Page 1

OUTDOOR POWER EQUIPMENT

24", 26" and 28"

SNOW

THROWERS

Model Numbers

317E610E000

317E640F000

317E660G000

MTD PRODUCTS INC • P.O. BOX 368022 • CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-8782M

Page 2

IMPORTANT

SAFEOPERATIONPRACTICES

THIS SYMBOLPOINTSOUT IMPORTANTSAFETYI1_STRUCTIONSWHICH, IF NOT FOLLOWED,COULDENDANGERTHEPERSONAL_

SAFETYAND/OR PROPERTYOF YOURSELFAND CTHERS. READAND FOLLOWALL INSTRUCTIONSIN THIS MANUAL BEFORE

ATTEMPTINGTOOPERATEYOURSNOWTHROWER•FAILURETOCOMPLYWITH THESEINSTRUCTIONSMAY RESULTIN PERSONAL,

INJURY.WHENYOUSEETHIS SYMBOL-- _IL HEEDITS WARNING.

,_ Yoursnowthrowerwas bull to be operatedaccordingto the rules for safe operation in this manual. As with [

m

DANGER: any type ofpowerequipmert, carelessnessor erroron the part of the operatorcan result in seriousinjury, if

Iyou violate any of these rules, you may causeseriousinjury to yourself or others.

TRAINING

1. Readthis owner's guide carefully in its entirety berg

ing to assemble or operatethis machine. Becomplet

with the controls and the proper use of this mact

operating it. Keepthis manual in a safe placefor futu

ular referenceand for ordering replacement parts.

2. Never allow children under 14 years old to oper;

thrower. Children 14 years old and over should ol

snow thrower under close parental supervision. Or

well acquainted with these rules of safe operation

allowed to useyour snow thrower.

3. No one should operatethis unit while intoxicatedor

medication that impairs the senses or reactions.

4. Keep the area of operation clear of all persons, espe

children andpets.

5. Exercise caution to avoid slipping or falling, espe_

operating in reverse.

_lb PREPARATION

1. Thoroughly inspect the areawhere the equipment is

and remove all door mats, sleds, boards, wires an_

eign objects.

2. Disengage all clutches and shift into neutral bef(

engine.

3. Do not operate equipment without wearing adeq_

outer garments. Do not wear jewelry, long scarfs or

clothing which could become entangled in moving I

footwear which will improve footing on slippery surf

4. Before working with gasoline, extinguish all cigarette

sources of ignition. Check the fuel before starting

Gasolineis an extremely flammable fuel. Do not fill

tank indoors, while the engine is running, or until

beenallowed to cool at leasttwo minutes. Replace

securely and wipe off any spilled gasoline before

engineas it maycause a fire or explosion.

5. Usea grounded three wire plug-in for all units with e

motors or electric starting motors.

6. Adjust collector housing height to clear gravel or cM

surface.

7. Neverattempt to make any adjustments while engin

(except where specifically recommended by manufa

8. Let engine and machine adjust to outdoor temper_

starting to clear snow.

9. Always wear safety glasses or eye shields during

while performing an adjustment or repair,to protec

foreign objects that may be thrown from the mac

direction.

OPERATION

1. Donot put hands or feet near or under rotating part,,

of discharge opening and augerat all times•

2. Exerciseextreme caution when operating on or cro

drives, walks, or roads. Stay alert for hidden hazan

Do not carry passengers.

3. After striking a foreign object, stop the engine,

from spark plug, and thoroughly inspect the snow

any damage. Repairthe damagebefore restarting a_

the snow thrower.

4. Ifthe snow thrower should start to vibrate abnorm_

engine and check immediately for the cause.

generally a warning of trouble.

eattempt-

,flyfamiliar

ine before

e andreg-

te a snow

tly operate

ly persons

shouldbe

rhiletaking

"iallysmall

;iallywhen

tobe used

otherfop

re starting

latewinter

)therloose

)arts.Wear

ices.

sandother

:heengine.

1le gasoline

enginehas

asolinecap

;tartingthe

ectric drive

ushedrock

_isrunning

:turer).

ture before

( perationor

teyesfrom

_mein any

•Keepclear

;singgravel

s or traffic.

r,'move wire

thrower for

doperating

Ily, stop the

/ibration is

5. Stop enginewheneveryouleavethe operatingposition,before

uncloggingthe collector/impellerhousingor dischargeguide,

and makingany repairs,adjustments,or inspections.Never

placeyour handin the dischargeor collectoropenings.Usea

stickorwoodenbroomhandleto unclogthe dischargeopening.

6. Takeallpossibleprecautionswhenleavingtheunitunattended.

Disengagethe collector/impeller,shift into neutral,stop the

engine,andremovethekey.

7. Whencleaning,repairing,or inspecting,makecertaincollector/

impellerandall movingpartshavestopped.Disconnectspark

plugwireandkeepawayfrom plugto preventaccidentalstart-

ing.

8. Do not run engineindoors,exceptwhenstartingengineand

transportingsnowthrower in or out of building.Opendoors.

Exhaustfumesaredangerous.

9. Do not clearsnowacrossthe faceof slopes.Exerciseextreme

cautionwhenchangingdirectionon slopes.Donotattemptto

clearsteepslopes.

10. Neveroperatesnowthrower withoutguards,plates,or other

safetyprotectiondevicesin place.

11. Neveroperatesnowthrowernearglassenclosure,automobiles,

window wells, drop off, etc., without properadjustmentsof

snowthrowerdischargeangle.Keepchildrenandpetsaway.

12. Do not overloadmachinecapacitybyattemptingto clearsnow

attoo fasta rate.

13. Neveroperatethemachineathightransportspeedsonslippery

surfaces.Lookbehindandusecarewhenbacking.

14. Neverdirectdischargeatbystandersorallowanyonein frontof

unit.

15. Disengagepowertocollector/impellerwhentransportingor not

inuse.

16. Useonly attachmentsandaccessoriesapprovedbythe manu-

facturer of snow thrower (such as wheel weights,counter

weights,cabs,etc.).

17. Neveroperatethesnowthrowerwithoutgoodvisibilityor light.

Alwaysbesureof yourfootingandkeepafirm holdonthehan-

dles.Walk,neverrun.

18. Mufflerand enginebecomehot andcan causea burn. Do not

touch.

,_ MAINTENANCEAND STORAGE

1. Check shear bolts, engine mounting bolts, etc., at frequent

intervalsfor propertightness to be sure equipmentis in safe

workingcondition.

2. Neverstorethe machine withfuel inthe fueltank insidea build-

ingwhere ignitionsources are present,such as hot water and

spaceheaters,clothesdryers,and thelike.Allow engineto _:ool

beforestoringin any enclosure.

