Page 1

Form No. 3357-361 Rev. A

Safety • Assembly • Operation • Tips & Techniques • Maintenance • Troubleshooting • Parts Lists • Warranty

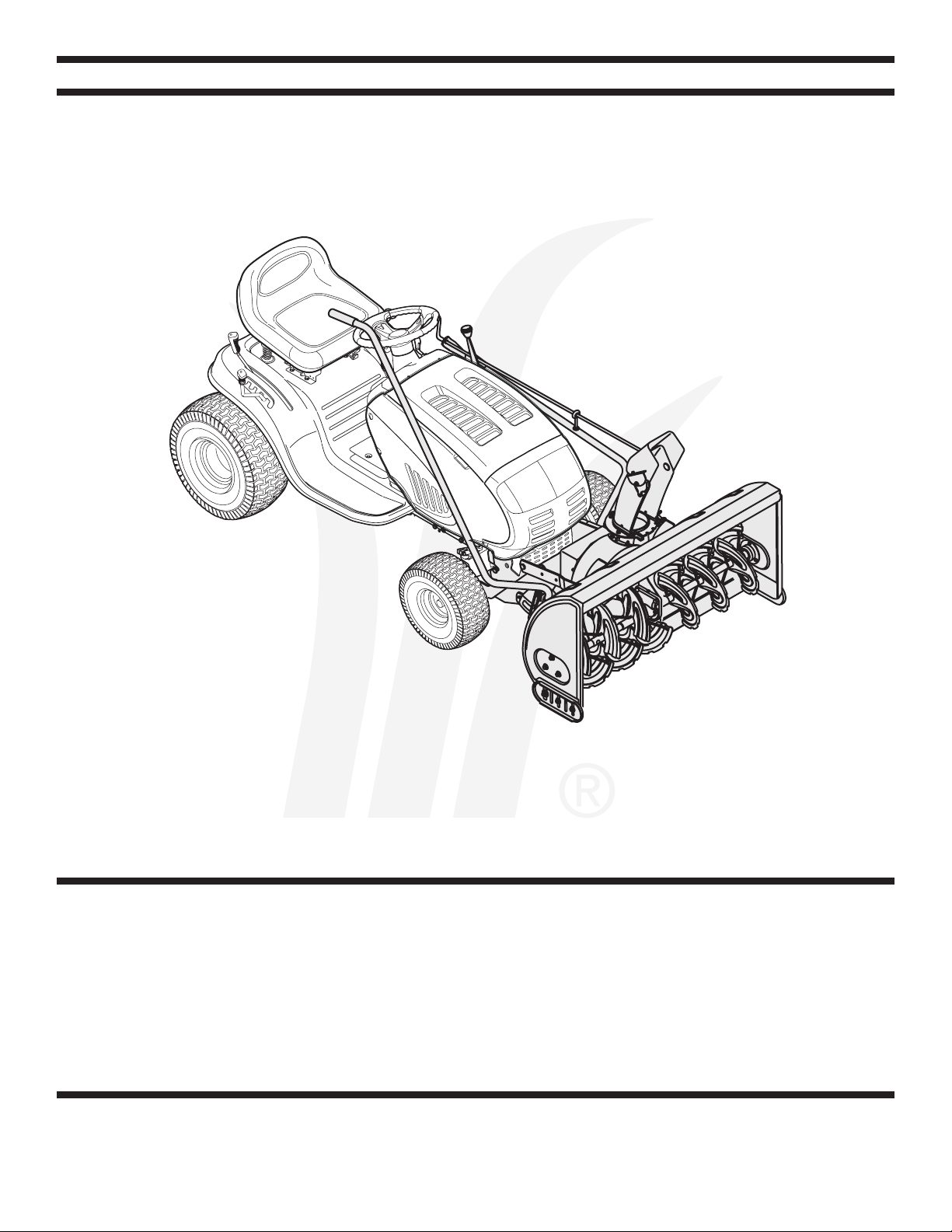

OPERATOR’S MANUAL

Model

OEM-190-032

190-032-101

42-inch Two-Stage Snow Thrower Attachment

For FastAttach™ Compatible Lawn Tractors & Garden Tractors

IMPORTANT

READ SAFETY RULES AND INSTRUCTIONS CAREFULLY BEFORE OPERATION

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland,

Ohio 44136-0019.

FORM NO. 769-01933C

PRINTED IN U.S.A.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

3/8/2006

Page 2

This Operator’s Manual is an important part of your snow thrower attachment. It will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

TABLE OF CONTENTS

1. Rider Model Identification ................................ Page 3

2. Snow Thrower Attachment Safety ................... Page 4-5

3. Carton Contents .............................................. Page 6-7

4. Assembly Models 600-649 & 800 Series ........ Page 8-13

5. Assembly All Model 700 Series ....................... Page 14-15

6. Attaching Controls ........................................... Page 16

7. Attaching Auger Housing ................................ Page 17

8. Routing Upper & Lower Drive Belts ................. Page 18-19

9. Controls ........................................................... Page 20

10.Operation ........................................................ Page 21

11. Adjustment

12. Maintenance ..................................................Page 23

13. Parts List ........................................................Page 24-29

13. Notes ............................................................. Page 30-31

Warranty ..........................................................Page 32

s ...................................................Page 22

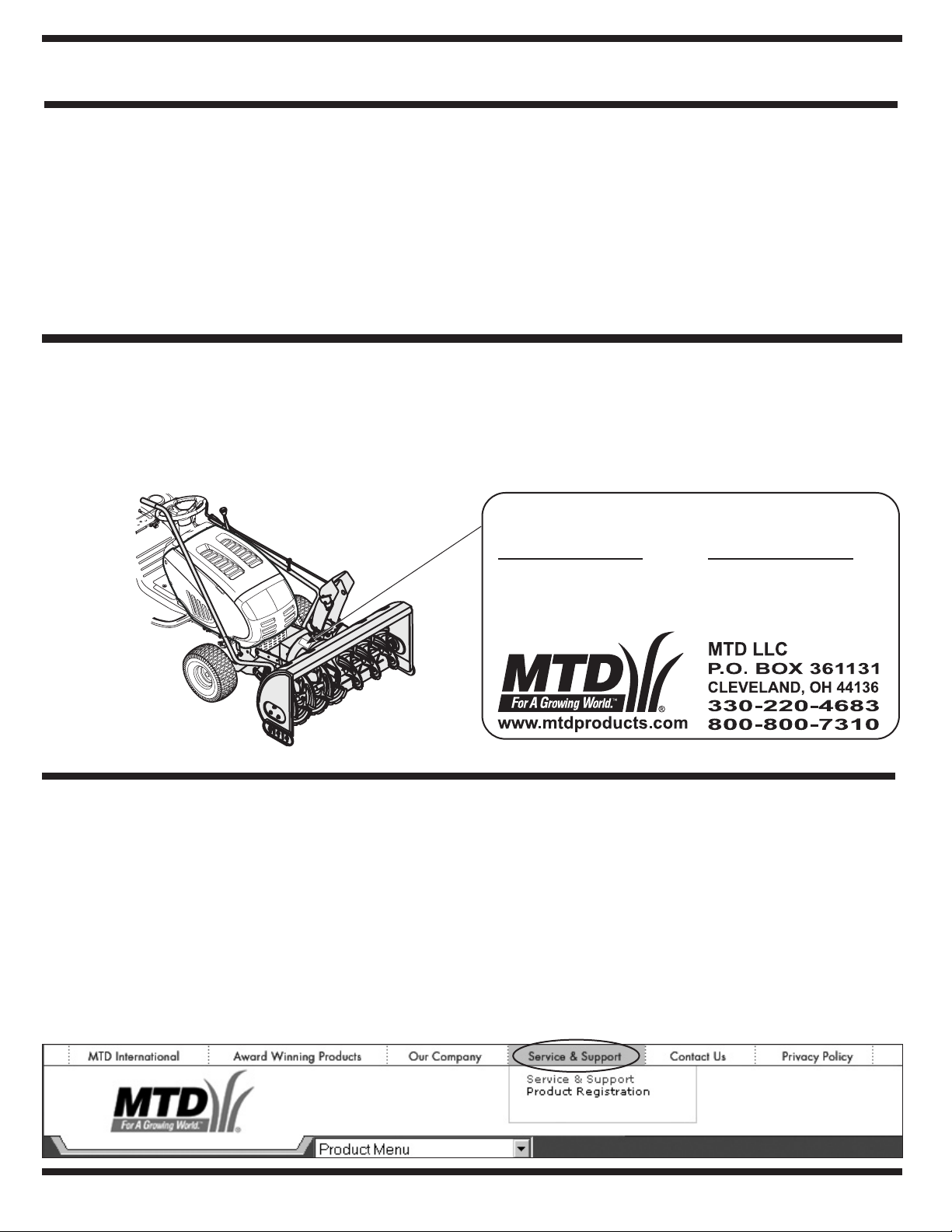

Finding and Recording Model Number

BEFORE YOU START ASSEMBLING YOUR NEW EQUIPMENT,

please locate the model plate and copy the information from it in this Operator’s Manual for future reference. The information on

the model plate is very important if you need help from our Customer Support Department or your authorized dealer. You can

locate it by looking on the top rear portion of the auger housing:

Model Number Serial Number

*Locate the model plate on your snow thrower attachment and copy the information from it in the space provided above for future reference.

Customer Support

Please do

purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of this

unit, you can seek help from the experts. Choose from the options below:

• Visit www.mtdproducts.com. Click on the Service & Support menu option.

• Phone a Customer Support Representative at 1-800-800-7310.

• Please have your unit’s model number and serial number ready when you call. See above to locate this information. You will

be asked to enter the serial number in order to process your call.

