Page 1

g

Water Purifier, Auto Still

Model

WG 250/1000

Instruction Manual

- Fourth Edition -

z Thank you for purchasing "Auto Still, WG

series" of Yamato Scientific Co., Ltd.

z To use this unit properly, read this "Instruction

Manual" thoroughly before using this unit.

Keep this instruction manual around this unit

for referring at anytime.

WARNING!:

Carefully read and thoroughly understand the

important warning items described in this

manual before usin

this unit.

Yamato Scientific Co. LTD.

This paper has been printed on recycled paper.

Page 2

Page 3

Contents

Cautions in Using with Safety................................................................1

• Explanation.................................................................................................................... 1

•

Table of Illustrated Symbols .......................................................................................... 2

•

Fundamental Matters of "WARNING!" and "CAUTION!"............................................... 3

Before Using this unit.............................................................................4

Requirements for Installation......................................................................................... 4

•

Description and Function of Each Part...............................................13

• Main Unit ..................................................................................................................... 13

•

Water Sampling Table and Multi-Purpose Distilled Water Sampling Port.................... 15

•

Piping System View..................................................................................................... 16

•

Principle of Operation.................................................................................................. 17

•

Control Panel............................................................................................................... 20

Operation Method .................................................................................21

Setup and Check before Use ...................................................................................... 21

•

•

Operation Procedure................................................................................................... 22

Sampling of Pure Water .............................................................................................. 23

•

•

Collection of Measured Amount of Pure Water ........................................................... 24

•

Collection of Measured Amount of Distilled Water ...................................................... 25

•

Display of Water Quality.............................................................................................. 27

•

Setting/Display of Submenu........................................................................................ 29

Handling Precautions ...........................................................................31

Maintenance Method.............................................................................32

• Daily Inspection and Maintenance .............................................................................. 32

•

Washing of Distiller...................................................................................................... 33

•

Replacement of Heater ............................................................................................... 37

•

Washing of Water Supply Hose Filter.......................................................................... 38

•

Replacement of Hose.................................................................................................. 38

Long storage and disposal...................................................................39

When not using this unit for long term / When disposing ............................................ 39

•

In the Event of Failure….......................................................................42

•

Failure indication and Its Contents .............................................................................. 42

•

Remedy for Trouble..................................................................................................... 45

•

Trouble Shooting......................................................................................................... 46

•

Measures in emergency.............................................................................................. 46

After Service and Warranty ..................................................................47

Specification..........................................................................................48

Wiring Diagram......................................................................................49

WG250 ........................................................................................................................ 49

•

•

WG1000 ...................................................................................................................... 50

Reference...............................................................................................51

List of Dangerous Substances .................................................................................... 51

•

Page 4

Explanation

Illustrated Symbols

Various symbols are used in this safety manual in order to use the unit without

danger of injury and damage of the unit. A list of problems caused by ignoring

the warnings and improper handling is divided as shown below.Be sure that you

understand the warnings and cautions in this manual before operating the unit.

Cautions in Using with Safety

MEANING OF ILLUSTRATED SYMBOLS

WARNING!

CAUTION!

If the warning is ignored, there is the danger of a problem that

may cause a serious accident or even fatality.

If the caution is ignored, there is the danger of a problem that may

cause injury/damage to property or the unit itself.

Meaning of Symbols

This symbol indicates items that urge the warning (including the caution).

A detailed warning message is shown adjacent to the symbol.

This symbol indicates items that are strictly prohibited.

A detailed message is shown adjacent to the symbol with specific actions not to

perform.

This symbol indicates items that should be always performed.

A detailed message with instructions is shown adjacent to the symbol.

1

Page 5

Table of Illustrated Symbols

Warning

Cautions in Using with Safety

Warning,

generally

Caution

Caution,

generally

Caution,

water only

Warning,

high voltage

Caution,

electrical shock

Caution,

deadly poison

Warning,

high temperature

Caution,

Warning,

drive train

Caution,

scald

no road heating

Warning,

explosive

Caution,

not to drench

Prohibit

Prohibit,

generally

Compulsion

Compulsion,

generally

inflammable

Compulsion,

connect to the

Prohibit,

grounding

terminal

to disassemble

Compulsion,

install on a flat

Prohibit,

surface

Prohibit,

to touch

Compulsion,

disconnect the

power plug

Compulsion,

periodical

inspection

2

Page 6

Cautions in Using with Safety

Fundamental Matters of "WARNING!" and "CAUTION!"

WARNING!

Do not use this unit in an area where there is flammable or explosive gas

Never use this unit in an area where there is flammable or explosive gas.

This unit is not explosion-proof. An arc may be generated when the power switch is turned on or off,

and fire/explosion may result. (Refer to Page 51 "List of Dangerous Substances".)

Be sure to connect grounding wire.

Connect to grounded plug socket. If no grounded plug socket is available, be sure to connect

grounding lead by use of ground adapter attached in nonstandard. Failure to do so could cause

electric shock or fire.

If a problem occurs

If smoke or strange odor should come out of this unit for some reason, turn off the power key right

away, and then turn off the circuit breaker and the main power. Immediately contact a service

technician for inspection. If this procedure is not followed, fire or electrical shock may result. Never

perform repair work yourself, since it is dangerous and not recommended.

Do not use the power cord if it is bundled or tangled

Do not use the power cord if it is bundled or tangled. If it is used in this manner, it can overheat and

fire may be caused.

Do not process, bend, wring, or stretch the power cord forcibly

Do not process, bend, wring, or stretch the power cord forcibly. Fire or electrical shock may result.

Do not disassemble or modify this unit

Do not disassemble or modify this unit. Fire or electrical shock or failure may be caused.

Do not touch hot portion

Boiler may be hot in some portion in operation or immediately after operation. Be aware of burns.

When performing maintenance of heater etc., ensure that the boiler is cooled down beforehand.

Close the tap when unit is out of service

When unit is out of service (at night or on holiday), be sure to close the tap so as to avoid water leakage

accident.

CAUTION!

During a thunder storm

During a thunderstorm, turn off the power key immediately, then turn off the circuit breaker and the main

power. If this procedure is not followed, fire or electrical shock may be caused.

Exercise care in handling washing liquid (Orgazor)

Principal component of washing liquid (Orgazor) is sulfamic acid, which is acidic almost equal to water

solution PH:1. Use protective tool (gloves, mask, and glasses) in handling. When it is touched by

human body, immediately wash it away with clean water.

3

Page 7

Requirements for Installation

Before Using this unit

WARNING!

1. Always ground this unit

• Connect the power plug to a receptacle with grounding connectors.

• Do not forget to ground this unit, to protect you and the unit from electrical shock in case of

power surge. Choose a receptacle with grounding connectors as often as possible.

• Do not connect the grounding wire to a gas pipe, or by means of a lightning rod or telephone

line. A fire or electrical shock will occur.

2. Choose a proper place for installation

• Do not install this unit in a place where:

♦ Rough or dirty surface.

♦ Flammable gas or corrosive gas is generated.

♦ Ambient temperature 35°C and above or 5°C and below.

♦ Ambient temperature fluctuates violently.

♦ There is direct sunlight.

♦ There is excessive humidity and dust.

♦ There is a constant vibration.

♦ Not horizontal surface.

♦ The power source is instable.

• Keep space around each product above the range shown below. Install units within sink

equipment if possible.

10cm or more

10cm

or more

Front side

10cm or more

10cm

or more

3. Do not use this unit in an area where there is flammable or explosive gas

• Never use this unit in an area where there is

flammable or explosive gas. This unit is not

explosion-proof. An arc may be generated

when the power switch is turned ON or OFF,

and fire/explosion may result. (To know about

flammable or explosive gas, refer to Page 51

"List of Dangerous Substances".)

4

Page 8

Requirements for Installation

4. Do not modify

• Never disassemble this unit.

• This unit has high voltage inside in some

portion, which may cause electric shock.

Contact dealers or Yamato Scientific Co., Ltd.

sales office for adjusting or repairing inside.

