f

PFRFORMANCE

_SA_E This Instruction Book Contains Information

For Several Models. Read And Keep This Book For

ture Reference, This Book Contains Important Information On:

TY;ASSEMBLY, OPERATION AND MAINTENANCE.

PRODUCT INFORMATION

The owner must be certain that all the product information is included with this unit.

This Information includes the INSTRUCTION BOOKS, the REPLACEMENT PARTS J

and the WARRANTIES. This Information must be included to make

sure state laws and other laws are followed. JJ

Model

50565x89

Record The Following Information About Your Unit. This Information

is Necessary When Ordering Parts Or In Case Of Loss Or Theft.

WHERE PURCHASED:

DATE PURCHASED: Month Day Year

MODEL NO.: DATE OF MANUFACTURE:

BUILT iN THE

_,_12008B j

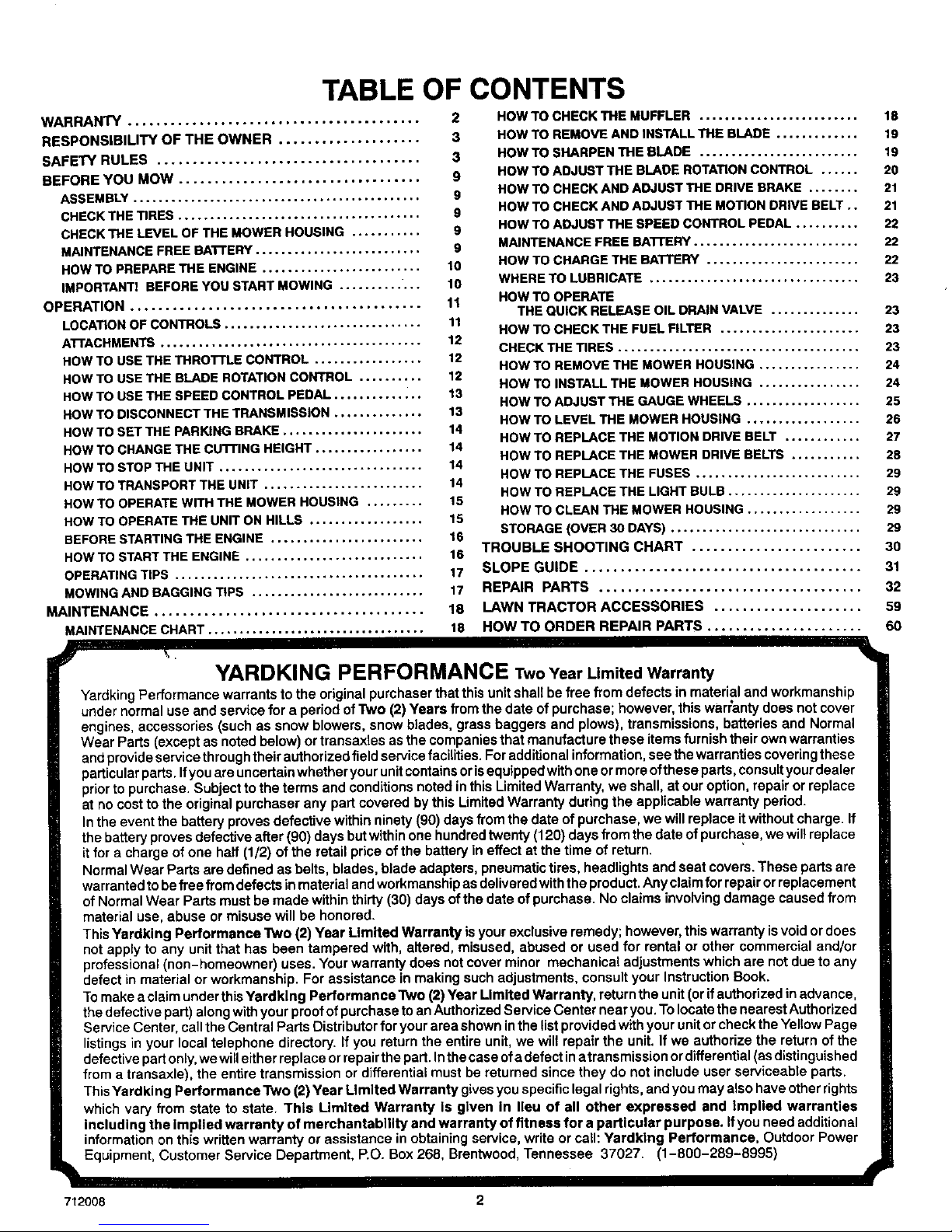

TABLE OF CONTENTS

WARRANTY ......................................... 2

RESPONSIBILITY OF THE OWNER .................... 3

SAFETY RULES ..................................... 3

BEFORE YOU MOW .................................. 9

ASSEMBLY ............................................. 9

CHECKTHE TIRES ...................................... 9

CHECKTHE LEVEL OF THE MOWER HOUSING ........... 9

HOW TO CHECK THE MUFFLER ......................... 18

HOW TO REMOVE AND INSTALL THE BLADE ............. 19

HOW TO SHARPEN THE BLADE ......................... 19

HOW TO ADJUST THE BLADE ROTATION CONTROL ...... 20

HOW TO CHECK AND ADJUST THE DRIVE BRAKE ........ 21

HOW TO CHECK AND ADJUST THE MOTION DRIVE BELT .. 21

HOW TO ADJUST THE SPEED CONTROL PEDAL .......... 22

22

MAINTENANCE FREE BA'R'ERY .......................... 9

MAINTENANCE FREE BATI'IERY ..........................

HOW TO PREPARE THE ENGINE ......................... 10

IMPORTANTI BEFORE YOU START MOWING ............. 10

OPERATION ......................................... 11

LOCATION OF CONTROLS ............................... 11

AI-rACHMENTS ......................................... 12

HOW TO USE THE THROTTLE CONTROL ................. 12

HOW TO USE THE BLADE ROTATION CONTROL .......... 12

HOW TO USE THE SPEED CONTROL PEDAL .............. 13

HOW TO DISCONNECT THE TRANSMISSION .............. 13

HOW TO SET THE PARKING BRAKE ...................... 14

HOW TO CHANGE THE CUl"FING HEIGHT ................. 14

HOW TO STOP THE UNIT ................................ 14

HOW TO TRANSPORT THE UNIT ......................... 14

HOW TO OPERATE WITH THE MOWER HOUSING ......... 15

HOW TO OPERATE THE UNIT ON HILLS .................. 15

BEFORE STARTING THE ENGINE ........................ 16

HOW TO START THE ENGINE ............................ 16

OPERATING TIPS ....................................... 17

MOWING AND BAGGING TIPS ........................... 17

MAINTENANCE ...................................... lS

MAINTENANCE CHART .................................. 18

HOW TO CHARGE THE BA'I'rERY ........................ 22

WHERE TO LUBRICATE ................................. 23

HOW TO OPERATE

THE QUICK RELEASE OIL DRAIN VALVE .............. 23

HOW TO CHECK THE FUEL FILTER ...................... 23

CHECK THE TIRES ...................................... 23

HOW TO REMOVE THE MOWER HOUSING ................ 24

HOW TO INSTALL THE MOWER HOUSING ................ 24

HOW TO ADJUST THE GAUGE WHEELS .................. 25

HOW TO LEVEL THE MOWER HOUSING .................. 26

HOW TO REPLACE THE MOTION DRIVE BELT ............ 27

HOW TO REPLACE THE MOWER DRIVE BELTS ........... 28

HOW TO REPLACE THE FUSES .......................... 29

HOW TO REPLACE THE LIGHT BULB ..................... 29

HOW TO CLEAN THE MOWER HOUSING .................. 29

STORAGE (OVER 30 DAYS) .............................. 29

TROUBLE SHOOTING CHART ........................ 30

SLOPE GUIDE ....................................... 31

REPAIR PARTS ..................................... 32

LAWN TRACTOR ACCESSORIES ..................... 59

HOW TO ORDER REPAIR PARTS ...................... 60

W \' •

YARDKING PERFORMANCE Two Year Limited Warranty

Yardking Performance warrants to the original purchaser that thisunit shall be free from defects in material and workmanship

under normal use and service for a period of Two (2) Years from the date of purchase; however, this wan:anty does not cover

engines, accessories (such as snow blowers, snow blades, grass baggers and plows), transmissions, batteries and Normal

Wear Parts (except as noted below) or transaxles as the companies that manufacture these items furnish their own warranties

and provideservice through their authorized field service facilities. Foradditional information, see the warranties covering these

particularparts, If you are uncertain whether your unit containsoris equipped withone ormore ofthese parts, consult your dealer

priorto purchase. Subject to the terms and conditions noted in this Limited Warranty, we shall, at our option, repair or replace

at no cost to the original purchaser any part covered by this Limited Warranty during the applicable warranty period.

In the event the battery proves defective within ninety (90) days from the date ofpurchase, we will replace it without charge If

the battery proves defective after (90) days but within one hundredtwenty (120) days from the date of purchase, we wilt replace

it for a charge of one hall (1/2) of the retail price of the battery in effect at the time of return.

Normal Wear Parts are defined as belts, blades, blade adapters, pneumatic tires, headlights and seat covers. These parts are

warranted to be free from defects in material and workmanship as delivered withthe product. Any claimfor repair or replacement

of Normal Wear Parts must be made within thirty (30) days ofthe date of purchase. No claims involving damage caused from

material use, abuse or misuse will be honored.

This Yardklng Performance Two (2) Year Limited Warranty is your exclusive remedy; however, this warranty isvoidor does

not apply to any unit that has been tampered with, altered, misused, abused or used for rental or other commercial and/or

professional (non-homeowner) uses. Your warranty does not cover minor mechanical adjustments which are not due to any

defect in material or workmanship. For assistance in making such adjustments, consult your Instruction Book.

To make a claim under thisYardklng Performance Two (2) Year Limited Warranty, return the unit (or ifauthorized inadvance,

the defective part) alongwith your proof of purchase to an Authorized Service Center near you. To locate the nearest Authorized

Service Center, call the Central Parts Distributorfor yourarea shown inthe listprovided with your unitor check the Yellow Page

listings in your local telephone directory. If you return the entire unit, we will repair the unit, If we authorize the return of the

defective part only,we willeither replace orrepair the part. Inthe case ofa defectin atransmission or differential (as distinguished

from a transaxle), the entire transmission or differential must be returned since they do not include user serviceabte parts.

ThisYardking Performance Two (2) Year Limited Warranty gives you specific legal rights, and you may also have other rights

which vary from state to state. This Limited Warranty is given in lieu of all other expressed and Implied warranties

including the implied warranty of merchantability and warranty of fitness for a particular purpose. Ifyou need additional

information on this written warranty or assistance in obtaining service, write or caU:Yardking Performance, Outdoor Power

IL Equipment, Customer Service Department, P.O. Box 268, Brentwood, Tennessee 37027. (1-800-289-8995)

i

712008 2

OWNER'S INFORMATION

Thisinstruction book isfor several different models. The instructions

are writtenfor a personwith some mechanical ability.Like most ser-

vice books,not allthe steps are described. Steps onhowto loosenor

tightenfasteners are steps anyone can followwithsome mechanical

ability.Read and followthese instructions before you use the unit.

Knowyour product: Ifyou understandthe unitand howthe unitoper-

ates,youwillgetthebestperformance.Asyou readthis manual,com-

pare the illustrationstothe unit.Learnthe location and the function of

thecontrols.Tohelp prevent an accident, followtheoperating instruc-

tionsandthesafetyrules. Keepthis manualfor future reference.

IMPORTANT: Many units are not assembled and are sold in car-

tons. Itisthe responsibility of the owner to make sure the assembly

instructionsin this manual are exactly followed. Other unitsare pur-

chased in an assembled condition. On assembled units, it is the re-

sponsibility of the owner to make sure the unit is correctly

assembled. The owner must carefully check the unit according to

the instructions in this manual before it is first used.

RESPONSIBILITY OF THE OWNER

The responsibility of the owner is to follow the instructions below.

1. Carefuny read and follow the rules for safe operation.

2. Follow all the assembly instructions.

3. Inspect the unit.

4. Make sure that the operator of the unit knows how to correctly

use all standard and accessory equipment.

5. Operate the unit only with guards, shields, and other safety

items in place and working correctly.

6, Correctly adjust the unit.

7. Service the unit onlywith authorized or approved replacement

parts.

8. Complete all maintenance on the unit.

Environmental Awareness

• Do not fill the engine's fuel tank completely full.

• Drain fuel for off-season storage.

• Use only unleaded gasoline.

• Service the air cleaner regularly.

• Change oil regularly. Use 30W oil in summer.

• Change oil regularly. Use 10W-30 oil in summer.

• Tune-upthe engine regularly.

• Keep equipment in efficient operating condition.

• Dispose of used engine oil properly.

SAFETY RULES

Safe Operation Practices for Ride-on Mowers

_ ARNING: This cultlng machine Is capable of amp_atlng hands and feet and throwing objects. Failure to obee_,e the

following safety Instructions could result in serious Injury or death.

I. General operation

t. Read, understandandfollowallinstructionsinthelnstruction Book,onthemachine,theengineandwith anyattachments before starting.

2. Only allow responsible adults, who are familiar with the instructions, to operate the machine.

3. Clear the area of objects such as rocks, toys, wire, etc., which could be picked up and thrown by the blade.

4. Be sure the area is clear of other people before mowing. Stop the machine if anyone enters the area.

5. Never carry passengers.

6. Turn off power to the blades or any attachments before backing up. Do not mow in reverse unless absolutely necessary. Always look

down and behind before and while backing.

7. Be awareofthe mowerdischargedirection and do notpointitat anyone. Do notoperatethe mowerwithouteither the entiregrass bagger

or the mower guard in place.

8. Slow down before turning.

9. Never leave a machine unattended with the engine running. Always turn off the blade(s), set the parking brake, stop the engine and

remove the key before dismounting.

