Page 1

L48N

L70N

L100N

Page 2

California

Proposition 65 Warning

California

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the state of

California to cause cancer, birth

defects, and other reproductive harm.

Battery posts, terminals, and related

accessories contain lead and lead

compounds, chemicals known to the

state of California to cause cancer and

reproductive harm.

Wash hands after handling.

Page 3

INTRODUCTION

L-N Operation Manual

Welcome to the world of Yanmar Engines!

Yanmar has been the leader in industrial diesel

engines for over 90 years. We developed the

world’s first practical small-sized diesel engine in

1933. Our engineers are continuously developing

new technology to keep Yanmar on the leadingedge of the industry. The L-N Series engine is

only one example of the new technology we have

developed. We are committed to maintaining our

environment, and are proud of our history of

innovation, quality and respect for operator safety.

To help you enjoy your Yanmar L-N Series engine

for many years to come, please follow these

recommendations:

• Read and understand this Operation Manual

before you operate the machine to ensure that

you follow safe operating practices and

maintenance procedures.

• Keep this Operation Manual in a convenient

place for easy access.

• Constant efforts are made to improve the

quality and performance of Yanmar products, so

some details included in this Operation Manual

may differ slightly from your engine. If you have

any questions about these differences, please

contact your authorized Yanmar industrial

engine dealer or distributor.

• The specifications and components (instrument

panel, fuel tank, etc.) described in this manual

may differ from ones installed on your machine.

Please refer to the manual provided by the

manufacturer of these components.

• If this Operation Manual is lost or damaged,

order a new one from your authorized Yanmar

industrial engine dealer or distributor.

• Make sure this manual is transferred to

subsequent owners. This manual should be

considered a permanent part of the engine and

remain with it.

L-N Operation Manual

i

Page 4

INTRODUCTION

RECORD OF OWNERSHIP

Take a few moments to record the information you need when you contact Yanmar for service, parts or

literature.

Engine Model: _____________________________________________________________________

Engine Serial No.: __________________________________________________________________

Date Purchased: ___________________________________________________________________

Dealer:____________________________________________________________________________

Dealer Phone:______________________________________________________________________

ii

L-N Operation Manual

Page 5

CONTENTS

L-N Operation Manual

Introduction .............................................................................................. i

Record of Ownership........................................................................... ii

Table of Contents................................................................................... iii

Yanmar Warranties................................................................................ vii

Yanmar Limited Warranty.................................................................. vii

What is Covered by this Warranty?............................................. vii

How Long is the Warranty Period?.............................................. vii

What the Engine Owner Must Do: ............................................... vii

To Locate an Authorized Yanmar Industrial Engine

Dealer or Distributor: .................................................................. viii

What Yanmar Will Do: ................................................................ viii

What is Not Covered by this Warranty? ..................................... viii

Warranty Limitations:.................................................................... ix

Warranty Modifications:................................................................ ix

Questions: .................................................................................... ix

Retail Purchaser Registration....................................................... ix

TABLE OF

Page

Safety........................................................................................................ 1

Safety Statements ............................................................................... 1

Safety Precautions .............................................................................. 2

Before You Operate....................................................................... 2

During Operation and Maintenance............................................... 2

L-N Operation Manual

iii

Page 6

TABLE OF CONTENTS

Product Overview.................................................................................. 13

Yanmar L-N Series Engine Features and Applications..................... 13

Component Identification................................................................... 14

Location of Labels ............................................................................. 15

Function of Major Engine Components............................................. 16

Air Cooled Engine ............................................................................. 17

Controls - Recoil Starter.................................................................... 17

Recoil Starter............................................................................... 17

Decompression Lever ................................................................. 17

Indicators and Controls – Electric Starter.......................................... 17

Indicators..................................................................................... 18

Controls ....................................................................................... 18

Inlet Air Heater ............................................................................ 19

Engine Speed Controls ............................................................... 19

Before You Operate .............................................................................. 21

Diesel Fuel ........................................................................................ 24

Diesel Fuel Specifications ........................................................... 24

Filling the Fuel Tank .................................................................... 25

Engine Oil.......................................................................................... 27

Engine Oil Specifications............................................................. 27

Engine Oil Viscosity..................................................................... 28

Checking Engine Oil.................................................................... 28

Adding Engine Oil........................................................................ 28

Engine Oil Capacity (Typical) ...................................................... 29

Daily Checks ..................................................................................... 29

Visual Checks.............................................................................. 29

Check Diesel Fuel and Engine Oil............................................... 30

Check Engine Speed Control (First Time Only) .......................... 30

Check Indicators.......................................................................... 30

Engine Operation .................................................................................. 31

Starting the Engine............................................................................ 37

Recoil Start.................................................................................. 37

Electric Start ................................................................................ 39

Check the Engine During Operation.................................................. 41

Adjust Engine Speed......................................................................... 43

Shutting Down the Engine................................................................. 44

Preparing To Stop Engine ........................................................... 44

Set Engine Speed Control to STOP............................................ 44

Electric Start Models ................................................................... 45

After The Engine Stops ............................................................... 46

iv

L-N Operation Manual

Page 7

TABLE OF CONTENTS

Periodic Maintenance ........................................................................... 47

Precautions ....................................................................................... 57

The Importance of Periodic Maintenance.................................... 57

Performing Periodic Maintenance ............................................... 57

The Importance of Daily Checks ................................................. 57

Keep a Log of Engine Hours and Daily Checks .......................... 57

Yanmar Replacement Parts ........................................................ 57

Tools Required ............................................................................ 57

Ask Your Authorized Yanmar Industrial Engine

Dealer or Distributor For Help...................................................... 57

Tightening Fasteners................................................................... 58

Standard Torque Chart...................................................................... 58

Periodic Maintenance Schedule........................................................ 59

Periodic Maintenance Procedures .................................................... 61

Daily, Before Operation ............................................................... 61

Daily, After Operation .................................................................. 66

After Initial 50 Hours of Operation ............................................... 68

Every 50 Hours of Operation....................................................... 70

Every 200 Hours of Operation..................................................... 71

Every 400 Hours of Operation..................................................... 75

Every 1000 Hours of Operation................................................... 76

Every 1500 Hours of Operation................................................... 76

Every 2000 Hours of Operation................................................... 77

Troubleshooting.................................................................................... 79

Troubleshooting Chart....................................................................... 79

Troubleshooting Information.............................................................. 81

Long Term Storage ............................................................................... 83

Before You Place the Engine in Long Term Storage ........................ 83

Returning the Engine to Service........................................................ 85

Specifications........................................................................................ 87

General.............................................................................................. 87

Description of Model Number...................................................... 87

Engine Speed Specifications....................................................... 87

Engine General Specifications .................................................... 88

Principal Engine Specifications ......................................................... 89

Engine Specifications .................................................................. 89

L-N Operation Manual

v

Page 8

TABLE OF CONTENTS

This Page Intentionally Left Blank

vi

L-N Operation Manual

Page 9

YANMAR

WARRANTIES

L-N Operation Manual

YANMAR LIMITED WARRANTY

What is Covered by this Warranty?

Yanmar warrants to the original retail purchaser that a new Yanmar L-N Series Industrial Engine will be

free from defects in material and / or workmanship for the duration of the warranty period.

THIS WARRANTY IS PROVIDED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

YANMAR SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, except where such disclaimer is prohibited by law. IF SUCH

DISCLAIMER IS PROHIBITED BY LAW, THEN IMPLIED WARRANTIES SHALL BE LIMITED IN

DURATION TO THE LIFE OF THE EXPRESS WARRANTY.

How Long is the Warranty Period?

The Yanmar standard limited warranty period begins on the date of the delivery of the new Yanmar L-N

Series Industrial Engine to the first retail purchaser and extends for a period of twenty-four (24) months

or two-thousand (2000) engine operation hours, whichever occurs first.

What the Engine Owner Must Do:

If you believe your Yanmar engine has experienced a failure due to a defect in material and / or

workmanship, you must contact an authorized Yanmar industrial engine dealer or distributor within thirty

(30) days of discovering the failure. You must provide proof of ownership of the engine, proof of the date

of the engine purchase and delivery, and documentation of the Acceptable forms of proof of delivery date

include, but are not limited to: the original warranty registration or sales receipts or other documents

maintained in the ordinary course of business by Yanmar dealers and / or distributors, indicating the date

of delivery of the Yanmar product to the original retail purchaser. This information is necessary to

establish whether the Yanmar product is still within the warranty period. Thus, Yanmar strongly

recommends you register your engine as soon as possible after purchase in order to facilitate any future

warranty matters.

You are responsible for the transportation of the engine to and from the repair location as designated by

Yanmar.

L-N Operation Manual

vii

Page 10

YANMAR WARRANTIES

Yanmar Limited Warranty - Continued

To Locate an Authorized Yanmar Industrial Engine Dealer or Distributor:

You can locate your nearest authorized Yanmar industrial engine dealer or distributor by visiting the

Yanmar Corp., LTD. website at:

http://www.yanmar.co.jp

on “English Page.”)

• “Click” on “Network” in the web site heading to view the “Yanmar Worldwide Network.”

• Choose and “Click” on the desired product group.

• “Click” on the Icon closest to your region.

• “Click” on the desired country or Associate company to locate your nearest authorized Yanmar

industrial engine dealer or distributor.

• You may also contact Yanmar by clicking on “Inquiry” in the web site heading and typing in your

question or comment.

(The Japanese language page will be displayed.) For English language “click”

What Yanmar Will Do:

Yanmar warrants to the original retail purchaser of a new Yanmar engine that Yanmar will make such

repairs and / or replacements at Yanmar’s option, of any part(s) of the Yanmar product covered by this

Warranty found to be defective in material and/or workmanship. Such repairs and / or replacements will

be made at a location designated by Yanmar at no cost to the purchaser for parts or labor.

What is Not Covered by this Warranty?

This Warranty does not cover parts affected by or damaged by any reason other than defective materials

or workmanship including, but not limited to, accident, misuse, abuse, “Acts of God,” neglect, improper

installation, improper maintenance, improper storage, the use of unsuitable attachments or parts, the

use of contaminated fuels, the use of fuels, oils, lubricants, or fluids other than those recommended in

your Yanmar Operation Manual, unauthorized alterations or modifications, ordinary wear and tear, and

rust or corrosion. This Warranty does not cover the cost of parts and / or labor required to perform

normal / scheduled maintenance on your Yanmar engine. This Warranty does not cover consumable

parts such as, but not limited to, filters, belts, hoses, fuel injector nozzles, lubricants and cleaning fluids.

