Yanmar 3JH4E, 4JH4E, 4JH4-TE, 4JH4-HTE Service Manual

Publication No. 0BJH4-G00101

History of Revision

Manual Name Service Manual for Marine Diesel Engine

Engine Model: 3JH4E / 4JH4E / 4JH4-TE / 4JH4-HTE

Number

of

revision

New edition February 2004

R1 Jan.

Date of

revision

Aug.

2006

2007

Reason for

correction

Adding

4JH4-TE /

4JH4-HTE.

Outline of correction

• 4JH4-TE and 4JH4-HTE added.

• Manual code "M9961-03E091"

was changed to "0BJH4-G00100".

• 3 / 4JH4E alternator standard. Page 4, 5, 304,

• Correction the procedure of

measurement and adjustment of

intake and exhaust valves.

Correction item

No (page)

308.

Page 63 - 67. YMI Business

Corrected by

Marine Business

Development

Dept.

Development

Department

Printed in Japan

FOREWORD

This service manual has been compiled for engineers engaged in sales, service, inspection and

maintenance. Accordingly, descriptions of the construction and functions of the engine are emphasized

in this manual, while items, which should already be common knowledge, are omitted.

One characteristic of a marine diesel engine is that its performance in a vessel is governed by the

applicability of the vessel's hull construction and its steering system.

Engine installation, fitting out and propeller selection have a substantial effect on the performance of the

engine and the vessel. Moreover, when the engine runs unevenly or when trouble occurs, it is essential

to check a wide range of operating conditions - such as installation to the full and suitability of the ship's

piping and propeller - and not just the engine itself. To get maximum performance from this engine, you

should completely understand its functions, construction and capabilities, as well as proper use and

servicing.

Use this manual as a handy reference in daily inspection and maintenance, and as a text for engineering

guidance.

Model 3JH4E and 4JH4-TE have been used for the illustrations in this service manual, but they apply to

other models in the JH4 series engines.

California

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth defects, and other reproductive harm.

(only for 3JH4E)

California

Proposition 65 Warning

Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm.

Wash hands, after handling.

(only for 3JH4E)

©2006 YANMAR CO., LTD

All rights reserved. This manual may not be

reproduced or copied, in whole or in part,

without the written permission of YANMAR

CO., LTD.

CONTENTS

1. General ............................................................................................................................ 1

1.1 Exterior views ......................................................................................................... 1

1.2 Specifications ..........................................................................................................4

1.3 Fuel oil, lubricating oil and coolant ........................................................................ 10

1.3.1 Fuel oil....................................................................................................... 10

1.3.2 Lubricating oil ............................................................................................ 12

1.3.3 Coolant...................................................................................................... 13

1.4 Engine outline ....................................................................................................... 14

1.5 Piping diagrams .................................................................................................... 33

1.6 Exhaust Gas Emission Regulation in U.S.A. only ................................................. 46

1.6.1 Engines under 37kw: 3JH4E..................................................................... 46

1.6.2 Engines of 37kW or more: 4JH4-TE and 4JH4-HTE................................. 49

2. Inspection and adjustment .............................................................................................52

2.1 Periodic maintenance schedule ............................................................................ 52

2.2 Periodic inspection and maintenance procedure .................................................. 54

2.2.1 Check before starting ................................................................................ 54

2.2.2 Inspection after initial 50 hours or one month operation ........................... 60

2.2.3 Inspection every 50 hours or monthly ....................................................... 69

2.2.4 Inspection every 250 hours or one year.................................................... 74

2.2.5 Inspection every two years........................................................................ 84

2.2.6 Inspection every 1,000 hours or four years............................................... 84

2.3 Adjusting the no-load maximum or minimum speed ............................................. 94

2.4 Sensor inspection ................................................................................................. 95

2.4.1 Oil pressure switch.................................................................................... 95

2.4.2 Thermo switch........................................................................................... 95

2.5 Thermostat inspection ..........................................................................................96

2.6 Adjusting operation ............................................................................................... 97

2.6.1 Preliminary precautions............................................................................. 97

2.6.2 Adjusting operation procedure .................................................................. 97

2.6.3 Check points and precautions during running........................................... 98

2.7 Long storage .........................................................................................................99

3. Troubleshooting ...........................................................................................................100

3.1 Preparation before troubleshooting ....................................................................100

3.2 Quick reference chart for troubleshooting ........................................................... 101

3.3 Troubleshooting (Concerning engine and fuel injection equipment) ................... 117

3.4 Troubleshooting by measuring compression pressure ....................................... 120

4. Disassembly and reassembly ......................................................................................122

4.1 Disassembly and reassembly precautions ......................................................... 122

4.2 Disassembly and reassembly tools .................................................................... 123

4.2.1 General hand tools.................................................................................. 123

4.2.2 Special hand tools................................................................................... 125

4.2.3 Measuring instruments............................................................................ 131

4.2.4 Other material ......................................................................................... 136

4.3 Disassembly and reassembly ............................................................................. 138

4.3.1 Disassembly............................................................................................ 138

4.3.2 Reassembly ............................................................................................ 156

5. Inspection and servicing of basic engine parts ............................................................175

5.1 Cylinder block ..................................................................................................... 175

5.1.1 Inspection of parts................................................................................... 175

5.1.2 Cleaning of oil holes................................................................................ 175

5.1.3 Color check procedure ............................................................................ 176

5.1.4 Replacement of cup plugs....................................................................... 177

5.1.5 Cylinder bore measurement.................................................................... 178

5.2 Cylinder head ......................................................................................................179

5.2.1 Inspecting the cylinder head ................................................................... 181

5.2.2 Valve seat correction procedure ............................................................. 182

5.2.3 Intake/exhaust valves, valve guides........................................................ 184

5.2.4 Valve springs........................................................................................... 188

5.2.5 Assembling the cylinder head ................................................................. 190

5.2.6 Measuring top clearance......................................................................... 191

5.2.7 Intake and exhaust rocker arms.............................................................. 192

5.2.8 Adjustment of valve clearance ................................................................ 193

5.3 Piston and piston pins .........................................................................................194

5.3.1 Piston ...................................................................................................... 195

5.3.2 Piston pin ................................................................................................ 196

5.3.3 Piston rings ............................................................................................. 197

5.4 Connecting rod ...................................................................................................200

