,

OperatingYourSnowThrower.

Engineoverheats 1. Carburetornotadjustedproperly. 1. ContactServtceCenter.

Excessive 1. Loosepartsordamagedauger. 1. Stopengineimmediatelyand

Vibration disconnectsparkplugwire.Tighten

all boltsandnuts.Ifvibration

continues,haveunitservicedbya

ServiceCenter.

Lossof power 1. Sparkplugwireloose. 1. Connectandtightensparkplug

wire.

2. Gascapventholepugged. 2. Removeiceandsnowfromgas

cap.Be certainventholeisclear.

. 3. Exhaustportplugged. 3. ContactServiceCenter.

Unit fails

to propelitself

1. Drivecontrolcable in needofadjust-

ment.

2. Drivebeltlooseor damaged.

1. Adjustdrivecontrolcable.Referto

"Adjustments".

2. Replacedrivebelt.

1. Stopengineimmediatelyand

disconnectsparkplugwire.Clean

chuteassemblyandinsideof auger

housingwith clean-outtoolora

stick.

2. Stopengineimmediatelyand

disconnectsparkplugwire.

Removeobjectfromaugerw th

5. Shearpin(s) sheared.

clean-outtoolora stick,

3. Referto AugerControlTest .

4. Referto Maintenancesection.

5. Replacewith newshearpin(s).

20

Page 21

MANUFACTURER'S LIMITED WARRANTY

Thelimitedwarrantysetforthbelowis givenby MTDLLCwithrespect

tonewmerchandisepurchasedandusedin theUnitedStatesand/orits

territoriesandpossessions,andby MTDProductsLimitedwithrespectto

newmerchandisepurchasedandusedin Canadaand/oritsterritoriesand

possessions(eitherentityrespectively,"MTD").

MTDwarrantsthisproduct(excludingits normalwearpartsasdescribed

below)againstdefectsinmaterialandworkmanshipfor a periodoftwo

(2) yearscommencingon thedate oforiginalpurchaseandwill,at its

option,repairor replace,freeof charge,anypartfoundto be defective

in materialsor workmanship.Thislimitedwarrantyshallonlyapplyif

thisproducthasbeenoperatedand maintainedin accordancewiththe

Operator'sManualfurnishedwiththeproduct,andhasnotbeensubjectto

misuse,abuse,commercialuse,neglect,accident,impropermaintenance,

alteration,vandalism,theft,fire,water,or damagebecauseof otherperilor

naturaldisaster.Damageresultingfromthe installationor use ofanypart,

accessoryorattachmentnotapprovedbyMTDforusewiththeproduct(s)

coveredbythismanualwillvoid yourwarrantyasto anyresultingdamage.

Normalwearpartsarewarrantedto befreefromdefectsinmaterialand

workmanshipfora periodof thirty(30)daysfromthedateof purchase.

Normalwearpartsinclude,butare notlimitedto itemssuchas: batteries,

belts,blades,bladeadapters,grassbags,riderdeckwheels,seats,snow

throwerskidshoes,frictionwheels,shaveplates,augerspiralrubberand

tires.

HOWTOOBTAINSERVICE:Warrantyserviceis available,WITH

PROOFOFPURCHASE,throughyourlocalauthorizedservicedealer.To

locatethedealerin yourarea;

Inthe U.S.A.:

CheckyourYellowPages,or contactMTD LLCat EO.Box361131,

Cleveland,Ohio44136-0019,orcall1-800-800-7310or 1-330-220-4683

or logontoourWeb siteat www.mtdproducts.com.

In Canada:

ContactMTDProductsLimited,Kitchener,ONN2G4J1,or call1-800-

668-1238or logon toourWebsiteatwww.mtdcanada.com.

