Page 1

● Thank you very much for purchasing this Yamato

Pure LineⓇ WL220T.

● Please read the “Operating Instructions” and

“Warranty” before operating this unit to assure proper

operation. After reading these documents, be sure to

store them securely together with the “Warranty” at a

handy place for future reference.

Warning:

Before operating the unit, be sure to read

carefully and fully understand important

warnings in the operating instructions.

Water Purifier

R

Pure Line

○

WL220T

Instruction Manual

Second edition

Yamato Scientific America Inc.

Santa Clara,CA

The documents are printed on recycled paper.

Page 2

Page 3

Contents

1. Safety precautions ............................................................................................................................. 1

Explanation of pictograms ................................................................................................................. 1

List of symbols ................................................................................................................................... 2

Warning・Caution .............................................................................................................................. 3

2. Before operating the unit ................................................................................................................... 5

Installing procedures and preparation before operation ................................................................... 5

Precautions for installation ................................................................................................................ 6

Installation procedures ....................................................................................................................... 8

3. Names and Functions of Parts ........................................................................................................ 13

Main unit .......................................................................................................................................... 13

Piping diagram ................................................................................................................................. 14

Operation panel ............................................................................................................................... 16

4.Operation Method ............................................................................................................................. 17

Pre-start preparation and checks .................................................................................................... 17

Operation method ............................................................................................................................ 17

Water supply to the tank .................................................................................................................. 18

Water supply to the constant temperature and humidity chamber .................................................. 18

Selecting the water quality unit ........................................................................................................ 19

Water quality and water quality display ........................................................................................... 20

Water quality characteristics data (reference) ................................................................................. 21

Data of deterioration of tank water quality (reference) .................................................................... 22

5. Useful Functions .............................................................................................................................. 23

List of optional parts ......................................................................................................................... 23

Setting of the input terminal for remote water supply (optional)...................................................... 24

Setting of the external alarm output (optional) ................................................................................ 24

6. Maintenance procedures ................................................................................................................. 25

Maintenance and inspection ............................................................................................................ 25

Replacing the ion exchange resin cartridges .................................................................................. 25

Resetting after replacement of consumable parts (when an alarm is triggered) .......................... 26

Washing the supply hose strainer ................................................................................................... 27

Replace the piping hose. ................................................................................................................. 27

7. When the unit is not to be used for a long time or when disposing ................................................ 28

Requests in case of disposal ........................................................................................................... 28

8.Troubleshooting Guide ..................................................................................................................... 30

Display and contents ....................................................................................................................... 30

If a malfunction is suspected ........................................................................................................... 31

Troubleshooting ............................................................................................................................... 32

9. After sales service and warranty ..................................................................................................... 33

When requesting a repair ................................................................................................................ 33

10.Specifications ................................................................................................................................. 34

11.Electric diagram .............................................................................................................................. 35

Wiring diagram ................................................................................................................................. 35

Part symbols of wiring diagram ....................................................................................................... 36

12.Replacement part table .................................................................................................................. 37

13. List of dangerous materials ........................................................................................................... 38

14. Standard installation manual ......................................................................................................... 39

Page 4

1. Safety precautions

About pictograms

A variety of pictograms are indicated in this operating instruction and on

products for safe operation. Possible results from improper operation

ignoring them are as follows.

Be sure to fully understand the descriptions below before proceeding to the

text.

Warning

Caution

Indicates a situation which may result in minor injury (Note 2) and

property damages (Note 3.)

(Note 1)Serious injury means a wound, an electrical shock, a bone fracture or intoxication that may

leave after effects or require hospitalization or outpatient visits for a long time.

(Note 2)Minor injury means a wound or an electrical shock that does not require hospitalization or

outpatient visits for a long time.

(Note 3)Property damage means damage to facilities, devices and buildings or other properties.

Meanings of pictograms

This pictogram indicates a matter that encourages the user to adhere to warning

(“caution” included).

Specific description of warning is indicated near this pictogram.

This pictogram indicates prohibitions

Specific prohibition is indicated near this pictogram.

This pictogram indicates matters that the user must perform

Specific instruction is indicated near this pictogram.

Indicates a situation which may result in death or serious injury (Note 1.)

Explanation of pictograms

1

Page 5

General warnings

Danger!: High

voltage

Danger!: High

temperature

Danger!: Moving

part

Danger!: Hazard

of explosion

General cautions

Electrical shock!

Burning!

Caution for no

liquid heating!

Caution for water

leak!

For water only

Poisonous

material

General bans

Fire ban

Do not

disassemble

Do not touch

General

compulsions

Connect ground

wire

Install levelly

Pull out the power

plug

Regular

inspection

Warning

Caution

1. Safety precautions

List of symbols

Prohibitions

Compulsions

2

Page 6

1. Safety precaution

Warning

Never operate the unit in an atmosphere containing flammable or explosive gas

Never operate the unit in an atmosphere containing flammable or explosive gas.

Otherwise, an explosion or a fire may result since the unit is not explosion-proof.

See section “13. List of dangerous materials” on page38.

Be sure to connect the earth wire.

Connect the earth wire to the earth socket outlet. If the earth socket outlet is not available, use the

grounding adaptor to connect the earth lead to the ground. Otherwise, electric leakage occurs,

causing electric shock or fire.

Be sure to insert the power cord plug firmly.

Insert firmly the power cord to the extreme depth of the main body power socket. If not inserted

firmly, overheat or fire may occur.

Stop using in case of abnormality

Should any fuming or questionable odor be detected, turn OFF the power switch on the righthand side of main body immediately, and disconnect the power plug from the master power

supply. Then request inspection to the shop from which you have purchased the product, our

sales office or our customer service center.

If left unattended, such abnormality may cause fire or electric shock.

Never use electrical power cords bundled.

When these are used bundled, they might overheat causing a fire.

Take care not to damage electrical power cords.

Avoid tightly bend, pull with a strong force or twist to prevent electrical power cords from damaging.

A fire or an electrical shock may result.

Never try to disassemble or alter the unit.

Never try to disassemble or alter the unit. A malfunction, a fire or an electrical shock may result.

Always keep the tap closed when the product is not operated.

Always keep the tap closed when the product is not to be operated (during nighttime or holidays).

Otherwise, water leakage may occur.

Do not place an object on this product.

Any object, if placed on the system, may drop. Placement of the solvent may also cause trouble.

Do not ride on this product.

The person riding on the product may overturn or the system may be damaged, resulting in injury

or trouble.

Warning・Caution

3

Page 7

1. Safety precautions

Warning

Install the unit at a place higher than the connecting port on the constant

temperature and humidity chamber.

This unit is dedicated for the constant temperature and humidity chamber and supplies water to

it by gravity. Installing the unit at a place lower than the connecting port of the constant

temperature and humidity chamber may cause insufficient supply of water to the chamber or a

malfunction.

When installing the unit on the constant temperature and humidity chamber, be

sure to use the optional “Installation tray”(See “5. Useful Functions” on P. 23).

Do not adjust the reducing valve.

The reducing valve has been set to the water supply rate of about 1.0L/min(raw water pressure:

3×100kPa, reducing valve pressure:0.4×100kPa) at the factory. Never attempt to readjust the

reducing valve.

If the factory setting of the valve is lost, water leak or reduction in flow may result.