5.4.1 Inspecting the connection rod ................................................................. 201

5.4.2 Crank pin metal ....................................................................................... 202

5.4.3 Piston pin bushing................................................................................... 204

5.5 Crankshaft and main bearing ..............................................................................205

5.5.1 Crankshaft............................................................................................... 205

5.5.2 Main bearing ........................................................................................... 208

5.6 Camshaft and tappets .........................................................................................209

5.6.1 Camshaft................................................................................................. 209

5.6.2 Tappets ................................................................................................... 211

5.7 Timing gear ......................................................................................................... 212

5.7.1 Inspecting the gears................................................................................ 212

5.7.2 Gear timing marks................................................................................... 212

5.8 Flywheel and housing .........................................................................................213

5.8.1 Position of top dead center and fuel injection timing............................... 214

5.8.2 Damper disc ............................................................................................ 214

6. Fuel Injection equipment .............................................................................................215

6.1 Fuel Injection pump/governor for 3JH4E and 4JH4E ......................................... 215

6.1.1 Fuel system diagram............................................................................... 215

6.1.2 Fuel injection pump service data............................................................. 216

6.1.3 Fuel injection pump structure .................................................................. 219

6.1.4 Removing a fuel injection pump .............................................................. 220

6.1.5 Installing a fuel injection pump ................................................................ 221

6.1.6 Adjusting fuel injection timing.................................................................. 221

6.1.7 Troubleshooting of fuel injection pump ................................................... 221

6.1.8 Tools ....................................................................................................... 222

6.2 Fuel feed pump ...................................................................................................224

6.2.1 Construction of fuel feed pump ............................................................... 224

6.2.2 Fuel feed pump specifications................................................................. 224

6.2.3 Disassembly and reassembly of fuel feed pump..................................... 225

6.2.4 Fuel feed pump inspection ...................................................................... 226

6.3 Fuel injection pump/ governor for 4JH4-TE and 4JH4-HTE ............................... 227

6.3.1 Fuel system diagram............................................................................... 227

6.3.2 Fuel injection pump structure .................................................................. 228

6.3.3 Fuel injection pump service data............................................................. 233

6.3.4 Removing a fuel injection pump .............................................................. 234

6.3.5 Installing a fuel injection pump ................................................................ 235

6.3.6 Adjusting fuel injection timing.................................................................. 235

6.3.7 Troubleshooting of fuel injection pump ................................................... 236

6.4 Fuel injection nozzle ........................................................................................... 237

6.5 Fuel Filter ............................................................................................................239

6.5.1 Fuel filter for 3JH4E and 4JH4E.............................................................. 239

6.5.2 Fuel filter for 4JH4-TE and 4JH4-HTE .................................................... 240

6.6 Fuel tank ............................................................................................................. 241

7. Intake and exhaust system .......................................................................................... 242

7.1 Intake system ......................................................................................................242

7.1.1 3JH4E and 4JH4E................................................................................... 242

7.1.2 4JH4-TE .................................................................................................. 242

7.1.3 4JH4-HTE ............................................................................................... 242

7.1.4 Breather system (A reductor to intake air system of blowby gas) ........... 243

7.1.5 Diaphragm assy inspection (only for 3JH4E and 4JH4E) ....................... 244

7.2 Exhaust system ..................................................................................................245

7.2.1 Exhaust system for 3JH4E and 4JH4E ................................................... 245

7.2.2 Exhaust system for 4JH4-TE and 4JH4-HTE.......................................... 246

7.2.3 Mixing elbow inspection .......................................................................... 246

7.3 Turbocharger ......................................................................................................247

8. Lubrication system .......................................................................................................252

8.1 Lubrication system ..............................................................................................252

8.2 Lube oil pump ..................................................................................................... 253

8.2.1 Lube oil pump construction ..................................................................... 253

8.2.2 Specifications of lube oil pump................................................................ 253

8.2.3 Lube oil pump disassembly and reassembly .......................................... 254

8.2.4 Lube oil pump inspection ........................................................................ 255

8.2.5 Oil pressure control valve construction ................................................... 256

8.3 Lube oil filter .......................................................................................................257

8.3.1 Lube oil filter construction ....................................................................... 257

8.3.2 Lube oil filter replacement ....................................................................... 257

8.4 Lube oil cooler ....................................................................................................258

8.4.1 Lube oil cooler construction .................................................................... 258

8.4.2 Inspecting the lube oil cooler................................................................... 258

8.5 Piston cooling oil nozzle ..................................................................................... 259

8.6 Rotary waste oil pump (Optional) ....................................................................... 260

9. Coolant system ............................................................................................................261

9.1 Coolant system ................................................................................................... 261

9.2 Seawater pump ...................................................................................................263

9.2.1 Specifications of seawater pump ............................................................ 264

9.2.2 Seawater pump disassembly .................................................................. 265

9.2.3 Seawater pump Inspection...................................................................... 265

9.2.4 Seawater pump reassembly.................................................................... 266

9.3 Fresh water pump ............................................................................................... 267

9.3.1 Fresh water pump construction............................................................... 267

9.3.2 Specifications of fresh water pump ......................................................... 268

9.3.3 Fresh water pump disassembly .............................................................. 268

9.3.4 Fresh water pump inspection .................................................................. 269

9.4 Heat exchanger ..................................................................................................271

9.4.1 Heat exchanger construction .................................................................. 271

9.4.2 Specifications of heat exchanger ............................................................ 271

9.4.3 Disassembly and reassembly of the heat exchanger.............................. 271

9.4.4 Heat exchanger inspection...................................................................... 272

9.5 Pressure cap and coolant recovery tank ............................................................ 273

9.5.1 Pressure cap construction....................................................................... 273

9.5.2 Pressure cap pressure control ................................................................ 273

9.5.3 Pressure cap inspection.......................................................................... 273

9.5.4 Replacing filler neck ................................................................................ 274

9.5.5 Function of the coolant recovery tank ..................................................... 275

9.5.6 Specifications of coolant recovery tank................................................... 275

9.5.7 Mounting the coolant recovery tank ........................................................ 276

9.5.8 Precautions on usage of the coolant recovery tank ................................ 276

9.6 Thermostat ..........................................................................................................277