Thislimitedwarrantydoesnotprovidecoveragein thefollowingcases:

a. Theengineor componentpartsthereof.Theseitemsmaycarrya

separatemanufacturer'swarranty.Refertoapplicablemanufacturer's

warrantyfortermsandconditions.

b. Logsplitterpumps,valves,andcylindershavea separateone-year

warranty.

c. Routinemaintenanceitemssuchaslubricants,filters,blade

sharpening,tune-ups,brakeadjustments,clutchadjustments,deck

adjustments,andnormaldeteriorationof theexteriorfinishdueto use

orexposure.

d. Servicecompletedbysomeoneotherthananauthorizedservice

dealer.

e. MTDdoesnotextendanywarrantyforproductssoldor exported

outsideofthe UnitedStatesand/orCanada,andtheirrespectivepos-

sessionsandterritories,exceptthosesoldthroughMTD'sauthorized

channelsofexportdistribution.

f. Replacementpartsthatarenot genuineMTDparts.

g. Transportationchargesandservicecalls.

h. If Productsare usedcommercially.(MTDmayseparatelyoffer Limited

CommercialWarrantiesoncertainselectproducts.Askyourdealeror

retailerfordetailsorcontactMTDServicefor moreinformation.)

No implied warranty, including anyimplied warranty of merchant-

ability of fitness for a particular purpose, applies after the applicable

period of express written warranty aboveas to the parts as identi-

fied. Noother expresswarranty,whetherwritten or oral, exceptas

mentioned above,given by anyperson or entity, including a dealer

or retailer, with respect to any product, shall bind MTD.Duringthe

period of the warranty, the exclusiveremedyis repair or replacement

of the product as set forth above.

Theprovisionsas setforth in thiswarrantyprovidethe soleand

exclusiveremedyarisingfrom thesale.MTDshallnot be liable

for incidentalorconsequentiallossor damageincluding,without

limitation,expensesincurredfor substituteorreplacementlawncare

servicesor for rentalexpensestotemporarilyreplacea warranted

product.

Somejurisdictionsdonotallowthe exclusionorlimitationof incidentalor

consequentialdamages,or limitationson howlonganimpliedwarranty

lasts,sothe aboveexclusionsor limitationsmaynotapplyto you.

Innoeventshall recoveryof anykind begreaterthantheamountof the

purchasepriceof theproductsold.Alteration of safety features of the

product shallvoid this warranty. Youassumetheriskandliabilityfor

loss,damage,orinjurytoyouandyourpropertyand/ortoothersandtheir

propertyarisingout ofthe misuseorinabilityto usetheproduct.

Thislimitedwarrantyshallnotextendto anyoneotherthanthe original

purchaseror tothe personforwhomitwaspurchasedasa gift.

HOWLOCALLAWSRELATETOTHIS WARRANTY:Thislimitedwar-

rantygivesyouspecificlegalrights,andyoumayalso haveotherrights

thatvary indifferentjurisdictions.

IMPORTANT:OwnermustpresentOriginalProofof Purchasetoobtain

warrantycoverage.

MTD LLC, P.O.BOX 361131CLEVELAND,OHIO 44136-0019; Phone: 1-800-800-7310

MTD Products Ltd., P.O. BOX1386, KITCHENER, ON N2G 4J1; Phone: 1-800-668-1238

21

Page 22

__Tk

/

/

22

Page 23

REF

NO.

N ° DE

REF

18B

42A

42B

42C

42D

42E

42G

42H

43A

43B

18A

42F

PART

NO.

