Page 1

OPERATOR’S MANUAL

FRONT TINE

TILLERS

300 Series

IMPORTANT: READ

SAFETY RULES AND

INSTRUCTIONS CAREFULLY

MTD PRODUCTS LTD. P.O. BOX 1386 KITCHENER, ON N2G 4J1

PRINTED IN THE U.S.A.

772C0730

(10/04)

Page 2

TABLE OF CONTENTS

Content Page

Customer Support 2

Important Safe Operation Practices 3

Assembly 5

Controls 7

Operation 8

Adjustments 10

Content Page

Lubrication 11

Maintenance 11

Off-Season Storage 13

Troubleshooting 13

Parts Lists/Pièces détachées 14

Warranty 18

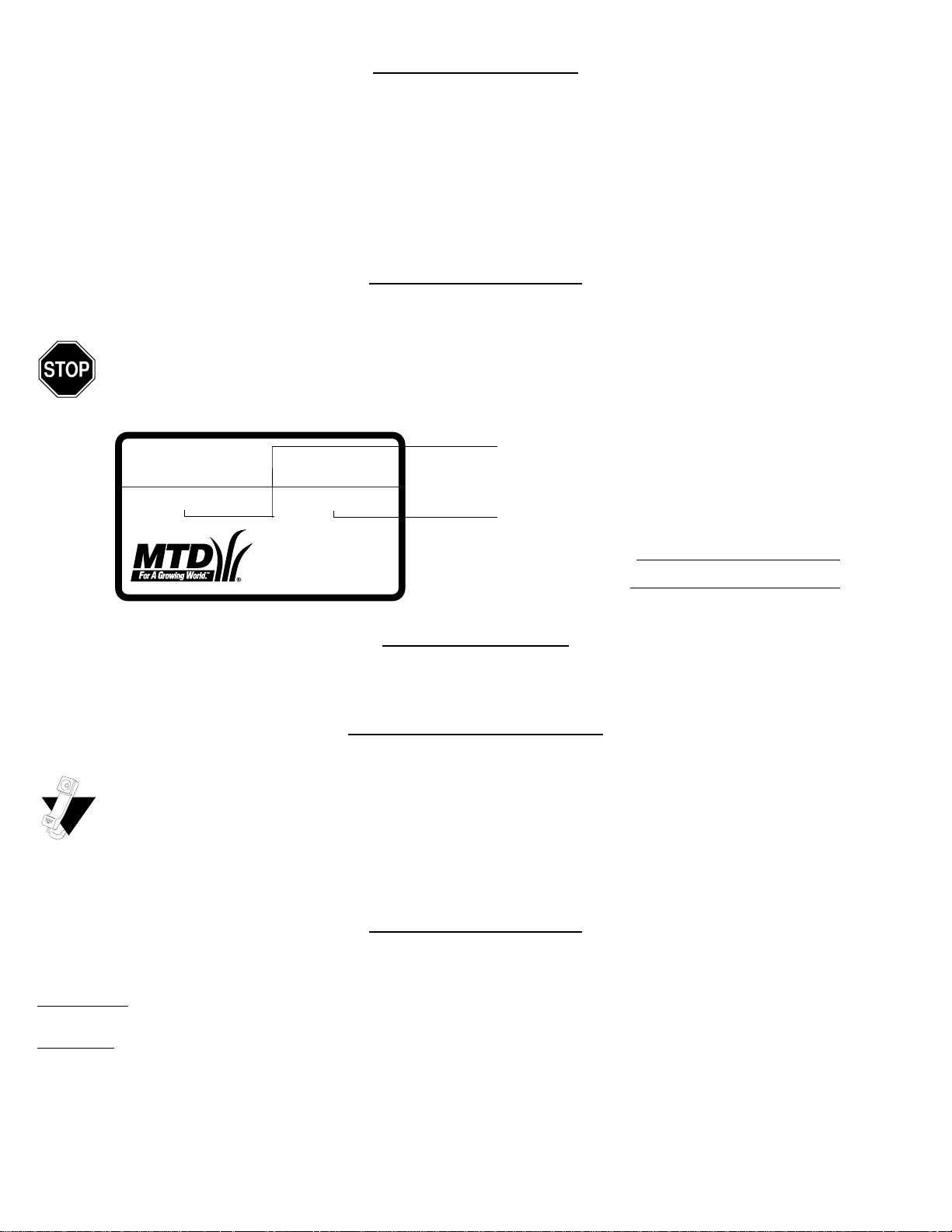

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new equipment. It will help you assemble, prepare and maintain the unit for best

performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the information from

it in the space provided below. A sample model plate is also given below. You can locate the model plate by standing at the operating

position and looking down at the rear of the deck . This information will be necessary to use the manufacturer’s web site and/or help

from the Customer Support Department or an authorized service dealer.

This is where your model number will be.

Model Number

Numéro de modèle

XXXXXXXXXX

www.mtdcanada.com

Serial Number

Numéro de série

XXXXXXXXXXX

MTD PRODUCTS LIMITED

KITCHENER, ON N2G 4J1

1-800-668-1238

This is where your serial number will be.

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, specifications, warranty and

service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed separately with your unit for more information.

CALLING CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from which it was purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of this unit,

please call a Customer Support Representataive.

For US Customers: 1- (330) 220-4MTD (4683) or 1- (800)-800-7310

For Canadian Customers: 1-800-668-1238

Please have your unit’s model number and serial number ready when you call. See previous section to locate this information. You will be asked

to enter the serial number in order to process your call.

HOW TO OBTAIN SERVICE

Service is available, WITH PROOF OF PURCHASE, through your local authorized service dealer. To locate the dealer in your

area;

In the U.S.A.

Ohio 44136-0019, or call 1-800-800-7310 or 1-330-220-4683 or log on to our Web site at www.mtdproducts.com.

In Canada

www.mtdcanada.com.

: Check your Yellow Pages, or contact customer support listed about MTD LLC at P.O. Box 361131, Cleveland,

: Contact MTD Products Limited, Kitchener, ON N2G 4J1, or call 1-800-668-1238 or log on to our Web site at

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate your tiller. Failure to comply with these instructions may result in personal

injury. when you see this symbol— HEED ITS WARNING

DANGER: Your tiller was built to be operated according to the rules for safe operation in this manual.

As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This tiller is capable of amputating hands and feet. Failure to observe the following safety

instructions could result in serious injury or death.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, children and pets at

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

PREPARATION

1. Thoroughly inspect the area where the equipment is to be used. Remove all stones, sticks, wire, and other foreign objects which could be tripped over and cause personal injury.

2. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Loose fitting clothes and

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

3. Disengage clutch levers and shift (if provided) lever into neutral ("N") before starting the engine.

4. Never leave this machine unattended with the engine running.

5. Never attempt to make any adjustments while the engine is running, except where specifically recommended in the operator’s manual.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are

explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes

which can ignite. Wash your skin and change

clothes immediately.

7. Use only an approved gasoline container.

8. Extinguish all cigarettes, cigars, pipes and other

9. Never fuel machine indoors.

10. Never remove gas cap or add fuel while the

11. Allow engine to cool at least two minutes before

12. Never over fill fuel tank. Fill tank to no more than

13. Replace gasoline cap and tighten securely.

14. If gasoline is spilled, wipe it off the engine and

15. Never store the machine or fuel container inside

16. Allow a machine to cool at least 5 minutes before

OPERATION

1. Do not put hands or feet near rotating parts.

2. Do not operate the machine while under the

3. Never operate this machine without good visibility

4. Keep bystanders, helpers, children and pets at

5. Be careful when tilling in hard ground. The tines

6. Exercise extreme caution when operating on or

7. Never operate the machine at high transport

8. Exercise caution to avoid slipping or falling.

.

sources of ignition.

engine is hot or running.

refueling.

½ inch below bottom of filler neck to allow space

for fuel expansion.

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace,

clothes dryer or other gas appliances.

storing.

Contact with the rotating parts can amputate

hands and feet.

influence of alcohol or drugs.

or light. Always be sure of your footing and keep a

firm hold on the handles.

least 75 feet from the machine while it is in

operation. Stop machine if anyone enters the area.

may catch in the ground and propel the tiller

forward. If this occurs, let go of the handle bars and

do not restrain the machine.

crossing gravel surfaces. Stay alert for hidden

hazards or traffic. Do not carry passengers.

speeds on hard or slippery surfaces.

3

Page 4

9. Look down and behind and use care when in reverse or pulling machine towards you.

10. Start the engine according to the instructions found in this manual and keep feet well away from the tines at all times.

11. After striking a foreign object, stop the engine, disconnect the spark plug wire(s) and ground against the engine. Thoroughly inspect the machine for any damage. Repair the damage before starting and operating.

12. Disengage all clutch levers and stop the engine before you leave the operating position (behind the handles). Wait until the tines come to a complete stop before unclogging the tines, making any adjustments, or inspections.

13. Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless, and deadly gas.

14. Muffler and engine become hot and can cause a burn. Do not touch.

15. Use caution when tilling near fences, buildings and underground utilities. Rotating tines can cause property damage or personal injury.

16. Do not overload machine capacity by attempting to till soil too deep at too fast of a rate.

17. If the machine should start making unusual noise or vibration, stop the engine, disconnect the spark plug wire and ground it against the engine. Inspect thoroughly for damage. Repair any damage before starting and operating.

18. Keep all shields, guards and safety devices in place and operating properly.

19. Never pick up or carry machine while the engine is running.

20. Use only accessories and attachments approved for this machine by the machine manufacturer. Failure to do so, can result in serious injury.

21. If situations occur which are not covered in this manual, use care and good judgment. Contact your authorized dealer for assistance.

MAINTENANCE & STORAGE

1. Never tamper with safety devices. Check their proper operation regularly.

2. Check bolts and screws for proper tightness at frequent intervals to keep the machine in safe working condition. Also, visually inspect machine for any damage.

3. Before cleaning, repairing, or inspecting, make certain the tine(s) and all moving parts have stopped. Disconnect the spark plug wire and ground against the engine to prevent unintended starting.

4. Do not change the engine governor settings or over-speed the engine. The governor controls the maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as necessary.

6. Follow this manual for safe loading, unloading, transporting, and storage of this machine.

7. Never store the machine or fuel container inside where there is an open flame, spark or pilot light as on a water heater, space heater, furnace, clothes dryer or other gas appliances.

8. Always refer to the operator’s manual for proper instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for gas, oil, etc. to protect the environment.

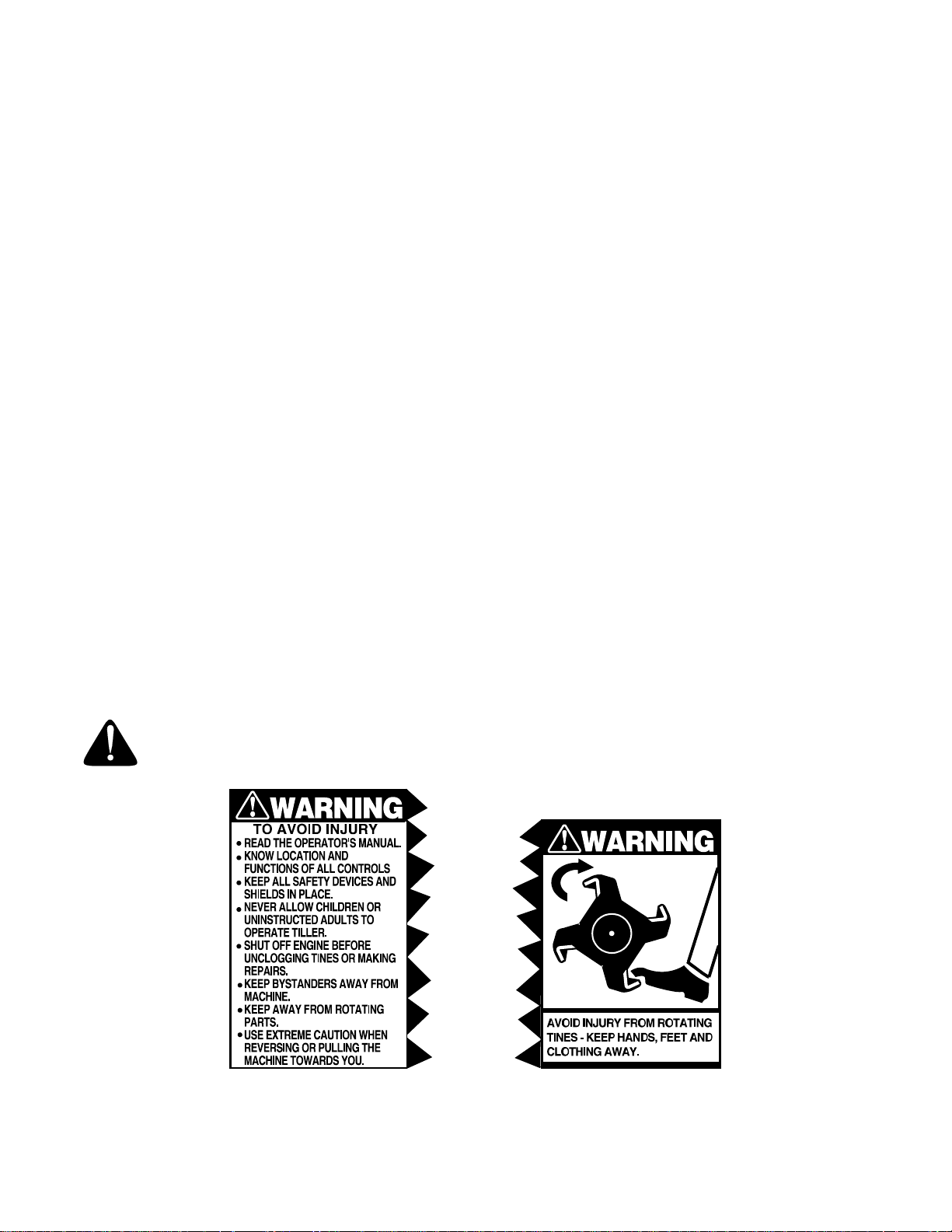

WARNING — YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this manual and on the machine.

