Page 1

OPERATOR’S MANUAL

DIESEL TRACTOR

EF393T

Original instructions

en

Page 2

http://yanmar.com

OPERATOR’S MANUAL

0A041-ENXXXX

Oct. 2014

DIESEL TRACTOR

DIESEL TRACTOR

EF393T

Original instructions

Page 3

EF393T OM

SAFETY

Never attempt to operate or service this machine until you have first read and

understood all of the applicable Safety Instructions that are set forth in this

Manual.

The failure to comply with all relevant Safety Instructions could result in bodily

injury.

Page 4

EF393T OM

TO THE OWNER

This instruction manual describes how to maintain your tractor in good condition and how to

operate it safely and correctly. Please read this manual carefully before using the tractor.

Keep this manual close to your tractor , after you have read th rough it. If you lose or damage

this manual, ask your YANMAR dealer for a new manual right away.

IMPROVEMENT

Sometimes parts are changed to improve or upgrade the features of the tractor, or for other

reasons. Therefore, the parts shown in this manual may not apply to your tractor.

Note:

All data are subject to change without prior warning. Some illustrations and

photographs may show optional accessories.

A Roll-over Protective Structure (ROPS) is optional.

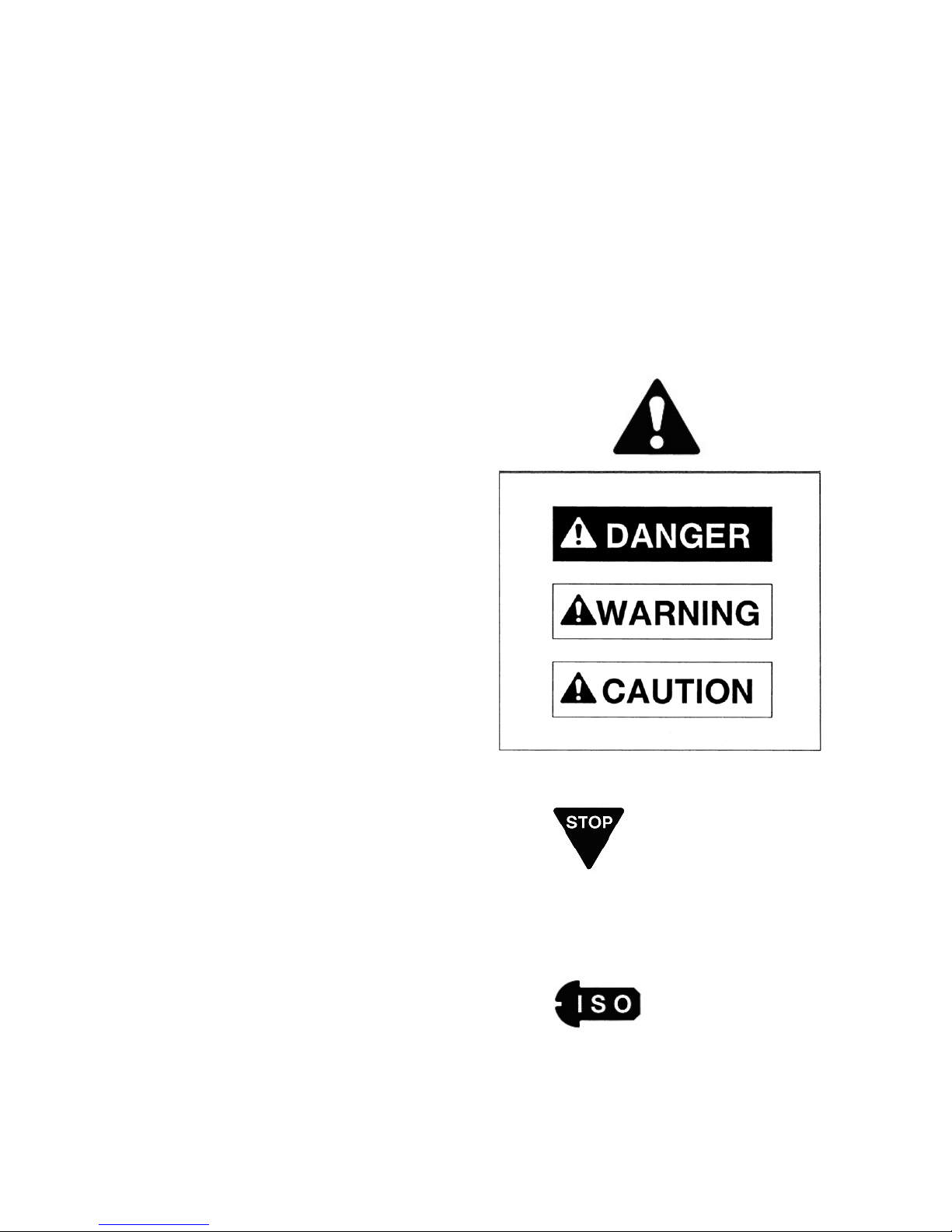

SYMBOLS USED

1. Safety-alert Symbol

This is the safety-alert symbol. When you see

this symbol on your tractor or in this manual, be

alert to the possibility of personal injury and

carefully read the messages that follow.

2. Signal Words

The signal words "DANGER" "WARNING"

"CAUTION" are used with the safety-alert symbol.

(1) "DANGER" indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury .

(2) "WARNING" indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

(3) "CAUTION" indicates a potentially

hazardous situation which, if not avoided,

could result in minor or moderate injury.

3. Service instructions

(1) This stop symbol indicates important proper

operation or service messages in this

manual. When you see this symbol,

carefully read the messages that follow.

IMPORTANT

(2) “NOTE” describe precautions to take while

working.

NOTE

4. Measurements

This tractor is of metric design. All hardware are

therefore metric (ISO). Make sure to use the

specified metric hardware when service becomes

necessary.

5. Direction

Right-hand and Left-hand sides of the tractor are

determined by facing in the direction of the tractor

forward travel.

Page 5

EF393T OM

TABLE OF CONTENTS

SAFETY INSTRUCTIONS 1

AFTER SALES SERVICES 15

TRACTOR OUTLINE 17

PARTS NAMES 18

LABEL LOCATIONS 19

CONTROLS 21

OPERATIONS

1. Pre-operation checks

2. Break-in (initial 50 hours)

3. Before starting

4. Start and stop

4-1. Start and stop engine

4-2. Start, gear shifting and stop tractor

5. Driving on a road

6. Driving on a slope

7. Driving in and out of fields

8. Setting adequate speed

9. Turning in a field

10. Differential gear lock

11. Loading and unloading

12. Wheel tread

13. Hydraulic power take off

14. Using 3-point hitch

15. Drawbar hitch

16. General precautions on attaching and

detaching an implement

17. Power steering

18. Safety frame (ROPS)

19. Tightening torque of bolts and nuts

29

29

33

33

34

34

35

37

38

38

38

39

39

40

41

42

42

44

44

45

45

45

OPENING BONNET 46

AFTER OPERATION 47

Page 6

EF393T OM

PERIODICAL SERVICE

1. Check intervals

2. Oil and grease

3. Capacity of oil and water

4. Equivalent oil to transmission fluid TF500

5. Fuel system

5-1. Fuel and refill

5-2. Drain and cleaning of water separator

5-3. Replacing fuel filter (cartridge type)

6. Oil and filter

6-1. Engine oil and filter

6-2. Transmission-hydraulic oil and filter

6-3. Front axle oil

7. Engine coolant

8. Radiator screen

9. Cleaning air cleaner element (dua l element)

10. Checking battery

10-1 Check battery

10-2. Removing and installing battery

10-3. Charging battery

11. Checking pipes and hoses

12. Checking electric wires

13. Greasing

14. Adjusting brake pedal

15. Adjusting clutch pedal

16. Checking steering wheel

17. Adjusting fan belt

18. Checking and adjusting toe-in

19. Replacing fuse

19-1. Fuse box

19-2. Slow blow fuse

20. Checking tire and wheel

21. Color of exhaust gas

49

49

50

50

50

51

51

51

52

53

53

54

55

56

57

57

58

59

59

60

60

60

61

62

62

63

63

64

64

64

65

65

65

TROUBLESHOOTING 66

SPECIFICATIONS 69

IMPLEMENT CAPACITIES 70

Page 7

EF393T OM

1

SAFETY INSTRUCTIONS

DANGER

Read these instructions carefully.

Important instructions are given for the safe operation

and servicing of the tractor.

Failure to follow these instructions is likely to result in

an accident involving death or serious injury.

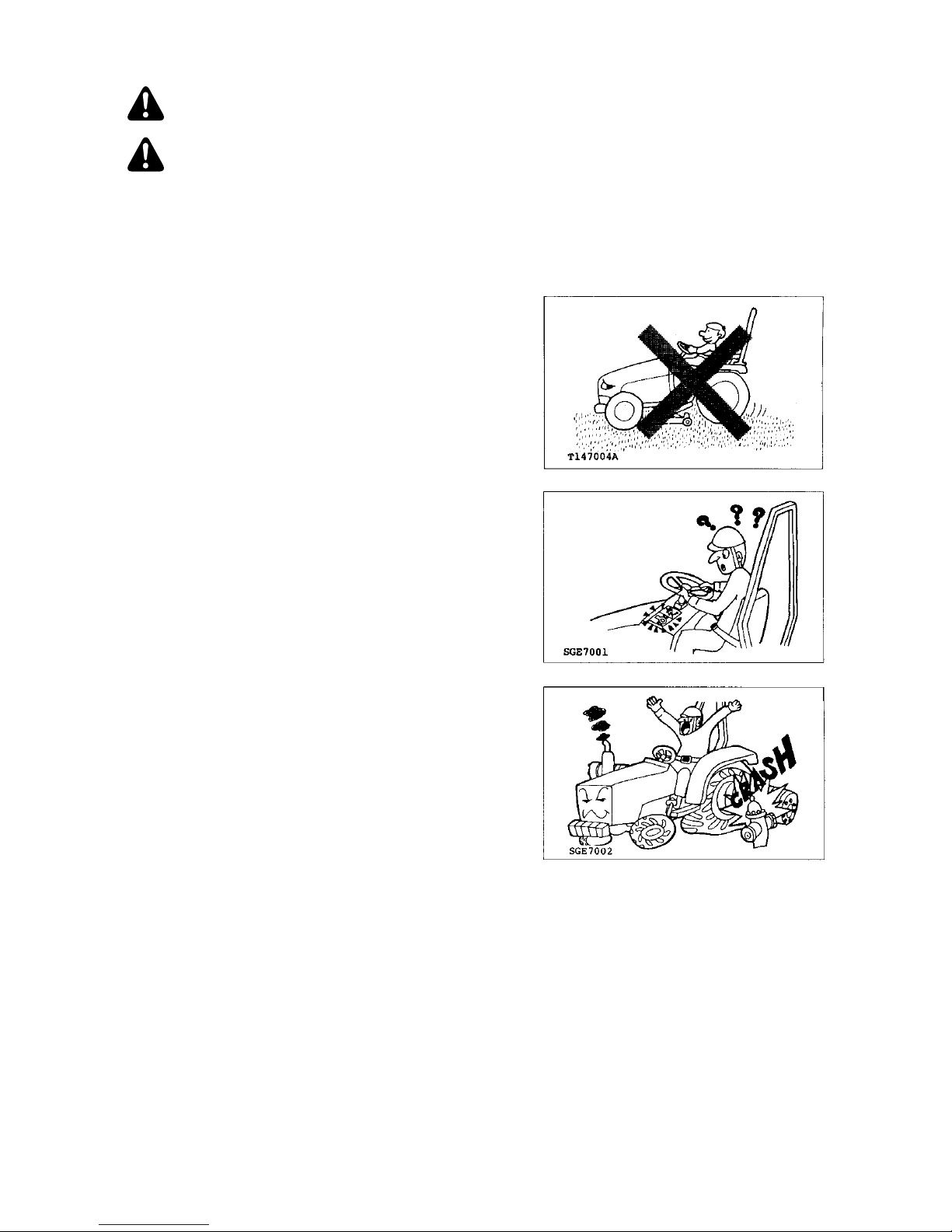

STUDY THE TRACTOR AND

IMPLEMENTS

Do not permit anyone unfamiliar with the tractor or the

operations of its implements to use the machine.

The operator’s manual should be considered a

permanent part of the tractor and should remain with

the tractor.

Know the positions and functions of all controls and the

meaning of any identification symbols on your controls,

gauges, and indicators before attempting to operate the

tractor.

Know how to stop the engine in an emergency.

Make sure you understand the capabilities, operating

characteristics and limitations of the tractor and

implement, such as maximum ballast weight, hydraulic

lifting capacity, speed, turning radius, operating

clearances etc.