• In routine maintenance and inspection, follow

the procedure described in the instruction

manual. Do avoid modification by customer

because it may lead to trouble.

5. Installation on horizontal surface

• Set this unit to the flattest place. Setting this

unit on rough or slope place could cause the

unexpectible trouble or malfunction.

• The unit WG250 weighs 55kg gross, and the

unit WG10000 weights 105kg gross. Two or

more persons are required for carrying or

setting these units. Specially be careful for

carrying WG1000 because its location of the

center of gravity is high.

Before Using this unit

6. Choose a correct power distribution board or receptacle

• Use a plug socket conforming to electric capacity (capacity 15A or greater).

• When power capacity is insufficient, sampling of distilled water goes short, and normal control

is disabled by fall of power voltage. Connect to power equipment having sufficient power

capacity.

Electric capacity:

WG250: 100V AC Single phase 15A

WG1000: 200V AC Single phase 20A

7. Handling of power code

• Do not entangle the power cord. This will cause overheating and possibly a fire.

• Do not bend or twist the power cord, or apply excessive tension to it. This may cause a fire

and electrical shock.

• Do not lay the power cord under a desk or chair, and do not allow it to be pinched in order to

prevent it from being damaged and to avoid a fire or electrical shock.

• Keep the power cord away from any heating equipment such as a room heater. The cord's

insulation may melt and cause a fire or electrical shock.

• If the power cord becomes damaged (wiring exposed, breakage, etc.), immediately turn off the

power at the rear of this unit and shut off the main supply power. Then contact your nearest

dealer for replacement of the power cord. Leaving it may cause a fire or electrical shock.

• Connect the power plug to the receptacle which is supplied appropriate power and voltage.

5

Page 9

Requirements for Installation

8. Connection of power cord

• Always ensure that breaker on power unit side is "Off" before connecting power cord. Power

plug of WG250 uses 3-core cord including grounding wire, and the plug is grounded type. If

your plug socket is not compatible (2P), use a ground adapter attached in nonstandard. In

using ground adapter, be sure to ground a grounding lead.

9. Connect the water supply hose securely

• If not connecting the water supply hose securely, the water supply hose or connection port

may be disconnected, resulting in water leakage such as water bursting forth.

• Take the connection port body and supply hose out of attachments to the unit. Install the unit

on a horizontal and stable place nearby tap and sink.

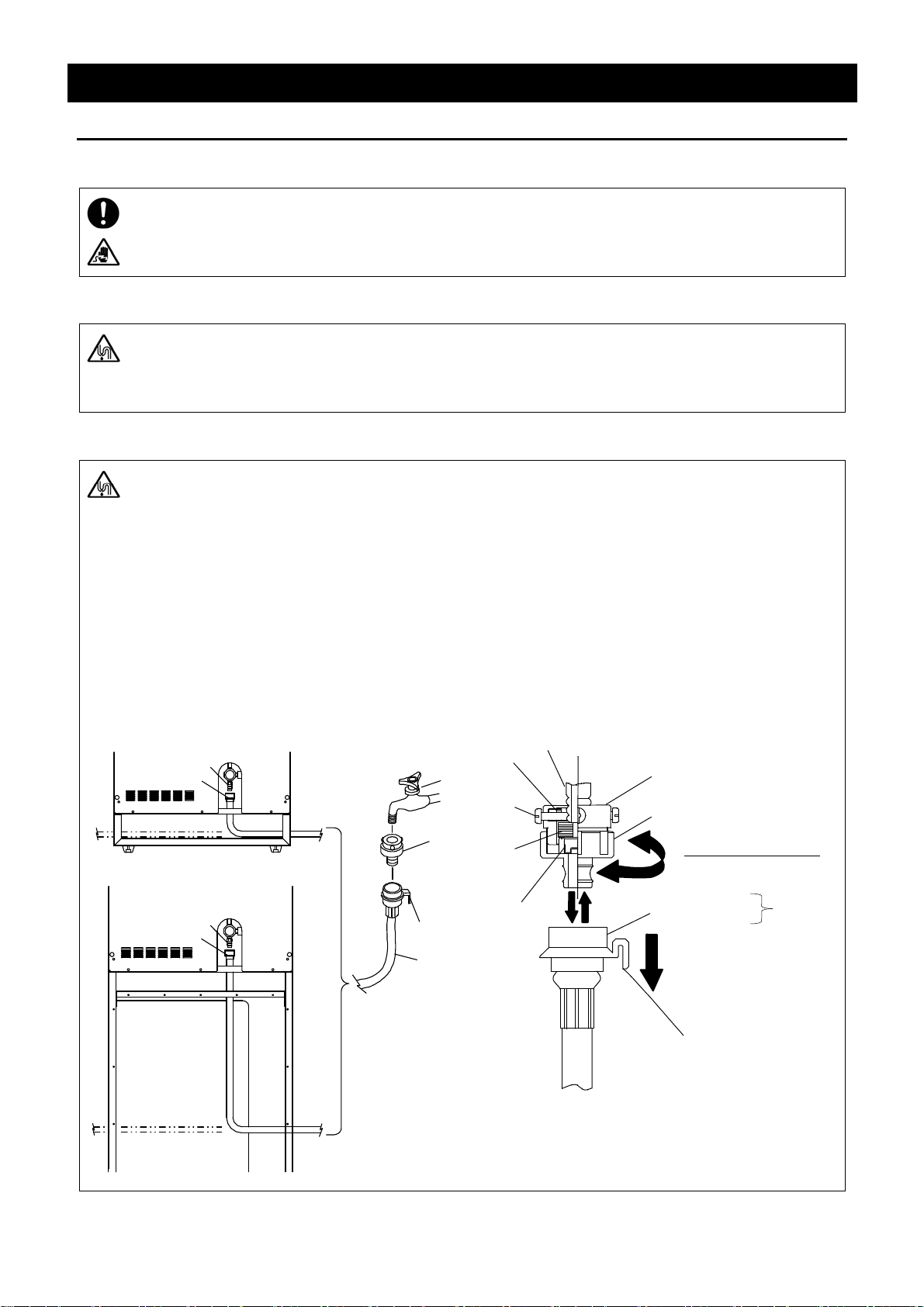

10. Connect the tap side

1. Slide the sleeve of socket ③ on connection port side in the arrow direction, then connection

port body and water supply hose can be separated. There separate the two parts.

2. Once loosen the plug ② from the ring ①.

3. Tighten the 4 mounting screws ⑤ uniformly while pressing the ring ① slightly and uniformly

to make the packing ⑥ in flat contact with water tap. If the tap is a chemical tap, adjust the

position so that the mounting screw is located at the bottom valley of tap nipple as shown.

4. Turn the plug ② clockwise to tighten securely. This will allow the tap and connection port to

be sealed by packing ⑥.

5. Insert the socket ③ securely to the plug ② with the sleeve slid in the arrow direction. The

sleeve returns to the original position when released, and then connection is completed.

In case that the socket is removed, the valve attached on the connection side of the main unit

stops the flow of water.

Water supply port

Sleeve on water

supply port

Water supply port

Sleeve on water

supply port

WG250

Tap

Connection

port body

Socket on

connection

port side

Water supply

hose

④

⑤

⑥

⑦

Before Using this unit

Tap

①

②

Connection Port Body

①Ring

②Plug

③

③Socket

④Spacer

⑤Mounting Screw

⑥Packing

⑦Filter

One-touch

Joint

Sleeve

Water supply hose

WG1000

6

Page 10

Before Using this unit

Requirements for Installation

11. Observe the specified pressure range of raw water from waterworks

• Apply the range of city water pressure between 0.5 X 100kPa and 5 X 100kPa (0.5 - 5kgf/cm2)

including nighttime.

• Range of raw water pressure is the same when "Water Supply Port Unit" (optional accessory)

is used.

12. Connection on body side

1. Remove the rubber cap from the water supply port plug

⑧.

