Page 1

Operator’s Manual

Garden Shredder Mulcher

Model

English

MTD1400K

IMPORTANT: READ SAFETY RULES

AND INSTRUCTIONS CAREFULLY

P/N 6096-200123 © 2006

PRINTED IN CHINA

Page 2

TABLE OF CONTENTS

Warranty Statement Page 1

Rules for Safe Operation Pages 2- 7

Assembly Instructions Page 8

Operating Instructions Page 8- 10

Maintenance Instructions Page 10 - 11

Specifications Page 11

Parts List Page 12

Notes Page 13

Manufacturer’s Limited Warranty Page 14

WARRANTY STATEMENT

TWO YEAR LIMITED WARRANTY ON YARD MACHINES SHREDDER

For two years from the date of purchase, when this Shredder is used and maintained according to the

operator’s manual, Yard Machines will repair any defect in material for workmanship free of charge.

If this Shredder is used for commercial or rental purposes, this warranty applies for only 90 days from

the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS SHREDDER TO THE NEAREST MTD

REPAIR DEALER.

This warraanty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Page 3

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your atten

tion to possible dangers. The safety symbols, and their

explanations, deserve your careful attention and understanding. The safety warnings do not by themselves

eliminate any danger

give are not substitutes for proper accident prevention

measures.

SYMBOL MEANING

SAFETY ALERT:

caution. Attention is required in order to

avoid serious personal injury. May be used

in conjunction with other symbols or pictographs.

NOTE: Advises you of information or instructions vital to

the operation or maintenance of the equipment.

Read the Operator’s Manual(s) and follow all warnings

and safety instructions.

Failure to do so can result in serious injury to the

operator and/or bystanders.

. The instructions or warnings they

Indicates

danger,

warning or

-

FOR QUESTIONS, CALL 1-800-668-1238

SYMBOL MEANING

DANGER:

result in serious injury to yourself or to others. Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

WARNING:

result in injury to yourself and others.

Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

CAUTION:

result in property damage or personal injury

to yourself or to others. Always follow the

safety precautions to reduce the risk of fire,

electric shock and personal injury.

Failure to obey a

safety warning will

Failure to obey a

safety warning can

Failure to obey a

safety war

ning may

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

When using the

WARNING:

Please r

ating the unit in or

of the operator and any bystanders. Please

keep these instr

• Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Children must not operate the unit. Teens must be

accompanied and guided by an adult.

All guar

•

properly before operating the unit.

Inspect the unit befor

•

Make sur

Replace par

any way

aged par

ds and safety attachments must be installed

e all fasteners ar

. Do not operate the unit with loose or dam-

ts.

ead these instr

ts that ar

uctions for later use.

e use. Replace damaged parts.

e in place and secur

e cracked, chipped or damaged in

unit, safety rules.

uctions befor

der to ensur

e oper

e the safety

e.

• Carefully inspect the area before starting the unit.

Remove all debris and hard or sharp objects such as

glass, wire, etc.

• Clear the area of children, bystanders, and pets. At a

minimum, keep all children, bystanders, and pets outside a 50 feet (15m.) radius; there still may be a risk to

bystanders from thrown objects. Bystanders should be

-

encouraged to wear eye protection. If you are

approached, stop the unit immediately.

21

Page 4

RULES FOR SAFE OPERATION RULES FOR SAFE OPERATION

PLEASE READ - SAVE THESE

INSTRUCTIONS

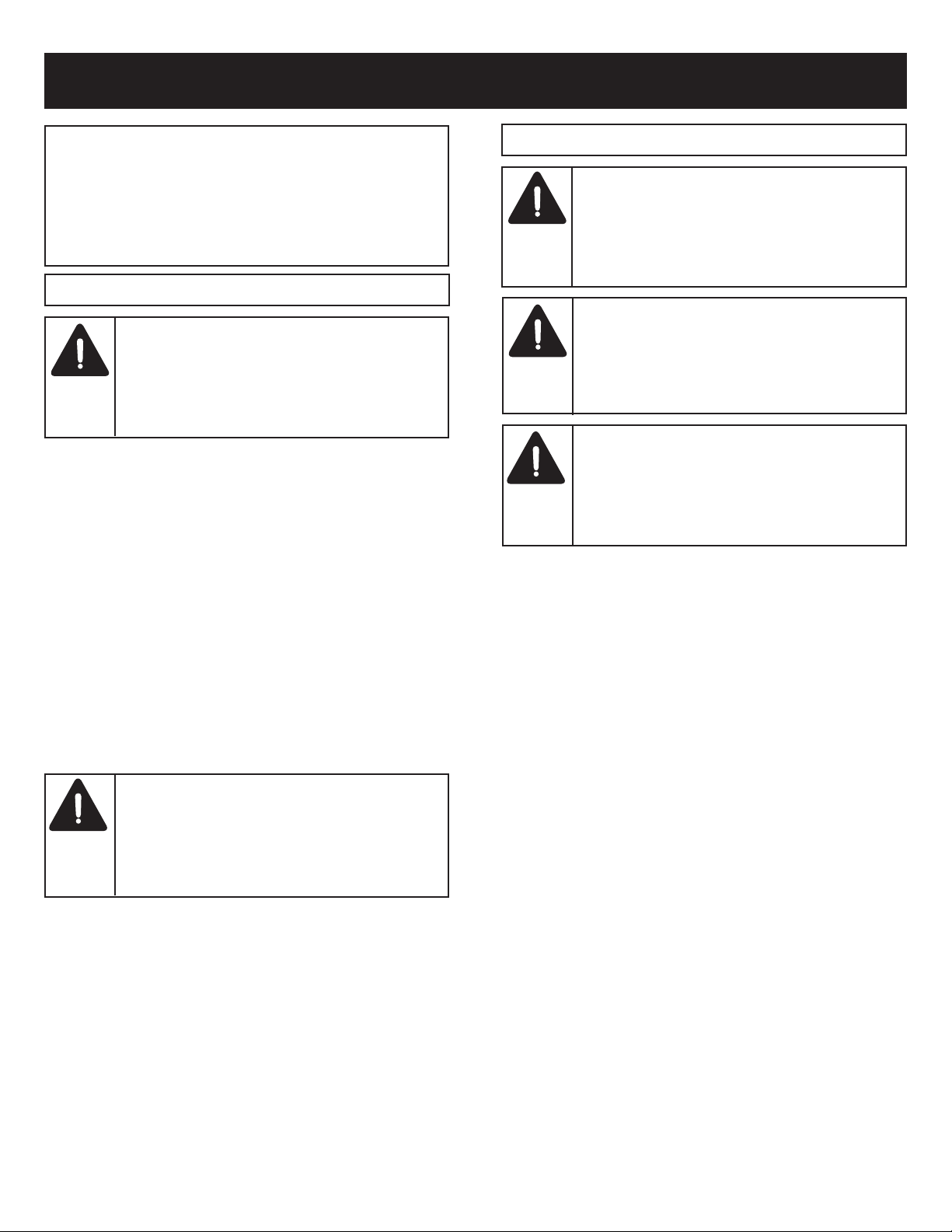

When using an electrical

cautions should always be followed to reduce the risk of

fire, electric shock, and personal injury, including the following.

gardening tools, basic safety pre-

WARNING

TO REDUCE THE RISK OF ELECTRIC

SHOCK, BURNS, FIRE OR PERSONAL

INJURY:

1. FOLLOW ALL SAFETY INSTRUCTIONS listed in

this manual before/during operation of this shredder.

2. GROUNDING INSTRUCTIONS this tool should be

grounded while in use to reduce the risk of electric

shock to the operator. The tool is equipped with a 3conductor cord and 3-prong grounding plug to fit the

proper grounding receptacle. The green or green and

yellow wire to live terminal. If your unit is for use on

less than 150 volts, it has a plug as illustrated in

sketch A in Figure 1 on page 2. If it is for use on 150

to 250 volts, it has a plug as illustrated in sketch D,

Fig.1, Page 2.

An adapter, sketches B and C, is available for

connecting plugs as illustrated in sketch A to 2-prong

receptacles. The green-colored rigid ear, lug, or the

like, must be connected to permanent ground, such

as a properly grounded outlet box. No adapter is

available for the plug illustrated in sketch D.

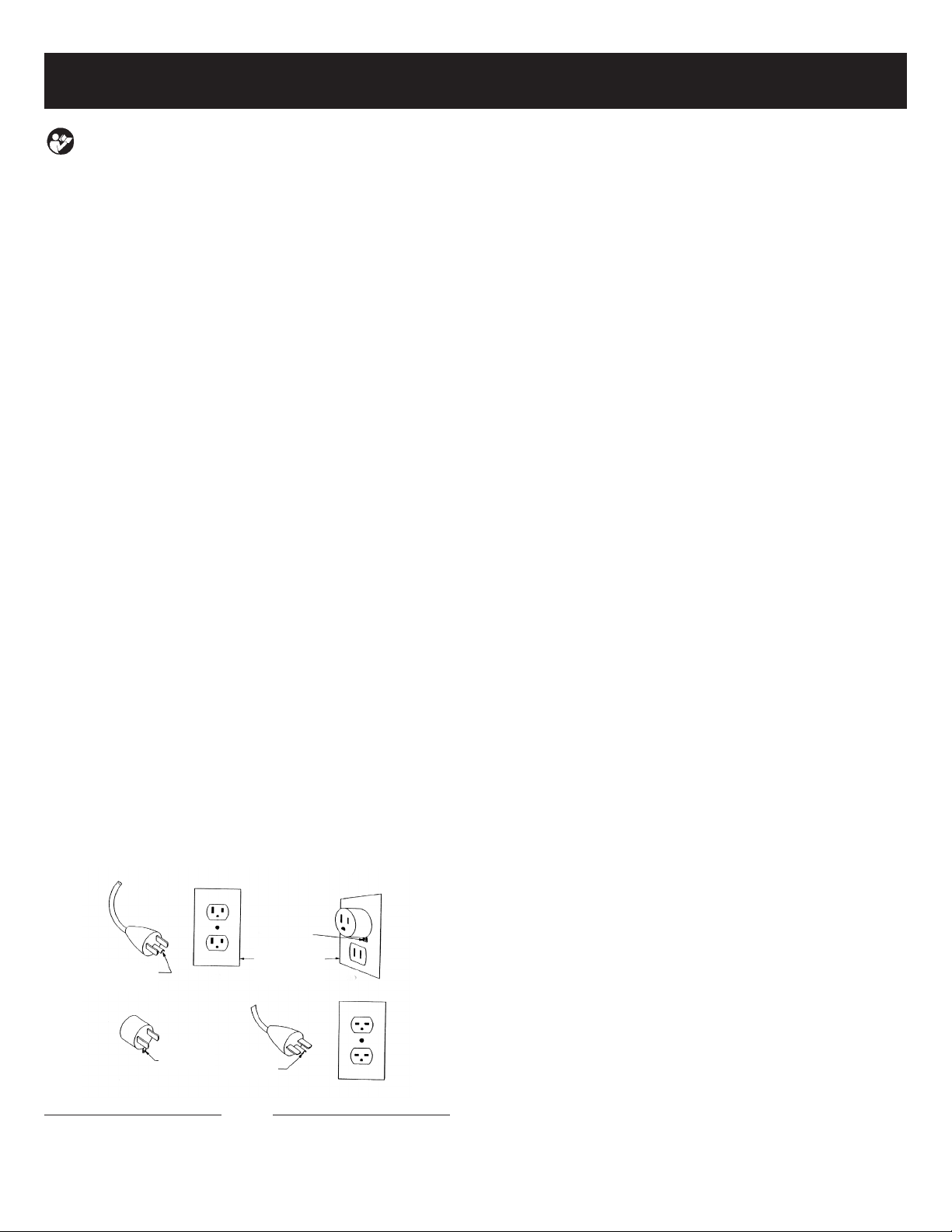

EXTENSION CORD - Use only with an extension

3.

cord intended for outdoor use. Match wire gauge to

the cord length. See table below. A 2-wire cord without a gr

appliance is double insulated. If in doubt of pr

wire size, use the next heavier gauge. Please note

that the smaller the gauge number

cor

GROUNDING

ound connection may be used since this

, the heavier the

d.