Do not add extra ballast weight to compensate for a

load that is too heavy.

Page 8

EF393T OM

2

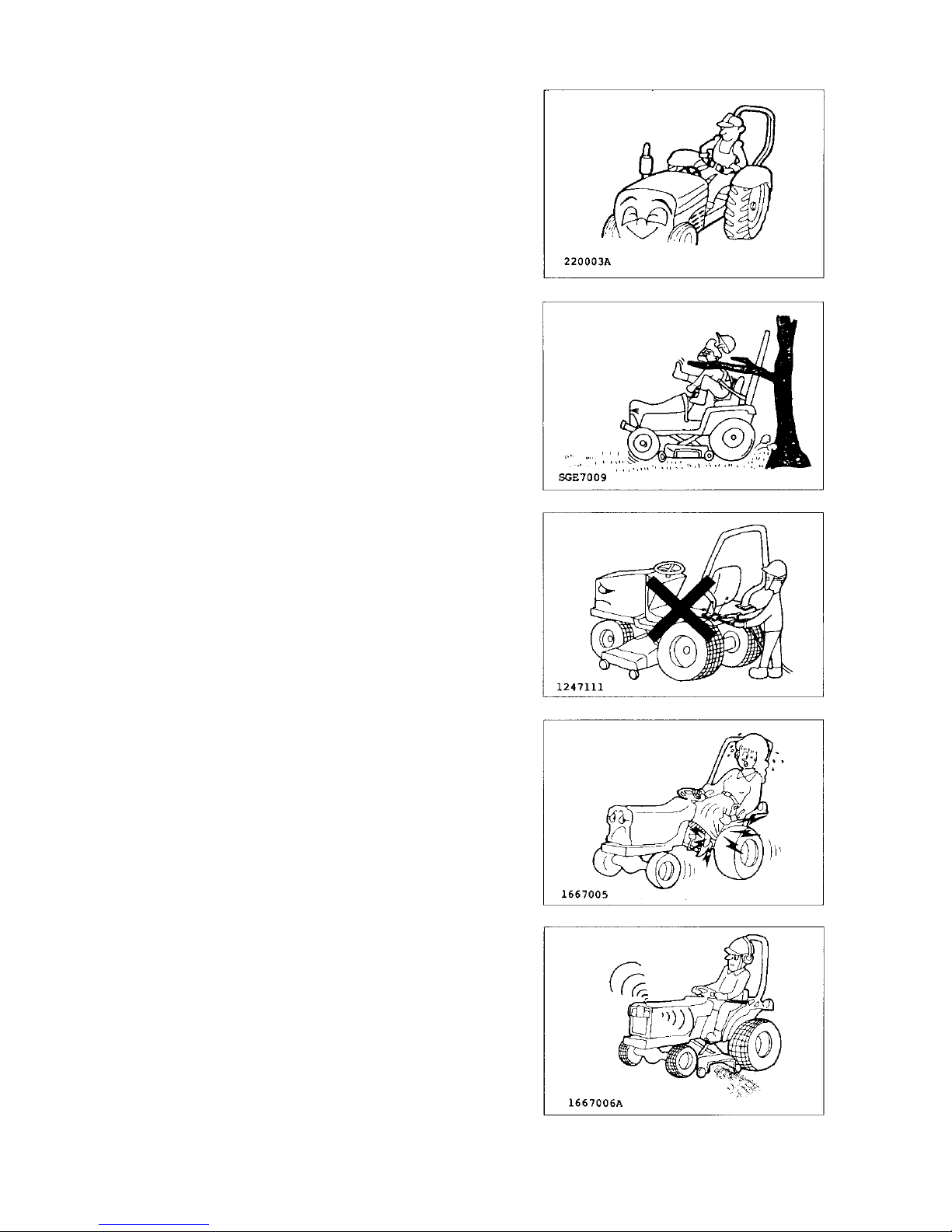

PROTECT OPERATOR SAFELY

Install an approved Roll-over Protective Structure

(ROPS) for safe operation. If a tractor rolls over without

a ROPS, death or serious injury is likely.

Always fasten the seat belt while operating the tractor

with Roll-over Protective Structure (ROPS) up.

Do not use the seat belt if the foldable Roll-over

Protective Structure (ROPS) is in the folded position or

the tractor does not have the Roll-over Protective

Structure (ROPS).

Extreme caution is required when operating a tractor

around trees or other overhead obstructions, such as

guy wires or power lines. Interference between the

ROPS and these obstructions may cause the tractor to

tip backwards.

Do not modify any structural portions of the ROPS by

welding, bending, grinding or cutting them. If any

component of the ROPS is damaged or involved in a

rollover incident, replace it with a complete new cage.

Do not attempt to repair the original one. Damaged or

modified structural parts impair the strength of the

ROPS and may lead to injury.

Avoid loose fitting or baggy clothing, torn clothing,

bulging pockets, frayed edges or heavy cuffs. Loose

frayed and bulky clothing can easily become entangled

in rotating parts. Wear work clothes and work shoes or

boots. Also you may need a: SAFETY HELMET,

SAFETY SHOES, EYE PROTECTION, HEAVY DUTY

GLOVES, HEARING PROTECTION, REFLECTIVE

CLOTHING, OR A RESPIRATOR/FILTER MASK.

Wear whatever safety gear and clothing is necessary

for the job.

Prolonged exposure to loud noise can cause

impairment or permanent loss of hearing. Wear a

suitable hearing protective device such as ear

protectors or earplugs to protect against objectionable

or uncomfortable noise.

Page 9

EF393T OM

3

BEFORE OPERATING

Do not operate the tractor when tired, sick, sleepy,

drunk, feeling overworked, taking medicine, pregnant,

suffering from mental disease or if other improper

conditions are present. These conditions impair a

person’s skill and judgment. When you begin feeling

tired while operating the tractor, take a 10-mi nute brea k

to stretch, walk about, lie down or snack. Do not

continue if you still feel tired after taking a break.

Remove oil, grease or mud from the hand rails, steps,

pedals, controls, and floor to avoid slips or loss of

control.

In winter, scrape off any ice or snow on the hand rails,

steps, pedals, controls, and floor .

To attach or remove an implement, refer to the

implement and tractor manufacturer’s manuals for the

proper procedures.

To unhitch an implement, move to a level area, lower

the implement to the ground and then block the

equipment in position before unhitching. If an

implement has wheels, block them to prevent it from

rolling.

Make sure

(1) The tractor and implements are in good

condition and properly adjusted.

(2) To check for loo sen ed bolts, adequate

lubricants, damaged or under-inflated tires,

safety shields and devices, steering and

braking linkages, hydraulic leaks, etc. Refer to

this manual for more detailed information.

(3) That implements are properly attached and

hooked up. Check that the PTO U-joint yoke

and locking devices are securely latched on

their shafts.

(4) That the tractor’s PTO speed matches the

implement’s specifications.

Page 10

EF393T OM

4

STARTING

START THE ENGINE SAFELY

If you operate the engine inside a closed building, be

sure there is plenty of ventilation before starting the

engine. Exhaust fumes are poisonous. Carbon

monoxide is especially dangerous because it is

odorless and colorless. You can easily be overcome

without realizing it.

Always stay near the tractor and keep the parking

brake set securely while warming it up.

Only start the engine from the operator’s seat. Never

start the engine while standing on the ground.

Before you start the engine:

(1) Sit in the operator’s seat and adjust the seat

position if necessary.

(2) Make sure the ROPS is in working condition

and seat belt securely fastened.

(3) Lower any implement to the ground.

(4) Place speed shift lever and the PTO switch in

neutral.

(5) Set the parking brake.

(6) Disengage the PTO for the neutral position.

(7) Check all the instruments, gauges and indicator

lights.

(8) Be sure everyone is clear of the tractor and

implement.

Page 11

EF393T OM

5

DURING OPERATION

OPERATE THE TRACTOR SAFELY

Keep people and pets a safe distance away when

starting and operating the tractor and implement.

Do not permit any person other than the operator to

ride or board the tractor or implements, including any

wagons.

Do not play games with the tractor.

Never allow children to ride on your lap.

Do not touch the muffler, radiator, engine or other high

temperature parts before they have cooled down

completely.

Do not try to get on or off a moving tractor or

implements. Always use the hand rails and steps and

face the tractor when getting on and off.

Never use control levers as a hand hold and never step

on foot controls when getting on and off.

Do not get on the tractor with wet or greasy hands, or

muddy shoes. Do not jump off the tractor. Be aware of

slippery conditions on the ground.

Make sure you check the connecting points on your

equipment.

Keep hands, feet and clothing away from power-driven

parts. Keep others away from articulated joints, hitches,

drawbar, lift arms, PTO drives, cylinders, and anything

else that moves.

Never stand, or allow anyone else to stand, between

the tractor and an implement, unless the engine is

turned off and the parking brake is engaged securely.

Page 12

EF393T OM

6

OPERATE THE TRACTOR SAFELY (continued)

Oversized implements are dangerous for tractor

operation and are not safe for you. Refer to the

implement’s operator manual for the minimum and

maximum horsepower requirements and weights that

are allowed.

When using a heavy implement in front, always install

ballast or an implement on the rear for safe, stable

steering control.

When using a heavy implement on a rear 3-point hitch,

always install ballast or an implement on the front for

safe, stable steering control.

Slow the tractor down when crossing rough ground, tall

grass or weeds. Rocks, holes and stumps may be

hidden in the brush.

Do not let your tractor bounce. Y ou may lose steering

control.

Never use the tractor to round up farm animals.

Do not allow the tractor to coast downhill with the clutch

in, or with the gear shift in neutral.

When operating the tractor on a slope, set the wheel

tread as wide as possible for maximum stability, reduce

the engine speed and avoid quick application of the

brakes or sharp turns.

Stay off hills and slopes which are too steep.

Page 13

EF393T OM

7

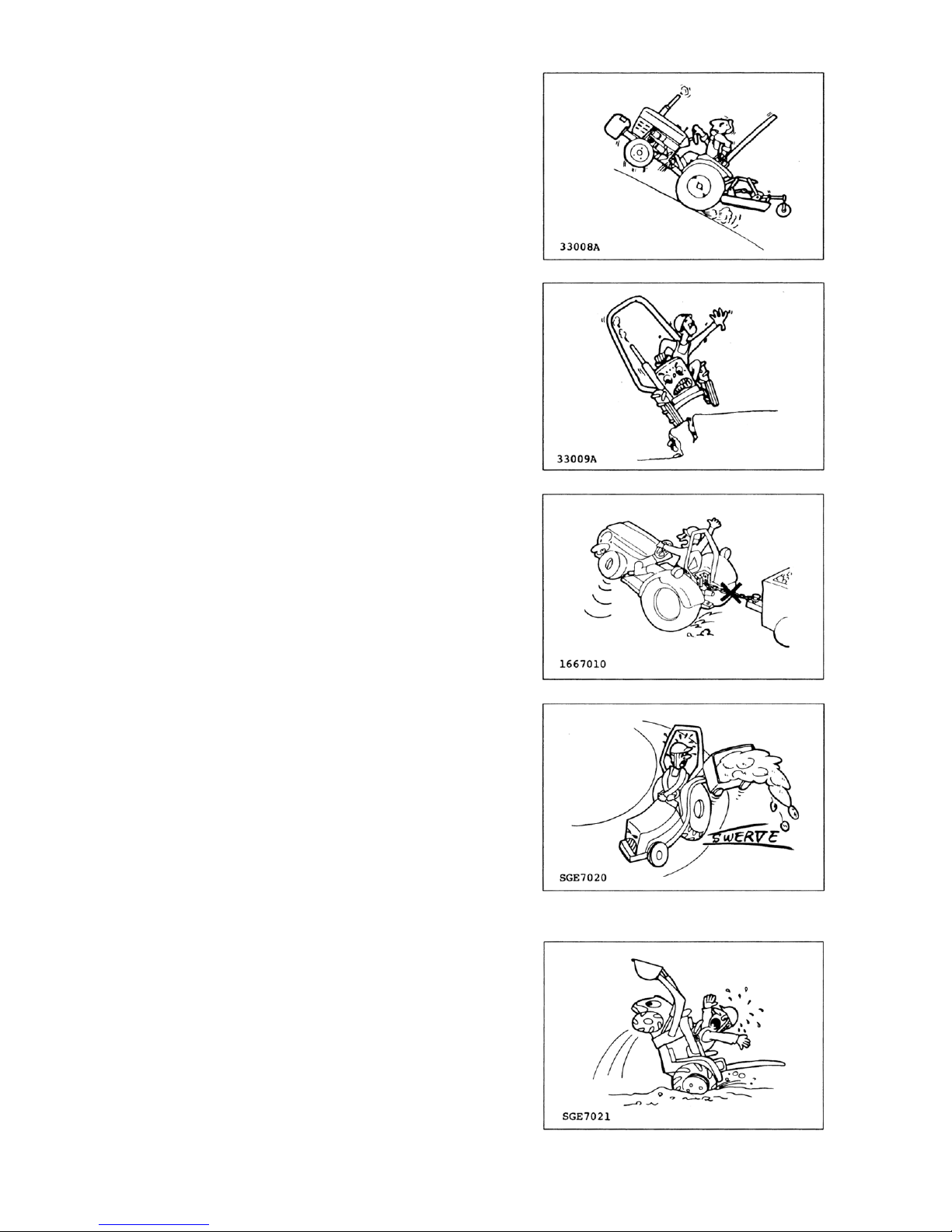

AVOID TIPPING OVER

When starting the tractor on an uphill slope, shift to as

low a gear as possible and reduce the engine speed to

avoid tipping over backward.

