Page 1

OPERATOR’S MANUAL

REAR TINE

TILLER

MODEL

450 Series

IMPORTANT: READ

SAFETY RULES AND

INSTRUCTIONS CAREFULLY

MTD PRODUCTS LTD. P.O. BOX 1386 KITCHENER, ON N2G 4J1

PRINTED IN THE U.S.A.

772C0731

(10/04)

Page 2

TABLE OF CONTENTS

Content Page

Customer Support 2

Important Safe Operation Practices 3

Loose Parts 5

Assembly 6

Controls 8

Operation 9

How To Use Your Tiller 10

Content Page

Adjustments 11

Lubrication 11

Maintenance 11

Off-Season Storage 12

Trouble Shooting Guide 13

Parts Lists/Pièces détachées 14

Warranty 20

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new equipment. It will help you assemble, prepare and maintain the unit for

best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the

information from it in the space provided below. A sample model plate is also given below. You can locate the model

plate by standing at the operating position and looking down at the rear of the deck . This information will be

necessary to use the manufacturer’s web site and/or help from the Customer Support Department or an authorized

service dealer.

This is where your model number will be.

Model Number

Numéro de modèle

XXXXXXXXXX

Serial Number

Numéro de série

XXXXXXXXXXX

This is where your serial number will be.

www.mtdcanada.com

MTD PRODUCTS LIMITED

KITCHENER, ON N2G 4J1

1-800-668-1238

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, specifications,

warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed separately with your unit for

more information.

CALLING CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from which it was purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call a Customer Support Representataive.

For US Customers: 1- (330) 220-4MTD (4683) or 1- (800)-800-7310

For Canadian Customers: 1-800-668-1238

Please have your unit’s model number and serial number ready when you call. See previous section to locate this information.

You will be asked to enter the serial number in order to process your call.

HOW TO OBTAIN SERVICE

Service is available, WITH PROOF OF PURCHASE, through your local authorized service dealer. To locate the

dealer in your area;

In the U.S.A.

: Check your Yellow Pages, or contact customer support listed about MTD LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-800-800-7310 or 1-330-220-4683 or log on to our Web site at

www.mtdproducts.com.

In Canada

: Contact MTD Products Limited, Kitchener, ON N2G 4J1, or call 1-800-668-1238 or log on to our Web

site at www.mtdcanada.com.

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate your tiller. Failure to comply with these instructions may result in personal

injury. when you see this symbol— HEED ITS WARNING

DANGER: Your tiller was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This tiller is capable of amputating hands and feet. Failure to observe the following safety

instructions could result in serious injury or death.

TRAINING

1. Read, understand, and follow all instructions on the machine and in the manual(s) before attempting to assemble and operate. Keep this manual in a safe place for future and regular reference and for ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, children and pets at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

PREPARATION

1. Thoroughly inspect the area where the equipment is to be used. Remove all stones, sticks, wire, and other foreign objects which could be tripped over and cause personal injury.

2. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fitting clothes and

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

3. Disengage clutch levers and shift (if provided) lever into neutral ("N") before starting the engine.

4. Never leave this machine unattended with the engine running.

5. Never attempt to make any adjustments while the engine is running, except where specifically recommended in the operator’s manual.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are

explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes

which can ignite. Wash your skin and change

clothes immediately.

7. Use only an approved gasoline container.

8. Extinguish all cigarettes, cigars, pipes and other

9. Never fuel machine indoors.

10. Never remove gas cap or add fuel while the

11. Allow engine to cool at least two minutes before

12. Never over fill fuel tank. Fill tank to no more than

13. Replace gasoline cap and tighten securely.

14. If gasoline is spilled, wipe it off the engine and

15. Never store the machine or fuel container inside

16. Allow a machine to cool at least 5 minutes before

OPERATION

1. Do not put hands or feet near rotating parts.

2. Do not operate the machine while under the

3. Never operate this machine without good visibility

4. Keep bystanders, helpers, children and pets at

5. Be careful when tilling in hard ground. The tines

6. Exercise extreme caution when operating on or

7. Never operate the machine at high transport

8. Exercise caution to avoid slipping or falling.

.

sources of ignition.

engine is hot or running.

refueling.

½ inch below bottom of filler neck to allow space

for fuel expansion.

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace,

clothes dryer or other gas appliances.

storing.

Contact with the rotating parts can amputate

hands and feet.

influence of alcohol or drugs.

or light. Always be sure of your footing and keep a

firm hold on the handles.

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

may catch in the ground and propel the tiller

forward. If this occurs, let go of the handle bars and

do not restrain the machine.

crossing gravel surfaces. Stay alert for hidden

hazards or traffic. Do not carry passengers.

speeds on hard or slippery surfaces.

3

Page 4

9. Look down and behind and use care when in reverse or pulling machine towards you.

10. Start the engine according to the instructions found in this manual and keep feet well away from the tines at all times.

11. After striking a foreign object, stop the engine, disconnect the spark plug wire(s) and ground against the engine. Thoroughly inspect the machine for any damage. Repair the damage before starting and operating.

12. Disengage all clutch levers and stop the engine before you leave the operating position (behind the handles). Wait until the tines come to a complete stop before unclogging the tines, making any adjustments, or inspections.

13. Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless, and deadly gas.

14. Muffler and engine become hot and can cause a burn. Do not touch.

15. Use caution when tilling near fences, buildings and underground utilities. Rotating tines can cause property damage or personal injury.

16. Do not overload machine capacity by attempting to till soil too deep at too fast of a rate.

17. If the machine should start making unusual noise or vibration, stop the engine, disconnect the spark plug wire and ground it against the engine. Inspect thoroughly for damage. Repair any damage before starting and operating.

18. Keep all shields, guards and safety devices in place and operating properly.

19. Never pick up or carry machine while the engine is running.

20. Use only accessories and attachments approved for this machine by the machine manufacturer. Failure to do so, can result in serious injury.

21. If situations occur which are not covered in this manual, use care and good judgment. Contact your authorized dealer for assistance.

MAINTENANCE & STORAGE

1. Never tamper with safety devices. Check their proper operation regularly.

2. Check bolts and screws for proper tightness at frequent intervals to keep the machine in safe working condition. Also, visually inspect machine for any damage.

3. Before cleaning, repairing, or inspecting, make certain the tine(s) and all moving parts have stopped. Disconnect the spark plug wire and ground against the engine to prevent unintended starting.

4. Do not change the engine governor settings or over-speed the engine. The governor controls the maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as necessary.

6. Follow this manual for safe loading, unloading, transporting, and storage of this machine.

7. Never store the machine or fuel container inside where there is an open flame, spark or pilot light as on a water heater, space heater, furnace, clothes dryer or other gas appliances.

8. Always refer to the operator’s manual for proper instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for gas, oil, etc. to protect the environment.

WARNING — YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this manual and on the machine.

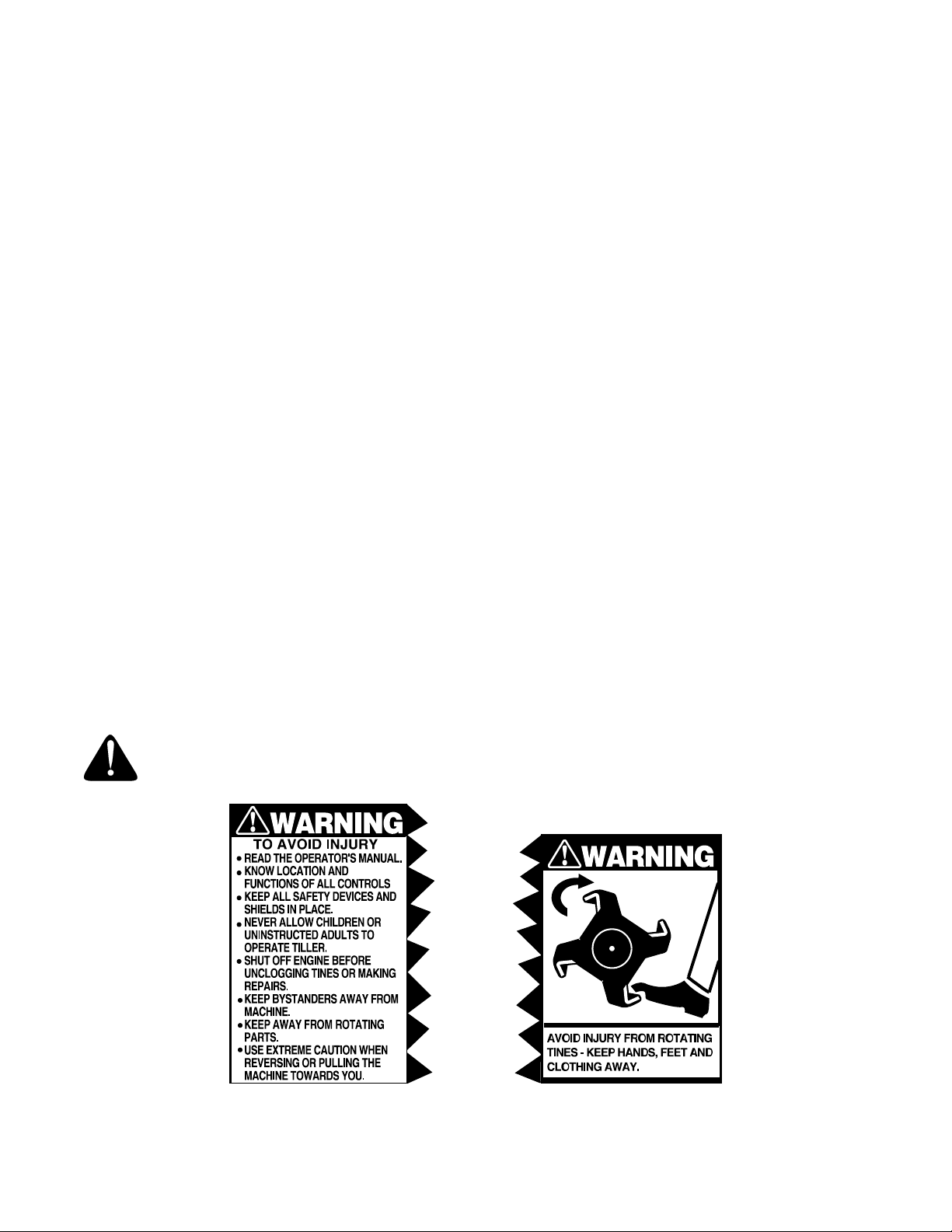

Figure 1 Safety labels found on your unit

4

Page 5

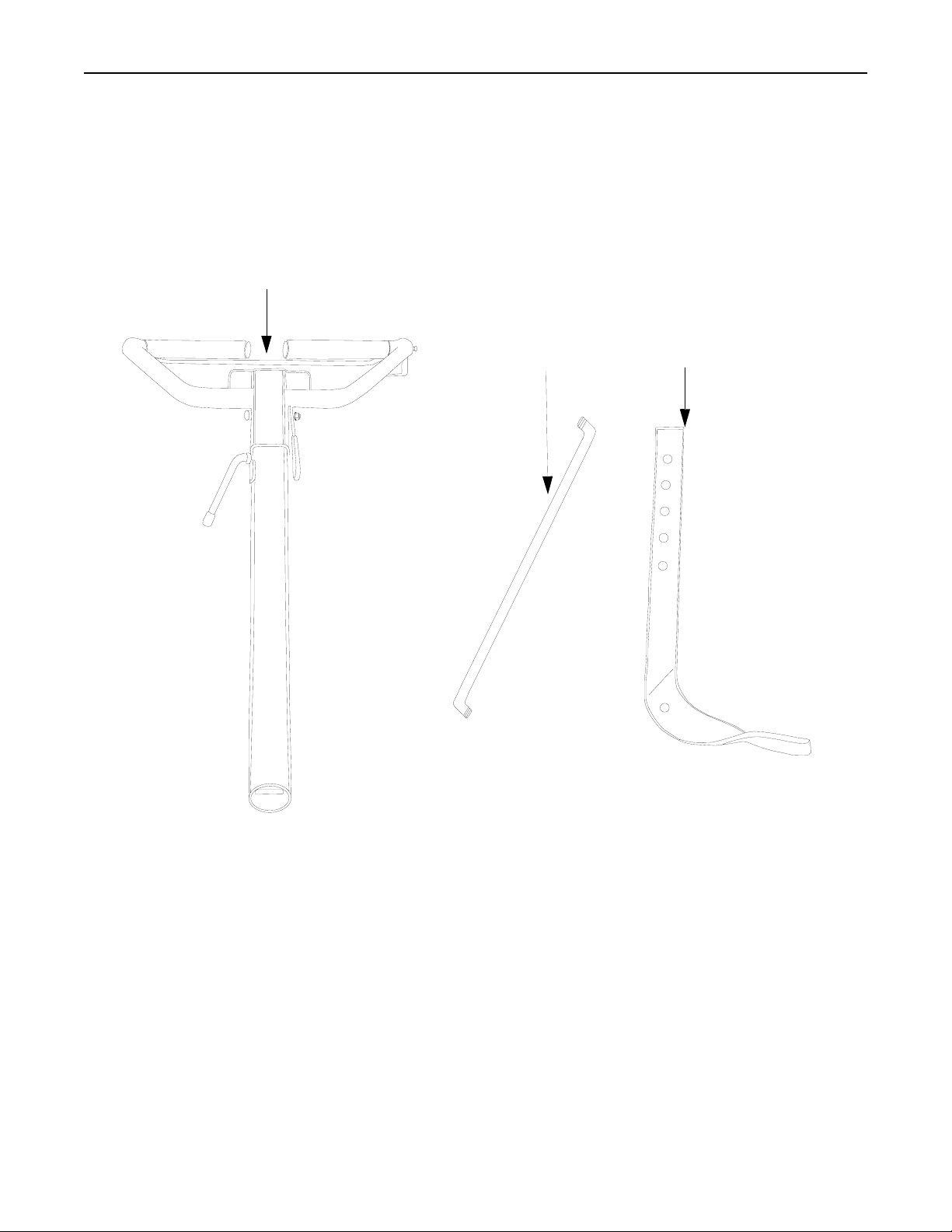

SECTION 2: LOOSE PARTS

Handle

Assembly

Control

Rod

Depth

Stake

Assembly

NOTE: All hardware needed for assembly is attached to the loose parts or the tiller.