This Warranty does not cover the cost of shipping the product to or from the warranty repair facility.

viii

L-N Operation Manual

Page 11

YANMAR WARRANTIES

Yanmar Limited Warranty - Continued

Warranty Limitations:

The foregoing is Yanmar’s only obligation to you and your exclusive remedy for breach of

warranty. Failure to follow the requirements for submitting a claim under this Warranty may result in a

waiver of all claims for damages and other relief. In no event shall Yanmar or any authorized

industrial engine dealer or distributor be liable for incidental, special or consequential damages.

Such consequential damages may include, but not be limited to, loss of revenue, loan payments, cost of

rental of substitute equipment, insurance coverage, storage, lodging, transportation, fuel, mileage and

telephone costs. The limitations in this Warranty apply regardless of whether your claims are based on

breach of contract, tort (including negligence and strict liability) or any other theory. Any action arising

hereunder must be brought within one (1) year after the cause of action accrues or it shall be barred.

Some states and countries do not allow certain limitations on warranties or for breach of warranties. This

Warranty gives you specific legal rights, and you may also have other rights which vary from

state to state and country to country. Limitations set forth in this paragraph shall not apply to the

extent that they are prohibited by law.

Warranty Modifications:

Except as modified in writing and signed by the parties, this Warranty is and shall remain the complete

and exclusive agreement between the parties with respect to warranties, superseding all prior

agreements, written and oral, and all other communications between the parties relating to warranties.

No person or entity is authorized to give any other warranty or to assume any other obligation on

behalf of Yanmar, either orally or in writing.

Questions:

If you have any questions or concerns regarding this Warranty, please call or write to the nearest

authorized Yanmar industrial engine dealer or distributor or other authorized facility.

Retail Purchaser Registration

It is very important for the original retail purchaser to register the Yanmar product. Registration

enables Yanmar to provide the best support for your Yanmar product.

At the time of purchase, Yanmar highly recommends registering the retail purchaser’s information

through website http://www.yanmar.co.jp

If it is not possible to access the website, please contact the nearest authorized Yanmar industrial engine

dealer or distributor.

as soon as possible.

L-N Operation Manual

ix

Page 12

YANMAR WARRANTIES

This Page Intentionally Left Blank

x

L-N Operation Manual

Page 13

L-N Operation Manual

SAFETY

SAFETY STATEMENTS

Yanmar is concerned for your safety and your

machine’s condition. Safety statements are one

of the primary ways to call your attention to the

potential hazards associated with Yanmar L-N

Series engine operation. Follow the precautions

listed throughout the manual before operation,

during operation and during periodic

maintenance procedures for your safety, the

safety of others and to protect the performance of

your engine. Keep the labels from becoming dirty

or torn and replace them if they are lost or

damaged. Also, if you need to replace a part that

has a label attached to it, make sure you order

the new part and label at the same time.

This safety alert symbol appears with

most safety statements. It means

A

attention, become alert, your safety is

involved! Please read and abide by the

message that follows the safety alert

symbol.

A DANGER

Danger (the word “DANGER” is in white

letters with a red rectangle behind it) –

indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. Danger

is limited to the most extreme

situations.

0000001en

A WARNING

Warning (the word “WARNING” is in

black letters with an orange rectangle

behind it) – indicates a potentially

hazardous situation which, if not

avoided, could result in death or serious

injury.

0000001en

A CAUTION

Caution (the word “CAUTION” is in black

letters with a yellow rectangle behind it)

– indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

0000001en

CAUTION

Caution without the safety alert symbol

indicates a potentially hazardous

situation that can cause damage to the

machine, personal property and / or the

environment or cause the machine to

operate improperly.

0000001en

L-N Operation Manual

1

Page 14

SAFETY

SAFETY PRECAUTIONS

Before You Operate

CAUTION

NEVER permit anyone to operate the

engine or driven machine without proper

training.

• Read and understand this Operation

Manual before you operate the

machine to ensure that you follow safe

operating practices and maintenance

procedures.

• Machine safety signs and labels are

additional reminders for safe operating

and maintenance techniques.

• See your authorized Yanmar industrial

engine dealer or distributor for

additional training.

During Operation and Maintenance

A DANGER

EXPLOSION HAZARD!

• Keep the area around the battery well

ventilated. While the engine is running

or the battery is charging, hydrogen

gas is produced which can be easily

ignited.

• Keep sparks, open flame and any other

form of ignition away.

• Failure to comply will result in death or

serious injury.

0000003en

A DANGER

0000002en

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• When you remove any fuel system

component to perform maintenance

(such as changing the fuel filter) place

an approved container under the

opening to catch the fuel.

• NEVER use a shop rag to catch the

fuel. Vapors from the rag are extremely

flammable and explosive.

• Wipe up any spills immediately.

• Wear eye protection. The fuel system

is under pressure and fuel could spray

out when you remove any fuel system

component.

• Failure to comply will result in death or

serious injury.

0000009en

2

L-N Operation Manual

Page 15

SAFETY

A DANGER

FIRE AND EXPLOSION HAZARD!

• Only use the key switch to start the

engine.

• NEVER jump start the engine. Sparks

caused by jumping the battery to the

starter terminals may cause a fire or

explosion.

• Failure to comply will result in death or

serious injury.

0000004en

A DANGER

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• NEVER remove the fuel cap with the

engine running.

• Failure to comply will result in death or

serious injury.

0000011en

A DANGER

FIRE AND EXPLOSION HAZARD!

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• NEVER use diesel fuel as a cleaning

agent.

• Failure to comply will result in death or

serious injury.

0000012en

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Only fill the fuel tank with diesel fuel.

Filling the fuel tank with gasoline may

result in a fire.

• NEVER refuel with the engine running.

• Wipe up all spills immediately.

• Keep sparks, open flames or any other

form of ignition (match, cigarette,

static electric source) away when

fueling / refueling.

• NEVER overfill the fuel tank.

• Fill the fuel tank and store fuel in a

well-ventilated area only.

• Failure to comply will result in death or

serious injury.

0000005en

L-N Operation Manual

3

Page 16

SAFETY

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Be sure to place the diesel fuel

container on the ground when

transferring the diesel fuel from the

pump to the container. Hold the hose

nozzle firmly against the side of the

container while filling it. This prevents

static electricity build-up which could

cause sparks and ignite fuel vapors.

• NEVER place diesel fuel or other

flammable material such as oil, hay or

dried grass close to the engine during

engine operation or shortly after shut

down.

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Before you operate the engine, check

for fuel leaks. Replace rubberized fuel

hoses every two years or every 2000

hours of engine operation, whichever

comes first, even if the engine has

been out of service. Rubberized fuel

lines tend to dry out and become

brittle after two years or 2000 hours of

engine operation, whichever comes

first.

• Failure to comply will result in death or

serious injury.

0000015en

• Failure to comply will result in death or

serious injury.

0000014en

A DANGER

EXPLOSION HAZARD!

• NEVER check the remaining battery

charge by shorting out the terminals.

This will result in a spark and may

cause an explosion or fire. Use a

hydrometer to check the remaining

battery charge.

• If the electrolyte is frozen, slowly warm

the battery before you recharge it.

• Failure to comply will result in death or

serious injury.

0000007en

4

L-N Operation Manual

Page 17

SAFETY

A DANGER

CRUSH HAZARD!

• When you need to transport an engine

for repair, have a helper assist you to

attach it to a hoist and load it on a

truck.

• NEVER stand under a hoisted engine.

If the hoist mechanism fails, the

engine will fall on you, causing serious

injury or death.

• Failure to comply will result in death or

serious injury.

0000008en

A WARNING

SEVER HAZARD!

• Keep hands and other body parts

away from moving / rotating parts

such as the cooling fan / flywheel.

• Wear tight fitting clothing and keep

your hair short or tie it back while the

engine is running.

• Remove all jewelry before you operate

or service the machine.

• NEVER start the engine in gear.

Sudden movement of the engine

and / or machine could cause death or

serious personal injury.

• NEVER operate the engine without the

guards in place.

• Before you start the engine make sure

that all bystanders are clear of the

area.

• Keep children and pets away while the

engine is operating.

• Check before starting the engine that

any tools or shop rags used during

maintenance have been removed from

the area.

• Failure to comply could result in death

or serious injury.

0000002enLV

L-N Operation Manual

5

Page 18

SAFETY

A WARNING

EXHAUST HAZARD!

• NEVER operate the engine in an

enclosed area such as a garage,

tunnel, underground room, manhole or

ship’s hold without proper ventilation.

• NEVER block windows, vents, or other

means of ventilation if the engine is

operating in an enclosed area. All

internal combustion engines create

carbon monoxide gas during

operation. Accumulation of this gas

within an enclosure could cause

illness or even death.

• Make sure that all connections are

tightened to specifications after repair

is made to the exhaust system.

• Failure to comply could result in death

or serious injury.

0000003en

A WARNING

EXPOSURE HAZARD!

• Wear personal protective equipment

such as gloves, work shoes, eye and

hearing protection as required by the

task at hand.

• NEVER wear jewelry, unbuttoned

cuffs, ties or loose fitting clothing

when you are working near

moving / rotating parts such as the

cooling fan, flywheel or PTO shaft.

• ALWAYS tie long hair back when you

are working near moving / rotating

parts such as a cooling fan, flywheel,

or PTO shaft.

• NEVER operate the engine while

wearing a headset to listen to music or

radio because it will be difficult to hear

the warning signals.

A WARNING

ALCOHOL AND DRUG HAZARD!

• NEVER operate the engine while you

under the influence of alcohol or

are

drugs.

• NEVER operate the engine when you

are feeling ill.

• Failure to comply could result in death

or serious injury.

0000004en

• Failure to comply could result in death

or serious injury.

0000005en

6

L-N Operation Manual

Page 19

SAFETY

A WARNING

BURN HAZARD!

• Batteries contain sulfuric acid. NEVER

allow battery fluid to come in contact

with clothing, skin or eyes. Severe

burns could result. ALWAYS wear

safety goggles and protective clothing

when servicing the battery. If contact

with the skin and / or eyes should

occur, flush with a large amount of

water and obtain prompt medical

treatment.

• Failure to comply could result in death

or serious injury.

0000007en

A WARNING

A WARNING

SHOCK HAZARD!

• Turn off the battery switch (if

equipped) or disconnect the negative

battery cable before servicing the

electrical system.

• Check the electrical harnesses for

cracks, abrasions, and damaged or

corroded connectors. ALWAYS keep

the connectors and terminals clean.

• Failure to comply could result in death

or serious injury.

0000009en

A WARNING

HIGH PRESSURE HAZARD!

