Page 1

OPERATOR’S MANUAL

Front Tine Tiller

Model 030

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO.

770-10473.fm

(1/2001)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices................................................................... 3

Assembling Your Tiller ....................................................................................... 5

Know Your Tiller................................................................................................. 6

Operating Your Tiller .......................................................................................... 7

Making Adjustments .......................................................................................... 9

Maintaining Your Tiller ....................................................................................... 10

Troubleshooting ................................................................................................. 11

Parts List............................................................................................................ 12

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new tiller. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by looking down at the rear of the tiller. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the

equipment in the space below.

(Model Number)

CLEVELAND, OHIO 44136

(Serial Number)

MTD PRODUCTS INC

Copy the model number here:

Copy the serial number here:

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Dealer Referral Line.

Call 1- (330) 220-4MTD (4683) or 1- (800)-800-7310 to reach a Customer Support

representative. Please have your unit’s model number and serial number ready when you

call. See previous section to locate this information. You will be asked to enter the serial

number in order to process your call.

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failure to comply with these instructions may

result in personal injury. When you see this symbol— heed its warning.

WARNING: Engine exhaust, some of its constituents, and certain vehicle components contain or

emit chemicals known to State of California to cause cancer and birth defects or other reproductive

harm

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet. Failure to observe the

following safety instructions could result in serious injury or death.

Tra in in g

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over should

read and understand the operation instructions and

safety rules in this manual and should be trained

and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Keep bystanders, helpers, pets and children at least

75 feet from the machine while it is in operation.

Stop machine if anyone enters the area.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used. Remove all stones, sticks, wire, and

other foreign objects which could be tripped over

and cause personal injury.

2. Wear sturdy, rough-soled work shoes and close

fitting slacks and shirt. Loose fitting clothes or

jewelry can be caught in movable parts. Never

operate this machine in bare feet or sandals.

3. Disengage clutch levers and shift (if provided) into

neutral (“N”) before starting the engine.

4. Never leave this machine unattended with the

engine running.

5. Never attempt to make any adjustments while

engine is running, except where specifically

recommended in the operator’s manual.

6. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

7. Use only an approved gasoline container.

8. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

9. Never fuel machine indoors.

10. Never remove gas cap or add fuel while the engine

is hot or running.

11. Allow engine to cool at least two minutes before

refueling.

12. Never over fill fuel tank. Fill tank to no more than ½

inch below bottom of filler neck to provide space for

fuel expansion.

13. Replace gasoline cap and tighten securely.

14. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

15. Never store the machine or fuel container inside

near an open flame, spark or pilot light (e.g.

furnace, water or space heater, clothes dryer etc.).

16. Allow machine to cool 5 minutes before storing.

Operation

1. Do not put hands or feet near rotating parts. Contact

with the rotating parts can amputate hands and feet.

2. Do not operate machine while under the influence

of alcohol or drugs.

3. Never operate this machine without good visibility

or light. Always be sure of your footing and keep a

firm hold on the handles.

4. Keep bystanders, helpers, pets, and children at

least 75 feet from the machine while it is in

operation. Stop the machine if anyone enters the

area.

5. Be careful when tilling in hard ground. The tines

may catch in the ground and propel the tiller

forward. If this occurs, let go of the handle bars and

do not restrain the machine.

6. Exercise extreme caution when operating on or

crossing gravel surfaces. Stay alert for hidden

hazards or traffic. Do not carry passengers.

7. Never operate the machine at high transport

speeds on hard or slippery surfaces.

8. Exercise caution to avoid slipping or falling.

3

Page 4

9. Look down and behind and use care when in

reverse or pulling machine towards you.

10. Start the engine according to the instructions found

in this manual and keep feet well away from the

tines at all times.

11. After striking a foreign object, stop the engine,

disconnect the spark plug wire and ground against

the engine. Thoroughly inspect the machine for any

damage. Repair the damage before starting and

operating.

12. Disengage all clutch levers and stop engine before

you leave the operating position (behind the

handles). Wait until the tines come to a complete

stop before unclogging the tines, making any

adjustments, or inspections.

13. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

14. Muffler and engine become hot and can cause a

burn. Do not touch.

15. Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause

property damage or personal injury.

16. Do not overload machine capacity by attempting to

till soil to deep at to fast of a rate.

17. If the machine should start making an unusual noise

or vibration, stop the engine, disconnect the spark

plug wire and ground it against the engine. Inspect

thoroughly for damage. Repair any damage before

starting and operating.

18. Keep all shields, guards and safety devices in place

and operating properly.

19. Never pick up or carry machine while the engine is

running.

20. Use only attachments and accessories approved by

the manufacturer. Failure to do so, can result in

personal injury.

21. If situations occur which are not covered in this

manual, use care and good judgment. Contact your

dealer or telephone 1-800-800-7310 for assistance

and the name of your nearest servicing dealer.

3. Before cleaning, repairing, or inspecting, stop the

engine and make certain the tines and all moving

parts have stopped. Disconnect the spark plug wire

and ground it against the engine to prevent

unintended starting.

4. Do not change the engine governor settings or overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

5. Maintain or replace safety and instruction labels, as

necessary.

6. Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

such as a water heater, furnace, clothes dryer etc.

8. Always refer to the operator’s manual for proper

instructions on off-season storage.

9. If the fuel tank has to be drained, do this outdoors.

10. Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

Your Responsibility

1. Restrict the use of this power machine to persons

who read, understand and follow the warnings and

instructions in this manual and on the machine.