10. Turn off power to attachment(s) when transporting or not in use. Turn off the blade(s) when not mowing.

11. Stop the engine before removing the grass bagger or unclogging the chute.

12. Mow only in daylight or good artificial light.

13. Do not operate the machine while under the influence of alcohol or drugs or when very tired.

14. Watch for traffic when operating near or crossing roadways.

15. Use extra caution when loading or unloading the machine into a trailer or truck.

16. Turn off all attachment clutches before attempting to start the engine.

17. Alwayswearg_ggIes,safetyg_asses_raneyeshie_dwheny_u_peratetheunitt_pr_tecty_ureyesfr_mf_reign_bjectsthatcanbe

thrown from the unit. Always wear eye protection when you make an adjustment or repair to the machine.

18. Use care when pulling loads or using heavy equipment.

a. Use only approved drawbar hitch points.

b. Limit loads to those you can safely control.

c. Do not turn sharply. Use care when backing.

d. Use counterweights or wheel weights when suggested in the Instruction Book.

19. Do not operate this machine if you are taking drugs or other medication which can cause drowsiness or affect your abildy to operate

this machine.

712008

OWNER'S INFORMATION

20, Do notuse this machine if you are mentally or physically unable to operate this machine safely.

II. Slope operation

Slopes and rough terrain are major factors related to loss-of-control and tip-over accidents, which can result In severe injury

or death. ALL slopes require extra caution. If you cannot back up the slope or if you feel uneasy on the slope, do not mow it. See

the "Slope Guide" In the back of this book to check for safe operation.

DO

1. Mow up and down slopes, not across.

2, Remove obstacles such as rocks, limbs, etc...

3. Watch for holes, ruts or bumps. Uneven terrain could overturn the machine. Tallgrass can hide obstacles.

4. Use slow speed on slopes. Do not make sudden speed changes.

5. Follow the manufacturer's recommendations for wheel weights or counterweights to improve stability.

6. Use extra care with grass baggers or other attachments, they can change the stability of the machine,

7. Keep all movement on the slopes slow and gradual. Do not make sudden changes in speed or direction.

8. Avoid starting or stopping on a slope. If tires lose traction, turn off the blades and proceed slowly straight down the slope.

DO NOT

1. Do not turn on slopes unless absolutely necessary, then only turn slowly and gradually downhill, ifpossible.

2. Do not mow drop-offs, ditches or embankments. A wheel over the edge or an edge caving in could cause a sudden overturn and an

injury or death.

3. Do not mow on wet grass. Reduced traction could cause sliding,

4. Do not try to stabilize the machine by putting your foot on the ground.

5. Do not use a grass bagger or other rear mounted accessories on Steep slopes (greater than 10 degrees).

III. Children

Tragic accidents can occur if the operator Is not alert to the presence of children. Children are often attracted to the machine and

the mowing activity. NEVER assume that children will remain where you last saw them.

1. Keep children out of the mowing area and in the watchful care of another responsible adult.

2. Be alert and turn the engine off ifchildren enter the area.

3. Before and when backing, look behind and down for small children.

4. Never carry c_'lildrenorany passengers, even with the blades off. They may fall off and be seriously injured or interfere with the safe

operation of the machine,

5. Never allow children to operate the machine. Instruct children in the potential dangers of the machine.

6. Use extra care when approaching blind corners, shrubs, trees or other objects that may obscure vision.

IV. Service

t, Use extra care when handling gasoline and other fuels. Fuels are flammable and the vapors are explosive.

a, Use only an approved container.

b. Never remove the gas cap or add fuel with the engine running, Allow the engine to cool for several minutes before refueling, bo

not smoke.

c. Never refuel the machine indoors.

d. Never store the machine with fuel in the tank or fuel container inside where there is an open flame, such as a water heater.

2. Never start or run the engine inside a closed area.

3. Keep all nuts and bolts, especially the blade attachment nutstight. Frequently check the blade(s) for wear or damage such as cracks

and nicks. A blade that is bent or damaged must be immediately replaced with an original equipment blade from an authorized service

dealer. For safety, replace the blade every two years. Keep the equipment in good condition.

4. Never tamper with the safety devices. Check their proper operation regularly,

5. To reduce fire hazards, keep the machine free of grass, leaves or other debds build-up. Clean up oil or fuel spills. Allow the machine

to cool before storing.

6. Stop and inspect the equipment if you strike an object. Repair, if necessary, before restarting.

7. Never make adjustments or repairs with the engine running. The carburetor can be adjusted with the engine running. Do not change

the engine governor settings or over-speed the engine.

8. Grass bagger components are subiect to wear, damage and detedoration, which could expose moving parts or allow objects to be

thrown. For storage, always make sure the grass bag is empty. Frequently check components and replace with manufacturer's recom-

mended parts when necessaTy.

9. Mower blade(s)are sharp end can cut. Wrap the blade(s)or wear gloves and use extra caution when servicing them orthe blade housing

area.

10. Check the brake operation frequently. Adjust and service as required.

11. Wait for all movement to stop before servicing any part of the unit.

Look for this symbol to Indicate Important safety

precautions. This symbol Indicates: "Attentlonl

Become Alertl Your Safety Is At Risk."

712008

4

Eachpersonthatoperatespower

equipmentmustlearntousecorrectand

safe mowing procedures. To help you

learn, carefully read the following

pages. Most of the time the operator was

not correctly shown or did not read the

instructions on the unit or in the Instruction

Book before using the unit. Also, some

operators do not have enough experience.

The result is unsafe use, endangering the

operator, bystanders and the equipment.

Another result can be a poor appearance

of the area mowed.

Read this book. Read the instructions on

the unit. Operate the mower according to

the Safe Mowing Guide. Follow all safety

rules, cautions or warnings in this book

and on the unit. Make sure anyone that

uses the unit reads the instructions and is

told how to safely operate the mower.

The mower will give you good service and

durability, if operated in normal conditions.

tfthe mower is not correctly serviced or is

used where the terrain is rough or

unsuitable, product performance and

safety will be decreased.

Correct clothing is an important part of safe

mowing. Safety glasses will protect the

eyes from objects discharged by the

mower. Safety shoes with steel plates can

protect a foot from injury by the blade. For

protection from objects discharged from

the mower, wear clothing that will cover the

arms and legs.

Before you start cutting the grass, practice

using the mower in a large open and level

area. Learn the location of the controls on

the mower. Know the purpose of the

712008

SAFE MOWING GUIDE

controls and how they work. In an

emergency, how fast you can stop the

blade is important. Learn how to control

the mower at all times.

Many engines are started by hand. When

you use a pull start or rope start, place

your feet apart and away from the blade(s).

Hold the rope handle tight. Never wrap the

rope around your arm or fingers for •

"better grip". To start the engine, follow the

instructions on the mower, in this book and

in the engine operating instructions.

For electric start engines, sit in the seat to

start the engine. The battery can be

dangerous. Follow the instructions on the

battery, the acid container, and in this book

when working with the battery. Even small

batteries have enough voltage to cause an

injury.Always be careful.

The mower is designed to be operated by

one person. Never let another person ride

with you on the unit or on any accessories.

A passenger will make the unit harder to

control, blockthe visibility or distract the

operator and is dangerous to the operator,

the passenger and the equipment. Without

a passenger seat, the passenger can fail

from the mower or contact dangerous

parts. A mower is not a toy for showing off

or for giving rides,

Never cut a wet lawn. Wet grass can

cause an accident, affect mower

performance and can cause problems with

future lawn growth and appearance. Wet

grass is slippery and can cause the mower

to slip. Someone can get injured by

touching the blade(s). Wet grass tends to

clogthe mower, causing poor discharge.

Cut wet grass will collect on the lawn,

retarding the growth of the grass. Also,

getting the mower wet will cause parts to

rust and decrease the life of the unit.

When you look over the lawn, remember

obstacles that cannot be removed, like

pipes, stumps or rocks. Keep away from

these obstacles that can cause damage to

the mower or injury to the operator or a

person near the mower, Clear the area of

rocks, toys, wire or other loose objects.

These items can damage the mower or

can be discharged by the mower blade.

The blade of a power mower rotates very

fast. It can discharge rocks and other

objects over a long distance which can be

dangerous. The force of the objects can

break windows, cause injuries or even put

an eye out. Most of the time the injury is to

a person, like a child. Keep every person

completely away from the area to be

mowed. Make sure the grass is not

discharged toward anyone. Planning your

mowing pattern has a double advantage. It

can decrease the possibility of an injury

and make the clean up after mowing

easier.

Check the terrain of the area to be mowed.

Mow in a pattern that wilt keep you away

from dangerous areas. Check the distance

you need to stop and the distance

available to turn. Slopes and rough terrain

must be mowed carefully and some areas

must not be mowed at all. With riding

mowers, mow up and down the hill. When

you must mow rough terrain or on slopes,

drive slowly and stop in these areas only in

an emergency. Before you ride up or down

a slope, try to back straight up the slope.

Do notride up or down a slope that is too

steep to back straight up. See the "Guide"

in the back of this Instruction Book to

check any slopes.

Before you start cutting, make sure the

mower was completely assembled

according to the instruction P..':':.k.If the

mower was completely assembled at the

store, you must still check the mower

according to the assembly instructions.

Make sure the mower is correctly

assembled and that all fasteners are tight.

Make sure the engine has the correct

amount of oil. Check these items often

during the life of the mower.

Your mower has a gasoline engine.

Gasoline is a dangerous fuel. Keep

gasoline only in an approved safety

gasoline container. Do not keep large

amounts of gasoline. When you add

gasoline to the fuel tank, do not smoke.

Store the gasoline container and the

mower in an area that has good ventilation.

Also, keep the gasoline away from any

flames tike the pilot light of a furnace or

any other source of ignition. If the mower is

to be stored for more than a few weeks,

remove the gasoline from the fuel tank.

When inside an enclosure, do not add

gasoline to the fuel tank. Before you add

gasoline, move the mower outside and add

gasoline carefully. Before you start the

engine, remove any gasoline from the

outside of the fuel tank or from the mower.

Warm gasoline will expand. Leave some

space in the fuel tank for the gasoline to

expand. Also, the fuel cap has a vent hole

for fuel vapors. Always use the correct fuel

cap. Failure to follow safety rules about

gasoline will caus_efires and explosions,

injury to you anda&mage to the equipment

and other property.

If you add gasoline to an engine that is

running or hot, the result can be an

explosion. Before you add gasoline, stop

the engine and let the engine cool for

several minutes. Remove dry grass and

other debris from the mower. Keep the

mower clean to improve the performance,

help the engine and transmission run

cooler, extend the life of moving pads, and

decrease the danger of a fire.

Fires and explosions are not the only

dangers when working around a mower.

The engine, transmission, and the muffler

will get hot in several minutes when the

engine isrunning. Do not touch these parts

of the mower. Stop the engine. Let the

712008

SAFE MOWING GUIDE

engine and transmission cool before

servicing the mower. Remember, exhaust

fumes are dangerous. Never operate the

engine inside a building.

When youget a newmower,itcanbea

newexperienceforthe family.Telleach

personhowa mowercan be dangerous.

Remember, a mowerisnota toy.A mower

isnottobe usedbychildrenoranyonenot

oldenough,strongenoughorthatdoesnot

haveexperience.

If the mower is not correctly assembled,

not operated correctly, or not regularly

serviced, the mower can be dangerous.

The most important rule tofollow is always

use good judgement and common sense.

Mow safely and carefully.

Your mower will easily cut thick grass.

Fingers, feet and other parts can also be

cut by the blade. Injuries occur when the

operator does not think and reaches into

the chute opening. Always operate the

mower as ifthe blade is rotating. Do not

service or make an adjustment, except to

the carburetor, while the engine is running.

When you mow, remember that children

are attracted to the mower. Always use

caution when mowing around obstacles

like trees or shrubs or when moving

backward. Only mow in a forward direction

if possible. Your visibility is decreased

when you mow backward. Also, the blades

are made to cut while the unit is moving

forward. If you mow backward, the cutting

performance decreases.

Before you leave the mower, stop the

engine. Remove the key. Disengage and

lower any attachment. Set the parking

brake. Never mount or dismount from the

seat while the engine is running. An

accident can occur ifyou touch the brake,

speed control pedal, throttle, or blade

control while the engine is running. Mount

and dismount from the seat on the side of

the unit that is marked ENTER-EXIT.

Use onlyaccessoriesthatare factory

approvedfor yourmower.Thewrong

accessory candecreasethe safetyofthe

mowerand can evendamagethe unit.

Read andfollowthe instructions included

withthe accessoryandthe mower.

Use only originalequipmentor

replacementpartsthat arefactory

approvedforservice.Ifyouneed service,

selectan Authorized ServiceCenterfor

yourmower.Ifyoudothe workonthe unit,

followtheinstructionsInthe Instruction

Book.

Make sure you are in good condition when

you mow. When you mow for several hours

your reflexes will decrease and your mind

will not be as alert. Take a short break or

an accident can occur. If the temperature is

hot, use caution to prevent dehydration. If

you are tired, angry or not completely alert,

do not operate the mower. If you use

alcohol, medication or drugs, do not use

the mower or any type of power

equipment.

Engine speed is a key to safe mowing and

to a good looking lawn. The maximum

speed of the engine was set at the factory.

Do not change the setting of the engine

governor.

Select the maximum engine and ground

speed that is right for the terrain and the

height of the grass. The blade cuts best

when the engine is operating at maximum

speed. The engine and transmission will

also run cooler at maximum engine speed.

6

SAFE MOWING GUIDE

Also, the grass bagger will function better

when the engine is operating at maximum

speed. On slopes, decrease the ground

speed and use care making sure the

mower feels safe to operate.

If the weather conditions are bad, do not

mow. If weather conditions become bad,

stop cutting and finish later. It is dangerous

to cut grass in the rain. Always find

protection in an electrical storm. If the

weather conditions are extra dry, protect

your eyes with safety glasses from the dust

and from the objects discharged by the

mower. Also, a dust or a pollen mask can

help.

Your mower is equipped with a number of

safety devices which are important to the

safety of the operator and bystanders and

must never be changed or removed from

the mower. If a safety device is lost,

damaged or no longer functions, repair or

replace the device before you operate the

mower.

