Yanmar Tne Servicemanual

SERVISEMANUAL

INDUSTRIALDIESELENGINE

MODELTNEseries

FOREWORD

This Service Manual describes the procedure

TNE series engine (Special swirl precombustion chamber (hereinafter "Indirect injection

and

Direct injection systems}.

Before starting service

and

maintenance

Manual carefully to your full understanding

in

may differ

the structure

machines (such

as the generator, pump, compressor,

and

applicable specification from that loaded on each

of

maintenance

of

TNE engine, you are requested

and

to take careful note that the standard TNE engine

and

and

service

combine, etc.).

of

the Yanmar industrial

system")

to

read this Service

of

individual driven

For further information, carefully read the Service Manual issued for each driven machine.

This Service Manual

the content

of

maintenance for the purpose

in

subject

to

changes, with

Setup before

or

without notice, with respect

of

improving engine quality.

work

to

the structure

To perform work efficiently, the following setup (preparation) is necessary.

1.

Customer

(1) Previous date of service

ledger

check

(2) Check on which month (and at what time) the last service was performed, what

problem occurred, and what the history of the customer (engine) is.

and

2.

Stock

control

of

parts

(1) Stock check for consumable parts, periodic replacement parts, etc., that are

required for service.

(2) Provision of check list, parts list and parts card.

3.

Provision

(1) Work (process) time table

of

service

record

(2) Check sheet (including used parts list)

~)~.uffimentd~~p~1

. .

(4) Operation data and quality (for maintenance of performance and quality)

Disassembly

4.

and

reassembly

tools

(1) Tools

(2) Measuring devices

Other instruments and equipment necessary for service

(3)

This product has been developed, designed and produced in

accordance with the Standards for Quality System of

Organization for Standardization) under the

Inspection Institute), SSI (British Standards Institution)

- 19871

BS

5750:

Part 1 : 19871

- 19871 JIS

Z9901

-1991

FM23056 JQA-0099

ISO

9001

Certified

(International

following authorized institutions: JMI (Japan Machinery and

Metals

Institution) and EQNET (The European Network tor Quality

System Assessment and Certification).

Certified under the following standards:

ISO

9001

EN

29001

ISO 9001

CONTENTS

1.

Specifications and Performance •..•...................•.•...•.•.....••••....•••.•.•...........•.......•.•...•.•.

1-1

1-2

1-3

1-4

1-5

1-6

1-7 3TNE84..............................................................................................................

1-8

1-9

1-10

1-11

1-12 3TNE84T............................................................................................................

1-13

2.

Cross

2-1

2-2

2TNE68..............................................................................................................

3TNE68

3TNE74

3TNE78A

3TNE82A

3TNE82

3TNE88

4TNE82..............................................................................................................

4TNE84.............................................................................................................. 1-10

4TNE88..............................................................................................................

4TNE84T............................................................................................................ 1-13

Sectional Views .................•.........••.•..•••.•••...•...........•.......•...•••••....•...•...•.....•.....•.

Special

Direct

.... ....

....................... ...................... .........................................................

.............................................................................................................. 1-3

..

................................. ........ ............ .......................... ........ .......... ........

........................................................................................................... 1-5

.............................................................................................................. 1-6

.............................................................................................................. 1-8

Swirl

Pre-combustion Chamber System ...............................................

Injection

System.......... ................................ ...... ........ .............................. 2-2

1-1

1-1

1-2

1-4

1-7

1-9

1-11

1-12

2-1

2-1

3.

Cooling Water, Lubricating Oil

3-1

3-2 lubricating oil........................................ .............................................................

3-3

4.

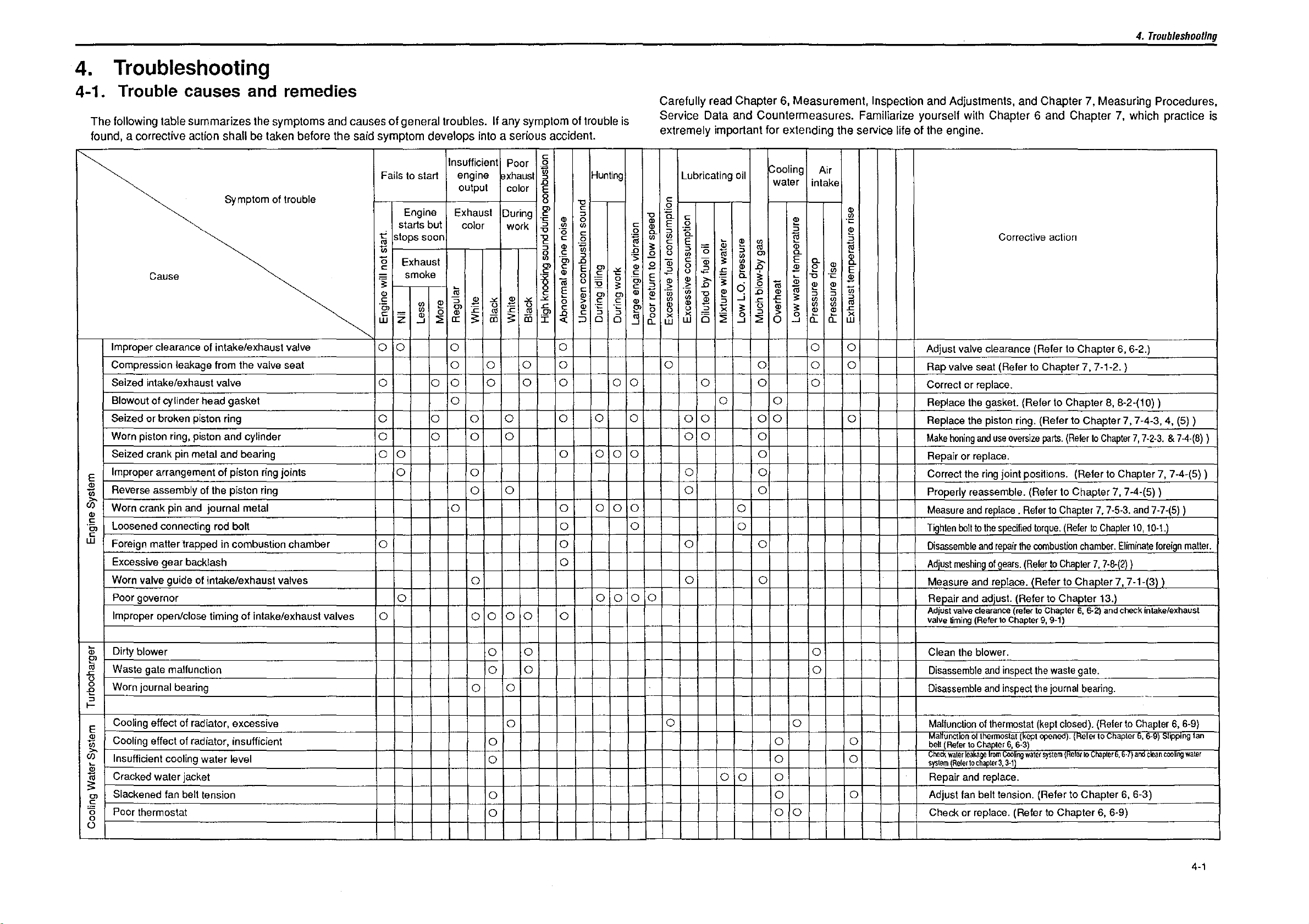

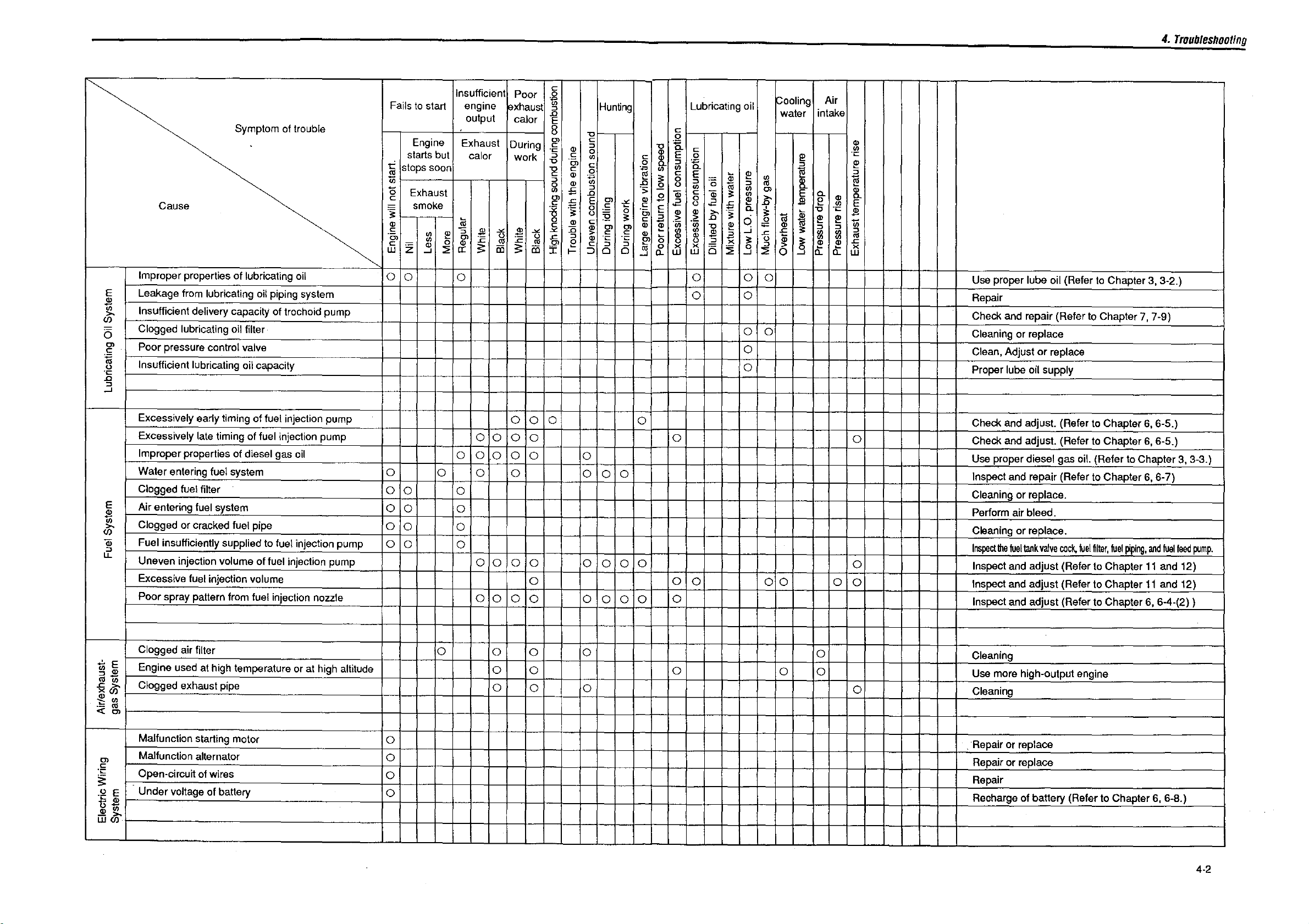

Troubleshooting ............................................................................................................