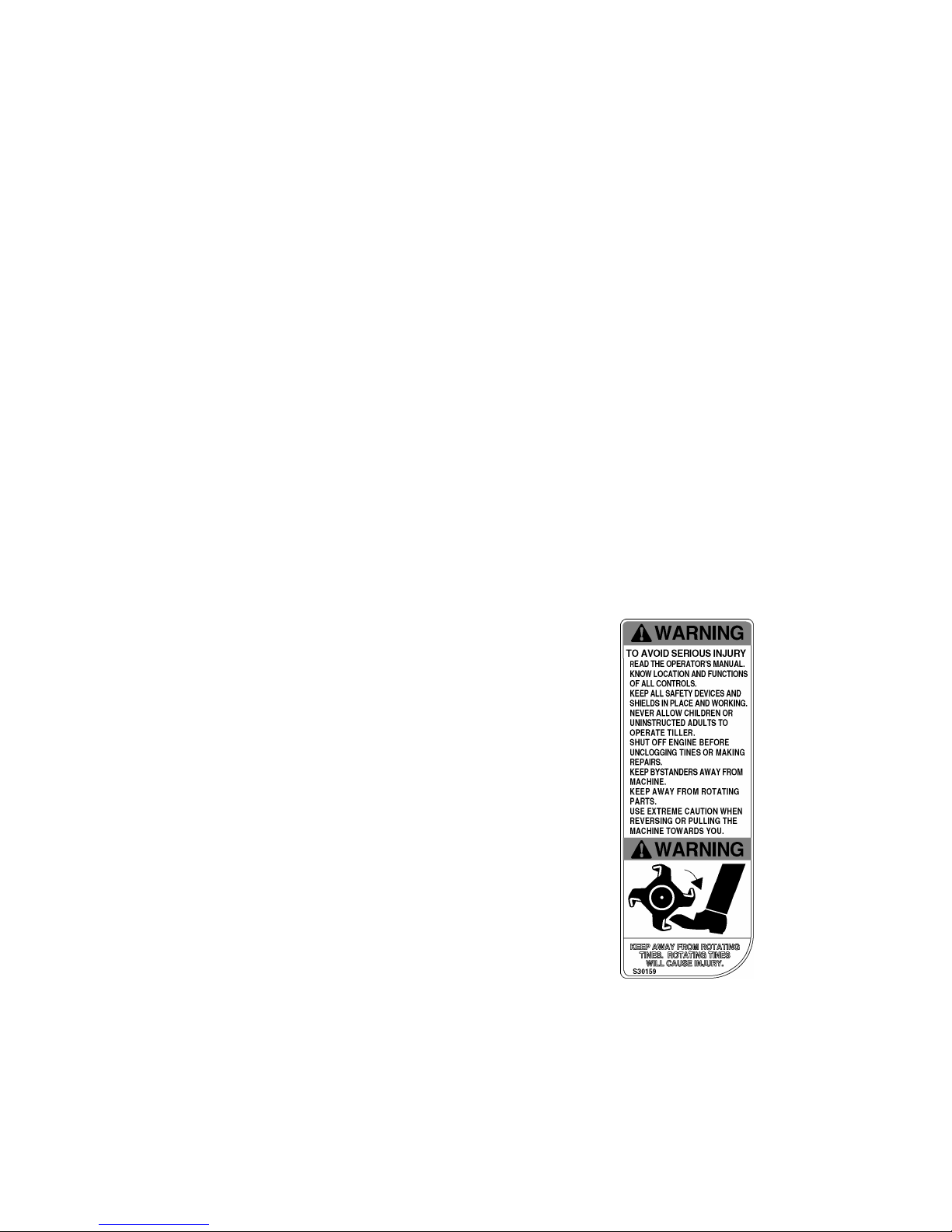

2. The safety label on the tiller is reproduced below for

your review. To ensure safe operation of the tiller,

follow the instructions on all labels closely.

Maintenance & Storage

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness at

frequent intervals to keep the machine in safe

working condition. Also, visually inspect machine for

any damage.