2. Insert the socket ⑨ securely to the plug ⑧ on body

side with the sleeve slid in the arrow direction. The

sleeve returns to the original position when released,

and then connection is completed. The socket

contains a valve inside, which opens only when the

socket is connected by plug; otherwise, water is not fed

because this valve does not open.

Body side

⑧

⑨

13. Connect the water supply hose to the tap provided with sink equipment

• If the water supply hose is

connected to a tap without

sink equipment, flood damage

may be caused when water

supply hose is disconnected

or damaged; therefore be

sure to connect to a tap

having sink equipment.

Connection port Body

Sink

Tap

Socket on

connection

port side

Water supply hose

14. When the sink equipment is remote from water tap, use "Water Supply Port Unit"

(optional accessory)

• "Water Supply Port Unit" is designed to loosen the connection to the tap harder than the set of

standard water supply hoses when water pressure fluctuates.

15. In case that there is no tap

• In case that there is no tap, use appropriate joint shown in the optional "Coupler joints for feed

water".

7

Page 11

Requirements for Installation

16. Connect the drain hose securely

• If the drain hose is not connected securely, it may be disconnected, leaking water in the unit,

or leading to trouble of system.

1. Pick up the drain hose (with elbow) and the hose clamp from the main unit accessories.

2. Always make sure that the earth leakage breaker of the unit is "OFF".

3. Remove the rubber stopper from the outlet of the drain port hose on the main unit.

4. Push the hose clamp into the elbow of the drain hose, and next, put the elbow into the drain

outlet hose of the main unit, then tighten the hose clamp securely.

5. Pull the hose out from the drain hose-end outlet at right/left or backside of the main unit.

For WG1000 unit, be sure to set the hose in the hose holder at the backside plate.

Hose

clamp

Drain port hose

on the main un it

Before Using this unit

Hose holder

Elbow

Drain port

17. Use care in routing of drain hose

• Do avoid making bend or projection of drain hose.

• In case that the drain hose is bent and the drain cannot be performed, back-flow or breakage

of the cooling hose might occur.

• Place the drain hose lower than the drain port of this unit. Further, avoid piping which allows

paddle in the hose or at the hose outlet, because it is a resistance against drain.

• Place the end of drain hose where drain is allowed. When distilled water is being prepared,

cooling water is drained approx. 2 liters/min (approx. 2.6 liters/min in WG1000). Also drain

further increases when boiler water is drained, and sufficient drain equipment is required.

Drain hose (accessory)

WG250

Hose clamp

Drain hose

WG1000

8

Page 12

Before Using this unit

Requirements for Installation

18. Check the drain temperature of cooling water

• Drain temperature may exceed 60℃ in drainage from boiler. Drain to a place remote from

working environment not to be touched easily because there is a danger of burns.

• High-temperature cooling water could flow out. If vinyl chloride tube is used for the water

drain unit of the sink, such a tube could deteriorate. Water should be drained to a place away

from the drain tube of the sink. Even if VP tube (JIS K6741) is used for the vinyl chloride

tube, DV-RR joint is used for the joint, and even if insert socket (JIS K6739) is used, the water

drain trap in the nonstandard options should be used when the control temp. cannot be

lowered (60℃ or lower). Even if the drain temperature is 60℃ or lower, and if the

above-mentioned tubes and joint are not used, the drain trap in the nonstandard options

should be used.

19. When drain temperature of sink equipment does not fall under 60℃

• Use a drain trap (optional accessory).

• Drain trap makes temperature fall by accumulating cooled drain water temporarily. Further, it

mixes city water and cooled-down drain water, makes mixed water temperature fall, then lets

drain to sink equipment.

• Contact your dealer or Yamato Scientific sales office for detail of drain trap.

9

Page 13

Before Using this unit

Requirements for Installation

20. Install the ion exchange resin cartridge (CPC-S) securely

• Install the ion exchange resin cartridge (CPC-S) following the procedure shown below.

• Connect securely because insecure connection may cause water leakage.

1. Make sure that the earth leakage breaker of this unit is "Off" and that the tap is tightened.

2. Take the ion exchange resin cartridge out of attachments to the unit.

3. Place the ion exchange resin cartridge taken out on the receiver within the unit. (See Fig.1.)

4. Fix the ion exchange resin cartridge with the band of receiver. (See Fig.2.)

Fig.1

Fig.2

5. Remove the rubber cap attached to the inlet and outlet of ion exchange resin cartridge.

6. Fit in the coupler marked with (IN) to the inlet of ion exchange resin cartridge (left) until click is

heard. (See Fig.3.)

7. Fit in the coupler marked with (OUT) to the outlet of ion exchange resin cartridge (right) until

click is heard. (See Fig.3.)

Coupler may be hard at first. When applying force in inserting, do not make it curved because

insertion port may be broken.

Reset switch

T

U

O

N

I

IN

Fig.3

OUT

Fig.4

8. Coupler can be removed easily from the ion exchange resin cartridge by pulling it toward

yourself while pushing the black part of the coupler to the depth.

9. After changing, turn the breaker on and wait for about ten second, then press and hold the

reset switch till a beep is heard. (See Fig.4.)

10

Page 14

Requirements for Installation

21. Secure the pre-treatment cartridge securely

• Connect the hose in the body securely following the procedure shown below.

• Insecure connection may cause disconnection of connection hose, resulting in accident by

water leakage.

1. Make sure that the earth leakage breaker of this unit is "OFF" and that the tap is tightened.

2. Take the pre-treatment cartridge ① out of attachments to the body.

3. Inlet and outlet of the pre-treatment cartridge ① are provided with a cap, so remove it.

4. When the front door of this unit is opened, connection hose marked IN and OUT is found in

the coupler; there make connection matching them with IN and OUT on pre-treatment

cartridge ①.

5. In connecting, mate the coupler and port of cartridge while sliding the blue portion ③ of

coupler toward the hose, push in, then release the blue portion ③.

6. When connection is finished, place the pre-treatment cartridge at the position shown on the

right (near side on the left of distilled water tank) as paying attention to the bend of hose.

②

Before Using this unit

22. After installation

• This unit may topple over due to unexpected earthquake or shock causing injury. Take an

appropriate measure against toppling for safety.

(For WG1000, earthquake-resistant fittings are optionally available.)

①

Fig.6

Fig.5

11

Page 15

2. Before Using this unit

Requirements for Installation

22. Install the membrane filter firmly.

• Install the membrane filter as follows:

• Unless firm connection is made, water may leak from the threaded portion and may be mixed

into and contaminate the sampled pure water. Always ensure firm connection.

(1) Take out two membrane filters and seal tape from among accessories of the main

body.

(2) Pay attention to the direction of arrow mark on the membrane filter. Wind the

seal tape clockwise as viewed from the tape windind side two to three turns while

pulling the tape slightly. Remaining tape should be cut away.

(3) Screw the membrane filter, with the seal tape applied side on the top side, while

taking care not to crush threads. Check for water leak during sampling of pure

water. If any, screw the membrane filter further.

WARNING!

12

Page 16

p

p

p

Main Unit

WG250

Boiler

Heater

Heater

terminal block

Description and Function of Each Part

Distilled water tank

Reset switch

Drain cock

Leakage detection electrode

Pre-treatment cartridge

Control panel

Ion exchange resin cartridge (CPC-S)

Water sampling table

Earth leakage breaker

Drain port

(2pcs each at right/left)

Multi-purpose distilled water

sampling port

Product number sticker

Drain switch for

water sam

Distilled water

sam

ling port

Ion exchange water

sam

ling port

ling table

13

Page 17

p

r

Main Unit

WG1000

Description and Function of Each Part

Ion exchange resin cartridge (CPC-S)

Reset switch

Boiler

Heater

Water sampling table

Pre-treatment cartridge

Knurled Screw

Tank

Leakage detection electrode

Control panel

Earth leakage breaker

Leakage detection electrode

Product number

sticke

Drain switch for

water sam

Drain port

(2pcs each at right/left)

Multi-purpose distilled water

sampling port

14

ling table

Page 18

p

p

Description and Function of Each Part

Water Sampling Table and Multi-Purpose Distilled Water Sampling Port

Water sampling table

Use the water sampling table by pulling it out frontward. Because coolant for condenser is used, so

for draining the water in the following cases (and coolant is not flowed), press the drain switch

specifically used for the water sampling table at right side of the unit.