NOTE: Cable tie not shown.

5

Page 6

SECTION 3: ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see separate

engine manual for proper fuel and engine oil

recommendations.

NOTE: Left and right is determined from the

operator’s position, standing behind the tiller.

TOOLS REQUIRED FOR ASSEMBLY

Adjustable Wrenches

Pair of Pliers

Screw Driver

TO REMOVE UNIT FROM CARTON

1. Remove staples, break glue on top flaps, or cut tape at carton end and peel along top flap to open carton.

2. Remove loose parts included with unit (i.e., operator’s manual, etc.).

3. Cut corners and lay carton down flat.

4. Remove packing material.

5. Roll or slide unit out of carton. Check carton thoroughly for loose parts.

6. Extend control cable and lay on the floor. Be careful not to bend or kink control cable.

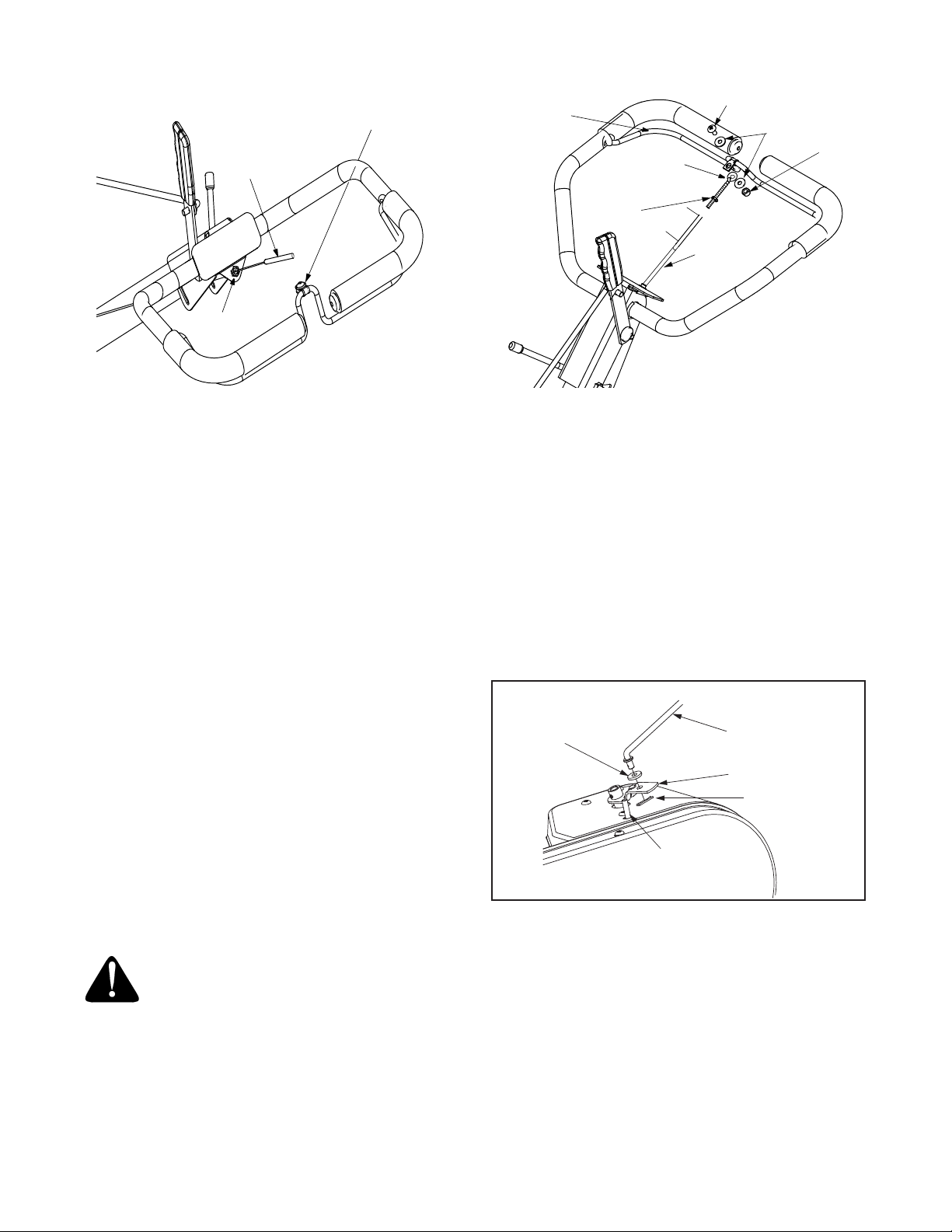

Hex Bolt

Flat Washer

T-Knob

Clevis Pin

Hairpin Clip

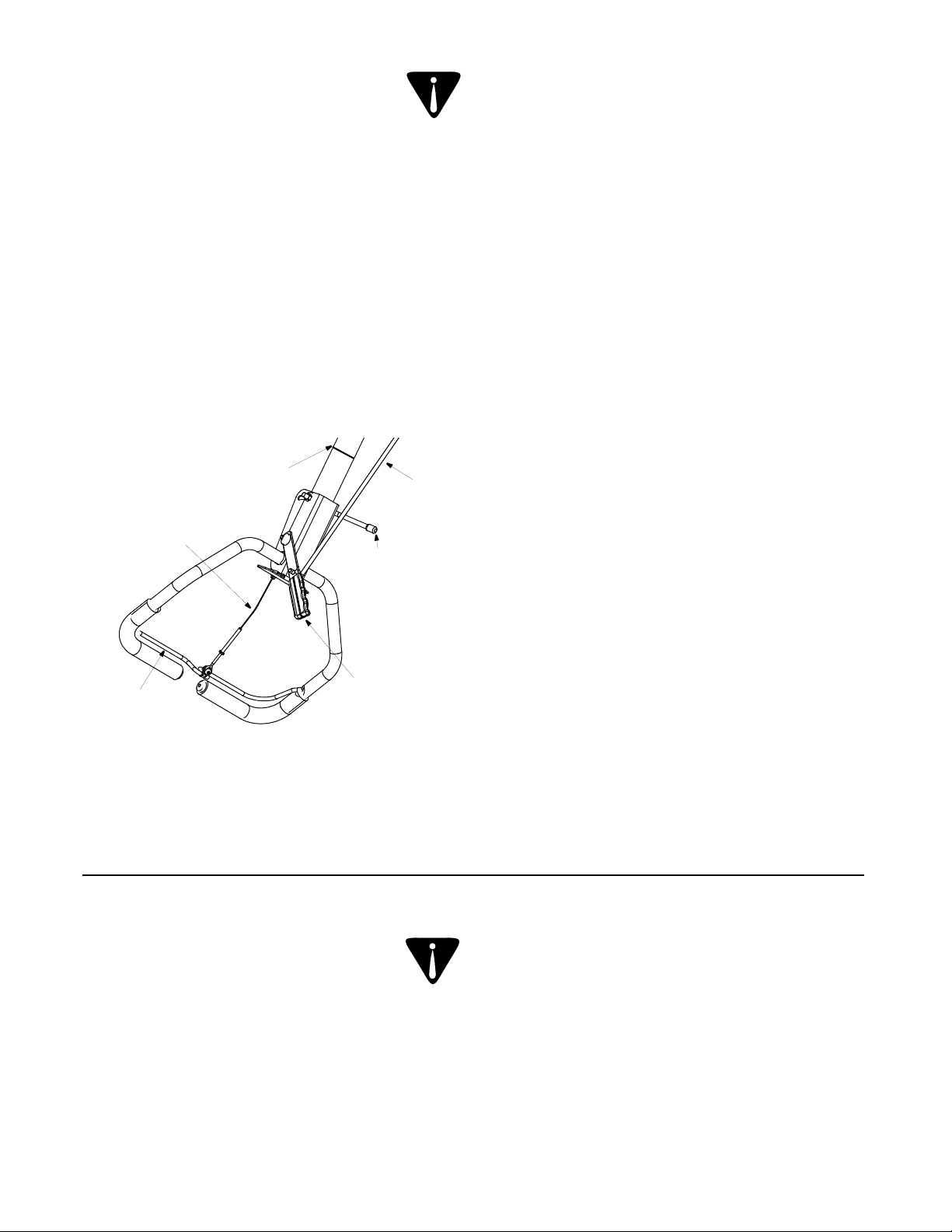

ATTACHING DEPTH STAKE ASSEMBLY

1. Tip the tiller forward so it rests on front counterweight.

2. Raise the tine shield hinge flap assembly. Remove "T" knob, flat washer and hex bolt from depth stake. Insert the depth stake assembly in front of spacer (under the tine shield) and up through the tine shield assembly as shown in Figure 1.

3. Insert clevis pin through the tine shield and the second hole from top of the depth stake. Secure with hairpin clip.

4. Insert hex bolt into the top hole of the depth stake assembly. Place flat washer on hex bolt and thread “T” knob onto the hex bolt. See Figure 1. Tighten securely.

5. Tip the tiller back down so it rests on the depth stake (transport position).

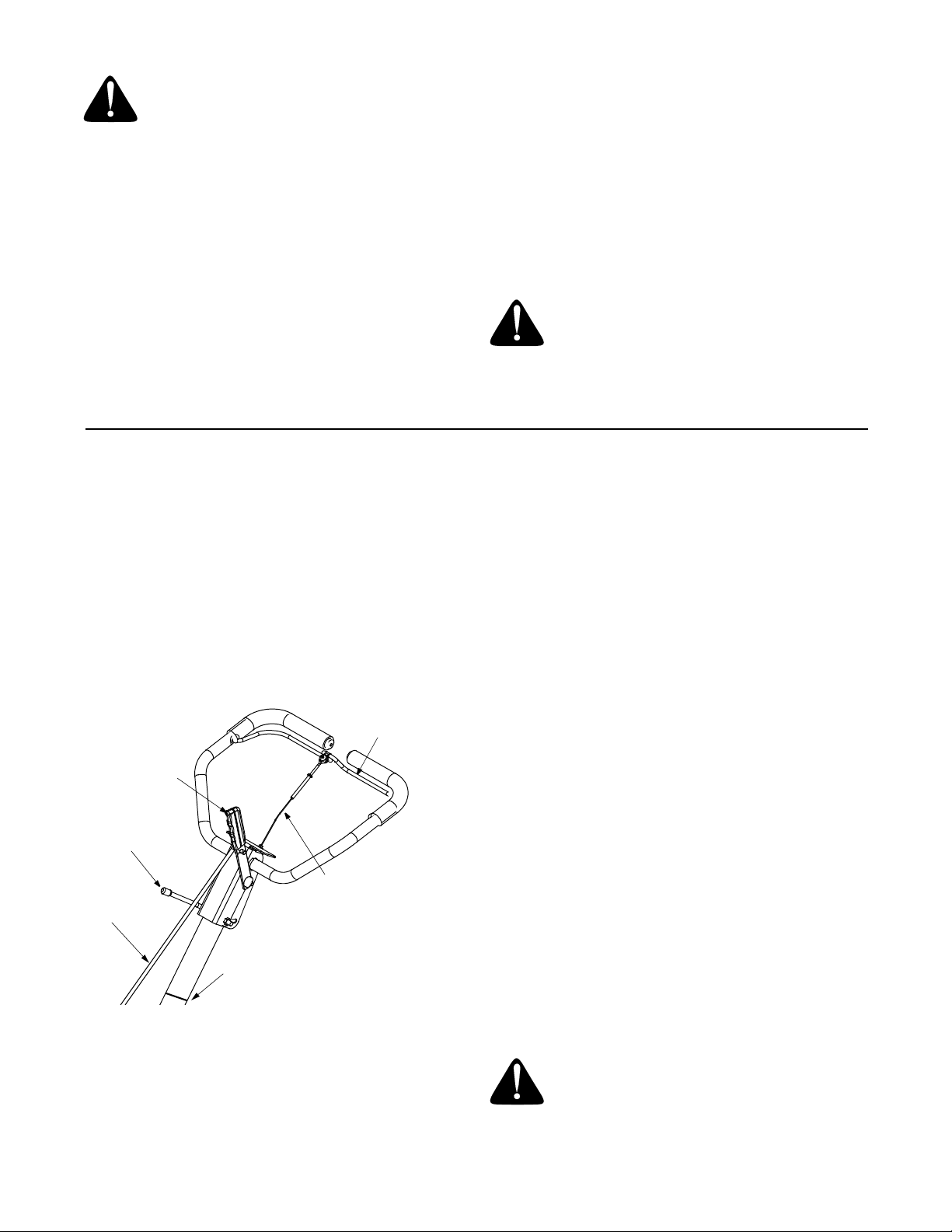

ATTACHING THE HANDLE ASSEMBLY

Remove

Handle

Assembly

Handle

Bracket

Rear Tine

Shield

Depth Stake

WARNING: Disconnect the spark plug

wire and ground against the engine to

prevent unintended starting.