Do not drive near the edge of a gully or a steep

embankment. Avoid holes, ditches, etc. which may

cause the tractor to tip over, especially on hillsides or

steep slopes.

When operating on slopes or rough uneven ground, it is

important to have as much distance as possible

between the wheels. Operate the tractor carefully at the

lowest speed.

Do not pull carts etc. from the top link or the top link

hinge, rear axle, or any point above the drawbar. Doing

so could cause the tractor to tip over backward. Only

attach items to be pulled to the drawbar.

Use care when pulling loads or installing a heavy

implement.

(1) Only use approved hitch points.

(2) Limit loads to those which you can control

safely.

(3) Limit travel speeds so that you can control the

tractor safely.

(4) Do not turn too quickly.

(5) Use care when backing up.

(6) Install the amount of ballast recommended in

the operator’s manual.

Driving forward out of ditch or in muddy conditions, or

up a steep slope, could cause the tractor to tip over

backward. If the mud is deep enough it will keep the

wheels from turning. Then, the tractor will rotate up and

back around the axle very quickly. When stuck in

muddy conditions, do not remove the implement or

ballast weight. Always ba ck out.

Page 14

EF393T OM

8

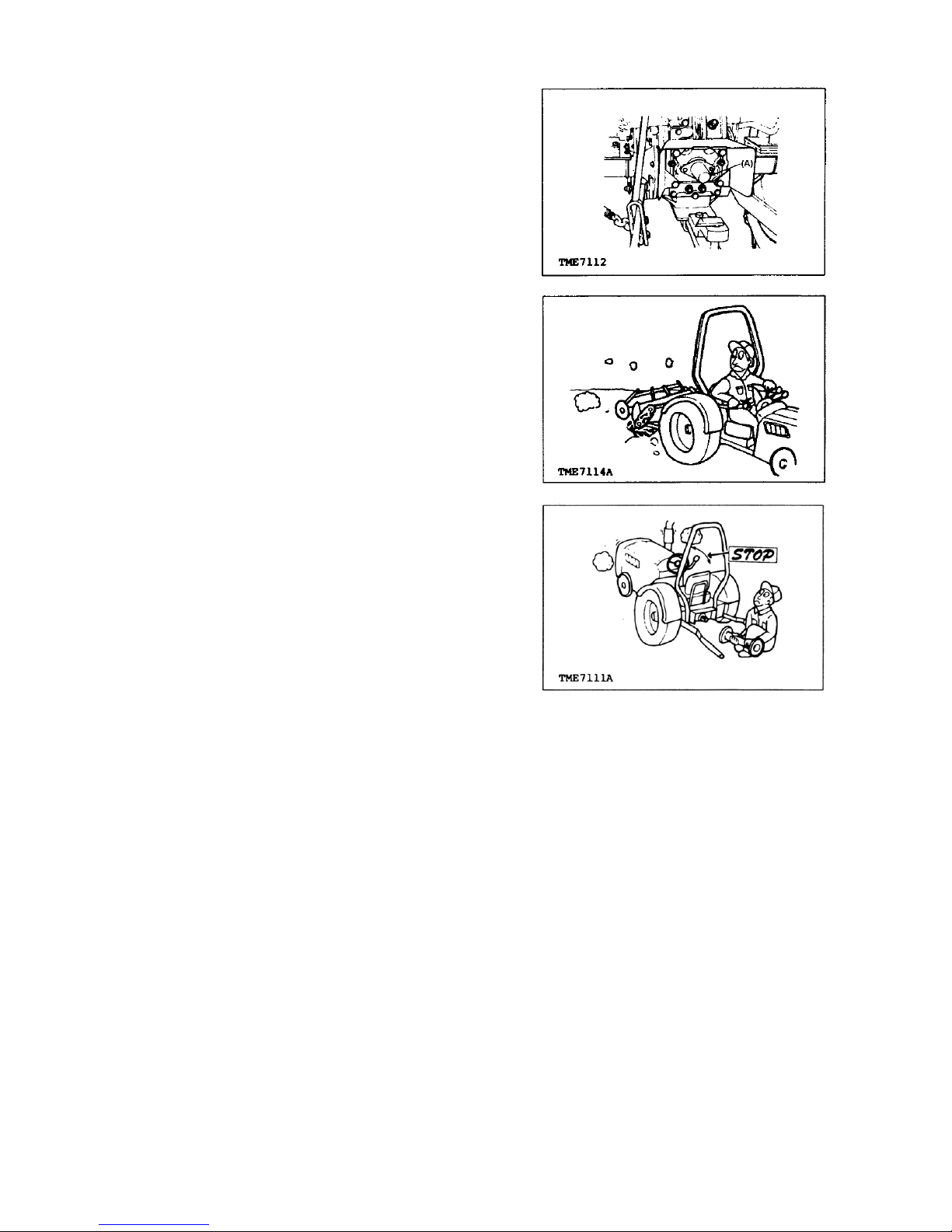

STAY CLEAR OF THE PTO

The PTO shaft safety guard (A) should be installed

when the PTO system is not in use.

Make sure that the tractor PTO speed matches the

implement’s required PTO speed.

Do not drive or operate the implement beyond the

tractor’s PTO speed.

Stop the engine and be sure the PTO has stopped

moving before:

(1) Connecting or disconnecting the PTO shaft.

(2) Making any adjustment to the PTO drive or

3-point hitch.

(3) Adjusting, cleaning or servicing PTO driven

implements.

Page 15

EF393T OM

9

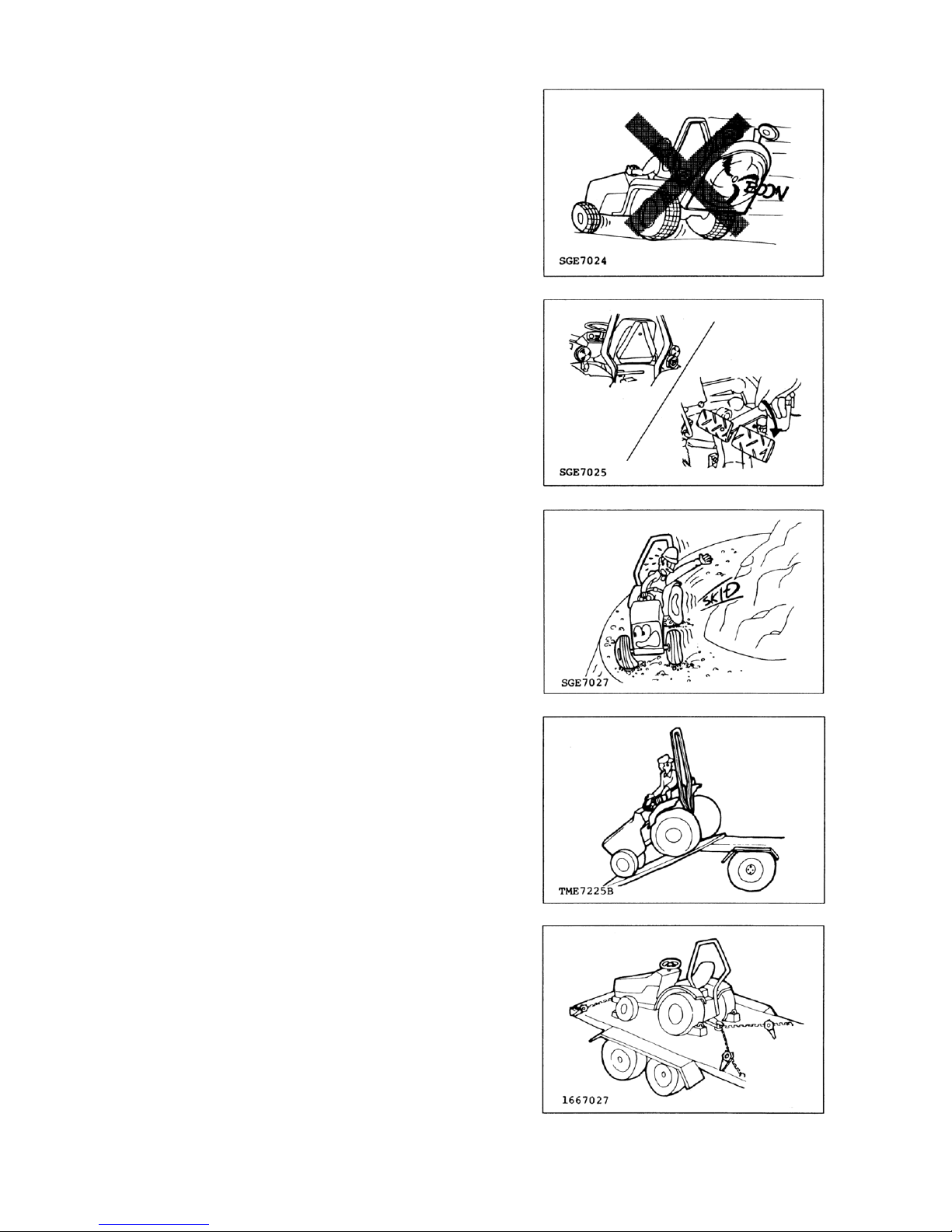

TRANSPORTING

Raise all implements and place them in the

locked-for-transport position.

Do not drive the tractor on the road with implements in

motion.

Couple the brake pedals together for travel at road

speeds. (This only applies to models with two brake

pedals.)

Do not make sharp turns at road speeds.

Always dim your headlights when another vehicle is

coming toward you. Keep the lights adjusted so that

they will not blind the driver of another vehicle.

Before going down a steep hill, shift to the lowest speed

in order to control tractor with the least braking

possible. Do not coast downhill.

Do not stop or start suddenly when going uphill or

downhill.

When loading (or unloading) the tractor onto a vehicle,

use care as follows:

(1) Use a strong loading ramp or loading dock.

(2) Use the lowest reverse speed and drive up the

loading ramp backward.

(3) Set the parking brake and place wheel blocks

firmly under the vehicle’s wheels.

(4) Do not try to drive onto a trailer from the bank of

a ditch.

Secure the tractor and any other load with chains. Be

sure they are tight.

If chains are not available, use rope, wire, blocks, or a

winch cable. Check the load after traveling a few

kilometers, and every 100 km thereafter, to make sure

that the ties are not coming loose. Also, check after

rough bumps in the road.

