Yard Machines 317E660G000, 317E610E000, 317E640F000 Owner's Manual

OUTDOOR POWER EQUIPMENT

24", 26" and 28"

SNOW

THROWERS

Model Numbers

317E610E000

317E640F000

317E660G000

MTD PRODUCTS INC • P.O. BOX 368022 • CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-8782M

IMPORTANT

SAFEOPERATIONPRACTICES

THIS SYMBOLPOINTSOUT IMPORTANTSAFETYI1_STRUCTIONSWHICH, IF NOT FOLLOWED,COULDENDANGERTHEPERSONAL_

SAFETYAND/OR PROPERTYOF YOURSELFAND CTHERS. READAND FOLLOWALL INSTRUCTIONSIN THIS MANUAL BEFORE

ATTEMPTINGTOOPERATEYOURSNOWTHROWER•FAILURETOCOMPLYWITH THESEINSTRUCTIONSMAY RESULTIN PERSONAL,

INJURY.WHENYOUSEETHIS SYMBOL-- _IL HEEDITS WARNING.

,_ Yoursnowthrowerwas bull to be operatedaccordingto the rules for safe operation in this manual. As with [

m

DANGER: any type ofpowerequipmert, carelessnessor erroron the part of the operatorcan result in seriousinjury, if

Iyou violate any of these rules, you may causeseriousinjury to yourself or others.

TRAINING

1. Readthis owner's guide carefully in its entirety berg

ing to assemble or operatethis machine. Becomplet

with the controls and the proper use of this mact

operating it. Keepthis manual in a safe placefor futu

ular referenceand for ordering replacement parts.

2. Never allow children under 14 years old to oper;

thrower. Children 14 years old and over should ol

snow thrower under close parental supervision. Or

well acquainted with these rules of safe operation

allowed to useyour snow thrower.

3. No one should operatethis unit while intoxicatedor

medication that impairs the senses or reactions.

4. Keep the area of operation clear of all persons, espe

children andpets.

5. Exercise caution to avoid slipping or falling, espe_

operating in reverse.

_lb PREPARATION

1. Thoroughly inspect the areawhere the equipment is

and remove all door mats, sleds, boards, wires an_

eign objects.

2. Disengage all clutches and shift into neutral bef(

engine.

3. Do not operate equipment without wearing adeq_

outer garments. Do not wear jewelry, long scarfs or

clothing which could become entangled in moving I

footwear which will improve footing on slippery surf

4. Before working with gasoline, extinguish all cigarette

sources of ignition. Check the fuel before starting

Gasolineis an extremely flammable fuel. Do not fill

tank indoors, while the engine is running, or until

beenallowed to cool at leasttwo minutes. Replace

securely and wipe off any spilled gasoline before

engineas it maycause a fire or explosion.

5. Usea grounded three wire plug-in for all units with e

motors or electric starting motors.

6. Adjust collector housing height to clear gravel or cM

surface.

7. Neverattempt to make any adjustments while engin

(except where specifically recommended by manufa

8. Let engine and machine adjust to outdoor temper_

starting to clear snow.

9. Always wear safety glasses or eye shields during

while performing an adjustment or repair,to protec

foreign objects that may be thrown from the mac

direction.

OPERATION

1. Donot put hands or feet near or under rotating part,,

of discharge opening and augerat all times•

2. Exerciseextreme caution when operating on or cro

drives, walks, or roads. Stay alert for hidden hazan

Do not carry passengers.

3. After striking a foreign object, stop the engine,

from spark plug, and thoroughly inspect the snow

any damage. Repairthe damagebefore restarting a_

the snow thrower.

4. Ifthe snow thrower should start to vibrate abnorm_

engine and check immediately for the cause.

generally a warning of trouble.

eattempt-

,flyfamiliar

ine before

e andreg-

te a snow

tly operate

ly persons

shouldbe

rhiletaking

"iallysmall

;iallywhen

tobe used

otherfop

re starting

latewinter

)therloose

)arts.Wear

ices.

sandother

:heengine.