Figure 1

Figure 2

1. Remove top two bolts and flange lock nuts from handle mounting brackets as shown in Figure 2. Do not remove the bottom bolt and nut.

2. Place handle assembly in position between the handle mounting brackets. See Figure 2.

3. Line up holes in handle with holes in handle mounting brackets. Secure with hardware removed in step 1.

6

Page 7

Slot Head Screw,

Nut, Flat Washers

Internally Threaded

Tube

Clutch

Bail

Threaded

Eyebolt

Slot Head Screw

Flat Washers

1/4”

Nut

Plastic Fitting

Figure 3

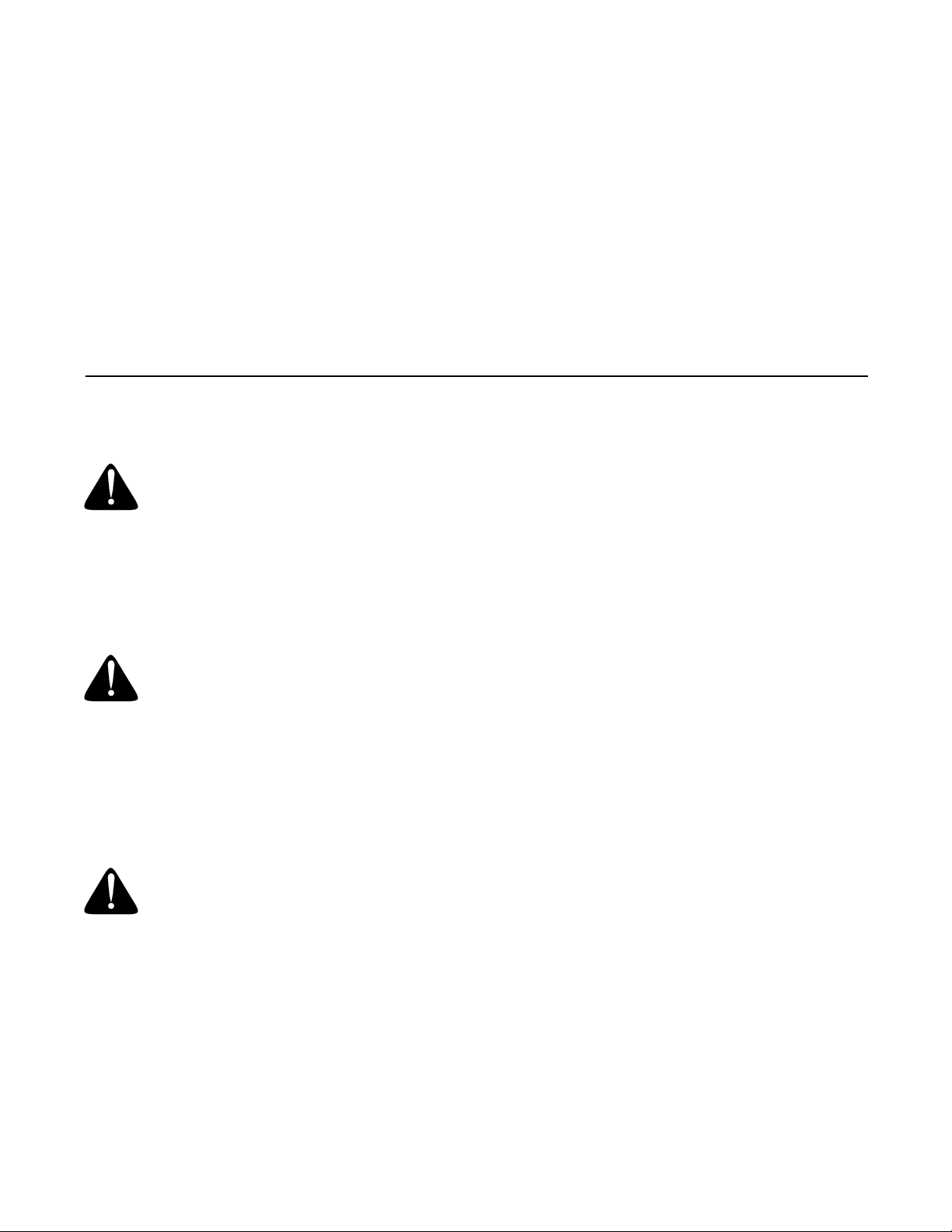

ATTACHING THE CLUTCH CABLE

Attach the clutch cable to the handle as follows (be

careful not to kink the cable).

1. Remove threaded eyebolt and nut from the end of the cable.

2. Route the clutch cable to the right side of the handle mounting brackets and underneath the handle.

3. Push the cable through the hole in the center of the handle and snap in the plastic fitting. See Figure 3.

4. Remove slot head screw, nut and two flat washers from the clutch bail.

5. Fasten the threaded eyebolt onto bail as shown in Figure 4. The parts go together from top to bottom as follows: Slot Head Screw, Flat Washer, Clip, Eyebolt, Flat Washer and 1/4” Nut.

6. Thread eyebolt and #10 nut, removed in step 1, into the internally threaded tube at the end of the cable. Thread engagement should be about 3/4”. Tighten nut against tube at end of cable. See Figure 4.

#10

Nut

”

4

/

3

Internally

Threaded

Tube

Figure 4

ATTACHING THE CONTROL ROD

• Make sure the handle assembly is in the highest

position.

• Remove hairpin clips from control rod, (rubber

washers to remain on control rod).

• Insert the shorter, (angled), end of the control rod

through the indicator bracket on the shift cover and

secure with hairpin clip that was removed in step 1.

See Figure 5.

• Insert the longer end of the control rod through the

hole in the gear selector handle and secure with

hairpin clip.See Figure 6.

Rubber

Washer

Idler Pulley Rod

Control Rod

Indicator Bracket

Hairpin Clip

NOTE: Do not overtighten control wire. Too much

tension may cause it to break.

WARNING:

clutch cable adjustment before operating

the tiller.

Be certain to check the

Figure 5

CHECKING THE CLUTCH ADJUSTMENT

IMPORTANT:

gasoline before checking this adjustment. Refer to the

separate engine manual packed with your tiller for

proper fuel and engine oil recommendations.

Position the tiller so the front counterweight is against

a solid object, such as a wall. With the gear selection

lever in NEUTRAL, start the engine. Refer to the

separate engine manual.

Standing on the right side of the tiller, examine the belt

(inside the belt cover). It should not be turning.

7

Service the engine with oil and

Page 8

WARNING: Do not put fingers under the

belt cover.

If the belt turns without bail engaged, adjust by

unthreading the internally threaded tube at the end of

the cable a few turns clockwise (when standing in

operator’s position), and then retighten the nut against

the tube.

Now move the shift lever to FORWARD (Wheels

Forward) position. Carefully engage the clutch by lifting

the clutch control bail against the handle. The wheels

should spin.

If the wheels do not spin with the unit in forward,

adjust by unthreading the tube at the end of the cable a

few turns counter-clockwise, (when standing in

operator’s position), and then retighten the nut against

the tube.

Recheck both adjustments, and readjust as necessary.

SECTION 4: CONTROLS

NOTE: A secondary cable adjustment is available if

you reach the point that additional adjustment is

needed. Remove the belt cover and move the hex nuts

at the other end of the cable towards the end of the

casing. Then readjust the hex nuts at the handle.

TIRE PRESSURE

The tires on your unit may be over-inflated for shipping

purposes. Reduce the tire pressure before operating

the unit. Recommended operating tire pressure is

approximately 20 p.s.i. (check sidewall of tire for tire

manufacturer’s recommended pressure).

WARNING: Maximum tire pressure

under any circumstances is 30 p.s.i. Equal

tire pressure should be maintained on

both tires.

THROTTLE CONTROL

The throttle control lever is located on the engine. It

controls the engine speed and stops the engine. See

Engine manual for further information.

CHOKE LEVER (if equipped)

The choke lever is located to the left of the throttle. It is

used to enrich the fuel mixture in the carburetor when

starting a cold engine. See Engine manual for further

information.

Clutch

Gear Selection Handle

Height

Adjustment

Lever

Control

Rod

Clutch

Cable

Cable Tie

Figure 6

Control

Bail

below). Pull or push the handle so that the indicator on

top of shift cover points to the operating mode desired.

See Figure 6.

NEUTRAL—Transmission is in neutral.

REVERSE—Reverse wheel drive.

FORWARD Modes:

Wheels Forward— Forward wheel drive only.

Tines Reverse— Forward wheel drive and reverse

tine drive.

Tines Forward— Forward wheel and tine drive.

IMPORTANT: Use the reverse tine drive when

tilling virgin ground, sod, or hard soil. Use the forward

tine drive when cultivating or tilling soft ground.

NOTE: If difficulty is encountered in moving the gear

selection handle, move the tiller forward or backward

slightly to allow the gears to synchronize.

• To shift into forward or reverse wheel drive,

move tiller forward slightly then backward to

allow the gears to synchronize.

• To shift into forward wheels and tine drive, push

forward slightly on the gear selection handle and

slowly engage the clutch control allowing the

gears to synchronize.

• To stop forward movement and tine drive,

release the clutch control. Do not shift gears

with the clutch control engaged except when

engaging the tines.

GEAR SELECTION HANDLE

The gear selection handle is located in the center of

the handle on the tiller. It is used to select NEUTRAL,

REVERSE, or one of the FORWARD modes (see

WARNING: Make certain unit is in

NEUTRAL when starting the engine.

8

Page 9

DEPTH STAKE

The depth bar controls the tilling depth. Refer to

SECTION 6: HOW TO USE YOUR TILLER on page

10.

ENGINE CONTROLS

See the separate engine manual for additional

information and functions of the engine controls.

PRIMER BUTTON (if equipped)

The primer button is located behind the air cleaner. It

is used to enrich the fuel mixture in the carburetor

when starting a cold engine.

SECTION 5: OPERATION

HANDLE ADJUSTMENT

The handle may be adjusted to be raised or lowered in

line with the tiller. To adjust the handle position loosen

the handle height adjustment crank a few turns. Pivot

handle up or down to desired position. Tighten crank.

See Figure 6.

CLUTCH CONTROL BAIL

The clutch control bail is located below the handle.

See Figure 6. Lifting the clutch control bail against the

handle engages the wheel and tine drive mechanisms.

NOTE: Never engage clutch lever while shifting.

NOTE: Engine is shipped WITHOUT oil.

WARNING: Read, understand, and

follow all instructions and warnings on

the machine and in this manual before

operating.

BEFORE STARTING

Service engine with gasoline and oil as instructed in

the separate engine manual packed with your tiller.

Read instructions carefully.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running.

TO START ENGINE

NOTE: When pushing the unit with the engine off,

you will hear a ratcheting sound (gear noise) which is

normal.

WARNING: Be Sure No One Is Standing

In Front Of The Tiller While The Engine Is

Running Or Being Started.

1. Place gear selection lever in NEUTRAL.

2. Place the throttle control lever in the FAST (rabbit) position. Place the engine speed control in the START position.

3. Move choke lever to CHOKE position or if equipped, push primer two (2) or three (3) times. Wait about two (2) seconds between each push.

4. Stand at side of tiller. Grasp the starter handle and pull out slowly, until it pulls slightly harder. Let rope rewind slowly.

5. Pull starter handle rapidly. Do not allow handle to snap back. Allow it to rewind slowly while keeping a firm hold on the starter handle.

6. Repeat steps 3 and 4 until engine starts.

7. As engine warms up and begins to operate evenly, move choke lever gradually to RUN position. If engine falters, return to choke position, then slowly move to RUN position.

NOTE: Refer to engine manual for additional engine

information.