Figure 1 Safety labels found on your unit

4

Page 5

SECTION 2: ASSEMBLY INSTRUCTIONS

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, see separate

engine manual for proper fuel and engine oil

recommendations.

NOTE: Left and right is determined from the

operator’s position, standing behind the tiller.

REMOVING UNIT FROM CARTON

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton.

• Remove all loose parts included with unit (i.e.,

operator’s manual, etc.)

• Cut along corners, lay carton down flat, and remove

packing material.

• Roll or slide unit out of carton and check carton

thoroughly for loose parts.

• Extend control cable(s) to the rear of the tiller and

lay them on the floor. Be careful not to bend or kink

control cable(s).

TOOLS REQUIRED FOR ASSEMBLY

(1)-1/2" Wrench or Socket*

(1)-Pair of Pliers

(1)-3/8" Wrench*

*An adjustable wrench may be used.

This owner's guide covers two different model

tillers. Model 340 has forward tine drive only.

Model 390 has both forward and reverse tine drive.

Follow only the instructions which pertain to your

model tiller. See the model plate on your tiller for

the correct model number.

LOOSE PARTS IN CARTON

1. Tailpiece

2. Depth Stake

3. Handle Assembly

NOTE: All hardware required for assembly has been

placed in position on the tiller.

Hex Nut and

Cupped Washer

Tailpiece

Depth

Stake

Self-Tapping

Screws

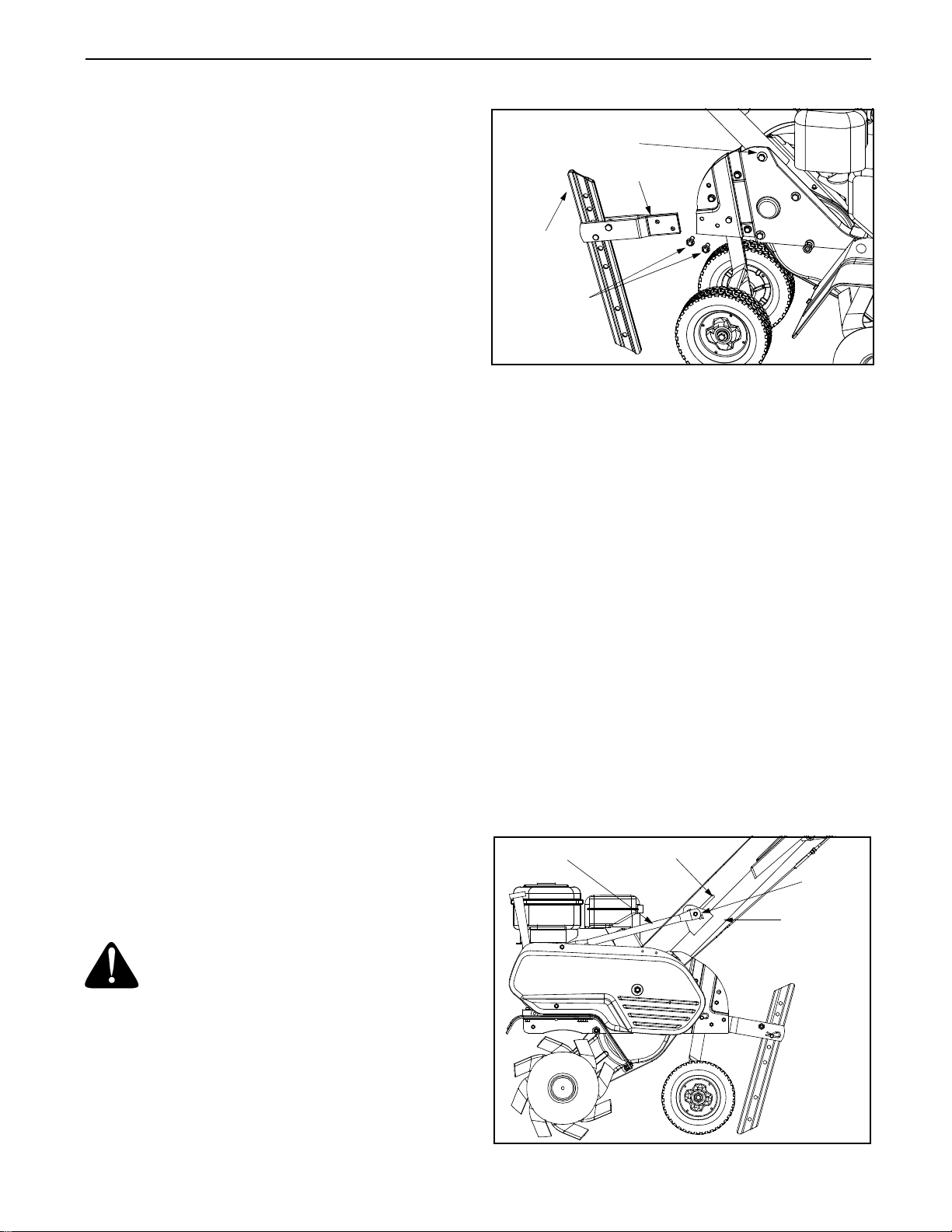

Figure 2

ATTACHING THE HANDLE ASSEMBLY

1. Remove the hex bolt and cupped washer from the top right side of the frame halves. Hold the cable guide bracket on the left side of the frame as it will fall when the bolt is removed. See Figure 3.

2. Insert the handle assembly between the two frame

halves. Insert the hex bolt just removed through

the frame halves, handle assembly, and into the

cable guide bracket (notch in cable guide bracket

goes over the flange on the frame). Tighten

securely.

3. Loosen the hand knob which secures the handle brace to the handle assembly.

4. Remove the handle knob and hardware from the handle brace. Insert the carriage screw through the welded bracket on the handle and into the end of the handle brace. See Figure 3.

5. Secure with cupped washer and handle knob.

6. Select one of the three handle height positions (three notches in welded bracket), and tighten the hand knob to secure the handle in desired position. Make certain carriage bolt is seated securely into one of the three positions provided.

Handle

Brace

Handle

Crank

U-Nut

BEFORE ASSEMBLY

WARNING: Disconnect the spark plug wire

and ground against the engine to prevent

unintended starting.

ATTACHING THE TAILPIECE AND DEPTH STAKE

1. Remove the two self-tapping screws on the frame. Slide the tailpiece into the frame, with the lower hole in the tailpiece toward the front.

2. Secure with screws just removed. See Figure 2.

Handle

Assembly

Figure 3

5

Page 6

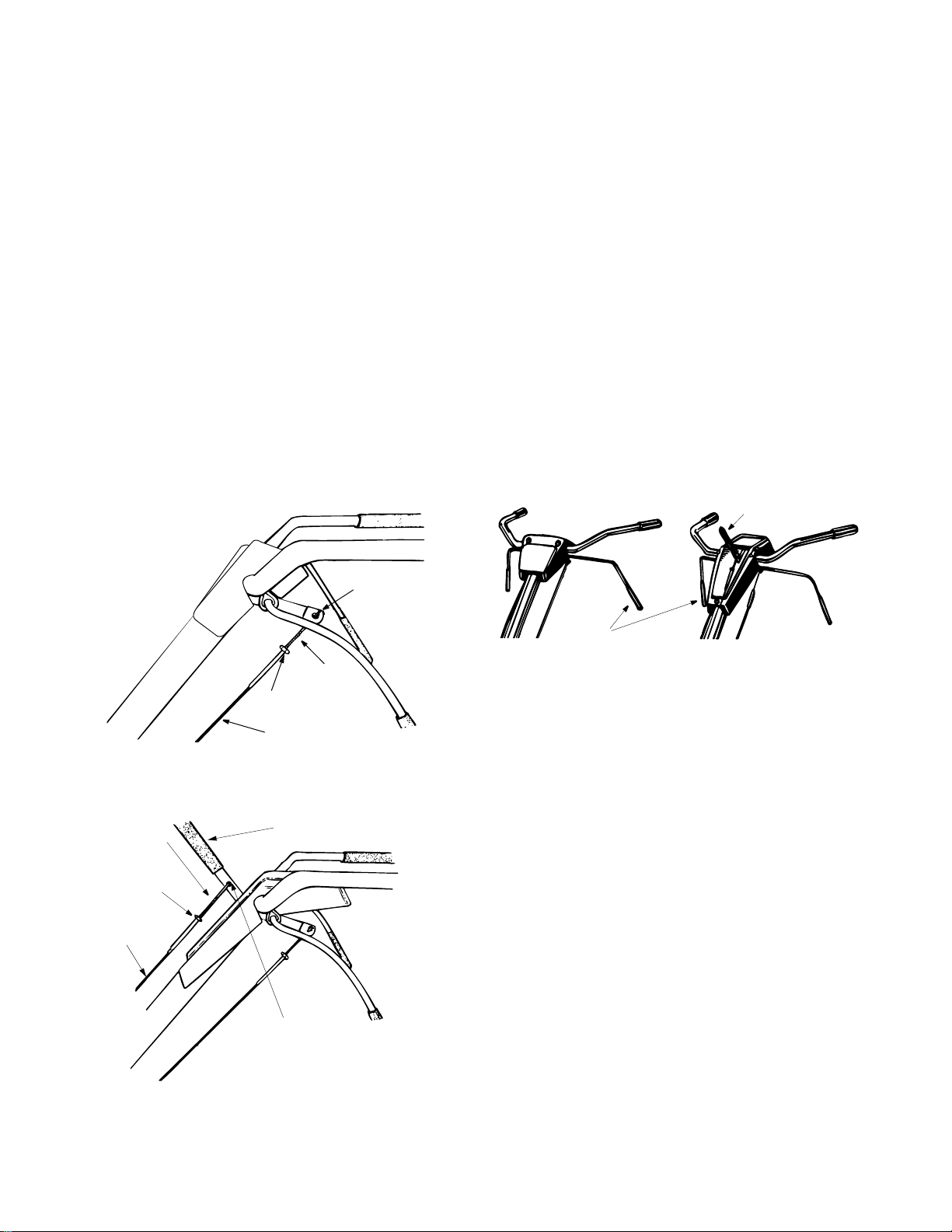

ATTACHING THE CLUTCH CONTROL CABLES

FORWARD CABLE

Attach the end of the forward cable to the bracket

underneath the handle assembly as follows. (On

model 390, the forward clutch cable is the cable which

is attached closer to the rear of the tiller).

1. Loosen the hex nut on the threaded rod near the end of the cable, and move it up the rod as far as it will go. See

2. Unthread the rod from the rest of the cable. Hook the “Z” end of the rod into the bracket underneath the handle assembly from the right hand side. See Figure 4 or Figure 5.

3. Thread the rod back into the cable until the cable is straight. Do not tighten it enough to put any tension on the spring. See Figure 4 or Figure 5.

4. Thread the hex nut down against the end of cable. Use a pair of pliers and a wrench to lock the nut against the rod.

NOTE: Do not overtighten control cable. Too much

tension may cause it to break when engaged.

REVERSE CABLE (Model 390 Only)

The reverse clutch cable is the cable which is attached

closer to the front of the tiller. Attach the end of the

reverse cable to the reverse tine engagement handle

above the handle assembly, in the same manner as

you attached the forward cable. See Figure 5.