NOT

return the unit to the retailer from which it was

2

Page 3

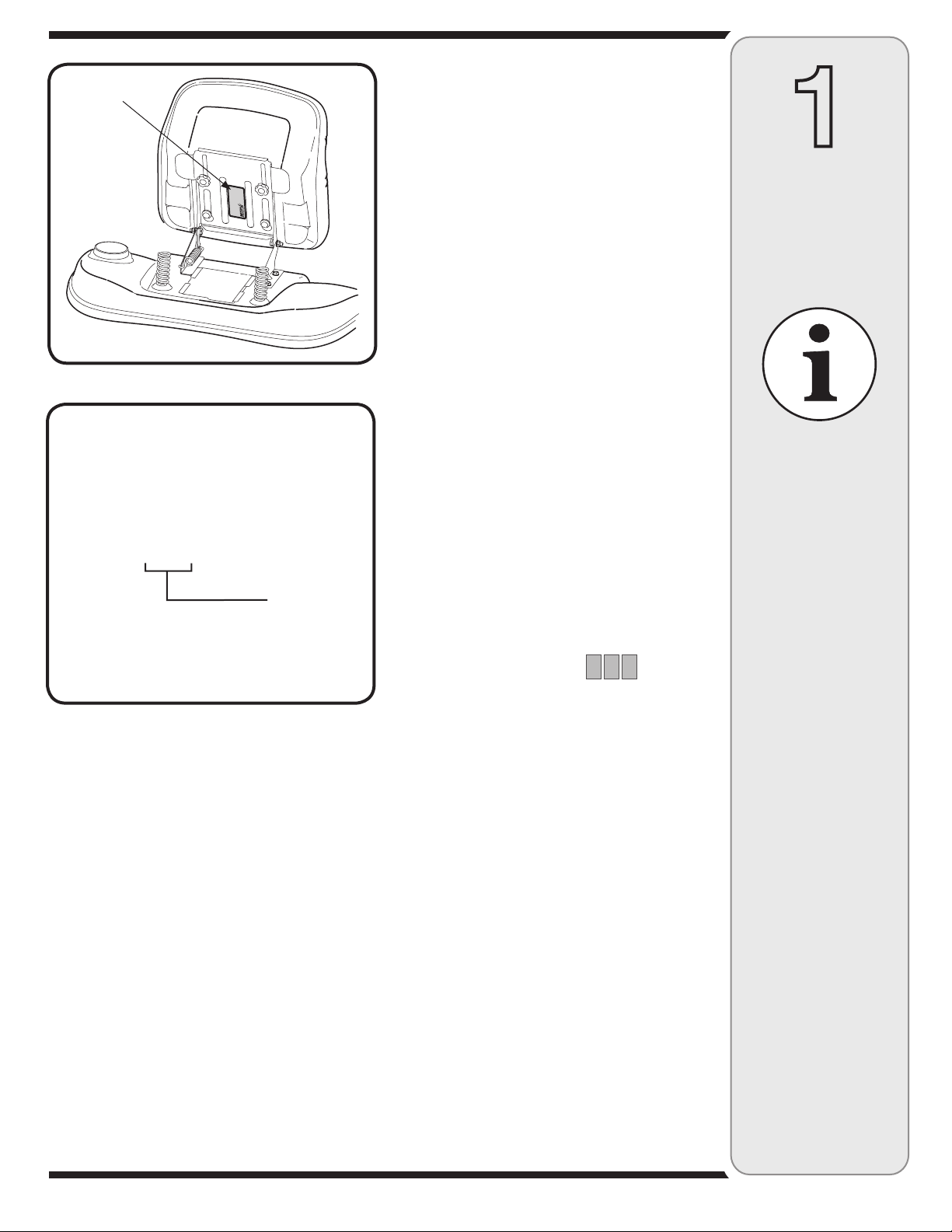

Model Plate

FastAttach™ Snow

Thrower Attachment

Figure 1

Sample Model Number

1 3 A M

7 9 0

G 0 0 0

Indicates Model Series 700

NOTE: This Operator’s Manual covers several models.

1

Snow thrower hook-up instructions vary by model. Not

1

6

3

0

3

13

8

1

1

4

6

4

1

3

4

6

H

7

-

-

O

3

C

,

0

0

L

D

X

2

N

L

0

O

A

2

8

B

L

-

-

E

D

.

V

0

T

0

O

E

3

.

L

0

M

P

C

3

8

m

s

t

o

c

c

.

u

d

o

r

p

d

t

m

w

.

w

w

all features discussed in this manual are applicable to all

snow thrower attachments.

To The Owner

Rider Model

Identification

Model OEM-190-032 42-inch two-stage snow thrower

attachment is designed for use on FastAttach™ Compatible

Lawn Tractors and Garden Tractors ONLY. It will NOT fit nor

operate properly or safely on ANY other tractor.

Determine The Model

of Your Rider

Since this manual is designed for installation of your new

snow thrower attachment on several different rider units,

it is important for you to determine which model of rider

you have. Therefore you will know which set of instructions in the following pages to follow.

To determine which model of rider you have, you will

need to locate the rider’s model plate, located under the

seat. Simply flip the seat up and locate the model plate,

which will consist of an 11 digit/letter model number

and a serial number. For ease in this installation and

for future use, copy your rider’s model number & serial

number below now:

and RIGHT indicate the

the tractor when facing

forward in the operator’s

position. Reference to

the FRONT indicates the

grille end; to the REAR,

the rear end of the rider.

NOTE:

References to LEFT

left and right sides of

Figure

Rider Model Number:__ __ __ __ __ __ __ __ __ __ __

2

Rider Serial Number:_________________________

th

The 5

, 6th & 7th numbers from the left in your model

number determine your rider’s model series. See Figure 2.

When you fill in your model number in the space above,

the actual model series number should fall into the gray

shaded area.

Now that you have determined what model rider you

are attaching this snow thrower attachment to, follow

the instructions in the following pages according to your

model of rider. You can locate which instructions apply to

your model of rider by the gray-shaded area in the border

of each page. For instance, an 809 or 80R would signify

that you should follow the instructions for Model Series

800.

3

Page 4

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of California to cause cancer and

birth defects or other reproductive harm.

2

Safe

Operation

Practices

WARNING

This symbol points

out important safety

instructions which, if

not followed, could

endanger the personal

safety and/or property

of yourself and others.

Read and follow all

instructions in this

manual before attempting to operate

this machine. Failure

to comply with these

instructions may result

in personal injury. When

you see this symbol.

HEED ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without proper

instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

1. Thoroughly inspect the area where the equipment is to be

used. Remove all doormats, newspapers, sleds, boards,

wires and other foreign objects, which could be tripped over

or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during operation

and while performing an adjustment or repair to protect your

eyes. Thrown objects which ricochet can cause serious

injury to the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing, which could become entangled in moving

parts. Wear footwear which will improve footing on slippery

surfaces.

4. Use a grounded three-wire extension cord and receptacle

for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all control levers before starting the engine.

7. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator’s manual.

8. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

9. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely flammable

and the vapors are explosive. Serious personal injury can

occur when gasoline is spilled on yourself or your clothes,

which can ignite. Wash your skin and change clothes

immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is hot

or running.

e. Allow engine to cool at least two minutes before refuel

ing.

f. Never over fill fuel tank. Fill tank to no more than ½ inch

below bottom of filler neck to provide space for fuel

expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and equip

ment. Move machine to another area. Wait 5 minutes

before starting the engine.

i. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light (e.g. furnace,

water heater, space heater, clothes dryer etc.).

j. Allow machine to cool at least 5 minutes before storing.

Preparation

-

-

4

Page 5

Operation

1. Do not put hands or feet near rotating parts, in the

auger/impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/ impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine unsafe

and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged chute assembly.

Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless and

deadly gas.

6. Do not operate machine while under the influence of alcohol

or drugs.

7. Muffler and engine become hot and can cause a burn. Do

not touch.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while operat

ing on slopes.

10. Plan your snow-throwing pattern to avoid discharge towards

windows, walls, cars etc. Thus, avoiding possible property

damage or personal injury caused by a ricochet.

11. Never direct discharge at children, bystanders and pets or

allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

14. Disengage power to the auger/impeller when transporting or

not in use.

15. Never operate machine at high transport speeds on slippery

surfaces. Look down and behind and use care when

backing up.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire and ground it against

the engine. Inspect thoroughly for damage. Repair any

damage before starting and operating.

17. Disengage all control levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the chute assembly, making any adjustments, or

inspections.

18. Never put your hand in the discharge or collector openings.

Always use the clean-out tool provided to unclog the dis

charge opening. Do not unclog chute assembly while engine

is running. Shut off engine and remain behind handles until

all moving parts have stopped before unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. If situations occur which are not covered in this manual,

use care and good judgment. Contact your dealer or call

(800) 800-7310 for assistance and the name of your nearest

servicing dealer..

-

Maintenance & Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and adjust

ment sections of this manual.

2. Before cleaning, repairing, or inspecting machine disen

gage all control levers and stop the engine. Wait until the

auger/impeller come to a complete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original equipment

manufacturer’s (OEM) parts only. “Use of parts which do

not meet the original equipment specifications may lead to

improper performance and compromise safety ! ”

6. Check controls periodically to verify they engage and

disengage properly and adjust, if necessary. Refer to the

adjustment section in this operator’s manual for instructions.

7. Maintain or replace safety and instruction labels, as neces

sary.

8. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator’s manual for proper instructions

on off-season storage.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and may

include the following emission control systems: Engine Modifica

tion (EM) and Three Way Catalyst (TWC) if so equipped.

Your Responsibility

Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in this manual

and on the machine.

-

-

2

Safe

Operation

Practices

WARNING

-

This symbol points

out important safety

instructions, which if

not followed, could

endanger the personal

safety and/or property

of yourself and others.

Read and follow all

instructions in this manual before attempting to

operate this machine.

Failure to comply with

these instructions may

result in personal injury.

When you see this

-

symbol.