9.6.1 Functioning of thermostat........................................................................ 277

9.6.2 Thermostat construction.......................................................................... 277

9.6.3 Characteristics of thermostat .................................................................. 277

9.6.4 Thermostat inspection............................................................................. 277

9.6.5 Testing the thermostat ............................................................................ 277

9.7 Bilge pump and bilge strainer (Optional) ............................................................ 278

9.7.1 Introduction ............................................................................................. 278

9.7.2 Description .............................................................................................. 279

9.7.3 Cautions .................................................................................................. 280

9.7.4 Assembly procedure ............................................................................... 281

9.7.5 Cautions for assembling.......................................................................... 283

9.7.6 Troubleshooting ...................................................................................... 285

10. Reduction and reversing gear ...................................................................................286

10.1 Specifications of 3JH4E marine gears .............................................................. 286

10.2 Specifications of 4JH4E and marine gears ....................................................... 287

10.3 Specifications of 4JH4-TE and 4JH4-HTE marine gears .................................. 288

11. Remote control system (Optional) ............................................................................. 290

11.1 Remote control system ..................................................................................... 290

11.1.1 Construction of remote control system.................................................. 290

11.1.2 Remote control device components...................................................... 290

11.2 Remote control installation ...............................................................................292

11.3 Remote control inspection ................................................................................ 295

11.4 Remote control adjustment ...............................................................................296

12. Electrical system ........................................................................................................297

12.1 Electrical system ...............................................................................................297

12.1.1 Wiring diagram ...................................................................................... 298

12.2 Battery .............................................................................................................. 300

12.3 Starting motor ...................................................................................................301

12.3.1 Specifications ........................................................................................ 301

12.3.2 Characteristics ...................................................................................... 301

12.3.3 Structure................................................................................................ 302

12.3.4 Wiring diameter of a starting motor ....................................................... 303

12.4 Alternator 12V/60A (Optional) ...........................................................................304

12.4.1 Specifications ........................................................................................ 304

12.4.2 Structure................................................................................................ 305

12.4.3 Wiring diagram ...................................................................................... 306

12.4.4 Standard output characteristics............................................................. 306

12.4.5 Inspection.............................................................................................. 307

12.5 Alternator 12V/80A (Standard) .........................................................................308

12.5.1 Specifications ........................................................................................ 308

12.5.2 Structure................................................................................................ 309

12.5.3 Wiring diagram ...................................................................................... 310

12.5.4 Standard output characteristics............................................................. 310

12.6 Instrument panel ............................................................................................... 311

12.6.1 B-type instrument panel (Selectable optional) ...................................... 311

12.6.2 C-type instrument panel (Selectable optional) ...................................... 311

12.7 Warning devices ...............................................................................................312

12.7.1 Oil pressure alarm................................................................................. 312

12.7.2 Sender unit for lube oil pressure gauge ................................................ 313

12.7.3 Coolant temperature alarm ................................................................... 314

12.7.4 Sender unit for the coolant temperature gauge..................................... 314

12.8 Air heater (Optional) .........................................................................................315

12.9 Electric engine stopping device ........................................................................316

13. Service standards ...................................................................................................... 317

13.1 Engine tuning .................................................................................................... 317

13.2 Engine body ...................................................................................................... 319

13.2.1 Cylinder head ........................................................................................ 319

13.2.2 Camshaft and gear train........................................................................ 321

13.2.3 Cylinder block........................................................................................ 322

13.3 Lubricating oil system (Trochoid pump) ............................................................ 326

14. Tightening torque for bolts and nuts ..........................................................................327

14.1 Main bolt and nut .............................................................................................. 327

14.2 Standard bolts and nuts (without lube oil) .........................................................327

FOR SAFETY

1. SAFETY LABELS

• Most accidents are caused by negligence of basic safety rules and precautions. For accident

prevention, it is important to avoid such causes before development to accidents.

Please read this manual carefully before starting repair or maintenance to fully understand safety

precautions and appropriate inspection and maintenance procedures.

Attempting at a repair or maintenance job without sufficient knowledge may cause an unexpected

accident.

• It is impossible to cover every possible danger in repair or maintenance in the manual. Sufficient

consideration for safety is required in addition to the matters marked . Especially for

safety precautions in a repair or maintenance job not described in this manual, receive instructions

from a knowledgeable leader.

• Safety marks used in this manual and their meanings are as follows:

DANGER-indicates an imminent hazardous situation which, if

not avoided, WILL result in death or serious injury.

WARNING-indicates a potentially hazardous situation which, if

not avoided, COULD result in death or serious injury.

CAUTION-indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

• NOTICE - indicates that if not observed, the product performance or quality may not be

guaranteed.

2. Safety Precautions

(1) SERVICE AREA

• Sufficient Ventilation

Inhalation of exhaust fumes and dust particles may be hazardous to ones

health. Running engines welding, sanding, painting, and polishing tasks

should be only done in well ventilated areas.

• Safe / Adequate Work Area

The service area should be clean, spacious, level and free from holes in

the floor, to prevent "slip" or "trip and fall" type accidents.

• Clean, orderly arranged place

No dust, mud, oil or parts should be left on the floor surface.

[Failure to Observe]

An unexpected accident may be caused.

• Bright, Safely Illuminated Area

The work area should be well lit or illuminated in a safe manner. For work

in enclosed or dark areas, a "drop cord" should be utilized. The drop cord

must have a wire cage to prevent bulb breakage and possible ignition of

flammable substances.

• Safety Equipment

Fire extinguisher(s), first aid kit and eye wash / shower station should be

close at hand (or easily accessible) in case of an emergency.

(2) WORK - WEAR (GARMENTS)

• Safe Work Clothing

Appropriate safety wear (gloves, special shoes / boots, eye / ear

protection, head gear, harness', clothing, etc.) should be used / worn to

match the task at hand. Avoid wearing jewelry, unbuttoned cuffs, ties or

Well fitting !!

loose fitting clothes around moving machinery. A serious accident may

occur if caught in moving / rotating machinery.