4

Page 5

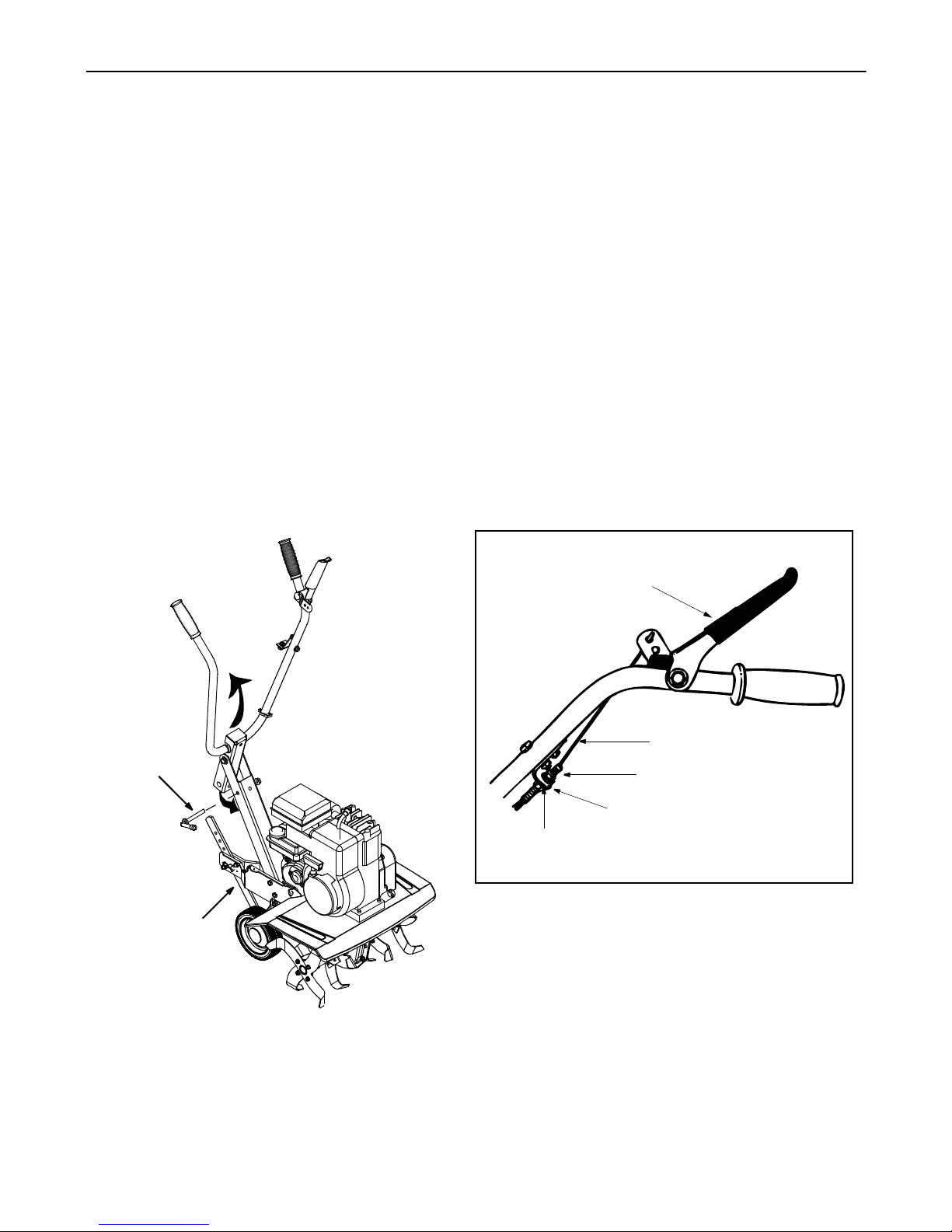

SECTION 2: ASSEMBLING YOUR TILLER

IMPORTANT:

in the engine. Be certain to service engine with gasoline

and oil, as instructed in the engine manual, before

operating your tiller. (The engine manual is packed

seperately and shipped in the tiller carton.)

NOTE: Reference to right or left side of the tiller is

observed from the operating position.

This unit is shipped without gasoline or oil

Removing Unit From Carton

• Remove staples, break glue on top flaps, or cut

tape at carton end and peel along top flap to open

carton. Remove loose parts (i.e., operator’s

manual, etc.) from carton.

• Cut along corners, lay carton down flat, and remove

packing material. Roll or slide unit out of carton and

check carton thoroughly again before discarding.

• Extend control cables to the rear of the tiller and lay

them on the floor. Do not bend or kink cables.

Setting up the Tiller

• Disconnect the spark plug wire and move it away

from the spark plug.

• Remove the handle lever from the handle.

• Lift up and pull back on the handle to raise to the

operating position. Reinsert handle lever and

tighten securely.

• Pull depth stake down into the operating position.

Please refer to instructions in detail on page 8.

Check Cable Adjustment

• With the clutch lever disengaged, pull starter rope

slowly several times. Tines should not turn. If tines

do turn, the cable is not adjusted properly.

• To adjust cable, loosen bottom nut at cable bracket

slightly to provide additional slack in cable wire

while clutch is disengaged. See Figure 1 inset.

• Tighten top nut and check again for proper

adjustment. See Figure 1 inset.

Tine Clutch

Control Lever

Handle

Lever

Depth Stake

Lift

handle

up

Clutch Cable

Top Hex Nut

Cable

Bracket

Bottom

Hex Nut

Figure 1

5

Page 6

SECTION 3: KNOW YOUR TILLER

Read this operator’s manual and safety rules before operating your tiller. Compare the illustrations in Figure 2 with

your tiller to familiarize yourself with the location of various controls and adjustments. Save this manual for future

reference.

Throttle Control

The throttle control lever is located on the engine. It

controls the engine’s speed and stops the engine.

• With the throttle control pushed completely to the

right, the carburetor is in START or FAST position.

Use maximum engine speed for deep tilling.

• Pull the throttle control back to reduce engine

speed to IDLE. Throttle control should be at IDLE

for transporting the tiller.

• Pull the throttle completely back to stop the engine.

Choke Lever

The choke lever is located near the throttle control. It is

used to enrich the fuel mixture when starting a cold

engine.

Starter Handle

The starter handle is located on the engine and is

used to manually start the engine.

Tine Clutch Control

The clutch control lever is located on the left handle.

Squeezing the lever against the handle engages the

tine drive. Release the lever to stop the tines from

turning.

Depth Stake

The depth stake is located in the rear of the tiller and it

controls the tilling depth. See page 8 for instruction on

its adjustment.

Stopping Engine

• Move throttle control lever to STOP or OFF

position.

• Disconnect spark plug wire from spark plug and

ground against the engine.

Handle

Assembly

Choke

Throttle Control

Handle

Lever

Depth

Stake

Tine Clutch

Spark

Plug

Recoil Starter

Tine

Shield

Tines

Starter Handle

Figure 2

SECTION 4: OPERATING YOUR TILLER

Before Starting

• Service the engine with gasoline and oil as

instructed in the engine manual packed seperately

with your tiller. Read instructions carefully.

WARNING: Never fill fuel tank indoors with

engine running or until the engine has been

allowed to cool for two minutes after running.

• Check clutch adjustment as instructed on page 5.

Starting Engine

WARNING: Be sure no one is standing in

front of the tiller while the engine is running or

being started.

• Attach spark plug wire to spark plug. Make sure the

metal cap on the end of the spark plug is fastened

securely over the metal tip on the spark plug.

• Make sure that the tine clutch lever is disengaged.

6

Page 7

• Place the throttle control in the FAST position.

• Move choke lever to CHOKE position. A warm

engine requires little or no choke.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope

will pull slightly harder at this point). Let the rope

rewind slowly.

• Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on starter handle. Let rope rewind

slowly. Do not let starter handle snap back against

starter. Repeat until engine starts.

• When engine starts, move choke lever on engine

halfway between CHOKE and RUN. As the engine

warms up, move the lever to RUN position.

the throttle control in SLOW position, the unit will

walk freely on the lawn. If the operator does not

allow the tiller to move freely, the unit will start to till

the surface. See Figure 4.

Depth Stake

in transport

position

Using Your Tiller

Your tiller is a precision-built machine for preparing

seed beds, cultivating, furrowing, and mulching.The

instructions below are designed towards your

convenience in using the tiller.