N ° DE

PIECE

1

7t0-t652

2

73t-04792A

73t-05353

3

732-0705

4

71t-t268B

5

746-04229

6

732-04345

7

790-00207A

8

684-04156A

9

750-04474

10

7t4-0t26

11

710-0602

12

7t7-042t0

13

712-04063

14

741-0245

15

790-00206A

16

756-0625

t7

738-0924A

6t8-04288

6t8-04287

19

726-04012

20

750-04477

2t

748-0234

22

732-04311

23

73t-05297

24

7t6-0t04

25

736-0t88

26

736-0626

27

741-04076

28

738-04180

29

73t-04873

30

710-0654A

3t

710-0788

32

790-00185

33

34

736-0242

35

7t0-0627

36

684-04154

37

790-00096

38

748-0t90

39

738-04184A

40

790-00316

41

656-04025A

42

618-04283A

7tt-04416A

618-04284

7t7-t209A

736-0502

736-0336

7t7-t2t0A

6t8-04285

7t6-0t94

43

684-04159

735-04054

790-00174

44

7t6-0t36

45

726-022t

46

790-00t83B

47

756-04109

48

736-0505

49

7t0-t245B

50

736-0tt9

51

790-00230

52

741-09t9

53

750-04571

54

732-04308A

55

7t0-0672

56

756-04252

57

754-0367

58

710-0809

59

790-00208A

60

748-041t2A

6t

732-0264

62

7t2-0413

63

750-04303

64

756-04113

65

736-0247

66

7t0-0t9t

67

748-04053A

68

746-0956A

69

790-00186

70

750-0767

7t

712-04065

72

754-04050

73

710-075t

74

790-002t7A

75

790-002t8A

76

712-04064

77

7t0-0896

78

736-0t73

79

736-0320

80

735-04100

81

735-04099

82

736-30t5

83

790-00289A

84

746-04230

Hex Wash Hd TT Scr. 1/4-20 x .625

Belt Cover (w/4 Way Chute Control)

Belt Cover (Std.)

Cable Control Wire

Drive Shaft Actuator

Drive Clutch Cable 44.83" Lg.

Extension Spring .50D x t.71 Lg.

Guide Bracket - Drive Cable

Shift Rod Ass'y

Axle Support Tube

#9 HI-Pro Key 3/t6x 3/4 Dia HT

Hex Wash Hd Tapp Scr 5/16-18 x 1.00

Gear, 56T

Flange Lock-Nut 5/t6-18 Gr. F Nylon

Hex. Flange Bearing.751" ID

Guide Bracket - Auger Cable

Cable Guide Roller

Hex Shld.Scr.t/4-28 x .375

Dogg Assembly - LH

Dogg Assembly - RH

Push Nut

Spacer .340 x .750 x .360" Lg.

Shoulder Spacer

Torsion Spring .750 ID x .968" Lg.

Spacer

Retaining Ring

Flat Washer .760 ID x 1.49 OD

Flat Washer .580 x 1.125 x .080

Ball Bearing

Axle

Spacer

Hex Wash HD Tap Scr 3/8-16 x .88

Hex Bolt t/4-20 x t.00

Shaft Retainer - LH

See chart on page 30.

Cupped Washer .345 ID x .88 OD x .060

Hex L-Bolt 5/t6-24 x .75 Gr. 5

Friction Wheel Support Brkt Ass'y

Auger Cable Guide Bracket

Spacer .513 ID x 1.0

Shoulder Screw .373 x. 105:TT 1/4-20

Frame Cover

Friction Wheel Disc Assembly

Drive Shaft Assembly (w/o Friction Wheel Ass'y)

Hex Drive Shaft (500)

Planetary Carrier Ass'y

Gear t 2T

Fiat Washer .58 x t .t 2 x .02

Flat Washer 5/8 ID x 1.00D

Gear 18T

Ring Planetary Gear Ass'y (500)

Retaining Ring 1.56 diam.

Friction Wheel Assembly

Friction Wheel Rubber

Friction Plate

Retainer Ring

Cap Speed Nut 1/4 Rod

Wheel Drive Frame

Auger Pulley

Fiat Washer .34 x t .50 x .150

Hex Bolt 6/16-24 x 0.875

L-Wash 5/161D

Bearing Sleeve

Ball Bearing 20 x 47 x 14:6204:DS

Spacer

Torsion Spring .850 ID x .354" Lg.

Hex HD. Cap Scr. 5/16-24 x 1.25 Lg.

Pulley Half

Belt 3/8 X 34.4" Lg.

