Page 1

insert image here

YANMAR 4TNV, Elec.Control.Governor (Tier III)

We build a better future

ENGINE TRAINING

for R55-7A, R55W-7A, R80-7A

EDITOR

PIETER EVERAERTS

R55-9, R55W-9, R60CR-9, R80CR-9

aug. 2012

Page 2

CONTENT

PAGE

1] GENERAL 03

2] ELECTRONIC CONTROL SYSTEM (ECO) 06

3] INJECTION PUMP 10

4] EXHAUST GAS RECIRCULATION (EGR) 43

5] COOLANT TEMP SENSOR 45

6] ELECTRICS 47

7] ENGINE VIEW 51

8] ENGINE ERROR CODE SYSTEM 52

9] YANMAR DIAGNOSTIC TOOL 58

10] FUEL PUMP ADJUSTMENT & &REPLACEMENT 61

PAGE

- 2 -

Related manuals:

TNV-ECO-manual.pdf (>Ceres : TNV-SERIES-ECM, part 1)

TNV-ECO-diagnostic tool.pdf (>Ceres : TNV-SERIES-ECM, part 2)

TNV-ECO-troubleshooting.pdf

TNV-INJ-mechanical.pdf (>Ceres: YANMAR FUEL INJECTION)

TNV-service-mechanical.pdf (>Ceres: YANMAR 3TNV, 4TNV)

HHIE TRAINING CENTRE

Hyundai Heavy Industries Europe

Vossendaal 11

2440 Geel - Belgium

Tel 0032 (0)14 56 22 00

Fax 0032 (0)14 56 22 65

Arranged by Pieter Everaerts

Instructor HHIE

Tel 0032 (0)14 56 22 44

Fax 0032 (0)14 56 22 65

Page 3

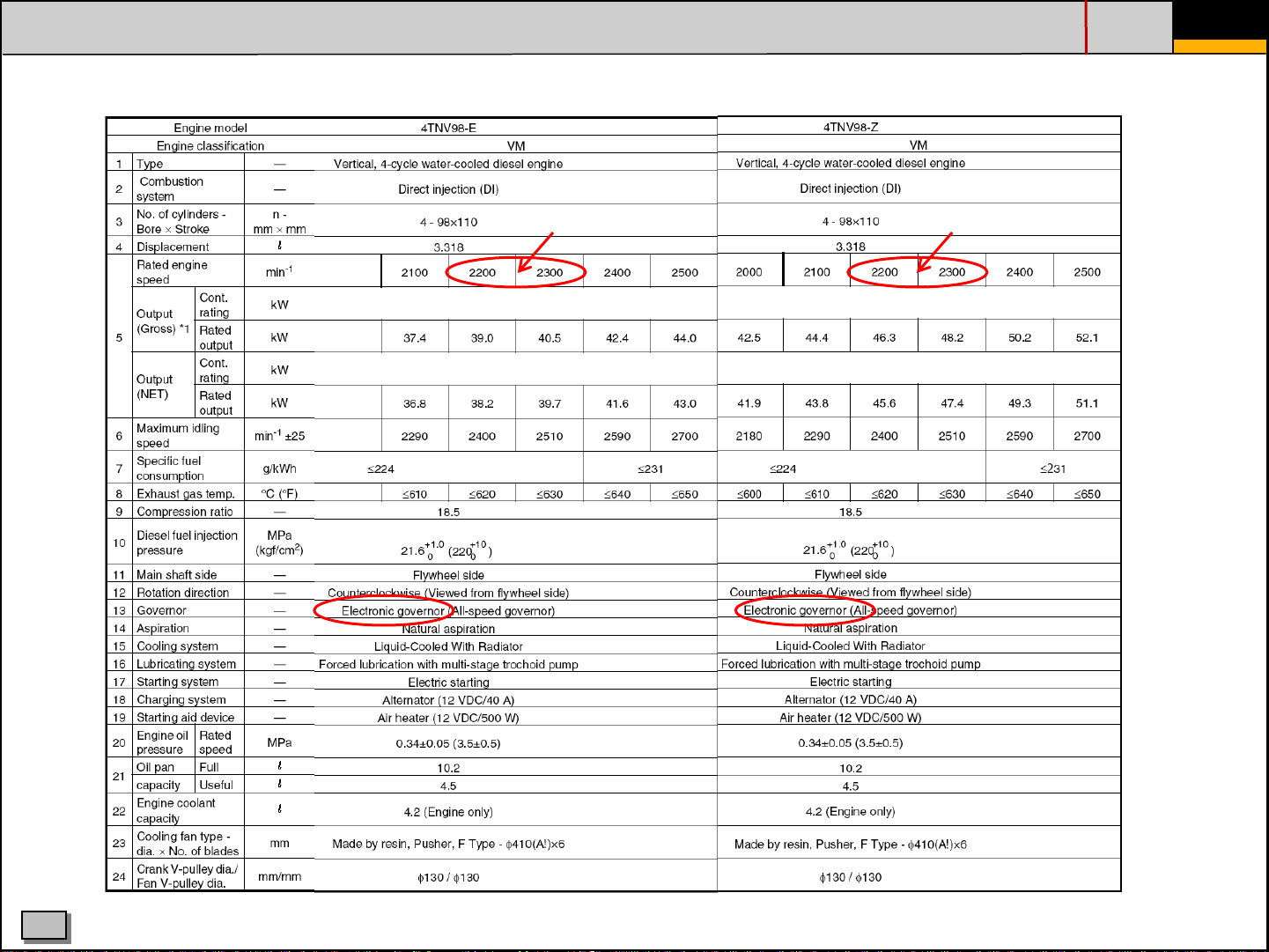

YANMAR R55(W)-7 R80-7 R55(W)-7A R80-7A

Engine model 4TNV94L 4TNV98

4TNV98-EPHYB 4TNV98-ZVHYB

Content / HP (Rated Gross) at rpm 3054cc / 53HP at 2200 rpm 3318cc / 60HP at 2100 rpm 3319cc / 57HP at 2400 rpm 3319cc / 59.6HP at 2100 rpm

Max. Torque at RPM 20.6 kgf at 1400 rpm 25.2 kgf at 1000 rpm 20.5 kgf at 1550 rpm 24.5 kgf at 1000 rpm

SETTING MAX RPM 2300±50 (R55-7) 2250±50 2260±50 2250±50

2400±50 (R55W-7) ("M" mode selected) ("H" mode selected)

1. GENERAL - OVERVIEW

PAGE

- 3 -

(All listed engines are Yanmar "NV3-Series engines" >> Range 3000...4000cc: all direct injection)

# cyl

cyl bore (mm)

derating output

eco -eng.)

Explanation of engine model names (-7A/-9)

E or Z stands for kind of output

P, V rated eng. speed

HY Hyundai

B excavator

-9 Series same engines

-7A "adapted technologie" to meet Tier III

High idle Low idle eng. type

(M mode)

(higher fuel injection pressure)

R55-9 2200±30 1000±30 4NTV98-EPHYBU

R55W-9 2200±50 1050±100 4NTV98-EPHYBU

Electric Control of Exhaust Gas Regulation

Electric Control of Governor (= "ECO")

R60CR-9 2200±50 1000±50 4NTV98-EPHYBU

R80CR-9 2100±50 1000±50 4NTV98-ZVHYB

standard output

eco -eng.)

C

HHIE TRAINING CENTRE

At full charge,

eng. drop is max “150 rpm”

Page 4

1. GENERAL - SPECIFICATION

PAGE

- 4 -

R55(W)-7A R80-7A

2260 2250

C

HHIE TRAINING CENTRE

Page 5

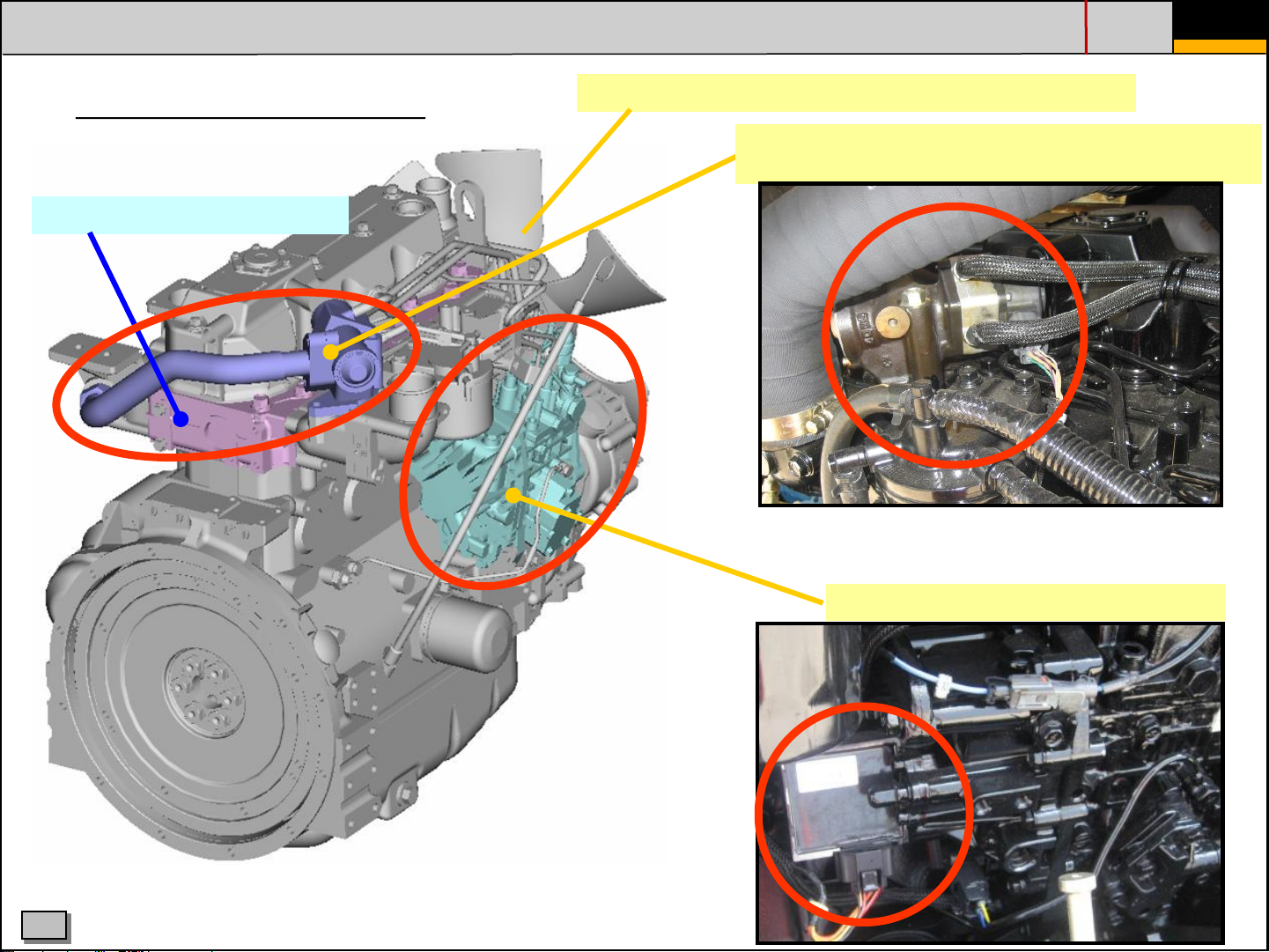

1. GENERAL - ENGINE LAY-OUT

PAGE

- 5 -

NV3, adapted (tier III)