4-1

4-2

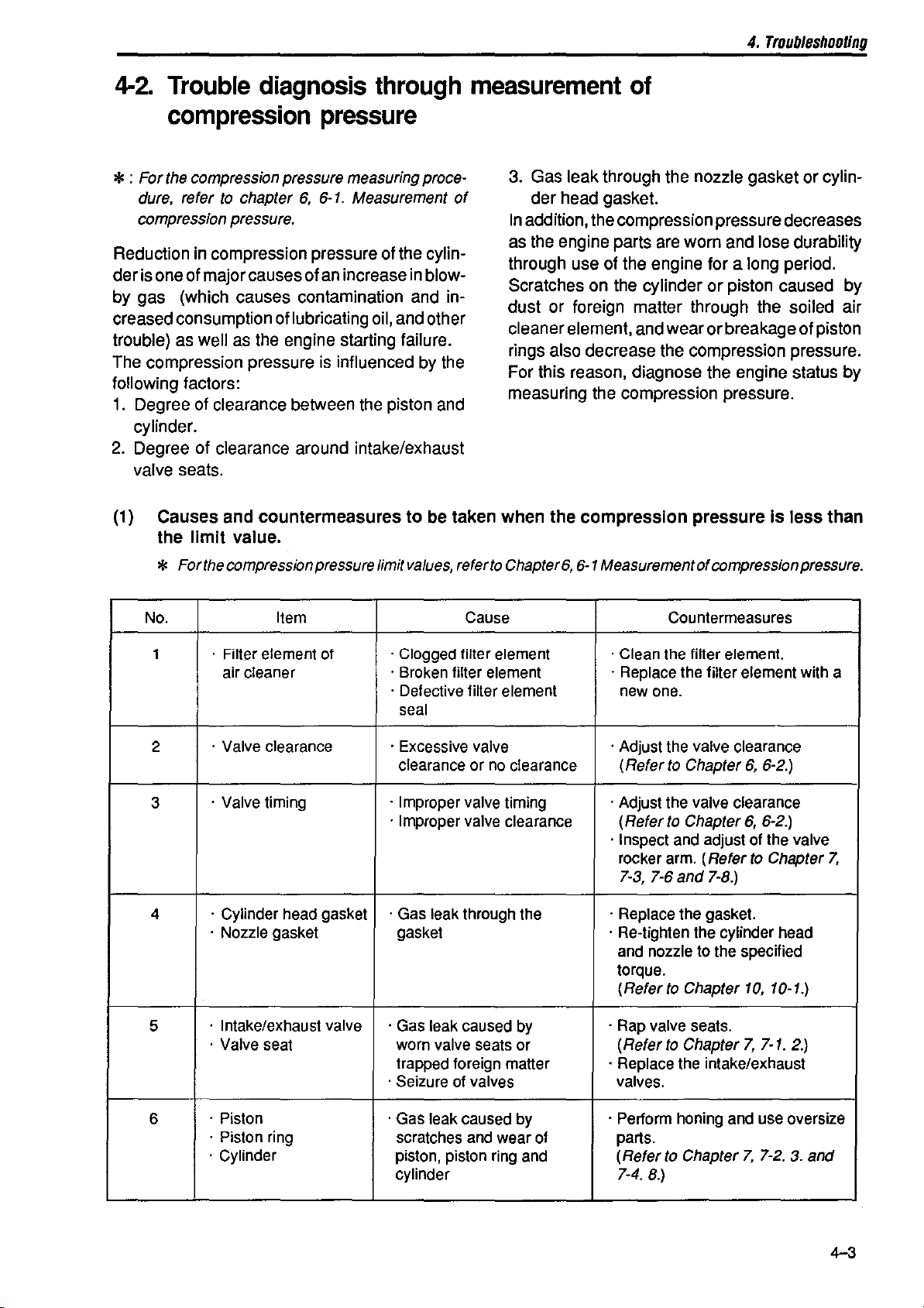

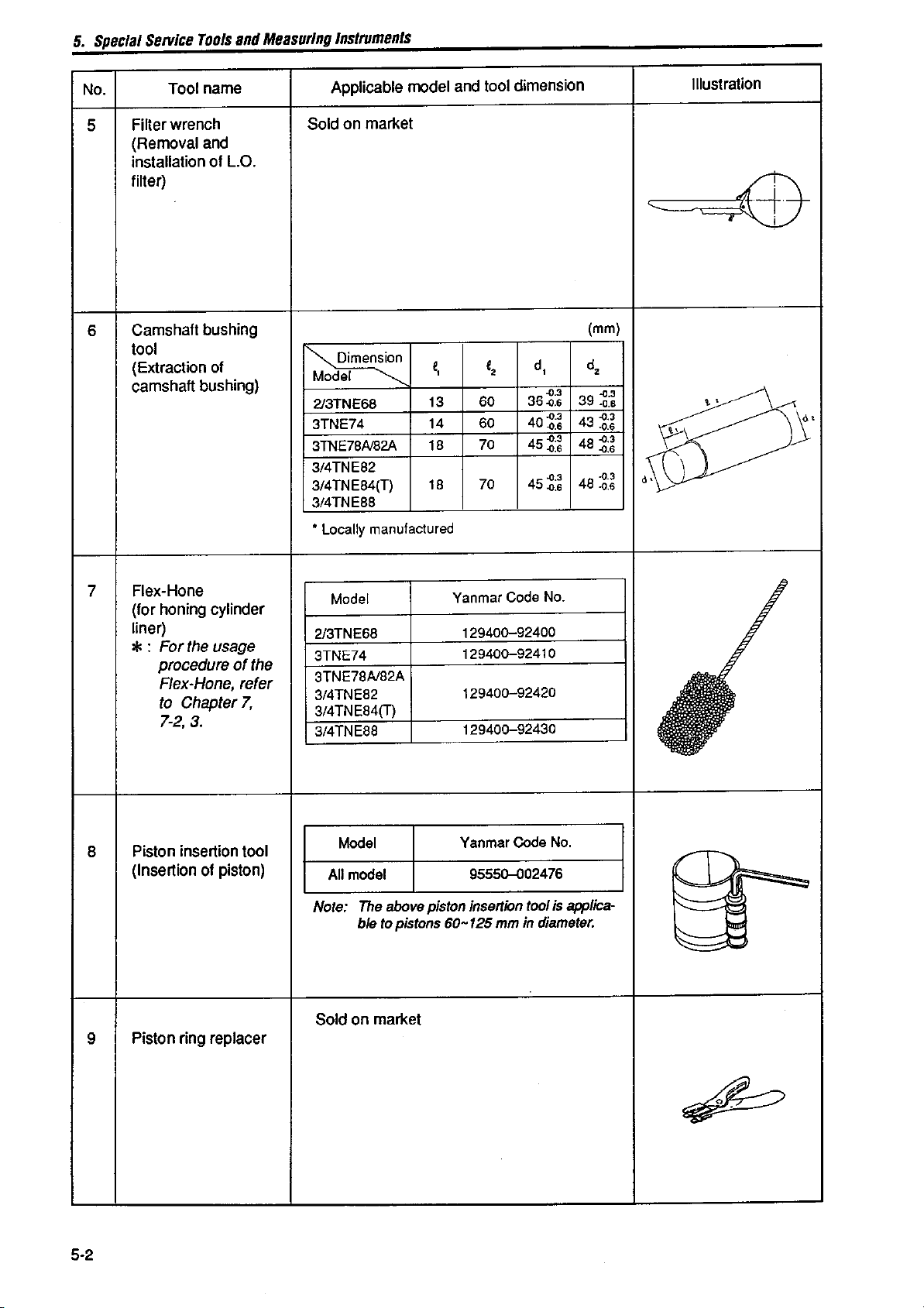

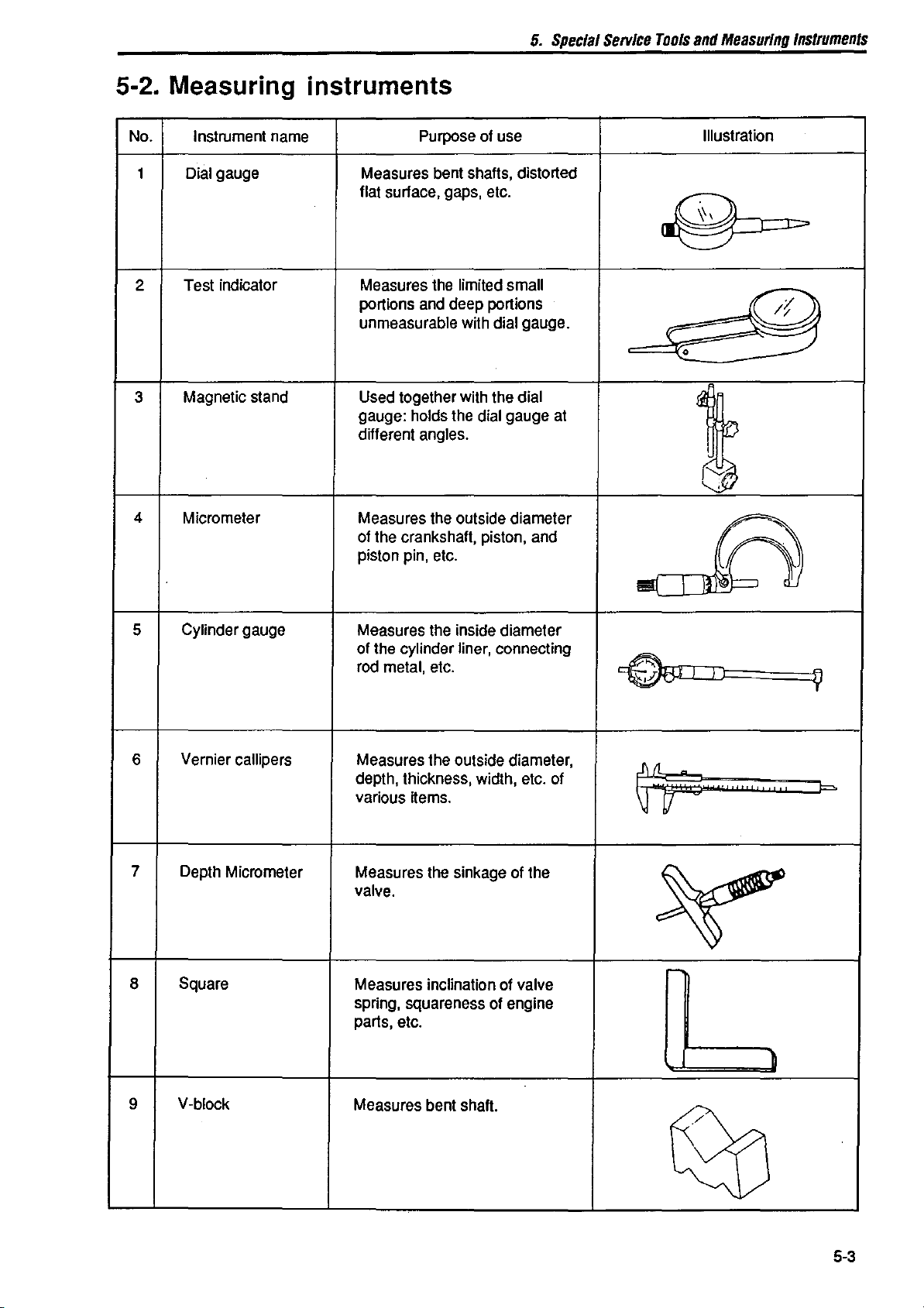

5. Special Service Tools and Measuring Instruments ...................................................

5-1

5-2

6.

Measurement, Inspection

6-1

6-2

6-3

6-4 Measuring and checking the

6-5

6-6

6-7

6-8

6-9

6-10 Checking the

6-11

Cooling

Fuel

Trouble

Trouble

Special service tools.......... ...................... ..................... .................... ............ .....

Measuring instruments ....................................................................................... 5-3

Measuring the compression pressure ......... ................. ................ .......... ............

Adjusting

Checking the V

of

Checking and adjusting the

Adjusting

Checking the

Checking the battery ............................. .............................................................

Checking sensors .............................................................................................. 6-13

Checking the

water .....................................................................................................

oil

.................... ............. .............. .............. .............. ..... ............................... 3-3

causes and remedies............................................................................

diagnosis through measurement

the valve head clearance .................. ................................................. 6-3

-belt

the

fuel

injection

the no-load

COOling

oil

cooler ....................................................................................... 6-14

piston

and

Fuel

Oil

..............................................................

of

compression pressure .................. 4-3

and

Adjustment ................................................................

tension ...... ............................. ................ ............................

injection

valve ........................................... ........................... .............. 6-4

fuel

maximum

water system and radiator

cooling

nozzle ...................................................................

pressure and spray patterns

injection

(or

timing

minimum)

................................................

revolutions ................................ 6-10

for

water leakage .................. 6-10

3-1

3-1

3-1

4-1

4-1

5-1

5-1

6-1

6-1

6-4

6-8

6-11

6-15

7. Measuring Procedures, Service Data and Corrective Action ...................................

7-1

Cylinder head

...

...... ........•......... ...... ...................... ........ ........

...

........... ........ ........

7-2 Cylinder block .................................................................................................... 7-7

7-3

Valve rocker arm..... ........ ...... .......... ...... .............. ............................................... 7-10

7-4 Piston and piston ring ...... ...................... .................................. ........ .................. 7-12

7·5 Connecting rod................ ............ .......... ............. ............. ................................... 7-17

7-6 Camshaft............................................................................................................

7-7 Crankshaft.......................................................................................................... 7-22

7-8

7-9

Gears ................................................................................................................ .

Trochoid pump .................................................................................................

..

7-1

7-1

7-20

7·25

7-27

8.

Disassembly and Reassembly .................................................................................... .

8-1

8-2 Precautions before and during reassembly .....................................................

9. Service Data ................................................................................................................. .

9-1

9-2

9-3

9-4

9-5

9-6 Connecting

9-7

9-8 Crankshaft ........................................................................................................

9-9

9-1

10. Tightening Torque ........................................................................................................

10-1

Disassembly ...................................................................................................... .

..

Cylinder head ...................................................................................................

..

Cylinder block ................................................................................................... .

Valve rocker

arm

............................................................................................... .

Piston ................................................................................................................ .

Piston ring ........................................................................................................

rod

.................................................................................................

..

..

Camshaft ........................................................................................................... .

..

Side

gap and backlash ....................................................................................... 9-6

0 Others ................................................................................................................ 9-6

Main

bolVnut ......................................................................................................

10-2 Standard bolt and nut.. .................. ...... ..................... ..........................................

11. Fuel Injection Pump

11·1

Exploded views

for

Indirect Injection System ....................................................

(YPFR

type)

..

........ ........ ................ ..... ............ ........ .....

...

......

.•..

11-2 Disassembly ....................................................................................................... 11-2

11·3 Inspection......... .................................................................................................. 11-3

11-4 Reassembly .............................. ................... ................. ........... ............. ............. 11-5

8-1

8-1

8-6

9-1

9·1

9-2

9·2

9-3

9-4

9-5

9-5

9-5

10-1

10-1

10-1

11-1

11-1

12. Fuel Injection Pump

12-1

Exploded Views (YPES type).............................................................................

for

Direct Injection System .......................................................

12-2 Special service tools for disassembly and reassembly.... .................................. 12·2

12-3 Disassembly.......................... ........ ............................................................... ...... 12-3

12-4 Inspection........................................................................................................... 12-7

12-5 Reassembly .......................................................... ......................... ........ ...... ......

12-1

12·1

12·9

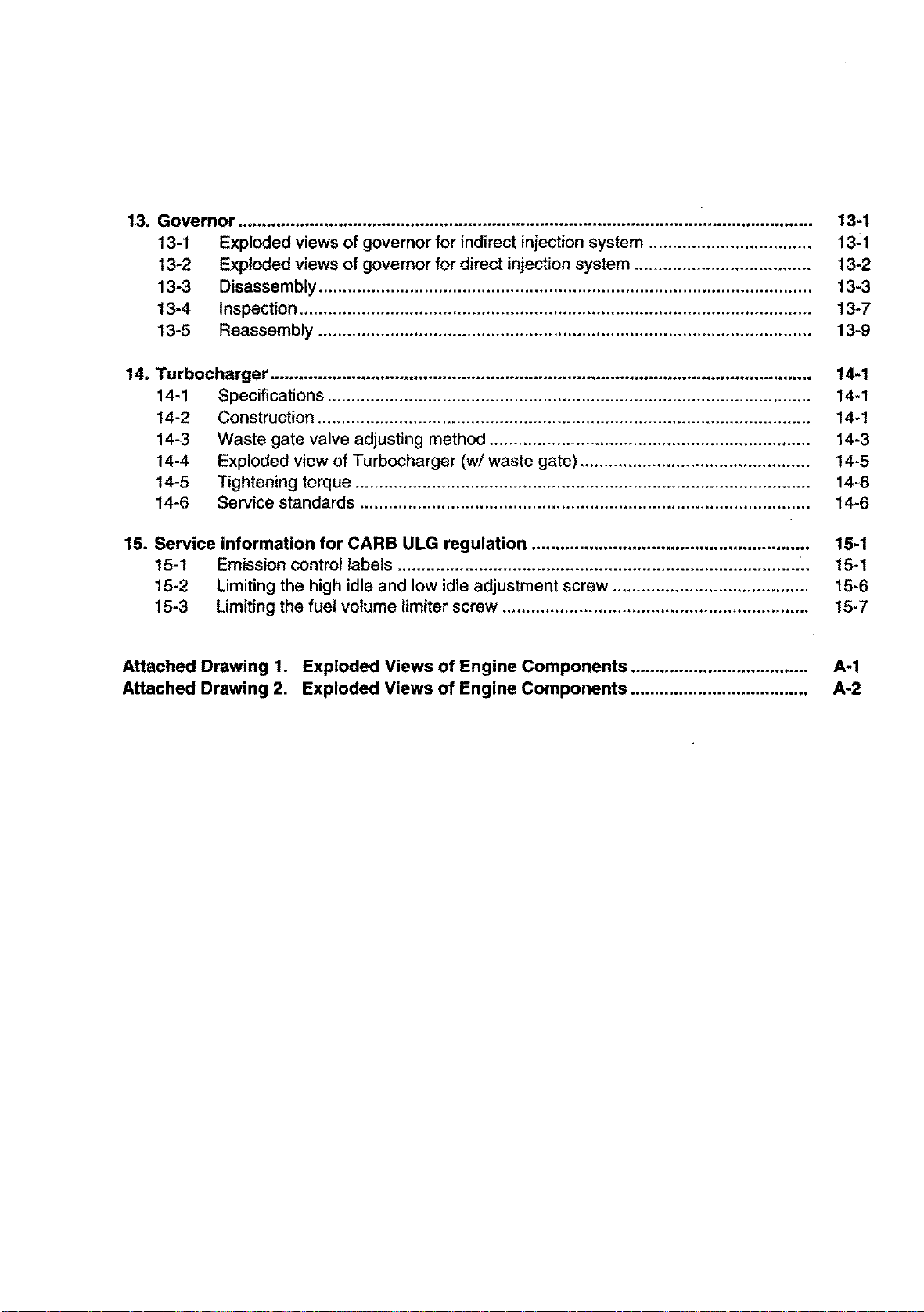

13. Governor ......................................................................................... ........ .......................

13-1

13-2 Exploded views of governor for direct injection system ..................................... 13-2

13-3 Disassembly................ ............................. .....

13-4 Inspection........................................................................................................... 13-7

13-5 Reassembly.... ....... ...... ...... .................... ........ ........... ................. ................

Exploded views of governorfor indirect injection system

....

..........................

...

...............................

.....

........... ....... 13-3

.... ....

13·1

13-1

13-9

14. Turbocharger .................................................................................................................

14-1

14-2 Construction .......................................................................................................

14-3 Waste gate valve adjusting method ....

14·4 Exploded view of Turbocharger (wI waste gate)

14-5 Tightening torque ............................. ................ ........... ............ ........................... 14-6

14-6

Service Information

15.

15-1

15-2 Limiting

15-3 Limiting the fuel volume

Attached Drawing

Attached Drawing

Specifications .....................................................................................................

.... ....

........ ......

Service standards ................................................................................... ........... 14-6

for

CARS ULG regulation ..........................................................

Emission control labels ...................................................................................

the

high idle

1.

Exploded Views

2.

Exploded Views

and

low idle adjustment screw......................................... 15-6

limiter screw.... ............................................................ 15-7

of

Engine Components .....................................

of

Engine Components ..................................... A·2

..

....

................ ..... ......... ....... 14-3

...

........

.... ....

............ .......... ..... 14-5

:..

14·1

14·1

14-1

15·1

15-1

A·1

o Descriptive Breakdown of Model Name

o

TN

E 0 0

(A)

(T)

-,-

- 0 0

o Application Category

L-

_________

'------.

Shipping identifier

Turbocharger

Model subdivision

Cylinder bore (mm)

Model code

Number of cylinders

(3

or 4)

Application code

CL

CH

VM

VH

*

For

engine application category described in Chapter

Usage

Generator drive

General use

Eng. Rev. type

Constant

Variable

1.

Specifications

Revolution speed (rpm)

1500/1800

3000/3600

2000 ~ 3000

3000 ~ 3600

and

Performance.

1.

Specifications and Performance

1.

Specifications

and

Performance

1-1

en

z

0

~

C,)

u::

i3

w

0..

en

2TNE68

Item Unit

Application

Type

Combustion system

No.

of cylinders - Bore x Stroke mm

Displacement

Firing_order

Revolution speed rpm 2000

Continuous

Output*

Max. revolution speed at

no load

Min. revolution speed at

no

load

Direction of rotation

Power take off

Compression ratio

Fuel injection timing

(FlO, b.T.D.C.)

Compression pressure

Fuel injection pressure

Recommended diesel gas

Lubrication system

Lubricating

Recommended lubricating oil

Cooling system

Cooling water capacity

Cooling

Crank

V·pulley dia.l

Governor

Starting system

*1

DimenSions L x W x H

rating (10.5) (12.4)

Max. rating

oil capacity

Max/Effective

fan

No. of blade x dia.

Fan V·pulley dia.

* Output conditions:

other

conditions

Model

-

-

-

e

-

kW(HP)

kW(HP)

rpm

-

-

-

deg

MPa

IlkQficm"

MPa

.Ikgf/cm')

oil

-

-

e

-

-

e

mm Discharge

mm

-

- Electrical

mm

Intake

back

pressure $ 250

complying

-

5.74

(7.8)

2180'~ 2375'~ 2570'~

with

JIS 0 1005-1986.

VM

Vertical, 4·cycle water·cooled diesel engine

Special swirl pre·combustion chamber

2200

-

6.25

(8.5) (9.3)

ISO 8217 DMA,

2600 2800

2400

- -

6.84 7.43 7.94 8.46

(10.1 ) (10.8) (11.5) (11.5) (13.6) (11.8) (12.5) (13.1 )

2780+~

5800 51500 5800

Counterclockwise (viewed from flywheel)

14±1

3.24±O.1 (33±1), at 250 rpm

Forced lubrication with trochoid pump

BS

1.6/0.6

API grade CC class

Liquid coolinglRadiator

Mechanical centrifugal governor (All speed

373.5 x 417 x

498/383.5

mmAq,

Exhaust

After

minimum

2TNE68

I

2-68x72

0.523

1-2

3000 3600 3200

3000

7.72

-

-

8,46

3180+~

2970'~

Flywheel

11.8·'g

2869

0.6 (for engine only)

$95/$85

x 417 x 498

3180'~

23.0

(120·'g)

AI

or

A2 (Cetane No. 45 min.)

or

type, 5 x $290

383.5 x 409 x 540

back

pressure $ 550

30

hour's

run·in.