Hex Bolt 1/4-20 x 1.25

Wheel Drive Idler Bracket

Shoulder Spacer

Extension Spring 3/80D x 2.50

Jam L-Nut 5/8-18 Gr. 5 Nylon

Spacer .875 ID x 1.185 OD

Pulley Half

Fiat Washer .40 ID x 1.25 OD x .160

Hex Screw 3/8-24 x 1.25

Pulley Adapter

Steering Cable

Shaft Retainer - RH

Axle Spacer

Flange Lock-Nut 3/8-16 Gr. F Nylon

Belt .5 x 35.0" Lg.

Hex Bolt t/4-20 x .62 Gr. 5

Pivot Bracket

Shift Bracket

Flange Lock-Nut 1/4-20 Gr. F Nylon

Hex Wash. Hd. TT Scr. t/4-t4 x .625

Flat Washer .28 ID x .74 DE x .063

Flat Washer .38 x 1.38 x .t 25

(Rear left hole)(w/Tec. 318-358 cc engine)

Plug 1/2"

Plug 3/8"

Flat Washer .469 x .875 x .t05

Cover Plate (optional)

Auger Clutch Cable 47.23" Lg.

DESCRiPTiON

DESCRiPTiON

Vis taraudee 1/4_20 x 0,625

Couvre-courroie(avec comm. de la goulotte _ 4 fonctions)

Couvre-courroie (Std.)

Fil de commande de lac&ble

Regulateur

C&ble de t'entrainement 44,83 pc de Ig.

Ressort d'extension 0,5 DE x t,71 pc de Ig.

Support - cgible de I'entrainement

Tige de changement de la vitesses

Tuyau de support de I'essieu

Clavette HI-Pro no. 9 - 3/t6 x 3/4 dia.

Vis autofileteuse & t@e hex et rondelle 5/16-18

Engrenage 56 dents

Contre-ecrou _ embase 5/16-18Qual. F nylon

Roulement & bride & six pans 0,751 DI

Support - C&ble de tari@e

Guide du c&ble

Vis & epaulement t/4-28 x 0,375

CG - cliquet

CD - ctiquet

Ecrou & enfoncer

Entretoise 0,340 x 0,750 x 0,360 pc de Ig.

Entretoise & epaulement

Ressort de torsion 0,750 DI x 0,968 pc de Ig.

Entretoise

Anneau de retenue

Rondelte plate 0,760 DI x 1,49 DE

Rondelle plate 0,580 x 1,125 x 0,080

Roulement & billes

Essieu

Entretoise

Vis autotaraudee 3/8-t6 x 0,88

Vis & t@e hex. t/4-20 x 1,00

Retenue d'arbre CG

Voir tableau de ta page 30.

Rondelle creuse 0,345 DI x 0,88 DE x 0,060

Boulon hex. 5/t6-24 x 0,75 Qual. 5

Support de la roue du friction

Support, guide de la c&ble de latari@e

Entretoise 0,513 DI x 1,0

Vis & epaulement 0,373 x 0,105:1/4-20

Couvercle

Disque de roue du friction

Arbre d'entrainement (sans ensemble de la roue frottement)

Arbre d'entrainement (500)

Porte-roue

Engrenage t2 dents

Rondelle plate 0,58 x t ,12 x 0,02

Rondelle plate 5/8 DIx 1,0 DE

Engrenage 18 dents

Ensemble de I'engrenage (500)

Bague de retenue 1,56 diam.

Ensemble de la roue de frottement

Roue du friction en caoutchouc

Plaque du friction

Bague de retenue

Chapeau & enfoncer

Ch&ssis de I'entratnement de roue

Poulie de la tari@e

Rondelle plate 0,34 x 1,50 x 0,150

Bouton hex. 5/t6-24 x 0,875

Rondelle frein 5/t6 DI

Routement

Roulement & billes 20 x 47 x 14:6204:DS

Entretoise

Ressort de torsion 0,850 DI x 0,354 pc de Ig.

Vis & t_te hexagonal 5/16-24 x 1,25 pc de Ig

Poulie, demi

Courroie trapezoi'dale 3/8 X 34,4 pc de Ig.