(3) TOOLS

• Appropriate Lifting / Holding

When lifting an engine, use only a lifting device (crane, jack, etc.) with

sufficient lifting capacity. Do not overload the device. Use only a chain,

cable, or lifting strap as an attaching device. Do not use rope, serious

injury may result.

To hold or support an engine, secure the engine to a support stand, test

bed or test cart designed to carry the weight of the engine. Do not

overload this device, serious injury may result.

Never run an engine without being properly secured to an engine support

stand, test bed or test cart, serious injury may result.

• Appropriate Tools

Always use tools that are designed for the task at hand. Incorrect usage

of tools may result in damage to the engine and or serious personal injury.

(4) GENUINE PARTS and MATERIALS

• Genuine Parts

Always use genuine YANMAR parts or YANMAR recommended parts and

goods. Damage to the engine, shortened engine life and or personal

injury may result.

(5) FASTENER TORQUE

• Torquing Fasteners

Always follow the torque values and procedures as designated in the

service manual. Incorrect values, procedures and or tools may cause

damage to the engine and or personal injury.

(6) Electrical

• Short Circuits

Always disconnect the (-) Negative battery cable before working on the

electrical system. An accidental "short circuit" may cause damage, fire

and or personal injury. Remember to connect the (-) Negative battery

cable (back onto the battery) LAST

• Charging Batteries

Charging wet celled batteries produces hydrogen gas. Hydrogen gas is

extremely explosive. Keep sparks, open flame and any other form of

ignition away. Explosion may occur causing severe personal injury.

• Battery Electrolyte

Batteries contain sulfuric acid. Do NOT allow it to come in contact with

clothing, skin and or eyes, severe burns will result.

(7) WASTE MANAGEMENT

Observe the following instructions with regard to hazardous waste

disposal. Negligence of these will have a serious impact on environmental

pollution concerns.

1) Waste fluids such as lube oil, fuel and coolant shall be carefully put

into separate sealed containers and disposed of properly.

2) Do NOT dispose of waste materials irresponsibly by dumping them

into the sewer, overland or into natural waterways.

3) Waste materials such as oil, fuel, coolant, solvents, filter elements and

batteries, must be disposed of properly according to local ordinances.

Consult the local authorities or reclamation facility.

(8) FURTHER PRECAUTIONS

• Fueling / Refueling

Keep sparks, open flames or any other form of ignition (match, cigarette,

etc.) away when fueling / refueling the unit. Fire and or an explosion may

result.

• Hot Surfaces.

Do NOT touch the engine (or any of its components) during running or

shortly after shutting it down. Scalding / serious burns may result. Allow

the engine to cool down before attempting to approach the unit.

• Rotating Parts

Be careful around moving / rotating parts. Loose clothing, jewelry, ties or

tools may become entangled causing damage to the engine and or

severe personal injury.

• Preventing burns from scalding

1) Never open the filler cap shortly after shutting the engine down.

Steam and hot water will spurt out and seriously burn you. Allow the

engine to cool down before attempt to open the filler cap.

2) Securely tighten the filler cap after checking the coolant.

Steam can spurt out during engine running, if tightening loose.

• Safety Label Check

Pay attention to the product safety label.

A safety label (caution plate) is affixed on the product for calling special

attention to safety.If it is missing or illegible, always affix a new one.

3. Precautions for Service Work

(1) Precautions for Safety

Read the safety precautions given at the beginning of this manual carefully and always mind safety in

work.

(2) Preparation for Service Work

Preparation is necessary for accurate, efficient service work. Check the customer ledger file for the

history of the engine.

• Preceding service date

• Period / operation hours after preceding service

• Problems and actions in preceding service

• Replacement parts expected to be required for service

• Recording form / check sheet required for service

(3) Preparation before Disassembly

• Prepare general tools, special service tools, measuring instruments, oil, grease, non-reusable parts,

and parts expected to be required for replacement.

• When disassembling complicated portions, put match-marks and other marks at places not

adversely affecting the function for easy reassembly.

(4) Precautions in Disassembly

• Each time a parts is removed, check the part installed state, deformation, damage, roughening,

surface defect, etc.

• Arrange the removed parts orderly with clear distinction between those to be replaced and those to

be used again.

• Parts to be used again shall be washed and cleaned sufficiently.

• Select especially clean locations and use clean tools for disassembly of hydraulic units such as the

fuel injection pump.

(5) Precautions for Inspection and Measurement

Inspect and measure parts to be used again as required to determine whether they are reusable or not.

(6) Precautions for Reassembly

• Reassemble correct parts in correct order according to the specified standards (tightening torques,

and adjustment standards). Apply oil important bolts and nuts before tightening when specified.

• Always use genuine parts for replacement.

• Always use new oil seals, O-rings, packing and cotter pins.

• Apply sealant to packing depending on the place where they are used. Apply of grease to sliding

contact portions, and apply grease to oil seal lips.

(7) Precautions for Adjustment and Check

Use measuring instruments for adjustment to the specified service standards.