Cylinder head with 4 valves

Optimization of injection bore diameter→Reduce PM

Electronic control of EGR (exhaust gas recirculation)

to achieve lower NOx

Electronic Control of Governor (ECO)

C

HHIE TRAINING CENTRE

Page 6

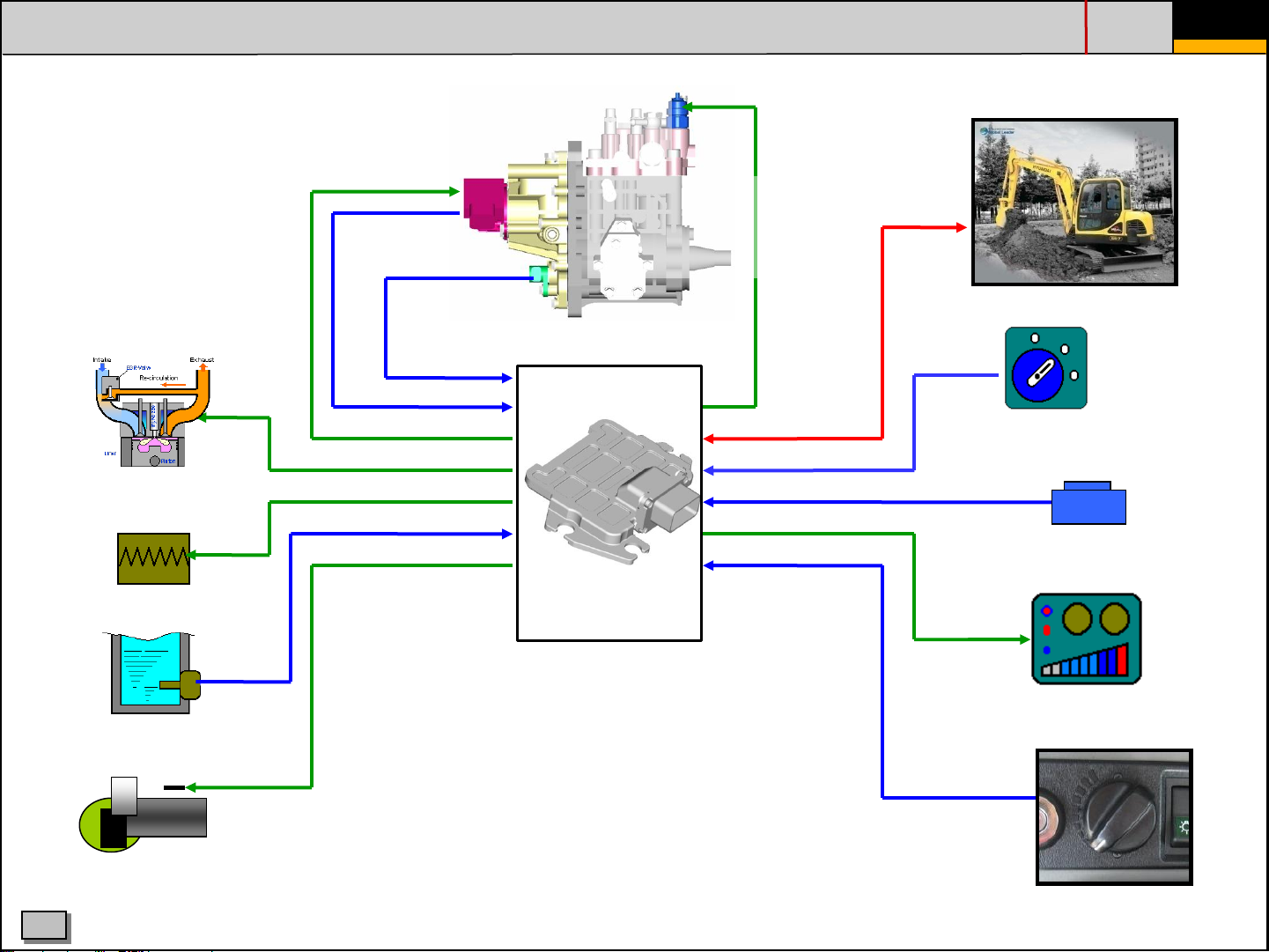

2. ELECTRONIC CONTROL SYSTEM (ECO)

PAGE

- 6 -

EGR

Air heater

Actuator

Rack position

sensor

Engine speed sensor

Electronic

control

governor

CSD valve (cold start device)