METAL SCREW

COVER OF

GROUNDED

PIN

(C)

(A)

ADAPTER

GROUNDIN

G MEANS

DUTLET BOX

GROUNDIN

G PIN

Fig. 1

(B)

(D)

oper

4.

AVOID DANGEROUS ENVIRONMENT - Do not use

appliance in damp or wet locations.

5. DON’T USE IN RAIN - Water entering a power tool

will increase the risk of electric shock.

6. DO NOT ABUSE CORD - Never yank it to discon-

nect from receptacle. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged

cords immediately. Damaged cords increase the risk

of electric shock.

7.

KEEP CHILDREN AWAY - All visitors should be kept

at a distance from work area.

DRESS PROPERLY - Do not wear loose clothing or

8.

jewelry. They can be caught in moving parts. Use of

rubber gloves and substantial footwear is recommended when working outdoors. Wear protective hair

covering to contain long hair.

9. USE SAFETY GLASSES - Always use face or dust

mask if operation is dusty.

STAY ALERT, WATCH WHAT YOU ARE DOING AND

10.

USE COMMON SENSE WHEN OPERATING A

POWER TOOL. Do not use tools while tired or under

the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

11. AVOID UNINTENTIONAL STARTING. Do not move

plugged-in appliance with finger on switch. Be sure

switch is off when plugging in.

12. DO NOT OVERREACH. Keep proper footing and balance at all times. Proper footing and balance enables

better control of the tool in unexpected conditions.

13. NO ACCESSORIES OR ATTACHMENTS ARE

NECESSARY FOR THE OPERATION OF THIS

GARDENING TOOL. The use of any accessories or

attachments for this gardening tool is not recommended. Such use of any attachment or accessory

may incr

14.

USE RIGHT APPLIANCE. Do not use appliance for

ease the risk of injur

y to the user.

any job except that for which it is intended.

15. GROUND FAULT CIRCUIT INTERRUPTER(GFCI)

PROTECTION SHOULD BE PROVIDED ON THE

CIRCUIT(S) OR OUTLET(S) TO BE USED FOR

THE GARDENING APPLIANCE. Receptacles are

available having built-in GFCI pr

otection and may be

used for this measure of safety.

16. WARNING! DTo reduce the risk of electric shock,

use only with an extension cord intended for outdoor use, such as an extension cor

d of cor

d type

SW-A, SOW-A, STW-A, STOW-A, SJW-A, SJOW-A,

SJTW-A, SJTOW-A.

Extension cor

ds of the type specified above ar

available at local har

dwar

es.Extension cor

e stor

e

dMake sure your extension cord is in good condition.

When using an extension cor

d, be sure to use one

Page 5

heavy enough to carry the current your product will

draw. An undersized extension cord will cause a drop

in line voltage resulting in loss of power and overheating. Table 1 shows the correct size to use depending

on cor

d length and nameplate ampere rating. If in

doubt, use the next heavier gage. Number, the heavier the cord. To reduce the risk of disconnection of

appliance cord from the extension cord during operating: Make a knot as shown in Fig. 2;

Volts

120V

Ampere Rating

More than Not more than

0-6

6-10

10-12

12-16

METHOD OF SECURING EXTENSION CORD

CORD SET

(A) TIE CORD AS SHOWN

DO NOT FORCE TOOL. The correct tools will do the

17.

APPLIANCE CORD

Total length of cord in feet

25 50

18

16

18

16

16

16

14

12

Not recommended

TABLE 1

(B) CONNECT PLUG AND

RECEPTACLE

Fig. 2

100 150

16

14

14

job better and safer at the rate for which it is

designed.

DISCONNECT THE PLUG FROM THE POWER

18.

SOURCE BEFORE MAKING ANY ADJUSTMENT

CHANGING ACCESSORIES, OR STORING THE

TOOL. Such preventive safety measures reduce the

risk of star

19.

STORE IDLE TOOLS INDOORS. When not in use,

ting the tool accidentally

.

tools should be stored indoors in dry, and high or

locked-up place, out of reach of children.

20.

MAINT

sharp and clean for best per

AIN TOOLS WITH CARE.

mance and to r

for

Keep cutting tools

the risk of injury. Follow instructions for lubricating

and changing accessories. Inspect tool cor

ed by an author

, and if damaged, have it r

cally

epair

ized service facility. Keep handling surface dry,

om oil and grease.

clean, and fr

21.

CHECK DAMAGED P

the tool, a guar

ee fr

d or other par

TS.

AR

Befor

t that is damaged

e fur

ther use of

should be carefully checked to determine that it will

m its intended function.

operate pr

operly and per

check for alignment of moving par

for

ts, binding of

moving parts, breakage of parts, mounting, and any

16

14

14

educe

d periodi

other condition that may affect its operation. A

guard or other part that is damaged should be properly repaired or replaced by an authorized service

center unless indicated elsewhere in this manual.

SHREDDER SAFETY RULES:

1. Extreme caution should be taken to ensure shreddable material does not contain metal. Rocks, bottles.

Cans or other foreign objects.

2. Do not allow hands or any other part of the body, or

clothing to enter inside the feeding chambers or discharge chute, while machine is operating.

3. Wear gloves while operating the machine.

4. Before starting the machine, ensure that all screws

and other fasteners are properly secured.

5. Machine should be operated on firm level surfaces

only.

6. Before starting the machine, check that the cutting

chamber is empty.

7. Motor should be kept clean of debris and other

accumulations.

8. Keep all guards and deflections in good working

condition.

9. Stand clear of discharge chute at all times.

10.

Do not over reach and keep face and body back form

the feed opening.

11. Never pull the machine by the power cord and keep

cord away form water or sharp edges.

12. Disconnect the power cord when the machine is not

in use.

13. If machine should become clogged, switch off the

motor, disconnect the power cord, make sure all moving parts are completely stopped before cleaning

,

-

-

43

clogged debris.

14. Ensure the power cord is always in good condition. A

cord with broken insulation is extremely dangerous

and can result in fire, electric shock or serious personal injury.

15. The operation of any tools can result in foreign objects

being thrown into your eyes, which can result in

severe eye damage Before operating power tool,

always wear safety goggles or safety glasses with side

shields and a full face shield when needed. We recommend wide Vision Safety Mask for use over eyeglasses or standard safety glasses with side shields.

Page 6

RULES FOR SAFE OPERATION

EXPLANATION OF NOTE, WARNING, and

WARRANTY SYMBOL

1. A NOTE is used to convey additional information, or

highlight a particular explanation, or to expand a step

instruction.

2. A WARNING identifies a procedure which, if not

undertaken or if improperly done, can result in a serious personal injury or damage to the unit and/or

both.

3.

4.

(WARRANTY SYMBOL) serves notice that

unless instructions or procedures are followed, any

damage will void the warranty and repairs will be at

owner’s expense. Service other than user maintenance should be performed by a Yard Machines

Authorized Service Center. Damage or conditions

caused by improper maintenance practices which

render this product inoperable will void the manufacturer’s warranty.

FOR WARRANTY OR SERVICE contact the nearest

Yard Machines Authorized Service Center by calling

800# on back cover.

SAVE THESE INSTRUCTIONS

5

Page 7

RULES FOR SAFE OPERATION

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and inter

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

national symbols and pictographs that may appear on this product.

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning, or caution.

May be used in conjunction with

other symbols or pictographs.

• WARNING - READ OPERATOR'S

MANUAL

Read the Operator’s Manual(s) and

follow all warnings and safety

instructions. Failure to do so can

result in serious injury to the operator

and/or bystanders.

• WEAR HEAD, EYE AND HEARING

PROTECTION

WARNING: Thrown objects and loud

noise can cause severe eye injury

and hearing loss. Wear eye protection meeting ANSI Z87.1-1989 standards and ear protection when operating this unit. Falling objects can

cause severe head injury. Wear head

protection when operating this unit.

Use a full face shield when needed.

SYMBOL MEANING

• WARNING - WEAR GLOVES TO

PROTECT YOUR HANDS

• WARNING - WEAR SAFETY BOOTS

TO PROTECT AGAINST ELECTRIC

SHOCK

• WARNING - DO NOT ESPOSE TO

RAIN

6

Page 8

KNOW YOUR UNIT

TOP HOPPER

RULES FOR SAFE OPERATION ASSEMBLY INSTRUCTIONS

TOP HOPPER

SAFETY SCREWS

ON/OFF SWITCH

WHEEL(R)

WHEEL COVERS

OVERLOAD

PROTECTION

SWITCH

TOP HOPPER

KNOB

DISCHARGE CHUTE

WHEEL(L)

LEG(R)

LEG(L)

Page 9

LOOSE PARTS LIST

Assemble the following parts in accordance with the

instructions on the following pages.

• Hopper Assembly

• Connecting Tube Assembly

• Hex Wrench

• 5 Safety Set Screws M5 X 15

• 2 Split Pins

• 2 Wheels

• 2 Flat Washers 12mm

• 2 Hex Screws M8 X 40

• 2 Flat Washers 8mm

• 2 Spring W

• 2 Wheel Covers

HOW TO ASSEMBLE YOUR SHREDDER (FIG. 3)

1. Push the large diameter section of the axle into the axle

tube and secure the axle into position using the M8 x

40 hex screws and star washer. (2 per side)

2. Push the wheel and then the 12mm flat washer over the

axle.

3. Push the split pin through the hole in the end of the axle

and bend the ends over using pliers.

4. Fix on wheel covers.

HOPPER (FIG.4) Place the hopper on top of the feed

tube and align the fixing holes. Secure with the safety

set screws.

ashers 8mm

Fig. 3

Fig. 4

OPERATING INSTRUCTIONS

Read and understand

CAUTION:

this owners manual before using your

Shredder. Failure to comply can result in accidents involving fire, electric shock, or serious

personal injury.