3. Always referto owner's guide instructionsfor importantdetails

if snowthroweris to be storedfor an extendedperiod.

4. Run machine a few minutes after throwing snow to prevent

freezeup ofcollector/impeller.

5. Check clutchcontrolsperiodicallyto verify they engage and dis-

engage properly and readjust if necessary.Refer to owner's

guidefor adjustmentinstructions.

Page 3

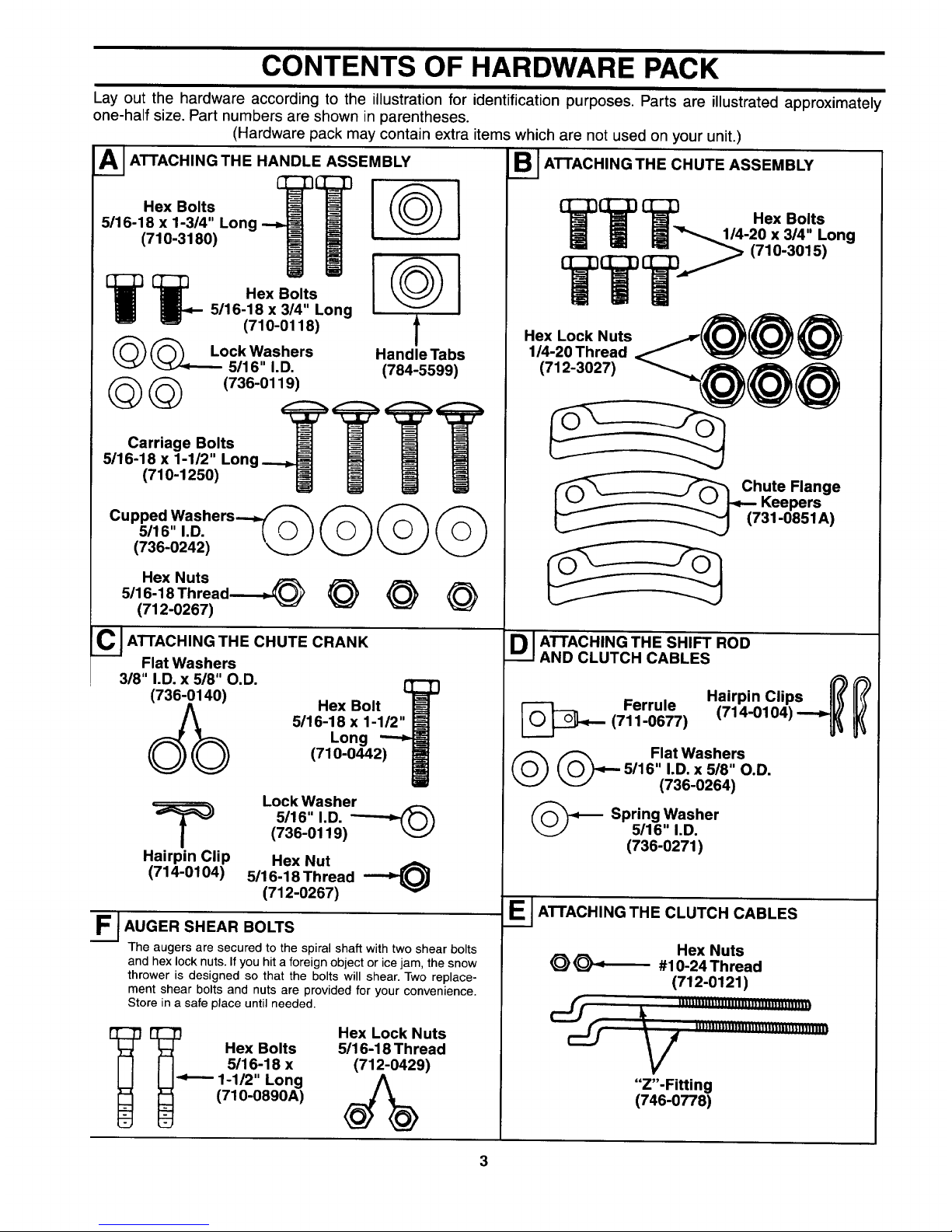

CONTENTS OF HARDWARE PACK

Lay out the hardware according to the illustration for identification purposes. Parts are illustrated approximately

one-half size. Part numbers are shown in parentheses.

(Hardware pack may contain extra items which are not used on your unit.)

A_ ATTACHING THE HANDLE ASSEMBLY

Hex Bolts [

5/16-18 x 1-3/4" Long

(710-3180)

[__ Hex Bolts

5116-18 x 3/4" Long

(710-0118)

(_(_ Lock Washers

5/16" I.D.

(_(_ (736-0119)

Carriage Bolts

5/16-18 x 1-1/2" Long

(710-1250)

@1

@

f

Handle Tabs

(784-5599)

Cupped Washers_

5/16" I.D. _ _

(736-0242) _._.j'

Hex Nuts

5/16-18 Thread-_,._ @

(712-0267)

C JATrACHING THE CHUTE CRANK

Flat Washers

318" I.D. x 518" O.D.

Hex Bolt

5/16-18 x 1-1/2"

Long

(710-0442)

Lock Washer

5116" I.D.

(736-0119)

Hairpin Clip Hex Nut

(714-0104) 5/16-18 Thread --_

(712-0267)

F.__ AUGER SHEAR BOLTS

The augers are secured to the spiral shaft with two shear bolts

and hex lock nuts. If you hit a foreign object or ice jam, the snow

thrower is designed so that the bolts will shear. Two replace-

ment shear bolts and nuts are provided for your convenience.

Store in a safe place until needed.

_ _.,_._ Hex Bolts

5/16-18 x

1-1/2" Long

(710-0890A)

Hex Lock Nuts

5/16-18 Thread

(712-0429)

S I ATTACHING THE CHUTE ASSEMBLY

TTT .exoo,,.

1/4-20 x 3/4" Long

TT T _ (710-3015)

Hex Lock Nuts.@@ @

1/4-20 Thread

@@@

ute Flange

Keepers

31-0851A)

D I ATTACHING THE SHIFT ROD

AND CLUTCH CABLES

Ferrule

(711-0677)

Hairpin Clips ['_

(714-0104) ---_

(_(_ Flat Washers

5/16" I.D. x 5/8" O.D.

(736-0264)

(_ Spring Washer

5/16" I.D.