It is best to mow during the day. If you

must mow at night, make sure there is

enough light for safe operation.

Your mower will require regular

maintenance and service. The

maintenance schedule depends on the

hours of use. Also, mowing conditions can

change the schedule. Check the

Instruction Book for more information.

Correct maintenance will help the mower

function safely.

Do not service the

mower (except for the

carburetor adjustment)

while the engine is m,.

running. Before you I_

service the unit, even t_]_

with the engine stopped,W I''

always disconnect the

wire from the spark plug

to prevent the engine

from starting.

If you hit a large object during operation,

stop the engine. Remove the wire from the

spark plug. Carefully inspect the mower for

damage. Before you start the engine

again, make the necessary repairs. If you

feel new or excessive vibration,

immediately stop the engine and check for

the problem. Vibration can be a warning of

a problem. Keep all nuts, bolts and screws

tight.

The blade is the most dangerous part of

the mower. Frequently check the blade and

the blade mounting fasteners. Keep the

fasteners tight. If the blade hits a solid

object, stop the engine. Remove the wire

from the spark plug. Check for a blade that

is bent, cracked or for other damages.

Before you start the engine, replace a

damaged blade(s). For safety, replace the

blade every two years.

A sharp blade decreases the workload on

the engine and more evenly cuts grass.

Frequently sharpen the blade for a better

looking cut. Use the left side of the mower

housing to trim near an object.

A grass bagger is a good accessory for

your mower. For best performance and

safety, make sure the grass bagger is

approved for use with your mower. Follow

the assembly and operation instructions

included with the grass bagger.

Some grass baggers require a special

blade for best performance. Before you

attach, check, or empty the grass bagger,

always stop the engine. Before each use of

the grass bagger, check for cracks, wear or

deterioration. Before you use the grass

bagger, replace a damaged part with a

replacement part approved bythe factory.

For you to have a good green lawn, follow

the mowing procedures below. Do not cut

the grass too short. If you cut the grass too

short you can cause the grass to become

yellow or make the lawn look brown. Use a

lower height of cut in cool months when

the grass is thicker. Raise the height of cut

in hot dry periods. Ifyou cut the grass with

a blade that is not sharp or at a slow

engine speed you can damage the grass.

Move the throttle control to the FAST

position when mowing and using the grass

bagger. Also, use a slower ground speed

when using the grass bagger.

If yau change the direction or pattern of cut

slightly every time you mow will make the

grass grow stronger and thicker. Do not

add oil or gasoline to the mower while on

the lawn. Spilled oil or gasoline can kill the

grass. In high or thick grass, do not try to

cut all the grass the first time. Raise the

height of cut on the first cutting and lower

the height for the next cutting. Another way

is to cut only part of the width of the mower

and decrease your ground speed (not the

engine) to move more slowly so that the

mower can discharge the grass as it

moves forward.

Understand the controls and how they

work. Learn the ground speed(s) of your

mower. Check the stopping distance

required at different travel speeds. Check

the turning radius of the mower. The

controls on your riding mower are different

from an automobile. The throttle is

operated by hand and holds the engine

speed constant until it is changed. The

location of the travel speed control is

different from that of an automobile. Also,

the brake and clutch systems are different.

Remember the procedures to follow in an

emergency. Remember, turning off the

engine ignition switch will stop the blade

and the ddve mechanism. If the traction of

the wheels is lost or does not feel safe,

disengage all systems and stop the

engine. Dismount from the mower. Push

the unit to a safe place before you begin

mowing again,

Your unit has an electrical system that

includes an operator presence switch in

the seat. The operator presence switch

detects if the operator is sitting on the seat.

The engine will stop if the operator leaves

the seat when the blade engagement

control is engaged. This operator presence

switch is a safety device only. It must not

regularly be used to stop the engine or the

blade. There are other control systems on

the mower for this purpose. Always keep

the operator presence switch and other

safety devices and controls in place and

operating for your protection.

Remember, your mower is a tool that can

be dangerous if it is not correctly used.

Follow the instructions in this Instruction

Book. Safe and careful use of the mower

will give you many safe hours of problem

free use,

712008 7

STEPS TO FOLLOW

BEFORE MOWING

• Be sure to dress correctly. Wear hard shoes, not sandals or tennis shoes.

• Examine the blade. A blade that is bent, cracked, or damaged must be replaced with a factory replacement blade.

• Fill the fuel tank outside. Clean off spilled fuel.

• Read and follow the Owner's Manual, the instTuctions with the engine, and the instructions with any attachments. Owner's Manual

instructions are for your safety and the safety of others.

• Exhaust fumes are dangerous. Start the engine outside.

• Make sure all safety devices are in place and working correctly.

• Operation ofthe mower is only for a person that has experience.

• Wet grass can be dangerous. Let the grass dry.

• Instruct children and others to keep away from the work area.

• Never cut the grass without good light.

• Pick up loose objects. Remove them from the mowing area.

WHILE MOWING

• Watch for fixed objects and avoid them. They can damage the mower or cause injury.

• A hot engine, muffler, and transmission will cause a burn. Do not touch.

• Inclines and slopes must be carefully mowed. See the "Guide" in the back of this book to check a slope.

• Lack of daylight or good artificial light is cause to stop mowing.

• Examine the mower, the blade, and other parts for damage after hitting a foreign object or if the unit vibrates excessively.

• Do not make adjustments or repairs without stopping the engine. Disconnect the spark plug wire.

• On or near r_ads, watch out for traffic. Direct discharge away from roads.

• When mowing, avoid areas where traction is unsure. Look back before changing direction of travel.

• Inheavy grass, raise the cutting height. Cut slower. Stop the engine to remove clogged grass from the mower.

• Never remove any safety related parts.

• Do not pour gasoline into a engine that is hot or running.

AFTER MOWING

• AJways let the mower cool before storing in an enclosed area.

• Foreign material on the mower is dangerous. Clean off grass, leaves, grease and oil before storing.

• Tighten all loose nuts, bolts and screws before you use the unit.

• Empty and clean any grass catcher or other accessory.

• Remove the key °r disc°nnect the spark plug wire to prevent unauth°rized use"

• Make sure the mower is not kept near a source of ignition. Gas fumes can cause an explosion.

• Only original parts or factory approved substitutes can be used to service the mower.

• When storing the mower for an extended period, remove the fuel from the fuel tank.

• Instruct children to leave the mower alone. It is not a toy.

• Never keep gasoline near a source of ignition. Always use an approved container. Keep gasoline away from children.

• Lubricate according to the Instruction Book. See "Lubrication".

IMPORTANT--Read the Instruction Book. Keep this book for future use and reference.

,_ WARNING: Look for this symbol to point out important

safety precautions. It means: "Attention! Become Alert!

Your Safety Is Involved."

712008 8

BEFORE YOU MOW

ASSEMBLY

This instruction book isfor several models. Some parts oraccesso-

ries are not included on all models. Read and follow the assembly

and adjustment instructions for your mower. Do not discard any

parts or material untilthe unit is assembled.

A WARNING: Before doing any assembly or mainte-

nance to the mower, remove the wire from the spark

plug.

NOTE: In this Instruction book, left and right describe the loca-

tion of a part with the operator on the seat.

CHECK THE TIRES

Check the air pressure inthe tires. "13reswith too much air pressure

will cause the unit to ride rough. Also, the wrong air pressure will

keep the mower housing from cuttinglevel. The correct airpressure

(PSI) is 14 PSI (1 BAR). The tires were over inflated for shipment.

CHECK THE LEVEL OF THE MOWER HOUSING

Make sure the level of cut is still correct. After you mow a short

distance, look at the area that was cut. Ifthe mower housing does

not cut level, see the instructions on "How To Level The Mower

Housing" in the Maintenance section of this instruction book.

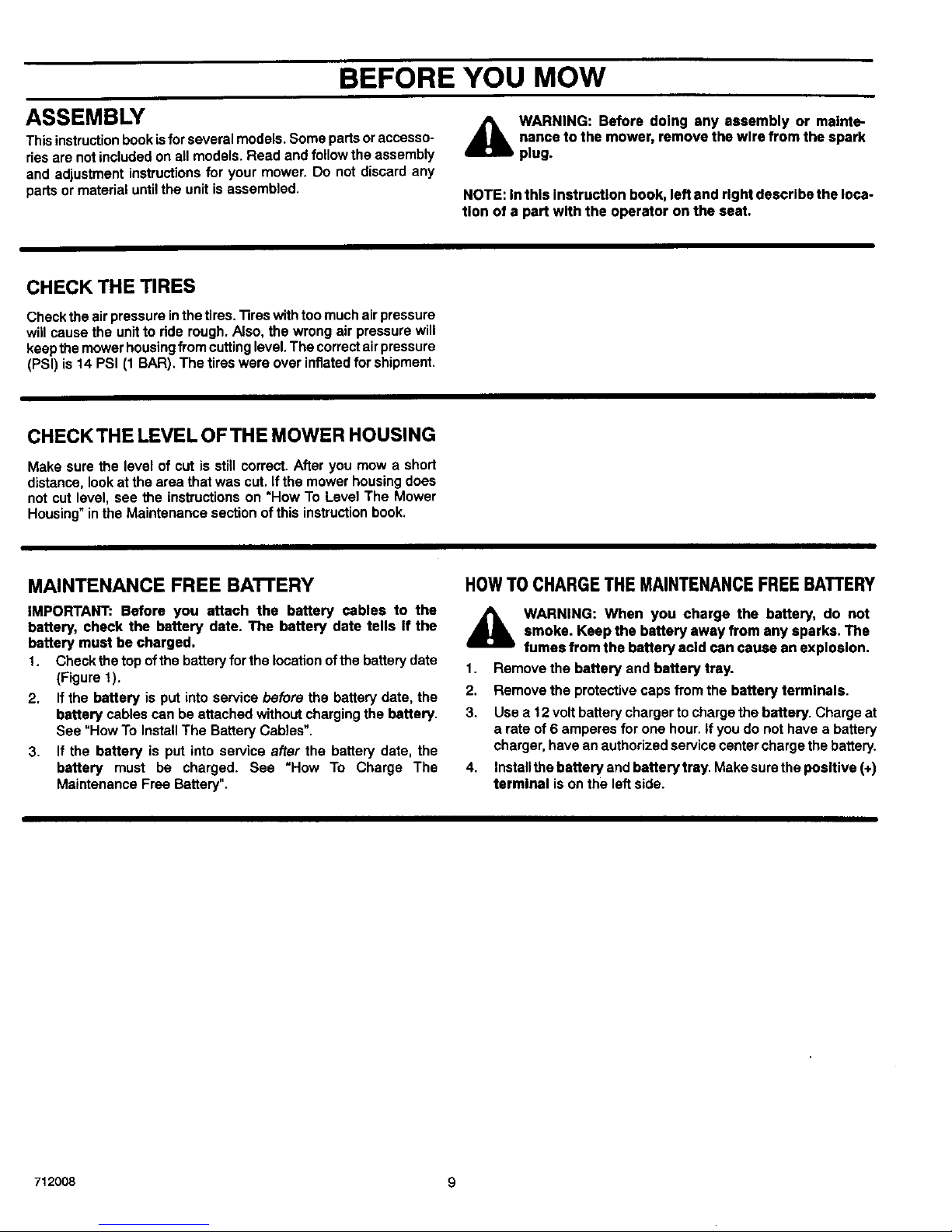

MAINTENANCE FREE BA'I-rERY

IMPORTANT: Before you attach the battery cables to the

battery, check the battery date. The battery date tells If the

battery must be charged.

t. Check the top ofthe battery for the location of the battery date

(Figure t).

2. If the battery is put into service before the battery date, the

battery cables can be attached without charging the battery.

See "How To Install The Battery Cables".

3. If the battery is put into service after the battery date, the

battery must be charged. See "How To Charge The

Maintenance Free Battery".

HOWTOCHARGETHEMAINTENANCEFREEBATrERY

A

1.

2.

3.

4.

WARNING: When you charge the battery, do not

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

Remove the battery and battery tray.

Remove the protective caps from the battery terminals.

Use a 12 volt battery charger to charge the battery. Charge at

a rate of 6 amperes for one hour. if you do not have a battery

charger, have an authorized service center charge the battery.

Install the battery and battery tray. Make sure the positive (+)

terminal is on the left side.