Page 16

EF393T OM

10

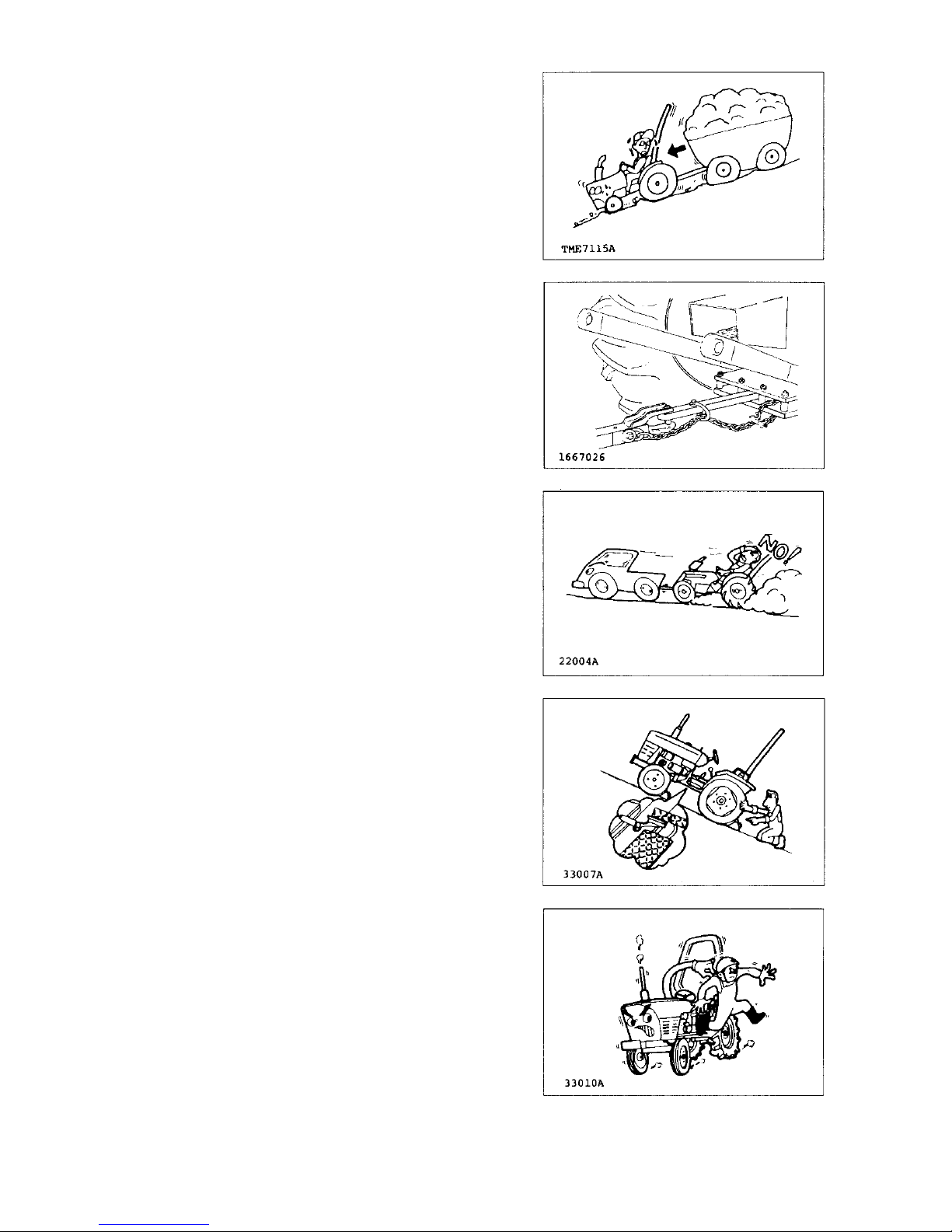

TOWING

When towing a load that weighs more than the tractor,

the trailer should have its own brakes. When towing,

drive slowly, avoid hills and apply the brakes gently.

A safety chain will help control an implement being

pulled if it accidentally separates from the drawbar

while traveling. Using appropriate adapter parts, attach

the chain to the tractor drawbar support or to some

other specified anchor location. Leave only enough

slack in the chain to permit turning.

Do not tow the tractor faster than the tractor’s

maximum travel speed in the highest gear, and never

more than 25 km/h (16 mph).

Check local regulations concerning towing. Towing is

illegal in some countries.

AFTER THE DAY’S OPERATION

PARK THE TRACTOR SAFELY

Park tractor on a firm level surface.

When parking the tractor, couple the brake pedals

together and set the parking brake securely. When you

must park on a slope, position the tractor at a right

angle to the slope and set the parking brake securely.

Then, block both the front and rear wheels.

Take all possible precautions as follows when leaving

tractor unattended:

(1) Disengage the PTO and lower any implement to

the ground.

(2) Move all shift levers to neutral.

(3) Couple the brake pedals together and set the

parking brake lever.

(4) Run the engine for 2 to 3 minutes at one-third

throttle speed and no load in order to cool it.

(5) Stop the engine and remove the key.

(6) Cycle the hydraulic controls to eliminate any

residual pressure.

Page 17

EF393T OM

11

MAINTENANCE AND SERVICE

AVOID EXPLOSIONS OR FIRES

Refuel the tractor when the engine is cool and in a

well-ventilated area, preferably outside.

Never fill the fuel tank with the engine running.

Be sure to use the correct type and grade of fuel.

Keep all sparks, flames and smoking materials well

away while handling fuel.

Ground the fuel funnel or nozzle against the filler neck

on the tractor to prevent sparks.

Do not overfill the tank or spill the fuel. If fuel is spilled,

wipe it up immediately . Install the fuel tank cap securely

after refueling.

Be sure there is plenty of ventilation before charging

the battery. Gas produced while charging the battery is

explosive.

Keep all sparks, flames, and smoking materials well

away from battery. Hydrogen gas at a concentration as

low as 7 per cent can explode in the presence of a

spark or open flame and spatter acid.

Use a flashlight to check the battery electrolyte level.

Never use an open flame or match to check.

Keep the engine clean and free of grass, leaves, or

excessive grease.

Let the engine cool down before storing the tractor in

an enclosure or covering it with a sheet.

Page 18

EF393T OM

12

MAINTENANCE AND SERVICE (continued)

Do not service the tractor while it is in motion or while

the engine is running.

Before servicing the tractor, always set the parking

brake, block the wheels, lower the implement, release

all hydraulic pressure and place all the controls in

neutral.

Use only the correct tools and equipment.

Unauthorized modification to the tractor may impair its

function, create an unsafe situation and reduce the

tractor’s useful working life.

Do not use substitute parts that may not meet the

strength and design requirements or may not fit the

tractor.

Do not use repair parts not approved by YANMAR.

Remove the radiator cap only when the coolant

temperature is low. Wait at least one hour after

operation, to allow the coolant to cool down.

Cover the radiator cap with a cloth before opening it

and release the pressure gradually before completely

removing the cap.

Do not service the hydraulic system when the hydraulic

oil is hot.

Do not set the relief valve pressure higher than stated

in the tractor or implement specifications.

Do not close off the overflow or bypass lines.

Page 19

EF393T OM

13

MAINTENANCE AND SERVICE (continued)

Hydraulic oil or diesel fuel escaping under pressure can

penetrate the skin and cause serious injury. Before

disconnecting any lines, be sure to relieve all pressure.

Before applying pressure, be sure all connections are

tight and all components are in good condition.

Fluid escaping under pressure from a very small hole

can be almost invisible. Wear safety goggles for eye

protection and use a piece of cardboard to check for

suspected leaks. Do not use your hands. If injured by

escaping fluid, see a doctor at once. Serious infections

and other problems can develop if proper medical

treatment is not administered immediately.

Disconnect the battery ground cable before working on

the electrical system or working in any area where you

might come into contact with electrical components.

Disconnect the ground cable first and reconnect it last.

The sulfuric acid in a battery is poisonous. It can

destroy clothing and burn the skin. Wear eye protection

and rubber gloves when filling the battery. If you spill

acid on yourself, flush your skin with water and apply

baking soda or lime to neutralize the acid. Then seek

medical attention right away. If acid is swallowed, get

medical attention immediately!

Page 20

EF393T OM

14

Storage

Whenever the tractor will not be used for a few months,

do the following:

(1) Drain the fuel tank.

(2) Lower any implement still attached.

(3) Set the parking brake and block the wheels.

(4) Remove the battery and store it in a cool, dry

place, out of the reach of children.

CAUTION

ALWAYS BE ENVIRONMENTALLY

RESPONSIBLE

Follow the guidelines of the governmental agency

for the proper disposal of hazardous materials such

as engine oil, diesel fuel, engine coolant and,

machine fluid, grease.

NEVER dispose of hazardous materials

irresponsibly by dumping them into a sewer, on the

ground, or into groundwater or waterways.

Failure to follow these procedures may seriously

harm the environment.

Comply with legal regulations and guidelines for

disposal of: empty containers for fuel, cooling water

(coolant), oil, grease; fuel/oil filters; batteries;

machine itself; machine accessories; and

packaging materials.

Page 21

EF393T OM

15

AFTER SALES SERVICES

After sales services

When your tractor is not working normally, check it

referring to the troubleshooting section. You can of

course consult with your service representative.

Whenever you ask service to your service

representative, following information are very helpful to

identify your tractor.

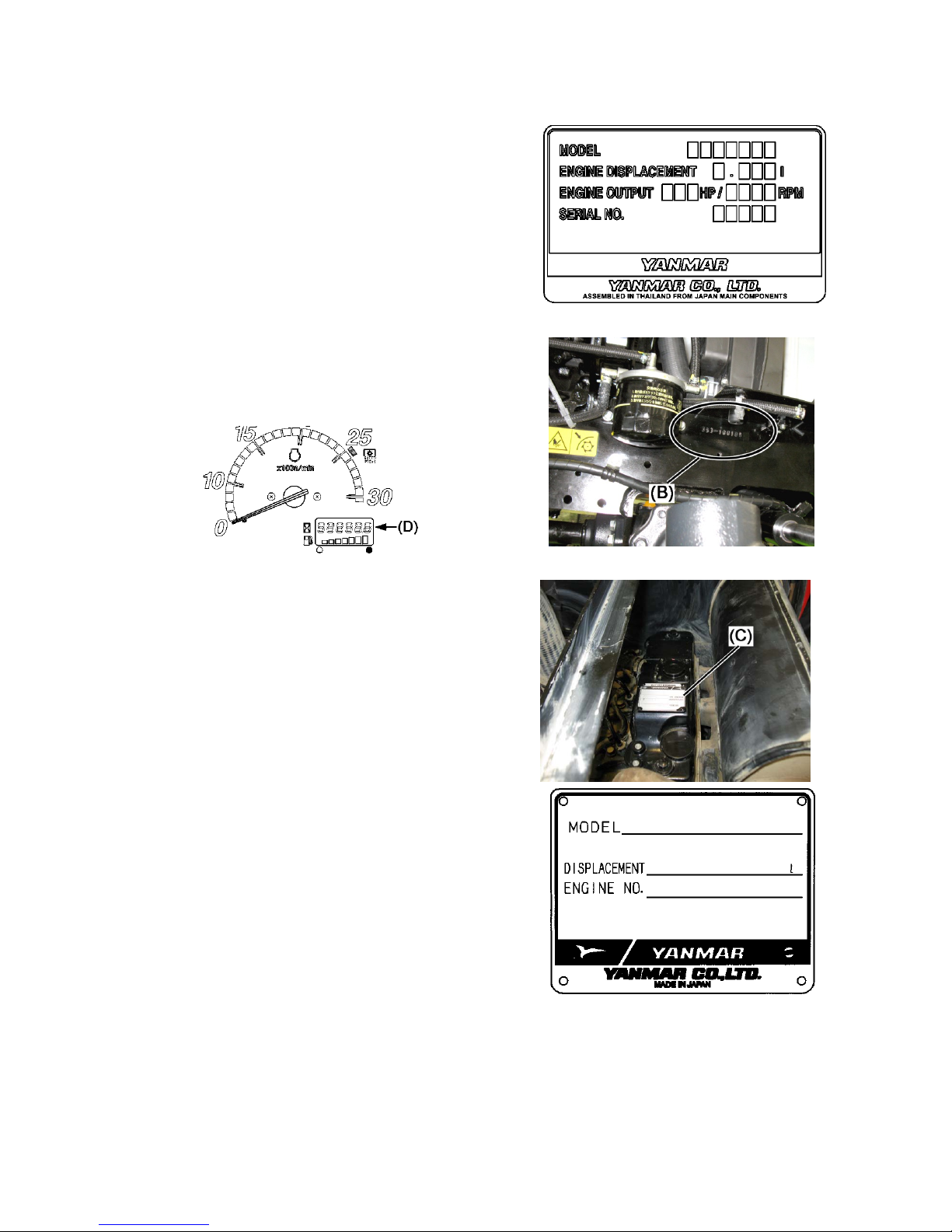

1) The label of tractor model name and serial number

(A) is on the left rear fender and the stamp of the

serial number (B) is on right side of front frame.

2) Engine model name and serial number (C).

3) Hour-meter (D) shows estimated hours of

operation. Turn on key switch to read hours.

4) Operating conditions.

Kind of work and implement used when a problem

is happened.

5) Any other information when a trouble is occurred.

Noise, vibration, function etc.

Availability of spare parts

Maintenance parts or spare parts are available for 10

years after the production of this tractor series has

been discontinued. However, special parts will be

subject to consultation. Yanmar may be able to supply

a particular part after the normal supplying period.

(A) Tractor model name & serial number

(B) Tractor serial number

(C) Engine model name & serial number

Page 22

EF393T OM

16

WARNING

Do not move the tractor if the wheel mounting bolts or

nuts are loose. If the tractor is driven with loose nuts or

bolts, there is a possibility that an accident will occur.

Make daily and periodic wheel inspections to check for

loose nuts and bolts on the wheels. If they are loose,

retighten them to the specified torque.

IMPORTANT

The first 50 hours of handling and maintenance greatly

affect the service life and performance of a new tractor. In

particular, pay special attention to the following points

during this period of time.