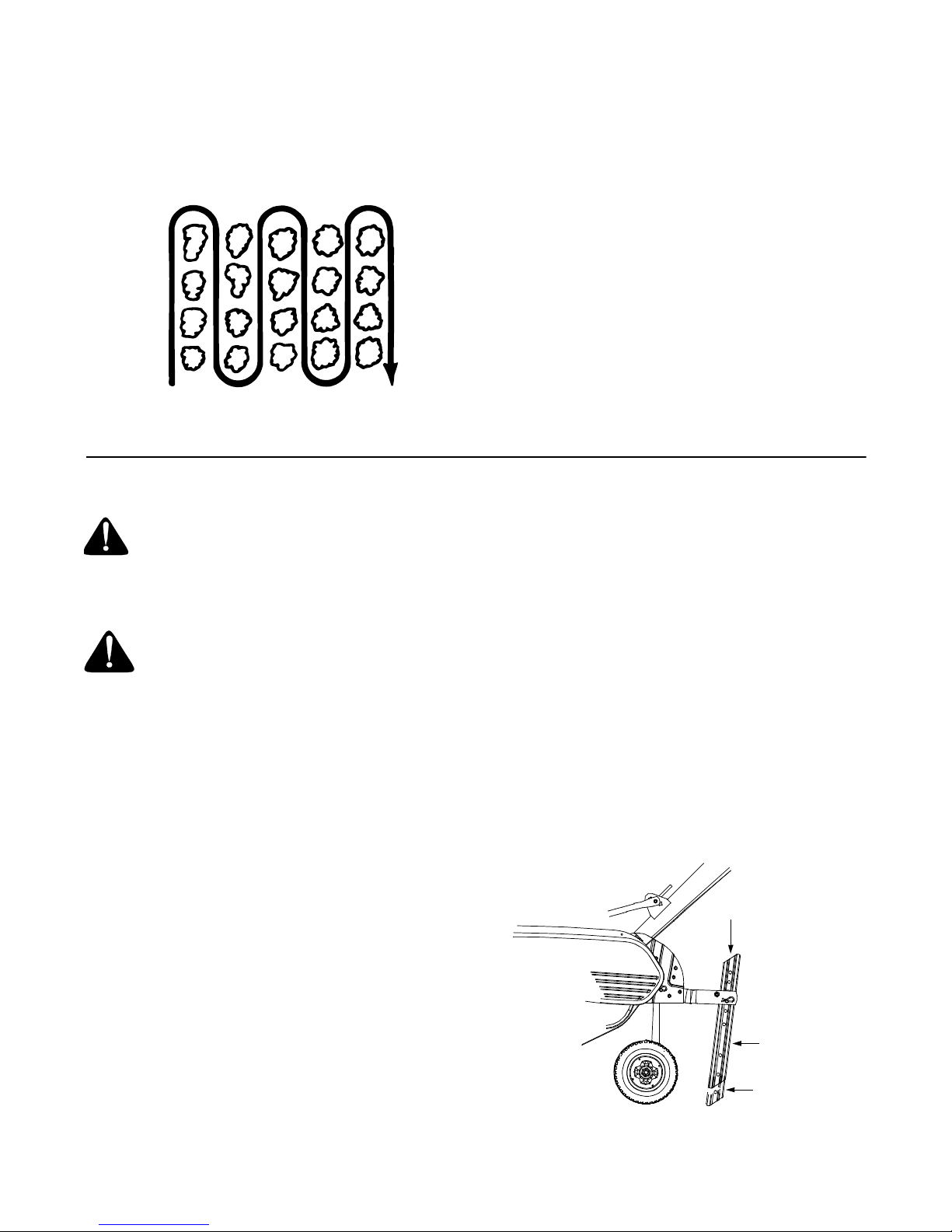

• When tilling, leave approximately 8 inches of

untilled soil between the first and second tilling

paths, then make the third path between the first

and second. See Figure 3.

• In some soils, the desired depth is obtained by

going over the garden two or three times. In the

latter case, the depth stake should be lowered

before each succeeding pass over the garden.

• Passes should be made across the length and

width of the garden alternately. See Figure 3.

Rocks, which are turned up, should be removed

from the garden area before proceeding with tilling.

Depth Stake

in tilling

position

Figure 4

Cultivating

For cultivating, a two to three inch depth is desirable.

With the outer tines in place on the equipment, the

working width of the machine is 18 inches. With the

outer tines removed for cultivation purposes, the

working width may be reduced to 14 inches.

• To reduce the width of ground tilled, set the throttle

to a slow walking speed.

• Remove the two self-tapping screws on the outside

of the tines using a 3/8" wrench. Remove the first

tine and replace the hardware to secure the rest.

Figure 3

Using Depth Stake

Please refer to page 8 for instructions.

Handle Pressure

Further control of tilling depth and travel speed can be

obtained by variation of pressure on the handles.

• A downward pressure on the handles will reduce

the working depth and increase the forward speed.

• An upward pressure on the handles will increase

the working depth and reduce the forward speed.

The type of soil and working conditions will determine

the actual setting of the depth stake and the handle

pressure required.

Transporting the Tiller

• To transport the tiller to or from the garden, pivot

the depth stake forward and out of the way. With

Self-Tapping

Screw

Remove both

outer

tines

7

Figure 5

h

t

d

i

w

s

e

h

c

n

i

4

1

h

t

d

i

w

s

e

h

c

n

i

0

1

Page 8

• Minimum tilling width is 10 inches. For that, you will

have to remove both sets of outer tines. Remove

these tines by removing the two self-tapping screws

on the outside of the tines. See Figure 5.

• When laying out plant rows, be sure to allow

enough width to permit cultivation between the

rows. See Figure 6.

Figure 6

SECTION 5: MAKING ADJUSTMENTS

Other Uses

1. Your tiller can be used for preparation of lawn area

for seeding. The tiller will prepare an evenly deep

seed bed, hence allowing better lawn growth.

2. Your tiller may be used for loosening hard soil for

excavation with a shovel. In this case, no tedious

hand work will be necessary.

3. Your tiller may be used for mixing compost in the

pile, or for mixing it with the soil in your garden. This

should be done after the soil has been broken to

the full working depth.

Stopping Engine

• Move throttle control lever to STOP or OFF

position. Disconnect spark plug wire from spark

plug and ground against the engine.

WARNING: Do not at any time make any

adjustments without first stopping the engine

and disconnecting the spark plug wire.

Carburetor

WARNING: If any adjustments are made to

the engine while the engine is running (e.g.

carburetor), keep clear of all moving parts. Be

careful of heated surfaces and muffler.

Minor carburetor adjustments may be required to

compensate for differences in fuel, temperature,

altitude and load. To adjust carburetor, refer to the

separate engine manual packed with your mower.

NOTE: A dirty air cleaner will cause an engine to run

rough. Be certain air cleaner is clean and attached to

the carburetor before adjusting carburetor.