Cut the connecting hose of the constant temperature and humidity chamber to a

necessary length before use.

Run the connecting hose for the constant temperature and humidity chamber without a kink or

twisting so that any trap (water pool) will not occur at any point along the hose.

Be sure to install the unit level.

The unit is equipped with a leak detecting sensor in case of a leak accident. Be sure to install the

unit level since the sensor may not operate properly if the unit is installed inclined by three degree

or more in back and forth or left or right direction.

Caution

In case of thundering

When thundering begins, turn OFF the power switch on the right-hand side of main body

immediately and pull out the power cord.

Otherwise, lightening may cause failure of the control circuit of the system or may cause fire

and electric shock.

In case of power failure

Although the unit will stop when a power outage occurs, the unit will not supply water to the tank

if water is left in the tank at the recovery from the power outage while the power switch is ON. In

contrast, it will start supplying water to the tank to the highest level if it is empty at the time of

recovery.

Turn the power switch on the right side of the unit to OFF for safety when a power outage occurs.

To resume operation, follow the steps in “Turning power on” in the ”4.Operation Method” on P.17

Warning・Cautions

4

Page 8

Installing procedures and preparation before operation

Warning

・ Be sure to connect the earth wire (green wire of the power cord) to the earth wire or to

the earth terminal.

・ Never connect the earth wire to the gas pipe or water pipe, in order to prevent fire.

・ The earth wire must never be used for grounding of the telephone line and lightning

arrestor. This is to prevent fire and electric shock.

・ Never use the branch socket outlet because it causes hazardous heat generation.

Used of ground socket outlet recommended

When using a diode socket outlet

When there is no ground terminal.

●In this case, class D grounding work is

necessary and please consult your dealer or

our customer service center.

Ground adaptor

●Insert the ground adaptor into a power plug

confirming the polarity of the outlet. Connect

the grounding wire (green) of the ground

adaptor to the ground terminal on the power

supply equipment。

Take special care not to install the

unit at a place described below:

・ Uneven surfaces or dirty surfaces

・ Where flammable gas or corrosive

gas exists

・ Where the ambient temperature is

5℃ or less

・ Where the ambient temperature is

35℃ or more

・ Where temperature changes

severely

・ Where dusty and humidity is high

・ Where subject to direct sunlight

・ Where vibration is severe

・ Where unstable power supply

・ Where uneven floor(within

reference±3 degree)

・ Where raw water pressure is high

・Where with raw water pressure is

low

・ Outdoors

・At a place lower than the suction

port of the constant temperature

and humidity chamber

・On a device or a laboratory table

(with locked adjusters, etc.)

It is recommended to secure the space of the range wider than the one shown above around

the product.

Toward front

by 30cm or more

10cm or more

3-pole power plug with an

earth terminal

Earth wire

3-pole power plug with an

earth terminal

w

G

W

Earth pole

10cm or more

10cm or more

1. Be sure to connect the earth wire.

2. Before operating the unit

2. Carefully select an installation site.

5

Page 9

2. Before operating the unit

● Never operate the unit in an atmosphere containing flammable or explosive gas. Since

This product is not of an explosion-proof structure. Accordingly, when the power switch

on the right side of the unit is turned ON/OFF and in the course of operation, arc may

occur, possibly causing fire and explosion.

● See the section “13. List of dangerous materials” on page 38 for flammable and explosive

gases.

● If it is not installed level, the leak detection function may not operate properly when

water should leak at the pipes in the unit. The permissible error in the levelness

shall be ±3 degree and properly set the adjusters of the constant temperature and

humidity chamber or of the laboratory table to make it level.

● The unit weight is about 17kg. Handle with care during transportation and installation.

● Use the socket outlet appropriate to the power capacity (1A or larger capacity).

● The deficient power capacity causes not only decrease in the water supplying rate, but

makes correct control impossible due to drop of the supply voltage. Always connect the

product to the power supply system with sufficient allowance in the supply voltage.

Power capacity : WL220T Single phase AC100~240V 0.5A or less

● Note that the use of extension with a cord reel may cause drop of the voltage. Avoid

starburst connection with branch socket outlet so as to prevent fire and electric shock.

爆発性ガス

可燃性ガス

WL220T

W

L

2

2

0

T

Flammable gas

Explosive gas

Precautions for installation

3. Never operate the unit in an atmosphere containing flammable or explosive gas.

4. Install on a level surface.

5. Take the power supply from the dedicated socket outlet.

6

Page 10

● Connect the attached power cord to the power socket. Confirm that the power switch on the right

side of the main body is OFF, and connect the power cord plug to the socket outlet. The power cord

plug attached to this product is the three-wire cord including the earth wire, and the plug is also of

a ground plug. If the socket outlet to be used does not match the plug (that is, the 2P outlet), use

the ground adapter. When using this adapter, be sure to connect the earth lead wire to the ground.

●Never use electrical power cords bundled. When these are used bundled, they might overheat

causing a fire.

●Do not convert, forcibly bend, twist or pull the power cord. Otherwise, a fire or an electrical shock

may result.

●Do not place the power cord under a desk or a chair, or sand between objects to avoid it from being

damaged. Otherwise, a fire or an electrical shock may result.

●Do not place the power cord close to a stove or other heat generating device. Sheath of the cord

may burn and result in a fire or an electrical shock.

●If the power cord should be damaged (exposure of core wire or disconnection), immediately turn

the power supply in the right side of the main body off, disconnect the power plug and ask your

dealer to replace the cord. If the unit is operated with a damaged power cord, a fire or an electrical

shock may result.

●Connect the power cord to an appropriate wall outlet or distribution board.

● Use the supply water pressure within a range of 0.5~5×100kPa(0.5~5kgf/cm2) 24 hours a

day.

Note that the water feeding range to the tank becomes 1.0 L/min or less at the raw water pressure

of 1.0×100kPa (1kgf/cm2) or less.

● The raw water pressure range is the same even when the optional water inlet unit (see Page 23)

is used.

● When installing the unit at a higher place such as on the constant temperature and humidity bath,

the product may fall off during an earthquake and cause a dangerous situation. We strongly

recommend using the optional installation tray to stably secure the unit. The installation tray can

accept leak water and discharge using the drain hose when a water leak accident should occur.

Power outlet

Power cord

6. Connecting the power cord

2. Before operating the unit

Precautions when installing the unit

7. Handling of a power cord

8. Be sure to keep the raw water pressure from water supply within the specified range.

9. Use the installation tray (optional).

7

Page 11

2. Before operating the unit

●Take out the water supply hose included in the accessories of the main unit.

●Failure to securely connect it may cause water to gush out and to result in a leak.

●First tighten the main valve before connecting the water supply hose to the water pipe side.

(1)Wrap included seal tape around

the nipple ① of the water supply

hose. Wrap the seal tape

clockwise looked from you two to

three rounds while lightly pulling it

and cut off excess portion.

(2)Connect the water pipe side screw

and the nipple ① using a wrench.

Take care so that the cap part of

the Y-strainer ② will be the under

side.

※The size of the water supply hose screw is 1/2 male. When the size of the water pipe

side screw is other than 1/2 female, prepare a nipple of a different diameter.

※Use tap water as raw water.