• Avoid skin contact with the high

pressure diesel fuel spray caused by a

fuel system leak such as a broken fuel

injection line. High pressure fuel can

penetrate your skin and result in

serious injury. If you are exposed to

high pressure fuel spray, obtain

prompt medical treatment.

• NEVER check for a fuel leak with your

hands. ALWAYS use a piece of wood

or cardboard. Have your authorized

Yanmar industrial engine dealer or

distributor repair the damage.

• Failure to comply could result in death

or serious injury.

0000008en

SEVER HAZARD!

• Stop the engine before you begin to

service it.

• NEVER leave the key in the key switch

when you are servicing the engine.

Someone may accidentally start the

engine and not realize you are

servicing it. This could result in a

serious injury.

• If you must service the engine while it

is operating, remove all jewelry, tie

long hair back, and keep your hands,

other body parts and clothing away

from moving / rotating parts.

• Failure to comply could result in death

or serious injury.

0000010en

L-N Operation Manual

7

Page 20

SAFETY

A WARNING

BURN HAZARD!

• If you must drain the engine oil while it

is still hot, stay clear of the hot engine

oil to avoid being scalded. Make sure

you wear eye protection.

• Failure to comply could result in death

or serious injury.

0000011en

A WARNING

BURN HAZARD!

• Keep your hands and other body parts

away from hot engine surfaces such

as the muffler, exhaust pipe,

turbocharger (if equipped) and engine

block during operation and shortly

after you shut the engine down. These

surfaces are extremely hot while the

engine is operating and could

seriously burn you.

A CAUTION

FLYING OBJECT HAZARD!

• ALWAYS wear eye protection when

servicing the engine and when using

compressed air or high-pressure

water. Dust, flying debris, compressed

air, pressurized water or steam may

injure your eyes.

• Failure to comply may result in minor

or moderate injury.

0000003en

CAUTION

• Only use diesel fuels recommended by

Yanmar for the best engine

performance, to prevent engine

damage.

• Only use clean diesel fuel.

• NEVER remove inlet fuel screen from

the filler port. If removed, dirt and

debris could get into the fuel system

causing it to clog.

0000004enLV

• Failure to comply could result in death

or serious injury.

0000015en

CAUTION

NEVER attempt to adjust the low or high

idle speed limit screw. This may impair

the safety and performance of the

machine and shorten its life. If

adjustment is ever required, contact

your authorized Yanmar industrial

engine dealer or distributor.

0000045en

8

L-N Operation Manual

Page 21

SAFETY

CAUTION

If any problem is noted during the visual

check, the necessary corrective action

should be taken before you operate the

engine.

0000021en

CAUTION

NEVER hold the key in the START

position for longer than 15 seconds or

the starter motor will overheat.

0000007en

CAUTION

The illustrations and descriptions of

optional equipment in this manual, such

as the operator’s console, are for a

typical engine installation. Refer to the

documentation supplied by the optional

equipment manufacturer for specific

operation and maintenance instructions.

0000018en

CAUTION

If any indicator illuminates during

engine operation stop the engine

immediately. Determine the cause and

repair the problem before you continue

to operate the engine.

0000029en

CAUTION

Observe the following environmental

operating conditions to maintain engine

performance and avoid premature

engine wear:

• Avoid operating in extremely dusty

conditions.

• Avoid operating in the presence of

chemical gases or fumes.

• Avoid operating in a corrosive

atmosphere such as salt water spray.

• NEVER install the engine in a

floodplain unless proper precautions

are taken to avoid being subject to a

flood.

• NEVER expose the engine to the rain.

0000003en

CAUTION

NEVER allow the recoil handle to snap

back against the engine. Return the

handle to the starting position gently to

prevent damage to the starter.

0000066en

L-N Operation Manual

9

Page 22

SAFETY

CAUTION

Observe the following environmental

operating conditions to maintain engine

performance and avoid premature

engine wear:

• NEVER run the engine if the ambient

temperature is above +40°C or below 10°C

If the ambient temperature exceeds

+40°C the engine may overheat and

cause the engine oil to break down.

If the ambient temperature falls

below -10°C rubber components

such as gaskets and seals will

harden causing premature engine

wear and damage.

Contact your authorized Yanmar

industrial engine dealer or

distributor if the engine will be

operated in either temperature

extreme.

• Contact your authorized Yanmar

industrial engine dealer or distributor

if you need to operate the engine at

high altitudes. At high altitudes the

engine will lose power, run rough, and

produce exhaust gases that exceed

the design specifications.

0000065enLN

CAUTION

• Only use the engine oil specified.

Other engine oils may affect warranty

coverage, cause internal engine

components to seize, or shorten

engine life.

• Prevent dirt and debris from

contaminating the engine oil. Carefully

clean the oil cap / dipstick and the

surrounding area before you remove

the cap.

• NEVER mix different types of engine

oil. This may adversely affect the

lubricating properties of the engine oil.

• NEVER overfill. Overfilling may result

in white exhaust smoke, engine

overspeed or internal damage.

0000005en

CAUTION

• NEVER overfill the engine with engine

oil.

• ALWAYS keep the oil level between the

upper and lower lines on the oil

cap / dipstick.

0000015en

CAUTION

For maximum engine life, Yanmar

recommends that when shutting the

engine down, you allow the engine to

idle, without load, for 5 minutes. This

will allow the engine components that

operate at high temperatures, such as

exhaust system, to cool slightly before

the engine itself is shut down.

0000008en

10

CAUTION

NEVER use an engine starting aid such

as ether. Engine damage will result.

0000009en

L-N Operation Manual

Page 23

SAFETY

CAUTION

Make sure the engine is installed on a

level surface. If a continuously running

engine is installed at an angle greater

than 20° (in any direction) or if an engine

runs for short periods of time (less than

3 minutes) at an angle greater than 25°

in any direction, engine oil may enter the

combustion chamber causing exessive

engine speed and generate white smoke

and also may occur unsatisfactory oil

pressure. These may cause serious

engine damage.

0000010enTNE

CAUTION

New Engine Break In:

• On the initial engine start-up, allow the

engine to idle for approximately 15

minutes while you check for proper

engine oil pressure, diesel fuel leaks,

engine oil leaks, and for proper

operation of the indicators and / or

gauges.

• During the first hour of operation, vary

the engine speed and the load on the

engine. Short periods of maximum

engine speed and load are desirable.

Avoid prolonged operation at

minimum or maximum engine speeds

and loads for the next 100 hours.

• During the break-in period, carefully

observe the engine oil pressure and

engine temperature.

• During the break-in period, check the

engine oil levels frequently.

0000011en

CAUTION

• NEVER attempt to modify the engine’s

design or safety features such as

defeating the engine speed limit

control or the fuel injection quantity

control.

• Failure to comply may impair the

engine’s safety and performance

characteristics and shorten the

engine’s life. Any alterations to this

engine may affect the warranty

coverage of your engine. See Yanmar

Limited Warranty on page 1.

0000044enLVOM

CAUTION

Be environmentally responsible. Follow

these procedures for hazardous waste

disposal. Failure to follow these

procedures may seriously harm the

environment.

• Follow the guidelines of the

governmental agency for the proper

disposal of hazardous materials such

as engine oil, diesel fuel and engine

coolant. Consult the local authorities

or reclamation facility.

• NEVER dispose of hazardous

materials irresponsibly by dumping

them into a sewer, on the ground or

into ground water or waterways.

0000013en

CAUTION

NEVER engage the starter motor while

the engine is running. This may damage

the starter motor pinion and / or ring

gear.

0000012en

L-N Operation Manual

CAUTION

Protect the air cleaner, and electric

components from damage when you

use steam or use high-pressure water to

clean the engine.

0000014en

11

Page 24

SAFETY

CAUTION

The tightening torque in the Standard

Torque C hart (page 12) should be

carefully observed.

• Apply 60% torque to bolts that are not

listed.

• Apply 80% torque when tightened to

aluminum alloy.

0000023enLVOM

CAUTION

Establish a periodic maintenance plan

according to the engine application and

make sure you perform the required

periodic maintenance at intervals

indicated. Failure to follow these

guidelines will impair the engine’s safety

and performance characteristics,

shorten the engine’s life and may affect

the warranty coverage on your engine.

See Yanmar Limited Warranty on page 1.

Consult your authorized Yanmar

industrial engine dealer or distributor for

assistance when checking items marked

with a

.

0000024enLVOM

CAUTION

• When the engine is operated in dusty

conditions, clean the air cleaner

element more frequently.

• NEVER operate the engine with the air

cleaner or element(s) removed. This

may cause foreign material to enter the

engine and damage it.

0000026en

CAUTION

Tips while starting engine with recoil

starter (See Start The Engine on

page 11.):

• Pulling out the recoil starter handle

too hard or fast will damage the

equipment.

• ALWAYS pull recoil starter handle all

the way out or the engine will not start.

• NEVER allow the recoil starter handle

to snap back against the engine.

Return the handle to the starting

position gently to prevent damage to

the recoil starter.

0000068enLVOM

CAUTION

It is important to perform daily checks.

See Daily Checks on page 9.

Periodic maintenance prevents

unexpected downtime, reduces the

number of accidents due to poor

machine performance and helps extend

the life of the engine.

0000060enLVOM

CAUTION

If the engine continues to run after you

position the engine speed control to the

STOP position, turn the fuel cock to the

CLOSED position.

0000069en

12

L-N Operation Manual

Page 25

PRODUCT OVERVIEW

L-N Operation Manual

YANMAR L-N SERIES ENGINE FEATURES AND APPLICATIONS

To achieve the highest performing miniaturized

and light-weight diesel engines, Yanmar Co., Ltd.

developed the L-N series single cylinder, aircooled, diesel engine using the most advanced

single cylinder technologies.

Especially, the fuel injection pump / line / nozzle

direct-injection system has been optimized to

reduce emissions.

Yanmar L-N Series engines are designed to

supply power to a wide variety of driven machines

including:

• Pumps

• Power Generation

• Construction

•Agriculture

We are sure that you will agree these features

provide excellent value in an industrial diesel

engine.

These engines are designed to deliver power to

driven machines by means of a “direct coupled

drive” or “belt drive.” In direct coupled drive

engine applications, the engine’s flywheel

housing or end plate is coupled directly to the

driven machine. In belt drive engine applications,

a belt drive is used to power the driven machine.

The engine is designed for a wide range of

applications. Options are available to customize

the application.

Since designing the application and installing the

engine require special knowledge and skill,

always consult your authorized Yanmar industrial

engine dealer or distributor for these services.