(1) Refrain from sudden acceleration and sudden

braking.

(2) Do not increase the speed too much or carry any

more load than is necessary.

(3) Operate the tractor only after the engine has warmed

up sufficiently.

(4) Slow down on a rough road or on a slope.

(5) Check the tightness of the wheel mounting bolts

after the first 10 hours and again after the first 50

hours. If they are loose, retighten them. (For specific

tightening torques, refer to the table in the instruction

manual.)

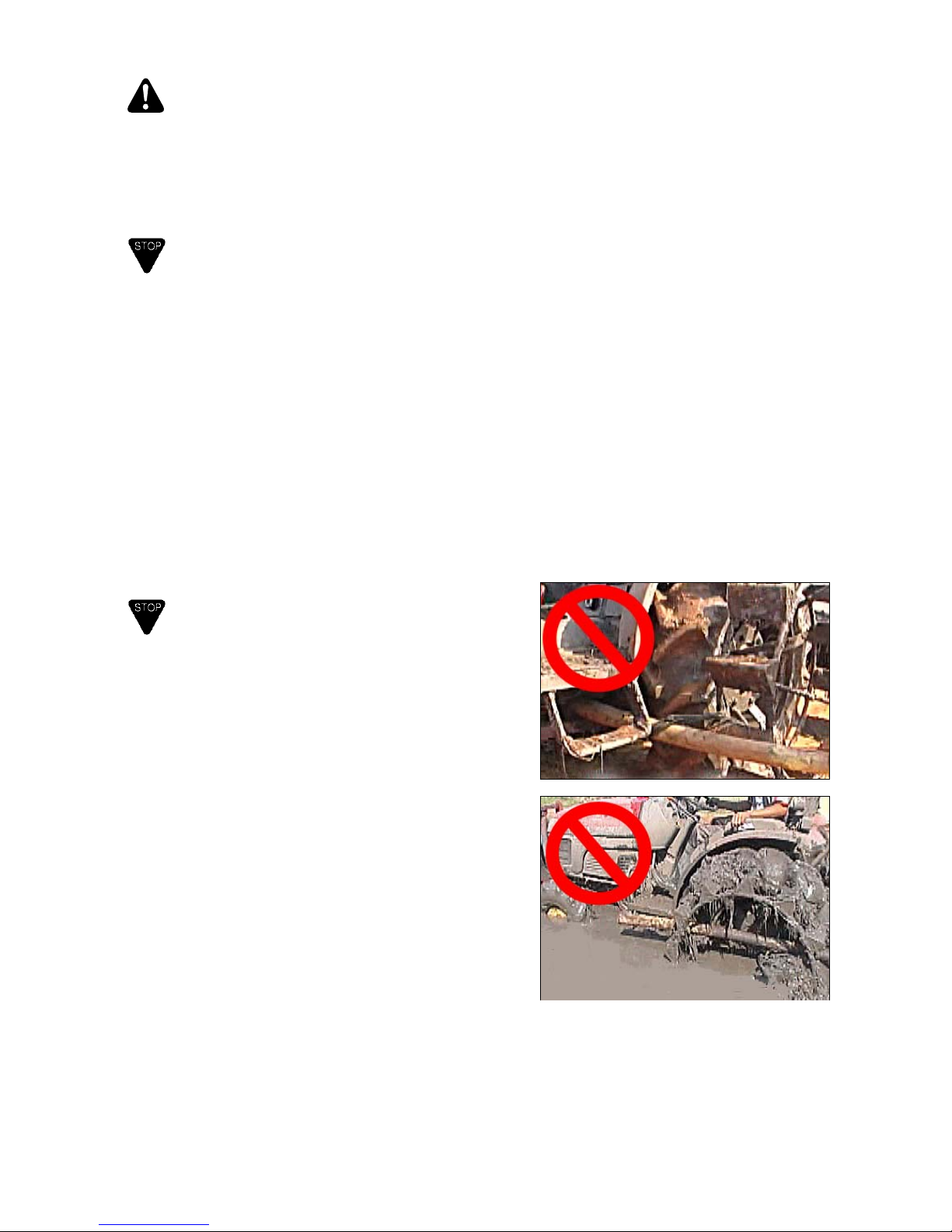

IMPORTANT

When the tractor gets stuck in a muddy portion in field, do

not tie a piece of lumber, log or pipe to the front or re ar

wheels to drive out of the muddy portion.

It may break transmission and/or rear axle inner parts or

cases.

Put a ladder bridge under the wheels and then drive out.

Or use strong rope or chain to pull it out of the muddy

portion slowly by the other tractor or so.

Note:

These photos show rear tire with cage

wheel.

Page 23

EF393T OM

17

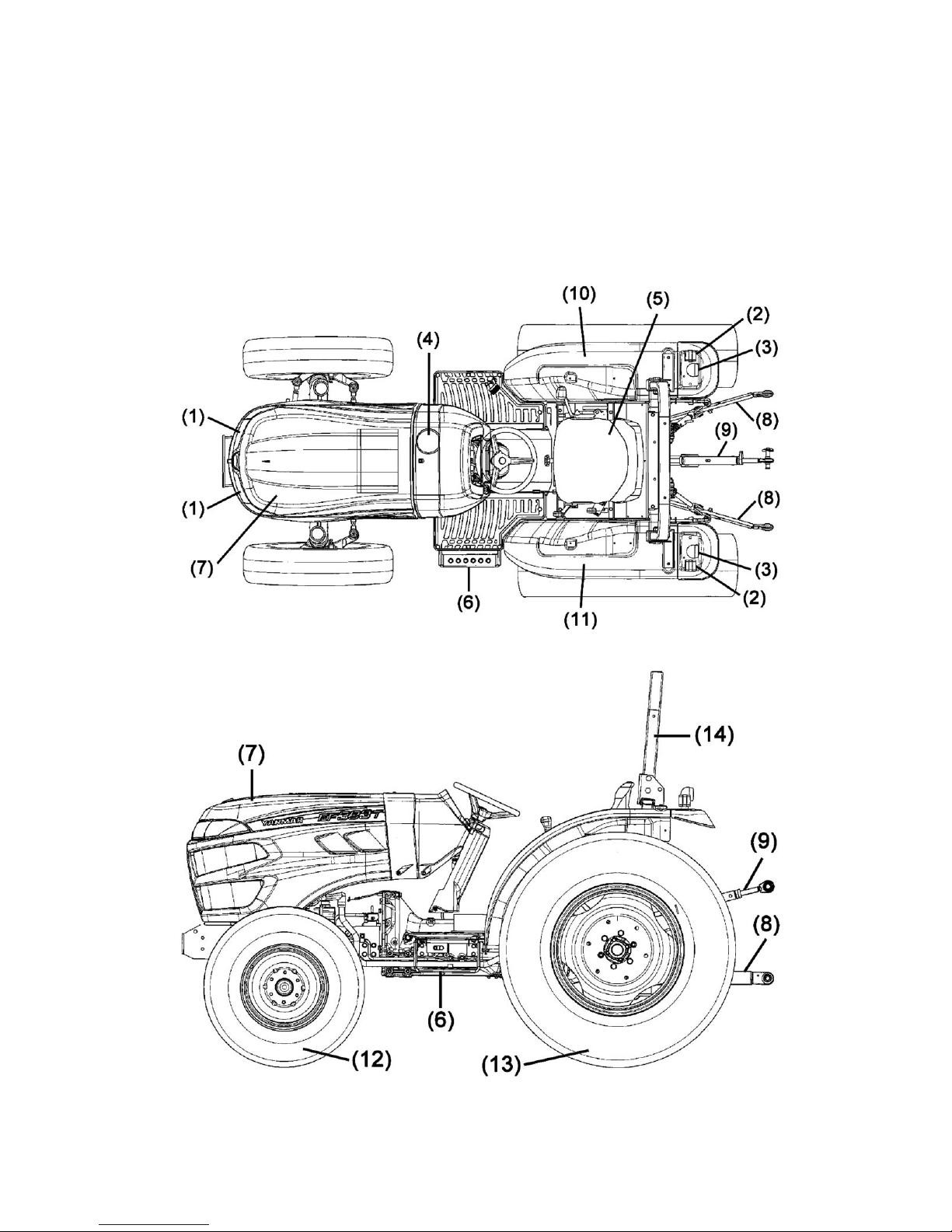

TRACTOR OUTLINE

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Head light

T urn signal lamp

Tail lamp

Fuel refill port

Operator’s seat

Sub-step

Bonnet

(8)

(9)

(10)

(11)

(12)

(13)

(14)

Lower link

T op link

Fender, R

Fender, L

Front tire

Rear tire

ROPS (Safety frame)

Page 24

EF393T OM

18

PARTS NAMES

(1) Main switch

(2) Accelerator lever

(3) Parking brake lever

(4) Combination switch

Head light, turn signal, horn

(5) Reverser lever

(6) Clutch pedal

(7) Range gear shift lever

(8) PTO gear shift lever

(9) Brake pedal connector

(10) Brake pedal

(1 1) Foot accelerator pedal

(12) Main gear shift lever

(13) Position control lever

(14) Differential gear lock pedal

(15) Seat adjust lever

(16) Stop & slow return valve

(17) Front wheel drive lever

(18) Seat belt

Page 25

EF393T OM

19

Meter panel indicators

(1) Fuel gauge

(2) Engine coolant alarm lamp

(3) Engine speed meter, RPM

(4) Hour meter

(5) Battery charge pilot lamp

(6) Engine oil pressure pilot lamp

LABEL LOCATIONS

Keep the safety instructions labels clean and clearly visible for your safety. If any of them are damaged or

missing, replace them with new ones.

(1) 1A8310-65340

Label, fire caution

(2) 198163-65930

Label, caution muffler

(3) 1A8310-65310

Label, caution

(4)198283-65651

Label, Thailand only

(5) (6) 1A7874-65360

Label, brake coupling

(13) 1A8310-65300

Label, warning escape

Page 26

EF393T OM

20

(7) 198163-65930

Label, caution muffler

(8) 198163-65940

Label, safety cover

(9) 1A6150-93151

Label, PTO shaft cover

(10) 198163-65350

Label, danger shaft rotate

(1 1) 198163-65950

Label, seat belt

(12)

Page 27

EF393T OM

21

CONTROLS

ENGINE

Main switch

The switch is used to turn on and off the engine

OFF

The electric current is shut off.

The engine stops. (The key can be

removed.)

(5) Battery charge lamp

(6) Engine oil pressure lamp

ON

The electric current is on. If the engine is

stopped, the engine oil pressure lamp (6)

and battery charge lamp (5) turn on.

START Starter motor runs to start the engine, when

range shift lever is at neutral.

Release the key when the engine starts and

the key returns to the “ON” position

automatically.

Accelerator lever

The accelerator lever (A) is used to increase or

decrease the engine speed or keep the engine at a

constant speed.

(A) Accelerator lever

(S) Slower engine speed

(F) Faster engine speed

Accelerator pedal

The accelerator pedal (A) is used to increase or

decrease the engine speed, mainly during travel on a

road. To increase the engine speed, depress the pedal.

(A) Accelerator pedal

Page 28

EF393T OM

22

TRAVELLING, PTO RE RELATED FUNCTIONS

Main shift lever

The transmission has 4 main gear shifts.

Depress the clutch pedal fully, and move the lever to

desired position.

(A) Main shift lever

IMPORTANT

Be sure the tractor stops whenever shifting. If not, it

may cause damage to transmission gears.

Range shift lever

The transmission has 2 range gear shift aside from 4

main gear shifts.

(B) Range shift lever

2: High Speed range

1: Low speed range

N: Neutral

IMPORTANT

Be sure tractor stops when shifting. Do not change

Range shift lever while moving.

Reverser lever

Reverser lever changes the direction of travel of the

tractor, forward or reverse. Depress the clutch pedal

and stop tractor whenever shift the lever.

Lift up the lever to put it in a required position.

(A) Reverser lever

F: Forward

N: Neutral

R: Reverse

WARNING

Be sure to stop the tractor when shifting. Never

change Reverser lever while moving. Sudden change

of running direction back and forward may cause

serious injury.

Page 29

EF393T OM

23

PTO shift lever

The transmission has 2 PTO speeds. To change the

speed, depress the clutch pedal fully.

(C) PTO shift lever

PTO speed at engine 2,800 rpm

1 584 rpm

2 836 rpm

CAUTION

Strictly maintain the PTO speed as specified by the

implement. Otherwise, the implement or transmission

can be damaged and may cause an injury.

Brake pedal

Tractor has brake pedals for right and le ft turn

independently and they can be applied separately.

For a sharp turn in the field, depress the brake in which

direction you want to turn. For driving on a road, be

sure to connect both pedals with the connector.