(736-0271)

E__ ATTACHING THE CLUTCH CABLES

Hex Nuts

_ _ #10-24 Thread

(712-0121)

• V ""_'""""m"I_"""m'_l_

"Z'-Fitting

(746-0778)

Page 4

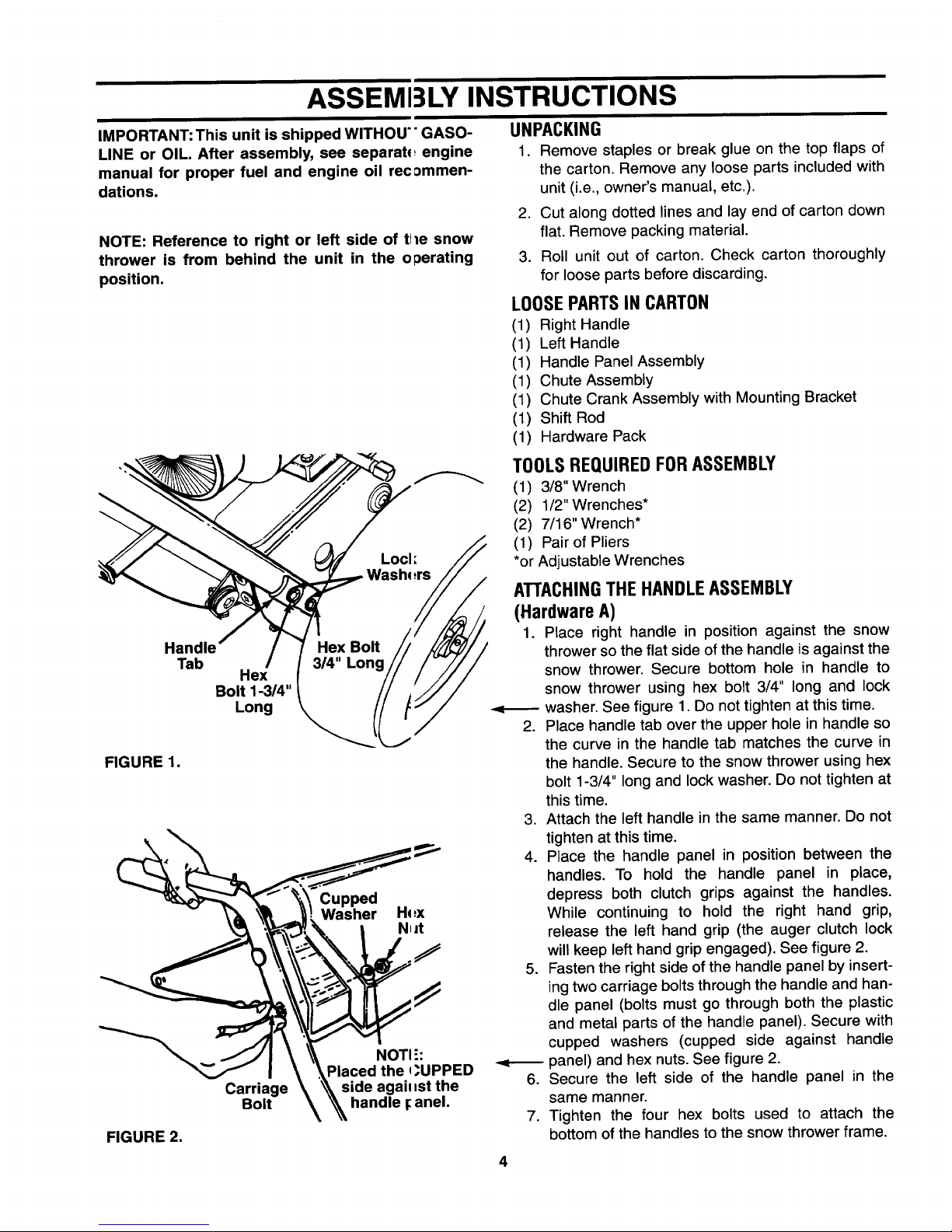

ASSEMI3LY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOU'" GASO-

LINE or OIL. After assembly, see separab_ engine

manual for proper fuel and engine oil rec:_mmen-

dations.

NOTE: Reference to right or left side of tile snow

thrower is from behind the unit in the operating

position.

Handle

Tab

Hex

Bolt 1-3/4"

Long

FIGURE 1.

Cupped

Washer Hq:x

N_it

FIGURE 2.

Carriage

Bolt

NOTI ":

Placed the q_UPPED

side agail _st the

handle _anel.

UNPACKING

1. Remove staples or break glue on the top flaps of

the carton. Remove any loose parts included with

unit (i.e., owner's manual, etc.).

2. Cut along dotted lines and lay end of carton down

flat. Remove packing material.

3. Roll unit out of carton. Check carton thoroughly

for loose parts before discarding.

LOOSE PARTS IN CARTON

(1) Right Handle

(1) Left Handle

(1) Handle Panel Assembly

(1) Chute Assembly

(1) Chute Crank Assembly with Mounting Bracket

(1) Shift Rod

(1) Hardware Pack

TOOLS REQUIRED FOR ASSEMBLY

(1) 3/8" Wrench

(2) 1/2" Wrenches*

(2) 7/16" Wrench*

(1) Pair of Pliers

*or Adjustable Wrenches

ATTACHINGTHE HANDLEASSEMBLY

(HardwareA)

1. Place right handle in position against the snow

thrower so the flat side of the handle is against the

snow thrower. Secure bottom hole in handle to

snow thrower using hex bolt 3/4" long and lock

washer. See figure 1. Do not tighten at this time.

Place handle tab over the upper hole in handle so

the curve in the handle tab matches the curve in

the handle. Secure to the snow thrower using hex

bolt 1-3/4" long and lock washer. Do not tighten at

this time.

3. Attach the left handle in the same manner. Do not

tighten at this time.

4. Place the handle panel in position between the

handles. To hold the handle panel in place,

depress both clutch grips against the handles.

While continuing to hold the right hand grip,

release the left hand grip (the auger clutch lock

will keep left hand grip engaged). See figure 2.

5. Fasten the right side of the handle panel by insert-

ing two carriage bolts through the handle and han-

dle panel (bolts must go through both the plastic

and metal parts of the handle panel). Secure with

cupped washers (cupped side against handle

panel) and hex nuts. See figure 2.

Secure the left side of the handle panel in the

same manner.

7. Tighten the four hex bolts used to attach the

bottom of the handles to the snow thrower frame.

4

Page 5

FIGURE 3.