FINAL CLUTCH ADJUSTMENT

To check the clutch cable adjustment, proceed as

follows.

1. Disconnect the spark plug wire and move it away from the spark plug to prevent accidental starting.

2. Engage and release the forward tine engagement

handle, then the reverse tine engagement lever

(model 390 only). If an excessive noise is heard

when releasing either the tine drive clutch handle

or lever, the cable may be too loose. Adjust either

the forward or reverse clutch cable by loosening

the hex nut, threading the rod into the cable one or

two turns, then retightening the nut. See Figure 6.

Model 340

Reverse Tine

Engagement Handle

Threaded

Rod

Hex Nut

Reverse

Cable

Threaded

Rod

Hex Nut

Cable

Figure 4 Model 340

Reverse Tine

Engagement Handle

“Z” End

Hooked In

Bracket

Engagement Handle

3. With tine engagement handles in neutral

(released) as shown in Figure 6, pull the starter

rope several times. The tines should not turn. If

they turn forward, loosen the hex nut on the

forward cable (underneath the handle assembly).

See Figure 5. If they turn toward the rear (model

390 only), loosen the hex nut on the reverse cable

(above the handle assembly). Unthread the rod

from the cable 2 or 3 turns. Retighten the hex nut,

and check again for correct adjustment. See

Figure 6.

Tine

Model 390

Figure 6

“Z” End

Hooked In

Bracket

Figure 5 Model 390

6

Page 7

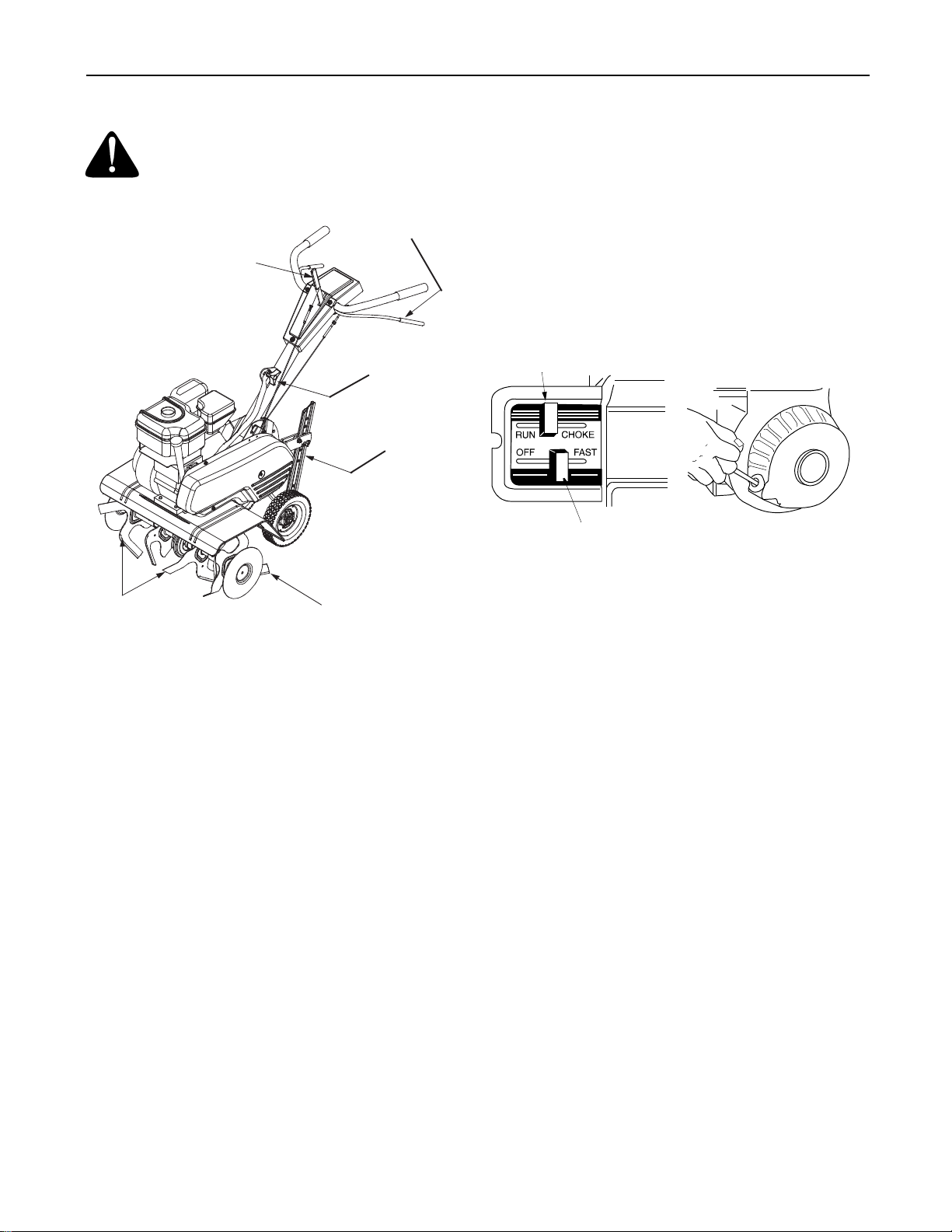

SECTION 3: CONTROLS

Tines

WARNING: Read, understand, and follow

all instructions and warnings on the machine

and in this manual before operating.

Forward Tine

Engagement

Reverse Tine

Engagement

Lever

Figure 7 Model 390 Shown

Lever

End

Cap

Handle Knob

Depth Stake

REVERSE TINE DRIVE CLUTCH LEVER

(Model 390 Only)

The reverse tine drive clutch lever is located on top of

the handle panel. Pull the lever to the rear to move the

tines in reverse. Release the lever to stop the reverse

tine drive. See Figure 7.

NOTE: Never engage both the forward and reverse

tine drives at the same time. Engaging both forward

and reverse tine drives at the same time could damage

the belt drives and cause the engine to stall.

Choke

Models 340/390

Throttle Control

Figure 8

DEPTH STAKE

The depth stake controls the tilling depth. Refer to

"HOW TO USE YOUR TILLER" SECTION" for more

details.

THROTTLE CONTROL

The throttle control lever is located on the engine. It controls the engine speed and stops the engine. See Figure 8.

CHOKE LEVER

The choke lever is located above the throttle control. It

is used to enrich the fuel mixture when starting a cold

engine. See Figure 8.

FORWARD TINE ENGAGEMENT HANDLE

The forward tine engagement handle is located

beneath the tiller handle. Squeezing the handle up

against the tiller handle engages the tines. Release the

handle to stop the tines. See Figure 7.

TINE AND END CAPS

The tilling tines and end caps are used to cultivate,

furrow, and prepare your garden for seeding. The end

caps are used to avoid tilled soil from overflowing onto

unwanted areas.

HANDLE KNOB

The handle knob is attached to the handle and is used

to adjust the height of the handle to three different

settings.

ENGINE CONTROLS

See the separate engine manual for the location and

function of the other controls on the engine.

7

Page 8

SECTION 4: OPERATION

WARNING: Read, understand, and follow

all instructions and warnings on the machine

and in this manual before operating.

GAS AND OIL FILL-UP

Service the engine with GASOLINE and OIL as

instructed in the separate engine manual packed with

your tiller. Read instructions carefully.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoors or while the

engine is hot or running.

TO START ENGINE

WARNING:

front of the tiller while the engine is running or

being started.

1. Attach spark plug wire to spark plug. Make certain the metal loop on the end of the spark plug wire (inside the boot) is fastened securely over the metal tip on the spark plug.

2. Make certain the tine engagement controls are in the neutral position (released). See Figure 7.

3. Place the throttle control lever in FAST position. (See Figure 8 ).

4. Move choke lever to CHOKE position. (A warm engine requires little or no choke.)

5. Grasp starter handle and pull rope out slowly until engine reaches start of compression cycle (rope will pull slightly harder at this point). Let the rope rewind slowly.

6. Pull rope with a rapid, continuous, full arm stroke. Keep a firm grip on starter handle. Let rope rewind slowly. Do not let starter handle snap back against starter. Repeat preceding instructions 5 and 6 until engine starts.

7. When engine starts, move choke lever on engine halfway between CHOKE and RUN.

8. Move throttle control to IDLE position for a few minutes warm-up. Move choke lever to RUN position as engine warms up.