Tine Clutch Control

Periodic adjustment of the belt tension may be required

due to normal stretch and wear on the belt.

• To adjust, loosen top nut at the cable bracket

slightly to take up some slack in the cable wire.

Retighten the bottom nut against the bracket and

check adjustment again.

Depth Stake

The depth stake acts as a brake for the tiller and

controls the depth and speed at which the machine will

operate.

• Remove clevis pin and hairpin clip to raise or lower

depth stake. See Figure 7.

a. When the depth stake is lower, forward

speed of the machine is reduced, and the

working depth increased. See Figure 7.

b. When the depth stake is raised, the forward

speed is increased and the working depth of

the machine is reduced. See Figure 7.

• The working depth of the machine may be

predetermined by setting the depth stake and

wheels. The wheels are about four inches from the

ground when the tines and depth stake are resting

on the ground. This setting will permit a working

depth of about four inches.

Depth

Stake

Tine Width

The tilling width of the unit is 18 inches, but can be

reduced to 14 inches. Refer to page 7 for instructions.

Shallow Tilling

Deep Tilling

Figure 7

8

Page 9

SECTION 6: MAINTAINING YOUR TILLER

Lubrication

Always stop engine and disconnect spark

plug wire before cleaning, lubricating or

doing any kind of maintenance on your

tiller.

Pivot Points: Remove the belt cover and lubricate all

moving parts and pivot points at least once a season.

Chain Drive: The chain case is lubricated and sealed

at the factory.

Engine: Follow the engine manual for lubrication

specifications and instructions.

Tines: Remove tines and lubricate shaft with light oil.

Lubricate

See engine manual

for instruction

Lubricate

Lubricate

Figure 8

Cleaning

• Clean the engine regularly with a cloth or brush.

• Keep the cooling system (blower housing area)

clean to permit proper air circulation. Be certain to

remove all dirt and combustible debris from muffler

area.

• Clean the underside of the tine shield after each

use. Dirt washes off the tines easier if washed off

immediately.

Replacing Belt

• Disconnect and ground spark plug wire against the

engine.

• Lift the belt cover assembly off the tiller. Be careful

not to bend or kink the clutch cable.

• Remove the belt and position the new belt on

engine pulley and chain case pulley.

NOTE: Upon reassembly of belt cover, place the belt

over top of the idler pulley and between engine pulley

and weld pin on belt cover assembly. See Figure 9.

• Fasten belt cover assembly in position. Secure with

the hardware removed earlier.

Figure 9

Engine

Refer to the separate engine manual for all engine

maintenance instructions.

• Maintain engine oil as instructed in the engine

manual.

• Poor engine performance and flooding usually

indicate that the air cleaner needs to be serviced.

For instructions, refer to the engine manual.

• The spark plug should be cleaned and the gap

reset once a season. For instructions, refer to the

engine manual.

Off-Season Storage

If the tiller will not be used for a period longer than 30

days, the following steps should be taken to prepare the

tiller for storage.

• Clean the exterior of engine and the entire tiller

thoroughly.

• Refer to the engine manual for correct engine

storage instructions.

• Remove tines from the tine shaft and lubricate shaft

with oil.

• Wipe tines with oiled rag to prevent rust.

• Store tiller in a clean, dry area. Do not store next to

corrosive materials, such as fertilizer.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rustproof the equipment. Using a light oil or

silicone, coat the equipment, especially any springs,

bearings and cables.