712008 9

BEFORE YOU MOW

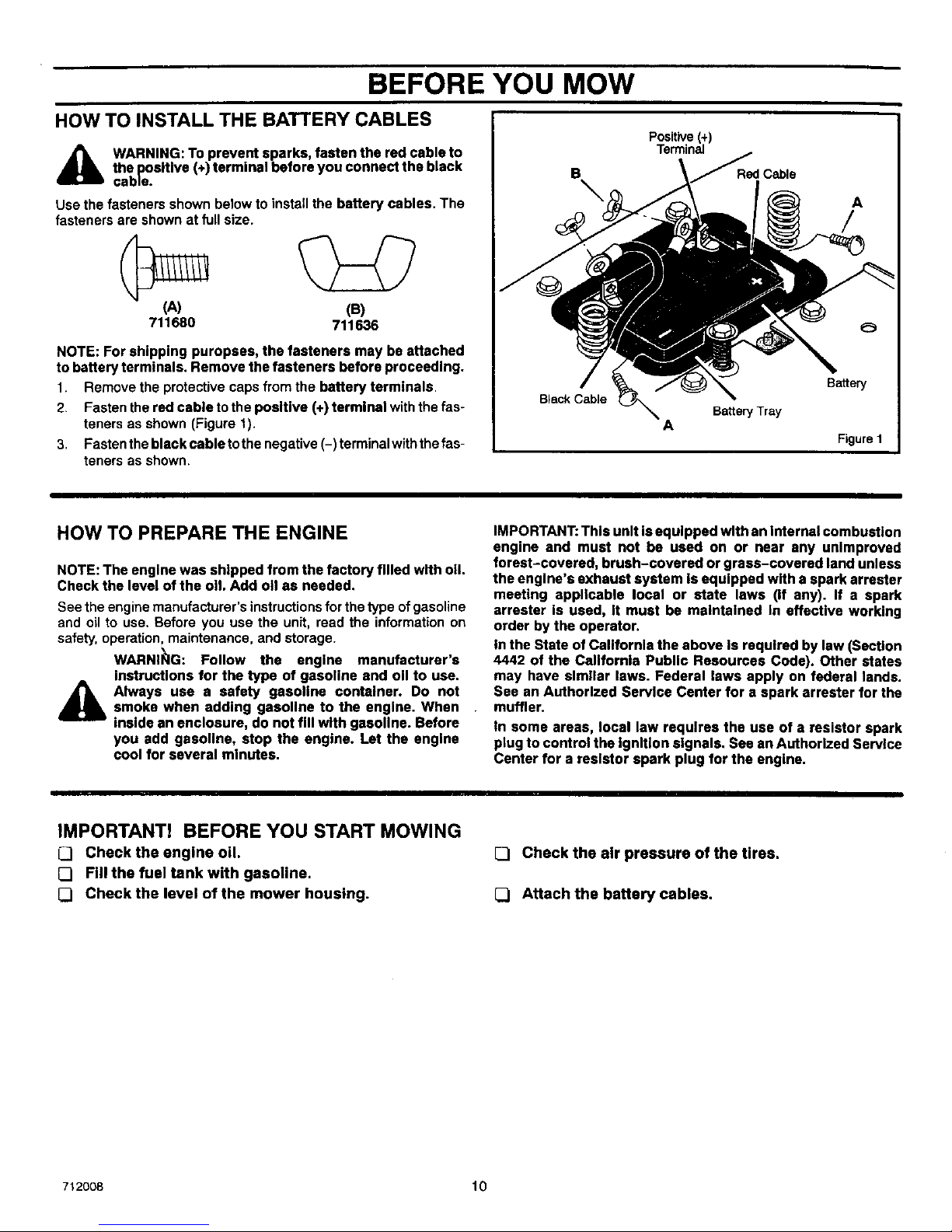

HOW TO INSTALL THE BATTERY CABLES

_ WARNING: To prevent sparks, fasten the red cable to

the positive (+) terminal before you connect the black

cable.

Use the fasteners shown below to install the battery cables. The

fasteners are shown at full size.

(A) (B)

711680 711636

NOTE: For shipping puropses, the fasteners may be attached

to battery terminals. Remove the fasteners before proceeding.

1. Remove the protective caps from the battery terminals,

2. Fasten the red cable to the positive (+) terminal with the fas-

teners as shown (Figure t).

3, Fasten the black cable to the negative (-) terminal with thefas-

teners as shown.

B

Black Cable

Positive(+)

Terminal

A

Battery Tray

A

/

Battery

Figure I

I

HOW TO PREPARE THE ENGINE

NOTE: The engine was shipped from the factory filled with oil

Check the level of the oil Add oll as needed.

See the engine manufacturer's instructionsfor the type of gasoline

and oil to use. Before you use the unit, read the information on

safety, operation, maintenance, and storage.

WARNI_IG: Follow the engine manufacturer's

instructions for the type of gasoline and oll to use.

_lk lways use a safety gasoline container. Do notsmoke when adding gasoline to the engine. When

inside an enclosure, do not fill with gasoline. Before

you add gasoline, stop the engine. Let the engine

cool for several minutes.

IMPORTANT: This unit is equipped with an Internal combustion

engine and must not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless

the engine's exhaust system Is equipped with a spark arrester

meeting applicable local or state laws (If any). If a spark

arrester is used, It must be maintained in effective working

order by the operator.

In the State of California the above Is required by law (Section

4442 of the California Public Resources Code). Other states

may have similar laws. Federal laws apply on federal lands.

See an Authorized Service Center for a spark arrester for the

muffler.

tn some areas, local law requires the use of a resistor spark

plug to control the Ignition signals. See an Authorized Service

Center for a resistor spark plug for the engine.

IMPORTANT! BEFORE YOU START MOWING

CJ Check the engine oil.

[] Fill the fuel tank with gasoline.

[] Check the level of the mower housing.

[] Check the air pressure of the tires.

[] Attach the battery cables.

712008 10

OPERATION

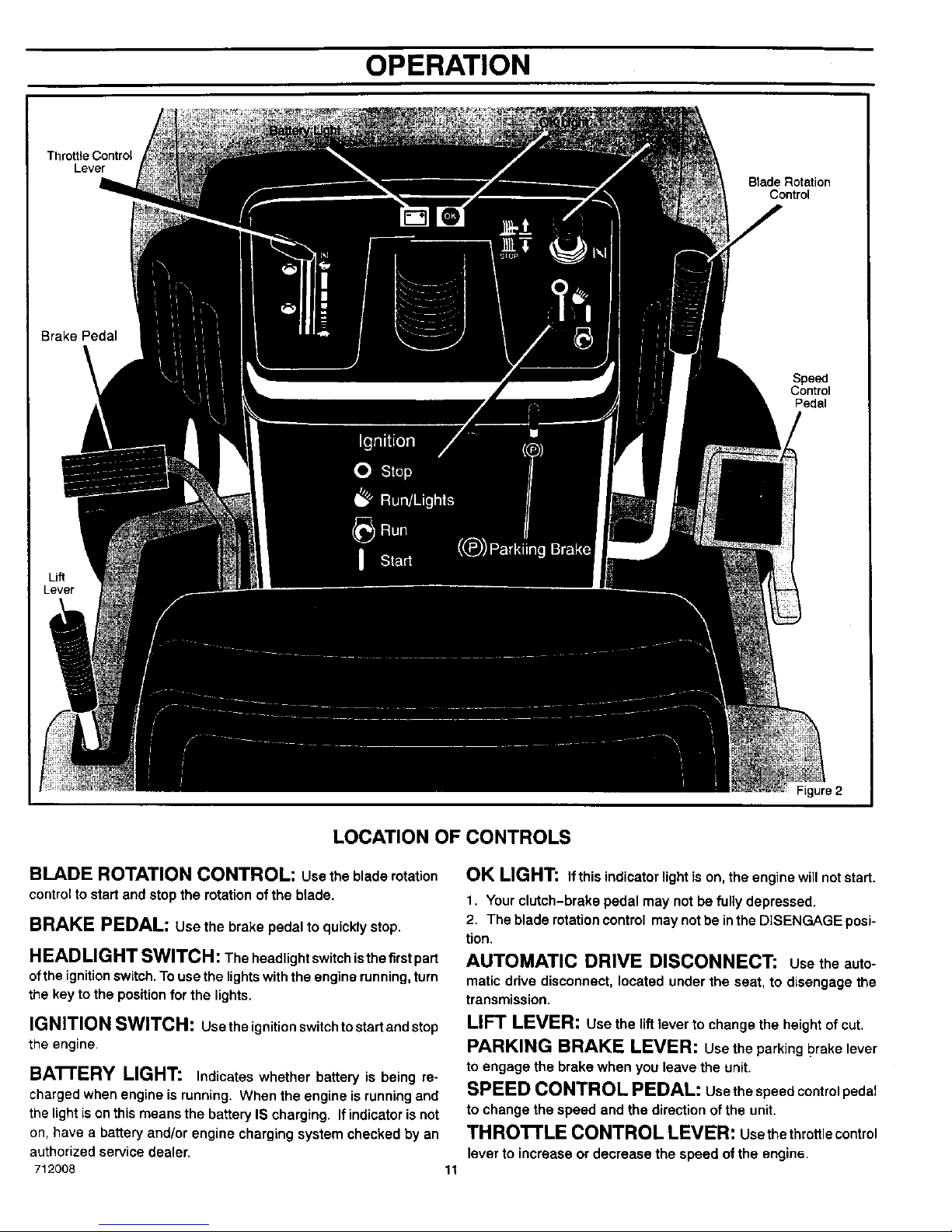

Throttle Control

Lever

Blade Rotation

Control

Brake Pedal

Speed

Control

Pedal

Lever

Figure 2

LOCATION OF CONTROLS

BLADE ROTATION CONTROL: usethebladerotation

control to start and stop the rotation of the blade.

BRAKE PEDAL: use the brake pedal to quickly stop.

HLAD LIGHT SWITCH: The headlight switch isthe firstpart

ofthe ignitionswitch. To use the lightswith the engine running, turn

the key to the position for the lights.

IGNITION SWITCH: Usetheignitionswitchtostartandstop

the engine.

BATTERY LIGHT: Indicates whether battery is being re-

charged when engine is running. When the engine is running and

the light is on this means the battery IS charging. If indicator is not

on, have a battery and/or engine charging system checked by an

authorized service dealer.

712008 11

OK LIGHT: If this indicator light is on, the engine will not start.

1. Your clutch-brake pedal may not be fully depressed.

2. The blade rotation control may not be inthe DISENGAGE posi-

tion.

AUTOMATIC DRIVE DISCONNECT: usetheauto-

maticdrive disconnect, located under the seat, to disengage the

transmission.

LIFT LEVER: use the lift lever to change the height of cut.

PARKING BRAKE LEVER: usethe parkingI?rakelever

to engage the brake when you leave the unit.

SPEED CONTROL PEDAL: usethespeedcontrolpedal

to change the speed and the direction ofthe unit.

TH ROTTLE CONTROL LEVER: usethethrottlecontrol

lever to increase or decrease the speed of the engine.

OPERATION

ATrACHMENTS HOWTO USETHE BLADE ROTATIONCONTROL

This unitcan use many different attachments. See the attachment

page in this book. This unit can pull attachments like a lawn

sweeper, a lawn aerator, or a hopper spreader. This unit can not use

attachments that engage the ground like a plow, a disk harrow, or

a cultivator.

HOW TO USE THE THRO'I-rLE CONTROL

Use the throttle control to increase or decrease the speed of the

engine

CAUTION: Always operate the engine with the throttle control

in the FAST position. If the engine runs for several minutes at

slower than the FAST position, the engine and transmission

will overheat and can be damaged.

1. The FAST position is marked with a detent. For normal opera-

tion and when using a grass bagger, move the throttle control

to the FAST position. For maximum charging of the battery and

for a cooler running engine and transmission, operate the en-

gine in the FAST position.

2 For transport and to tow pull behind attachments, control the

ground speed with the speed control pedal.

3. The engine governor is set at the factory for maximum perform-

ance. Do not adjust the governor to increase the speed of the

engine.

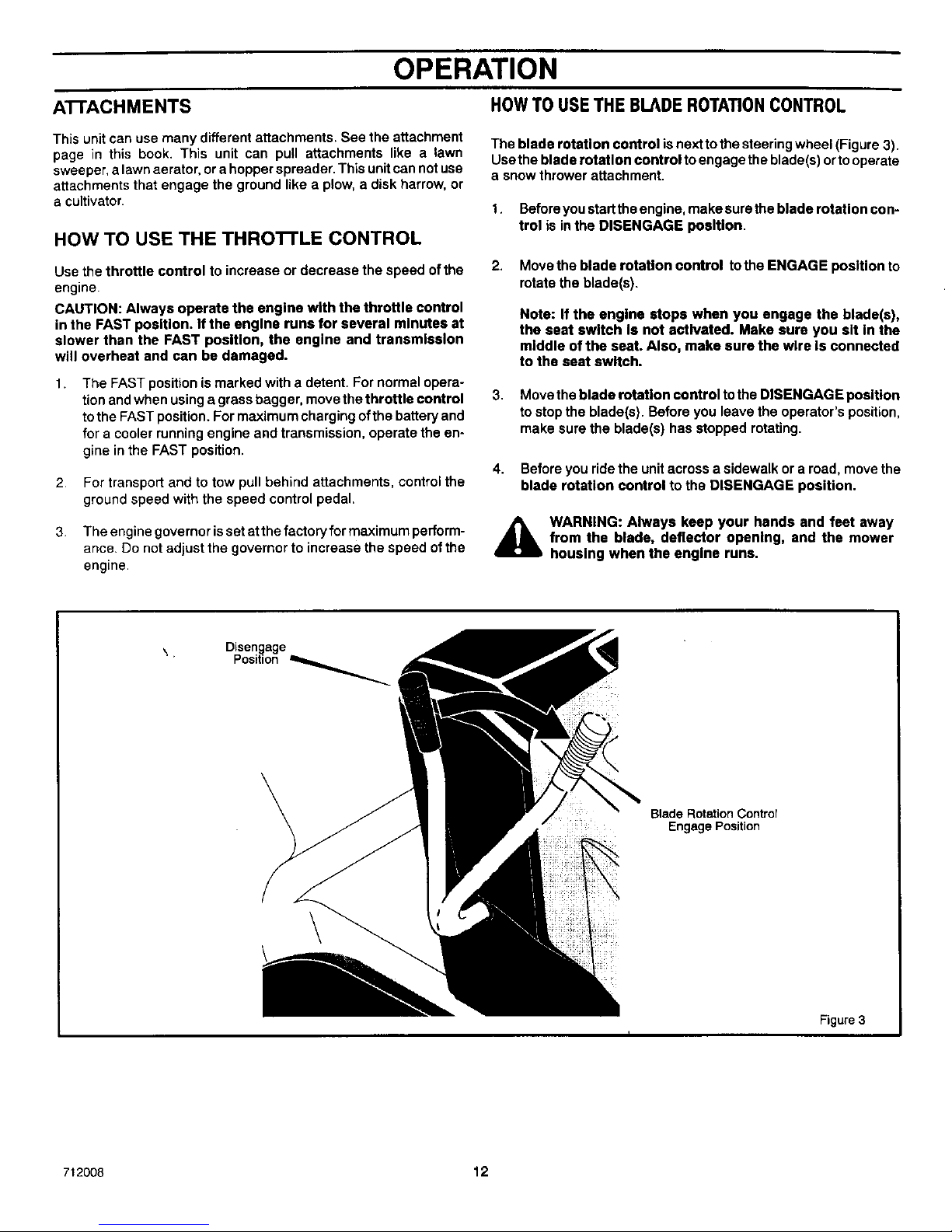

The blade rotation control is next to the steering wheel (Figure 3).