1le gasoline

enginehas

asolinecap

;tartingthe

ectric drive

ushedrock

_isrunning

:turer).

ture before

( perationor

teyesfrom

_mein any

•Keepclear

;singgravel

s or traffic.

r,'move wire

thrower for

doperating

Ily, stop the

/ibration is

5. Stop enginewheneveryouleavethe operatingposition,before

uncloggingthe collector/impellerhousingor dischargeguide,

and makingany repairs,adjustments,or inspections.Never

placeyour handin the dischargeor collectoropenings.Usea

stickorwoodenbroomhandleto unclogthe dischargeopening.

6. Takeallpossibleprecautionswhenleavingtheunitunattended.

Disengagethe collector/impeller,shift into neutral,stop the

engine,andremovethekey.

7. Whencleaning,repairing,or inspecting,makecertaincollector/

impellerandall movingpartshavestopped.Disconnectspark

plugwireandkeepawayfrom plugto preventaccidentalstart-

ing.

8. Do not run engineindoors,exceptwhenstartingengineand

transportingsnowthrower in or out of building.Opendoors.

Exhaustfumesaredangerous.

9. Do not clearsnowacrossthe faceof slopes.Exerciseextreme

cautionwhenchangingdirectionon slopes.Donotattemptto

clearsteepslopes.

10. Neveroperatesnowthrower withoutguards,plates,or other

safetyprotectiondevicesin place.

11. Neveroperatesnowthrowernearglassenclosure,automobiles,

window wells, drop off, etc., without properadjustmentsof

snowthrowerdischargeangle.Keepchildrenandpetsaway.

12. Do not overloadmachinecapacitybyattemptingto clearsnow

attoo fasta rate.

13. Neveroperatethemachineathightransportspeedsonslippery

surfaces.Lookbehindandusecarewhenbacking.

14. Neverdirectdischargeatbystandersorallowanyonein frontof

unit.

15. Disengagepowertocollector/impellerwhentransportingor not

inuse.

16. Useonly attachmentsandaccessoriesapprovedbythe manu-

facturer of snow thrower (such as wheel weights,counter

weights,cabs,etc.).

17. Neveroperatethesnowthrowerwithoutgoodvisibilityor light.

Alwaysbesureof yourfootingandkeepafirm holdonthehan-

dles.Walk,neverrun.

18. Mufflerand enginebecomehot andcan causea burn. Do not

touch.

,_ MAINTENANCEAND STORAGE

1. Check shear bolts, engine mounting bolts, etc., at frequent

intervalsfor propertightness to be sure equipmentis in safe

workingcondition.

2. Neverstorethe machine withfuel inthe fueltank insidea build-

ingwhere ignitionsources are present,such as hot water and

spaceheaters,clothesdryers,and thelike.Allow engineto _:ool

beforestoringin any enclosure.

3. Always referto owner's guide instructionsfor importantdetails

if snowthroweris to be storedfor an extendedperiod.

4. Run machine a few minutes after throwing snow to prevent

freezeup ofcollector/impeller.

5. Check clutchcontrolsperiodicallyto verify they engage and dis-

engage properly and readjust if necessary.Refer to owner's

guidefor adjustmentinstructions.