Be sure no one is standing in

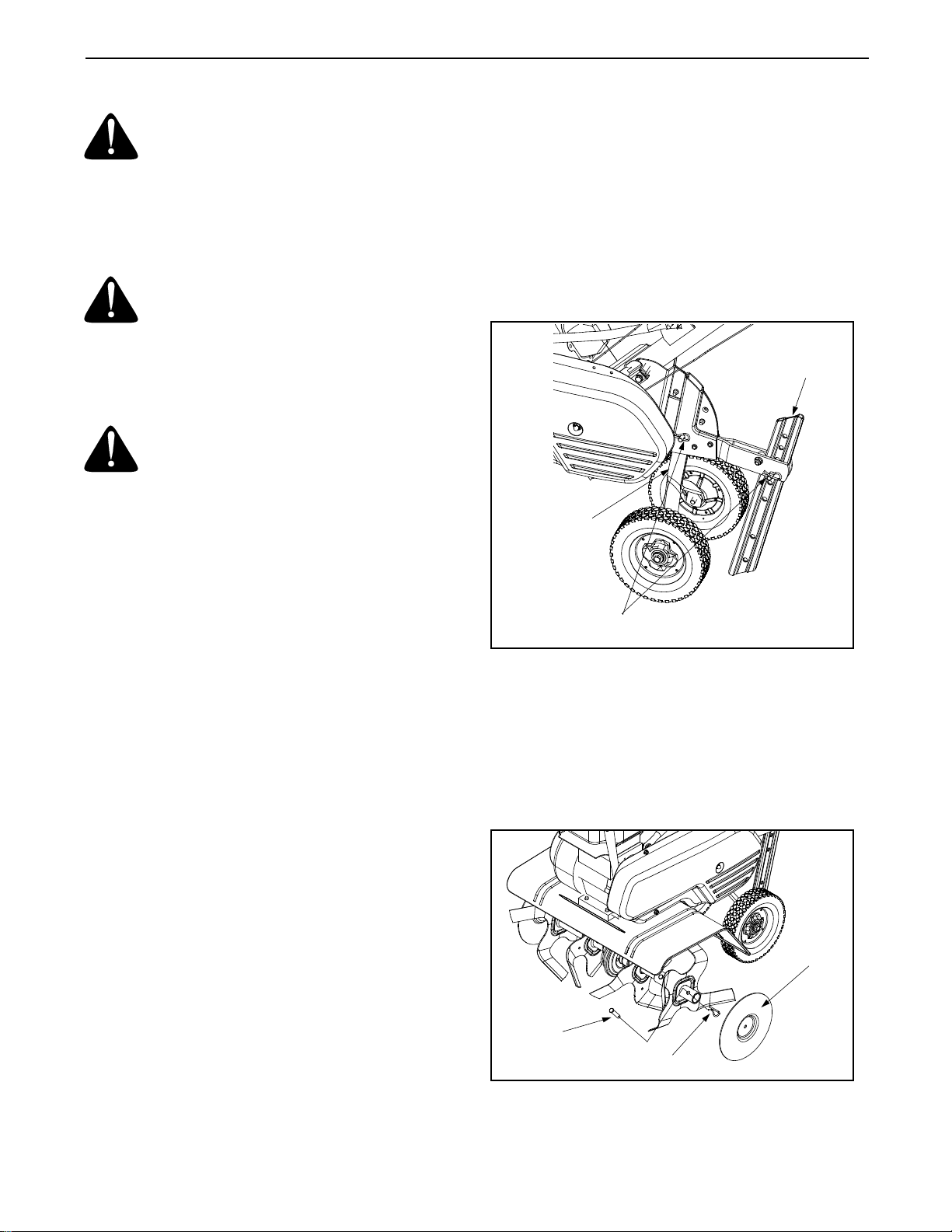

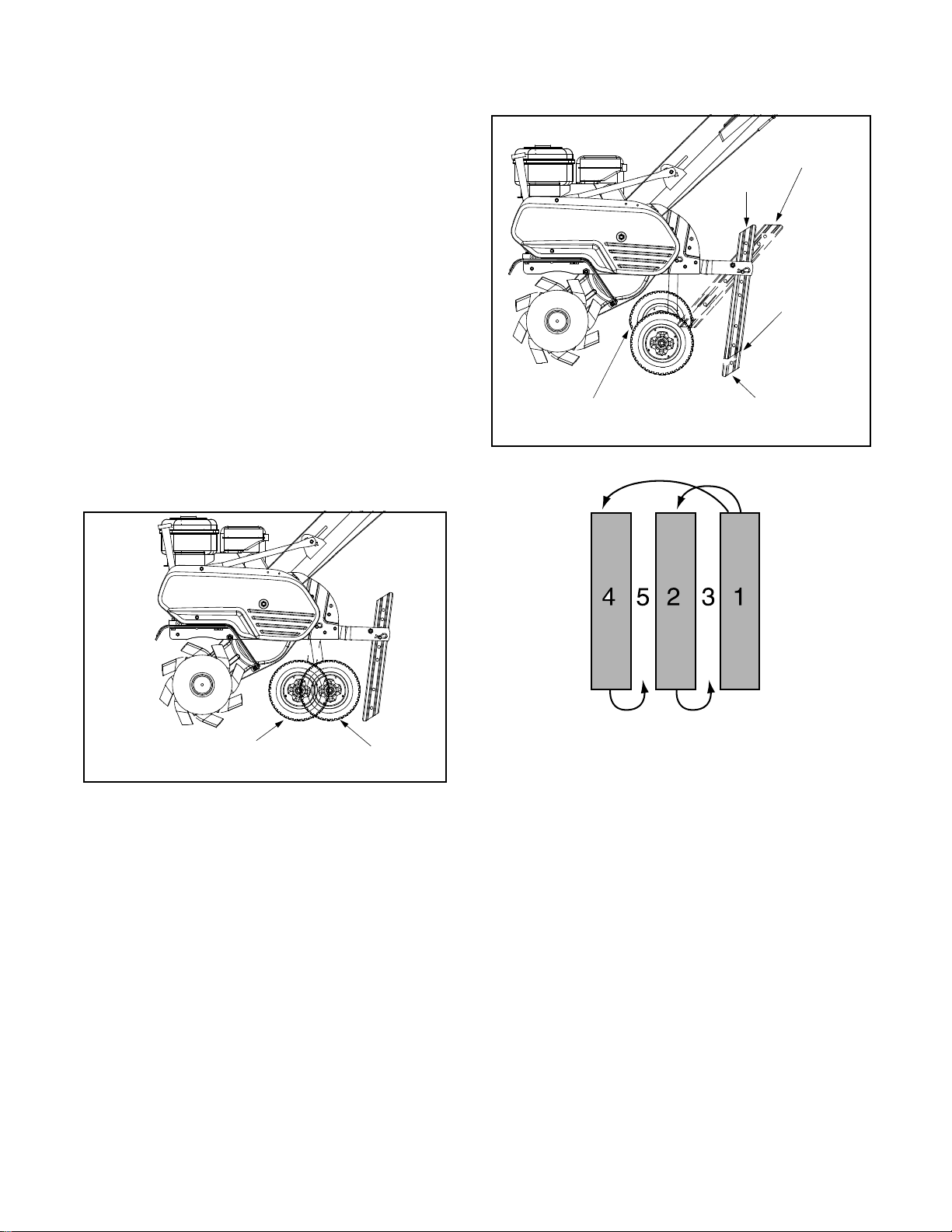

WHEEL POSITION

NOTE:

such that the unit sits level. While tilling, as the tines

enter the ground and the front of the tiller lowers, the

wheels must be raised to level the unit. Follow the

steps below to adjust the wheels.

• Remove the clevis pin and hairpin clip from wheel

The tiller is shipped with the wheels adjusted

yoke, raising the wheels to the desired height, and

replacing the clevis pin and hairpin clip. (See Figure

9.)

Depth

Stake

Wheel Yoke

Hairpin Clips

and Clevis Pins

Figure 9

REMOVING END CAPS

The end cap are used to avoid tilled soil from getting

onto unwanted areas. You can remove each end cap

from the outer axle by removing the hairpin clip and

clevis pin that secure it. Slide end cap off the axle to

remove. See Figure 10.

NOTE: After starting engine and prior to using the

tiller, be certain to check the clutch adjustment as

described in “Finall Clutch Adjustment” section of the

Assembly Instructions.

TO STOP ENGINE

1. Move throttle control lever to STOP or OFF position.

2. Disconnect spark plug wire from spark plug and ground against the engine to prevent accidental starting while equipment is unattended.

8

Clevis

Pin

End

Cap

Hairpin Clip

Figure 10

Page 9

CONTROLLING SPEED AND TILLING DEPTH

WHEEL YOKE ADJUSTMENT:

1. Place wheel yoke so that the wheels are forward (nearest point between wheels and tines) for shallow tilling, cultivating and transport. The forward speed will increase.

2. Turn yoke around (farthest point between wheels and tines) for deep tilling. Forward speed will decrease. (See Figure 11.)

the garden. Passes should be made across the length

and width of the garden alternately. Rocks which are

turned up should be removed from the garden area.

Transport

Depth

Stake

Position

Depth Stake Adjustment:

The depth stake acts as a brake for the tiller and

controls the depth and speed at which the machine will

operate.

1. By increasing the depth of the depth stake, the forward speed of the machine is reduced, and the working depth is increased. (See Figure 12.)

2. When the depth stake is raised, the working depth of the machine is reduced and the forward speed is increased.

• Remove the clevis pin and hairpin clip to raise or

lower depth stake. (See Figure 9.)

Raised Wheel Setting

For Deep Tilling

Figure 12

Shallow Tilling

Fast Forward

Deep Tilling

Slow Forward

Shallow

Tilling

Figure 11

Deep

Tilling

IMPORTANT: The working depth of the machine

may be predetermined by setting the depth stake and

wheels so that the wheels are about four inches from

the ground when the tines and depth stake are resting

on the ground. This setting will permit a working depth

of about four inches. When presetting the working

depth, the handles should be adjusted so the hand

grips are a little above waist height because the tiller

will be lower when the tines and depth stake penetrate

the ground. See Figure 12.

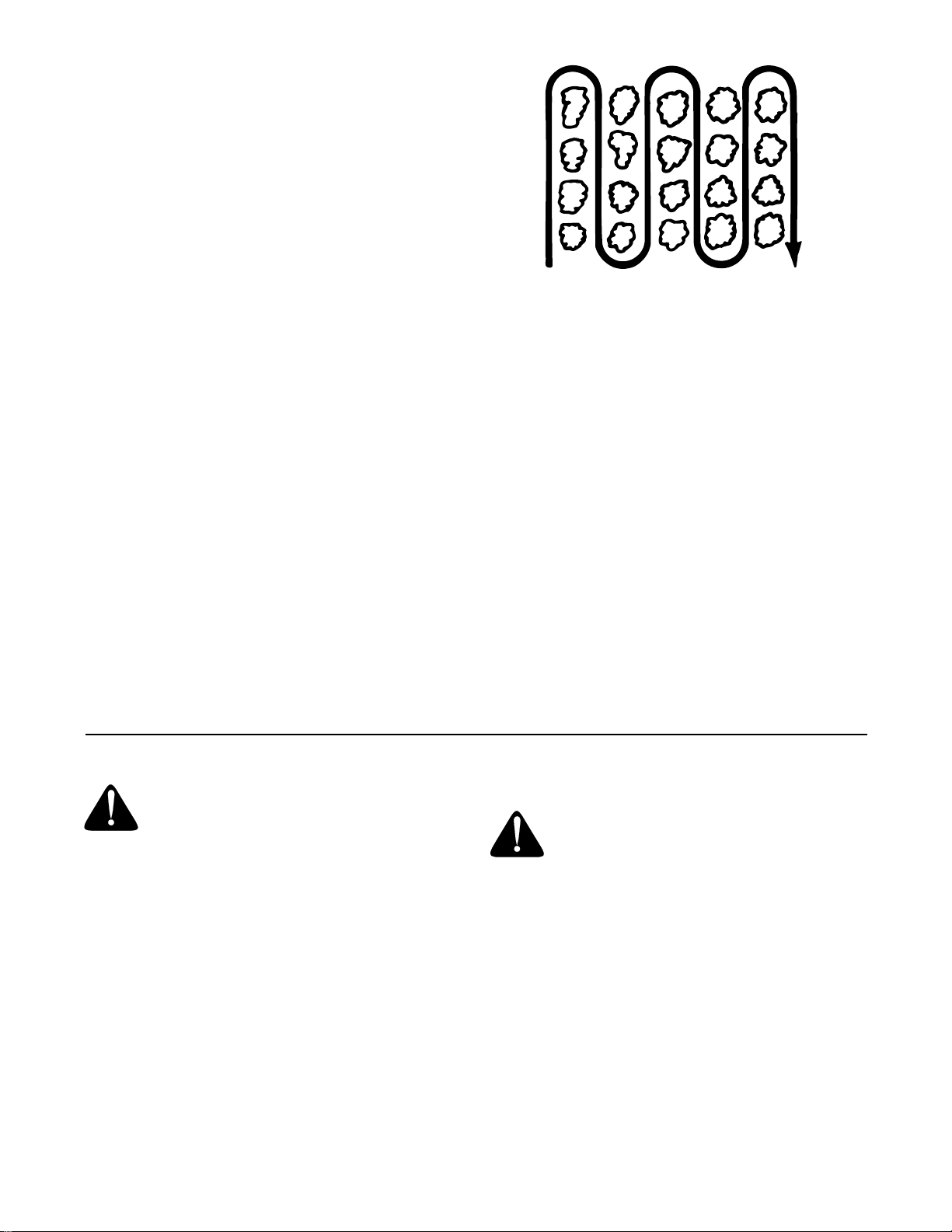

When tilling, leave approximately 8 inches of untilled

soil between the first and second tilling paths, then

make the third path between the first and second as

shown in Figure 13. In some soils, the desired depth is

obtained the first time over the garden. In other soils,

the desired depth is obtained by going over the garden

two or three times. In the latter case, the depth stake

should be lowered before each succeeding pass over

Figure 13

Handle Pressure:

Further control of tilling depth and travel speed can be

obtained by variation of pressure on the handles.

1. A downward pressure on the handles will reduce the working depth and increase the forward speed.

2. An upward pressure on the handles will increase the working depth and reduce the forward speed.

NOTE: The type of soil and working conditions will

determine the actual setting of the depth stake and the

handle pressure required.

Throttle Control: The throttle control lever adjusts the

engine speed and stops the engine. With the throttle

control lever pushed completely forward, the carburetor

is in START position. Pulling the throttle control back

slightly adjusts the engine speed to FAST. Pulling the

throttle back further reduces the engine speed to

SLOW. Pull the throttle completely back to stop the

engine.

Use maximum engine speed for deep tilling. Move the

throttle control to SLOW when transporting the tiller.

9

Page 10

TRANSPORTING THE TILLER

To transport the tiller to or from the garden, pivot the

depth stake forward, out of the way. (See Figure 12.)

With the throttle control in SLOW position, the unit will

walk freely on top of the lawn. If the operator does not

allow the tiller to move freely, the unit will start to till

the surface.

HOW TO USE YOUR TILLER

Your tiller is a precision built machine designed for

seed bed preparation, cultivating, furrowing and

mulching. It is engineered to minimize the hardest

work in the vegetable or flower garden, to till the soil

for planting and cultivating, and to perform many other

useful labor saving tasks in the garden. With the

proper amount of care and maintenance, this machine

will provide the owner with many years of service.

CULTIVATING

For cultivating, a two to three inch depth is desirable.

Set the wheels and depth stake so that the wheels are

about two inches above the ground while the tiller is

resting on the tines and depth stake will allow the

machine to work at cultivating depth. The throttle

should be set to control forward movement to a slow

walking speed. With the outer tines installed, the

working width of the machine is 22 or 24 inches. For

cultivation, this may be reduced to 13 inches by

removing the outer tines. Refer to Tine Width

Adjustment in Adjustment section. When laying out

plant rows, be sure to allow enough width to permit

cultivation between the rows. In growing corn or similar

crops, check-row planting will permit cross cultivation

and practically eliminate hand hoeing. (See .Figure

14).

Figure 14

The tiller has many uses other than tilling and

cultivating a garden. One of these is the preparation of

lawn area for seeding. The tiller will prepare a deep

seed bed which will be free of hard untilled spots,

allowing a better stand of grass to grow. The tiller is

very useful for loosening hard soil for excavation with a

shovel. No tedious hand pickwork will be necessary.

Your tiller may be used for mixing compost in the pile,

or for mixing it with the soil in your garden. This should

be done after the soil has been broken to the full

working depth. The compost should be worked in to a

depth of six to seven inches. This may be done by

working the length of the garden, and then by making

separate passes across its width. The addition of

decayed organic matter will substantially increase the

fertility of your garden. For proper decaying action,

fertilizer should be applied and worked in with the

mulch materials. Breaking up leaves and straw and

mixing it with several inches of soil causes the soil to

hold moisture longer and allows proper aeration of the

plant root system. This also retards the growth of

weeds.