Connect the Shr

1.

t and stop the Shr

o star

2. T

located at the rear of the Motor (Fig. 5)

OVERLOAD PROTECTION AND MOTOR

JAMMING If over

protection switch may cut out the motor. To restart, firstly

switch the machine of

Loosen caging knobs and r

then remove any clogged debris from the cutting cham-

. If the top cover assembly becomes jammed and will

ber

not lift of

through the back chute of the top hopper to rotate the Vcutter to enable the top cover assembly to be r

Reset motor overload pr

f, tur

edder to a suitable power outlet.

feeding clogs the machine the overload

f and disconnect the power cor

n the V

-cutter by pushing a piece of wood

otection switch (Fig. 5)

the safety instructions in

ess the switch

, depr

edder

emove top cover assembly

emoved.

d.

,

ON/OFF

SWITCH

OVERLOAD

PROTECTION

SWITCH

Fig. 5

87

Page 10

OPERATING INSTRUCTIONS

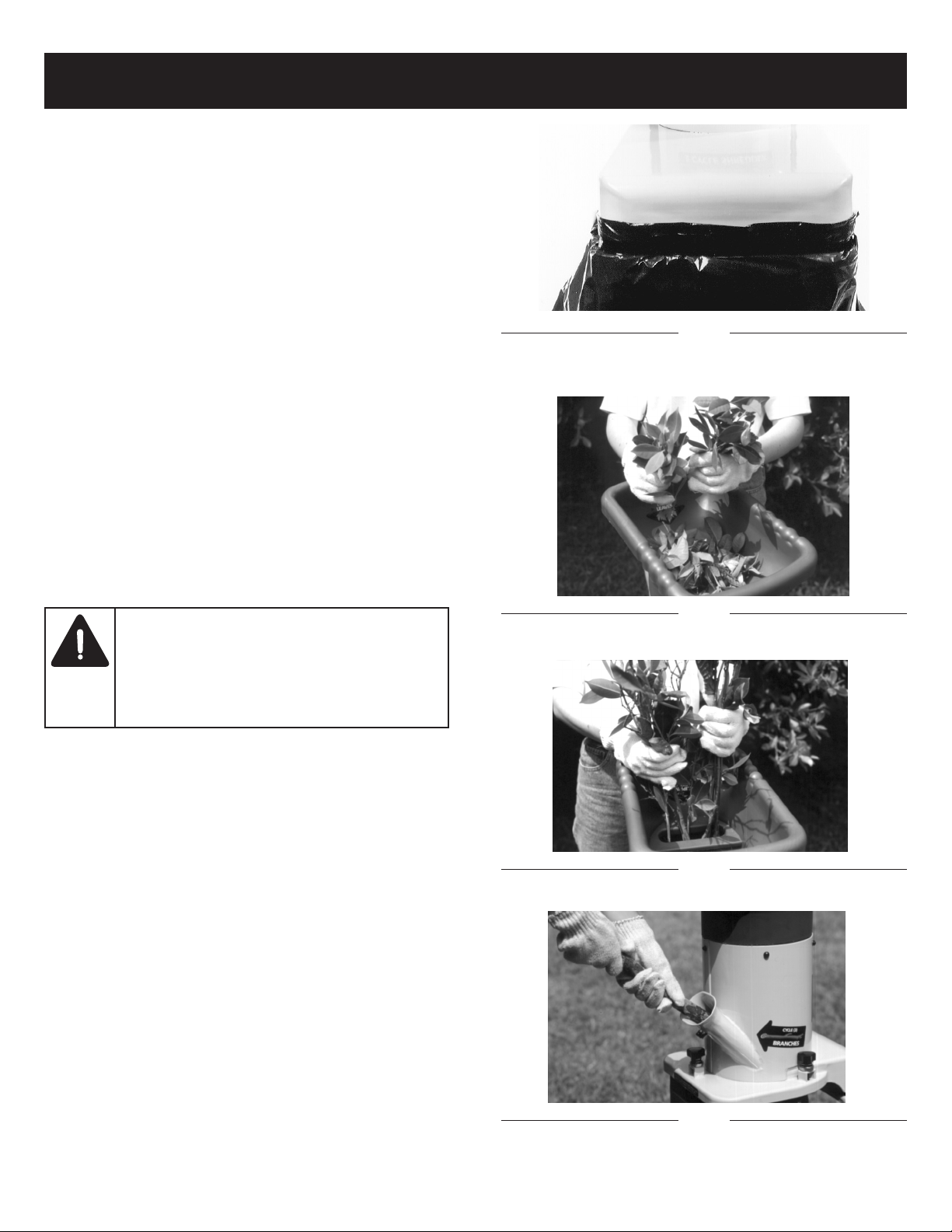

ATTACHING MULCH BAG Place a heavy duty trash bag

using the mulch bag strap. (Fig. 6)

TOP HOPPER-FRONT CHUT The large sloping front

chute of the Top Hopper is designed to accept leaves

and small garden clippings. Shredding and mulching is

achieved by natural suction of the debris thr

blade chamber.

Do not overfeed and do not feed wet, soggy material into

the Shredder as this may clog the blade chamber and the

discharge chute. (Fig. 7)

TOPHOPPER-BLACK CHUTE The smaller back chute of

the top Hopper accepts medium to larger size garden

clippings.

Shredding and mulching is achieved through the same

action as the front chute. If a finer type mulch is required

than is initially achieved, re-feed the mulch through again

until the desired result is obtained. (Fig. 8).

Do not feed solid branches through the two Top Hopper

chutes.

SIDE CHUTE The elongated chute located at the rear of

the machine is specially designed to accept solid garden

clippings and branches up to 1-1/2" (38mm) in diameter.

IMPORTANT: When feeding long, large diameter material, control the rate of feed by pulling back on the material

so as not to stall or overload the motor. (Fig. 9)

Do not under any cir-

WARNING:

hands inside the geeding chutes while the

machine is operation. Force feeding of debris is

not necessary due to the natural suction action

of the shredder.

cumstances, place

ough the

Fig. 6

Fig. 7

UNPACKING

1. Carefully remove all parts from the shipping carton.

Do not discar

2.

parts using the parts list.

3. If all parts have been included proceed to assembly.

If you are missing a parts, contact the retailer you pur-

4.

chased it for

Shredder.

Examine all the parts to make sure no break age has

5.

ed during shipping. Any damaged par

r

occur

replaced before attempting to use the Shredder.

d material until you have identified all the

m befor

e attempting to assemble your

t should be

Fig. 8

Fig. 9

Page 11

OPERATING INSTRUCTIONS

MATERIAL PUSH STICK User material push stick sup-

plied to push remaining material into hopper opening. DO

NOT USE HANDS. (Fig. 10)

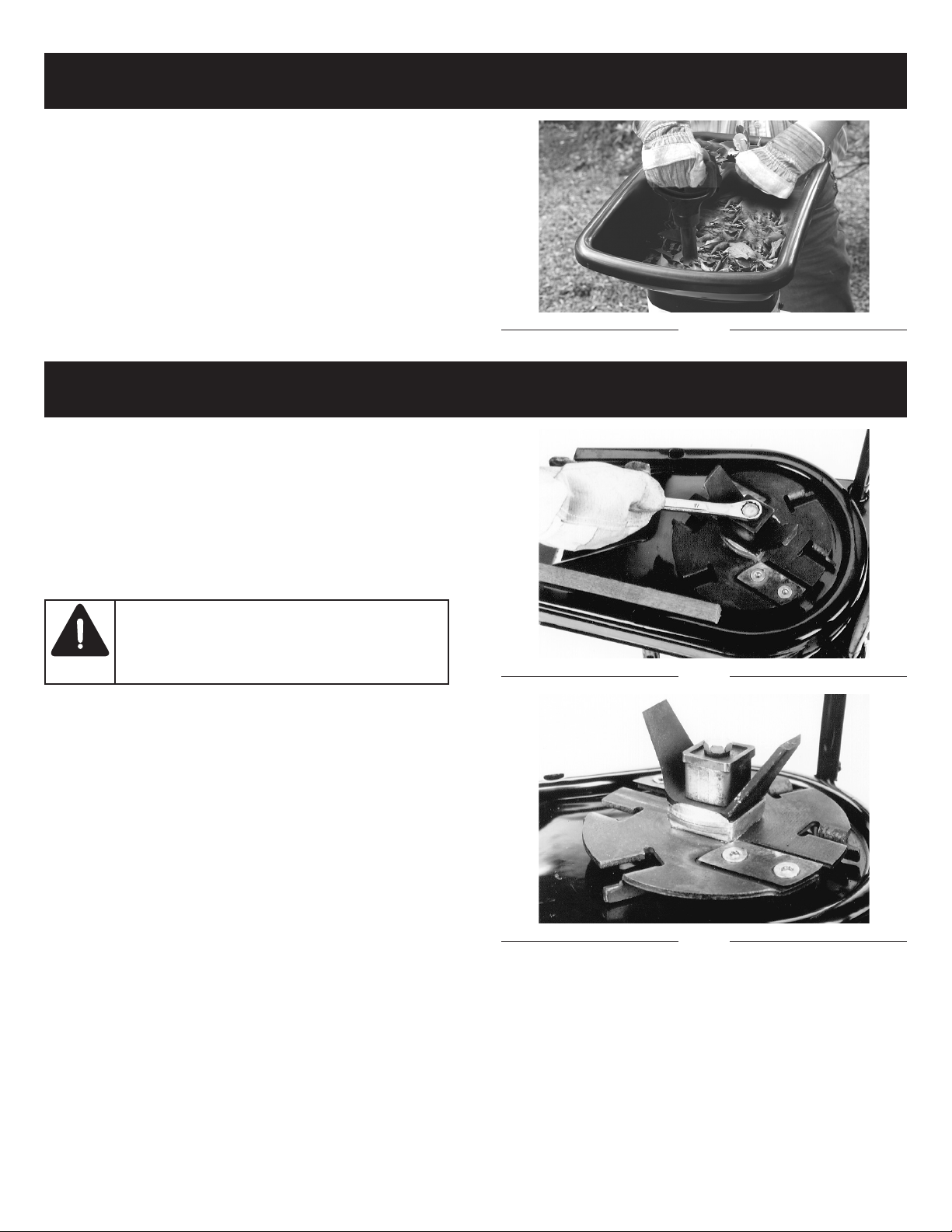

MAINTENANCE INSTRUCTIONS

Your Shredder has been designed for a low level of maintenance, involving routine cleaning and inspection. The

motor of the Shredder is maintenance free and requires

no attention. For the best results the blades must be kept

sharp at all times. The blades have dramatically less cutting power when blunt.

The Shredder will tear rather than cut when the blades

are blunt. When this occurs rotate the double sided

blades or replace the blades immediately.

Before attempting

WARNING:

switch the machine off and disconnect the

power cord.

V-CUTTER MAINTENANCE

1. Switch the machine off and disconnect the power cord

ensuring all moving parts are completely stopped.