CH VH

3400 3600

9.12

10.0

3780+~

higher

- -

8.68 9.19 9.64

3425'~

3640~

16±1

2.311.0

ty~

373.5 x

417 x 540

383.5x417 x

mmAq,

-

3850+~

I

540

*1

w

Governing

C,)

perform·

z

<{

ance

~

(full speed

a:

range)

0

u.

a:

w

0..

L.a.

*1.

Designation

Dry weight

press.

of

CUCH

application: engine with flywheel housing

VMNH

application: engine with back plateiwith flywheel hausing

kg

Transient speed

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

engine dimension and dry weight in numerals.

%

%

sec

rpm 530

MPa

(kgf/cm')

59 I 58

0.25±0.05 0.29±0.05

(2.5±O.5)

55/65

$12 510

57

(3.0±0.5) (3.5±O.5

I

56

I

,,0.06

56

(;>0.6)

65

$5 $7

520 530

O.34±O·~r

55/65

512

1-1

1.

Specificallons

and

Performance

1-2 3TNE68

Item Unit

Application

Type

Combustion svstem

No. of cvlinders - Bore x Stroke mm

Displacement

Firing order

Revolution speed

Continuous

Output*

Max. revolution speed at

no load

Min. revolution speed at

no

load

Direction of rotation

Power take off

Ul

Compression ratio

z

0

Fuel injection timing

(FlO, b.T.D.C.)

~

u

Compression pressure

u:

5

w

Fuel injection pressure

Il.

Ul

Recommended diesel gas oil

Lubrication system

Lubricating oil capacity

Recommended lubricating oil

Cooling system

Cooling water capacity

Coolingfan

Crank

V-pulley dia.!

Governor

Starting system

*1

Dimensions

rating

Max. rating

Max/Effective

No. of blade x dia.

Fan V-pulley dia.

Lx

W x H

• Output conditions:

other

Model

-

-

-

-

rpm

kW(HP) - -

kW(HP)

rpm

-

-

-

deg

MPa

(kaf/cm')

MPa

(kaf/cm')

-

-

€ 2.4/1.0 3.0/1.0

-

-

€ 0.9 (for engine only)

mm

mm

-

-

mm

Intake

back

conditions

complying

pressure ~ 250

with

JIS D 1005-1986.

VM

Vertical, 4-cvcle water-cooled diesel en!line

Special swirl pre-combustion chamber

mmAq,

3-68x72

€

1-3-2-1

2000 2200 2400 2600 2800 3000 3000

-

-

8.6 9.4

(11.5) (12.6) (13.8)

2180":

2375

463.5 x

10.3

":

2570":

Counterclockwise (viewed from flywheel)

ISO 8217 DMA, BS 2869

Mechanical centrifugal governor (All speed type)

401

x 496 I 473.5 x 401 x 496

11.2 12.0 12.9

(15.0) (16.1) (17.3) (17.3)

2780

$800

14±1

Forced lubrication with trochoid pump

API !lrade CC class

- -

":

2970":

3.24±0.1 (33±1), at 250 rpm

11.8+'~

Liquid coolinglRadiator

Pusher type, 5 x $310

$105/$85

Electrical

Exhaust

After

minimum

3TNE68

0.784

3180":

Flywheel

23.0

(120+'g)

AI

or

back

pressure ~ 550

30

hour's

run-in.

CH

T

3600 3200

11.7 13.7

(15.7) (18.4)

15.1

12.9

(20.2 (17.6) (18.5) (19.4)

3180'~

3780'~

3455'~

$1500

16±1

A2 (Cetane No. 45 min.)

or

higher

473.5x401 x 496

463.5 x

473.5 x

VH

3400 3600

- - -

13.1 13.8 14.5

3670

$800

401 x 4961

401

mmAq,

":

3890

x 496

":

*1

Dry weight

Transient speed

w

Governing

u

perform-

z

«

ance

::;;

(full speed

a:

0 range)

"-

a:

w

Il.

L.O. press.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH

VMNH

1-2

difference

Steady state

sDeed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

application: engine with flywheel housing

application: engine with back platelwith flywheel hausing

kg

% $12

%

sec

rpm

MPa

(kgf/em')

$9 I $8 I

~.25±0.~~

2.5±O.5

70/81

57

:>30 :>20

I

~:29±O.~~

3.0±0.5 3.5±O.5

$6

I

I

>0.06 (?0.6)-

$6

81

SID

$5 $8

70/81

s12

$30

~:34±0.~~

1.

Specifications

and

Performance

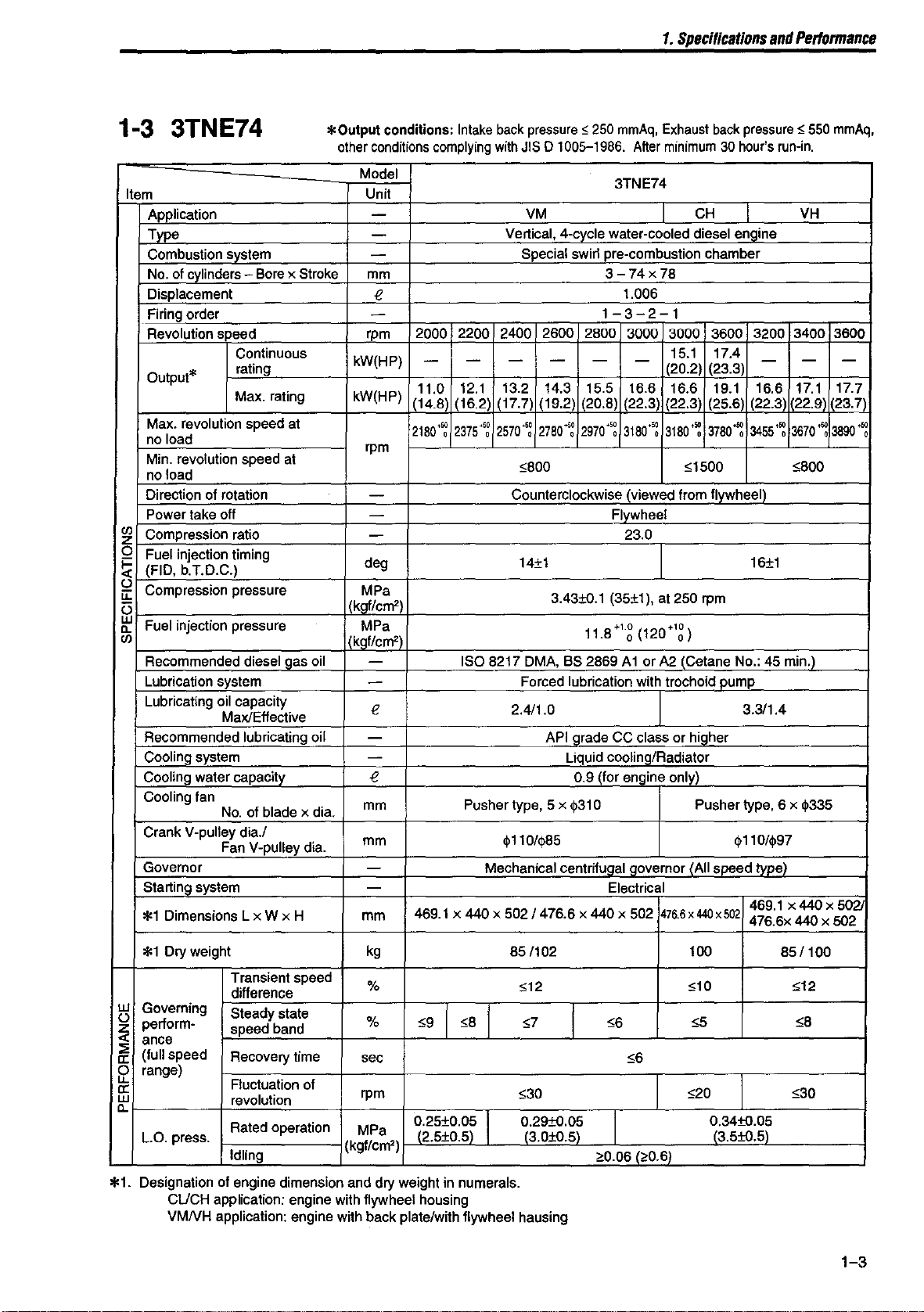

1-3 3TNE74

Item

Application

Type

Combustion system

cylinders - Bore x Stroke mm

No. of

Displacement

Firing order

Revolution speed

Continuous

Output*

revolution speed at

Max.

no load

Min. revolution speed at

load

no

Direction of rotation

Power take off

(/)

Compression ratio

z

0

Fuel injection timing

(FlO, b.T.D.C.)

~

()

Compression

iL:

(3

UJ

Fuel injection pressure MPa

"-

(/)

Recommended

Lubrication system

Lubricating

Recommended

Cooling system

Coolil1g

Cooling

V·pulley dia.!

Crank

Governor

Starting system

*1

Dimensions L x W x H

rating

Max. rating kW(HP)

pressure

diesel gas oil

oil capacity

Max/Effective

lubricating oil

water capacity

fan

No.

of blade x dia.

Fan V·pulley dia.

*Output

conditions:

other conditions

Model

Unit

-

-

-

f!

-

rpm

kW(HP)

rpm

-

-

Intake

back

pressure ~ 250

complying

2000 2200 2400 2600 2800

-

11.0

(14.8) (16.2)

2180+~

with

JIS 0 1005-1986.

VM

Vertical, 4·cycle water·cooled diesel engine

Special swirl pre·combustion chamber

- -

13.2

12.1

(17.7)

2375'~

2570'~

~800

Counterclockwise (viewed from flywheel)

-

14.3

(20.8)

(19.2)

2970'~

2780":

-

15.5 16.6

mmAq,

3TNE74

3-74x78

1-3-2-1

Flywheel

-

deg

MPa

(kgf/cm')

kgf/cm')

-

ISO 8217 DMA, BS 2869

-

f!

-

-

f!

mm Pusher type, 5 x

mm

14±1 16±1

3.43±O.1

(35±1), at 250 rpm

11.8·'g

Forced lubrication with trochoid pump

2.411.0

API grade CC class or higher

Liquid coolinQ/Radiator

0.9 (for engine only)

~310

~110/<1>8S

- Mechanical centrifugal governor

- Electrical

mm

469.1 x 440 x

S02/476.6

x 440 x

Exhaust

After

minimum

1.006

3000 3000 3600

-

(20.2) (23.3)

(22.3) (22.3) (25.6)

3180":

3180'~

23.0

(120·'g)

Alar

A2 (Cetane No.: 45 min.)

S02

476.6

back

30

CH

15.1

17.4

16.6 19.1

3780":

~1500

Pusher type, 6 x

LAII

speed type)

x

440

x

502

pressure ~ 550

hour's run·in.

-

16.6

VH

- -

17.1

3670":

~800

~335

x 440 x

~

3200 3400 3600

(22.3) 22.9 (23.7)

3455~

3.311.4

~110/~97

469.1

476.6x 440 x 502

mmAq,

17.7

3890~

S021

*1

Dry weight

Transient speed

UJ

Governing

()

perform·

z

..:

ance

~

(full speed

0:

range)

rr

0:

UJ

"-

L.O. press.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH application: engine with flywheel housing

VMNH

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

application: engine with back plate/with flywheel hausing

kg

% $12

%

sec

rpm

MPa

(kgf/cm')

,,9 I ,,8

~:2S±0.~~

2.S+0.S

I

8SI102

,;7

,,30

0.29±O.05

.

(3.0±O.S)

,,6

I

1

>0.06 (;'0.6)

,,6

100

$10 ,;12

"S

,;20 ,,30

0.34±O.OS

(3.S±O.S)

8SI100

,,8

1-3

1.

Specincations

and

Performance

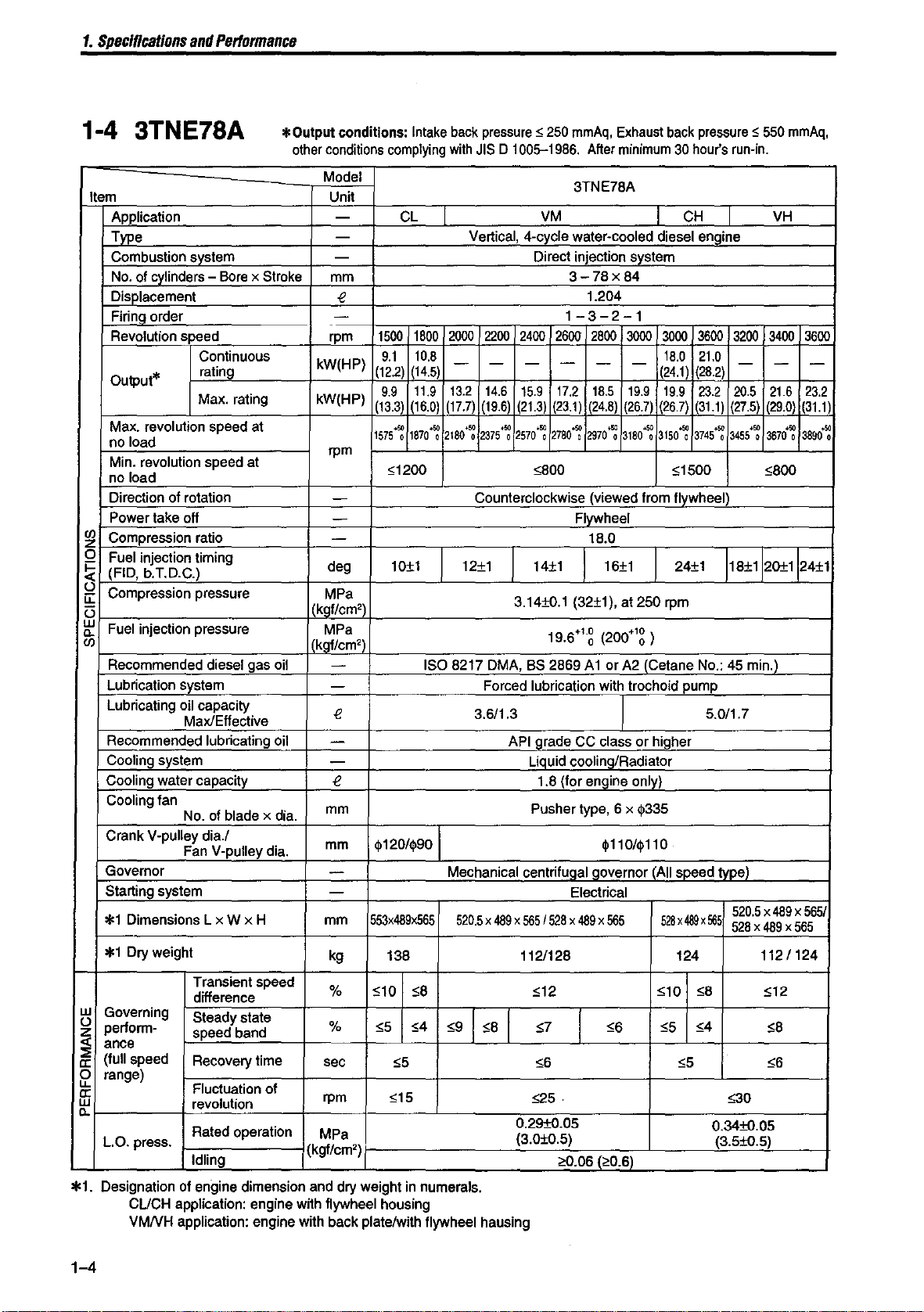

1-4 3TNE78A

*

Output

conditions:

other conditions complying

Intake back pressure ~ 250

mmAq,

with

JIS D 1005-1986. After minimum

Exhaust back pressure ~ 550

30

hou(s run-in.

mmAq,

Model

item Unit

Application

Type

Combustion system

No. of cylinders - Bore x Stroke

Displacement

Firing order

Revolution speed

Continuous

Output*

Max. revolution speed at

no load

Min. revolution speed at

no load

Direction of rotation

Power take off

en

Compression ratio

z

0

Fuel injection timing

(FID, b.T.D.C.)

~

()

Compression pressure

u::

U

w

Fuel injection pressure

a.

en

Recommended diesel gas oil

Lubrication system

Lubricating oil capacity

Recommended lubricating oil

Cooling system

Cooling water

Cooling fan

Crank V-pulley dia.!

Governor

Starting system

*1

Dimensions L x W x H

*1

Dry weight

w

Governing

()

perform-

z

c(

ance

::0

(full speed

cr:

0

range)

"-

cr:

w

a.

L.O. press.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH

VMNH

rating

Max. rating

Max/Effective

capac~y

No. of blade x dia.

Fan V-pulley dia.

Transient speed

difference

Steady state

speed band

Recovery time

Fluctuation

revolution

Rated operation

Idling

application: engine with flywheel housing

application: engine with back plateiwith flywheel hausing

of

-

-

-

mm

t!