\

Chute Assembly

Hex Head

Screw

Flat Washer

Lock Nut

Chute

Flange

Keeper

Lock Washer

Hex Nut

_m

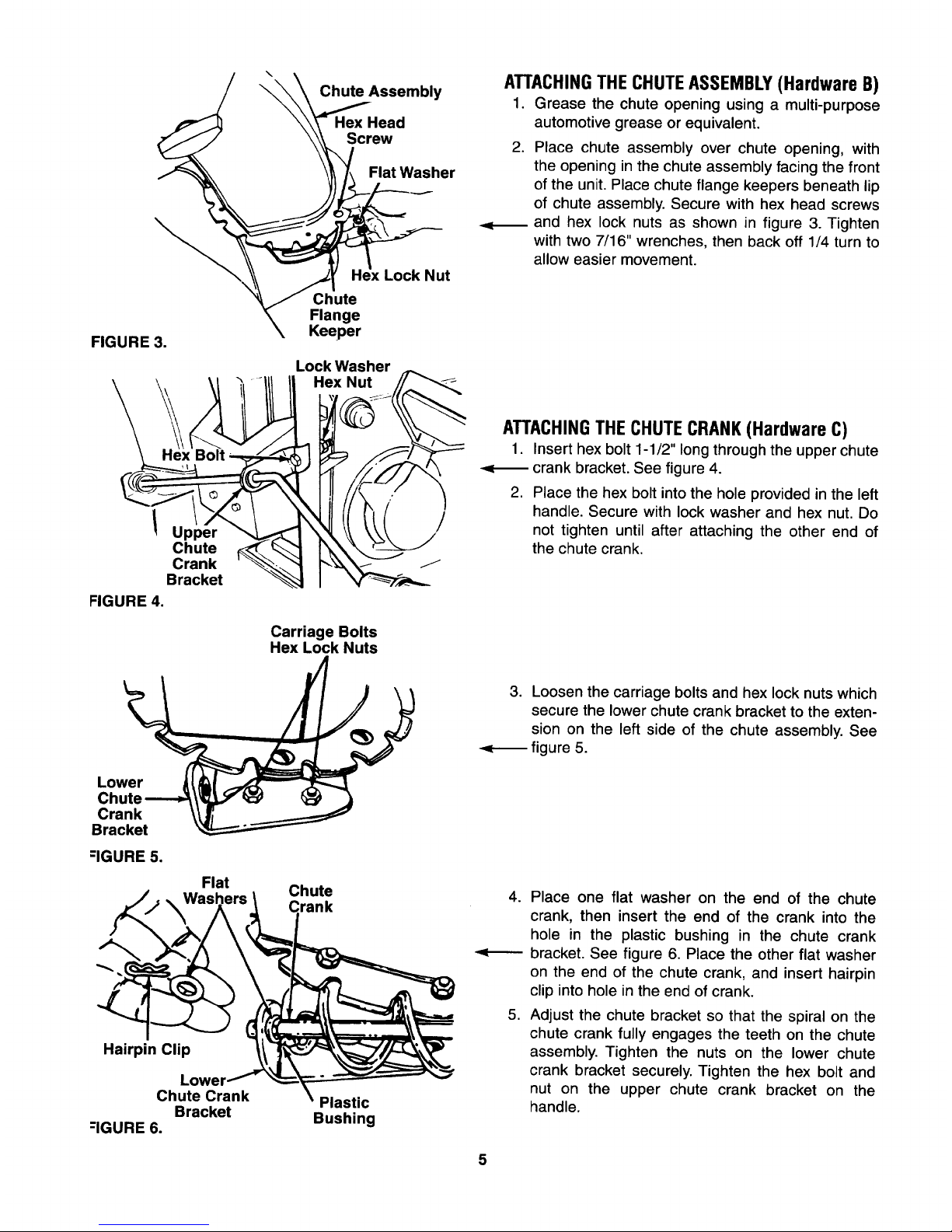

ATTACHINGTHE CHUTEASSEMBLY(Hardware B)

1. Grease the chute opening using a multi-purpose

automotive grease or equivalent.

.

Place chute assembly over chute opening, with

the opening in the chute assembly facing the front

of the unit. Place chute flange keepers beneath lip

of chute assembly. Secure with hex head screws

and hex lock nuts as shown in figure 3. Tighten

with two 7/16" wrenches, then back off 1/4 turn to

allow easier movement.

Upper

Chute

Crank

Bracket

FIGURE 4.

Carriage Bolts

Hex Lock Nuts

ATTACHINGTHE CHUTECRANK (Hardware C)

1. Insert hex bolt 1-1/2" long through the upper chute

-<_ crank bracket. See figure 4.

2. Place the hex bolt into the hole provided in the left

handle. Secure with lock washer and hex nut. Do

not tighten until after attaching the other end of

the chute crank.

Lower

Chute

Crank

Bracket

-IGURE 5.

Flat

Hairpin Clip

Lower

Chute Crank

Bracket

--IGURE 6.

Chute

rank

Plastic

Bushing

3. Loosen the carriage bolts and hex lock nuts which

secure the lower chute crank bracket to the exten-

sion on the left side of the chute assembly. See

figure 5.

4. Place one flat washer on the end of the chute

crank, then insert the end of the crank into the

hole in the plastic bushing in the chute crank

bracket. See figure 6. Place the other flat washer

on the end of the chute crank, and insert hairpin

clip into hole in the end of crank.

5. Adjust the chute bracket so that the spiral on the

chute crank fully engages the teeth on the chute

assembly. Tighten the nuts on the lower chute

crank bracket securely. Tighten the hex bolt and

nut on the upper chute crank bracket on the

handle.

5

Page 6

IMPORTANT:Attachthe shift rod andcl itch cables as follows. THEN CHECK THE ADJUSTMENTS AS

INSTRUCTED, AND MAKE ANY FINAL A[)JUSTMENTS NECESSARY BEFORE OPERATING YOUR SNOW

THROWER. Failure to follow the instructi,)ns may cause damage to the snow thrower.

Tracti°_ hiftClutchDrive Lever

I1 Washer Fer u e

J/Shift

1Arm

_ssembly

ATTACHINGTHE SHIFT ROD (Hardware D)

1. Place the shift lever (on the handle panel) in the

sixth (6) speed position (all the way forward).

Place the bent end of the shift rod into the hole in

the shift arm assembly. See figure 7. Secure with

spring washer, flat washer and hairpin clip.

3. Start threading the ferrule onto the other end of the

shift rod. Push down on the shift rod (and shift arm

assembly) as far as it will go.

4. Thread the ferrule onto the shift rod until the ferrule

lines up with the upper hole in the shift lever

(beneath the handle panel). Insert the ferrule into

the upper hole in the shift lever from the left side

when adjustment is correct. Secure with flat

washer and hairpin clip.

Make certain to check for correct adjustment of the

shift rod as instructed in the Final Adjustment section

before operating the snow thrower.

FIGURE 7.

Hex Jam

Nut

/

/

Cable is Strai

FIGURE 8.reViewed from Underside of H_nndle

Panel

ATTACHINGTHE CLUTCH CABLES(Hardware E)

The "Z" end of the clutch cables are hooked into the

clutch grips on each handle. Attach cables as follows.

