7x7 Edgemont Garden Shed

Assembly Instructions

866-210-9273

info@yardcraft.com

Thank you for the purchase of this Edgemont Garden Shed. This manual is designed to simplify the as-

sembly process; however we recommend having an experienced carpenter involved in the project. Please

read through the entire manual before starting!

The building put together for this manual was a 7’x7’ Edgemont Garden Shed. It took 2 men approximately 4 hours using the tools shown. However; it may take you longer, since it will probably be a new project for you.

Take a deep breath and get at it; the satisfaction and enjoyment of this building awaits! Have Fun!

You have purchased a product that consists of heavy, bulky pieces. With your purchase, you assume

full responsibility to have the necessary manpower and/or equipment to unload the items. You also

agree that any damage that happens to the equipment, product, or individuals during the entire construction process, is your responsibility, and neither the seller, nor the manufacturer, will be held liable

for any such damage.

In addition to the materials provided you will need approximately 3 bundles of shingles, 1/2 bundle

cappers, 2 gallons of paint for the siding, 2 quarts paint for the trim, and one tube of caulk.

Tools Required For Job

-Hammer

-Screw Gun

-Tape Measure

-Tin Snips

-Carpenter Square

-(2) Step Ladders

-5/32 Allen Wrench

-Carpenter Pencil

(866) 210-9273 - info@yardcraft.com

2

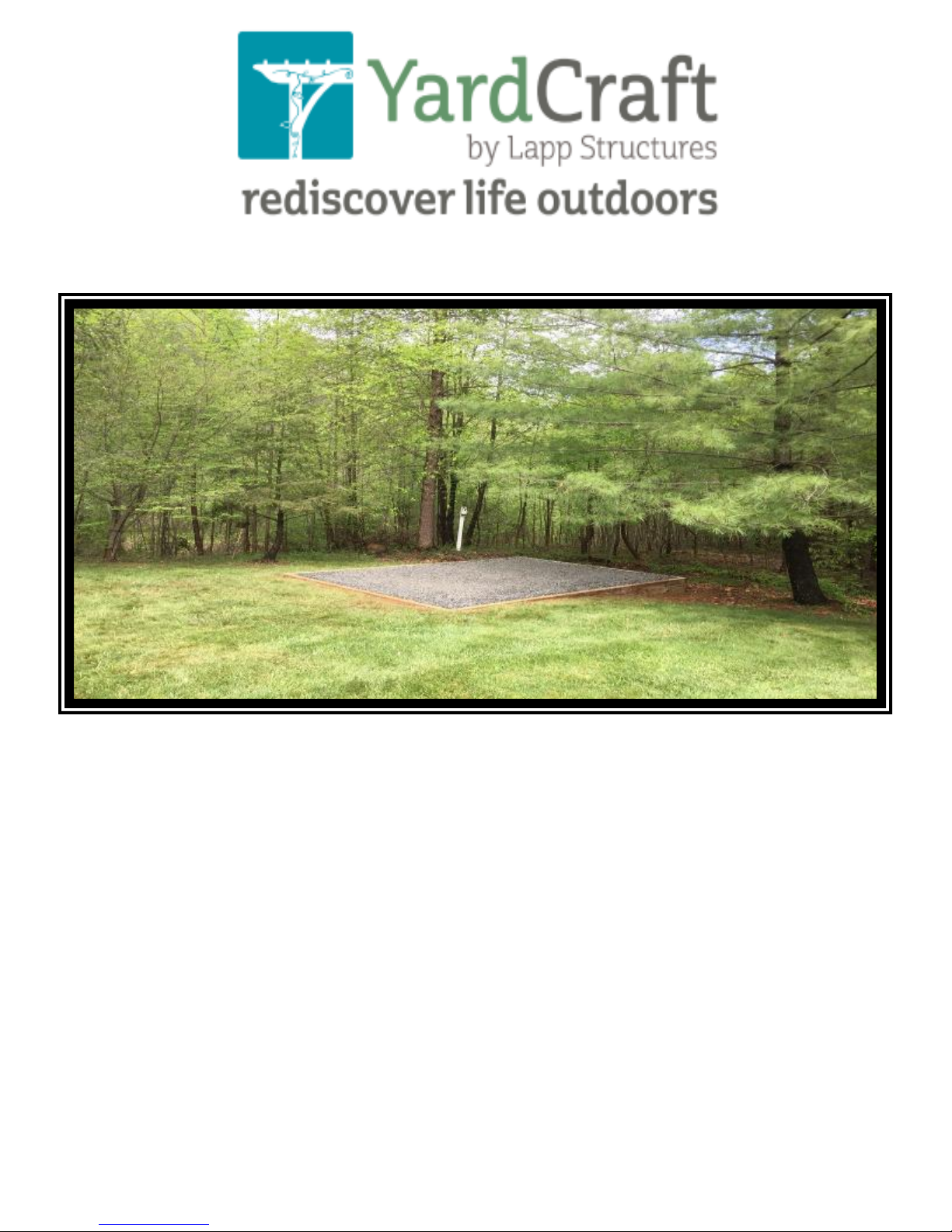

Shed Pad Preparation

Site Preparation

The best thing you can do to contribute to the longevity of your new building is to install