SECTION 5: ADJUSTMENTS

WARNING: Disconnect the spark plug

wire and ground against the engine before

performing any adjustments, repairs, or

maintenance.

WHEEL ADJUSTMENTS

To adjust the wheel yoke and wheel position, refer to

WHEEL POSITION on page 8.

DEPTH STAKE ADJUSTMENT

To adjust the depth stake, refer to WHEEL POSITION

on page 8.

CLUTCH CONTROL ADJUSTMENTS

Periodic adjustment of the belt tension may be required

due to normal stretch and wear on the belt. To adjust

the clutch control lever, refer to the Final Adjustment

section of assembly instructions.

ENGINE

Refer to the separate engine manual for engine adjustment instructions.

CARBURETOR ADJUSTMENT

WARNING: If any adjustments are made

to the engine while the engine is running

(e.g. carburetor), disengage all clutches and

tines. Keep clear of all moving parts. Be

careful of heated surfaces and muffler.

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude or load. If adjustments are needed, refer to the

engine manual packed with the tiller.

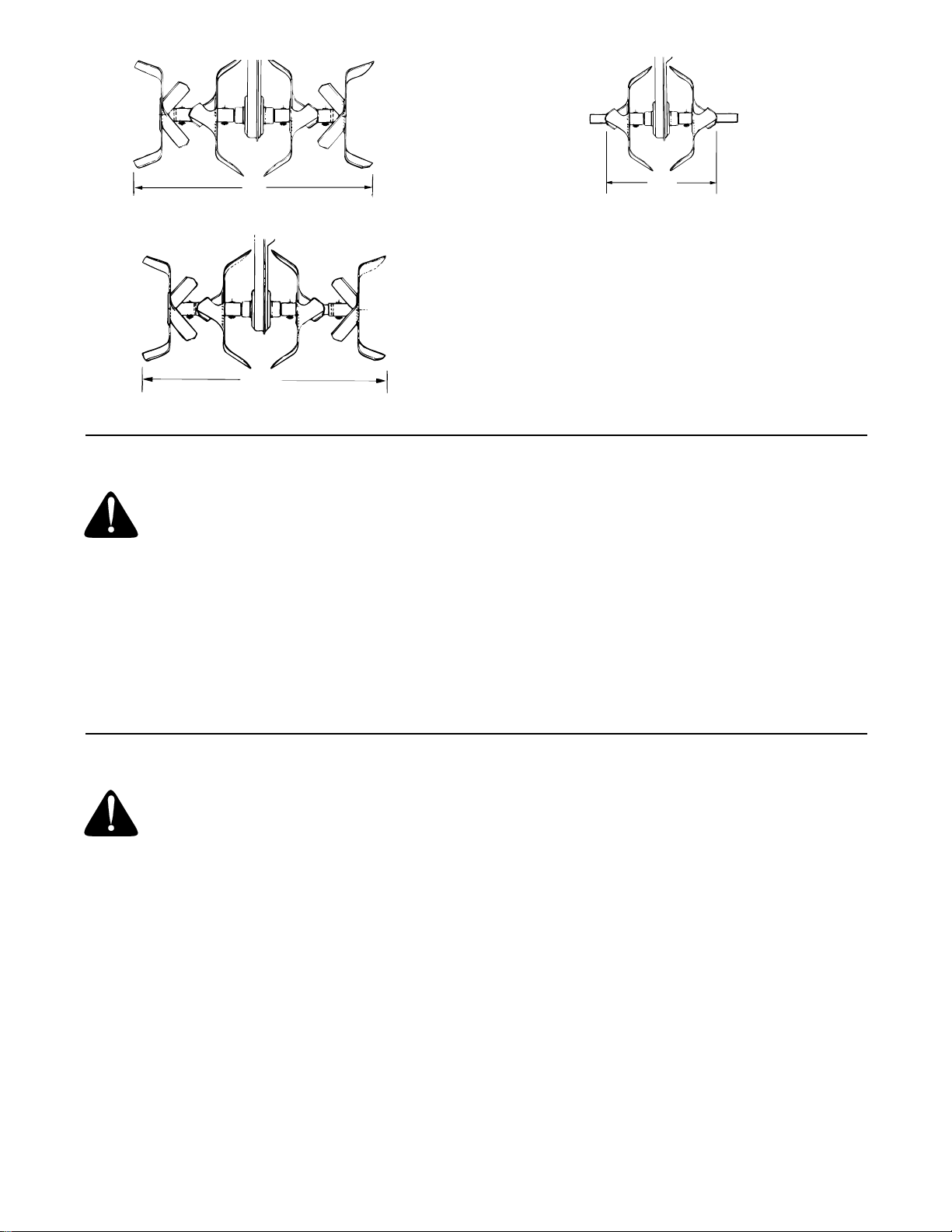

TINE WIDTH ADJUSTMENT

The tilling width of the unit is 22 inches. (See Figure

15.) Tilling width can be increased to 24 inches by

removing the clevis pins and hairpin clips, sliding the

outer tines out one inch, and securing in this position

with the clevis pins and hairpin clips. (See Figure 16.)

For cultivation, reduce the tine width to 13 inches by

removing the outer tines completely. (See Figure 17.)

10

Page 11

22"

Figure 15

24"

Figure 16

SECTION 6: LUBRICATION

13"

Figure 17

NOTE: A dirty air cleaner will cause engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor. Do not

make unnecessary adjustments. Factory settings are

satisfactory for most applications and conditions.

WARNING: Always stop engine and

disconnect spark plug wire before cleaning,

lubricating or doing any kind of work on tiller.

Tine Engagement Handle/Lever

• Lubricate the pivot points on the tine handle/lever

and the cable at least once a season with light oil.

The controls must operate freely in both directions.

Pivot Points

• Lubricate all pivot points and linkages at least once

a season with light oil.

SECTION 7: MAINTENANCE

WARNING: Disconnect spark plug wire

and ground it against the engine before

performing any repairs or maintenance.

TROUBLE SHOOTING

Refer to page 13 of this manual for trouble shooting

information.

ENGINE

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

IMPORTANT: Do not attempt to start the engine

when the oil level is inadequate.

Service air cleaner every 25 hours under normal

conditions. Clean after every hour under extremely

dusty conditions. Poor engine performance and

flooding usually indicates that the air cleaner should be

Tine Shafts

• Remove the tine assemblies and lubricate the tine

shafts at least once a season.

Wheel Shafts

• Remove wheel assemblies and lubricate the axle

shafts at least once a season.

Transmission

• The transmission is pre-lubricated and sealed at

the factory. It requires no checking unless the

transmission is disassembled. See an authorized

service dealer if the transmission is disassembled.

serviced. To service the air cleaner, refer to the

separate engine manual packed with your unit.

IMPORTANT: Never run your engine without air

cleaner completely assembled.

The spark plug should be cleaned and the gap reset

after every 25 hours of engine operation. Spark plug

replacement is recommended at the start of each

season; check engine manual for correct plug type and

gap specifications.

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean

to permit proper air circulation which is essential to

engine performance and life. Be certain to remove all

dirt and combustible debris from muffler area.

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed off

immediately instead of after it dries.

11

Page 12

NOTE: We do NOT recommend the use of pressure

washers to clean your unit. They may cause damage

to electric components, spindles, pulleys, bearings or

the engine. The use of pressure washers will result in

shortened life and reduced serviceability.

BELT REMOVAL AND REPLACEMENT

Your tiller has been engineered with belts made of

special material (Kevlar Tensile). They should not be

replaced with an off-the-shelf belt. If belt replacement

is required, order belt or belts by part number from

your nearest authorized service dealer.

Forward Drive Belt - Part No. 754-0428

Reverse Drive Belt (390 Only) - Part No. 754-0429

Reverse Drive Belt (Model 390 Only)

1. Disconnect and ground the spark plug wire against the engine.

2. Remove the two hex washer screws from the front of belt cover and remove the hex nut and flat washer from the side of the belt cover.

3. Remove belt cover. See Figure 18. Lift the belt off the transmission pulley.

4. Remove the hex nut which secures the reverse idler pulley to the idler bracket. Slide the idler pulley out and remove the belt. See Figure 19.

Self-Tapping

Screws

Reverse

Idler

Pulley

Hex Nut and Washer

Belt

Cover

Figure 18

Forward Belt

Engine

Pulley

Figure 20 Model 390 Shown

5. Reassemble the new belt, following instructions in

reverse order. Make certain the reverse drive belt

is assembled with the wide side of the belt against

the transmission and engine pulleys. Be certain to

adjust the clutch control as instructed in the final

clutch adjustment section of assembly instructions

Forward Drive Belt (See Figure 20)

1. Model 340: Remove the belt cover by following step 1 and step 2 of the previous section. Model 390: Remove the reverse drive belt as instructed in the previous section.

2. Remove the belt keeper from the idler pulley by removing the idler pulley nut.

3. Lift belt off the idler pulley and transmission pulley. See Figure 20.

4. Using a 9/16" wrench, remove bolt from engine pulley.

5. Push reverse idler pulley bracket forward, and remove engine pulley and belt. See Figure 20.

6. Reassemble the new belt, following instructions in

reverse order. Make certain the forward drive belt

is assembled with the wide side of the belt away

from the transmission and engine pulleys. Be

certain to adjust the clutch control as instructed in

the final clutch adjustment section of assembly

instructions.

Forward

Belt

Idler Pulley Nut

Hex Nut

Engine Pulley

Reverse Belt

Figure 19 Model 390 Shown

Transmission

Pulley

12

Page 13

SECTION 8: OFF-SEASON STORAGE

If the tiller is to be inoperative for a period longer

than 30 days, the following precautions are

recommended.

3. Wipe tines with oiled rag to prevent rust.

4. Store in a clean, dry area. Do not store next to corrosive materials, such as fertilizer.

1. Clean the exterior of engine and entire tiller thoroughly. Lubricate the tiller as described in the lubrication instructions.

2. Refer to the engine manual for correct engine storage instructions.

NOTE: When storing any type of power equipment

in an unventilated or metal storage shed, care

should be taken to rustproof the equipment. Using a

light oil or silicone, coat the equipment, especially

any springs, bearings and cables.

SECTION 9: TROUBLE SHOOTING GUIDE

Trouble Possible Cause(s) Corrective Action

Engine fails to

start

Engine runs

erratic

Engine overheats

Tines do not

engage

Fuel tank empty, or stale fuel.

Throttle control lever not in correct

starting position (if so equipped).

Blocked fuel line.

Choke not in ON position.

Spark plug wire disconnected.

Faulty spark plug.

Engine flooded.

Unit running on CHOKE.

Spark plug wire loose.

Blocked fuel line or stale fuel.

Vent in gas cap plugged.

Water or dirt in fuel system.

Dirty air cleaner.

Carburetor out of adjustment.

Engine oil level low.

Dirty air cleaner.

Air flow restricted.

Carburetor not adjusted properly.

Foreign object lodged in tines.

Tine clevis pin(s) missing.

Pulley and idler not in correct

adjustment.

Control cable not adjusted properly.

Belt worn and/or stretched.

Fill tank with clean, fresh gasoline. Fuel will not last over

thirty days unless a fuel stabilizer is used.

Move throttle lever to start position.

Clean fuel line.

Move switch to ON position.

Connect wire to spark plug.

Clean, adjust gap or replace.

Refer to the engine manual packed with your unit.

Move choke lever to OFF position.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean, fresh gasoline. Fuel will

not last over thirty days unless a fuel stabilizer is used.

Clear vent.

Drain fuel tank. Refill with fresh fuel.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Adjust carburetor as instructed in separate engine manual.

Dislodge foreign object.

Replace tine clevis pin(s).

Take unit to authorized service dealer.

Adjust control cable (see assembly instructions).

Replace belt.

NOTE: For repairs beyond the minor adjustments above, contact your local authorized service dealer.

13

Page 14

3

1

4

9

11

29

30

19

30

12

16

18

31

13

28

32

15

27

14

22

26

49

23

2

8

5

20

37

7

2

17

21

35

36

10

6

37

42

30

60

38

50

30

43

27

40

34

41

39

33

46

25

24

23

47

48

14

Page 15

REF PAR T

NO. NO.