1. Thread the hex nuts (in hardware pack) all the

way up the threaded portion of the "Z" ends of the

clutch cables.

2. Make certain each cable is in groove of cable

roller guides. Place the clutch grip in the raised

(up) position.

3. Thread the cable onto the threaded portion of the

"Z" end until there is no slack in the cable, but the

cable is NOT tight. Do not overtighten cable.

See figure 8.

&

WARNING: If cable is tightened so there is

tension on the cable with the clutch grip

released, the safety features of the snow

thrower may be overridden.

4. When correct adjustment is reached, tighten the

hex nut against the bottom portion of the cable to

lock it in position.

FINAL ADJUSTMENTS

Auger Drive Clutch

To check the adjustment of the auger drive clutch,

push forward on the left hand clutch grip (depress the

rubber bumper). There should be slack in the cable.

Release the clutch grip. The cable should be straight.

Make certain you can depress the auger drive clutch

grip against the left handle completely.

Page 7

If necessary,loosenthe hexjamnutandthreadthe

cablein(forlessslack)orout(formoreslack)asnec-

essary.Referto figure8. Recheckthe adjustment.

Tightenthejam nutagainstthe cablewhencorrect

adjustmentisreached.

Traction Drive Clutch and Shift Lever Adjustment

To check the adjustment of the traction drive clutch

and shift lever, tip the snow thrower forward so that it

rests on the auger housing. First move the shift lever

all the way forward to sixth (6) position. With the trac-

tion drive lever released, spin the snow thrower wheels

by hand. They should turn freely. Then engage the

traction drive clutch grip. The wheels should stop turn-

ing.

Now release the traction drive clutch grip, and spin the

wheels again. Move the shift lever back to the fast

reverse position, then all the way forward again. There

should be no resistance in the shift lever, and the

wheels should keep turning.

If you have resistance when moving the shift lever or

the wheels stop when they should not, loosen the jam

nut on the traction drive cable and unthread the cable

one turn. If the wheels do not stop when you engage

the traction drive clutch grip, loosen the jam nut on the

traction drive cable and thread the cable in one turn.

Recheck the adjustment and repeat adjustment as

necessary. Tighten the jam nut to secure the cable

when correct adjustment is reached.

NOTE: If you are uncertain that you have reached the

correct adjustment, refer to the Adjustment section on

page 10.

ADJUSTING THE SKID SHOES

The space between the shave plate and the ground

can be adjusted. For close snow removal, place skid

shoes in the low position. Use middle or high position

when area to be cleared is uneven. See figure 9.

Adjust skid shoes by loosening the four hex nuts and

carriage bolts and moving skid shoes to desired posi-

tion. Make certain the entire bottom surface of skid

shoe is against the ground to avoid uneven wear on

the skid shoes. Retighten nuts and bolts securely.

It is not recommended that you operate this snow

thrower on gravel as loose gravel can be easily picked

up and thrown by the auger causing an injury or dam-

age to the snow thrower.

Skid

Shoe

FIGURE 9.

uts

Carriage Bolts

TIREPRESSURE(PneumaticTires)

The tires are over-inflated for shipping purposes.

Check tire pressure and reduce to 15 to 20 psi.

NOTE: If the tire pressure is not equal in both tires, the

un# may pull to one side or the other.

Auger

Drive

CONTROLS

Traction

Drive/

Auger

Clutch

Lock

SHIFT LEVER

(See figures 10 and 11)

The shift lever is located in the center of

the handle panel. The shift lever may be

moved into one of eight positions. Run

engine with throttle in the fast position.

Use the shift lever to determine ground

speed.

Forwardmone of six speeds. Position

number one (1) is the slowest. Position

number six (6) is the fastest.

FIGURE 10.

7

Reverse--two reverse (R) speeds. "R"

closest to the operator (all the way

back) is the faster of the two.

FIGURE 11.

Page 8

AUGER DRIVE (See figure 10)

The auger drive clutch is located on the let handle.

Squeeze the clutch grip to engage the augers.

Release to stop the snow throwing action. (Traction

drive clutch must also be released.)

TRACTIONDRIVE/AUGERCLUTCHLOCK

(See figure 10)

The traction drive clutch is located on the rigl _thandle.

Squeeze the traction drive clutch to engage'he wheel

drive. Release to stop.

This same lever also locks the auger clutch s,) you can

turn the chute crank without interrupting he snow

throwing process. If the auger drive clutch is engaged

with the traction drive clutch engaged, the operator

can release the auger drive clutch (on the le :t handle)

and the augers will remain engaged. Releas_ the trac-

tion drive clutch to stop both the augers a_d wheel

drive (auger drive clutch must also be releasl _d).

CHUTE CRANK(See figure 10)

The chute crank is located on left hand si Je of the

snow thrower.

To change the direction in which snow is thr _wn, turn

chute crank as follows:

1. Crank clockwise to discharge to the left.

2. Crank counterclockwise to discharge to l he right.

THROTTLE CONTROL(See figure 12)

The throttle control is located on the engin_. It regu-

lates the speed of the engine.

SAFETYIGNITIONSWITCH(see figure12)

The ignition key must be inserted in the switch before

the unit will start. Remove the ignition key when snow

thrower is not in use.

FUELSHUT-OFFVALVE

The fuel shut-off valve,

located under fuel tank, con-

trols fuel flow from tank.

Choke

Primer

Ignition

Key

Throttle

Control

FIGURE 12.reModel 610E Shown

Starter

Handle

OPERATION

GASAND OIL FILL-UP

Service the engine with gasoline an J oil as

instructed in the separate engine manual p_cked with

your snow thrower. Read instructions care1 ully.

NOTE: Your snow thrower is shipped withoL t oil; how-

ever, a small amount of oil may be presen' from the

factory. Do not overfill.

_ WARNING: Never fill fuel tank indoors,

with engine running or while _;ngine is

hot. Do not smoke when filling ft el tank.

Electric Starter

WARNING: The electric starter is equipp_d with a

three-wire power cord and plug, and is d_signed to

operate on 120 volt AC household current. It must be

properly grounded at all times to avoid the 3ossibility

of electric shock which may be injurioLs to the

operator. Follow all instructions carefully. I)etermine

that your house wiring is a three-wire grounded

system. Ask a licensed electrician if yoL are not

certain. If your house wiring system is not a :hree-wire

grounded system, do not use this electric starter under

any conditions. If your system is grounded and a

three-hole receptacle is not available at the point your

starter will normally be used, one should be installed

by a licensed electrician.

When connecting the power cord, always connect cord

to switch box on engine first, then plug the other end

into a three-hole grounded receptacle.