9

Page 10

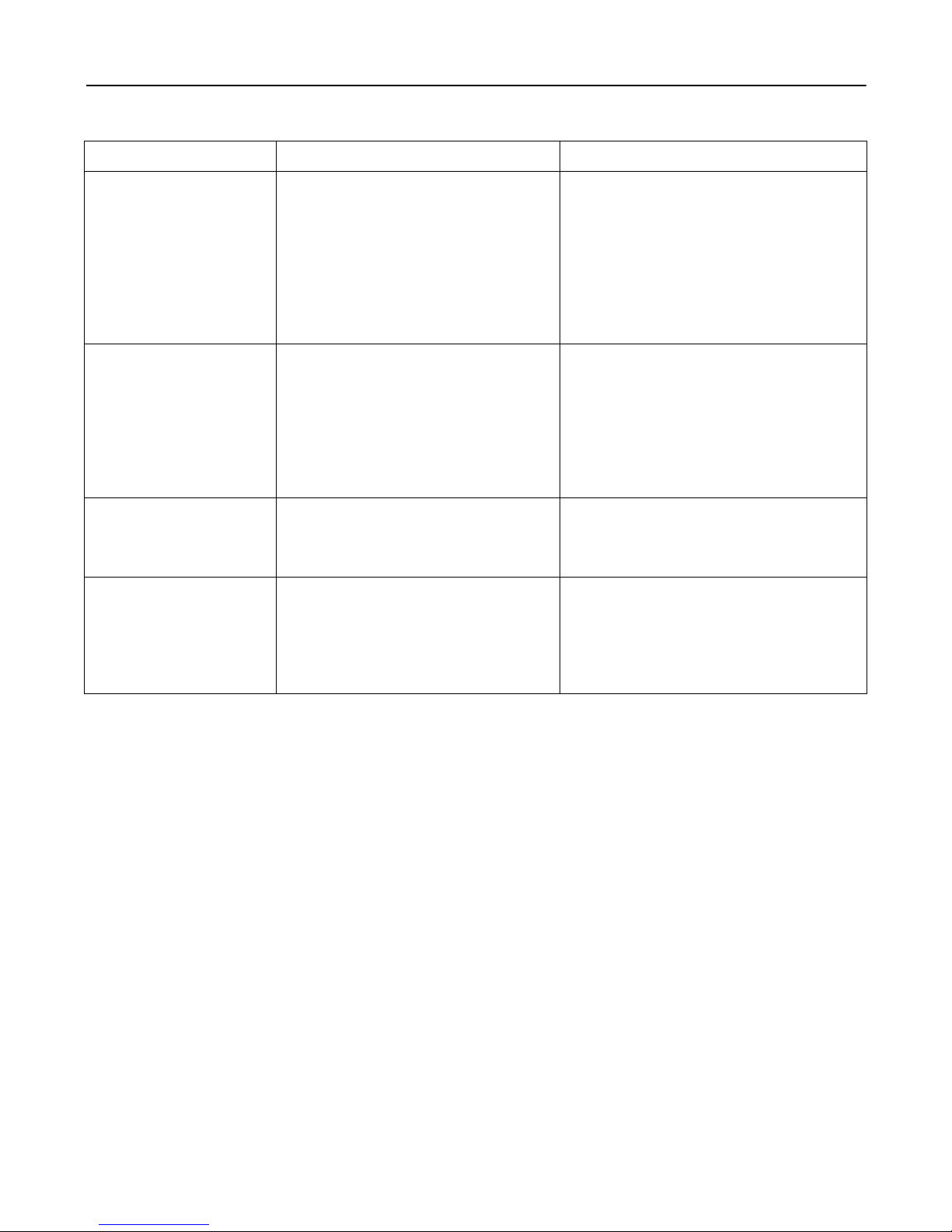

SECTION 7: TROUBLESHOOTING

Problem Cause Remedy

Engine fails to start 1. Spark plug wire disconnected.

2. Fuel tank empty or stale fuel.

3. Throttle control lever not in correct

starting position. (If equipped)

4. Choke not in ON position.

5. Blocked fuel line.

6. Faulty spark plug.

7. Engine flooded

Engine runs erratic 1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Vent plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

3. Air flow restricted.

4. Carburetor not adjusted properly.

Tines do not engage 1. Foreign object lodged in tines.

2. Tine clevis pin(s) missing.

3. Pulley and idler not in correct

adjustment.

4. Control cable not adjusted properly.

5. Belt worn and/or stretched.

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest service dealer.

1. Connect wire to spark plug.

2. Fill tank with clean, fresh gasoline.

3. Move throttle lever to start position.

4. Move switch to ON position.

5. Clean fuel line.

6. Clean, adjust gap, or replace.

7. Wait a few minutes to restart, but do not

prime.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean, fresh

gasoline

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6. Clean following engine manual.

7. Refer to engine manual.

1. Fill crankcase with proper oil.

2. Clean air cleaner.

3. Remove blower housing and clean.

4. Refer to engine manual.

1. Stop tiller completely, check and

discard foreign object.