They will help you:

• Select optional equipment. Optional equipment

should be selected to match the work

conditions and environment.

• Maximize engine performance with a minimum

amount of downtime and safety related

incidents by carefully matching the

characteristics of the engine with the driven

machine.

L-N Operation Manual

• Plan for safe fuel piping, exhaust piping,

electrical wiring, ventilation and accurate

engine installation.

• Design your applications so they meet

requirements of the local authorities.

13

Page 26

PRODUCT OVERVIEW

COMPONENT IDENTIFICATION

Figure 1 shows where major engine components are located.

(1)

(11)

(3)

(10)

(4)

(9)

(2)

(8)

(7)

1. Fuel Drain Plug

2. Decompression Lever

3. Air Cleaner

4. Recoil Starter Handle

5. Recoil Starter

6. Oil Cap / Dipstick

7. Oil Drain Plug

(6)

(5)

(6)

(7)

Figure 1

(12)

(13)

0001126A

8. Engine Speed Control Lever

9. Fuel Injection Pump

10. Fuel Cock

11. Fuel Tank

12. PTO Shaft

13. Oil Filter

Note: L48N standard engines are not equipped with covers. L70N and L100N engines are represented

in this manual.

14

L-N Operation Manual

Page 27

LOCATION OF LABELS

Figure 2 shows the location of regulatory and

safety labels on Yanmar L-N Series engines.

PRODUCT OVERVIEW

(1)

Typical location of the engine nameplate is shown

(Figure 2, (1)).

0001126C-01

Figure 2

Engine Nameplate (Typical)

0001585-02

L-N Operation Manual

15

Page 28

PRODUCT OVERVIEW

FUNCTION OF MAJOR ENGINE COMPONENTS

Components Functions

Air Cleaner The air cleaner prevents airborne contaminants from entering the

engine. Periodic replacement of the air cleaner filter element is

necessary. See the Periodic Maintenance Schedule on page 59 for

the replacement frequency.

Dynamo (Optional) If the engine is equipped with the electric starting option, a dynamo

is located between engine body and flywheel. The dynamo supplies

electricity to the engine systems and charges the battery while the

engine is running.

Electric Fuel Pump (Optional) The electric fuel pump (if equipped) makes sure there is a constant

supply of diesel fuel to the fuel injection pump. The electric fuel

pump is electro-magnetic and runs on 12 VDC.

Engine Oil Filter The engine oil filter removes contaminants and sediments from the

engine oil. Periodic cleaning of the oil filter is necessary. See the

Periodic Maintenance Schedule on page 59 for the frequency of

cleaning.

Fuel Filters Two fuel filters are provided to remove contaminants and

sediments from the diesel fuel. The inlet fuel screen is located

inside the fuel tank filler port. Since it uses a mesh construction, it

can be cleaned. The outlet fuel filter is a replaceable cartridge that

is located at the outlet of the fuel tank. Periodic cleaning /

replacement is required. See Periodic Maintenance Schedule on

page 59.

Fuel Tank The fuel tank is a reservoir that holds diesel fuel. When fuel leaves

the fuel tank it goes to the fuel injection pump. Since fuel is used to

keep fuel system components cool and lubricated, more fuel than is

necessary for combustion enters the fuel system. Any fuel that is

not used for combustion is returned to the fuel tank. The fuel tank is

a required engine component.

Oil Cap / Dipstick (Engine Oil) The engine oil cap / dipstick combines the oil cap and dipstick in

one assembly. The dipstick part of the assembly is used to

determine the amount of engine oil in the crankcase.

Side Filler Ports

(Engine Oil)

You can fill the crankcase with engine oil from either side of the

engine depending upon which one is most convenient.

Starter Motor (Optional) If the engine is equipped with the electric starting option, the starter

motor is powered by the battery. When you turn the key switch in

the operator’s console to the START position, the starter motor

engages with the ring gear installed on the flywheel and starts the

flywheel in motion.

16

L-N Operation Manual

Page 29

PRODUCT OVERVIEW

AIR COOLED ENGINE

The L-N engine is air-cooled by means of a

cooling fan. The cooling system consists of a fan

attached to the flywheel.

CONTROLS - RECOIL STARTER

The L-N Series engines are equipped with a

recoil or electric starter. This section explains the

controls available with the recoil starter.

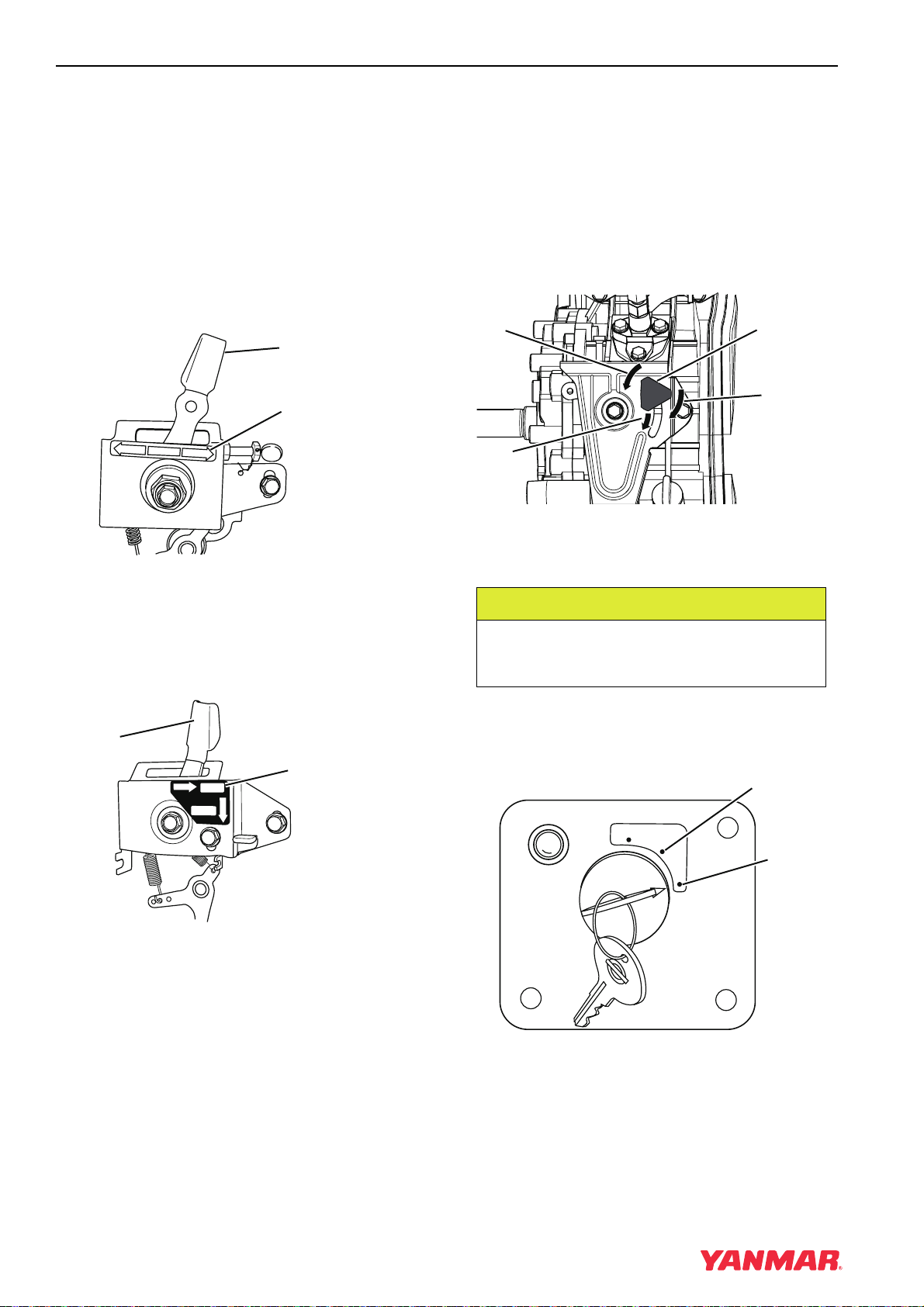

Recoil Starter

A recoil starter allows you to manually start an

engine by pulling on the recoil starter handle

(Figure 3, (1)). When you pull on the handle you

set the flywheel and crankshaft in motion. The

recoil starter is spring loaded so the handle and

attached cable automatically return to the recoil

starter assembly.

Decompression Lever

The decompression lever (Figure 4, (1)) helps

you start the engine by reducing the effort

needed to pull the recoil starter handle. The

decompression lever will automatically return to

the original position when the engine starts.

Some L-N model engines have an automatic,

internal compression release mechanism and do

not have the external compression release lever.

Refer to the specific instructions for your driven

machine.

(1)

Figure 3

(1)

0001126B

0001347A

Figure 4

INDICATORS AND CONTROLS

– ELECTRIC STARTER

If an L-N series engine is ordered with an electric

starter it will include a key switch and may also

have indicators to monitor engine functions.

CAUTION

The illustrations and descriptions of

optional equipment in this manual, such

as the operator’s console, are for a

typical engine installation. Refer to the

documentation supplied by the optional

equipment manufacturer for specific

operation and maintenance instructions.

0000018en

L-N Operation Manual

17

Page 30

PRODUCT OVERVIEW

Indicators

Battery - (Figure 5, (1)) - Your driven machine

may have a battery indicator that comes on if

there is a problem in the charging system. This

indicator does not indicate whether the battery is

discharged. See Troubleshooting Chart on

page 79.

Heat - If your engine has an inlet air heater, it may

have a heat indicator that lights when the inlet air

heater is activated. Follow the instructions

provided by the driven machine manufacturer for

the operation of this indicator.