When disconnecting the power cord, always unplug

the end from the three-hole grounded receptacle first.

TO STARTENGINE

IMPORTANT: If unit shows any sign of motion (drive or

augers) with the clutch grips disengaged, shut engine

off immediately. Readjust as instructed in the "Final

Adjustments" section of the Assembly Instructions.

1. Attach spark plug wire to spark plug.

2. Make certain the fuel shut-off valve is in the open

(vertical) position.

3. Make certain the auger drive and traction drive

clutch grips are in the disengaged (released)

position.

Page 9

4. Move throttle control up to FAST position. Insert

ignition key into slot. See figure 12. Be certain it

snaps into place. Do not turn key.

5. Rotate choke knob to FULL choke position (cold

engine start).

If engine is warm, place choke in OFF position

instead of FULL.

6. Connect power cord to switch box on engine. Plug

the other end of power cord into a three-hole,

grounded 120 volt AC receptacle.

7. Recoil Start Only: Push primer button two or

three times. If engine is warm, push primer button

once only. See figure 12.

NOTE: Always cover vent hole in primer button when

pushing. Adc/itiona/priming may be necessary for first

start if temperature is below 15°F.

8. Electric Start: Push starter button on top of the

switch box to crank the engine. When engine

starts, release starter button.

Recoil Start: Grasp starter handle (see figure 12)

and pull rope out slowly, until it pulls slightly

harder. Let rope rewind slowly. Pull starter handle

rapidly.Do not allow handle to snap back. Allow it

to rewind slowly while keeping a firm hold on the

starter handle.

9. Repeat step 8 until engine starts. If engine fails to

start, repeat steps 7 and 8 until engine starts.

10. As engine warms up and begins to operate evenly,

rotate choke knob slowly to OFF position. If

engine falters, return to FULL choke, then slowly

move to OFF position.

Electric Starter: Connect power cord to switch box on

engine, then to 120 volt AC receptacle. With the

engine running, push starter button and spin the

starter for several seconds. The unusual sound made

by spinning the starter will not harm engine or starter.

Disconnect the power cord from receptacle first, and

then from switch box.

Recoil Starter (Optional Instructions): With engine

running, pull starter rope with a rapid, continuous full

arm stroke three or four times. Pulling the starter rope

will produce a loud clattering sound, which is not

harmful to the engine or starter.

3. To stop engine, remove the ignition key. Do not

turn key. Disconnect the spark plug wire from the

spark plug to prevent accidental starting while

equipment is unattended.

NOTE: Do not lose ignition key. Keep it in a safe place.

Engine will not start without the ignition key.

4. Wipe all snow and moisture from the carburetor

cover in the area of the control levers. Also, move

control levers back and forth several times. Leave

throttle control lever in the STOP or OFF position.

Leave choke control in the FULL choke position.

AVOIDINJURYFROM ROTATING

AUGERm KEEPHANDS, FEET

ANDCLOTHINGAWAY. s7as

TO STOP ENGINE

1. Run engine for a few minutes before stopping to

help dry off any moisture on the engine.

2. To help prevent possible freeze-up of starter, pro-

ceed as follows.

TO ENGAGEDRIVE

1. With the engine running near top speed, move

shift lever into one of the six FORWARD positions

or two REVERSE positions. Select a speed

appropriate for the snow conditions that exist. Use

the slower speeds until you are familiar with the

operation of the snow thrower.

2. Squeeze the traction drive clutch grip against the

right handle and the snow thrower will move.

Release it and the drive motion will stop.

NOTE: NEVER move shift lever without first releasing

the drive clutch.

TO ENGAGEAUGERS

To engage the augers and start the snow throwing

action, squeeze the auger clutch grip against the left

handle. Release to stop the augers (traction drive

clutch grip must also be released).

The auger drive clutch can also be locked so you can

turn the chute crank without interrupting the snow

throwing process. Refer to "Traction Drive/Auger

Clutch Lock" in the Control section.

9

Page 10

TIRECHAINS(OptionalEquipment)

Tire chains should be used whenever extra t'action is

needed.

OPERATINGTIPS

NOTE: Allow the engine to warm up for a fev, minutes

as the engine will not develop full pow6r until it

reaches operating temperature.

_ WARNING: Temperature of muf:ler and

surrounding areas may exceecl 150°1=.

Avoid these areas.

1. For most efficient snow removal, rem<_ve snow

immediately after it falls.

2. Discharge snow downwind whenever possible.

Slightly overlap each previous swath.

3. Set the skid shoes 1/4" below the scrap,=r bar for

normal usage. The skid shoes may be adjusted

upward for hard-packed snow. If you (hoose to

use this snow thrower on gravel or crus ned rock,

adjust the skid shoes downward and us e caution

to avoid picking up gravel or rock with 1he shave

plate or augers.

4. Be certain to follow the precautions lised under

"To Stop Engine" on page 9 to preven possible

freeze-up.

5. Clean the snow thrower thoroughly after each

use.

ADJUSTMENTS

_1) WARNING: NEVER attempt to cle an chute

or make any adjustments while, mgine is

running.

CHUTEASSEMBLYADJUSTMENT

The distance snow is thrown can be acjusted by

adjusting the angle of the chute assembly. TPe sharper

the angle, the shorter the distance snow s thrown.

See figure 13.

To adjust chute assembly, loosen the hand _nob. Pivot

the top of the chute assembly to position1 desired.

Retighten the hand knob.

FIGURE 13.

Hand

Knob

SKIDSHOEADJUSTMENT

The space between the shave plate and the ground

can be adjusted. Refer to page 7 of the Assembly

Instructions.

TRACTION DRIVE CLUTCH ADJUSTMENT

Refer to the Final Adjustment section of the Assembly

Instructions to adjust the traction drive clutch. If you

are uncertain that you have reached the correct

adjustment, the adjustment can be physically checked

as follows.

With the snow thrower tipped forward (be certain to

drain the gasoline or place plastic film under the gas

cap if the snow thrower has already been operated),

remove the frame cover underneath the snow thrower

by removing six self-tapping screws.

With the traction drive clutch released, there must be

clearance between the friction wheel and the drive

plate in all positions of the shift lever. With the traction

drive clutched engaged, the friction wheel must con-

tact the drive plate. See figure 14.

If adjustment is necessary, loosen the jam nut on the

traction drive cable and thread the cable in or out as

necessary. Tighten the jam nut to secure the cable

when correct adjustment is reached. Reassemble the

frame cover.

NOTE: If you placed plastic under the gas cap, be cer-

tain to remove it.