2. Replace tine clevis pin(s).

3. Take unit to authorized service dealer.

4. Adjust control cable.

5. Replace belt.

10

Page 11

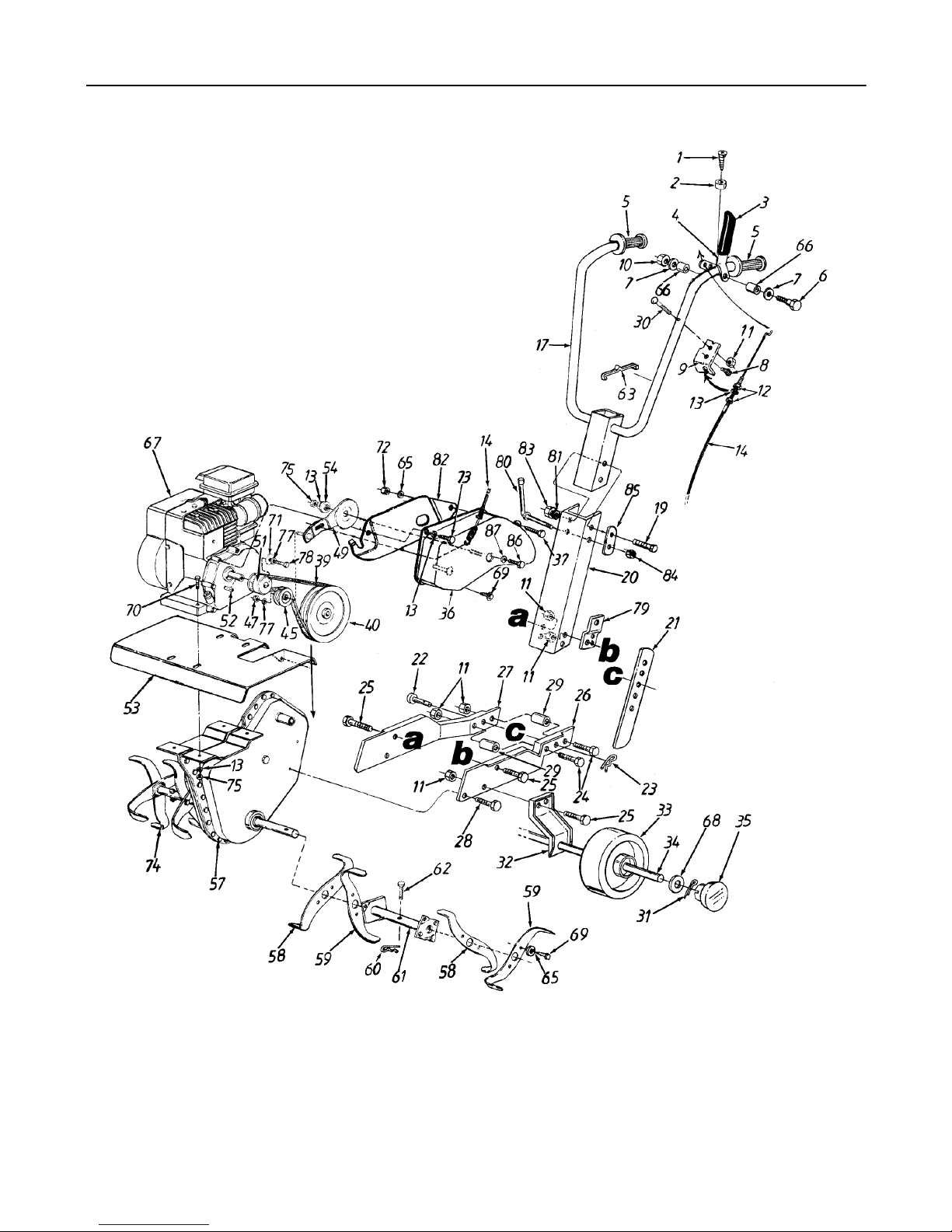

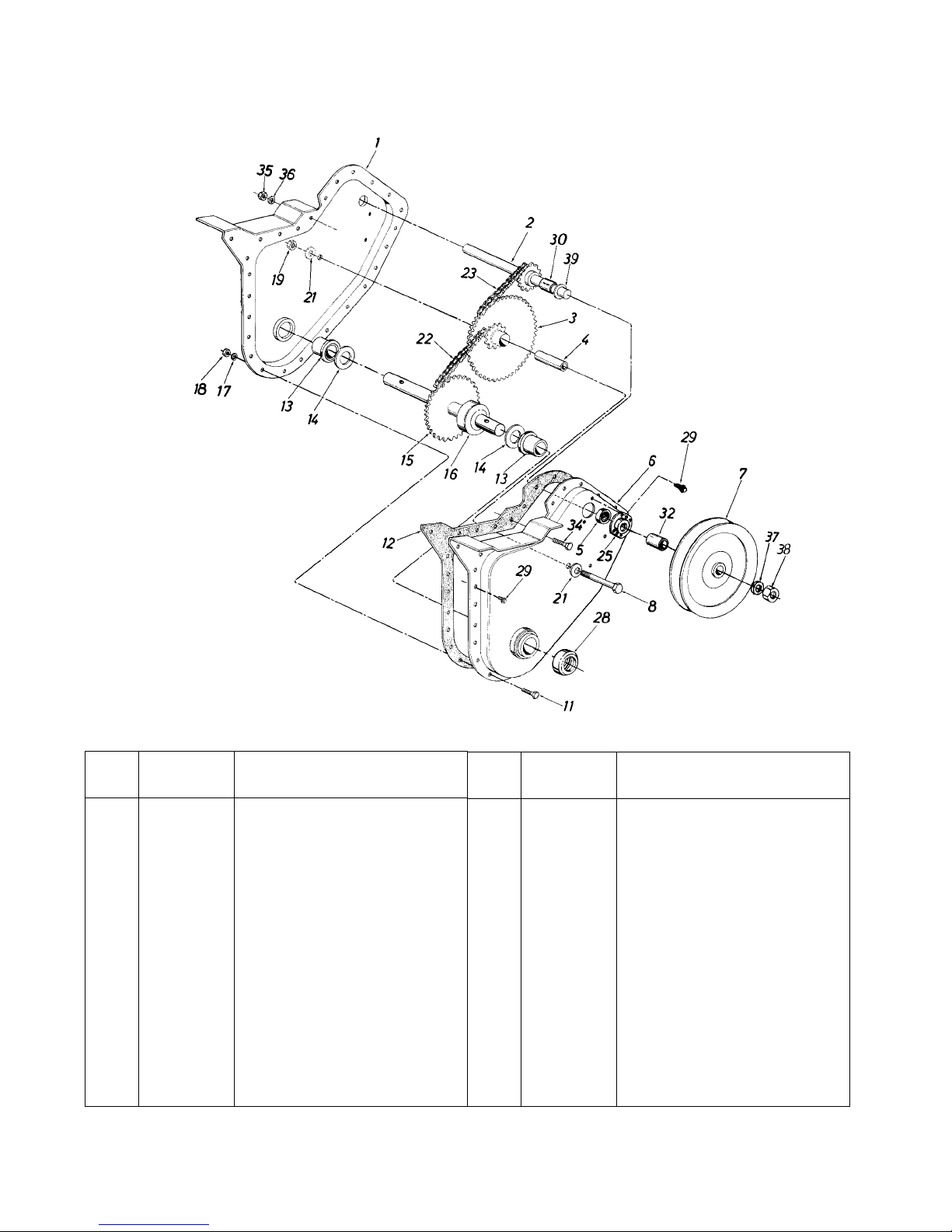

SECTION 8: PARTS LIST FOR MODEL SERIES 030

11

Page 12

Model Series 030

Ref.

No.

1 710-0779A Tap Scr. #10 x 1/2" Lg.

2 720-0263 Rubber Bumper

3 731-0473 Vinyl Grip

4 686-0002 Clutch Lever Ass’y.

5 720-0233 Handle Grip

6 710-0501 Hex Bolt 1/4-20 x 2" Lg.*

7 736-3090 Fl-Wash. 1/4" I.D.

8 710-1201 Hex Tap Scr. 1/4-20 x 1/2" Lg.

9 15093C Cable Bracket

10 712-0324 Lock Nut 1/4-20 Thd.

11 712-0429 Lock Nut 5/16-18 Thd.

12 712-0256 Hex Jam Nut 5/16-24 Thd.

13 736-0119 L-Wash. 5/16" I.D.*

14 746-0926 Clutch Control Cable

17 649-0018 Handle Ass’y.

19 710-3022 Hex Bolt 3/8-16 x 2.75

20 786-0146 Handle Channel–Frame

21 04764 Depth Stake

22 711-0653 Clevis Pin

23 714-0145 Hairpin Cotter

24 710-0376 Hex Bolt 5/16-18 x 1" Lg.*

25 710-0759 Hex Bolt 5/16-18 x 5/8" Lg.*

26 786-0011 L.H. Frame Half

27 786-0010 R.H. Frame Half

28 710-0607 Hex Tap. Scr. 5/16-18 x 1/2" Lg

29 750-0845 Spacer

30 710-1090 Hex Bolt 5/16-18 x 1-1/4" Lg.

31 714-3017 Cotter Pin

32 786-0012 Wheel Bracket

33 634-0013 Wheel–6"

34 738-0855 Axle–Wheel

35 720-0258 Hub Cap

36 786-0151A Belt Cover

37 710-0751 Hex Bolt 1/4-20 x .620" Lg.*

39 754-0216 V-Belt

40 756-0996 Pulley–Chain Case

Part No. Part Description

Ref.

No.

45 756-0199 Flat Idler Pulley

47 712-0116 Hex Jam L-Nut 3/8-24 Thd.

49 784-0016 Idler Arm Ass’y.

51 756-0286 Engine Pulley

52 714-0122 Square Key 3/16" x .75" Lg.

53 786-0148A Tine Shield

54 736-0289 Washer–Bushing

57 686-0093A Chain Case Ass’y. C omp.