Usethe blade rotation control toengage the blade(s) orto operate

a snow thrower attachment.

1. Before you startthe engine, make sure the blade rotation con-

trol is inthe DISENGAGE position.

2. Move the blade rotation control tothe ENGAGE position to

rotate the blade(s).

Note: If the engine stops when you engage the blade(s),

the seat switch Is not activated. Make sure you sit In the

middle of the seat. Also, make sure the wire Is connected

to the seat switch.

3. Move the blade rotation control tothe DISENGAGE position

tostop the blade(s). Before you leave the operator's position,

make sure the blade(s) has stopped rotating.

4. Before you ride the unit across a sidewalk or a road, move the

blade rotation control to the DISENGAGE position.

_ WARNING: Always keep your hands and feet away

from the blade, deflector opening, and the mower

housing when the engine runs.

Disengage

Position _

Blade Rotation Control

Engage Position

\

Figure 3

712008 12

OPERATION

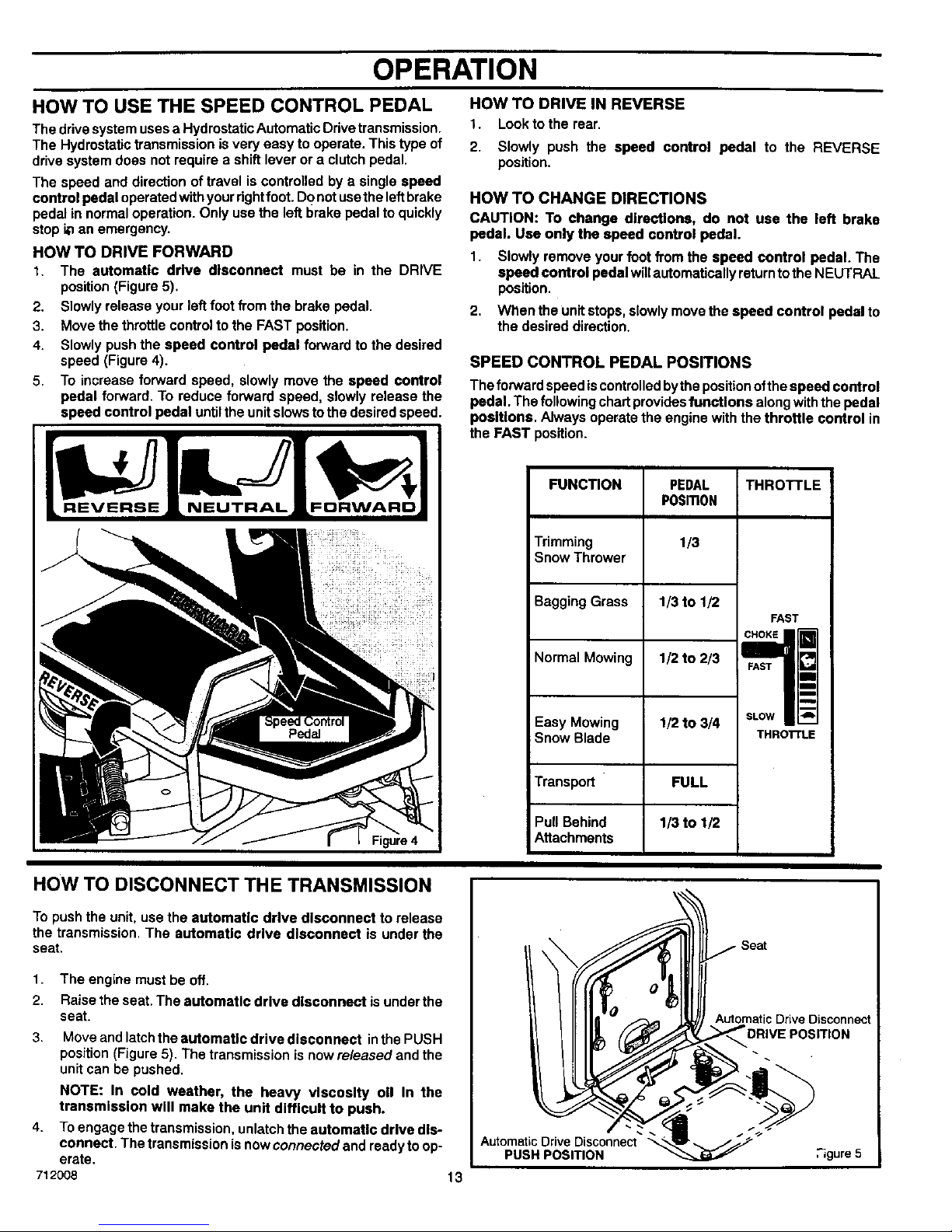

HOW TO USE THE SPEED CONTROL PEDAL

The drive system uses a Hydrostatic Automatic Drive transmission.

The Hydrostatic transmission is very easy to operate. This type of

drive system does not require a shift lever or a clutch pedal.

The speed and direction of travel is controlled by a single speed

control pedal operated with your dght foot. Do not usethe left brake

pedal in normal operation. Only use the left brake pedal to quickly

stop i_ an emergency.

HOW TO DRIVE FORWARD

1. The automatic drive disconnect must be in the DRIVE

position (Figure 5),

2. Slowly release your left foot from the brake pedal.

3. Move the throttle control to the FAST position.

4. Slowly push the speed control pedal forward to the desired

speed (Figure 4).

5. To increase forward speed, slowly move the speed control

pedal forward. To reduce forward speed, slowly release the

speed control pedal untilthe unit slowsto the desired speed.

HOW TO DRIVE IN REVERSE

1. Look to the rear.

2. Slowly push the speed control pedal to the REVERSE

position.

HOW TO CHANGE DIRECTIONS

CAUTION: To change directions, do not use the left brake

pedal. Use only the speed control pedal.

1. Slowly remove your foot from the speed control pedal. The

speed control pedal willautomatically returnto the NEUTRAL

position.

2. When the Unit stops, slowly move the speed control pedal to

the desired direction.

SPEED CONTROL PEDAL POSITIONS

The forward speed is controlled bythe position of the speed control

pedal. The following chart provides functions along withthe pedal

positions. Always operate the engine with the throttle control in

the FAST position.

FUNCTION THROTTLE

Trimming

Snow Thrower

Bagging Grass

Normal Mowing

Easy Mowing

Snow Blade

Transport

Pull Behind

Attachments

PEDAL

P0Sm0N

1/3

1/3 to 1/2

1/2 to 2/3

1/2 to 3/4

FULL

1/3 to 1/2

FAST

CHOKE

FAST

m

m

m

m

SLOW

THROI"rLE

HOW TO DISCONNECT THE TRANSMISSION

To push the unit, use the automatic drive disconnect to release

the transmission, The automatic drive disconnect is under the

seat.

1. The engine must be off.

2. Raise the seat. The automatic drive disconnect is under the

seat.

3,

4.

712008

Move and latch the automatic drive disconnect inthe PUSH

position (Figure 5). The transmission is now released and the

unit can be pushed.

NOTE: In cold weather, the heavy viscosity oll In the

transmission will make the unit difficult to push.

To engage the transmission, unlatch the automatic drive dis-

connect. The transmission isnow connected and ready to op-

erate.

13

/

Automatic Drive Disconnec

AutomaticDrive Disconnect

PUSH POSITION .igure 5

OPERATION

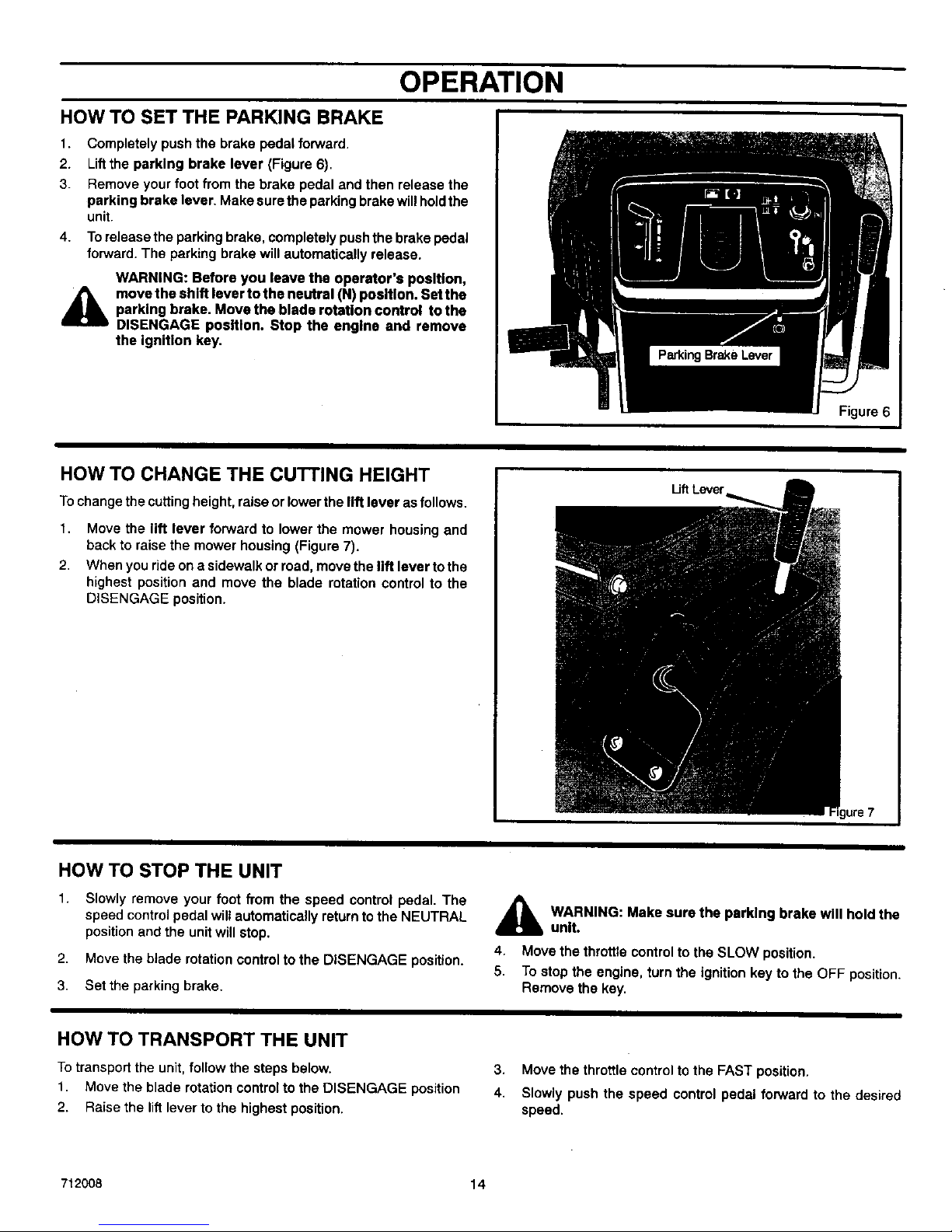

HOW TO SET THE PARKING BRAKE

1. Completely push the brake pedal forward,

2. lift the parking brake lever (Figure 6).

3. Remove your foot from the brake pedal and then release the

parking brake lever. Make sure the parking brake will holdthe

unit.

4. Torelease the parking brake, completely push the brake pedal

forward. The parking brake will automatically release.

A

WARNING: Before you leave the operator's position,

move the shift lever to the neutral (N) position. Set the

parking brake. Move the blade rotation control to the

DISENGAGE position. Stop the engine and remove

the ignition key.

Figure 6

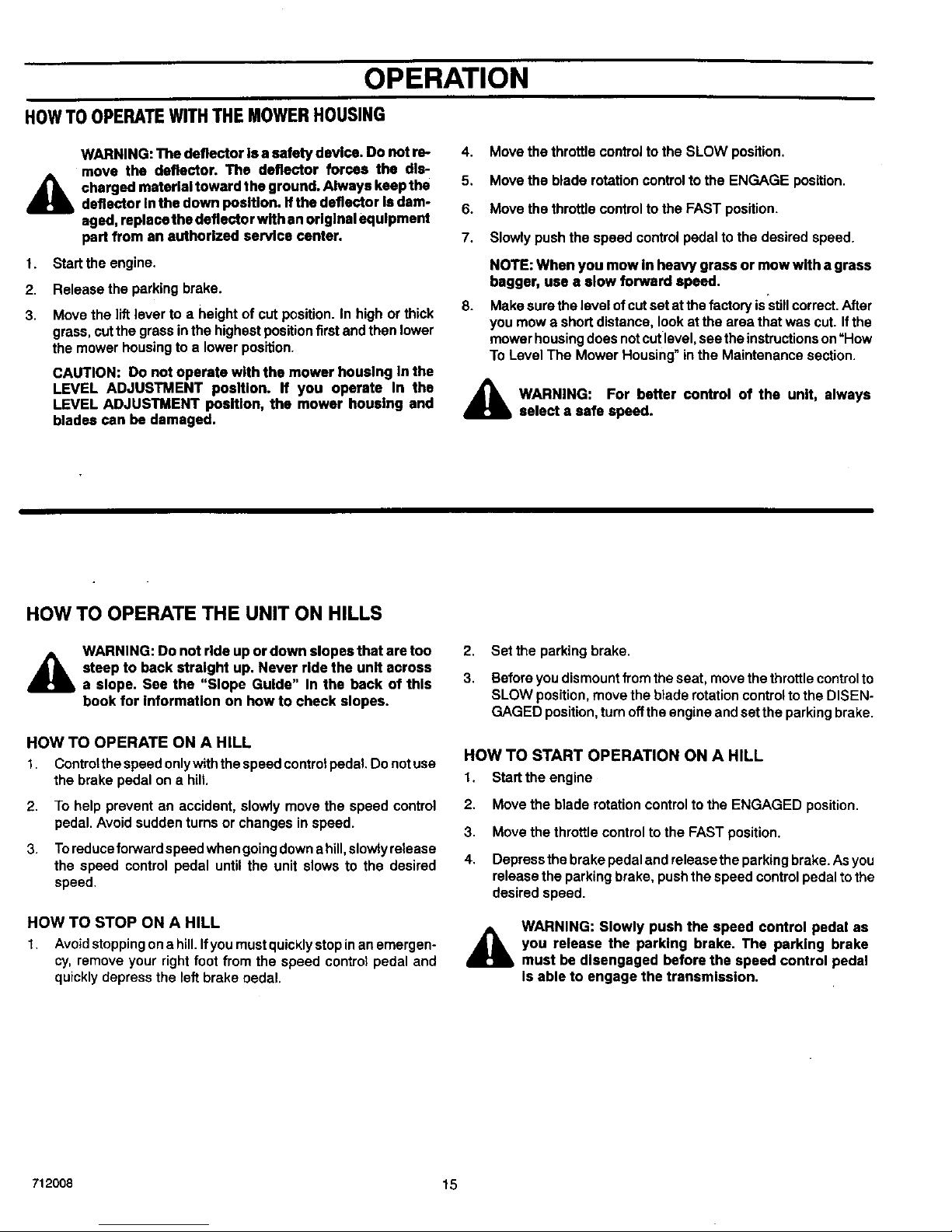

HOW TO CHANGE THE CUTTING HEIGHT

Tochange the cutting height, raise or lower the lift lever as follows.