Controls

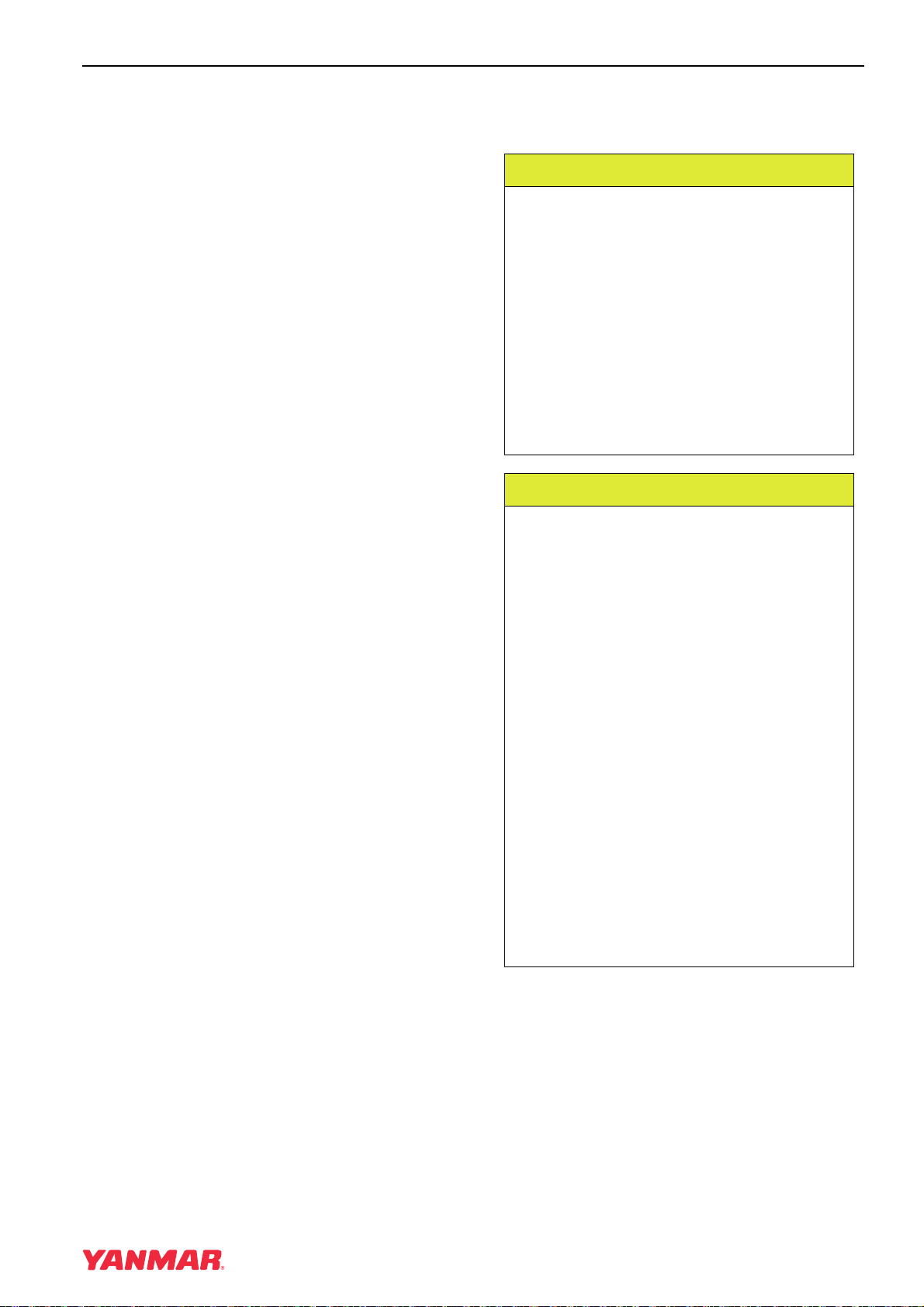

Key Switch

If your engine is equipped with electric start it

may have a three position key switch - OFF, ON,

and START. See Figure 5 for an illustration of a

typical key switch.

(1)

OFF

ON

(2)

STA RT

(3)

(4)

0001549A

Figure 5

OFF (key straight up and down) (Figure 5, (2)) When you turn the key to this position the engine

shuts down. Electric current to the battery

indicator and other electric devices is shut off.

You can insert and remove the key in this

position.

CAUTION

For maximum engine life, Yanmar

recommends that when shutting the

engine down, you allow the engine to

idle, without load, for 5 minutes. This

will allow the engine components that

operate at high temperatures, such as

exhaust system, to cool slightly before

the engine itself is shut down.

0000008en

ON (Figure 5, (3)) - This is the position the key

will be in when the engine is running. When the

engine is not running, use this position to

energize the optional devices such as indicators

or electric fuel pump.

CAUTION

Only hold the key in the START position

for 15 seconds or the starter motor will

overheat.

0000020en

START (Figure 5, (4)) - Turn the key to this

position to start the engine. As soon as the

engine starts, release the key and it will

automatically return to the ON position. Some key

switches may be equipped with a feature that

prevents you from turning the key to the START

position while the engine is running. In these

configurations, you cannot turn the key to the

START position without first returning the key to

the OFF position.

18

L-N Operation Manual

Page 31

Inlet Air Heater

PRODUCT OVERVIEW

Some engines may be equipped with an inlet air

heater. Heated inlet air helps the engine to start

easier in cold weather. During the engine starting

sequence the inlet air heater is activated for

several seconds. If the engine is equipped with an

air inlet heater timer, after the heat indicator goes

out, the engine can be started.