HEED IT’S WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

5

Page 6

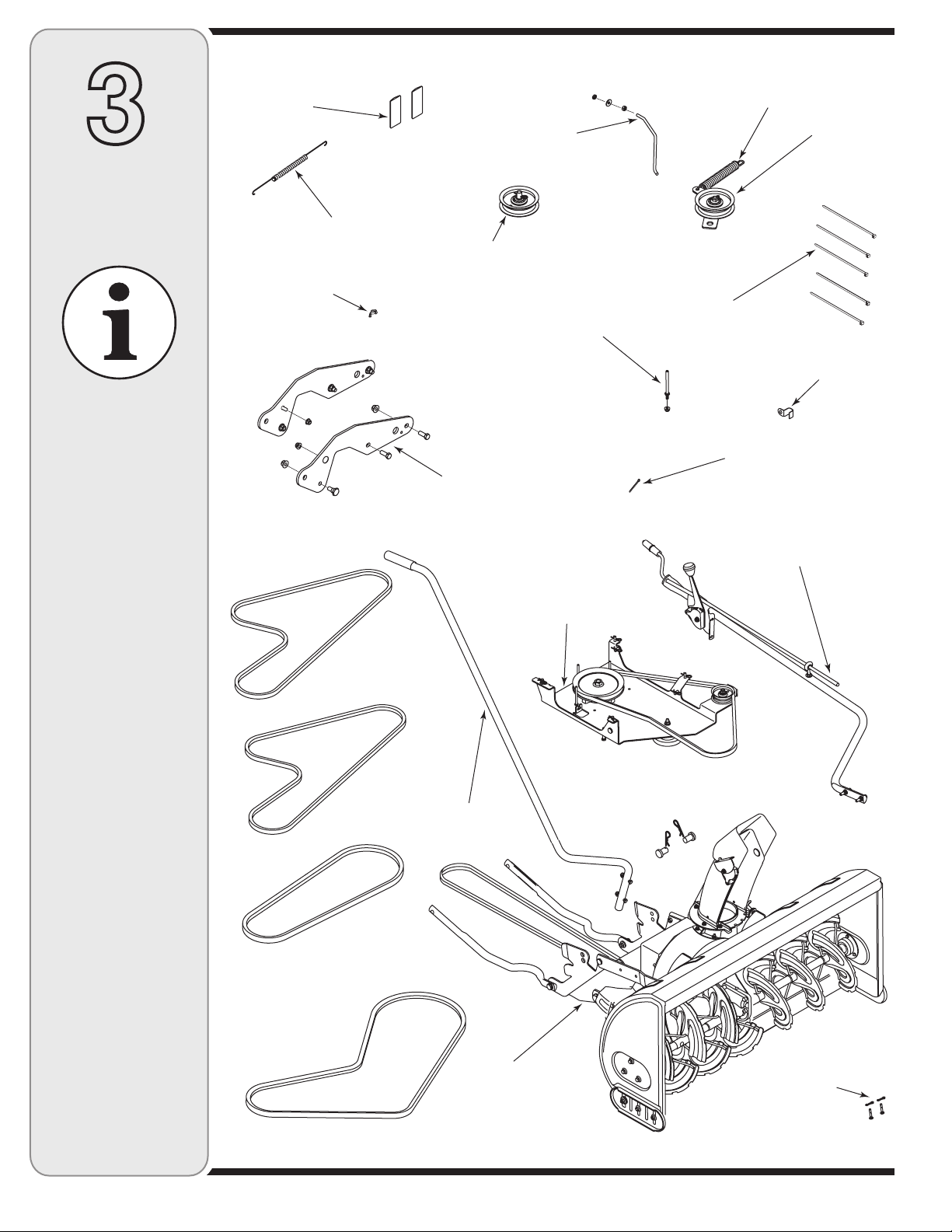

3

Carton

Self-Adhesive

Reflectors

Extension Spring

Idler Assembly

Belt Keeper & Hardware

Contents

If you are missing

any parts, please

do not contact the

retailer where you

purchased this unit,

call MTD directly at

1-330-220-4MTD or

toll free at

1-800-800-7310.

Extension Spring

Wing Nut

Upper V-Belt

(754-0490)

Idler Pulley & Pin

Belt Keeper

& Hardware

Assembl

& Hardware

y Brackets

Undercarriage Assembly

Cable Ties

Clamp

Cotter Pin

Chute Directional

Support w/ Tilt Lever

& Upper Crank Rod

Upper V-Belt

(754-0481)

Upper V-Belt

(754-0498)

Upper V-Belt

(754-0435)

Lift Handle

Assembl

y

Auger Housing

Assembl

Linkage

y w/

6

k Pins &

Clic

Clevis Pins

Spare Shear Bolts

x Lock Nuts

& He

Page 7

CONTENTS OF CARTON

Before beginning installation, remove all parts from the carton to make sure everything is present. Carton

contents are listed below and shown in Figure 3. Hardware part numbers are shown in parentheses.

• One Auger Housing Assembly w/ Lower V-belt

• One Undercarriage Assembly (w/ Upper V-belt 754-0371A)

• One Idler Assembly w/ Extension Spring (732-0594A)

• One Idler Pulley (756-0627B) and Pin (650-0040) w/ Hair Pin Clip (714-0145)

• One Belt Keeper (747-04135) w/ Bell Washer (736-0270) Jam Nut (712-0298) & Hex Nut (712-3006)

• One Lift Handle Assembly

• One Upper Chute Crank Rod

• One Chute Directional Support w / Tilt Lever

• Five Cable Ties (725-0157)

• Two Spare Shear Pins (738-04124) & Cotter Pins (714-04040)

• One Cotter Pin (714-0507)

• Two Self-adhesive Reflectors (730-3000)

• One Upper V-belt (754-0481)

• One Upper V-belt (754-0435)

• One Upper V-belt (754-0490)

• One Upper V-belt (754-0498)

• Left & Right Assembly Brackets (683-04215 & 683-04214) & Hardware (710-0514 Hex Screw, 712-04065

Flange Nut, 738-0143 Shoulder Screw & 712-04063 Flange Nut)

• Belt Keeper (711-1000) & Flange Lock Nut (712-04063 )

• Wing Nut (712-04100)

• 16mm Clamp (726-0354)

• Extension Spring (732-04237)

• Clevis Pin (711-0332)

• Click Pin (714-0145)

3

Carton

Contents

If you are missing

any parts, please

do not contact the

retailer where you

purchased this unit,

call MTD directly at

1-330-220-4MTD

or toll free at

1-800-800-7310.

7

Page 8

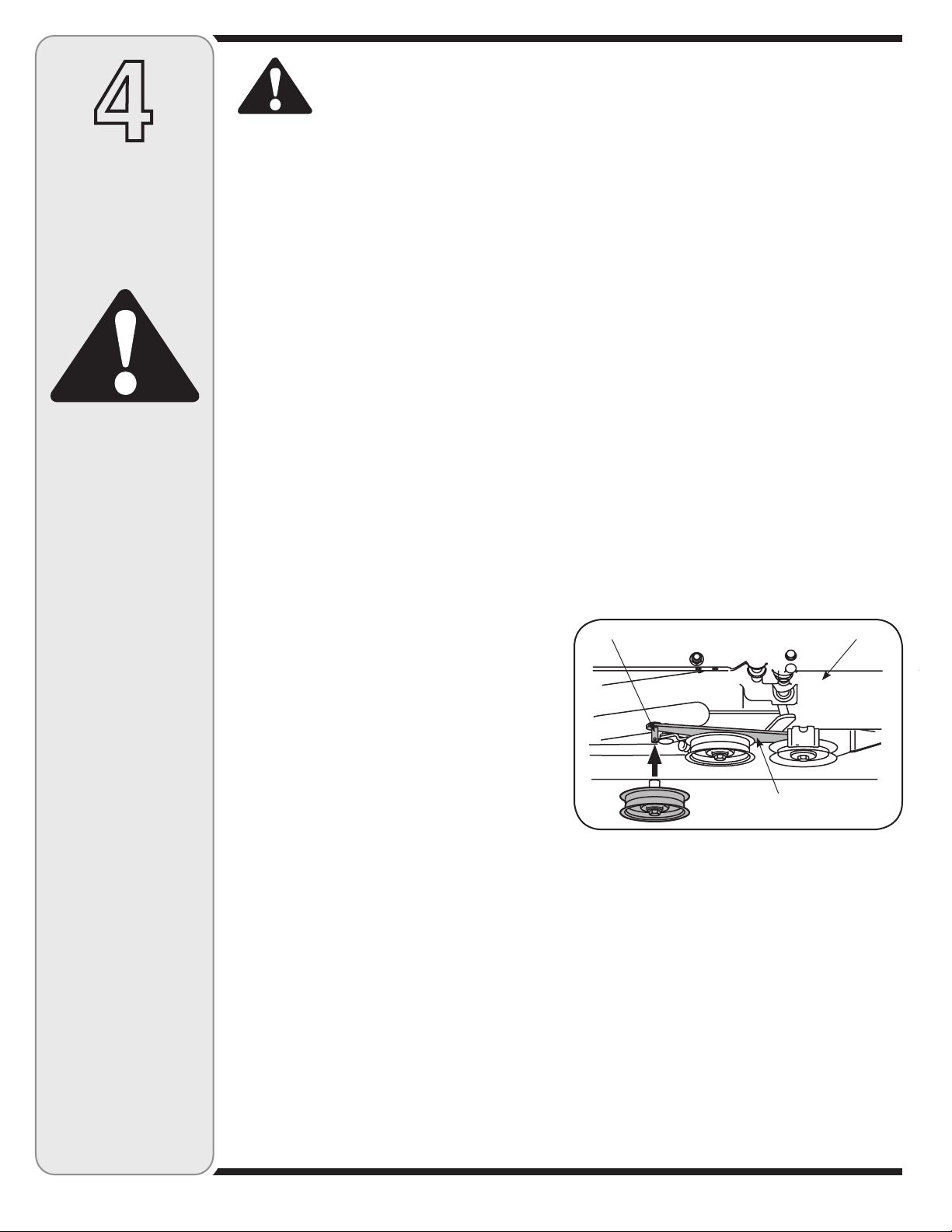

4

WARNING: Before installing attachment, place tractor on a firm and level

surface. Place the PTO in the disengaged (OFF) position, set the parking

brake, shut engine off and remove key

to prevent unintended starting.

Assembly

Model Series

600-649 &

All 800 series.

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

NOTE: References to LEFT and RIGHT indicate the left

and right sides of the tractor when facing forward in the

operator’s position. Reference to the FRONT indicates

the grille end; to the REAR the drawbar end.

IMPORTANT: You must first figure out which model of

rider you are attaching this snow thrower to. Refer to

Determine Your Model of Rider on page 3 of this manual

to determine what model rider you are attempting to

install this attachment to. Then proceed to the applicable

instructions for your model of rider.