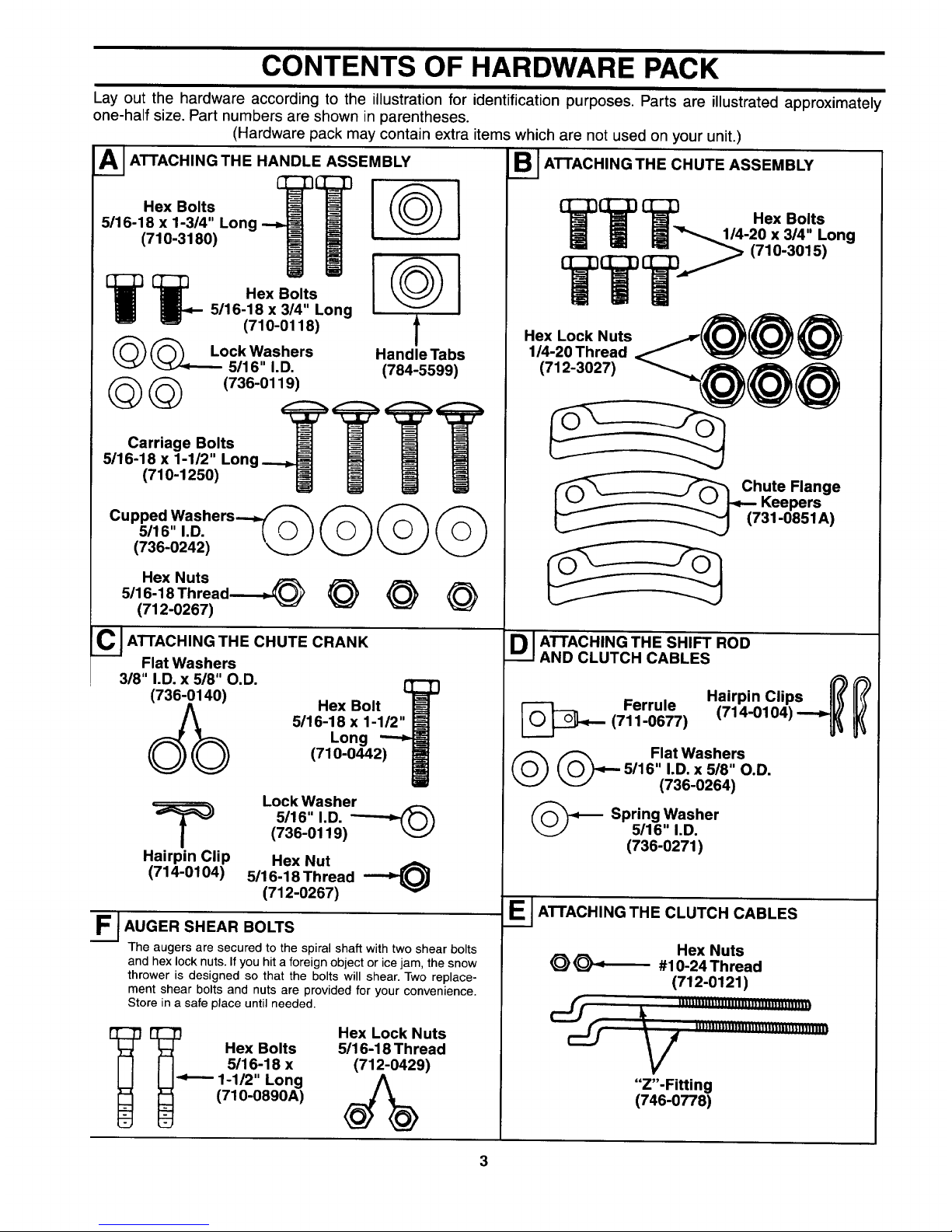

CONTENTS OF HARDWARE PACK

Lay out the hardware according to the illustration for identification purposes. Parts are illustrated approximately

one-half size. Part numbers are shown in parentheses.

(Hardware pack may contain extra items which are not used on your unit.)

A_ ATTACHING THE HANDLE ASSEMBLY

Hex Bolts [

5/16-18 x 1-3/4" Long

(710-3180)

[__ Hex Bolts

5116-18 x 3/4" Long

(710-0118)

(_(_ Lock Washers

5/16" I.D.

(_(_ (736-0119)

Carriage Bolts

5/16-18 x 1-1/2" Long

(710-1250)

@1

@

f

Handle Tabs

(784-5599)

Cupped Washers_

5/16" I.D. _ _

(736-0242) _._.j'

Hex Nuts

5/16-18 Thread-_,._ @

(712-0267)

C JATrACHING THE CHUTE CRANK

Flat Washers

318" I.D. x 518" O.D.

Hex Bolt

5/16-18 x 1-1/2"

Long

(710-0442)

Lock Washer

5116" I.D.