Fuel

injection pump

ECU

CAN

OFF

ON

START

Key switch

Switch

Coolant temp. sensor

Starter

C

Display

Accelerator

HHIE TRAINING CENTRE

Page 7

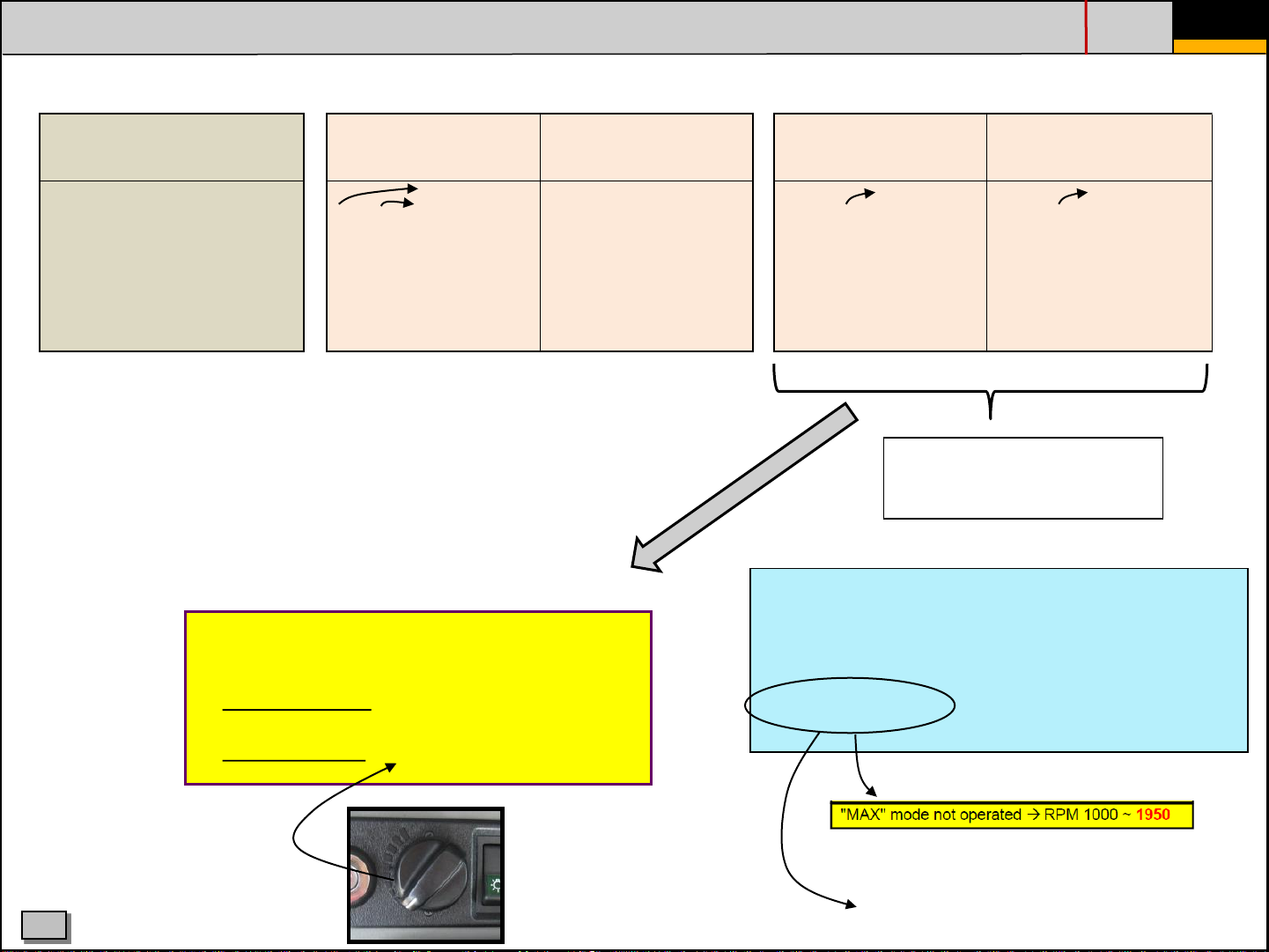

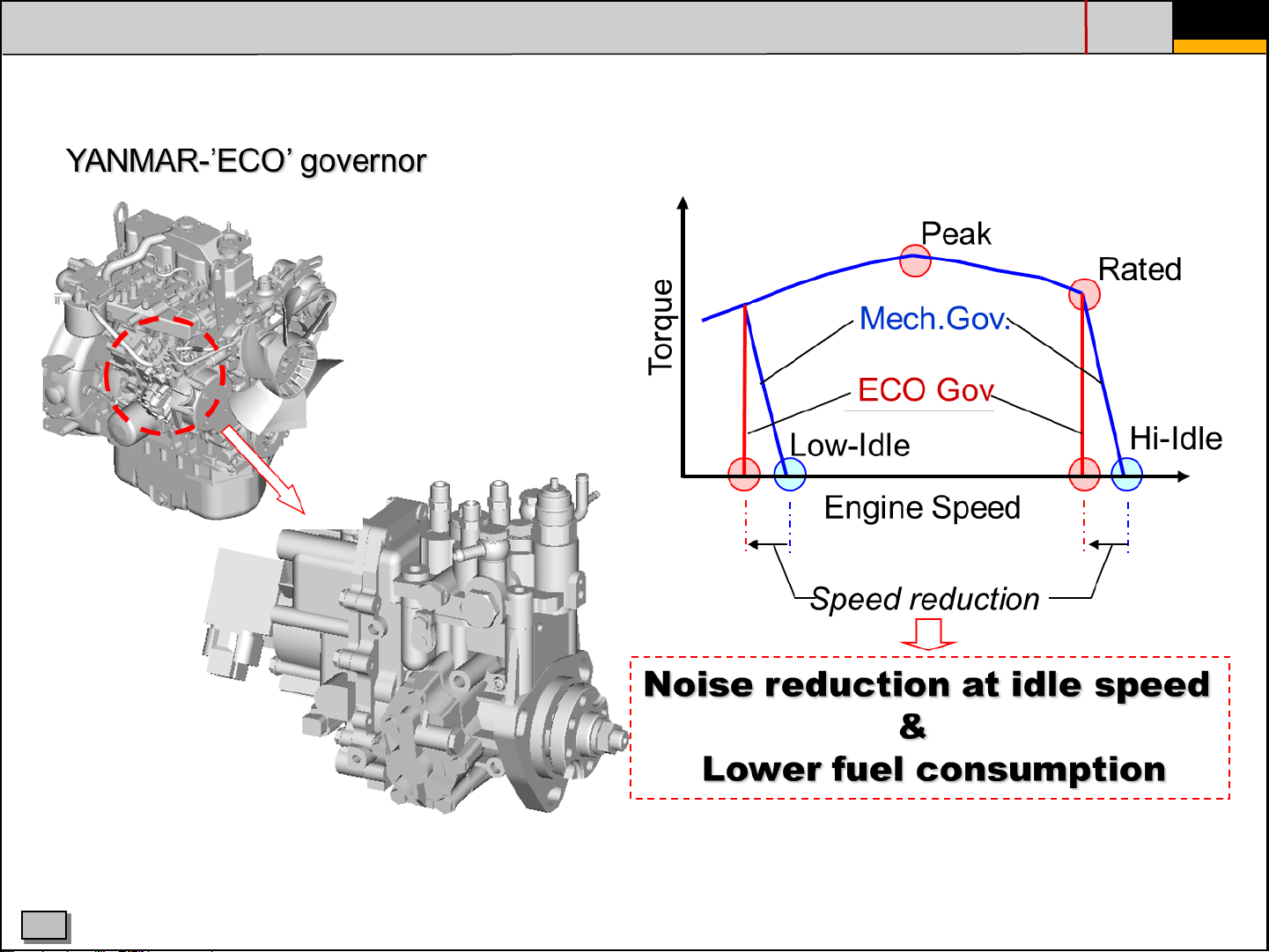

2. ELECTRONIC CONTROL SYSTEM ECO GOVERNOR

PAGE

- 7 -

C

HHIE TRAINING CENTRE

Page 8

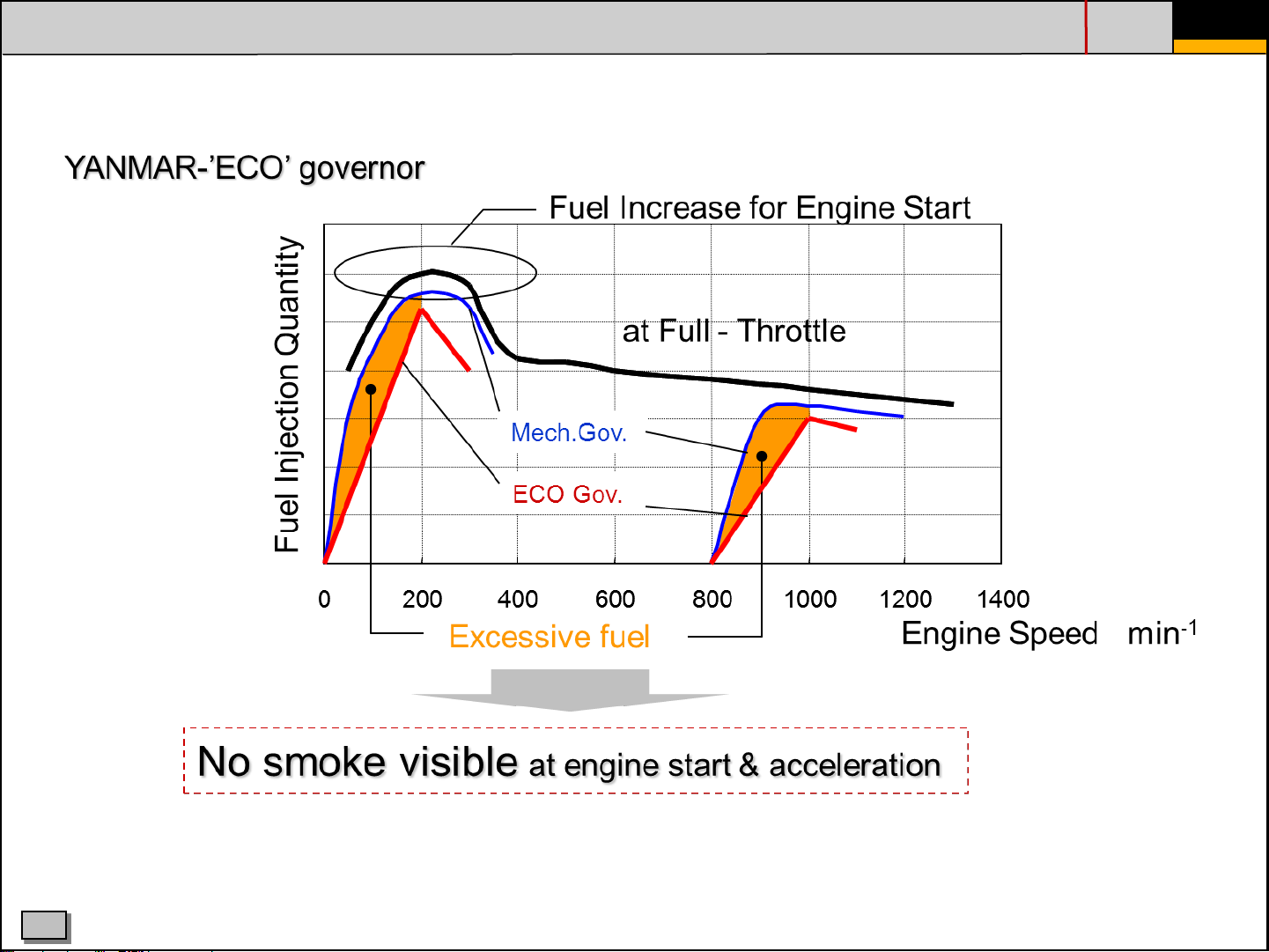

2. ELECTRONIC CONTROL SYSTEM ECO GOVERNOR

PAGE

- 8 -

C

HHIE TRAINING CENTRE

Page 9

2. ELECTRONIC CONTROL SYSTEM 2G ECO GOVERNOR

Eco-Governor is Yanmar’s unique electronics control governor system which has been

used for over 10 years mainly on agricultural machines. Yanmar has renewed this

system to aplly to all equipment and named it “2G Eco-Governor” which means second

generation Eco-Governor. In addition an EGR valve is controlled by this system.