.r,c.,on

Ij_II ._ Wheel

ve____ '-_

,r'te

t

FIGURE 14.

m

B

AUGERCLUTCH ADJUSTMENT

To adjust the auger clutch, refer to Final Adjustment

section of Assembly Instructions.

SHIFT ROD ADJUSTMENT

To adjust the shift rod, separate the shift rod and fer-

rule from the shift lever by removing the hairpin clip

and flat washer from the ferrule underneath the handle

panel. Refer to figure 7. Adjust as specified in the

Assembly Instructions.

10

Page 11

CARBURETORADJUSTMENT

_ WARNING: If any adjustments are made to

the engine while the engine is running

(e.g. carburetor), keep clear of all moving

parts. Be careful of heated surfaces and

muffler.

Minor carburetor adjustment may be required to com-

pensate for differences in fuel, temperature, altitude

and load.

Refer to the separate engine manual packed with your

unit for carburetor adjustment information.

DRIVE WHEELS

The wheels may be adjusted for two different methods

of operation. The adjustment is made by placing the

klick pins in one of two different holes on the right side

of the unit. See figure 15.

1. One Wheel DrivingmPlace klick pin in the out-

side axle hole on the right side. This position gives

power drive to the left wheel only, making the unit

easier to maneuver.

,

Both Wheels Driving--Place klick pin in the hole

in the hub next to the rim on the right side. This

position is good for heavy snow as there is power

drive in both wheels.

WHEELS

Oil or spray lubricant into wheel bearings at least once

a season. Remove wheels, clean and coat axles with a

multi-purpose automotive grease. See figure 16.

Oil Bearings

or Spray Lubricant

FIGURE 16.

CHUTE CRANK

The gear on the end of the chute crank should be

greased with multi-purpose automotive grease once a

season.

AUGERSHAFT

At least once a season, remove shear bolts on auger

shaft. Oil or spray lubricant inside shaft. See figure 17.

Also lubricate the auger bearings at least once a

season.

Outside Hole

in Axle

FIGURE 15.

LUBRICATION

_b) WARNING: Disconnect the spark plug

wire and ground against the engine

before performing any lubrication or

maintenance.

ENGINE

Refer to engine manual for all engine lubrication

instructions.

_ WARNING: When following instructions in

separate engine manual for draining oil,

be sure to protect frame to avoid oil

dripping onto transmission parts.

Shear Bolts

FIGURE 17.

Bearings

GEARSHAFT

Lubricate the gear shaft with "Slick 50 Grease" at least

once a season or after every 25 hours of operation

(available at automotive stores, or order part number

737-0290). Refer to figure 14.

IMPORTANT: Keep all grease and oil off of the

rubber friction wheel and aluminum drive plate.

11

Page 12

DRIVEANDSHIFTINGMECHANISM

At least once a season or after every 25 h(urs of

operation, remove rear cover. Lubricate any gears,

bearings, shafts, and shifting mechanism at lea.,_tonce

a season. Use engine oil or a spray lubricant. Avoid

getting oil on rubber friction wheel and aluurdnum

drive plate. Refer to figure 14.

TRACTIONDRIVE/AUGERCLUTCHLOCK

The cams on the ends of the control rods whicll inter-

lock the traction drive and auger drive clutche _ must

be lubricated at least once a season or every lwenty-

five hours of operation, The cams can be acq'essed

beneath the handle panel. Use a multi-purposq; auto-

motive grease,

GEAR CASE

The gear case is lubricated with grease at the Factory

and does not require checking. If disassembled Forany

reason, lubricate with 2 ounces of Shell _klvania

grease EPR00, part number 737-0168. Before

reassembling, remove old sealant and apply 'Loctite

5699" or equivalent.

IMPORTANT: Do not overfill the gear _=ase.

Damage to the seals could result. Be sur,,_the

vent plug is free of grease in order to r_lieve

pressure.

To remove shave plate, remove the carriage bolts,

belleville washers and hex nuts which attach it to the

snow thrower housing. Reassemble new shave plate,

making sure heads of the carriage bolts are to the

inside of the housing. Tighten securely.

ENGINE

Refer to separate engine manual for all engine mainte-

nance procedures.

BELTREMOVAL AND REPLACEMENT

,_WARNING: Disconnect the sparkwire from the spark plug and ground.

plug

AUGERBELTS

NOTE: It is necessary to remove both belts in order to

change either one. If changing just one belt, be certain

to check the condition of the other belt (model 610E

has only one auger belt).

1. Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws.

See figure 18.

MAINTENANCE

AUGERS

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. See figure 17. If you hit

a foreign object or ice jam, the snow thrcwer is

designed so that the hex bolts will shear.

If the augers will not turn, check to see if the bol :s have

sheared. Two replacement shear bolts and h ,_xlock

nuts have been provided with the snow thrower. For

future use, order part number 710-0890 (shear bolt

5/16-18 x 1.5" long) and 712-0429 (hex insert I)ck nut

5/16-18 thread).

SHAVEPLATEAND SKID SHOES

The shave plate and skid shoes on the botton_ of the

snow thrower are subject to wear. They sheuld be

checked periodically and replaced when neces:;ary.

To remove skid shoes, remove the four carriag .=bolts,

belleville washers and hex nuts which attach Inem to

the snow thrower. Reassemble new skid sho ,_swith

the four carriage bolts, belleville washers (cupp.=d side

goes against skid shoes) and hex nuts. Make certain

the skid shoes are adjusted to be level.

12

Belt Self-Tapping

Cover Screws

FIGURE 18.

2. Drain the gasoline from the snow thrower, or place

a piece of plastic under the gas cap.

3. Tip the snow thrower up and forward so that it

rests on the housing.

4. Remove six self-tapping screws from the frame

cover underneath the snow thrower.

5. Roll the front and rear auger belts off the engine

pulley. See figure 19.

Page 13

Rear

Auger

Drive

Belt

Englne

lulley

Front

Auger

Belt

Friction

Wheel

Engine

Pulley

Pulley Idler

Pulley

FIGURE 19.

Support

Bracket

Rear

Auger

Belt

Frame

6. Unhook the idler spring from the hex bolt on the

auger housing. See figure 20.

7. Back out the stop bolt to allow the belts to slip

between the bolt and auger pulley. See figure 21.

NOTE: It may be necessary to loosen the six hex nuts

that fasten the frame to the auger housing to aid in belt

removaL

8. Lift the rear auger belt from the auger pulley, and

slip belt between the support bracket and the

auger pulley. See figure 20. Repeat this step for

front auger belt (except model 610E).

9. Replace both auger drive belts by following

instructions in reverse order.

DRIVE BELT

1. Follow steps 1 through 4 of previous instructions.

2. Pull idler pulley up, and lift belt off engine pulley

and friction wheel disc. See figure 19.