(736-0119)

Hairpin Clip Hex Nut

(714-0104) 5/16-18 Thread --_

(712-0267)

F.__ AUGER SHEAR BOLTS

The augers are secured to the spiral shaft with two shear bolts

and hex lock nuts. If you hit a foreign object or ice jam, the snow

thrower is designed so that the bolts will shear. Two replace-

ment shear bolts and nuts are provided for your convenience.

Store in a safe place until needed.

_ _.,_._ Hex Bolts

5/16-18 x

1-1/2" Long

(710-0890A)

Hex Lock Nuts

5/16-18 Thread

(712-0429)

S I ATTACHING THE CHUTE ASSEMBLY

TTT .exoo,,.

1/4-20 x 3/4" Long

TT T _ (710-3015)

Hex Lock Nuts.@@ @

1/4-20 Thread

@@@

ute Flange

Keepers

31-0851A)

D I ATTACHING THE SHIFT ROD

AND CLUTCH CABLES

Ferrule

(711-0677)

Hairpin Clips ['_

(714-0104) ---_

(_(_ Flat Washers

5/16" I.D. x 5/8" O.D.

(736-0264)

(_ Spring Washer

5/16" I.D.

(736-0271)

E__ ATTACHING THE CLUTCH CABLES

Hex Nuts

_ _ #10-24 Thread

(712-0121)

• V ""_'""""m"I_"""m'_l_

"Z'-Fitting

(746-0778)