N° DE N° DE

RÉF PIÈCE DE SCRIP TION DE SCRIP TION

1 712-0442 Acorn Lock Nut 1/4-20 Écrou crénelé

2 736-3020 Flat Washer .266 ID x .625 OD Rondelle plate 0,266 DI x 0,625 DE

3 720-0270A Reverse Handle Grip Poignée

4 731-1600 Handle cover (w/o throttle) Couvercle de poignée (sans obturateur)

5 710-0779A Truss Mach Tapp Scr #10 x .50 Vis taraudée NO 10 x 0,50

6 720-0274 Grip Poignée

7 712-0287 Hex Nut 1/4-20 Écrou hex 1/4-20

8 726-0135 Cap Speed Nut 5/16" Rod Écrou rapide 5/16

9 686-0083 Clutch Handle Assembly Poignée d’embrayage

10 720-0269 Grip-Clutch Poignée d’embrayage

11 710-0641 Screw - .250-20 x 2.25 Hex Wash Vis auto-fileteuse AB à tête hex et rondelle

12 731-1645A Clutch Handle Holder Poignée d’embrayage

13 736-0140 Flat Washer .385 ID x .62 OD x .06 Rondelle frein 0,385 DI x 0,62 DE x 0,06

14 686-0014A Reverse Handle Ass’y Poignée arrière

15 736-0264 Flat Washer .344 ID x .625 OD x .063 Rondelle plate 0,344 DI x 0,625 DE x 0,063

16 649-0022B Handle Ass’y Complete Ensemble de poignée

17 710-1236 Carriage Screw 5/16-18 x 1.0 Boulon ordinaire 5/16-18 x 1,0

18 720-0195 Hand Knob Bouton

19 749-1401 Handle Brace Support de poignée

20 736-0921 L-Washer 1/2" ID Rondelle frein 1/2 DI

21 710-3194 Hex Bolt 1/2-20 Gr. 5 Boulon hex 1/2-20 Qual. 5

22 786-0005 Depth Bar Barre de profondeur

23 714-0149B Internal Cotter Pin Goupille fendue interne

24 712-3004A Hex Flange L-Nut 5/16-18 Contre-écrou à embase 5/16-18

25 786-0003 Tail Piece Brkt. (LH) Support de la partie arrière (CG)

26 786-0004 Tail Piece Brkt. (RH) Support de la partie arrière (CD)

27 711-0415 Clevis Pin 3/8 Dia Axe de chape 3/8 Dia.

28 710-0805 Hex Bolt 5/16 - 18 x 1.50" Lg. Gr. 5 Boulon Hex 5/16 - 18 x 1,50 po de lg Qual. 5

29 710-0189 Hex Screw 5/16-18 x 3.00 Vis à tête hexagonale 5/16-18 x 3,00

30 736-0242 Bell. Washer .345 ID x .88 OD x .06 Rondelle creuse 0,345 DI x 0,88 DE x 0,060

31 711-1036A Spec. Hex. Nut Écrou hex spéciale

32 736-0119 L-Wash 5/16 ID Rondelle frein 5/16 DI

33 710-3008 Hex Bolt 5/16-18 x .75" Lg. Gr. 5 Boulon hex. 5/16-18 x 0,75 po de lg. Qual. 5

34 786-0129 Cable Guide Bracket Support du câble

35 710-0604A Hex Wash HD Scr 5/16-18 x .62 Vis taraudée 5/16-18 x 0,62

36 710-0602 Hex Wash Hd Tapp Scr 5/16-18 x 1.00 Vis auto-fileteuse à tête hex et rondelle 5/16-18

37 738-0934 Shoulder Bolt 5/16-18 Boulon épaulement 5/16-18

38 786-0138A Frame RH Bâti - droite

39 786-0139A Frame LH Bâti -gauche

40 736-0171 Lockwasher 7/16 ID Rondelle frein 7/16 DI

41 712-0240 Hex Jam Nut 7/16-20 Contre-écrou hexagonal 7/16-20

42 710-0176 Hex Scr 5/16-18 x 2.75 Vis à tête hexagonale 5/16 x 2,75

43 712-0429 Hex Ins. L-Nut 5/16-18 Contre-écrou de blocage 5/16-18

46 686-0081A Wheel Hanger Brkt. Ass’y Support de roue

47 734-1781 Wheel Ass’y 8" x 1.80 Ensemble de roue 8 x 1,80

734-1566 Wheel Ass’y 8" x 1.75 Ensemble de roue 8 x 1,75

48 738-0929 Shoulder Screw .496 ID x 1.445 OD Vis à èpaulement 0,496 DI x 1,445 DE

49 750-0890 Spacer .32" ID x .75" OD Entretoise 0,32 DI x 0,75 DE

50 686-0091 Chain Case Ass’y. Complete Ensemble de carter de la chaîne - complet

15

340_390

5.21.04

Page 16

25

26

24

24

42

43

13

14

47

30

3

29

5

46

45

31

33

38

44

4

5

32

10

37

48

34

35

9

7

36

27

40

28

41

49

39

25

8

6

23

22

11

16

21

19

1

19

2

20

3

17

18

16

Page 17

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DESCRIPTION DESCRIPTION

1 712-0392 Hex Lock Stop Nut 1/4-28 Contre-écrou d’arrêt 1/4-28

2 736-3020 Flat Washer .266 ID x .625 OD Rondelle plate 0,266 DI x 0,625 DE

3 710-0599 Hex Wash S-Tapp Scr 1/4-20 x .50 Vis autotaraudeuse à rondelle hex. de 1/4-20 x 0,5

4 711-0920 Belt Cover Bolt Boulon - couvercle courroie

5 712-3004A Hex Flange L-Nut 5/16-18 Contre-écrou à embase 5/16-18

6 710-0723 Hex Screw 3/8-16 X 1.25 Vis à tête hexagonale 3/8-16 X 1,25

7 756-0313 Flat Idler 2.0 X 1.0 w/flange Tendeur de plate 2,0 X 1,0 avec collet

8 786-0149 Belt Idler keeper Tendeur le dispositif de retenue de la courroie

9 786-0144 Idler Bracket Support de tendeur

10 712-0266 Hex Cent L-Nut 3/8-16 Contre-écrou de blocage 3/8-16

11 786-0057 Belt Cover Couvercle de la courroie

13 786-0043A Tine Shield Bouclier de dents

14 710-3008 Hex Bolt 5/16-18 x .75" Lg. Gr. 5 Boulon hex. 5/16-18 x 0,75 po de lg. Qual. 5

16 686-0091 Chain Case Assembly Complete Ensemble de carter de la chaîne - complet

17 686-0106 Tine Disc Ends Disque des dents

18 714-0149B Internal Cotter Pin Goupille fendue interne

19 711-0415 Clevis Pin 3/8 Dia Axe de chape 3/8 Dia.

20 642-0005 Outer Tine Ass’y LH Ensemble des dents extérieur gauche

20 642-0004 Outer Tine Ass’y RH Ensemble des dents extérieur droit

21 642-0003 Inner Tine Ass’y - LH Ensemble des dents intérieur - gauche

21 642-0002 Inner Tine Ass’y - RH Ensemble des dents intérieur - droit

22 746-0918 Forward Clutch Cable Câble de commande de l’embrayage avant

23 746-0953 Reverse Clutch Cable Câble de commande de l’embrayage arrière

24 756-0585 Flat Pulley 6" Dia. Poulie plate 6 po diam.

25 750-0892 Spacer .64" Dia. x 2.4" Lg. Entretoise 0,64 diam. x 2,4 po de lg.

26 748-0350 Pulley Mounting Adapter Adapteur-montage du poulie

27 736-0112 Cupped Washer .56 ID x 1.5" Rondelle creuse 0,56 DI x 1,5

28 712-3029 Hex Jam Nut 1/2-20 Gr. 5 Conte-écrou hexagonal 1/2-20 Qual. 5

29 732-0697 Return Spring 2.7" Lg. Ressort 2,7 po de lg

30 786-0040B Reverse Mounting Bracket Support

31 736-0119 L-Wash 5/16 ID Rondelle frein 5/16 DI

32 710-0237 Hex Cap Scr. 5/16-24 x .625" Lg. Vis à chapeau hex. 5/16-24 x 0,625 po de lg

33 756-0971 Outer Engine Pulley Half Moitie extérieure de la poulie motrice

34 756-0600 Outer Engine Pulley Half Poulie-demi

35 736-0452 Cupped Washer Rondelle creuse

36 710-0152 Hex Cap Screw 3/8-24 X 1.00 Vis à chapeau hex. 3/8-24 X 1,00

37 686-0013 Reverse Arm Ass’y Bras arrière

38 712-0266 Hex Cent L-Nut 3/8-16 Contre-écrou de blocage 3/8-16

39 710-0102 Hex Screw 3/8-16 X 1.25 Vis â tête hexagonale 3/8-16 X 1.25

40 756-0313 Flat Idler 2.0 X 1.0 w/flange Tendeur de plate 2,0 X 1,0 avec collet

41 786-0041 Keeper Plate Plaque

42 710-0502A Hex Washer Scr 3/8-16 X 1.25 Vis à chapeau à six pans 3/8-16 x 1,25 po

43 786-0145A Engine Plate Plaque du moteur

44 786-0053 Tine Shield Support Support de protection des dents

45 736-0171 Lockwasher 7/16 ID Rondelle frein 7/16 DI

46 712-0240 Hex Jam Nut 7/16-20 Contre-écrou hexagonal 7/16-20

47 754-0428 “V” Belt (Forward) Courroie trapezoïdale (avant)

48 754-0429 “V” Belt (Reverse) Courroie trapezoïdale (arrière)

49 738-0930 Shoulder Bolt Vis à épaulée

21A-390

12.02.03

17

Page 18

TWO YEAR LIMITED WARRANTY

For TWO YEARS from the date of retail purchase within Canada, MTD PRODUCTS LIMITED will, at its option, re

pair or replace, for the original purchaser, free of charge, any part or parts found to be defective in material or

workmanship.

This warranty does not cover:

1. Any part which has become inoperative due to misuse, commercial use, abuse, neglect, accident, im

proper maintenance or alteration; or

2. The unit if it has not been operated and/or maintained in accordance with the owner’s instructions fur

nished with the unit; or

3. The engine or motor or component parts thereof which carry separate warranties from their manufac

turers. Please refer to The applicable manufacturer’s warranty on these items; or

4. Batteries and normal wear parts except as noted below. Log splitter pumps, valves and cylinders or

component parts thereof are covered by a one year warranty; or

5 Routine maintenance items such as lubricants, filters, blade sharpening and tune-ups, or adjustments

such as brake, clutch or deck; or

6. Normal deterioration of the exterior finish due to use or exposure.

Full Ninety Day Warranty on Battery: For ninety (90) days from the date of retail purchase, if any battery included

with this unit proves defective in material or workmanship and our testing determines the battery will not hold a

charge, MTD PRODUCTS LIMITED will replace the battery at no charge to the original purchaser.

Additional Limited Thirty Day Warranty on Battery: After ninety (90) days but within one hundred twenty (120)

days from the date of purchase, MTD PRODUCTS LIMITED will replace the defective battery, for the original purchaser, for a cost of one-half (1/2) of the current retail price of the battery in effect at the date of return.

Full Sixty Day Warranty on Normal Wear Parts: Normal wear parts are defined as belts, blade adapters, blades,

grass bags, seats, tires, rider deck wheels and clutch parts (friction wheels). These parts are warranted to the original purchaser to be free from defects in material and workmanship for a period of sixty (60) days from the date of

retail purchase.

How to Obtain Service: Warranty service is available, with proof of purchase, through your local authorized service dealer or distributor. If you do not know the dealer or distributor in your area, please write to the Service

Department of MTD PRODUCTS LIMITED, P. O. BOX 1386, KITCHENER, Ontario, N2G 4J1. The return of a com

plete unit will not be accepted by the factory unless prior written permission has been extended by MTD

PRODUCTS LIMITED.

Transportation Charges: Transportation charges for the movement of any power equipment unit or attachment

are the responsibility of the purchaser. Transportation charges for any part submitted for replacement under this

warranty must be paid by the purchaser unless such return is requested in writing by MTD PRODUCTS LIMITED.

Other Warranties: All other warranties, express or implied, including any implied warranty of merchantability is lim

ited in its duration to that set forth in this express limited warranty. The provisions as set forth in this warranty

provide the sole and exclusive remedy of MTD PRODUCTS LIMITED obligations arising from the sale of its prod

ucts.

MTD PRODUCTS LIMITED will not be liable for incidental or consequential loss or damage.

-

-

-

-

-

-

-

18

Page 19

NOTES

19

Page 20

NOTES

20

Page 21

16

NOTES

Page 22

15

rect.