Your tractor’s cutting deck, PTO belt and front deck

stabilizer bracket must be removed prior to mounting

the snow thrower attachment. Refer to your tractor’s

Operator’s Manual for detailed instructions. If your

tractor is equipped with any front-end accessory (i.e.

front bumper kit), it must also be removed.

Mounting the

Idler Pulley and Pin

(Manual PTO Tractors equipped with

a 38- or 42-inch deck ONLY)

Frame Mount Dual Idler Style 2004 & Prior

NOTE: If you engage your tractor’s cutting deck by

using your left hand to pivot a lever forward, your tractor

has a Manual PTO. If you engage your tractor’s cutting

deck by pulling outward on a small knob located on the

tractor’s dash, your tractor has an Electric PTO.

The idler pulley and pin (packaged separately, refer to

pages 6-7) must be installed to the PTO engagement

plate of all manual PTO tractors with a dual-belt drive

38- or 42-inch cutting deck. If applicable, proceed as

follows. Otherwise, proceed to Mounting the Under-

carriage Assembly.

Locate the PTO engagement plate beneath your tractor.

See Figure 4.

Note the location of the weld pin on the rear portion of

the PTO engagement plate. This pin is where the deck

brake cable attaches, when operating the tractor with

the cutting deck mounted.

Remove the hair pin clip from the idler pulley and pin

(packaged separately). Refer to pages 6-7.

Position the idler pulley and pin onto the weld pin of the

PTO engagement plate and secure with the hairpin clip

just removed.

NOTE: This Idler pulley must be removed when

remounting the tractor’s cutting deck.

Weld Pin Tractor Frame

PTO Engagement Plate

Figure 4

8

Page 9

Flange Nut, Washer &

Shoulder Spacer

Double-idler Bracket/Front Pulley

Figure 5

Undercarriage

Shoulder Spacer

(Facing Up)

Flat Washer

Flange Nut

Figure 6

3-in. Hex Bolt

Spacers

Shoulder Spacer

(Facing Down)

Reversing the

Idler Assembly Hardware

(Manual PTO Garden Tractors

equipped with a 46-inch deck ONLY)

If you’re mounting this snow thrower attachment to a

tractor equipped with any deck other than a manually

engaged 46-inch, proceed to either:

1. Mounting the Idler Assembly (for tractors equipped

with a 42, 46, 50 & 54-inch deck ONLY) in this

section

2. Mounting the Idler Pulley and Pin (for Manual PTO

tractors equipped with a 38- or 42-inch deck ONLY)

previously in this section, or

3. Mounting the Undercarriage Assembly (all

tractors not mentioned above) on page 12.

These instructions are for mounting this snow thrower

attachment to a GARDEN TRACTOR (Model Series

800) equipped with a Manual PTO and a 46-inch deck.

NOTE: If you own a Manual PTO Lawn Tractor with

a 46-inch deck, you can disregard the following steps;

they are unnecessary. A LAWN TRACTOR is any 600649 Series mower, an 800 Series mower is a GARDEN

TRACTOR. Refer to Determine Your Model of Rider

on page 3 of this manual to determine what model rider

you are attempting to install this attachment to.

1. Remove the flange nut, washer and shoulder

spacer which secures the double-idler bracket to the

undercarriage. See Figure 5.

2. Remove the 3-inch hex bolt from the bottom of the

front pulley, to free it from the undercarriage.

3. Reassemble with the 3-inch hex bolt on top of the

undercarriage and the flange nut securing the pulley

from the bottom. See Figure 6.

IMPORTANT: Components must be reassembled in the

exact order illustrated in Figure 6.

4

Assembly

Model Series

600-649 &

All 800 series.

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Bell Washer

Jam Nut

Figure 7

Mounting the Belt Keeper

(Manual PTO Garden Tractors equipped

with a 46-inch deck ONLY)

The belt keeper and hardware (packaged separately,

refer to page 6-7) must be installed around the engine

pulley of all Manual PTO Garden Tractors with a 46-inch

cutting deck. To do so, proceed as follows:

1. Locate the engine pulley by looking beneath the front

area of your tractor.

2. Secure the belt keeper to the inside of the tractor’s

frame with the hex nut, bell washer and jam nut as

shown in Figure 7.

3. Make certain the cupped portion of the bell washer is

facing IN before tightening the jam nut.

9

Page 10

4

Assembly

Model Series

600-649 &

All 800 series

Cub Cadet

11C & 13C

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Mounting the Idler Assembly

(42, 46, 50, 54 inch Decks

with Electric PTO)

If you’re mounting this snow thrower attachment to a

tractor equipped with any deck other than a 42, 46, 50

or 54-inch deck with electric PTO, proceed to Mounting

the Undercarriage Assembly (all tractors) .

However, if you’re mounting this snow thrower attachment to a tractor equipped with a 42, 46, 50 or 54-inch

deck with electric PTO, proceed as follows:

NOTE: If you engage your tractor’s cutting deck by

using your left hand to pivot a lever forward, your tractor

has a Manual PTO. If you engage your tractor’s cutting

deck by pulling outward on a small knob located on the

tractor’s dash, your tractor has an Electric PTO.

1. Remove the flange nut and washer noted in Figure

8, which secures the double-idler bracket to the

undercarriage. Leave the Shoulder Spacer in place.

2. Attach the idler assembly (packaged separately)

over the hex screw and shoulder spacer on the

surface of the undercarriage. See Figure 8.

3. Fasten the idler bracket to the undercarriage with the

hardware just removed. See Figure 8.

4. Attach one end of the extension spring (732-0594A)

to the hole in the idler assembly just mounted and

the opposite end of the extension spring to the

keeper pin as illustrated in Figure 8.

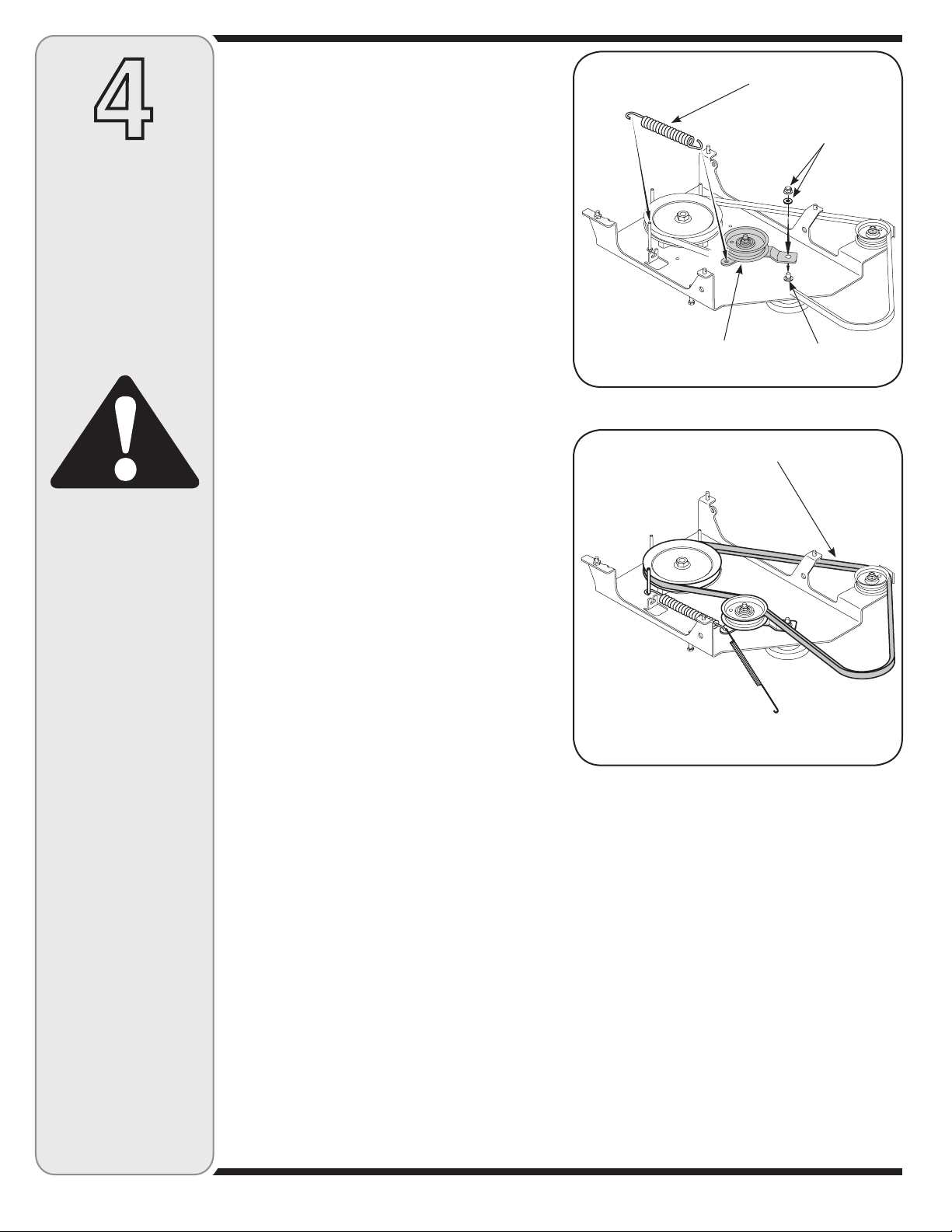

5. Position the upper v-belt (754-0371A) as illustrated

in Figure 9.

NOTE: For a complete detailed diagram of how to route

the upper v-belt, see Routing The Upper Drive Belt

beginning at the top of page 18.

NOTE: Proceed to the top of page 12 for continued

installation instructions for the 600, 800, 11C & 13C

model series.

Idler Bracket & Pulley

Upper V-belt (754-0371A)

Extension Spring

Flange Lock Nut

& Flat Washer

Shoulder Spacer

Figure 8

Figure 9

10

Page 11

PTO Cable

Slotted

Fitting

Threaded Pin

Click Pins

Clevis Pins

Spindle Pulley

Extension Spring

Belt Keeper Pin

Flange Lock

Nut & Washer

Idler Pulley &

Idler Bracket

Figure 10a

V-Belt

Undercarriage Assembly

Figure 10b

Belt Keeper

Pin

V-Belt

Figure 11

Undercarriage Assembly

1. Remove the v-belt (754-0371A), this belt will be

replaced later with another v-belt (754-0498) included

in this carton. Also, remove all of the Clevis Pins and

Click pins as seen in Figure 10b.