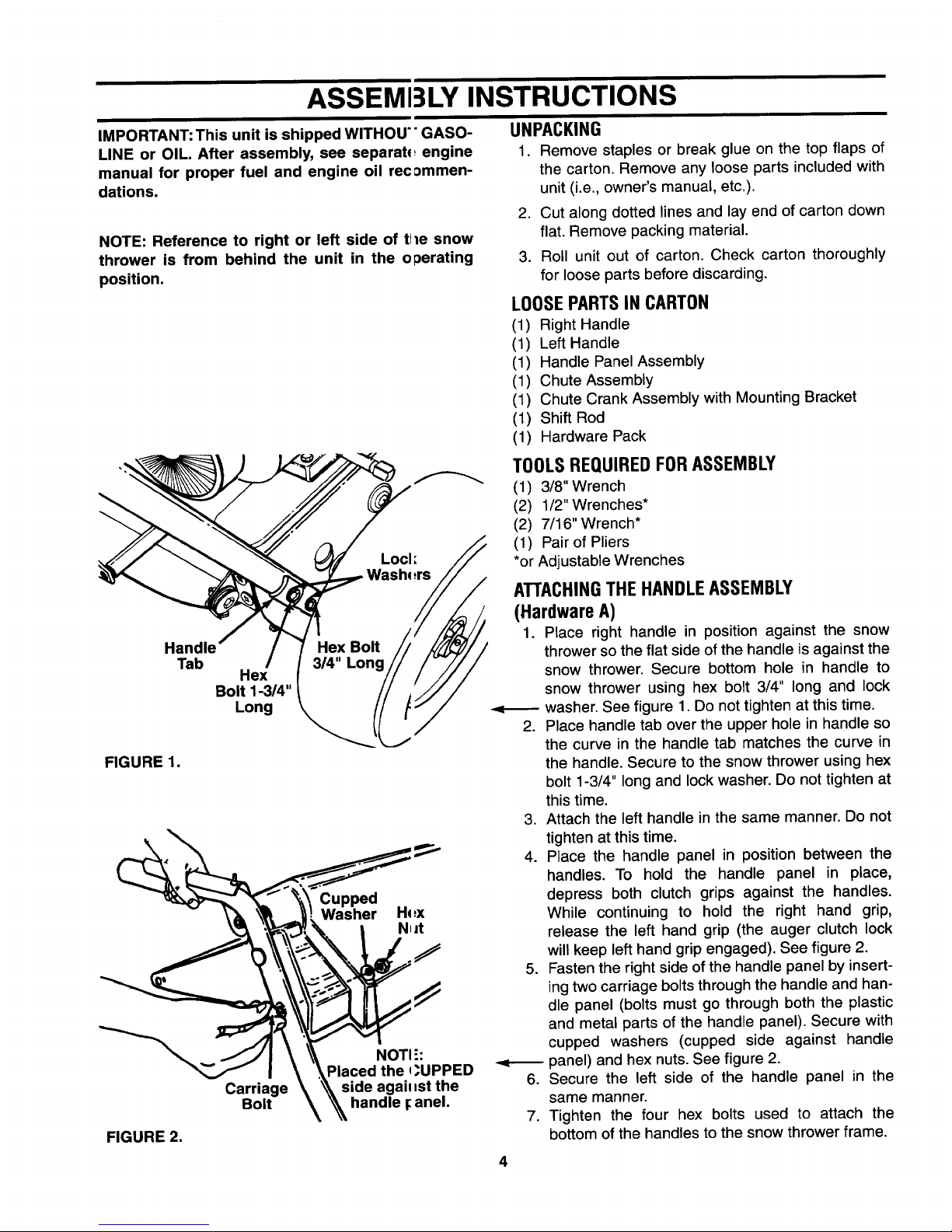

ASSEMI3LY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOU'" GASO-

LINE or OIL. After assembly, see separab_ engine

manual for proper fuel and engine oil rec:_mmen-

dations.

NOTE: Reference to right or left side of tile snow

thrower is from behind the unit in the operating

position.

Handle

Tab

Hex

Bolt 1-3/4"

Long

FIGURE 1.

Cupped

Washer Hq:x

N_it

FIGURE 2.

Carriage

Bolt

NOTI ":

Placed the q_UPPED

side agail _st the

handle _anel.

UNPACKING

1. Remove staples or break glue on the top flaps of

the carton. Remove any loose parts included with

unit (i.e., owner's manual, etc.).

2. Cut along dotted lines and lay end of carton down

flat. Remove packing material.

3. Roll unit out of carton. Check carton thoroughly

for loose parts before discarding.

LOOSE PARTS IN CARTON

(1) Right Handle

(1) Left Handle

(1) Handle Panel Assembly

(1) Chute Assembly

(1) Chute Crank Assembly with Mounting Bracket

(1) Shift Rod

(1) Hardware Pack

TOOLS REQUIRED FOR ASSEMBLY

(1) 3/8" Wrench

(2) 1/2" Wrenches*

(2) 7/16" Wrench*

(1) Pair of Pliers

*or Adjustable Wrenches

ATTACHINGTHE HANDLEASSEMBLY

(HardwareA)

1. Place right handle in position against the snow

thrower so the flat side of the handle is against the

snow thrower. Secure bottom hole in handle to

snow thrower using hex bolt 3/4" long and lock

washer. See figure 1. Do not tighten at this time.

Place handle tab over the upper hole in handle so

the curve in the handle tab matches the curve in

the handle. Secure to the snow thrower using hex

bolt 1-3/4" long and lock washer. Do not tighten at

this time.

3. Attach the left handle in the same manner. Do not

tighten at this time.

4. Place the handle panel in position between the

handles. To hold the handle panel in place,

depress both clutch grips against the handles.

While continuing to hold the right hand grip,

release the left hand grip (the auger clutch lock

will keep left hand grip engaged). See figure 2.

5. Fasten the right side of the handle panel by insert-

ing two carriage bolts through the handle and han-

dle panel (bolts must go through both the plastic

and metal parts of the handle panel). Secure with

cupped washers (cupped side against handle

panel) and hex nuts. See figure 2.

Secure the left side of the handle panel in the

same manner.

7. Tighten the four hex bolts used to attach the

bottom of the handles to the snow thrower frame.

4

FIGURE 3.