Boulon hex. 1/4-20 x 1,25

Support

Entretoise epaul6e

Ressort d'extension 3/8 DE x 2,50

Ecrou de blocage 5/8-t8 Qual. 5 Nylon

Entretoise 0,875 DI x t,185 DE

Moitie poulie

Rondelle plate 0,40 DI x t,25 DE x 0,160

Vis _ t_te hexagonale 3/6-24 x 1,25

Adaptateur de la poulie

C_ble

Retenue d'arbre CD

Entretoise - essieu

Contre-ecrou & embase 3/8-16 Qual. F nylon

Courroie 0,5 x 35,0 pc de Ig.

Boulon hexagonale 1/4-20 x 0,62 Qual. 5

Support de pivot

Support de changement de la vitesses

Contre-ecrou & embase t/4-20 Qual. F nylon

Vis taraudee t/4-14 x 0,625

Rondelle frein 0,28 DI x 0,74 DE x 0,063

Rondelle plate 0,38 x 1,28 x 0,125 (arriere gauche trou)

(avec Tec. 3t8-358 cc moteur)

Bouchon t/2 pc

Bouchon 3/8 pc

Rondelle plate 0,469 x 0,875 x 0,105

Plaque (en option)

C&ble de la tari@e 47,23 pc de Ig.

31A-5003

09.27.07

23

Page 24

9\

22

4

14

9

17

35

53

33 46

11 51

50

41 11 30

/ _32

NOTE:Housing maynot be exactlyas shown.

REMARQUE' L'habitaclepeut_tre legerement

different.

"®_"7

24

Page 25

REF

NO.

N° DE

REF

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

38

39

40

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

1

2

3

4

5

7

8

9

PART

NO.

N° DE

PII_CE

731-2643

684-04057A

710-0347

710-0451

710-0703

712-04063

712-04064

712-04065

725-0157

731-04871

726-04012

731-04705

732-04460

736-0174

731-2635

738-0143

738-0281

720-0284

741-0245

741-0309

756-0981B

790-00075

790-00080A

710-04484

684-04107

684-04108

714-04040

736-0188

738-04124A

741-0493A

790-00087A

790-00138A

790-00181

790-00091

737-3000

731-04870

741-0661A

746-04230

784-5580

719-04291

719-04292

721-0338

741-0662

710-0642

714-0161

715-04021

717-04126

718-04071

721-0325

721-0327

736-0351

736-3084

741-0663

736-0242

721-0328

737-0168

731-05984

710-0451

710-0276

DESCRIPTION

Clean-Out Tool

Impeller Ass'y 12 po

Hex Screw 3/8-16 x 1.75

Carriage Bolt 5/16-18 x .75

Carriage Screw 1/4-20 x .75 Gr. 5

Flange Locknut 5/16-18 Gr. F Nylon

Hex L-Flanged Nut 1/4-20 Gr. F Nylon

Hex L-Flanged Nut 3/8-16 Gr. F Nylon

Cable Tie

Spacer 1.25 x .75 x 3/16" Lg.

Push-on Nut .25 dia.

Chute Adapter

Extension Spring .38 OD x 4.59" Lg.

Wave Washer .660 ID x .88 OD x .010

Cleanout Tool Mount

Shld. Scr..500 Dia. x .335" Lg.

Shoulder Scr .625 Dia x .170

Hand Knob

Hex. Flange Brg..751" I.D.

Self-aligning bearing

Flat Idler Pulley 2.75" OD

Bearing Housing 1.85 ID

Auger Idler Brake Bracket

Hex TT Screw 3/8-16 x .75

See chart on page 30.

Spiral Ass'y LH

Spiral Ass'y RH

Bow Tie Cotter Pin

See chart on page 30.

Flat Washer .760 ID x 1.49 OD

Shear Pin .25 x 1.5 Gr. 2

Flange Bushing

Bushing Housing

Bushing Housing (w/grease fitting hole)

See chart on page 30.