NOTE: After starting engine and prior to using the

tiller, be certain to check the clutch adjustment as

described in “Checking the Clutch Adjustment” section

of Assembly Instructions.

TO STOP ENGINE

1. Move throttle control to the STOP position.

2. Disconnect spark plug wire and ground to prevent

accidentally starting while equipment is

unattended.

NOTE: After the first ten hours of operation, recheck

the clutch adjustment. Refer to “Checking the Clutch

Adjustment” section of the Assembly Instructions.

NOTE: A warm engine may not require choking.

9

Page 10

SECTION 6: HOW TO USE YOUR TILLER

WARNING: Be certain the spark plug

wire is disconnected and grounded

against the engine when performing any

adjustments.

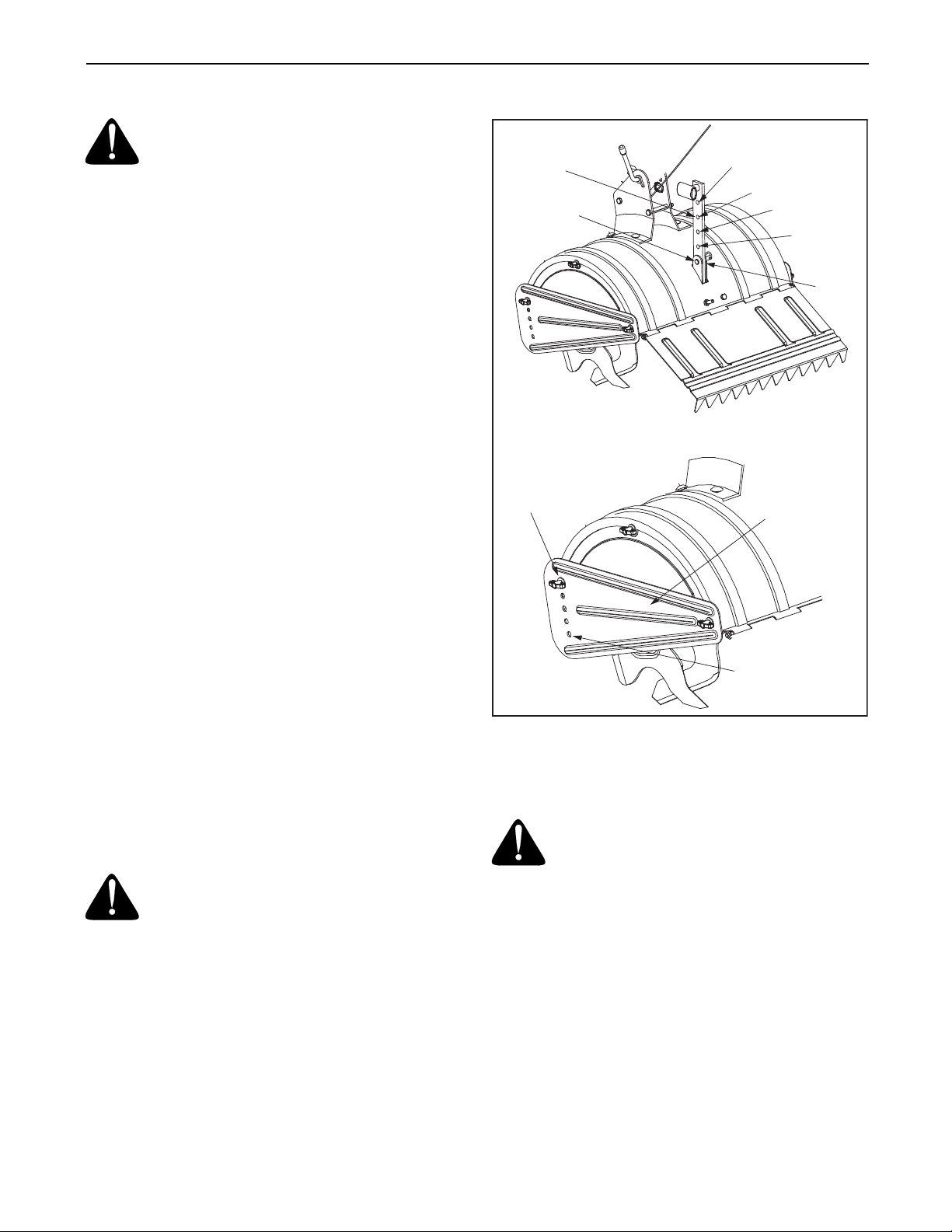

Tilling depth is controlled by the depth stake which can

be adjusted to five different settings. See Figure 7.

Adjust the side shields as shown in Figure 7, as you

adjust the depth stake. Be certain spark plug wire is

disconnected and grounded against the engine.

1. When using the tiller for the first time, use the second adjustment hole from the top (1" of tilling depth). See Figure 7.

2. When breaking up sod and for shallow cultivation,

use the setting which gives 1" of tilling depth

(second hole from the top). Place the side shields

in their lowest position. For further depth, raise the

depth stake and side shields and make one or two

more passes over the area.

3. When tilling loose soil, depth stake may be raised to its highest position (use bottom adjustment hole) to give the deepest tilling depth. Raise the side shields to their highest position.

4. To transport tiller, lower the depth stake (use top adjustment hole).

To adjust the depth stake, remove the clevis pin and

hairpin clip. See Figure 7. Move the depth stake to the

desired setting and secure with the clevis pin and

hairpin clip.

To adjust the side shields, remove the wing nuts. See

Figure 7. Place side shield in position desired. Replace

wing nuts and tighten securely.

TO OPERATE THE TILLER:

1. Select the depth stake setting.

2. Start engine as instructed on page 9.

3. Move gear selection handle to one of the forward modes or reverse.

WARNING: Do not move the gear

selection handle with the wheels or tines

engaged. Make certain the unit is stopped

completely before changing the gear

selection.

To transport tiller, do not engage the tines. Select the

wheel drive only.

For best results, it is recommended the garden be tilled

twice (lengthwise, then widthwise) to pulverize the soil.

Use This

Position

First Time

Clevis Pin

Use This Hole For

Lowest (shallowest)

Position

WARNING: Do not push down on the

handles so that the wheels are lifted off

the ground while using the reverse tine

drive, or the tiller could move backward

and cause personal injury.

Figure 7

Transport Position

1”

3”

5”

7”

Side Shields

Use This Hole For

Highest (Deepest)

Position

IMPORTANT: Use the reverse tine drive when

tilling virgin ground, sod or hard soil. Use the forward

tine drive when cultivating or tilling soft ground.

4. Squeeze the clutch control bail against the handle to engage the wheels and tines.

NOTE: Make certain the gear selection indicator is

correctly positioned before engaging the clutch handle.

If it is between gears, the engine will stall.

10

Page 11

SECTION 7: ADJUSTMENTS

WARNING: Never attempt to make any

adjustments while the engine is running,

except where specified in operator’s

manual.

HANDLE ADJUSTMENT

The handle height may be adjusted. Refer to the

Control section for details of handle adjustment.

BELT TENSION ADJUSTMENT

Periodic adjustment of the belt tension may be

required due to normal stretch and wear on the belt.

Adjustment is needed if the tines or wheels seem to

hesitate while turning, but the engine maintains the

same speed.

To adjust the tension on the belt, refer to clutch

adjustment information in “Checking the Clutch

Adjustment” section of the Assembly Instructions.

After belt tension has been adjusted, if the belt is

excessively stretched, you may need to adjust the idler

pulley rod. This can easily be checked.

With the engine off and the clutch control bail

disengaged, shift the gear selection handle to each

forward mode. If the indicator bracket touches the idler

pulley rod, (with the clutch control bail disengaged),

then an adjustment is necessary.

1. Disconnect and ground out spark plug wire against the engine.

2. Remove the belt cover as described in the belt replacement section on page 12.

3. Remove the hairpin clip and flat washer from the idler pulley rod. See Figure 9.

4. Move the idler pulley rod to the lower hole in the idler bracket. See Figure 9.

5. Replace the wave washer and hairpin clip.

6. Check clearance of the idler pulley rod to the indicator bracket by shifting to each forward mode, as before.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running,

(e.g. carburetor), disengage all clutches

and tines. Keep clear of all moving parts.

Be careful of heated surfaces and muffler.

Never make unnecessary adjustments. The factory

settings are correct for most applications. If

adjustments are needed, refer to the separate engine

manual packed with your tiller.

SECTION 8: LUBRICATION

Transmission—The transmission is pre-lubricated

and sealed at the factory. It requires no checking

unless the transmission is disassembled. To fill with

grease, lay the right half of the transmission on its

side. Add 30 ounces of Benalene 920 grease. Apply a

bead of RTV or silicone sealant to the right half of the

transmission, all the way around the gear

compartment. Assemble the left half to it. This grease

can be obtained at your nearest authorized dealer.

Order part number 737-0300.

SECTION 9: MAINTENANCE

WARNING: Disconnect the spark plug

wire and ground it against the engine

before performing any repairs or

maintenance.

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Clutch Bail—Lubricate the pivot point on the clutch

bail and the cable at least once a season with light oil.

The control must operate freely in both directions.

Pivot Points—Lubricate all pivot points and linkages

at least once a season with light oil.

Tine Shaft—Remove tines at least once a season and

lubricate with oil.

Wheel Axle—Remove the wheel assemblies at least

once a season and lubricate with oil.

Service air cleaner every ten hours under normal

conditions. Clean every hour under extremely dusty

conditions. Poor engine performance and flooding

usually indicates that the air cleaner should be

serviced. To service the air cleaner, refer to the

separate engine manual packed with your unit.

IMPORTANT: Never run your engine without air

cleaner completely assembled.

11

Page 12

The spark plug should be cleaned and the gap reset

every 25 hours of engine operation. Spark plug

replacement is recommended at the start of each tiller

season; check engine manual for correct plug type and

gap specification.

Clean the engine regularly with a cloth or brush. Keep

the cooling system (blower housing area) clean to

permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

Torx Screws

Belt Cover

Hex Cap Nut

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed off

immediately instead of after it dries. Always towel dry

the tiller afterwards and apply a light coat of oil or

silicone to prevent rusting or water damage.

IMPORTANT: Never use a "pressure washer" to

clean your tiller. Water can penetrate tight areas of the

tiller and its chain case and cause serious damage to

the unit.

BELT REPLACEMENT

Your tiller has been engineered with a belt made of

special material (Kevlar Tensile) for longer life and

better performance. It should not be replaced with an

off-the-shelf belt.

If belt replacement is required, order belt or belts by

part number from your nearest authorized dealer.

Part No. 754-0434—‘‘V’’ Belt

1. Disconnect and ground the spark plug wire against the engine.

2. Remove the belt cover from the left side of the tiller as follows: See Figure 8. Remove two torx screws from the top of belt cover.

3. Remove the hex cap nut and flat washer from the side of the belt cover. Remove the hex screw at the bottom of the front of the cover.

4. Remove the belt keeper bracket located behind the engine pulley by removing two hex bolts and lock washers. See Figure 9.

5. Remove belt. Reassemble new belt, following instructions in reverse order.

Self Tap

Screw

Figure 8

Idler

Pulley

Rod

Engine

Pulley

Belt Keeper

Brkt.

Figure 9

Idler

Brkt.

TIRES

Recommended operating tire pressure is

approximately 20 p.s.i. (check sidewall of tire for tire

manufacturer’s recommended pressure). Maximum

tire pressure under any circumstances is 30 p.s.i.

Equal tire pressure should be maintained on both tires.

When installing a tire to the rim, be certain rim is clean

and free of rust. Lubricate both the tire and rim

generously. Never inflate to over 30 p.s.i. to seat

beads.

WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause tire/

rim assembly to burst with force sufficient

to cause serious injury.

NOTE: Upon reassembly, make certain the belt is

routed over the idler pulley and inside of belt keepers

by engine pulley. See Figure 9.

SECTION 10: OFF-SEASON STORAGE

If the tiller will not be used for a period longer than 30

days, the following steps should be taken to prepare

the tiller for storage.

1. Clean the exterior of engine and the entire tiller thoroughly. Lubricate the tiller as described in the lubrication instructions.

12

2. We do NOT recommend the use of pressure washers to clean your unit. They may cause damage to electric components, spindles, pulleys, bearings or the engine. The use of pressure washers will result in shortened life and reduced serviceability.

Page 13

3. Refer to the engine manual for correct engine storage instructions.

4. Wipe tines with oiled rag to prevent rust.

5. Store tiller in a clean, dry area. Do not store next to corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment

in an unventilated or metal storage shed, care

should be taken to rustproof the equipment. Using a

light oil or silicone, coat the equipment, especially

any springs, bearings and cables.

SECTION 11: TROUBLE SHOOTING GUIDE

Trouble Possible Cause(s) Corrective Action

Engine fails to

start

Engine runs

erratic

Engine overheats

Tines do not

engage

Tines skip over

ground

Fuel tank empty, or stale fuel.