1. Move the lift lever forward to lower the mower housing and

back to raise the mower housing (Figure 7).

2. When you ride on a sidewalk or road, move the lift lever tothe

highest position and move the blade rotation control to the

DISENGAGE position.

Uft Lever

HOW TO STOP THE UNIT

1.

Slowly remove your foot from the speed control pedal. The

speed control pedal wilt automatically return to the NEUTRAL

position and the unit will stop.

2. Move the blade rotation control to the DISENGAGE position.

3. Set the parking brake.

_lb ARNING: Make sure the parking brake will holdthe

unit.

4. Move the throttle control to the SLOW position.

5. To stop the engine, turn the ignition key to the OFF position.

Remove the key.

HOW TO TRANSPORT THE UNIT

To transport the unit, follow the steps below.

1. Move the blade rotation control to the DISENGAGE position

2. Raise the lift lever to the highest position.

3. Move the throttle control to the FAST position.

4. Slowly push the speed control pedal forward to the desired

speed.

712008 14

OPERATION

HOWTO OPERATEWITHTHE MOWERHOUSING

A

1.

2,

3,

WARNING: The deflector is a safety device. Do not re-

move the deflector. The deflector forces the dis-

charged material toward the ground. Always keep the

deflector In the down position. If the deflector Is dam-

aged, replace the deflector with an original equipment

part from an authorized service center.

Start the engine.

Release the parking brake.

Move the lift lever to a height of cut position. In high or thick

grass, cutthe grass in the highest positionfirst and then lower

the mower housing to a lower position.

CAUTION: Do notoperate with the mower housing In the

LEVEL ADJUSTMENT position. If you operate In the

LEVEL ADJUSTMENT position, the mower housing and

bladescan be damaged.

4. Move the throttle control to the SLOW position.

5. Move the blade rotation control to the ENGAGE position.

6. Move the throttle control to the FAST position.

7. Slowly push the speed control pedal to the desired speed.

NOTE: When you mow In heavy grass or mow with a grass

bagger, use a slow forward speed.

8. Make sure the level ofcut set at the factory isstill correct. After

you mow a short distance, look at the area that was cut. If the

mower housing does notcut level, see the instructions on "How

To Level The Mower Housing" in the Maintenance section.

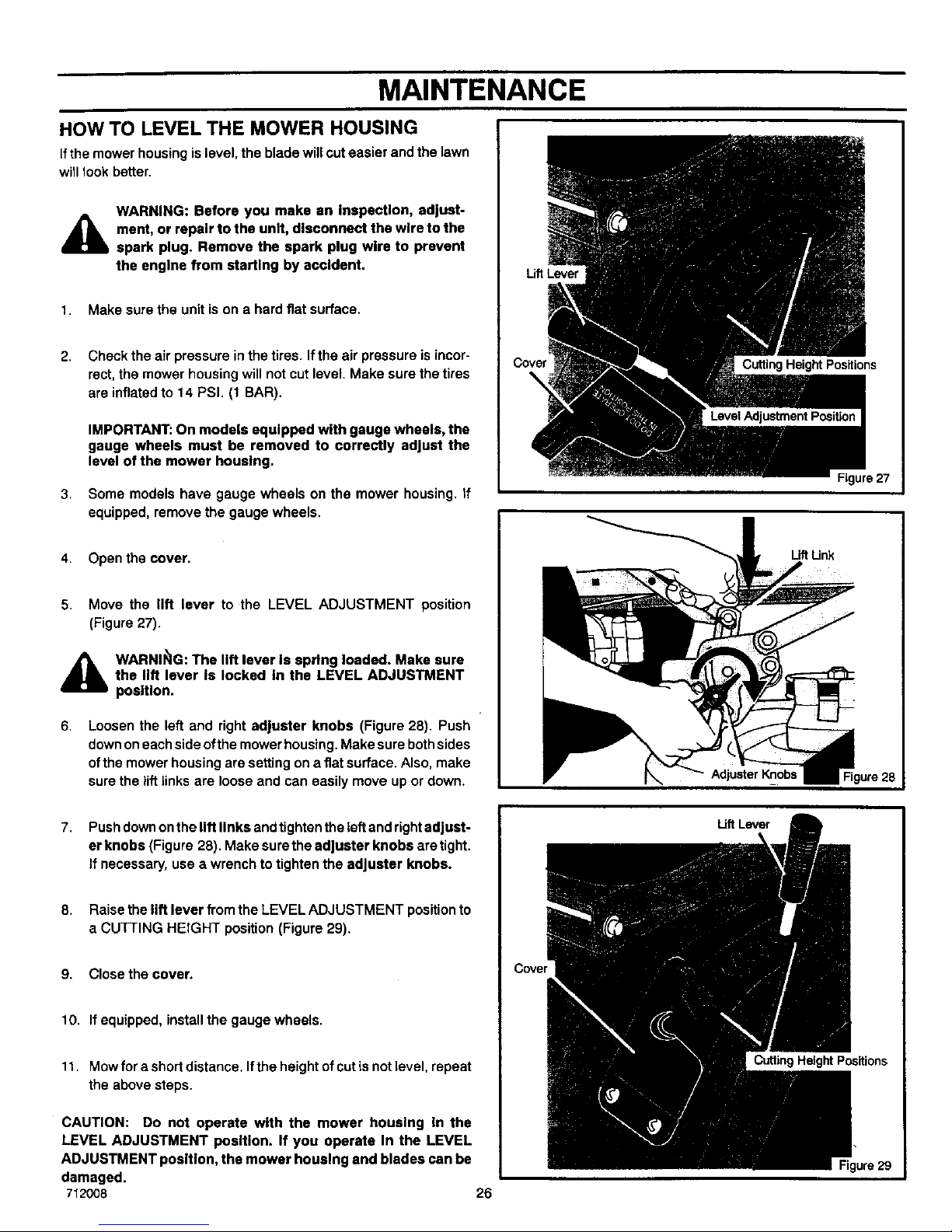

_ ARNING: For better control of the unit, always

select a safe speed.

HOW TO OPERATE THE UNIT ON HILLS

,_ WARNING: Do not ride up or down slopes that are too

steep to back straight up. Never ride the unit across

a slope. See the "Slope Guide" In the back of this

book for information on how to check elopes.

HOW TO OPERATE ON A HILL

1. Controtthe speed onlywith the speed controlpedal. Do not use

the brake pedal on a hill.

2. To help prevent an accident, slowly move the speed control

pedal. Avoid sudden turns or changes in speed.

3. To reduce forward speed when going down a hill,slowly release

the speed control pedal until the unit slows to the desired

speed.

HOW TO STOP ON A HILL

1. Avoidstopping ona hill.Ifyou must quickly stop in an emergen-

cy, remove your right foot from the speed control pedal and

quickly depress the left brake oedal.

2,

3,

Set the parking brake.

Before you dismount from the seat, move the throttle controlto

SLOW position, move the blade rotation control to the DISEN-

GAGED position, turn offthe engine and set the parking brake.

HOW TO START OPERATION ON A HILL

1. Start the engine

2. Move the blade rotation control to the ENGAGED position.

3. Move the throttle control to the FAST position.

4. Depress the brake pedal and release the parking brake. As you

release the parking brake, push the speed control pedal to the

desired speed.

4_ WARNING: Slowly push the speed control pedal as

you release the parking brake. The parking brake

must be disengaged before the speed control pedal

Is able to engage the transmission.

712008 15

OPERATION

BEFORE STARTING THE ENGINE

CHECK THE OIL

NOTE: The engine was shipped from the factory filled with o11.

Check the level of the oil Add oll as needed. See the engine

manufacturer's Instructions for the type of gasoline and oll to

use.

1. Make sure the unit is level.

NOTE: Do not check the level of the oll while the engine

runs.

2. Check the oil.Follow the procedure in the engine manufactur-

er's instructions.

3. If necessary, add oil until the oil reaches the FULL mark on the

dipstick.The quantity of oil needed from ADD to FULL is shown

on the dipstick. Do not add too much oil.

CAUTION: A mixture of alcohol (ethanol or methanol) and

gasoline (called gasohol), will attract moisture and cause acid

deposits during storage. While the unit Is In storage, the acids

in the fuel can damage the fuel system.

To prevent engine problems with the fuel system, empty the fuel

system before storage of 30 days or longer as follows.

1. Drain the fuel tank.

2. Start the engine. Let the engine run untilthe fuel lines and the

carburetor are empty.

3. Afterstorage,makesureyou use freshfuel. See the storage

instructionsforadditionalinformation.

4. Neveruseenginecleanerorcarburetorcleanerinthefuel tank

orpermanentdamagecan occur.

ADD GASOLINE

A

WARNING: Always use a safety gasoline container.

Do not smoke when adding gasoline to the fuel tank.

Do not add gasoline when you are Inside an enclo-

sure. Before you add gasoline, stop the engine and

let the engine cool for several minutes.

Fill the fuel tank with regular FuelTank

unleaded gasoline. Do not use (F /

premium unleaded gasoline.

Make sure the gasoline is fresh

and clean, Leaded gasoline wilt

increase deposits and shorten

the life of the va_,es.

CARBURETOR

The factory settings forthe carburetor are for most conditions. Ifthe

engine is operated under the following conditions, you can adjust

the carburetor mixture. To adjust the carburetor, see the engine

manufacturer's instructions.

1. The engine has a loss of power or does not run smooth.

2. A change from summer to winter operation.

3. A 40 degree change inthe operation temperature. The carbure-

tor was adjusted at 80 degrees at the factory.

4. The engine is operated above 4,000 feet.

HOW TO START THE ENGINE

A

WARNING: The electrical system has an operator

presence system that includes a sensor switch for the

seat, These components tell the electrical system If

the operator is sitting on the seat. This system will

stop the engine when the operator leaves the seat If

the blade rotation control Is engaged or if the trans-

mission Is engaged. For your protection, always

make sure this system operates correctly,

2.

3.

4.

NOTE: The engine will not start unless you depress the brake

pedal or engage the parking brake and move the blade rotation 5.

control to the DISENGAGE position. 6,

1. Push the brake pedal completely forward. Keep your foot on

the pedal.

Make sure the blade rotation control is in the DISENGAGE

position.

Move the throttle control completely forward to the CHOKE or

FAST position. Some models have a separate choke knob. Pull

the choke knob to the full CHOKE position.

Turn the ignition kay to the START position. Release the key

when the engine starts.

NOTE: If the engine does not start after four or five tries,

see the TROUBLE SHOOTING CHART,

Slowly move the throttle control to the SLOW position.

Let a cold engine run for several minutes. Begin work when the

engine is warm. To start a hot engine, move the throttle control

to a position between FAST and SLOW.

712008 16

OPERATION

OPERATING TIPS

1.

2.

3.

4.

Check the blade rotation controlfor correct adjustment. Forthe

blade(s) to disengage correctly, the adjustment must be cor-

rect.

Beforeyouusetheunit,checktheoilintheengineandaddoil

ifnecessary,

If the engine will not start, flint make sure the wire is attached

to the spark plug.

Make sure allthe belts are inside all the belt guides. See the in-

structions on how to remove and install the motion drive and

mower drive belts.

5.

6.

7.

8.

Before you make an inspection, adjustment (except forthe car-

buretor) or repair, make sure the wire fTomthe spark plug isdis-

connected,

For longer life of the battery on electric start models, charge the

battery every three months.

Use the speed control pedal to change the ground speed, not

the throttle control.

Belt noise can occur when the blade is engaged. This noise is

normal and does not affect the operation ofthe unit.