①Nipple

Screw dia.1/2

②Y-strainer

Cap part

Seal tape

①Nipple

Screw dia.1/2

Water pipe

side screw

1. Always connect the feed water hose firmly.

2. Make connections on the water faucet side.

Installation procedures

8

Page 12

2. Before operating the unit

(1) Remove rubber cap from the water

inlet plug ⑧.

(2) With the sleeve slid in the direction

indicated with arrow, and insert the

main body water inlet plug ⑧ to

the socket ⑨ . Connection is

completed when the sleeve returns

to the original position when

released. The socket has a built-in

valve. This valve does not open

and allow water to flow unless

connected with the inlet valve⑧.

Main body side

The “water inlet plug unit” has its own valve and enables you to remove the water supply hose

without tightening the main plug of the water pipe. It also has a structure that prevents the

connection to the water plug from loosening even when tap water pressure fluctuates.

Take out the hook included in the

accessories of the main unit.

(1) Attach the hook on the back of this

product. The hook has a magnet

and can be placed at any place you

want.

(2) Put the tank drain hose on the

hook.

※ Although the tank drain hose is

plugged, if it is laid on the floor and

the plug comes off, water in the tank

will be drained. Be sure to put the

tank drain hose on the hook. If you

use the optional “installation tray”

(See “5 Useful function”. on P-23), it

will not cause any problem if you do

not use the hook and connect the

tank drain hose directly to the

installation tray.

Sleeve

Hook

Tank drain hose

⑨ Socket

⑧ Inlet valve

Valve

Installation procedures

3. Carry out connection on the main body side.

4. If you want a part with a valve, use the optional “water inlet plug unit” (see P.29).

5. Put the tank drain hose on the hook.

9

Page 13

2.Before operating the unit

Take out the connecting hose of the constant temperature and humidity chamber(φ9mm×

φ13mm 3m) included in the accessories of the main unit.

(1)Remove the screws on that hold the left side cover to the main unit.

(2)Remove the screws that hold the cock installing plate.

(3)Connect the connecting hose of the constant temperature and humidity chamber(I.D.:

φ9mm)to the cock. After connecting the hose, secure it with attached hose clamp.

(4) Run the connected hose through the hole on the back plate and connect to the

connecting port on the constant temperature and humidity chamber.

※ Cock has been shipped in the closed status. After connecting the hose, turn the cock by

90° anticlockwise to open it.

※ Cut the connecting hose of the constant temperature and humidity chamber into an

appropriate length to prevent it from kinking or twisting.

When the optional “remote water supply input terminal” is used

(1)Install the connecting hose of the constant temperature and humidity chamber to the

solenoid valve nipple on the back side.

Cock securing

plate

Left side cover

Cock (open state)

Constant temperature

and humidity chamber

connecting hose

Constant temperature

and humidity chamber

connecting hose

Hose clamp

Installation procedures

6. Install the connecting hose of the constant temperature and humidity chamber to

the cock on the left side of the main unit.

10

Page 14

2. Before operating the unit

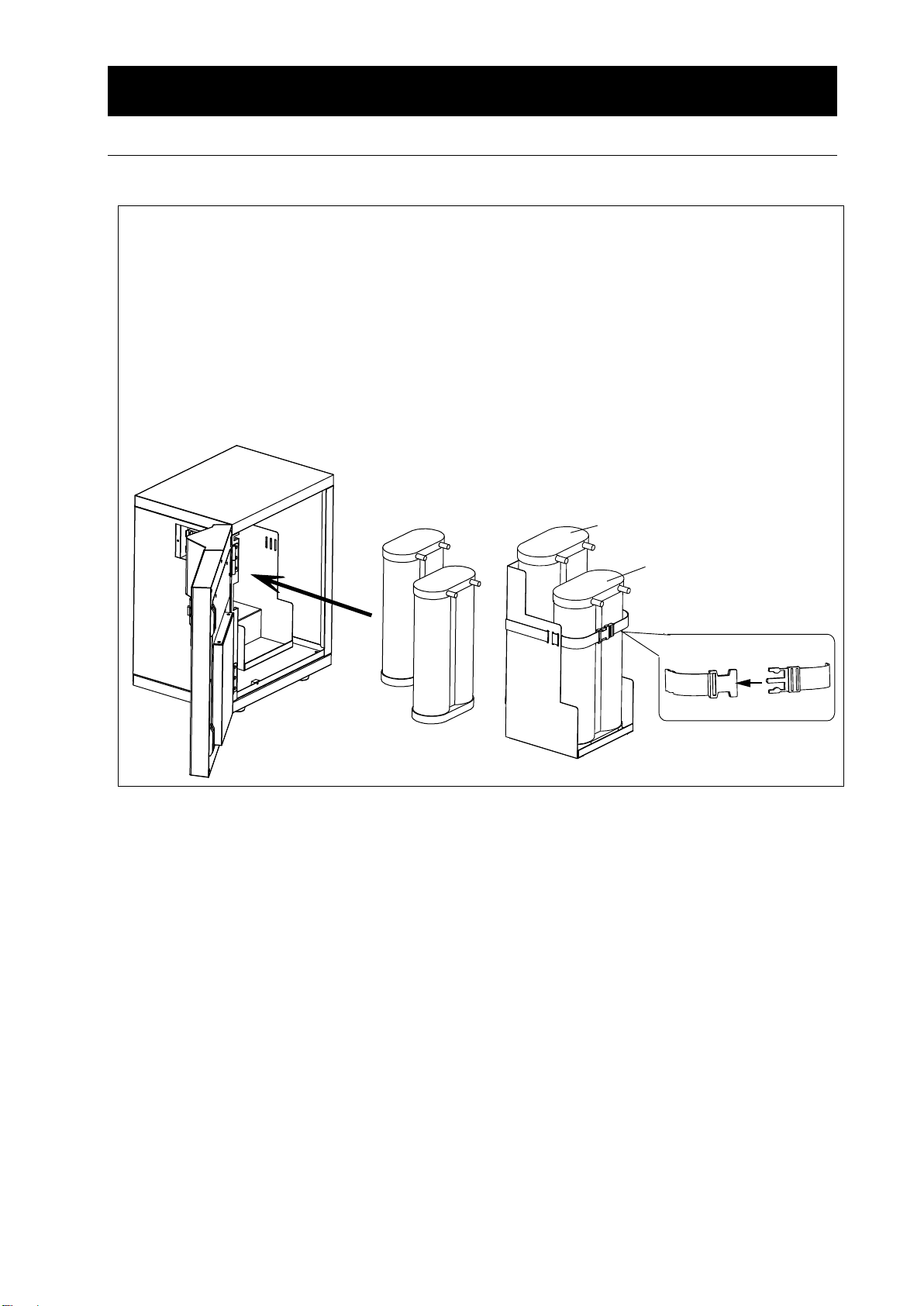

● Install the ion exchange resin cartridge (CPC-P, CPC-E) as follows:

(1) Confirm that the power switch on the right side of main body is OFF and that the faucet is

closed.

(2) Install the selected ion exchange resin cartridge firmly to the resin installation plate inside

the system. For installation of the ion exchange resin cartridge of WL220, provide CPCP in the front and CPC-E in the rear.(See Figs. 01)

(3) Secure the ion exchange resin cartridge with a band to the resin installation plate.