-

rpm

kW(HP)

kW(HP)

rpm

-

-

-

deg

MPa

(kgf/cm')

MPa

I (kgf/cm')

-

-

t! 3.6/1.3

-

-

t!

mm Pusher type, 6 x

mm

-

- Electrical

mm

kg

% S10

%

sec

rpm

MPa

(kgf/cm')

CL VM

1800

1500

9.1

(12.2) (14.5) (24.1)

9.9

(13.3

(16.0) (17.7) (19.6)

1575~ 1870~

~1200

10±1 12±1 14±1 16±1 24±1

~120/~90

553x489x565

138

S8

,,5

S4

,,5

S15

3TNE78A

I

Vertical, 4-cycle water-cooled diesel engine

Direct injection system

3-78x84

1.204

1-3-2-1

2000 2200

10.8

- - -

13.2

11.9

2180~

ISO 8217 DMA, BS 2869

Mechanical centrifuQal Qovernor (All speed type)

520.5 x 489

,,91

2400

2600

2800

3000 3000

-

- -

14.6 15.9

2375'~ 2570'~

Counterclockwise (viewed from

Forced lubrication with trochoid pump

API grade

S8

1

17.2 18.5

(23.1)

(21.3)

(24.8) (26.7) (26.7)

,.

2780~

2970

0

~800

Flywheel

18.0

3.14±O.1 (32±1),

19.6+'g (200+'g )

Al

or

CC

class

Liquid cooling/Radiator

1.8 (for engine only)

~110/~110

x

565/528

x

489 x 565

1121128 124

~12

g

~6

525·

0.29±O.05

(3.0±0.5)

>0.06 (?0.6)

,,6

1

18.0

19.9

19.9

3180'~

3150~

~1500

at

250 rpm

A2 (Cetane No.: 45 min.)

or

higher

~335

528

~10

S5

CH VH

3600

3200 3400

21.0

- -

(28.2)

23.2 20.5 21.6 23.2

(31.

t)

(27.5) (29.0) (31.1)

..,

3455

3745~

fly~heel)

5.0/1.7

x

4a9 x 565

~8

S4

,,5 ,,6

,

3670~

~800

18±1

20±1 24±1

520.5 x 489 x 565/

528 x 489 x 565

112/124

,,12

s8

S30

O.34±O.OS

(3.S±O.5)

3600

-

3800+~

1-4

1.

Specifications

and

Performance

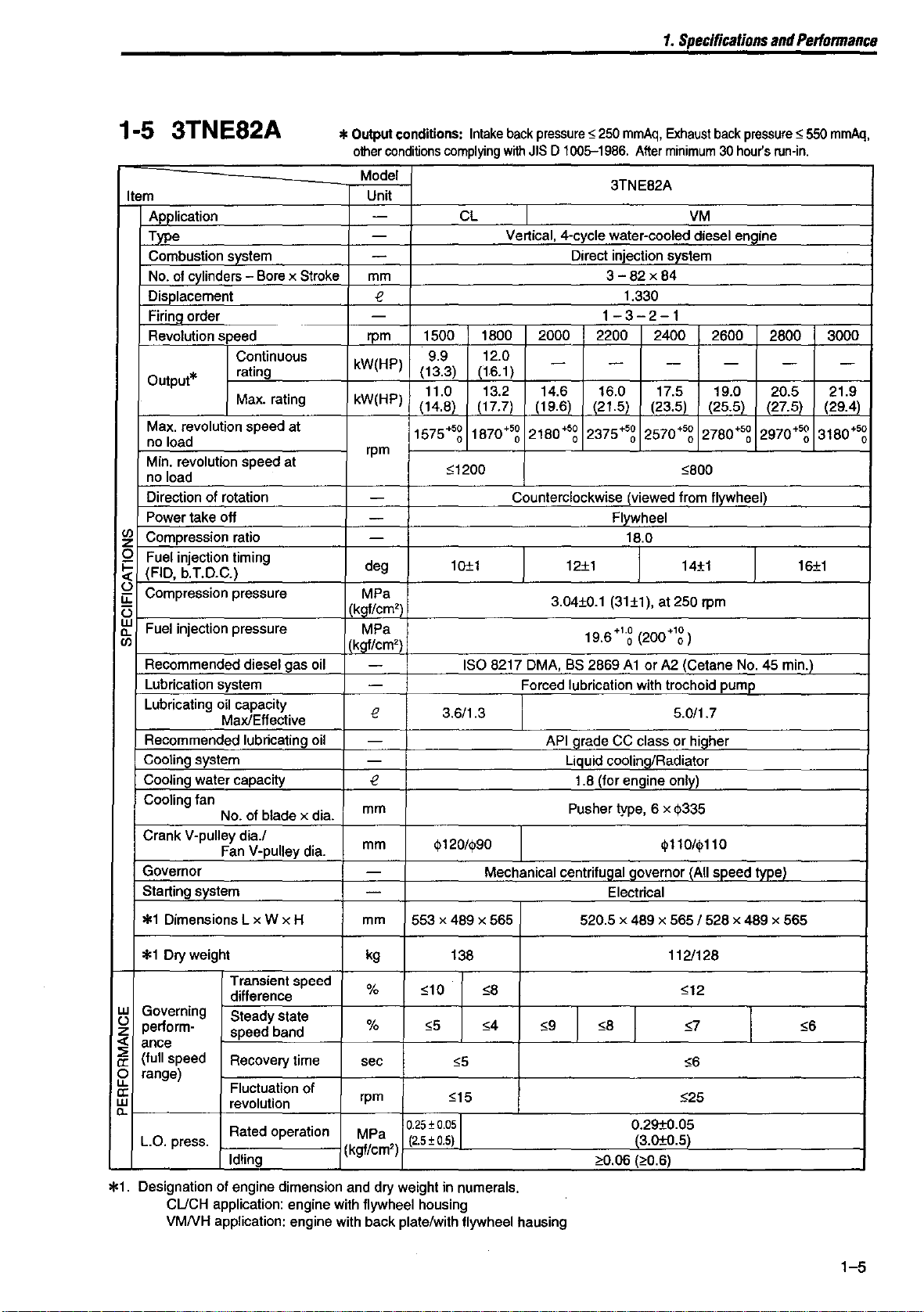

1-5 3TNE82A

Item

Application

Type

Combustion system

No.

of

cylinders - Bore x Stroke

Displacement

Firino order

Revolution speed

Continuous

Output*

Max. revolution speed at

no load

Min. revolution speed at

no load

Direction of rotation

Power take off

C/J

Compression ratio

z

0

Fuel injection timing

(FID, b.T.D.C.)

~

()

Compression pressure

u:

t5

w

Fuel injection pressure

0-

C/J

Recommended diesel gas oil

Lubrication system

Lubricating oil capacity

Recommended lubricating oil

Cooling system

Cooling water capacity

Cooling fan

Crank V-pulley dia.!

Governor

Starting system

*1

Dimensions L x W x H

rating

Max. rating

Max/Effective

No. of

blade x dia.

Fan V-pulley dia.

*

Output

conditions:

other

conditions

Model

Unit

-

-

-

mm

€

-

rpm 1500 1800 2000 2200 2400 2600

kW(HP)

kW(HP)

rpm

-

-

-

deg 10±1 12±1 14±1

MPa

(kgf/cm')

MPa

IlkQf/cm')

-

-

€

-

-

(13.3) (16.1)

(14.8) (17.7)

1575+

Intake

back

pressure';

complying

9.9

11.0

50

';1200 ';800

3.6/1.3 5.0/1.7

with

JIS

0 1005-1986,

CL VM

Vertical, 4-cycle water-cooled diesel engine

12.0

13.2

1870+

0

ISO 8217 DMA, BS 2869

- -

14.6

(19.6) (21.5)

50

2180+

0

Counterclockwise (viewed from flywheel)

3.04±O.1 (31±1), at

Forced lubrication with trochoid pump

API grade CC class

250

mmAq,

Exhaust

After

minimum

3TNE82A

Direct injection system

3-82x84

1.330

1-3-2-1

- - - -

16.0 17.5 19.0

50

2375+

0

19.6+'g (200+'g)

Liquid cooling/Radiator

(23.5) (25.5) (27.5) (29.4)

50

2570+

0

Flywheel

18.0

Al

or

A2 (Cetane No. 45 min.)

or

250 rpm

€ 1.8 (for engine only)

mm Pusher type, 6 x

mm

-

-

mm

<1>120/<1>90

Mechanical centrifugal governor (All speed type)

553 x 489 x 565

Electrical

520.5 x 489 x

<1>335

<1>110/<1>110

565/

back

pressure';

30

hour's

50

2780+~

0

higher

528 x 489 x 565

run-in.

2800

20.5

2970+

550

50

0

16±1

mmAq,

3000

21.9

3180+

.

50

0

*1

Dry weight

Transient speed

w

Governing

()

perform-

z

<{

ance

::;;

(full speed

cr:

0 range)

"-

cr:

w

0-

l.0.

press.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH

VMNH

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

application: engine with flywheel housing

application: engine with back plate/with flywheel hausing

kg

%

%

sec

rpm ';15

MPa

(kgf/cm')

,;10 ,;8

,;5 ,;4 ,;9

0.25 ± 0.05

(2.5

+0.5)

138 1121128

';12

,;5

,;8

I

>0.06 (>0.6)

I

0.29±O.05

(3.0±0.5)

,;7

,;6

';25

I

,;6

1-5

1.

Specifications

and

Performance

1-6 3TNE82

Item

Application

TYl'.e

Combustion system

No.

of

cylinders Displacement

Firing order

Revolution speed

Continuous

Output*

Max.

revolution speed

no

.

load

Min.

revolution speed at

no

load

Direction of rotation

Power take off

til

Compression ratio

z

0

Fuel

injection timing

(FID, b.T.D.C.)

~

Compression pressure

u::

U

w

Fuel

<>.

til

injection pressure

Recommended diesel gas

Lubrication system

Lubricating

Recommended lubricating oil

Cooling system

Cooling water capacity

Cooling fan

Crank V-pulley dia.!

Governor

Starting system

*1

Dimensions L x W x H

rating

Max.

oil

capacity

Max/Effective

No.

Fan

*

Output

other

Bore x Stroke

rating kW(HP)

at

~kgf/cm')

oil

of blade x

V-pulley dia.

dia.

conditions:

conditions

Model

Unit

-

-

-

mm

Intake

complying

CL

back

pressure ~ 250

with

JIS D 1005-1986.

Vertical, 4-cycle water·cooled diesel engine

Direct injection system

mmAq,

3TNE82

VM

3-82x90

€

-

(26.7)

24.7)

••

2780~

0

~800

1-3-2-1

Flywheel

-

rpm

kW(HP)

rpm

-

-

1800

1500

10.5 12.7

(14.1

11.6 14.0

(15.6

1570+~

~1200

2000 2200 2400 2600

(17.0)

15.5 16.9 18.4 19.9

(18.8)

(20.8)

••

2160+~

1870

0

- - -

(22.7)

2375+~

2570

Counterclockwise (viewed from flywheel)

-

deg

MPa

(k9t/cm')

MPa

-

-

€

-

-

€

mm

mm

-

10±1 12±1 14±1

3.04

ISO

8217

DMA,

Forced lubrication with trochoid pump

4.7/1.8

API

<1>120/<1>90

Mechanical centrifugal governor (All speed type)

±

0.1

(31 ± 1),

19.6+1~

BS

2869

grade

CC

Liquid cooling/Radiator

2.0 (for engine only)

Pusher type, 6 x

- Electrical

mm

589x486><623

556 x 486

x 623/

564 x 486 x 623

Exhaust

After

minimum

1.425

2800

3000 3000

-

21.3

(31.1\

(28.6)

2970·~

3180'~

18.0

16±1

(200+1~)

AI

or

A2

class or higher

<1>110/<1>110

back

I

21.0

-

(28.2)

23.2

23.2

(31.1 ) (36.1)

3150~

~1500

24±1

at 250

rpm

(Cetane

<1>335

!;s4

x

30

CH

486 x 623

pressure

hour's

3800

24.4

(32.7)

26.9

3745~

No.

6.9/2.1

~550

run-in.

3200

3400

- - -

24.4

(32.7) (34.3) (36.1)

•• ••

3455

0

3670

~800

18±1

20±1

45

min.)

556 x 486 x 623

564 x 486 x 623

mmAq,

VH

3800

26.9

25.6

3890~

0

24±1

*1

Dry weight

Transient speed

w

Governing

()

perform-

Z

«

ance

::;

(full speed

a:

range)

f2

a:

w

<>.

L.a. press.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH application: engine with flywheel housing

VMNH application: engine with back plate/with flywheel hausing

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

kg

%

%

sec

rpm

MPa

(kgf/cm')

161

~10

$5 $4

~5

~15

0.29±O.05

(3.0±0.5)

1-6

~

$8

138/155 149

$12

$7

I I

~6

$25

>0.06j>0.6L

$6

~:34±O.~~

3.5±O.5

~10

~5

$5

~

$4

1381149

$12

~

~6

~30

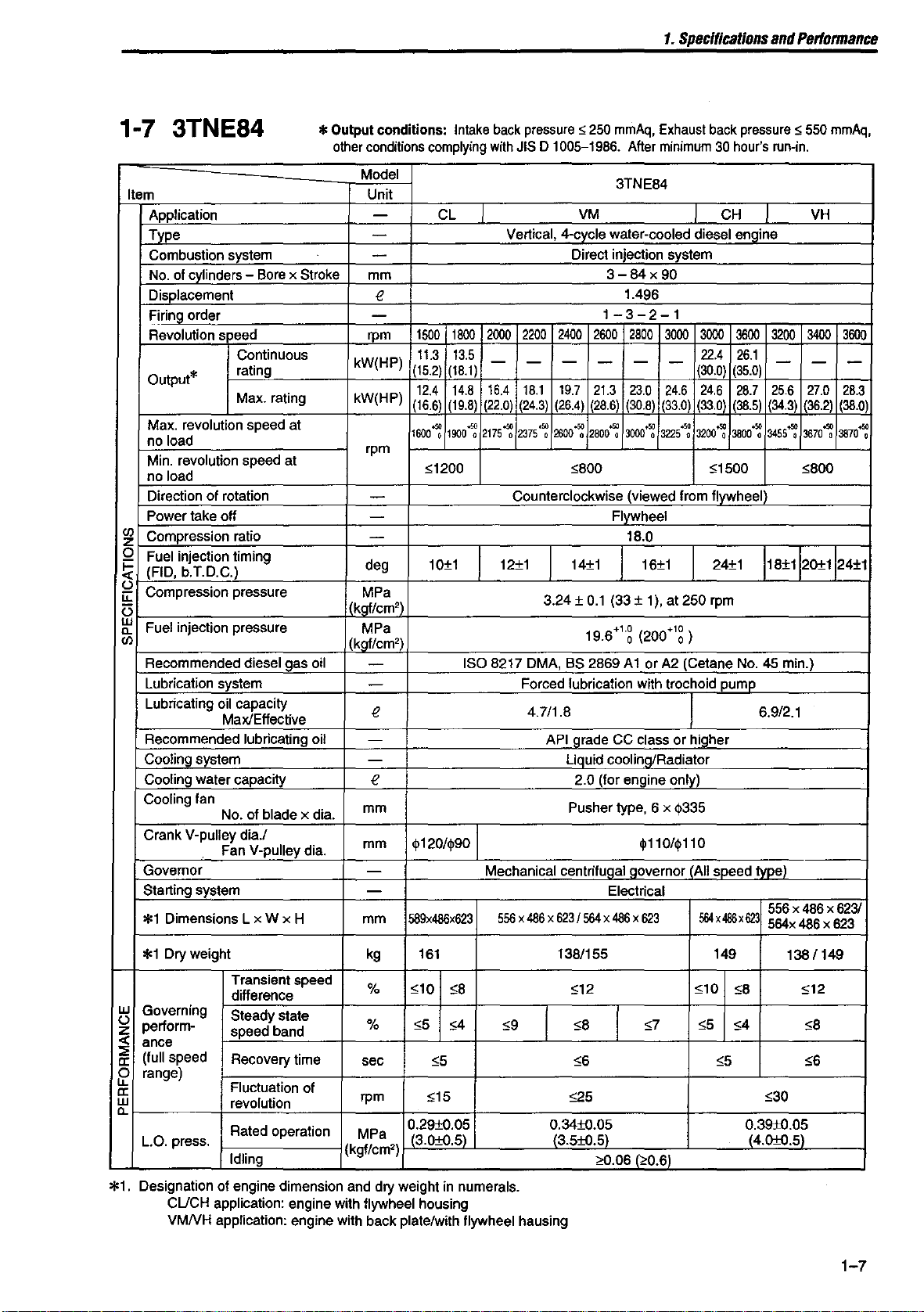

1-7 3TNE84

*

Output

other

conditions:

conditions

Intake

complying

back

pressure $ 250

with

JIS D 1005-1986.

mmAq,

After

1.

Specifications

Exhaust

minimum

back

30

hour's

and

Performance

pressure $ 550

run·in.

mmAq,

Item

Application

Type

Combustion system

No.

of

cylinders Displacement

Firing order

Revolution s

Output*

Max.

revolution speed at

no

load

Min.

revolution speed at

no

load

Direction of rotation

take off

Power

en

Compression ratio

z

0

Fuel

injection timing

(FID,

~

()

u:

(3

w

a.

en

b.T.D.C.)

Compression pressure

Fuel

injection pressure

Recommended diesel gas

Lubrication system

Lubricating

Recommended lubricating oil

Cooling system

Cooling water capacity

Cooling

Crank

Governor

Starting system

*1

fan

V-pulley dia.l

Dimensions L x W x H

Bore x Stroke

eed

Continuous

rating

Max.

oil

capacity

Max/Effective

No.

of blade x dia.

Fan

V-pulley dia.

Model

Unit

-

-

-

mm

e

-

rpm

kW(HP)

rating kW(HP)

rpm

-

-

-

deg

MPa

I (kgf/cm'!.