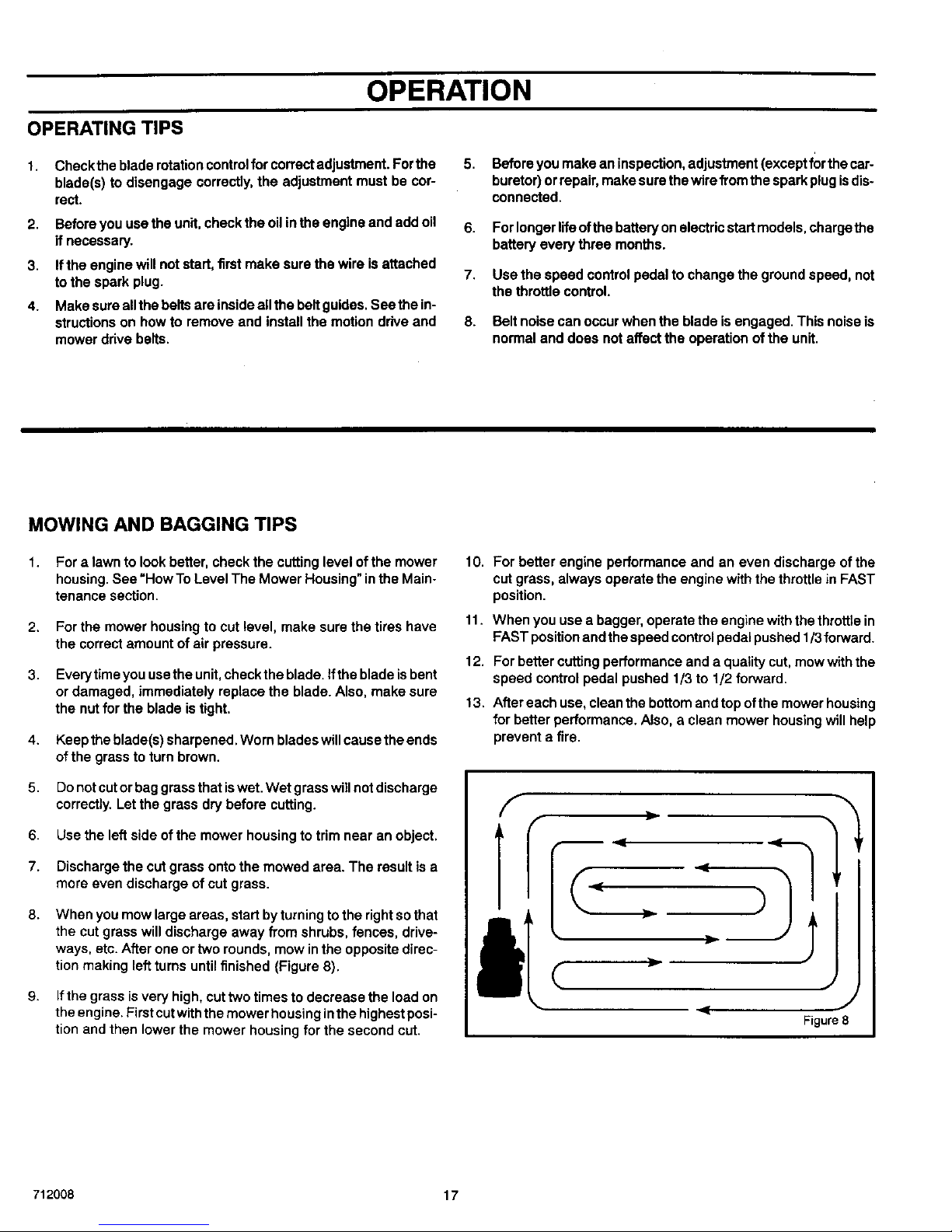

MOWING AND BAGGING TIPS

1. For a lawn to lookbetter, check the cutting level of the mower

housing. See =How To Level The Mower Housing" in the Main-

tenance section.

2. For the mower housing to cut level, make sure the tires have

the correct amount of air pressure.

3. Every time you use the unit,check the blade, if the blade isbent

or damaged, immediately replace the blade. Also, make sure

the nutfor the blade is tight.

4. Keep the blade(s) sharpened. Worn blades willcause the ends

of the grass to turn brown.

5. Donot cut or bag grass that iswet. Wet grass will not discharge

correctly. Let the grass dry before cutting.

6. Use the left side of the mower housing to trim near an object.

7. Discharge the cut grass onto the mowed area. The result is a

more even discharge of cut grass.

8.

9.

When you mow large areas, start by turning tothe right so that

the cut grass will discharge away from shrubs, fences, drive-

ways, etc. After one or two rounds, mow inthe opposite direc-

tion making left turns until finished (Figure 8).

Ifthe grass isvery high, cut two times to decrease the load on

the engine. First cutwiththe mower housing inthe highest posi-

tion and then lower the mower housing for the second cut.

10.

11.

12.

13.

For better engine performance and an even discharge of the

cut grass, always operate the engine with the throttle in FAST

position.

When you use a bagger, operate the engine with the throttle in

FAST positionand the speed control pedal pushed 1/3 forward.

For better cutting performance and a quality cut, mow with the

speed control pedal pushed 1/3 to 1/2 forward.

After each use, clean the bottom and top of the mower housing

for better performance. Also, a clean mower housing will help

prevent a fire.

712008 17

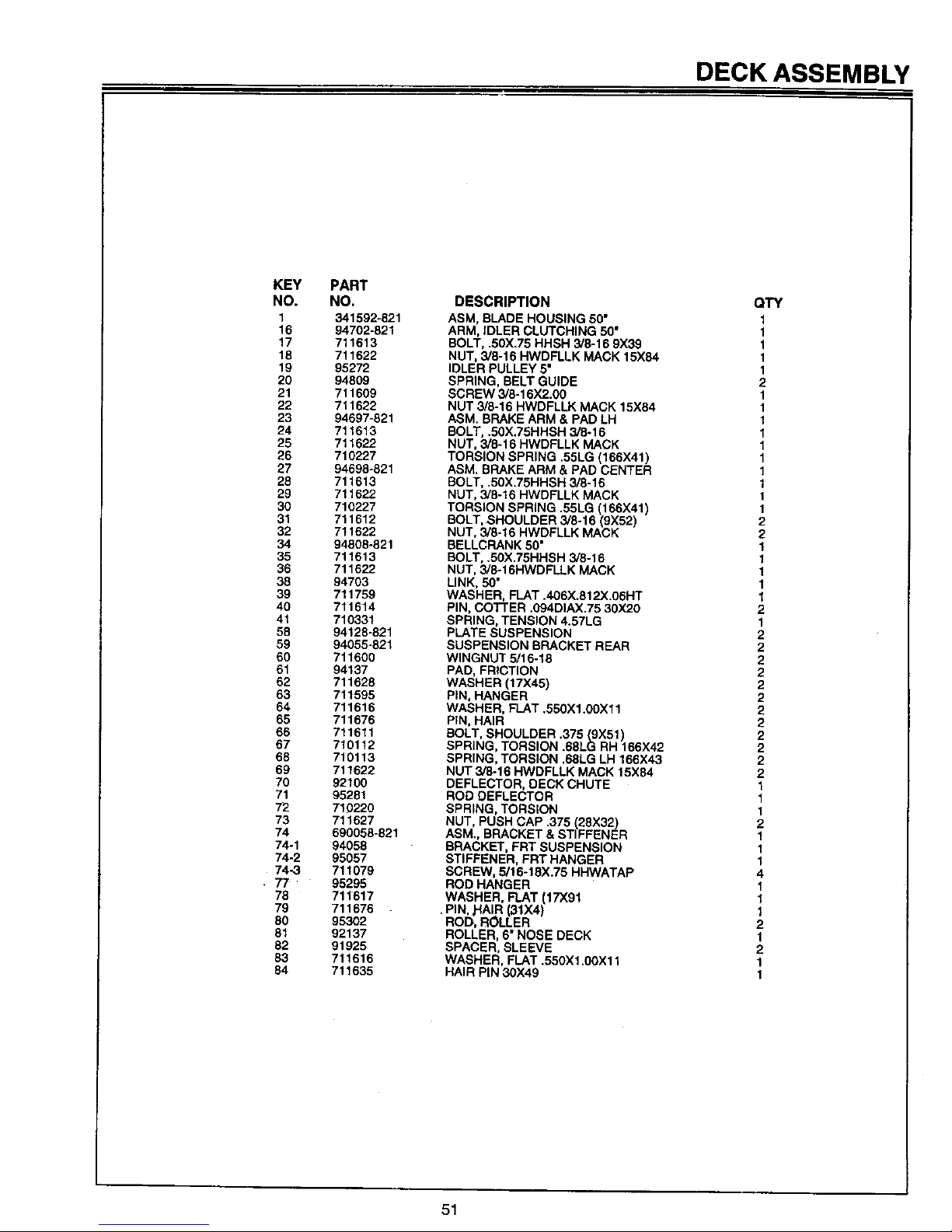

MAINTENANCE

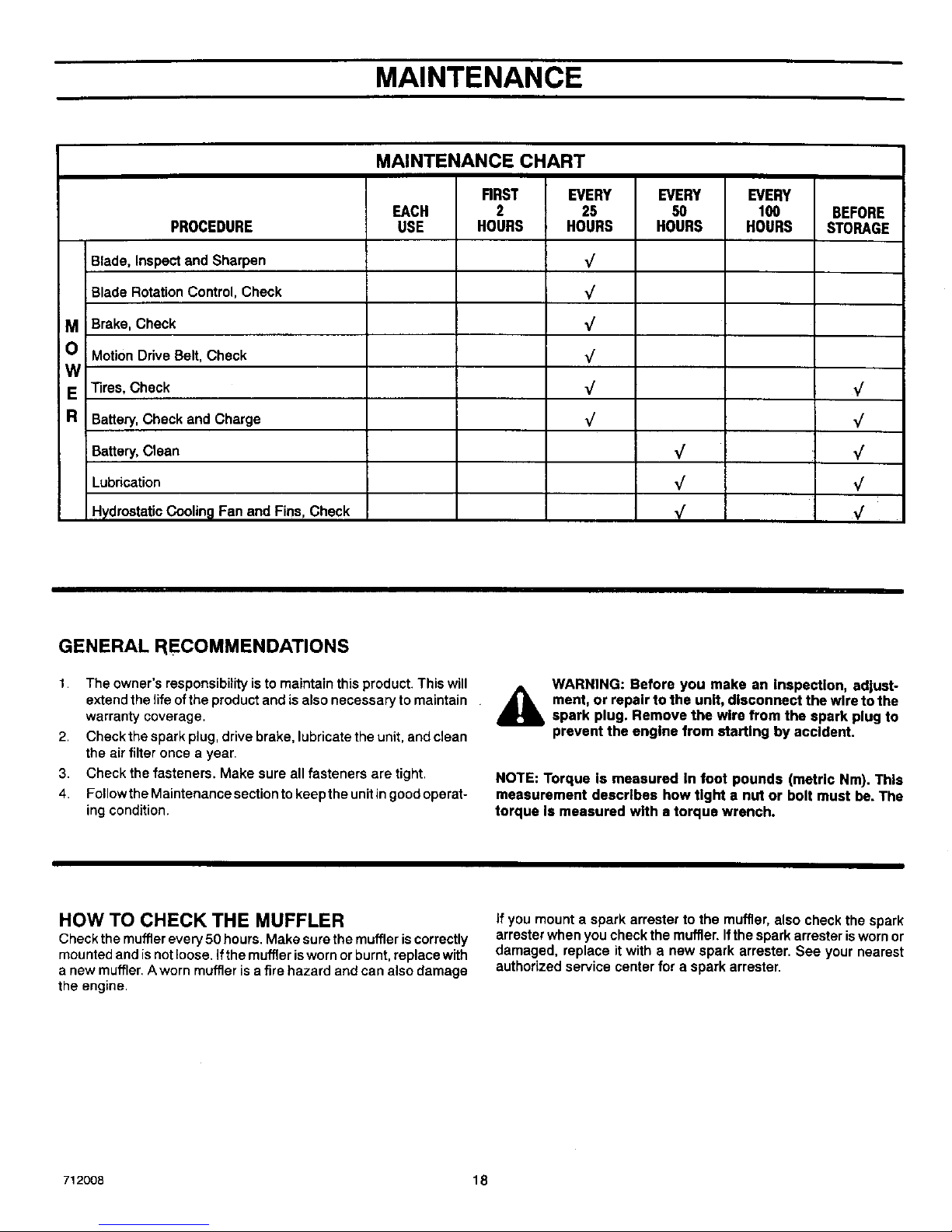

MAINTENANCE CHART

RRST EVERY EVERY EVERY

EACH 2 25 50 100 BEFORE

PROCEDURE USE HOURS HOURS HOURS HOURS STORAGE

Blade, Inspect and Sharpen _/

Blade Rotation Control, Check _/

M Brake, Check _/

O Motion Drive Belt, Check _/

W

E Tires, Check _/ _/

R Battery, Check and Charge _/ _/

Battery, Clean V

Lubrication ,,/ _/

Hydrostatic Cooling Fan and Fins, Check _/ V"

GENERAL RECOMMENDATIONS

t. The owner's responsibility is to maintain this product. This will A WARNING: Before you make an inspection, adjust-

extend the life ofthe product and is also necessary tomaintain AL ment, or repair to the unit, disconnect the wire to the

warranty coverage. _ spark plug. Remove the wire from the spark plug to

2. Check the spark plug, drive brake, lubricate the unit, and clean prevent the engine from starting by accident.

the air filter once a year.

3. Check the fasteners, Make sure all fasteners are tight. NOTE: Torque Is measured In foot pounds (metric Nm). This

4. FollowtheMaintenancesectiontokeeptheunitin goodoperat- measurement describes how tight a nut or bolt must be. The

ing condition, torque Is measured with a torque wrench.

HOW TO CHECK THE MUFFLER

Check the muffler every 50 hours. Make sure the muffler is correctly

mounted and isnot loose, ifthe muffler is worn or burnt,replace with

a new muffler.A worn muffler is a fire hazard and can also damage

the engine.

If you mount a spark arrester to the muffler, also check the spark

arrester when you check the muffler, Ifthe spark arrester is worn or

damaged, replace it with a new spark arrester, See your nearest

authorized service center for a spark arrester,

712008 18

MAINTENANCE

INSPECT BLADE

WARNING: Before you inspect or remove the blade,

disconnect the wire to the spark plug. If the blade hits

_IL an object, stop the engine. Check the unit for dam-

age. The blade has sharp edges. When you hold the

blade, use gloves or cloth material to protect your

hands.

If you keep the blade sharp and inspect the blade for damage, the

blade willcut better and be more safe to operate. Frequently check

the blade for excessive wear, cracks, or other damage. Frequently

check the nut that holds the blade. Keep the nut tight. If the blade

hits an object, stop the engine. Disconnectthewire tothe spark plug.

See if the blade is bent or damaged. Check the blade adapter for

damage. Before you operate the unit, replace damaged parts with

original equipment parts. See the authorized service center in your

area. Every three years, have an authorized service person inspect

the blade or replace the old blade with an original equipment part.