PAGE

- 9 -

C

Idling speed control After heat control Communication function

Idling speed will be adjusted

depending on cooling water

temperature

Engine warm-up time reduced,

protection at high idle & less

white smoke

Starting aid devices stay

activated after start

HHIE TRAINING CENTRE

Data logging by ECO system

Connection for troubleshooting

Possible to monitor engine

performance

System diagnosis incl history

Page 10

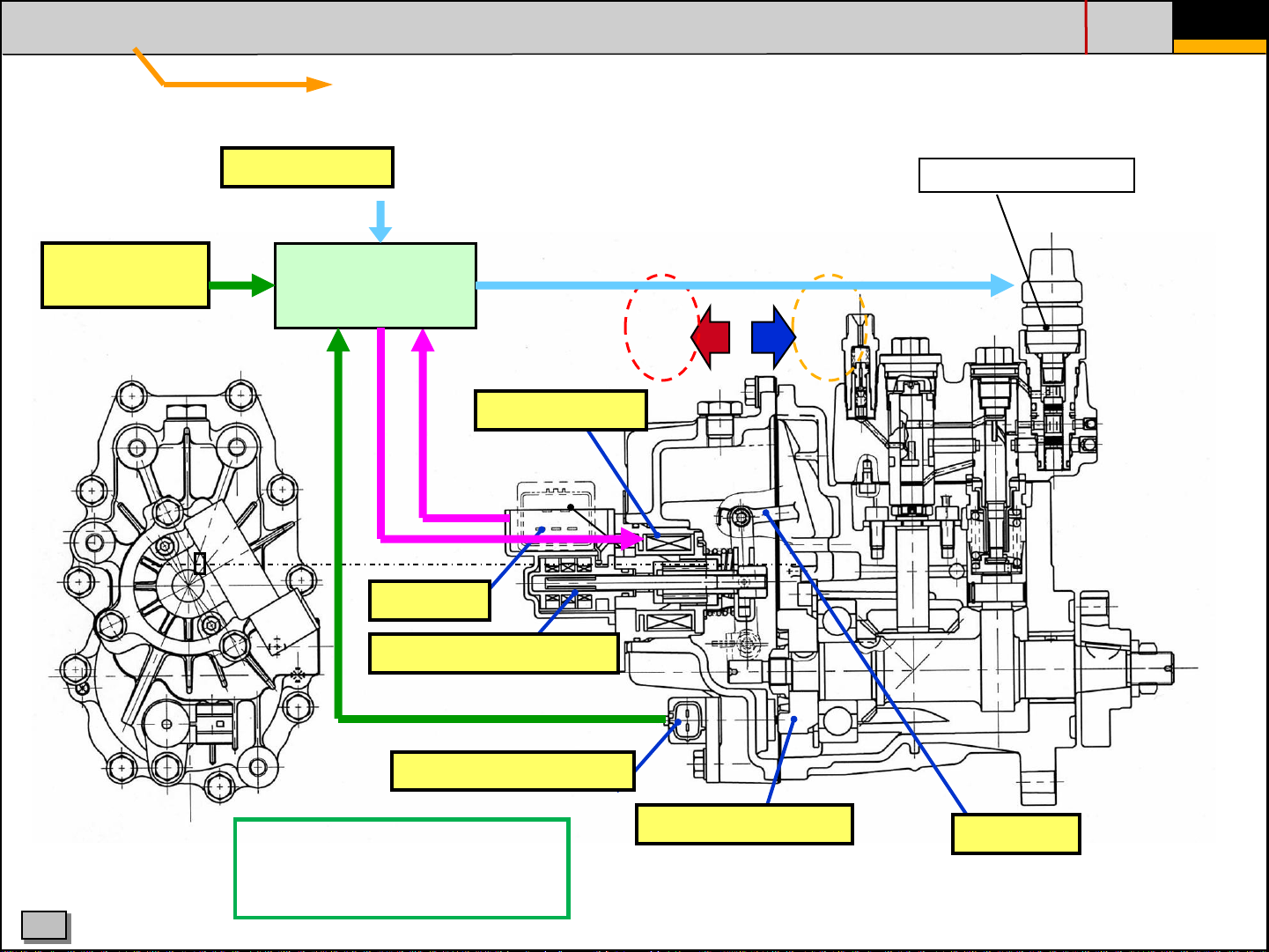

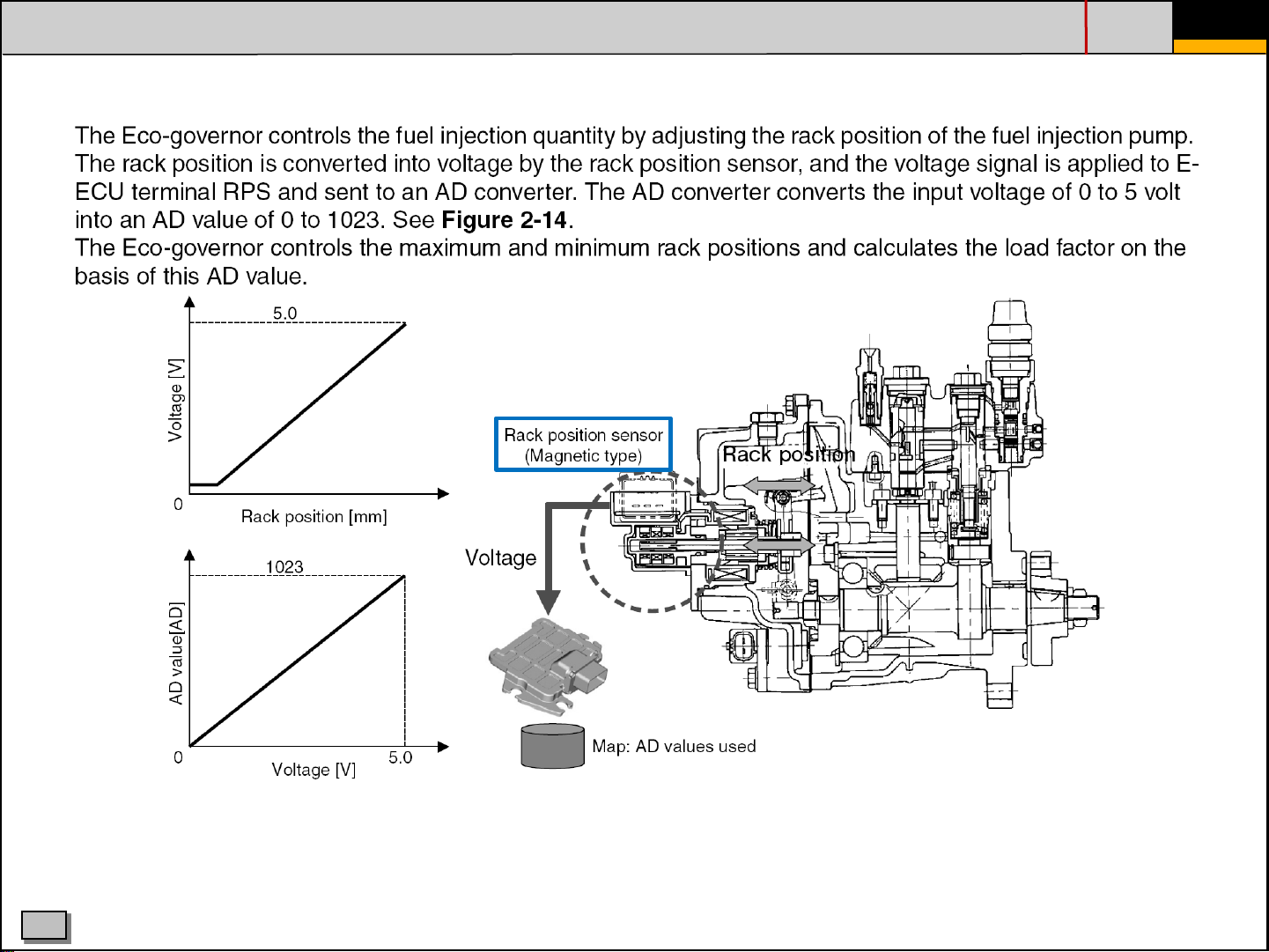

3. INJECTION PUMP - RACK CONTROL

Electronically control rack by ECU

PAGE

- 10 -

Target

engine speed

Water Temp.

ECU

Actuator force

Actuator

Rack act.

Rack position sensor

Fuel

+

Solenoid valve CSD

Spring return

Fuel

-

C

Engine speed sensor

when replacing the pump, data files

need to be written to the ECU>> See

"TNV-ECO-diagnostic tool.pdf, p51

for more information

HHIE TRAINING CENTRE

Engine speed gear

Rack

Page 11

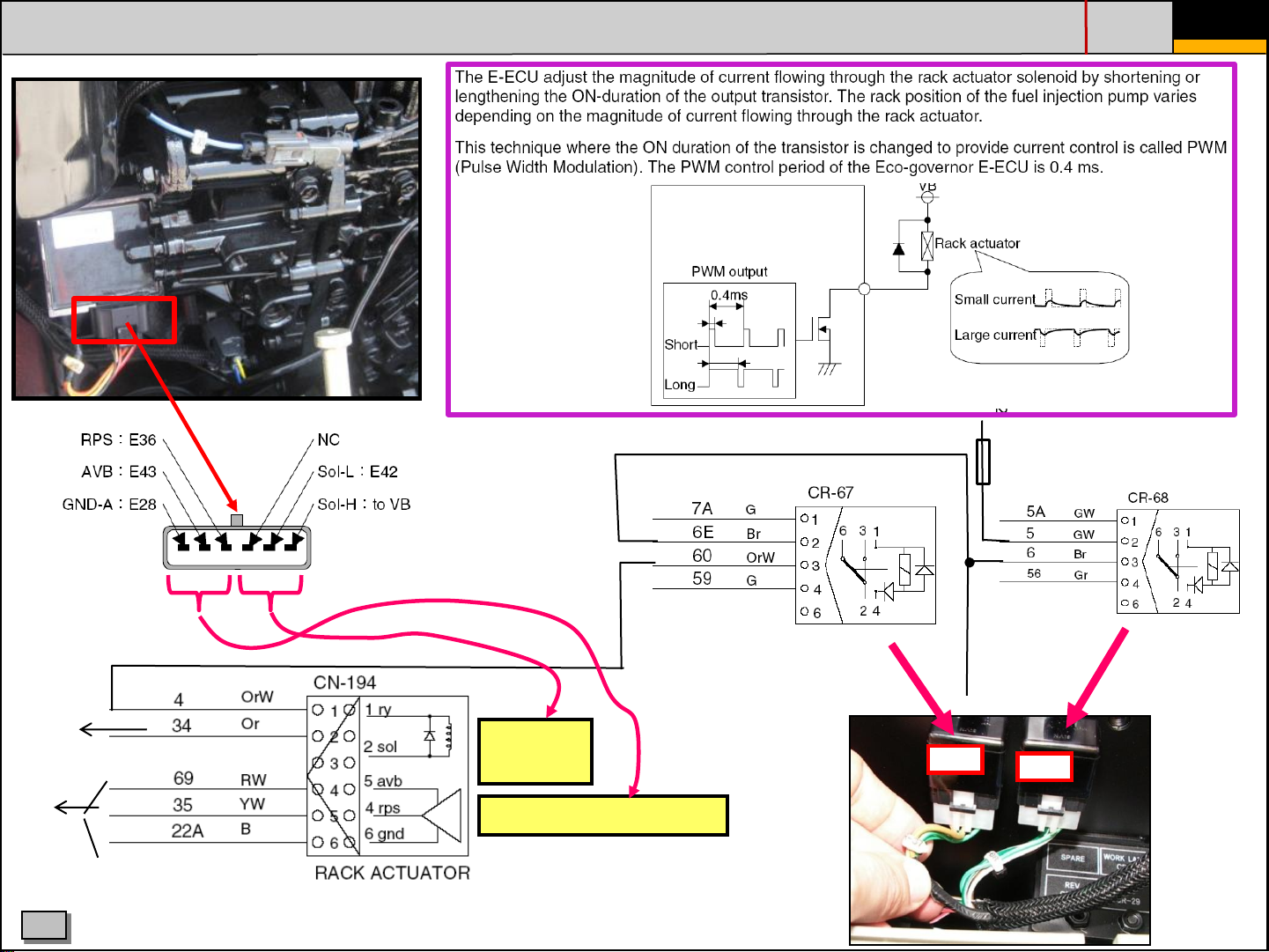

3. INJECTION PUMP - RACK CONTROL

PAGE

- 11 -

ECU

pin

nr. 42

12V fuse ECU

to ECU (pin 42)

(neg. control)

to ECU

C

6 5 4 3 2 1

Rack

actuator

Rack position sensor

HHIE TRAINING CENTRE

Relay

rack actuator

CR67

Relay

ECU Main

Power

CR68

Page 12

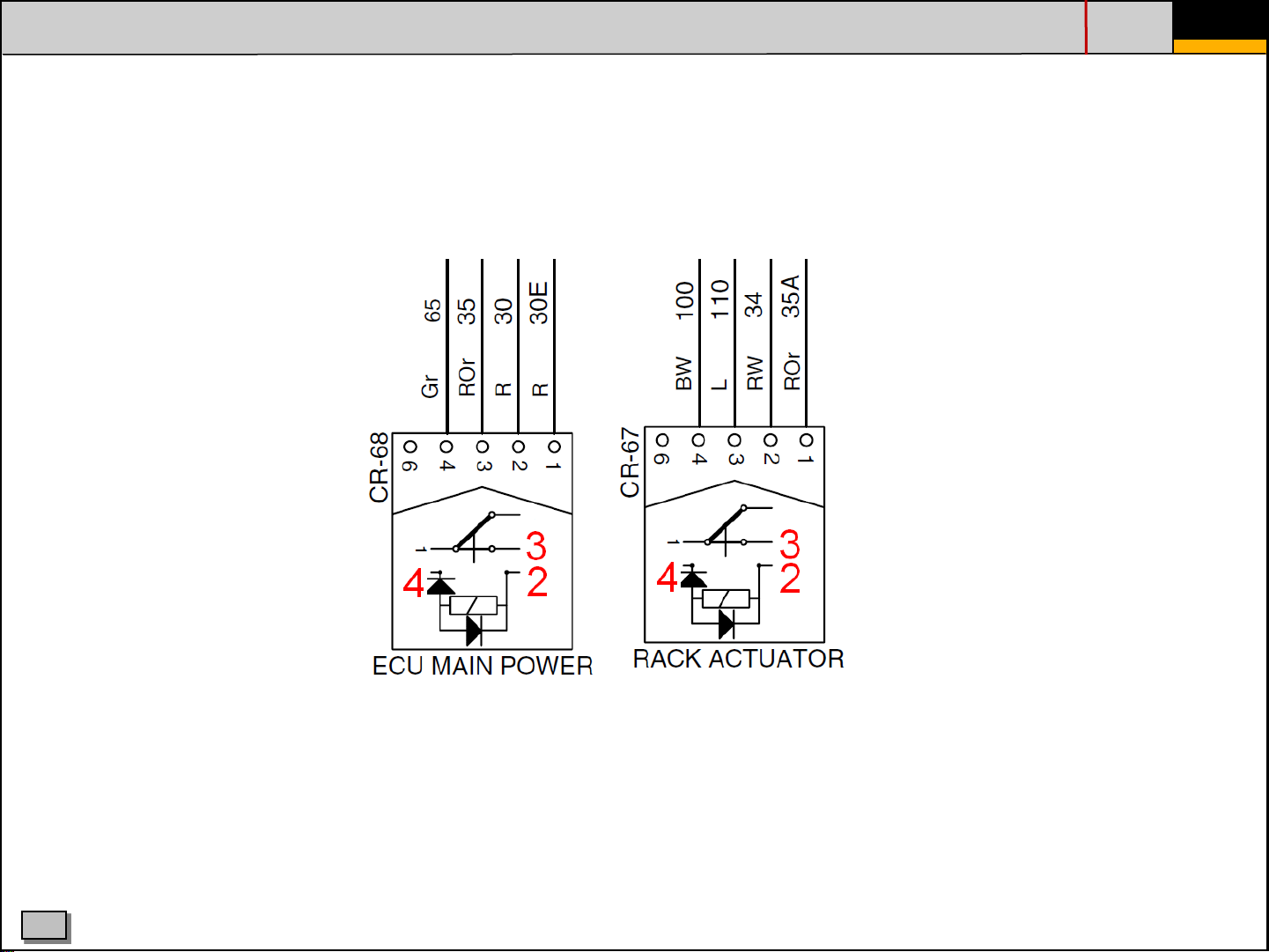

3. INJECTION PUMP - RACK CONTROL

CORRECTED PIN LAY OUT FOR CR-68 (ecu main power) AND CR-67 (rack actuator) ON R80-7A