Throttle control lever not in correct

starting position (if so equipped).

Blocked fuel line.

Dirty aircleaner.

Choke not in ON position.

Spark plug wire disconnected.

Faulty spark plug.

Engine flooded.

Unit running on CHOKE.

Spark plug wire loose.

Blocked fuel line or stale fuel.

Vent in gas cap plugged.

Water or dirt in fuel system.

Dirty air cleaner.

Carburetor out of adjustment.

Engine oil level low.

Dirty air cleaner.

Air flow restricted.

Carburetor not adjusted properly.

Foreign object lodged in tines.

Tine clevis pin(s) missing.

Pulley and idler not in correct

adjustment.

Not shifting properly.

Control cable not adjusted properly.

Belt worn and/or stretched.

Improper rotation. Forward rotation should only be used on soil that has

Fill tank with clean, fresh gasoline. Fuel will not last over

thirty days unless a fuel stabilizer is used.

Move throttle lever to start position.

Clean fuel line.

Refer to the engine manual packed with your unit.

Move switch to ON position.

Connect wire to spark plug.

Clean, adjust gap or replace.

Refer to the engine manual packed with your unit.

Move choke lever to OFF position.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean, fresh gasoline. Fuel will

not last over thirty days unless a fuel stabilizer is used.

Clear vent.

Drain fuel tank. Refill with fresh fuel.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Adjust carburetor as instructed in separate engine manual.

Dislodge foreign object.

Replace tine clevis pin(s).

Take unit to authorized service dealer.

Refer to Controls section of operator’s manual for proper

shifting procedures.

Adjust control cable (see assembly instructions).

Replace belt.

already been tilled, not on virgin soil.

Wheels do not

engage

Clevis pin missing.

Tiller is not being shifted properly.

Control cable not adjusted properly.

Belt worn and/or stretched.

Replace clevis pin.

Refer to Controls section of operator’s manual for proper

shifting procedures.

Adjust control cable (see assembly instructions).

Replace belt.

NOTE: For repairs beyond the minor adjustments above, contact your local authorized service dealer.

13

Page 14

13

16

52

10

12

34

29

16

55

45

36

1

18

36

8

55

53

17

6

3

5

36

42

23

7

22

32

47

46

21

37

33

40

31

28

17

44

15

27

43

4

20

50

51

34

29

45

26

41

16

55

36

55

19

16

14

44

14

35

49

54

33

14

16

2

36

24

28

25

10

9

14

48

14

11

Page 15

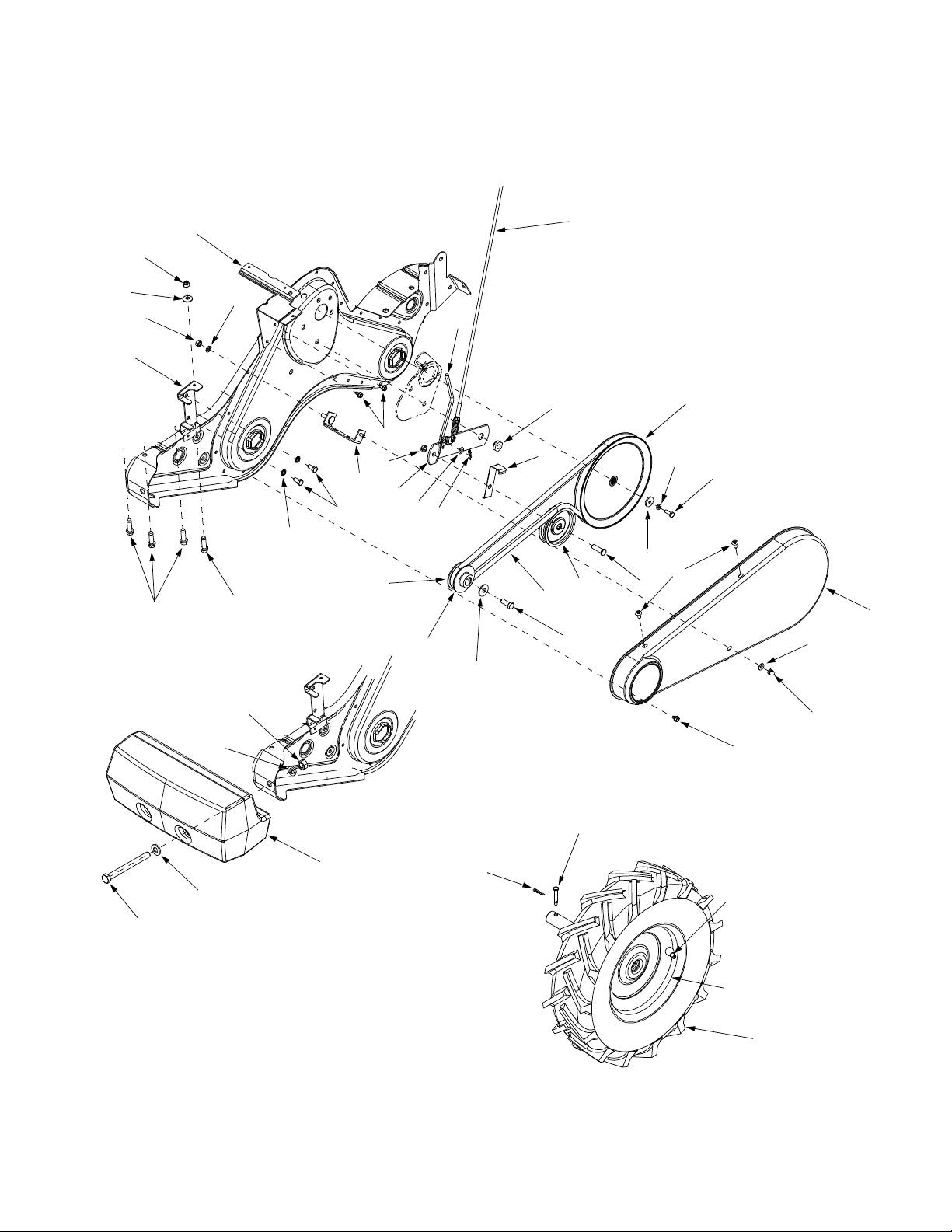

REF.

NO.

N°. DE

RÉF.

PART

NO.

N° DE

PIÈCE DESCRIPTION DESCRIPTION

1 611-0020 Wheel Shaft Ass'y 33T Arbre de roue 33 dents

2 611-0021 Tine Shaft Ass'y 18T Arbre de dents - 18 dents

3 611-0128 Jack Shaft Ass'y Arbre secondaire

4 611-0129 Input Shaft Ass'y Arbre

5 617-0058 Rev. Idler Gear Ass'y 30T Engrenage 30 dents

6 617-0059 Fr. Idler Gear Ass'y 30 T Engrenage 30 dents

7 617-0060 Tine Input Sprocket Ass'y 9T Pignon - 9 dents

8 617-0061 Wheel Input Sprocket Ass'y 10T Engrenage 10 dents

9 617-0062 Gear Ass'y 11T Engrenage 11 dents

10 686-0108 RH Housing Ass'y Boîtier de transmission - droite

11 710-0376 Hex. Scr 5/16-18 x 1.00 Gr. 5 Vis à tête hex. 5/16-18 x 1,00 Qual. 5

12 710-0599 Hex Wash S-Tapp Scr 1/4-20 x .50 Vis autotaraudeuse à rondelle hex. de 1/4-20 x 0,5

13 710-0604A Self-tapping Screw 5/16-18 x .625 Vis autotaraudeuse 5/16-18 x 0,625 po

14 710-3008 Hex Bolt 5/16-18 x .75" Lg. Gr. 5 Boulon hex. 5/16-18 x 0,75 po de lg. Qual. 5

15 711-1349 Input Shaft Arbre

16 712-0378 Hex Nut 7/16-20 Écrou à six pans 7/16-20

17 712-3004A Hex Flange L-Nut 5/16-18 Gr. 5 Contre-écrou de collet hex. 5/16-18 Qual. 5

18 713-0367 #420 Chain 1/2 Pitch x 50 Links-Endless Chaîne, no 420 pas de 1/2 x 50 maillons

19 713-0484 #50 Chain 5/8 Pitch x 54 Links Chaîne no 50, 5/8 x 54 maillons

20 716-0865 Snap Ring Joint

21 717-0853 Shifting Fork Fourchette

22 717-1582 Spur Gear 44T Engrenage 44 dents

23 717-1583 Spur Gear 30T Engrenage 30 dents

24 717-1584 Spur Gear 30T Engrenage 30 dents

25 717-1585 Spur Gear 44T Engrenage 44 dents

26 717-1587 Spur Gear 44T Engrenage 44 dents

27 717-1594 Spur Gear 16T Engrenage 16 dents

28 721-0378 Seal 1.0" Shaft Joint de 1,0 diam. arbre

29 721-0379 Seal .75 Shaft Joint de 0,75 diam. arbre

31 726-0277 Taper Cap Plug Bouchon à capuchon effilé

32 732-0496 Compression Spring .50" Lg. Ressort de compression 0,50 po de lg

33 736-0163 Flat Washer 1.03 ID x 1.62 OD x .03 Rondelle plate 1,03 DI x 1,62 DE x 0,03

34 736-0351 Flat Washer .76 ID x 1.5 OD x .03 Rondelle plate 0,76 DI x 1,5 DE x 0,03

35 736-0226 Flat Washer .469 ID x .88 OD x .063 Rondelle plate 0,469 DI x 0,88 DE x 0,063

36 736-0518 Thrust Wash. .445 ID x 1.92 OD Rondelle de butée 0,445 DI x 1,92 DE

37 736-3088 Flat Washer .635" ID x 1.59 OD Rondelle plate 0,635 DI x 1,59 DE

40 738-0645 Detent Shaft 1/2" Dia. Arbre à cliquet de 1/2 po de diamètre

41 738-0648 Jack Shaft 5/8" Dia. x 2.38 Arbre secondaire 5/8" diam. x 2,38

42 738-1013 Jack Shaft .625 x 5.0 Arbre secondaire 0,625 x 5,0

43 741-0124 Ball Bearing Roulement à billes

44 741-0420 Tine Shaft Brg. 1.002 x 2.50 Roulement de l'arbre des dents - 1,002 x 2,50

45 741-0421 Wheel Brg. .752" x 2.5” Roulement 0,752 po x 2,50 po

46 741-0563 Ball Bearing w/snap ring Roulement à billes avec bague

47 741-0862 Ball Detent .250 DIA Bille de verrouillage 0,250 dia.

48 750-0258 Spacer .315" ID x .375" Lg. Entretoise 0,315 DI x 0,375 po de lg.

49 750-0570 Step Spacer Cale d'espacement

50 750-0664 Spacer .505 ID x .88 OD Entretoise 0,505 DI x 0,88 DE

51 750-0671 Spacer .75" ID x .50" Lg. Entretoise 0,75 DI x 0,50 po de lg

52 786-0171 LH Chain Case Ass'y Ensemble de carter de chaîne de gauche

53 786-0238 Gear Positioner Bracket Support

54 736-0171 Lockwasher 7/16 ID Rondelle frein 7/16 DI

55 736-0407 Cupped Washer, .45 x 1.0 x .062 Rondelle creuse 0,45 x 1,0 x 0,062 po

686-0107 Gear Case Ass'y Complete Ensemble de carter de l'engrenage complet

214-450

11.28.03

15

Page 16

67

2

70

12

15

12

46

42

61

25

62

27

60

37

60

22

61

5

17

70

69

68

10

23

19

1

11

7

3

20

18

8

14

6

16

4

34

64

9

27

38

30

39

63

26

21

32

36

33

31

29

24

44

26

49

30

26

59

41

16

66

28

40

30

35

6

58

51

65

53

55

50

54

57

56

Page 17

REF.

NO.

N°. DE

RÉF.

1 747-1152 Shift Rod Tige de changement de vitesses

2 649-0041 Upper Handle Assembly Guidon supérieur

3 649-0034 Lower Handle Ass'y Guidon inférieur

4 710-3005 Hex Bolt 3/8-16 x 1.25 Boulon hex. 3/8-16 x 1,25

5 710-3056 Hex Bolt 5/16-18 x 3.25 Boulon hex. 5/16-18 x 3,25

6 711-0415 Clevis Pin 3/8 Dia Axe de chape 3/8 Dia.