(See Figs. 02)

CPC-E

樹脂(後)

CPC-P

樹脂(前)

バンド

Band

CPC-E resin

(rear)

CPC-P resin

(front)

Fig. 01

Fig. 02

Installation procedures

7. Connect the ion exchange resin cartridge(CPC-P, CPC-E) firmly.

11

Page 15

2. Before operating the unit

●Connect ion exchange resin cartridges (CPC-C and CPC-E) as follows.

Remove a rubber cap from the inlet and outlet of each ion exchange resin cartridge.

(1) Press the coupler with ( 4 ,OUT) mark into the

outlet (right side) of the ion exchange resin

cartridge (CPC-E) till it clicks.

(2) Press the coupler with ( 3 ,IN) mark into the inlet

(left side) of the ion exchange resin cartridge

(CPC-E) till it clicks and press the coupler with

( 2 ,OUT) mark into the inlet (right side) of the ion

exchange resin cartridge (CPC-P) till it clicks.

(3) Press the coupler with ( 1 ,IN) mark into

the inlet (left side) of the ion exchange resin

cartridge (CPC-P) till it clicks. (See Fig. 03)

※ Initially, the coupler may be hard to insert and application of excessive force for insertion may

cause the insertion port to break. When this is hard to insert, carry out connection in a state as

removed from the resin installation plate while taking care not to insert in the bent state.

※ Once the coupler is inserted, pull on the hose to confirm connection and to make sure that the

coupler is not disconnected.

※ Set the coupler connected to the ion exchange resin cartridge (CPC-P) to face laterally (on the

left side as viewed from the front). If the coupler is allowed to face downward, it contacts the

door back plate to make door closing impossible.

※The coupler can be removed with ease by pulling on it while pressing a black portion to the depth.

For removal, reverse the order (1→2→3→4) of installation. Note also that water may drip from

the ion exchange resin cartridge when the coupler is disconnected.

※ Reverse installation of ion exchange resin cartridges or wrong connection of IN and OUT of

each cartridge may cause failure, resulting in shorter service life of the cartridges.

Install the unit at a place higher than the connecting port on the constant temperature

and humidity chamber. When installing the unit on the constant temperature and

humidity chamber, be sure to use the optional “Installation tray”((See “5 Useful

function”. on P-23).

The product may topple down and cause a personal injury due to an earthquake or an

unexpected shock. Implement appropriate preventive measures for safety.

CPC-P

樹脂(前)

CPC-E

樹脂(後)

採水口へ

給水口から

Fig. 03

CPC-E resin

(rear)

CPC-P resin

(front)

To water supplying port

From water

inlet

Installation procedures

8.After installation

12

Page 16

3. Names and Functions of Parts

Water quality sensor

Leak detecting sensor

Ion exchange resin cartridge

Front:CPC-P, back:CPC-E

Product code:253262

※CPC-P and CPC-E are set

Air filter

Operation

panel

Rating

sticker

Serial number sticker

Water supply

port

Power cord

Ext. alarm output

terminal (optional)

Remote watersupply

input terminal

(optional)

Decorative board

Reducing

valve

Power switch

○: [OFF]

―: [ON]

Internal tank

Cock

Tank drain hose

Leak detecting

sensor

Solenoid valve (optional) for

supply to the constant

temperature and humidity

chamber

Main unit

Note: The reducing valve has been set to the water supply rate of about 1.0L/min(raw water pressure:3×

100kPa, reducing valve pressure:0.4×100kPa) at the factory. Never attempt to readjust the reducing

valve.

Front Back

13

Page 17

3. Names and Functions of Parts

1. Water supply hose

6. Water quality sensor

2. Reducing valve

7. Tank

3. Water supply solenoid valve

8. Air filter

4. Ion exchange resin cartridge (CPC-P)

9. Cock

5. Ion exchange resin cartridge (CPC-E)

10. Drain cock

1. Water supply hose

7. Tank

2. Reducing valve

8. Air filter

3. Water supply solenoid valve

9. Cock

4. Ion exchange resin cartridge (CPC-P)

10. Drain cock

5. Ion exchange resin cartridge (CPC-E)

11. Water supply solenoid valve (optional)

6. Water quality sensor

②

③

④

⑤

⑥

⑦

⑩

⑧

⑨

②

③

④

⑤

⑥

⑦

⑨

⑧

⑩

⑪

Optional

①

To constant temp. &

humid. chamber

Tap water main valve

①

To constant temp. & h

umid.

chamber

Tap water main valve

Piping diagram

※ The reducing valve pressure has been set to 0.4×100kPa(raw water pressure:3×100kPa)

at the factory.

Remote water supply input terminal (optional)

※ The reducing valve pressure has been set to 0.4×100kPa(raw water pressure:3×100kPa)

at the factory.

14

Page 18

3.Names and functions of parts

①

②

③

④

⑤

⑦

⑥

⑥

Water supply to the tank

● Ion exchange water flows through ① reducing valve, ②water supply solenoid valve, ③ & ④ion

exchange resin cartridges (CPC-P & CPC-E) and ⑤water quality sensor and is supplied to the ⑥

tank.

Water supplying to the constant temperature and humidity chamber

●Ion exchange water in the tank will be supplied to the constant temperature and humidity chamber

after flowing through the ⑥ tank and the ⑦ cock when the solenoid valve of the constant

temperature and humidity chamber opens.

※ The water supply solenoid valve opens or closes in response to signals from the constant

temperature and humidity chamber in the case the supply terminal option is employed for the

constant temperature and humidity chamber.

15

Page 19

3.Names and functions of parts

No.

Nomenclature

Control/operation

①

Water quality display

Displays the quality of deionized water.

②

Information display

Displays errors, replacement timing of consumable

parts and the unit operation status.

③

CLR key

Used when consumables are replaced

④

UNIT key

Selects the water quality unit (×10-4S/m⇔×104Ω・m)

⑤

Water quality unit lamp

The side of the water quality unit selected will come on.

0 1 2 3 4 5 6 7 8

9

A B C D E F G H I

J

K L M N O P Q R S

T

U V W X Y Z -

Blank

①

③

⑤ ④ ②

Operation panel

List of displayed characters

16

Page 20

4.Operation Method

Be sure to check again before use.

(1)Confirmation of water feed

・Confirm that the feed water hose is firmly connected.

・Open the faucet.

・Confirm that the connection of feed water hose is free from water leakage.

(2)Confirmation of power supply

・Check if the power cord is connected to the appropriate socket outlet.

・Confirm that the power cord is inserted to the depth of main body power cord socket outlet.

Upon completion of preparation, start operation as follows.

Power application

Power switch

OFF ON

① Set the power switch on the right side of main

body to “ON(―).”

Operation panel (initial display)

●Initial display for 4 seconds

l

○

Pre-start preparation and checks

Operation method

17

Page 21

4.Operating procedures

Water supply to the tank

When the tank is empty

● Automatically start supplying water to the

tank.

● The information display shows an

animation of supplying water to the tank.

Animation of supplying water to the tank

When the tank is full or has remaining water

● Animation of supplying water to the tank is

turned off in the information display

※ After initial powering on or replacement of the ion exchange resin cartridge, discharge

water completely at the tank discharge port on the back when the tank has become full.

Be sure to turn power OFF because supplying water to the tank will start if power is ON.