2. Wear gloves when attempting any maintenance to the

cutting blades.

JAMMING if blades become jammed r

motor. If blades can not be worked loose refer to disassembly instr

DISASSEMBLY

1. Loosen caging knobs and remove the top cover

assembly.

2. Rotate the cutter base anti clockwise and place a piece

of wood between the cutter base and cutting chamber

wall so as to stop the cutting base retating. (Fig. 11)

3. Remove the center hold down bolt by turning it anti

clockwise using a 17 mm spanner

4. Remove the square washer, square bush, V-cutter to

expose cutter base.

SHREDDING BLADES MAINTENANCE

To inspect or renew the double sided shredding blades

there is no need to remove the cutter base. To remove

simply undo the counter sunk screws with the 6mm hex

wrench supplied with the machine and turn them through

180 These blades are double ground and can be used on

both sides. When blunt on both sides renew and ensure

uctions (Item 1) and then remove obstruction.

any maintenance

otate knob under

.

Fig. 10

Fig. 11

Fig. 12

they are screwed in tightly.

ASSEMBLY This is carried out in the reverse sequence to

that of disassembly but with careful inspection of all

components. Ensure that cutter base is assembled with

the scraping plates facing down towards the motor and

that the spring washer is situated under the head of the

centre hold down bolt. (Fig. 12)

109

Page 12

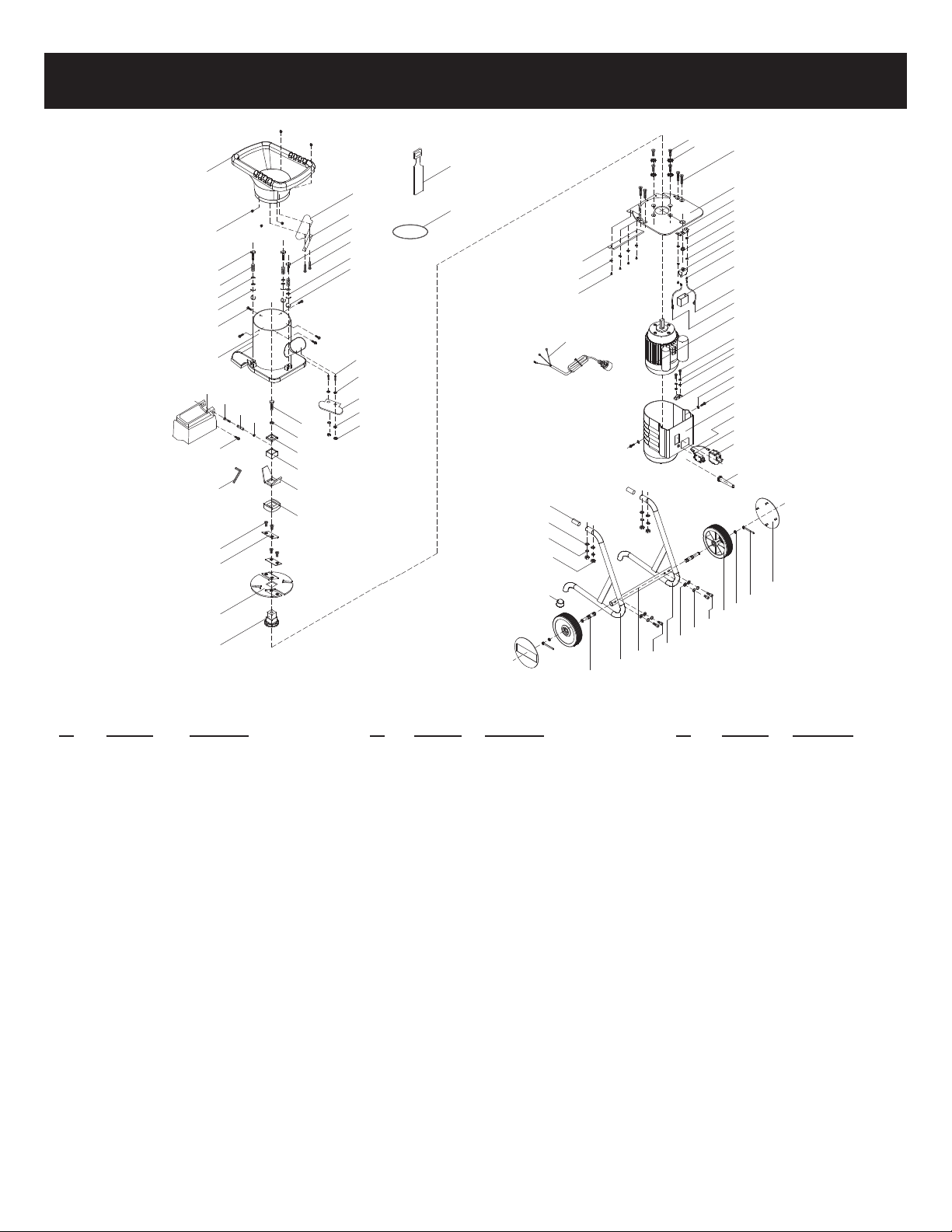

3939

4545

4444

1313

5151

5757

5656

6666

6767

6868

4040

1616

1616

1616

1818

1010

1

515

1818

5252

4646

4747

4848

5

353

6

161

6464

7070

7171

2525

2222

2

020

1818

1919

2

121

1212

1111

1414

6262

2424

55

6969

6565

6060

5959

5858

5050

4343

4

141

3535

3737

1717

99

44

66

77

7

7

77

1

313

5454

6363

2323

2

626

5555

4949

4242

3636

3838

3434

1

818

88

55

33

3

3

22

22

11

4141

1313

5

5

2727

2828

2929

3030

3131

3232

3

333

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Parts No.

6266-200103

6200-200101

6134-200101

6024-200101

6WSB-08

6014-200101

6STBBM05-15

6270-200111

6263-200102

6158-200101

6134-200102

6SDABB04-20

6WFZ-08

6CE-06

6SDAZ-04-10

6WFZ-04

6263-200101

6NAZ-04

6WSB-04

6262-200106

6SDAZ-05-55

6059-200101

6NAZ-05

6SXDZ-10-35

Description

TOP HOPPER

SCREW

KNOB

RESTRAINNIG SPRING

SPRING WASHER

WASHER

SCREW

BODY

DUST PLATE

CUTTER CLAMP

KNOB

SCREW

WASHER

E RING

SCREW

WASHER

DUST PLATE

NUT

SPRING WASHER

RESTRAINING COVER

SCREW

BRACKET TUBE

NUT

SCREW

No.

37

38

39

40

41

42

43

44

45

46

47

48

25

26

27

28

29

30

31

32

33

34

35

36

Parts No.

6207-200102

6036-200101

6262-200101

6022-200001

6SDAZ-04-08

6262-200001

6010-200004

6010-200005

6099-200103

6SDABB04-14

6043-840001

6WFZ-06

6WSB-10

6158-200002

6156-200001

6250-200003

6267-200001

6200-200002

6250-200001

6268-200101

6124-200101

6200-200001

6WDB-08

6200-200102

Description

BRACKET CLAMP

SWITCH HOLDER

SWITCH COVER

CUT-OUT SWITCH

SCREW

SWITCH COVER

INTERNAL WIRE I

INTERNAL WIRE II

MOTOR ASS'Y

SCREW

CORD CLAMP

WASHER

SPRING WASHER

CUTTER CLAMP

SQUARE BUSH

V-CUTTER

V-CUTTER BASE

SCREW M10x10

CUTTER (BLADE)

CUTTER BASE

CUTTER BUSH

SCREW M8x18

SPRING WASHER

SCREW

No.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

Parts No.

6SDAZ-06-12

6086-200104

6010-200006

6272-200002

6022-200002

6199-200002

6100-200101

6011-200005

6111-200101

6NAZ-08

6027-200101

6111-200102

6004-200104

6087-200102

6SRCB-08-16

6004-200103

6SRCB-08-40

6228-200013

6WFZ-12

6PB-26

6067-200007

6SJABB03-10

Description

SCREW

MOTOR COVER

INTERNAL WIRE

THERMOSTAT

ON/OFF SWITCH

CORD GUARD

PLATE

POWER CORD

STRENGTEN SHAFT

NUT

FRAME GASKET

WHEEL SHAFT

LEFT HOLDER

CONNECTING TUBE

SCREW

RIGHT HOLDER

SCREW

WHEEL

WASHER

PIN

WHEEL COVER

SCREW

71 6042-200001 WRENCH

72 6188-200402 MARTERIAL PUSH STICK

73 6280-200001 STARP BAG HOLD

MAINTENANCE INSTRUCTIONS

Before replacing the top cover assembly ensure that the

V-cutter is positioned as shown in (Fig. 13) Replace the

top cover assembly and secure tightly the caging knobs.

If caging Knobs are not tight the motor will not start due

to the motor lock out switch not bein activated.

CLEANING After use, always wipe clean the outside of

the Shredder to remove any build up of material with a

damp cloth. Clean the inside of the cutting chamber and

remove any left over material, Do not hose down with

water.

IMPORTANT: Before replacing top cover assembly

ensure that the V-cutter is positioned as shown in (Fig.

13).

Replace the top cover assembly together with the top

cover screw knob ensuring this is tight. If the top cover

screw knob is not tight the motor will not start due to the

motor lock out switch not being activated.

SPECIFICATIONS

Fig. 13

MODEL NO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MTD1400K

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V~, 60Hz, 14Amp

Hopper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .394x270x200mm (15-1/2”x10-5/8”x7-7/8”)

No Load Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 300 min-1/RPM

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77 Lbs (35 Kg)

11 12

Page 13

PARTS LIST

3939

4545

4444

1313

5151

5757

5656

6666

6767

6868

4040

1616

1616

1616

1818

1010

1

515

1818

5252

4646

4747

4848

5

353

6

161

6464

7070

7171

2525

2222

2

020

1818

1919

2

121

1212

1111

1414

6262

2424

55

6969

6565

6060

5959

5858

5050

4343

4

141

3535

3737

1717

99

44

66

77

7

7

77

1

313

5454

6363

2323

2

626

5555

4949

4242

3636

3838

3434

1

818

88

55

33

3

3

22

22

11

4141

1313

5

5

2727

2828

2929

3030

3131

3232

3

333

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Parts No.

6266-200103

6200-200101

6134-200101

6024-200101

6WSB-08

6014-200101

6STBBM05-15

6270-200111

6263-200102

6158-200101

6134-200102

6SDABB04-20

6WFZ-08

6CE-06

6SDAZ-04-10

6WFZ-04

6263-200101

6NAZ-04

6WSB-04

6262-200106

6SDAZ-05-55

6059-200101

6NAZ-05

6SXDZ-10-35

Description

TOP HOPPER

SCREW

KNOB

RESTRAINNIG SPRING

SPRING WASHER

WASHER

SCREW

BODY

DUST PLATE

CUTTER CLAMP

KNOB

SCREW

WASHER

E RING

SCREW

WASHER

DUST PLATE

NUT

SPRING WASHER

RESTRAINING COVER

SCREW

BRACKET TUBE

NUT

SCREW

No.