2. Remove

out in Figure 10a, leaving the spacer underneath it in

place. Mount the idler pulley (756-0627D) and idler

bracket (783-1291) from the loose parts included in

this carton. Replace the flange lock nut and washer.

3. Locate

spring (Part No. 732-04237, which is .50” wide x 12”

long) packaged with the loose parts in this carton.

See Figure 11 for reference.

NOTE:

embossed on the outside of the belt.

Route the belt around the spindle pulley, inside of

the belt keepers and to the inside of the idler pulley.

The spring will connect to the Idler bracket but you

may install this once the undercarriage is mounted.

Otherwise it could fall off or get in the way in the

following steps. If you wish to connect this later, retain

the spring for later installation. See the Figure 11.

4. Attach the PTO cable to the idler bracket, then fit the

cable into the slotted fitting as seen in Figure 10a

NOTE: The PTO cable should be hanging down under

you tractor after you removed the mowing deck. You

will need to slide the undercarriage unit under your trac

tor in position for which it will be mounted. The slanted

side should be pointed towards the front of your tractor.

Mounting Undercarriage Assembly

Make certain the correct upper drive belt (754-0498) is

installed on the undercarriage assembly. If the appropri

ate belt is not installed, replace it with the correct belt

prior to proceeding with mounting the undercarriage.

IMPORTANT: Make certain that the flat side of the belt

is facing outward as it sits against both the idler pulley

and spindle pulley. This allows the “V” side of the belt to

ride snugly in both pulleys.

1. The undercarriage assembly should be in position

beneath the tractor, since you already connected the

PTO cable in the previous steps.

2. There should already be a threaded pin installed in one

of the mounting holes of the undercarriage assembly. If

not installed, install it now as in Figure 10b.

Lift the undercarriage assembly up, inserting the

weld pins on the assembly up through the aligning

holes found along the tractor’s frame rails. Fasten

with hairpin clips and flat washers removed earlier.

See inset image in Figure 11.

3. Connect the extension spring found in your units

loose parts that was mentioned earlier. This spring

connects to the idler bracket on the undercarriage

assemble and the hole on the rear right-hand snow

thrower mounting bracket. See Figure 11.

4. Attach the lower auger drive belt by routing it around

and through the pulley system as seen in Figure 11

NOTE: Proceed to page 16 for next installation steps.

the flange lock nut and washer as pointed

v-belt part No. 754-0498 and the extension

The V-belt can be identified by the part number

.

.

4

Assembly

Model Series

600-649 &

Cub Cadet 11C

(38 & 42-inch

Decks with

Cable-Drive PTO)

Deck Idler/

Pull Style

2005 & Later

-

WARNING

Before installing

-

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

NOTE:

Proper belt routing

diagrams can be

found on page 18-19

of this manual.

11

Page 12

4

Assembly

Model Series

600-649 &

All 800 series

Cub Cadet

11C & 13C

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Because this snow thrower attachment is compatible

with several model lawn tractors and garden tractors

with either an electric PTO or a manual PTO, four upper

drive belts are included. If you have had any problems

locating the proper upper belts for installation in the

previous steps, use the table below for quick reference.

Refer to the table below to determine which upper drive

belt is applicable to your tractor; non-applicable belts

can be discarded. The v-belt can be identified by the

part number embossed on the outside of the belt.

Upper Drive Belt Reference Chart

Deck Size Electric PTO Manual PTO

54-in. Deck 754-0371A N/A

50-in. Deck 754-0371A 754-0481

46-in. Deck 754-0371A 754-0490

(Garden Tractor)

46-in. Deck 754-0371A 754-0481

(Lawn Tractor)

42-in. Deck 754-0371A 754-0481

(single-belt drive)

42-in. Deck 754-0371A 754-0435

(dual-belt drive)

38-in Deck N/A 754-0435

(dual-belt drive)

NOTE: If you engage your tractor’s cutting deck by

using your left hand to pivot a lever forward, your tractor

has a Manual PTO. If you engage your tractor’s cutting

deck by pulling outward on a small knob located on the

tractor’s dash, your tractor has an Electric PTO.

Mounting The

Undercarriage Assembly

(All 600-649 & 800 Model Series Tractors)

1. Remove and retain the four hairpin clips from the weld

pins found the top side of the undercarriage assembly,

and also the 4 clevis pins with hairpin clips. Retain

this hardware for later installation. See Figure 12

IMPORTANT: Make certain the correct upper drive

belt is installed on the undercarriage assembly prior to

proceeding with mounting the undercarriage. Make sure

that the upper v-belt is routed to the INSIDE of the belt

keeper found on the undercarriage idler pulley and the

keeper pins found around the spindle pulley. Also, make

certain that the flat side of the belt is facing outward.

2. Position the undercarriage assembly beneath the

tractor. For manual PTO units, hook up the PTO

cable as described earlier in this section

3. Move the tractor’s deck lift lever into the lowest notch

on the fender allowing the lift arms to drop. See

Figure 13.

.

.

V-Belt

Click Pins

Belt Keeper

Clevis Pins

Undercarriage Assembly

Figure 12

Deck Lift

Lever

Lift Arm

Figure 13

12

Page 13

Lift Arm

Clevis Pin

Figure 14

Spring Attached

to Idler Pulley

4. Align the holes in the rear of the lift arms with the

holes in the rear of the undercarriage and insert the

clevis pins removed in step 1. Fasten with the hairpin

clips. See Figure 14.

5. Move the tractor’s deck lift lever into the top notch on

the right fender allowing the lift arms and the rear of

the undercarriage assembly to rise.

6. Insert the weldpins found on the top side of the rear

portion of the undercarriage assembly up through the

aligning holes found along the tractor’s frame rail. See

Figure 15.

7. Fasten with the hairpin clips removed in step 1.

8. Repeat the previous two steps on the front portion of

the undercarriage assembly.

9. Connect the extension spring to the tractor’s frame rail

in the hole provided. See Figure 16.

NOTE: The other end of the spring is attached to the

idler pulley. For an example of where this spring should

attach, see Figure 14.

NOTE: Refer to the Routing the Upper Drive Belt

section of this manual (Page 18) for proper upper drive

belt installation instructions. Routing The Lower Drive

Belt instructions can also be found in that section.

4

Assembly

Model Series

600-649 &

All 800 series

Cub Cadet

11C & 13C

WARNING

Figure 15

Figure 16

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

13

Page 14

5

Bracket &

Undercarriage

Assembly

Model Series

700-799

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Bracket Assembly

WARNING: Before installing attachment, place tractor on a firm and level

surface. Place the PTO in the disengaged (OFF) position, set the parking

brake, shut engine off and remove key

to prevent unintended starting.

NOTE: Your tractor’s cutting deck, PTO belt and

front deck stabilizer bracket must be removed prior to

mounting the snow thrower attachment. Refer to your

tractor’s Operator’s Manual for detailed instructions. If

your tractor is equipped with any front-end accessory

(i.e. front bumper kit), it must also be removed.

1. Install a shoulder screw (738-0143) and flange lock

nut (712-04065) in the top front hole of each snow

thrower assembly bracket as in Figure 17.

2. Mount snow thrower assembly brackets (683-04214

& 683-04215) to your tractor using the loose

hardware included (Hex Screw 710-0514 & Flange

Lock Nut 712-04065). See Figure 17.

NOTE: Remove the wiring harness from tractor frame

(left side only) and mount on the outside of the assembly

bracket using the clamp (726-0354) included with your

hardware pack.

Undercarriage Assembly

1. Remove the threaded pin, click pins and clevis pins

from your undercarriage assembly and retain for

installation later. Also, remove the v-belt (754-0371A),

this belt will be replaced later with another v-belt

(754-0498) included in this carton. See Figure 18.

2. Remove the flange lock nut and flat washer as

pointed out in Figure 19, leaving the spacer underneath it in place. Mount the idler pulley (756-0627D)

and idler bracket (783-1291) from the loose parts

included in this carton. Replace the nut and washer.

3. Attach the PTO cable to the idler bracket, then fit the

cable into the slotted fitting as seen in Figure 19.

NOTE: The PTO cable should be hanging down under

you tractor after you removed the mowing deck. You

will need to slide the undercarriage unit under your tractor in position for which it will be mounted. The slanted

side should be pointed towards the front of your tractor.

4. Locate v-belt part No. 754-0498 and the extension

spring (Part No. 732-04237, which is .50” wide x 12”

long) packaged with the loose parts in this carton.

NOTE: The V-belt can be identified by the part number

embossed on the outside of the belt.

5. Route the belt around the spindle pulley, inside of

the belt keepers and to the inside of the idler pulley.

The spring will connect to the Idler bracket but you

may install this once the undercarriage is mounted.

Otherwise it could fall off or get in the way in the

following steps. If you wish to connect this later,

retain the spring for later installation. See the Figure

20 illustration on the following page.

Wiring Harness

Clamp

NOTE: Left

side view

Hex Screws

Shoulder

Screw

Threaded Pin

Clevis Pins

PTO Cable

Slotted

Fitting

Flange

Lock

Nuts

Figure 17

V-Belt

Undercarriage Assembly

Figure 18

Belt Keeper Pin

Flange Lock

Nut & Washer

Idler Pulley &

Idler Bracket

Figure 19

14

Page 15

Spindle Pulley

Belt Keeper

Pin

6. Install the additional belt keeper pin and hardware

included with the loose parts in this carton. See

Figure 19 for belt keeper location placement.

Extension Spring

Remove Nut

V-Belt

Figure 20

Figure 21

A B

Figure 22

Hairpin Clip

Mounting the Undercarriage

Assembly

Make certain the correct upper drive belt (754-0498) is

installed on the undercarriage assembly. If the appropriate belt is not installed, replace it with the correct belt

prior to proceeding with mounting the undercarriage.

IMPORTANT: Make certain that the flat side of the belt

is facing outward as it sits against both the idler pulley

and spindle pulley. This allows the “V” side of the belt to

ride snugly in both pulleys.

1. The undercarriage assembly should be in position

beneath the tractor, since you already connected the

PTO cable in the previous steps.