Drift Cutter - Optional

Reversible Slide Shoe (steel)

Grease Fitting (optional)

Spacer 1.25 x .75 x 1.00

Flange Bearing.75 ID x 1.00D x .975

Auger Clutch Cable

Slide Shoe

RH Reduced Auger Housing

LH Reduced Auger Housing

Oil Seal .75 x 1.0 x .125

Flange Bearing .75 ID x 1.00 OD x .50

Thd Forming Scr. 1/4-20 x .75

See chart on page 30.

Hi Pro Key 3/16 x 5/8

Dowel Pin .25 OD x 1.2

Worm Shaft .75 OD

See chart on page 30.

Thrust Collar

Plug, 1/4 x .437

Oil Seal .75x 1 x .131

Flat Washer .76 ID x 1.50D x .03

FI. Washer .510 x 1.120 x .060

Flange Bearing .75 ID x 1.00D x .925

Cupped Washer .345 ID x .88 OD x .060

Loctite Sealant 5699

Grease - AIvania EP Lead Free

Reversible Slide Shoe (plastic)

Carriage Bolt 5/16-18 x .75 (w/steel

slide shoes)

Carriage Bolt 5/16-18 x 1.0 (w/plastic

slide shoes)

DESCRIPTION

Outil de d6gagement de la goulotte

Ventilateur

Visa t_te hex 3/8-16 x 1,75

Boulon ordinaire 5/16-18 x 0,75

Boulon ordinaire 1/4-20 x 0,75 Qual. 5

Contre-6crou a embase 5/16-18 Qual. Fnylon

Contre-6crou a embase 1/4-20 Qual. F nylon

Contre-ecrou a embase 3/8-16 Qual. F nylon

Attache c_ble

Entretoise 1,25 x 0,75 x 3/16 po de Ig.

Ecrou pousser 0,25 diam.

Adaptateur de goulotte d'6jection

Ressort d'extension 0,38 DE x 4,59 po de Ig.

Rondelle ondul6e 0,660 DI x 0,88 DE x 0,010

Montage de la outil de d6gagement de lagoulotte

Visa 6paulement dia. 0,500 pox 0,335 po de Ig.

Vis a epaulement dia 0,625 x 0,170 po

Bouton

Roulement 0,75 DI

Roulement auto-aligneur

Poulie tendeur 2,75 DE

Carter de la roulement 1,85 DI

Support

Vis taraud6e 3/8-16 x 0,75

Voir tableau de la page 30.

Tari@e CG

Tari@e CD

Goupille fendue

Voir tableau de la page 30.

Rondelle plate 0,760 DI x 1,49 DE

Goupille de cisaillement 0,25 x 1,5 po de Ig

Collet a bride

Carter de la collet

Carter de la collet (avec trou pour raccord de graissage)

Voir tableau de la page 30.

Virole de reglage - en option

Patin reversible (acier)

Raccord de graissage (en option)

Entretoise 1,25 x 0,75 x 1,00 po de Ig.

Roulement 0,75 DI x 1,0 DE x 0,975

C_ble de tari@e

Sabot coulissant

Carter de I'engrenage CD

Carter de I'engrenage CG

Joint d'etanch6it6 d'huile 0,75 x 1,0 x 0,125

Roulement 0,75 DI x 1,00 DE x 0,50

Vis taraud6e 1/4-20 x 0,75

Voir tableau de la page 30.

CI6 3/16 x 5/8

Goupille 0,25 x 1,2

Arbre 0,75 DE

Voir tableau de la page 30.

Collet

Bouchon 1/4 x 0,437

Joint d'huile 0,75 DI x 1 x 0,131

Rondelle plate 0,76 DI x 1,5 DE x 0,03

Rondelle frein 0,510 x 1,120 x 0,060

Roulement 0,75 DI x 1,0 DE x 0,925

Rondelle creuse 0,345 DI x 0,88 DE x 0,060

Loctite

Graisseur

Patin reversible (plastique)

Boulon ordinaire 5/16-18 x 0,75 (avec sabot

coulissant acier)

Boulon ordinaire 5/16-18 x 1,0 (avec sabot

coulissant acier)

31A-6002

6.21.07

25

Page 26

StylesH,K,L,P & Q

* With heated grips only/Avec poign6es chauff_es seuJement.