※ If there is water remaining in the tank, supplying water to the tank will not start even when power

is turned ON.

Supplying water to the constant temperature

and humidity chamber

Standard specification(natural fall system)

●The solenoid valve in the constant

temperature and humidity chamber opens to

start supplying water to the constant

temperature and humidity chamber

automatically.

●The information display is blank.

Remote water supply terminal (optional)

●The optional remote water supply terminal

has a solenoid valve for supplying water.

●External output of the constant temperature

and humidity chamber opens the water

supply solenoid valve in WL220T to start

supplying water to the constant temperature

and humidity chamber automatically.

●The information display shows an animation

during water supply to the constant

temperature and humidity chamber.

Animation of supplying water to the constant

temperature and humidity chamber

Water supply to the tank

Water supply to the constant temperature and humidity chamber

18

Page 22

4.Operating procedures

Selecting the water quality unit

Press the UNIT key, and the water quality unit

can be changed.

To change the water quality unit:

● Electric conductivity (conductivity) display

●Specific resistance display

For details, refer to “Electric Conductivity (Conductivity)” of P. 20

Selecting the water quality unit

19

Page 23

4.Operation Method

Measuring the electric conductivity (conductivity)

The Water Quality Display of operation panel shows the electric conductivity at the outlet of ion

exchange resin cartridge. Use the displayed reading as a guideline to determine the cartridge

replacement timing. Read the conductivity while the electrode is fully immersed in water, that is,

while the deionized water is flowing.

Correct reading cannot be made in the following cases because of failure of immersion of electrode

into the water or the effects of air bubbles:

1. During initial operation period and while the unit is down

2. Immediately after replacement of ion exchange resin cartridge and the pretreatment cartridge

(optional).

Electric conductivity (conductivity)

・ The electric conductivity is the numerical value representing the easiness of the material to

conduct electricity. Water tends to conduct electricity more readily with increasing content of

dissolved electrolyte, that is, impurities. The numerical value of such conductivity decreases with

decreasing content of electrolyte.

・ The smaller numerical value of electric conductivity means higher purity of pure water.

Note however that the numerical value of electric conductivity refers only to electrolyte and not

to non-electrolytes (organic and colloidal substances, dissolved gases, microorganisms). The

value does not represent the total purity and should be handled only as one of indices to

represent the water purity.

・ The resistivity (R) is a factor representing the content the same as for the electric conductivity

(ρ). Since the resistivity is the reciprocal of electric conductivity, the higher numerical value

of resistivity means higher purity.

R[Ω・m]=

1

or

R[×104Ω・m]=

1

ρ[S/m]

ρ[×10-4S/m]

Accordingly, factors for the theoretical pure water are defined as follows:

R=18.2×10

4

Ω・m(18.2MΩ・cm)25℃

ρ=0.055×10-4S/m(0.055μS/cm)25℃

Water quality of deionized water

Deionized water

Water with the lowest electric conductivity can be obtained by eliminating most of

electrolytes in water, except that non-electrolytes can be removed. More or less

deterioration of purity may be observed immediately after replacement of resin or at

resumption of water flow after shutdown of the system.

Water quality and water quality display

20

Page 24

4.Operating procedures

0

2

4

6

8

10

12

14

16

18

20

0 100 200 300 400 500 600 700 800

※Tap water of Yamanashi Pref. ・・electric conductivity: 200×10-4S/m

Total water amount(L)

Specific resistance

(×10

4

Ω・

m)

Time (minute)

Specific resistance

(×10

4

Ω・

m)

Water quality characteristics data (reference)

The use life of the ion exchange resin cartridge is about 700L (at electric conductivity of 200×10-4S/m).

One of water quality characteristics of water immediately after replacement of the ion exchange resin

cartridge is the transient characteristic above which requires several minutes to be stable. Thus fill the

3L tank immediately after replacement of the ion exchange resin cartridge and then discharge water in

the tank completely at the discharge port. Use the data as a reference only since the same results will

not be always obtained depending on the specific cartridge or raw water quality.

21

Page 25

4.Operating procedures

Number of days (day)

Specific resistance

(×10

4

Ω・

m)

※Tap water of Kanagawa pref. ・・・Electric conductivity150×10-4S/m

Electric conductivity

(×10

-4

S/m

)

0

2

4

6

8

10

12

14

16

18

20

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

比抵抗値

電気伝導率

Specific resistance

Electric conductivity

Data of deterioration of tank water quality (reference)

The quality of pure water in the tank will deteriorate if it is left as it is. The water quality is A3 (electric

conductance: 1×10-4S/m or lower) at the time of supplying to the tank, which will be A1 (5×10-4S/m

or lower) in three days. The reason pure water shall be used for the constant temperature and

humidity chamber is to prevent accumulation of stone of humidifying water, which means pure water

having quality of A1 (5×10-4S/m or lower) or higher may be used. If the water in the tank is not

used for one month, the A1 quality (5×10-4S/m or lower) may be maintained.

Use the data as a reference only since the same results will not be always obtained depending on

the specific cartridge or raw water quality.

22

Page 26

5. Useful Functions

Item name

Product

code

Supported

model

Remarks

Installation tray

(OWL50)

253271

WL220T

This unit can be stably fixed on the constant

temperature and humidity chamber. The tray

has a discharge port and is put under the unit

so that leak water will not drip onto the

constant temperature and humidity chamber.

Feed water port unit

(OWH10)

253686

WL200

WL220

WL220T

Used when the raw water feed port is not

equipped with the sink. Install a faucet to the

water supply line.

Reducing valve for

raw water

(OWG42)

253769

WL200

WL220

WL220T

Used to keep the raw water pressure

constant. Use this valve when the raw water

pressure is not constant or is

5×100kPa (5kgf/cm2) or more.

Remote water

supply input terminal

(OWL48)

※2

253272

WL220T

This terminal is used when you want to supply

water to the constant temperature and

humidity chamber with the supply signals

from that chamber. A solenoid valve for

supplying water is added inside the unit. This

shall be specified at the time of placing an

order.

Power cord 4m

(OWL52)

253273

WL220T

This is used when the existing power cord is

short.

※ Do not use this power cord for electric

appliances other than the supported products

of Yamato.

MIZU guard

254199

Y-MGB

A line type leak sensor is installed around the

water purifier. This detects a small amount of

leak on the unit and closes the water supply

pipe to the unit with a motor valve to stop

leak.

List of optional parts

※1 Please specify at the time of placing the order for the main unit.

23

Page 27

5. Useful Functions

Connect terminals

(Example)Connect the switch for use.

Connect to the remote supply input terminal in the

upper portion of the left side of main body.

REMOTE

Non-voltage contact input

・Supplying

Shorting the contacts causes start of supplying

water.

・Supplying stop

Opening the contacts causes stop of supplying

water.

※ Do not apply voltage to the input terminal for

remote water supply. It will result in a malfunction

of the unit.

※ When you use the unit with remote operation, we

recommend use of the MIZU guard (product

code: 254199) that detects water leak from a

wrong operation signal or a malfunction of the

unit and stops water supply for safety.

Connecting the terminal

(Terminal block size:M4)

Connect to the external alarm output terminal in the

upper portion of the left side of main body.