PAGE

- 12 -

C

HHIE TRAINING CENTRE

Page 13

3. INJECTION PUMP - RACK POSITION SENSOR

PAGE

- 13 -

C

HHIE TRAINING CENTRE

Page 14

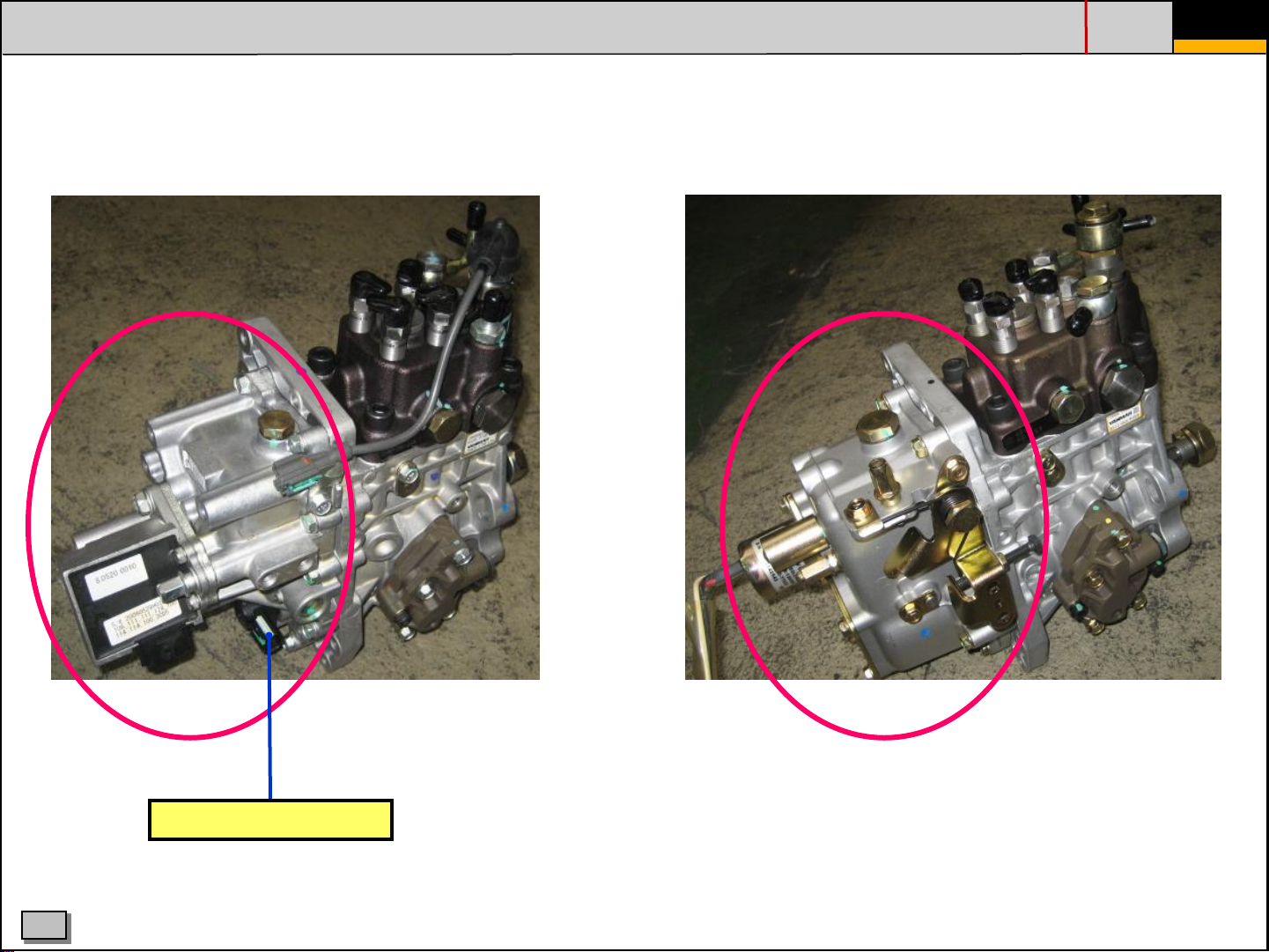

3. INJECTION PUMP - ECO 2G GOVERNOR VERSUS MECHANICAL GOVERNOR

INJ. PUMP WITH EL. GOVERNOR (on -7A & -9) INJ. PUMP WITH MECHANICAL GOVERNOR (on -7)