-

MTD PRODUCTS LIMITED ne peut être tenue responsable pour toute perte ou tout dommage accidentel ou indi

découlant de la vente de ses produits.

dans cette garantie constituent le recours unique et exclusif quant aux obligations de MTD PRODUCTS LIMITED

de qualité marchande, se limitent à la durée stipulée dans cette garantie limitée expresse. Les conditions stipulées

Autres garanties: Toutes les autres garanties, qu’elles soient expresses ou tacites, y compris les garanties tacites

par MTD PRODUCTS LIMITED.

de cette garantie doivent être pris en charge par l’acheteur, sauf si le renvoi de la machine est demandé par écrit

charge de l’acheteur. Les frais de transport d’une pièce quelconque envoyée à des fins de remplacement en vertu

Frais de transport: Les frais relatifs au transport de toute machine motorisée ou de tout accessoire sont à la

LIMITED.

accepter le renvoi d’une machine complète si une autorisation n’a pas été accordée par écrit par MTD PRODUCTS

service après-vente de MTD PRODUCTS LIMITED, C.P. 1386, Kitchener (Ontario) N2G 4J1. L’usine ne peut

vous ne connaissez pas l’adresse de l’atelier de réparations ou du distributeur de votre région, adressez-vous au

Pour faire honorer la garantie: Présentez une preuve d’achat à l’atelier de réparations ou au distributeur agréé. Si

détail.

matière et de fabrication à l’acheteur initial pour une période de soixante (60) jours à partir de la date d’achat au

frottement) sont considérés comme des pièces à usure normale. Elles sont garanties exemptes de vices de

sacs à herbe, sièges, pneus, roues du plateau de coupe des tondeuses à siège, et pièces d’embrayage (roues de

Garantie complète de soixante jours des pièces à usure normale: Les courroies, adaptateurs de lame, lames,

vigueur au moment du retour de la batterie.

remplacer la batterie défectueuse à l’acheteur initial pour la moitié du prix de vente au détail de la batterie, en

jours, mais dans un délai de cent vingt (120) jours de la date d’achat, MTD PRODUCTS LIMITED s’engage à

Garantie limitée supplémentaire de trente jours de la batterie: A l’expiration du délai de quatre-vingt-dix (90)

délai de quatre-vingt-dix (90) jours à partir de la date d’achat au détail.

vice de matière ou de fabrication et si nos essais confirment qu’elle ne peut pas maintenir une charge, dans un

gratuitement la batterie à l’acheteur initial, si la batterie fournie avec la machine s’avère défectueuse en raison d’un

Garantie complète de quatre-vingt-dix jours de la batterie: MTD PRODUCTS LIMITED s’engage à remplacer

tion aux intempéries.

-

6. La détérioration normale de la finition extérieure du fait de l’utilisation de la machine et de son exposi

réglages des freins, de l’embrayage ou du plateau de coupe;

5. Les articles d’entretien courant tels que les lubrifiants, filtres, aiguisage de lames et révisions, ou les

soupapes et cylindres des fendeuses à bois sont garantis pendant un an;

4. Les batteries et les pièces présentant une usure normale énumérées plus bas. Les pompes,

respectifs. Veuillez consulter la garantie qui s’applique à la pièce en particulier;

3. Le moteur, le moteur électrique ou l’un de ses composants car ils sont garantis par leurs fabricants

l’accompagnaient;

2. La machine si elle n’a pas été utilisée et/ou entretenue conformément aux instructions qui

abusif, une négligence, un entretien incorrect ou une modification;

1. Les pièces rendues inutilisables par un emploi incorrect, une utilisation commerciale, un emploi

Cette garantie ne couvre pas:

de DEUX ANS à partir de la date d’achat au détail au Canada.

pièce ou partie de pièce qui s’avère défectueuse en raison d’un vice de matière ou de fabrication, dans un délai

MTD PRODUCTS LIMITED s’engage à réparer ou à remplacer gratuitement, à son choix, à l’acheteur initial, toute

PIÈCES SOUS GARANTIE ET SERVICE APRÈS-VENTE

Page 23

14

technique agréée.

REMARQUE: Pour toute réparation autre que les ajustements mineurs ci-dessus, adressez-vous à la station

Remplacez la courroie.

instructions.)

Réglez le câble de commande (voir les

Adressez-vous à la station technique agréée.

Remplacez l’axe de chape des dents.

Dégagez l’objet.

station technique agréée.

Réglez le carburateur ou adressez-vous à la

Consultez la notice d’emploi du moteur.

Consultez la notice d’emploi du moteur.

Faites le plein d’huile du carter.

Consultez la notice d’emploi du moteur.

Consultez la notice d’emploi du moteur.

avec une essence propre et fraîche.

Videz le réservoir à carburant. Faites le plein

Débouchez l’évent.

avec une essence propre et fraîche.

Nettoyez la conduite d’essence. Faites le plein

Branchez et serrez le fil de la bougie.

Ouvrez le volet de départ

Consultez la notice d’emploi du moteur.

bougie.

Nettoyez, réglez l’écartement ou remplacez la

Branchez le fil à la bougie.

Ouvrez le volet de départ.

Consultez la notice d’emploi du moteur.

bougie.

Nettoyez, réglez l’écartement ou remplacez la

démarrage.

Placez la commande des gaz à la position de

fraîche.

Faites le plein avec une essence propre et

Courroie usée ou étirée.

Mauvais réglage du câble de commande.

réglés.

Le poulie et le tendeur ne sont pas bien

L’axe de chape des dents est manquant.

Objet dans les dents.

Le carburateur n’est pas bien réglé.

Restriction de la circulation d’air.

Filtre à air sale.

Le niveau d’huile est trop bas.

Carburateur mal réglé.

Filtre à air sale.

système.

Présence d’eau ou de saleté dans le

résservoir.

Évent bouché dans le cauchon du

éventée.

Conduite d’essence bouchée ou essence

Fil de la bougie desserré.

Volet de départ fermé.

Moteur noyé.

Bougie défectueuse.

Fil de la bougie débranché.

Volet de départ fermé.

Filtre à air sale.

Canalisation de carburnat bouchée.

position de démarrage.

La commande des gaz ne se trouve pas en

éventée.

pas.

Les dents ne s’enclenchent

Le moteur surchauffe.

irrégulièrement.

Le moteur tourne

Le moteur ne démarre pas. Le réservoir est vide ou l’essence est

Problème Cause(s) Possible(s) Solution

CHAPITRE 9: EN CAS DE PROBLÈME

Page 24

13

iè

sec. Ne le remisez pas près de matériaux

6. Remisez le motoculteur dans un abri propre et

pour les protéger contre la rouille.

5. Essuyez les dents avec un chiffon imbibé d’huile

motoculteur.

4. Nettoyez complètement le moteur et le

motoculteur.

notice d’utilisation du moteur qui accompagne le

en suivant les instructions fournies dans la

3. Protégez l’intérieur du moteur pour le remisage

faites le plein avec de l’huile fraîche.

moteur a tourné et quand il est encore chaud) et

2. Videz toute l’huile du carter (à faire après que le

d’une flamme.

et câbles.

ou de silicone, en particulier les ressorts, roulements

Recouvrez l’équipement d’une mince couche d’huile

remiser dans un abri non aéré ou métallique.

l’équipement contre la rouille si vous devez le

REMARQUE: Prenez soin de protéger

corrosifs comme des engrais.

réservoir si vous fumez ou à proximité

AVERTISSEMENT: Ne videz pas le

qu’il tombe en panne d’essence.

d’essence. Laissez le moteur touner jusqu’à ce

1. À l’extérieur, videz complètement le réservoir

pendant plus de 30 jours, procédez comme suit.

Si vous ne prévoyez pas d’utiliser le motoculteur

CHAPITRE 8: REMISAGE HORS SAISON

et la courroie. Voir la Figure 20.

arrière vers l’avant et démontez la poulie motrice

5. Poussez le support du tendeur de marche

Figure 20 Modèle 390 Illstrée

de marche avant

Tendeur

transmission

Poulie de la

Courroie

motrice

Poulie

arrière

de marche

Tendeur

l’embrayage.

instructions du chapitre sur le dernier réglage de

l’embrayage est bien réglée selon les

de la transmission. Vérifiez que la commande de

de la courroie soit contre les poulies motrice et

est installée de manière que le côté le plus large

Assurez-vous qui la courroie de marche avant

instructions de-dessus dans l’ordre inverse.

6. Installez la courroie neuve en suivant les

transmission

Poulie de la

Courroie de marche avant

re

boulon de la poulie motrice.

4. Utilisez une clé de 9/16es de po pour enlever le

la poulie motrice. Voir la Figure 20.

3. Dégagez la courroie de la poulie transmission et

poulie de tension.

de la poulie de tension en enlevant l’écrou de la

2. Dégagez le dispositif de retenue de la courrole

chapitre précédent.

la marche arrière, suivez les instructions du

Pour modèle 390: Pour démonter le courroie de

enlever le courvre-courroie.

paragraphes 1 et 2 u chapitre précédent pour

1. Pour modèle 340: Suivez les instructions des

Courroie de Marche Avant (Voir la Figure 19)

Figure 19 Modèle 390 Illstrée

Courroie de marche arrière

Poulie motrice

six pans

Écrou à

Tendeur arr

Page 25

12

l’embrayage.

instructions du chapitre sur le dernier réglage de

l’embrayage est bien réglée selon les

de la transmission. Vérifiez que la commande de

de la courroie soit contre les poulies motrice et

est installée de manière que le côté le plus large

Assurez-vous qui la courroie de marche arrière

instructions de-dessus dans l’ordre inverse.

6. Installez la courroie neuve en suivant les

Figure 18

courroie

Couvre-

Écrou à six pans et rondelle

et rondelles plate

Vis

auto-taraudeuses

(Voir la Figure 19.)

Faites glisser le tendeur et enlevez la courroie.

de marche arrière sur le support du tendeur.

5. Enlevez l’écrou à six pans qui retient le tendeur

4. Dégagez la courroie de la poulie transmission.

Retirez le couvre-courroie.

rondelle plate du côté du couvre-courroie.

3. Enlevez l’écrou de blocage à six pans et la

couvre-courroie. (Voir la Figure 18.)

taraudeuses et les rondelles plates sur l’avant du

motoculteur en retireant les deux vis auto-

2. Dégagez le couvre-courroie du côté gauche du

masse contre le moteur.

1. Débranchez le fil de la bougie et mettez-le à la

seulement)

Courroie de Marche Arrière (Modèle 390

Pièce no. 754-0429

Courroie de marche arrière (390 seulement) —

Courroie de marche avant — Pièce no. 754-0428

dépositaire agréé le plus proche.

les courroies par leurs numéros de pièce au

Si la courroie doit être remplacée, commandez la ou

pas la remplacer par une courroie ordinaire.

longévité et de meilleures performances. Il ne faut

Kevlar Tensile qui lui assurera une plus grande

Ce motoculteur exige une courroie spéciale en

REMPLACEMENT DE LA COURROIE

d’entretien ou une réparation.

moteur avant d’effectuer une opération

de la bougie et mettez-le à la terre contre le

AVERTISSEMENT: Débranchez le fil

la vie de la machine et à limiter sa facilité d’entretien.

ou le moteur. L’emploi d’eau a tendance à raccourcir

électriques, les fusées, les poulies, les roulements

Cela risque en effet d’endommager les composants

pression pour nettoyer la machine est déconseillée.

REMARQUE: L’utilisation d’un nettoyeur sous

facile à enlever si elle n’est pas sèche.

dents après chaque utilisation. La saleté est plus

Nettoyez le dessous du dispositif de protection des

NETTOYAGE DES DENTS

combustibles se trouvant à proximité du silencieux.

tous les brins d’herbe, la saleté et autres débris

performances et à la longévité du moteur. Enlevez

circulation d’air essentielle aux bonnes

du venilateur) propre pour assurer la bonne

Gardez le système de refroidissement (à proximité

une brosse.

Nettoyez le moteur régulièrement avec un linge ou

notice d’utilisation.

de bougie à utiliser et l’écartement correct dans la

bougie au début de chaque saison. Vérifiez le type

par saison. Il est recommandé de remplacer la

Nettoyez la bougie et ajustez l’écartement une fois

fournie.

si le filtre à air n’est pas complètement installé

IMPORTANT: Ne faites jamais tourner le moteur

moteur.

doit être nettoyé. Consultez la notice d’utilisation du

moteur et sa «noyade» indiquent que le filtre à air

poussiéreuses. Une mauvaise performance du

intervalles plus rapprochés dans des conditions très

conditions d’utilisation normales. Nettoyez-le à

Nettoyez le filtre à air toutes les 25 heures dans des

le moteur quand le niveau d'huile est insuffisant.

MPORTANT: N'essayez pas de mettre en marche

suivez-les.

motoculteur. Lisez attentivement les instructions et

notice d’utilisation du moteur fournie avec le

Employez l’huile à moteur recommandée dans la

à l’entretien du moteur.