1. General

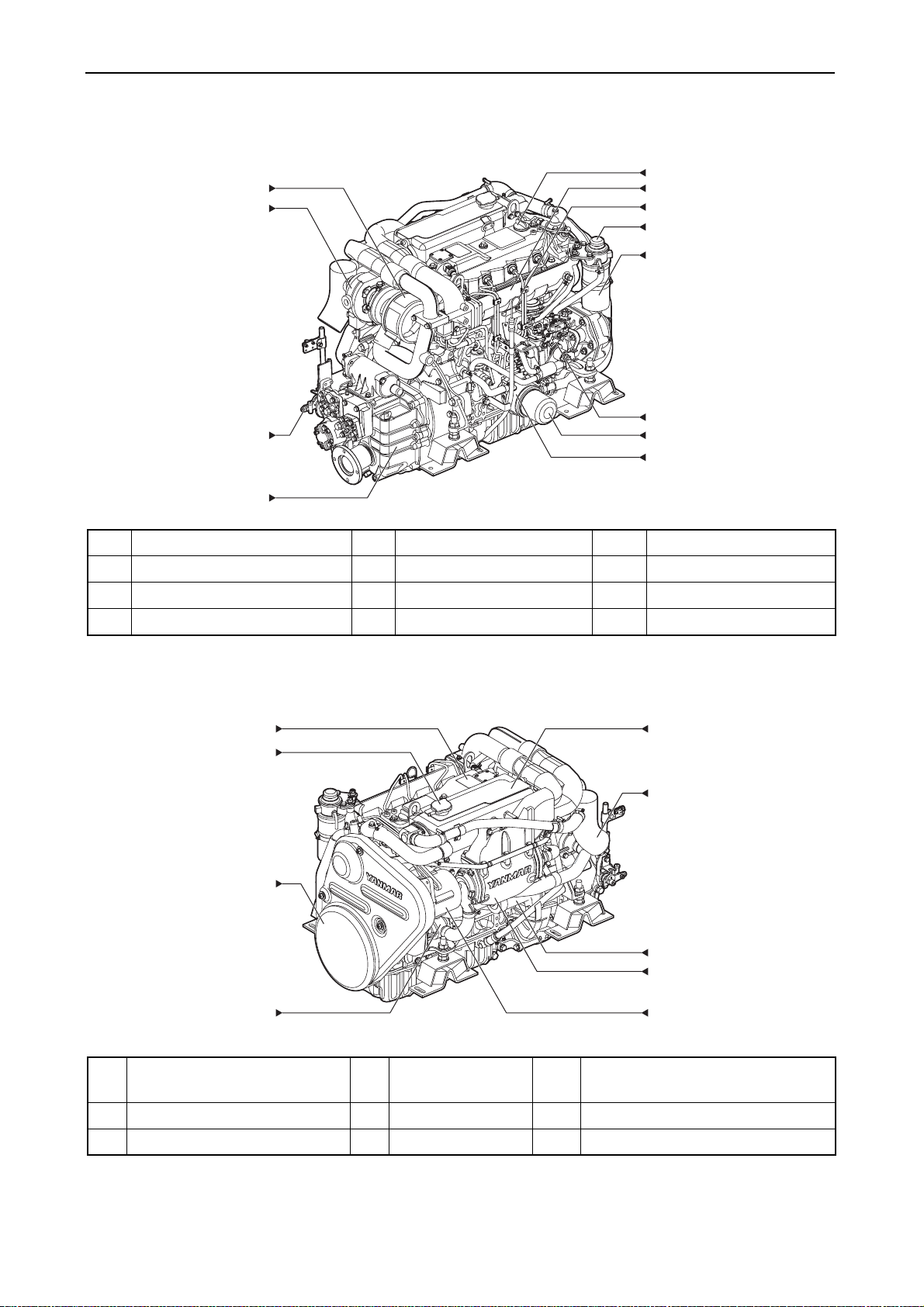

1.1 Exterior views

(1) 3JH4E

• Operation side

1. General

(1)

(2)

(3)

(1) Intake silencer (5) Lube oil filter (9) Fuel filter

(2) Shift lever (6) Fuel feed pump (10) Dipstick

(3) Marine gear (7) Oil filter cap (11) Intake manifold

(4) Oil cooler (8) Fuel injection pump

(11)

(10)

(9)

(8)

(7)

(6)

(5)

(4)

010297-01X

• Non operation side

(1)

(2)

(3)

(1) Coolant filler cap (4) Starter motor (7) Alternator

(2) Engine name plate

(on the rocker arm cover)

(3) Seawater pump (6) Exhaust manifold

(5) Exhaust mixing elbow (8) Coolant tank/Heat exchanger

(8)

(7)

(6)

(5)

(4)

010298-01X

<Note> This illustration shows the 3JH4E with Yanmar marine gear (Model:KM35P).

1

1. General

(2) 4JH4-TE

• Operation side

(1)

(2)

(3)

(12)

(11)

(10)

(9)

(8)

(7)

(6)

(5)

(4)

008831-01X

(1) Intake silencer (5) Lube oil cooler (9) Fuel priming pump

(2) Turbocharger (6) Lube oil filter (10) Dipstick

(3) Shift lever (7) Fuel injection pump (11) Intake manifold

(4) Marine gear (KMH4A) (8) Fuel filter (12) Oil filler cap

• Non operation side

(1)

(8)

(2)

(7)

(3)

(6)

(4)

(1) Engine name plate

(4) Seawater pump (7) Exhaust mixing elbow

(5)

008832-01X

(on the rocker arm cover)

(2) Coolant filler cap (5) Alternator (8) Coolant tank/Heat exchanger

(3) Belt cover (6) Starter motor

<Note> This illustration shows the 4JH4-TE with Yanmar marine gear (Model: KMH4A).

2

(3) 4JH4-HTE

• Operation side

(1)

(2)

(3)

1. General

(12)

(11)

(10)

(9)

(8)

(7)

(6)

(5)

(4)

008392-01X

(1) Intake silencer (5) Lube oil cooler (9) Fuel priming pump

(2) Turbocharger (6) Lube oil filter (10) Dipstick

(3) Shift lever (7) Fuel injection pump (11) Intake manifold

(4) Marine gear (KMH4A) (8) Fuel filter (12) Oil filler cap

• Non operation side

(1)

(9)

(2)

(8)

(3)

(7)

(6)

008393-01X

(5)

(1) Engine name plate

(4)

(4) Seawater pump (7) Starter motor

(on the rocker arm cover)

(2) Coolant filler cap (5) Alternator (8) Exhaust mixing elbow

(3) Belt cover (6) Intercooler (9) Coolant tank/Heat exchanger

<Note> This illustration shows the 4JH4-HTE with Yanmar marine gear (Model: KMH4A).