a quality pad. We recommend a minimum of a 6-12″ crushed stone base, at least 2′ larger than your building in both directions. Crushed stone allows for drainage should any

moisture get underneath your shed.

Drainage is of utmost importance, as the greatest enemy to any shed is moisture. If you

look at older sheds around your neighborhood, you will notice that many of them are

beginning to rot around the bottom of the structure. This is because most, if not all, of

those sheds do not have a prepared base underneath them. As rain falls from the edge

of the roof, it deflects off of the ground and splashes onto the sidewalls of the shed.

Over the years, this will cause the doors and lower siding of these sheds to rot. Using

stone as a base, the water is able to be absorbed into the ground instead of splashing

against your building.

IMPORTANT: Pad needs to be level for a more efficient building process!

(866) 210-9273 - info@yardcraft.com

3

Unpack The Kit

(1) Place the package as close to

the assembly location as possible.

(2) Cut package bands.

(3) Remove and organize parts

from package.

If You Got A Floor With This Unit,

(Skip Steps 4-9)

(4) Locate and lay out the pressure

treated 2x4 Sill Plates, cutting

them to length as needed.

NOTE: Perimeter needs to be

square, and exactly 7’x7’

Steps 5 to 9 are for concrete

foundations only.

(5) Fasten the sill sealer (Not provided) to the bottom of the sill

plate. (You will need approximately 30 feet)

(6) After making sure the sill

plates are in the proper position,

pre-drill holes, then fasten to the

foundation, using 3” Tapcon

screws, (Not provided)

(7) After all the walls are set, permanently anchor the walls, first; pre

-drilling the holes, using a 1/2” concrete bit, (Not provided) then,

move to next step.

(866) 210-9273 - info@yardcraft.com

(8) Fasten the walls to the foundation, using 1/2” x 7” galvanized

wedge anchors, (Not provided) and

space them every 4 to 6 feet, or according to local code requirements.

(9) Ask your local hardware department for any additional info on

how to properly install the anchoring system, or refer to the video at

www.youtube.com/watch?