To avoid unnecessary wear of brake discs, do not rest

foot on the brake pedal during operation.

(A) Brake pedals

(B) Brake pedal connector

WARNING

Be sure to connect the both brake pedals with the

connector when driving on a road. Tractor may turn

over by one-sided braking in high speed.

Parking brake lever

To apply parking brake;

Connect brake pedals, depress brake pedals and raise

parking brake lever.

To release parking brake;

Depress brake pedals slightly and down parking brake

lever.

(A) Parking brake lever

(B) Brake pedals

(C) Brake connector

(L) Apply parking brake

(R) Release parking brake

CAUTION

Be sure to connect the both brake pedals with the

connector when applying parking brake. If not, only

left tire is locked and it may not brake tractor

sufficiently.

Page 30

EF393T OM

24

Clutch pedal

The clutch is a device for connecting and disconnecting

engine power to the transmission.

To disconnect engine power to the transmission,

depress the clutch pedal fully.

To connect the engine power, release the clutch pedal

gradually and the engine power transmits to

transmission.

IMPORTANT

Do not rest your foot on the clutch pedal while

operating. The clutch disc may wear prematurely.

(A) Clutch pedal

Differential gear lock pedal

A differential gear system is equipped on front and rear

axles of this tractor for smooth turning.

Depressing this pedal locks rear axle differential gear

box and rear wheels rotate as if right and left axles are

connected. When one side rear wheel spins and the

other does not rotate, depress the pedal to lock the

differential gear for escaping.

To unlock differential, release the depressed pedal.

IMPORTANT

When differential gear is locked, drive tractor slow

speed and keep going straight. Never steer tractor

while depressing the pedal.

WARNING

Never fail to unlock the differential gear after escaping

from the place. Otherwise, you cannot make an

intended turn and an accident may result.

(A) Differential gear lock pedal

(R) Release lock (release pedal)

(L) Lock differential gear

(keep depressing pedal)

Front wheel drive lever

The lever engages or disengages front wheel drive.

Depress clutch pedal and move the lever when tractor

stops.

(A) Front wheel drive lever

(2w) OFF: Two-wheel drive

(4w) ON: Four-wheel drive

IMPORTANT

Be sure to stop the tractor whenever move the lever.

Disengage front wheel drive when drive with high gear

on a road, hard surface place or towing trailer. The

front tire may wear prematurely or front axle gears may

break in case of heavy braking.

Page 31

EF393T OM

25

HYDRAULIC SYSTEM

Position control lever

Position control lever holds desired height of a rear

hitched implement.

Lever stopper (B) limits lowering an implement to limit

the working range of the lever, or when t raveling o n

road.

(A) Position control lever

(B) Lever stopper

(C) Raise

(D) Lower

Hydraulic stop and slow return valve

The stop and slow return valve controls lowering speed

of implement.

(A) Hydraulic stop and slow return valve

(C) The lowering speed of implement becomes

slower and it stops hydraulic flow when turned

fully.

(O) It opens the valve and the lowering speed of

implement becomes fast (normal speed).

IMPORTANT

When driving on a road with rear hitched implement,

open the hydraulic stop and slow return valve and fix

the hydraulic control lever in raise position with stopper .

Do not operate the hydraulic control lever when the

valve is fully closed. Otherwise, it may damage

hydraulic parts.

Page 32

EF393T OM

26

ELECTRIC SYSTEM

T urn signal switch

Turn signal functions when key switch turns on.

Turn the turn signal switch anticlockwise to blink right

side turn signal lamp and turn clockwise to blink left

side lamp.

(A) Turn signal switch

(R) Right lamp blinks.

(L) Left lamp blinks.

Head light switch

Headlights turn on when key switch turns on.

Turn head light switch clockwise to turn on head lights.

(B) Light switch

(OFF) Headlights turn off.

(L) Headlights turn on with low beam.

(H) Headlights turn on with high beam.

CAUTION

When there is an oncoming vehicle in night time, be

sure to switch to low beam position. If keep on high

beam, it may cause traffic accident.

Horn button

Horn functions in any positions of the key switch.

Push horn button to blow horn.

(C) Horn button

Page 33

EF393T OM

27

INSTRUMENT PANEL

(1) Fuel gauge

(2) Engine coolant alarm lamp

(3) Tachometer

(4) Hour meter

(5) Battery charge pilot lamp

(6) Engine oil pressure pilot lamp

(1) Fuel gauge

It indicates fuel level remained in fuel tank when key switch turns on.

(a) Full

(b) 1/2

(c) Empty soon

(d) Empty warning

The fuel tank will be empty in a short time.

The indicated amount is approximate.

(2) Engine coolant alarm lamp

It indicates engine coolant temperature.

If the lamp turns on, reduce engine speed to idling and wait for cooling

down. Find out the cause and call your dealer if necessary.

When the lamp is;

(1) turning on: 100 degree centigrade

(2) blinking: 110 degree centigrade or short circuit

(3) T ach ometer

Indicates engine speed in revolution per minute (RPM).

It also indicates PTO shaft speed 540rpm when the needle stands at

the yellow mark in the position 1 of PTO shift lever.

(A) Yellow mark

(4) Hour meter

It shows actual operating time of the engine in hourly unit. It counts

whenever the engine is running. For example, 10.5 means 10 hours

and 30 minutes of the engine running time.

(5) Battery charge pilot lamp

This lamp lights when the key switch is in “ON” position.

The charge lamp turns off when engine starts. If the lamp does not

turn off at 1500rpm engine speed or higher, see your dealer.

(6) Engine oil pressure pilot lamp

This lamp lights when the key switch is in “ON” position and goes of f

when the engine starts. If the lamp does not turn off after engine

starts, stop the engine immediately and check oil level. If oil level is

sufficient, see your dealer.

Page 34

EF393T OM

28

OTHERS

Seat adjust lever

It adjusts the operator’s seat position in 5 steps backward

or forward.

Raise the lever and slide forward or backward to desired

position. Lower the lever to latch the seat.

(A) Seat adjust lever

Seat belt

WARNING

Always fasten seat belt while operating the tractor with

the Roll-over Protective Structure (ROPS).

Do not use the seat belt if the tractor does not have the

ROPS.

(A) Seat belt

(B) PRESS button

Fasten the seat belt properly without twisting. Adjust the

belt length to operator figure.

Press “PRESS” button on the buckle to unfasten seat belt.

Opening bonnet

(1) Raise the lever to open bonnet. The bonnet goes up

and is hold with gas damper.

(A) Bonnet open lever

(B) Gas damper

Page 35

EF393T OM

29

OPERATIONS

1. Pre-operation checks

DANGER

1) Never smoke or use bare lamps/lights during oil

replenishing.

2) Never fill fuel oil while the engine is running or hot.

3) After filling fuel, be sure to cover the fuel tank with

screw-top and wipe off spilled fuel. If not, a fire may be

caused.

4) Check the fuel lines daily. Fuel leaks on a damaged

fuel line.

WARNING

1) Whenever servicing the tractor, place it on a flat and

leveled area. Be sure no traffic neither people around

the tractor. Otherwise, the tractor can cause an

unexpected accident.

2) Whenever servicing under rear hitched implement,

close hydraulic stop and slow return valve (A) and place

lock device or support to the implement. Otherwise the

implement may fall down incidentally and it can cause

injuries.

(C) Close

CAUTION

1) Never fail to stop the engine before checks or

maintenance. If not, you may be trapped in a rotating

part and heavily injured.

2) To check or service the tractor, wait until the engine and

muffler are cooled down. If not, you may got burned

and be injured.

3) Never fail to reinstall covers and parts detached for

service. Otherwise, you may be trapped in the tractor

and heavily injured.

Page 36

EF393T OM

30

For safety reasons, always check the tractor before

day's work. Remove any abnormalities.

At least check the followings in order:

(1) Abnormalities in previo us day

(2) Walk around the tractor to look into:

• Deformed, damaged, wearing or lost exposed parts

• Air inflation pressure and wear of tires

• Loosened or lost bolts and nuts of the tire rims and

disks

(3) Check inside the bonnet

• Engine oil level and leaks.

• Fuel oil amount, leak and damages on fuel lines.

• Engine coolant level, leaks and damage on

lines.

• Battery electrolyte (liquid).

Depending on battery type;

Check electrolyte level, to be between upper and

lower limit.

Check the color of the hydrometer , to be green.

• Clogging or dirt in air filter.

• Tension or damage of cooling fan belt.

Page 37

EF393T OM

31

• Radiator screen, grille and engine room for dust.

• Hydraulic joint and lines for damages and loose

connection.

• Check electrical wirings for wear or damages of

lead sheaths and loose connections.

(4) Check operating system

• Play of brake pedals.

Brake pedals must have reasonable play (A)

and plays of both right and left brake pedals

must be equal. (25-35mm)

• Play of clutch pedal.

Clutch pedal must have reasonable play (A).

(15-25mm)

• Play of steering wheel.

Steering wheel must have reasonable play (A).

(20-50mm)

Page 38

EF393T OM

32

(5) Check hitched implement

• PTO Drive shaft lock pin must be in groove of

PTO output and input shafts.

• Pins must be inserted in proper positions.

• Loosened bolts and nuts.

• Damaged or worn parts.

• Connection of 3-point linkage.

(6) Start the engine and check:

• Abnormal sound or noise.

• Color and smell of exhaust gas.

• Function of each lamp, gauge and meter

Page 39

EF393T OM

33

2. Break-in (initial 50 hours)

The new tractor should be carefully operated for the first 50

hours. It will surely have an effect on the lifetime and

performance of the tractor throughout the life. Pay attention

to the following points in particular:

(1) Avoid quick start or abrupt brake if it is not in

emergency case.

(2) Do not operate in higher speed or heavier load more

than necessary. Do not operate with full load.

Avoid from operation such engine speed comes down

by a load or smoke while working.

(3) Start operation after the engine is sufficiently warmed

up.

(4) Slow down on the rough road or slope.

(5) Check tire fixing bolts at the first 10 hours and 50

hours operation. If loosened, tighten it.

See “12. Wheel tread” for bolt tightening torque.

(6) Check the tractor at the time of first 50 hours

operation.

3. Before starting

WARNING

1) Before starting the engine, sit on the operator’s seat and

make sure shift levers (reverser, PTO shift, range shift,

main shift) are at neutral position, and position control

lever is at down position. Negligence may cause tractor

sudden start and serious injury.

2) Do not run engine in a closed room. Run the engine in

well-ventilated area. If you are forced to start the engine

in a confined room, make sure the ventilation is proper.

Exhaust gas is poisonous and it can lead to death.

CAUTION

1) Before and after operation, never fail to check and service

the tractor. Particular check will be required at brake

pedals, controls, steering devices and tire rim fitting bolts.

Negligence can cause a heavy injury or accident to the

tractor and the human.

2) Set the parking brake during the warm-up operation.

Otherwise the tractor may abruptly start to run.

Page 40

EF393T OM

34

4. Start and stop

4-1. Start and stop engine

Start engine

IMPORTANT

1) Do not run the engine starter motor for more than 10

seconds. It may cause a breakage of the starter

motor. If the engine does not start, keep it cool for

2-5 minutes before retry. Then, execute steps (3) (4).

2) Never turn the main switch to start position while

engine is running.

(1) Open the fuel cock of water separator (A).

(A) Water separator

(B) Fuel cock (O) Open

(2) Put the reverser lever and PTO shift lever to ”N”

position.

(3) Set position control lever in the LOW position.

Make sure that the implement is lowered.

(4) Push accelerator lever forward to higher speed

position.

(5) Insert the key and turn it to “ON” position.

Check pilot lamps on meter panel;

(A) Battery charge pilot lamp is on.

(B) Engine oil pressure pilot lamp is on.

(6) Turn the key switch to “START” position.

(7) As engine starts, immediately release key switch and it

goes back to “ON” position automatically.

When engine starts, battery charge and engine

pressure pilot lamps turn off.

(8) Warm up the engine by running without load at 1500

rpm for about 5 minutes. Especially if the temperature

is below 0°C, at least 10 minutes warm-up is required.

(A) Reverser lever

(C) PTO shift lever

(A) Position control lever

(A) Accelerator lever

Page 41

EF393T OM

35

Stop engine

(1) Pull accelerator lever (A) rearward (S) to decrease

engine speeds.

(2) Turn key switch to “ OFF” position.

(3) See main shift lever, range shift lever, reverser

lever and PTO shift lever are in neutral positions.

IMPORTANT

Sudden stop of heated engine may cause engine

overheating. Prior to stop engine, keep engine

running at 1200 - 1500 rpm for about 2 minutes to cool

down.