5

15

52

12

43

27

40

_ 24

_11

41

34

Model Number/

Numero de modele

31AE6GKF500

t

Style

18

60

25 *

8

35

18

35

44

26

Page 27

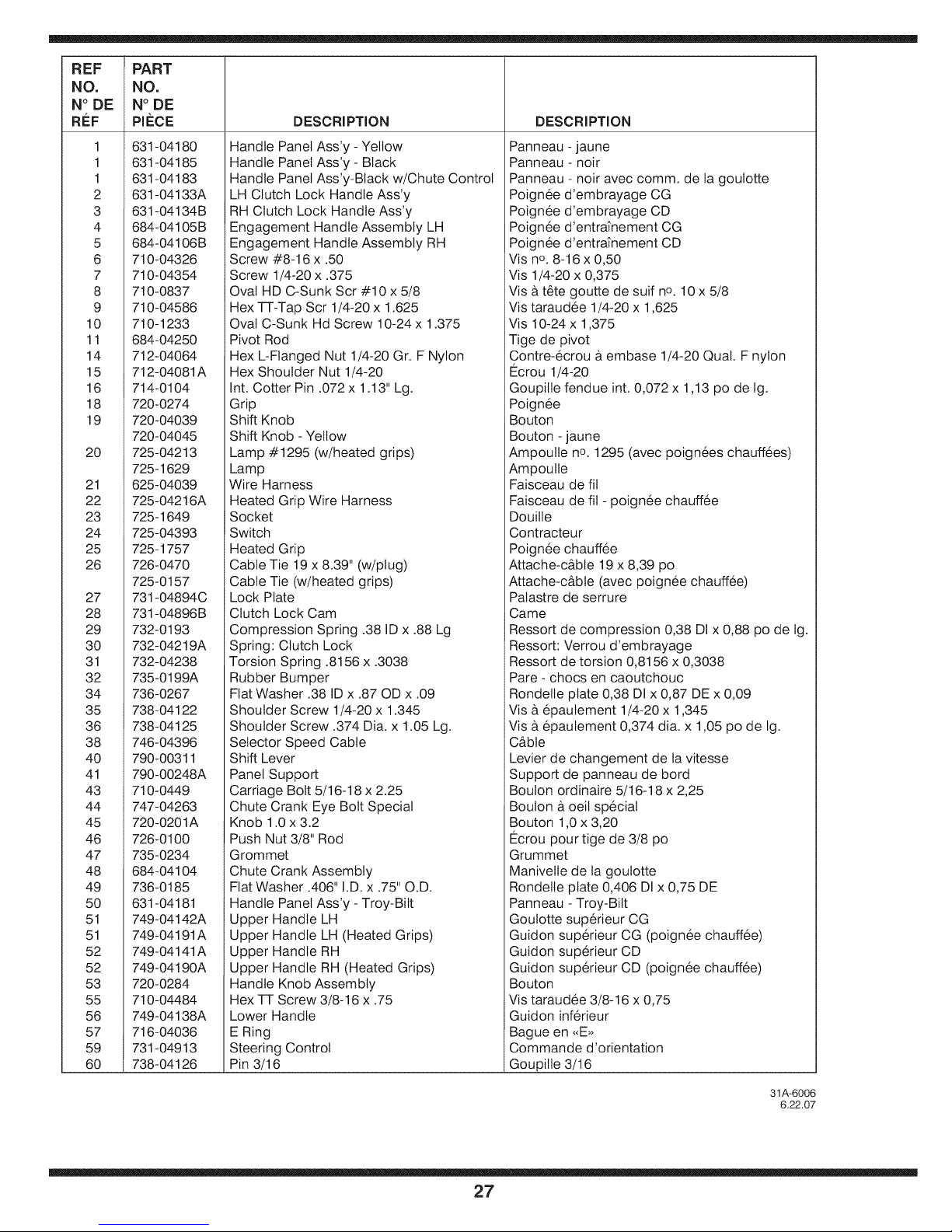

REF PART

NO. NO.