MPa

(kgf/cm'

oil

-

-

e

-

-

e

mm

mm

-

-

mm

3TNE84

CL

Vertical, 4-cycle water-cooled diesel engine

1500 1800

11.3

(15.2) (18.1) (30.0)

12.4 14.8

(16.6) (19.8)

1600~

$1200 $800 $1500 $800

10±1 12±1

<1>120/<1>90

589x486x623

2000

2200

13.5

-

-

16.4

18.1

(22.0) (24.3)

.~

217S.sg

1900

ISO

2375·~

0

Counterclockwise (viewed from flywheel)

8217

DMA,

Forced lubrication with trochoid pump

4.7/1.8

Mechanical centrifugal governor (All speed type)

556 x 486

VM

Direct injection system

3-84x90

1.496

1-3-2-1

2400 2600 2800

-

19.7

(26.4)

2600.sg

14±1 16±1

3.24 ±

BS

API

grade

Liquid cooling/Radiator

2.0 (for engine only)

Pusher type, 6 x

x

6231

564 x 486 x 623

-

-

21.3

23.0

(30.8)

(28.6)

2800+~

3000+~

Flywheel

18.0

0.1

(33 ±

1),

19.6+': (200+':

2869

AI

or

CC

class or higher

<1>110/<1>110

Electrical

CH

I

3000

3000

3600

22.4

-

24.6 24.6 28.7

(33.0)

.~

3225

•

at 250

)

A2

(Cetane

<1>335

26.1

(35.0)

(33.0

(38.5)

3200~

3800

24±1

rpm

No.

564 x 486 x 623

3200

-

25.6

(34.3\

.~

3455~

0

18±1

45

min.)

6.9/2.1

556 x 486

564x

VH

3400

3600

-

-

27.0 28.3

(36.2) (38.0)

..,

3870~

3670

0

20±1 24±1

x

6231

486 x 623

*1

Dry weight

Transient speed

w

Governing

()

perform-

z

..:

ance

:;

(full speed

a:

0

range)

LL

a:

w

a.

L.a. press.

*1.

Designation of engine dimension

CUCH application: engine with flywheel housing

VMNH application: engine with back platelwith

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

kg

%

%

sec

rpm

MPa

(kgf/cm')

and

dry weight

161

$10

$8

$5

54

,;5 ,;6 ,;5 ,;6

,;15 ,;25 ,;30

0.29±O.05

(3.0±0.5)

in

S9 S8

numerals.

flywheel hausing

138/155 149

$12

, ,

0.34±O.05

(3.5±O.5)

>0.06

$7

r"O.6)

S10

,;5

S8

,;4 ,;8

O.39±O.O5

(4.0±0.5)

1381149

S12

1-7

1.

SpecificatlDns

and

PerfDrmance

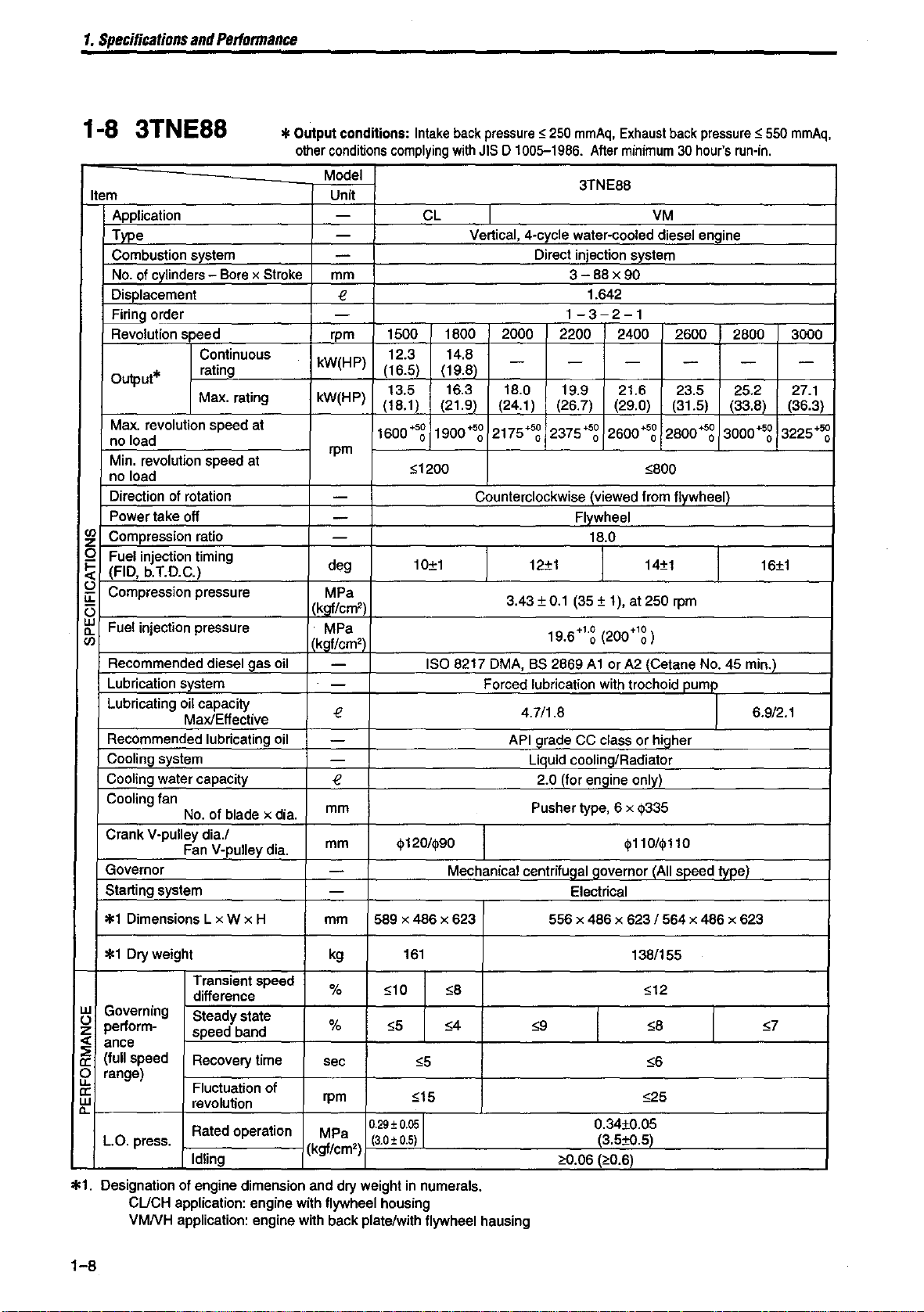

1-8 3TNE88

Item

Application

Twe

Combustion svstem

No.

of cylinders - Bore x Stroke

DisDiacement

.£irir1.9 order

Revolution speed

Continuous

Output*

Max.

revolution speed at

no load

Min. revolution speed at

no

load

Direction of rotation

Power

take off

en

Compression ratio

z

0

Fuel injection timing

(FlO, b.T.D.C.)

~

()

Compression pressure

u:

U

UJ

Fuel injection pressure

"-

en

Recommended diesel gas oil

Lubrication svstem

Lubricating oil capacity

Recommended

Cooling

Cooling water capacity

Cooling

V·pulley

Crank

Governor

Starting system

rating (16.5) (19.8)

Max. rating

Max/Effective

lubricating oil

system

fan

No.

of

blade x dia.

dia.i

Fan V-pulley dia.

*

Output

conditions:

other conditions complying with JIS 0 1005-1986. After minimum

Model

Unit

-

-

-

mm

€

-

rpm

kW(HP)

kW(HP)

rpm

-

-

-

deg

MPa

(kOi/cm')

MPa

I (kOi/cm')

-

-

€

-

-

€

mm

mm

-

Intake back pressure ~ 250

CL VM

Vertical, 4-cycle water-cooled diesel enqine

1500

12.3 14.8

13.5

(18.1) (21.9 (24.1 ) (26.7)

1600+'g

<1>120/$90

1800 2000

-

16'~1

1900

~1200

10±1 12±1 14±1

ISO 8217 DMA, BS 2869

Mechanical centrifuQal qovernor (All speed type)

18.0

+'0

2175+

0 0

Counterclockwise (viewed from flYWheel)

3.43 ±

Forced lubrication with trochoid pum

4.7/1.8 6.9/2.1

API qrade CC class

mmAq,

3TNE88

Direct injection system

3-88x90

1.642

1-3-2-1

2200 2400 2600

- -

19.9 21.6 23.5

50

2375

+'g

Flvwheel

18.0

0.1

(35 ± 1), at 250 rpm

19.6 +'g (200

Al

Liquid cooling/Radiator

2.0 (for engine only)

Pusher type, 6 x $335

Exhaust back pressure ~ 550

(29.0) (31.5)

2600+'g 2800+'g

+'g

or

A2 (Cetane No. 45 min.)

or

<1>110/<1>110

- Electrical

30

-

~800

)

hiqher

hour's run-in.

2800

-

25.~)

(33.8

3000+'g

mmAq,

3000

-

27.1

(36.3)

3225+'g

16±1

*1

Dimensions L x W x H mm 589 x 486 x 623

*1

Dry weight

Transient speed

UJ

Governing

()

perform-

z

<{

ance

::<

(full speed

a:

0 range)

u.

a:

UJ

"-

press.

L.O.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH

VMNH

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

application: engine with flywheel housing

application: engine with back plate/with flywheel hausing

kg

%

% $5

sec

rpm $15 $25

MPa

(kgf/cm')

161

~10

0.29 ± 0.05

(3.0 ± 0.5)

1-8

$5

$8

$4

556 x 486 x 623 / 564 x 486 x 623

138/155

$12

$9 $8 $7

I

$6

0.34±O.05

(3.5±O.5)

>0.06 (>0.6)

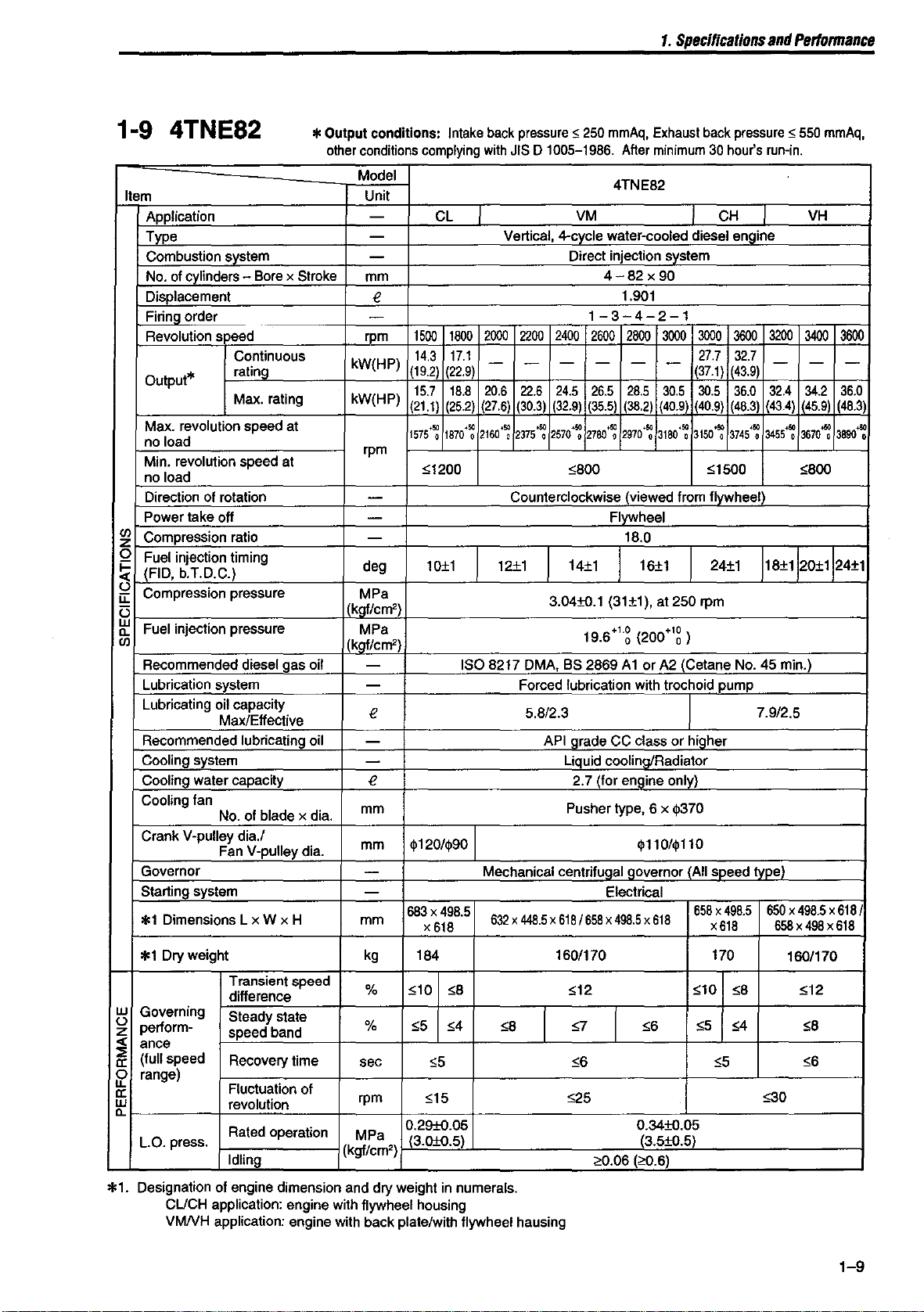

1-9 4TNE82

Item

Application

Type

Combustion system

No. of cylinders - Bore x

Displacement

order

Firing

Revolution

Output*

Max. revolution speed at

no load

Min. revolution speed at

no load

Direction of rotation

Power take off

en

Compression ratio

z

a

Fuel injection timing

(FID, b.T.D.C.)

~

u

Compression pressure

u:

ti

w

Fuel injection pressure

a.

en

Recommended diesel gas oil

Lubrication system

Lubricating oil capacity

Recommended lubricating oil

Cooling system

Cooling water capacity

Cooling fan

Crank V-pulley

Governor

Starting system

*1

Dimensions L x W x H

seed

Continuous

rating

Max. rating

Max/Effective

No. of blade x dia.

dia.!

Fan V-pulley dia.

*

Output

conditions: Intake back pressure $ 250 mmAq, Exhaust back pressure $

other conditions complying with

Model

Unit

-

CL

-

-

Stroke

mm

t!

-

rpm

kW(HP)

kW(HP)

rpm

1500 1800

14.3

(19.2)

15.7

(21.1) (25.2) (27.6) (30.3)

1575+~

$1200

-

-

-

deg

MPa

I (kgf/cm')

MPa

(kgf/cm')

10±1 12±1

-

-

t!

-

-

t!

mm

mm

~120/~90

-

-

683 x 498.5

mm

x

618

JIS D 1005-1986. After minimum

4TNE82

I

Vertical, 4-cycle water-cooled diesel engine

2000

2200

17.1

-

(22.9)

18.8

1870'~

ISO 8217 DMA, BS

-

20.6

22.6

2160'~

237S.sg

Counterclockwise (viewed from flywheel)

Forced lubrication with trochoid pump

5.8/2.3

Mechanical centrifuQal governor (All

632 x 448.5

VM

Direct injection system

4-82x90

1-3-4-2-1

2400

2600 2800

- - -

24.5

26.5

(32.9) (35.5)

2780·~

2570~

5800

Flywheel

14±1

3.04±O.1 (31±1), at

19.6"g

2869

APlJlrade

x

618/658

CC

Liquid coolinQiRadiator

2.7 (for engine only)

Pusher type, 6 x

Electrical

x

498.5 x 618

1.

Specifications

I

1.901

3000

3000 3600

27.7

-

(37.1)

28.5

30.5

(38.2)

2970+~

18.0

16±1

(200"g

Alar

class

~110/~110

30.5

(40.9

(40.9)

3180+~

3150'~

250

rpm

)

A2

(Cetane No.

or

higher

~370

658 x 498.5

and

Performance

30

hour's run-in.

CH VH

3200

32.7

- - -

(43.9)

32.4

36.0

(43.4)

(48.3)

374S.sg

3455~

$1500

24±1 18±1

45

min.)

7.9/2.5

speed

type)

x618

650 x 498.5

658

550

mmAq,

3400

3600

36.0

34.2

45.9)

(48.3)

..,

aaw":

3670

0

5800

20±1 24±1

x

6181

x

498 x 618

*1

Dry weight

Transient speed

w

Governing

u

periorm-

z

..:

ance

::e

(full speed

a:

range)

12

a:

w

a.

L.a.

press.

*1.

Designation of engine dimension and dry weight in numerals.

CUCH

VMNH

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

application: engine with flywheel housing

application: engine with back platelwith flywheel hausing

kg 184

%

%

sec

rpm

MPa

(kgf/cm')

510

58

55 54

,;5

$15

0.29±O.05 0.34±O.05

I (3.0±0.5)

58

160/170 170

512

$7

I I

56 55

,;25

>0.06 (>0.6)

56

(3.5±O.5)

510

55

58

$4

160/170

512

58

56

530

1-9

1.