\

Chute Assembly

Hex Head

Screw

Flat Washer

Lock Nut

Chute

Flange

Keeper

Lock Washer

Hex Nut

_m

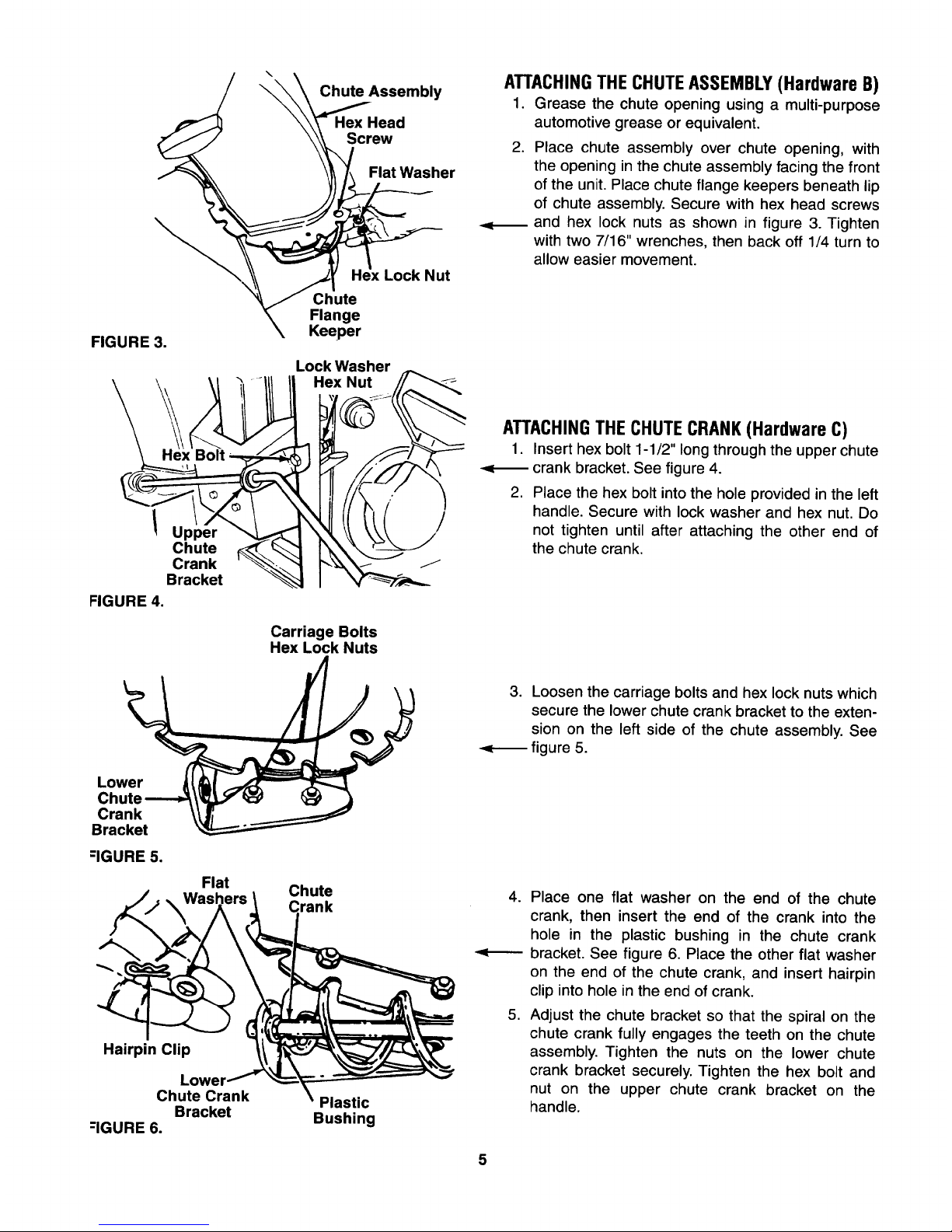

ATTACHINGTHE CHUTEASSEMBLY(Hardware B)

1. Grease the chute opening using a multi-purpose

automotive grease or equivalent.

.

Place chute assembly over chute opening, with

the opening in the chute assembly facing the front

of the unit. Place chute flange keepers beneath lip

of chute assembly. Secure with hex head screws

and hex lock nuts as shown in figure 3. Tighten

with two 7/16" wrenches, then back off 1/4 turn to

allow easier movement.