v=3JI_9ggbmcY

4

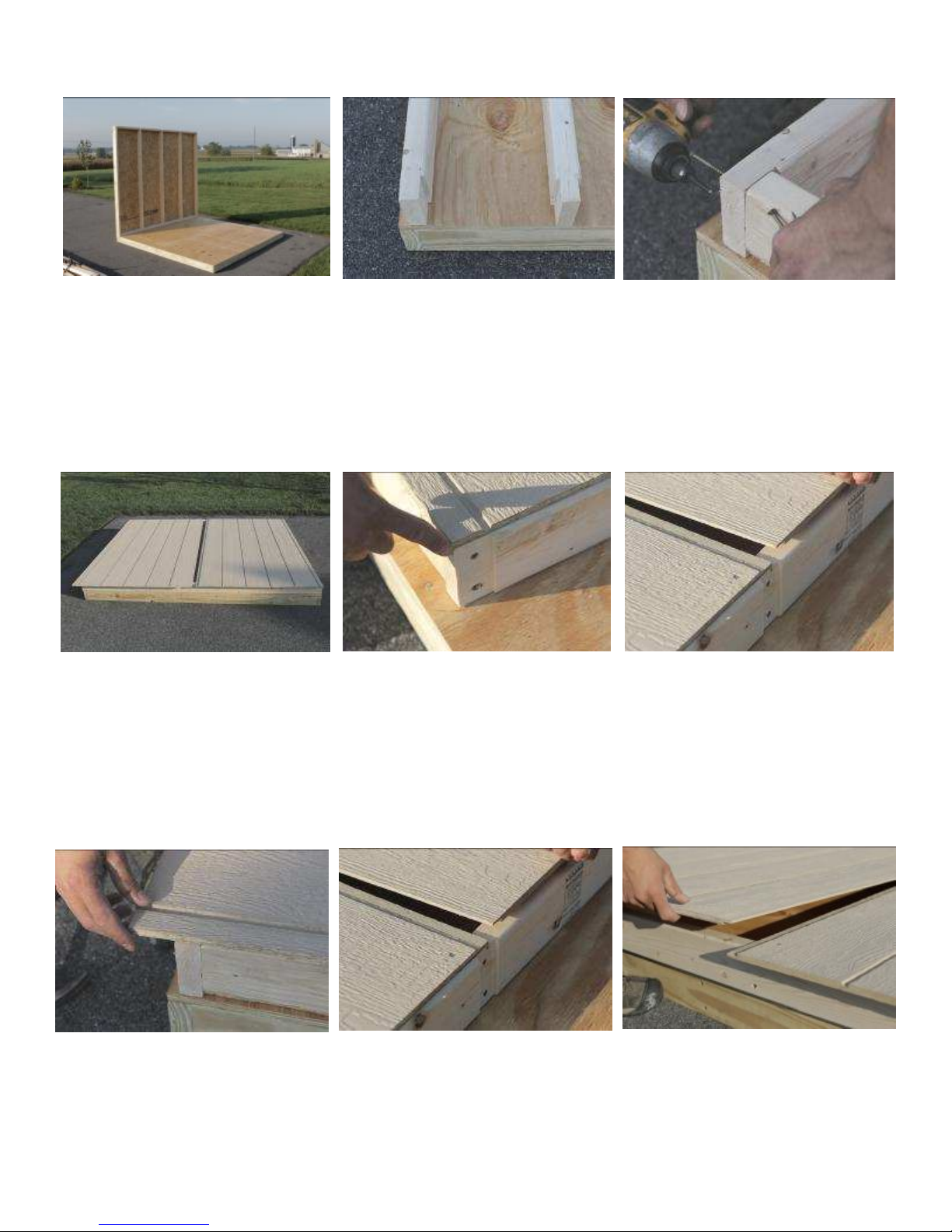

Assemble Floor

(10) Locate the parts to assemble

the floor joists.

(13) After making sure the pad is

level, locate the parts to assemble

the floor joists, and scatter them

out as shown.

(11) Locate the hardware & fasteners.

(14) Note: The band boards have

dado grooves precut to ensure

proper joist placement.

(12) Remove and organize them

for easy access.

(15) Begin with the end joist, making sure the band board is flush

with the joist.

(16) Continue this method for rest

of floor joists, using two 3” screws

per joist. *Holes are predrilled*

(866) 210-9273 - info@yardcraft.com

(17) Before proceeding with flooring, ensure that floor is square.

Both measurements need to be

equal.

(18) If measurements are not

equal, move the ends of the band

board left or right, accordingly.

5

Install Flooring

(19) Layout the flooring. (21) Attach the corner of the floor-

(22) Nail along the gable, making

sure flooring is flush with the floor

joist. Use an 8” to 12” nail spacing.

(20) Start on the front right corner

with the first piece, making sure

flooring is flush with perimeter.

NOTE: Both pieces of flooring are

41-7/8”x84”

(23) Now; nail front left corner,

again; making sure flooring is

flush with the band board.

ing, using 2” nails.

(24) Before you finish attaching

the first row flooring to the joist,

make marks 12” on center for a

guide to adjust the joist when nailing.

(25) Repeat previous steps for back

piece, using an 8” to 12” nail spacing, and ensuring all flooring is either flush or parallel with the floor

joists.

(866) 210-9273 - info@yardcraft.com

(26) Finally, make sure flooring is

nailed to all floor joists, then you

are ready for wall placement.

(27) Ready for walls! Refer to next

step.

6

Assemble Walls

(28) Locate and lay out the parts to

assemble the left wall.

Note: (Dados are 21” on center)

(31) Repeat the process for the rest

of the wall studs; then lay out the

siding as shown, with factory

edges; overlap/underlap towards

the center.

(29) Use the dadoed 2x4’s for top

& bottom plate. The 2x4 plate on

the right; with dado’s on both the

top & bottom, is for the top plate.

(32) Starting on the top side of the

wall, align siding with both the

dado top plate & wall stud as

shown, then fasten with one 2”

nail.

(30) Insert two 3” screws through

the pre-drilled holes to attach bottom plate to each wall stud. Make

sure bottom plate and wall studs

are flush.

(33) Next; move along the top, to

the corner of the piece shown, fasten with 1 nail, then finish nailing

along the top of this piece, using

an 8” to 12” nail spacing, before

moving to next step.

(34) Now; align the bottom corner

of the siding with bottom corner of

wall as shown, before fastening.

(866) 210-9273 - info@yardcraft.com

(35) Put the next piece in place,

flush with the previous piece, making sure the splice looks similar to

the other grooves. Then fasten this

corner of the siding, and along the

entire top plate.

(36) Place the bottom of this piece

in the correct position, again; making sure the splice looks similar to

the other grooves. Then fasten the

corner.

7

Loading...

Loading...