7 712-0379 Hex Flange Nut 3/8-24 Thd. Écrou à six pans à collet de 3/8 - fil. 24

8 712-0429 Hex Ins. L-Nut 5/16-18 Gr. 5 Nylon Contre-écrou de blocage 5/16-18 Qual. 5 nylon

9 714-0147 Hairpin Goupille

10 720-0313 Grip Poignée

11 720-0210A Small "T" Knob Bouton en <<T>> (Petite)

12 720-0278A Foam Grip (2 req'd) Poignée de mousse (qté. 2)

14 726-0317 Cable Tie Attache câble

15 735-0246 Vinyl End Plug Bouchon - vinyl

16 736-0117 Flat Washer .385 ID x .62 OD x .033 Rondelle plate 0,385 DI x 0,62 DE x 0,033

17 736-0242 Cupped Washer .340 ID x .872 OD x .060 Rondelle creuse 0,340 DI x 0,872 DE x 0,060

18 738-0958 Shoulder Spacer Cale d'épaulement

19 784-0190 Handle Adj. Crank Manivelle de réglage du guidon

20 784-0191 Bracket Hex Nut Retainer Support de retenue à écrou à six pans

21 786-0120 Depth Bar Barre de profondeur d'attelage

22 747-1219 Clutch Bail Barre de commande de l'embrayage

23 786-0181 Shift Lever Rod Tige de levier de changement de vitesses

24 686-0044A Tine Shield Cover Ass'y Couvercle

25 710-0176 Hex Scr 5/16-18 x 2.75 Vis à tête hexagonale 5/16 x 2,75

26 710-3008 Hex Bolt 5/16-18 x .75" Lg. Gr. 5 Boulon hex. 5/16-18 x 0,75 po de lg. qual. 5

27 710-3097 Carriage Bolt 3/8-16 x 1.0" Lg. Boulon ordinaire 3/8-16 x 1,0 po de lg

28 712-0421 Wing Nut Écrou à oreilles

29 736-0169 L-Wash 3/8 ID Rondelle frein 3/8 DI

30 712-3004A Hex Flange L-Nut 5/16-18 Gr. 5 Contre-écrou de collet hex. 5/16-18 Qual. 5

31 726-0106 Push Cap Coiffe

32 738-0849 Hex Screw 5/16-18 x .75 Vis à tête hex. 5/16-18 x 0,75

33 747-0432 Tiller Flap Rod Tige de protecteur de dents

34 750-0885A Spacer .322 ID x .625 OD Entretoise 0,322 DI x 0,625 DE

35 786-0090 Side Shield Dispositif de protection latéral

36 786-0113 Rear Tine Shield Protecteur de dents

37 786-0176 RH Handle Brkt. Support du guidon - droite

38 786-0177 LH Handle Brkt. Support du guidon - gauche

39 786-0178 Tine Shield Bouclieur de dents

40 786-0179 Tine Shield Brkt. Support de bouclier de dents

41 786-0180 Shoulder Spacer Brkt. Support

42 686-0109 Shift Crank Ass'y Manivelle de changement de la vitesse

44 710-1017 Torx Mach. AB-Tapp Scr. 1/4 x .62" Lg. Vis torx AB 1/4 x 0,62 po de lg

46 715-0120 Spring Pin Roll 3/16 Dia. Goupille ronde à ressort de 5/16

49 784-0208C Shift Cover Couvercle

50 784-0160 Tine Adapter Ass'y 18” Adaptateur des dents 18 po

51 712-3054 Hex L-Nut 3/8-24 (Grade 5) Écrou de blocage 3/8-24 (qual. 5)

53 742-0305 13" Dia. Articulating Tine Dent d'articulation de 13 po de diamètre

54 738-0689 Shld. Scr. 1/2 Dia. x .175 Vis à épaulement 1/2 x 0,175

55 736-0208 Flat Washer .51 ID x 1.50 OD x .075 Rondelle plate 0,51 DI x 1,50 DE x 0,075

56 736-0253 Cupped Washer .505 ID x 1.00 OD x .075 Rondelle creuse 0,505 DI x 1,00 DE x 0,075

57 738-0688 Shld. Bolt 1/2" Dia. x .320 Boulon épaulée 1/2 diam. x 0,320

58 784-0205 Tine Ass'y Comp. 18” Ensemble des dents 18 po

59 714-0149B Internal Cotter Pin Goupille fendue interne

60 735-0127 Rubber Washer Rondelle en caoutchouc

61 714-0104 Int. Cotter Pin 5/16 Dia. Goupille fendue 5/16 dia.

62 710-3022 Hex Screw 3/8-16 x 2.75" Lg. Vis à tête hex 3/8-16 x 2,75 po de lg.

63 736-0204 Flat Washer .34 ID x .62 OD x .03 Rondelle plate 0,34 DI x 0,62 DE x 0,03

64 712-0431 Flanged Lock Nut 3/8-16 Gr. F Contre-écrou de collet hex. 3/8-16 Qual. F

65 736-0169 L-Wash 3/8 ID Rondelle frein 3/8 DI

66 712-3017 Hex Nut 3/8-16 Gr. 5 Écrou hex. 3/8-16 Qual. 5

67 710-0946 Truss Mach. Scr. 1/4-20 x .62" LG. Vis taraudée 1/4-20 x 0,62 po de lg

68 712-0324 Hex Ins. Locknut 1/4-20 Gr. 8 Nylon Écrou de blocage 1/4-20 Qual. 8 nylon

69 726-0273 Battery Hose Clamp Collier

70 736-3090 Flat Washer .260 x .72 x .060 Rondelle plate 0,260 x 0,72 x 0,060

PAR T

NO.

N° DE

PIÈCE DESCRIPTION DESCRIPTION

214-4501

10.12.04

17

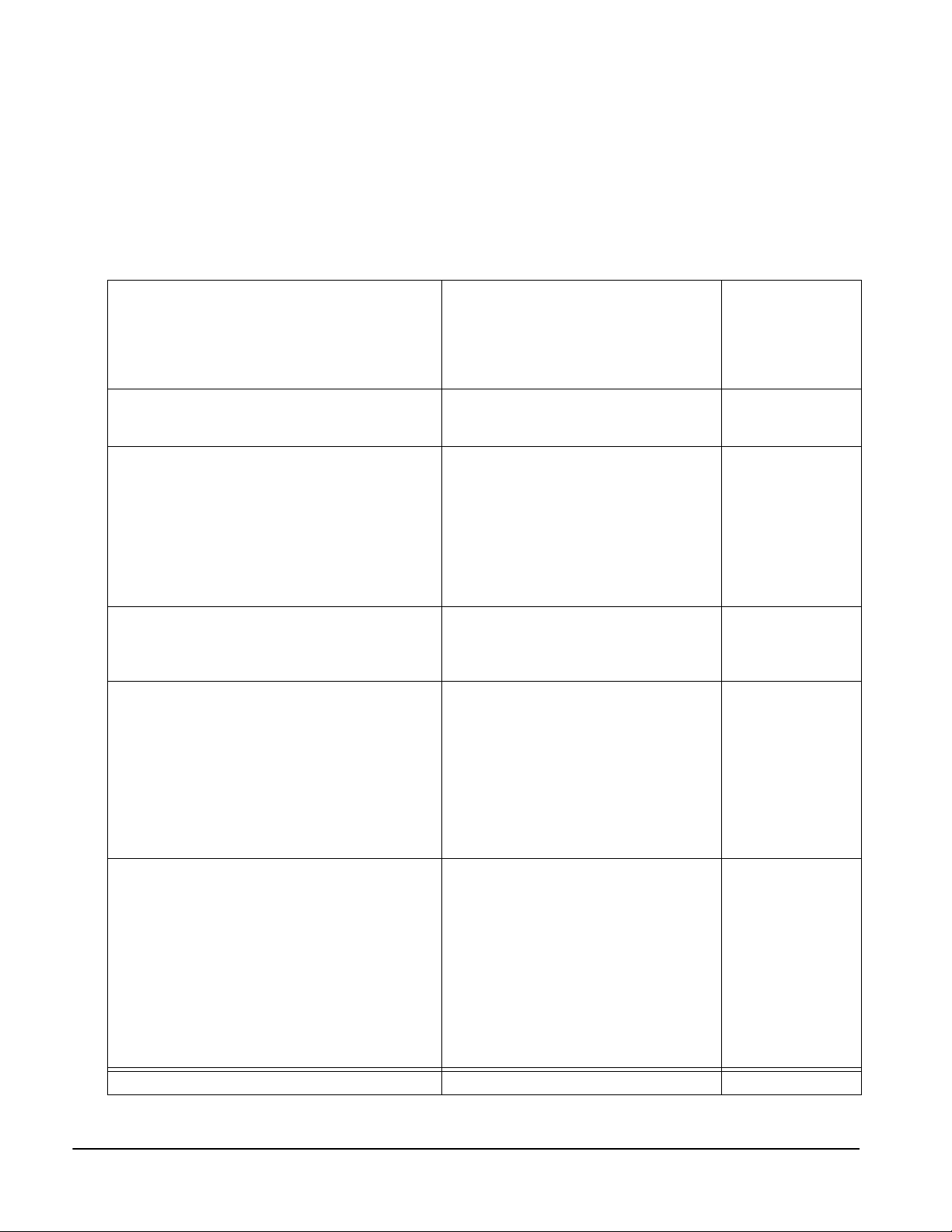

Page 18

45

27

18

44

26

45

12

19

17

6

8

1

25

22

14

10

23

16

2

11

4

33

35

28

13

21

20

5

24

15

3

40

7

43

42

41

34

37

38

36

39

10

32

31

30

29

18

Page 19

REF.

NO.

N°. DE

RÉF.

PART

NO.

N° DE

PIÈCE DESCRIPTION DESCRIPTION

1 686-0111 Belt Cover Brkt Ass'y Support de couvercle de la courroie

2 710-0237 Hex Screw 5/16-24 x .625 Gr. 5 Vis à tête hexagonale 5/16-24 x 0,625 Qual. 5

3 710-0412 Hex Scr 1/4-28 x .75 Vis à tête hexagonale 1/4-28 x 0,75

4 710-0502A Hex Washer Scr 3/8-16 x 1.25 Vis à chapeau à six pans 3/8-16 x 1,25 po

5 710-0152 Hex Scr 3/8-24 x 1.00 Vis à tête hexagonale 3/8-24 x 1,00

6 710-0599 Hex Wash S-Tapp Scr 1/4-20 x .50 Vis autotaraudeuse à rondelle hex. de 1/4-20 x 0,5

7 710-0723 Hex Screw 3/8-16 x 1.25 Vis à tête hexagonale 3/8-16 x 1,25

8 712-0266 Hex Cent L-Nut 3/8-16 Contre-écrou de blocage 3/8-16

10 714-0104 Int. Cotter Pin 5/16 Dia. Goupille fendue 5/16 dia.

11 736-0104 Internal L-Washer Rondelle frein interne

12 736-0119 L-Wash 5/16 ID Rondelle frein 5/16 DI

13 736-0176 Flat Washer .265 ID x .938 OD x .120 Rondelle plate 0,265 DI x 0,938 DE x 0,120

14 736-0271 Shakeproof Spring Washer Rondelle anti-vibration

15 736-0329 L-Wash 1/4 ID Rondelle frein 1/4 DI

16 736-0452 Cupped Washer .396 ID x 1.140 OD Rondelle creuse 0,396 DI x 1,140 DE

17 738-0876 Shoulder Nut 7/16-20 Écrou à épaulement 7/16-20

18 746-1117 Clutch Cable Câble de l'embrayage

19 747-1159 Idler Pulley Rod Tige de poulie tendeur

20 754-0434 Belt: 4L x 58.16" Lg. Courroie: 4L x 58,16 po de lg.

21 756-0405 Flat Idler w/flanges 3-3/4" OD Tendeur plat à brides de 3-3/4 de po de DE

22 756-0971 Inner Engine Pulley Half Moitié intérieure de la poulie motrice

23 756-0972 Outer Engine Pulley Half Moitié extérieure de la poulie motrice

24 756-1162 Input Pulley Poulie

25 786-0064A Idler Bracket Support de tendeur

26 785-0186 Belt Keeper Brkt. Support

27 786-0187 Shift Cover Brkt. Support

28 786-0193 Idler Belt Keeper Protecteur de la courroie

29 634-0238 Wheel Ass'y RH 16 x 4 x 8 Gray Ensemble de roue CD 16 x 4 x 8 gris

634-0239 Wheel Ass'y LH 16 x 4 x 8 Gray Ensemble de roue CG 16 x 4 x 8 gris

734-0808 Tire Only (16") Pneu seulement (16 po.)

30 634-0108 Rim Only Jante seulement

31 734-0255 Air Valve Soupape à air

32 711-1017 Clevis Pin Axe de chape

33 710-0805 Hex Bolt 5/16-18 x 1.50" Lg. Gr. 5 Boulon hexagonal 5/16-18 x 1,50 po de lg Qual. 5

34 710-0382 Hex Bolt 1/2-13 x 5.00" Lg. Vis à tête hex. 1/2-13 x 5,00

35 712-0206 Hex Nut 1/2-13 Écrou hexagonal 1/2-13

36 723-0381 Counterweight 40 Lbs. Contre poids 40 lbs.

37 736-0326 Flat Washer .510 ID x 1.00 OD x .125 Rondelle plate 0,510 DI x 1,00 DE x 0,125

38 736-0921 L-Washer 1/2" ID Rondelle frein 1/2 DI

39 710-0653 Hex Wash HD Tapp Scr 1/4-20 x .38 Vis auto-taraudeuse hexagonale 1/4-20 x 0,38

40 710-1017 Torx Mach. AB-Tapp Scr. 1/4 x .62" Lg. Vis torx AB 1/4 x 0,62 po de lg.