3

1. General

1.2 Specifications

(1) 3JH4E series (3JH4E, 3JH4BE, 3JH4CE, 3JH4ME)

Official engine model name unit 3JH4E

Company internal model name

Marine gear model - KM35P KM35A SD50 Bobtail

Use - Pleasure use

Type - Vertical water cooled 4 cycle diesel engine

Combustion system - Direct injection

Air charging - Naturally aspirated

Number of cylinders - 3

Bore x stroke mm(inch) 88 x 90 (3.46 x 3.54)

Displacement L 1 .642

Continuous

power

Fuel stop

power

Installation - Flexible mounting

Fuel injection timing

Fuel injection opening

pressure

Main power take off - At flywheel side

Direction of

rotation

Cooling system - Fresh water cooling with heat exchanger

Lubrication system - Complete enclosed forced lubrication

Coolant capacity (fresh)

Lubricating

oil capacity

(engine)

Starting

system

Engine

dimension

Flywheel major dimension mm(inch) Ø300 x 66 (11.8 x 2.6)

Engine dry mass

(include marine gear)

Output at

crankshaft /

Engine speed

Output at

crankshaft /

Engine speed

Output at

propeller shaft /

Engine speed

Crankshaft - Counter-clockwise viewed from stern

Propeller shaft

(Ahead)

Rake angle deg.

Total (Note 4)

Oil pan only

Effective (Note 5)

Type - Electric

Starting motor

AC generator V-A 12V-80A (12V-60A optional)

Overall length

Overall width 539 (21.2) 539 (21.2) 539 (21.2) 539 (21.2)

Overall height 623 (24.5) 623 (24.5) 623 (24.5) 623 (24.5)

- 3JH4E 3JH4BE 3JH4CE 3JH4ME

kW(HP)/min

kW(HP)/min

kW(HP)/min

deg b.T.D.C.

(kgf/cm

L(quart) Engine:4.5 (4.8), Coolant recovery tank : 0.8 (0.8)

L(quart)

mm(inch)

-1

-1

-1

MPa

2

)

- Clockwise viewed from stern - -

V-k W

kg 185 186

(at Fuel temp. 25°C)

(at Fuel temp. 40°C)

at rake angle 8 deg

5.0±0.3 (5.3±0.3) 5.5±0.3 (5.8±0.3) 5.5±0.3 (5.8±0.3) 5.5±0.3 (5.8±0.3)

4.5±0.3 (4.8±0.3) 5.0±0.3 (5.3±0.3) 5.0±0.3 (5.3±0.3) 5.0±0.3 (5.3±0.3)

1.1 (1.2) 1.2 (1.3) 1.2 (1.3) 1.2 (1.3)

777 (30.6) 776 (30.6) 700 (27.6) 700 (27.6)

29.4(40.0) / 3000 (at Fuel temp. 25°C)

28.7(39.0) / 3000 (at Fuel temp. 40°C)

28.0(38.1) / 3000

27.4(37.3) / 3000

26.7(36.3) / 2907

--

FID 12±1 (FIC-Air 13±1)

21.6±0.5 (220±5)

at rake angle 0 deg

DC 12V-1.4 kW

213

(engine:173)

173

(Note)

1. Rating condition: ISO 3046-1, ISO 8665

• Fuel temperature 25°C at the inlet of the fuel injection pump. (ISO 3046-1, 1995)

• Fuel temperature 40°C at the inlet of the fuel injection pump. (ISO 8665)

2. 1HP (metric horse power) ≒ 0.7355 kW

3. Fuel condition: Density at 15°C = 0.842

4. The "Total" oil quantity includes: Oil in oil pan and oil in channels, coolers and filter.

5. The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale.

4

1. General

(2) 4JH4E series (4JH4E, 4JH4FE, 4JH4BE, 4JH4B4E, 4JH4CE, 4JH4ME)

Official engine model name unit 4JH4E

Company internal model name

Marine gear model

Use

Type

Combustion system

Air charging

Number of cylinders

Bore x stroke mm(inch) 88 x 90 (3.46 x 3.54)

Displacement L 2.190

Continuous

power

Output at

crankshaft/

Engine speed

Output at

crankshaft/

Fuel stop

power

Engine speed

Output at

propeller shaft /

Engine speed

Installation - Flexible mounting

Fuel injection timing

Fuel injection opening pressure

Main power take off

Direction of

rotation

Crankshaft

Propeller shaft

(Ahead)

Cooling system

Lubrication system

Coolant capacity (fresh) L (quart) Engine 6.0(6.3), Coolant recovery tank: 0.8(0.8)

Rake angle deg. at rake angle 8 deg at rake angle 0 deg

Lubricating

oil capacity

(engine)

Total (Note 4)

Oil pan only 4.5±0.3(4.8±0.3) 5.0±0.3(5.3±0.3)

Effective (Note 5) 1.2(1.3) 1.4(1.5)

Type - Electric

Starting

system

Starting motor V-kW DC 12V-1.4 kW

AC generator V-A 12V-80A (12V-60A optional)

Overall length

Engine

dimension

Overall width 560(22.0) 560(22.0) 560(22.0) 560(22.0) 560(22.0)

Overall height 618(24.3) 618(24.3) 618(24.3) 618(24.3) 618(24.3)

Flywheel major dimension mm(inch) Ø300 x 66(11.8 x 2.6)

Engine dry mass

(include marine gear)

- 4JH4E 4JH4FE 4JH4BE 4JH4B4E 4JH4CE 4JH4ME

- KM35P ZF30M KM35A2 KM4A1 SD50 Bobtail

-

-

-

-

-

kW(HP)/min

kW(HP)/min

kW(HP)/min

-1

-1

-1

deg b.T.D.C.