PAGE

- 14 -

C

Engine speed sensor

• magnetic type

• detects eng. speed with 12 pulsers attached

to the camshaft

HHIE TRAINING CENTRE

Page 15

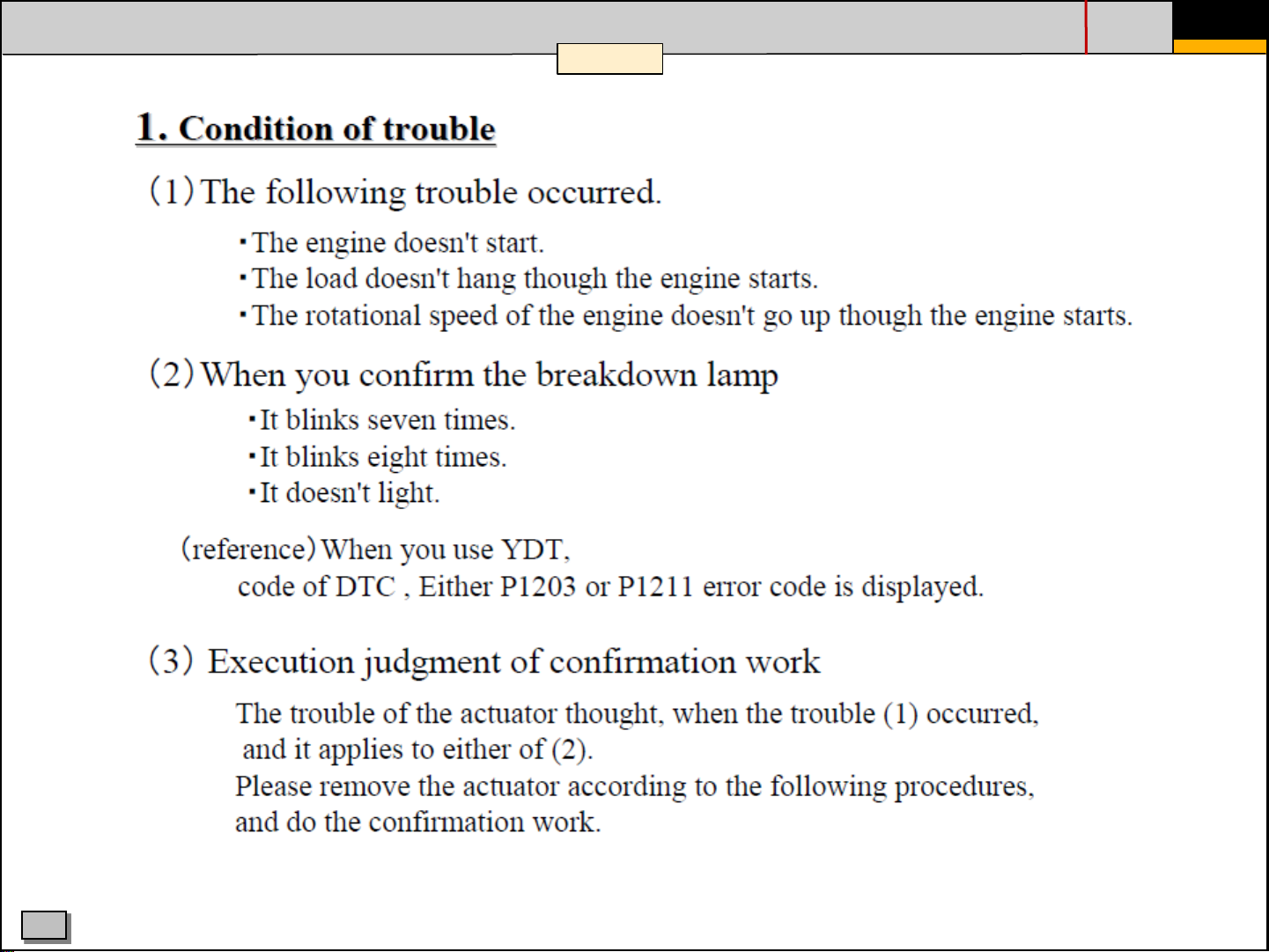

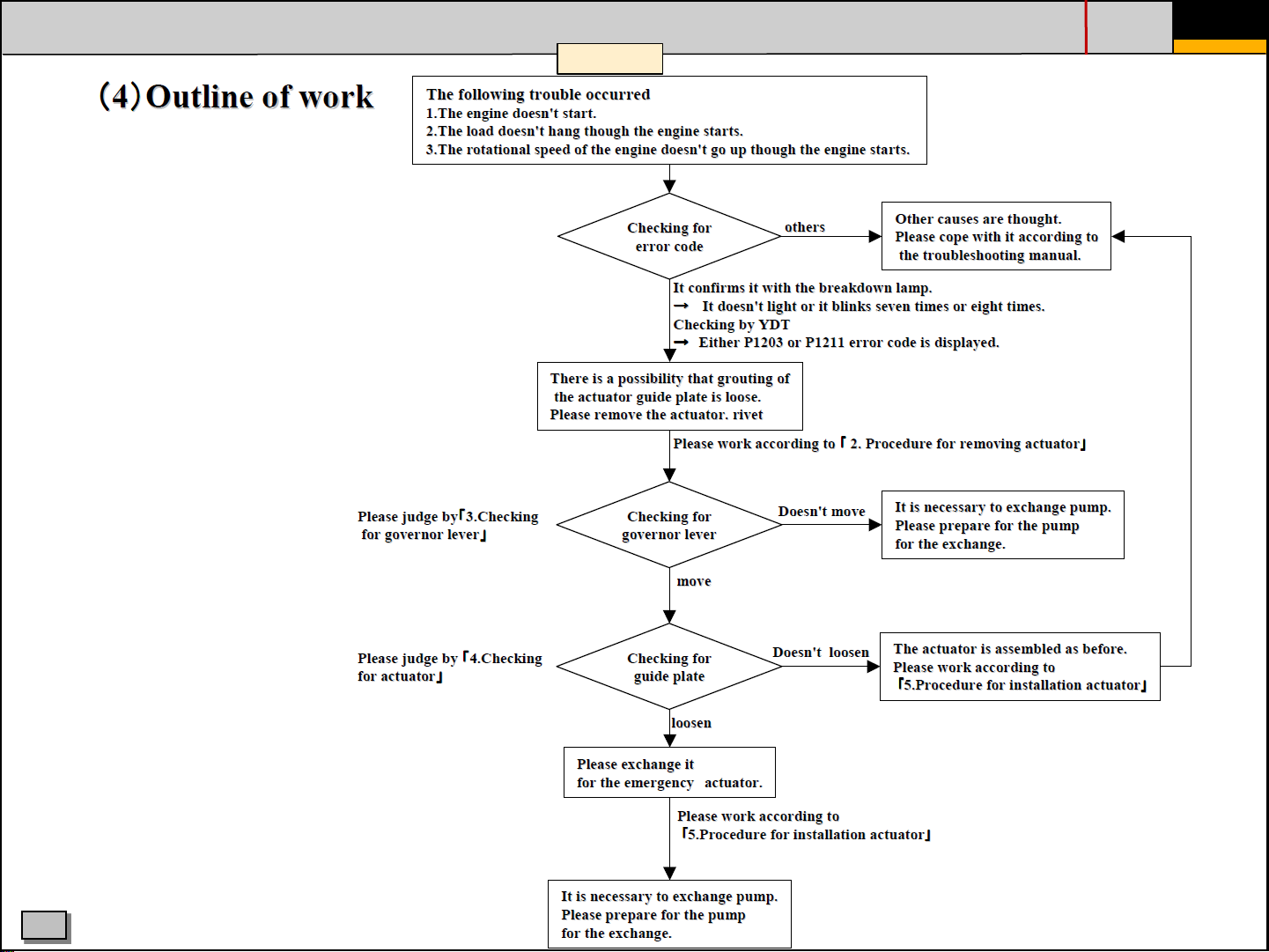

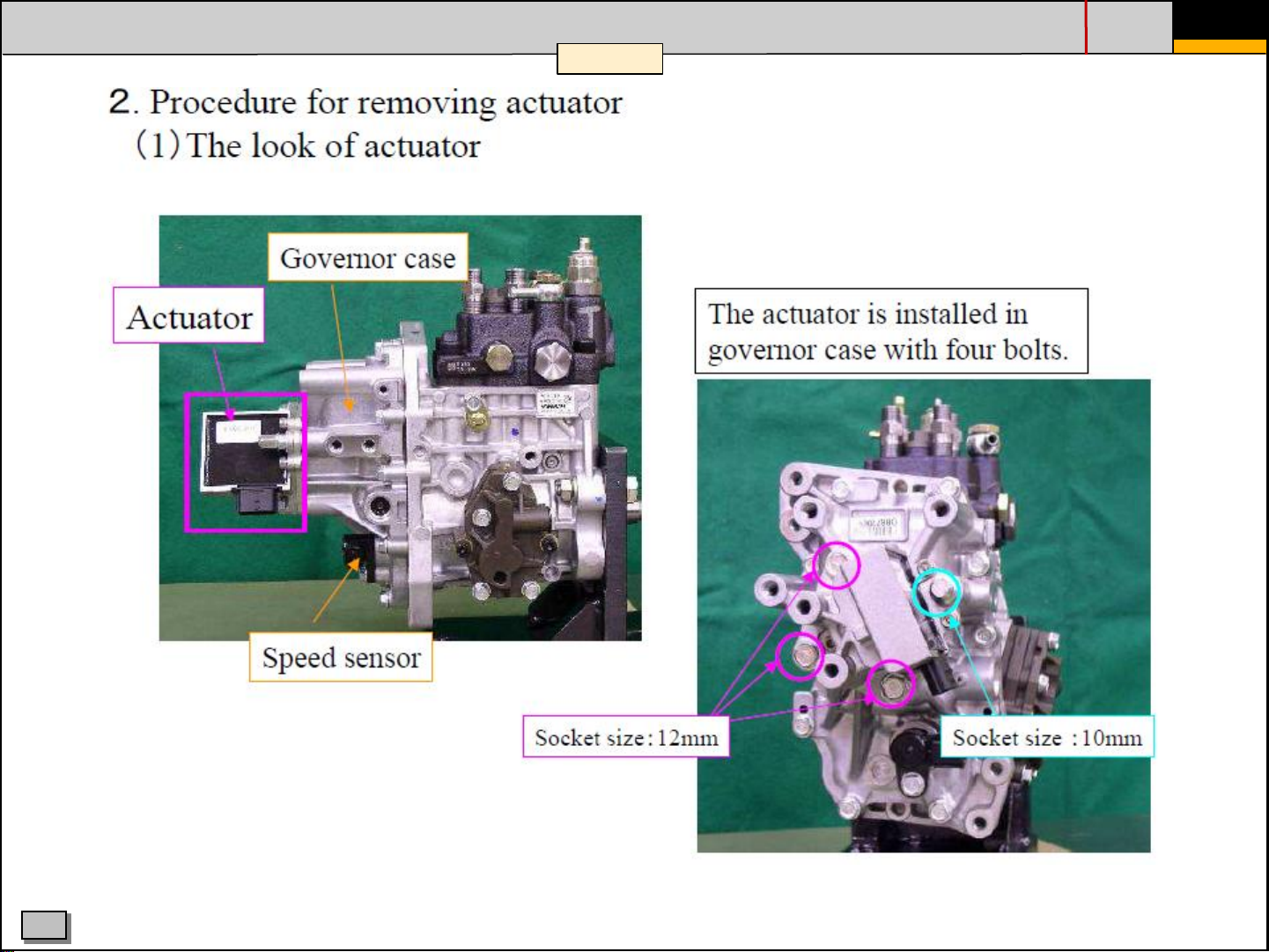

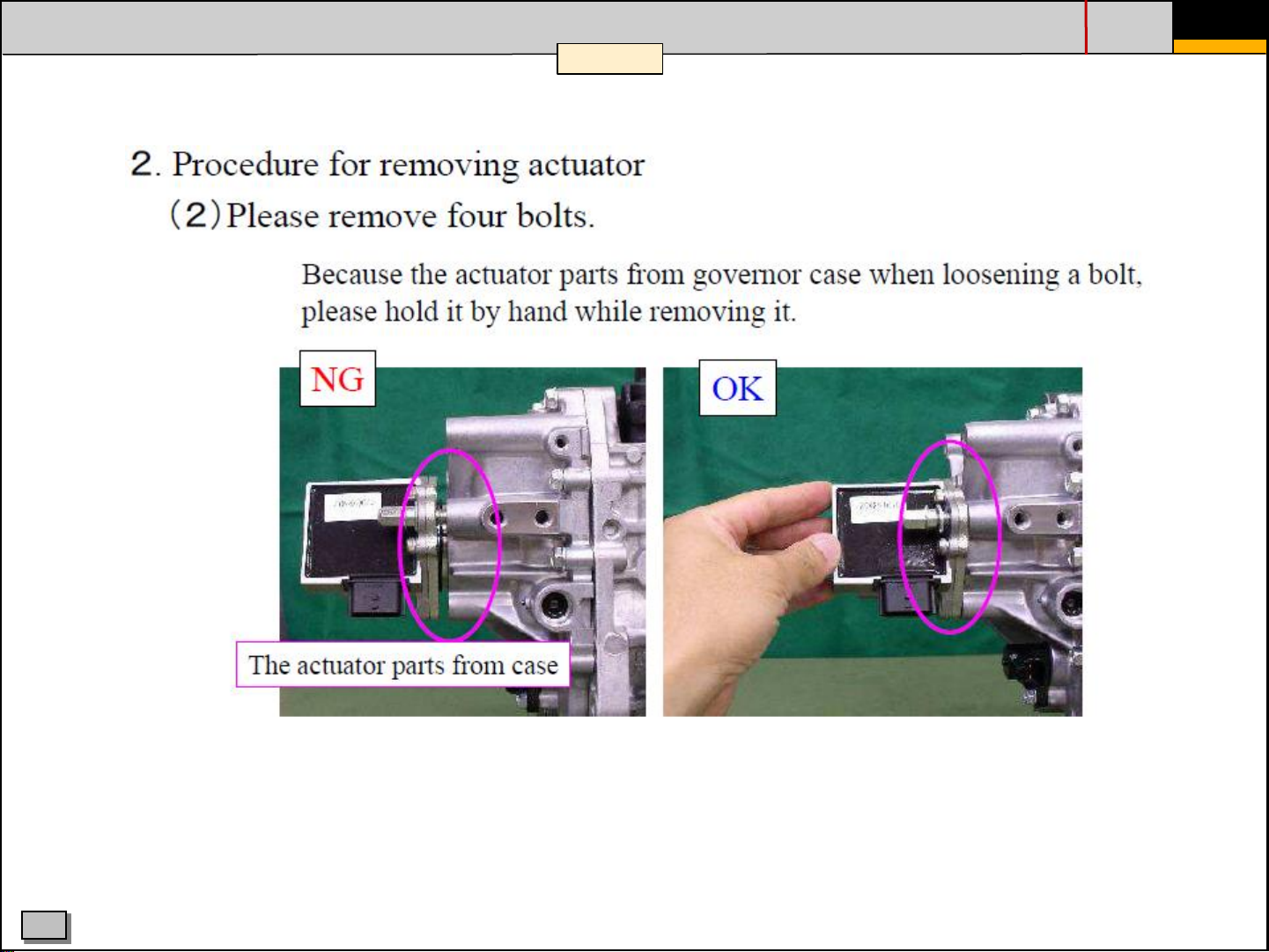

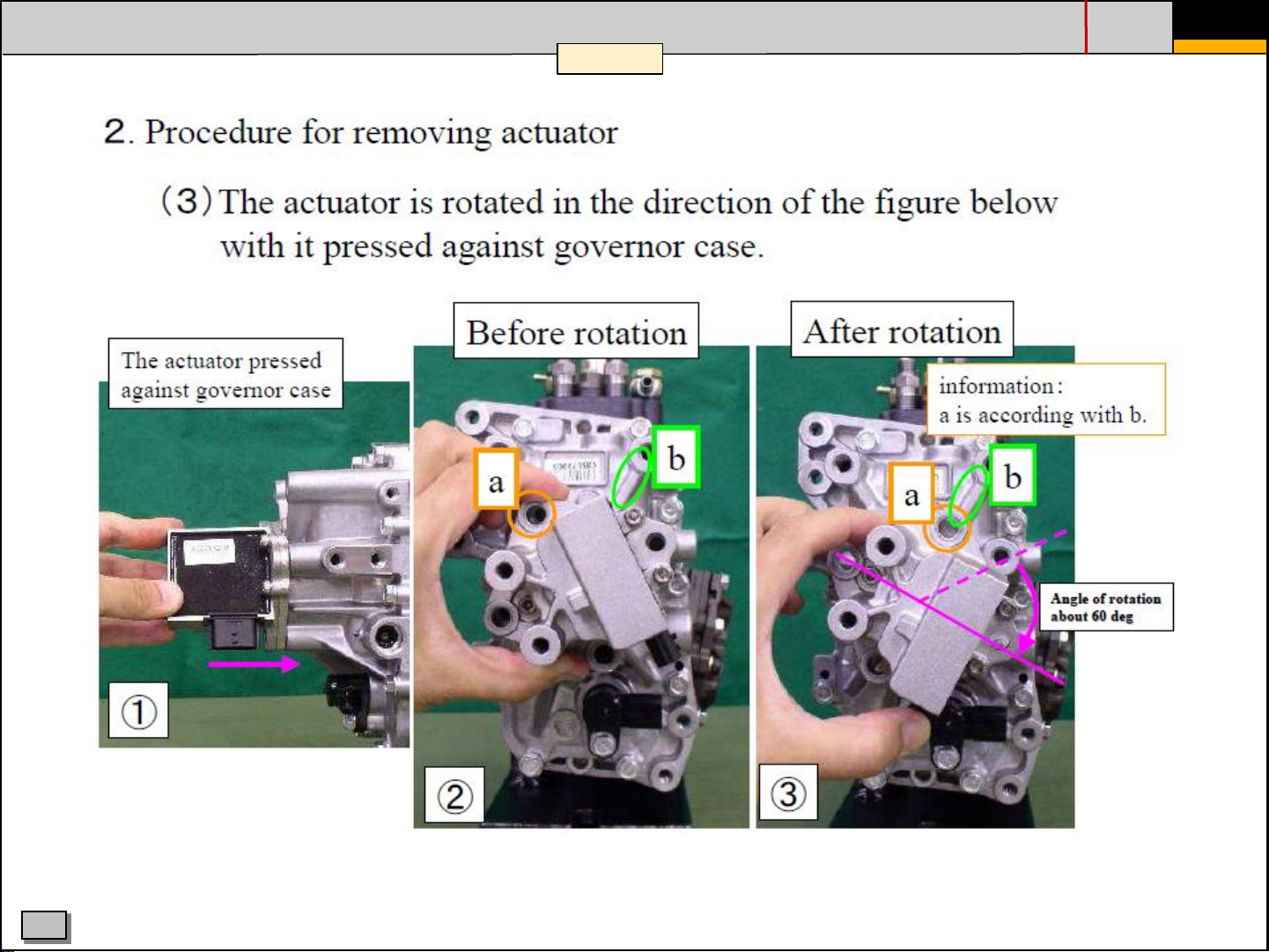

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

1 / 19

PAGE

- 15 -

C

HHIE TRAINING CENTRE

Page 16

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

2 / 19

PAGE

- 16 -

C

HHIE TRAINING CENTRE

Page 17

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

3 / 19

PAGE

- 17 -

C

HHIE TRAINING CENTRE

Page 18

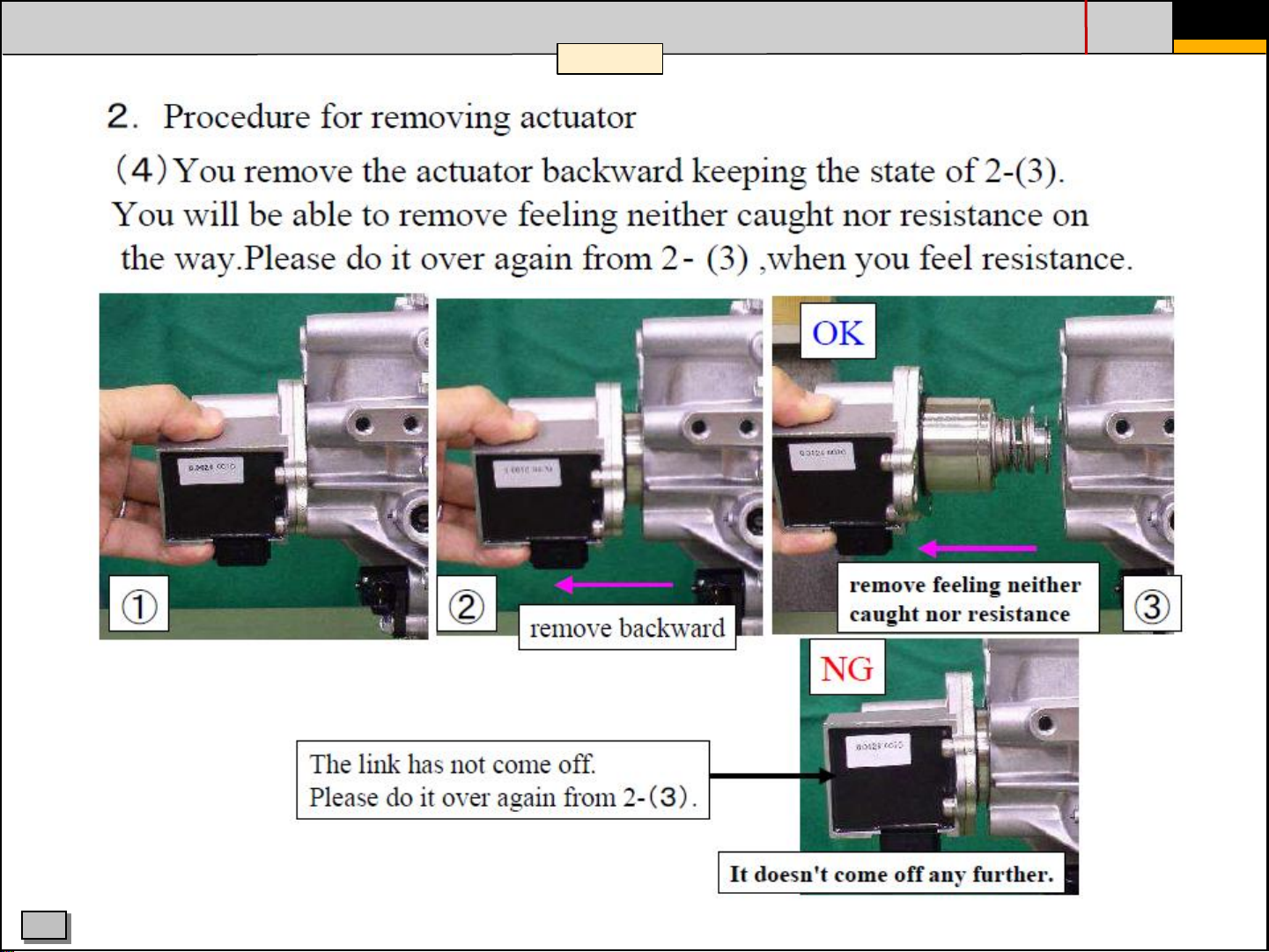

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

4 / 19

PAGE

- 18 -

C

HHIE TRAINING CENTRE

Page 19

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

5 / 19

PAGE

- 19 -

C

HHIE TRAINING CENTRE

Page 20

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

6 / 19

PAGE

- 20 -

C

HHIE TRAINING CENTRE

Page 21

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

7 / 19

PAGE

- 21 -

C

HHIE TRAINING CENTRE

Page 22

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

8 / 19

PAGE

- 22 -

C

HHIE TRAINING CENTRE

Page 23

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

9 / 19

PAGE

- 23 -

C

HHIE TRAINING CENTRE

Page 24

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

10 / 19

PAGE

- 24 -

C

HHIE TRAINING CENTRE

Page 25

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

11 / 19

PAGE

- 25 -

C

HHIE TRAINING CENTRE

Page 26

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

12 / 19

PAGE

- 26 -

C

HHIE TRAINING CENTRE

Page 27

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

13 / 19

PAGE

- 27 -

C

HHIE TRAINING CENTRE

Page 28

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

14 / 19

PAGE

- 28 -

C

HHIE TRAINING CENTRE

Page 29

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

15 / 19

PAGE

- 29 -

C

HHIE TRAINING CENTRE

Page 30

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