37

38

39

40

41

42

43

44

45

46

47

48

25

26

27

28

29

30

31

32

33

34

35

36

Parts No.

6207-200102

6036-200101

6262-200101

6022-200001

6SDAZ-04-08

6262-200001

6010-200004

6010-200005

6099-200103

6SDABB04-14

6043-840001

6WFZ-06

6WSB-10

6158-200002

6156-200001

6250-200003

6267-200001

6200-200002

6250-200001

6268-200101

6124-200101

6200-200001

6WDB-08

6200-200102

Description

BRACKET CLAMP

SWITCH HOLDER

SWITCH COVER

CUT-OUT SWITCH

SCREW

SWITCH COVER

INTERNAL WIRE I

INTERNAL WIRE II

MOTOR ASS'Y

SCREW

CORD CLAMP

WASHER

SPRING WASHER

CUTTER CLAMP

SQUARE BUSH

V-CUTTER

V-CUTTER BASE

SCREW M10x10

CUTTER (BLADE)

CUTTER BASE

CUTTER BUSH

SCREW M8x18

SPRING WASHER

SCREW

No.

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

Parts No.

6SDAZ-06-12

6086-200104

6010-200006

6272-200002

6022-200002

6199-200002

6100-200101

6011-200005

6111-200101

6NAZ-08

6027-200101

6111-200102

6004-200104

6087-200102

6SRCB-08-16

6004-200103

6SRCB-08-40

6228-200013

6WFZ-12

6PB-26

6067-200007

6SJABB03-10

Description

SCREW

MOTOR COVER

INTERNAL WIRE

THERMOSTAT

ON/OFF SWITCH

CORD GUARD

PLATE

POWER CORD

STRENGTEN SHAFT

NUT

FRAME GASKET

WHEEL SHAFT

LEFT HOLDER

CONNECTING TUBE

SCREW

RIGHT HOLDER

SCREW

WHEEL

WASHER

PIN

WHEEL COVER

SCREW

71 6042-200001 WRENCH

72 6188-200402 MARTERIAL PUSH STICK

73 6280-200001 STARP BAG HOLD

Page 14

NOTES

13 14

Page 15

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by MTD

LLC (“MTD”) with respect to new merchandise purchased and

used in the United States, its possessions and territories.

MTD warrants this product against defects in material and

workmanship for a period of two (2) year commencing on the

date of original purchase and will, at its option, repair or replace,

free of charge, any part found to be defective in material or

workmanship. This limited warranty shall only apply if this

product has been operated and maintained in accordance with

the Operator’s Manual furnished with the product, and has not

been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water or damage because of

other peril or natural disaster. Damage resulting from the

installation or use of any accessory or attachment not approved

by MTD for use with the product(s) covered by this manual will

void your warranty as to any resulting damage. This warranty is

limited to ninety (90) days from the date of original retail

purchase for any MTD product that is used for rental or

commercial purposes, or any other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in your

area, please check for a listing in the Yellow Pages or contact

the Customer Service Department of MTD LLC by calling

1-866-747-9816 or writing to P.O. Box 361131, Cleveland OH

44136-0019 or if in Canada call 1-800-668-1238. No product

returned directly to the factory will be accepted unless prior

written permission has been extended by the Customer Service

Department of MTD LLC.

This limited warranty does not provide coverage in the

following cases:

Blade.

A.

MTD does not extend any warranty for products sold or

B.

expor

ted outside of the United States of America, its

possessions and territories, except those sold through

MTD’s authorized channels of export distribution.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose, applies

after the applicable period of express written warranty

above as to the parts as identified. No other express

warranty or guaranty, whether written or oral, except as

mentioned above, given by any person or entity, including

a dealer or retailer, with respect to any product shall bind

MTD. During the period of the Warranty, the exclusive

remedy is repair or replacement of the product as set

forth above.

long an implied war

not apply to you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

shall not be liable for incidental or consequential loss or

damages including, without limitation, expenses incurred

for substitute or replacement lawn care services, for

transportation or for related expenses, or for rental

expenses to temporarily replace a warranted product.

(Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of the safety features of the product shall void this Warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the use or misuse or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for whom

it was purchased as a gift.

How State Law Relates to this W

gives you specific legal rights, and you may also have other

rights which vary from state to state.

To locate your nearest service dealer dial 1-866-747-9816 in

the United States or 1-800-668-1238 in Canada.

(Some states do not allow limitations on how

ranty lasts, so the above limitation may

arranty:

This war

ranty

MTD reserves the right to change or improve the design of

any MTD Product without assuming any obligation to modify

oduct pr

any pr

eviously manufactur

ed.

MTD LLC

P.O. Box 361131

Cleveland, OH 44136-0019

Page 16

Manual de Utilisation

Défibreur Mulcher

de Jardin

Francais

Mod

MTD1400K

è

le

IMPORTANT: LISEZ LES RÈGLES ET

CONSIGNES DE SÉCURITÉ SOIGNEUSEMENT

P/N 6096-200123 © 2006

PRINTED IN CHINA

Page 17

TABLE DES MATIÈRES

Declaration de Garantie Page 16

Règles de sécurité Pages 17 - 22

Assemblage Page 23

Instructions D’utilisation Page 23 - 25

Maintenance Page 25 - 26

Spécifications Page 26

Liste des pièces Page 27

Remarque Page 28

Garantie Limitée du Fabricant Page 29

DECLARATION DE GARANTIE

GARANTIE LIMITEE DE DEUX ANS SUR LE DÉFIBREUR DE YARD MACHINES

Pendant deux années à partir de la date d'achat, quand ce défibreur est utilisé et maintenu selon le

manuel de l'opérateur, Yard Machines réparera n'importe quel vice de matériau pour la main-d'œuvre

gratuitement.

Si ce défibreur est utilisé pour des buts commerciaux ou de location, cette garantie ne s'applique que

pendant 90 jours à partir de la date d'achat.

LE SERVICE DE GARANTIE EST DISPONIBLE EN RENVOYANT CE DÉFIBREUR AU SERVICE DE

REPARATION DU REVENDEUR MTD LE PLUS PROCHE.

Cette garantie vous donne des droits légaux spécifiques, et vous pouvez également avoir d'autres

droits qui varient d'un état à l'autre.

16

Page 18

RÈGLES DE SÉCURITÉ

Les symboles de sécurité attir

des dangers potentiels. Ces symboles et leurs détails

explicatifs méritent que vous les lisiez et compreniez

bien. Les avertissements de sécurité ne peuvent éviter

les dangers de par eux-mêmes. Les consignes ou

mises en garde qu'ils donnent ne remplacent pas des

mesures préventives appropriées contre les accidents.

SYMBOLE SIGNIFICATION

ent votre attention sur

ALERTE DE SÉCURITÉ:

indique un danger, un avertissement ou une

mise en garde. Soyez vigilant afin d'éviter toute

blessure grave. Ce symbole peut être combiné

à d'autres symboles ou pictogrammes.

REMARQUE: donne des informations ou des instructions

vitales pour le fonctionnement ou l'entretien de

l'équipement.

Lisez le(s) manuel(s) de l'utilisateur et suivez tous

les avertissements et consignes de sécurité.

Vous pourriez à défaut entraîner des blessures

graves pour vous ou d'autres personnes.

SYMBOLE SIGNIFICATION

DANGER:

causer dommages matériels ou blessures

graves pour tous. Respectez les consignes

de sécurité afin de réduire les risques

d'incendie, d'électrocution et de blessures.

AVERTISSEMENT:

respect d’un avertissement peut causer

dommages matériels ou blessures graves

pour tous. Respectez les consignes de

sécurité afin de réduire les risques d'incendie,

d'électrocution et de blessures.

MISE EN GARDE:

d’un avertissement peut causer dommages

matériels ou blessures graves pour tous.

Respectez toujours les consignes de sécurité

afin de réduire les risques d'incendie,

d'électrocution et de blessures.

le non-respect d’un

avertissement peut

le

non-

le nonrespect

SI VOUS AVEZ DES QUESTIONS, APPELEZ LE

1-800-668-1238

• IMPORTANTES CONSIGNES DE SÉCURITÉ •

LIRE TOUTES LES INSTRUCTIONS

AVANT UTILISATION

AVERTISSEMENT:

soig-neusement les consignes de sécurité

lorsque vous utilisez cet appareil. Dans l'intérêt de votre sécurité et de celle des personnes à proximité, prenez soin de lire ces

instructions avant de faire fonctionner la

machine. Veuillez garder les instructions en

lieu sûr pour usage ultérieur.

euillez lire les instructions avec soin. Familiarisez-vous

V

•

avec les commandes et l'utilisation correcte de cet

appareil.

• N'utilisez pas l'appareil si vous êtes fatigué, malade ou

sous l'ef

Les enfants et adolescents de moins de 15 ans ne

•

doivent pas utiliser l'appareil exceptés les adolescents

assistés d'un adulte.

•

Inspectez l'appar

endommagées. Regardez s'il y a des fuites de carburant.

Assurez-vous que les fixations sont solidement en place.

fet de l'alcool, de dr

eil avant utilisation. Remplacez les pièces

ogues ou de médicaments.

suivez

Remplacez les pièces de l'accessoire de coupe qui sont

fendillées, ébréchées ou endommagées. Assurez-vous

que l'accessoire de coupe est correctement installé et

solidement fixé. Assurez-vous que le protecteur d'acces-

e de coupe est correctement fixé et positionné comme

soir

recommandé. Vous risquez sinon de causer des blessures

à l'opérateur et aux spectateurs, et d'endommager l'ap-

eil.

par

N'utilisez que du fil de r

•

can. N'utilisez jamais de fil ou de cordon à renfort

métallique car ils peuvent se briser et se transformer en

ojectile danger

pr

Dégagez la zone de coupe avant chaque usage. Enlevez

•

tous les objets pouvant être projetés ou happés par l'accessoire de coupe : cailloux, verre brisé, clous, fil ou

ficelle. Éloignez enfants, spectateurs et animaux de la

zone de coupe. Tenez-les à au moins 15 m (50 pi) de là

mais sachez que les spectateurs risquent quand même

e atteints par des objets pr

d'êtr

ter des pr

por

le moteur et l'accessoire de coupe si quelqu'un s'ap-

oche de vous.

pr

17 18

otecteurs oculair

emplacement d’origine du fabri-

eux.

ojetés. Conseillez-leur de

rêtez immédiatement

es. Ar

Page 19

RÈGLES DE SÉCURITÉ

LIRE ET CONSERVER CES

INSTRUCTIONS

Lorsqu'un appar

élémentaires doivent toujours être prises pour assurer une

sécurité maximum et une performance optimale. Lire cette

Notice avant d'assembler et d'utiliser cet appareil. Ne pas

se conformer aux instructions peut causer des secousses

électriques, des brûlures, un incendie ou des blessures

corporelles.

eil électrique est utilisé, des précautions

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES DE

BRÛLURES, D'INCENDIE, DE SECOUSSES

ÉLECTRIQUES OU DE BLESSURES :

1. RESPECTER TOUTES LES MESURES DE

SÉCURITÉ figurant dans cette Notice avant et durant

l'utilisation du défibreur.