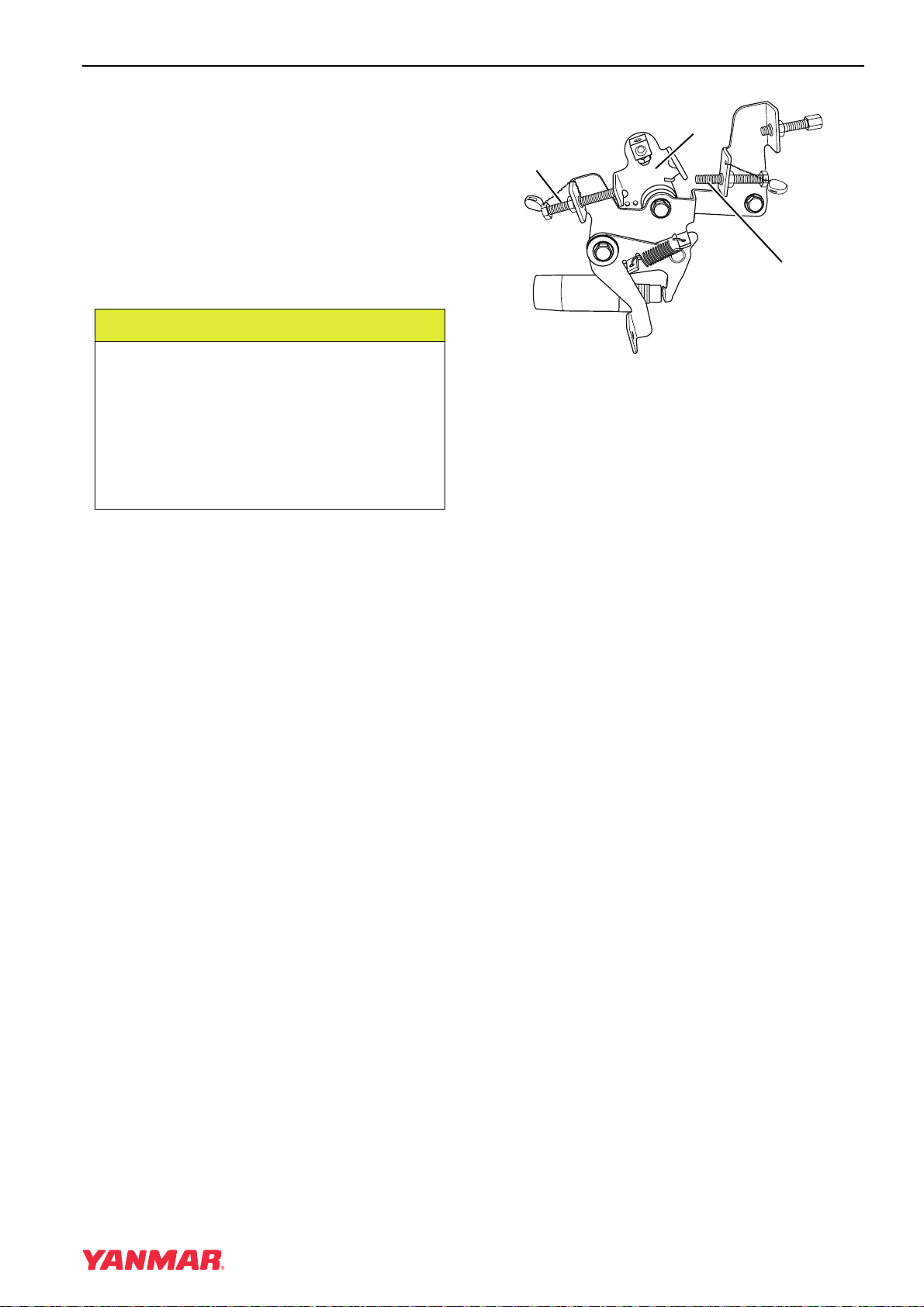

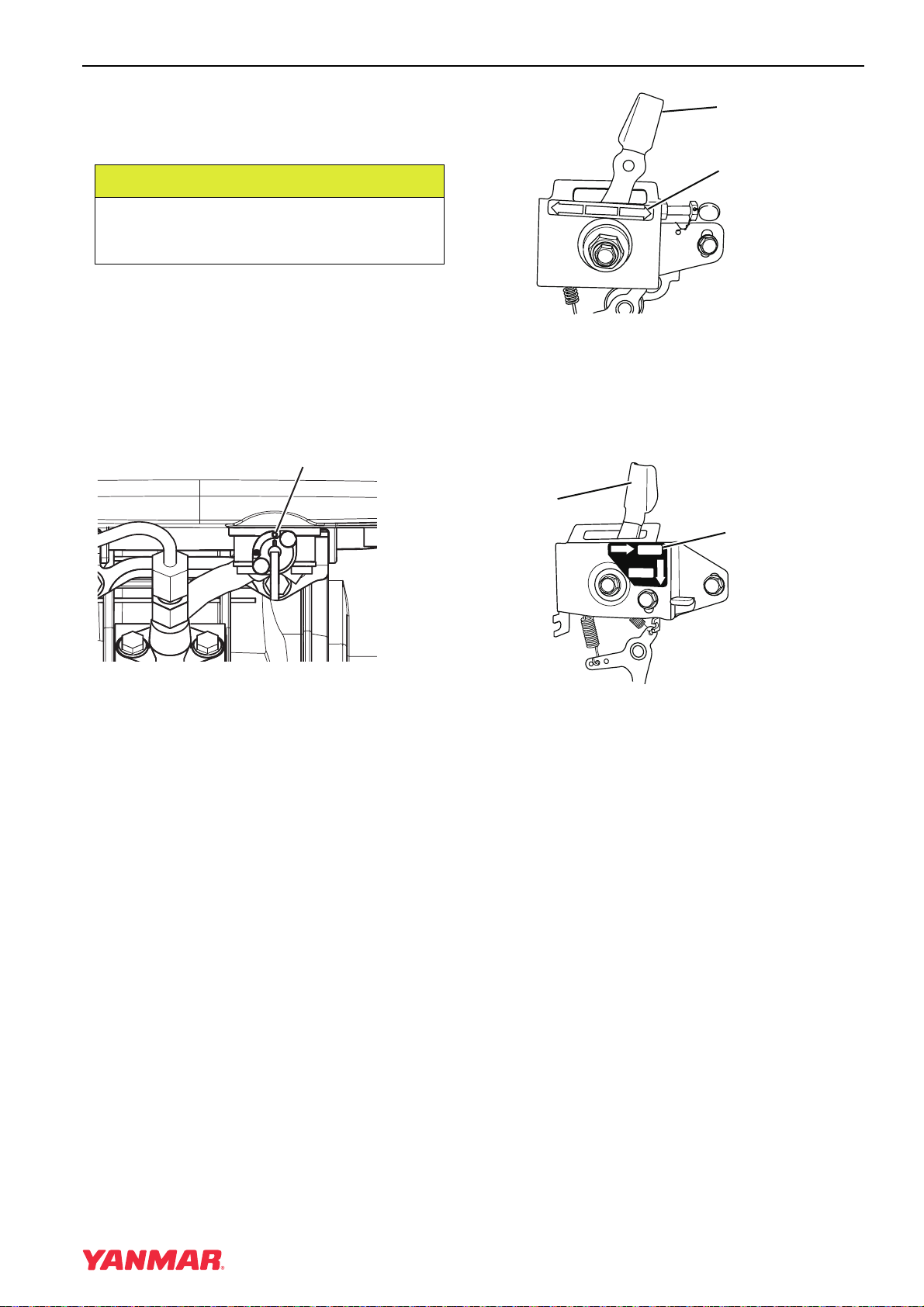

Engine Speed Controls

CAUTION

NEVER attempt to adjust the low or high

idle speed limit screw. This may impair

the safety and performance of the

machine and shorten its life. If

adjustment is ever required, contact

your authorized Yanmar industrial

engine dealer or distributor.

0000045en

Several types of engine speed controls are

used in L-N engine applications. This

illustration shows a typical example. Refer to

the operating instructions for the driven

machine.

(1)

(2)

(3)

0001346A

Figure 6

The speed control lever (Figure 6, (1)) controls

the engine speed. The lever could be linked to the

engine speed control device.

The low idle speed limit screw (Figure 6, (2)) sets

engine speed while it is idling.

The high idle speed limit screw (Figure 6, (3))

restricts the maximum engine speed when the

engine is operated without a load.

L-N Operation Manual

19

Page 32

PRODUCT OVERVIEW

This Page Intentionally Left Blank

20

L-N Operation Manual

Page 33

BEFORE YOU

OPERATE

L-N Operation Manual

This section of the Operation Manual describes

the diesel fuel and engine oil specifications and

how to replenish them. It also describes the daily

engine checkout.

CAUTION

NEVER permit anyone to operate the

engine or driven machine without proper

training.

• Read and understand this Operation

Manual before you operate the

machine to ensure that you follow safe

operating practices and maintenance

procedures.

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Only fill the fuel tank with diesel fuel.

Filling the fuel tank with gasoline may

result in a fire.

• NEVER refuel with the engine running.

• Wipe up all spills immediately.

• Keep sparks, open flames or any other

form of ignition (match, cigarette,

static electric source) away when

fueling / refueling.

• Machine safety signs and labels are

additional reminders for safe operating

and maintenance techniques.

• See your authorized Yanmar industrial

engine dealer or distributor for

additional training.

0000002en

• NEVER overfill the fuel tank.

• Fill the fuel tank and store fuel in a

well-ventilated area only.

• Failure to comply will result in death or

serious injury.

0000005en

L-N Operation Manual

21

Page 34

BEFORE YOU OPERATE

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Be sure to place the diesel fuel

container on the ground when

transferring the diesel fuel from the

pump to the container. Hold the hose

nozzle firmly against the side of the

container while filling it. This prevents

static electricity build-up which could

cause sparks and ignite fuel vapors.

• NEVER place diesel fuel or other

flammable material such as oil, hay or

dried grass close to the engine during

engine operation or shortly after shut

down.

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Before you operate the engine, check

for fuel leaks. Replace rubberized fuel

hoses every two years or every 2000

hours of engine operation, whichever

comes first, even if the engine has

been out of service. Rubberized fuel

lines tend to dry out and become

brittle after two years or 2000 hours of

engine operation, whichever comes

first.

• Failure to comply will result in death or

serious injury.

0000015en

• Failure to comply will result in death or

serious injury.

0000014en

A WARNING

HIGH PRESSURE HAZARD!

• Avoid skin contact with the high

pressure diesel fuel spray caused by a

fuel system leak such as a broken fuel

injection line. High pressure fuel can

penetrate your skin and result in

serious injury. If you are exposed to

high pressure fuel spray, obtain

prompt medical treatment.

• NEVER check for a fuel leak with your

hands. ALWAYS use a piece of wood

or cardboard. Have your authorized

Yanmar industrial engine dealer or

distributor repair the damage.

• Failure to comply could result in death

or serious injury.

0000008en

22

L-N Operation Manual

Page 35

BEFORE YOU OPERATE

A WARNING

BURN HAZARD!

• Keep your hands and other body parts

away from hot engine surfaces such

as the muffler, exhaust pipe,

turbocharger (if equipped) and engine

block during operation and shortly

after you shut the engine down. These

surfaces are extremely hot while the

engine is operating and could

seriously burn you.

• Failure to comply could result in death

or serious injury.

0000015en

A WARNING

CAUTION

• Only use diesel fuels recommended by

Yanmar for the best engine

performance, to prevent engine

damage.

• Only use clean diesel fuel.

• NEVER remove inlet fuel screen from

the filler port. If removed, dirt and

debris could get into the fuel system

causing it to clog.

0000004enLV

CAUTION

• Only use the engine oil specified.

Other engine oils may affect warranty

coverage, cause internal engine

components to seize, or shorten

engine life.

• Prevent dirt and debris from

contaminating the engine oil. Carefully

clean the oil cap / dipstick and the

surrounding area before you remove

the cap.

BURN HAZARD!

• If you must drain the engine oil while it

is still hot, stay clear of the hot engine

oil to avoid being scalded. Make sure

you wear eye protection.

• Failure to comply could result in death

or serious injury.

0000011en

• NEVER mix different types of engine

oil. This may adversely affect the

lubricating properties of the engine oil.

• NEVER overfill. Overfilling may result

in white exhaust smoke, engine

overspeed or internal damage.

0000005en

CAUTION

If any problem is noted during the visual

check, the necessary corrective action

should be taken before you operate the

engine.

0000021en

L-N Operation Manual

23

Page 36

BEFORE YOU OPERATE

DIESEL FUEL

Diesel Fuel Specifications

Diesel fuel should comply with the following

specifications. The table lists several worldwide

specifications for diesel fuels.

Diesel Fuel Specification Location

No. 2-D, No. 1-D, ASTM D975-94 USA

EN590:96 European Union

ISO 8217 DMX International

BS 2869-A1 or A2 United Kingdom

JIS K2204 Grade No.2 Japan

KSM-2610 Korea

GB252 China

Additional Technical Fuel Requirements

• The fuel cetane number should be equal to 45

or higher.

• The sulfur content must not exceed 0.5% by

volume. Less than 0.05% is preferred.

• Bio-Diesel fuels. See Bio-Diesel Fuels on

page 24.

• NEVER mix kerosene, used engine oil, or

residual fuels with the diesel fuel.

• Water and sediment in the fuel should not

exceed 0.05% by volume.

• Keep the fuel tank and fuel-handling equipment

clean at all times.

• Poor quality fuel can reduce engine

performance and / or cause engine damage.

• Fuel additives are not recommended. Some

fuel additives may cause poor engine

performance. Consult your Yanmar

representative for more information.

• Ash content not to exceed 0.01% by volume.

• Carbon residue content not to exceed 0.35% by

volume. Less than 0.1% is preferred.

• Total aromatics content should not exceed 35%

by volume. Less than 30% is preferred.

• PAH (polycyclic aromatic hydrocarbons) content

should be below 10% by volume.

• Metal content of Na, Mg, Si, and Al should be

equal to or lower than 1 mass ppm. (Test

analysis method JPI-5S-44-95)

• Lubricity: Wear mark of WS1.4 should be Max.

µm at HFRR test.

460

Bio-Diesel Fuels

In Europe and in the United States, as well as

some other countries, non-mineral oil based fuel

resources such as RME (Rapeseed Methyl Ester)

and SOME (Soybean Methyl Ester), collectively

known as FAME (Fatty Acid Methyl Esters), are

being used as extenders for mineral oil derived

diesel fuels.

Yanmar approves the use of bio-diesel fuels that

do not exceed a blend of 5% (by volume) of

FAME with 95% (by volume) of approved mineral

oil derived diesel fuel. Such bio-diesel fuels are

known in the marketplace as B5 diesel fuels.

These B5 diesel fuels must meet certain

requirements.

1. The bio-fuels must meet the minimum

specifications for the country in which they

are used.

• In Europe, bio-diesel fuels must comply with

the European Standard EN14214.

• In the United States, bio-diesel fuels must

comply with the American Standard ASTM

D-6751.

2. Bio-fuels should be purchased only from

recognized and authorized diesel fuel

suppliers.

Precautions and concerns regarding the use

of bio-fuels:

1. Free methanol in FAME may result in

corrosion of aluminum and zinc FIE

components.

2. Free water in FAME may result in plugging of

fuel filters and increased bacterial growth.

24

L-N Operation Manual

Page 37

BEFORE YOU OPERATE

3. High viscosity at low temperatures may result

in fuel delivery problems, injection pump

seizures, and poor injection nozzle spray

atomization.

4. FAME may have adverse effects on some

elastomers (seal materials) and may result in

fuel leakage and dilution of the engine

lubricating oil.

5. Even bio-diesel fuels that comply with a

suitable standard as delivered, will require

additional care and attention to maintain the

quality of the fuel in the equipment or other

fuel tanks. It is important to maintain a supply

of clean, fresh fuel. Regular flushing of the

fuel system, and/or fuel storage containers,

may be necessary.

6. The use of bio-diesel fuels that do not comply

with the standards as agreed to by the diesel

engine manufacturers and the diesel fuel

injection equipment manufacturers, or biodiesel fuels that have degraded as per the

precautions and concerns above, may affect

the warranty coverage of your engine. See

Yanmar Limited Warranty on page vii.

Filling the Fuel Tank

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Only fill the fuel tank with diesel fuel.