3. Back out the stop bolt until the support bracket

rests on the auger pulley. See figure 21.

4. Slip belt between friction wheel and friction wheel

disc. See figure 21. Remove and replace belt.

Reassemble following the instructions in reverse

order.

NOTE: The support bracket must rest on the stop bolt

after the new belt has been assembled. See figure 21.

Auger

Pulley

Pulley

FIGURE 20.

Idler

Spring

Auger

Houslng

Bracket

Spring

Friction

Wheel

i D Bolt

FIGURE 21.

\

CHANGINGTHEFRICTIONWHEELRUBBER

The rubber on the friction wheel is subject to wear and

should be checked after 25 hours of operation, and

periodically thereafter. Replace the friction wheel

rubber if any signs of wear or cracking are found.

1. Drain the gasoline from the snow thrower, or place

a piece of plastic under the gas cap.

2. Tip the snow thrower up and forward, so that it

rests on the housing.

13

Page 14

3. Removesixself-tappingscrewsfromthe frame

coverunderneaththesnowthrower.

4. Removetheklickpinswhichsecurethev'heels,

andremovethewheelsfromtheaxle.

5. Usinga 7/8"wrenchtoholdtheshaft,Ioos,,=n,but

do not completelyremove,the hexnutal_dbell

washerontheleftendofgearshaft.Seefigure

22.

6. LightlytapthehexnuttodislodgetheballLearing

from the right side of frame. Remove the tex nut

and bell washer from left end of shaft.

7. Slide the gear shaft to the right and slide t_e fric-

tion wheel assembly from the shaft.

8. Remove the six screws from the friction wheel

assembly (three from each side). Remove t 7e fric-

tion wheel rubber from between the frictior wheel

plate.

9. Reassemble new friction wheel rubber to the

friction wheel assembly, tightening the six _crews

in rotation and with equal force.

10. Position the friction wheel assembly up o,_to the

pin of the shift rod assembly, and slide th,_ shaft

through the assembly. Reassemble in _everse

order.

FIGURE 22.

If unit is to be stored over 30 days, prepare for storage

as follows:

1. Remove all gasoline from carburetor and fuel tank

to prevent gum deposits from forming on these

parts and causing possible malfunction of engine.

a. Run engine until fuel tank is empty and engine

stops due to lack of fuel.

b. Drain carburetor by pressing upward on bowl

drain, located below the carburetor cover.

&

WARNING: Drain fuel into approved con-

tainer outdoors, away from open flame.

Be certain engine is cool. Do not smoke.

Fuel left in engine during warm weather

deteriorates and will cause serious start-

ing problems.

NOTE: Fuel stabilizer (such as STA-BIL) is an accept-

able alternative in minimizing the formation of fuel

gum deposits during storage. Add stabilizer to

gasoline in fuel tank or storage container. Always

follow mix ratio found on stabilizer container. Run

engine at least 10 minutes after adding stabilizer to

allow it to reach carburetor. Do not drain carburetor if

using fuel stabilizer.

2. Remove spark plug and pour one (1) ounce of

engine oil through spark plug hole into cylinder.

Crank engine several times to distribute oil.

Replace spark plug.

3. Remove all dirt from exterior of engine and equip-

ment.

4. Follow lubrication recommendations on page 11.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rust proof the equipment. Using a light off or

silicone, coat the equipment, especially any chains,

springs, bearings and cables.

OFF-SEASON STORA(;E

&

WARNING: Never store engine with fuel in

tank indoors or in poorly ventilate(J areas,

where fuel fumes may reach ar open

flame, spark or pilot light as on a fl Jrnace,

water heater, clothes dryer or otl'er gas

appliance.

14

Page 15

TROUBLE SHOOTING GUIDE

Trouble

Engine fails to start

Engine runs erratic

Loss of power

Engine overheats

Excessive vibration

Hard to shift, or will

not shift

Unit fails to propel itself

Unit fails to discharge

snow

Possible Cause(s)

1. Fuel tank empty, or stale fuel.

2. Fuel shut-off valve closed.

3. Key not in switch on engine.

4. Spark plug wire disconnected.

5. Blocked fuel line.

6. Faulty spark plug.

1. Unit running on CHOKE.

2. Blocked fuel line or stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

1. Spark plug wire loose.

2. Gas cap vent hole plugged.

1. Engine oil level low.

2. Carburetor not adjusted properly.

Loose parts or damaged impeller.

Shift rod misadjusted.

1. Incorrect adjustment of drive clutch.

2. Drive belt loose or damaged.

1. Auger shear bolt broken.

2. Discharge chute clogged.

3. Foreign object lodged in auger.

4. Incorrect adjustment of auger drive

clutch.

5. Auger drive belt loose or damaged.

Corrective Action

1. Fill tank with clean, fresh gasoline.

2. Open shut-off valve.

3. Insert key.

4. Connect wire to spark plug.

5. Clean fuel line.

6. Clean, adjust gap or replace.

1. Turn choke knob to OFF position.

2. Clean fuel line; fill tank with clean

fresh gasoline.

3. Use carburetor bowl drain to drain

fuel tank. Refill with fresh fuel.

4. Adjust carburetor. See separate

engine manual.

1. Connect and tighten spark plug

wire.

2. Remove ice and snow from cap.

Be certain vent hole is clear.

1. Fill crankcase with proper oil.

2. Adjust carburetor. See separate

engine manual.

Stop engine immediately and

disconnect spark plug wire. Tighten

all bolts and nuts. Make all

necessary repairs. If vibration

continues, have unit serviced by

authorized service dealer.

Readjust shift rod. See Adjustment

section of this manual.

1. Adjust drive clutch. Refer to

Adjustment section.

2. Replace drive belt. Refer to

Maintenance section.

1. Replace auger shear bolt. Refer to

Maintenance section.

2. Stop engine immediately and

disconnect spark plug wire. Clean

discharge chute and inside of auger

housing.

3. Stop engine immediately and

disconnect spark plug wire.

Remove object from auger.

4. Adjust auger clutch. Refer to

Adjustment section.

5. Replace auger drive belt. Refer to

Maintenance section.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized service

dealer.

15

Page 16

Plate

_hoe

A

0

T

L

T

Page 17

_oriesor Service Information,

800-80017310

Model Number Serial Number

0000000000000000000000

Product Number

00000000000

May not fill all the above spaces

lhe only way to ensure the performance of your

product isto use original equipment parts and

.]ccessories. MTD designs and engineers quality

parts to exacting specifications. When you

substitute, you take a chance on quality,

reliability, safety and performance. Use MTD

original equipment,

the best buy on the American Landscape.

- American Made Ametlcan Owned I

Loading...

Loading...