2.

INSTRUCTIONS DE MISE À LA MASSE, Cet outil

doit être mis à la masse lors de son utilisation afin de

réduire tout risque d’électrocution pour l’utilisateur.

L’outil est équipé d’un cordon électrique à 3 conducteurs et d’une prise à 3 broches avec masse afin de

s’adapter au réceptacle de masse adéquate. Le fil

vert ou vert et jaune est connecté au terminal. Si votre

appareil est destinéà être utilisésous une tension

inférieur à 150 volts, il possède une prise comme

celle illustrée dans le schéma A de la figure 1 à la

page 2. S’il est destiné à être utilisé sous 150 ou 250

volts, il possède une prise comme illustré dans le

schéma D Fig. 1, page 2.

Un adaptateur, schéma B et C, est disponible pour

brancher les prises femelles à broches comme illustré sur le schéma A. Les oreilles rigides, poignées ou

autres de couleur verte, doivent être connectées à

une masse per

avec une prise de terre correcte. Aucun adaptateur

n’est four

3.

INSPECTER L'APP

DOMMAGES qu'auraient pu subir le car

électrique ou à la fiche. Toutes les fixations doivent

e bien ser

êtr

gâchette ne per

Ne jamais utiliser l'appareil si le cordon électrique ou

la fiche est endommagé, si le moteur ou le coupeherbe lui-même ne fonctionne pas cor

s'il est tombé, s'il a été endommagé, laissé à l'extérieur ou plongé dans l'eau. Ne pas utiliser l'appar

si les tr

ous de ventilation sont bouchés. T

enlever les débris qui risqueraient de limiter la circulation de l'air par les tr

les pièces endommagées qui sont ébréchées,

cassées ou qui ont été endommagées d'une manière

ou d'une autr

causer de graves blessur

manente, telle qu’un boîtier de prise

ni pour la prise illustrée dans le schéma D.

AREIL À LA RECHERCHE DE

, le cor

ter

rées. Ne pas utiliser l'appar

met pas de l'ar

rêter adéquatement.

ectement ou

r

don

eil si la

oujours

ous de ventilation. Remplacer

e et qui risqueraient d'êtr

es. Gar

e projetées et

den le couteau de

eil

coupeur aigu.

VIS MÉTALLIQUE

CACHE DU

BROCHE DE

MISE À LA

TERRE

(C)

4.

EVITER UN ENVIRONNEMENT DANGEREUX: ne

ATEUR

ADAPT

PLOT DE

MISE À LA

TERRE

(A)

BOÎTIER DE

PRISE AVEC

TERRE

BROCHE DE

MISE À LA

TERRE

Fig. 1

(B)

(D)

pas utiliser l’outil dans des endroits humides ou

mouillés.

NE PAS UTILISER SOUS LA PLUIE. Si l’eau pénètre

5.

un outil électrique, les risques d’électrocution augmentent.

6. NE PAS MALTRAITER LE CORDON. Ne jamais le

tirer pour le débrancher. Garder le cordon loin de

toute source de chaleur, huile, angle saillant ou

pièce amovible. Remplacer immédiatement les cordons endommagés. Ils augmentent le risque de

chocs électriques.

TENIR LES ENFANTS À L’ÉCART: Tenir tout le

7.

monde à l’écart de la zone de travail.

8. PORTER DES VÊTEMENTS APPROPRIÉS:

Ne porter ni bijoux ni vêtements amples; ils peuvent

se faire prendre dans une partie mobile de l’appareil.

L’utilisation de gants et chaussures en caoutchouc

est recommandée pour travail à l’extérieur. Couvrir

les cheveux longs.

TER DES LUNETTES DE PROTECTION -

POR

9.

Porter un masque ou autre pour vous protéger de la

poussière.

10. RESTEZ VIGILAN; F

VOUS F

AITES. UTILISEZ VOTRE SENS COMMUN

AITES ATTENTION À CE QUE

QUAND VOUS UTILISEZ UN APPAREIL

ÉLECTRIQUE. N’utilisez pas l’appar

de fatigue ou sous l’influence de dr

eil par moments

ogues, alcool ou

médicaments. Un instant d’inattention peut causer

de graves blessures.

11. EVITER LES DÉMARRAGES ACCIDENTELS: Ne

pas garder le doigt sur l’interrupteur en déplaçant un

outil branché. S’assurer que le commutateur est en

position d’ar

12.

NE PAS TENIR L’APPAREIL À BOUT DE BRAS:

rêt û avant de brancher l’appar

eil.

Veuillez à toujours bien être campé et gardez toujours

votr

e équilibr

e. Une bonne postur

e et équilibr

e vous

permettent de mieux contrôler l’outil en toutes cir

constances.

13.

AUCUN ACCESSOIRE OU PIÈCE N’EST

NÉCESSAIRE AVEC CET OUTIL DE JARDIN. Leu

Page 20

RÈGLES DE SÉCURITÉ

RÈGLES DE SÉCURITÉ

utilisation n’est pas recommandée car cela risque

d’augmenter les risques de blessures.

14. UTILISEZ LE MATÉRIEL ADÉQUAT. N’utilisez pas

de matériel dans des travaux pour lesquels il n’est

pas prévu.

15. UN INTERRUPTEUR AVEC PROTECTION DE

DÉFAUT DE MISE À LA MASSE (GFCI) DOIT ÊTRE

JOINT AU CIRCUIT (S) OU AUX PRISES DEVANT

ÊTRE UTILISÉS POUR LES MATÉRIELS DE

JARDINS.

Des réceptacles avec protection GFCI

sont disponibles et doivent être utilisés pour cette

mesure de sécurité.

16. ATTENTION! Pour diminuer le risque d’électrocu-

tion, utilisez uniquement des rallonges destinées à

un usage en extérieur, telles que des rallonges ayant

un type de cordon SW-A, SOW-A, STW-A, STOW-A,

SJW-A, SJOW-A, SJTW-A, SJTOW-A.

Les rallonges des types spécifiés ci-dessus sont

disponibles dans toutes les quincailleries.

Rallonges-Assurez vous que votre rallonge est en

bon état. Lorsque vous utilisez une rallonge, assurez

vous d’en utiliser une assez puissante pour supporter le courant consommé par votre matériel. Une rallonge sous calibrée entraînera une baisse de tension

dans la ligne ce qui créera une perte de puissance et

une surchauffe. Le Tableau 1 montre la taille correcte à utiliser en fonction de la longueur du cordon

et de l’ampérage stipulé sur la plaque de l’outil. En

cas de doute, utilisez le calibrage immédiatement audessus, pour un cordon plus puissant. Pour diminuer

le risque que le cordon de l’appareil se débranche de

la rallonge en cours d’utilisation:

Faites un nœud ainsi qu’il est montré dans la Figure

2;

olts

V

120V

Ampérage Plus de

Pasplus de

0-6

6-10

10-12

12-16

NE PAS FORCER L’APPAREIL: L’utiliser à la puis

17.

Longueur totale du cor

25 50

18

18

16

14

TABLEAU 1

16

16

16

12

sance conçue et il aura une meilleur

don en pieds

100 150

16

14

14

Pas recommand

e per

16

14

14

mance

for

é

et les risques de blessure seront réduites.

18.

DÉBRANCHER L’OUTIL AVANT DE L’AJUSTER,

CHANGER LES ACCESSOIRES OU LE REMISER.

Cela empêche de faire démarrer l’outil

accidentellement.

19. REMISER À L

’INTÉRIEUR.

Lorsqu’il n’est pas en

utilisation, remiser l’appareil dans un endroit sec,

inaccessible aux enfants.

20. ENTRETENIR L

AREIL SOIGNEUSEMENT

’APP

:

MÉTHODE POUR BRANCHER CORRECTEMENT UNE RALLONGE

ROLLONGE

(A) NOUER AINSI QU’IL

EST DÉCRIT

CORDON DE L

’APPAREIL

Fig. 2

(B) CONNECTER LA PRIS

MÂLE AVEC LA PRISE

FEMELLE

Garder la partie tranchante propre et aiguisée pour

une performance optimale et un moindre risque de

blessures. Suivre les instructions de lubrification et

de changements de pièces. Contrôler le cordon d’al

imentation de votre défibreur périodiquement, et si

endommagé, le faire réparer par un service après

vente agréé. Vérifier les prolongateurs périodique

ment et les remplacer si endommagés. Garder les

poignées sèches, propres et exemptes de toute trace

d’huile ou graisse.

VÉRIFIER LES PIÈCES ENDOMMAGÉES: Avant

21.

toute utilisation de l’outil, toute pièce endommagée

doit être soigneusement inspectée afin de déterminer si son fonctionnement est adéquat à sa fonction

prévue. Contrôler le montage, l’alignement et les fixations des pièces mobiles, vérifier qu’il n’y a pas de

pièces cassées ou tout autre problème qui

affecteraient son fonctionnement. Toute pièce

endommagée devrait être réparée correctement ou

remplacée par un centre de service agréé sauf indication contraire dans ce manue.

MESURES DE SECURITE DU BROYEUR DE JARDIN

1.

ATTENTION! Veillez particuliérement à ce que les matiéres

devant être broy es ne contiennent pas de métal, de pierres,

de bouteilles, de canettes ou tout autre objet étranger.

2.

PRÉCAUTION! Ne mettez pas vos mains ou toute

autr

tie du corps à l'intérieur de la chambr

e par

e de

chargement ou de la descente de déchargement,

veillez aussi à ce que les habits n'entrent pas à l'in

térieur de la chambr

e ou de la descente lorsque la

machine fonctionne.

3. Portez des gants lorsque vous vous servez de la

machine.

4. Avant de mettre la machine en route, assurez-vous

que toutes les vis et autres dispositifs d'assemblage

ectement fixés.

sont cor

r

5. La machine doit être utilisée seulement sur un sol

plan et ferme.

vant de mettre la machine en route assurez-vous

A

6.

que la chambre de chargement est vide.

7. Le moteur doit être propre de tout d bris ou de tout

e dépôt.

autr

19 20

Page 21

RÈGLES DE SÉCURITÉ

RÈGLES DE SÉCURITÉ

8. Maintenez toutes les protections et tous les

déflecteurs en bon état de marche.

9. A tout moment restez à l'écart de la descente de

déchargement.

Ne vous approchez pas trop et gardez votre visage et

10.

votre corps à l'écart de l'ouverture de chargement.

11. Ne tirez jamais la machine par son fil d'alimentation et

maintenez le fil à l'écart de l'eau et de tout objet

coupant.

12. Débranchez le fil d'alimentation lorsque la machine

n'est pas utilisée.