16 / 19

PAGE

- 30 -

C

HHIE TRAINING CENTRE

Page 31

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

17 / 19

PAGE

- 31 -

C

HHIE TRAINING CENTRE

Page 32

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

18 / 19

PAGE

- 32 -

C

HHIE TRAINING CENTRE

Page 33

3. INJECTION PUMP - TROUBLESHOOTING FOR ACTUATOR & GOVERNOR-LEVER

19 / 19

PAGE

- 33 -

C

HHIE TRAINING CENTRE

Page 34

Temp coolant ≤ 5

at start

Temp coolant > 5

at

ACTIVATION:

CDS valve opens

(for

DISACTIVATION:

CDS valve closes

3. INJECTION PUMP - COLD START DEVICE (CSD)

PAGE

- 34 -

Solenoid valve CSD

Electric symbol

C

ECU

°C

HHIE TRAINING CENTRE

max. 5 min)

start

°C

Page 35

3. INJECTION PUMP - COLD START DEVICE (CSD)

PAGE

- 35 -

COLD START DEVICE on

YANMAR engine R55-7A

C

HHIE TRAINING CENTRE

Page 36

3. INJECTION PUMP - COLD START DEVICE (CSD)

PAGE

- 36 -

C

HHIE TRAINING CENTRE

Page 37

3. INJECTION PUMP - COLD START DEVICE (CSD)

PAGE

- 37 -

In case of CSD failure,

normaly only the solenoid

valve (1) needs to be

exchanged. All other parts

can remain in the FIP!

If other parts are or need to

be removed as well, the

easiest way to mount back is

shown in the next slides

C

HHIE TRAINING CENTRE

Page 38

3. INJECTION PUMP - COLD START DEVICE (CSD)

HOW TO RE-MOUNT PARTS OF CSD

PAGE

- 38 -

Mount the timer holder

C

Insert the timer spring

HHIE TRAINING CENTRE

Page 39

3. INJECTION PUMP - COLD START DEVICE (CSD)

PAGE

- 39 -

Insert the timer piston

(with some diesel for

lubrication)

C

HHIE TRAINING CENTRE

Page 40

3. INJECTION PUMP - COLD START DEVICE (CSD)

Insert the timer cap

PAGE

- 40 -

C

Timer cap installed

HHIE TRAINING CENTRE

Page 41

3. INJECTION PUMP - COLD START DEVICE (CSD)

Place the solenoid plunger

PAGE

- 41 -

C

And the solenoid spring

HHIE TRAINING CENTRE

Page 42

3. INJECTION PUMP - COLD START DEVICE (CSD)

PAGE

- 42 -

Finaly mount the solenoid

valve. Make sure that the

o-ring is mounted correct

as shown here. At

disassembly the o-ring

cán remain seated on the

solenoid plunger!