Filling the fuel tank with gasoline may

result in a fire.

• NEVER refuel with the engine running.

• Wipe up all spills immediately.

• Keep sparks, open flames or any other

form of ignition (match, cigarette,

static electric source) away when

fueling / refueling.

• NEVER overfill the fuel tank.

• Fill the fuel tank and store fuel in a

well-ventilated area only.

• Failure to comply will result in death or

serious injury.

0000005en

L-N Operation Manual

25

Page 38

BEFORE YOU OPERATE

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Be sure to place the diesel fuel

container on the ground when

transferring the diesel fuel from the

pump to the container. Hold the hose

nozzle firmly against the side of the

container while filling it. This prevents

static electricity build-up which could

cause sparks and ignite fuel vapors.

• NEVER place diesel fuel or other

flammable material such as oil, hay or

dried grass close to the engine during

engine operation or shortly after shut

down.

A DANGER

FIRE AND EXPLOSION HAZARD!

• Diesel fuel is extremely flammable and

explosive under certain conditions.

• Before you operate the engine, check

for fuel leaks. Replace rubberized fuel

hoses every two years or every 2000

hours of engine operation, whichever

comes first, even if the engine has

been out of service. Rubberized fuel

lines tend to dry out and become

brittle after two years or 2000 hours of

engine operation, whichever comes

first.

• Failure to comply will result in death or

serious injury.

0000015en

• Failure to comply will result in death or

serious injury.

0000014en

CAUTION

• Only use diesel fuels recommended by

Yanmar for the best engine

performance, to prevent engine

damage.

• Only use clean diesel fuel.

• NEVER remove inlet fuel screen from

the filler port. If removed, dirt and

debris could get into the fuel system

causing it to clog.

0000004enLV

Note that a typical fuel tank is shown. The fuel

tank on your engine may be different. Also note

that the inlet fuel screen is shown removed

from the fuel tank for clarity. ALWAYS make

sure the inlet fuel screen remains inside of the

fuel tank while fueling!

26

L-N Operation Manual

Page 39

BEFORE YOU OPERATE

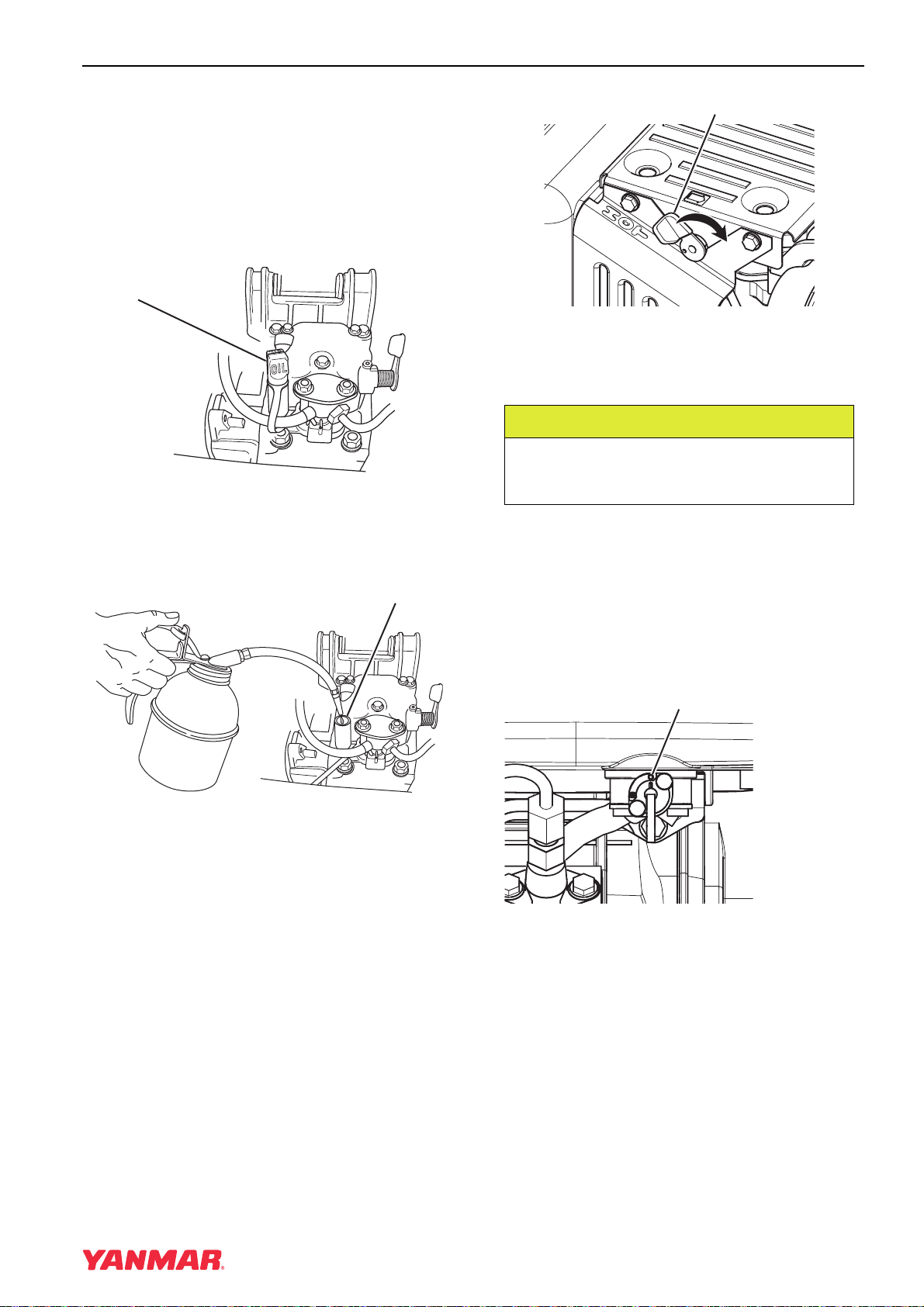

1. Clean the area around the fuel cap

(Figure 1, (1)).

2. Remove the fuel cap (Figure 1, (1)) from the

fuel tank (Figure 1, (3)).

3. Stop fueling when the fuel is at the same level

as the red ring (Figure 1, (4)) at the bottom of

the inlet fuel screen. NEVER overfill the fuel

tank.

4. Replace the fuel cap (Figure 1, (1)) and hand

tighten. Over-tightening the fuel cap will

damage it.

(1)

(2)

(4)

(3)

0001552B

Figure 1

ENGINE OIL

CAUTION

• Only use the engine oil specified.

Other engine oils may affect warranty

coverage, cause internal engine

components to seize, or shorten

engine life.

• Prevent dirt and debris from

contaminating the engine oil. Carefully

clean the oil cap / dipstick and the

surrounding area before you remove

the cap.

• NEVER mix different types of engine

oil. This may adversely affect the

lubricating properties of the engine oil.

• NEVER overfill. Overfilling may result

in white exhaust smoke, engine

overspeed or internal damage.

0000005en

Engine Oil Specifications

Use an engine oil that meets or exceeds the

following guidelines and classifications:

Service Categories

• API Service Categories CD or higher

• ACEA Service Categories E-3, E-4, and E-5

• JASO Service Category DH-1

Definitions

• API Classification (American Petroleum

Institute)

• ACEA Classification (Association des

Constructeurs Européens d’Automobilies)

• JASO (Japanese Automobile Standards

Organization)

Notes:

1. Be sure the engine oil, engine oil storage

containers, and engine oil filling equipment

are free of sediments and water.

L-N Operation Manual

27

Page 40

BEFORE YOU OPERATE

2. Change the engine oil after the first 50 hours

of operation and then at every 200 hours

thereafter.

3. Select the oil viscosity based on the ambient

temperature where the engine is being

operated. See SAE Service Grade Viscosity

Chart (Figure 2).

4. Yanmar does not recommend the use of

engine oil “additives.”

Additional Technical Engine oil Requirements:

The engine oil must be changed when the Total

Base Number (TBN) has been reduced to 2.0.

TBN (mgKOH/g) test method; JIS K-201-5.2-2

(HCI), ASTM D4739 (HCI)

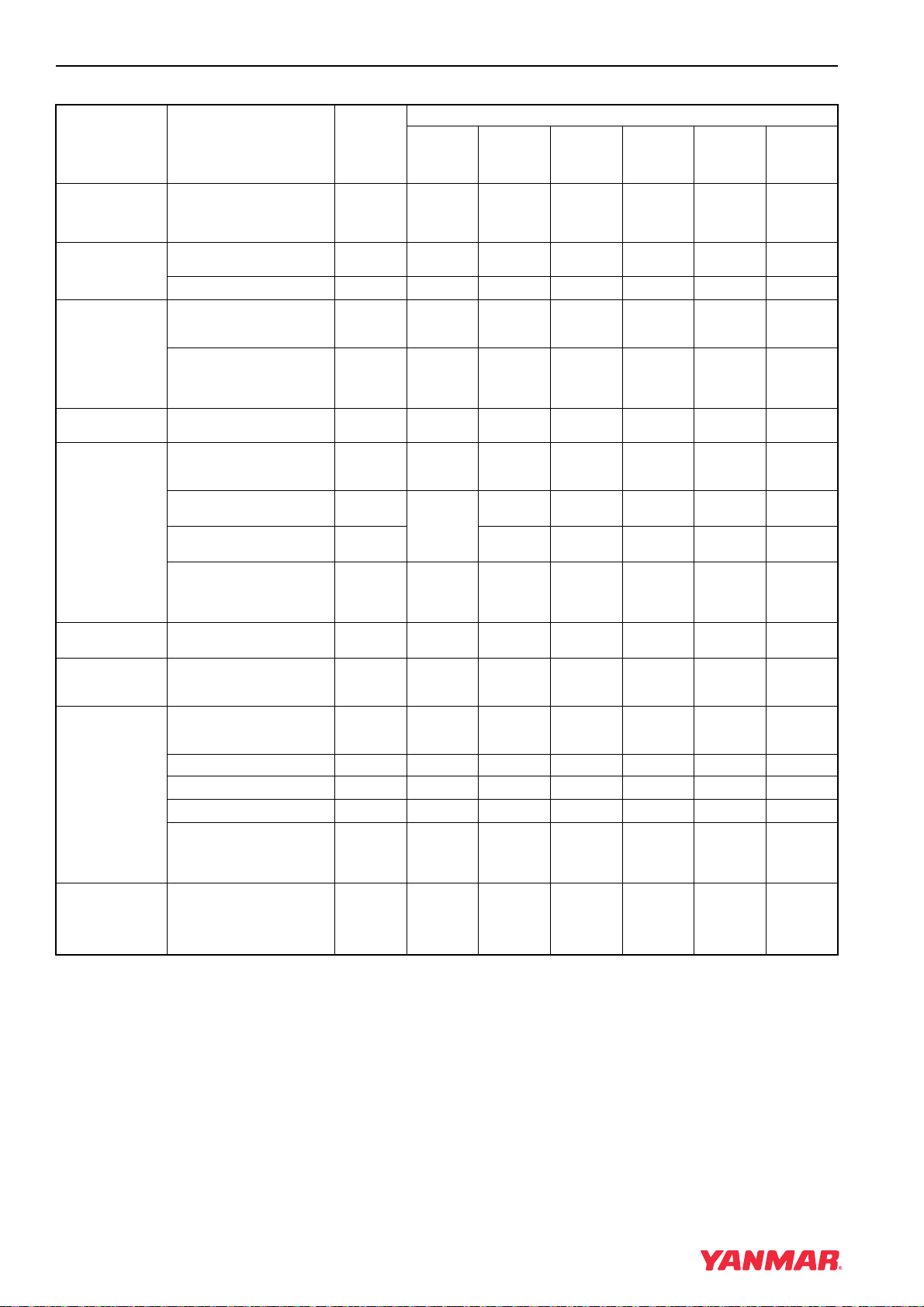

Engine Oil Viscosity

Select the appropriate engine oil viscosity based

on the ambient temperature and use the SAE

Service Grade Viscosity Chart in Figure 2.