Coolant flows for one minute, and then, the water sampling table is drained. After that, returns to the

condition before pressing the switch.

① When the tank is filled to capacity (Distillation is not operated.)

② When drawing pure water

③ While standby time (the breaker is turned on, and POWER key is turned off.)

WG250

Drain switch for

water sampling table

Multi-purpose distilled

water sam

ling port

Water sampling table

WG1000

Drain switch for

water sampling table

Water sampling table

Multi-purpose distilled

water sam

ling port

Multi-purpose distilled water intake opening

The multi-purpose distilled water intake opening is located at right side surface of the unit, and

one-touch joint is installed at the opening. Distilled water in the tank can be filled by removing the plug

stopper, and connect the hard tube ofφ8 of outer diameter. Moreover, the one-touch joint is available

as connection port for optional goods.

Notice that distilled water pours when removing the plug stopper because the one-touch joint

does not have the check valve.

15

Page 19

Piping System View

Description and Function of Each Part

1 Pressure reduction valve 17 Boiler water supply solenoid valve

2 Pressure switch 18

3 Cooling water solenoid valve 19 Ion exchange water sampling solenoid valve

4 Raw water supply solenoid valve 20 Distilled water sampling solenoid valve

5 Pre-treatment cartridge 21 Ion exchange water flow sensor

Ion exchange resin cartridge (CPC-S)

6

(Two pieces are used for WG1000 type.)

7 Float cylinder 23 Ion exchange water sampling port

8 Float switch 1 24 Distilled water sampling port

9 Float switch 2

10 Boiler drain solenoid valve

11 Boiler drain cock

12 Boiler

13 Heater

Initial accumulated water drain

solenoid valve

22 Distilled water flow sensor

25

Distilled water tank

26

Float switch 3

27

Air filter

28

Distilled water sampling pump

29

Distilled water tank drain port

14 Condenser

15 Ion exchange water quality gauge electrode

16

Distilled water quality gauge electrode

16

30

Multi-purpose distilled water sampling port

31

Aspirator

32

Membrane filter

Page 20

Description and Function of Each Part

Principle of Operation

Description of the operation mechanism of WG250/1000 by each step.

1. Drain of the boiler

Turn on the earth leakage breaker and press POWER key. And after 15 seconds passed, boiler drain

solenoid valve (10) opens for approx. 40 seconds, and cooling water solenoid valve (3) opens for approx. 30

seconds at the same time. Drain of the boiler is performed every 5 hours during distillation.

2. Boiler Water Supply and Distilling Operation

When drain of the boiler is finished, both of raw water supply solenoid valve (4) and boiler water supply

solenoid valve (17) open at the same time in order to supply water to boiler (12). When float switch 1 (8) in

float cylinder (7) detects water level, heater (13) is turned on and distillation starts. With float switch 2 (9),

water supply to the boiler is controlled by opening/closing raw water supply solenoid valve (4) and boiler

water supply solenoid valve (17).

17

Page 21

Principle of Operation

3. Flow of Cooling Water

Description and Function of Each Part

During distillation, water is supplied and discharged in the order: (1) pressure-reducing valve, (3) cooling

water solenoid valve and condenser (14). When the distilled water tank is full, or when ion exchanged water

is sampled, distillation is stopped, and the cooling water is also stopped automatically.

4. Sampling of Distilled Water

For 10 minutes after starting distillation, initial distilled water condensed in condenser (14) is drained by

opening initial accumulated water drain solenoid valve (18). Then distilled water is stored in distilled water

tank (25) by distilled water quality gauge electrode (16). Distillation stops as the tank is full when float switch

3 (26) on the top in the tank operates. The stored water is collected by distilled water sampling pump (28)

through distilled water sampling solenoid valve (20), distilled water flow sensor (22), distilled water sampling

port (24), and membrane filter (32).

18

Page 22

Principle of Operation

5. Sampling Ion Exchanged Water

Description and Function of Each Part

Ion exchange water is sampled by way of the pressure-reducing valve (1), raw water supply solenoid valve

(4), pre-treatment cartridge (5), ion exchange resin cartridge (6), ion exchange water quality electrode (15),

ion exchange water sampling solenoid valve (19), ion exchange water flow sensor (21), ion exchange water

sampling port (23), and membrane filter (32).

19

Page 23

Control Panel

⑪

Description and Function of Each Part

①

⑩

MF

POWER

②

⑨

CONDUCTIVITY

⑧

⑦

MEASURED

CONTINUOUS

FILL

PURE

WATER

⑥

POWER key Turns on/off the power of the controller.

①

Message indication area Indicates the measured value and setting value.

②

WATER LEVEL lamp Indicates water level in the distilled water tank in five levels.

③

DITILLED WATER key Starts/stops drawing distilled water.

④

▲▼ key Selects the value setting item.

⑤

PURE WATER key Starts/stops drawing pure water.

⑥

FILL key Switches water collecting method. (Measured filling/Continuous filling)

⑦

FILL lamp Lights up when either of MEASURED or CONTINUOUS is selected.

⑧

CONDUCTIVITY key

⑨

M key

⑩

F key (Cancels the setting) then returns to the previous setting item.

⑪

Switches conductivity indication unit.(S/mΩ・m)

Used when entering submenu or maintenance mode.

Also (confirms the setting) then shifts to the next setting item.

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

③

④

⑤

Description of ③ WATER LEVEL lamp

This lamp indicates the storage amount of distilled water in the tank in five levels. When this red lamp lights,

distilled water cannot be collected for empty drive prevention of the pump.

When this red lamp lights, distilled

water cannot be collected for empty drive prevention of the pump. When water keeps being stored, and a

red lamp in the lower is blinked, distilled water can be gathered. In addition, a red lamp in the lower is

turned off when the amount of storing water increases, a green lamp since the second step lamp, and the

amount of storing water can be confirmed.

<EMPTY> <FULL>

FULL

EMPTY

Lighting

Blinking

FULL

Lighting

EMPTY

Sampling pump operational range

FULL

EMPTY

20

FULL

Lighting

EMPTY

FULL

Lighting

EMPTY

FULL

Lighting

EMPTY

Page 24

Setup and Check before Use

Operation Method

WARNING!

1. Check of water supply

Check that the water supply hose is securely connected.

Open the tap.

Check that water does not leak from connection of water supply hose.

2. Check of drain

Check that the drain hose is securely connected.

Check that the drain hose is free from bend or projection.

When the drain hose is bent or the like, system does not operate normally, and in addition, it may

lead to water leakage accident. Inspect from time to time, and ensure that water is drained

properly.

3. Check of power supply

Check that the power cord is connected to appropriate plug socket.

4. Before operation

Turn on the earth leakage breaker, then, perform calibration before pressing POWER key.

Perform calibration operation at first-time using this unit (refer to page 22) and when changing the

heater of the boiler (refer to page 37).

Press POWER key while holding down PURE WATER key and DISTILLED WATER key.

Perform calibration operation (at the measured values of heater temperature and power-supply

voltage) for about five minutes, after then, distillation starts automatically. Key operation becomes

disable while calibration operation. In case that power failure occurs while calibration operation,

please perform calibration again.

5. Caution at initial operation

In sampling distilled water in initial energization and drain from distilled water storage tank, air is

contained in the pump and piping, and it takes time until sampling is started.

In sampling ion exchanged water immediately after changing pre-treatment cartridge or ion

exchange resin cartridge, it also takes time until sampling is started. Further, when each

cartridge is changed, drain about 5 liters in order to remove initial impurities.