Spocifications

and

Performance

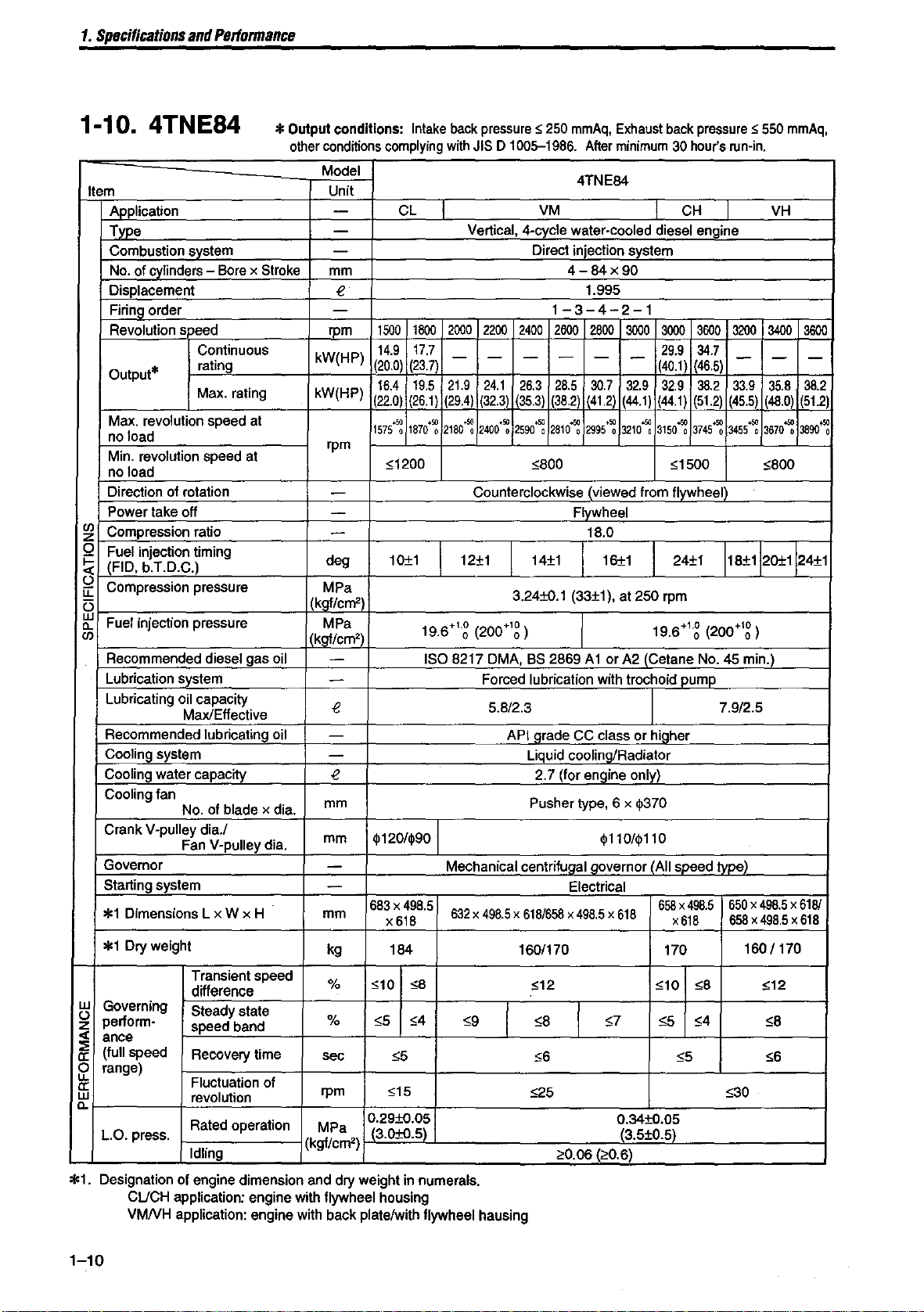

1-10. 4TNE84

Item

Application

Type

Combustion system

No.

of cylinders Displacement

Firing order

Revolution speed

Continuous

Output*

Max.

revolution speed

no

load

Min.

revolution speed at

no

load

Direction of rotation

Power

C/l

Compression ratio

z

0

Fuel

injection timing

(FID, b.T.D.C.)

~

0

Compression pressure

u::

Q

w

Fuel

0..

C/l

w

0

z

<C

::;:

a:

0 range)

u..

a:

w

0..

*'.

injection pressure

Recommended

Lubrication system

Lubricating

Recommended

Cooling system

Cooling water capacny

Cooling

Crank V-pulley dia.!

Governor

Starting system

*1

Dimensions L x W x H

*1

Dry weight

Governing

performance

(full speed

L.O. press.

DeSignation

CUCH application:

VMNH application: engine with back plate/with flywheel hausing

rating

Max.

take off

diesel gas

oil

capacity

Max/Effective

lubricating oil

fan

No.

of

Fan

V-pulley dia.

Transient speed

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

of engine dimension and dry weight

*

Output

conditions:

other

conditions

Model

Unit

-

-

-

Bore x Stroke

mm

e

-

rpm

kW(HP)

rating kW(HP)

at

rpm

-

-

-

deg

MPa

(kgf/Cm'1

MPa

kgf/cm')

oil

-

-

e

-

-

e 2.7 (for engine only)

blade x dia.

mm

mm

- Mechanical centrifugal governor (All speed type)

-

mm

kg

% SIO

% $5

sec

rpm

MPa

(kgf/cm')

engine with flywheel housing

Intake

back

pressure"

complying

CL

1500

14.9

(200)

16.4

(22.0) (26.1)

1575·~

,,1200 ,,800 ,,1500 ,,800

10±1

<1>120/<1>90

683 x 498.5

x618

184 160/170

$5

$15

0.29±O.05

(3.0±0.5)

with

JIS D 1005-1986.

I

Vertical, 4-cycle water-cooled diesel engine

1800

2000

2200 2400

17.7

- - - - -

(23.7)

21.9

19.5

1870+~

19.6+'g (200+'g) 19.6+'·g (200+'g)

ISO

S8

,,4

in

numerals.

24.1

(32.3)

(29.4)

2180+~ 2400+~

Counterclockwise (viewed from flywheel)

12±1 14±1

8217

DMA,

Forced lubrication with trochoid pump

5.8/2.3 7.9/2.5

632 x 498.5 x 618/658 x 498.5 x 618

,,9

250

mmAq,

Exhaust

After

minimum

4TNE84

VM

Direct injection system

4-84x90

1.995

1-3-4-2-1

2600 2800

26.3 28.5

(38.2)

(35.3)

2590+~

2810~

Flywheel

3.24±O.1

API

I I

(33±1), at 250

BS

2869 AI or

grade

CC

Liquid cooling/Radiator

Pusher type, 6 x

Electrical

S12 $10

sa

$6 $5

$25

>0.06 (>0.6)

3000 3000 3600 3200

30.7

32.9

41.2

(44.1) (44.1)

,.

2995

0

3210

18.0

16±1

A2

class or higher

<1>"0/<1>"0

$7

(:34±O.05

3.5±O.5)

back

30

29.9

-

(40.1) (46.5)

32.9

••

3150~

0

24±1

rpm

(Cetane

<1>370

658 x 498.5

x618

170

$5

pressure"

hour's

run-in.

CH

I

34.7

-

38.2

33.9

(51.2)

(45.5) (48.0)

3745~

3455~ 3670~

18±1

No.

45

min.)

650 x 498.5 x 6181

65B x 498.5 x 618

160/170

$8 $12

$4

$30

550

mmAq,

VH

3400

3600

- -

35.8 38.2

(51.2)

3890":

20±1 24±1

$8

,,6

1-10

1.

Specifications

and

PBrformanClJ

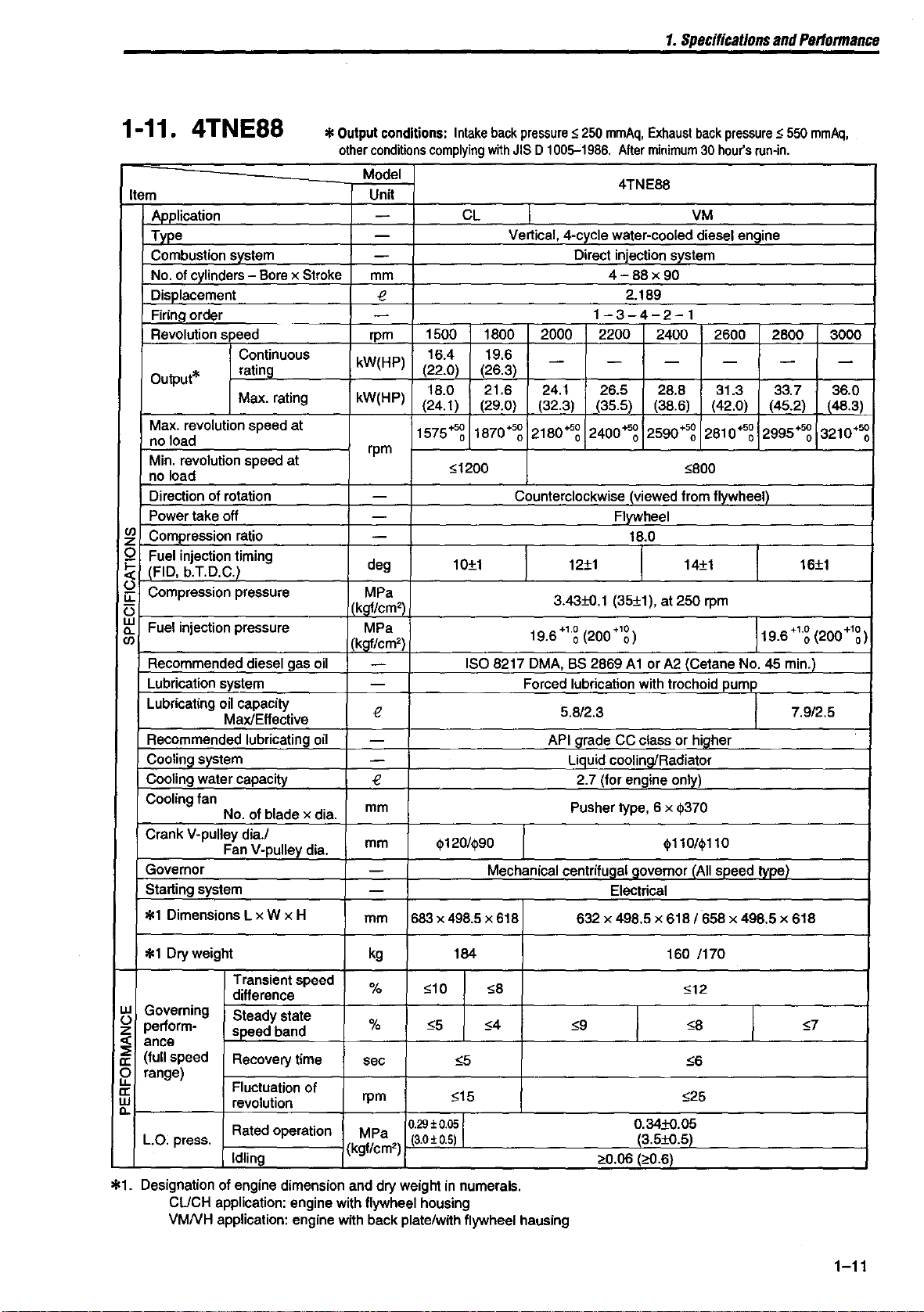

1-11. 4TNE88

Item

flpplication

Tvoe

Combustion system

01

cvlinders - Bore x Stroke mm

No.

Displacement

Firin" order

Revolution speed rpm

Continuous

Output*

Max. revolution speed at

no load

Min. revolution speed at

load

no

Direction

Power take off

C/l

Compression ratio

z

0

Fuel

injection;.~iming

(FlO, b.T.D.C.

~

()

Compression pressure

u:

(3

w

Fuel injection pressure

a.

C/l

Recommended diesel cas oil

Lubrication system

Lubricating

Recommended lubricating

Coolina system

Cooling

Cooling

Crank

V-pulley dia.!

Governor

Starting system

*1

DimenSions L x W x H

ratina

Max. rating

01

rotation

oil capacity

Max/Effective

water capacity

Ian

No.

01

blade x dia.

Fan V-pulley dia.

* output conditions:

oil

Intake

back

other

kW(HP)

kW(HP)

conditions

Model

Unit

-

-

-

f!

-

rpm

-

pressure ~ 250

complying

1500

16.4

(22.0) (26.3)

18.0 21.6 24.1 26.5

(24.1 )

1575+5~

with

JIS D 1005-1986.

CL

(29.0)

1870+

~1200

I

Vertical, 4-cvcle water-cooled diesel engine

1800 2000 2200 2400 2600 2800 3000

19.6

-

(32.3) (35.5)

s

g

2180+5~

Counterclockwise (viewed Irom Ilvwheel)

mmAq,

Direct injection system

4-88x90

1-3-4-2-1

- -

2400+5~

-

- 18.0

deg

MPa

(kiii/cm')

MPa

,

'kiii/cm')

-

10±1

ISO 8217 DMA, BS 2869

-

f!

-

-

f!

mm Pusher type, 6 x

mm

-

$120/$90 $110/$110

Mechanical centriluaal covemor (All speed type)

- Electrical

683

mm

x 498.5 x 618

12±1

3.43±O.1 (35±1), at 250 rpm

19.6

+1~

(200

Forced lubrication with trochoid pum

5.812.3

API arade CC class or hiaher

Liquid coolin-aiRadiator

2.7 (lor enQine only)

632 x 498.5 x

Exhausl

back

pressure ~ 550

After

minimum

4TNE88

2.189

30

VM

hours

-

28.8

(38.6)

2590+5~

Flvwheel

+1~)

Al

or A2 (Cetane No. 45 min.)

618/658

31.3 33.7

(42.0) (45.2) (48.3)

2810+5~

~800

14±1 16±1

$370

x 498.5 x 618

mmAq,

run·in.

- -

36.0

2995+~

19.6+1~

3210+5~

(200+1~)

7.9/2.5

*1

w

Goveming

()

pertorm-

z

«

ance

::;:

(lull speed

II:

0 range)

LL

II:

w

a.

L.O. press.

*1.

Designation

Dry weight

01

CUCH

application: engine with flywheel housing

VMNH

application: engine with back plate/with Ilywheel hausing

kg

Transient speed

difference

Steady state

speed band

Recovery time

Fluctuation

revolution

Rated operation

Idling

engine dimension and dry weight in numerals.

01

%

%

sec

rpm

MPa

(kgl/cm')

184 160 /170

,,10

,,5

0.29±0.05

(3.0 i O.S)

,,8

,,4

';5

,,15 ,;25

,,9

>0.06 (;,(l.6)

';12

I

~:34±O.~~

,;;a

';6

3.5±O.5

,;;7

1-11

1.

Specifications

and

Performance

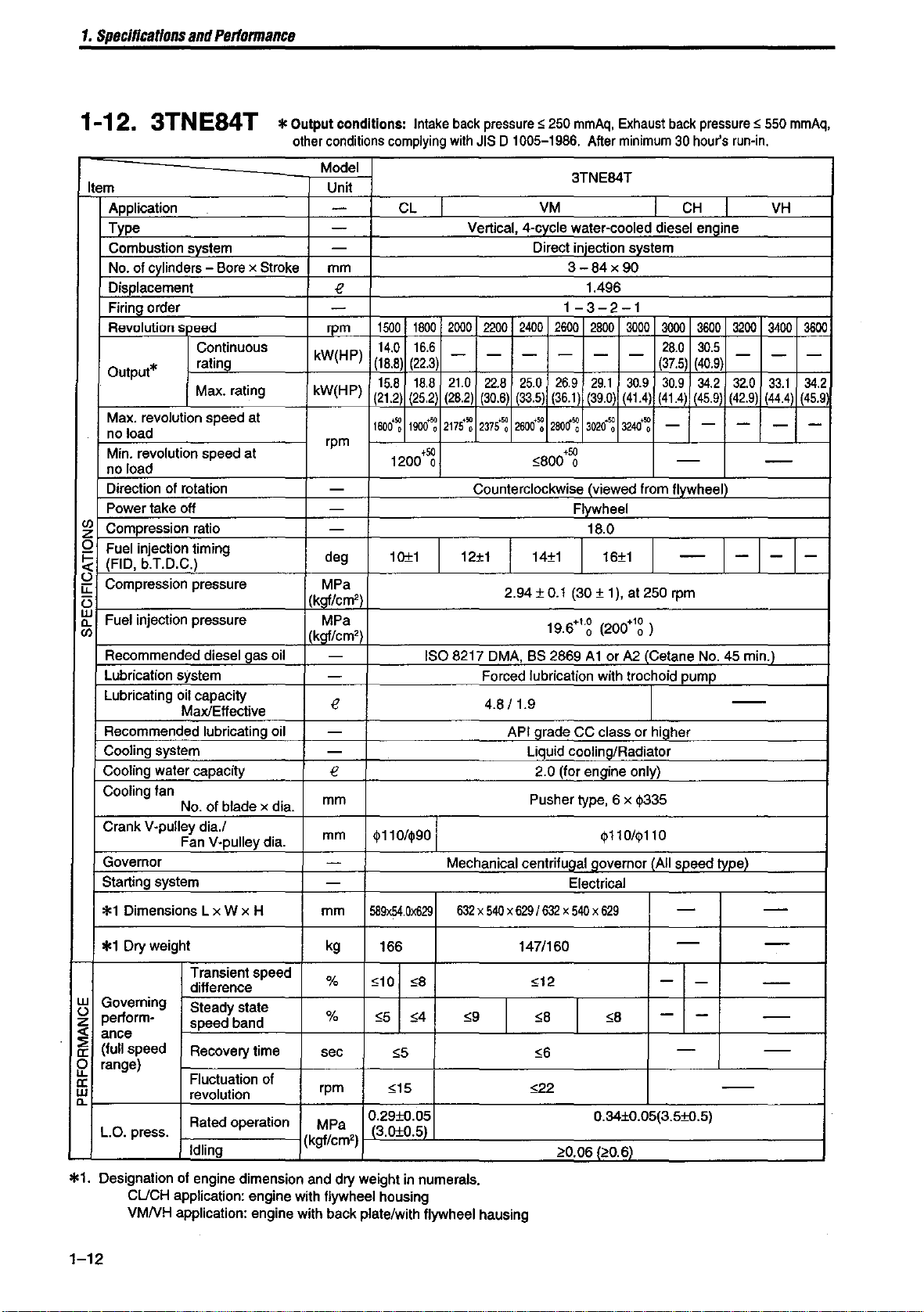

1-12. 3TN E84T *

Item Unit

Application

Type

Combustion system

No.

of cylinders -

Displacement

Firing order

Revolution s

Output*

Max.

revolution speed

no

load

Min.

revolution speed at

no load

Direction of rotation

Power take

en

Compression ratio

z

0

Fuel

injection timing

(FID,

5

iI

U

w

"-

en

b.T.D.C.)