2. Remove the nut from the rear undercarriage mounting stud located on the tractors frame rail on the right

side of the tractor. See Figure 21.

3. Lift the undercarriage assembly up, inserting the

weld pins on the assembly up through the aligning

holes found along the tractor’s frame rails. Fasten

with hairpin clips and flat washers removed earlier.

See B in Figure 22.

The rear hole on the right side will fit over the stud

already installed on your tractor. Fasten with the

wing nut (included with your hardware pack) and flat

washer removed earlier. See A in Figure 22.

4. Connect the extension spring found in your units

loose parts that was mentioned earlier. This spring

connects to the idler bracket on the undercarriage

assemble and the hole on the rear right-hand snow

thrower mounting bracket. See Figure 23.

5. Attach the lower auger drive belt by routing it around

and through the pulley system as seen in Figure 23.

NOTE: Proper belt routing diagrams can be found on

page 18-19 of this manual.

5

Bracket &

Undercarriage

Assembly

Model Series

700-799

WARNING

Before installing

attachment, place

tractor on a firm and

level surface. Place the

PTO in the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

IMPORTANT:

Make certain that the flat

side of the belt is facing

outward as it sits against

both the idler pulley

and spindle pulley. This

allows the “V” side of the

belt to ride snugly in

both pulleys.

Figure 23

15

Page 16

Upper Chute

Crank Rod

6

Assembling

Controls

All Models

NOTE:

All references to left

or right side of the

snow thrower is

from the operating

position only.

Joint Block

Lower Chute

Crank Rod

B

Attaching the Chute

Directional Control

1. Secure the upper chute crank rod to the joint block

(A) on the lower chute crank rod with the cotter pin

(B) provided. See Figure 24.

2. Attach the chute directional control assembly to the

upper lift link on the left side of the auger housing

assembly with two hex screws as illustrated in Figure

25. Secure with two flange nuts.

3. Fasten the chute tilt cables to the chute directional

control with two of the cable ties provided. Pull the

cable ties until they’re snug and trim off excess.

A

Chute Directional

Control Assembly

Figure 24

Attaching The

Lift Handle

1. Attach the lift handle to the lift bracket on the right

side of the auger housing assembly with the two hex

screws and two flange nuts provided. See Figure 26.

2. Fasten the lift cable to the lift handle with two of the

cable ties provided. Pull the cable ties until they’re

snug and trim off any excess.

Lift Handle

Upper Lift Link

Figure 25

Chute Directional

Control Assembly

Auger Housing Assembly

Figure 26

Attaching the Reflectors

Peel off the backing from each of the reflectors to expose

the adhesive surface. Adhere the reflectors to the rear of

the tractor’s fender (one on the left and one on the right)

so that the reflectors simulate taillights.

16

Page 17

Inset B

Figure 27

Mounting Auger Assembly

1. Position the auger housing assembly in front of the tractor

as seen in Figure 27. Lay the belt and support tubes out as

seen above.

IMPORTANT: If you are installing this snow thrower

attachment on any mower model with a letter designation

(i.e. 60R or 80R, 80T, etc.) then the heat shield on the

auger housing must be removed. Do not remove this heat

shield on any other model of mower. To determine your

model number, see page 2-3 of this manual.

IMPORTANT: It will be necessary to have a second

person assist you to complete the following steps.

2. Carefully move the tractor forward (by

pushing, NOT driving it) so that the support

tubes found on the rear of the auger hous

ing assembly are positioned between the

tractor’s front tires. Set the parking brake.

WARNING: Before installing attachment, place tractor on a firm and level surface. Place

the PTO in the disengaged (OFF) position, set the

parking brake, shut engine off and remove key to

prevent unintended starting.

3. With the help of an assistant, lift up the auger housing

up and move the attachment back aligning the hooks

found on the rear of the lift assembly over the shoulder

bolts found on both the left and the right sides of the

tractor’s front pivot support brackets. See Figure 27

Inset A.

Inset A

4. Maneuver the auger housing until the mounting holes

lineup. Insert a clevis pin from your hardware pack

and secure with a click pin, into the tractor’s front pivot

support brackets seen in Figure 27 Inset B.

5. Repeat Step 4 on the left side, inserting a clevis pin

secured with a click pin.

Attaching the Support

Tubes

1. Secure the right support tube to the front of the

undercarriage assembly with the clevis pin and

hairpin clip removed earlier. See Figure 28.

2. Repeat the previous step on the left side.

-

Figure 28

7

Mounting

Auger

Housing

All Models

WARNING

Before installing

attachment, place

tractor on a firm and

level surface. Place

the PTO in the disengaged (OFF) position,

set the parking brake,

shut engine off and

remove key to prevent

unintended starting.

17

Page 18

Routing the Upper Drive Belt (Tractors Models with an Electric PTO)

8

Belt

Routing

Various Models

WARNING

Before installing

attachment, place

tractor on a firm and

level surface. Place

the PTO in the disengaged (OFF) position,

set the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Spindle Pulley

Idler Pulley

Engine Pulley

All electric PTO

Decks 42, 46, 50, 54

PTO Idler Pulley

Figure 29

1. Attach and route the upper drive belt around the spindle pulley and idler pulley found on the undercarriage, the

electric PTO clutch and the PTO idler pulley as illustrated in Figure 29. Make sure that the belt is routed to the

INSIDE of the belt keeper on the undercarriage idler pulley and the remaining keeper pins found around the

spindle pulley.

IMPORTANT: Make certain that the flat side of the belt is facing outward as it sits against both the electric PTO

clutch and spindle pulley. This allows the “V” side of the belt to ride snugly in both pulleys.

Routing the Upper Drive Belt (Tractor Models 700 Series; and 600 Series 2005 &

newer cable drive PTO)

Spindle Pulley Engine Pulley

All Manual PTO

Decks 38 & 42

IMPORTANT:

Make certain that the

flat side of the belt is

facing outward. This

allows the “V” side of

the belt to ride snugly

in both pulleys.

PTO Idler Pulley

Figure 30

1. Attach and route the upper drive belt around the engine pulley and spindle pulley, routed to the INSIDE of the

PTO idler pulley on the undercarriage. Make sure the belt is routed inside of the belt keeper pins found around

the spindle pulley and engine pulley. See Figure 30.

IMPORTANT: Make certain that the flat side of the belt is facing outward. This allows the “V” side of the belt to ride

snugly in both pulleys.

18

Page 19

Routing the Upper Drive Belt (Older Style Tractors )

8

46 inch Manual

Older Style Setup

42 in. Electric and

Manual Older Style

Setup

Figure 31

1. Attach and route the proper upper drive belt (refer to the table on page 12) around the spindle pulley and idler

pulley found on the undercarriage, the lower portion of the engine pulley and the two pulleys found on the PTO

double-idler bracket as illustrated in Figure 31. Make sure that the belt is routed to the INSIDE of all belt keepers

on the idler pulleys and the keeper pins found around the spindle pulley

IMPORTANT: Make certain that the flat side of the belt is facing outward. This allows the “V” side of the belt to ride

snugly in both pulleys.

Belt

Routing

Various Models

WARNING

Before installing

attachment, place

tractor on a firm and

level surface. Place

the PTO in the disengaged (OFF) position,

set the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Routing the Lower Drive Belt (All Tractors Models)

Left Side

Spindle Pulley

Right Side

1. Attach and route the lower drive belt around the lower pulley on the spindle assembly, both pulleys on the doubleidler bracket found beneath the undercarriage, and the drive pulley found on the rear of the snow thrower housing

as illustrated in Figure 32.

2. Attach the tension spring (found on the undercarriage double-idler bracket) to the hex screw if it is not already

attached.

Undercarriage

Double-Idler Bracket

Figure 32

Snow Thrower Drive Pulley

IMPORTANT:

Make certain that the

flat side of the belt is

facing outward. This

allows the “V” side of

the belt to ride snugly

in both pulleys.

19

Page 20

9

Controls

WARNING

Be familiar with all

controls and their

proper operation.

Know how to stop

the machine and

disengage them

quickly.

WARNING: Be familiar with all

controls and their proper operation.

Know how to stop the machine and

disengage them quickly.

Engaging the Augers

and Impeller

Power to the snow thrower attachment is activated by

engaging the tractor’s PTO.

1. Place the tractor’s throttle control in the FAST (rabbit) position and allow it to remain there for efficient

snow removal.

2. Move the PTO knob or PTO lever (on tractor’s so

equipped) into the “ON” position to engage the

augers and impeller.

3. Move the PTO knob or PTO lever (on tractor’s so

equipped) into the “OFF” position to disengage the

augers and impeller.

NOTE: The PTO knob (on units so equipped) cannot

be in the engaged (ON) position when the tractor is

driving in the reverse direction. The PTO knob must be

in the disengaged (OFF) position when the shift lever

is placed in REVERSE or the electric PTO clutch will

automatically shut off.

Refer to your tractor’s Operator’s Manual for more

information regarding your tractor’s PTO and safety

interlock system.

Chute Directional

Control

The chute directional control assembly is found on the left

side of the tractor and includes both the chute tilt lever as

well as the chute crank. Both affect the direction that the

discharged snow is thrown.

To pivot the upper section of discharge chute, affecting

the distance and angle which the snow is thrown, move

the chute tilt lever forward or rearward into a desired

position.

The direction which snow is thrown can be changed

by rotating the discharge chute with the chute crank.

Turn the chute crank clockwise to rotate the chute and

discharge snow to the left. Crank it counterclockwise to

rotate the chute and discharge snow to the right.

NOTE:

The PTO knob (on

units so equipped)

cannot be in the

engaged (ON) position

when the tractor is

driving in the reverse

direction. The PTO

knob must be in the

disengaged (OFF)

position when the

shift lever is placed

in REVERSE or the

electric PTO clutch

will automatically

shut off.

Lift Handle

The lift handle is located on the right side of the tractor

and is used to raise and lower the snow thrower

attachment.

1. To raise the snow thrower attachment off of the

ground, pull rearward and down on the lift handle

until you feel the lift latch on the right side of the

snow thrower engage, locking the snow thrower in a

raised position.