41 712-0392 Hex Lock Stop Nut 1/4-28 Contre-écrou d'arrêt 1/4-28

42 736-3020 Flat Washer .266 ID x .625 OD Rondelle plate 0,266 DI x 0,625 DE

43 784-0158A Belt Cover Couvercle courroie

44 736-0242 Cupped Washer .340 ID x .872 OD x .060 Rondelle creuse 0,340 DI x 0,872 DE x 0,060

45 712-3010 Hex Nut 5/16-18 hd. Gr. 5 Écrou hexagonal 5/16-18 Qual. 5

737-0298 Oil Drain Tube Tuyau de vidange d'huile

737-0132 Pipe Cap 1/4 x 18 N.P.T. Capuchon de tuyau 1/4 x 18

215-4502

10.22.04

19

Page 20

TWO YEAR LIMITED WARRANTY

For TWO YEARS from the date of retail purchase within Canada, MTD PRODUCTS LIMITED will, at its option, re

pair or replace, for the original purchaser, free of charge, any part or parts found to be defective in material or

workmanship.

This warranty does not cover:

1. Any part which has become inoperative due to misuse, commercial use, abuse, neglect, accident, im

proper maintenance or alteration; or

2. The unit if it has not been operated and/or maintained in accordance with the owner’s instructions fur

nished with the unit; or

3. The engine or motor or component parts thereof which carry separate warranties from their manufac

turers. Please refer to The applicable manufacturer’s warranty on these items; or

4. Batteries and normal wear parts except as noted below. Log splitter pumps, valves and cylinders or

component parts thereof are covered by a one year warranty; or

5 Routine maintenance items such as lubricants, filters, blade sharpening and tune-ups, or adjustments

such as brake, clutch or deck; or

6. Normal deterioration of the exterior finish due to use or exposure.

Full Ninety Day Warranty on Battery: For ninety (90) days from the date of retail purchase, if any battery included

with this unit proves defective in material or workmanship and our testing determines the battery will not hold a

charge, MTD PRODUCTS LIMITED will replace the battery at no charge to the original purchaser.

Additional Limited Thirty Day Warranty on Battery: After ninety (90) days but within one hundred twenty (120)

days from the date of purchase, MTD PRODUCTS LIMITED will replace the defective battery, for the original purchaser, for a cost of one-half (1/2) of the current retail price of the battery in effect at the date of return.

Full Sixty Day Warranty on Normal Wear Parts: Normal wear parts are defined as belts, blade adapters, blades,

grass bags, seats, tires, rider deck wheels and clutch parts (friction wheels). These parts are warranted to the original purchaser to be free from defects in material and workmanship for a period of sixty (60) days from the date of

retail purchase.

How to Obtain Service: Warranty service is available, with proof of purchase, through your local authorized service dealer or distributor. If you do not know the dealer or distributor in your area, please write to the Service

Department of MTD PRODUCTS LIMITED, P. O. BOX 1386, KITCHENER, Ontario, N2G 4J1. The return of a com

plete unit will not be accepted by the factory unless prior written permission has been extended by MTD

PRODUCTS LIMITED.

Transportation Charges: Transportation charges for the movement of any power equipment unit or attachment

are the responsibility of the purchaser. Transportation charges for any part submitted for replacement under this

warranty must be paid by the purchaser unless such return is requested in writing by MTD PRODUCTS LIMITED.

Other Warranties: All other warranties, express or implied, including any implied warranty of merchantability is lim

ited in its duration to that set forth in this express limited warranty. The provisions as set forth in this warranty

provide the sole and exclusive remedy of MTD PRODUCTS LIMITED obligations arising from the sale of its prod

ucts.

MTD PRODUCTS LIMITED will not be liable for incidental or consequential loss or damage.

-

-

-

-

-

-

-

20

Page 21

16

NOTES

Page 22

15

rect.

-

MTD PRODUCTS LIMITED ne peut être tenue responsable pour toute perte ou tout dommage accidentel ou indi

découlant de la vente de ses produits.

dans cette garantie constituent le recours unique et exclusif quant aux obligations de MTD PRODUCTS LIMITED

de qualité marchande, se limitent à la durée stipulée dans cette garantie limitée expresse. Les conditions stipulées

Autres garanties: Toutes les autres garanties, qu’elles soient expresses ou tacites, y compris les garanties tacites

par MTD PRODUCTS LIMITED.

de cette garantie doivent être pris en charge par l’acheteur, sauf si le renvoi de la machine est demandé par écrit

charge de l’acheteur. Les frais de transport d’une pièce quelconque envoyée à des fins de remplacement en vertu

Frais de transport: Les frais relatifs au transport de toute machine motorisée ou de tout accessoire sont à la

LIMITED.

accepter le renvoi d’une machine complète si une autorisation n’a pas été accordée par écrit par MTD PRODUCTS

service après-vente de MTD PRODUCTS LIMITED, C.P. 1386, Kitchener (Ontario) N2G 4J1. L’usine ne peut

vous ne connaissez pas l’adresse de l’atelier de réparations ou du distributeur de votre région, adressez-vous au

Pour faire honorer la garantie: Présentez une preuve d’achat à l’atelier de réparations ou au distributeur agréé. Si

détail.

matière et de fabrication à l’acheteur initial pour une période de soixante (60) jours à partir de la date d’achat au

frottement) sont considérés comme des pièces à usure normale. Elles sont garanties exemptes de vices de

sacs à herbe, sièges, pneus, roues du plateau de coupe des tondeuses à siège, et pièces d’embrayage (roues de

Garantie complète de soixante jours des pièces à usure normale: Les courroies, adaptateurs de lame, lames,

vigueur au moment du retour de la batterie.

remplacer la batterie défectueuse à l’acheteur initial pour la moitié du prix de vente au détail de la batterie, en

jours, mais dans un délai de cent vingt (120) jours de la date d’achat, MTD PRODUCTS LIMITED s’engage à

Garantie limitée supplémentaire de trente jours de la batterie: A l’expiration du délai de quatre-vingt-dix (90)

délai de quatre-vingt-dix (90) jours à partir de la date d’achat au détail.

vice de matière ou de fabrication et si nos essais confirment qu’elle ne peut pas maintenir une charge, dans un

gratuitement la batterie à l’acheteur initial, si la batterie fournie avec la machine s’avère défectueuse en raison d’un

Garantie complète de quatre-vingt-dix jours de la batterie: MTD PRODUCTS LIMITED s’engage à remplacer

tion aux intempéries.

-

6. La détérioration normale de la finition extérieure du fait de l’utilisation de la machine et de son exposi

réglages des freins, de l’embrayage ou du plateau de coupe;

5. Les articles d’entretien courant tels que les lubrifiants, filtres, aiguisage de lames et révisions, ou les

soupapes et cylindres des fendeuses à bois sont garantis pendant un an;

4. Les batteries et les pièces présentant une usure normale énumérées plus bas. Les pompes,

respectifs. Veuillez consulter la garantie qui s’applique à la pièce en particulier;

3. Le moteur, le moteur électrique ou l’un de ses composants car ils sont garantis par leurs fabricants

l’accompagnaient;

2. La machine si elle n’a pas été utilisée et/ou entretenue conformément aux instructions qui

abusif, une négligence, un entretien incorrect ou une modification;

1. Les pièces rendues inutilisables par un emploi incorrect, une utilisation commerciale, un emploi

Cette garantie ne couvre pas:

de DEUX ANS à partir de la date d’achat au détail au Canada.

pièce ou partie de pièce qui s’avère défectueuse en raison d’un vice de matière ou de fabrication, dans un délai

MTD PRODUCTS LIMITED s’engage à réparer ou à remplacer gratuitement, à son choix, à l’acheteur initial, toute

PIÈCES SOUS GARANTIE ET SERVICE APRÈS-VENTE

Page 23

14

n

technique agréée.

REMARQUE: Pour toute réparation autre que les ajustements mineurs ci-dessus, adressez-vous à la statio

Remplacez la courroie.

Réglez le câble de commande (voir les instructions).

d’utilisation.

le chapitre sur les commandes de la notice

V oir les instructions de changement de vitesses dans

Remplacez l’axe de chape.

travaillée.

être employée sur le sol meuble, non sur le sol non

Remplacez la courroie.

Réglez le câble de commande (voir les instructions.)

d’utilisation.

le chapitre sur les commandes de la notice

V oir les instructions de changement de vitesses dans

agréée

Faites réparer la machine par une station technique

Remplacez l’axe de chape des dents.

Dégagez l’objet.

Consultez la notice d’utilisation du moteur

Faites le plein d’huile du carter.

Consultez la notice d’utilisation du moteur.

Consultez la notice d’utilisation du moteur.

L’évent du capuchon du réservoir est bouchée.

Consultez la notice d’utilisation du moteur.

Consultez la notice d’utilisation du moteur.

propre et fraîche.

videz le réservoir. Faites le plein avec une essence

Débranchez la conduite d’essence au carburateur et

une essence propre et fraîche.

Nettoyez la conduite d’essence. Faites le plein avec

Branchez et serrez le fil de la bougie.

Ouvrez le volet de départ.

Nettoyez la canalisation.

Consultez la notice d’utilisation du moteur.

bougie.

Nettoyez, réglez l’écartement ou remplacez la

d’utiliser un stabilisateur de carburant.

L’essence doit être utilisée dans les 30 jours à moins

Faites le plein avec une essence propre et fraîche.

Branchez le fil à la bougie.

Ouvrez le volet de départ.

démarrage.

Placez la commande des gaz à la position de

Consultez la notice d’utilisation du moteur.

Courroie usée ou étirée.

Mauvais réglage du câble de commande.

changées correctement.

Les vitesses du motoculteur ne sont pas

L’axe de chape est manquant.

Rotation inexacte. La rotation des dents vers l'avant devrait seulement

Courroie usée ou étirée.

Mauvais réglage du câble de commande.

changées correctement.

Les vitesses du motoculteur ne sont pas

correctement réglées.

La poulie et la poulie de tension ne sont pas

L’axe de chape des dents est manquant.

Objet dans les dents.

La circulation d’air est gênée.

Niveau d’huile trop bas.

Filtre à air sale.

Carburateur mal réglé.

Vent in gas cap plugged.

Filtre à air sale.

Carburateur mal réglé.

Eau ou saleté dans le système de carburant.

essence éventée.

Conduite d’essence bouchée ou

Fil de la bougie desserré.

Volet de départ fermé.

Canalisation de carburant bouchée.

Moteur noyé.

Bougie défectueuse.

éventée.

Le réservoir est vide ou l’essence est

Fil de la bougie débranché.

Volet de départ fermé.

position de démarrage.

La commande des gaz ne se trouve pas en

Filtre à air sale.

s’enclenchent pas.

Les roues ne

dessus la terre.

Les dents saut au-

s’enclenchent pas.

Les dents ne

chauffe.

Le moteur sur-

irrégulièrement.

Le moteur tourne

démarre pas.

Le moteur ne

Problème Cause(s) Possible(s) Solution

CHAPITRE 13: GUIDE DE DÉPANNAGE

Page 24

13

mobiles, avec une huile légère ou de la silicone.

machine, en particulier les câbles et toutes les pièces

un abri métallique non ventilé. Enduisez toute la

le matériel contre la rouille s’il doit être entreposé dans

REMARQUE: Il est très important de bien protéger

comme des engrais par exemple.

sec. Ne le remisez pas près de produits corrosifs

5. Remisez le motoculteur dans un endroit propre et

pour les empêcher de rouiller.

4. Essuyez les dents avec un chiffon imbibé d’huile

aux instructions de remisage.

3. Consultez la notice d’utilisation du moteur quant

motoculteur et à limiter sa facilité d’entretien.

d’eau a tendance à raccourcir la vie du

poulies, les roulements ou le moteur. L’emploi

les composants électriques, les fusées, les

déconseillée. Cela risque en effet d’endommager

boyau d’arrosage pour nettoyer le tracteur est

2. L’utilisation d’un nettoyeur sous pression ou d’un

instructions.

motoculteur. Lubrifiez le motoculteur selon les

1. Nettoyez l’extérieur du moteur et tout le

la façon suivante.

pendant une période de plus de 30 jours, procédez de

Si vous ne prévoyez pas d’utiliser le motoculteur

CHAPITRE 12: REMISAGE HORS SAISON

et provoquer des blessures graves.

effet faire éclater l’ensemble pneu et jante

talons. Une pression excessive peut en

pour installer les

2

à plus de 30 lb/po

AVERTISSEMENT: Ne gonflez jamais

pour installer les talons.