(A) Accelerator lever (S) Slow speed

4-2. Start, gear shifting and stop tractor

Start tractor

(1) Be sure right and left brake pedals are connected

by connector.

(2) Set engine speed about 1500 rpm.

(A) Brake pedals (B) Connector

(3) Move position control lever backward and raise rear

hitched implement.

(A) Position control lever

(C) Raise rear hitch implement

(4) Depress clutch pedal fully and shift main shift lever

and range shift lever to desired speed.

(A) Main shift lever

(B) Range shift lever

(5) Shift reverser lever to forward or reverse.

(6) Release clutch pedal gradually and tractor starts.

IMPORTANT

1) Never rest your foot on clutch pedal while operating.

It will cause premature wearing of clutch disc.

2) Be sure to apply the parking brake when you leave

the tractor.

3) Look around the tractor before starting.

(A) Reverser lever (N) Neutral

(F) Forward (R) Reverse

Page 42

EF393T OM

36

Gear shifting

(1) Main shift lever

Depress clutch pedal fully and shift lever to desired

speed after tractor stops.

(2) Range shift lever

Depress clutch pedal fully and shift reverser lever

to desired speed after tractor stops.

(3) Reverser lever

Depress clutch pedal fully and shift reverser lever

to (F) or (R) after tractor stops.

IMPORTANT

Never shift the main shift, range shift and reverser lever

while tractor is moving. If not, it may cause breakage

of transmission inner gear.

Stop tractor

(1) Pull accelerator lever backward to reduce speed.

(2) Depress clutch pedal and brake pedals at the same

time.

(3) Shift range shift, reverser and PTO shift levers to

“N” position.

(4) Make sure brake pedals are connected with

connector and apply parking brake (lock brake pedal

with parking brake lever).

(5) Lower rear hitch implement if it is attached.

(6) Turn key switch to “OFF” position and remove the

key.

(A) Parking brake lever (B) Brake pedals

(C) Connector

(L) Lock (R) Release

Page 43

EF393T OM

37

5. Driving on a road

WARNING

1) Make sure that left and right brake pedals are

connected whenever traveling on a road or cross a

farm ridge. One-sided braking effect will roll over

the tractor or result in a sharp turn.

2) Follow the traffic regulations and rules in your place

when running on a road. Strictly one operator only

on tractor.

CAUTION

Remove an implement when traveling on a road. If

not, an accident may result in.

Put the PTO shift lever in “N”.

(1) Connect right and left brake.

(2) Shift PTO shift lever to “N” position.

(3) Open hydraulic stop and slow return valve fully.

(A) Hydraulic stop and slow return valve

(O) Open valve

(4) Move position control lever up and lock it with

stopper.

CAUTION

Make sure that position control lever is held when

traveling on a road. If not, hand may touch position

control lever incidentally and implement would go

down. It may cause an accident and injury.

(A) Brake pedals (B) Connector

(C) PTO shift lever

(A) Position control lever (B) Stopper

(C) Raise rear hitched implement

IMPORTANT

1) Adjust the traveling speed with the foot accelerator

pedal.

2) When you turn tractor or change traveling course,

notify others by turning signal lamp.

3) When there is on-coming vehicle in night time, make

headlight be low beam.

4) Disengage front wheel drive except in special case.

Page 44

EF393T OM

38

6. Driving on a slope

WARNING

1) Select a correct speed before approaching a slope.

Never change shift levers on a slope. Tractor may

coast down unintentionally.

2) Never travel on the slope with reverser lever, main

shift lever or range shift lever set in “N” position.

3) Never depress the clutch pedal on a slope. Tractor

may coast down unintentionally and it may cause an

accident.

4) To start on an up-slope, shift gears to low speed and

engage clutch slowly and carefully. Abrupt start will

jump up the front wheel.

5) Do not park tractor on a slope as much as possible.

If it is required, apply parking brake and put wheel

block to avoid from coasting down.

(1) Select slow speed before going into a slope.

(2) Travel slowly on a slo pe.

(3) Apply engine bra ke on a down-slope.

7. Driving in and out of a field

WARNING

1) Be sure to connect left and right brake pedals with

connector. One-sided brake results in causing a

roll over.

2) In case field ridge is high, use a gangplank with

sufficient strength. Lower an implement and go

through ridge in slow speed.

3) If a way to field is steep slope, go up with a reverse

gear.

(A) Ridge

8. Setting adequate speed

8 forward speeds and 8 reverse speeds are available

by the combination of main, range and reverser shift

levers. Select adequate speed for works.

Suggested operation by working speed.

Shift

Main

shift

Range

shift

Speed

(km/hr)

Operation

F1 1

1

1.90

Rotary

F2 2 2.74

F3 3 3.92

F4 4 5.91 Spreader

F5 1

2

6.79

Plow

F6 2 9.79

F7 3 14.0

Traveling with

the trailer

F8 4 21.1

(At engine speed: 2800rpm)

Page 45

EF393T OM

39

9. T urning in a field

WARNING

Release foot from differential lock pedal to release

differential gear before turning. Otherwise, tractor

cannot turn when it is, required and an accident may

result.

Unlatch brake pedal connector in a field.

(1) Reduce the engine speed.

(2) Move position control lever rearward to raise the

implement

(3) Turn steering wh eel to desired direction and

depress brake pedal in the same direction of

steering wheel turn at the same time.

Ex:

When you turn steering wheel clockwise to turn

right, depress right side brake at the same time.

(A) Differential lock pedal (R) Release

(B) Brake pedal

(C) Brake pedal connector

10. Differential gear lock

WARNING

1) Release differential gear lock before making a turn.

Otherwise, tractor cannot turn and an accident will

result.

2) Never depress differential lock pedal while traveling

on a road. If you depress the pedal, you could not

steer and may cause an accident and injury.

Differential gear lock system is effective when one side

rear wheel is locked and the other tire slips. When

differential gear is locked, right and left rear axle rotate

as if both axles are connected. It is easier to go out

from muddy and slippery place.

Operation

(1) Lower engine speed.

(2) Depress differential lock pedal.

(3) Release the pedal to unlock differential gear lock.

If it is difficult to unlock the differential system,

depress clutch pedal or step on right and left brake

pedal alternately.

IMPORTANT

Never turn steering wheel while differential lock

pedal is depressed.

(A) Differential lock pedal

(R) Release lock (Release pedal)

(L) Apply differential lock (Depress pedal)

Page 46

EF393T OM

40

11. Loading and unloading

DANGER

1) Never steer tractor on loading bridge while loading

into or unloading from cargo truck. Drive tractor in

slowest speed. If not, loss of control can result in

injure or damage the tractor.

2) Never depress clutch pedal on loading bridge.

Tractor may coast down and cause injury.

3) Connect left and right brake pedals with the

connector. If not, tractor may steer unintentionally

when depress one side brake pedal only. Tractor

may fall down from loading bridge and may cause

injury.

4) Never stand against loading bridge. Be away from

loading work.

WARNING

1) Loading bridge must be of sufficient size, st rength and

with anti-slip surface. Length of the loading bridge

must be longer than 4-time of floor deck height. Fix

loading bridge with floor deck of truck.

2) Reverse tractor for loading into truck, go forward for

unloading. Shift gear to slow speed.

3) Tie tractor firmly to truck with a rope of sufficient

strength.

(1) Loading truck preparation

Park the truck on a flat and leveled place where is wide

enough and no traffic expected.

Stop truck engine and apply the parking brake.

Block wheels of the truck.

(2) Loading

Connect right and left brake pedals with the connector.

Shift gear levers to slow speed.

Slow down engine speed and reverse tractor to load.

Make sure tractor is aligned with loading bridge.

[If engine stops on loading bridge]

Depress brake pedal immediately and gradually release

brake pedal to go down slowly.

Start engine and load again.

(3) On the floor deck

Apply parking brake of tractor.

Stop tractor engine.

Lower rear hitched implement if any.

Tie tractor with truck

(4) Unloading

Untie tractor.

Start engine and shift gears to low speed.

Raise rear hitched implement if any.

Start tractor forward in slow speed. Do not steer.

(A) Brake pedal (B) Connector

Page 47

EF393T OM

41

12. Wheel tread

IMPORTANT

The tread of front and rear wheel is not adjustable.

Wheel tread

Tire Size

(ply rate) Wheel tread (mm)

Front 8-16 (4) 1,065

Rear 12.4-24 (6) 1,120

Rear wheel

(A) Wheel disc

(a) Wheel tread

Tightening torque of wheel disc mounting bult and nut

Tire N-m

Kgf-m

Front 118-147 12.5-15.0

Rear 177-196 18.0-20.0

Front wheel disc mounting bolt: M14x24 fine tread

Rear wheel disc monting bolt and nut

(a) Bolt M14x24 fine tread

(b) Stud bolt M14x31 fine trad, nut M14 fine tread

and lock washer M14

DANGER

Do not move the tractor if the wheel mounting bolts

or nuts are loose. If the tractor is driven with loose

nuts or bolts, there is a possibility that an accident

will occur.

Make daily and periodic wheel inspections to check

for loose nuts and bolts on the wheels. If they are

loose, retighten them to the specified torque.

Page 48

EF393T OM

42

13. Hydraulic power take off

Single action cylinder

In case of single action cylinder, remove the

hydraulic outlet plug (A) on right side of control valve,

and connect hydraulic hose from cylinder of

implement.

<Operation>

(1) Set the position control lever in the lower position.

(2) Fasten the hydraulic stop/slow return valve (B) at

fully clockwise position.

(3) Operate the position control lever to move the

implement.

(A) Hydraulic outlet (single action) (G3/8)

(B) Hydraulic stop/slow return valve

(C) Hydraulic outlet (double action, out) (G3/8)

(D) Hydraulic outlet (double action, in) (G3/8)

(E) High pressure pipe

(F) Relief valve

(G) Hydraulic control valve

Double action cylinder

<Connection>

(1) Remove operator’s seat.

(2) Remove the dust cover under the seat.

(3) Remove the high pressure pipe (E).

(4) Connect hydraulic hose to port (C) that the oil goes

to SCV and connect hose to port (D) that oil comes

back from SCV.

(5) Install the dust cover and the seat.

Keep the high pressure pipe for the time when

removing SCV.

14. Using 3-point hitch

3-point rear hitch type is Category 1.

T op link

Adjust length of top link (A) to implement. Loosen

lock nut turn turnbuckle on top link and adjust the

length.

Follow instructions of implements.

(A) Top link (BL) Lift link, Left

(BR) Lift link, Right (C) Check chain

(D) Lower link

Page 49

EF393T OM

43

Lift link and lower link

Set lower link hole and lift link hole according to

implement and work.

Lower link hitch point height

Lower link

Lift link

hole (a)

Lift link

hole (b)

Lift link

hole (c)

hole

Hitch

point

height

(1)

X

270 212

162

Y

857 817

785

(2)

X 453 403 338

Y 848 818 785

(mm)

X: Minimum height of lower link hitch point

Y: Maximum height of lower ling hitch point

Heights would vary according to tire air pressure, lift

arm free play and/or field condition etc.

(A) Lower link (B) Lift link

(C) Lift arm (D) Ground

Check chain

Check chain adjustment.

(1) For implements such as a plough, harrow and su bsoil

plow, adjust check chains so as an imple ment could

be swung about 5 cm. Make sure that lower ling

does not hit tire.

(2) For implements such as a rotary tiller and mower,

adjust check chains so that an implement can move

1cm to right and left.

IMPORTANT

When an implement is not attached to tractor, tie lower

links to avoid from hitting rear tire while driving.

(C) Check chain

(E)

Page 50

EF393T OM

44

15. Drawbar hitch

Use Drawbar when towing a trailer.

IMPORTANT

Remove the drawbar if the drawbar interferes with an

implement. When attaching a PTO driven implement, PTO

drive shaft may interfere with the drawbar and it may cause

breakage of related parts.

(A) Drawbar

16. General precautions on attaching and detaching an

implement

WARNING

1) When moving the tractor to attach an implement, never

allow a person between the tractor and the implement.

Always keep the moving speed in the lowest.

2) Attach or detach an implement on a flat and leveled

ground in a safe way. Use lights during nighttime work.

3) When leaving the tractor for attaching or detaching an

implement, never fail to set the parking brake and stop the

engine.

4) Be sure to use the tractor’s original drawbar hitch for

towing work.

5) Attaching an implement results in a considerable longer

overall length. Pay attention to bystanders or

constructions nearby when driving tractor.

6) Never place objects on the tractor or try to use your own

body as counterbalance the tractor. Use only authorized

genuine balance weight or implement.

7) Maximum counter weight on front bracket and rear wheel

is;

Front bracket: 150 kgs

Rear wheel weight: 100kgs for each wheel

8) Add the front weight so that the weight of the front axle

may always become 20% or more of the total weight.