2. To lower the snow thrower, push downward on the

lift handle until there is enough slack in the lift cable

so that you may squeeze the trigger control. With

the trigger control squeezed, gently allow the snow

thrower to lower until it reaches the ground.

20

Page 21

OPERATION

WARNING: Read, understand, and

follow all instructions and warnings

on the tractor, attachment, and in the

Operator’s Manuals before operating.

Your snow thrower attachment is capable of displacing

snow and clearing a path a width of 42 inches.

Observe the following operating instructions for efficient

snow removal.

1. Become familiar with and comfortable using all of

your tractor’s controls as instructed in your tractor’s

Operator’s Manual before operating it with the snow

thrower attachment.

2. Make certain the correct weight (and volume) of

motor oil in is your tractor’s engine as instructed in

the engine Owner’s Guide packed with the tractor’s

Operator’s Manual.

3. Always operate the snow thrower with the tractor’s

engine at maximum RPM (full throttle).

4. NEVER override any safety features on either your

tractor or the snow thrower attachment.

5. Make certain that all nuts, bolts, and hardware are

fastened securely and tight on both the tractor and the

snow thrower attachment prior to use.

6. Make certain the snow thrower is assembled properly and mounted to the tractor as instructed in this

manual.

8. Test all the controls (tractor PTO, snow thrower lift

handle, chute tilt lever & chute crank) for smooth

operation prior to operating the snow thrower in snow.

9. Make all adjustments (i.e. skid shoes, lift latch) before

operating your snow thrower attachment. Follow

instructions in the Adjustments section of this manual

when doing so.

10. Engage the tractor’s PTO to activate power to the

augers and impeller BEFORE driving the tractor

forward and into snow.

11. Keep your tractor’s ground-speed slow. The slower

your tractor is traveling, the more effectively the snow

thrower attachment can displace snow.

12. Adjust ground speed for snow conditions and become

familiar with different snow applications. Your snow

thrower attachment will operate differently in wet

heavy snow than it will it light, fluffy snow.

13. Overlap a previously cleared path when necessary

(deep snow) so as not to overload the auger housing

with snow.

14. NEVER drive the tractor into a snow bank. The snow

thrower attachment is not a dozer plow. The lift linkage

and/or the snow thrower drive system can be damaged as a result of “plowing” with the snow thrower

attachment.

15. If the augers become jammed with a chunk of ice or

a foreign object, move the PTO into the disengaged

(OFF) position immediately and turn off the tractor’s

engine and remove the ignition key. Examine the auger

area thoroughly for damage and do NOT operate the

snow thrower attachment until any damage is repaired.

IMPORTANT: The augers are secured to the spiral

shaft with two shear bolts and hex lock nuts. If you hit

a hard foreign object or an ice jam, the snow thrower is

designed so that the bolts may shear. Two replacement

shear bolts and hex lock nuts are provided for your

convenience. Store in a safe place until needed. NEVER

replace the auger shear bolts with standard hex bolts.

Any damage to the auger gearbox or other components

as a result of doing so will NOT be covered by your

snow thrower’s warranty.

16. Whenever possible, discharge snow downwind.

17. Do NOT attempt to remove ice or hard-packed frozen snow.

18. When the tractor (with the snow thrower attachment

mounted) is not in service, use the lift lever to lower

the auger housing assembly to the ground to relieve

strain on the tractor’s front end between uses.

19. Always use tire chains and rear wheel weights on

your tractor where extra traction is needed. Refer to

the table to the right to determine which kits will fit

your tractor (tire dimensions are can be found on the

sidewalls of your tractor’s tires).

20. Use drift cutters to aid in displacing snow through

deep, drifted areas.

Tire Chain Kit Number

Garden Tractors

23” x 9.5” tires OEM-190-964

22” x 7.5” tires OEM-190-974

Lawn Tractors

20” x 10.0” tires OEM-190-916

20” x 8.0” tires OEM-190-658

18” x 9.5” tires OEM-190-657

18” x 8.5” tires OEM-190-754

18” x 6.5” tires OEM-190-664

Wheel Weight Kit Number

All Garden Tractors OEM-190-784

All Lawn Tractors OEM-190-215

Drift Cutter Kit Number

All Tractors OEM-390-679

NOTE: None of the kits in the table are included as

standard equipment with snow thrower attachment

OEM-190-032. Call our Customer Support Department

as instructed on page 2 of this manual for availability

and information regarding these kits.

10

Operation

WARNING

Read, understand,

and follow all instruc-

tions and warnings

on the tractor, at-

tachment, and in the

Operator’s Manuals

before operating.

IMPORTANT:

The augers are secured

to the spiral shaft with

two shear bolts and hex

lock nuts. If you hit a

hard foreign object or

an ice jam, the snow

thrower is designed

so that the bolts may

shear. Two replacement

shear bolts and hex

lock nuts are provided

for your convenience.

Store in a safe place

until needed. NEVER

replace the auger shear

bolts with standard hex

bolts. Any damage to

the auger gearbox or

other components as a

result of doing so

will NOT be covered

by your snow

thrower’s warranty.

21

Page 22

11

Adjustments

All Models

WARNING

Never attempt

to make any

adjustments while

the engine is running,

except where

specified in the

Operator’s Manual.

Place tractor on a

firm and level

surface. Place

the PTO in the

disengaged (OFF)

position, set the

parking brake,

shut engine off,

and remove key

to prevent

unintended starting.

Making Adjustments

WARNING: Never attempt to make any

adjustments while the engine is running,

except where specified in the Operator’s

Manual. Place tractor on a firm and level

surface. Place the PTO in the disengaged (OFF) position, set the parking

brake, shut engine off, and remove key

to prevent unintended starting.

Lift Adjustment

If the lift index rod doesn’t latch securely or the pivot

release has too much slack in it, an adjustment can be

made as follows:

1. Loosen the upper hex nut a few turns, then tighten the

lower hex nut to shorten the cable length. See Figure 33.

2. Loosen the lower hex nut a few turns, then tighten the

upper hex nut to lengthen the cable. See Figure 33.

Lower Chute Crank

Support Bracket Adjustment

If the spiral at the base of the lower chute crank isn’t

fully engaging with the notches in the lower chute

assembly, the support bracket can be adjusted inward

or outward as follows:

1. Loosen, but do NOT remove the two hex nuts which

secure the support bracket to the snow thrower

housing. See Figure 34.

2. Adjust the support bracket inward or outward so

that the spiral is fully engaged in the notches on the

chute before retightening the hex nuts.

Skid Shoe Adjustment

The space between the shave plate and the ground

can be adjusted by repositioning the skid shoes found

on either side of the snow thrower’s auger housing.

For close snow removal, place skid shoes in the low

position. Use a middle or high position when the area to

be cleared is uneven.

IMPORTANT: It is NOT recommended that this snow

thrower be operated on a gravel surface, as loose

stones can be easily picked up and thrown by the

machine. If you must operate on a gravel surface,

ALWAYS adjust the skid shoes into the HIGH position to

allow the shave plate maximum clearance.

Adjust skid shoes as follows:

1. Loosen, but do NOT remove, the three hex nuts which

fasten the skid shoe to the auger housing. See Figure 35.

2. Raise or lower the skid shoe to desired position.

NOTE: Make certain the entire base of both skid shoes

are against the ground to avoid uneven wear on the skid

shoes. When one side does wear out, the skid shoes

are reversible.

3. Retighten the hex nuts loosened earlier.

4. Repeat this adjustment on the skid shoe found on

the opposite side of the snow thrower.

Hex Nuts

Lift Index Rod

Hex Nuts

Lift Cable

Figure 33

Spiral

Support

Bracket

Figure 34

Skid Shoe

Hex Nut

Figure 35

22

Page 23

Lube Spiral

and Chute Base

Joint Block

Maintenance

WARNING: Before lubricating,

repairing, or inspecting, place tractor

on a firm and level surface. Place the

PTO in the disengaged (OFF) position,

set the parking brake, shut engine off,

and remove key to prevent unintended

starting.

Lubrication of

Chute Directional Control

The spiral on the end of the lower chute crank, the base

of the discharge chute itself and the joint blocks which

connect the lower and upper chute cranks should be

lubed with multi-purpose automotive grease once a

season. See Figure 36.

12

Maintenance

All Models

Shear Pin

Figure 36

Spacers

Figure 37

Bearing

Auger Shaft

1. At least once a season, remove the shear bolts on

the auger shaft. Oil or spray lubricant inside and

on the plastic bearings on the shaft and near the

holes where the shear bolts were removed before

reattaching them. See Figure 37.

WARNING

Before lubricating,

repairing, or

inspecting, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off, and

remove key to prevent

unintended starting.

23

Page 24

24

Page 25

13

REF

NO.

10 Self Tapping Screw 8

11 Bow-Tie Cotter Pin

12 Hex Nut, 5/16-18 6

13 Hex Nut, 5/16-24 2

14 Spirol Pin, 1/4 x 1-1/2 2

15 Flat Washer, .344 x 1.125 x .12 3

16 Bell Washer, .340 x .872 17

17 Hex Flange Bearing, .75 ID 2

18 Flange Bushing, .80 x .91 12

19 Skid Plate Bracket, 42” 1

20 Slide Shoe 2

21 Spacer, .75 x .125 x .5 4

22 Hex Bearing Housing, 1.0 2

23 RH Reducer Housing

24 LH Reducer Housing 1

25 Housing Brace Plate 1

26 Self Tapping Screw, 1/4-20 x .75 5

27 Spiral Axle, 41.5” 1

28 Hi-Pro Key, 3/16 x 5/8 1

29 Spring Spirol Pin, .25 x 1.25 1

30 Worm Gear, 20-tooth 1

31 Worm Shaft 1

32 Thrust Collar 1

33 Grease Plug 1

PART

NUMBER

1 Auger Gear Box (Incl. Ref. 23-41) 1

2 Impeller Assembly, 12” 1

3 Housing Assembly 1

4 Housing Brace Bracket 1

5 LH Spiral Auger 3

6 RH Spiral Auger 3

7 Hex Cap Screw, 5/16-24 x .75 2

8 Carriage Bolt, 5/16-18 x .62 10

9 Splined Carriage Screw 2

DESCRIPTION Qty

REF

NO.