Compression pressure

Fuel

injection pressure

Recommended diesel gas oil

Lubrication system

Lubricating

Recommended lubricating oil

Cooling system

Cooling water capacity

Cooling fan

Crank V-pulley dia.l

Governor

Starting system

Bore x Stroke

eed

Continuous

rating

Max.

rating kW(HP)

off

oil

capacity

Max/Effective

No.

of blade x dia.

Fan

V·pulley dia.

at

Output

other

conditions

Model

mm

rpm

kW(HP)

rpm

deg

MPa

(kgf/cm'i

MPa

I (k!'lf/cm')

-

-

-

mm

mm

- Mechanical centrifugal governor (All speed type)

- Electrical

conditions:

-

-

-

f!

-

1500 1800

14.0 16.6

(18.8)

15.8 18.8

(21.2)

1600~

-

-

-

-

f!

f!

<1>110/<1>90

Intake

back

pressure

complying

CL

with

JIS

Vertical. 4-cycle water-cooled diesel engine

2000 2200

- - - - - -

(22.3)

21.0

22.8

(28.2)

(25.2)

1900~

(30.6)

2175·~

2375·~

1200+~

Counterclockwise (viewed from flywheel)

10±1

12±1 14±1 16±1

ISO

8217

DMA,

Forced lubrication with trochoid pump

4.8/1.9

~

250

mmAq,

D t

005-1986,

VM

Direct inection system

2400

25.0 26.9

(33.5) (36.1)

2600+~

~800

2.94 ±

BS

API

grade

Liquid cooling/Radiator

2.0 (for engine only)

Pusher type, 6 x

After

3TNE84T

3-84x90

1.496

1-3-2-1

2600

2800

29.1

(39.0)

3020·~

2800~

+50

0

Flywheel

18.0

0.1

(30 ± 1),

19.6+1g

2869

(200+'g

Al

CC

class or higher

<1>110/<1>110

Exhaust

minimum

I

3000

30.9 30.9

(41.4) (41.4)

3240~

at

250

)

or

A2

(Cetane

<1>335

back

pressure

30

hour's

CH

3000

3600 3200 3400

28.0

30.5

(37.5) (40.9)

34.2 32.0

(45.9)

-

-

-

-

rpm

No.

~

550

run-in.

VH

-

-

33.1

(42.9) (44.4)

-

-

--

-

- -

45

min.)

--

mmAq,

3BOO

-

34.2

(45.9

-

*1

Dimensions

*1

Dry weight

w

Governing

0

perform-

z

<C

ance

::;:

(full speed

II:

0

range)

u.

II:

w

"-

L.O. press.

*1.

Designation of engine dimension and dry weight

CUCH application: engine with flywheel housing

VMNH application: engine with back plate/with flywheel hausing

Lx

W x H

Transient speed

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

mm

kg

%

%

sec $5

rpm

MPa

(kgf/cm')

1-12

589x54.0x629

166

,;10

~8

~5

~4 ~9

~15

0.29±O.05

(3.0±0.5)

in

numerals.

632 x 540

x

6291

632 x 540 x 629

147/160

~12

~8

I I

~6

~22

>0.06 (?0.6)

- -

-

- -

-

,;8

0.34±O.05(3.5±O.5)

-

-

-

--

--

--

--

1.

Specifications

and

Performance

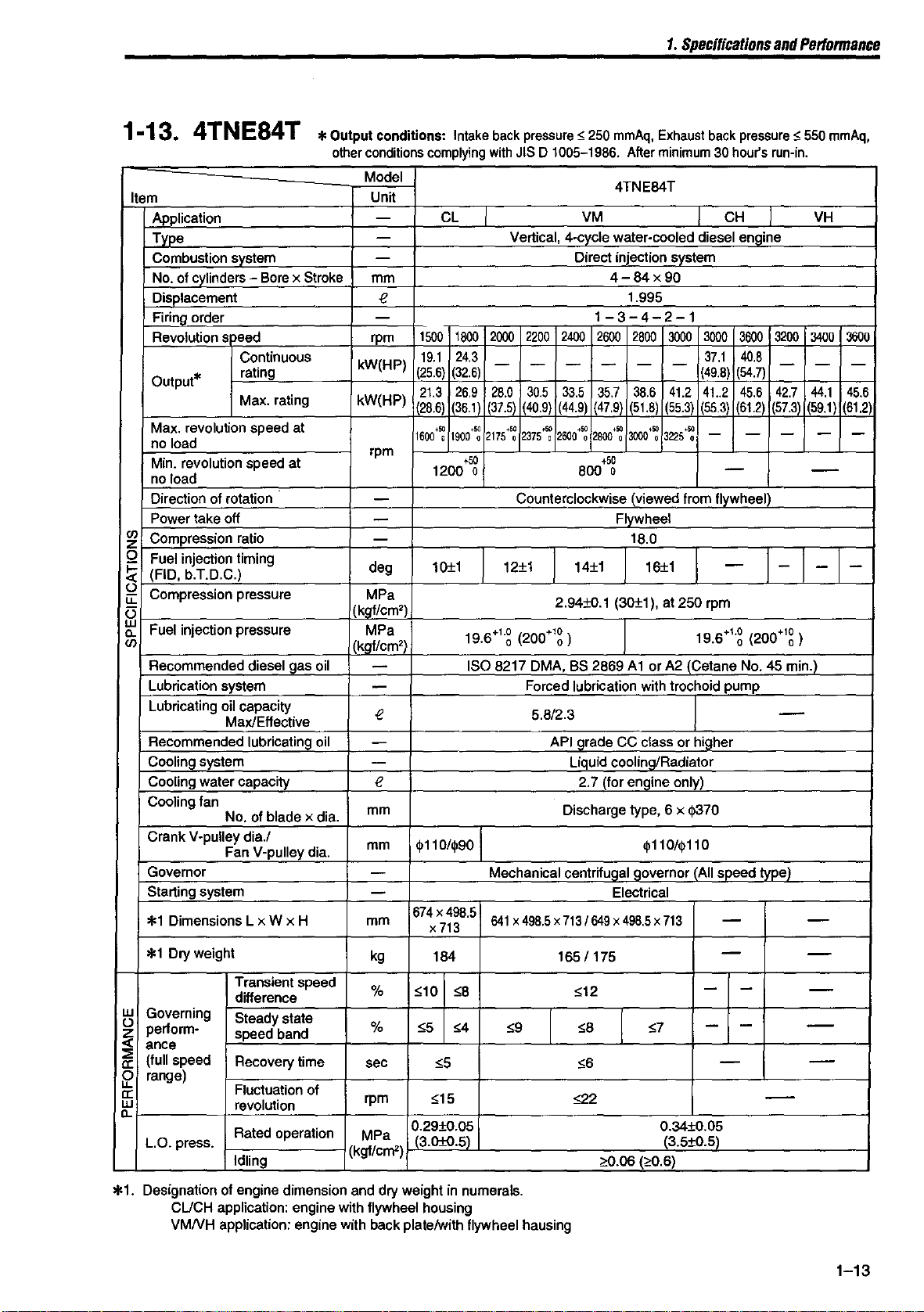

1-13. 4TNE84T *

Item

AEPlication

Type -

Combustion system

No. of

cylinders - Bore x Stroke

Displacement

Firingorder

Revolution speed rpm

Continuous

Output*

Max. revolution speed at

no load

Min. revolution speed at

no load

Direction of rotation

Power take off

en

Compression ratio

Z

0

Fuel injection timing

(FID, b.T.D.C.)

~

0

Compression pressure

u:

(3

w

Fuel injection pressure

0-

en

Recommended

Lubrication system

Lubricating oil capacity

Recommended lubricating

Cooling system

Cooling water capacity

Cooling fan

Crank

V-pulley dia.!

Governor

Starting system

*1

Dimensions L x W x H

*1

Dry weight

w

Governing

0

perfonm-

~

ance

::;

(full speed

cr:

0 range)

"-

cr:

w

0-

L.O. press.

rating

Max. rating kW(HP)

diesel gas oil

Max/Effective

oil

No. of blade x dia.

Fan V-pulley dia.

Transient speed

difference

Steady state

speed band

Recovery time

Fluctuation of

revolution

Rated operation

Idling

Output

conditions: Intake back pressure 5

other conditions complying

Model

Unit

-

CL

I

-

mm

€

-

1500

1800

24.3

-

19.1

(25.6) (32.6)

26.9

21.3

(26.6)

1600+~

1200 0 800 0 -

(37.5)

(36.1t

,.

2175~

1900

0

+50

kW(HP)

rpm

with

JIS D 1005-1986. After minimum 30 hour's run-in.

Vertical, 4·cycle water-cooled diesel engine

2000 2200 2400 2600

- -

26.0

30.5

(40.9)

2375~ 2600~

Counterclockwise (viewed from flywheel)

250

VM CH VH

Direct injection system

1-3-4-2-1

- -

33.5

35.7

(44.9)

(47.9)

2800

,50

-

-

deg

MPa

(kgf/cm')

MPa

{kgf/cm'\

-

-

€

-

-

€ 2.7 (for engine only)

mm

mm

-

10±1 12±1 14±1 16±1

2.94±O.1 (30±1), at 250 rpm

19.6"~

ISO 8217 DMA, BS 2869

$110/$90

(200"~

Mechanical centrifugal governor (All speed type)

)

Forced lubrication with trochoid

5.8/2.3

API grade

Liquid cooling/Radiator

Discharge type, 6 x $370

-

mm

sec

rpm

MPa

(kgf/cm')

674 x 498.5

x713

kg

% 510

%

184

55

55

515

0.29±O.05

(3.0±0.5) (3.5+0.5)

,,8

,;;4

641 x 498.5

59 58

I I

x

713/649

165/175

512

56

522

;'0.06

mmAq,

Exhaust back pressure 5

4TNE84T

4-84x90

1.995

2600

- -

36.6

(51.8) (55.3) (55.3) (61.2) (57.3)

,.

3000+~

•

Flywheel

18.0

3000

3000

41.2

3225·~

37.1

(49.8)

41..2

- -

3600

40.6

(54.7)

45.6

-

A1

or

CC

class

$110/$110

Electrical

x

498.5 x 713

19.6"~

A2 (Cetane No. 45 min.)

or

higher

(200+1~

pump

- -

-

-

-

-

57

(;'0.6)

-

-

O.34±O.O5

550

3200

3400

-

42.7

44.1

(59.1) (61.2)

- - -

-

-

)

-

-

-

-

-

--

mmAq,

- -

-

3600

45.6

-

*1.

Designation of engine dimension and dry weight in numerais.

CUCH

application: engine with flywheel housing

VMNH

application: engine with back plateiwith flywheel hausing

1-13

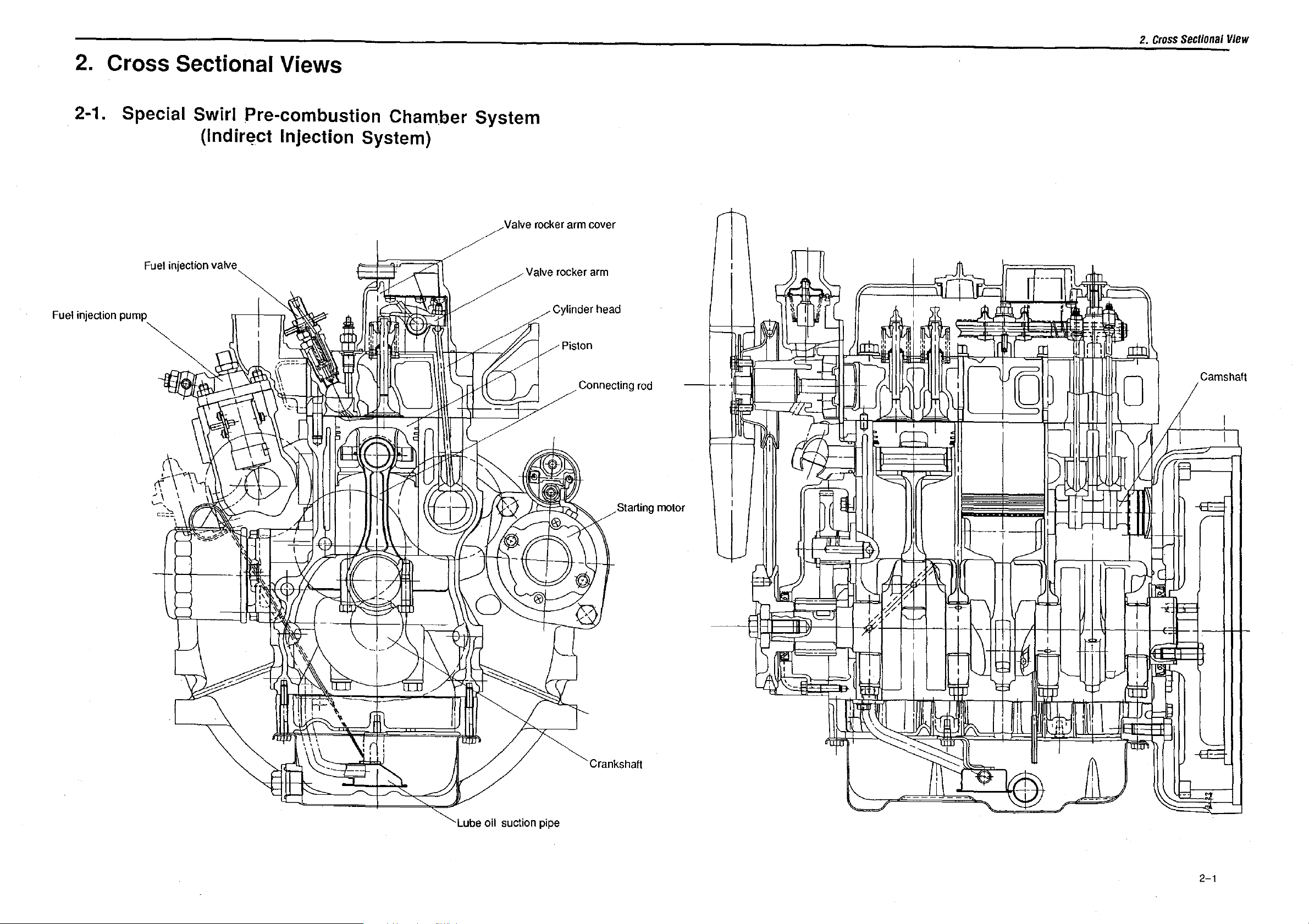

2.