C

HHIE TRAINING CENTRE

Page 43

4. EXHAUST GAS RECIRCULATION (EGR)

Electric controlling

EGR

VALVE

ECU

goal of EGR valve:

PAGE

- 43 -

Speed & Load

& temp-coolant

Output

Electronic Control

for EGR valve

Intake Air

Exhaust Gas

combustion temp. reduction

NOx reduction

EGR principe:

By recirculating exhaust gases in the intake, the available gases to combust will be diminuished and that causes

slowing down & cooling of the combustion process by several hundred degrees, thus reducing NOx formation.

!! For electronically controlled EGR engine, it is necessary tu use fuel with max. 1000 ppm of sulfur !!! In

case of too much sulfur parts, sulfuric acid can be formed (due to the presence of recycled sulfur dioxide) and

cause corrosion on the cylinder liner and other major components

EGR domain

Engine Speed

C

HHIE TRAINING CENTRE

Page 44

4. EXHAUST GAS RECIRCULATION (EGR)

Output from ECU to EGR valve:

PAGE

- 44 -

Fig 2-22

C

EGR

VALVE

(A)

+12V

(A)

(B)

+12V

(B)

HHIE TRAINING CENTRE

Page 45

5. COOLANT(WATER) TEMP SENSORS CD-8 & CD-30

yanmar

PAGE

- 45 -

Hyundai

water temp. sensor

CD-30

(21EA-62010 for R55-7A )

C

Yanmar

water temp. sensor

CD-8

(XJAU-00896 for R55-7A)

HHIE TRAINING CENTRE

Page 46

5. COOLANT(WATER) TEMP SENSOR CD-8 (YANMAR )

PAGE

- 46 -

Voltage sig.

0.3 ~ 4.7 V

(HOT temp COLD temp)

C

Yanmar

water temp. sensor

CD-8

HHIE TRAINING CENTRE

Page 47

6a. LOCATION OF YANMAR ECU (& other electric components)

R55-7A

ENGINE

CONTROL

UNIT

R55-7A

DIAGNOSTIC PLUG

YANMAR CN 148

PAGE

- 47 -

ECU

RESISTOR RS-1

C

CR23

START

RELAY

CR24

AIR HEATER

RELAY

HHIE TRAINING CENTRE

Page 48

6a. LOCATION OF YANMAR ECU (& other electric components)

PAGE

- 48 -

R80CR-9 (first model)

VIEW BEHIND CAB

ECU

ENGINE CONTROL

UNIT

R80CR-9

(later model)

VIEW

RH SIDE OF CAB

ECU

C

DIAGNOSTIC PLUG

YANMAR CN148

HHIE TRAINING CENTRE

VIEW BEHIND CAB

ECU

R60CR-9

(later model)

Page 49

6b. STARTER CONTROL

Starter Control

Starter safety control

PAGE

- 49 -

Changeable(Option)

C

325 rpm

675 rpm

HHIE TRAINING CENTRE

Page 50

6c. ECU INPUTS & OUTPUTS

Eng. oil ps

Overheat lamp

(accel dial)

Find detailed info on ECU in/outputs:

in "elec-control-manual" p. 2-15/2-16-2-17

M-mode function

Eng. oil ps

Cluster

- 50 -

water temp

HYUNDAI

YANMAR

PAGE

C

Plug for

diagnose &

programming

to CDS

valve

HHIE TRAINING CENTRE

page 17

Page 51

7. ENGINE VIEW

Air cleaner SW

CD 10

CSD valve (Cold

start device) CD 62

EGR valve (Exhaust

Gas Recirculation)

CN 193

RACK

ACTUATOR

CN 194

Lift pump

CN 145

Water Temp

CD 8

(Yanmar)

Water Temp

CD 30

(Hyundai)

Pre heater

CN 80

Eng Oil

press CD 18

PAGE - 51 -

Tacho

(speed)

sensor

CD 17

C

Page 52

8a. ENGINE ERROR CODE SYSTEM -7A Series

When the ECU (engine control unit) detects an active engine fault,

the engine fault warning lamp on the cluster lights up and the beeper inside cluster starts beeping

Each engine fault code generates a specified amount of beeps with specified length:

Example 1

PAGE

- 52 -

LISTEN TO LENGTH &

FREQUENCE OF

BEEPS FOR

TROUBLESHOOTING !

“Accelerator engine failure” BEEPS CODE = “5”

In this case the beeper creates 5 “short” beeps

Example 2

“ERG valve failure” BEEPS CODE = “1 - 3”

In this case the beeper creates 1 “long” beep,

followed by 3 “short” beeps

In case of simultaneous engine faults, the different beep patterns will appear successively, in order of increasing number of beeps.

A complete overview of the engine errors list can be found on next pages

C

HHIE TRAINING CENTRE

Page 53

ENGINE ERROR CODES LIST

C

PAGE - 53 -

Number

of

beeps

Page 54

ENGINE ERROR CODES LIST

C

PAGE - 54 -

Number

of

beeps

Page 55

ENGINE ERROR CODES LIST

C

PAGE - 55 -

Number

of

beeps

Page 56

8b. ENGINE ERROR CODE SYSTEM -9 Series

PAGE

- 56 -

C

SEE FULL LIST ON NEXT PAGES

HHIE TRAINING CENTRE

Find more info about Hyundai error

codes & Cluster functioning in the

manual: “CLUSTER 5~8 ton exc.”

YANMAR

To visualise other fault

codes, use the buttons:

Page 57

8b. ENGINE ERROR CODE SYSTEM -9 Series

PAGE

- 57 -

C

HHIE TRAINING CENTRE

Page 58

9. YANMAR ENGINE DIAGNOSTIC TOOL (YEDST)

PAGE

- 58 -

PC Requirements PC/AT compatible

Part nr. of Yanmar Engine Diagnostic Tool : XJAU-01062

interface

USB cable

+ "CD"

cable to connect

in CN148

(diagn. plug)

Mind that some repair works (or others) can only be done by application

of the YEDST tool !

C

-replacing of pump

-calibrating of ECU

-tuning of engine

HHIE TRAINING CENTRE

ECU

Page 59

9. YANMAR ENGINE DIAGNOSTIC TOOL (YEDST) - EXTRACT

>> CONFIGURATION MENU (FOR REPLACE OF ECU, PUMP)

When you mount a new ECU, you need to copy the data from the injection

pump to the ECU: the data per injection pump is "individual " and "engine

specific.

PAGE

- 59 -

FULL INFO SEE

PAGES 44...48 OF

YEDST MANUAL

C

...

Pump data controller

...

...

HHIE TRAINING CENTRE

Page 60

9. YANMAR ENGINE DIAGNOSTIC TOOL (YEDST) - EXTRACT

When you mount a new injection pump, the data from this pump needs to

be written to the ECU: in that case the ECU is updated according to the

settings of the new pump

PAGE

- 60 -

☞

At page 50

of YEDST

manual

>> CALIBRATION MENU (YEDST)

(APS)

>> TUNING (YEDST)

C

HHIE TRAINING CENTRE

☞

☞

At page 51

of YEDST

manual

At page 52

of YEDST

manual

Page 61

10a. FUEL PUMP ADJUSTMENT

Before you adjust the pump timing make sure to

mark the current position! Also attach a mark

sticker on the engine next to the mark on the fuel

pump so you can measure how far you adjust the

fuel pump.

PAGE

- 61 -

C

HHIE TRAINING CENTRE

Page 62

10a. FUEL PUMP ADJUSTMENT

To be able to adjust the fuel pump you first have to loosen 7 bolts. 3 on the rear support and 4

on the flange at the distribution side. In red line you see the position of 2 of them behind the

pump house. These can be reached using a ¼, 14mm socket and extensions as shown in the

picture. The nuts and bolts don’t have to be removed just loosened.

PAGE

- 62 -

C

HHIE TRAINING CENTRE

Page 63

10a. FUEL PUMP ADJUSTMENT

The fuel pump can be tilted to advance or retard the fuel injection moment. To make this

possible the 7 bolts used to fixate the pump are provided with slotted holes.

PAGE

- 63 -

C

HHIE TRAINING CENTRE

Page 64

10a. FUEL PUMP ADJUSTMENT

To advance the fuel injection you have to turn clockwise when looking to the front of the

engine, the delay the fuel injection, turn counter-clockwise.

PAGE

- 64 -

C

HHIE TRAINING CENTRE

Page 65

10b. FUEL PUMP REPLACEMENT

If you like to replace the fuel pump you have to follow the previous steps but this time

completely remove the 7 mounting bolts on the pump and the support on the rear of the pump.

You also have to disconnect the fuel, oil & electric lines. Be carefull for high pressure when you

are disconnecting the fuel lines!

Proceed by removing the fuel pump drive gear cover. Then remove the center nut. NEVER

loosen the four flange bolts! They connect the fuel pump drive gear to the flange through slotted

holes. When they are loosened the fuel pump drive gear can rotate freely and all references of

timing will be lost!

PAGE

- 65 -

C

HHIE TRAINING CENTRE

Page 66

10b. FUEL PUMP REPLACEMENT

PAGE

- 66 -

Normally it is enough to put a mark on fuel pump drive gear

and idler to be able to reassemble the pump on the correct

position after removal. But when the injection pump was

mounted in the wrong position or the engine has rotated after

removal of the pump there is a more precise way to put

everything right on time.

On the crankshaft pully are 3 timing marks, 2 bulges and 1

notch. You have to align this notch to the 0° mark on the

distribution cover (TDC cyl.1), make sure that cyl 1 is not only

on his TDC but also on compression AND be able to see the

“B” mark on the idler in the middle (not to high or to low) of

the opening from the fuel pump driver cover. These 3

situations combined appear only once every !50! Crankshaft

revolutions so a little patience can be helpfull...

When you have the engine in this position you can align the

“B” mark on the fuel pump drive gear with the “B” mark of the

idler and the gears will be positioned perfectly.

C

HHIE TRAINING CENTRE

Page 67

10b. FUEL PUMP REPLACEMENT

PAGE

- 67 -

If you replace the pump you have to calculate the injection timing difference between these pumps:

1) Remove the old pump and take a note of the timing index recorded in that pump.

2) Read the timing on the new pump and calculate the difference between new and old angle.

3) Put the pump temporarily on the gear case and install the drive gear accordingly to the ID marks you

made earlier. (Tightening torque of installation nut => 113 – 123 Nm)

4) Use the marking on the sticker to adjust the calculated (2) injection angle difference.

5) If you have calculated a positive angle correction value, push the fuel pump away from the cylinder block

to delay the injection timing and vice versa to advance the timing in case of a negative value.

C

HHIE TRAINING CENTRE

Page 68

10b. FUEL PUMP REPLACEMENT

If there is no timing index on the pump body

you can find it in this table buy using the

pump ID number.

PAGE

- 68 -

C

HHIE TRAINING CENTRE

Page 69

END

PAGE

- 69 -

C

HHIE TRAINING CENTRE

Loading...

Loading...