58 04922 R.H. Tine Blade

59 04923 L.H. Tine Blade

60 714-0149B Hairpin Cotter

61 04918 Adapter Ass’y.–Tine

62 711-0702 Clevis Pin

63 726-0306 Cable Tie–Plastic

65 736-0329 L-Wash. 1/4" I.D.*

66 750-0846 Spacer

67 — Engine

68 736-3050 Fl-Wash. .406 I.D.

69 710-0599 Tap Scr. 1/4-20 x 1/2" Lg.

70 710-0502A Hex Bolt 3/8-16

71 736-0258 Fl-Wash. 3/8" I.D. x 1" O.D.

72 712-0287 Hex Nut 1/4-20 Thd.*

73 710-0107 Hex Bolt 5/16-24 x .5" Lg.

74 04921 Tine Blade Ass’y. C o mp.

75 712-0267 Hex Nut 5/16-18 Thd.*

77 736-0169 L-Wash. 3/8" I.D.*

78 710-0152 Hex Bolt 3/8-24 x 1" Lg.

79 786-0046 Belt Cover Bracket

80 784-0190 Handle Adj. Crank

81 736-0300 Fl-Wash. .385" I.D. x .87" O.D.

82 786-0153 Belt Cover—Rear

83 712-0431 Hex L-Nut 3/8-16 Thd.

84 712-0379 Hex Flange L-Nut 3/8-24 Thd.

85 784-0191 Retainer Bracket

86 710-3008 Hex Bolt 5/16-18 x .75" Lg.

87 736-0264 Fl-Wash. .330 I.D.

Part No. Part Description

12

Page 13

Model Series 030

Ref.

No.

1 686-0085 Chain Case Ass’y.—R.H.

2 611-0057 Input Shaft Ass’y.

3 04757A Hub and Sprocket Ass’y.

4 750-0351 Bearing Inner Race

5 741-0155 Ball Bearing

6 686-0087 Chain Case Ass’y.—L.H.

7 756-0996 Pulley—Chain Case

8 710-0369 Hex Bolt 3/8-24 x 2.5"*

11 710-0195 Hex Bolt 1/4-28 x .625"*

12 721-0156A Gasket

13 741-0227 Flange Brg. .879" I.D.

14 736-0265 Fl-Wash. .88" I.D. x 1.5"

15 04920 Tine Shaft Ass’y.

16 750-0354A Spacer 7/8" I.D.

17 736-0329 L-Wash. 1/4" I.D.*

18 712-0138 Hex Nut 1/4-28 Thd.*

19 712-0116 Hex Ins. L-Nut 3/8-24 Thd.

Part No. Part Description

Ref.

No.

21 736-0219 Bell-Wash. .406" I.D.

22 713-0215 Chain #420 1/2" Pitch 38 Links

23 713-0216 Chain #35 .375" Pitch 50 Links

25 05034A Bearing Housing

28 721-0392 Shaft Seal

29 710-0599 Hex Wash. Hd. Self-Tap Scr.

30 750-0471 Spacer .63" I.D. x .77" O.D. x .38"

32 750-0999 Spacer .647 x .77"

34 710-3008 Hex Bolt 5/16-18 x .75" Lg.*

35 712-0267 Hex Nut 5/16-18 Thd.*

36 736-0119 L-Wash. 5/16" I.D.*

37 736-0105 Bell-Wash. .38" I.D. x .88" O.D.

38 712-0379 Hex Flange L-Nut 3/8-24 Thd.

39 736-0302 Washer .652 I.D.

— 686-0093A Chain Case Ass’y. C o m p.

13

Part No. Part Description

713-0154 #420 Master Link

713-0139 #35 Master Link

Page 14

YOUR NOTES

Date Comments

14

Page 15

YOUR NOTES

Date Comments

15

Page 16

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by MTD

PRODUCTS INC (“MTD”) with respect to new merchandise

purchased and used in the United States, its possessions

and territories.

MTD warrants this product against defects in material and

workmanship for a period of two (2) years commencing on

the date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in

material or workmanship. This limited warranty shall only

apply if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse, commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water or damage because

of other peril or natural disaster. Damage resulting from the

installation or use of any accessory or attachment not

approved by MTD Products Inc. for use with the product(s)

covered by this manual will void your warranty as to any

resulting damages.

Normal wear parts or components thereof are subject to

separate terms as follows: All normal wear part or component failures will be covered on the product for a period of

90 days regardless of cause. After 90 days, but within the

two year period, normal wear part failures will be covered

ONLY IF caused by defects in material or workmanship of

OTHER component parts. Normal wear parts and components include, but are not limited to, belts, blades, blade

adapters, grass bags, rider deck wheels, seats, snow

thrower skid shoes, shave plates and tires. Batteries are

covered by a 90-day limited replacement warranty.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in

your area, please check for a listing in the Yellow Pages or

contact the Customer Service Department of MTD PRODUCTS INC by calling 1-800-800-7310 or writing to P.O. Box

368022, Cleveland, Ohio 44136-9722.

This limited warranty does not provide coverage in the

following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Please refer

to the applicable manufacturer’s warranty on these

items.

b. Log splitter pumps, valves and cylinders have a sepa-

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening and tune-ups, or adjustments such

as brake adjustments, clutch adjustments or deck

adjustments; and normal deterioration of the exterior

finish due to use or exposure.

d. MTD does not extend any warranty for products sold

or exported outside of the United States of America,

its possessions and territories, except those sold

through MTD’s authorized channels of export distribu-

tion.

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind MTD. During the period of the Warranty, the exclusive remedy is repair or replacement of

the product as set forth above. (Some states do not

allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

shall not be liable for incidental or consequential loss

or damages including, without limitation, expenses

incurred for substitute or replacement lawn care services, for transportation or for related expenses, or for

rental expenses to temporarily replace a warranted

product. (Some states do not allow the exclusion or limita-

tion of incidental or consequential damages, so the above

exclusion or limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of the safety features of the product shall void this Warranty. You assume the risk and liability for loss, damage, or

injury to you and your property and/or to others and their

property arising out of the use or misuse or inability to use

the product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for

whom it was purchased as a gift.

How State Law Relates to this Warranty: This limited

warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Loading...

Loading...