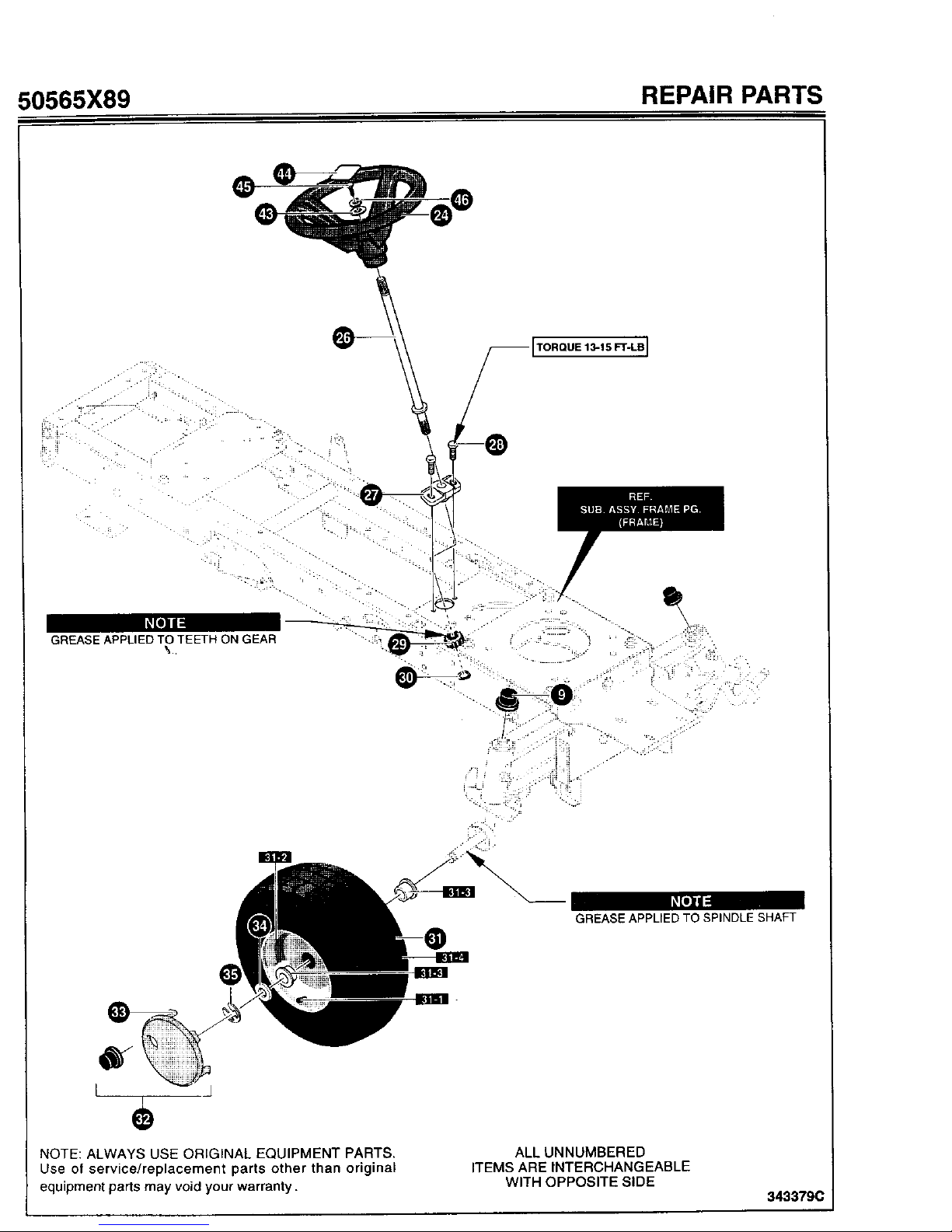

HOW TO REMOVE AND INSTALL THE BLADE

1. Remove the mower housing. See the instructionson "How To

Remove The Mower Housing"

2. Use a piece of wood to keep the blade from rotating.

3. Remove the nut that holds the blade (Figure 9).

Hi-Uft

Edge Up

Mandrel

Blade

Blade Adapter

Belleville Washer

_/asher

Nut Figure 9

4.

5.

6.

7.

8.

A

Check the blade and the blade adapter according to the in-

structions for "Inspect Blade". Replace a badly worn or dam-

aged blade with an original equipment blade. See an

authorized service center in your area.

Clean the topand bottom of the mower housing. Remove allthe

grass and debris.

Mount the blade and blade adapter on the mandrel

(Figure 9).

Mount the blade so that the hi-lift edges are up. Ifthe blade

is upside down, the blade will not cut correctly and can cause

an accident.

Fasten the blade withthe originalwashers and nut. Make sure

the outside rim of the Bellevllle washer is against the blade

(Figure 10).

WARNING: Always keep the nut tight that holds the

blade. A loose nut or blade can cause an accident.

712008

9. "lighten the nut that holds the blade to a torque of 35 foot

pounds (47,5 N-m).

10. Install the mower housing. See "How To Install The Mower

Housing".

BladeA

Blade

W her

r Nut

Be,,eviUeWasher _J

(Outsiderimmust be

againsttheblade.) I

Figure 10

HOW TO SHARPEN THE BLADE

WARNING: Vibration can be caused If the blade is

d_lb not correctly balanced or Ifthe blade is damaged. A

blade that is damaged with cracks can break and

cause an accident.

Keep a sharp edge on the blade. A blade that isnot sharp willcause

the tips of the grass to become brown.

1. Sharpen the blade two times a year or every 25 hours.

2. Remove the blade according tothe instructionsin "How To Re-

move And Install The Blade".

3. Clean the blade with a brush, soap and water. Check the ;

blade, Look for cracks, nicks, or other damage. Replace a

badlyworn ordamaged bladewith an original equipment blade.

See an authorized service center in your area.

4. Sharpen the blade with a file (Figure 11). Make sure you keep

the original bevel angle.

5. Make sure the blade is balanced. Use a screwdriver and hold

the blade parallel tothe ground (Fig ure 11). A blade that isbal-

anced wilt stay parallel to the ground. If the blade is not bal-

anced, the heavy end will rotate toward the ground. Sharpen

the heavy end untilthe blade is balanced.

6. A new blade will cutbetter than a badly worn blade. Every three

years, have an authorized service person inspect the blade or

replace the old blade with an original equipment blade.

7. Assemble the blade according to the instructions"How To Re-

move And Install The Blade".

19

Screwdriv__

I Blade isbalanced

whenparaielto theground.

Ground Figure11

MAINTENANCE

HOW TO ADJUST THE BLADE ROTATION CONTROL 6. Attachthewiretothesparkplug. Uowforashortdistanceand

_k ARNING: To prevent an injury, the blade rotation

control must operate correctly.

In normal usage, the blade rotation control will not require an

adjustment. However, ifthe cutting performance decreases or the

quality of cut is poor, make the following changes.

1. When you mow, make sure the throttle control in in the FAST

position.

2. Move the blade rotation control tothe DISENGAGE position

(Figure 12).

3. Stop the engine. Disconnect the wire from the spark plug.

again check the quality of cut. If necessary, move the blade

drive spring to the bottom ho/e.

7.

Again check the quality of cut. If the quality of cut has not im-

proved, replace the mower drive belt. See "How To Replace

The Mower Drive Belt".If replacing the belt does not correctthe

problem, take the unit to an authorized service center.

8,

Move the blade rotation control to the DISENGAGE posi-

tion. Stop the engine, Disconnect the wire from the spark plug.

Check the operation ofthe blade brake. Rotate the pulleys with

your hand, Make sure the brake pads are pressed tightly

against the pulleys (Figure 14).

4

Blade Rotation Control

Engage Position

\

Figure 12

Check the blade(s). Keep a sharp edge on the blade(s). A blade

that is not sharp will cause the tips of the grass to become

brown.

,_ WARNING: If the brake pads do not press tightly

against the pulleys, take the unit to an authorized

service center.

Blade Brake

(Pad Against Pulley)

//

Figure 14

5.

712008

Disconnect the blade drive spring from the blade control

rod. Move the blade drive spring to the midd/e ho/e

(Figure 13). This will increase the tension on the mower drive

belt.

DISENGAGE POSITION

Top Hole (New Belt

Blade

Control Rod MiddleHole

Blade DriveSpring Figure13

20

9.

Move the blade rotation control to the ENGAGE position.

Check the pads for the blade brake. Ifthe pads are excessively

worn or damaged, replace the brake pad assembBes. Correct

replacement parts and assistance are available from an autho-

rized service center.

10. Attach the wire to the spark plug. Mow for a short distance and

again check the operation ofthe blade rotation control.

11.

When you move the blade rotation control to the

DISENGAGE position, all movement will stop within five se-

conds. If there is movement of the belt or the blades continue

to rotate, engage and disengage the blade rotation control

five times to remove any excess rubber from a new mower

drive belt. If you need assistance, take the unit to an autho-

nzed service center.

12. if you replace the mower drive belt, move the blade drive

spring to the top hole (Figure 13).

MAINTENANCE

HOW TO CHECK AND ADJUST THE DRIVE BRAKE

Completely push the brake pedal forward. Set the parking brake.

Move the automatic drive disconnect to the PUSH position, Push

the unit. Ifthe rear wheels rotate, adjust or replace the brake pads.

Adjust the drive brake as foUows.

1. The location of the drive brake is on the right side of the

gearbox (Figure 15).

2. Make sure the parking brake is set and the automatic drive

disconnect is in the PUSH position. Turn the hex nut in a

clockwise direction until the rear wheels do not turn when the

unit is pushed forward.

3_

4.

Release the parking brake and push the unit. Ifthe unit does not

roll, turn the hex nut in a counterclockwise direction until the

unit rolls.

Set the parking brake. Push the unit. If the rear wheels do not

turn, the drive brake is correctly adjusted. Release the parking

brake.

A

WARNING: If you cannot correctly adjust the drive

brake, replace the brake pads. Correct replacement

parts and assistance are available from an autho-

rized service center.

HOW TO CHECK AND ADJUST THE MOTION DRIVE BELT

Ifthe motion drive belt is loose, the belt will slip when; (1) going up 7. If the belt still slips after the belt has been adjusted, then the

a hill, (2) pulling a heavy load, or (3) the unit will not move forward, motion drive belt is worn or damaged and must be replaced.

Adjust the belt as follows. See "How To Replace The Motion Drive Belt".

A

WARNING: Before you make an Inepectlon, adjust-

ment, or repair to the unit, disconnect the wire to the

spark plug. Remove the wire from the spark plug to

prevent the engine from starting by accident.

1.

2.

3.

4.

5.

Check the routing of the motion drive belt. Make sure the belt

is installed correctly and is inside all the belt guides.

Remove the cotter pin, washer, and brake spring from the

adjustable nut (Figure 16).

Disconnect the adjustable nut from the brake lever assembly

and the parking brake latch.

Use the cotter pin removed instep 2. Holdthe cotter pin at the

back ofthe slot and move the brake lever assembly rearward

against the cotter pin. This will set a 1/8 Inch (3 ram) gap be-

tween the brake lever assembly and the back of the slot

(Figure 16).

Turn the adjustable nut untilthe nut willfit through the hole in

the brake lever,

6. Assemble the adjustable nut to the parking brake latch,

brake lever and brake spring. Fasten with the washer and

cotter pin.

712008 21

MAINTENANCE

HOWTO ADJUST THE SPEED CONTROLPEDAL

Ifthe unitwill not go into REVERSE or ifthe unit moves very slowly

in REVERSE, adjust the speed control pedal as follows.

1. Stop the engine.

2. Setthe parking brake.

3. Remove the hair pin from the adjuster nut (Figure 17). Dis-

connect the adjuster nut from the yoke assembly.

4. Rotate the adjuster nut one turn in the direction shown in

Figure 17.

NOTE: Too much adjustment will cause REVERSE speed

to be too fast and the FORWARD speed to be reduced.

5. Attach the adjuster nut tothe yoke assembly with the hair pin.

6. To checkthe adjustment, drive the unit. Ifthe adjustment iscor-

rect, the unit will now go into REVERSE.

IMPORTANT: If you need assistance, go to the nearest

Authorized Service Center. They have the equipment and

experience to make the adjustment.

Adj

Speed Control Pedal

7 Yoke Assembly

Figure 17

MAINTENANCE FREE BATTERY

HOW TO REMOVE THE BATTERY

Tocharge or clean the battery, remove the battery from the unit as

follows.

\,

WARNING: To prevent sparks, disconnect the black

battery cable from the usgstlve (-)farmlnal before you

A disconnect the red cable.

WARNING: The battery contains sulfuric add which Is

harmful to the skin, eyes and clothing. Ifthe acid gets

on the body or clothing, wash with water.

1. Disconnect the black cable from the negative (-) terminal

(Figure 18).

2. Disconnect the red cable from the positive (+) terminal.

3. Lift the battery tray and the battery out of the unit.

1. Before you charge the battery, remove the battery.

2. To charge the battery, use a 12 volt battery charger. Charge at

a rate of 6 amperes for 1 hour.

3. Install the battery.

A WARNING: To prevent sparks, fasten the red cable to

the positive (+) terminal before you connect the black

cable.

4.

5.

Fasten the red cable to the positive (+) terminal with the fas-

teners as shown.

Fasten the black cable tothe negative (-) terminal withthe fas-

teners as shown.

HOW TO CLEAN THE BATTERY

1 Remove the battery.

2. Wash the battery with asolution of one gallon ofwater and four

tablespoons of baking soda (sodium bicarbonate). Make sure

the solution does not get into the battery cells.

3, Clean the terminals and the ends of the cables with a wire

brush.

4, Install the battery.

5, To prevent corrosion, apply grease to the battery terminals.

HOW TO CHARGE THE BATTERY

A

712008

WARNING: When you charge the battery, do not

smoke. Keep the battery away from any sparks. The

fumes from the battery acid can cause an explosion.

22

MAINTENANCE

WHERE TO LUBRICATE

"j Models with grease fittings: Lubricate with grease gun.

/ Apply grease with a brush to the areas shown.

,_ Lubricate the areas shown with engine oil.