2

. Conservez une

2

30 lb/po

pneu et la jante. Ne gonflez jamais le pneu à plus de

rouille avant d’y installer un pneu. Lubrifiez bien le

Assurez-vous toujours que la jante est propre et sans

pression égale sur les deux pneus.

toujours être inférieure à 30 lb/po

souvenez-vous que la pressions maximale doit

renseignement ne figure pas sur vos pneus,

pneu, inscrite sur le flanc de celui-ci. Si ce

pression maximale, recommandée par le fabricant du

La pression recommandée est de 20 lb/po2. Vérifiez la

PRESSION DES PNEUS

tendeur. Voir la Figure 10 .

entre les dispositifs de retenue près de la poulie du

courroie passe au-dessus de la poulie du tendeur et

REMARQUE: Lors du remontage, vérifiez que la

Page 25

12

Figure 10

du guide

de tendeur

Support

Support

motrice

Poulie

garantit une durée de vie plus longue et vous assure

matériau spécial, à savoir du Kevlar Tensile, qui leur

Le motoculteur utilise des courroies réalisées dans un

REMPLACEMENT DE LA COURROIE

gravement endommager la machine.

en particulier dans le carter à chaîne et peut

L’eau risque de pénétrer partout dans le motoculteur,

nettoyage sous pression pour nettoyer le motoculteur.

IMPORTANT: N’utilisez jamais un appareil de

tension

poulie de

Tige de la

Figure 9

Écrou à six pans

à capuchon

Écrou a six pans

Couvre-courroie

Vis auto-taraudeuses

en procédant dans l’ordre inverse.

5. Démontez la courroie. Installez la courroie neuve

Figure 10.

boulons hex. et les deux rondelles-frein. Voir la

derrière la poulie motrice en retirant les deux

4. Démontez le support du guide qui se trouve

couvre-courroie.

courroie. Enlevez la vis hex. sur le bas à l’avant du

plate qui se trouvent sur le côté du couvre-

3. Enlevez l’écrou à six pans à chapeau et la rondelle

courroie.

les deux auto-taraudeuses du dessus du couvremotoculteur comme suit. Voir la Figure 9 . Enlevez

2. Démontez le couvre-courroie du côté gauche du

terre contre le moteur.

1. Débranchez le fil de la bougie et mettez-le à la

754-0434 - Courroie trapézoïdale.

à la station technique la plus proche. Pièce de la no. modèle nécessaire en indiquant le numéro de la pièce

Si vous devez remplacer les courroies, commandez le

n’importe quelle courroie.

de meilleures performances. Ne les remplacez pas par

quelconque.

réparation ou une opération d’entretien

contre le moteur avant d’effectuer une

de la bougie et mettez-le à la masse

AVERTISSEMENT: Débranchez le fil

la rouille ou dommages de l'eau.

couche mince de l’huile ou de silicone pour empêcher

motoculteur avec une serviette après et appliquez une

à enlever si elle n’est pas sèche. Essuyez toujours le

dents après chaque utilisation. La saleté est plus facile

Nettoyez le dessous du dispositif de protection des

NETTOYAGE DES DENTS

et saleté sont éliminés de la proximité du silencieux.

à la durabilité du moteur. Vérifiez que tous les débris

bonne circulation d’air essentielle aux performances et

(compartiment du ventilateur) propre pour assurer la

une brosse. Gardez le système de refroidissement

Nettoyez régulièrement le moteur avec un linge ou

quant au type de bougie à utiliser et à l’écartement.

saison. Consultez la notice d’utilisation du moteur

moteur. Remplacez la bougie au début de chaque

réglé toutes les 25 heures de fonctionnement du

La bougie doit être nettoyée et l’écartement doit être

le filtre à air n’est pas complètement installé fournie.

IMPORTANT: Ne faites jamais tourner le moteur si

avant de nettoyer le filtre à air.

Consultez la notice d’utilisation du moteur fournie

sont des indications que le filtre à air doit être nettoyé.

Une mauvaise performance du moteur et sa «noyade»

chaque heure dans des conditions très poussiéreuses.

toutes les dix heures de fonctionnement. Nettoyez-le

Dans les conditions normales, nettoyez le filtre à air

attentivement les instructions et suivez-les.

d’utilisation du moteur fournie avec la tondeuse. Lisez

Utilisez l’huile à moteur recommandée dans la notice

tout ce qui concerne l’entretien du moteur.

Consultez la notice d’utilisation du moteur pour

MOTEUR

CHAPITRE 11: ENTRETIEN

fois par saison et lubrifiez-les avec de l’huile.

Arbre des roues—Démontez les roues au moins une

fois par saison et lubrifiez-les avec de l’huile.

Arbre des dents—Démontez les dents au moins une

Page 26

11

Commandez la pièce no 737-0300.

fois par saison avec une huile légère.

pivotement et les tringles de commande au moins une

Points de pivotement — Lubrifiez tous les points de

facilement dans les deux directions.

une fois par saison. La commande doit bouger

de commande de l’embrayage et le câble au moins

huile légère, lubrifiez le point de pivotement de la barre

Barre de commande de l’embrayge — Avec une

graisse chez le concessionnaire agréé le plus proche.

la moitié gauche. Vous pouvez vous procurer la

Versez 30 onces de graisse Benalene 920. Assemblez

posez la moitié droite de la transmission sur son côté.

raison quelconque. Pour faire le plein de graisse,

aucune vérification sauf si elle est démontée pour une

fermée hermétiquement à l’usine. Elle ne nécessite

Transmission — La transmission a été lubrifiée et

CHAPITRE 10: LUBRIFICATION

pas serrée), il faut effectuer le réglage.

poulie de tension (quand la barre d’embrayage n’est

avant. Si le support de l’indicateur tou che la tige de la

d’utilisation du moteur fournie avec le motoculteur.

des réglages sont nécessaires, consultez la notice

l’usine conviennent dans la plupart des situations. Si

Ne faites jamais de réglages inutiles. Les réglages de

pas les surfaces chaudes ni le silencieux.

toutes les pièces mobiles et ne touchez

embrayages et lames. Éloignez-vous de

carburateur), débrayez tous les

pendant qu’il tourne (par ex. au

des réglages quelconques au moteur

AVERTISSEMENT: Si vous devez faire

RÉGLAGES DU CARBURATEUR

chaque vitesse en marche avant.

touche pas le support indicateur en passant à

6. Vérifiez que la tige de la poulie de tension ne

en place.

5. Remettez la rondelle ondulée et la goupille-épingle

Voir la Figure 10.

trou le plus bas du support de la poulie de tension.

4. Déplacez la tige de la poulie de tension dans le

tige de la poulie de tension. Voir la Figure 10.

3. Retirez la goupille-épingle et la rondelle plate de la

sur le remplacement de la courroie, à la page 12.

2. Démontez le couvre-courroie décrit dans la section

masse contre le moteur.

1. Débranchez le fil de la bougie et mettez-le à la

d’utilisation.

d’instructions spéciales dans la notice

pendant que le moteur tourne, sauf en cas

d’effectuer un réglage quelconque

AVERTISSEMENT: N’essayez jamais

sélection des vitesses à chaque mode en marche

l’embrayage non serrée, passez la manette de

Le moteur à l’arrêt et la barre de commande de

vérification est simple à faire.

ajuster la tige de la poulie de tension. Cette

Si la courroie est très étirée, il faudra peut-être aussi

instructions de montage.

section concernant le réglage de l’embrayage des

Pour régler la tension de la courroie, consultez la

que le moteur tourne au même régime.

rotation des dents ou des roues paraît saccadée et

de la courroie. Un ajustement est nécessaire quand la

tre rendu nécessaire par l’usure normale et l’étirement

Le réglage périodique de la tension de la courroie peut

COURROIE

RÉGLAGE DE LA TENSION DE LA

renseignements.

chapitre sur les commandes pour plus de

On peut ajuster la hauteur du guidon. Consultez le

RÉGLAGES DU GUIDON

CHAPITRE 9: RÉGLAGES

de reculer et de blesser quelqu’un.

embrayées. Le motoculteur risque en effet

soulèvent du sol quand les dents sont

dents pénètrent dans la terre.

profondément) pour vous assurer que les

guide de profondeur (travaillez moins

tournent en marche avant, abaissez le

AVERTISSEMENT: Quand les dents

de la largeur) pour bien pulvériser la terre.

deux fois le potager (dans le sens de la longueur, puis

Vous obtiendrez de meilleurs résultats en labourant

les guidons pour que les roues se

AVERTISSEMENT: N’appuyez pas sur

dents. Embrayez seulement les roues.

Pour déplacer le motoculteur, n’enclenchez pas les

entre deux vitesses, le moteur va caler.

d’enclencher la manette d’embrayage. S’il se trouve

de la vitesse est correctement positionné avant

REMARQUE: Vérifiez que l’indicateur de sélection

Page 27

7 po.

5 po.

haute

(profond) la plus

pour la position

Utilisez ce trou

latéraux

protections

Dispositif de

3 po.

1 po.

déplacement

Position de

10

vitesse.

complètement arrêté avant de changer la

Attendez que le motoculteur soit

les roues ou les dents sont embrayées.

manette de sélection de la vitesse quand

AVERTISSEMENT: Ne déplacez pas la

arrière.

l’une des positions de marche avant ou en marche

3. Placez la manette de sélection de la vitesse à

la page 9.

2. Mettez le moteur en marche de la façon indiquée à

1. Choisissez le réglage du guide de profondeur.

embrayer les roues et les dents.

4. Appuyez la manette contre le guidon pour

avant pour travailler de la terre meuble.

une terre dure. Faites tourner les dents en marche

arrière dans de la terre non travaillée, du gazon ou

IMPORTANT: Faites tourner les dents en marche

Figure 8

la plus basse

(peu profond)

pour la position

Utilisez ce trou

chape

Axe de

première fois

position la

Utilisez cette

réglage.

contre le moteur avant d’effectuer tout

de la bougie et mettez-le à la masse

MOTOCULTEUR:

UTILISATION PROPREMENT DITE DU

écrous à oreilles et serrez à fond.

panneau latéral à la position voulue. Replacez les

panneaux latéraux. Voir la Figure 8. Placez un

Enlevez les écrous à oreilles pour ajuster les

en place avec l’axe de chape et la goupille épingle.

le guide de profondeur à la position voulue. Maintenez

ajuster le guide de profondeur. Voir la Figure 8. Placez

Enlevez l’axe de chape et la goupille épingle pour

profondeur (trou du haut).

4. Pour déplacer le motoculteur, abaissez le guide de

haute.

Relevez les dispositifs latéraux à la position la plus

(trou inférieur) pour travailler profondément.

guide de profondeur à la position la plus haute

3. Pour travailler une terre non compacte, relevez le

effectuez un ou deux passages.

de profondeur et les dispositifs latéraux et

Pour travailler plus profondément, relevez le guide

protection latéraux à la position la plus basse.

partir du haut). Installez les dispositifs de

une profondeur de travail de 1 po (deuxième trou à

profondeur, employez le réglage correspondant à

2. Pour retourner l’herbe et sarcler à faible

haut (profondeur de travail: 1 po). Voir la Figure 8.

employez le deuxième trou de régla ge à partir du

1. Lors de la première utilisation du motoculteur,

débranché et mis à la masse contre le moteur.

guide de profondeur. Vérifiez que le fil de la bougie est

protection latéraux comme à la Figure 8 en réglant le

différentes. Voir la Figure 8. Ajustez les dispositifs de

profondeur qui peut être réglé à cinq positions

La profondeur de travail es t contrôlée par le guide de

AVERTISSEMENT: Débranchez le fil

CHAPITRE 8: MODE D’EMPLOI DU MOTOCULTEUR

dans le chapitre «Assemblage».

fonctionnement. Consultez «Réglez l'embrayage»

l’embrayage après les dix premières heures de

REMARQUE: Vérifiez à nouveau le réglage de

Page 28

9

quand l’équipement n’est pas surveillé.

terre pour empêcher tout démarrage accidentel

2. Débranchez le fil de la bougie et mettez-le à la

«STOP» (Arrêt).

1. Placez la commande de l’obturateur à la position

de moteur à la position «START».

«FAST» (lapin). Placez la commande de vitesse

2. Placez la commande de l’obturateur à la position

POINT MORT.

1. Placez la manette de sélection de la vitesse au

POUR ARRÊTER LE MOTEUR

au moment du démarrage.

«Assemblage», «Réglez l'embrayage».

l'embrayage qui est expliqué dans le chapitre

d'utiliser le motoculteur, vérifiez le réglage de

REMARQUE: Quand le moteur tourne et avant

moteur pour obtenir plus de renseignements.

REMARQUE: Veuillez lire la notice d'utilisation du

nouveau de la déplacer.

revenez à la position de départ, puis essayez à

vers la position «Run». Si le moteur hésite,

progressivement la commande du volet de départ

tourner plus régulièrement, déplacez

7. Quand le moteur est chaud et qu'il commence à

moteur démarre.

6. Répétez les paragraphes 3 et 4 jusqu’à ce que le

démarreur.

revenir lentement en tenant bien la poignée du