N° DE N° DE

RI_F PII_CE DESCRiPTiON DESCRiPTiON

1 631-04180

1 631-04185

1 631-04183

2 631-04133A

3 631-04134B

4 684-04105B

5 684-04106B

6 710-04326

7 710-04354

8 710-0837

9 710-04586

10 710-1233

11 684-04250

14 712-04064

15 712-04081A

16 714-0104

18 720-0274

19 720-04039

720-04045

20 725-04213

725-1629

21 625-04039

22 725-04216A

23 725-1649

24 725-04393

25 725-1757

26 726-0470

725-0157

27 731-04894C

28 731-04896B

29 732-0193

30 732-04219A

31 732-04238

32 735-0199A

34 736-0267

35 738-04122

36 738-04125

38 746-04396

40 790-00311

41 790-00248A

43 710-0449

44 747-04263

45 720-0201A

46 726-0100

47 735-0234

48 684-04104

49 736-0185

50 631-04181

51 749-04142A

51 749-04191A

52 749-04141A

52 749-04190A

53 720-0284

55 710-04484

56 749-04138A

57 716-04036

59 731-04913

60 738-04126

Handle Panel Ass'y - Yellow

Handle Panel Ass'y - Black

Handle Panel Ass'y-Black w/Chute Control

LH Clutch Lock Handle Ass'y

RH Clutch Lock Handle Ass'y

Engagement Handle Assembly LH

Engagement Handle Assembly RH

Screw #8-16 x .50

Screw 1/4-20 x .375

Oval HD C-Sunk Scr #10 x 5/8

Hex -l-T-Tap Scr 1/4-20 x 1.625

Oval C-Sunk Hd Screw 10-24 x 1.375

Pivot Rod

Hex L-Flanged Nut 1/4-20 Gr. F Nylon

Hex Shoulder Nut 1/4-20

int. Cotter Pin .072 x 1.13" Lg.

Grip

Shift Knob

Shift Knob - Yellow

Lamp #1295 (w/heated grips)

Lamp

Wire Harness

Heated Grip Wire Harness

Socket

Switch

Heated Grip

Cable Tie 19 x 8.39" (w/plug)

Cable Tie (w/heated grips)

Lock Plate

Clutch Lock Cam

Compression Spring .38 iD x .88 Lg

Spring: Clutch Lock

Torsion Spring .8156 x .3038

Rubber Bumper

Flat Washer .38 ID x .87 OD x .09

Shoulder Screw 1/4-20 x 1.345

Shoulder Screw .374 Dia. x 1.05 Lg.

Selector Speed Cable

Shift Lever

Panel Support

Carriage Bolt 5/16-18 x 2.25

Chute Crank Eye Bolt Special

Knob 1.0 x 3.2

Push Nut 3/8" Rod

Grommet

Chute Crank Assembly

Flat Washer .406" i.D. x .75" O.D.

Handle Panel Ass'y - Troy-Bilt

Upper Handle LH

Upper Handle LH (Heated Grips)

Upper Handle RH

Upper Handle RH (Heated Grips)

Handle Knob Assembly

Hex TT Screw 3/8-16 x .75

Lower Handle

E Ring

Steering Control

Pin 3/16

Panneau - jaune

Panneau - noir

Panneau - noir avec comm. de la goulotte

Poignee d'embrayage CG

Poignee d'embrayage CD

Poignee d'entraTnement CG

Poignee d'entraTnement CD

Vis no 8-16 x 0,50

Vis 1/4-20 x 0,375

Vis & t@e goutte de suif no. 10 x 5/8

Vis taraudee 1/4-20 x 1,625

Vis 10-24 x 1,375

Tige de pivot

Contre-ecrou a embase 1/4-20 Qual. F nylon

I_crou 1/4-20

Goupitle fendue int. 0,072 x 1,13 pc de Ig.

Poignee

Bouton

Bouton - jaune

Ampoulte no 1295 (avec poignees chauffees)