21

Page 25

Operation Procedure

When operation is set up, follow the procedure below for operation:

1. Turning on power

When first-time using the unit, perform calibration

operation.

1. Turn on the earth leakage breaker.

2. Press POWER key while holding PURE WATER

key and DISTILLED WATER key.

3. After five minutes passed, distillation starts

automatically. (Clause 3)

From the second time using:

① Turn on the earth leakage breaker.

② Press POWER key.

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

POWER

Yamato

Auto Still

WG250

2005/11/1 12:00

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

②

Operation Method

② ②

2. Drain of the boiler

MF

Boiler Drainage

DW/DI Water

Not Available

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

3. Distillation operation

MF

In Distillation

Tank Empty

Distill-Water NA

Continuous

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

POWER

POWER

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

Drain of the boiler starts.

Drain of the boiler starts when turning on/off the earth

leakage breaker, and when five hours passed after

distillation starts. (Drain of the boiler does not start if

POWER key is not turned on.)

Distillation operation starts.

When there is no water in the tank, the left screen

display and the below screen display are alternately

indicated at 5 seconds interval. The value ・・・×

10-4S/m is indicated while initial distilled water is

drained (approx. 10 minutes), after that, the below

screen is displayed.

In Distillation

DW-Conductivity

Continuous

0.854×10

-4

S/m

It takes approx. 4 hours till the tank is filled at the water

collection available level. The above screen appears.

When the tank is full, the below screen appears.

DistillationStop

Tank Full

Continuous

22

Page 26

Sampling of Pure Water

Continuous collection of pure water

0.06×10

POWER

-4

S/m

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

DI sampling

DIS-Conductivity

Continuous

WATER

LEVEL

FULL

EMPTY

Operation Method

PURE WATER lamp lights up by pressing

PURE WATER key while “CONTINUOUS” lamp

is ON. Then, pure water can be collected.

Collecting water stops by pressing PURE

WATER key again. Then, PURE WATER lamp

is turned on. After water collection is finished,

it returns to distillation operation.

PURE

WATER

DISTILLED

WATER

Continuous collection of distilled water

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

DW sampling

Continuous

POWER

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

DISTILLED WATER lamp lights up by pressing

DISTILLED WATER key while “CONTINUOUS”

lamp is ON. Then, distilled water can be

collected.

Collecting water stops by pressing DISTILLED

WATER key again. Then, DISTILLED WATER

lamp is turned on. After water collection is

finished, it returns to distillation operation.

23

Page 27

Collection of Measured Amount of Pure Water

1. Switching water collection method

Switch to “MEASURED” amount water collection

method.

Switch from “CONTINUOUS” to “MEASURED” by

pressing FILL key.

MF

DW-Conductivity

Measured: 0.1L

POWER

In Distillation

-4

0.85×10

S/m

Operation Method

CONDUCTIVITY

PURE

WATER

FILL

MEASURED

CONTINUOUS

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

2. Amount of collecting water setting

0.85×10

POWER

-4

S/m

①

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

In Distillation

DW-Conductivity

Measured: 20.0L

Set the amount of collecting pure water. The same

setting screen is used for setting of pure water and

distilled water.

1. Set the amount of pure water by pressing ▲▼ key.

Set up to 30 liters for WG250, or up to 100 liters for

WG1000.

2. After setting, pressing PURE WATER key starts

water collection.

3. Collecting

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

②

DI sampling

DIS-Conductivity

0.85×10

Measured: 18.2L

POWER

-4

S/m

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

Water collection of measured amount starts.

1. The counter starts decrementing from the setting

value.

2. When collecting water is finished, message

"Measured: 0.0L" appears on the window.

3. Go back to clause 2.

If pressing PURE WATER key while collecting water,

the operation stops and the setting value is reset.

24

Page 28

Collection of Measured Amount of Distilled Water

1. Switching water collection method

Switch to “MEASURED” amount water collection

method.

Switch from “CONTINUOUS” to “MEASURED” by

pressing FILL key.

MF

DW-Conductivity

Measured: 0.1L

POWER

In Distillation

-4

0.85×10

S/m

Operation Method

CONDUCTIVITY

PURE

WATER

FILL

MEASURED

CONTINUOUS

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

2. Amount of collecting water setting

0.85×10

POWER

-4

S/m

①

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

In Distillation

DW-Conductivity

Measured: 20.0L

Set the amount of collecting distilled water. The same

setting screen is used for setting of pure water and

distilled water.

1. Set the amount of distilled water by pressing ▲▼

key.

Set up to 30 liters for WG250, or up to 100 liters for

WG1000.

2. After setting, pressing DISTILLED WATER key

starts water collection.

3. Collecting

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

POWER

DW sampling

DW-Conductivity

0.85×10

Measured: 18.2L

②

Water collection of measured amount starts.

1. The counter starts decrementing from the setting

value.

-4

S/m

2. When collecting water is finished, message

"Measured: 0.0L" appears on the window.

WATER

LEVEL

FULL

3. Go back to clause 2.

If pressing DISTILLED WATER key while collecting

EMPTY

DISTILLED

WATER

water, the operation stops and the setting value is

reset.

25

Page 29

Collection of Measured Amount of Distilled Water

In case that the tank becomes empty while collecting water

1. The left screen is displayed when the tank becomes

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

POWER

In Distillation

Tank Empty

Distill-Water NA

Measured: 15.0L

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

③

empty during collecting water, and DISTILLED

WATER lamp blinks and operation of water

collection is suspended.

2. Distillation starts.

3. In case that "EMPTY" lamp of WATER LEVEL

display does not light up, press DISTILLED WATER

key again to start collecting water. If PURE

WATER key is pressed under this condition, the

holding condition is released.

4. After collecting water is finished, "Measured: 0.0L"

appears on the window, and return to the screen of

Clause 2.

Operation Method

26

Page 30

Display of Water Quality

Switching conductivity unit

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

DW-Conductivity

Continuous

POWER

DW sampling

0.85×10

-4

S/m

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

Operation Method

Switch the conductivity unit.

Pressing CONDUCTIVITY key for 2 seconds switches

the conductivity unit.

Ex)

In case of switching the conductivity unit during

collecting distilled water

DW sampling

DW-Conductivity

Continuous

0.85×10

-4

S/m

DW sampling

DW-Resistivity

1.17×10

Continuous

4

Ω・m

Switching conductivity display

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

PURE

WATER

DW-Conductivity

Continuous

POWER

DW sampling

0.85×10

-4

S/m

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

Switch the conductivity display. The conductivity of

distilled water is displayed during distillation, and the

conductivity of pure water is displayed during collecting

pure water.

Pressing CONDUCTIVITY key switches the

conductivity display for either of pure water or distilled

water.

Ex)

In case that you want to see the conductivity of pure

water during collecting distilled water: In case that

the conductivity of pure water

DW sampling

DW-Conductivity

Continuous

0.85×10

-4

S/m

DW sampling

DIS-Conductivity

Continuous

0.06×10

-4

S/m

If not pressing any keys, the conductivity display is

returned.

27

Page 31

Operation Method

Display of Water Quality

Measurement of Electric Conductivity

The water conductivity meter on the control panel displays the conductivity at the outlets of the

ion-exchange resin cartridge and the condenser for distilled water. The displayed value can be used

as an index for replacing the ion-exchange resin cartridge. The value of conductivity is valid only

when the electrode is fully damped with water, or when pure water is dripped. Correct value is not

displayed in the following cases because the electrode is not damped or air bubbles are produced.

1. At beginning of operation and during halts

2. Just after changing pretreatment cartridge or ion-exchange resin cartridge

3. Just after distillation starts

Electric conductivity

Electric conductivity is a value indicating easiness of flowing of electricity. In the case of water,

electricity flows the more easily when the more electrolyte i.e. impurity is solved, so the value of

conductivity is the greater; when the less electrolyte is solved, the smaller is the value.

When the value of electric conductivity is the smaller, the better is purity of pure water.