ATTENTION! Si la machine venait à se bloquer,

13.

éteignez le moteur, débranchez le fil d'alimentation,

assurez-vous que toutes les parties mobiles sont com

plètement arrêtées avant de dégager les d bris respon

sables du bourrage.

14. ATTENTION! Assurez-vous que le fil d'alimentation est

toujours en bon état. Un fil comportant une isolation

défectueuse est extrêmement dangereux et peut

occasionner un incendie, une électrocution ou de

sévères blessures corporelles.

ATTENTION! L'utilisation de tout outil peut entraîner

15.

l'introduction d'un corps étranger dans vos yeux, ce

qui peut entraîner de sévères blessures aux yeux.

Avant d'utiliser des outils électriques, portez toujours

des lunettes de protection comportant des

protections latérales et un masque englobant tout le

visage lorsque cela est nécessaire. Nous

recommandons des masques de protection à large

vision pouvant être utilisés par-dessus des lunettes

de vue ou des lunettes de protection normales avec

protections latérales.

4.

POUR TOUT ENTRETIEN OU SERVICE AU TITRE

DE LA GARANTIE prenez contact avec le Centre de

maintenance agréé MTD le plus proche en appelant

le numérogrtuit 800# mentionné sur le capot arrière.

CONSERVER CES INSTRUCIONS

EXPLICATION DES NOTA, AVERTISSEMENTS ET SYMBOLES DE LA GARANTIE

1. Un NOTA est destiné à fournir des informations com-

plémentaires, à éclaircir un point particulier ou à

expliquer plus en détail une étape.

Un AVER

2.

risque de causer de graves blessures corporelles ou

de graves dommages à l'appareil et/ou les deux si

elle n'est pas r

Le

3.

procédures ou instructions n'ont pas été respectées,

les dommages causés annuler

les réparations ser

Pour des services autres que ceux d'entretien à

effectuer par l'utilisateur, s'adresser à un Centre de

réparation agréé Y

ricant sera nulle et non avenue si des dommages ou

des conditions causés par de mauvaises pratiques

d'entr

TISSEMENT

espectée ou si elle est mal ef

(SYMBOLE DE GARANTIE) indique que si les

endent le pr

etien r

identifie une pr

ont la garantie et que

ont à la char

d Machines. La garantie du fab

ar

oduit inutilisable.

ge du pr

océdur

e qui

fectuée.

opriétair

e.

-

Page 22

RÈGLES DE SÉCURITÉ

SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX

Ce manuel de l'utilisateur décrit les symboles et pictogrammes de sécurité et internationaux pouvant apparaître sur ce

produit. Consultez le manuel de l'utilisateur pour les informations concernant la sécurité, le montage, le fonctionnement,

etien et les réparations.

l'entr

SYMBOLE SIGNIFICATION

• SYMBOLE ALERTE DE

SÉCURITÉ

Indique un danger, un avertissement

ou une mise en garde. Ce symbole

peut être combiné à d'autres symboles ou pictogrammes.

• AVERTISSEMENT - LISEZ LE

MANUEL DE L'UTILISATEUR

Lisez le manuel de l'utilisateur et suivez tous les avertissements et consignes de sécurité. Vous pourriez à

défaut entraîner des blessures graves

pour vous ou d'autres personnes

• PORTEZ DES PROTECTIONS

(TÊTE, YEUX ET OREILLES)

AVERTISSEMENT: les objets pro-

jetés et les bruits forts peuvent

endommager la vue et l’ouïe. Portez

une visière de norme ANSI Z87.11989 et des protège-oreilles pendant

l'utilisation. la chute d’objets peut

causer des blessures graves à la

tête. Pr

l'utilisation de l'appareil.

otégez-vous la tête pendant

SYMBOLE SIGNIFICATION

• AVERTISSEMENT - Portez des

gants pour vous protéger les mains.

• AVERTISSEMENT - Portez des

chaussures de sécurité pour protéger

vos pieds.

• AVERTISSEMENT - Ne pas utiliser la

machine quard il pleut.

21 22

Page 23

RÈGLES DE SÉCURITÉ

FAMILIARISEZ-VOUS AVEC VOTRE APPAREIL

DISTRIBUTEUR SUPÉRIEUR

VIS SUPÉRIEURES DE

SSÛRETÉ DE DISTRIBUTEUR

INTERRUPTEUR

ON-OFF

ROUE(R)

COUVERTURES

DE ROUE

INTERRUPTEUR

DE PROTECTION

DE SURCHARGE

BOUTON SUPÉRIEUR

DE DISTRIBUTEUR

DESCENDEUR DE DÉCHARGE

ROUE(L)

JAMBE(R)

JAMBE(L)

Page 24

ASSEMBLAGE

LISTE PARTIELLE DES PIÈCES

Assemblez les pièces suivantes conformément aux

uctions des pages qui suivent.

instr

• Assemblage du magasin

• Connexion du tube d'assemblage

Clé Hexagonale

•

• Jeu de 5 Vis de Sécurité M5 x 15

• 2 Goupilles fendues

• 2 Roues

• 2 Rondelles Plates 12mm

• 2 Vis Hexagonales M8 x 40

• 2 rondelles Plates 8 mm

• 2 Rondelles bloquante 8 mm

• 2 Capots de Roue

COMMENT ASSEMBLER VOTRE DÉFIBREUR (FIG. 3)

1. Poussez la section à large diamètre de l'essieu dans le

tube d'essieu et fixez l'essieu en position au moyen des

vis hexagonales M8

par côté )

2. Poussez la roue et la rondelle en étoile de 12 mm sur

l'essieu.

3. Passez la goupille fendue à travers le trou situé à l'ex-

trémité de l'essieu et rabattez ses extr mit s au moyen

d'une paire de pinces.

MAGASIN (Fig. 4) Placez le magasin au sommet du tube

de remplissage et alignez les trous de fixation.

Assurez la fixation au moyen du jeu de vis de sécurité.

X 40 etédes rondelles en étoile. (2

Fig. 3

Fig. 4

INSTRUCTIONS D’UTILISATION

Lisez et comprenez

ATTENTION:

instructions de sécurité contenues dans ce

manuel d'utilisateur avant d'utiliser votre

Défibreur. Le non-respect de ces instructions

rait entraîner des accidents tels que l'in

pour

cendie, l'électrocution ou des blessures corporelles sérieuses.

1. Connectez le Défibreur à une prise de courant

adéquate.

2. Pour mettre en route et arrêter le Défibreur, appuyez

suré à l'interrupteur situé à l'arriére du moteur (Fig. 5)

PROTECTION DE SURCHARGE ET BLOQUAGE

MOTEUR

En cas de surcharge de la machine l'interrupteur de protection de sur

er commencez tout d'abor

r

mar

et débranchez le fil d'alimentation.

Desserrez le bouton de capot et retirez l'ensemble du

couver

rage dans la chambr

vercle supérieur était coincé et ne pouvait pas être

cle supérieur

charge peut arrêter le moteur. Pour redé-

d par éteindr

, puis retirez tout débris formant bour-

e de coupe. Si l'ensemble du cou

bien toutes les

e la machine

-

INTERRUPTEUR

-

INTERRUPTEUR

DE PROTECTION

DE SURCHARGE

Fig. 5

enlevé, faites tourner le coupeur en V en introduisant une

pièce de bois à travers la descente ar

ner le coupeur en V per

supérieur afin de fair

ainsi de retirer l'ensemble du couvercle sup rieur.

Réamor

5).

cer l'interrupteur de protection de surcharge (Fig.

e tour

ON-OFF

rière du magasin

mettant

23

Page 25

INSTRUCTIONS D’UTILISATION

FIXATION DU SAC À COMPOSTE Placez un sac à

ordures à forte résistance en utilisant la sangle de fixation

de sac à composte. (Fig. 6)

DESCENTE AVANT DU MAGASIN SUPÉRIEUR La large

descente avant de la par

conçue afin de recevoir des feuilles et des petits déchets

de jardin. Le broyage et la mise en composte sont réalisés par aspiration naturelle des débris à travers la chambre de coupe. Ne surchargez pas et n'introduisez pas de

matières détrempées ou mouillées dans le Défibreur car

cela pourrait obstruer la chambre de coupe et la

descente de déchargement. (Fig. 7).

DESCENTE ARRIÈRE DU MAGASIN SUPÉRIEUR La

descente arrière plus petite du magasin supérieur peut

r

ecevoir des déchets de jardin de taille moyenne ou large

taille. Le broyage et

déchiquetage sont réalisés de la même façon que par la

descente avant. Si vous désirez un déchiquetage plus fin

que celui réalisé précédemment, rechargez les copeaux

dans la descente jusqu'à ce que le r sultat voulu soit

obtenu. (Fig. 8).

Ne chargez pas les deux descentes du magasin

supérieur avec des grosses branches.

DESCENTES LATÉRALES Les descentes allongées

situées à l'arrière de la machine sont conçues spécialement pour recevoir des débris de jardin plus importants

et des branches allant jusqu' à 38mm de diamètre.

IMPORTANT: Lorsque vous chargez de longs et gros

matériaux, contrôlez la vitesse de chargement en

retenant les matériaux afin de ne pas coincer ou de faire

forcer le moteur. (Fig. 9)

tie supérieure du magasin est

Fig. 6

Fig. 7

En aucune circon

ATTENTION:

devez introduire vos mains dans les descentes

pendant que la machine est en route. Il n'est

pas nécessair

débris étant donné l'action de succion naturelle

du Défibreur.

DEBALLAGE

ez avec précaution toutes les pièces contenues

Retir

1.

dans l'emballage.

2. Ne jetez aucun élément tant que vous ne les avez pas

tous identifiés au moyen de la liste de pièces.

Si toutes les pièces sont présentes pr

3.

l'assemblage.

S'il vous manque une pièce, contactez le vendeur

4.

chez qui vous avez acheté l'appar

d'assembler votre Défibreur.

e de for

stance vous ne

cer le chargement des

oc dez à

eil avant de tenter

-

Fig. 8

Fig. 9

24

Page 26

INSTRUCTIONS D’UTILISATION

BÂTON MATÉRIEL DE POUSSÉE

Bâton matériel de poussée d'utilisateur fourni pour

pousser le matériel restant dans l'ouverture de distributeur. N'EMPLOYEZ PAS HANDS.(Fig. 10)

MAINTENANCE

Votre Défibreur a été con u afin de ne nécessiter que peu

d'entretien, comprenant les nettoyages de routine et les

vérifications. Le moteur du Défibreur ne réclame aucun

entretien et ne nécessite aucune attention particuliére.

Pour obtenir les meilleurs résultats, les lames devront

être maintenues parfaitement aiguisées. Le pouvoir

coupant des lames diminue grandement lorsqu'elles sont

émoussées. Le Défibreur aura tendance à déchirer plutôt

que de couper lorsque les lames sont émoussées.

Lorsque cela se produit, retournez les lames à double

tranchant ou remplacez les lames immédiatement.