ALARM Relay a contact (Normal Open)

Contact capacity: AC250V 1A (resistance load)

DC30V 1A (resistance load)

Example) Alarm lamp or buzzer can be

connected to the terminal.

・ The relay contact closes at a time of alarm of

consumables and in case of abnormality in the

unit.

・ The external alarm output is maintained even

while the buzzer is cancelled temporarily.

・ External alarm is canceled when the power key

is OFF.

Load

REMOTE

(←Rear)

(Front→)

ALARM

Connected load

ALARM

REMOTE

Load

power

Setting of the input terminal for remote water supply (optional)

The remote water supply function that uses the input terminal for remote water supply can be used

to supply water stored in the tank to the constant temperature and humidity chamber by

opening/closing the solenoid valve in the unit using remote signals from the chamber.

This is a function to output the alarm signal in case of abnormality of the main body or to notify the

consumables replacement timing.

Setting of the external alarm output (optional)

24

Page 28

6. Maintenance procedures

Maintenance/inspection items

Timing

Remarks

Replacement of the ion

exchange resin cartridge CPCP & CPC-E

(See P.11, 12)

When

appears on the

information display.

Replacement timing: About 700L of

raw water of 200×10-4S/m

Washing of the supply hose

strainer

(See P.27.)

Six months

Perform this earlier when raw water

quality is low.

Replacement of the piping

hose.

(See P.27.)

Two years

Check the connections every month

for water leak.

See “7. Connect the ion exchange resin cartridge(CPC-P, CPC-E) firmly.” on P.16 for how to

replace. The alarm is reset automatically when water quality improves after replacement.

・ Spare cartridges will gradually deteriorate during storage even if you do not use them.

Prepare new spare parts sufficiently before the expected replacement timing judged based

on the actual use status. Rough storage period is about four months.

・ We would be grateful if you return used cartridges to us using the specified letter of transmittal

attached to the new cartridge. We promote adequate disposal, recovery and recycling for

preservation of the environment. If you want to dispose used cartridges, follow the appropriate

disposing method as non-combustible waste.

・ When you replace ion exchange resin cartridges, replace both CPC-P and CPC-E cartridges

at the same time. If not, a sufficient amount of water cannot be supplied to maintain the

specified water quality.

・ After having replaced each cartridge, discharge all water at the tank discharge port on the

back when the tank has become full in order to remove initial foreign matters. Be sure to turn

power OFF before discharging since water will be supplied to the tank if power is left ON.

Maintenance and inspection

Frequency of maintenance and inspection

(We recommend daily inspection to assure stable operation of our products.)

※ Deterioration of water quality indicates that you need to replace consumable parts.

※ Actual timing for replacement will differ depending on the raw water quality.

Replacing the ion exchange resin cartridges

25

Page 29

6.Maintenance procedures

Resetting a consumable part error

① Turn the power switch on the right side of the

main unit ON.

② Keep the CLR key on the operation panel

pressed longer to sound the acceptance beep

and to reset the indication.

※ Perform resetting operation only after having replaced consumable parts.

※ Even if you keep the CLR key longer without replacing the ion exchange resin cartridges (CPC-

P and CPC-E), alarm will be triggered again unless water quality improves.

Resetting after replacement of consumable parts (when an alarm is triggered)

Error of consumable parts will be displayed when water quality has deteriorated. Once consumable

parts have been replaced, the error will be reset automatically when water quality improves. You can

also reset errors manually using the procedures below.

26

Page 30

6.Maintenance procedures

Washing the supply hose strainer

(1) Turn the power switch on the right side of the main

unit OFF, close the main cock of the tap water pipe

and then remove the ① cap using a wrench.

(2) Take out the ② screen in the strainer by pulling it

in the direction of the arrow.

(3) Clean the ② screen carefully using compressed

air or detergent not to damage the metal mesh.

(4) Replace the ② screen to the original position

following the procedures above in the reversed

order and then tighten the① cap using a wrench.

※ Note that liquid inside will flow out when you remove the lower cover to wash the strainer

screen.

※ Failure to securely connection will cause water to spout and lead to water leak.

Replace the piping hose.

・Be sure to use our specified hose for replacement.

・The guideline for replacement of piping hose is two years.

※ Be sure to contact us before replacement.

②Screen

①Cap

Washing the supply hose strainer

Replace the piping hose.

27

Page 31

7. When the unit is not to be used for a long time

Warning

● Dispose of the product as a waste.

● When disposing of, do not leave the product in a place where children gather to play.

● Be sure to turn OFF the power switch on the right side of main body.

● Be sure to close the faucet.

● Fluctuating water supply pressure may cause water leakage, resulting in unexpected

accident.

Name of principal parts

Material

Principal components of exterior

Exterior

Ferrous, galvanized sheet steel, melamine resin baking finishing

Exterior back plate

Ferrous, galvanized sheet steel, melamine resin baking finishing

Door

ABS resin

Door back plate

Stainless steel plate SUS304

Installation plates (coated)

Ferrous, galvanized sheet steel, melamine resin baking finishing

Installation plates

(uncoated)

Stainless steel plate SUS304

Piping part installation plate

Stainless steel plate SUS304

Hinge

Stainless steel plate SUS

Rubber legs

Synthetic rubber

Nameplates

Polyester film

Principal components of water circuit system

Feed water port

Brass

Water quality sensor

Polypropylene resin

Tank

Polypropylene resin

Water circuit components

Ion exchange resin

Polyester resin

Water quality sensor electrode

Titanium

Reducing valve

Metallic:body of brass

or when disposing

1.For disposal

2. When the product is not to be operated in the nighttime and during holidays

Requests in case of disposal

Always pay attention to the preservation of the global environment.

・ We highly recommend taking the unit apart as far as possible for separation or recycling to

contribute to the preservation of the global environment. Major components and materials for the

unit are as follows:

28

Page 32

7. When the unit is not to be used for a long time

Name of principal parts

Material

Principal components of piping system

Feed water hose

Vinyl chloride

Piping hose

(transparent)

Vinyl

Hose clamp

Polyacetal

Hose nipple (resin white)

Polypropylene resin

Hose nipple (metal)

Brass

Principal components of electric system

Feed water electromagnetic

valve

Metallic: body of brass

Substrate

Composite component of fiber glass and other materials

Power cord and wiring

materials

Others

Wiring materials and substrates of synthetic rubber insulation and

resin insulation

When you are not going to use the unit for a long period of time, be sure to turn the power

switch on the right side to OFF, close the faucet, discharge water in the tank completely at

the tank discharge port on the back and then pull out the power plug of the unit from the

power outlet for safety.

Ion exchanger resin cartridges will deteriorate even if they are not used. Prepare new ion

exchange resin cartridges before resuming operation because the consumable part

replacement error is anticipated.

or when disposing

Requests in case of disposal

When the unit is not to be used for a long time

29

Page 33

8.Troubleshooting Guide

Alarm

Indication

Causes

Countermeasures

Water quality

error

Stops all operations when

disconnection/short circuit of the

temperature compensation sensor

of the water quality sensor or

temperature outside the

measurement range of 0 ℃~

100 ℃ continued beyond the

specified period.

Turn ON the power

switch on the right side

of main body again. If

error persists, call the

service center.

Controller

error

The settings stored in the memory

device in the substrate can not be

read correctly. Or stops all

operations when an abnormal

condition is detected for the A/D

circuit when the value is abnormal.