9) Install a cover on PTO shaft when it is not used.

Otherwise, it may cause injury.

10) For safe and correct operations, read the instruction

manual for an implement.

Negligence of safety precautions causes a serious injury

or death.

Page 51

EF393T OM

45

17. Power steering

This tractor is equipped with hydrostatic powered steering

system.

The hydraulic power assists steering works only when the

engine is running. The steering wheel may become a

little heavier at low engine speeds

WARNING

Whenever the engine is running, steering wheel turns with

light force. Avoid from abrupt steering or it may cause

uncontrollable steering and may cause accident or injury.

IMPORTANT

1) When the steering wheel is turned to its end, the relief

valve works and chirp sound comes out. If relief valve

works in a short time, it is not a problem but long time

work of valve may cause trouble in the hydraulic

system.

2) When tractor dose not run, do not turn steering wheel

as much as possible. It may cause damage on tires

or rims.

18. Safety frame (ROPS)

The safety frame is designed to protect the driver from

an accident. Never fail to use the safety frame when

the tractor is in use.

WARNING

Always fasten the seat belt while operating the tractor

with Roll-over Protective Structure up.

Do not use the seat belt if the foldable Roll-over

Protective Structure (ROPS) is in the folded position or

the tractor does not have the ROPS.

Do not modify the safety frame. Safety factor can be

lost.

Damaged frame should be replaced as a complete set.

Partial repair may lead loss of safety level.

19. Tightening torque of bolts and nuts

Bolts and nuts being used on this tractor are of grade “7T”

unless otherwise grade is not specified in this manual.

Tighten torques show on right table.

Bolt size Grade 7T

(mm) (N-m) (kgf-m)

M6 8 - 12 0.8 - 1.2

M8 23 - 30 2.3 - 3.0

M10 44 - 59 4.5 - 6.0

M12 78 - 98 8.0 - 10.0

M14 1 18 - 147 12.0 - 15.0

M16 167 - 206 17.0 - 21.0

M18 235 - 284 24.0 - 29.0

M20 323 - 402 33.0 - 41.0

Page 52

EF393T OM

46

OPENING BONNET

Bonnet

Opening

(1) Pull up the bonnet lever (A) to release the bonnet

lock.

(2) Lift the bonnet. The damper (B) keeps the bonnet

open.

(A) Bonnet lever

Closing

(1) Push down the bonnet.

(2) Make sure the bonnet is locked securely after

closing the bonnet.

(B) Bonnet damper

Page 53

EF393T OM

47

AFTER OPERATION

1. After operation

Clean thoroughly the tractor after daily operation to keep it in

good condition for a long time. In particular, clean lower and

front areas before storing it.

Wash the tractor with water and wipe off. Lubricate moving

parts and sliding parts. Apply grease to all grease nipples

especially after working in wet field.

IMPORTANT

Do not splash or

spray water on electrical parts. Water can

cause a trouble in the electrical system.

2. Care for long period of storage

WARNING

When tractor is stored for a long time, remove the battery and

main key. Deterioration of electric wire or rat biting may

cause electric leakage and may start a fire.

When storing for a long time, take following procedures.

(1) Turn off all switches and remove the main switch key.

(2) Place the tractor in a well ventilated place and remove

counterbalance weights or other implements.

(3) Coat exposed metallic parts with anti-rusting oils, engine

oils or greases.

(4) Fill up the fuel tank with fuel. Otherwise, moisture will

develop in the tank and cause rust. Close cock of water

separator and fuel filter.

(5) Charge the battery fully. Remove the battery from the

tractor and keep it in a dark and cool place. If the battery

is kept on the tractor, be sure to disconn ect the ground line

(negative lead).

(6) Drain coolant from the engine.

Move the hose clip and pull out the drain plug.

IMPORTANT

The battery is subject to self-discharge.

Charge it fully at least once a month.

(A) Coolant drain plug

(B) Hose clip

Page 54

EF393T OM

48

(7) Put blocks or stands under tractor to take weight off

tires. Protect tires from heat and sunlight.

(8) Inflate the front and rear tires with air to the normal

pressure.

Size, (ply number) kg/cm

2

(kPa)

Front tire 8-16, (4) 1.6 (157)

Rear tire 12.4-24, (6) 1.6 (157)

Page 55

EF393T OM

49

PERIODICAL SERVICE

WARNING

1) Stop the engine before servicing.

2) Service tractor on a flat and leveled place, free from normal traffic and bystanders.

3) Fix the tractor wheels not to move.

CAUTION

Check periodically fuel lines and power steering hoses for damages, wearing a nd loose connections. If

there is damage, wearing or loose, be sure to see your dealer. Otherwise an accident or injury can result.

Periodic inspection and maintenance in off-season will ensure the preferable conditions of your tractor. To

keep your tractor working in good conditions, ask your service dealer for a regular inspection.

It is recommended to replace fuel pipes, rubber hoses, and electrical wires every two years at least.

1. Check intervals

O: Replace x: Checks required

CHECK ITEMS 50 h 100h 150h 200h 250h 300h 350h 400h 450h 500h 550h 600h

Engine lubrication oil

O O O O O O O

Transmission oil

O x x x x O x x x x x O

Front axle oil

O x x x x O x x x x x O

Engine oil element

O O O

Radiator interior

Clean the interior of radiator when replacing cooling water

Water separator

element

Clean Clean Clean Clean Clean Clean Clean Clean Clean Clean Clean Clean

Fuel filter

O O

Cooling water

(Replace)

Check before every work (Replacing every year)

Transmission oil filter

O O O

Air cleaner element

x x x x x O x x x x x O

Clean dust net

x x x x x x x x x x x x

Clean cooling fan, radiator

x x x x x x x x x x x x

Battery liquid level Check before every work

Battery liquid gravity

x x x x x x

Fuel piping, connections

x x x x x x x x x x x x

Rubber hoses

(Power steering)

x x x x x x x x x x x x

Radiator hoses Replace hoses every two years

Hydraulic rubber hoses Replace hoses every two years

Fuel pipe, electric wires Replace pipes and wires every two years

Electric wiring,

connections

x x x x x x x x x x x x

Grease-up

x x x x x x x x x x x x

Fastening of steering

wheel fix nut

x x x x x x

Important nuts and

bolts

x x x x x x x

Cooling fan belt

x x x x x x x

Engine breather pipe

x x x x x x x x x x x x

Engine crank case

x

Clearance of exhaust

valve

x

Fuel injection valve

x

Alternator, start motor

x x x x

Hydraulic system

x x x x

Fixing bolts of tires

x x x x x x x

Check at the first 50 operating hours or after first one-year operation.

Page 56

EF393T OM

50

2. Oil and grease

Oil, Grease Type

Fuel oil Diesel fuel only

Engine oil API grade CD or better grade, 15W40

Transmission and

Hydraulic system oil

Yanmar TF-500 T ransmission fluid or equivalent

Front axle Gear oil SAE #90

Grease Multipurpose grade

3. Capacity of oil and water

(Unit: liters)

Fuel oil 38

Cooling Radiator 4.3

water Sub-tank 0.45

Engine oil 3.8

Transmission and

hydraulic system oil

28

Front axle oil 5.5

Power steering oil Common uses of transmission oil

All capacities are approximate.

4. Equivalent oil to transmission fluid TF500

Supplier Brand name

Mobil Mobil Fluid 425

Castrol Agricastrol MP

John Deere J14A, J20B

ESSO Torque Fluid 56

Shell Shell Tellus Oil 32 or 37

*Oil must not be mixed with other brand.

Page 57

EF393T OM

51

5. Fuel system

5-1. Fuel and refill

Use diesel fuel only.

DANGER

1) Never smoke or use a bare lamp/light during filling fuel.

2) After filling fuel, be sure to put the fuel tank cap back firmly.

Clean off spilled fuel.

3) Fill fuel after the engine stops and becomes cool. A fire may

result from heating.

IMPORTANT

1) Fill fuel tank at end of each day’s operation. This reduces

deposit of water in fuel tank.

2) Proper fuel storage is important. Keep all dirt, water, and

other contaminants out of fuel. Avoid from storing fuel for

long time.

Turn the key switch to ON position to check fuel amount in the

tank. Fuel gauge shows amount that fuel remained in the tank.

Refill fuel as required.

(A) Fuel gauge

(A) Fuel tank cap

5-2. Drain and cleaning of water separator

Water separator remov es water in fuel. When water is deposited

in the bowl of the separator, drain it.

(A) Water separator

(B) Fuel cock

(C) Strainer

(D) Drain cock

(E) Retaining ring

(a) Open (b) Close

(A) Water separator

(1) Turn the fuel cock to close position.

(2) Loosen the drain cock on the bottom of the water separator

and drain water. Do not remove drain cock.

(3) If water is dirty, loosen retaining ring and remove the bowl.

Clean inside of bowl and strainer .

(4) Tighten drain cock or reinstall the removed bowl, strainer to

the original position.

(5) Open fuel cock and see water separator is filled up with fuel.

Crank engine for about 5 – 10 seconds to bleed the air from

the fuel and start engine.

IMPORTANT

The water separator strainer is not required to replace regularly

unless it is damaged.

Page 58

EF393T OM

52

5-3. Replacing fuel filter (cartridge type)

Be sure to replace the fuel filter (cartridge type) regularly.

Replace

Every 300 hours

(1) Apply lubricating oil to the rubber rin g of fuel filter.

(2) Install it surely.

IMPORTANT

Be sure to use a genuine filter.

The allowance of plunger and the barrel in fuel injection pump

is very severe. If the filtering efficiency is low , it may cause a

trouble in fuel injection pump, such hard starting.

(B) Fuel filter

5-4. Bleeding fuel lines of air

If the engine stops due to lack of fuel or if the fuel strainer

element or fuel piping has ever been detached for

maintenance purpose, bleed air by the following procedure:

(1) Fill up fuel tank if engine stop by short of fuel.

(2) Turn the fuel cock to the "O" position (Open), and wait for

approximately ten seconds.

(3) See the bowl of water separator is filled with fuel and fuel

cock is open.

(4) Pull accelerator lever forward to the maximum speed

position.

(5) Turn the main switch in the start position and run the

starter motor for 5 - 10 seconds.

(6) If the engine did not start, run the starter motor again.

When the engine starts, air bleeding is finished.

IMPORTANT

Never run the starter motor more than 10 seconds. It may

cause breakage of starter motor. If you cannot start engine

within 10 seconds, restart engine after 2-5 minutes.

(A) Water separator (B)Fuel cock

(A) Accelerator lever

(F) Increase speed (higher speed)

Page 59

EF393T OM

53

6. Oil and filter

6-1. Engine oil and filter

DANGER

Never refill or add oil while the engine is hot or running. A

fire may occur or you may be burnt.

Check oil level

Pull out the oil gauge (A) and wipe off oil with a clean cloth.

Reinsert and remove it again to see if the oil level is within

the upper and lower marks.

If insufficient, add oil to reach to specified level zone (c).

Never add oil more than upper limit. It may cause more oil

consumption and carbon deposit in combustion system.

IMPORTANT

1) Park the tractor on a level place, apply parking brake and

stop engine to check oil level. If the tractor is on an

inclined place, oil level is not correct.

2) Check the oil level before engine starts or engine is cool.

Never check oil level immediately after engine stops.

Wait for at least 20 minutes.

3) Never dispose of oil in rivers, field or place that

contaminates nature. Have the oil handled by

professionals.

(A) Dipstick (B) Oil supply port

(A) Dipstick

(a) Upper limit (b) Lower limit

(c) Specified level zone

Replacing oil

Remove drain plug on the bottom of engine crankcase.

Refill new oil through the oil supply port. Select a proper

type of engine oil and replace it periodically.

Capacity Type

3.8 lit. CD or better grade, 15W40

Replace

First 50hrs and every 100 hrs.

(D) Drain plug

Engine oil filter

Replace

First 50hrs and every 300 hrs or every 2-3 times

of replacing engine oil, which comes earlier.

Replacing engine oil filter

(1) Drain engine oil.

(2) Turn engine oil filter an ticlockwise with a filter wrench.

(3) Apply a little engine oil on the rubber ring on the bottom

of the new filter and install it.

(4) Refill engine oil and run the engine until engine oil

pressure indicator lamp turns off.

(5) Stop engine and wait for about 20 minutes or more to

check the oil level. Add oil if necessary.

(C) Engine oil filter

Page 60

EF393T OM

54

6-2. Transmission-hydraulic oil and filter

The transmission oil functions as lubricant of

transmission gears, brake discs and hydraulic system

oil as well. The transmission oil quality and filter is

very important to keep good condition of transmission

and hydraulic system.

Check oil level