Here, electric conductivity indicates only electrolyte, and does not indicate content of

non-electrolyte (such as organic substance, colloid substance, dissolved gas, and microorganism),

and it is just an index indicating purity of pure water, and it does not represent all of purity.

Specific resistivity indicates the same contents as electric conductivity. Specific resistivity is

inversely related to electric conductivity, and when the value is the greater, the better is purity.

When obtaining specific resistivity from electric conductivity, where specific resistivity is R and

electric conductivityρ,

R[Ω・m]

So the theoretical value of pure water is as follows:

R=18.3×10

(Take notice that the resistivity is displayed in integer form (not in decimal) in the range 18 to 1 x

104Ω・m.)

ρ=0.055×10

=

4

Ω・m (18.3MΩ・cm) 25℃

-4

1

ρ

[/

S m]

S/m (0.055μS/cm) 25℃

or R[×10 Ω・m]

4

=

×10 S m]

ρ

1

[/

-4

Quality of ion exchange water and distilled water

Ion exchange water and distilled water have the following features respectively. Distinguish them

as necessary in use.

It is ideal to use pure water immediately after sampling; therefore be sure to drain water in distilled

water tank if it is out of use for a long time. If water has been stored in distilled water tank for a long

time, drain once, then store in distilled water tank newly before use.

1. Ion exchange water

Most of electrolyte in water is removed, and water with the lowest electric conductivity is obtained.

However, non-electrolyte cannot be removed. In addition, slight fall of purity is found while resin is

new and when water is fed again after halt of system.

2. Distilled water

Electrolyte and non-electrolyte can be removed in average except for low boiling point substance

such as ammonia. However, carbon dioxide gas in the atmosphere is absorbed and carbon oxide

is generated in the process of manufacturing (condensing/storing), and so the electric conductivity

is worse than ion exchange water, that is 1 to 2.5 X 10-4 S/m (1 to 2.5 μS/cm) at 25C, and

represents weak acid (pH5 to 6).

See "2 - Common item (11) Water" of JIS K0102 (Plant drain test procedure) for removal of

dissolved gas (oxygen and carbon dioxide) in pure water.

28

Page 32

Setting/Display of Submenu

1. Setting/display of submenu

Operation Method

POWER

WATER

LEVEL

FULL

EMPTY

DISTILLED

WATER

①,③

PURE

WATER

MF

CONDUCTIVITY

MEASURED

CONTINUOUS

FILL

Sub-Menu

1.Buzzer

③

2.Calendar

3.EXCH History

②

2. Setting/display of each item

2.1. Setting of ON/OFF of buzzer sound

Buzzer

1. Key Click

2. Error Buzz

Perform setting/display of submenu.

1. Pressing M key for 2 seconds displays the submenu.

2. Select the item to be set or displayed by pressing ▲▼

key.

3. Pressing M key confirms the setting and shifts to the

selection screen.

Press F key to (cancel the setting and) return the previous

setting screen.

If not pressing any keys for 2 minutes, the screen returns to

the previous display before setting/display of submenu.

Items of submenu are:

1) ON/OFF of buzzer sound

2) Calendar setting

3) Consumables change history

4) Maintenance history

5) Error occurrence history

6) Power failure occurrence history

7) Water cutoff occurrence history

8) Language selection

9) Power failure recovery function

To set a key clicking sound/alarm buzzer sound:

1. Select an item of submenu by pressing ▲▼ key.

2. Confirm the item by pressing M key. The selection

screen appears.

3. Specify "ON" or "OFF" of each item by pressing ▲▼

key, and confirm the setting by pressing M key.

4. Pressing F key returns to the submenu screen.

"ON" is set to buzzer sound at default setting.

2.2. Calendar setting

Calendar

2005 year

9/29 month/day

12:25 h:min

2.3. Consumables change history

Buzzer

1. Hollow Filter

2. Ion-Exchange-S

3. DW M-Filter

4. 6.DI M-Filter

To set the calendar:

1. Set the items (year/month/day/hour/minute)by pressing

▲▼ key.

2. Confirm the setting by pressing M key.

3. The set items are displayed. Check the set items and

confirm your entry by pressing M key to go to the

selection screen.

4. Pressing F key returns to the previous submenu screen.

To display the history of changing pretreatment filter,

ion-exchange resin (S), M filter for distilled water, and M

filter for pure water:

1. Display an item of submenu by pressing ▲▼ key.

2. Confirm the setting by pressing M key. The history

display appears.

3. Confirm the history by pressing ▲▼ key.

4. Pressing F key returns to the previous screen.

Up to 20 records are displayed for each change history. If it

exceeds 20 records, the oldest record is deleted.

29

Page 33

Setting/Display of Submenu

2.4. Maintenance history

Maintenance

History No.1

2005/09/29 12:25

Operation Method

To display the maintenance history:

1. Confirm the maintenance history by pressing ▲▼ key.

2. Pressing F key returns to the previous screen.

Up to 20 records are displayed for each change history. If it

exceeds 20 records, the oldest record is deleted.

2.5. Error occurrence history

Error History

History No.1

Leak error

2005/09/29 12:25

2.6. Power failure occurrence history

Outage History

History No.1

↓05/09/29 12:25

↑05/09/29 12:30

2.7. Water cutoff occurrence history

Water Alarm

History No.1

↓05/09/29 12:25

↑05/09/29 12:30

2.8. Language selection

Language

1. Japanese

2. English

To display the error occurrence history:

1. Confirm the maintenance history by pressing ▲▼ key.

2. Pressing F key returns to the previous screen.

Up to 20 records are displayed for each change history. If it

exceeds 20 records, the oldest record is deleted.

For details of error alarms, refer to page 42.

To display the power failure occurrence history:

1. Confirm the maintenance history by pressing ▲▼ key.

2. Pressing F key returns to the previous screen.

Up to 20 records are displayed for each change history. If it

exceeds 20 records, the oldest record is deleted.

To display the water cutoff occurrence history:

1. Confirm the maintenance history by pressing ▲▼ key.

2. Pressing F key returns to the previous screen.

Up to 20 records are displayed for each change history. If it

exceeds 20 records, the oldest record is deleted.

To select display language:

1. Select an item of submenu by pressing ▲▼ key.

2. Confirm the item by pressing M key. The submenu

screen appears.

2.9. Power failure recovery function

Resume Function

1. No

2. Yes

3. Finishing of setting/display

Press M key for 2 seconds.

To set the power failure recovery:

1. Select an item of submenu by pressing ▲▼ key.

2. Confirm the item by pressing M key. The submenu

screen appears.

This function is set to "invalid" at default setting.

The screen returns to the previous display before

setting/display submenu.

30

Page 34

Handling Precautions

WARNING!

If a problem occurs

If smoke or strange odor should come out of this unit for some reason, turn off the power key

right away, and then turn off the circuit breaker and the main power. Immediately contact a

service technician for inspection. If this procedure is not followed, fire or electrical shock may

result. Never perform repair work yourself, since it is dangerous and not recommended.

During a thunder storm

During a thunderstorm, turn off the power key immediately, then turn off the circuit breaker and

the main power. If this procedure is not followed, fire or electrical shock may be caused.

Take enough care in handling detergent (liquid)

• In storing detergent (liquid), store in enclosable container avoiding high temperature and

humidity.

• Principal component of detergent (liquid) Orgazor 10 is sulfamic acid (acidic with pH of water

solution approx. 1).

• In handling this detergent (liquid), use protective tools (gloves, mask, and glasses).

• When it is in contact with human body, wash it away with clean water.

• Neutralize the liquid with neutralizer (such as sodium hydroxide) after washing.

• Ensure neutralization with pH test paper, etc.

• Do not use empty container for beverage.

• Do not allow detergent to directly flow into agricultural irrigation canal or fields because it

causes withering of rice crop.

Do not step on this unit

Do not step on this unit. It will cause injury if this unit fall down or break.

Do not put anything on this unit

Do not put anything on this unit. It will cause injury if fall.