Cross Sectional Views

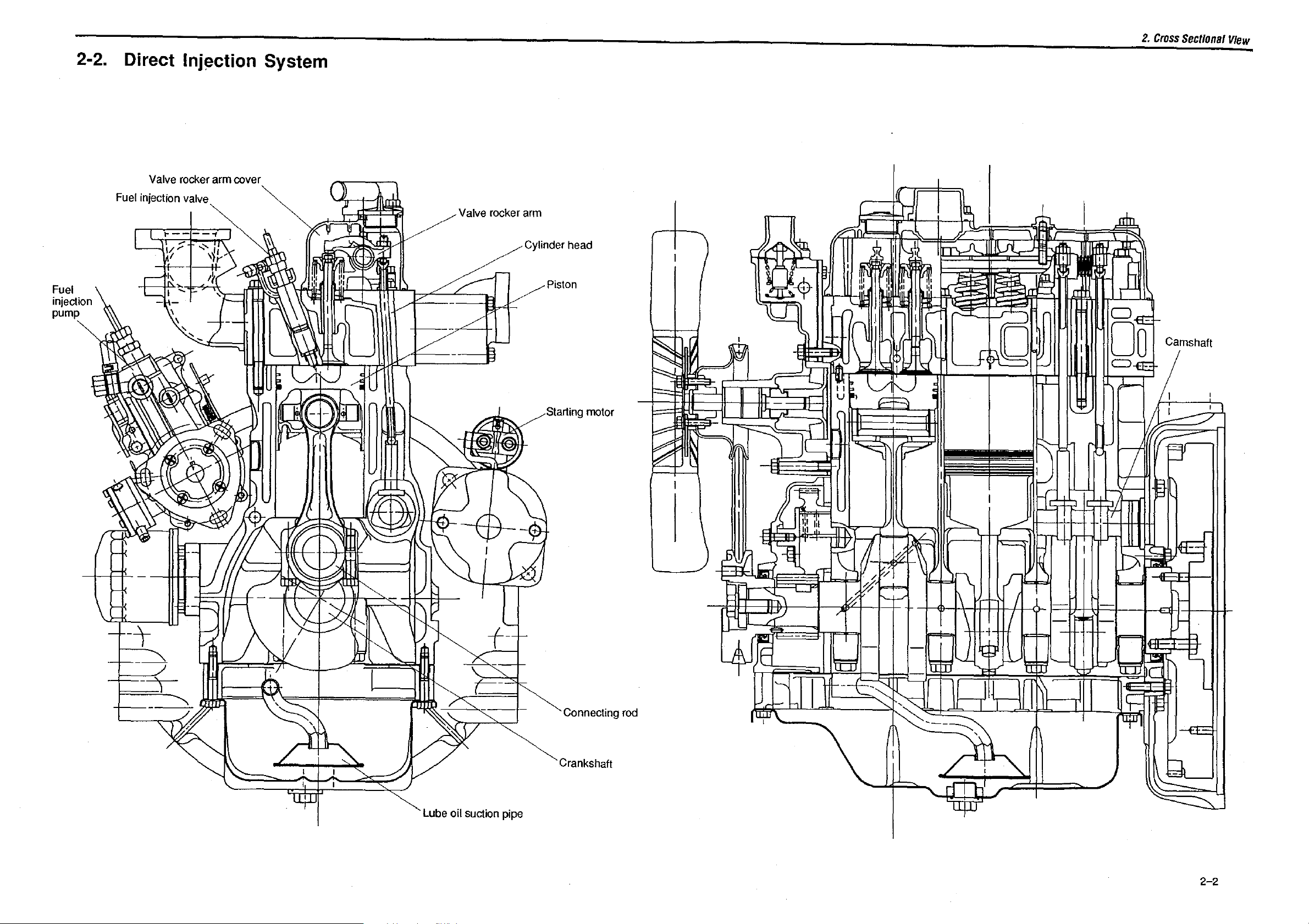

2-1. Special Swirl Pre-combustion Cham.ber System

2.

Cross

Sec/ional

View

Fuel injection pump

(Indir~ct

Fuel injection

Injection System)

rocker arm cover

Valve rocker arm

Cylinder head

Piston

Connecting

rod

I

Camshaft

oil suction pipe

If

Ur

r==

~~

it

lIB

I

=

r-

~f-

r--

r--

2-1

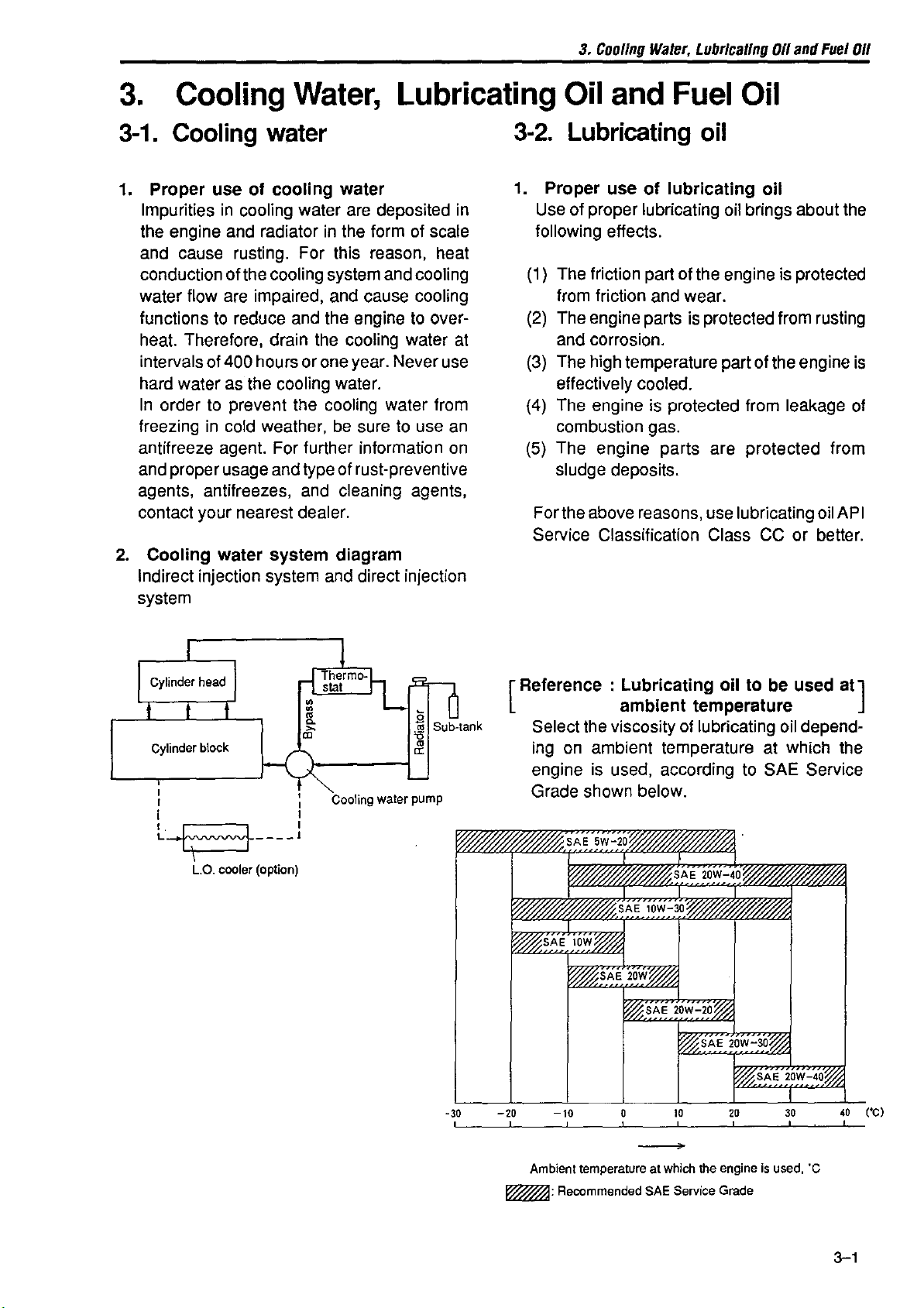

2-2. Direct Injection System

Valve rocker arm cover

Fuel injection valve

Valve

rocker arm

Cylinder head

2.

Cross

Sec/lonaf

View

Fuel

injection

pump

Piston

Camshaft

!

motor

Lube oil suction pipe

L

Connecting rod

.LD

2-2

3.

Cooling

Water.

Lubricating

Oil

and

Fuel

all

3.

Cooling

Water,

Lubricating Oil and Fuel Oil

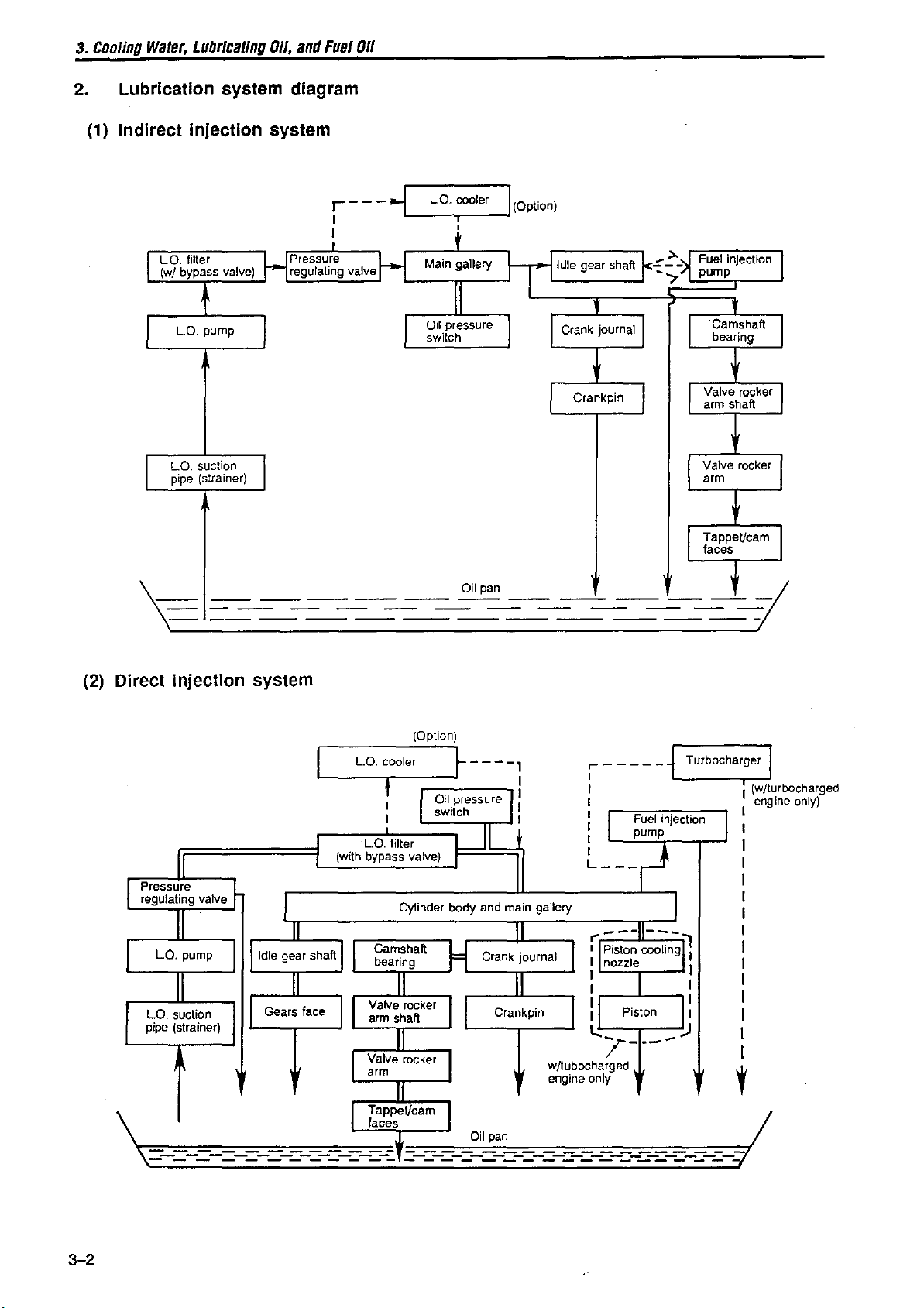

3-1. Cooling water

1. Proper

Impurities

the engine and radiator

and cause rusting. For this reason, heat

conduction

water flow are impaired, and cause cooling

functions

heat. Therefore, drain the cooling water at

intervals of

hard water as the cooling water.

In

order to prevent the cooling water from

freezing

antifreeze agent. For further information

and proper usage and type of rust-preventive

agents, antifreezes, and cleaning agents,

contact your nearest dealer.

2.

Cooling

Indirect injection system and direct injection

system

use

of

cooling

in

cooling water are deposited

water

in

the form

of

olthe cooling system and cooling

to

reduce and the engine

to

400 hours or one year. Never use

in

cold weather,

water

system

be

sure

diagram

to

scale

over-

use

in

an

on

3-2.

1. Proper

Lubricating oil

use

of

lubricating

oil

Use of proper lubricating oil brings about the

following effects.

(1) The friction part of the engine is protected

from friction and wear.

(2) The engine parts is protected from rusting

and corrosion.

(3) The high temperature part of the engine

effectively cooled.

(4) The engine is protected from leakage

combustion gas.

(5) The engine parts are protected from

sludge deposits.

Forthe above reasons, use lubricating oil

Service Classification Class CC or better.

is

of

API

Cylinder block

I

I

I 1

L-ff0+----1

L.O.

cooler

(opUon)

li

~

~

Cooling water pump

Sub-tank

·30

,

Reference :

[

Lubricating

ambient

temperature

oil

to

be used

Select the viscosity of lubricating oil depending

on

ambient temperature at which the

engine

is

used, according to SAE Service

Grade shown below.

-20

-I.

J

I

•

J

10

I

20

I

3.

at]

40

,

('C)

I

Ambient temperature at which

~:

Recommended

SAE

the

Service

engine

Grade

is

used. 'C

3-1

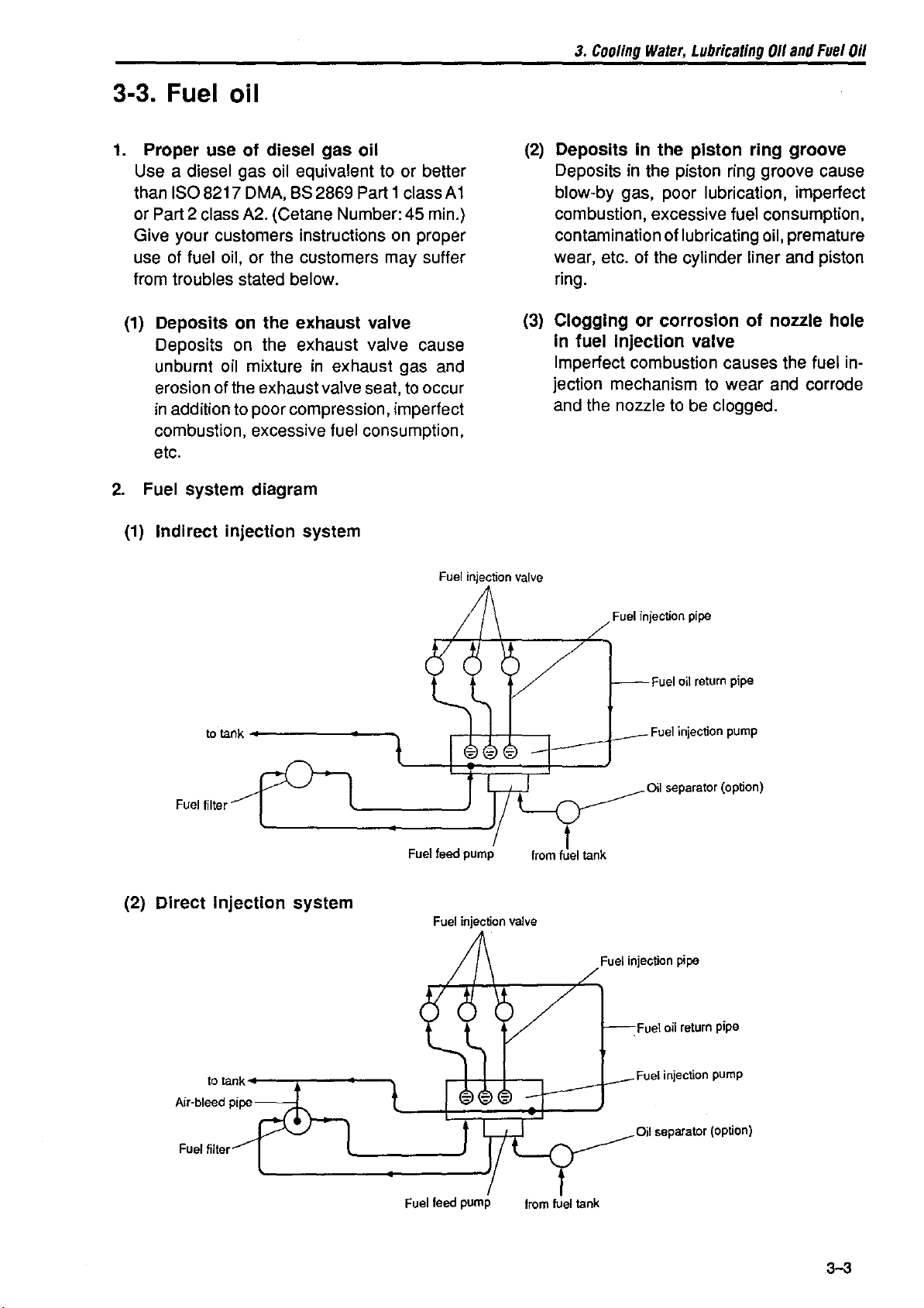

3.

Cooling

2.

(1) Indirect Injection system

Water,

Lubrlcallng

Lubrication system diagram

all,

and

Fuel

Oil

LO. suction

pipe (strainer)

\

______

--

--

--

---

---

Pressure

regulating valve

--

---

---

r - - -

I

I

--

---

-l

L.O. cooler I (Option)

---

---

---

Oilpan

--- ---

--

_____

---

Idle gear shaft

---

---

---

---

---

Fuel injection

pump

--

--

---

(

-

(2)

Direct Injection system

\

~\~~~_~_~_==_~_~==~r~_~_~_~~_~_~_~_~=_==_=_~~if

(Option)

L.O. cooler

~--~f~~=:---,:

I I

r--.,-~I

(with bypass valve)

~=;--il'

L.O. filter

~~~

faces

~----1

Oil

pan

r------

I

I (w/turbocharged

I

I

I

I

I

L

w/tubocharged

engine only

__

_

Turbocharger

L----r~

I

I

l

eng

/

ine only)

3-2

3.

Cooling

Water,

Lubricating

Off

and

Fuel

011

3-3. Fuel

1.

Proper use

oil

of

diesel

gas

oil

Use a diesel gas oil equivalent

than

IS08217

or Part 2 class

DMA,

8S2869 Part 1 ciassA1

A2.

(Cetane Number:

Give your customers instructions

use of

fuel oil, or

the

customers may suffer

from troubles stated below.

(1)

Deposits

Deposits

unburnt oil mixture

erosion of

in

addition

on

the

exhaust valve