Vertical water cooled 4 cycle diesel engine

40.5(55.1) / 3000 (at Fuel temp. 25 °C)

39.6(53.8) / 3000 (at Fuel temp. 40 °C)

38.5(52.3) / 3000 (at Fuel temp. 25 °C)

37.6(51.1) / 3000 (at Fuel temp. 40 °C)

Pleasure use

Direct injection

Naturally aspirated

4

36.8(50.0) / 2907

FID 13± 1 (FIC-Air 14± 1)

MPa 21.6±0.5

-

-

-

Clockwise viewed from stern -

-

-

Counter-clockwise viewed from stern

Fresh water cooling with heat exchanger

Complete enclosed forced lubrication

At flywheel side

5.0±0.3(5.3±0.3) 5.5±0.3(5.8±0.3)

L (quart)

871(34.3) 950(37.4) 864(34.0) 922(36.3) 795(31.3)

mm(inch)

kg

212 228 213 228

240

(engine:200)

-

200

(Note)

1. Rating condition: ISO 3046-1, ISO 8665

• Fuel temperature 25°C at the inlet of the fuel injection pump. (ISO 3046-1, 1995)

• Fuel temperature 40°C at the inlet of the fuel injection pump. (ISO 8665)

2. 1HP (metric horse power) ≒ 0.7355 kW

3. Fuel condition: Density at 15°C = 0.842

4. The "Total" oil quantity includes: Oil in oil pan and oil in channels, coolers and filter.

5. The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale.

5

1. General

Marine gear and sail drive for 3JH4E and 4JH4E

Marine gear

or sail drive

Model - KM35P

KM35A

(down angle: 7)

KM35A2

(down angle: 7)

Type - Mechanical cone clutch

Reduction ratio

(Forward/Reverse)

Propeller speed

(Forward/Reverse)*

- 2.36/3.16 2.61/3.16 2.33/3.04 2.64/3.04 2.33/3.06 2.64/3.06

-1

min

1231/921 1114/921 1246/955 1103/955 1246/950 1103/950

Lubrication system - Splash

Lubricating oil

capacity (total)

Lubricating oil

capacity (effect)

L

(quart)

0.5 (0.5) 0.65 (0.69) 0.65 (0.69)

0.05 (0.05) 0.15 (0.16) 0.15 (0.16)

Cooling system - Air cooling by fan on flywheel

Mass kg 12 13 13

Model - ZF30M kM4A1

(coupled at

boat builder)

Type -

Reduction ratio

(Forward/Reverse)

- 2.15/2.64 2.70/2.64

Mechanical multi

plate clutch

1.47/

1.47

Mechanical cone clutch

2.14/

2.14

2.63/

2.63

3.30/

3.30

SD50

2.32

Marine gear

or sail drive

Propeller speed

(Forward/Reverse)*

min

-1

1353/1103 1078/1103

Lubrication system - Splash Centrifugal pump Oil bath

Lubricating oil

capacity (total)

Lubricating oil

L

(quart)

capacity (effect)

Cooling system - Seawater cooling -

Mass kg 27.5 27.5 40

* At continuous power engine speed 2907 min

1983/

1983

1360/

1360

1106/

1106

882/

882

1.1 (1.2) 1.3 (1.4) 2.1(2.2)

0.2 (0.2) 0.2 (0.2) -

-1

1253

6

1. General

(3) 4JH4-TE series (4JH4-TFE, 4JH4-TBE, 4JH4-THE, 4JH4-TIE, 4JH4-TCE, 4JH4M-TE)

Official engine model name unit 4JH4-TE

Company internal model name

Marine gear model - ZF30M KM4A2 KMH4A ZF25A SD50-4T Bobtail

Use - Pleasure use

Type - Vertical water cooled 4 cycle diesel engine

Combustion system - Direct injection

Air charging - Turbocharged

Number of cylinders - 4

Bore x stroke mm (inch) 84 x 90 (3.31 x 3.54)

Displacement L 1.995

Continuous

power

Output at

crankshaft/

Engine speed

Output at

crankshaft/

Fuel stop

power

Engine speed

Output at

propeller shaft/

Engine speed

Installation - Flexible mounting

Fuel injection timing

Fuel injection opening

pressure

Main power take off - At flywheel side

Crankshaft - Counter-clockwise viewed from stern

Direction of

rotation

Propeller shaft

(Ahead)

Cooling system - Fresh water cooling with heat exchanger

Lubrication system - Complete enclosed forced lubrication

Coolant capacity (fresh) L (quart) Engine: 7.2(7.6), Coolant recovery tank: 0.8(0.8)

Rake angle deg. 7 deg 0 deg 7 or 0 deg

Lubricating

Total (Note 4)

oil capacity

(engine)

Oil pan only

Effective (Note 5)

Starting

system

Engine

dimension

Type - Electric

Starting motor V-kW DC 12V-1.4 kW

AC generator V-A 12V-80A (12V-60A optional)

Overall length

Overall width 616(24.3)

Overall height 659(25.9)

Flywheel major dimension mm (inch) D339 x 66 (13.3 x 2.6)

Engine dry mass

(include marine gear)

-

4JH4-TFE 4JH4-TBE 4JH4-THE 4JH4-TIE 4JH4-TCE 4JH4M-TE

kW (HP)/min

kW (HP)/min

kW (HP)/min

deg b.T.D.C.

-1

-1

-1

53.0(72.1) / 3200 (at Fuel temp. 40 °C)

55.2(75.1) / 3200 (at Fuel temp. 40 °C)

Plunger lift at Top Dead Center: 1.26±0.01mm (when W-C.S.D. is released)

FIT (at plunger lift 1.00mm with W-C.S.D. released): 2.55±1

50.2(68.3) / 3101

MPa 21.6±0.5

-

L (quart)

Clockwise

viewed

from stern

5.7±0.3

(6.0±0.3)

5.2±0.3

(5.5±0.3)

Clockwise or counter-clockwise

(Bi-rotation)

6.9±0.3

(7.3±0.3)

6.4±0.3

(6.8±0.3)

2.4(2.5)

923(36.3) 903(35.6) 933(36.7)

mm (inch)

kg 235 237 238 237

1017(40.0)

-

-

Refer

to left

Refer

to left

782(30.8) 782(30.8)

249

(engine 207)

207

(Note)

1. Rating condition: ISO 8665

• Fuel temperature 40°C at the inlet of the fuel injection pump. (ISO 8665)

2. 1HP (metric horse power) ≒ 0.7355 kW

3. Fuel condition: Density at 15°C = 0.842

4. The "Total" oil quantity includes: Oil in oil pan and oil in channels, coolers and filter.

5. The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale.

7

1. General

(4) 4JH4-HTE series (4JH4-HTFE, 4JH4-HTBE, 4JH4-HTHE, 4JH4-HTIE, 4JH4M-HTE)