Upper

Chute

Crank

Bracket

FIGURE 4.

Carriage Bolts

Hex Lock Nuts

ATTACHINGTHE CHUTECRANK (Hardware C)

1. Insert hex bolt 1-1/2" long through the upper chute

-<_ crank bracket. See figure 4.

2. Place the hex bolt into the hole provided in the left

handle. Secure with lock washer and hex nut. Do

not tighten until after attaching the other end of

the chute crank.

Lower

Chute

Crank

Bracket

-IGURE 5.

Flat

Hairpin Clip

Lower

Chute Crank

Bracket

--IGURE 6.

Chute

rank

Plastic

Bushing

3. Loosen the carriage bolts and hex lock nuts which

secure the lower chute crank bracket to the exten-

sion on the left side of the chute assembly. See

figure 5.

4. Place one flat washer on the end of the chute

crank, then insert the end of the crank into the

hole in the plastic bushing in the chute crank

bracket. See figure 6. Place the other flat washer

on the end of the chute crank, and insert hairpin

clip into hole in the end of crank.

5. Adjust the chute bracket so that the spiral on the

chute crank fully engages the teeth on the chute

assembly. Tighten the nuts on the lower chute

crank bracket securely. Tighten the hex bolt and

nut on the upper chute crank bracket on the

handle.

5

IMPORTANT:Attachthe shift rod andcl itch cables as follows. THEN CHECK THE ADJUSTMENTS AS

INSTRUCTED, AND MAKE ANY FINAL A[)JUSTMENTS NECESSARY BEFORE OPERATING YOUR SNOW

THROWER. Failure to follow the instructi,)ns may cause damage to the snow thrower.

Tracti°_ hiftClutchDrive Lever

I1 Washer Fer u e

J/Shift

1Arm

_ssembly

ATTACHINGTHE SHIFT ROD (Hardware D)

1. Place the shift lever (on the handle panel) in the

sixth (6) speed position (all the way forward).

Place the bent end of the shift rod into the hole in

the shift arm assembly. See figure 7. Secure with

spring washer, flat washer and hairpin clip.

3. Start threading the ferrule onto the other end of the

shift rod. Push down on the shift rod (and shift arm

assembly) as far as it will go.

4. Thread the ferrule onto the shift rod until the ferrule

lines up with the upper hole in the shift lever

(beneath the handle panel). Insert the ferrule into

the upper hole in the shift lever from the left side

when adjustment is correct. Secure with flat

washer and hairpin clip.

Make certain to check for correct adjustment of the

shift rod as instructed in the Final Adjustment section

before operating the snow thrower.

FIGURE 7.

Hex Jam

Nut

/

/

Cable is Strai

FIGURE 8.reViewed from Underside of H_nndle

Panel

ATTACHINGTHE CLUTCH CABLES(Hardware E)

The "Z" end of the clutch cables are hooked into the

clutch grips on each handle. Attach cables as follows.

1. Thread the hex nuts (in hardware pack) all the

way up the threaded portion of the "Z" ends of the

clutch cables.

2. Make certain each cable is in groove of cable

roller guides. Place the clutch grip in the raised

(up) position.

3. Thread the cable onto the threaded portion of the

"Z" end until there is no slack in the cable, but the

cable is NOT tight. Do not overtighten cable.

See figure 8.

&

WARNING: If cable is tightened so there is

tension on the cable with the clutch grip

released, the safety features of the snow

thrower may be overridden.

4. When correct adjustment is reached, tighten the

hex nut against the bottom portion of the cable to

lock it in position.

FINAL ADJUSTMENTS

Auger Drive Clutch

To check the adjustment of the auger drive clutch,

push forward on the left hand clutch grip (depress the

rubber bumper). There should be slack in the cable.

Release the clutch grip. The cable should be straight.

Make certain you can depress the auger drive clutch

grip against the left handle completely.

Loading...

Loading...