Fig. 10

Avant de com-

ATTENTION:

tien éteignez la machine et débranchez le fil

d'alimentation.

ENTRETIEN DU COUPEUR EN V

1. Eteignez la machine et débranchez le fil d'alimentation

et assurez vous que toutes les parties mobiles sont

complètement arrêtées.

2. Portez des gants lorsque vous entreprenez tout entre-

tien sur les lames de coupe.

BLOQUAGE Si les lames venaient à se coincer, tournez

le bouton situé sous le moteur. Si vous ne pouvez pas

donner un peu de jeu aux lames reportez-vous aux

instructions de démontage (élément 1) et dégager ce qui

obstrue.

DÉMONTAGE

1. Desserrez les boutons de capot et retirez l'assem-

blage du couvercle supérieur.

2. Faites tourner la base de coupe dans le sens inverse

des aiguilles d'une montre et placez une pièce de bois

entre la base de coupe et la paroi de la chambre de

coupe afin de coincer la base de coupe. (Fig. 11)

3. Retirez l'écrou de retenue central en le tournant dans

le sens nverse des aiguilles d'une montre au moyen

d'une clé de 17 mm.

4. Retirez la rondelle carrée, du r ceptacle carré, du

mencer tout entre-

Fig. 11

Fig. 12

coupeur en V afin de découvrir la base de coupe.

ENTRETIEN DES LAMES DE COUPE

Pour vérifier ou changer les lames de coupe à double

tranchant il n'est pas nécessaire de retirer la base de

coupe. Pour les retirer dévissez simplement les écrous

prisonniers à l'aide de la clé hexagonale de 6 mm fournie

avec la machine et tournez les à 180. Ces lames sont à

double tranchant et peuvent êtr

face. Lorsqu'elles sont émoussées sur les deux côtés

changez-les et assur

ment.

25

ez-vous qu'elles sont fixées fer

e utilisées sur chaque

me

-

Page 27

MAINTENANCE

ASSEMBLAGE Procédez de la façon inverse utilisée

pour le démontage mais en vérifiant soigneusement

chaque élément. Assurez-vous que la base de coupe est

assemblée avec les plateaux racleurs dirigés vers le

moteur et que la rondelle bloquante est située sous

l'écrou central de fixation. (Fig.12)

Avant de replacer l'ensemble du couvercle supérieur

assurez-vous que le cooupeur en V est positionné ainsi

qu'il est montré sur la Fig. 13. Replacez l'ensemble du

couvercle supérieur et fixez fermiiment les boutons de

capot. Si le bouton de capot n'est pas serré fermement,

le moteur ne démarrera pas étant donné que l'interrupteur de fermeture ne sera pas activé.

NETTOYAGE Après utilisation, essuyez toujours

l'extérieur du Défibr

matiéres à l'aide d'un chiffon humide. Nettoyez l'intérieur

de la chambre de coupe et retirez tout débris. N'aspergez

pas au jet.

IMPORTANT: Avant de replacer l'ensemble du couvercle

supérieur assurez-vous que le coupeur en V est positionné ainsi qu'il est montr sur la (Fig. 13).

Replacez l'ensemble du couvercle supérieur avec le

bouton écrou de couvercle supérieur et assurez-vous

qu'il est bien serré. Si le bouton écrou du couvercle

supérieur n'est pas serré fermement, le moteur ne

démarrera pas étant donné que l'interrupteur de

fermeture ne sera pas activé.

eur pour retirer tout dépôt de

Fig. 13

SPÉCIFICATIONS

MODELÈ NO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MTD1400K

Pouissance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120V~, 60Hz, 14Amp

Taille du Magasin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394x270x200mm (15-1/2”x10-5/8”x7-7/8”)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 300 min

itesse à V

V

Poids Net. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Lbs (35 Kg)

ide

-1

/RPM

26

Page 28

LISTE DES PIÈCES

3939

4

545

4

444

1313

5151

5757

5656

6666

6767

6868

4040

1616

1616

1616

1

818

1010

1515

1

818

5252

4646

4747

4848

5353

6

161

6464

7070

7171

2525

2222

2020

1818

1919

2

121

1212

1111

1414

6262

2424

55

6969

6565

6060

5959

5858

5050

4343

4141

3535

3

737

1717

99

44

66

77

77

7

7

1313

5454

6363

2323

2626

5555

4949

4

242

3636

3838

3434

1818

88

55

33

33

22

22

11

4141

1313

5

5

2727

2828

2929

3030

3131

3232

3

333

Référence

6266-200103

6200-200101

6134-200101

6024-200101

6WSB-08

6014-200101

6STBBM05-15

6270-200111

6263-200102

6158-200101

6134-200102

6SDABB04-20

6WFZ-08

6CE-06

6SDAZ-04-10

6WFZ-04

6263-200101

6NAZ-04

6WSB-04

6262-200106

6SDAZ-05-55

6059-200101

6NAZ-05

6SXDZ-10-35

Description

DISTRIBUTEUR SUPÉRIEUR

VIS

BOUTON

RESSORT DE RESTRAINNIG

RONDELLE À RESSORT

RONDELLE

VIS

CORPS

PLAT DE LA POUSSIÈRE

BRIDE DE COUPEUR

BOUTON

VIS

RONDELLE

ANNEAU DE E

VIS

RONDELLE

PLAT DE LA POUSSIÈRE

ECROU

RONDELLE À RESSORT

COUVERTURE RETENANTE

VIS

TUBE DE PARENTHÈSE

ECROU

VIS

Référence

6207-200102

6036-200101

6262-200101

6022-200001

6SDAZ-04-08

6262-200001

6010-200004

6010-200005

6099-200103

6SDABB04-14

6043-840001

6WFZ-06

6WSB-10

6158-200002

6156-200001

6250-200003

6267-200001

6200-200002

6250-200001

6268-200101

6124-200101

6200-200001

6WDB-08

6200-200102

Description

BRIDE DE PARENTHÈSE

COMMUTEZ LE SUPPORT

COMMUTEZ LA COUVERTURE

COUPE-HORSDE COMMUTATEUR

VIS

COMMUTEZ LA COUVERTURE

FIL D'INTERAL I

FIL D'INTERAL II

MOTEUR ASS'Y

VIS

BRIDE DE CORDE

RONDELLE

RONDELLE À RESSORT

BRIDE DE COUPEUR

BUSH CARRÉ

V-COUPEUR

V- BASE DE COUPEUR

VIS M10x10

COUPEUR (LAME)

BASE DE COUPEUR

COUPEUR BUSH

VIS M8x18

RONDELLE À RESSORT

VIS

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

Description

VIS

COUVERTURE DE MOTEUR

FIL D'INTERAL

THERMOSTAT

SUR/OUTRE DE COMMUTEZ

GARDE DE CORDE

PLAT

CORDON D'ALIMEETATION

AXE DE STRENGTEN

ECROU

GARNITURE D'ARMATURE

AXE DE ROUE

SUPPORT GAUCHE

TUBE SE RELIANT

VIS

SUPPORT DROIT

VIS

ROUE

RONDELLE

GOUPILLE

COUVERTURE DE ROUE

VIS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

N˚

37

38

39

40

41

42

43

44

45

46

47

48

25

26

27

28

29

30

31

32

33

34

35

36

N˚

6SDAZ-06-12

6086-200104

6010-200006

6272-200002

6022-200002

6199-200002

6100-200101

6011-200005

6111-200101

6NAZ-08

6027-200101

6111-200102

6004-200104

6087-200102

6SRCB-08-16

6004-200103

6SRCB-08-40

6228-200013

6WFZ-12

6PB-26

6067-200007

6SJABB03-10

71 CLÉ6042-200001

72 BÂTON DE POUSSÉE DE MARTERIAL6188-200402

73 PRISE DE SAC DE STARP6280-200001

RéférenceN˚

27 28

Page 29

REMARQUE

Page 30

GARANTIE LIMITÉE DU FABRICANT POUR:

La garantie limitée énoncée ci-après est accordée par MTD

LLC (« MTD ») et concerne les marchandises neuves achetées

et utilisées aux États-Unis, ainsi que dans leurs possessions et

territoires.

MTD garantit ce produit contre tout vice de matière ou de façon

pendant une période de deux (2) ans à compter de la date

d’achat initiale et elle se réserve le choix de réparer ou de

remplacer, à titre gratuit, toute pièce présentant un vice de

matière ou de façon. Cette garantie limitée nes’ appliquera que

dans la mesure où le produit aura été utilisé et entretenu

mément au Guide de l’utilisateur fourni avec le produit et

confor

n’aura pas fait l’objet d’un usage inadéquat, abusif, commercial

ou négligent, d’un accident, d’un entretien inadéquat, d’une

modification, de vandalisme, d’un vol, d’un incendie, de dégâts

d’eau ou d’un endommagement résultant d’un autre péril ou

d’un désastre naturel. Les dommages résultats de l’installation

ou de l’utilisation de tout accessoire ou équipement non

approuvé par MTD pour une utilisation avec le(s) produit(s)

couvert(s) par le présent guide annuleront la garantie et ce qui

concerne les dommages qui en résulteraient éventuellement.La

présente garantie est limitée à quatre-vingt-dix (90) jours à

compter de la date d’achat au détail initiale pour tout produit

MTD utilisé à des fins locatives ou commerciales, ou toute

utilisation produisant des revenus.

POUR L’ENTRETIEN-DÉPANNAGE : l’Entretien-dépannage

au titre de la garantie est disponible, SUR PRÉSENTATION DE

PREUVE D’ACHAT, AUPRÈS DU DISTRIBUTEUR AGRÉÉ

LOCAL. Pour obtenir le nom du distributeur agréé local,

consulter les Pages Jaunes ou se mettre en rapport avec le

Service après-vente de MTD LLC. en appelant le 1-866-7479816 ou en écrivant au P.O. Box 361131, Cleveland OH

44136-0019 ou en appelant le 1-800-668-1238 au Canada.

Aucun pr

préalable du ser

accepté.

La garantie limitée n’offre aucune couverture dans les cas

suivants :

A. Lame

B. MTD n’accorde aucune garantie pour les produits vendus

MTD se réserve la droit de modifier ou d’améliorer la

conception de tout produit MTD sans assumer l’obligation de

modifier tout produit d’une fabrication plus ancienne.

oduit r

ou exportés des États-Unis, de leurs possessions et

es, exception faite en ce qui concer

ritoir

ter

vendus par l’inter

distribution à l’exportation.

né à l’usine sans per

etour

vice après-vente de MTD LLC ne sera

médiaire de ses canaux agréés de

mission écrite

ne les pr

oduits

Aucune garantie implicite, y compris toute garantie de

valeur marchande ou d’adaptation à une fin particulière, ne

s’applique après la période applicable de garantie expresse

écrite ci-dessus concernant les pièces qui sont identifiées.

Aucune autre garantie ou caution expresse, écrite ou orale,

à l’exception de celle mentionnée ci-dessus, accordée par

toute personne ou entité, y compris tout distributeur ou