5. Fully reinsert oil cap / dipstick (Figure 3, (1))

and hand tighten. Over-tightening the oil cap /

dipstick will damage it.

(1)

(2)

(3)

(4)

0001119A

(1)

SAE 10W

SAE 20W

SAE 10W-30

SAE 15W-40

SAE 20

SAE 30

SAE 40

(-20˚C) (-10˚C) (0˚C) (10˚C) (20˚C) (30˚C) (40˚C)

0000005-2

Figure 2

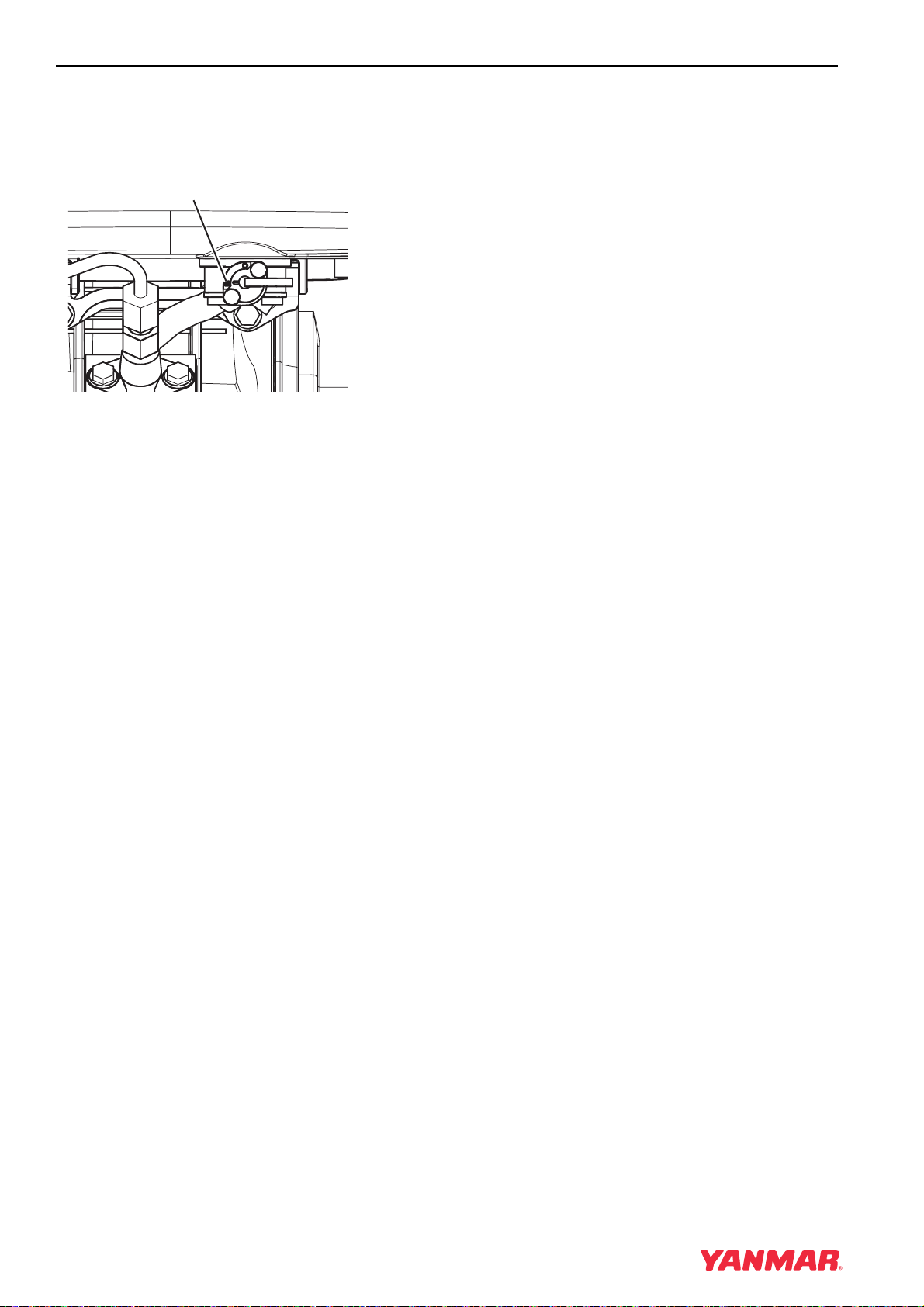

Checking Engine Oil

1. Make sure engine is level.

2. Remove oil cap / dipstick (Figure 3, (1)) from

either location and wipe with clean cloth.

3. Fully reinsert oil cap / dipstick but do not

screw in.

4. Remove oil cap / dipstick. The oil level should

be between upper (Figure 3, (2)) and lower

(Figure 3, (3)) lines on the oil cap / dipstick.

0001566A

Figure 3

Adding Engine Oil

1. Make sure engine is level.

2. Remove oil cap / dipstick (Figure 3, (1)).

3. Add indicated amount of engine oil at either

one of the engine oil filler ports

(Figure 3, (4)).

4. Wait one minute and check oil level.

5. Add more oil if necessary.

6. Fully reinsert oil cap / dipstick (Figure 3, (1))

and hand tighten. Over-tightening the oil cap /

dipstick will damage it.

28

L-N Operation Manual

Page 41

BEFORE YOU OPERATE

Engine Oil Capacity (Typical)

The following are the engine oil capacities for

various Yanmar L-N Series engines.

Engine Model

L48N 0.85 / 0.58 qt

L70N 1.11 / 0.69 qt

L100N 1.7 / 1.06 qt

Note: Oil capacity will vary depending upon

which optional oil pan is used. Refer to

the operation manual provided by the

driven machine manufacturer for the

actual engine oil capacity of your

machine.

Dipstick Upper Limit/

Lower Limit

(0.80 / 0.55 L)

(1.05 / 0.65 L)

(1.6 / 1.0 L)

DAILY CHECKS

Before you begin any job, make sure the Yanmar

L-N Series engine is in good operating condition.

Make sure you check the following items before

you start your shift and have any repairs

completed before you start work.

A WARNING

HIGH PRESSURE HAZARD!

• Avoid skin contact with the high

pressure diesel fuel spray caused by a

fuel system leak such as a broken fuel

injection line. High pressure fuel can

penetrate your skin and result in

serious injury. If you are exposed to

high pressure fuel spray, obtain

prompt medical treatment.

• NEVER check for a fuel leak with your

hands. ALWAYS use a piece of wood

or cardboard. Have your authorized

Yanmar industrial engine dealer or

distributor repair the damage.

• Failure to comply could result in death

or serious injury.

0000008en

Visual Checks

1. Check for engine oil leaks.

2. Check for fuel leaks.

3. Check for damaged or missing parts.

4. Check for loose, missing, or damaged

fasteners.

5. Check the electrical harnesses for cracks,

abrasions, and damaged or corroded

connectors.

6. Check hoses for cracks, abrasions, and

damaged, loose or corroded clamps.

L-N Operation Manual

29

Page 42

BEFORE YOU OPERATE

CAUTION

If any problem is noted during the visual

check, the necessary corrective action

should be taken before you operate the

engine.

0000021en

Check Diesel Fuel and Engine Oil

Follow the procedures in Diesel Fuel on page 24

and Engine Oil on page 27 to check these levels.

Check Engine Speed Control (First Time Only)

1. Check the engine speed control for smooth

operation and lubricate or clean as

necessary.

Indicator OFF to ON START to ON

Battery ON OFF (Stays On until dynamo is

2. Check engine speed control for proper

adjustments.

Check Indicators

If your engine has an electric starter, check the

battery indicator. Also check any other indicators

supplied by the driven machine manufacturer.

Battery - Stays On until the engine is running and

the dynamo is supplying charging current. This

indicator does not indicate whether the battery is

discharged.

Here is a summary of how these indicators

function. The table shows what happens when

you turn the key in a certain direction (e.g., OFF

to ON).

supplying charging current.

Remains On if there is a

problem in the charging

system. This indicator does not

indicate whether the battery is

discharged.)

30

L-N Operation Manual

Page 43

ENGINE OPERATION

L-N Operation Manual

This section of the Operation Manual describes

the procedures for starting the engine, checking

engine performance during operation, and

shutting the engine down.

CAUTION

NEVER permit anyone to operate the

engine or driven machine without proper

training.

• Read and understand this Operation

Manual before you operate the

machine to ensure that you follow safe

operating practices and maintenance

procedures.

A DANGER

EXPLOSION HAZARD!

• Keep the area around the battery well

ventilated. While the engine is running

or the battery is charging, hydrogen

gas is produced which can be easily

ignited.

• Keep sparks, open flame and any other

form of ignition away.

• Failure to comply will result in death or

serious injury.

0000003en

• Machine safety signs and labels are

additional reminders for safe operating

and maintenance techniques.

• See your authorized Yanmar industrial

engine dealer or distributor for

additional training.

0000002en

L-N Operation Manual

31

Page 44

ENGINE OPERATION

A DANGER

FIRE AND EXPLOSION HAZARD!

• Only use the key switch to start the

engine.

• NEVER jump start the engine. Sparks

caused by jumping the battery to the