Consultez la notice d’utilisation du moteur quant

MOTEUR

CAS DE PROBLÈME», à la page 14.

En case de problèmes, consultez le tableau «EN

EN CAS DE PROBLÈME

CHAPITRE 7: ENTRETIEN

Page 26

11

MOTOCULTEUR», page 8.

Consultez le chapitre «MODE D’EMPLOI DU

fonctionner facilement dans les deux directions.

de l'huile légère. Les commandes doivent

levier et le câble au moins une fois une saison avec

Lubrifiez les points de pivot sur la poignée de dent/

Poignée/Levier d’enclenchement de dent-

au moins une fois par saison.

Roues— Enlevez les roues et lubrifiez les essieux

axes de dent au moins une fois une saison.

Arbre des dents— Enlevez les dents et lubrifiez les

nécessaire de le vérifier.

lubrifié et rendu étanche à l’usine. Il n’est pas

Entraînement à chaîne — Le carter de chaîne a été

avec une huile à moteur SAE 30.

points de pivotage au moins une fois par saison

courroie et lubrifiez toutes les pièces mobiles et

Points de Pivotage — Démontez le carter de la

autre réglage sur le motoculteur.

avant tout nettoyage, toute lubrification ou

moteur et débranchez le fil de la bougie

Figure 17

13"

Figure 16

24"

RÉGLAGE DU GUIDE DE PROFONDEUR

MOTOCULTEUR», page 8.

roues, consultez le chapitre «MODE D’EMPLOI DU

Pour régler la fourche des roues et la position des

RÉGLAGE DES ROUES

AVERTISSEMENT: Arrêtez toujours le

CHAPITRE 6: LUBRIFICATION

plupart des situations.

inutile. Les réglages de l’usine conviennent dans la

avant d’ajuster celui-ci. N’effectuez aucun réglage

à air est propre et bien installé sur le carburateur

moteur de tourner régulièrement. Vérifiez que le filtre

REMARQUE: Un filtre à air sale empêche le

carburateur.

avec le motoculteur quant aux réglages du

Consultez la notice d’utilisation du moteur fournie

carburant, de température, d’altitude et de charge.

nécessaire pour compenser les différences de

Un réglage mineur du carburateur peut être

le silencieux.

et ne touchez pas les surfaces chaudes ni

Éloignez-vous de toutes les pièces mobiles

débrayez tous les embrayages et dents.

que le moteur tourne (par ex. carburateur),

effectuer un réglage quelconque pendant

Si vous devez

AVERTISSEMENT:

RÉGLAGE DU CARBURATEUR

Figure 15

22"

les dents extérieures. (Voir la Figure 17.)

réduisez la largeur de travail à 13 pouces en retirant

(Voir la Figure 16Figure 17.) Pour cultiver le sol,

avec les axes de chape et les goupilles épingles.

extérieures d’un pouce et bloquez-les en position

chape et les goupilles épingles, sortez les dents

largeur de travail à 24 pouces, enlevez les axes de

pouces. (Voir la Figure 15.) Pour augmenter la

La largeur de travail du motoculteur est de 22

RÉGLAGE DE LA LARGEUR DES DENTS

instructions d’assemblage.

«RÉGLAGE FINAL DE L’EMBRAYAGE» dans les

Pour régler l’embrayage, consultez le chapitre

RÉGLAGE DE L’EMBRAYAGE

réparation ou un entretien.

le moteur avant d’effectuer un réglage, une

de la bougie et mettez-le à la terre contre

AVERTISSEMENT: Débranchez le fil

CHAPITRE 5: RÉGLAGES

Page 27

10

profondeur permettra de travailler à la profondeur de

motoculteur repose sur les dents. Le guide de

pouces environ au-dessus du sol quand le

profondeur de façon que les roues se trouvent à 2

des mauvaises herbes.

les racines des plantes, tout en retardant la pousse

conserver l’humidité plus longtemps et de bien aérer

plusieurs pouces de terre permettent à celle-ci de

des feuilles et de la paille et leur mélange dans

mélangez les engrais au compost. Le déchiquetage

assurer la bonne décomposition du compost,

appréciablement la fertilité de votre jardin. Pour

organiques en décomposition augmente

dans le sens de la largeur. L’addition de matières

dans le sens de la longueur du jardin, puis repassez

profondeur de 6 à 8 pouces. Pour cela, travaillez

souhaitée. Le compost doit être enterré à une

qu’elle ait été labourée à la profondeur de travail

utiliser le motoculteur pour mélanger la terre après

Plus besoin de travailler à la pioche. Vous pouvez

terre calcaire pour tout travail ultérieur à la pelle.

motoculteur se révèlera aussi très utile pour aérer la

assurer une meilleure croissance de l’herbe. Le

profondeur et éliminer toutes les mottes pour

semer un gazon. Vous pourrez travailler en

Vous pourrez par exemple préparer la terre pour

sol et la cultrue, vous rendra bien d’autres services.

Ce motoculteur, outre la préparation superficielle du

Figure 14

3 pouces. Réglez les roues et le guide de

Il est conseillé de travailler à une profondeur de 2 à

PRÉPARATION DU SOL

creuser.

conducteur le retient, les dents commencent à

pas pour ne pas endommager l’herbe. Si le

que le motoculteur avance tout seul. Ne le retenez

l’obturateur à la position «SLOW» (Lent) jusqu’à ce

(Voir la Figure 12.) Placez la commande de

guide de profondeur à sa position la plus haute.

Pour amener le motoculteur au jardin, relevez le

DÉPLACEMENT DU MOTOCULTEUR

la position lente pour déplacer le motoculteur.

travailler en profondeur. Déplacez la manette à

Le moteur doit tourner au régime maximum pour

manette à fond pour l’arrêter.

moteur au régime «SLOW» (Lent). Tirez la

(Rapide)). Tirez-la encore pour amener le

pour que le moteur tourne plus vite («FAST»

(Démarrage). Tirez légèrement sur la manette

carburateur se trouve à la position «START»

l’obturateur est poussé vers l’avant, le

Lorsque le bouton de la commande de

régime du moteur et permet d’arrêter celui-ci.

4. Commande de l’obturateur: Elle détermine le

appliquer sur les mancherons.

réglage du guide de profondeur et la pression à

conditions de travail déterminent également le

ralentit les déplacements. Le type de sol et les

contraire augmente la profondeur de travail et

déplacement. Une pression vers le haut au

profondeur de travail et augmente la vitesse de

mancherons. Une pression vers le bas réduit la

vitesse de déplacement en appuyant sur les

également contrôler la profondeur de travail et la

.

pratiquement tout binage. (Voir la Figure 14).

Vous pouvez

Figure 13

3. Pression sur les mancherons:

le travail du sol en croisant et élimineront

semblable, les plantations en quinconce permettront

motoculteur. Pour la culture du maïs ou autre récolte

espace suffisant pour permettre le passage du

Lorsque vous tracez des sillons, pensez à laisser un

dents» dans la section des réglages.

Consultez le chapitre «Réglage de la largeur des

chapitre «Réglage de la largeur des dents».

suffit de retirer les dents extérieures. Consultez le

préparation du sol, elle peut être réduite à 13 po. Il

largeur de travail est de 22 ou 24 pouces. Pour la

Lorsque les dents extérieures sont installées, la

vitesse de déplacement.

placée pour que le moteur tourne lentement à une

«préparation du sol». La manette des gaz doit être

Page 28

9

t

les cailloux et pierres qui sont mis à jour.

longueur, puis dans le sens de la largeur. Enlevez

passage et parcourez le terrain dans le sens de la

cas, abaissez le guide de profondeur avant chaque

passer deux ou trois fois au même endroit. Dans ce

passage dans le jardin. Dans d’autres cas, il faut

la profondeur voulue est obtenue dès le premier

deuxième, comme à la Figure 13. Dans certains cas,

effectuez un troisième passage entre le premier et le

entre le premier et le deuxième passage, puis

Laissez à peu près 8 pouces de terre non retournée

le guide de profondeur. (Voir la Figure 12).

chape et la goupille épingle pour relever ou abaisser

vitesse de travail de la machine. Enlevez l’axe de

Il joue le rôle d’un frein et contrôle la profondeur et la

Réglage du guide de profondeur:

vitesse diminue. (Voir la Figure 11.)

des dents pour travailler plus en profondeur). La

2. Retournez la fourche (éloignez-la des roues et

déplacement.

également d’augmenter la vitesse de

pour cultiver et les déplacements. Ceci permet

la vitesse de déplacement.

on diminue la profondeur de travail et on augmente

Figure 12.) Quand on relève le guide de profondeur,

quand on augmente la profondeur de travail. (Voir la

La vitesse de déplacement du motoculteur baisse

Figure 12

déplacement lent

Travail en profondeur

rapide

déplacemen

profond

Travail peu

travail en profondeur

Réglage des roues pour

latéral

Disque

Figure 10

Bague de retenue

possible des dents) pour un travail en surface,

roues se trouvent plus en avant (le plus près

1. Placez la fourche des roues de façon que les

Réglage de la fourche des roues

PROFONDEUR DE TRAVAIL

CONTRÔLE DE LA VITESSE ET DE LA

chape

Axe de

Déplacement

profondeur

Figure 9

Guide de

Goupille épiingle

Figure 11

en profondeur

Travail

profond

Travail peu

Axe de chape

de roue

Support

profondeur

Guide de

Page 29

8

«CHOKE» (Volet fermé) et «RUN » (Marche).

sur le moteur à mi-distance entre la position

la Figure 10.

disque latéral et dégagez le disque de l’essieu. Voir

retenue et l’axe de chape qui retiennent chaque

être retirés de l’essieu externe. Retirez la bague de

terre travaillée de retomber sur l’extérieur, peuvent

Les disques latéraux, installés pour oempêcher la

DÉMONTAGE DES DISQUES LATÉRAUX

goupille épingle en place. (Voir la Figure 9.)

hauteur voulue et remettez l’axe de chape et la

la fourche des roues, relevez les roues à la

• Enlevez l’axe de chape et la goupille épingle de

moteur. Pour effecteur ce réglage,

niveau. Ceci est essentiel au bon fonctionnement du

doivent être relevées pour mettre la machine de

que l’avant du motoculteur s’abaisse, les roues

à mesure que les dents pénètrent dans la terre et

réglées pour que la machine soit de niveau. Au fur et

Pour l’expédition, les roues sont

REMARQUE:

RÉGLAGE DES ROUES

service.

assurera à son propriétaire des années d’excellent

jardin. Cette machine, si elle est bien entretenue,

pour effectuer bien d’autres tâches difficiles dans le

fleurs, pour labourer le sol, pour planter et cultiver et

jusqu’au travail le plus dur du jardin potager ou de

culture, le sillonnage et la mise en paillis. Elle facilite

conçue pour permettre la préparation des semis, la

Ce motoculteur est une machine de précision

MODE D’EMPLOI DU MOTOCULTEUR

tourne, déplacez la manette du volet de départ

le moteur se mette en route. Quand le moteur

6. Répétez les paragraphes 4 et 5 jusqu’à ce que

contre le démarreur.

revenir lentement. Ne la laissez pas claquer

la poignée du démarreur. Laissez la corde

mouvement rapide et continu. Tenez fermement

5. Tirez sur la corde en faisant un grand

corde revenir lentement.

résistance se fait sentir à ce moment.) Laissez la

atteigne le cycle de compression. (Une légère

(voir la Figure 8) jusqu’à ce que le moteur

4. Tirez lentement sur la poignée du démarreur

pas nécessaire si le moteur est chaud.

«CHOKE» (Volet fermé). Cette opération n’est

manette du volet de départ à la position

«FAST» (Rapide). (Voir la Figure 8).Déplacez la

3. Placez la commande de l’obturateur à la position

(Voir la Figure 6).

marche avant se trouve au point mort (ralâchée).

2. Vérifiez que la poignée d’embrayage de la

l’embout métallique de la bougie.

(dans la gaine en caoutchouc), est bien fixée sur

boucle métallique, au bout du fil de la bougie

1. Branchez le fil de la bougie. Assurez-vous que la

tourne ou au moment du démarrage.

motoculteur pendant que le moteur

personne ne se trouve devant le

AVERTISSEMENT: Vérifiez que

DÉMARRAGE DU MOTEUR

pas surveillée.

démarrage accidentel quand la machine n’est

terre contre le moteur pour empêcher tout

2. Débranchez le fil de la bougie et mettez-le à la

l’obturateur à la position «STOP» (Arrêt).

1. Placez la manette de la commande de

ARRÊT DU MOTEUR

AGE» dans les instructions d’assemblage.

chapitre «DERNIER RÉGLAGE DE L’EMBRAYde vérifier l'ajustement d'embrayage consultez le