Official engine model name unit 4JH4-HTE

Company internal model name

Marine gear model - ZF30M KM4A2 KMH4A ZF25A Bobtail

Use - Pleasure use

Type - Vertical water cooled 4 cycle diesel engine

Combustion system - Direct injection

Air charging - Turbocharged with intercooler

Number of cylinders - 4

Bore x stroke

Displacement L 1.995

Continuous

power

Output at

crankshaft/

Engine speed

Output at

crankshaft/

Fuel stop

power

Engine speed

Output at

propeller shaft/

Engine speed

Installation - Flexible mounting

Fuel injection timing

Fuel injection opening

pressure

Main power take off - At flywheel side

Crankshaft - Counter-clockwise viewed from stern

Direction of

rotation

Propeller shaft

(Ahead)

Cooling system - Fresh water cooling with heat exchanger

Lubrication system - Complete enclosed forced lubrication

Cooling water capacity (fresh) L (quart) Engine: 7.2(7.6), Coolant recovery tank: 0.8(0.8)

Rake angle deg. 7 deg 0 deg 7 or 0 deg

Lubricating

Total (Note 4)

oil capacity

(engine)

Oil pan only

Effective (Note 5)

Starting

system

Engine

dimension

Type - Electric

Starting motor V-kW DC 12V - 1.4 kW

AC generator V-A 12V-80A (12V-60A optional)

Overall length

Overall width 616(24.3)

Overall height 659(25.9)

Flywheel major dimension mm (inch) D339 x 66 (13.3 x 2.6)

Engine dry mass

(include marine gear)

-

mm (inch)

kW (HP)/min

kW (HP)/min

kW (HP)/min

deg

b.T.D.C.

4JH4-HTFE 4JH4-HTBE 4JH4-HTHE 4JH4-HTIE

84 x 90 (3.31 x 3.54)

-1

-1

-1

*1 77.7(106) / 3200 -

73.6(100) / 3101

*1 80.9(110) / 3200

Plunger lift at Top Dead Center: 1.26±0.01mm (when W-C.S.D. is released)

FIT (at plunger lift 1.00mm with W-C.S.D. released): 2.55±1

MPa 21.6±0.5

-

L (quart)

Clockwise

viewed from

stern

5.7±0.3

(6.0±0.3)

5.2±0.3

(5.5±0.3)

Clockwise or counter-clockwise

(Bi-rotation)

6.9±0.3

(7.3±0.3)

6.4±0.3

(6.8±0.3)

2.4(2.5)

923(36.3) 903(35.6) 933(36.7) 1017(40.0) 782(30.8)

mm (inch)

kg 245 247 248 247 217

4JH4M-HTE

-

Refer to left

Refer to left

(Note)

1. Rating condition: ISO 8665

* Fuel temperature 40°C at the inlet of the fuel injection pump. (ISO 8665)

2. 1HP (metric horse power) ≒ 0.7355 kW

3. Fuel condition: Density at 15°C = 0.842

4. The "Total" oil quantity includes: Oil in oil pan and oil in channels, coolers and filter.

5. The effective amount of oil shows the difference in maximum scale of the dipstick and minimum scale.

8

1. General

Marine gear and sail drive for 4JH4-TE and 4JH4-HTE

SD50-4T

Model - ZF30M KM4A2 KMH4A ZF25A

(coupled at

builder)

Down angle deg. 0 7 8 8 -

Applicable

engine model

-

4JH4-TE

4JH4-HTE

4JH4-TE

boat

Type -

Reduction ratio

(Forward/Reverse)

Propeller speed

(Forward/Reverse)*

min

-

-1

Mechanical

wet multiple

disk clutch

2.15/

1444/

117 6

2.64

2.70/

2.64

115 0 /

117 6

Mechanical

cone clutch

1.47/

1.47

2115/

2113

2.14/

2.14

1451/

1450

2.63/

1180/

1179

Lubrication system - Splash Centrifugal pump

2.63

Hydraulic wet

multiple disk

clutch

2.04/

2.04

1520/

1520

2.45/

2.45

1263/

1263

Hydraulic wet

multiple disk

clutch

1.93/

1.93

1607/

1607

2.48/

2.48

1250/

1250

Trochoid pump Trochoid pump

Mechanical

cone clutch

2.32

1337

Oil bath

QuickSilver

High

Performance

gear lube

Lube oil - ATF

API CD or higher

SAE #20 or #30

ATF

only

Lube oil capacity

(total)

1.1(1.2) 2.0(2.1) 2.0(2.1) 1.8(1.9) 2.1(2.2)

L (quart)

Lube oil capacity

(effect)

0.2(0.2) 0.2(0.2) 0.2(0.2) - 0.1(0.1)

Cooling system - Seawater cooling -

Mass kg 27.5 30 31 30 42

* At Continuous power: Engine speed 3101 min

-1

9

1. General

1.3 Fuel oil, lubricating oil and

coolant

1.3.1 Fuel oil

IMPORTANT:

Only use the recommended fuel to obtain the

best engine performance and to keep the

durability of the engine, also to comply with the

emission regulations.

(1) Selection of fuel oil

Diesel fuel oil should comply with the following

specifications.

• The fuel specifications need to comply with

each national standard or international

standards.

• ASTM D975 No.1-D

No.2-D ...... for USA

• EN590: 96 ..................... for EU

• ISO 8217 DMX .............. International

• BS 2869-A1 or A2 ......... for UK

• JIS K2204....................... for JAPAN

The following requirements also need to be

fulfilled.

• Cetane number should be equal to 45 or

higher.

• Sulphur content of the fuel.

It should not exceed 0.5% by volume.

(Preferably it should be below 0.05%)

• Water and sediment in the fuel oil should not

exceed 0.05% by volume.

• Ash should not exceed 0.01% by mass.

• 10% carbon residue content of the fuel.

It should not exceed 0.35% by volume.

(Preferably it should be below 0.1%)

• Aromatics (total) content of the fuel.

It should not exceed 35% by volume.

(Preferably it should be below 30% and

aromatics (PAH*) content of the fuel

preferably it should be below 10%)

PAH*: Polycyclic aromatic hydrocarbons.

• DO NOT use Biocide.

• DO NOT use Kerosene, residual fuels.

10

Loading...

Loading...