Turn ON the power

switch on the right side

of main body again. If

error persists, call the

service center.

Water leak

error

Stops all operations when water

splashes on the leak sensor.

Turn OFF the power

switch on the right side

of main body, check for

water leak at piping

components and call

the service center.

(See P.32.)

Float switch

error

Stops all operations when the

sensor input of the float switch is

abnormal.

Turn ON the power

switch on the right side

of main body again. If

error persists, call the

service center.

Display and contents

How to take the countermeasure

In case of display of the error as follows in the Error・Consumables Replacement Display, take note of

the content of error. Turn OFF the power switch on the right side of main body and close the faucet.

In case of abnormality, parts replacement or system check is necessary. Contact the shop from which

you have purchased the product, our sales office, or our service center.

Note that the serial number must also be informed together with the details of abnormality when

contacting us.

The contact address of the customer service center is shown at the end of this manual.

30

Page 34

8. Troubleshooting

Alarm

Display

Conditions

Countermeasure

Notifying ion

exchange resin

replacement

Water quality of

deionized water:

1×10-4S/m or more

1×104Ω・m or

less

Replace the ion exchange resin.

(See P. 11)

Continue supplying till the water

quality is improved and the CPC

display disappears after

replacement (automatic reset)

(Alarm display can be temporarily

reset by pressing CLR continuously

during alarm after replacement.)

Other displays

Display

Conditions

Countermeasures

Measurement

over range

Exceeding the upper limit

of water quality

measurement

・Electric conductivity

<0.05×10-4S/m

・Specific resistance>20×

104Ω・m

Discharge water in the tank at

the tank discharge port and

supply water to the tank again.

If any numeric value does not

appear after supplying water,

call the service center.

Exceeding the lower limit of

water quality

measurement

・Electric conductivity>10

×10-4S/m

・Specific resistance<0.1

×104Ω・m

Replace the ion exchange

resin. (See P.11.)

If any numeric value does not

appear after replacement, call

the service center.

Symptom

Probable cause

Power not applied

● Faulty connection of the power cord and power socket outlet

● Wire breakage of connection cord

● Faulty power switch

Water is not supplied to the

tank.

● Insufficient tap water pressure or water outage

● Water supply solenoid valve defective

● Faulty float switch

Supply of water to the tank

will not stop.

● Faulty water supply solenoid valve

● Faulty float switch

Water is not supplied to the

constant temperature and

humidity chamber.

● Cock is closed

● Faulty water supply solenoid valve (when option is set only)

Water quality is low.

● Deterioration of the CPC-P and CPC-E ion exchange resin

cartridges

● Air remaining in the ion exchange resin cartridge

● Ion exchange resin cartridge has not been used for an extended

period of time

Display and contents

※1 Use life of consumable parts depends on the raw water quality and will have influences on the

water quality value.

※2 The buzzer sound activated can be temporarily canceled by pressing any switch of the operation

panel (the error display continues). On detecting abnormality in the water quality again, the

buzzer sound is resumed for notification.

31

If a malfunction is suspected

Page 35

8.When a trouble occurs

Countermeasures when water leak detection error is displayed

1.Imperfect connection of the water supply port coupler and the ion exchange resin cartridge

coupler

※When water is leaking from other piping, immediately shut power off and close the main cock

of the tap water and consult your dealer or the general customer service center.

2.When water splashed on the ion exchange resin cartridge during its replacement work.

Countermeasures

(1) Turn the power switch on the right side of the main body to OFF.

(2) Isolate the leaking point. The leak detecting sensors are located at two points below:

・Inside the door.

・Inside the left cover of the cock.

(3) Wipe off water remaining in the bottom of the unit and allow it completely dry, remove the

screws that hold the water leak sensor and remove, carefully wipe and allow the electrode

off the main body to completely dry.

(4) When water has been wiped out, be sure to replace the leak detecting sensor to the original

position.

(5) Replace the door or the left side cover.

(6) Turn the power switch on the right side of the main body to ON, press the POWER key on

the operation panel to resume regular operation.

※ Be sure to first close the main cock of raw water before disassembling the piping assembly

for repairing water leak at a pipe or other work.

Leak detecting sensor

Leak detecting sensor

Troubleshooting

32

Page 36

9. After sales service and warranty

When requesting a repair

Warranty card (attached separately)

Minimum holding period of repair parts

See the warranty card or the nameplate on the unit.

See the section “3. Names and Functions of Parts” on page

13.

When requesting a repair

If any trouble occurs, immediately stop operation, turn the power switch off, disconnect the power

plug and contact your dealer or our sales office.

Information necessary for requesting a repair

● Model name of the product

● Serial number

● Date (y/m/d) of purchase

● Description of trouble (as in detail as possible)

Be sure to indicate the warranty card to our service representative.

● Warranty card is given by your dealer or one of our sales offices and please fill in your dealer,

date of purchase and other information and fax it to our customer center (the number is described

in the back cover), then store it securely.

● Warranty period is one full year from the date of purchase. Repair service for free is available

according to the conditions written on the warranty card.

● For repairs after the warranty period consult your dealer or one of our sales offices. Paid repair

service is available on your request when the product’s functionality can be maintained by repair.

The minimum holding period of repair parts for this product is seven years after end of production.

Repair parts here refer to parts necessary for maintaining performance of the product.

33

Page 37

10.Specifications

Model

WL220T

Performance

Water suctioning system

Ion exchange

Water supply system

Tap water connecting hose with a Y-strainer & 1/2 male screws for

tap water connection

Pure water quality

JIS K 0557 A3 ion exchange water

Yield of pure water ※2

Approx 1L/min of ion exchange water

Configuration

Ion exchange resin

cartridge ※4

2L ion exchange resin with activated charcoal(CPC-P) x 1

2L ion exchange resin (CPC-E) x 1

Internal tank

3L polyethylene tank

Detection of water

leakage

Forcibly shuts off the water supply solenoid valve when water leak

is detected.

Standards

Raw water pressure range

0.5~5×100kPa(0.5~5kgf/㎝2)

Safety unit

Circuit breaker, leak detecting sensor, reducing valve, water

quality abnormality alarm

Power supply(50/60Hz)

※3

Single phase AC100~240V 0.05~0.2A

External dimensions※4

(W×D×H)

350mm×350mm×450mm

Weight

Approx. 17kg(dry), approx. 20kg(tank is full)

Display

Water quality display

7-LED display(electric conductivity/specific resistance)

Other displays

Display to prompt replacement of consumable parts(CPC-P and

CPC-E:Replace simultaneously when water quality has

deteriorated)

Alarm display (water leak alarm)

Accessories

Water supply hose with Y-strainer (4m)

1

Power cord(2m) ※4

1

Constant temperature and humidity

chamber connection hose(3m)

1

Instruction manual

This document

Warranty card

1 sheet

Ion exchange resin (CPC-P)

1

Ion exchange resin (CPC-E) ※5

1

Seal tape

1

Hook

1

Hose clamp

2

Consumable parts

Part name

Model

Product code

Ion exchange resin cartridge

CPC-P + CPC-E

253262

※1

※1 The performance applies to the conditions with power supply of AC100~240V, room temperature

of 23℃±5℃, and humidity of 65%RH±20%.