In power failure (In case that the unit does not power failure recovery function)

When system has halted during operation due to power failure etc. and is provided with power

again, system is brought to standby status. When restarting operation, start from (Page 22 "1.

Turning on power").

31

Page 35

Maintenance Method

Daily Inspection and Maintenance

Timing of maintenance and inspection

(Perform daily inspection for stable use of product.)

Maintenance/check items Reference for timing Remarks

Throughput: About 5000 liters of city water

Replacement of

pre-treatment cartridge

Replacement of

membrane filter

Replacement of ion exchange

resin cartridge

Cleaning of distiller 3 months

Cleaning of water supply

hose filer

Replacement of hose 2 years Connections shall be checked monthly.

Drainage of distilled water tank 3 months

Approx. 6 months

Exchange message appears

on the indication area.

Approx. 3 months

Exchange message appears

on the indication area.

Exchange message appears

on the indication area.

(Displayed when the

conductivity of pure water is

more than 1 x 10

6 months

-4

S/m.)

in Tokyo.

If the quality of raw water is not good,

perform this maintenance as soon as

possible.

Throughput: approx. 500 liters for pure

water.

Need to exchange if the amount of collection

is less than the above value.

Throughput: About 700 liters of the raw

water of 200 x 10

WG1000 type)

If the quality of raw water is not good, start

the operation as soon as possible.

If not used for a long time, drain water from

the tank.

-4

S/m. (1400 liter for

Replacement of pre-treatment cartridge

See Page 11 "21. Secure the pre-treatment cartridge securely" for replacement procedure.

When the cartridge is put to use without replacement, life span of ion exchange resin cartridge

becomes short.

Please dispose used cartridge as nonconbustibles. When it is sent back to our company, fill in the

designated invoice attached to a new cartridge, and send it with the used cartridge to us.

Replacement of ion exchange resin cartridge

When a cartridge is stored for a long time, deterioration of water quality and fall of processing

capacity are found; therefore prepare a spare cartridge in a planned manner for replacement

timing. Standard for storage is about 4 months.

In replacement, see Page 10 "20. Install the ion exchange resin cartridge (CPC-S) securely".

When a cartridge is used without replacement, much scale is deposited on boiler and heater,

which causes decrease of distilled water sampling and damage to heater.

Please dispose used cartridge as nonconbustibles. When it is sent back to our company, fill in the

designated invoice attached to a new cartridge, and send it with the used cartridge to us.

We promote the reasonable disposal, collection, and recycling of cartridge for environmental

protection.

※ After changing the pretreatment cartridge, the membrane filter, or the ion-exchange resin cartridge,

press and hold the reset switch at backside of the door for two seconds till a beep is heard. Then the

warning indication is reset and the change record is registered in the consumables change history.

In case that two or more items are changed at the same time, they are registered in the consumables

change history in order of occurrence. However, be sure that the ion-exchange resin cartridge is

normally registered at the last. (Warning alarm for the ion-exchange resin cartridge is automatically

recovered.)

32

Page 36

Maintenance Method

Washing of Distiller

Dismounting of Distiller

1. Turn "OFF" the earth leakage breaker of the unit.

2. Close the tap.

3. Check that the boiler is not hot (longer than 30 minutes after the breaker is turned "OFF"), then open

the front door of the unit, and open the boiler water drain cock.

4. Disconnect the hose connected to the boiler ① and condenser ②. In disconnecting from the

distilled water outlet and boiler water supply and drain port, turn the hose band by use of tool and

displace the engaged portion (serrated portion). Take care in disconnecting because excessive

force applied to glass may cause damage.

②

Cooling Water

Outlet

Boiler Water Supply and

Drain Port

Cooling Water

Inlet

Distilled

Water

Outlet

①

5. Disconnect the hole plug at left plate, remove four screws with a screw driver, then remove the left

plate.

6. Loosen 4 screws on the right of terminal block located at the right top of the body frame with left side

plate dismounted by use of Phillips screwdriver, and disconnect the heater lead terminal.

(For WG1000, 8 pieces of screw are used because it has two heaters.)

33

Page 37

Maintenance Method

Washing of Distiller

7.

1) Disconnect the heater lead wire from grommet.

Note that, do not bend or pull the heater lead wire more than necessary.

2) Remove the two screws of boiler securing band with a Phillips screwdriver, and take the boiler

and condenser out of the body.

Grommet

3) Loosen the knurled screws (three) and remove the boiler and condenser.

Grommet

Condenser

Connecting

Hardware

Connection Port

with Condenser

Packing

Boiler

Washing of boiler

1. Adjust detergent liquid.

1) Prepare approx. 2 liters of hot water at 50 to 60°C.

2) Add attached scale detergent (Orgazor) approx. 200g to hot water prepared in 1) and agitate well.

2. Seal the hose connection port at the bottom of boiler (boiler supply and drain port) by use of rubber

stopper, etc.

3. Secure the boiler at a stable position to prevent washing liquid from spilling.

4. Pour in washing liquid through connection port with condenser with heater turned on.

Most scale is removed in 4 to 5 hours approximately. Drain washing liquid in the boiler. If much scale

is distiller deposited, pour in washing liquid newly, and repeat washing

1) When scale-removing work is finished, take the heater out of boiler and wash each of them

enough with city water. Here, in washing the heater with water, be sure to fill a larger beaker with

water and wash the heater inside so that lead wire and its routing port are not wet by water.

Avoid washing the heater directly with water from tap.

2) If solid scale distiller remains after washing by washing liquid, follow the remedy below:

Boiler: Scrub with brush etc. for removing.

Heater: Scrub with something soft such as wood piece or plastic.

In this connection, remove scale on the heater uniformly in general, never leaving solid scale in part. In

an extreme case, only such part has a great heat resistance, causing damage to the heater.

34

Page 38

Maintenance Method

Washing of Distiller

Washing of Condenser

1. Pour detergent liquid into the cooling pipe of condenser.

(See Page 34 "Washing of boiler" for formulating detergent liquid.)

Detergent

Liquid

Hose

Connection

Port

2. If detergent liquid should flow out of hose connection port, seal with rubber stopper. Most fur can

be removed in 4 - 5 hours approximately.

3. Drain detergent liquid, and then wash enough with city water.

Handling of Detergent Liquid (also refer to Page 31 "Handling Precautions")

1. Wash the boiler and heater sooner. If the more scale is deposited, the more difficult is its removal,

which may cause decrease of distilled water sampling and damage to heater.

2. When washing is finished, drain detergent liquid out of the unit, and apply neutralization by

neutralizer (such as sodium hydroxide). In neutralization, check that it is neutral by use of pH test

paper, etc. (Principal component of scale detergent: Sulfamic acid and pH of water solution: Acidic

approximately 1)

3. In storing this detergent, seal the agent and store in cold and dark place avoiding high temperature

and humidity.

4. In handling this detergent, be sure to use protective tools (gloves, mask, and glasses).

5. When it is in contact with human body, wash it away with clean water.

6. Do not use empty container for beverage.

7. Do not allow detergent to directly flow into agricultural irrigation canal or fields because it causes

withering of rice crop.

Installation of boiler

1. Secure the boiler with the boiler securing band so that connection port of condenser is horizontal.

Check that the packing is contained in the cap nut, and then install the heater into the boiler with

letters "YK-W-3" faced up.

Connection Port with

Condenser

Packing

YK-W-3

Heater

Cap Nut

Boiler Securing

Band

35

Page 39

r

Maintenance Method

Washing of Distiller

2. Attach 4 heater lead terminals to the terminal block.

Heater Lead

(wire diameter, thick)

Heater Lead

(wire diameter, thin)

3. Install the left side plate on the body.

4. Insert the hose to the boiler water supply and drain port, and secure with the hose band.

Installation of condenser

1. Place packing in the connection port of boiler with condenser, and secure with connecting hardware

so that the boiler and condenser are placed in the same direction.

Inlet Outlet

Boiler

Condenser

Connecting

Hardware

View from above

2. Connect the hose respectively to the cooling water inlet, outlet, and distilled water outlet of

condenser.