8

1

PART

NUMBER

34 Grease Seal 1

35 Flat Washer, .76 x 1.5 x .030 2

36 Flat Washer, .508 x 1.0 x .020 4

37 Thrust Washer,

38 Thrust Bearing, .75 x 1.25 x .078 1

39 Flange Bearing, .503 x .75 1

40 Flange Bearing, .75 x 1.0 x .59 1

41 Grease Seal 2

42 Chute Crank Assembly 1

43 Chute Crank Bracket 1

44 Chute Reinforcer

45 Splined Carriage Screw 2

46 Carriage Bolt, 5/16-18 x 1.5 1

47 Carriage Screw, 5/16-18 x 1.0 1

48 Screw, 1/4-20 x .75 4

49 Hex Index Washer Screw 1

50 Hex Cap Screw, 1/4-20 x .75 6

51 Nylon Hex Lock Nut, 1/4-20 10

52 Nylon Hex Lock Nut, 5/16-18 5

53 Spirol Pin, .125 x .82 1

54 Chute Flange Keeper 3

55 Lower Chute 1

56 Upper Chute

57 Adapter Chute 1

58 Chute Tilt Cable Guide 1

59 Plastic Bushing 2

60 Joint Block Assembly 1

61 Cable Bracket 1

62 Chute Crank Bracket 1

63 Flange Lock Nut, 5/16-18 6

64 Spacer 1.25 x .75 x 1.00 2

65 Sleeve .758 x 1.00 x 2.70 4

66 Shear Pin, .25 x 1.50 8

DESCRIPTION Qty.

.75 x 1.25 x .0615 2

Part List:

Snow

Thrower

Attachment

1

1

For parts and/or

accessories

please call

1-800-800-7310, or

1-330-220-4683

www.mtdproducts.com

NOTE:

For painted parts, please

refer to the list of color

codes below. Please add

the applicable color code,

wherever needed, to the

part number to order a

replacement part.

For instance, if a part

numbered 700-xxxx is

painted powder black, the

part number to order would

be 700-xxxx-0637.

Yardman Green - 0665

Black - 0637

.

25

Page 26

52

55

60

62

57

58

56

16

17

15

20

19

18

56

61

26

53

33

35

38

33

47

54

4

29

14

22

13

B

50

42

48

28

39

43

65

36

59

51

24

40

B

32

39

31

46

64

65

69

71

4

63

72

21

4

3

22

4

32

34

30

4

A

70

41

12

C

45

23

1

6

2

9

10

11

4

5

8

7

4

C

49

29

25

27

4

67

68

A

66

44

4

67

37

73

65

26

Page 27

REF

PART No. DESCRIPTION Qty.

NO.

1 Knob 1

2 Chute Tilt Handle 1

3 Chute Tilt Cable Guide 1

4 Nylon Hex Lock Nut, 5/16-18 22

5 Chute Tilt Bracket Assembly 1

6 Carriage Bolt, 5/16-18 x 1.5 2

7 Saddle Washer, .32 x .93 2

8 Plastic Bushing 1

9 Rubber Grommet , .44 x .94 x .5 1

10 Eye Bolt 1

11 Bell Washer, .340 x .872 1

12 Support Chute Tube 1

13 Cotter Pin, 3/32 x .75

14 Joint Block Assembly 1

15 Chute Crank Rod, .375 x 33 1

16 Chute Cable, 62” 1

17 Chute Cable w/ Clip, 62” 1

18 Rolled Pin, 1/8 x .63 1

19 Crank Knob 1

20 Push Cap, 3/8 ID 1

21 Rod, .375 x 11.375 1

22 Spirol Pin, .125 x .82 2

23 Rod Assembly 1

24 RH Support Plate Assembly 1

25 LH Support Plate Assembly 1

26 Lift Bracket Assembly 1

27 Hex Cap Screw, 5/16-18 x 1.50 2

28 Hex Cap Screw, 5/8-18 x 1.31 2

29 Hex Cap Screw, 5/16-18 x .75 4

30 Clevis Pin, .5 x .78 2

31 Slotted Hex Nut, 5/8-18 2

32 Hex Lock Nut, 3/8-16 4

33 Hex Lock Nut, 1/2-13 4

34 Cotter Pin, 1/8 x 1.25

35 Cotter Pin, .125 x .75 4

36 Snap Ring 1

37 Skid Plate 1

REF

PART No. DESCRIPTION Qty.

NO.

38 Flat Washer, .51 x 1.0 x .060 4

39 Flat Washer, .64 x 1.12 x .125 4

40 Bell Washer, .396 x 1.14 x .095 2

41 Drive Mounting Bracket 1

42 Shoulder Screw, .5 x .29, 3/8-16 2

43 Flange Bearing w/ Flats 2

44 Drive Pulley, 7” 1

45 Rod, 1/2 x 11.55 1

46 Link, 5.875 2

47 Link, 15.4 2

48 Link, 13.35 2

49 Heat Shield 1

50 Snow Thrower Lift Bracket

1

51 Hex Index Washer Screw #10-16 1

52 Pan Phillips Screw, #10-24 x .75 1

53 Hex Cap Screw, 5/16-18 x 1.75 2

54 Heavy Duty Spirol Pin, 1/4 x 1.5 1

55 Handle Grip 1

56 Cable Tie 5

57 Compression Spring 1

58 Flat Washer, .385 x .62 x .063 1

59 Flat Washer, .194 x .62 x .063 1

60 Lift Cable, 42” w/ Trigger Control 1

61 Lift Index Rod 1

62 Lift Handle Tube 1

63 Bearing Housing, 1.85 ID 1

64 Belt Cover 1

65 Hex Cap Screw, 3/8-16 x 1.0 8

66 Socket Head Cap Screw 1

67 Flange Lock Nut, 3/8-16 6

68 Square Key, 3/16 x .75 1

69 Hi-pro Key, 3/16 x .75 1

70 Right Angle Drive 1

71 Coupling

2

72 Flange Ball Bearing, .75 x 1.85 1

73 Belt Keeper Rod 1

13

Part List:

Snow

Thrower

Attachment

1

1

For parts and/or

accessories

please call

1-800-800-7310, or

1-330-220-4683

www.mtdproducts.com

.

* Refer to the table on page 6 for your tractor’s applicable upper v-belt.

27

Page 28

38

AA

51

54

1

44

AA

42

6

59

8

46

10

45

47

52

60

53

9

10

10

48

50

12

49

57

10

16

8

2

11

56

61

64

58

7

18

13

A

14

3

BB

8

12

6

9

4

39

40

41

39

38

43

BB

34

33

31

37

18

36

30

10

35

16

25

29

25

62

55

20

10

16

15

17

A

19

5

21

23

24

28

3

26

25

27

22

12

28

63

Page 29

REF

PART No. DESCRIPTION Qty.

NO.

1 Spindle Assembly (Incl. 38-44) 1

2 Pulley Mounting Bracket 1

3 Hex Cap Screw, 3/8-16 x 1.75 2

4 Self Tapping Screw 4

5 Clevis Pin, .5 x 1.18 2

6 Belt Keeper Pin † 4

7 Clevis Pin, 3/8 x .75 2

8 Nylon Hex Lock Nut, 5/16-18 4

9 Nylon Hex Lock Nut, 1/4-20 † 4

10 Hex Flange Lock Nut, 3/8-16 11

11 Hex Nut, 5/16-18 1

12 Click Pin, .092 x 1.64 7

13 Internal Cotter Pin, .125 x 1.75

14 Belt Guard 1

15 Flat Washer, .531 x .93 x .09 2

16 Flat Washer, .38 x .93 x .11 4

17 Shoulder Screw, 3/8-16 2

18 Shoulder Spacer, .625 x .169 2

19 LH Support Tube 1

20 RH Support Tube 1

21 Hex Lock Nut, 1/4-20 1

22 Bell Washer.265 x .75 x .062 1

23 Hex Nut 1/4-20 1

24 Belt Keeper Rod 1

25 Idler Pulley 3.50 dia. 3

26 Idler Assembly Spacer 1

27 Flange Lock Nut 3/8-16 1

28 Idler Bracket

29 Hex Cap Screw, 3/8-24 x 2 1

30 Hex Cap Screw, 3/8-16 x 3 1

31 Spacer 3

32 Nylon Jam Lock Nut, 3/8-24 1

* Refer to the table on page 6 for your tractor’s applicable upper v-belt.

† Used only on the model 700-799 Series units

REF

NO.

33 Hex Nut, 3/8-24 1

34 Extension Spring, .620 x 5.62 1

35 Lock Washer, 3/8 1

36 Idler pulley, 4” Diameter 1

37 Idler Pivot Arm 1

38 Flange Nut 5/8-18 2

39 Ball Bearing 2

40 Spacer 1

41 Deck Spindle Housing 1

42 Deck Pulley 7” 1

43 Pulley 3.75” 1

44 Spindle Shaft 1

45 Snow Thrower Support Brackets LH

2

46 Snow Thrower Support Brackets RH † 1

47 Shoulder Screw † 2

48 Hex Head Screw 3/8-16 x 1.00 † 4

49 Extension Spring .50 x 12.00 1

50 Clamp 16mm † 1

51 V-Belt † 1

52 Upper V-belt* 1

53 Upper V-belt* 1

54 Upper V-belt* 1

55 V-Belt 1

56 Hex Cap Screw, 5/16-18 x 1.75 1

57 Idler Pulley, Flat 2.75 OD 1

58

59 Wing Nut 5/16-18 † 1

60 Reflector 2

1

61 Double Idler Bracket Assembly 1

62 Extension Spring .91 x 7.33 1

63 V-Belt 1

64 Flat Washer

PART No. DESCRIPTION Qty.

† 1

Pin 5/16-18

1

13

Part List:

Snow

Thrower

Attachment

For parts and/or

accessories

please call

1-800-800-7310, or

1-330-220-4683

www.mtdproducts.com

.

29

Page 30

14

NOTES:

Use this page to make

notes and write down

important information.

30

Page 31

14

NOTES:

Use this page to make

notes and write down

important information.

31

Page 32

MANUFACTURER’S LIMITED WARRANTY FOR

The limited warranty set forth below is given by MTD LLC with respect

to new merchandise purchased and used in the United States, its

possessions and territories.