The ambient temperature of this unit ranges from 5℃ to 40℃. For the raw water temperature,

the guideline must be set to 10℃~35℃.

※2 When raw water is 1.0×100kPa(1kgf/cm2) or below, yield of pure water will be 1.0L/min or lower

and it takes time until the tank is filled with water.

※3 The 100V power cord (with 3P plug attached) is provided.

※4 No projection included

※5 CPC-E and CPC-P are marketed as a set and not sold separately and individually.

34

Page 38

11.Electric diagram

Water

feed solenoid

valve Water

supply

solenoid valve External alarm

output Water

quality

sensor Water leak detection

sensor 1 Water leak detection

sensor 2

・Circled numbers are marker numbers. ・Dotted lines are optional specifications.

Wiring diagram

35

Page 39

Symbol

Part name

Symbol

Part name

S

Power socket

MV1

Water supply solenoid valve

MCB

Circuit protector

Fs-1

Float switch for the internal tank

T1

Terminal block

E

Water quality sensor

CONT

Planar substrate

WL1

Leak detecting sensor1(front of the

main body)

PIO

Display substrate

WL2

Leak detecting sensor2(front of the

main body)

DC POWER

Switching power

Symbol

Part name

Symbol

Part name

X1

External alarm output relay

T2

Optional terminal block

MV2

Water supply solenoid valve

(Solenoid valve for supplying to

the constant temperature and

humidity chamber)

・Standard parts

・Optional parts

11.Electric diagram

Part symbols of wiring diagram

36

Page 40

12.Replacement part table

Part name

Code №

Specifications

Maker

Ion exchange resin cartridge

253262

CPC-P + CPC-E

Yamato

Water reserve tank

WL22T30210

WL22T-30210

Yamato

Air filter

9020020001

4210

German Science

Plastic flexible hose

3040060005

φ9mm×φ13mm

Yamato

One-touch joint

3140030008

QJ-22D

Wamoto

37

Page 41

13. List of dangerous materials

Never use an explosive substance a flammable substance or a substance containing

them for this device.

Explosive

substance

①Nitroglycol, glycerine trinitrate, cellulose nitrate and other explosive nitrate esters

②Trinitrobenzen, trinitrotoluene, picric acid and other explosive nitro compounds

③Acetyl hydroperoxide, methyl ethyl ketone peroxide, benzoyl peroxide and other organic

peroxides

④Metallic azide, including sodium azide, etc.

Explosive

substances

① Metal “lithium” ② metal “potassium” ③ metal “natrium” ④ yellow phosphorus ⑤

phosphorus sulfide ⑥ red phosphorus⑦ phosphorus sulfide⑧celluloids, calcium carbide

(a.k.a, carbide)⑨lime phosphide⑩magnesium powder⑪aluminum powder ⑫metal powder

other than magnesium and aluminum powder⑬sodium dithionous acid (a.k.a., hydrosulphite)

Oxidizing substances

①Potassium chlorate, sodium chlorate, ammonium chlorate, and other chlorates

②Potassium perchlorate, sodium perchlorate, ammonium perchlorate, and other perchlorates

③Potassium peroxide, sodium peroxide, barium peroxide, and other inorganic peroxides

④Potassium nitrate, sodium nitrate, ammonium nitrate, and other nitrates

⑤Sodium chlorite and other chlorites

⑥Calcium hypochlorite and other hypochlorites

Flammable substances

① Ethyl ether, gasoline, acetaldehyde, propylene chloride, carbon disulfide, and other

substances with ignition point at a degree 30 or more degrees below zero.

②n-hexane, ethylene oxide, acetone, benzene, methyl ethyl ketone and other substances with

ignition point between 30 degrees below zero and less than zero.

③Methanol, ethanol, xylene, pentyl n-acetate, (a.k.a.amyl n-acetate) and other substances

with ignition point between zero and less than 30 degrees.

④Kerosene, light oil, terebinth oil, isopenthyl alcohol(a.k.a. isoamyl alcohol), acetic acid and

other substances with ignition point between 30 degrees and less than 65 degrees.

Combustible

gas

Hydrogen, acetylene, ethylene, methane, ethane, propane, butane and other gases

combustible at 15℃ at one air pressure.

Quoted from the separate table 1 in Article 6, the enforcement order of the Industrial Safety

and Health Law; Dangerous Substances (in Article 1, 6 and in 3 of Article 9)

38

Page 42

14. Standard installation manual

Model

Serial number

Date

Installation

mgr.(company name)

Installation mgr.

Judg

ment

№

Item

Implementation method

TOC No. Reference page of the

operating instruction manual

Judg-

ment

Specifications

1

Accessories

Check for number of accessories on the

basis of the column for accessories.

10. Specifications field

P.34

2

Installation

・ Visually check the environmental

conditions

Caution:Take care for the environment

2. Before operating the unit

・On the installation site

P.5

・Secure sufficient space

・Check the level of the unit(±3℃ or less)

・ The proper height difference must be

assured between the water supplying

assembly of the unit and the water supply

destination (water supply assembly of

the constant temperature and humidity

chamber)

Operation-related matters

1

Source voltage

・Measure the user side voltage (outlet,

distribution board, etc.) with a tester

・Measure voltage during operation

(shall meet the specifications)

Caution: Always use a plug that meets

the specification for attaching to

the ELB.

2. Before operating the unit

・Be sure to connect the

ground wire.

・Power supply is ….

10.Specifications

・Specification - power

supply

P.5

P.7

P.34

2

Water supplying

Explain supplying to the customer while

referring to the manual

4.Operation Method

・Operation method

P.17~

20

Description

1

Operational

descriptions

Explain the customer about each assembly

as per the operation manual.

4. Operating procedures

・Operating procedures

1. Safety precautions

~ 13. List of dangerous

materials

P.17~

20

P.1~38

2

Error sign

Explain the error sign and the method to

reset it to the customer while referring to

the manual.

8. Troubleshooting

~9. After sales service and warranty

P.30~

33

3

Maintenance

and inspection

Explain operations of each component

according to the operational instructions

6. Maintenance procedures

・Daily inspection/

maintenance

P.25 ~

27

4

Completion of

installation

Entries

・Fill in the installation date and the

installation mgr. on the nameplate of the

main unit

・Fill in necessary information to the

warranty card and hand it over to the

customer

・Explanation of the route for after-sales

service

9. After sales service and warranty

P.33

* Install the product according to the following: (Confirm separately for optional items or special

specifications)

39

Page 43

Page 44

Yamato Scientific America, Inc.

925 Walsh Avenue, Santa Clara,

CA 95050, U.S.A

http://www.yamato-usa.com

Toll Free: 1-800-2-YAMATO(1-800-292-6286)

Limited liability

Be sure to use the unit strictly following the handling and operating instructions in this

operating instruction.

Yamato Scientific Co., Ltd. assumes no responsibility for an accident or a malfunction

caused by use of this product in any way not specified in this operating instruction.

Never attempt to perform matters prohibited in this operation instruction.

Otherwise, an unexpected accident may result.

Notice

● Descriptions in this operating instruction are subject to change without notice.

● We will replace a manual with a missing page or paging disorder.

Instruction Manual

Water Purifier

R

Pure Line

WL220T

Second Edition January 20, 2017

○

Loading...

Loading...