3. Close the boiler water drain cock.

Boiler Wate

Drain Cock

Open

Close

36

Page 40

Maintenance Method

Replacement of Heater

• If the heater should be disconnected or damaged due to deposit of scale, replace it by the

procedure below. (Also refer to Page 33 "Washing of Distiller" in working.)

1. Turn "OFF" the earth leakage breaker of this unit.

2. Close the tap.

3. Turn "OFF" earth leakage breaker, and when more than 30 minutes has passed, open the front door

of this unit, and open the boiler water drain cock.

4. Open the left side plate of the body, loosen the four screws on the right of the terminal block, and

disconnect the heater lead terminal.

5. Pull the heater lead out of the grommet.

6. Remove the cap nut of heater, and pull out the heater.

7. Remove the packing and cap nut from the damaged heater.

8. Install the packing and cap nut on the new heater. At that time, do not touch with bare hand in order

to prevent soiling by hand.

Packing

9. Install on the boiler so that "YK-W-3" mark of the heater is faced up.

10. Feed the heater lead wire through the grommet, check the heater lead wire attaching position, and

secure to the terminal block.

11. Mount the left side plate.

12. Close the boiler water drain cock.

13. Close the front door, and then open the tap.

14. Turn on the earth leakage breaker.

15. The standby screen appears at the display window of the control panel.

16. Perform calibrations by pressing POWER key while holding down PURE WATER key and

DISTILLED WATER key. (Refer to page 21.)

(Calibration is performed for storing the standard temperature of the sensors in each heater under

normal operation in the inner controller. Performing calibration detects errors when the temperature

rises higher than the standard temperature + 20℃.)

17. During calibration, a message is displayed at the message window of the control panel.

18. After approx. 5 minutes passed after starting calibration, normal operation starts automatically.

37

Page 41

Washing of Water Supply Hose Filter

1. After turning off the earth leakage breaker

on this unit, turn the tap off, slide the

sleeve to the direction of the arrow, then,

remove the water supply hose from the

connection port.

2. Remove the plug ② from ring ① as

turning.

3. Cleanse filter ⑦ attached to the packing

with water.

4. Wash the filter with spray, etc.

5. Assemble by reversing the procedure.

Tap

④

⑤

⑥

⑦

Water

Supply

Hose

Maintenance Method

①

②

Connection Port Body

①Ring

③

Sleeve

②Plug

③Socket

④Spacer

⑤Mounting Screw

⑥Packing

⑦Filter

One-touch

Joint

Tap side

Replacement of Hose

• Be sure to use a hose specified by Yamato Scientific for replacement.

38

Page 42

Long storage and disposal

When not using this unit for long term / When disposing

• If this unit is to be put out of service for a long time, be sure to turn of the earth leakage

breaker of this unit for safety, and close the tap. Water in the boiler and distilled water tank, if

stored as it is, will deteriorate in quality due to generated bacteria or algae. Drain water by

the procedure below:

Boiler Water Drain

1. In draining boiler water, turn off the earth

leakage breaker, ensure that the tap is

closed, then wait for 30 minutes or more,

and open the front door.

2. Open the boiler water drain cock.

3. Make sure that all water in the boiler and

float cylinder is drained.

4. Be sure to close the boiler water drain

cock. If boiler water drain cock is opened

in next use, water is not fed into the boiler,

and distillation is not started.

Open

Boiler Water

Close

39

Page 43

Long storage and disposal

When not using this unit for long term / When disposing

WARNING!

When disposing…

• Keep out of reach of children.

• Treat as large trash.

When the unit is out of service at night and on holidays

• Turn off the earth leakage breaker.

• Be sure to close the tap.

• Fluctuation of city water pressure may cause unexpected accident such as water leakage.

• In use in winter at a severely cold place, beware of freezing in the tank, boiler, condenser, etc.

while system is stopped.

Environmental protection should be considered

We request you to disassemble this unit as possible and recycle the reusable parts considering to the

environmental protection. The feature components of this unit and materials used are listed below.

Component Name Material

Main components of exterior

Exterior Made of iron, bonded steel plate, melamine resin baking finish

Exterior rear plate Made of iron, bonded steel plate, melamine resin baking finish

Door Made of iron, bonded steel plate, melamine resin baking finish

Door rear plate Stainless steel plate SUS 304

Mounting plate (painted) Made of iron, bonded steel plate, melamine resin baking finish

Mounting plate (unpainted) Stainless steel plate SUS 304

Electric parts mounting plate Aluminum

Hinge Stainless steel plate SUS

Rubber foot Synthetic rubber

Mounting tabs Stainless steel plate SUS 304

Production plates Polyester

Main components of water circuit system

Boiler Hard glass

Condenser Hard glass

Float cylinder Polypropylene

Pure water tank Polyethylene

Drain port Polypropylene

Float cylinder branch pipe Polypropylene

Electrode holder Polypropylene

Water sampling port Polypropylene

Control panel ABS resin

Water sampling table ABS resin

40

Page 44

Long storage and disposal

When not using this unit for long term / When disposing

Component Name Material

Main components of water circuit system

Resin cylinder case Polypropylene

Ion exchange resin Polystyrene Resin

Water quality gauge electrode Titanium

Heater Ceramic

Heater mounting nut Teflon

Main components of piping system

Water supply hose Vinyl chloride

Drain hose Ethylene propyne

Hose (transparent) Vinyl

Hose (milky transparent) Silicon

Hose clamp Polyacetal

Hose nipple (resin black) Polyamide

Hose nipple (resin white) Polypropylene

Hose nipple (metal) Brass

Main components of electric system

Casing: Polypropylene

Impeller: Polypropylene

Pump

Solenoid Valve

Float Switch Polypropylene

Power Cord, Wiring Material, etc. Wiring material and board coated by synthetic rubber and resin

Magnet: Ferrite magnet

Motor case: Iron

Rotor: Iron

Made of metal: Body, brass

Made of resin: Body, polyacetal

41

Page 45

Failure indication and Its Contents

Alarm Indication Condition Corrective measures

In the Event of Failure…

Water cutoff alarm

Pretreatment filter

exchange notification

Ion-exchange resin S

exchange notification

Membrane filter for

distilled water

exchange notification

Feed Water Alarm

Check

Flow & Pressure

It's time

to exchange

Hollow Filter

Water Quality NG

It's time

to exchange

Ion-EXCH Resin-S

Distilled Water

Membrane Filter

It's time

to exchange

When raw water pressure

decreases (<0.5kg f/cm

when water cutoff occurs

When 6 months passed

under continuous energizing

condition

When the conductivity of

pure water exceeds 1×10

S/m

When 3 months passed

under continuous energizing

condition

2

), or

-4

Check raw water.

Change the pretreatment

filter.

Press and hold the reset

switch on backside of the

door till a beep is heard.

Then, the alarm indication

is reset.

Change the ion-exchange

resin.

Press and hold the reset

switch on backside of the

door till a beep is heard.

Then, the alarm indication

is reset.

Change the membrane

filter for distilled water.

Press and hold the reset

switch on backside of the

door till a beep is heard.

Then, the alarm indication

is reset.

Membrane filter for

pure water exchange

notification

Maintenance time

notification

It's time

to exchange

Ion-EXCH Water

Membrane Filter

to maintenance

It's time

Service Call

Change the membrane

filter for pure water.

When 3 months passed

under continuous energizing

condition

When 3 years passed under

continuous energizing

condition

Press and hold the reset

switch on backside of the

door till a beep is heard.

Then, the alarm indication

is reset.

Perform maintenance of

the unit.

Press and hold the reset

switch on backside of the

door till a beep is heard.

Then, the alarm indication

is reset.

42

Page 46

Failure indication and Its Contents

Error Indication Cause Symptom Countermeasure

In the Event of Failure…

Controller error

Water leakage

error

Overheat of

heater

Burnout of

heater

Controller Error

Service Call

Leak Error